Page 1

RODsoft

Configuration software for ROD4-3… / ROD4-2… / ROD4

GB 02-11/08 50110695

SOFTWARE AND PROTOCOL DESCRIPTION

Page 2

Table of contents

1 General information ........................................................................................................... 4

1.1 About the program "RODsoft" .............................................................................................. 4

1.2 Explanation of symbols ........................................................................................................ 4

1.3 Contact address................................................................................................................... 4

2 Hardware and software installation ................................................................................. 5

2.1 Hardware ............................................................................................................................. 5

2.1.1 Connecting the rotoScan ROD4-3… ............................................................................................. 5

2.1.2 Interface assignment X1 and X2.................................................................................................... 6

2.1.3 Connector assignments for connection X1 ....................................................................................7

2.1.4 Connector assignments for connection X2 (RS 232).....................................................................8

2.1.5 Connector assignments for connection X2 (RS 422).....................................................................8

2.2 Software............................................................................................................................... 9

2.2.1 System requirements.....................................................................................................................9

2.2.2 Installation...................................................................................................................................... 9

3 First steps......................................................................................................................... 10

3.1 General remarks ................................................................................................................ 10

3.2 Launching the program ...................................................................................................... 10

3.3 Procedure / work areas ...................................................................................................... 14

4 Description of the user interface .................................................................................... 15

4.1 Graphical work area / detection fields ................................................................................ 15

4.1.1 Changing over between detection field pairs...............................................................................16

4.1.2 4-field mode................................................................................................................................. 19

4.1.3 Displaying measurement diagram/detection fields ...................................................................... 20

4.2 Tabs and toolbar ................................................................................................................ 21

4.2.1 Tabs.............................................................................................................................................21

4.2.2 Buttons.........................................................................................................................................21

4.3 The menu bar..................................................................................................................... 25

4.4 Displaying status information ............................................................................................. 30

4.4.1 Data source .................................................................................................................................30

4.4.2 Status bar .................................................................................................................................... 30

4.5 Access levels ..................................................................................................................... 31

4.6 Program settings................................................................................................................ 35

4.6.1 Configuring the serial interface....................................................................................................35

4.6.2 Setting the program language .....................................................................................................35

4.6.3 Selecting the background colour .................................................................................................36

Leuze electronic RODsoft 1

Page 3

Table of contents

5 Editing / configuring the device configuration ............................................................. 37

5.1 General information and procedure ................................................................................... 37

5.2 Current sensor configuration.............................................................................................. 39

5.3 Changing configuration parameters................................................................................... 39

5.3.1 Configuration Wizard....................................................................................................................39

5.3.2 Tree view of the configuration......................................................................................................46

5.3.3 Supplementary information on the "Presettings" parameter ........................................................53

5.3.4 Supplementary information on the "Power-up properties" parameter..........................................54

5.3.5 Supplementary information on the "Dust suppression" parameter...............................................55

5.3.6 Supplementary information on the "Admissible field pair changeovers" parameter.....................60

5.4 Storing/loading configuration ............................................................................................. 62

5.5 Transferring a configuration to the sensor ......................................................................... 62

5.6 Resetting sensor to factory settings................................................................................... 63

6 Working with detection fields ......................................................................................... 64

6.1 General information ........................................................................................................... 64

6.1.1 Position determination..................................................................................................................64

6.1.2 Enlarging or reducing the work area ............................................................................................65

6.1.3 Moving the display .......................................................................................................................66

6.2 Defining detection fields..................................................................................................... 67

6.2.1 Creating new detection fields.......................................................................................................68

6.2.2 Changing detection fields.............................................................................................................74

6.3 Reference boundaries........................................................................................................ 82

6.4 Saving and loading detection fields ................................................................................... 88

6.5 Transferring detection fields............................................................................................... 88

7 Measurement data transfer / protocol info .................................................................... 90

7.1 Time behaviour / transmission speed ................................................................................ 90

7.2 Protocol structure............................................................................................................... 93

7.2.1 Start..............................................................................................................................................93

7.2.2 Operation .....................................................................................................................................94

7.2.3 Option 1........................................................................................................................................94

7.2.4 Option 2........................................................................................................................................94

7.2.5 Option 3........................................................................................................................................95

7.2.6 Scan number................................................................................................................................95

7.2.7 Angular step size..........................................................................................................................95

7.2.8 Start angle....................................................................................................................................96

7.2.9 Stop angle ....................................................................................................................................96

7.2.10 Distance measurement value.......................................................................................................96

7.2.11 Check byte ...................................................................................................................................97

7.2.12 End...............................................................................................................................................97

7.3 Transmission of warning and error messages ................................................................... 98

7.3.1 Warning messages ......................................................................................................................98

7.3.2 Error messages............................................................................................................................98

2 RODsoft Leuze electronic

Page 4

Table of contents

8 System information and error handling......................................................................... 99

8.1 Loading status information from the sensor ....................................................................... 99

8.2 Loading diagnostic data from the sensor .........................................................................100

8.2.1 Diagnostic codes and causes....................................................................................................101

8.3 Create service file ............................................................................................................ 105

8.4 Adjust window supervision............................................................................................... 106

8.5 Resetting the sensor ........................................................................................................ 106

9 Appendix......................................................................................................................... 107

9.1 Terms and abbreviations ROD4-3… and RODsoft software ........................................... 107

Leuze electronic RODsoft 3

Page 5

General information

1 General information

1.1 About the program "RODsoft"

The software described here is intended for the configuration of the rotoScan ROD4 with the

use of a PC.

The present Version 1.16 of ROD4 the configuration software has been compiled for Micro-

®

soft

Windows 95/98/NT/2000/XP/Vista and permits the configuration of all ROD4 model

generations ROD4-3…, ROD4-2… and ROD4/ROD4-0….

Notice!

This manual describes software version 1.16 in combination with the latest device generation ROD4-3….The previous products (ROD4 and ROD4-2…) can also be configured with

RODsoft V1.16. In this case, parameters that are not supported are not displayed in the user

interface; the previous products only use functions and configuration values that existed at

that point in time.

With this software, it is possible to follow the measurement contour scanned by the ROD43… and to visualise any objects detected in the detection fields. The detection fields can be

created with the program and adjusted to conform to the environment.

By means of an easy-to-use software interface, the ROD4-3… can be configured for a wide

range of application areas.

Additional diagnostic and service functions round out the software.

1.2 Explanation of symbols

The symbols used in this description are explained below.

Attention!

This symbol precedes text messages which must strictly be observed. Failure to heed this

information can lead to injuries to personnel or damage to the equipment.

Notice!

This symbol indicates text passages containing important information.

1.3 Contact address

Leuze electronic GmbH + Co. KG

In der Braike 1

D- 73277 Owen/Teck

Telephone: +49 (0) 7021 573 0

Fax: +49 (0) 7021 573 199

www.leuze.de

4 RODsoft Leuze electronic

Page 6

Hardware and software installation

d

a

c

b

S

T

O

P

ok.

ok.

Leuze electronic

a) Connection for configuration only

b) Dummy connector

c) Connector X1 (15-pin, SUB-D)

d) Connector X2 (9-pin, SUB-D)

2 Hardware and software installation

2.1 Hardware

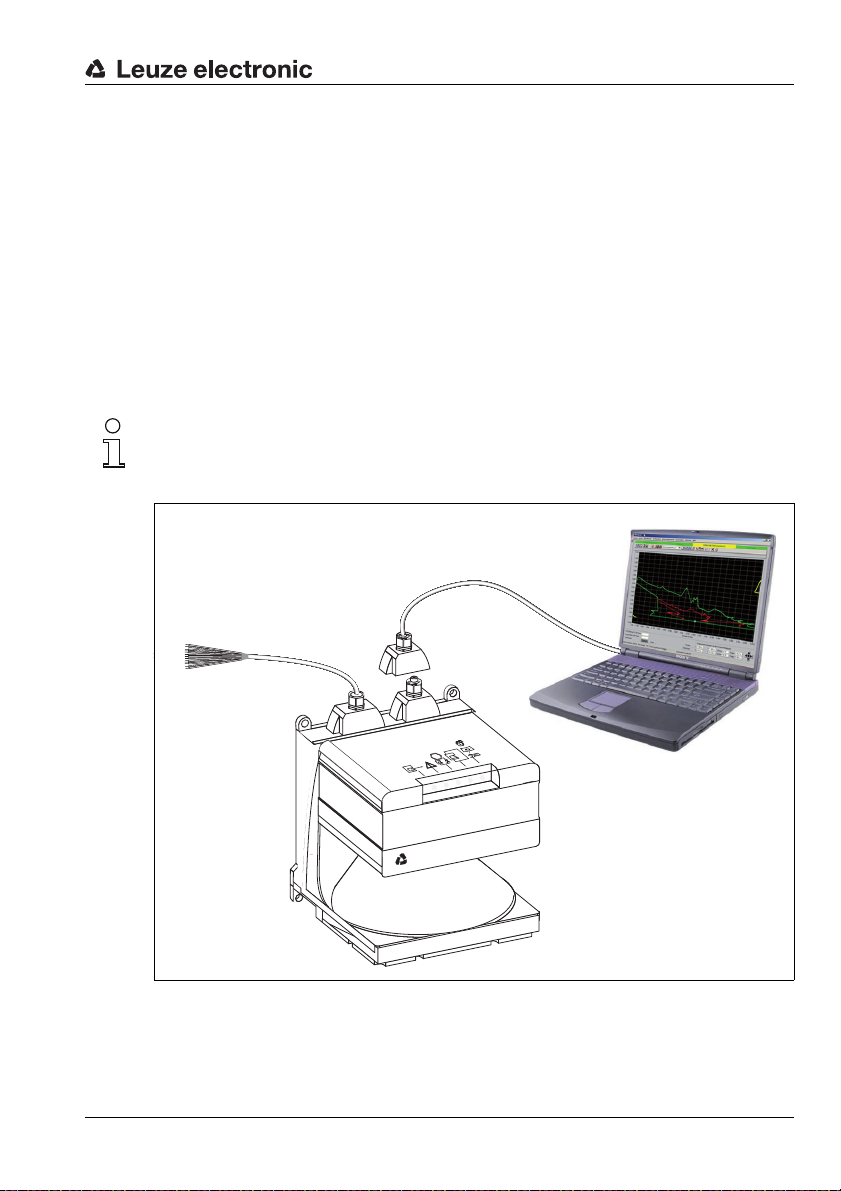

2.1.1 Connecting the rotoScan ROD4-3…

To configure the sensor, connect control cable (X1) to the power supply (safety transformer

24V, 2.5A, 1.25A semi-time-lag fuse) and the interface cable (X2) to the PC or notebook.

Before commissioning the system, please check the pin assignments, the wiring, the supply

voltage and the safeguarding. In spite of the sensor's robust housing and fittings, which

include various internal safety mechanisms, damages resulting from misconnection

cannot be excluded.

Notice!

The connection of the ROD4-3… is described here only briefly. Detailed information can be

found in the technical description "Area Scanning Distance Sensor rotoScan ROD4-3…".

