Page 1

24 V

DC

IEC 60947...

IEC 60947...

IP 65

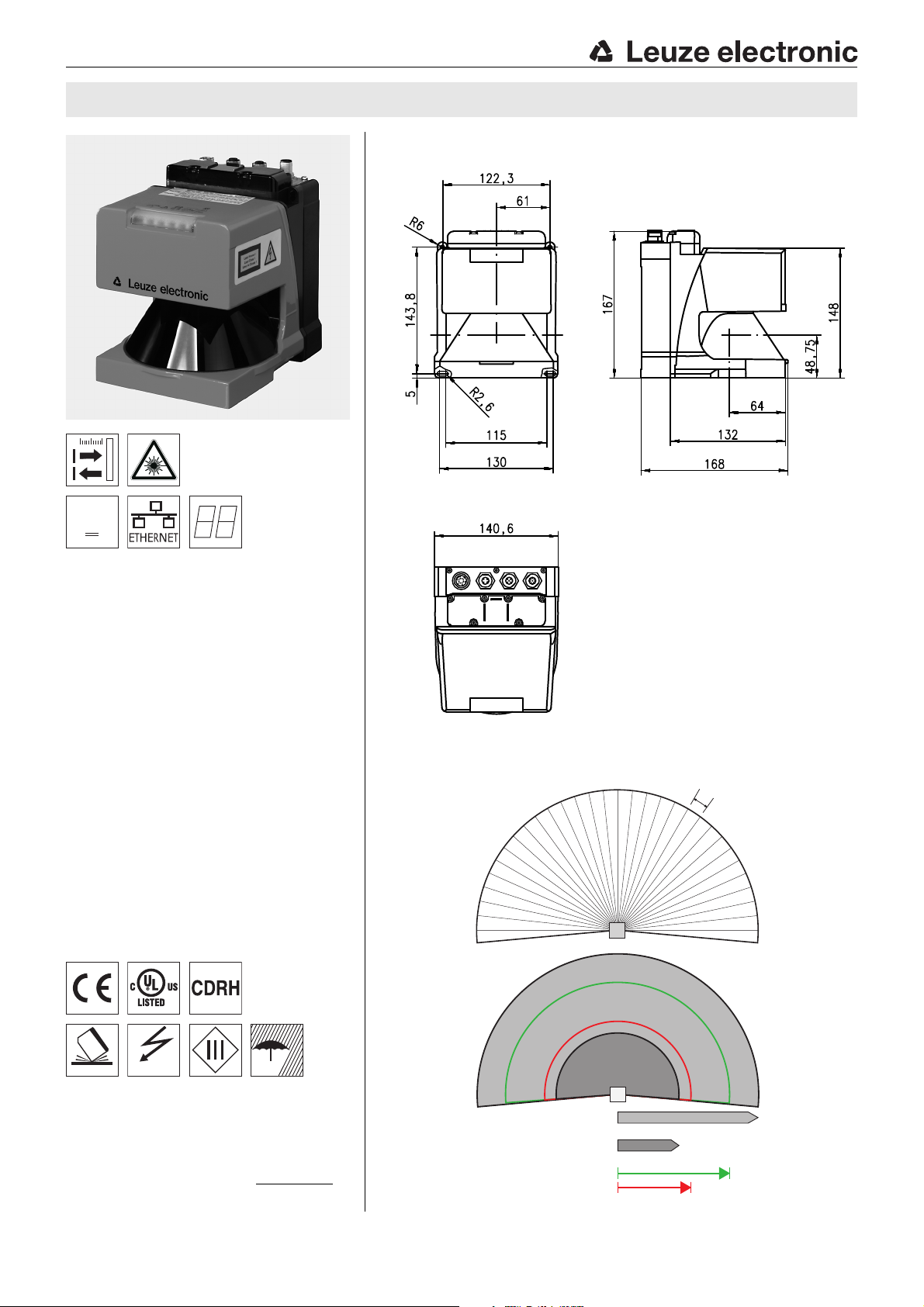

528 measurement sectors,

0.36° each

190° working range

ROD4 plus, ROD4-50 plus, ROD4-56 plus:

Measurement range max. 65m

ROD4-08 plus, ROD4-58 plus:

Measurement range max. 25m

Radius of far detection field: max. 50m

Radius of near detection field: max. 30m

rotoScan ROD4… plus Laser scanner

Dimensioned drawing

en 07-2015/07 50108253-01

0…65m

Measurement data transmission via Fast

Ethernet 100MBit/s

Measurement data transmission via

RS 232/422 serial interface

Measurement data reduction, measure-

ment data processing, measurement data

filtering and determination of extreme

values in the interface box

Several device versions:

- with/without heating, dust-insensitive version

- scanning rate 50Hz, for object measurem.

