Page 1

ROTOSCAN RS4

Safety Laser Scanners

e reserve the right to

EN 2011/03 - 607144

W

make technical changes

SAFE IMPLEMENTATION AND OPERATION

Original operating instructions

Page 2

© 2011

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen - Teck / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

info@leuze.de

Version 8.6

Page 3

Contents

1 About this document..................................................................................................................................................... 6

1.1 Other applicable documents .........................................................................................................................................6

1.2 Used symbols and signal words ...................................................................................................................................6

2 Safety............................................................................................................................................................................ 7

2.1 Proper use .................................................................................................................................................................... 7

2.2 Appropriately qualified person ......................................................................................................................................7

2.3 Responsibility for safety................................................................................................................................................ 7

2.4 Laser.............................................................................................................................................................................8

2.5 Handling the safety sensor ...........................................................................................................................................8

2.6 Usage limits .................................................................................................................................................................. 8

2.7 Guarantee the availability of the safety sensor.............................................................................................................9

2.8 Providing the company operating the machine with information................................................................................... 9

2.9 Exemption of liability ................................................................................................................................................... 10

3 Device description ......................................................................................................................................................11

3.1 Device overview.......................................................................................................................................................... 12

3.2 Display elements ........................................................................................................................................................12

3.3 Mounting system (option) ...........................................................................................................................................14

3.4 ConfigPlug (option).....................................................................................................................................................14

4 Functions .................................................................................................................................................................... 15

4.1 Start/restart interlock................................................................................................................................................... 15

4.1.1 Start interlock..............................................................................................................................................................15

4.1.2 Restart interlock.......................................................................................................................................................... 15

4.2 Start test .....................................................................................................................................................................15

4.3 Automatic start/restart.................................................................................................................................................15

4.3.1 Automatic start............................................................................................................................................................15

4.3.2 Automatic restart......................................................................................................................................................... 16

4.4 Dust suppression ........................................................................................................................................................ 16

4.5 Field pair switchover ................................................................................................................................................... 16

4.6 Reference boundary monitoring .................................................................................................................................17

4.7 MotionMonitoring ........................................................................................................................................................ 17

5 Applications ................................................................................................................................................................19

5.1 Stationary danger zone guarding................................................................................................................................ 19

5.2 Stationary point of operation guarding........................................................................................................................20

5.3 Stationary access guarding ........................................................................................................................................ 21

5.4 Mobile danger zone guarding .....................................................................................................................................22

5.5 Mobile side guarding................................................................................................................................................... 23

6 Mounting .....................................................................................................................................................................24

6.1 Basic infos ..................................................................................................................................................................24

6.2 Basic infos on the protective field dimensioning .........................................................................................................25

6.2.1 Handling unmonitored areas....................................................................................................................................... 25

6.2.2 Protective field setup with adjacent safety sensors .................................................................................................... 26

6.3 Stationary danger zone guarding................................................................................................................................ 28

6.3.1 Beam level height ....................................................................................................................................................... 29

6.3.2 Safety distance "S" ..................................................................................................................................................... 29

6.3.3 Additional distance "C" because of the possibility of reaching over............................................................................ 30

6.3.4 Machine response times, stopping time ..................................................................................................................... 30

6.3.5 Application-conditional additional distances for safety distance "S" ........................................................................... 31

6.3.6 Minimum distance "D" to the protective field contour..................................................................................................31

6.4 Stationary point of operation guarding........................................................................................................................32

6.4.1 Safety distance "S" ..................................................................................................................................................... 33

6.4.2 Additional distance C ..................................................................................................................................................33

6.4.3 Machine response times, stopping time ..................................................................................................................... 33

6.4.4 Protective field and reference boundary ..................................................................................................................... 34

6.5 Stationary access guarding ........................................................................................................................................ 34

6.5.1 Safety distance "S" .................................................................................................................................................... 35

6.5.2 Machine response times, stopping time ..................................................................................................................... 35

Leuze electronic RS4 3

Page 4

Contents

6.5.3 Protective field contour and reference boundary........................................................................................................36

6.6 Mobile danger zone guarding on DTSs ...................................................................................................................... 36

6.6.1 Basic requirements.....................................................................................................................................................37

6.6.2 Minimum distance D ................................................................................................................................................... 37

6.6.3 Protective field dimensions ........................................................................................................................................39

6.6.4 Test mode for MotionMonitoring................................................................................................................................. 39

6.7 Mobile side guarding on DTSs.................................................................................................................................... 40

7 Technical data ............................................................................................................................................................ 41

7.1 Safety.......................................................................................................................................................................... 41

7.2 Optics.......................................................................................................................................................................... 41

7.3 Protective field ............................................................................................................................................................42

7.4 Warning field............................................................................................................................................................... 42

7.5 Measured data............................................................................................................................................................ 42

7.6 Electrical power supply .............................................................................................................................................. 43

7.7 Software...................................................................................................................................................................... 44

7.8 Ambient conditions ..................................................................................................................................................... 44

7.9 Dimensions, weight..................................................................................................................................................... 45

8 Electrical connection...................................................................................................................................................47

8.1 Electrical power supply...............................................................................................................................................47

8.2 Interfaces .................................................................................................................................................................... 47

8.2.1 X1 plug interface assignment ..................................................................................................................................... 48

8.2.2 Interface assignment, plug X2 .................................................................................................................................... 49

8.3 Assemble cables......................................................................................................................................................... 50

8.4 Integrating the safety sensor into machine control system.........................................................................................51

8.4.1 Downstream safety circuit with start/restart interlock, contactor monitoring, without field pair switchover ................. 51

8.4.2 Programmable logic controller (PLC) with corresponding safety level and field pair switchover................................ 51

9 Parameters ................................................................................................................................................................. 53

9.1 Administrative parameters..........................................................................................................................................53

9.1.1 Safety Laser Scanner name ....................................................................................................................................... 53

9.1.2 Description..................................................................................................................................................................53

9.1.3 Start segment output ..................................................................................................................................................53

9.1.4 Stop segment output................................................................................................................................................... 53

9.1.5 Output resolution ........................................................................................................................................................53

9.1.6 Serial interface baud rate............................................................................................................................................ 54

9.1.7 Alarm incident............................................................................................................................................................. 54

9.1.8 Precalculated measured values output....................................................................................................................... 54

9.1.9 2nd measured value calculation segment .................................................................................................................. 54

9.1.10 3rd measured value calculation segment ................................................................................................................... 54

9.2 Safety-relevant parameters ........................................................................................................................................55

9.2.1 Application .................................................................................................................................................................. 55

9.2.2 Response times..........................................................................................................................................................55

9.2.3 Dust suppression ........................................................................................................................................................55

9.2.4 Applicable field pair selection with scanner start ........................................................................................................56

9.2.5 Permitted field pair switchovers ..................................................................................................................................56

9.3 Field pair .....................................................................................................................................................................56

9.3.1 Protective field/description .......................................................................................................................................... 56

9.3.2 Warning field/description ............................................................................................................................................ 56

9.4 MotionMonitoring ........................................................................................................................................................ 56

9.4.1 Vehicle width............................................................................................................................................................... 56

9.4.2 Protective field side additional distance......................................................................................................................56

9.4.3 Laser scanner installation point .................................................................................................................................. 57

9.4.4 Warning field prerun time............................................................................................................................................ 57

9.4.5 Vehicle response time ................................................................................................................................................ 57

9.4.6 Brake wear and tear additional distance..................................................................................................................... 57

9.4.7 Ambient influences additional distance....................................................................................................................... 57

9.4.8 Speed with PF ............................................................................................................................................................58

9.4.9 Braking distance with PF ............................................................................................................................................58

9.4.10 Standstill monitoring ................................................................................................................................................... 58

9.4.11 Creep and reverse ...................................................................................................................................................... 58

Leuze electronic RS4 4

Page 5

Contents

10 Setting the device into service .................................................................................................................................... 59

10.1 Before first start-up ..................................................................................................................................................... 59

10.2 Switching on ............................................................................................................................................................... 59

10.3 Shutting down .............................................................................................................................................................59

10.4 Restart ........................................................................................................................................................................ 59

10.5 Starting up the replacement device ............................................................................................................................ 60

10.6 Starting up a safety sensor with the MotionMonitoring function.................................................................................61

11 Testing ........................................................................................................................................................................ 66

11.1 Testing before first start-up and after machine modification....................................................................................... 66

11.2 Regular test by an appropriately qualified person ...................................................................................................... 67

11.3 Daily functions test...................................................................................................................................................... 67

12 Maintenance ............................................................................................................................................................... 69

12.1 Clean the front screen ................................................................................................................................................69

12.2 Clean scatter screens.................................................................................................................................................70

13 Diagnostics and removing errors ................................................................................................................................ 71

13.1 What to do in case of failure? ..................................................................................................................................... 71

13.2 Operating displays of the LEDs .................................................................................................................................. 71

13.3 LED warning and error displays.................................................................................................................................. 72

13.4 Diagnostics codes.......................................................................................................................................................73

14 Repairs .......................................................................................................................................................................78

14.1 Change the front screen .............................................................................................................................................78

15 Disposing .................................................................................................................................................................... 81

16 Service........................................................................................................................................................................ 82

17 Accessories ................................................................................................................................................................83

17.1 Accessories to choose from........................................................................................................................................ 83

