Page 1

Original operating instructions

ODS 9

Laser distance sensor

We reserve the right to make technical changes

EN • 2020-07-31 • 50138237

Page 2

© 2020

Leuze electronic GmbH + Co. KG

Leuze electronic GmbH + Co. KG ODS 9 2

Page 3

Table of contents

1 About this document ............................................................................................6

1.1 Used symbols and signal words .............................................................................................6

1.2 Important terms....................................................................................................................... 8

2 Safety .....................................................................................................................9

2.1 Intended use ........................................................................................................................... 9

2.2 Foreseeable misuse ............................................................................................................... 9

2.3 Competent persons .............................................................................................................. 10

2.4 Disclaimer ............................................................................................................................. 10

2.5 Laser safety notices.............................................................................................................. 11

3 Device description ..............................................................................................14

3.1 Device overview.................................................................................................................... 14

3.1.1 General information...........................................................................................................14

3.1.2 Operating principle ............................................................................................................15

3.1.3 Performance characteristics.............................................................................................. 15

3.1.4 Accessories .......................................................................................................................15

3.2 Connection technology .........................................................................................................16

3.3 Indicators and operational controls....................................................................................... 16

3.3.1 LED indicators ...................................................................................................................16

3.3.2 Control buttons ..................................................................................................................16

3.3.3 Display............................................................................................................................... 17

3.3.4 Meaning of the display icons .............................................................................................19

3.4 Configuration / menu structure ............................................................................................. 19

3.4.1 Input menu ........................................................................................................................20

3.4.2 Output_SSC1 menu ..........................................................................................................20

3.4.3 Output_SSC2 menu ..........................................................................................................21

3.4.4 Analog_Output menu ........................................................................................................23

3.4.5 Serial Menu .......................................................................................................................23

3.4.6 Application menu...............................................................................................................25

3.4.7 Settings menu ...................................................................................................................30

3.4.8 Ending configuration.......................................................................................................... 31

3.5 Configuration example.......................................................................................................... 31

Table of contents

4 Applications ........................................................................................................34

4.1 Wood width measurement .................................................................................................... 34

4.2 Assembly inspection ............................................................................................................. 35

5 Mounting..............................................................................................................36

5.1 Mounting with mounting system ........................................................................................... 36

6 Electrical connection..........................................................................................37

6.1 Overview............................................................................................................................... 37

6.2 Pin assignment .....................................................................................................................37

7 Starting up the device ........................................................................................40

7.1 Teaching and configuring output functions ........................................................................... 40

7.1.1 Setting the analog output ..................................................................................................40

7.1.2 Setting the switching outputs............................................................................................. 41

7.1.3 Teach-in / teach................................................................................................................. 46

7.1.4 Teaching the output functions via the multifunction input.................................................. 46

7.1.5 Teaching the output functions via the IO-Link system commands ....................................48

7.2 Setting measurement value processing and filtering ............................................................ 50

7.3 Reset to factory settings .......................................................................................................50

Leuze electronic GmbH + Co. KG ODS 9 3

Page 4

Table of contents

7.4 IO-Link interface ................................................................................................................... 50

7.4.1 Overview ...........................................................................................................................50

7.4.2 IO-Link process data .........................................................................................................52

7.5 Serial interface...................................................................................................................... 53

7.5.1 Measurement value output for various transmission types ............................................... 53

7.5.2 Commands for remote control operation........................................................................... 55

7.5.3 Termination of data lines ...................................................................................................57

7.5.4 Operation on the fieldbus and Ethernet............................................................................. 58

8 Connecting to a PC – SensorStudio ................................................................59

8.1 System requirements............................................................................................................ 60

8.2 Installing SensorStudio configuration software and IO-Link USB master............................ 60

8.2.1 Downloading configuration software .................................................................................60

8.2.2 Installing the SensorStudio FDT frame ............................................................................61

8.2.3 Installing drivers for IO-Link USB master ..........................................................................61

8.2.4 Connecting IO-Link USB master to the PC .......................................................................62

8.2.5 Connecting IO-Link USB master to the sensor .................................................................62

8.2.6 Installing the DTM and IODD ............................................................................................63

8.2.7 Importing device descriptions............................................................................................ 63

8.3 Starting the SensorStudio configuration software................................................................ 63

8.4 Short description of the SensorStudio configuration software ............................................. 65

8.4.1 FDT frame menu ...............................................................................................................66

8.4.2 IDENTIFICATION function ................................................................................................66

8.4.3 CONFIGURATION function............................................................................................... 67

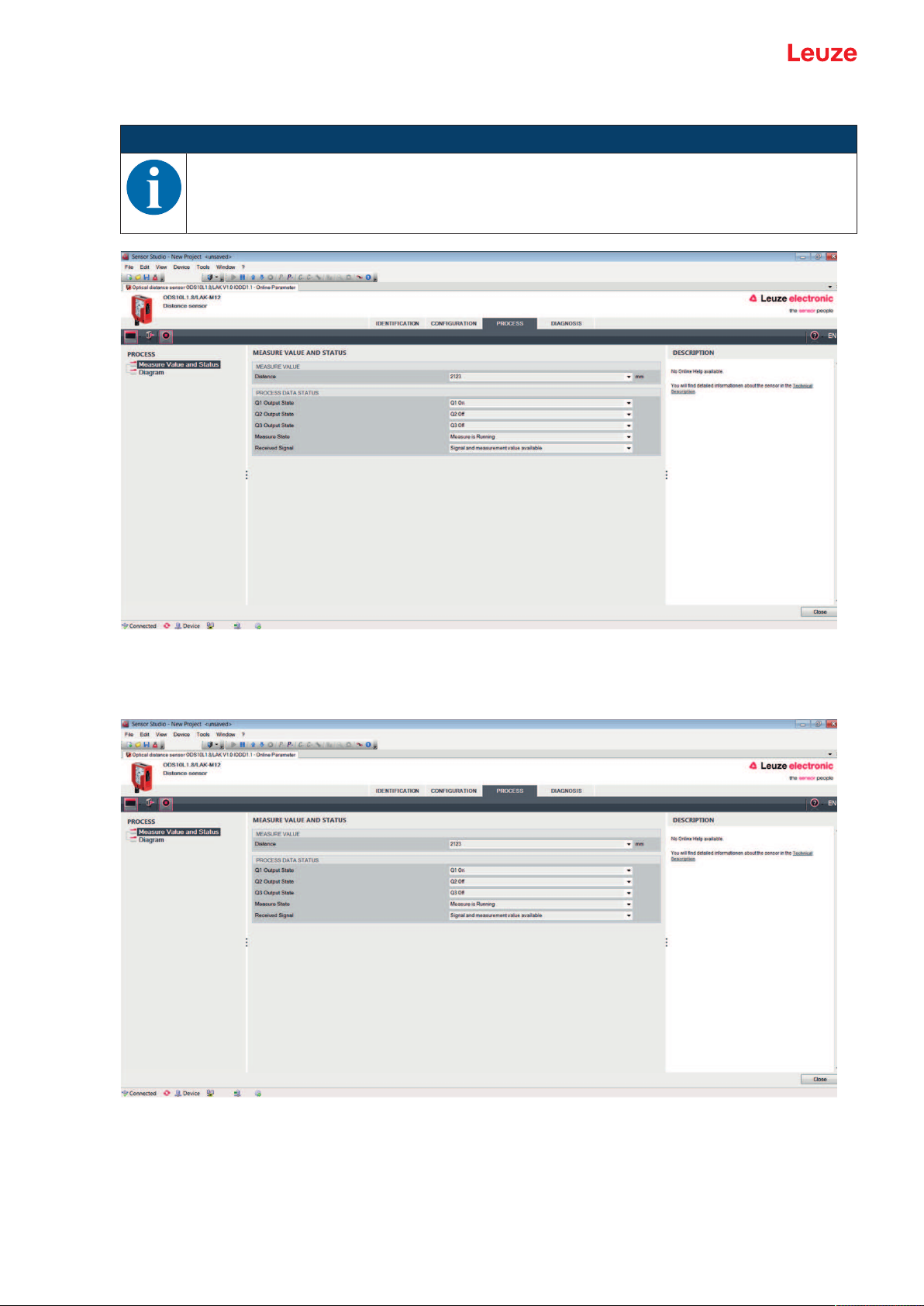

8.4.4 PROCESS function ...........................................................................................................69