Figure 2.1: Connecting the rotoScan ROD4-3…

Leuze electronic RODsoft 5

TNT 35/7-24V

Page 7

Hardware and software installation

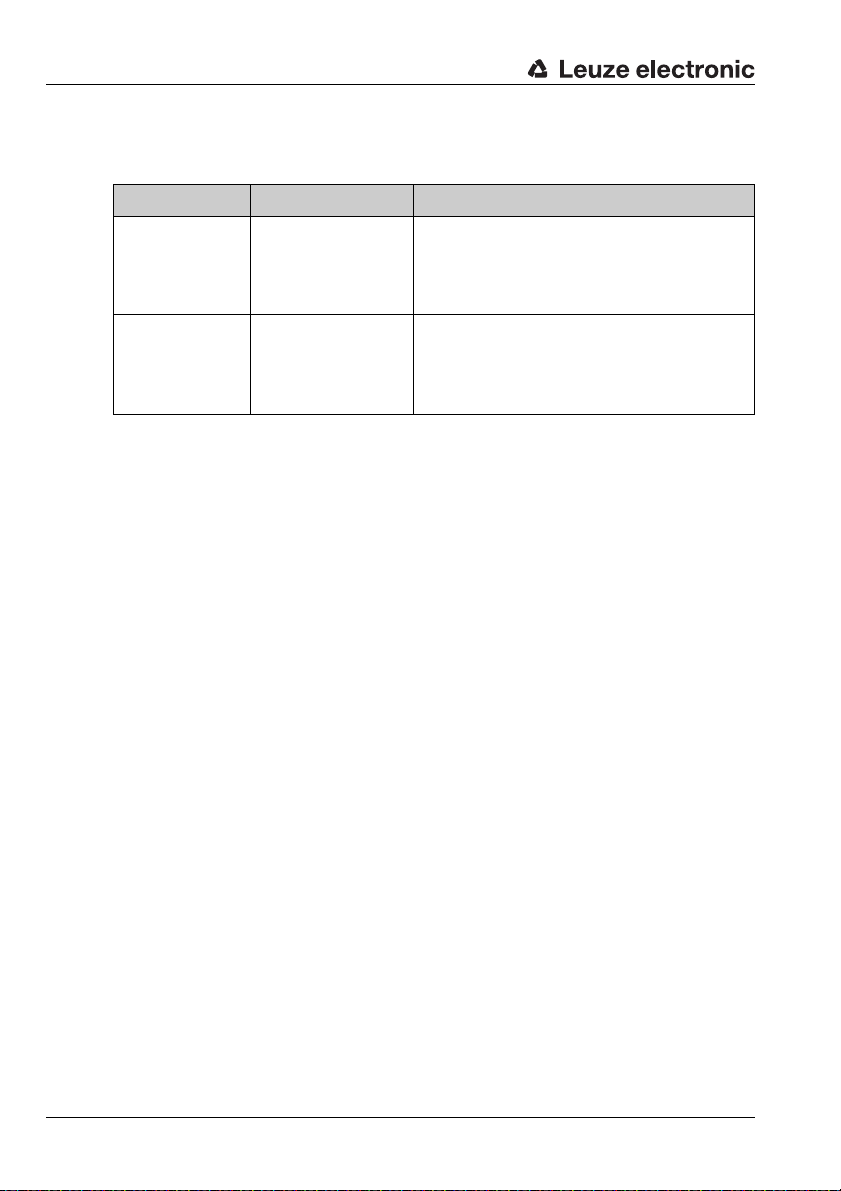

2.1.2 Interface assignment X1 and X2

Interfacees of the rotoScan ROD4-3…

Connection Connector Signals

X1 SUB-D 15-pin

X2 SUB-D 9-pin

Table 2.1: Interfaces X1 and X2

• Power supply

• Switching outputs/alarm output

• Inputs for field pair changeover

• Restart/reset input

• Configuration connector

rotoScan ROD4-3… <–> PC interface

• Parameter configuration

• Detection field definition

• Measurement data transfer

• Diagnosis

6 RODsoft Leuze electronic

Page 8

Hardware and software installation

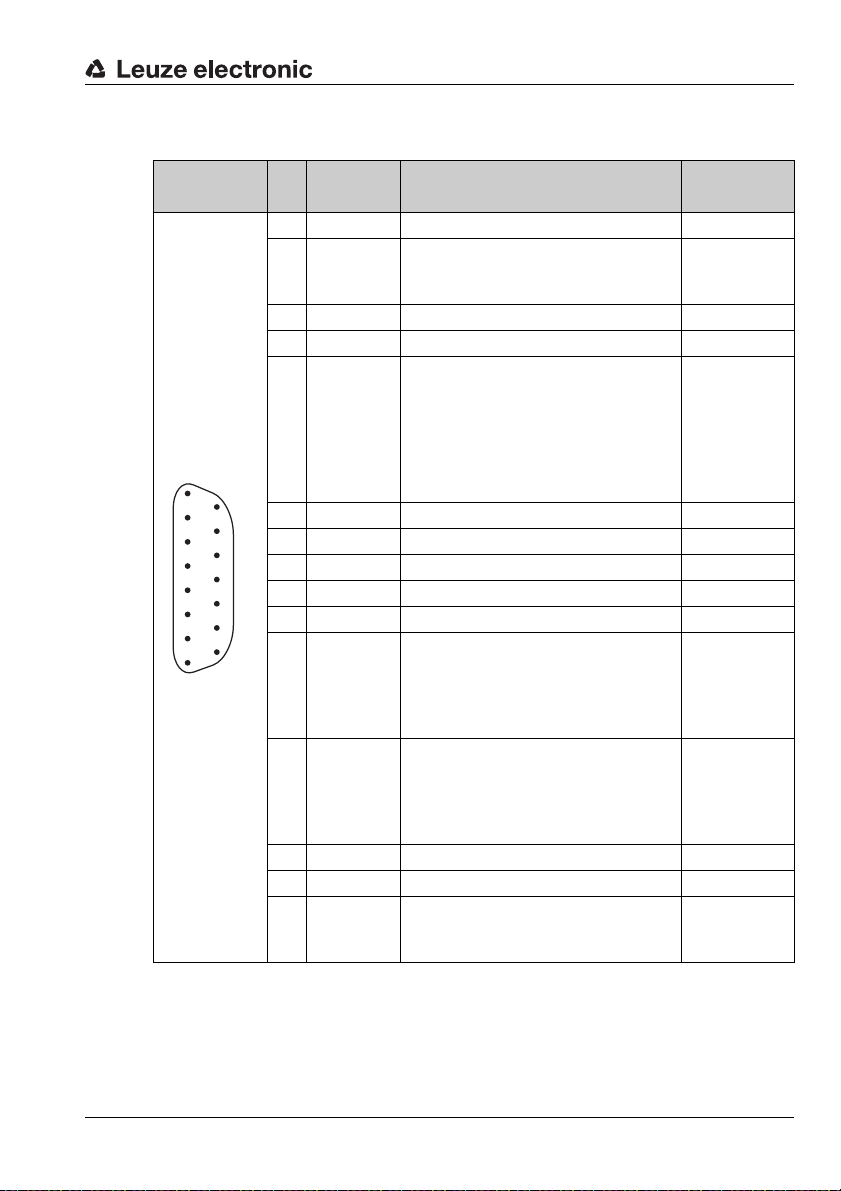

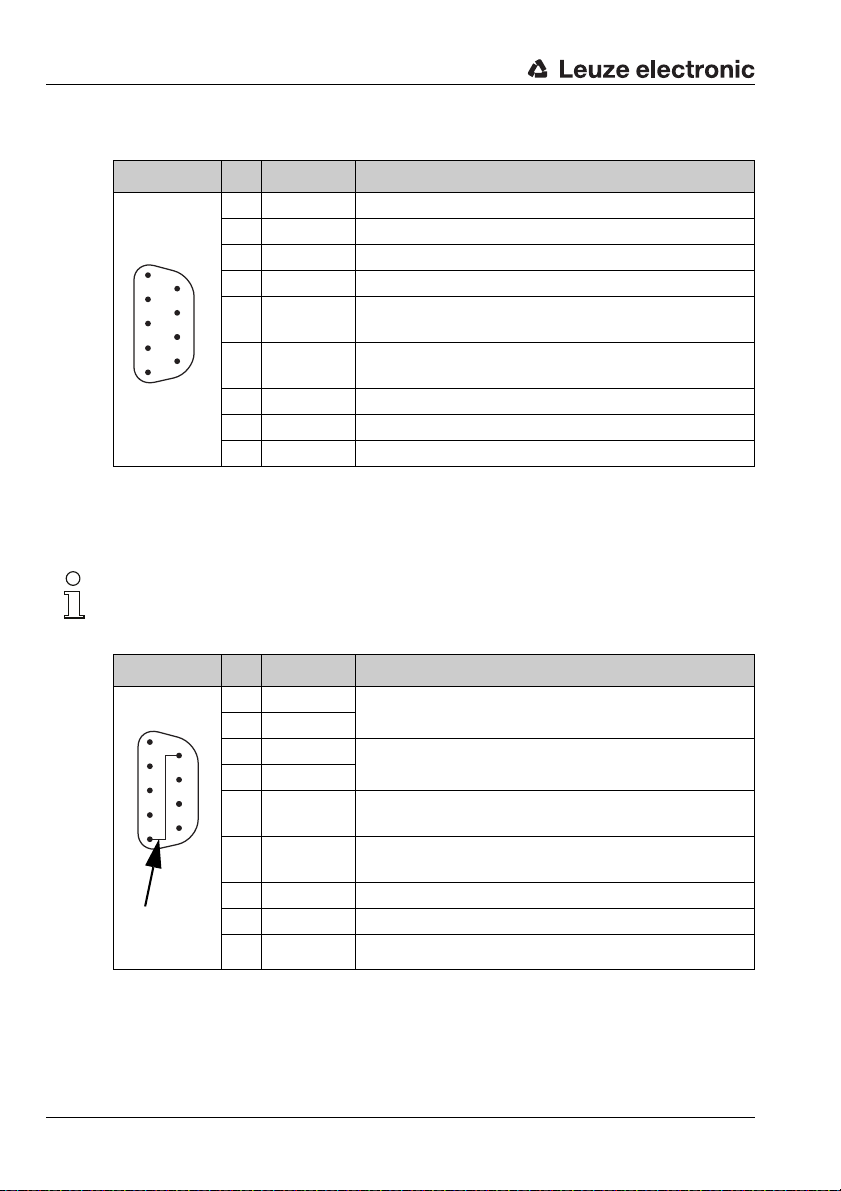

2.1.3 Connector assignments for connection X1

PIN Signal Description Wire colour

1 GND Supply voltage ground black

Safe input "restart-disable", reset of

2 Restart

3 UB Supply voltage +24V DC red

4 FPS1 Changeover of detection field pairs orange

5 ALARM1

8

7

6

5

4

3

2

1

15

6 FPS2 Changeover of detection field pairs green

14

7 FPS3 Changeover of detection field pairs violet

13

8 FPS4 Changeover of detection field pairs grey

12

9 NC Do not use! –

11

10 NC Do not use! –

10

9

11 Fn1

12 Fn2

13 NC Do not use! –

14 NC Do not use! white/brown

15 ALARM2

Table 2.2: SUB-D15 pin assignments for interface X1

the sensor and connection of the

restart button

Output for object detection in the far

detection field and for warning messages such as "Window lightly soiled"

or "Window heavily soiled" (configurable).

4-field mode: Output for object detection in detection field_f 1

Semiconductor output, shutdown on

object detection in the near detection

field, channel 1.

4-field mode: Output for object detection in detection field_n 1

Semiconductor output, shutdown on

object detection in the near detection

field, channel 2.

4-field mode: Output for object detection in detection field_n 2

Warning and error output

4-field mode: Output for object detection in detection field_f 2

KB-ROD4-…

blue

yellow

white

white/black

brown

TNT 35/7-24V

Leuze electronic RODsoft 7

Page 9

Hardware and software installation

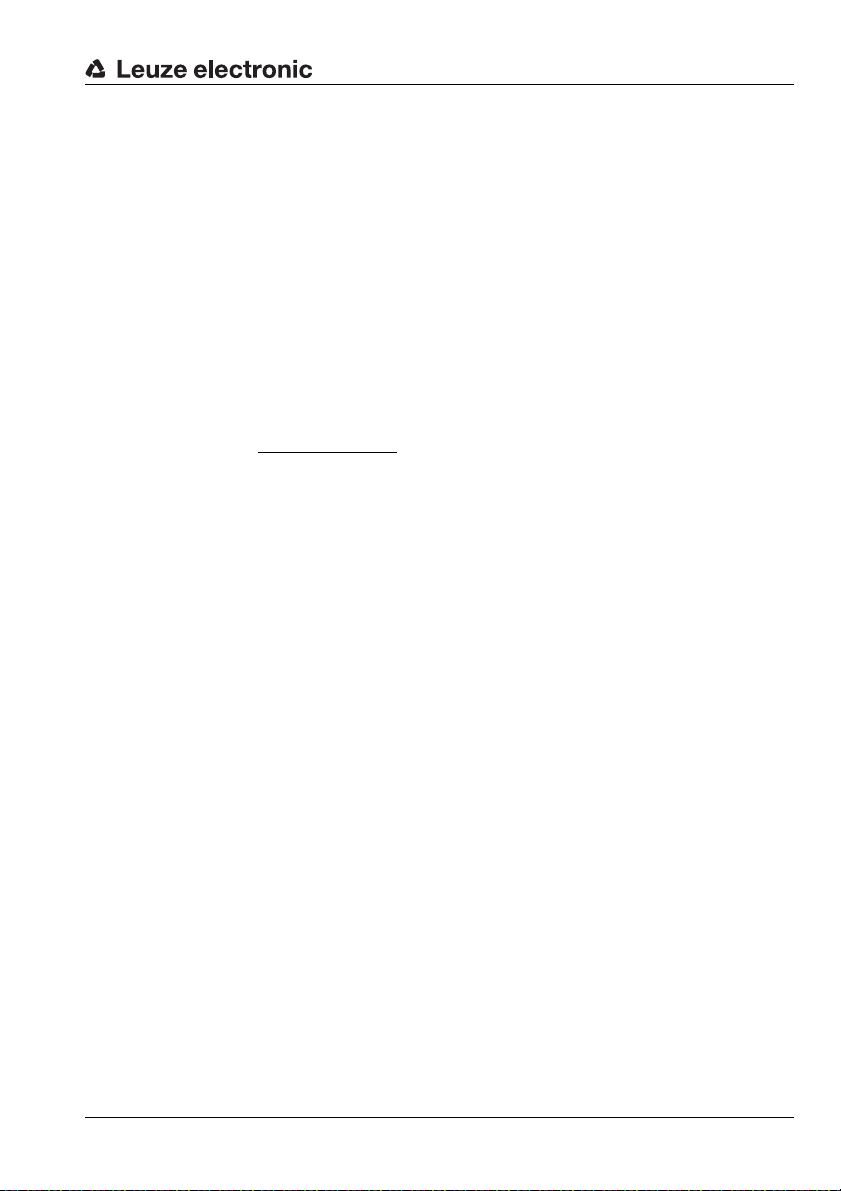

1

6

4

3

2

7

8

9

5

6

3

2

7

8

9

5

1

4

Connection

PIN5 to PIN6

2.1.4 Connector assignments for connection X2 (RS 232)

PIN Signal Description

1 NC Do not use!

2 TxD Data communication, transmission

3 RxD Data communication, reception

4 NC Do not use!

5 GND/shield

6 RS 232

7 NC Do not use!

8 NC Do not use!

9 Reserved Reserved for test purposes, not wired

Table 2.3: SUB-D 9-pin – pin assignments for connection X2 as RS 232 port

2.1.5 Connector assignments for connection X2 (RS 422)

Notice!

If you would like to work with an RS 422 interface, you must connect PIN 6 with PIN 5 (GND)

by means of a bridge.

Ground/shielding (to be connected only on the cabinet

side with PE)

Selection RS 232/RS 422,

selection as RS 232 interface: do not use!

PIN Signal Description

1 TxD+

2 TxD-

3 RxD-

4 RxD+

5 GND/shield

6 RS 422

RS 422 transmitted data

RS 422 received data

Ground/shielding (to be connected only on the cabinet

side with PE)

Selection RS 232/RS 422,

selection as RS 422 interface: bridge to PIN 5!

7 NC Do not use!

8 NC Do not use!

9 Reserved Reserved for test purposes, not wired

Table 2.4: SUB-D 9-pin – pin assignments for connection X2 as RS 422 port

8 RODsoft Leuze electronic

Page 10

2.2 Software

2.2.1 System requirements

• Intel® processor at Pentium® level or faster (or compatible models, e.g. AMD®)

• At least 16 MB RAM

•CD-ROM drive

• Hard disk with at least 30 MB available memory.

• Free RS 232 interface (serial) or alternatively RS 422

•Microsoft

2.2.2 Installation

The supplied installation CD-ROM is required for installing the RODsoft configuration software. Alternatively, the RODsoft configuration software is available for download on the

Internet under http://www.leuze.de

A self-explanatory installation routine is started with the Setup.exe setup program. After the

installation, the program is ready to be started.

®

Windows 95/98/NT/2000/XP

Hardware and software installation

.

Leuze electronic RODsoft 9

TNT 35/7-24V

Page 11

First steps

3 First steps

3.1 General remarks

Attention!

Ensure that the connectors for interfaces X1 and X2 are correctly fabricated and that all cables are correctly connected. Serious, partially irreparable device errors may result if the X1

interface of the rotoScan ROD4-3… is wired incorrectly. If the connector for the X2 interface

is wired incorrectly, the configuration data may either not be transferred at all or only in part.

Also be certain to read the document "Area Scanning Distance Sensor rotoScan ROD4-xx

- Technical Description". It contains important information on working with the RODsoft software.

Notice!

Switch on the power supply of the ROD4-3… before starting the ROD4-3… configuration

software. Data cannot otherwise be received by the device. However, even if the ROD4-3…

is not connected to the PC, you may still define parameters in Offline mode and save them

on the hard disk or evaluate previously stored data.

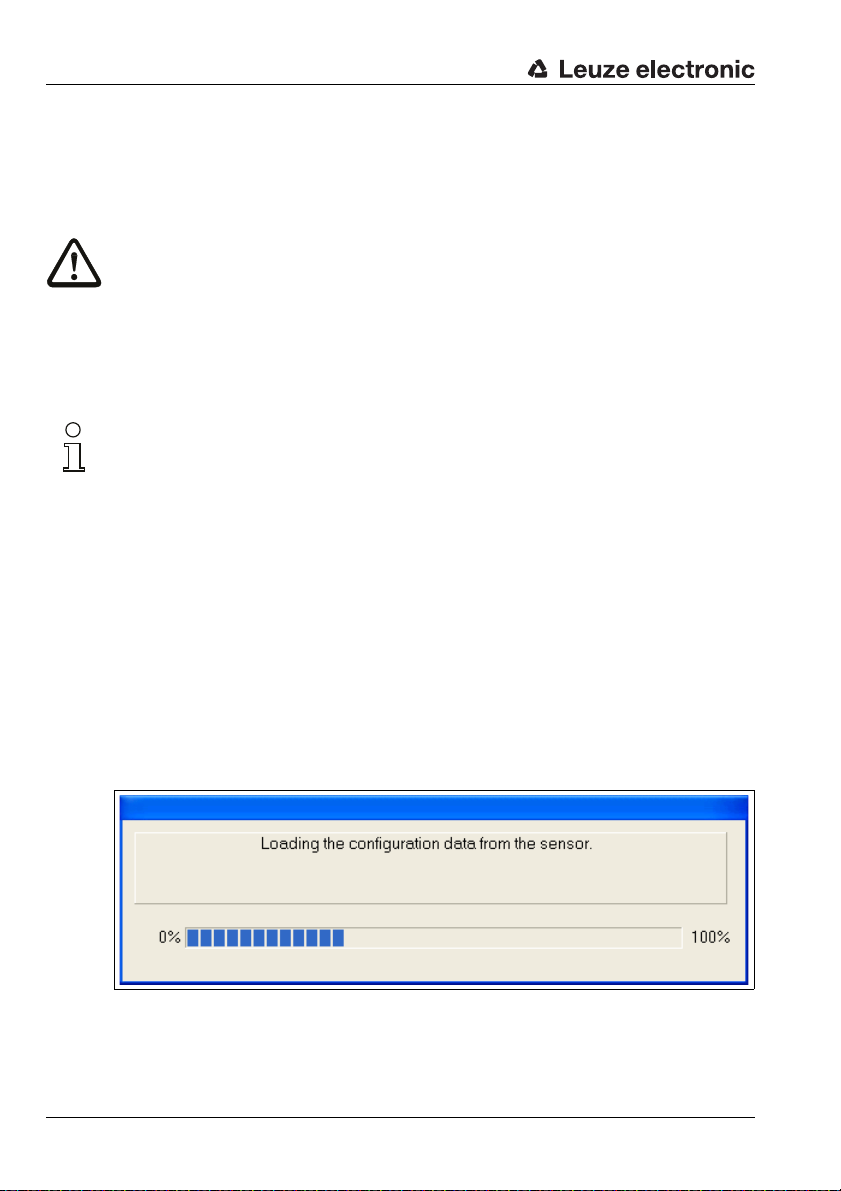

3.2 Launching the program

To start the RODsoft configuration software, make the following menu selection: Start → All

Programs → Leuze electronic → RODsoft, item RODsoft.