Leuze electronic RS4 5

Page 6

1 About this document

1.1 Other applicable documents

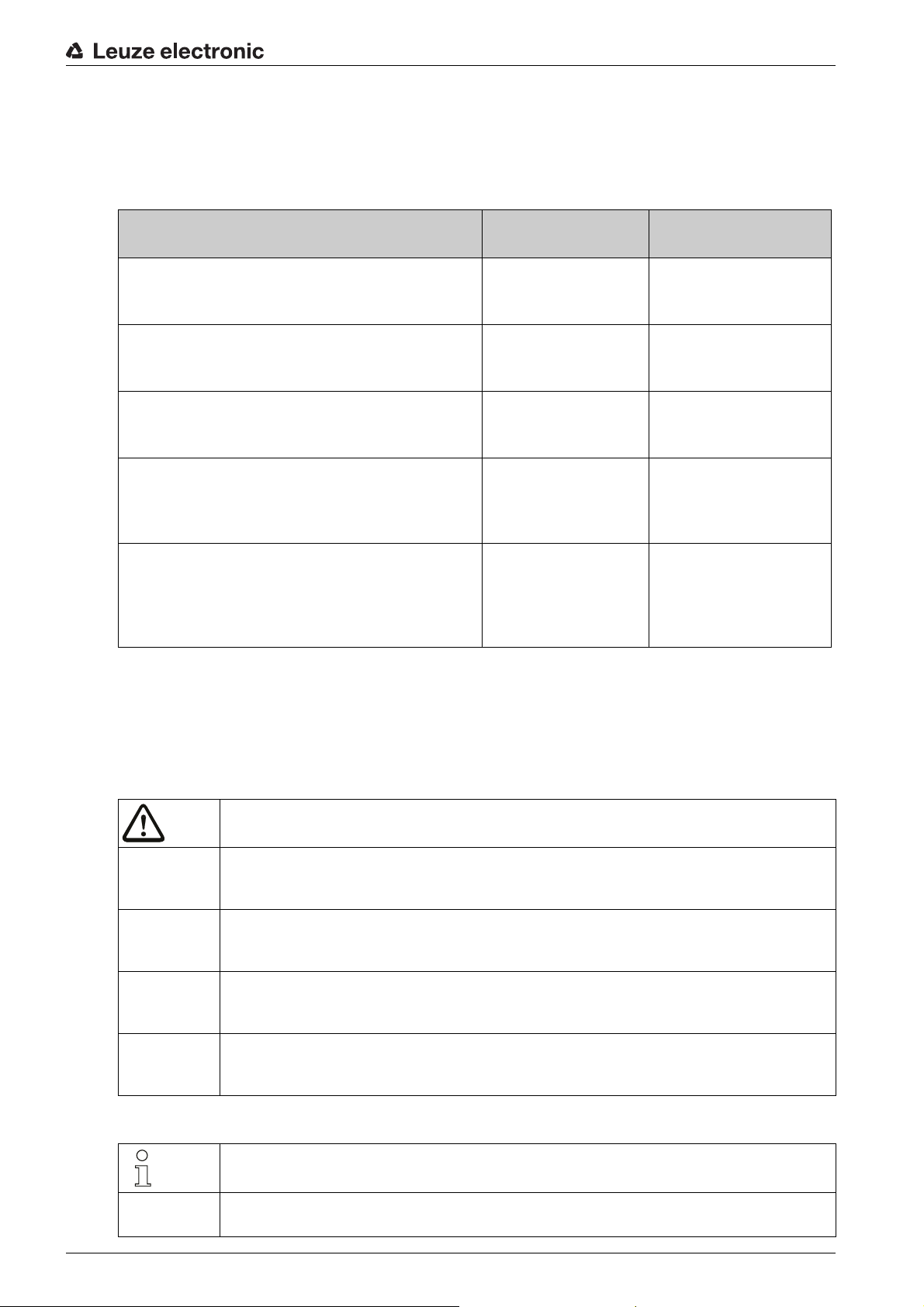

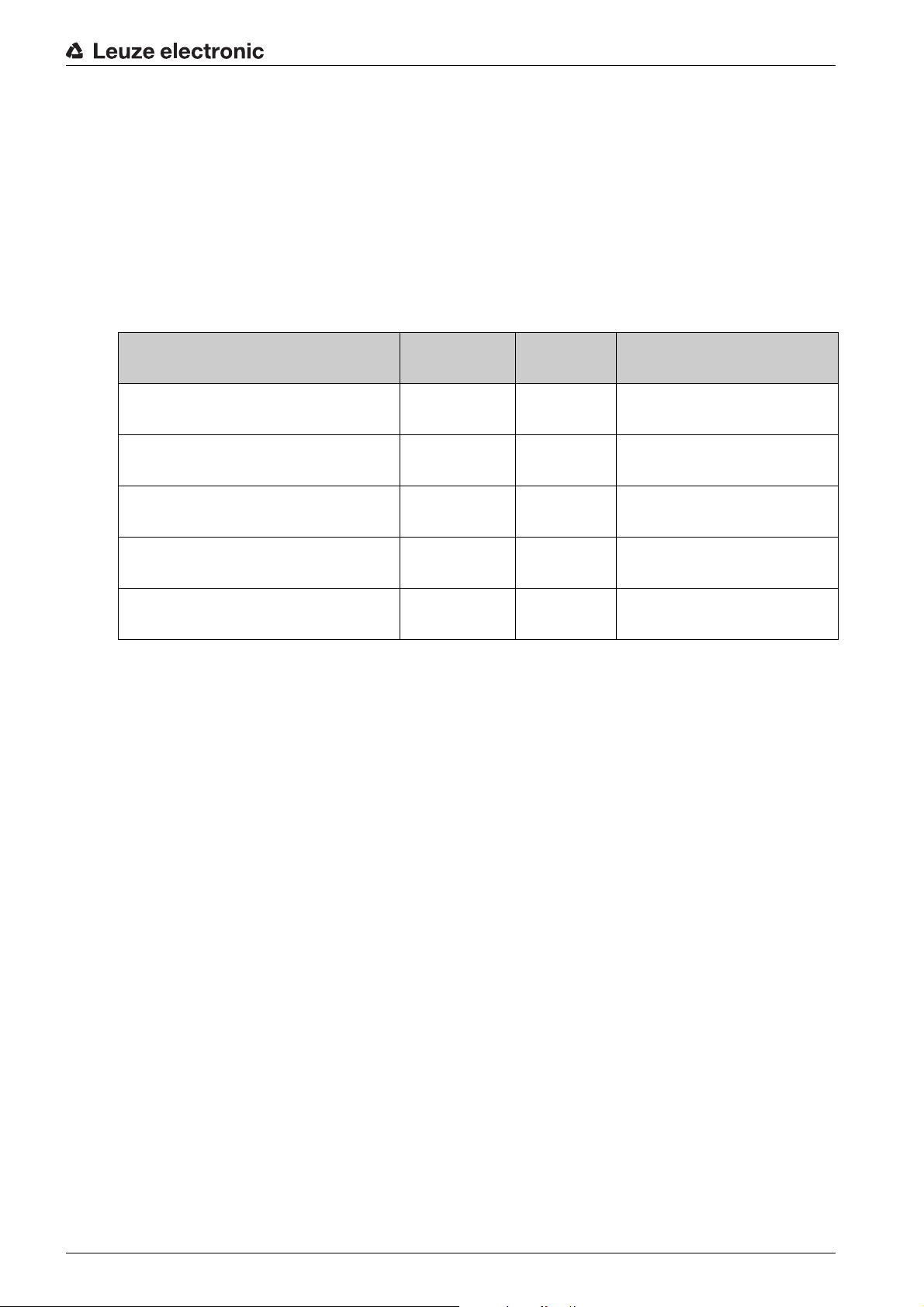

The information on the safety sensor is distributed over several documents to make working with the documents easier. You will find the documents and programs for the safety sensor in the following table:

About this document

Purpose and target group of the document Document/software

title

Software for users of the machine* for safety sensor

diagnostics if a fault occurs and for machine design

engineers* for configuring the safety sensor

Notes for the machine design engineer* Safe implementation

Notes for the machine design engineer* for configuring the safety sensor (Software RS4soft instructions)

Additional information on ROTOSCAN RS4/AS-i Additional information

Additional information on ROTOSCAN RS4/

PROFIsafe

* identifies the product that the safety sensor is installed in.

** You can download the current version of the software and all documents as PDF on the Internet at:

http://www.leuze.com/rotoscan

RS4soft Included with the product

and operation

(this document)

Safe parametering Art. no. 607143**

for the ROTOSCAN

RS4-4 connecting and

operating instructions

Additional information

for the ROTOSCAN

RS4-4 Laser Scanner

connecting and operating instructions

Source

delivery on CD-ROM**

Art. no. 607144**

Included with the product

delivery on CD-ROM

Included with the product

delivery on CD-ROM

Art. no. 607060**

Included with the product

delivery on CD-ROM

Art. no. 605054**

Included with the product

delivery on CD-ROM

1.2 Used symbols and signal words

Table 1.1: Warning symbols and signal words

Symbol for dangers

NOTICE Signal word for property damage

Indicates dangers that could damage the safety sensor if the measures for preventing

danger are not implemented.

CAUTION Signal word for minor injury

Indicates dangers that could slightly injure you if the measures for preventing danger are

not implemented.

WARNING Signal word for serious injury

Indicates dangers that could seriously or fatally injure you if the measures for preventing

danger are not implemented.

DANGER Signal word for life-threatening danger

Indicates dangers that could seriously or fatally injure you if the measures for preventing

danger are not implemented.

Table 1.2: Other symbols

Symbol for tips

Texts with this symbol provide you with further information on handling the safety sensor.

ª

Symbols for action steps

Text passages with this symbol instruct you to perform actions.

Leuze electronic RS4 6

Page 7

2 Safety

If the safety sensor is not selected and used correctly, severe accidents may result.

ª Carefully follow all notices regarding the safety sensor.

ª Make certain that all other people also know and observe the notices that apply to them.

The documents are part of the product. Non-observance presents a high risk to personal health and life.

ª Observe the documents on the CD ROM included with the product.

Alternatively you can also download the current documents on the Internet.

Internet: http://www.leuze.com/rotoscan

For an overview of other applicable documents (see chapter 1.1 „Other applicable documents“).

ª Read and observe the documents that apply for your activities in full before you work with the safety

sensor.

Safety

WARNING

Print out the relevant text parts to make reading and handling the documents easier.

2.1 Proper use

The safety sensor is used to protect people in danger zones or at points of operation on machines and to

protect objects and machine parts against the dangers of collision.

The safety sensor may only be used after it has been put into operation in accordance with the applicable

instructions, relevant rules and regulations on occupational health and safety at work and the recognized

safety-related rules and regulations have been placed on the machine by an appropriately qualified

person.

The safety sensor must be integrated into the machine's electrical control system in such a way that an

activation of the safety function safely stops or interrupts the dangerous process before a person can be

endangered.

If the machine does not allow the dangerous movement to be stopped at all times, you may not install the

safety sensor. Do not use the safety sensor, for example, together with a press with form-locking coupling.

2.2 Appropriately qualified person

Appropriately qualified is a person that,

• has acquired adequate knowledge and skills with regard to operating the machine, the configuration

and diagnostics software and testing the safety sensor through training and practical experience and

has proven their capabilities in practice,

• and is so well versed in the applicable rules and regulations on occupational health and safety at

work and the recognized safety-related rules and regulations that he/she can evaluate the safety of

the machine,

• and has been instructed in the machine's operation and safety rules and regulations,

• and has read and understood the respective applicable instructions for the safety sensor and the

machine's operating instructions,

• and has been charged by the respective person responsible for the machine's safety with the testing

of the safety sensor.

2.3 Responsibility for safety

The responsibility for the safety-assured use of the safety sensor and compliance with the regulations and

directives that apply in the country of use lies with the machine's manufacturer and company operating the

machine.

Leuze electronic RS4 7

Page 8

The manufacturer of the machine is responsible for:

• The safe design and construction of the machine.

• The safe implementation of the safety sensor.

• The provision of all relevant information to the operator company.

• Compliance with all regulations and directives for safely putting the machine into operation.

The operating company is responsible for:

• Instructing the operating staff.

• Maintaining the safe operation of the machine.

• Compliance with all occupational health and safety at work regulations and directives.

Passwords

Improperly set parameters on the safety sensor can cause serious accidents. The configuration of the

safety sensor is therefore protected by passwords.

ª Ensure that the passwords are kept locked away by the security officer.

ª The people responsible for the machine's safety must ensure that the appropriately qualified person can

properly perform the tests and work on the machine and the safety sensor in accordance with their

intended use.

2.4 Laser

The safety sensor corresponds with laser class 1. Additional activities for shielding the laser beams are

not required (safe for eyes).

Safety

ª Observe the applicable legal and local regulations for operating laser equipment.

2.5 Handling the safety sensor

ª Observe the permissible environmental conditions for storage and operation.

Front screen and scatter screens

The safety sensor's front screen and scatter screens must be clean, free of damage and properly installed.

ª Avoid touching the front screen and scatter screens.

ª Clean dirty screens immediately (according to these instructions).

ª Have damaged screens replaced immediately (according to these instructions).

Screwed-on cables

Improper handling can damage the safety sensor and result in safety-relevant signals not being sent. The

safety sensor's IP type of protection is only guaranteed with screwed-on plug cover caps.

ª Only operate, transport and store the safety sensor with screwed-on control cable (X1) and PC cable

(X2) or dummy plug (X2).

2.6 Usage limits

Laser Klasse 1

Laser Class 1

Laser de Classe 1

Only on closed rooms

The safety sensor is not suitable for use outdoors or under conditions with significant temperature

fluctuations. Humidity, condensation and other weather influences can impair the safety function.

ª Only use the safety sensor in closed rooms.

ª Observe all technical data and ambient conditions.

Industrial use only

The safety sensor is not suitable for residential areas, because it can cause radio interferences.

ª Only use the safety sensor in industrial environments.

Leuze electronic RS4 8

Page 9

Safety

Not on vehicles with combustion engines

The safety sensor is not suitable for use on vehicles with combustion engines, because alternators

or ignition systems can cause EMC disturbances.

ª Only use the safety sensor on vehicles without a combustion engine.

No changes on the safety sensor

The construction of the safety sensor may not be changed, because the protective function can no longer

be guaranteed if the safety sensor is changed. Manipulating the safety sensor also voids all warranty

claims against the manufacturer of the safety sensor.

Service life T

Values PL and PFH

according to ISO 13849-1: 2006

M

of the safety sensor refer to a service life TM of 20 years.

d

Repairs or the exchange of parts subject to wear and tear do not extend the service life.

Protective function limits

The safety sensor does not protect against:

• Projected (thrown out) parts

• Splashing/spraying liquids

• Gases and vapors

• Radiation

2.7 Guarantee the availability of the safety sensor

Vapors, smoke, dust, particles

Vapors, smoke, dust and all particles visible in the air can cause the machine to switch off unintentionally.

This can mislead the user into bypassing the safety devices.

ª Do not use the safety sensor in environments in which heavy vapors, smoke, dust or other visible par-

ticles occur at the beam level.

No stray light

Light sources can impair availability. Interfering light sources are:

• Infrared light

• Fluorescent light

• Strobe light

ª Ensure that there are no interfering light sources at beam level.

ª Prevent reflective surfaces at beam level.