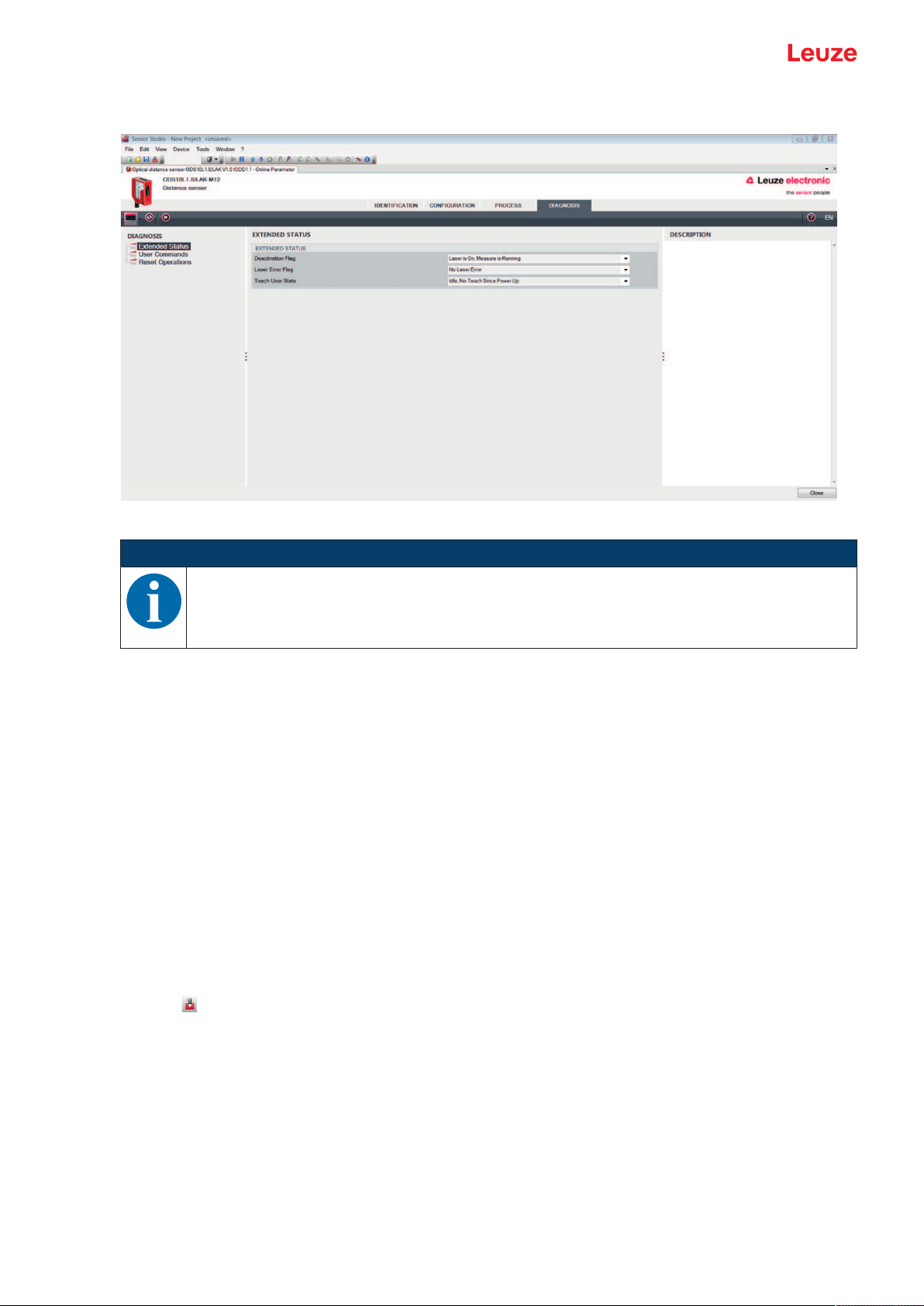

8.4.5 DIAGNOSIS function.........................................................................................................71

8.4.6 Exiting SensorStudio ........................................................................................................71

9 Troubleshooting..................................................................................................72

9.1 What to do in case of failure? ...............................................................................................72

9.2 LED indicators ...................................................................................................................... 72

9.3 Indicators in the display ........................................................................................................72

10 Care, maintenance and disposal .......................................................................73

10.1 Cleaning................................................................................................................................ 73

10.2 Servicing ............................................................................................................................... 73

10.3 Disposing .............................................................................................................................. 73

11 Service and support ...........................................................................................74

11.1 What to do should servicing be required? ............................................................................ 74

12 Technical data .....................................................................................................75

12.1 Measurement data................................................................................................................ 75

12.2 Optical data........................................................................................................................... 77

12.3 Indicators and operational controls....................................................................................... 78

12.4 Electrical data .......................................................................................................................78

12.5 Mechanical data.................................................................................................................... 78

12.6 Environmental data............................................................................................................... 79

12.7 Dimensioned drawings ......................................................................................................... 80

12.8 Dimensioned drawings: Accessories .................................................................................... 81

13 Order guide and accessories.............................................................................82

13.1 Type overview ODS9........................................................................................................... 82

13.2 Accessories – cables and connectors .................................................................................. 83

Leuze electronic GmbH + Co. KG ODS 9 4

Page 5

Table of contents

13.3 Other accessories................................................................................................................. 84

13.3.1 Accessories – PC connection............................................................................................ 84

13.3.2 Accessories – IO-Link master ...........................................................................................84

14 EC Declaration of Conformity ............................................................................85

Leuze electronic GmbH + Co. KG ODS 9 5

Page 6

About this document

1 About this document

1.1 Used symbols and signal words

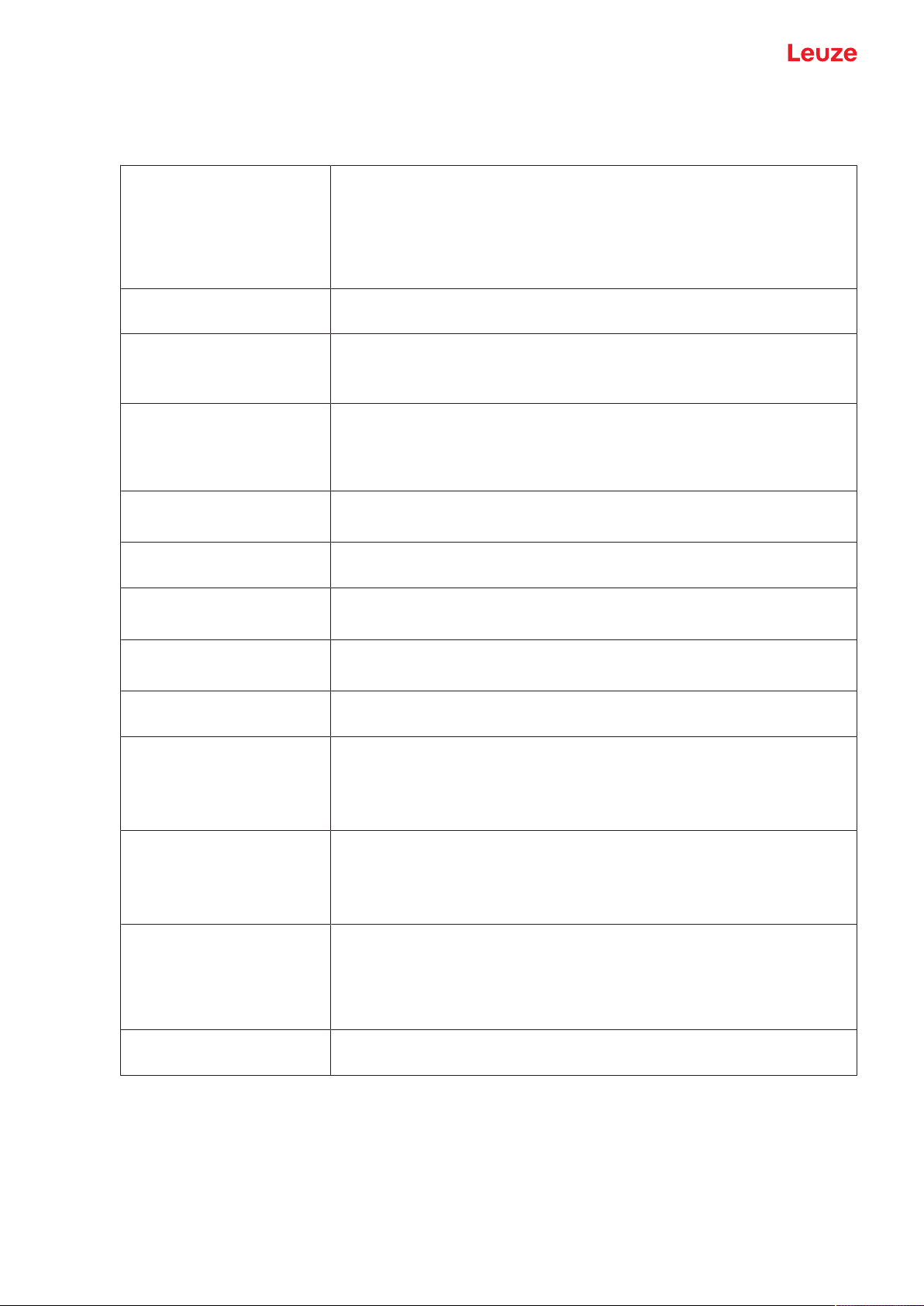

Tab.1.1: Warning symbols and signal words

Symbol indicating dangers to persons

Symbol indicating dangers from harmful laser radiation

NOTE Signal word for property damage

Indicates dangers that may result in property damage if the measures for danger avoidance are not followed.

CAUTION Signal word for minor injuries

Indicates dangers that may result in minor injury if the measures for danger

avoidance are not followed.

Tab.1.2: Other symbols

Symbol for tips

Text passages with this symbol provide you with further information.

Symbol for action steps

Text passages with this symbol instruct you to perform actions.

Leuze electronic GmbH + Co. KG ODS 9 6

Page 7

About this document

Tab.1.3: Terms and abbreviations

BG Background

DS Data Storage

DSUpload Data Storage Upload

DTM Device Type Manager

FDT Field Device Tool

FE Functional earth

IODD IODevice Description

Mode in which switching outputs react/switch when an object enters a set distance

Data memory of the connected IO-Link master

Upload to the data memory of the connected IO-Link master

Software device manager of the sensor

Software frame for management of device managers (DTM)

File with information on process data and device parameters

Max.

Min.