- scanning rate 25Hz, for object detection

and object measurement

- measurement range 25m or 65 m

Service interface for configuration

ROD4 plus and ROD4-08 plus:

7 storable and reversible detection fields for

object detection

Software:

RODplussoft

: Configuring measurement

applications

RODsoft

: Configuring detection fields

Measurement principle

Accessories:

(available separately)

Mounting system

We reserve the right to make changes • DS_ROD4plus_en_50108253_01.fm

Configuration software RODplussoft and

RODsoft

Various connection cables

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen Tel. +49 (0) 7021 573-0

info@leuze.com • www.leuze.com

(free download from www.leuze.de)

rotoScan ROD4… plus - 07

Page 2

B

A

C

C

C

A

C

C

B

rotoScan ROD4… plus

Specifications

Optical data

Measurement range ROD4plus, ROD4-50plus, ROD4-56plus: 0…65m

Radius of detection field

Scanning angle max. 190°

Angular resolution 0.36°

Scanning rate ROD4-5x plus: 50 scans/s or 20ms/scan

Transmitter Infrared laser diode

Wavelength 905nm

Impulse duration 3ns

Max. output power (peak) 15W

1)

ROD4-08plus, ROD4-58plus: 0...25m

near: 0 … 30m

far: 0 … 50m

ROD4 plus, ROD4-08 plus: 25 scans/s or 40ms/scan

Object measurement

Reflectivity from min. 1.8% (matte black)

Object size > 20mm at distance of 4 m

Response time ROD4-5x… plus: at least 20ms (corresponds to 1 scan)

Switching inputs 4 x +24 VDC

Switching outputs 4x PNP transistor outputs 24V/250mA

Measurement value resolution per

sector

Repeatability

2)

ROD4-x8 plus from 6% (dark gray)

> 100mm at distance of 15m

ROD4 plus, ROD4-08 plus: at least 40 ms (corresponds to 1

scan)

(FPS1 … 4 at Y1 for switching between detection fields)

additional restart input at Y1 and interface box

(Alarm, Warn, Near field 1, Near field 2)

5mm

ROD4 plus, ROD4-50 plus, ROD4-56 plus: ± 15mm

ROD4-08 plus, ROD4-58 plus: ± 20mm

Object detection (ROD4 plus, ROD4-08 plus)

Reflectivity from min. 1.8% (matte black)

Object size > 20mm at distance of 4 m

Response time at least 40ms (corresponds to 1 scan)

Number of detection field pairs 7 (selectable via switching inputs)

Switching inputs 4 x +24 VDC

Switching outputs 4x PNP transistor outputs 24V/250mA

Electrical data

Voltage supply

Overcurrent protection fuse 2.5A (4 A with heating) semi time-lag in the switch cabinet

Current consumption approx. 1A (use power supply with 2.5A), approx. 4 A with heat-

Power consumption < 75W at 24V including the outputs

Overvoltage protection overvoltage protection with protected limit stop

3)

ROD4-08 plus from 6% (dark gray)

> 100mm at distance of 15m

(FPS1 … 4 at Y1 for switching between detection fields)

additional restart input at Y1 and interface box

(Alarm, Warn, Near field 1, Near field 2)

+24VDC +20% / -30%

ing

Mechanical data

Housing diecast aluminum, plastic

Weight 2.3kg

Connection type 4 connectors (can be plugged from above)

Environmental data

Ambient temp. (operation/storage) -0°C … +50°C/-20°C … +50°C

VDE safety class III, protective extra-low voltage

Degree of protection IP 65

Laser class 1 (acc. to IEC 60825-1:2007 and 21 CFR 1040.10

Standards applied IEC 60947-5-2

Certifications UL 508, C22.2 No.14-13

1) Only applies for ROD4 plus, ROD4-08 plus

2) 10 … 90% diffuse reflection, at operating range of 4m

3) Protective Extra Low Voltage (PELV) - protective extra-low voltage with reliable disconnection.