ª Where applicable, take additional protective field distances into account.

ª Implement all additional measures to ensure that any special use of any effected beam types does not

impair the safety sensor's operation.

No obstructions in the protective field

ª Do not bring any additional window materials into the area monitored by the safety sensor.

2.8 Providing the company operating the machine with information

The machine manufacturer must inform the company operating the machine in detail and comprehensibly

about all activities that are required for the safety-assured operation of the machine with the safety sensor.

This also includes the forwarding of information from these instructions that the operating company

requires.

The type and content of the information may not, however, result in any questionable safety-related actions

by the user.

Where required, safety key, special tools and passwords should be maintained under the control of one or

more responsible or authorized people.

Leuze electronic RS4 9

Page 10

2.9 Exemption of liability

Leuze electronic GmbH + Co. KG is not liable in the following cases:

• safety sensor is not used as intended

• safety notices are not adhered to

• reasonably foreseeable misuse is not taken into account

• mounting and electrical connection are not properly performed

• proper function is not tested, see chapter 11 „Testing“

• changes (e.g., constructional, electrical) are made to the safety sensor.

Safety

Leuze electronic RS4 10

Page 11

3 Device description

1

1

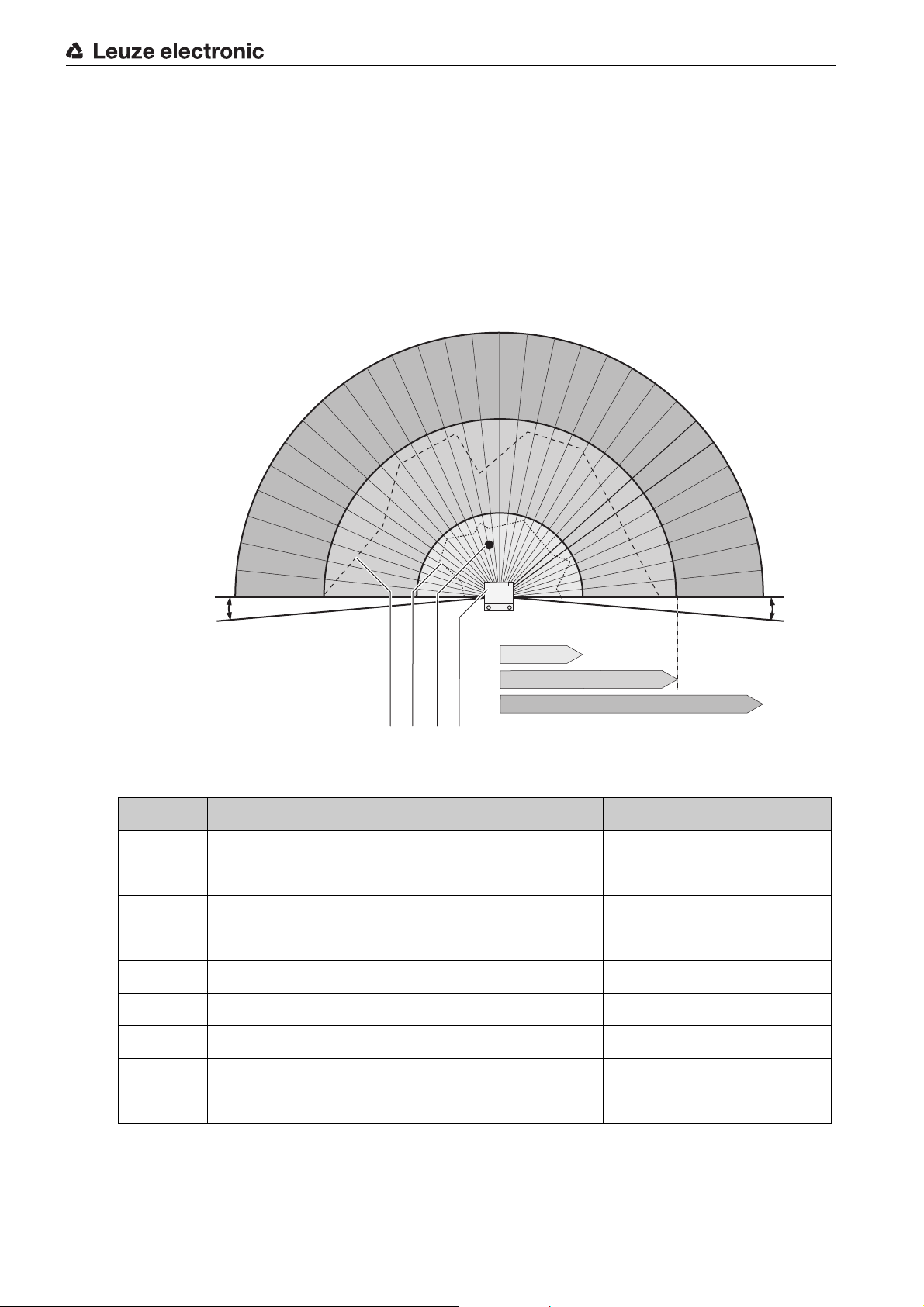

The ROTOSCAN RS4 safety sensor is an optical, two-dimensional measuring Safety Laser Scanner.

The safety sensor transmits periodic light pulses via a rotating deflection unit. The light pulses are reflected

by obstructions, e.g. people, and received by the safety sensor again and analyzed. The safety sensor

calculates the precise position of the obstruction from the light travel time and the angle of the deflection

unit at that time. If the obstruction is within a predefined area, the protective field, the safety sensor

performs a safety-related switching function. It switches the safety-related switching outputs off.

Only when the protective field is free again does the safety sensor reset the safety-related switching function, either automatically or following confirmation, depending on the operating mode.

The safety sensor can even detect people when they are wearing very dark clothes, which have a very

weak diffuse reflectance.