Maximum

Minimum

NEC National Electric Code

ODS Optical Distance Sensor

Optical distance sensor

OLED Organic Light Emitting Diode

Organic LED

PELV Protective Extra Low Voltage

Protective extra low voltage with reliable disconnection

Pt Point

Switching point

SIO Standard IO mode

Signal transfer without IO-Link

SP Setpoint

Position at which the switching point is set

SSC Switching Signal Channel

Abbreviation for the switching outputs acc. to Smart Sensor Profile

SSP Smart Sensor Profile

Profile acc. to IO-Link standard

UL Underwriters Laboratories

Leuze electronic GmbH + Co. KG ODS 9 7

Page 8

About this document

1.2 Important terms

Tab.1.4: Important terms

Response time

(Response time)

Also integration time or measurement time. Maximum length of time from

the occurrence of an erratic change in distance to the steady state of the

measurement value.

The response time depends on the set average calculation. Although the

average calculation increases the response time, it also improves reproducibility.

Resolution Smallest representable change in measurement value, distance and

speed.

Warmup time Time the sensor needs in order to reach the operating temperature. An op-

timal measurement is only possible after the end of the warmup time.

The warmup time is approximately 20minutes.

Output resolution The output resolution describes how the measurement values are pre-

sented on the display and digital interfaces.

Depending on the device model, the output resolution of the ODS9 is

0.01mm or 0.1mm and cannot be changed.

Output time

Time interval of measurement value updating at the interface.

(Output time)

Readiness delay The delay before start-up indicates the point in time when the first valid

measurement can be obtained after switching on.

Data storage

Data memory of the connected IO-Link master.

IO-Link data storage

DSUpload Data Storage Upload.

Upload to the data memory of the connected IO-Link master.

Accuracy Maximum expected deviation of the measurement value between the de-

termined and real distance value within the specified measurement range.

Light switching

Dark switching

The behavior of the switching output if an object is within the taught/configured switching distance.

• Light switching: switching output active (high)

• Dark switching: switching output not active (low)

Diffuse reflection Return and/or degree of reflection of the radiated light. Observe the specifi-

cations regarding diffuse reflection (see chapter 12 "Technical data").

• 90% is white

• 6% is black

Reproducibility Also repeatability. Deviation of multiple measurement results relative to

each other under identical conditions. Dependent on the measurement distance and the diffuse reflection of the measurement object.

The reproducibility can be considered as the measure of measurement

value noise and is affected by the configuration of the response time.

Triangulation measurement

principle

Distance measuring procedure, which determines the distance of an object

by the incidence angle of the light reflected from the object.

Leuze electronic GmbH + Co. KG ODS 9 8

Page 9

Safety

2 Safety

This sensor was developed, manufactured and tested in line with the applicable safety standards. It corresponds to the state of the art.

2.1 Intended use

The device is designed as an optoelectronic sensor for the optical, contactless measurement of the distance to objects.

Areas of application

The laser distance sensor is designed for the following areas of application:

• Distance measurement

• Thickness measurement

• Positioning

• Diameter determination

• Fill level indicator

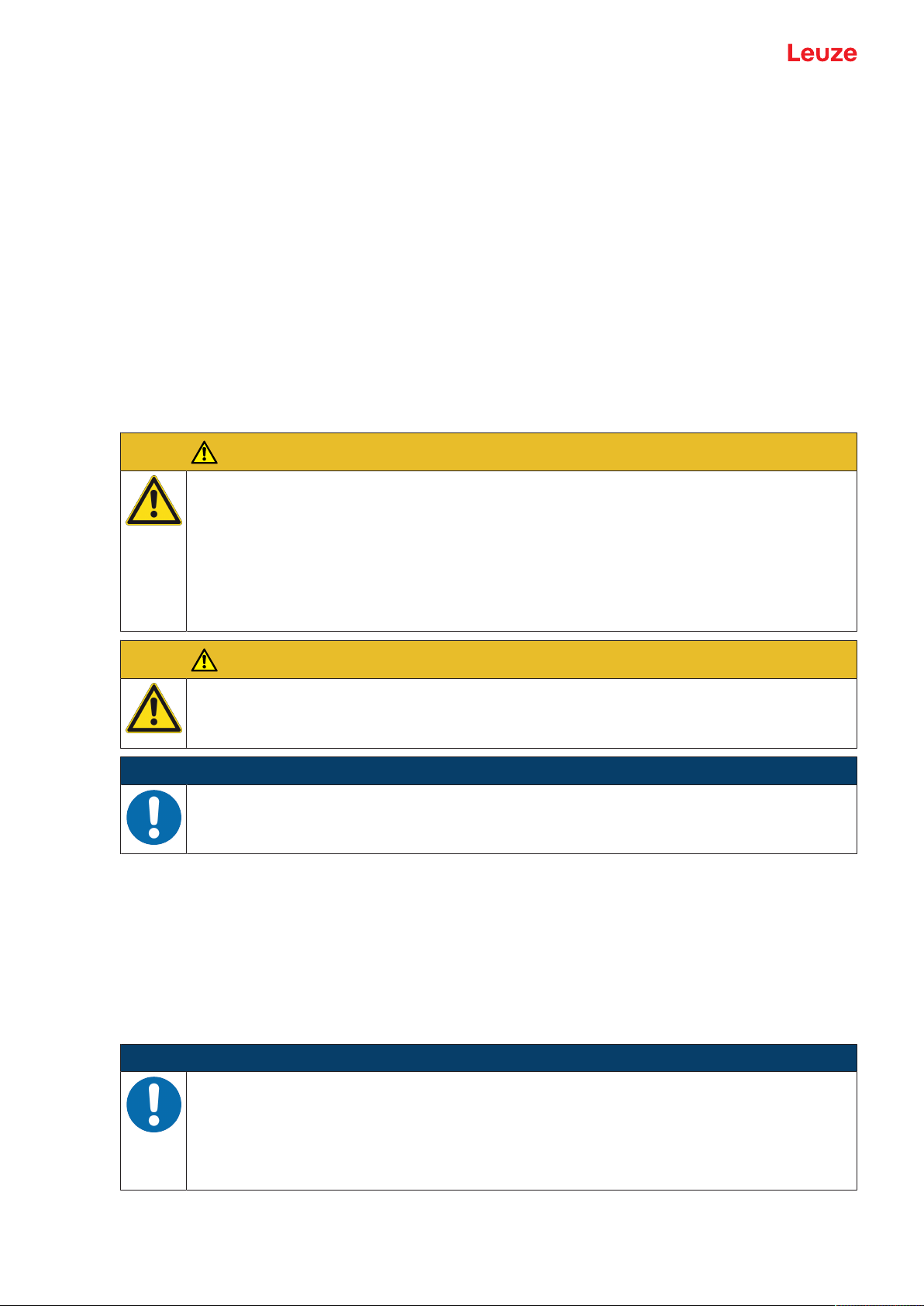

Observe intended use!

The protection of personnel and the device cannot be guaranteed if the device is operated in a

manner not complying with its intended use.

Ä Only operate the device in accordance with its intended use.

Ä LeuzeelectronicGmbH+Co.KG is not liable for damages caused by improper use.

Ä Read these operating instructions before commissioning the device. Knowledge of the oper-

CAUTION

ating instructions is an element of proper use.

CAUTION

UL applications!

For UL applications, use is only permitted in Class 2 circuits in accordance with the NEC (National Electric Code).

NOTICE

Comply with conditions and regulations!

Ä Observe the locally applicable legal regulations and the rules of the employer's liability insur-

ance association.

2.2 Foreseeable misuse

Any use other than that defined under "Intended use" or which goes beyond that use is considered improper use.

In particular, use of the device is not permitted in the following cases:

• in rooms with explosive atmospheres

• in circuits which are relevant to safety

• for medical purposes

NOTICE

Do not modify or otherwise interfere with the device!

Ä Do not carry out modifications or otherwise interfere with the device. The device must not be

tampered with and must not be changed in any way.

Ä The device must not be opened. There are no user-serviceable parts inside.

Ä Repairs must only be performed by Leuze electronic GmbH + Co. KG.

Leuze electronic GmbH + Co. KG ODS 9 9

Page 10

Safety

2.3 Competent persons

Connection, mounting, commissioning and adjustment of the device must only be carried out by competent

persons.

Prerequisites for competent persons:

• They have a suitable technical education.

• They are familiar with the rules and regulations for occupational safety and safety at work.

• They are familiar with the original operating instructions of the device.

• They have been instructed by the responsible person on the mounting and operation of the device.

Certified electricians

Electrical work must be carried out by a certified electrician.

Due to their technical training, knowledge and experience as well as their familiarity with relevant standards

and regulations, certified electricians are able to perform work on electrical systems and independently detect possible dangers.

In Germany, certified electricians must fulfill the requirements of accident-prevention regulations DGUV

(German Social Accident Insurance) provision 3 (e.g. electrician foreman). In other countries, there are respective regulations that must be observed.

2.4 Disclaimer

LeuzeelectronicGmbH+Co.KG is not liable in the following cases:

• The device is not being used properly.

• Reasonably foreseeable misuse is not taken into account.

• Mounting and electrical connection are not properly performed.

• Changes (e.g., constructional) are made to the device.