Retrieving configuration data from the ROD4-3…

After starting, your computer – together with the program – establishes a connection to the

rotoScan ROD4-3… and transfers the current configuration data from the ROD4-3… to the

program.

During this process, the following window appears on the screen:

Figure 3.1: Transfer of the current configuration data

10 RODsoft Leuze electronic

Page 12

First steps

Notice!

If this process is not completed successfully, the device is not ready for operation or the connection cable is connected incorrectly.

When starting the software without a ROD4-3… connected, you can still create a configu-

ration offline and save it as a file. Select the Authorized User (AU) access level (password:

ROD4LE) and edit the configuration data using the assistant.

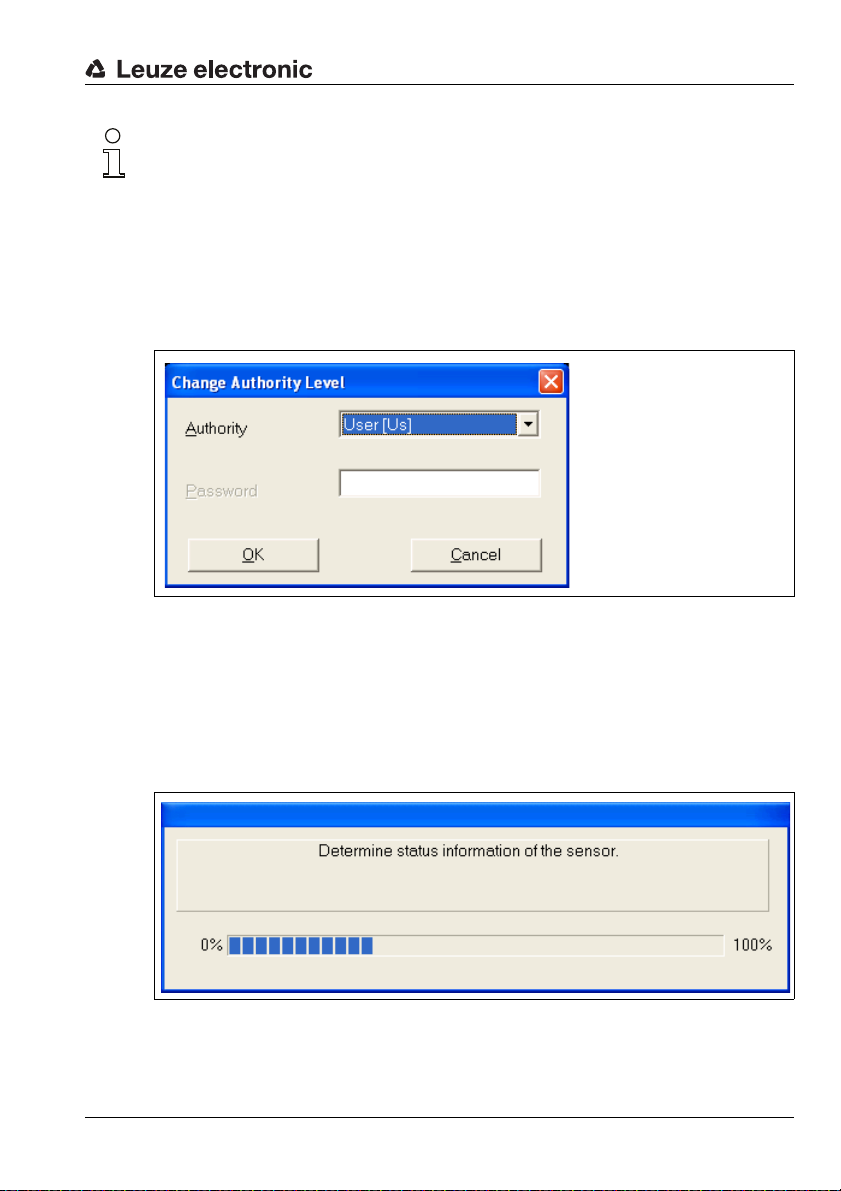

Defining the access level

In the next step, you are prompted by the program to identify your authorisation status by

selecting an access level and entering a password which has been defined for this level.

Figure 3.2: Changing the access level

For the default setting of the "User" access level, no password is required.

As User, you can display measurement values. Configuration parameters and detection

fields cannot be changed (see chapter 4.5).

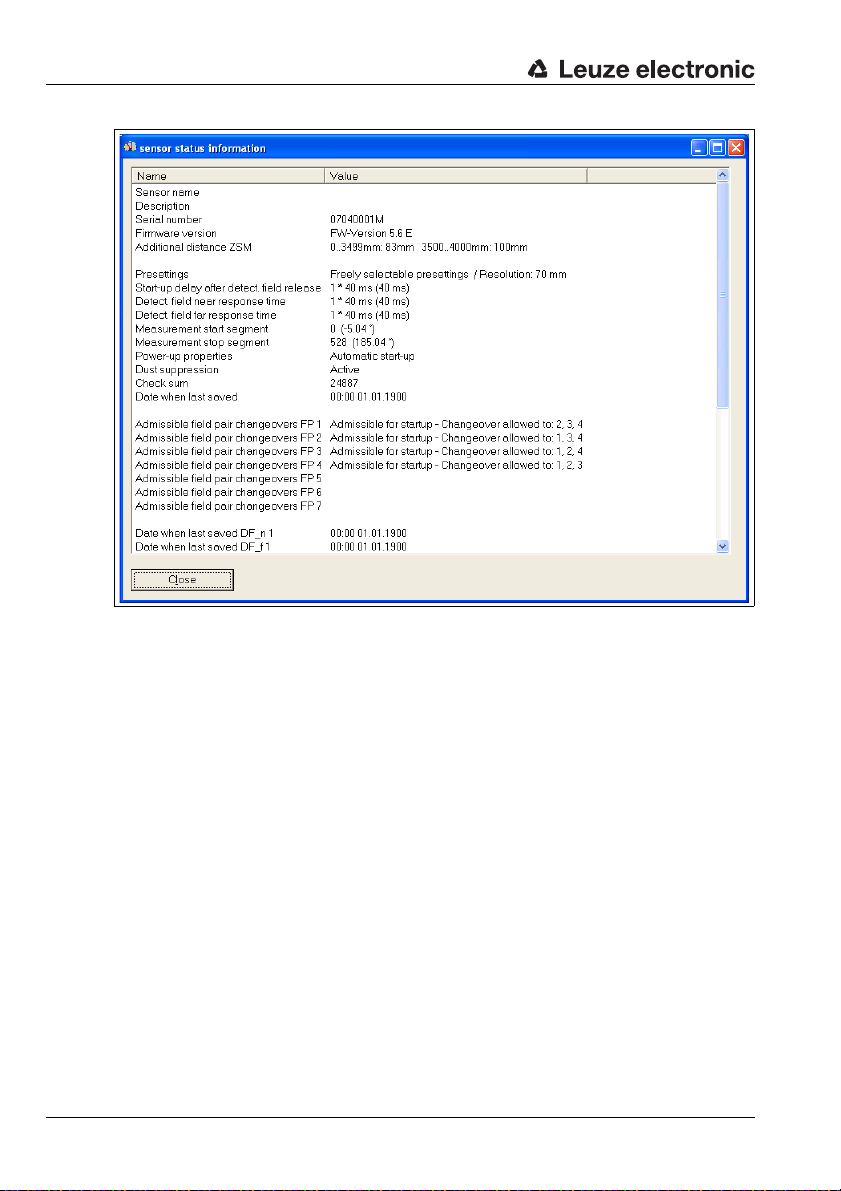

ROD4-3…Status information

If your access authorisation was accepted, the ROD4-3… status information is read in and

displayed in a window.

Figure 3.3: Reading in the status information

Leuze electronic RODsoft 11

TNT 35/7-24V

Page 13

First steps

Figure 3.4: ROD4-3…Status information

12 RODsoft Leuze electronic

Page 14

User interface of the program

1

2

3

4

5

1

Menu bar

2

Tab with the 4 work areas:

• Display measurement diagram (active = yellow)

• Configuration

• Define detection fields

• System data

3

Tab-dependent function buttons

4

Graphic work area

5

Status bar

After you close the window which contains the sensor status information, the user interface

of the configuration software appears in the foreground:

First steps

Figure 3.5: RODsoft user interface

Leuze electronic RODsoft 13

TNT 35/7-24V

Page 15

First steps

3.3 Procedure / work areas

With RODsoft, you can work both online (with connected sensor) as well as offline

(without connected sensor). To change the work area, click the appropriate tab. The active

tab is displayed in yellow.

Typical procedure

• Connect sensor and start program. The current configuration data are loaded by the

sensor.

• Select the Authorized User (AU) access level (password: ROD4LE).

The status information is loaded by the sensor.

• Edit the sensor configuration and define detection fields.

• Transfer new configuration to the sensor and back up the data by saving to a file.

• Test new configuration in measurement operation.

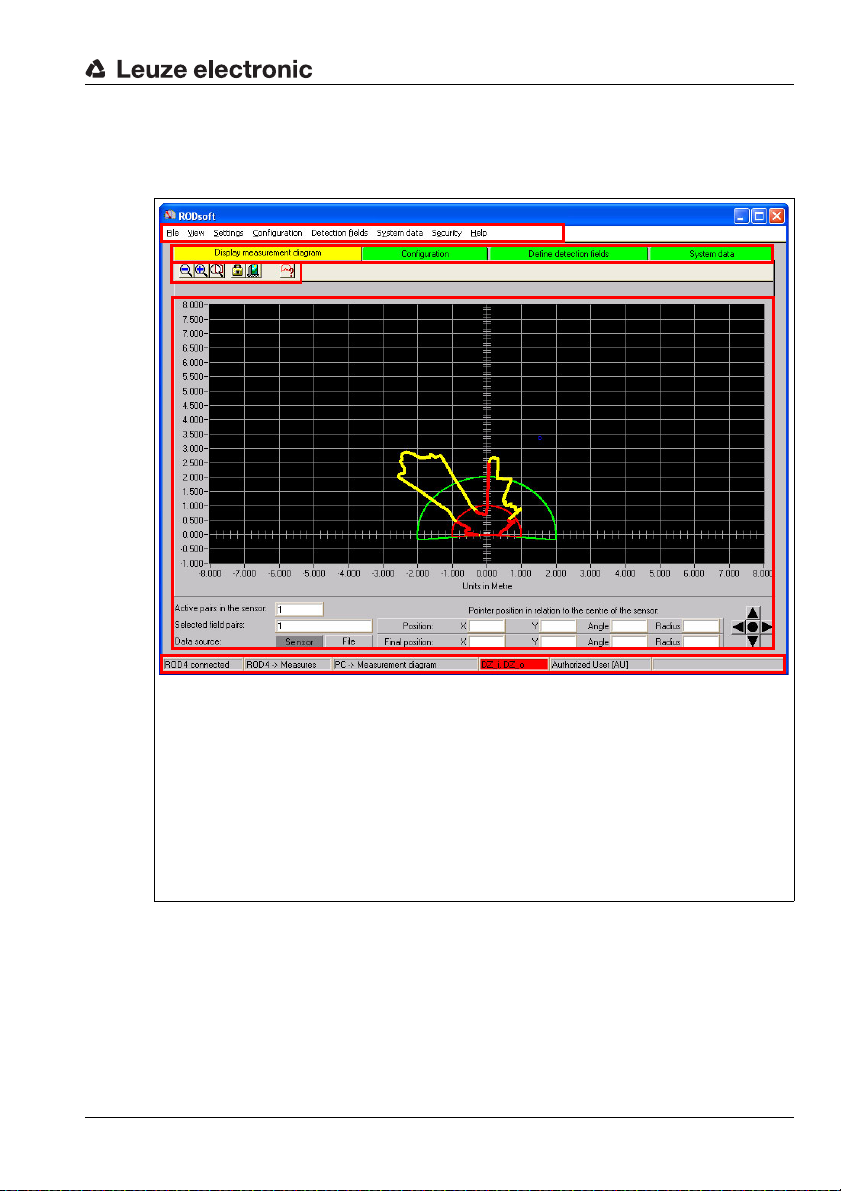

"Display measurement diagram" tab

Measurement operation is activated; the environment is scanned and the contours of

objects present in the measurement range are displayed in yellow. The current detection

fields are displayed here in red (near detection field) or green (far detection field).

"Configuration" tab

All functions necessary for configuring the sensor and setting parameters are available here.

The sensor configuration can be edited with the aid of the Configuration Wizard or directly

in the parameter tree structure. The configuration data can be loaded by the sensor or from

a file and saved to either the sensor or as a file.

For documentation purposes, the current configuration can be printed or saved as a text file.

In this work area, the sensor can be reset to standard configuration values (factory setting).

"Define detection fields" tab

This work area supports the application-specific definition of up to 7 detection field pairs. The

detection fields can be taught, created interactively with the mouse using the graphical interface or entered numerically. Detection fields which have already been defined can be

changed, faded out or borders cut on a segment-by-segment basis.

By defining a reference boundary, not only is the active near detection field monitored, but

the exact measurement values are also compared with the reference boundary.

Detection fields can be deleted, saved in the sensor or as a file and printed out.

"System data" tab

This work area is used primarily for device identification and diagnostics. Status information

and diagnostic data can be loaded by the sensor. A service file can be created which

contains all information necessary for diagnosing the sensor.

In addition, adjustment of the front window sensor can be performed here (e.g. following an

exchange) and the sensor can be reset.

14 RODsoft Leuze electronic

Page 16

Description of the user interface

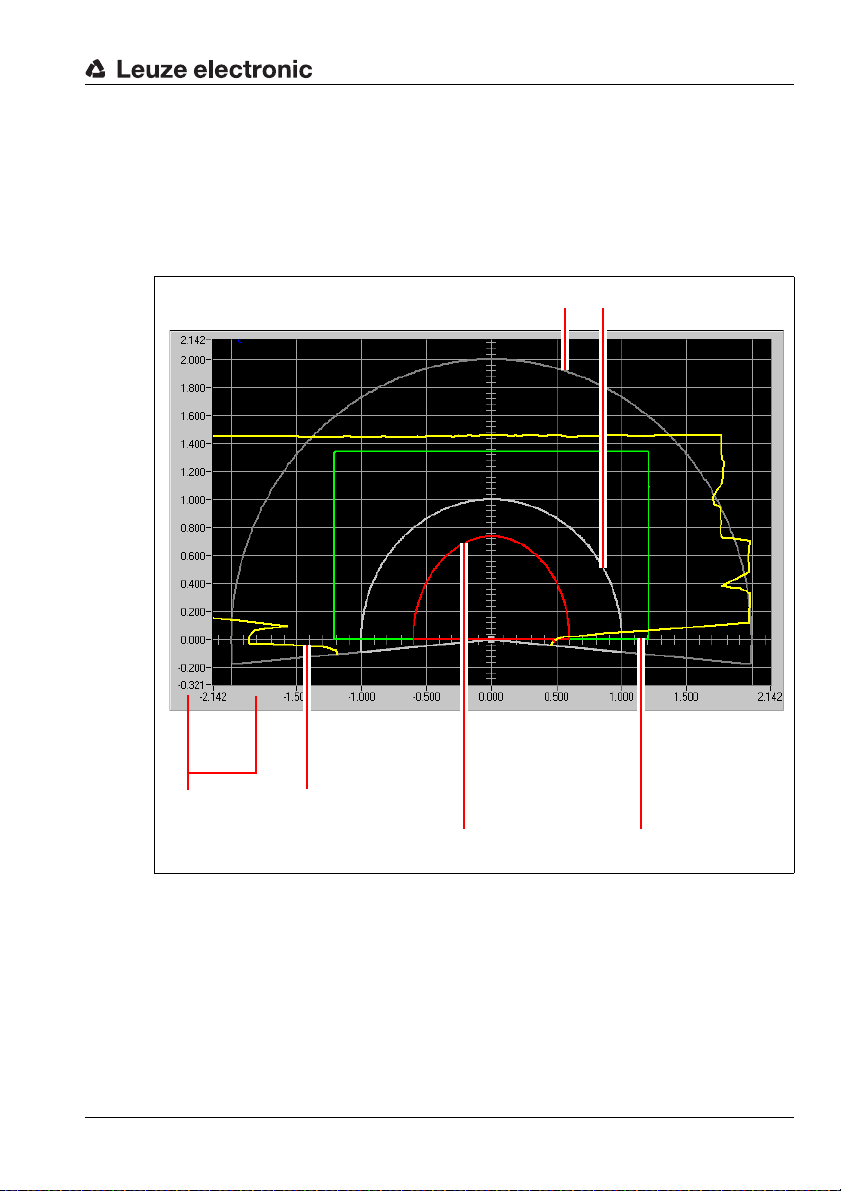

Rulers Measurement value

display (yellow)

Active detection field

near (red)

Active detection field

far (green)

Inactive detection fields (grey)

4 Description of the user interface

4.1 Graphical work area / detection fields

Various components comprise the actual graphical work area of the program. The work area

serves primarily for reading the measurement values and defining the detection fields.

