Page 1

IP 65

IEC 60947...

IEC 60947...

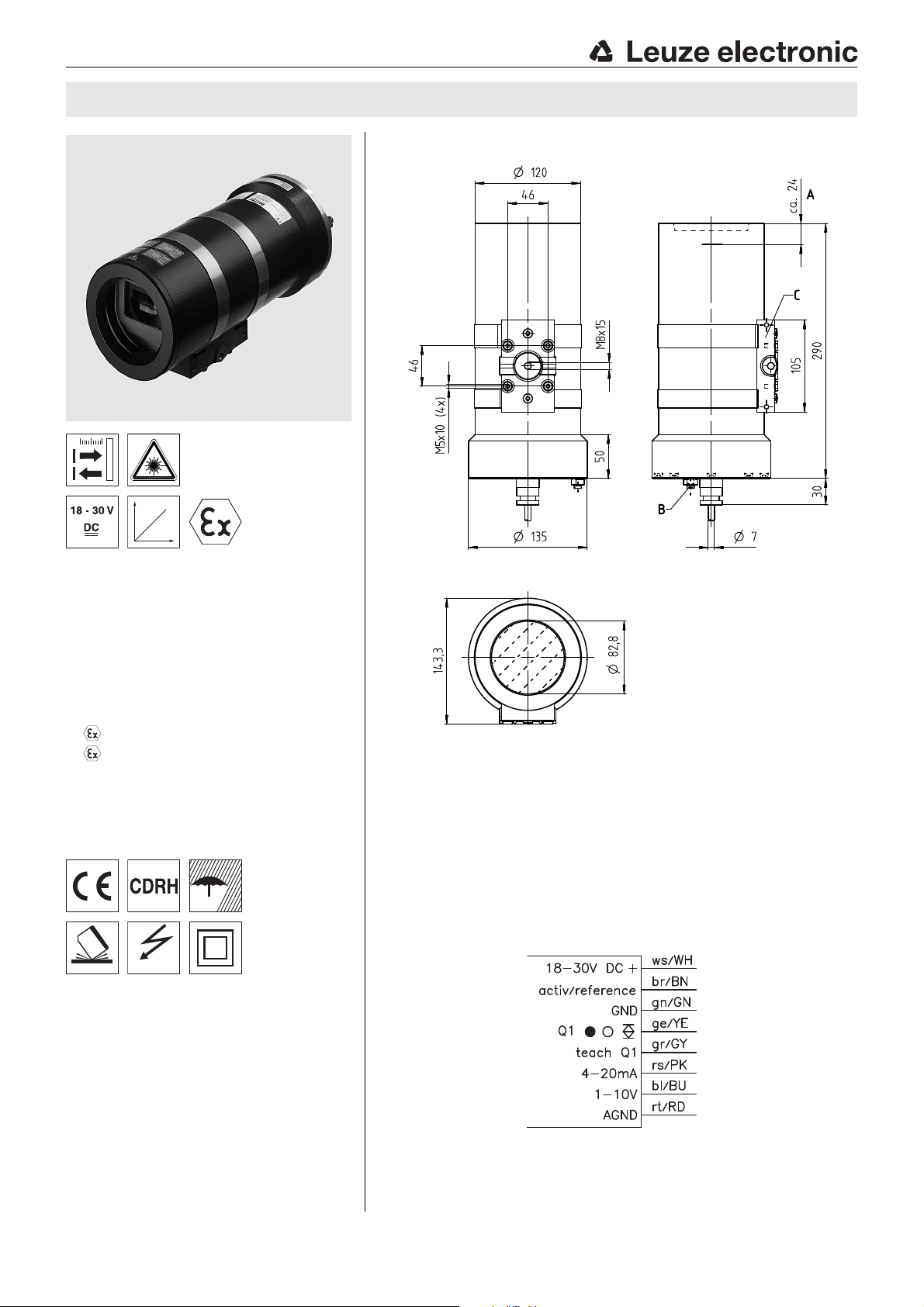

ODSL 30 Ex Optical laser distance sensors

Dimensioned drawing

en 02-2013/10 50122342

0.2 … 30m

Reflection-independent distance

information

High accuracy through referencing

Analogue current and voltage output

1 teachable analogue and switching output

Configuration via LC display and key pad

(the sensor must be removed from the

Ex housing for this purpose)