Leuze electronic GmbH + Co. KG ODS 9 10

Page 11

Safety

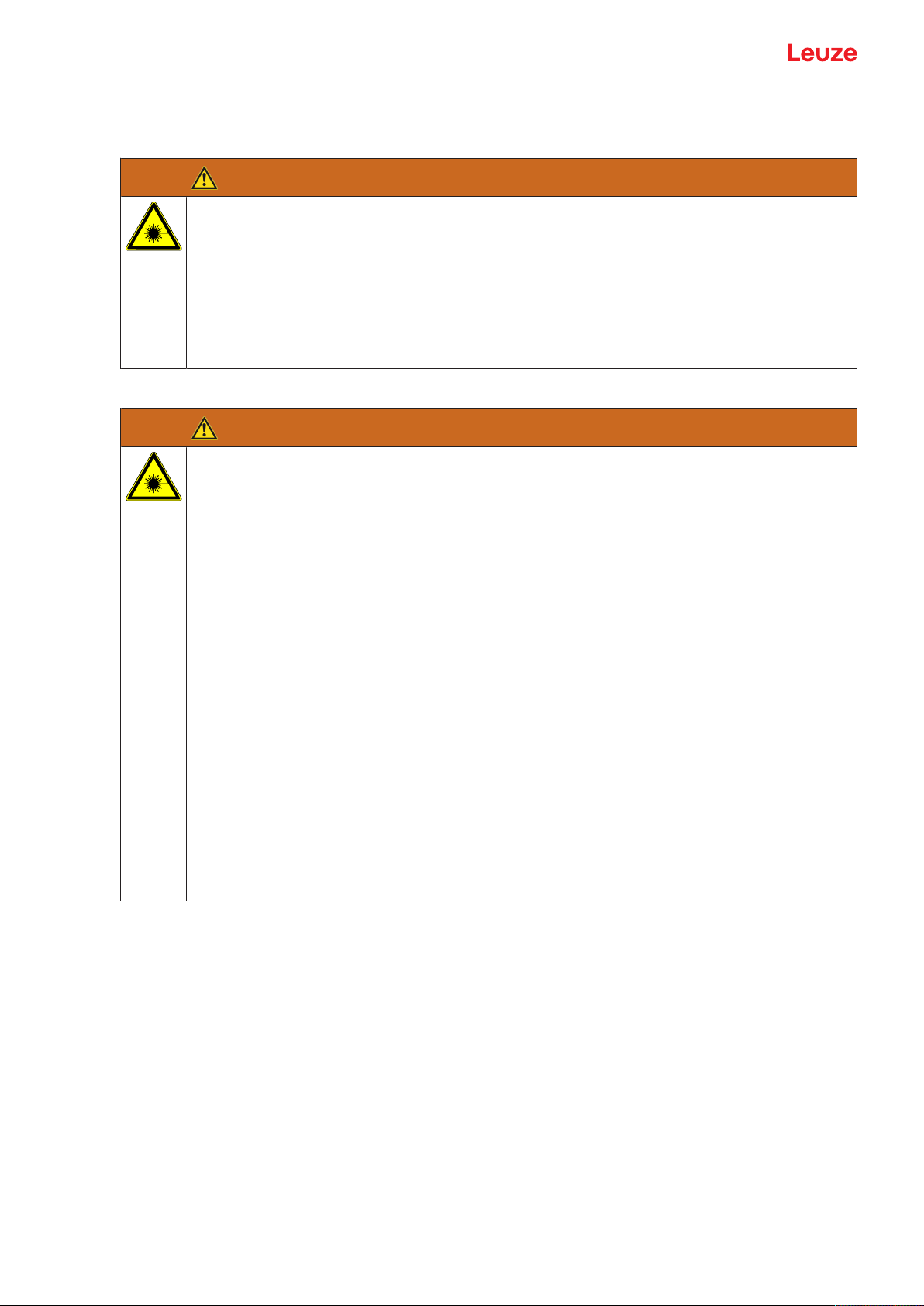

2.5 Laser safety notices

Laser class 1 (ODS9L1...)

ATTENTION

LASER RADIATION – CLASS 1 LASER PRODUCT

The device satisfies the requirements of IEC/EN 60825-1:2014 safety regulations for a product

of laser class1 and complies with 21 CFR 1040.10 except for conformance with IEC 60825-1

Ed. 3., as described in Laser Notice No. 56, dated May 8, 2019.

Ä Observe the applicable statutory and local laser protection regulations.

Ä The device must not be tampered with and must not be changed in any way.

There are no user-serviceable parts inside the device.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

Laser class 2 (ODS9L2...)

ATTENTION

LASER RADIATION – CLASS 2 LASER PRODUCT

Do not stare into beam!

The device satisfies the requirements of IEC/EN 60825-1:2014 safety regulations for a product

of laser class 2 and complies with 21 CFR 1040.10 except for conformance with IEC 60825-1

Ed. 3., as described in Laser Notice No. 56, dated May 8, 2019.

Ä Never look directly into the laser beam, the laser aperture(1) or in the direction of reflected

laser beams! If you look into the beam path over a longer time period, there is a risk of injury

to the retina.

Ä Do not point the laser beam of the device at persons!

Ä Interrupt the laser beam using a non-transparent, non-reflective object if the laser beam is

accidentally directed towards a person.

Ä When mounting and aligning the device, avoid reflections of the laser beam off reflective

surfaces!

Ä CAUTION! Use of controls or adjustments or performance of procedures other than speci-

fied herein may result in hazardous light exposure.

Ä Observe the applicable statutory and local laser protection regulations.

Ä The device must not be tampered with and must not be changed in any way.

There are no user-serviceable parts inside the device.

Ä Repairs must only be performed by Leuze electronic GmbH + Co. KG.

Ä The laser radiation emitted from the sensor is collimated. The laser is operated in pulse

mode. Pulse power, pulse duration and wavelength see chapter 12 "Technical data".

Leuze electronic GmbH + Co. KG ODS 9 11

Page 12

Safety

1

Fig.2.1: Laser aperture

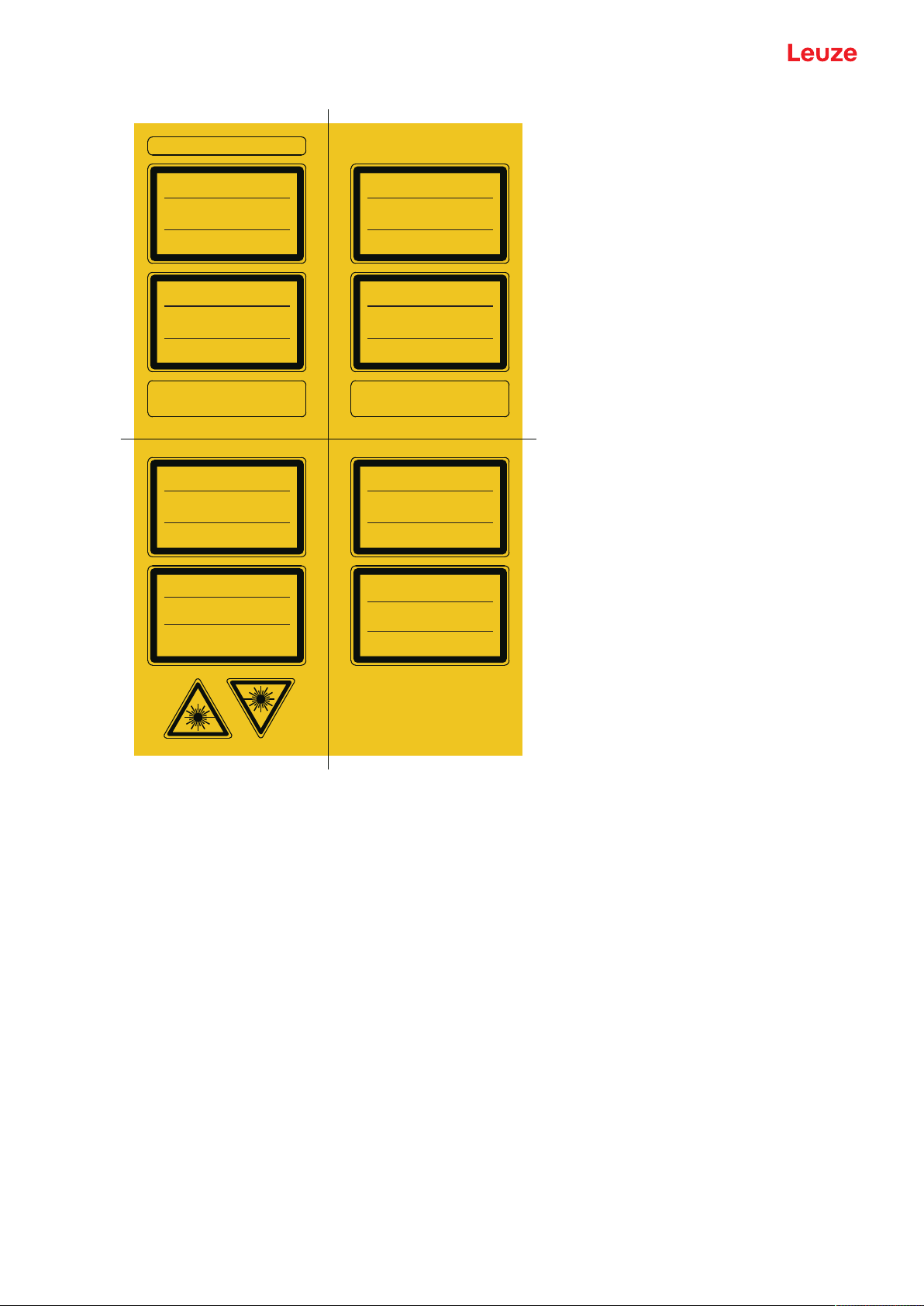

NOTICE

Affix laser information and warning signs!