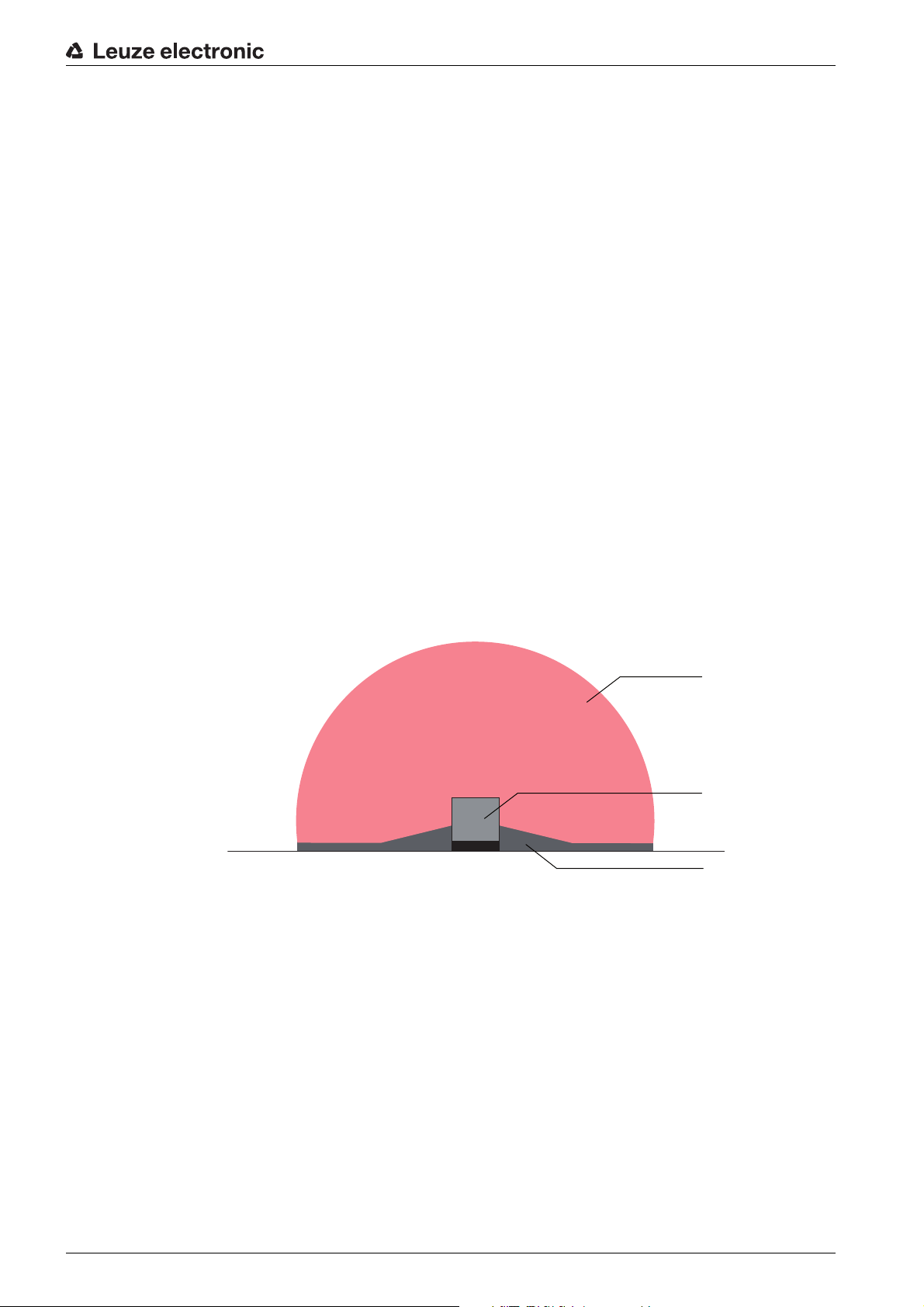

Device description

d

SF

WF

a

1 2

Figure 3.1: Safety sensor detection ranges

Pos. Description Comment

1 Configured warning field Example

2 Configured protective field Example

3 Object (person) in the protective field Example

4 Safety sensor

a Maximum measurement value logging 50 m

d Configurable protective and warning field extension -5°

e Configurable protective and warning field extension +5°

43

e

Leuze electronic RS4 11

PF Maximum protective field

WF Maximum warning field

Page 12

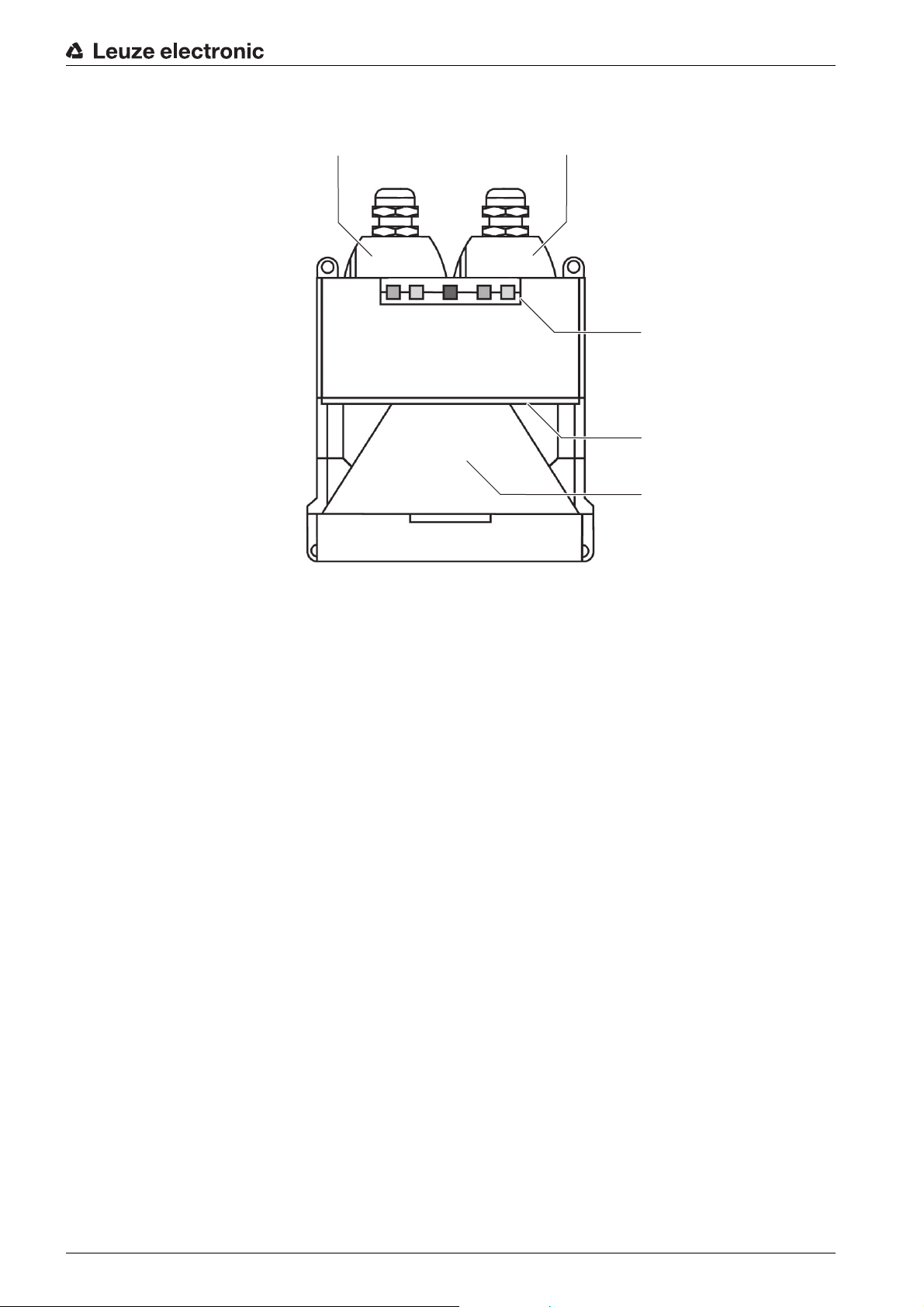

3.1 Device overview

2

4

5

3

1

Device description

1

1 X1 interface for controlling the machine, with protective cap

2 X2 interfaces for PC/laptop, with protective cap

3 Status display

4 Scatter screens

5 Front screen

Figure 3.2: Safety sensor overview

2

2

3

4

5

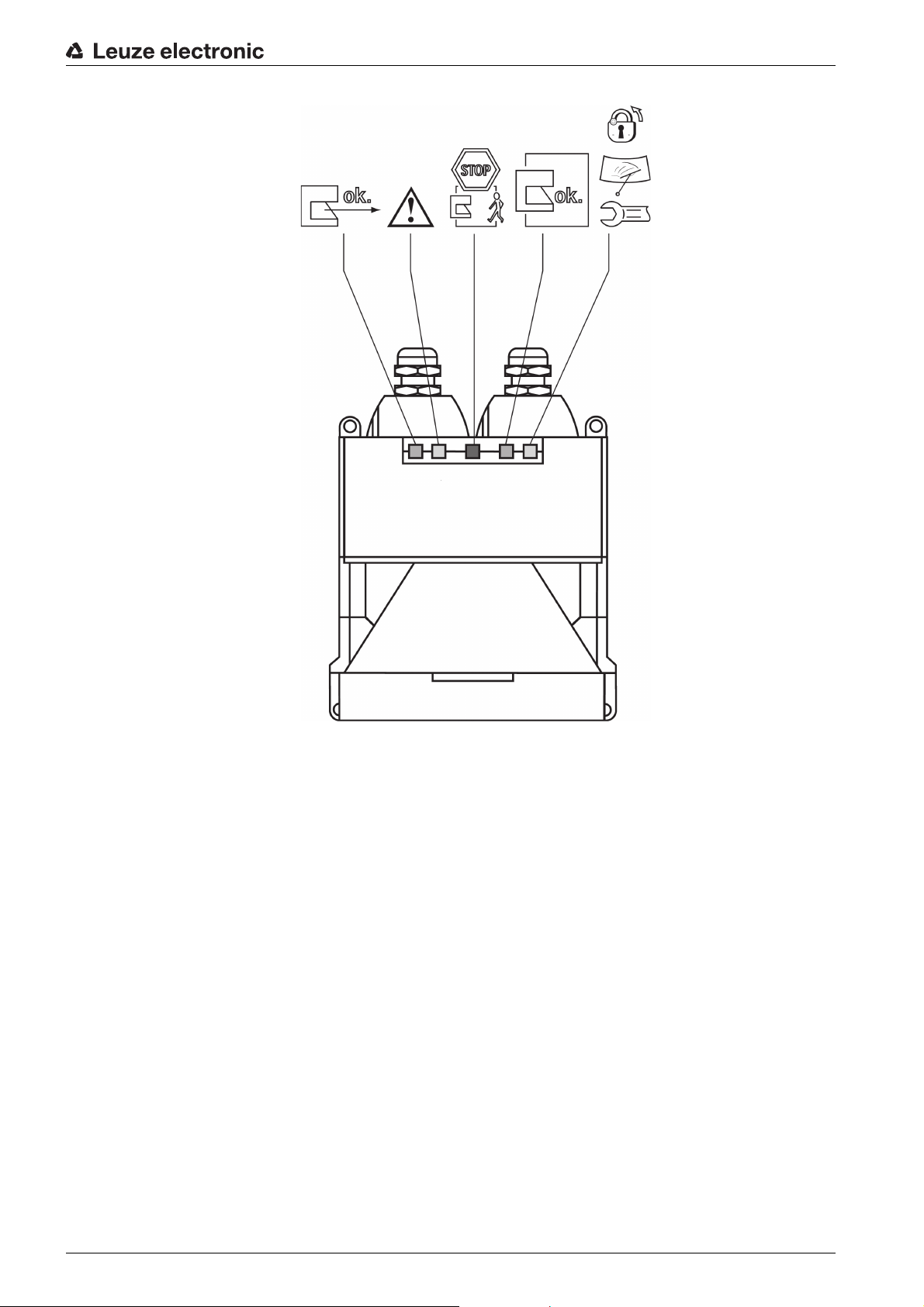

3.2 Display elements

Status display

Five LEDs on the front show the safety sensor's status

Leuze electronic RS4 12

Page 13

Device description

Figure 3.3: Status displays

1

3

52

4

Leuze electronic RS4 13

Page 14

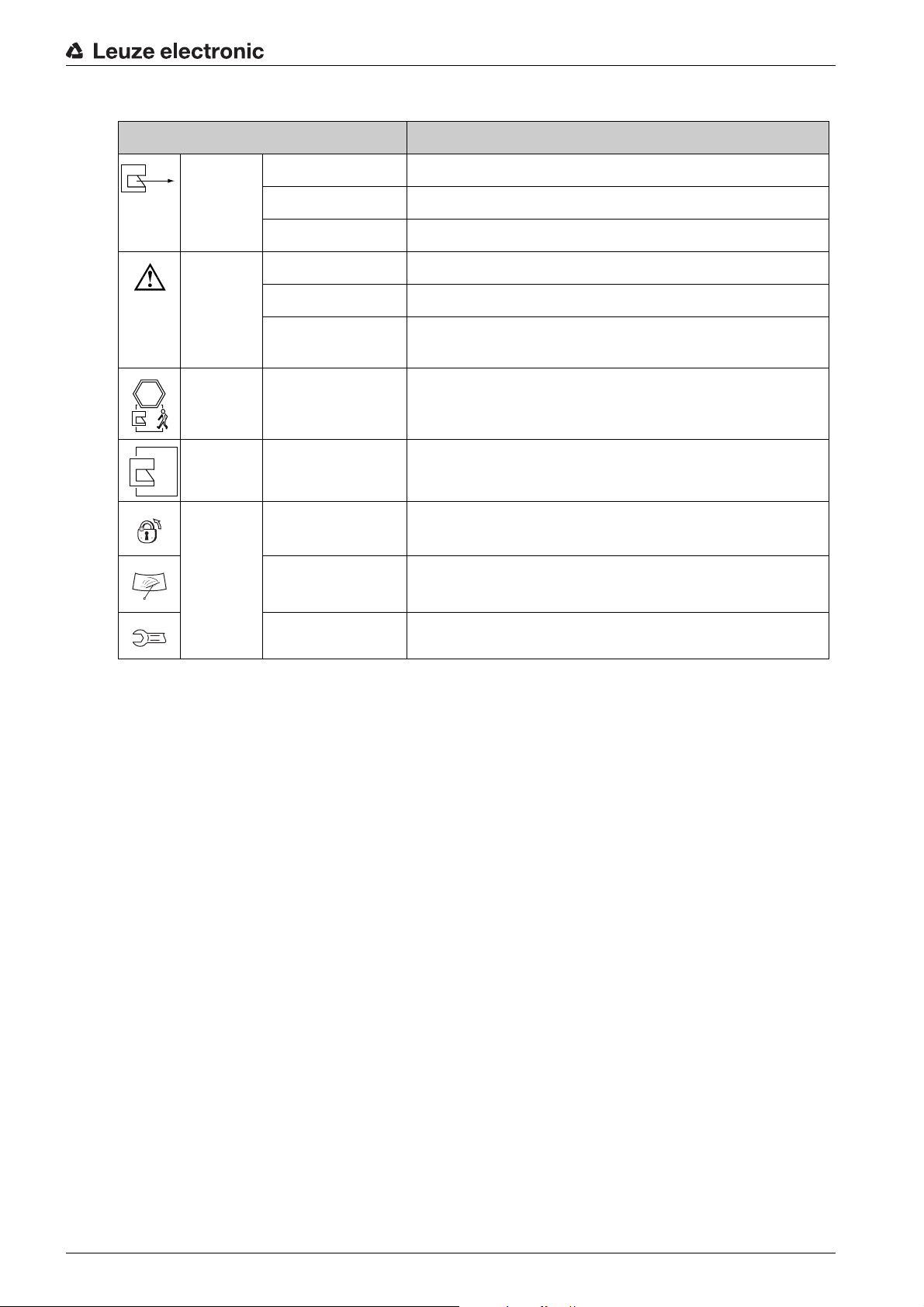

Table 3.1: Meaning of the LEDs

ok.

STOP

ok.

LED Meaning

1, green Lights Sensor function is active; the active protective field is free.

Flashes with 2 Hz Fault on the field pair control inputs.

Flashes with 4 Hz MotionMonitoring has detected a fault.

2, yellow Lights Active warning field is seized.

Flashes with 2 Hz Front screen is dirty.

Flashes with 4 Hz ConfigPlug configuration is not compatible with the safety

sensor.

3, red Lights Safety-related switching outputs (OSSD 1 and 2) are

switched off.

4, green Lights Safety-related switching outputs (OSSD 1 and 2) are

switched on.

Device description

5, yellow Lights Start/restart interlock locked.

Flashes with 2 Hz Front screen is dirty.

Flashes with 4 Hz Fault

3.3 Mounting system (option)

The mounting system makes it easier to install and align the safety sensor. The mounting system is available as an accessory (see chapter 17.1 „Accessories to choose from“).

3.4 ConfigPlug (option)

The ConfigPlug makes it easier to swap out the safety sensor. It saves the configuration when the PC is

configured and automatically transfers it with the device swap-out to the replacement device. The ConfigPlug is available as an accessory (see chapter 17.1 „Accessories to choose from“).

Leuze electronic RS4 14

Page 15

4 Functions

The functions of the safety sensor must be matched to the respective application and its safety requirements. You can activate, deactivate and adjust functions with parameters (list of all parameters of the

safety sensor see chapter 9 „Parameters“). You configure the functions with the help of the RS4soft configuration and diagnostics software.

4.1 Start/restart interlock

The start/restart interlock has two functions:

• Start interlock

• Restart interlock

Using start/restart interlock

ª In addition to the safety sensor you must also install the start/restart button. The machine operator starts

the machine with this start/restart button.

ª Position the start/restart button outside the danger zone so that it cannot be activated from the protective

fields and danger zones. The operator must be able to see all danger zones from this position.

ª Identify the zone to be released on the start/restart button so that its meaning is clear and easy to under-

stand.

ª Ensure that nobody is in the danger zone before pressing the start/restart button.

Functions

4.1.1 Start interlock

The start interlock function prevents the machine from starting automatically after switching on or after the

power supply returns.

The machine only starts when you press the start/restart button.

4.1.2 Restart interlock

The restart interlock prevents the machine from starting automatically, as soon as the protective field is

free again. The restart interlock function always includes the start interlock function.

The machine only starts again when you press the start/restart button.

4.2 Start test

The start test function compels the operator to interrupt the protective field once after the safety sensor

start, e.g. with a test rod. Only then can the machine be started.

Using the start test

If you combine the start test with the automatic restart function, the start test serves as an automatic start/

restart signal.