Figure 4.1: Objects on the work area

Rulers

"Meter" is the unit of measurement used for the rulers. When you zoom, the gradations on

the rulers change appropriately for the given zoom level.

Leuze electronic RODsoft 15

TNT 35/7-24V

Page 17

Description of the user interface

Displaying measurement values

In the "Display measurement diagram" tab, you can view the current measurement values

of the sensor as a yellow curve. The laser in the device scans the environment at a scanning

rate of 25Hz. If an object enters the scanning area, it is therefore detected by the laser within

no more than 40ms. In the display, the object is displayed simultaneously with the detection

by the laser.

Notice!

The display of the measurement values on the screen corresponds to the alignment of the

ROD4-3…. If a person or object e.g. in the view direction of the ROD4-3… enters the scanning area from the right, the measurement line changes at the right.

You can, however, also rotate the graphical work area by 180°.

In the "Configuration" and "System data" operating modes, the last measurement contour

measured prior to switching to the given operating mode is frozen on the screen.

Detection fields / detection field pairs

Eight reversible detection field pairs (7 configurable + 1 permanently defined) enable optimal

adaptation to the applications. A detection field pair is considered to be the combination of

both a near and far detection field. The following designations are used in the RODsoft

configuration software:

Detection field pair x consists of detection field_n x (near) and detection field_f x (far).

The near and far detection fields are represented by different colours in the RODsoft configuration software: near = red, far = green.

Detection field pairs 1 … 7 can be freely defined by the user. Detection field pair 8 is permanently defined. Both detection field_n 8 as well as detection field_f 8 are set to zero here.

This means that no area monitoring takes place when detection field pair 8 is activated, and

the respective outputs are switched on.

The near detection fields (1 … 7) can be defined with a radius of up to 30m; the far detection

fields (1 … 7) can be defined with a radius of up to 50m.

4.1.1 Changing over between detection field pairs

Attention!

Depending on which detection field pairs are configured, 1 or 2 detection field pairs

may be simultaneously active and simultaneously monitored!

Only detection field pairs 1 through 4 are configured

If only detection field pairs 1 through 4 are configured in the RODsoft configuration software,

i.e. it is only possible to start with a field pair between 1 and 4 and it is only possible to

changeover between a field pair between 1 and 4, then a maximum of 2 detection field pairs

may be simultaneously active and monitored.

16 RODsoft Leuze electronic

Page 18

Description of the user interface

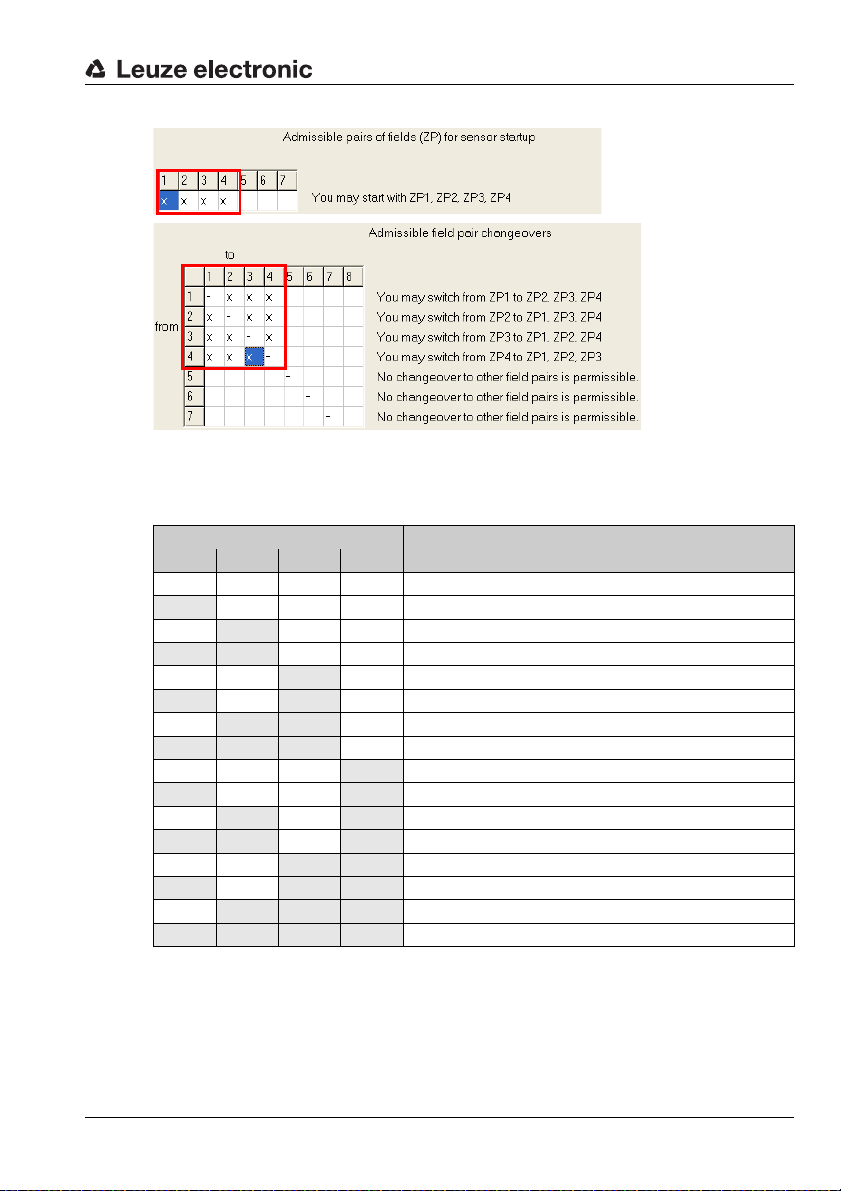

Figure 4.2: Configuring detection field pairs 1 through 4 only

The four control inputs FPS1 … FPS4 can be used to change over between the detection

field pairs. The following table shows the admissible control options.

Control input

FPS1 FPS2 FPS3 FPS4

0000 Detection field pair 1 is active

1000 Detection field pair 1 is active

0

1 100 Detection field pairs 1 and 2 are active

00

1010 Detection field pairs 1 and 3 are active

0

1 1 1 0 Not permitted

000

1001 Detection field pairs 1 and 4 are active

0

1 101 Not permitted

00

101 1 Not permitted

0

1 1 1 1 Not permitted

Table 4.1: Changeover of the detection field pairs via the control inputs

If an inadmissible state exists at the control inputs for more than 80 ms, the sensor switches

to the error state.

100 Detection field pair 2 is active

10 Detection field pair 3 is active

1 10 Detection field pairs 2 and 3 are active

1 Detection field pair 4 is active

101 Detection field pairs 2 and 4 are active

1 1 Detection field pairs 3 and 4 are active

1 1 1 Not permitted

Meaning

TNT 35/7-24V

Leuze electronic RODsoft 17

Page 19

Description of the user interface

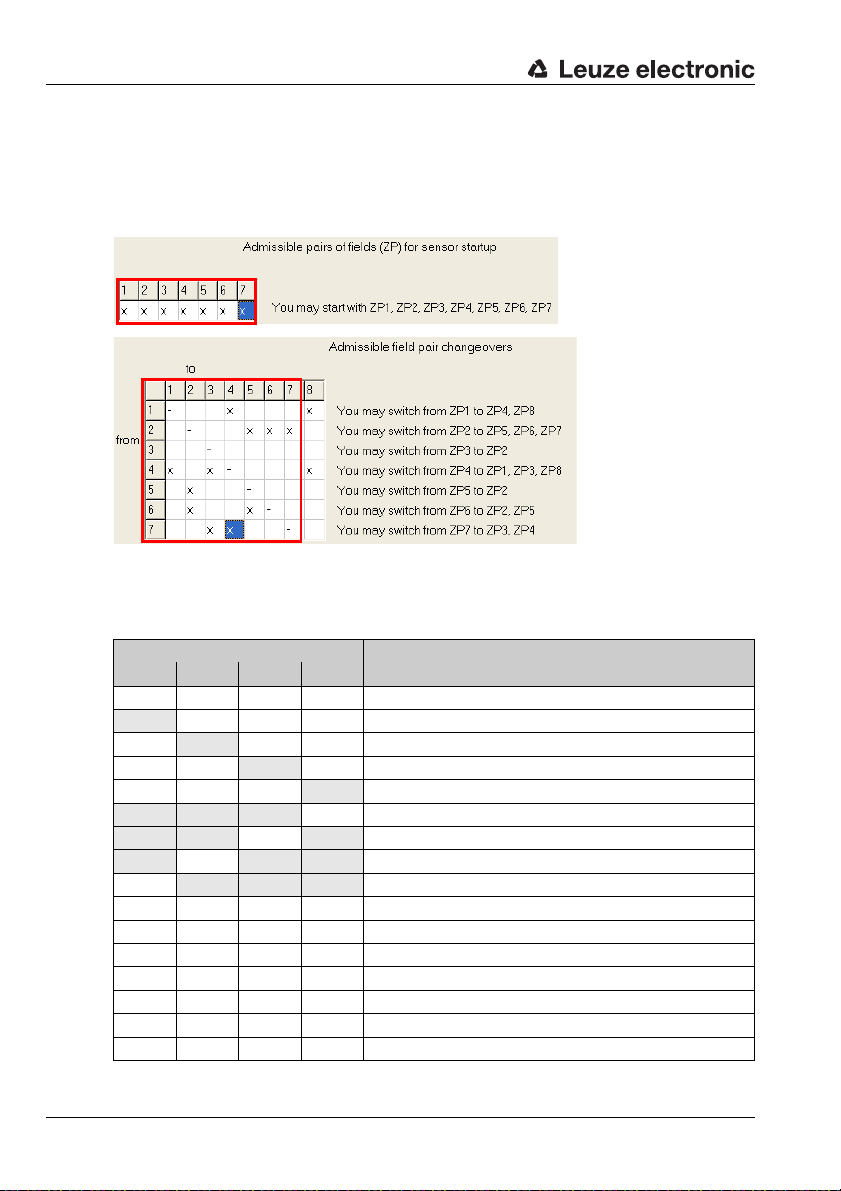

One of detection field pairs 5 through 8 is also configured

If, in addition to detection field pairs 1 through 4, at least one of detection field pairs 5 through

8 is also configured in the RODsoft configuration software, i.e. it is possible to start with a

field pair between 1 and 7 and/or it is possible to changeover between a field pair between

1 and 8, then only 1 detection field pair may be simultaneously active and monitored.

Figure 4.3: Also configuring detection field pairs 5 through 8

In this case, the four control inputs can be used to change over between the detection field

pairs as follows.

Control input

FPS1 FPS2 FPS3 FPS4

0000 Detection field pair 1 is active

1000 Detection field pair 1 is active

0

00

000

1 1 10 Detection field pair 5 is active

1 101 Detection field pair 6 is active

101 1 Detection field pair 7 is active

0

1100 Not permitted

1010 Not permitted

0110 Not permitted

1001 Not permitted

0101 Not permitted

0011 Not permitted

1111 Not permitted

Table 4.2: Changeover of the detection field pairs via the control inputs

100 Detection field pair 2 is active

10 Detection field pair 3 is active

1 Detection field pair 4 is active

1 1 1 Detection field pair 8 is active

Meaning

18 RODsoft Leuze electronic

Page 20

While changing over between 2 detection field pairs, inadmissible states at the control inputs

are tolerated for a duration of 40ms; after this period the sensor switches to the error state.

The changeover between 2 detection field pairs occurs within a system reaction time of

80ms.

4.1.2 4-field mode

In 4-field mode (configuration via RODsoft), all 4 detection fields of detection field

pairs 1 and 2 are simultaneously activated and evaluated. In this case, a separate output is

assigned to each detection field pair.

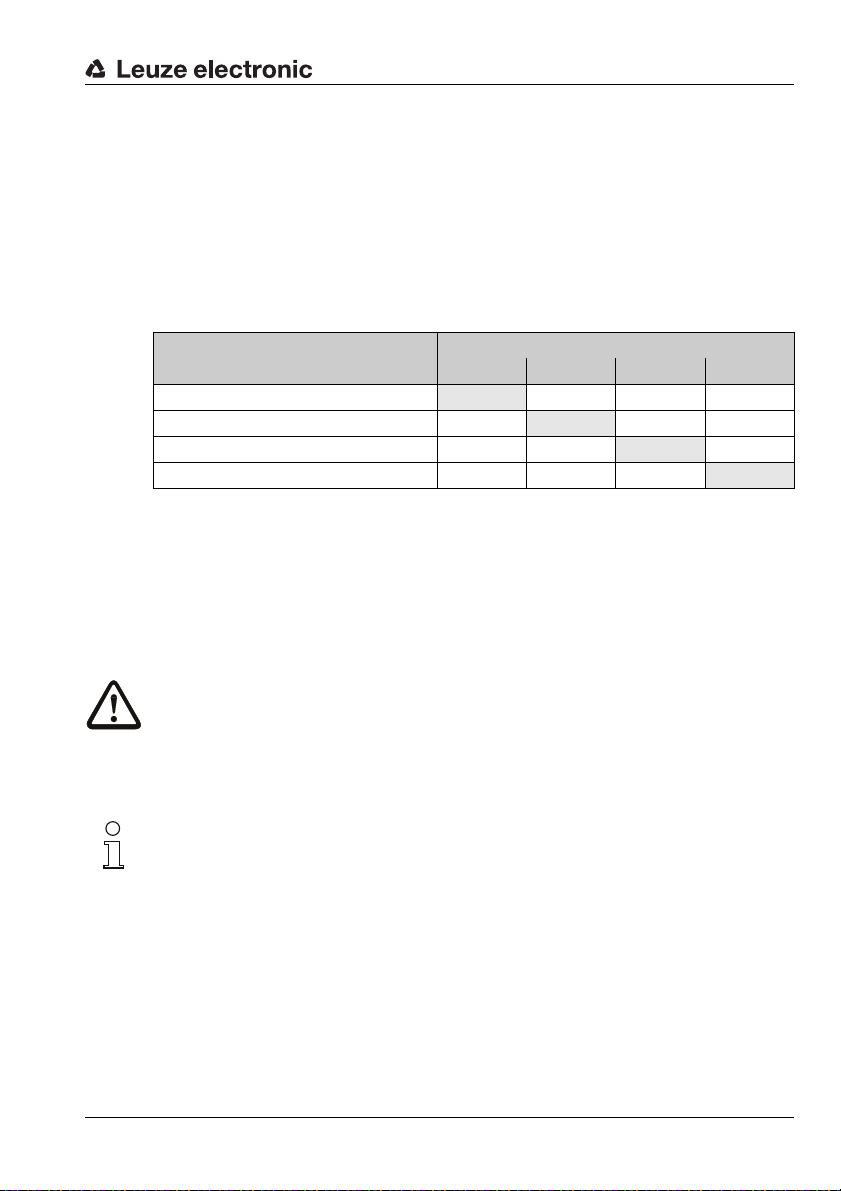

Detection field

Detection field_n 1

Detection field_n 2

Detection field_f 1

Detection field_f 2

Table 4.3: Assignment of detection field to switching output in 4-field mode

Inputs FPS1 … FPS4 are not evaluated in 4-field mode. Detection field changeover is not

possible in 4-field mode.

The 4-field mode is activated:

• in the configuration assistant under Presettings or

• using the menu command Configuration –> Change –> Configuration Parameters

–> Presettings.

Description of the user interface

Switching output

Fn1 Fn2 ALARM1 ALARM2

X

X

(X)

X

Attention!

Depending on the configuration, output ALARM1 may, in some cases, also signal device

warnings. This means that a violation of detection field_f 1 is not uniquely signalled under

certain circumstances.