Laser information and warning signs attached to the device. Also included with the device are

self-adhesive laser warning and laser information signs (stick-on labels) in multiple languages.

Ä Affix the laser information sheet to the device in the language appropriate for the place of

use.

When using the device in the US, use the stick-on label with the "Complies with

21CFR1040.10" notice.

Ä Affix the laser information and warning signs near the device if no signs are attached to the

device (e.g. because the device is too small) or if the attached laser information and warning

signs are concealed due to the installation position.

Affix the laser information and warning signs so that they are legible without exposing the

reader to the laser radiation of the device or other optical radiation.

Leuze electronic GmbH + Co. KG ODS 9 12

Page 13

Safety

LASERSTRAHLUNG

NICHT IN DEN STRAHL BLICKEN

LASER KLASSE 2

EN 60825-1:2014

Max. Leistung (peak):

Impulsdauer:

Wellenlänge:

RADIAZIONE LASER

NON FISSARE IL FASCIO

APARRECCHIO LASER DI CLASSE 2

EN 60825-1:2014

Potenza max. (peak):

Durata dell'impulso:

Lunghezza d'onda:

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

EN 60825-1:2014

Maximum Output (peak):

Pulse duration:

Wavelength:

RAYONNEMENT LASER

NE PAS REGARDER DANS LE FAISCEAU

APPAREIL À LASER DE CLASSE 2

EN 60825-1:2014

Puissance max. (crête):

Durée d`impulsion:

Longueur d`onde:

RADIACIÓN LÁSER

NO MIRAR FIJAMENTE AL HAZ

PRODUCTO LÁSER DE CLASE 2

EN 60825-1:2014

Potencia máx. (peak):

Duración del impulso:

Longitud de onda:

RADIAÇÃO LASER

NÃO OLHAR FIXAMENTE O FEIXE

EQUIPAMENTO LASER CLASSE 2

EN 60825-1:2014

Potência máx. (peak):

Período de pulso:

Comprimento de onda:

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

IEC 60825-1:2014

Complies with 21 CFR 1040.10

Maximum Output (peak):

Pulse duration:

Wavelength:

激光辐射

勿直视光束

2 类激光产品

IEC 60825-1:2014

最大输出(峰值):

脉冲持续时间:

波长:

1,8 mW

22 ms

650 nm

1,8 mW

22 ms

650 nm

1.8 mW

22 ms

650 nm

1,8 mW

22

m

s

650 nm

1,8 mW

22 ms

650 nm

1,8 mW

22 ms

650 nm

1.8 mW

22 ms

650 nm

1.8 mW

22 ms

650 nm

50106507-06

Fig.2.2: Laser information and warning signs

Leuze electronic GmbH + Co. KG ODS 9 13

Page 14

Device description

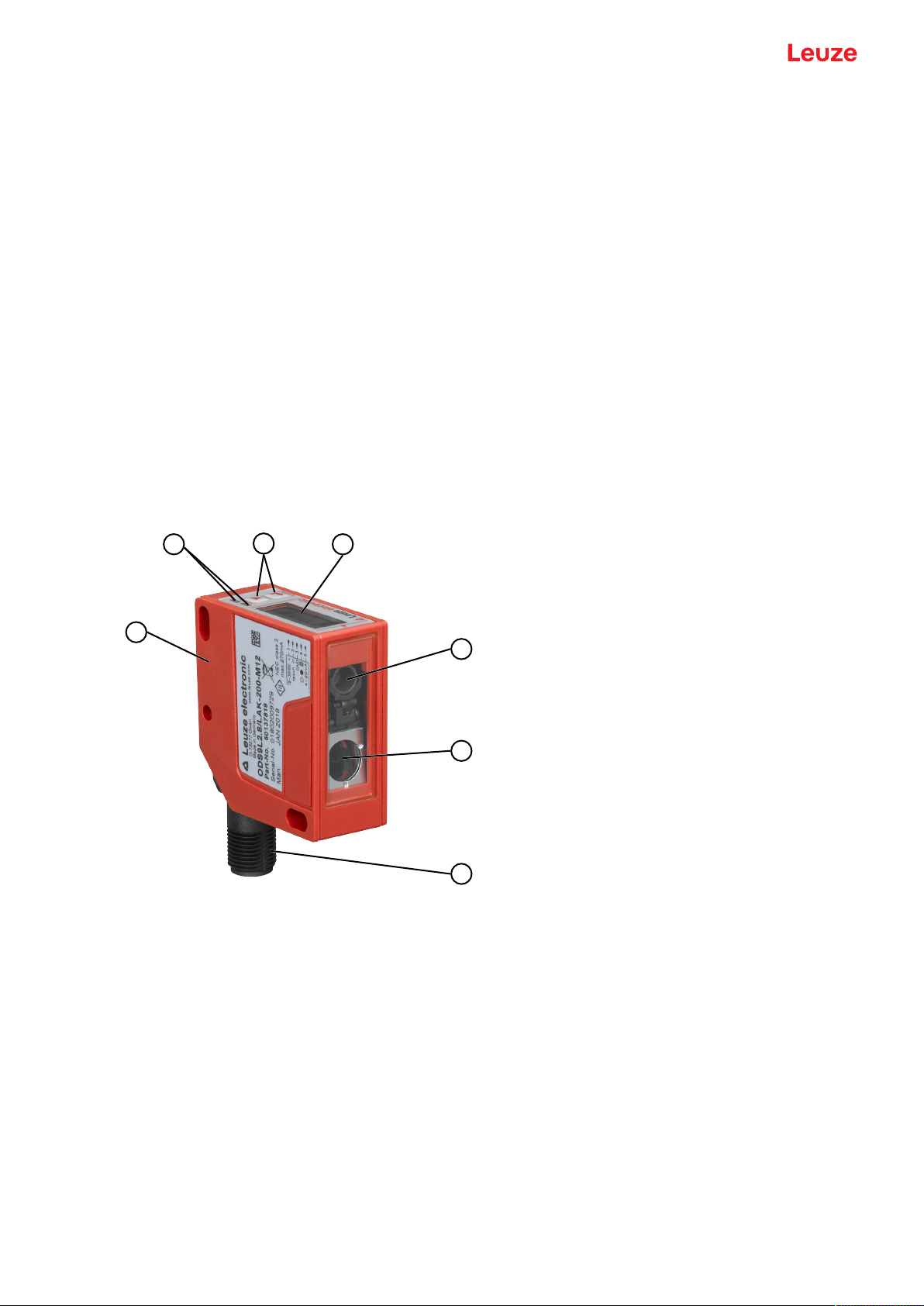

1

2

3

4

5

6

7

3 Device description

3.1 Device overview

3.1.1

General information

The laser distance sensor is an optical distance sensor that operates according to the triangulation measurement principle.

The sensor consists of the following components:

• Transmitter: laser spot

• Receiver

• White OLED display

• Control panel with control buttons

• Status LEDs

• Connection for connecting to the control: M12 connector

The sensor can be configured using display and control buttons.

With the SensorStudio configuration software, the sensors can be configured via the IO-Link interface with

a PC and the measurement values visualized. Stored parameter sets can be duplicated in other sensors.

The connection is made via the IO-Link USB master, which is available as an accessory.

1 Device housing

2 Status LEDs

3 Control buttons

4 Display

5 Transmitter

6 Receiver

7 Connection

Fig.3.1: Device construction

Leuze electronic GmbH + Co. KG ODS 9 14

Page 15

Device description

3.1.2

3.1.3

Operating principle

Triangulation measurement principle

Distance measuring procedure, which determines the distance of an object by the incidence angle of the

light reflected from the object.

Advantages of the triangulation measurement principle:

• Short response times and, thus, high measurement rates

• High accuracy

Performance characteristics

The most important performance characteristic of the ODS9 laser distance sensor:

• Measurement ranges:

50mm…650mm against objects (6…9% diffuse reflection)

• Analog current and voltage output (configurable)

Factory setting: current output

• OLED display and control buttons for configuration

• Configurable measurement range and measure mode

• Measurement value display in mm on OLED display

• IO-Link version 1.1

• Compliant with the "Smart Sensor Profile" specification

• Dual Channel: the IO-Link interface can be used in parallel with the other output functions.