4.3 Automatic start/restart

The machine starts automatically as soon as the machine is switched on or the supply voltage returns and

when the protective field is free again.

Using automatic start/restart

You can use the automatic start/restart function under the following conditions.

• The automatic start/restart function is taken over by a downstream safety-related component of the

machine control system.

or

• It is not possible to walk behind or go around the effective protective field.

ª Allow for an optical and/or acoustic start warning.

4.3.1 Automatic start

The automatic start function starts the machine automatically as soon as the supply voltage is present.

Leuze electronic RS4 15

Page 16

4.3.2 Automatic restart

The automatic restart function starts the machine automatically as soon as the protective field is free again.

4.4 Dust suppression

The dust suppression function increases the availability of the safety sensor when small particles are in

the air, e.g. material chips or insects.

Only deactivate the dust suppression function when, in addition to people, the safety sensor must also

detect extremely fast and small objects in your application.

If you use the safety sensor for the mobile danger zone guarding of DTSs, you must select the speed range

of your vehicle to optimize dust suppression.

4.5 Field pair switchover

The safety sensor has four or eight field pairs. Switchover between the field pairs is possible at all times,

provided the operating situation allows this.

During the switchover process the safety sensor monitors the field pair activated before the changeover

until a new one has been clearly activated. Use the field pair switchover when the danger zones vary

depending on the activity of the machine or the operating status, e.g. driverless transportation system

(DTSs), to control the protective field switchover for straight and curved stretches.

If the rules for field pair switchover are not complied with, the safety sensor signals a fault and the machine

stops.

Functions

Using field pair switchover

You can configure and switch over the field pairs according to the different requirements. The switchover

is performed via the corresponding control inputs on the X1 interface.

The precepts for the switchover depend on the amount of the selected field pairs and their numbers. The

activated field pair must correspond with the respective operating mode. The time of the switchover must

correspond with the machine's risk assessment. You must take the braking distances, response times and

machine stopping times, e.g. influenced by overlapping protective fields, into account.

If these rules are not complied with, the safety sensor goes to a fault status within 40 ms. The green LED

1 flashes with 2 Hz.

The following rules apply for switching over four field pairs:

• First the control unit must switch to a new field pair before it switches of the previous one.

• The switchover must be made within 1 sec. Both field pairs are monitored during the switchover

time.

• All field pairs must never be deactivated during the switchover.

• The switchover process performed by the control system must agree with the safety sensor's configuration. This configuration is specified with the configuration and diagnostics software.

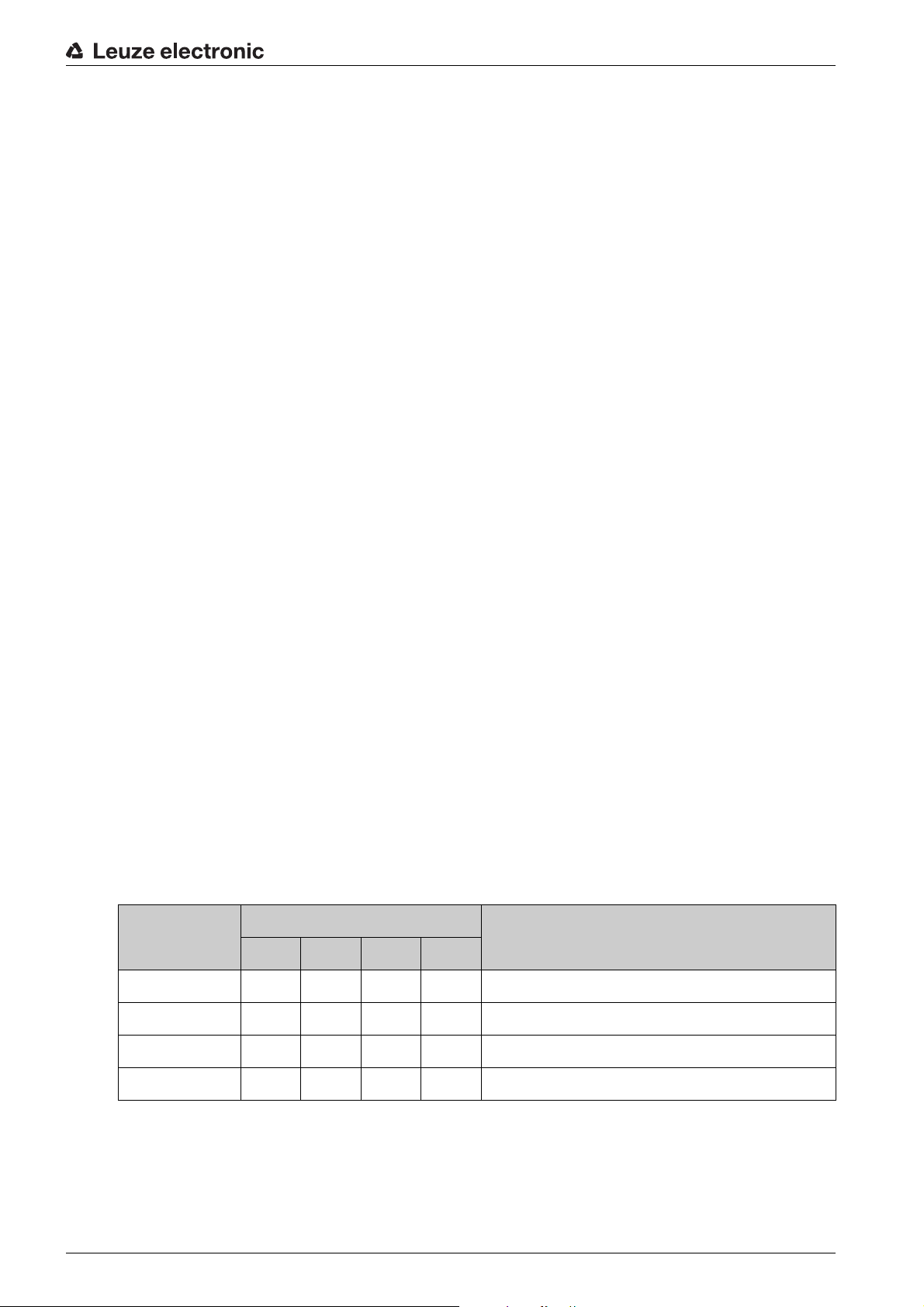

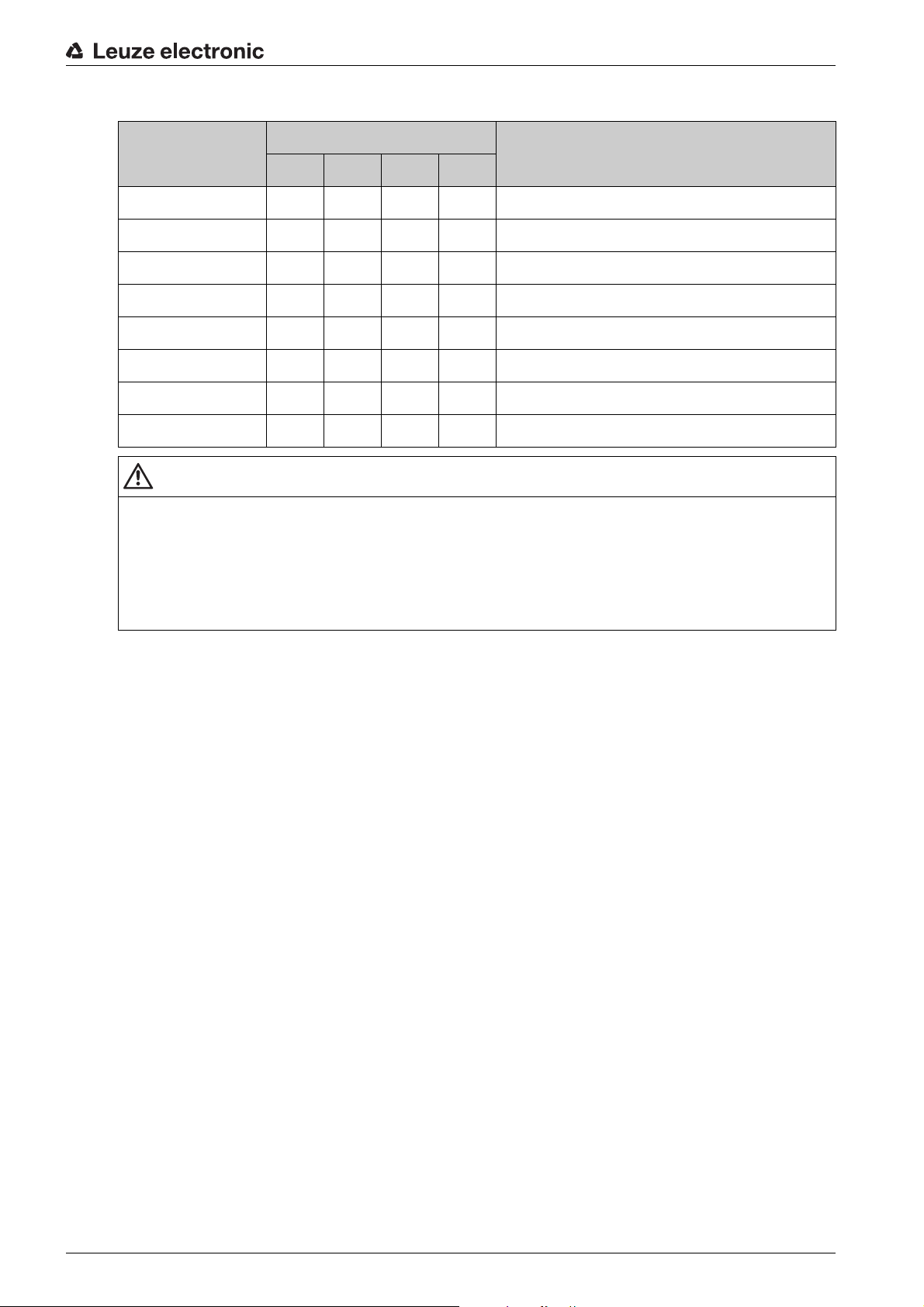

Table 4.1: Connection of control inputs FP1 to FP4 with activation of field pairs 1 to 4.

Field pair Control input Description

FP1 FP2 FP3 FP4

1 1000Field pair 1 is active

2 0100Field pair 2 is active

3 0010Field pair 3 is active

4 0001Field pair 4 is active

The following rules apply for switching over eight field pairs:

• The switchover must be made within 40 ms, i.e. after 40 ms an input connection must be valid and

stable. The old field pair is monitored during the switchover time. The new field pair is monitored after

max. 80 ms.

• The switchover process performed by the control system must agree with the safety sensor's configuration. This configuration is specified with the configuration and diagnostics software.

Leuze electronic RS4 16

Page 17

Functions

Table 4.2: Connection of control inputs FP1 to FP4 with activation of field pairs 1 to 8.

Field pair Control input Description

FP1 FP2 FP3 FP4

1 1000Field pair 1 is active

2 0100Field pair 2 is active

3 0010Field pair 3 is active

4 0001Field pair 4 is active

5 1110Field pair 5 is active

6 1101Field pair 6 is active

7 1011Field pair 7 is active

8 0111Field pair 8 is active

WARNING

Field pair switchover to field pair 8 deactivates the monitoring function

No field pair is now monitored; the safety outputs (OSSDs) remain constantly active.

ª Never start the safety sensor with field pair 8.

ª Only use field pair 8 when there is no danger for people present, e.g. with vehicles in creep and

reverse, in the area of loading or park positions or during machine cycles with which there is no danger

for the operating staff.

4.6 Reference boundary monitoring

The reference boundary monitoring function prevents unintentional misalignment and deliberate manipulation of the safety sensor. If a protective field contains an area with reference boundary, the safety sensor

not only monitors interruptions of the protective field, it also monitors the concurrence of the measured

area contour with the set reference boundary. If the measurement values of the area contour deviate from

the defined reference boundary by more than the tolerance zone, i.e., if no object is detected in the area

with reference boundary, the safety sensor switches off and the safety-related switching outputs (OSSDs)

switch to off. The reference boundary function is set together with the definition of the protective field

boundaries.

4.7 MotionMonitoring

The MotionMonitoring function assists you during the configuration of the safety sensor for the mobile

danger zone guarding application for side-tracking skates and, during travel operation of the side-tracking

skate, monitors whether the control has selected the correct protective field for the given operating situation.