All outputs are switched off during start-up. Outputs ALARM1 and ALARM2 are activated

during configuration.

Notice!

Operation with 3 detection fields

If only three detection fields are to act on three outputs, only use detection field_n 1, detection field_n 2 and detection field_f 2 and set the alarm signal type for ALARM1 to "Device

warning". The output ALARM1 will then only signal device warnings and is, as a result,

unique.

Operation with 2 detection fields

If only two or fewer independent outputs are needed, 4-field mode is not required and should

be deactivated with the appropriate RODsoft parameter.

Leuze electronic RODsoft 19

TNT 35/7-24V

Page 21

Description of the user interface

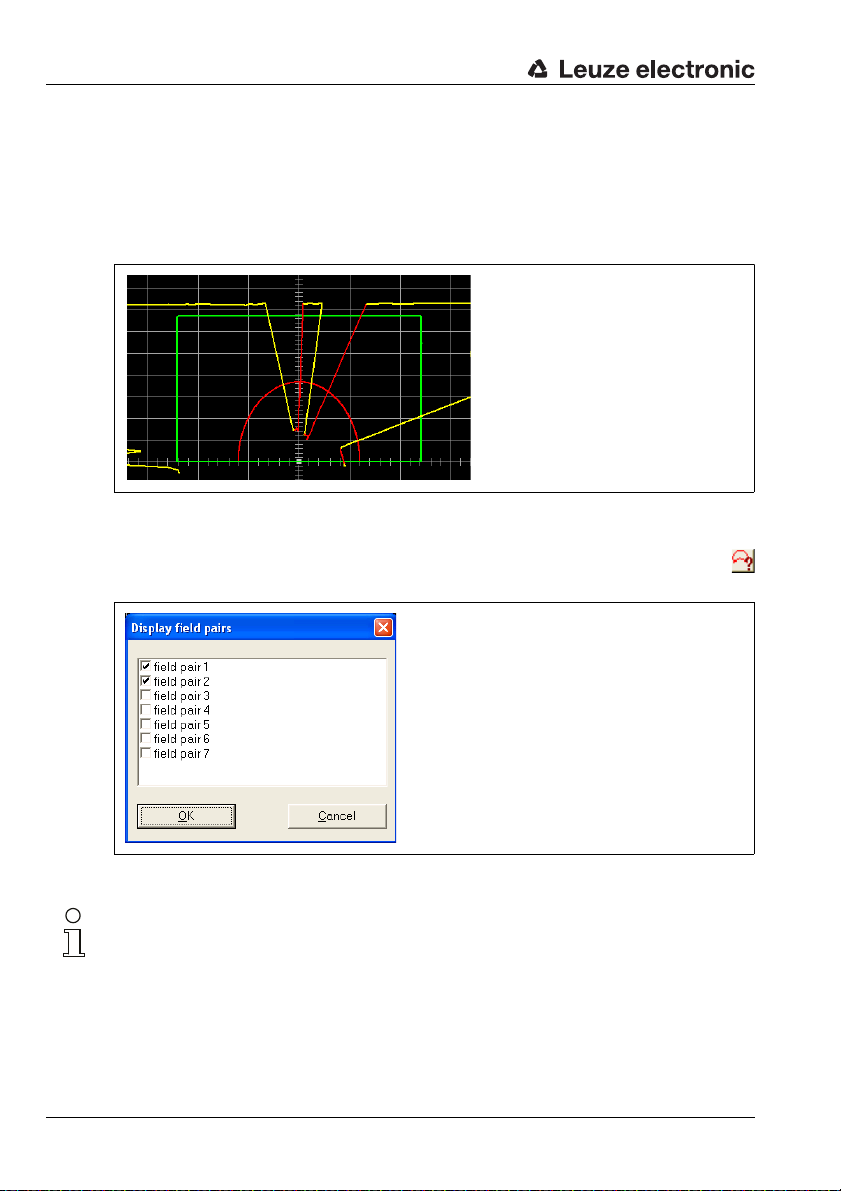

4.1.3 Displaying measurement diagram/detection fields

In "Display measurement diagram", you can always see if an object is approaching the

respective detection field or if an object has been detected within a detection field (the yellow

measurement contour enters the green or red area, see figure 4.4). If the entering of the

object into an active near detection field leads an object detection, the measurement contour

is coloured red at this position.

Figure 4.4: Object detection within the detection fields

If you would like to monitor only one detection field pair on the screen, you can fade out the

other detection field pairs using the Settings –> Display field pairs menu item or the

icon in the "Display measurement diagram" operating mode.

Figure 4.5: Selection of the detection field pair to be displayed

Notice!

Displaying/hiding a detection field in RODsoft has no effect on how it is monitored by the

sensor! Only after a detection field pair is activated via the control inputs is it monitored by

the sensor.

You can adapt detection fields to your application by editing them in the "Define detection

fields" operating mode (see chapter 6).

20 RODsoft Leuze electronic

Page 22

4.2 Tabs and toolbar

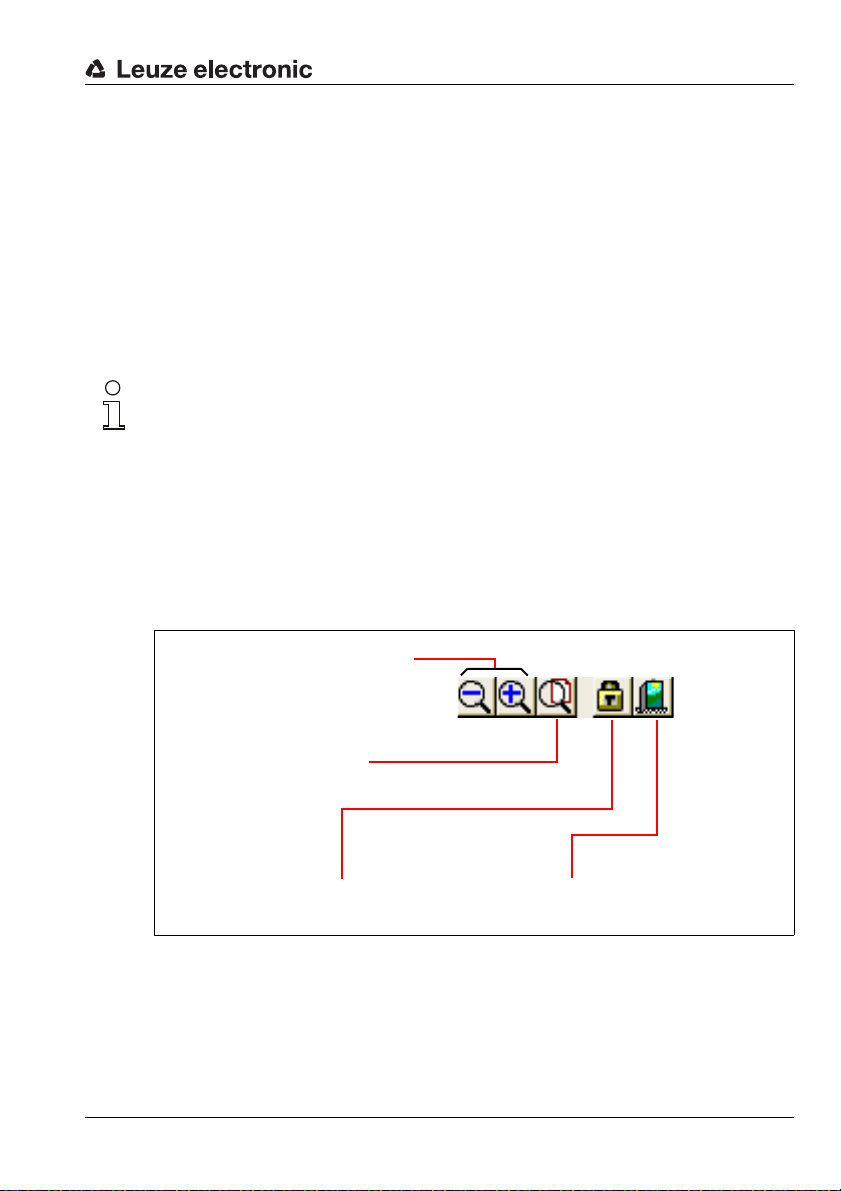

Changing the access level Exit program

RODsoft

Zoom

(display smaller/larger)

Zoom

(display complete

diagram area)

4.2.1 Tabs

To simplify work with the RODsoft configuration program, the software interface is divided

into 4 work areas (see chapter 3.3).

These work areas correspond to the four operating modes in the Settings –> Operating

mode menu and are displayed as tabs. Each tab or operating mode has a toolbar of its own.

How the detection field values are displayed is dependent on the selected operating mode.

You can select the operating mode either by Clicking the respective tab or with the

Settings –> Operating mode menu item.

Notice!

Depending on the adjustments made previously in a given operating mode, you may, under

certain circumstances, be prompted to update the data with the sensor before switching to

a different operating mode.

4.2.2 Buttons

The buttons in the toolbar serve as a shortcut to commands which can also be selected from

the menu bar.

General buttons

The following figure shows the general buttons, which are available in all 4 work areas:

Description of the user interface

Figure 4.6: General buttons

Leuze electronic RODsoft 21

TNT 35/7-24V

Page 23

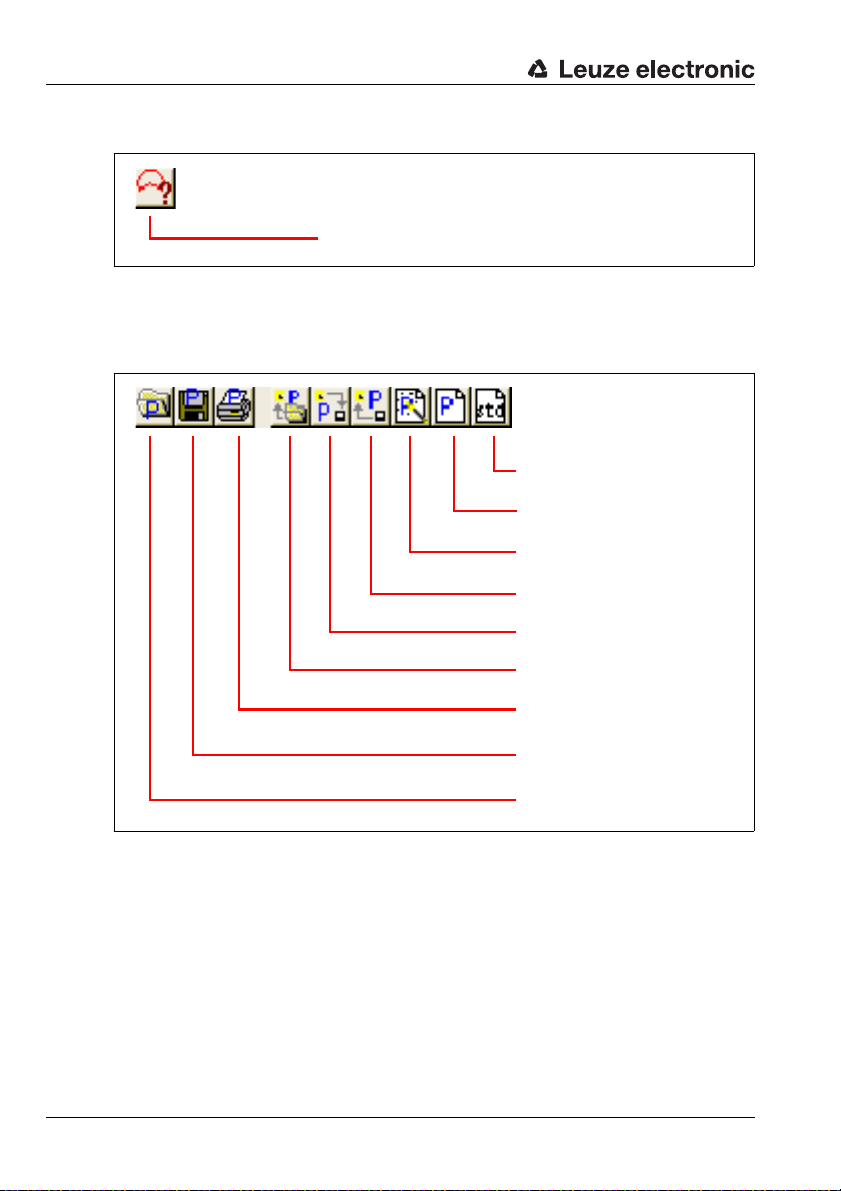

Description of the user interface

Selection of the detection

field pairs to be displayed [1,2,3,4,5,6,7]

Set default values in the sensor

(state on delivery)

Change configuration data

(tree structure)