EC type examination PTB 03 ATEX 1026

II 2G Ex d IIA T3

II 2D Ex td A21 IP 65 T80°C

Ex op is IIA T3 according to TÜV report

71386471

Cable 15m, 8-wire

Accessories:

(available separately)

Co-operative Target CTS 100x100

(reflectivity 50 … 90%)

A Reference level for the measurement (distance zero point)

B Earthing

C Mounting foot

Electrical connection

We reserve the right to make changes • DS_ODSL30V30MExd_en_50122342.fm

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen Tel. +49 (0) 7021 573-0

info@leuze.com • www.leuze.com

ODSL 30/V-30M Ex d - 02

Page 2

ODSL 30 Ex

Specifications

Optical data

Measurement range

Resolution

Light source laser

Wavelength 650nm

Max. output power 4mW

Pulse duration 267ns

Light spot divergent, ∅ 6mm at 10m

2)

Error limits for current output, relative to measurement range end value

Absolute measurement accuracy

Repeatability

Systematic measurement error 6mm (owing to glass pane)

Temperature drift typ. 0.5mm/°C (without referencing)

Timing

Measurement time

Delay before start-up ≤ 1s

Electrical data

Operating voltage U

Residual ripple ≤ 15% of UB

Power consumption ≤ 4W

Switching output PNP transistor, HIGH active (default),

Signal voltage high/low ≥ (U

Analog output R

Indicators

Green LED continuous light ready

Yellow LED continuous light object inside teach-in measurement distance

Mechanical data

Housing metal

Optics cover glass

Weight approx. 6500g

Connection type cable 15m, 8-wire

Environmental data

Ambient temp. (operation/storage) -10°C … +45°C / -40 °C … +70 °C

Protective circuit

VDE safety class

Protection class IP 65

Laser class 2 (in accordance with EN 60825-1)

Standards applied IEC 60947-5-2

1) Temperature range 0°C … +45°C

2) Display and output resolution 0.1mm configurable

3) In temperature range from 0°C to +45°C, measurement object ≥ 50x50mm², with factory settings;

different error limits apply at temperatures < 0°C

4) Same object, identical environmental conditions

5) Configurable, depends on the reflectivity of the object and on the max. detection range

6) 2=polarity reversal protection, 3=short circuit protection for all outputs

7) Rating voltage 250 VAC

1)

1)

4)

5)

B

off no voltage

off object outside teach-in measurement distance

6)

7)

0.2 … 30m (18 … 90 % diffuse reflection)

0.2 … 20m (6 … 90 % diffuse reflection)

0.1mm/1mm (factory setting)

measurement range up to 2.5m:

± 2% without referencing, ± 1% with referencing

measurement range 2.5m up to 5m:

± 1.5% without referencing, ± 1% with referencing

measurement range 5m up to 30m:

± 1% without referencing, ± 1% with referencing

± 0.5% of measurement value

30 … 100ms (factory setting: 100ms)

18 … 30V DC (incl. residual ripple)

NPN transistor or push-pull through configuration

-2 V)/≤ 2V

B

≥ 2kΩ (voltage)

L

RL≤ 500Ω (current)