For UL applications: only for use in class 2 circuits according to NEC.

-20°C … +50°C/-20°C … +50°C (with heating)

with Laser Notice No. 50)

3)

Order guide

Designation Part no.

Remarks

Intended use:

The laser scanners are optical

electronic sensors for optical,

contactless detection of

objects.

Operate in accordance with

intended use!

This product is not a safety sensor

and is not intended as personnel

protection.

The product may only be put into

operation by competent persons.

Only use the product in accor-

dance with the intended use.

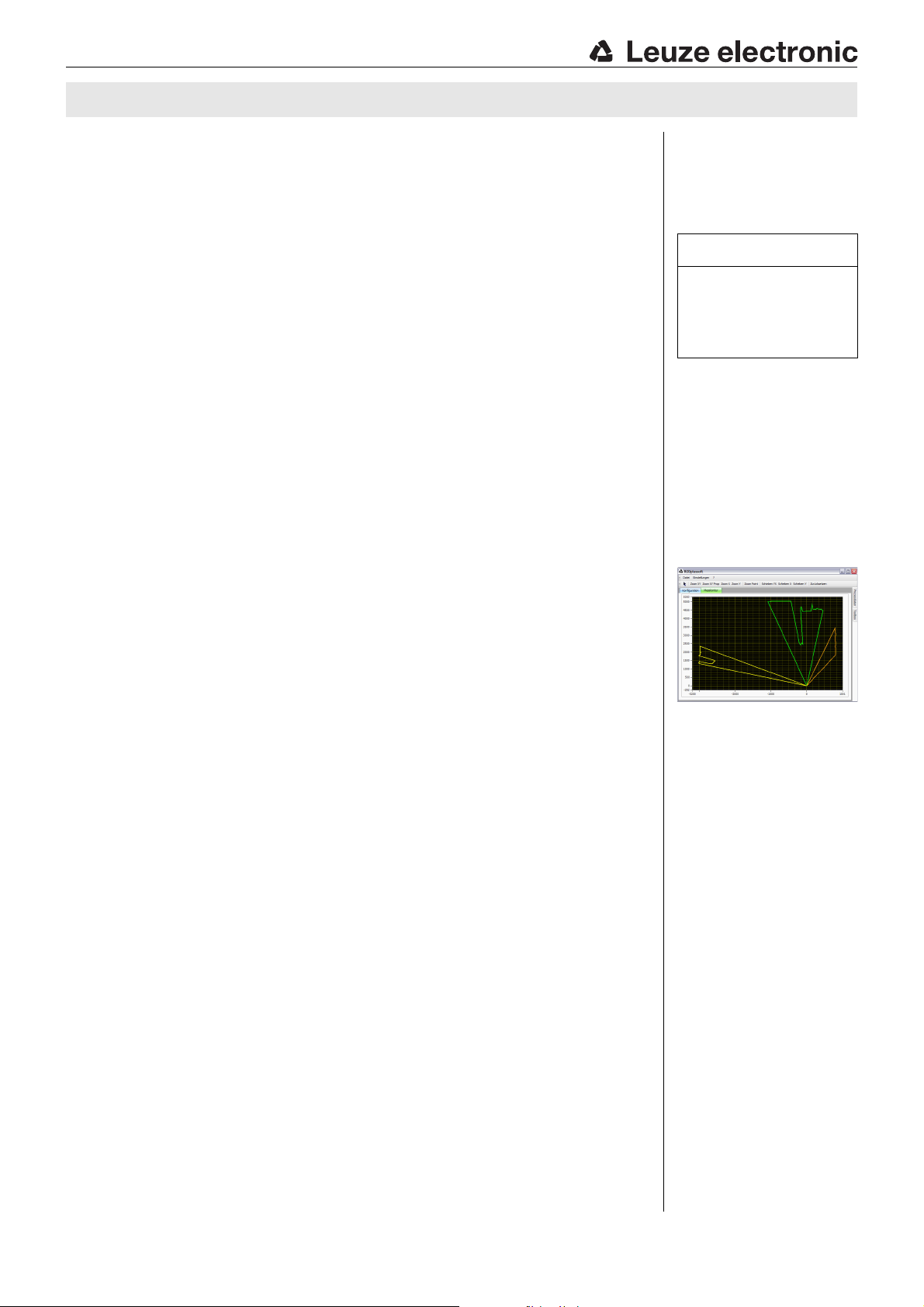

"RODplussoft" configuration

software

The configuration software

runs under Windows 2000/XP

and offers the following features:

Configuration of Ethernet

and serial interface

Configuration of up to 12

measurement segments

Visualization of measure-

ment values

Configuration of the data transmission in the

A

"Configuration" tab

Definition of measurement segments in the

B

"Toolbox"

Graphical display of the measurement values

C

of the measurement segments in various colors

Transfer of measurement

values in XY coordinates

or polar coordinates.