Call up Configuration Wizard

Transfer configuration data from the

PC to the sensor

Get configuration data from the sensor

Load configuration file from data carrier and transfer to the sensor

Print current configuration data

Save current configuration to file

Load configuration from file

Additional buttons in the "Display measurement diagram" operating mode

Figure 4.7: Specific icon in the "Display measurement diagram" operating mode

Additional buttons in the "Configuration" operating mode

Figure 4.8: Additional buttons in the "Configuration" operating mode

22 RODsoft Leuze electronic

Page 24

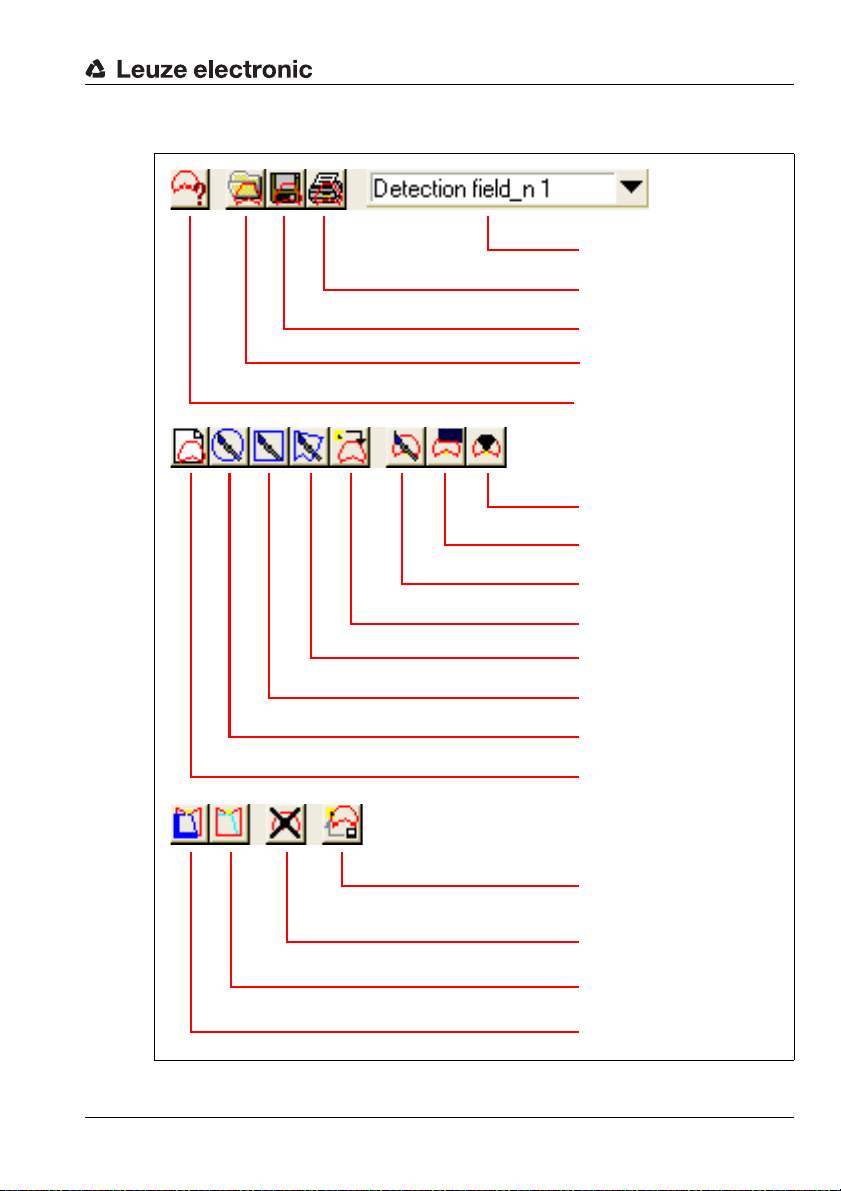

Description of the user interface

Selection of the detection field to

be edited

Print detection

field

Save detection field to file

Load detection field from file

Selection of the detection field

pair to be displayed

Fade out detection field segment

Cut detection field

Change detection field

segment

Teach-in detection field

Define polygonal detection field

Define rectangular detection

field

Define elliptical detection field

Input detection field numerically

Transfer modified detection

fields from the PC to the sensor

Delete detection field

Reset reference boundary definition of detection field segment

Set detection field segment as

reference boundary

Additional buttons in the "Define detection fields" operating mode

Figure 4.9: Additional buttons in the "Define detection fields" operating mode

Leuze electronic RODsoft 23

TNT 35/7-24V

Page 25

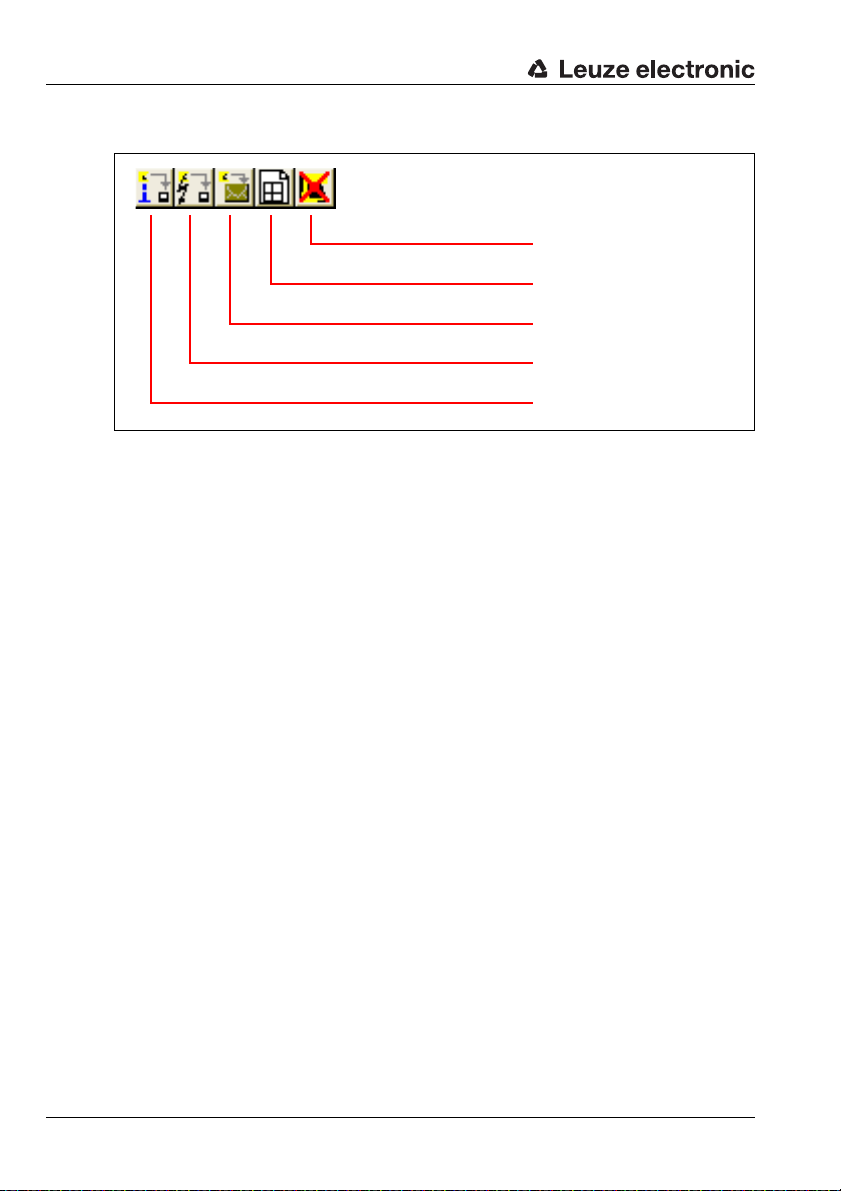

Description of the user interface

Reset sensor (restart)

Adjust optical window supervision

Create service file

Load diagnostic data from the

sensor

Load status information from the

sensor

Additional buttons in the "System data" operating mode

Figure 4.10: Additional buttons in the "System data" operating mode

24 RODsoft Leuze electronic

Page 26

4.3 The menu bar

All program commands are located in various menus.

Notice!

Some menu items can only be selected if you are in the appropriate tab (work area).

How the individual commands are used is described in detail in the following chapters. The

commands located in the menus are described briefly in the following overview.

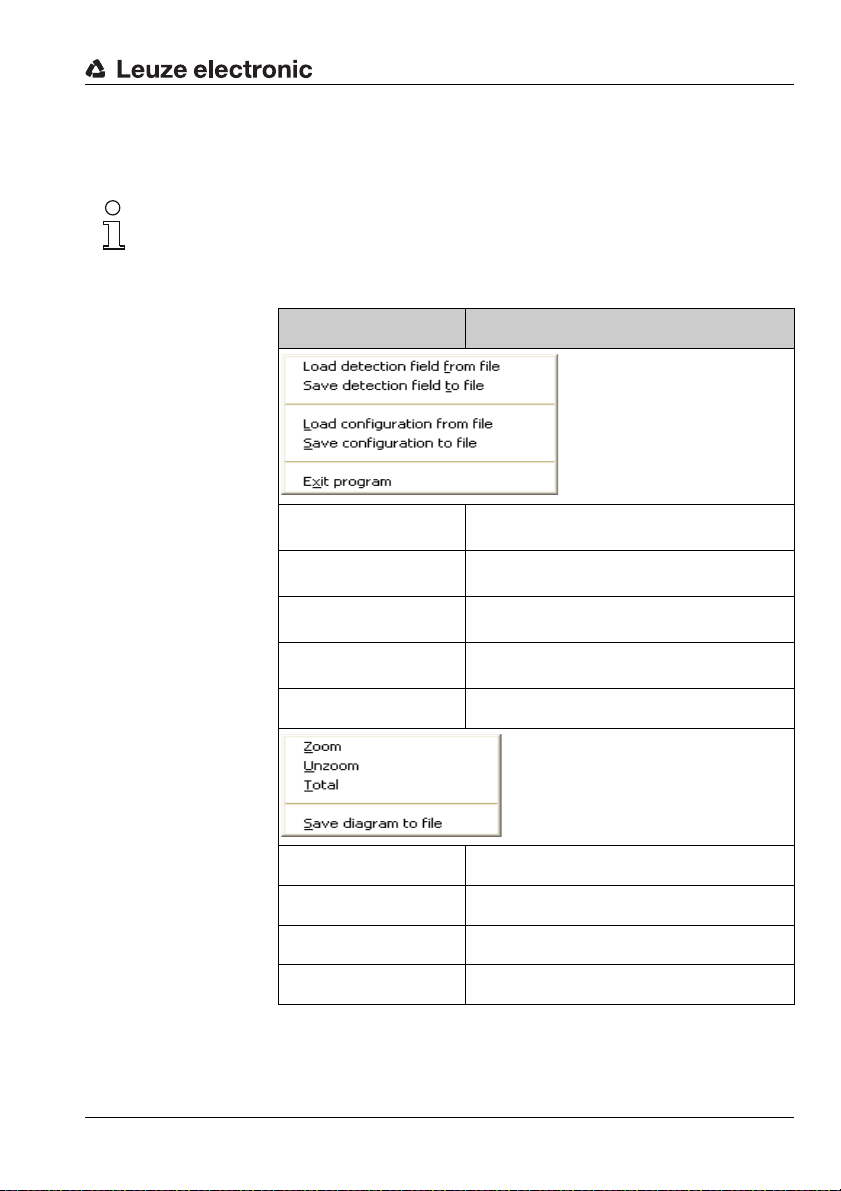

File menu

Description of the user interface

Command Function

View menu

Load detection field

from file

Save detection field to

file

Load configuration

from file

Save configuration to

file

Exit program Exit RODsoft

Zoom Enlarge view

Unzoom Reduce view

Tot al View to 100%

Save diagram to file Save active view as bitmap

Load saved detection fields

Save active detection field definition

Load stored configuration

Save active configuration

TNT 35/7-24V

Leuze electronic RODsoft 25

Page 27

Description of the user interface

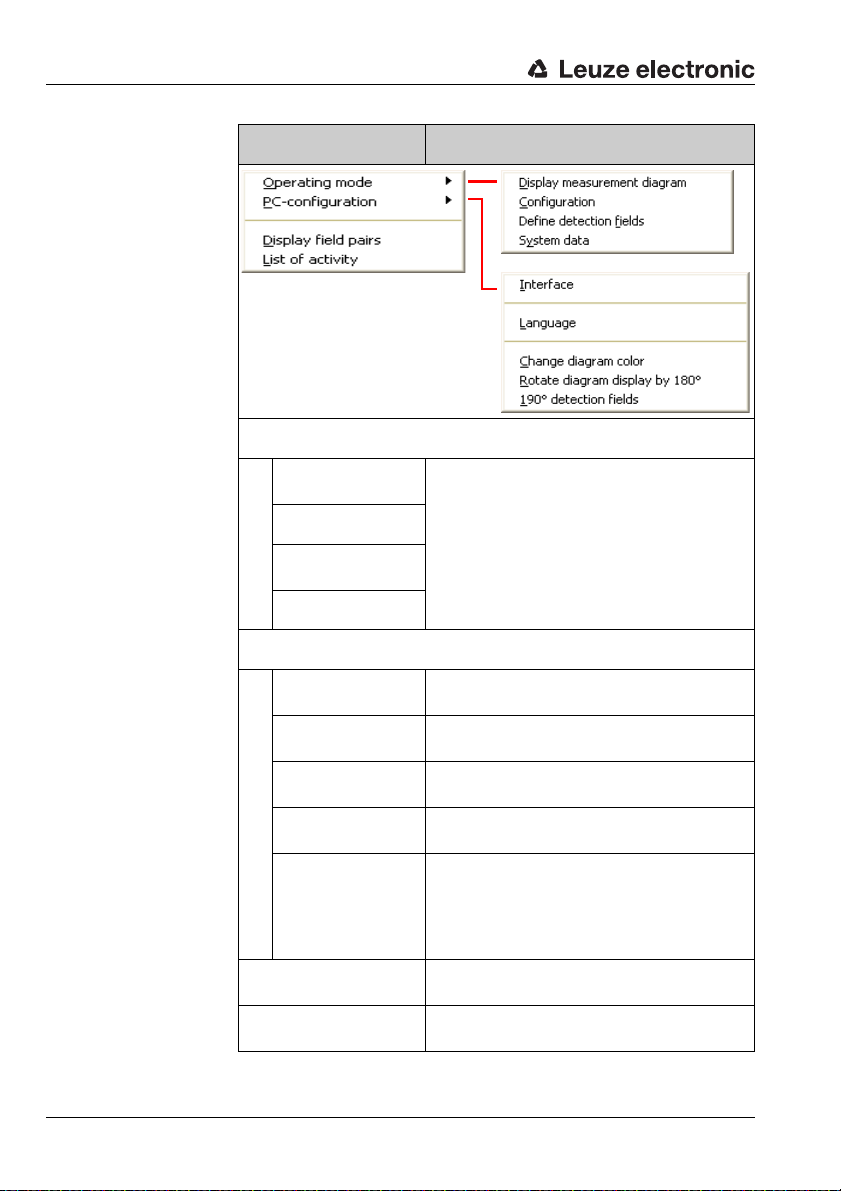

Command Function

Settings menu

Operating mode

Display measurement diagram

Configuration

Define

detection fields

System data

PC-configuration

Interface

Language

Change diagram

color

Rotate diagram

display by 180°

190°

detection fields

Display field pairs

List of activity

Switch between the four work areas (tabs)

Selection and configuration of the serial interface

Selection of the language version

(German / English) → expandable

Selection of the background colour

(black/white)

Rotate the entire diagram area by 180°

If this function is activated, expansion of the

detection field definition by an additional 10°

is enabled, i.e. from 180° to 190 °. Measurement value acquisition itself is not affected by

this.

Selection of the visible detection field pairs (1/

2/3/4/5/6/7)

Display program activities with date and time

in a separate window

26 RODsoft Leuze electronic

Page 28

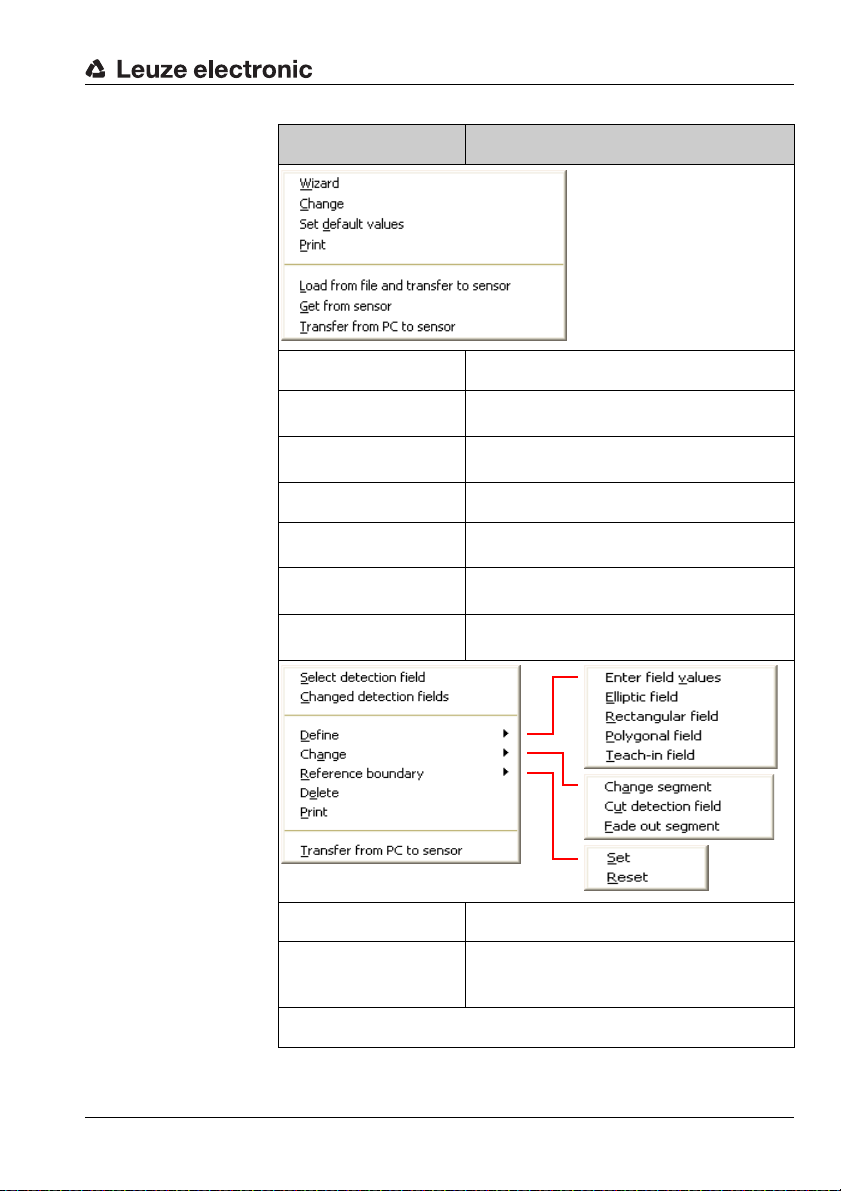

Configuration

menu

Detection fields

menu

Description of the user interface

Command Function

Wizard Start the Configuration Wizard

Change

Set default values in the

sensor

Print Print the current configuration

Load from file and

transfer to sensor

Get from sensor

Transfer from PC to

sensor

Change the configuration parameters

(tree structure)

The sensor is reset to the state upon delivery

(standard configuration)