2, 3

II, all-insulated

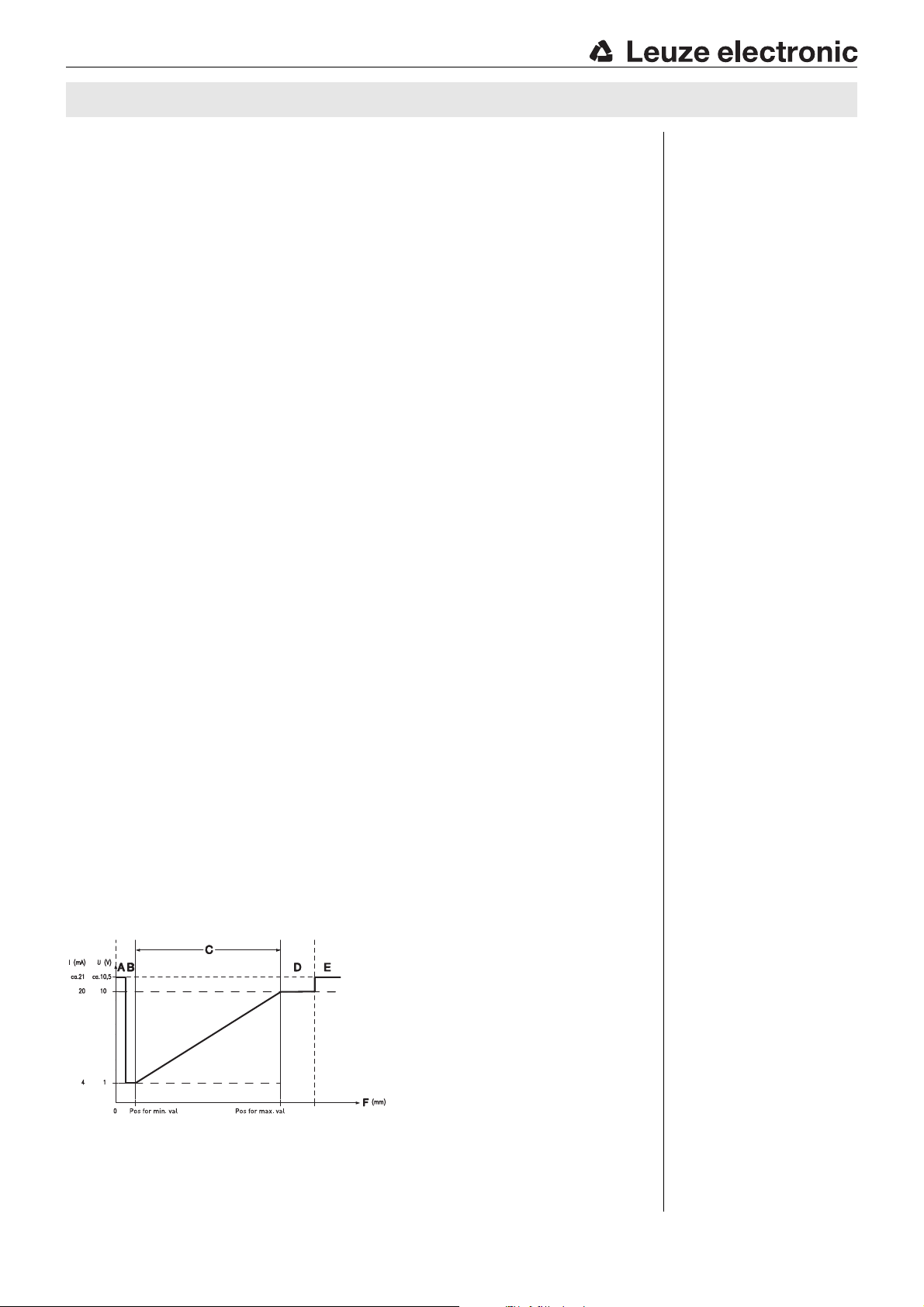

A Short range (no signal)

B Object present

C Measurement range

D Object present

E No object present (no signal)

F Measurement distance

3)

Remarks

Analog output:

The analog output is

factory-set to 200 to

5000mm with calibrated

current output. To adapt

the configuration, the

sensor must be removed

from the Ex housing.