Configuration software

"RODsoft"

(for ROD4(-08) plus only)

Definition of the detection

fields

Configuration of the scan-

ner parameters

Visualization of the detec-

tion fields and

measurement values

Display of status/diagnos-

tic information

Support of various

languages

For object detection / object measurement, scanning rate 25scans/s

ROD4 plus 50106481

With heating/dust-insensitive ROD4-08 plus 50106480

For object measurement, scanning rate 50scans/s

ROD4-50 plus 50113226

With heating ROD4-56 plus 50129795

With heating/dust-insensitive ROD4-58 plus 50113225

rotoScan ROD4… plus - 07 2015/07

Page 3

rotoScan ROD4… plus Laser scanner

Electrical connection - Assignment connector

Y1 Logic Y2 Ethernet Y3 Service Y4 RS 232/422

Pin Function Color Pin Function Color Pin Function Color Pin Function Color

A+U

B

C GND_IN bu (blue) 2 Rx+ wh 2 TxD wh 2 Tx- br

E FPS1 pi (pink) 3 Tx- or (orange) 3 GND bu 3 Rx- gn

G FPS2 gr (gray) 4 Rx- bu 4 RxD bl 4 Rx+ / RxD ye

J FPS3 ye (yellow) 5 NC 5 GND/shield gr

L FPS4 gn (green) 6 RS 422 detection pi

M Restart_IN br (brown) 7NC

N Near field 1 wh (white) 8NC

O Near field 2 vi (violet)

PAlarm bl (black)

R Warn wh-gn (white-green)

SNC

TNC

UNC

rd (red) 1 Tx+ ye 1 NC 1 TX+ / TxD wh

Installing the software RODplussoft

The RODplussoft configuration software is used for configuring the interfaces and the measurement functions of all of the ROD4… plus.

The RODplussoft configuration software can be found on the supplied CD. To install, follow the instructions in the respective readme

files, which can likewise be found on the supplied CD.

You can also download the respective, latest version of RODplussoft from www.leuze.com.

Unzip the ZIP file supplied into a suitable folder on your hard disk.

Start the installation by double-clicking on the setup.exe file.

Follow the instructions of the installation routine.

Notice!

Before installing RODplussoft, ensure that Microsoft® .NET Framework 2.0 SP1 or later is installed on your computer.

Install the RODsoft software (for ROD4 plus and ROD4-08 plus only)

You have to install the RODsoft software only if you wish to create detection fields for laser scanners of type ROD4 plus or

ROD4-08 plus.

Notice!

With ROD4-5… plus laser scanners, status and diagnostic information can be called up using RODsoft.

The RODsoft configuration software can be found on the supplied CD. To install, follow the instructions in the respective readme files,

which can likewise be found on the supplied CD.

You can also download the respective, latest version of RODsoft from www.leuze.com.

Unzip the ZIP file supplied into a suitable folder on your hard disk.

Start the installation by double-clicking on the setup.exe file.

Follow the instructions of the installation routine.

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen Tel. +49 (0) 7021 573-0 rotoScan ROD4… plus - 07

info@leuze.com • www.leuze.com

Page 4

rotoScan ROD4… plus

Establish connection to PC

The ROD4… plus is configured via a PC using the RODplussoft program, before it is integrated into the process control.

In order to be able to establish a TCP communication with the PC, the IP address of your PC and the IP address of the ROD4… plus

must lie in the same address range. The ROD4… plus has no built-in DHCP client, so you need to set the address manually. The easiest

way to do this is via the PC.

The ROD4… plus is set ex works as follows:

IP address: 192.168.060.003

Subnet mask: 255.255.255.0

Notice!

If you are using a desktop firewall, please ensure that the control can communicate with the ROD4… plus via the Ethernet

interface on ports 9008 and using TCP. Furthermore, the firewall must allow ICMP echo messages to pass through for

the connection test (ping).