• Communication interface RS232/RS485, depending on the device type

• Optional: multifunction input for deactivating the laser or for teaching the digital switching points (teachin)

Factory setting: input for deactivating the laser

• Optional: second switching output if the IO-Link interface is not used

For measurement against objects:

• Measurement range: 50mm…max. 650mm, dependent on device type

• Measurement against diffusely reflective objects

• Reflection-independent distance information

• Applications:

• Distance measurement

• Contour determination

• Thickness measurement

• Positioning

• Diameter determination

• Sag determination

• Stack height measurement

• Loop measurement

3.1.4

Accessories

Special accessories are available for the laser distance sensor (see chapter 13 "Order guide and accessories"):

• Mounting systems for mounting on rods

• Connection cables

• IO-Link USB master set for connecting to a PC

• IO-Link master for cascading or integrating in a higher-level network

Leuze electronic GmbH + Co. KG ODS 9 15

Page 16

Device description

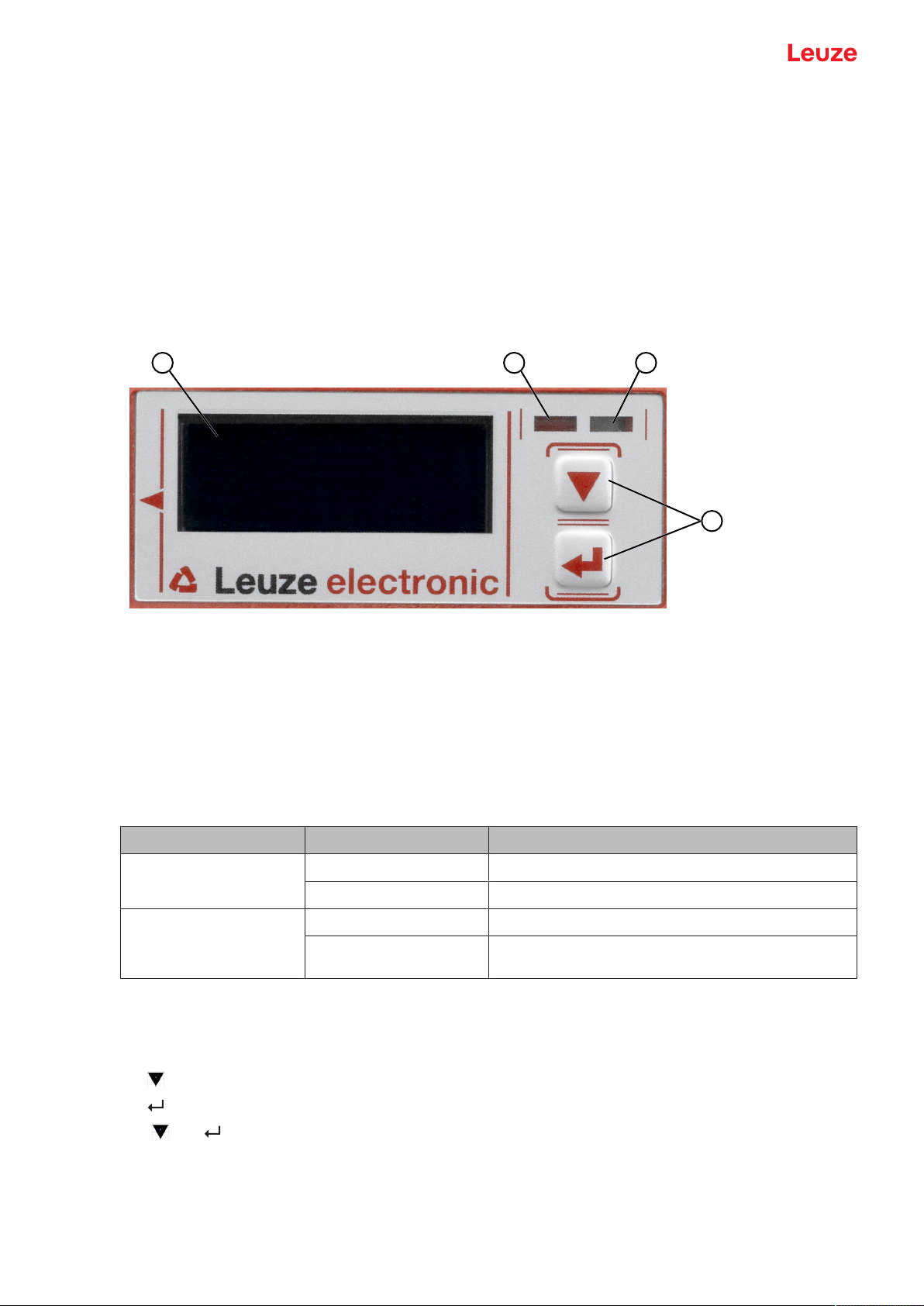

2 31

4

3.2 Connection technology

For the electrical connection of the laser distance sensor, the following connection variants are available:

• M12 connector, 5-pin, turns 180°

3.3 Indicators and operational controls

The device housing is provided with the following indicators and operational controls:

• OLED display

• Two control buttons

• Green LED: operating state (PWR)

• Orange LED: switching output information (SSC)

3.3.1

3.3.2

1 Display

2 Orange LED (SSC1/SSC2)

3 Green LED (PWR)

4 Control buttons

Fig.3.2: Indicators and operational controls

LED indicators

Tab.3.1: Meaning of the LED indicators on the device housing

LED Color, state Description

Green LED

PWR

Orange LED

Switching outputSSC1/

Green Sensor ready

Off No supply voltage

On Object detected in the switching range

Off No object detected in the switching range

SSC2

Control buttons

The sensor can be configured using display and control buttons. The display is controlled via the control

buttons. You can make adjustments in the application via the control buttons.

• – Scroll through the functions

• – Enter button: select function, confirm/enter value

The and buttons have different functions depending on the operating situation. These functions are

displayed via icons at the right edge of the display (see chapter 3.3.4 "Meaning of the display icons").

Leuze electronic GmbH + Co. KG ODS 9 16

Page 17

Device description

Navigating within the menus

Use the navigation button to move through the menu.

Activate the desired selection with the enter button .

The number of bars at the left edge of the display indicates the current menu level.

Selecting options

Set the desired option with the navigation button and the enter button .

Resetting to factory settings

Ä While switching on the supply voltage, press the enter button to reset the sensor configuration to the

factory settings.

Ä Press the enter button again to reset all parameters to factory settings. All parameter settings made

previously are permanently lost.

Press the navigation button to return to process mode without resetting the parameters.

NOTICE

You can also use the menu (see chapter 3.4 "Configuration / menu structure") or the SensorStudio configuration software to reset to factory settings (see chapter 8 "Connecting to a PC

– SensorStudio").

3.3.3

Display

The display changes depending on the current operating mode. The following display modes exist:

• Menu display

Press one of the two control buttons once or twice to access the menu display.

For information on operating via the menu, see chapter 3.4 "Configuration / menu structure" and the

configuration example (see chapter 3.5 "Configuration example").

• Process mode

After switching on the supply voltage and error-free initialization of the device, the green LED lights up

continuously. The laser distance sensor is in process mode.

In process mode, the current measurement value is displayed in the display, e.g. "267 mm".

NOTICE

In the menu display, the selectable or editable values are shown with inverted text colors (black

on white background).

If no key is pressed for approx. 6 minutes in the configuration menu, the device automatically returns to the process mode.

The sensor can be protected against unauthorized configuration change by activating the password query (see chapter 3.4.7 "Settings menu"). The password is permanently set to 165. In addition, a complete button lock can be activated using the lock function (device access locks,

bit2) (see the table "Status displays on the display").

Leuze electronic GmbH + Co. KG ODS 9 17

Page 18

Device description

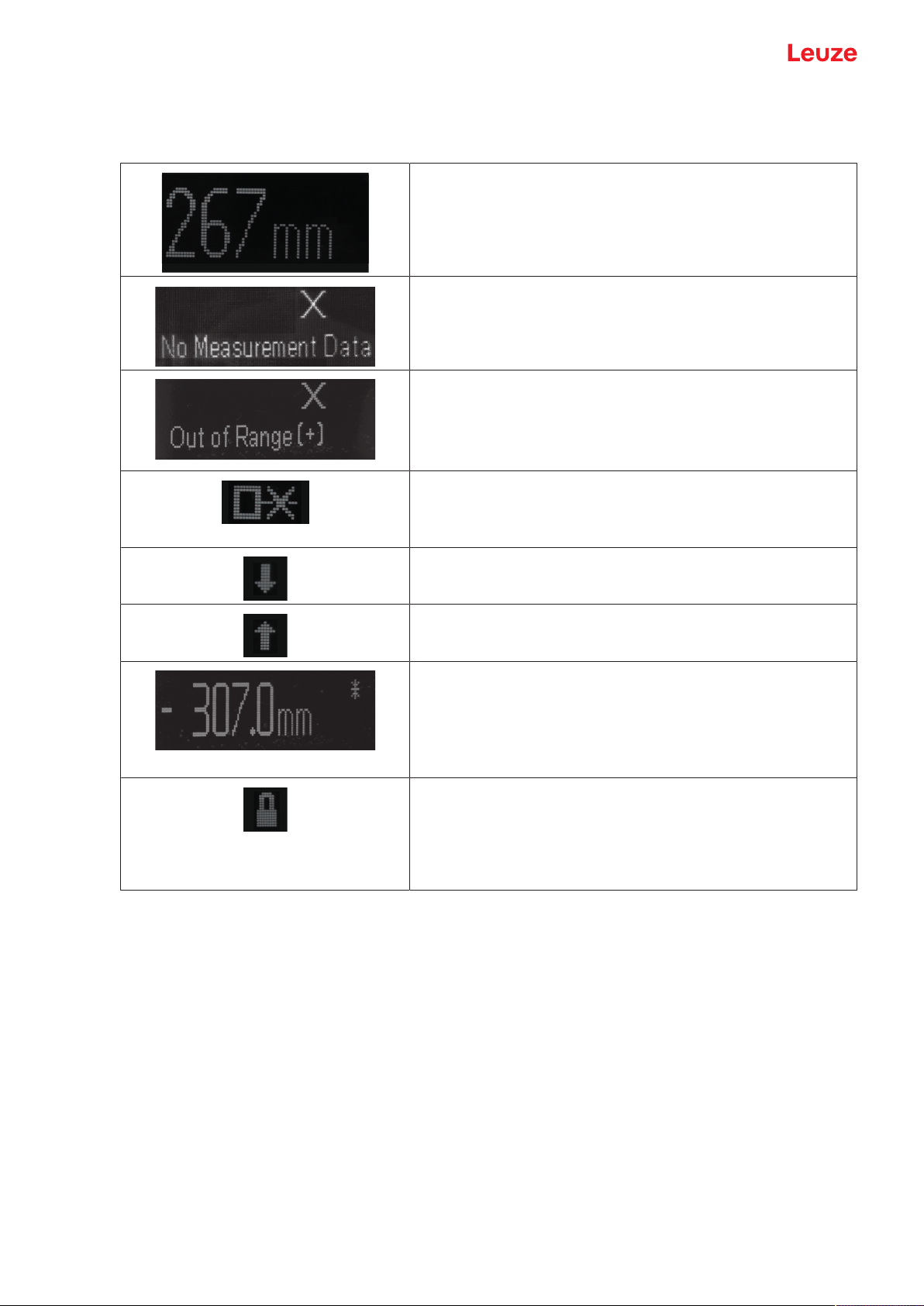

Status displays in process mode

Tab.3.2: Status displays on the display

Object distance in mm

No measurement value available, e.g. due to a weak or missing

reception signal.