Load a saved configuration file from a data

carrier and transfer to the sensor

Transfer configuration data from the sensor to

RODsoft

Transfer configuration data from RODsoft to

the sensor

Select detection field Selection of the detection field to be edited

Changed detection

fields

Define

Leuze electronic RODsoft 27

Displays the changed detection fields which

have not yet been transferred to the ROD43…

TNT 35/7-24V

Page 29

Description of the user interface

Command Function

Enter field values

System data

menu

Elliptic field

Rectangular field

Polygonal field

Teach-in field

Change

Change segments Edit selected detection field

Cut detection field Cut sides of the selected detection field

Fade out segment

Reference boundary

Set Define a reference boundary

Reset Remove a reference boundary

Delete Delete selected detection field

Print Print selected detection field

Transfer from PC to

sensor

Use corner points, ellipse, rectangle, polygon

and measurement contour to edit a detection

field

Remove individual segments of the selected

detection field

Send newly defined/changed detection fields

to the ROD4-3…

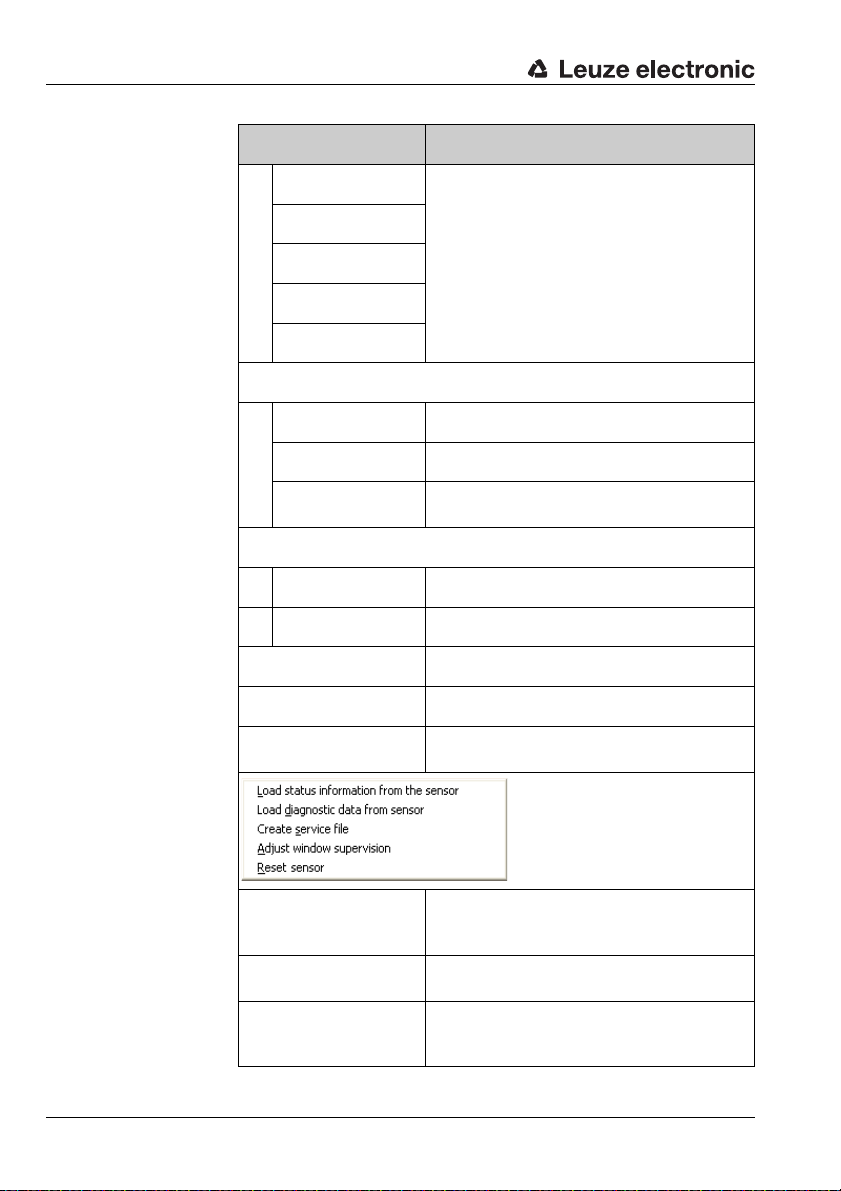

Loading status information from the sensor

Loading diagnostic

data from the sensor

Create service file

28 RODsoft Leuze electronic

Call up status information (parameter overview) from the sensor and display in a separate window

Display the last ROD4-3…-device errors

Create a service file with all device information and parameters necessary for remote

diagnostics

Page 30

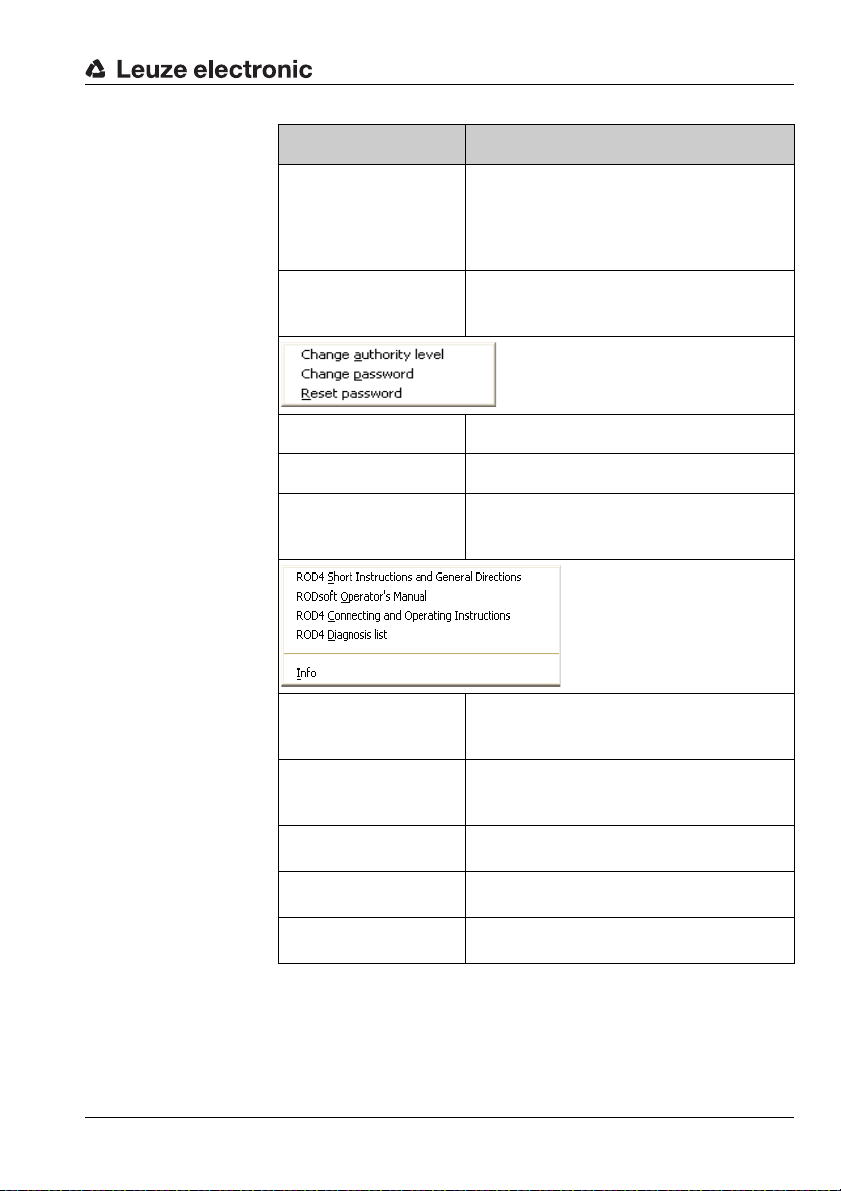

Security menu

Help menu

Description of the user interface

Command Function

This function is used for calibrating the front

Adjust window supervision

Reset sensor

Change access level Change access level

Change password Change password for the access level

Reset password

cover sensors following replacement of the

front cover. A special password, provided by

the Leuze service department, is required in

order to use the function.

This function sends a reset command to the

sensor (e.g. if no RESTART button is provided

and a device error has occurred).

If the "password is forgotten": displays the

password as an encrypted number to be sent

to LEUZE customer service for reactivation.

ROD4 Short Instructions and General

Directions

RODsoft

Operator's Manual

ROD4 Connecting and

Operating Instructions

ROD4Diagnostic list

Info

1) Adobe Acrobat Reader required

Displays a PDF file with short instructions and

general directions for using the ROD4-3…

1)

Displays the PDF version of the RODsoft

Software and Protocol Description

(this document)

Displays the PDF version of the technical

description ROD4-3…

Displays a PDF file with explanations of the

diagnostic codes

1)

1)

1)

Version information on the configuration software RODsoft

Table 4.4: Overview of the menu commands

Leuze electronic RODsoft 29

TNT 35/7-24V

Page 31

Description of the user interface

Current access

level

Connection

status

Currently selected

work area

Object detection in

the far (green) or near

(red) detection field

Operating state

of the sensor

4.4 Displaying status information

4.4.1 Data source

Figure 4.11: Display of data source for configuration data

The fields display the source of the configuration data, i.e. the source from which the current

configuration data were loaded or the location to which they were most recently written.

• "Sensor" field active (dark):

Data were loaded from or saved in the sensor.

• "File" field active (dark):

Data were loaded from or saved as a file.

• No field active:

Configuration data have not yet been loaded or saved, e.g. if the program was started

before the sensor was ready.

Notice!

The display also changes if only parts of the configuration data are loaded or saved (e.g.

only one detection field).

4.4.2 Status bar

Important information on the current hardware and software states are displayed in the

status bar:

• Connection status between sensor and PC

• Current operating state of the sensor

• State of the inputs and outputs

• The current access level

Figure 4.12: Status bar

The first field contains the operating state of the sensor. Following successful synchronisation of PC and sensor, the text of the info field changes from "ROD4 synchro" to "ROD4

connected".

30 RODsoft Leuze electronic

Page 32

The following field displays the operating mode (measurement operation) and any possible

error messages. In the next field, the active work area (operating mode) of the program is

displayed. The fourth field displays an object detection in one of the detection fields, far

(green) and/or near (red). In the last field, the currently selected access level (see chapter

4.5) is displayed:

•User [Us]

• Maintenance [Ma]

• Authorized User [AU]

• Production [Pr]

• Development [De]

4.5 Access levels

In order to ensure that the device is configured only by trained and authorised persons,

RODsoft provides different functionality for different access rights in the "Change Access

Level" dialogue.

Description of the user interface

Figure 4.13: Changing the access level

Access levels and access rights

Registration is by means of predefined access levels, each of which is protected against

unauthorised access by means of a password. In the "Authorized User" access level, detection fields can also be created "off-line", i.e. without a connected ROD4-3…. These detection

fields can then, for example, be stored on diskette.

The following access levels are available:

Leuze electronic RODsoft 31

TNT 35/7-24V

Page 33

Description of the user interface

I

Level (abbr.) Password Access

User (Us) No password

Maintenance (Ma) ROD4/GOY

Authorized User (AU) ROD4LE Full access to all functions

Production (Pr) Manufacturer-specific access

Development (De) Manufacturer-specific access

Table 4.5: Access levels and passwords

Passwords may be entered in either upper- or lower-case letters. No changes can be made

to the device configuration in the "User" access level. This level is, therefore, not password

protected. All functions which are not permitted in the given access levels are faded out in

grey. The current access level is displayed in the status display. (see section 4.4.2 "Status

bar").

Notice!

The password set at the factory for Authorized User (AU) is "ROD4LE". When configuring

the rotoScan ROD4-3… for the first time, the employee responsible for (Ma) and (AU) is to

define new passwords, save them and store the data carriers in a safe location.

General program settings, display and analysis

of measurement values, loading the current

ROD4-3… configuration data to the PC.

Changes cannot be made to the configuration

data!

Device configurations can be loaded from a diskette and stored in the ROD4-3….

Changes cannot be made to the configuration

data!

Figure 4.14: Notice for password changes

Changing the password

To change the password, select the Change password command from the Security menu.

In the following dialogue, enter a new password and repeat the entry to ensure correctness.

Confirm the entry with OK.

32 RODsoft Leuze electronic

Page 34

Description of the user interface

Figure 4.15: Changing the password

Attention!

→

If the password is no longer known, select the Security

Resetting the password

After actuating the Generate button, a security password is generated and displayed in red

text.

Reset password menu item.

Figure 4.16: Resetting the password

This is to be sent by either fax or mail to Leuze electronic together with the complete address

of the company, the user name and the sensor serial number. You will immediately receive

a confirmed single password which is to be entered in the "Set new password" dialogue.

Leuze electronic RODsoft 33

TNT 35/7-24V

Page 35

Description of the user interface

Figure 4.17: Confirming the single password

After the new password has been entered in both fields, access is restored to the sensor in

the "Authorized User (AU)" level.

If the confirmed single password is entered incorrectly, the sensor indicates an error

message by means of LED no. 5. Furthermore, a corresponding error message is displayed

on the screen after approx. 2 minutes. Please note that during this period RODsoft is disabled and no entry is possible.

Changing the access level

If you would like to change your access level during operation, select the Security →

Change access level menu item or click the icon, which is visible in all four toolbars. In

the following dialogue window, change to the desired level, enter the required password and

confirm the process with OK.

Figure 4.18: Changing the access level

34 RODsoft Leuze electronic

Page 36

4.6 Program settings

4.6.1 Configuring the serial interface

Use the Settings –> PC-configuration –> Interface menu item to set the serial interface

(COM…) and desired transmission rate in baud (bit/s) which are to be used.

Figure 4.19: Configuring the serial interface

4.6.2 Setting the program language

Use the Settings → PC-Configuration → Language menu item to select the program

language. Select between German, English, French and Italian.

Description of the user interface

Figure 4.20: Setting the program language

Notice!

A change of the language selection does not take effect until the program is restarted.

Leuze electronic RODsoft 35

TNT 35/7-24V

Page 37

Description of the user interface

4.6.3 Selecting the background colour

To better recognise the measurement curves (yellow), it is recommended that the background colour be set to black (default). On the other hand, when creating the detection fields,

white is better suited. To select between these two colours, select the Settings –> PC-

configuration –> Change diagram color menu item.

36 RODsoft Leuze electronic

Page 38

Editing / configuring the device configuration

5 Editing / configuring the device configuration

5.1 General information and procedure

Initial configuration

• Carefully study the guidelines and standards which apply to your application. For

information, refer to the "Safety information" chapter in the rotoScan ROD4-3… technical description.

• Start your PC with all necessary peripheral devices - without connecting the sensor.

• Install RODsoft.

• When unpacking the rotoScan ROD4-3…, avoid touching the front cover and the window monitoring sensors.

• Connect the rotoScan ROD4-3… via connector X1 accordance with the instructions.

• Connect the rotoScan ROD4-3… to the PC via connector X2 in accordance with the

instructions.

• After applying the operating voltage, the sensor indicates communication readiness

after approx. 10s. This is indicated by the message "ROD4 connected" on the screen.

• The predefined detection field pairs are, due to the factory settings, superimposed

upon one another; each pair is therefore only visible as a single contour. Only one

detection field pair is activated and displayed in colour at any one time.

• Please observe the specifications for the voltage supply in the rotoScan ROD4-3…

technical description.

• Take note of any objects detected on the basis of the predefined detection fields.

Changing a configuration or a detection field

• Note, that before making changes, error-free data communication must be possible.

This is indicated on the screen by the status message "ROD4 connected".

• Changes are only possible in the "Authorized User (AU)" access level and above.

• In addition, changes are only possible if a configuration is also loaded in the PC. This

can be performed via the hard disk or via the sensor.

• Changes to a configuration are accepted by RODsoft only following successful

acknowledgement (Accept or OK button).

• Changes take effect only after successful data transmission to the sensor.

• If detection fields are loaded as a file, e.g. from the hard disk, the plausibility of the

sensor configuration is to be checked.

• The safety notices in the rotoScan ROD4-3… technical description must be observed.

Leuze electronic RODsoft 37

TNT 35/7-24V

Page 39

Editing / configuring the device configuration

Creating a configuration without a connected sensor

• After calling up RODsoft, the "Authorized User (AU)" access level is to be selected.

• The measurement field is first displayed without measurement contours.

• Enter the password for the respective user level.

• A configuration file can be loaded into the PC from the hard disk. The file extension is

*.rs.

• Please note that the configuration files contain sensor configurations and detection

field definitions.

• A detection field file can be loaded into the PC from the hard disk.

The file extension is *.sf.

• Note that detection field files do not contain sensor configurations.

• Stored files can be loaded into the sensor.