If the PC is usually connected to a network using DHCP address allocation, the easiest way to access the ROD4… plus is by applying

an alternative configuration in the TCP/IP settings of the PC and connecting the ROD4… plus directly to the PC.

According to the default setting of 255.255.255.0 for the subnet mask, the IP address of the PC must then lie in the range 192.168.060.0

to 192.168.060.255 (e.g., 192.168.060.110, but not 192.168.060.003!), so that ROD4… plus and PC can communicate with each other.

If ROD4… plus and the PC have the same IP address, they cannot communicate with each other.

Configuring the IP address for a PC

Log in to your PC as an administrator.

Using Start->System control go to the Network connections

(Windows XP) menu or to the Network center and release center

(Windows 7) menu.

There, select

ing properties page.

Select the Internet protocol (TCP/IP) (by scrolling down, if necessary) and

click on Properties.

In the Internet protocol (TCP/IP) Properties window select the

Alternate configuration tab.

Set the IP address of the PC in the address range of the ROD4… plus.

Attention: not the same as for the ROD4… plus!

Set the Subnet mask of the PC to the same value as the one for the

ROD4… plus .

Close the configuration dialog by confirming all windows using OK.

Connect the Y2 interface of the ROD4… plus directly to the LAN port of your PC.

Use a KB ET-…-SA-RJ45 cable for the connection.

Local Area Connection

and right-click to open the correspond-

rotoScan ROD4… plus - 07 2015/07

Page 5

rotoScan ROD4… plus Laser scanner

Laser safety notices – laser class 1

ATTENTION, LASER RADIATION – LASER CLASS 1

The device fulfills the EN 60825-1:2007 safety regulations for a product in laser class 1 as well as the U.S. 21 CFR 1040.10 regulations

with deviations corresponding to "Laser Notice No. 50" from June 24th, 2007.

Adhere to the applicable legal and local regulations regarding protection from laser beams.

The device must not be tampered with and must not be changed in any way.

There are no user-serviceable parts inside the device.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

Commissioning

Switch on the supply voltage of the ROD4… plus.

Start the software RODplussoft.

The PC first tries to establish a network connection via the automatic configuration using Ethernet. This takes a few seconds, after which

the alternate configuration, which you just set, is activated. The PC can then communicate with the ROD4… plus via Ethernet.

Further information about configuring the ROD4… plus using RODplussoft software can be found in the Technical Description and Software and Protocol Description.

For the commissioning and integration of the laser scanner in the process control the following steps are necessary:

1.Configure the ROD4… plus - see chapter 6 of the Technical Description.

2.Configure, if necessary, detection fields with the RODsoft configuration software (Configuration –> Start RODsoft…

menu item) (for ROD4 plus and ROD4-08 plus only!). See section Configuring detection fields.

3.Program process control.

or

4.Connect the switching inputs and outputs accordingly - see chapter 5 of the Technical Description.

5.Adapt the IP configuration of the ROD4… plus such that it can communicate with the process control. This occurs in

RODplussoft in the Communication tab. Here you can change the network address and the corresponding net mask, via

which the ROD4… plus communicates with the process control.

6.Save the changed settings in the ROD4… plus using the Configuration -> Transmit to ROD4plus menu item.

7.Connect ROD4… plus to process control via the Ethernet interface Y2.

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen Tel. +49 (0) 7021 573-0 rotoScan ROD4… plus - 07

info@leuze.com • www.leuze.com

Page 6

Current measurement

values (yellow line)

Far detection field

(green line)

Near detection field

(red line)

rotoScan ROD4… plus

Configure the detection fields (for ROD4 plus and ROD4-08 plus only)

Commissioning procedure:

Connect the PC via the KB-ROD4plus… cable at the connection Y3 - Service to the ROD4(-08) plus.

From RODplussoft start the RODsoft configuration software via the Start RODsoft… menu item.

Enter the password "ROD4LE" in the level "Authorized User".

The detection field can be displayed under "Display measurement contour". Under "ROD4 configuration" the response times, the detection field switches and other parameters are defined. To configure the detection fields, select the "Define detection areas" field. Error

codes and other information are contained in the ROD4 system data.

A detailed description can be found in the user manual for the RODsoft configuration software.

rotoScan ROD4… plus - 07 2015/07

Loading...

Loading...