No object detected or reception signal too weak.

No object detected or reception signal too weak.

• Out of Range (+)

• Out of Range (-)

• +max

Sensor deactivated, laser switched off

• Via the input function (see chapter 3.4.1 "Input menu")

• Via the IO-Link command

The current measurement value is less than the lower limit

value of the analog output distance.

The current measurement value is greater than the upper limit

value of the analog output distance.

The measurement value has an offset and/or the gradient is

falling (-1)

Lock function: Button lock activated via IO-Link (device access

locks, bit3)

The button lock can also be enabled and set using the configuration software SensorStudio:

Configuration > Local operation

Leuze electronic GmbH + Co. KG ODS 9 18

Page 19

Device description

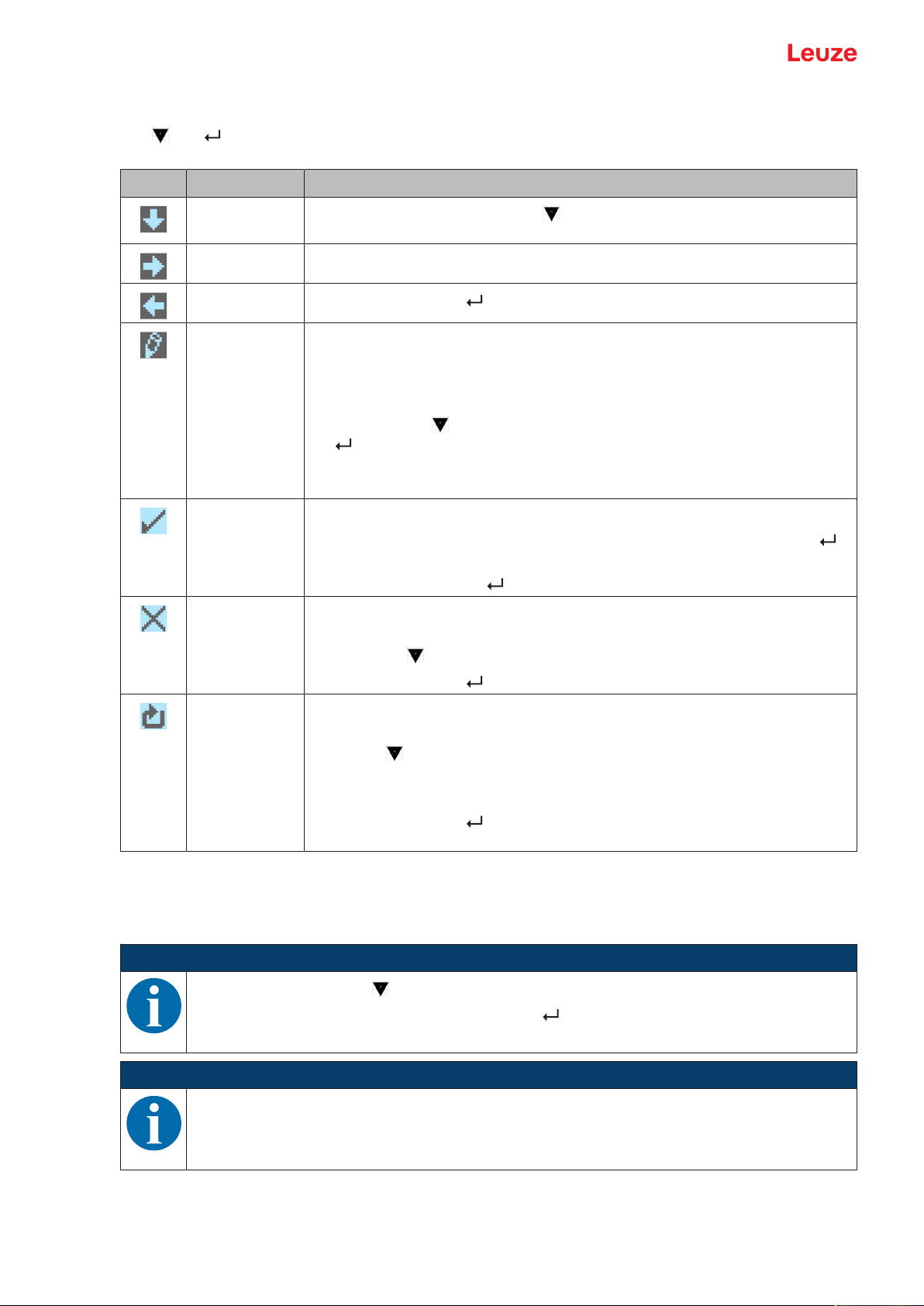

3.3.4

Meaning of the display icons

The and buttons have different functions depending on the operating situation. These functions are

displayed via icons at the right edge of the display.

Icon Position Function

First line

By pressing the navigation button you select the next parameter within a

menu level.

Second line Symbolizes the respective, next menu level that you have not yet selected.

Second line

Press the enter button to exit the menu level or the menu.

Second line Symbolizes the input mode.

The selected (highlighted) option field can be a fixed selection parameter or a

multi-digit input field.

With a multi-digit input field, you can change the active digit cyclically using the

navigation button and switch from one digit to the next using the enter button .

Note: If this icon does not appear, the local configuration lock is set via IO-Link

(index: 12, bit 2).

Second line Confirmation of the selection.

This icon appears when you complete an option field with theenterbutton

and the previously entered value is valid.

Pressing the enter button again saves and displays the change locally.

Second line Reject the selection.

This icon is accessed from the previous icon (check mark) by pressing thenavigationbutton .

Press the enter button to reject the current value or option parameter.

Second line Return to selection.

This icon is accessed from the previous icon (cross) by pressing thenavigationbutton .

This icon is also accessed if the value newly entered previously is outside the

permissible value range, making correction of the entry necessary.

Press the enter button to reset the current value or option parameter and

enter a new value or select a new option parameter.

3.4 Configuration / menu structure

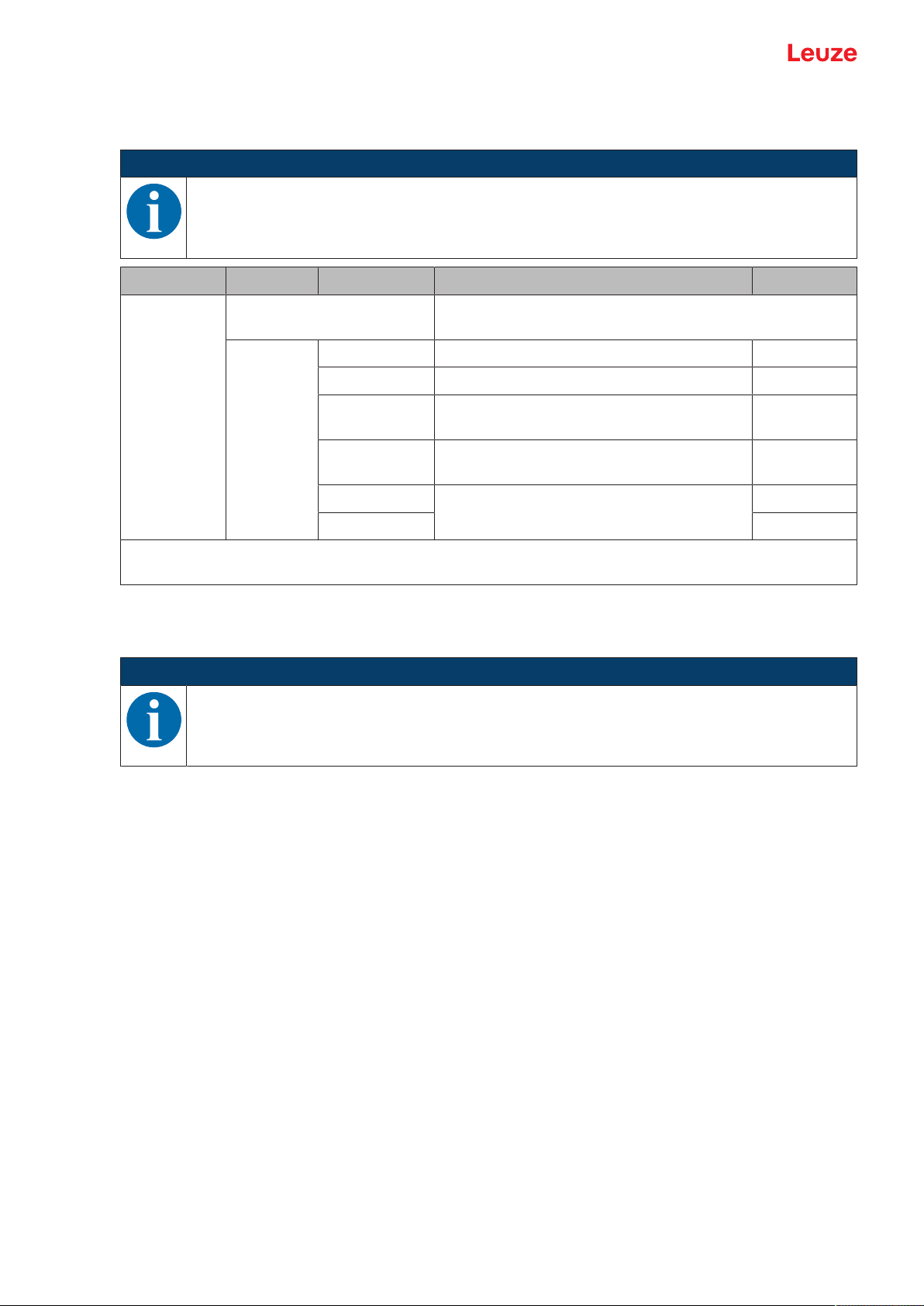

The following chapters show the structure of all menu items. For each sensor model, only the actually available menu items are present for entering values or for selecting settings.