38 RODsoft Leuze electronic

Page 40

Editing / configuring the device configuration

5.2 Current sensor configuration

Retrieving the configuration

If the ROD4-3… is connected to the PC on program start, the current parameters are automatically transferred from the device to the PC. This also occurs if the device was temporarily not connected to the PC (e.g. exchanging the device) and is detected by the program

as again being present on the serial interface.

If you have made changes to the configuration and have not transferred the previous configuration to the device, you have the option of manually loading the configuration stored in the

ROD4-3….

To do this, on the menu bar select the Configuration → Get from sensor menu item or

click the icon in the "Configuration" tab. The current device configuration will then be

read back in.

Attention!

Before making changes, store the current configurations! These can be used in the event of

incorrectly entered parameters to restore the original settings.

Information on storing configurations can be found in chapter 5.4.

5.3 Changing configuration parameters

Notice!

The device configuration can only be viewed and edited in the "Authorized User" access level.

In principle, there are 2 possibilities for editing the configuration data of the sensor:

• with the Configuration Wizard, which guides you step-by-step through the entry of

the most important parameters.

•directly in the tree structure for the parameters in the Configuration Parameters

window

5.3.1 Configuration Wizard

With the aid of the Configuration Wizard, you can edit the sensor's most important parameters. The parameters and their possible values will be explained in detail.

To start the Configuration Wizard,

• select the "Configuration" tab and then the

Configuration -> Wizard menu item or

• click the icon on the "Configuration" tab toolbar.

Leuze electronic RODsoft 39

TNT 35/7-24V

Page 41

Editing / configuring the device configuration

Figure 5.1: Configuration Wizard, pages 1 and 2

40 RODsoft Leuze electronic

Page 42

Editing / configuring the device configuration

b

Figure 5.2: Configuration Wizard, page 3

Leuze electronic RODsoft 41

TNT 35/7-24V

Page 43

Editing / configuring the device configuration

Figure 5.3: Configuration Wizard, pages 4 and optional page 4a

42 RODsoft Leuze electronic

Page 44

Editing / configuring the device configuration

Figure 5.4: Configuration Wizard, pages 5 and 6

Leuze electronic RODsoft 43

TNT 35/7-24V

Page 45

Editing / configuring the device configuration

Figure 5.5: Configuration Wizard, pages 7 and 8

44 RODsoft Leuze electronic

Page 46

Editing / configuring the device configuration

Figure 5.6: Configuration Wizard, page 9

Leuze electronic RODsoft 45

TNT 35/7-24V

Page 47

Editing / configuring the device configuration

The parameters are divided into

main groups (shown in a tree

structure)

Parameter selection

(double click the parameter to be changed)

Value entry for

parameters

5.3.2 Tree view of the configuration

To change the sensor's configuration parameters directly in the tree structure, open the

Configuration Parameters window as follows:

• Select the "Configuration" tab and then select the

Configuration -> Change menu item or

• click the icon on the "Configuration" tab toolbar.

A dialogue window consisting of three parts appears as illustrated in the following figure:

Figure 5.7: ROD4-3… Configuration parameters

To change a parameter, select the desired parameter group on the left side and double-click

the desired parameter in the middle.

The parameter can be changed on the right side of the window by entering a value or by

selecting a value from a list. To confirm your entry, you must click on Apply before exiting

the window with OK.

Notice!

In the Status field, R means read only; all other parameters can be changed.

46 RODsoft Leuze electronic

Page 48

Editing / configuring the device configuration

Folders "Administrative Parameters" and "Configuration Parameters"

Figure 5.8: Folders "Administrative Parameters" and "Configuration Parameters"

Leuze electronic RODsoft 47

TNT 35/7-24V

Page 49

Editing / configuring the device configuration

Description of the administrative parameters

Parameter Function/Setting Status Input option

Sensor name Sensor name Max. 20 characters

Additional

description

Output start

segment

Output stop

segment

Output resolution

User-side additional description Max. 100 characters

Definition of the first contour segment beginning with which the

measurement values are output

Definition of the last contour segment up to which the measurement

values are output

This value specifies the size of the

resolution interval. Assuming the

measurement contour is output

beginning with measurement value

0 through 528 and the resolution is

set to the value 4, the smallest

measurement value in each of the

sector ranges 0…3, 4…7, 8…11,

…, 524…527 is output.

Segments 0 … 528

(Segments 0 … 528 correspond to 190°,

segments 14 to 514 correspond to 180°)

Segments 0 … 528

(Segments 0 … 528 correspond to 190°,

segments 14 to 514 correspond to 180°)

1…8

48 RODsoft Leuze electronic

Page 50

Editing / configuring the device configuration

Parameter Function/Setting Status Input option

Change in the baud rate.

The max. baud rate for the PC inter-

Baud rate of

serial interface

face is 115200 baud (factory setting: 57600 baud).

Please observe the following

notices:

Baud rates above

115200 baud are suitable

for measurement data

transfer only since they no

longer permit access to the

sensor via PC/RODsoft.

Remedy: Reset the baud

rate to the factory setting

57600 baud (s. technical

description).

If using

ROD4

and

ROD4-

2…

sensors, it is advisable

to leave the factory setting

unchanged since higher

baud rates are not supported by

ROD4-2…

ROD4

and

sensors.

9600 to

687500baud

Transmission rates

ROD4-3…:

9600 Bd

19200 Bd

38400 Bd

57600 Bd

115200 Bd

345600 Bd

687500 Bd

Transmission rates for

ROD4/ROD4-2…:

9600 Bd

19200 Bd

38400 Bd

57600 Bd

109700 Bd

384000 Bd

768000 Bd

for

• None

•Device warning

Alarm output

signal

Selection of the event which leads

to a signal at output ALARM1

• Object in detection

field far

• Device warning or

object in detection

field far

Table 5.1: Description of "Administrative Parameters", Folder 1

Leuze electronic RODsoft 49

TNT 35/7-24V

Page 51

Editing / configuring the device configuration

Description of the "Configuration parameters"

Parameter Function/Setting Status Input option

Settings for the measurement value

resolution, the 4-field mode, the

power-up properties and the restart

disable are made in a separate window

Presettings

Settings for response times in multiples of 40ms for the near and far

detection fields are made in a separate window (factory setting: 80mm)

Start interlock/start-up

test/automatic start-up,

start-up delay

40ms … 10160ms

Response times

Measurement

start segment

Measurement

stop segment

50 RODsoft Leuze electronic

Measurement of the first contour

segment

Measurement of the last contour

segment

40ms … 2000ms in

multiples of 40ms

R

R

Page 52

Editing / configuring the device configuration

Parameter Function/Setting Status Input option

With activated dust suppression

(factory setting), sensor availability

is increased in the event of small

particles in the air, such as insects.

This also maximises the time which

may pass before cleaning of the

front cover becomes necessary.

• Activated

Dust suppression

Object size/

object speed

Notice: Please note that the settings relevant for the dust suppression must be carried out in different

parameter windows. For details

please refer tosection 5.3.5 "Supplementary information on the "Dust

suppression" parameter".

Object size:

Dust suppression parameter specifying the maximum size of interfering objects (factory setting:

70mm).

Object speed:

Parameter that must also be

observed for dust suppression. It

sets the maximum speed of

objects to be detected (factory setting: 1600mm/s).

(recommended)

• Deactivated

•35mm

•70mm

• 150mm

• 250mm

• Automatic

0 …10,0000mm/s

TNT 35/7-24V

Leuze electronic RODsoft 51

Page 53

Editing / configuring the device configuration

Parameter Function/Setting Status Input option

The admissible detection field pair

changeovers are defined in a separate window

Admissible

field pair

changeovers

Definition of the detection field pairs

with which the sensor may start

Admissible field

pairs for sensor

start-up

Table 5.2: Description of "Configuration Parameters", Folder 2

Click the desired fields to

define the admissible

field pair changeovers.

Click the desired fields to

define the admissible

field pairs.

52 RODsoft Leuze electronic

Page 54

Editing / configuring the device configuration

5.3.3 Supplementary information on the "Presettings" parameter

Standardised parameter presettings for various applications are offered for selection in a

dialogue window.

Figure 5.9: Parameters for presettings/power-up properties/restart

Here, you can find base setting for various application areas. Among others, the 4-field

mode is activated here (see chapter 4.1.2 "4-field mode"). The "Freely selectable presettings" selection offers maximum flexibility.

The "Resolution" parameter cannot be changed in RODsoft. Here, the term resolution is not

equivalent to other uses of the term, such as "output resolution" or "angular resolution".

Leuze electronic RODsoft 53

TNT 35/7-24V

Page 55

Editing / configuring the device configuration

5.3.4 Supplementary information on the "Power-up properties" parameter

Automatic start-up

After the sensor is switched on, outputs Fn1/Fn2 are enabled following a start-up

delay.

Start interlock

After the sensor is switched on, the restart button must be actuated (24V on PIN 2 of

interface X1 for max. 4s) in order to activate the outputs.

Start-up test

After switching on the sensor, the near detection fields must be clear after the start-up

delay period has passed; outputs Fn1/Fn2 are switched off. To activate outputs Fn1/

Fn2, at least one near detection field must be occupied and then again be cleared.

Restart

The restart behaviour determines how switching outputs Fn1/Fn2 are switched after a detection field is occupied in the event of subsequent non-occupancy.

Manual restart

The start interlock is active and the restart button must be actuated.

Automatic restart

The outputs are activated following a start-up delay.

54 RODsoft Leuze electronic

Page 56

Editing / configuring the device configuration

5.3.5 Supplementary information on the "Dust suppression" parameter

In the RODsoft configuration software, the following parameters determine the function of

the dust suppression:

• the dust suppression (factory setting: activated)

• the object size (factory setting: 70mm)

• the object speed (factory setting: 1600mm/s)

• the response time (factory setting: 80ms)

• the sector size

Notice!

Please note that the settings relevant for the dust suppression must be carried out in different parameter windows.

Dust suppression

With activated dust suppression (recommended), sensor availability is increased in

the event of small particles in the air, such as insects. This also maximises the time

which may pass before cleaning of the front cover becomes necessary. A deactivation

is generally not required.

Figure 5.10:Parameter "dust suppression"

Dust suppression is implemented globally, i.e. it is used in all detection fields.

Leuze electronic RODsoft 55

TNT 35/7-24V

Page 57

Editing / configuring the device configuration

Minimum object width cannot be edited as it is

a read parameter

For individual detection fields, the availability may also be increased by raising the

response times and the minimum object width by setting a sector size > 2 or

> minimum object width.

Notice!

If the sector size > 1, the entry for the minimum object size and the object size in millimeters

are irrelevant for this detection field.

Please find detailed information on minimum object width and sector size as prerequisites

for the object detection in table 5.3 on page 61.

Figure 5.11: Influencing the dust sensitivity for individual detection fields

56 RODsoft Leuze electronic

Page 58

Editing / configuring the device configuration

Object size/object speed

Figure 5.12:Parameter "Object size/object speed"

The object size parameter defines the maximum size up to which interfering objects

(e.g. particles in the air) should not be detected. Values that are too large prevent

object detection. Values that are too small increase the sensitivity to interfering

objects. The 'Automatic' setting results in less efficient dust suppression.

The object speed specifies the maximum speed of the objects that are to be

detected; if necessary, the speed of the sensor itself is to be taken into account. Values that are too small prevent object detection. Values that are too large and the

value '0 mm/s' increase the sensitivity to interfering objects.

Comment:

Speed refers not only to the speed at which an object moves toward the sensor

(speed component v

which objects may move in the detection field (speed components v

5.13). As area scanning occurs in the XY plane, speed component v

detected and evaluated. The maximum object speed can be best optimised through

in figure 5.13); it generally refers to the maximum speed with

x

and vy in figure

x

cannot be

z

testing.

Leuze electronic RODsoft 57

TNT 35/7-24V

Page 59

Editing / configuring the device configuration

v

x

v

y

v

z

Figure 5.13:Components of the object speed

Response time

Another important parameter is the response time.

Figure 5.14: Parameter "response time"

The longer the selected response time, the more calculating time is available for the

dust-suppression algorithm and, thus, the more powerful the dust suppression. With a

response time < 80ms, only the object size is evaluated.

Notice!

When specifying the response time, note that the object speed in a radial direction to the

must be taken into account.

sensor

58 RODsoft Leuze electronic

Page 60

Editing / configuring the device configuration

Dust suppression is more efficient the:

• greater the selected object size

• lower the selected object speed

• longer the response time

It is a good idea to optimise the values preset ex works (object size: 70mm, object speed:

1600mm/s, response time: 80ms) for the respective application through practical tests.

Notice!

By setting the object size parameter to "automatic" and the object speed parameter to

"0mm/s", you obtain a Compatibility mode for oldROD4/ROD4-2… models.

In addition, you should observe the following points:

Config. connector:If a ConfigPlug with ROD4-3… configuration (with activated dust

suppression) is plugged into a ROD4-2…, the configuration is accepted, but the old dust suppression used!

RODsoft: If a ROD4-3… configuration with new dust suppression is loaded

from a file while a ROD4 or ROD4-2… is plugged in, the new dust

suppression parameters are not displayed. The sensor uses the old

dust suppression following the transfer. The ROD4-3… configuration becomes a ROD4-2… compatible configuration.

A ROD4-3… configuration can also be loaded if a ROD4/ROD4-2…

was selected. The new dust suppression parameters are not displayed in this case. The sensor uses the old dust suppression following the transfer.

TNT 35/7-24V

Leuze electronic RODsoft 59

Page 61

Editing / configuring the device configuration

5.3.6 Supplementary information on the "Admissible field pair changeovers" parameter

With its seven freely configurable detection field pairs, the rotoScan ROD4-3… offers a high

degree of application flexibility. Through the assignment of the admissible changeover order

in the "Admissible field pair changeovers" dialogue, the detection field selection is monitored for plausibility. Inadmissible switching orders are detected and result in the switching

off of outputs Fn1/Fn2. Furthermore, each detection field can also be defined as an admis-

sible detection field on sensor start.

These function characteristics find application, for example, on driverless transport vehicles

for detection field changeovers for straight-ahead and curved paths as well as vehicle starts

in a straight line.

Detection field parameters

Figure 5.15: "Detection field" folder

60 RODsoft Leuze electronic

Page 62

Editing / configuring the device configuration

Parameter Function/Setting Status Input option

Description Detection field name 20 characters

Date when last

saved

Admissible

field pair change-

overs

Minimum object

width

Sector width

Table 5.3: Description of "Detection fields 1 … 7"

Date and time the detection field

was last saved

Specification of the detection field

pairs to which the device may

changeover

This parameter is permanently

stored and is calculated from the

maximum radius of the detection

field. Objects are detected if at least

the minimum number (multiple of

0.36°) of consecutive scanning

beams is incident on an object.

Notice:

After the transfer of the configuration from the PC into the ROD this

value may not necessarily be the

one that is actually active.

As the value is computed by the

ROD and is not loaded back into the

PC by the "Fast configuration", it

may differ. Manual loading of the

configuration data fixes this.

This parameter can be changed. If

the value for the sector size is > 1,

objects are detected if at least this

number (multiple of 0.36°) of consecutive scanning beams is incident

on an object.

If the sector width is > 1, the calculated minimum object size is immaterial.

R

R

R

1…30

TNT 35/7-24V

Leuze electronic RODsoft 61

Page 63

Editing / configuring the device configuration

5.4 Storing/loading configuration

To store the changed parameters, select the File –> Save configuration to file menu item

or click the symbol in the "Configuration" tab.

Here, you can enter the name of the file and select the folder in which the file is to be stored.

To reload a configuration, select the File –> Load configuration from file menu item or

click the symbol in the "Configuration" tab. Select the desired configuration file (*.rs)

and then click "Open".

The configuration saved in this file is now read into RODsoft.

5.5 Transferring a configuration to the sensor

Changed configuration parameters are initially stored only temporarily in your PC's main

memory.

Attention!

Store a modified configuration as a file so that in the event of transmission errors or program

crashes the changed settings can be reloaded.

In order for the modified data to be stored in the sensor, you must transfer them to the

device. To transfer the data to the sensor, select the Configuration → Transfer from PC

to sensor menu item or click the icon in the "Configuration" tab.

After transferring the data, the configuration parameters are read back by the sensor as a

check. An info window informs you of the successful transfer.