Teaching procedure

(factory setting):

Position the measurement

object at the desired measurement distance. Apply

+U

to the teach input.

B

Take teach input back to

GND, switching output

has now been taught.

Edge on line teach Q1

teaches output Q1.

During the teaching of Q1,

yellow LED Q1 will flash.

Activation/referencing

input:

Referencing is carried out

by applying the voltage

(for a duration of about

300ms).

If this process is activated

before the measurement,

the highest possible accuracy is achieved.

Laser warning signs:

It is important to attach

the stick-on labels delivered with the device! If the

signs could be covered

due to the installation

location of the device,

attach them close to the

device so that it is not

possible to look into the

laser beam when reading

the notices.

Approved purpose:

This product may only be

used by qualified personnel and must only be used

for the approved purpose.

This sensor is not a safety

sensor and is not to be

used for the protection of

persons.

Order guide

Designation Part no.

with connection cable 15m, 8-wire ODSL 30/V-30M Ex d 50122319

ODSL 30/V-30M Ex d - 02 2013/10

Page 3

ODSL 30 Ex Optical laser distance sensors

Notices for the safe use of sensors in potentially explosive areas

Intended application range

The distance sensors of the ODSL 30 Ex d series, without making contact, detect objects which are located in or move through

the light beam and measure the distance to these objects.

Validity

The sensors have an encapsulated, pressure-proof housing and can be used in the following areas with these classifications:

Device group Device category Equipment protection level Zone

II 2G Gb Zone 1

II 2D Db Zone 21

Attention!

Check whether the equipment classification corresponds to the requirements of the application.

The devices are not suited for the protection of persons and may not be used for emergency shutdown purposes.

A safe operation is only possible if the equipment is used properly and for its intended purpose.

Electrical equipment may endanger humans and (where applicable) animal health, and may threaten the safety of

goods if used incorrectly or under unfavorable conditions in potentially explosive areas.

The applicable national regulations (e.g. EN 60079-14) for the configuration and installation of explosion-proof sys-

tems must be observed

Installation, Commissioning

Attention!

Electrical equipment may endanger humans and (where applicable) animal health, and may threaten the safety of

goods if used incorrectly and under unfavorable conditions in potentially explosive areas.

A safe operation in potentially explosive areas is only possible if the equipment is used properly and for its intended

purpose.

The distance sensors of type ODSL 30 Ex d must only be installed and maintained by trained electricians.

When installing the sensors in Ex zones 1 and 21, the connection cable must be connected in a connection space

with increased safety Ex e, or outside the Ex area.

The housing must be connected at the marked external connection unit to the protective conductor system.

The respective applicable national regulations for the installation of electrical equipment in potentially explosive

areas must be observed.

Maintenance

No changes may be made to the devices of type ODSL 30 Ex d for potentially explosive areas.

Repairs to the sensors may only be performed by persons trained for such work or by the manufacturer. Defective devices must

be replaced immediately.

The housing must not be opened while the power is on! After switching off power, wait at least 10min. before opening the hous-

ing.

Cyclical maintenance of the sensors is not necessary.

Depending on the environmental conditions, it may occasionally be necessary to clean the light-emission surfaces of the sensors.

This cleaning must only be performed by persons trained for performing this task. A soft, damp cloth should be used for this

purpose. Cleaning agents that contain solvents must not be used.

Chemical resistance

The sensors of type ODSL 30 Ex d demonstrate good resistance against many diluted acids and bases.

Exposure to organic solvents is possible only under certain circumstances and only for short periods of time.

Resistance to chemicals should be examined on a case by case basis.

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen Tel. +49 (0) 7021 573-0 ODSL 30/V-30M Ex d - 02

info@leuze.com • www.leuze.com

Page 4

ODSL 30 Ex

ODSL 30/V-30M Ex d - 02 2013/10

Loading...

Loading...