Using its internal measurement values, the safety sensor calculates the current speed of the side-tracking

skate and compares this value with the speed configured in the speed matrix of the safety sensor for the

protective field. This control function of MotionMonitoring leads to the following behavior:

• If the speed is higher than the speed given for the protective field, the safety sensor corrects by one

protective field upwards. If a second correction is required with an even faster speed, the safety sensor stops the side-tracking skate.

• If the maximum speed is exceeded, the safety sensor stops the side-tracking skate immediately.

Two further functions are integrated into the MotionMonitoring function, which are assigned to the two field

pairs, 7 and 8:

• Further travel blocking – field pair 7

• Creep and reverse – field pair 8

Leuze electronic RS4 17

Page 18

Functions

Further travel blocking

The further travel blocking function prevents the side-tracking skated from moving as long as field pair 7

is active. The safety sensor switches the safety-related switching outputs in field pair 7 off. The sidetracking skate can start to move again when the control switches to another protective field.

Creep and reverse

A safety sensor is mounted in both directions when a side-tracking skate travels forwards and backwards.

The creep and reverse function deactivates the safety sensor that is positioned opposing the current travel

direction. This safety sensor only monitors the speed and direction of movement: no protective field and

no warning field is monitored; the safety-related switching outputs remain set to ON. The maximum speed

with a creep speed is 100 mm/s. If the side-tracking skate moves faster than 100 mm/s, the safety sensor

switches the safety-related switching outputs off and stops the side-tracking skate. The creep function is

used as the side-tracking skate approaches the minimum distance to loading and unloading stations.

Using MotionMonitoring

Requirements for using the MotionMonitoring function:

• Side-tracking skate (AGV) with linear movement

• Transportation path length max. 50 m

• Transportation path restricted at both ends by a wall or boundary

Pedestrian traffic on the transportation path is possible because it is included in the calculations by

the safety sensor

• Side-tracking skate speed 6 m/s

• Only one side-tracking skate per path

ª Enter the speed levels of the AGV and the braking distance with maximum speed in the speed matrix

with the configuration.

The software interpolates the missing braking distances and automatically defines the protective and

warning fields.

During the initial start up, the configuration and diagnostic software displays the calculated measurement

values for speed and distance and a speed monitoring status display in a separate dialog field.

Notices on starting up a safety sensor with the MotionMonitoring function (see chapter 10 „Setting the

device into service“).

Function sequence

The protective field activated by the vehicle control— specified by protective field contour and travel

speed— is monitored by the safety sensor for protective field violation and excess travel speed!

The following steps describe the principle operating procedure of the MotionMonitoring function:

• Via 4 standard outputs, the vehicle control activates the protective field that is adapted to the operating system on the control inputs of the safety sensor:

• small protective field for slow travel

• medium protective field for moderate travel

• large protective field for fast travel

• PF8 for reverse travel

• The safety sensor monitors this protective field and switches off in the event of a violation.

• While the protective field is free, the safety sensor ascertains the current travel speed and travel

direction.

• The travel speed and travel direction are compared with the values configured in the speed matrix.

• If in agreement, i.e., the measured speed is smaller than the configured value, the system functions

correctly and the safety sensor activates alarm output 2.

• If the measured speed is greater than the configured value, the safety sensor assumes that a fault

has occurred in the system and deactivates alarm output 2.

Faults lead to two escalation levels:

• The protective field is corrected for a short time (5 s) while the next larger is automatically moni-

tored by the safety sensor.

• If the speed increases further or if the maximum speed is exceeded, the safety sensor switches off

the safety-related switching outputs; an entry appears in the diagnostics list.

Leuze electronic RS4 18

Page 19

5 Applications

3

4

3

3

The following chapters essentially describe the safety sensor's usage possibilities. To safely configure and

mount the safety sensor for the respective application (see chapter 6 „Mounting“).

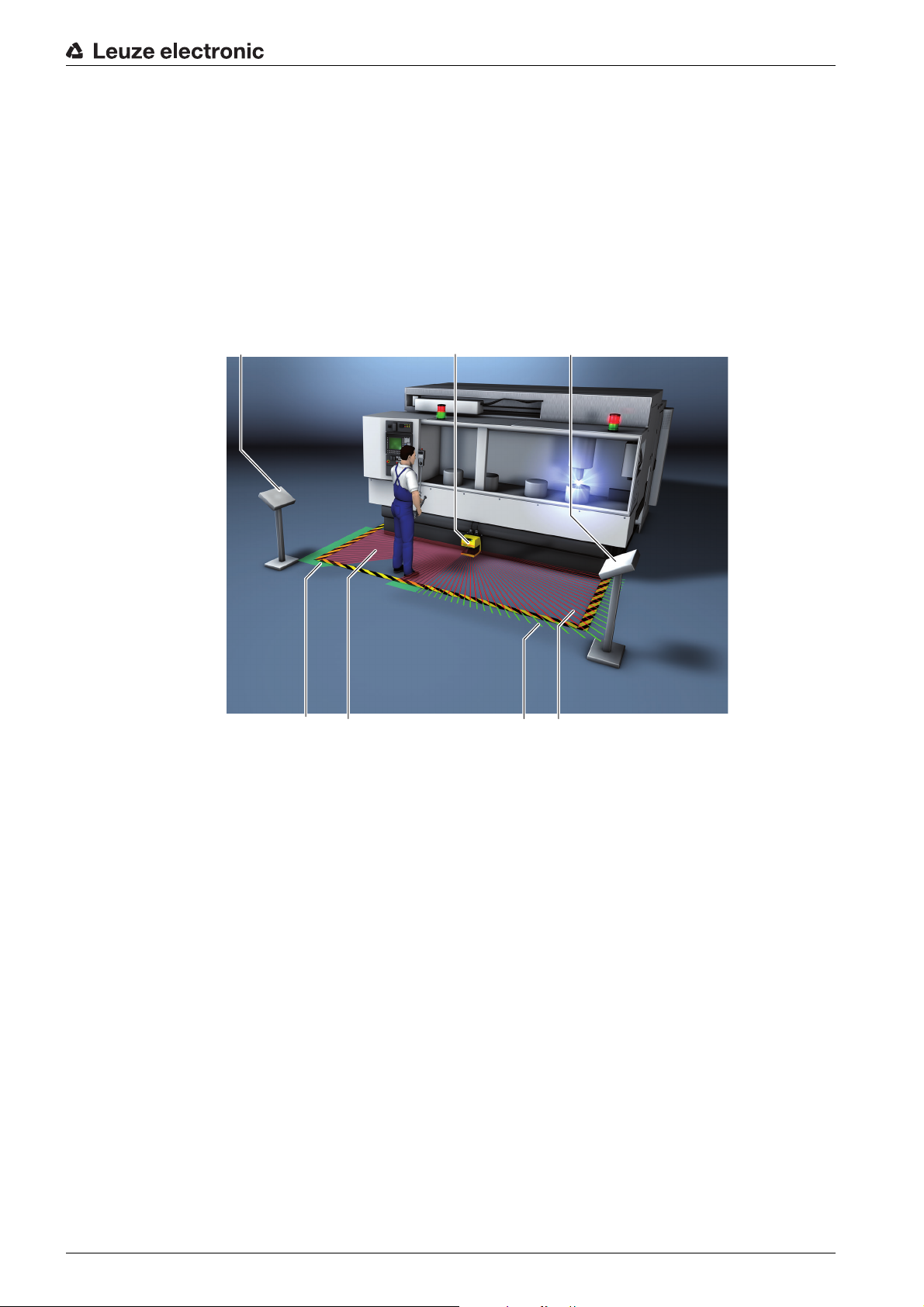

5.1 Stationary danger zone guarding

Stationary danger zone guarding enables a very spacious protection of people on machines that are to

remain as accessible as much as possible. The safety sensor is applied as a stop-activating and presencedetecting protective device. The safety sensor's protective field is set up horizontally in front of the machine

or system's point of operation.

You can also use the stationary danger zone guarding if you do have to guard areas under the machine

or at the rear that are not visible.

Applications

1

4

6

1 EMERGENCY STOP command device and start/restart button

2 Safety sensor

3 Protective field 2, activated

4 Protective field 1, deactivated

5 Warning field 2, activated

6 Warning field 1, deactivated

2

5

1

3

Figure 5.1: Stationary danger zone guarding with two alternating work areas

Leuze electronic RS4 19

Page 20

5.2 Stationary point of operation guarding

3

4

3

3

Hand and arm protection are always required when people must work at the point of operation. The safety

sensor is applied as a stop-activating and presence-detecting protective device. The safety sensor's

protective field is set up vertically in front of the machine or system's point of operation. With small protective field dimensions the safety sensor provides the correspondingly required high resolution level. A sufficient safety distance to the point of operation ensures the finger protection.

Applications

5

3

1 Safety sensor

2 Reference boundaries of both protective fields

3 EMERGENCY STOP command device and start/restart button

4 Protective field 1, activated

5 Protective field 2, deactivated

1

4

2

3

Figure 5.2: Stationary point of operation guarding with protective field switchover

Leuze electronic RS4 20

Page 21

5.3 Stationary access guarding

4

3

3

Stationary access guarding protects people that step into a danger zone. The vertically aligned protective

field of the safety sensor detects the passage of a person. A side post and the floor serve as reference

boundary for monitoring the position of the protective field. In contrast to danger zone guarding, the safety

sensor no longer registers a person in the danger zone after the passage. This is why the start/restart inter-

lock function is vital for access guarding.

Applications

1

3

1 Safety sensor

2 Reference boundary of the protective field

3 EMERGENCY STOP command device and start/restart button

4 Protective field

Figure 5.3: Stationary access guarding

4

2

Leuze electronic RS4 21

Page 22

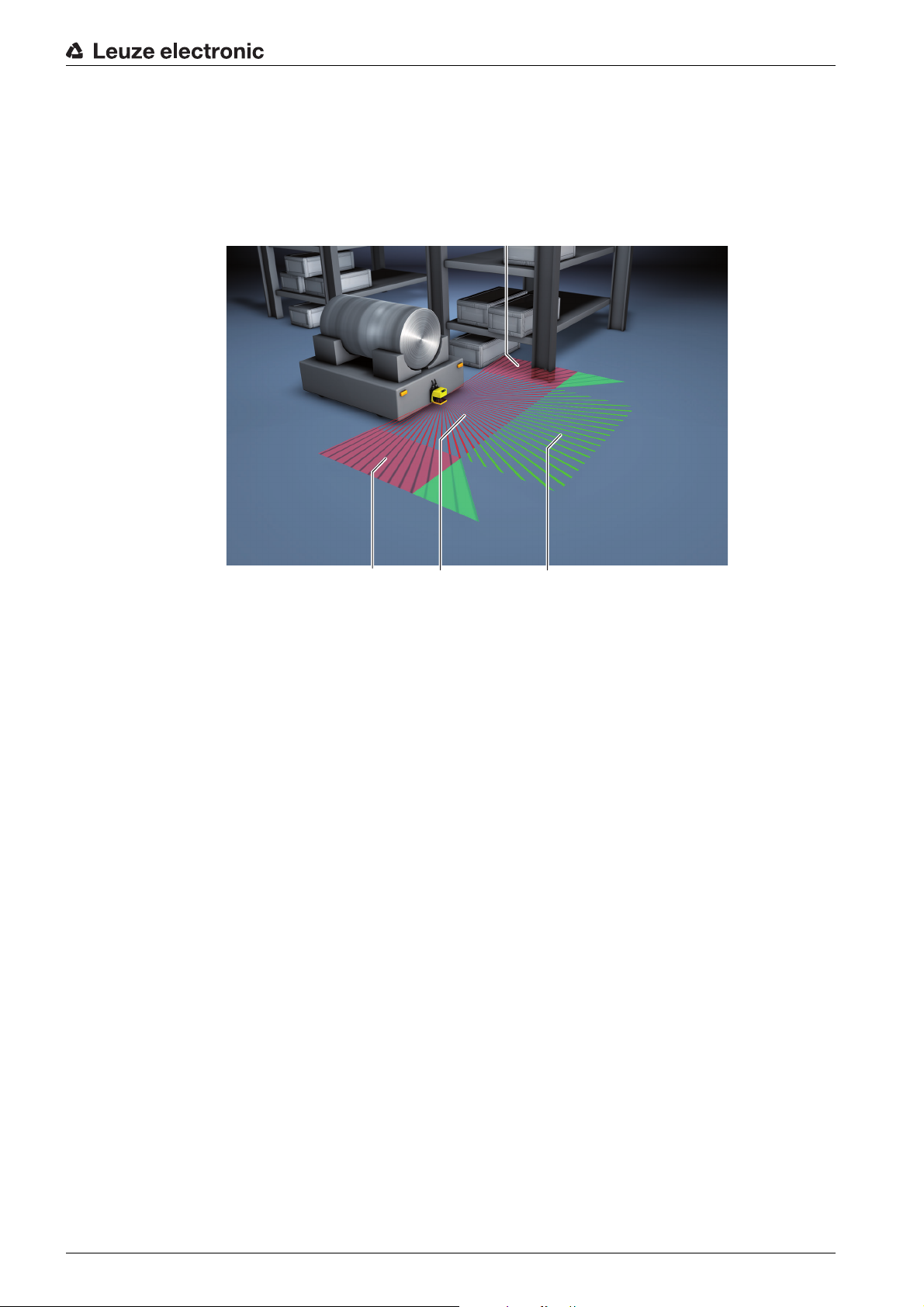

5.4 Mobile danger zone guarding

4

3

3

Mobile danger zone guarding protects people that are located in the transportation path of an automated

guided vehicle. The distance between the protective field front edge and the vehicle front must be greater

than the stopping distance of the vehicle with selected speed and maximum load. A safe control system

selects speed-dependent protective fields and can activate side horizontal protective fields for curved

stretches.

Applications

3

4

1 Protective field 1 for forward travel, activated

2 Warning field 1 for forward travel, activated

3 Protective field 2 for curved stretch, left, deactivated

4 Protective field 3 for curved stretch, right, deactivated

Figure 5.4: Mobile danger zone guarding

1

2

Leuze electronic RS4 22

Page 23

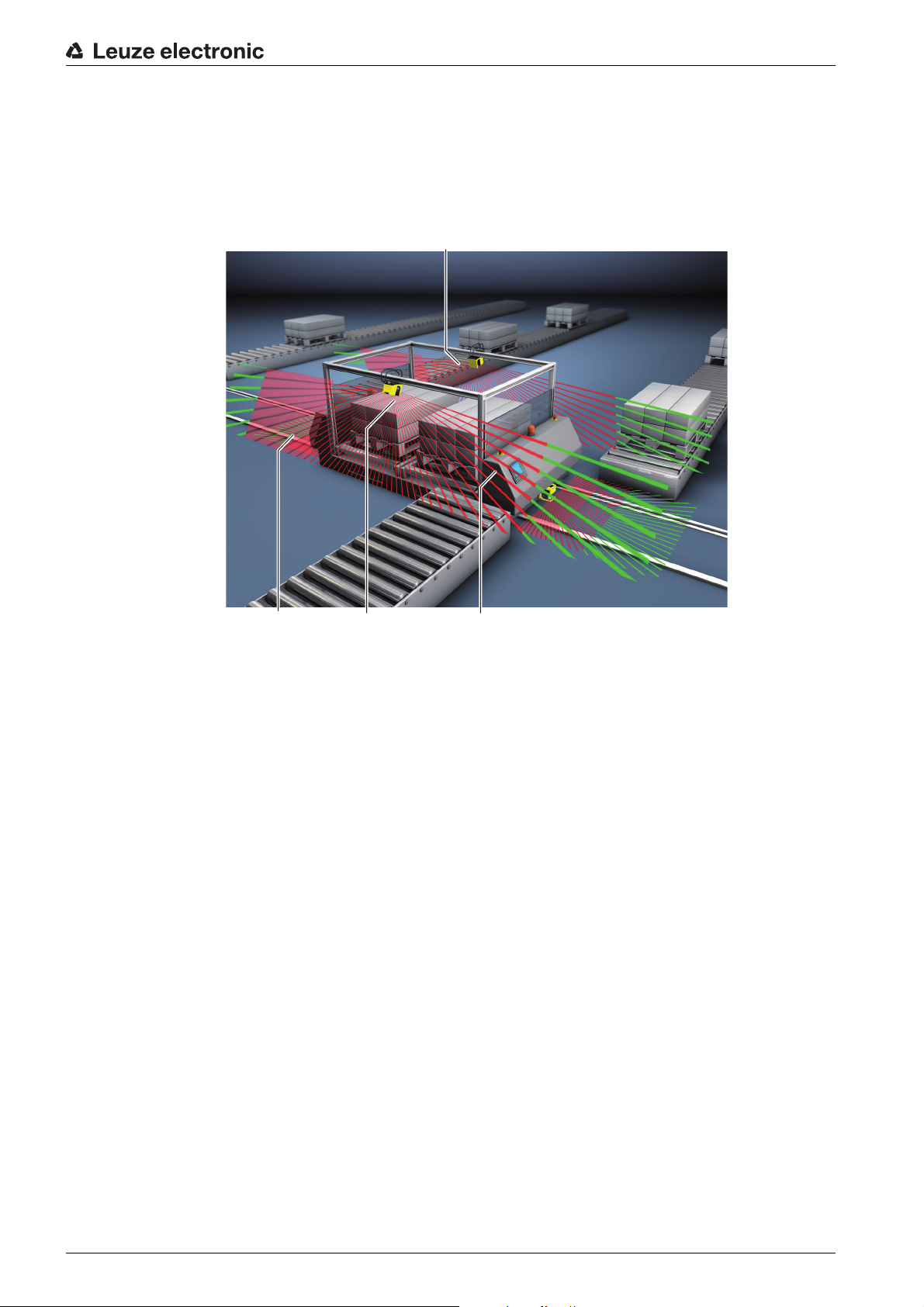

5.5 Mobile side guarding

4

3

3

Mobile side guarding protects people and objects that are located on the vehicles path. This application is

used when very low arranged conveyor lanes do not permit an unobstructed passage of horizontal, lateral

overlaying protective fields. The safety sensors are positioned laterally and the protective fields are

arranged vertically, at a slight tilt. The position of the front edges of the side protective fields is oriented

here on the position of the front edge of the horizontal protective field.

Applications

4

2

1 Protective field and warning field pair for forward travel, activated

2 Protective field and warning field pair for reverse travel, deactivated

3 Protective field and warning field pair for side guarding, right, activated

4 Protective field and warning field pair for side guarding, left, activated

3

1

Figure 5.5: Mobile side guarding on side-tracking skates

Leuze electronic RS4 23

Page 24

6 Mounting

6.1 Basic infos

The safety sensor's protective function is only guaranteed when the device arrangement, configuration,

protective field dimensioning and installation are coordinated with the respective application.

The installation work must only be performed by an appropriately qualified person in compliance with the

applicable standards and these instructions. The installation must be thoroughly inspected on completion.

ª You must observe and comply with the respective relevant machine-specific standards and regulations.

Basic procedure

ª Select the appropriate device type for the application.

Application Device type Resolution Configuration and installa-

Mounting

tion notes

Stationary danger zone safeguarding RS4-x

RS4-xE

Stationary point of operation guarding RS4-xE 30-40 mm see chapter 6.4 „Stationary

Stationary access guarding RS4-xE 150 mm see chapter 6.5 „Stationary

Mobile danger zone guarding on DTSs RS4-x

RS4-xM

Mobile side guarding on DTSs RS4-x 150 mm see chapter 6.7 „Mobile side

ª Determine the installation point.

ª Determine whether you are going to install the safety sensor with or without the mounting system.

ª During mounting, use the four supplied M5 screws or four similar screws with a diameter of 5 mm, and

make certain that the mounting elements or mounting construction supports at least four times the

weight of the device with or without mounting system.

ª Determine the size of the protective field on the basis of the point of installation, the calculated safety

distances and additional distances.

ª Determine the start/restart operating mode required for the application.

ª If you are using start/restart interlock, determine the position for the start/restart button.

ª Determine the conditions for the field pair switchover, if required.

ª Configure the safety sensor with the configuration and diagnostics software.

Many safety-relevant parameters are preset in the configuration and diagnostics software. Use these

preset values where possible.

ª Create a record document for the device configuration and protective field dimensioning. The document

must be signed by the person responsible for the configuration.

Include this document with the machine documentation.

ª Install protective enclosures or safety bars if the safety sensor is in an exposed position.

ª If there is a risk that the safety sensor will be used as a climbing aid, install a suitable physical cover

over the safety sensor.

Ensure that machine parts, protective grids or covers do not impair the safety sensor's field of vision.

50-70 mm see chapter 6.3 „Stationary

danger zone guarding“

point of operation guarding“

access guarding“

70 mm see chapter 6.6 „Mobile dan-

ger zone guarding on DTSs“

guarding on DTSs“

Leuze electronic RS4 24

Page 25

6.2 Basic infos on the protective field dimensioning

ª Dimension the protective field big enough that the safety sensor's switch-off signal can stop the danger-

ous movement in good time.

If several protective fields are selected with field switchover, this condition applies for all protective

fields.

Protective fields with a radius of less than 200 mm (safety sensor close range) are not permitted and

are therefore preset as minimum contour.

ª If you cannot sufficiently dimension a protective field, use additional protective measures, e.g. protec-

tive grids.

ª Ensure that the protective field cannot be walked behind in the direction of the danger zone.

ª Observe all delay times, e.g. safety sensor response times, control element response times, braking

times or machine or AGV stopping times.

ª Take changed delay times, which, for example, can be caused by reducing the braking force, into

account.

ª Observe shadowing effects, e.g. surfaces and areas behind static objects. People in the shadows of

these objects will not be detected by the safety sensor.

ª Observe the lateral tolerance when dimensioning the protective fields (see chapter 7 „Technical data“).

ª Do not use cone-shaped protective field contours, as these do not guarantee any protective effect.

ª Take the additional distances required for the application into account.

Mounting

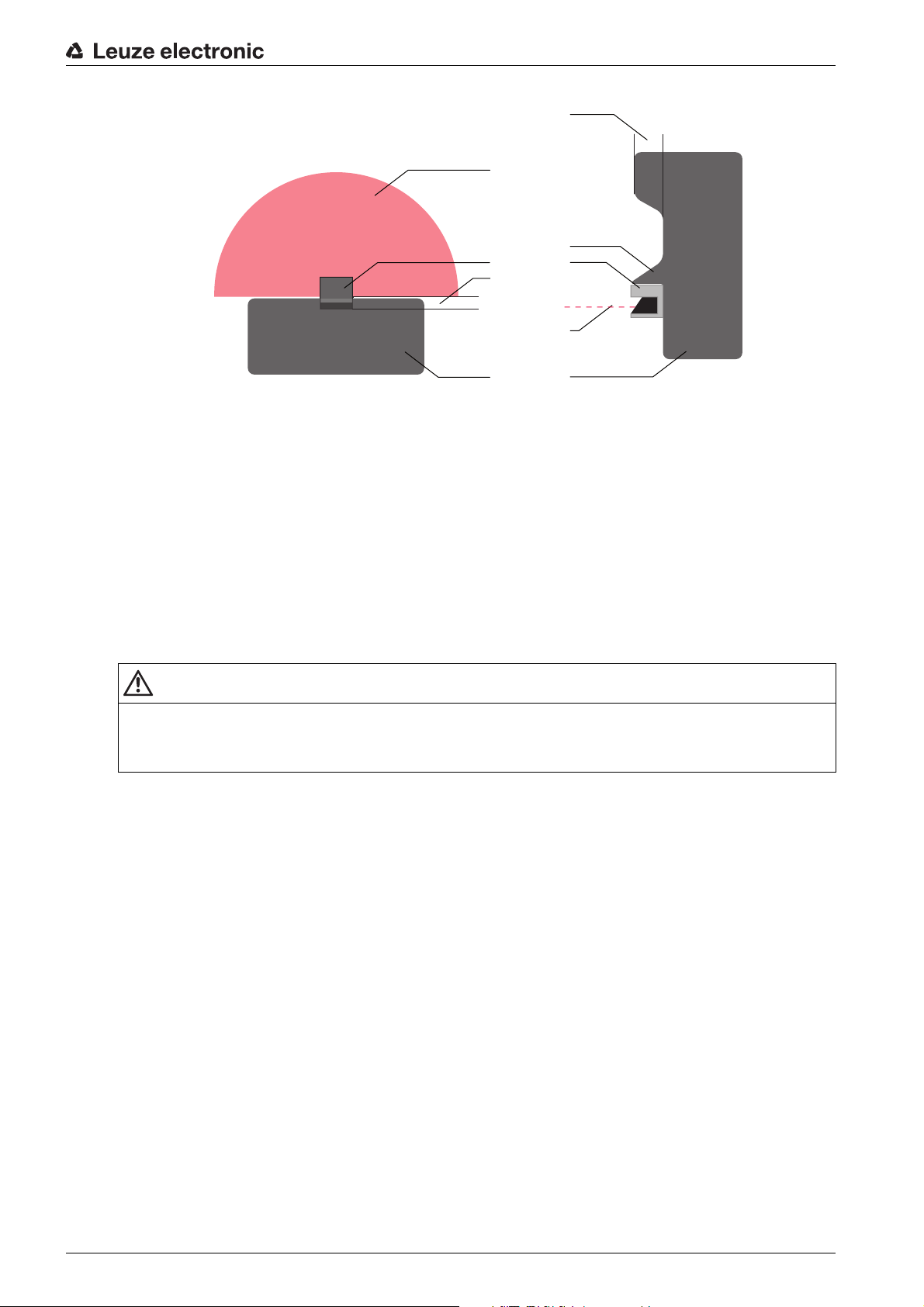

6.2.1 Handling unmonitored areas

There is an area behind the safety sensor that the safety sensor does not monitor. Unmonitored areas can

also materialize, e.g. if you install a safety sensor on a rounded off vehicle front.

It must not be possible to walk behind unmonitored areas.

1 Safety sensor

2 Protective field

3 Unmonitored area

Figure 6.1: Protective field shape – unmonitored areas

ª Prevent access to an unmonitored area with screens.

ª Prevent walking behind by countersinking the safety sensor into the machine contour.

2

1

3

Leuze electronic RS4 25

Page 26

Mounting

1

2

5

3

1

3

2

1 Countersinking into the machine contour

2 Protective field

3 Safety sensor

4 Machine

5 Physical cover

Figure 6.2: Stepping behind protection by countersinking into the machine contour

ª Use a physical cover set at an angle over the safety sensor if you expect that the safety sensor will be

used as a climbing aid or standing surface.

6.2.2 Protective field setup with adjacent safety sensors

The safety sensor has been developed in a way that prevents several safety sensors from interfering with

one another as much as possible. Several adjacent safety sensors can, however, cause the response time

to increase if the fields overlap.

WARNING

The response time extends with reciprocal influencing of adjacent safety sensors.

ª If you do not plan for any measures against reciprocal influencing, take a response time extension of

40 ms into account with the safety distance calculation.

ª Plan for shielding with stationary applications.

The shielding must be at least as high as the safety sensor's front screen and flush with the front housing

edge.

If you plan for a shielding that is still within the countersinking in the machine contour, the resolution of

the protective fields must not be impaired at any accessible points.

You require the reciprocal shielding with both horizontal and vertical alignment of the protective fields.

4

4

Leuze electronic RS4 26

Page 27

Mounting

3

1

2

4

5

4

1

2

1 Point of operation

2 Safety sensor

3 Machine with countersinking for Sensor installation

4 Protective fields

5 Shielding

Figure 6.3: Shielding prevents reciprocal influencing of safety sensors set up beside one another.

ª Install the safety sensors off-set on the height.

100 mm

Figure 6.4: Height offset installation, parallel alignment

ª Install the safety sensors with crossed alignment.

Figure 6.5: Installation beside one another, without height offset, crossed alignment

Leuze electronic RS4 27

Page 28

Figure 6.6: Opposing installation, without height offset, crossed alignment

6.3 Stationary danger zone guarding

Mounting

Figure 6.7: Safety sensor activates the stop and, with protective field with rear area protection, performs

a presence-detecting function

Procedure

ª Determine the height of the beam level.

ª Calculate the necessary safety distance and determine the required additional distances for your appli-

cation.

ª Define the protective field boundaries and the warning field boundaries if required.

ª Configure the protective field so that the safety-related switching outputs are switched off from every

accessible point with sufficient minimum distance "D".

ª Mark the protective field boundaries on the floor.

You can easily test the safety sensor along this marking.

Leuze electronic RS4 28

Page 29

6.3.1 Beam level height

The minimum height of the beam level depends on the safety sensor resolution. To detect a human leg a

resolution of 50 mm is required at ankle height, and 70 mm at calf height (300 mm off the floor).

Mounting

Figure 6.8: Beam level close to the floor – 50 mm

resolution is required

H

Lowest permissible beam height from the standing surface level in mm

MIN

d Safety sensor resolution in mm

H

= 1000 mm

MAX

6.3.2 Safety distance "S"

The B standard, ISO 13855/EN999 specifies the general formula for the safety distance as follows:

Figure 6.9: Beam level at 300 mm – 70 mm reso-

lution is required

S Safety distance in mm

K Approach speed in mm/s

For parallel approach on a horizontally arranged protective field: 1600 mm/s

T

Safety sensor response time in s

1

T

Safety interface device response time in s, if used

2

T

Machine stopping time plus addition for deterioration in s

3

C Additional distance because of the possibility of reaching over in mm

Leuze electronic RS4 29

Page 30

6.3.3 Additional distance "C" because of the possibility of reaching over

You prevent reaching the point of operation by reaching over with the additional distance "C":

H Beam level height above the floor in mm

C

= 850 mm

MIN

H

= 1000 mm

MAX

Mounting

C

C

H

Figure 6.10: Beam level H = 300 mm,

C = 1080 mm

6.3.4 Machine response times, stopping time

The safety sensor's rotary mirror rotates on its own axis every 40 ms. One revolution is a scan. At least

two consecutive scans must be interrupted so that the safety-related switching outputs switch off. The

safety sensor's minimum response time is therefore 80 ms.

If you want to increase the safety sensor's availability in an environment with fine particles, increase the

number of interrupted scans after which the safety-related switching outputs switch off. With each additional scan the response time T

increases by 40 ms. With K = 1600 mm/s the safety distance increases

1

by 64 mm per additional scan.

ª Select a response time T1 of at least 120 ms or higher.

ª If you use a safety interface device, take the response time T2 from the safety interface device's techni-

cal data.

ª Determine the machine/system's stopping time T3.

If data is not available, you can commission Leuze electronic to perform measurements (see chapter 16

„Service“).

ª If an increase in the stopping time within the regular test periods is to be expected, take an additional

value into account for the machine's stopping time

H

Figure 6.11: Beam level H = 875 mm to 1000 mm,

C = 850 mm

T3.

Leuze electronic RS4 30

Page 31

6.3.5 Application-conditional additional distances for safety distance "S"

The protective field boundaries must be defined so that the calculated safety distance "S" to the point of

operation, extended by the additional distances, is complied with everywhere. Where this is not possible

or does not make sense, you can use hard guards as supplementary measures.

1

D

2

R

G

S

S

D

S

D

1 Routing machine with free space for sensor protective field in the area under the machine table

2 Safety sensor

3 Protective field contour

4 Warning field contour

S Calculated safety distance S

D Minimum distance "D" (= safety distance S + additional distance Z

R

Greater protective field radius without additional distances, measured from the rotation axis of the

G

rotary mirror

Figure 6.12: Defining the protective field contour for a stationary, horizontal protective field

+ if required, Z

SM

Mounting

3

4

)

REFL

ª Define the limits of the protective field using the safety distance "S" without an additional distance.

ª Determine the biggest protective field radius RG for this protective field.

The biggest protective field radius determines the additional distance ZSM for the system-conditional

measurement error, by which the protective field contour must be enlarged.

The position of the rotary mirror's center point with regard to the housing is provided by the dimensional

drawing (see fig. 7.1).

Table 6.1: Additional distance Z

for the protective field contour because of measurement error

SM

Biggest protective field radius RG without additional

distances

< 3.5 m 83 mm

u 3.5 m 100 mm

ª Avoid retro-reflectors at the beam level behind the protective field boundary. If this is not possible, add

another additional distance Z

of 100 mm.

REFL

6.3.6 Minimum distance "D" to the protective field contour

The minimum distance "D" is the distance between point of operation and protective field contour.

Additional distance

Z

SM

D Minimum distance between point of operation and protective field contour in mm

Z

Additional distance for system-conditional measurement error

SM

Z

Additional distance with retro-reflectors

REFL

ª If the protective field runs up against fixed boundaries, such as walls or machine frames, take a coun-

tersinking into the machine contour of at least the size of the necessary additional distance ZSM, and Z

REFL

where required, into account. With the protective field contour under these conditions, stay about 50 mm

away from the machine surface.

Leuze electronic RS4 31

Page 32

ª If the protective field runs up against hard guards, ensure that the protective field ends under instead

of in front of the hard guards. The width of the lower post must correspond with the size of the required

additional distances.

ª If all dangers in the fenced off area are covered by the safety sensor and the height of the beam level

is 300

mm, you can raise the bottom edge of the hard guards from 200 mm to 350 mm. The protective

field reaching to under the hard guards takes over the protective function of preventing an adult from

crawling under in this case.

ª Prevent obstructions within the calculated protective field boundaries. If this is not possible, implement

protective measures so that the point of operation cannot be reached from out of the shadow of the

obstruction.

6.4 Stationary point of operation guarding

Mounting

1

2

1 Safety sensor

2 Reference boundary

Figure 6.13: The safety sensor takes over the stop-activating and presence-detecting function if walking

behind the protective field is not possible.

The following resolutions are required:

• Detection of an adult's hand: 30 mm

• Arm detection: 40 mm

The required finger protection is ensured here by an additional distance "C", which depends on the

resolution, in addition to the safety distance.

Procedure

ª Calculate the necessary safety distance and determine the required additional distances for your appli-

cation.

ª In the configuration and diagnostics software, select the hand protection or arm protection presetting.

The protective field boundaries are automatically restricted as a result to the values listed in the technical data.

ª Specify the protective field boundaries and define the areas that monitor the position of the protective

field as reference boundary.

Leuze electronic RS4 32

Page 33

6.4.1 Safety distance "S"

The B standard, ISO 13855/EN999 specifies the general formula for the safety distance as follows:

S Safety distance in mm

K Approach speed in mm/s

For normal approach on a vertically arranged protective field: 2000 mm/s

T

Safety sensor response time in s

1

T

Safety interface device response time in s, if used

2

T

Machine stopping time plus addition for deterioration in s

3

C Additional distance in mm because of possible penetration into the protective field before the stop

function activates

Mounting

Depending on the calculated value of the safety distance, you must proceed differently with the result:

ª If S is e 500 mm, use the calculated result.

ª If S is > 500 mm, calculate the safety distance again with the approach speed K = 1600 mm/s.

If S is therefore u 500 mm, use this value.

If S is therefore S < 500 mm, use at least S = 500 mm.

6.4.2 Additional distance C

With a resolution less than 14 mm, a finger or the flat of a hand can penetrate a stretch into the protective

field without the stop function activating. You must therefore include an additional distance "C".

d Safety sensor resolution (30 mm and 40 mm)

For 30 mm resolution the additional distance C = 128 mm; for 40 mm resolution C = 208 mm.

6.4.3 Machine response times, stopping time

The safety sensor's rotary mirror rotates on its own axis every 40 ms. One revolution is a scan. With each

additional scan the response time T

increases by 40 ms. With K = 2000 mm/s approach speed this corre-

1

sponds with an increase in the safety distance of 80 mm per additional scan. With K = 1600 mm/s it is

64 mm.

ª Select a response time T1 of at least 80 ms or higher.

ª If you use a safety interface device, take the response time T2 from the safety interface device's techni-

cal data.

ª Determine the machine/system's stopping time T3.

If data is not available, you can commission Leuze electronic to perform measurements (see chapter 16

„Service“).

ª If an increase in the stopping time within the regular test periods is to be expected, take an additional

value into account for the machine's stopping time

T3.

Leuze electronic RS4 33

Page 34

6.4.4 Protective field and reference boundary

With a vertical protective field, you must define at least two sides of the protective field contour as reference boundary in accordance with IEC/EN 61496-3. The objective is to monitor the position of the protective field with regard to its marginal area. If the arrangement misaligns and the distance of the safety sensor

to the reference surface changes as a result, switch the safety-related switching outputs off.

1

Mounting

e

3

4

S

1 Physical frame for reference boundary