NOTICE

Use the navigation button to move through the menu.

Activate the desired selection with the enter button .

NOTICE

The number of bars at the left edge of the display indicates the current menu level.

For information on the meaning of the display icons, see chapter 3.3.4 "Meaning of the display

icons".

Leuze electronic GmbH + Co. KG ODS 9 19

Page 20

Device description

3.4.1

Input menu

The function of the switching input on pin5 is set in the Input menu.

NOTICE

The Input menu is only available for sensors with multifunction input on pin 5 (ODS9…/LAK…).

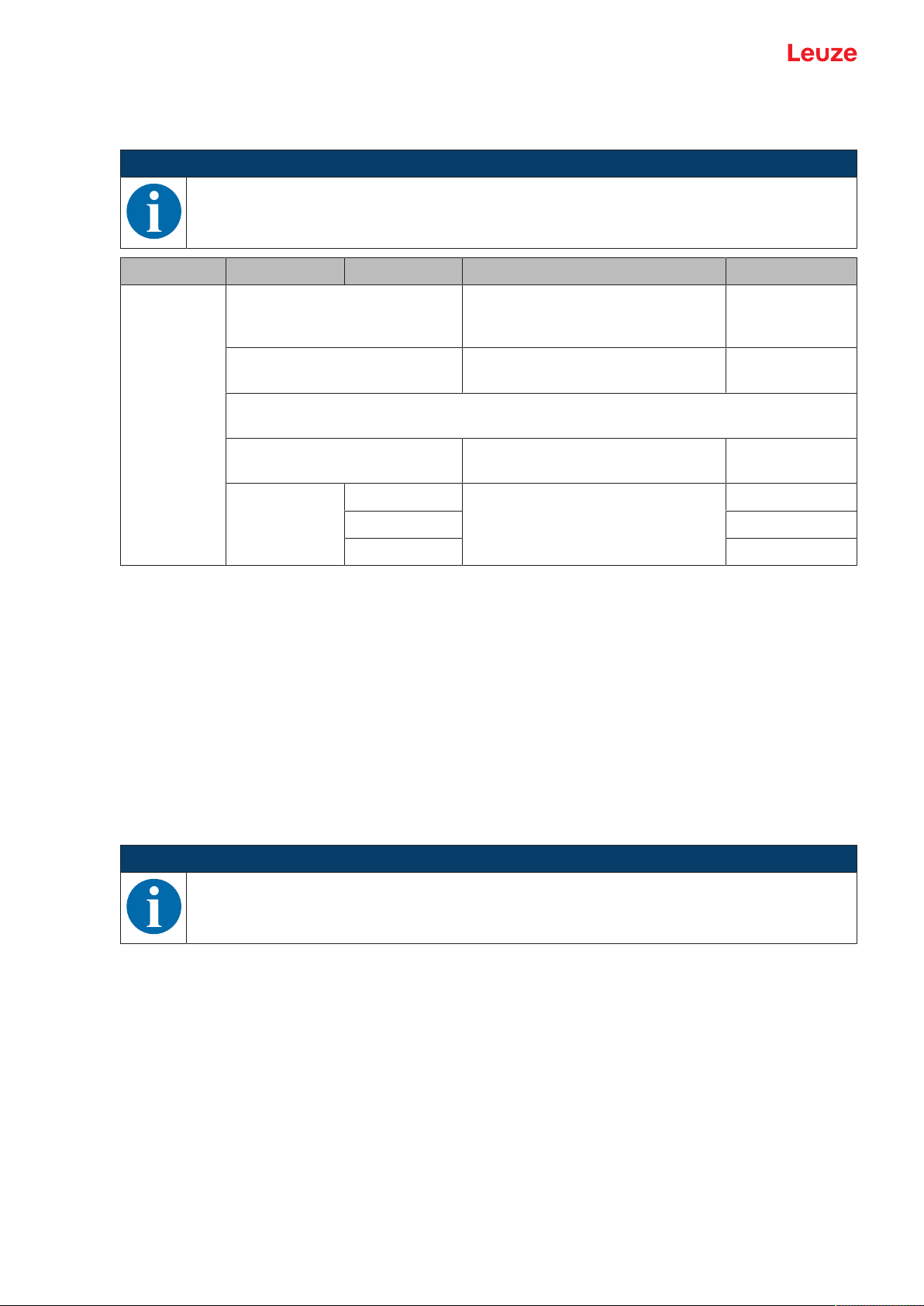

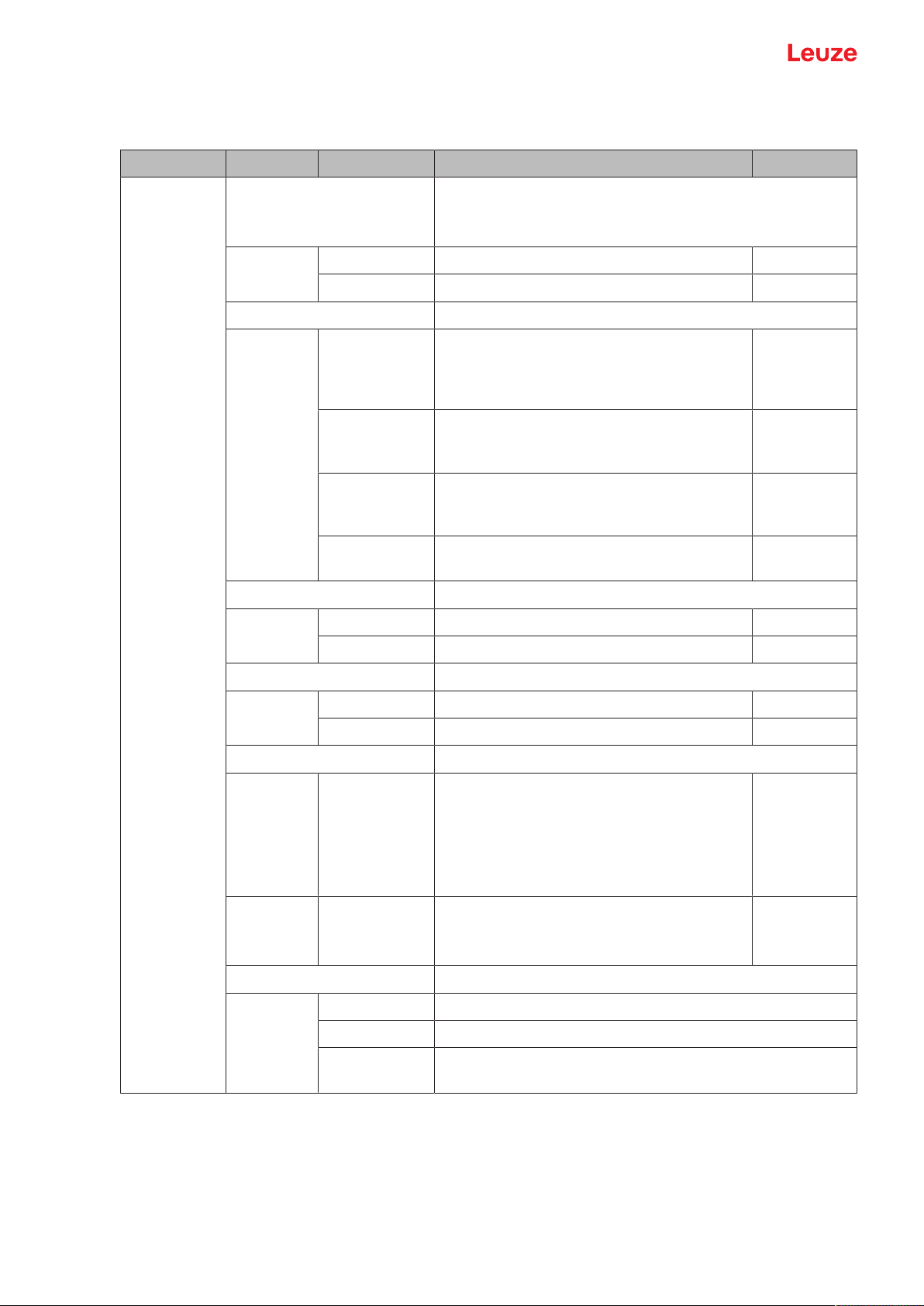

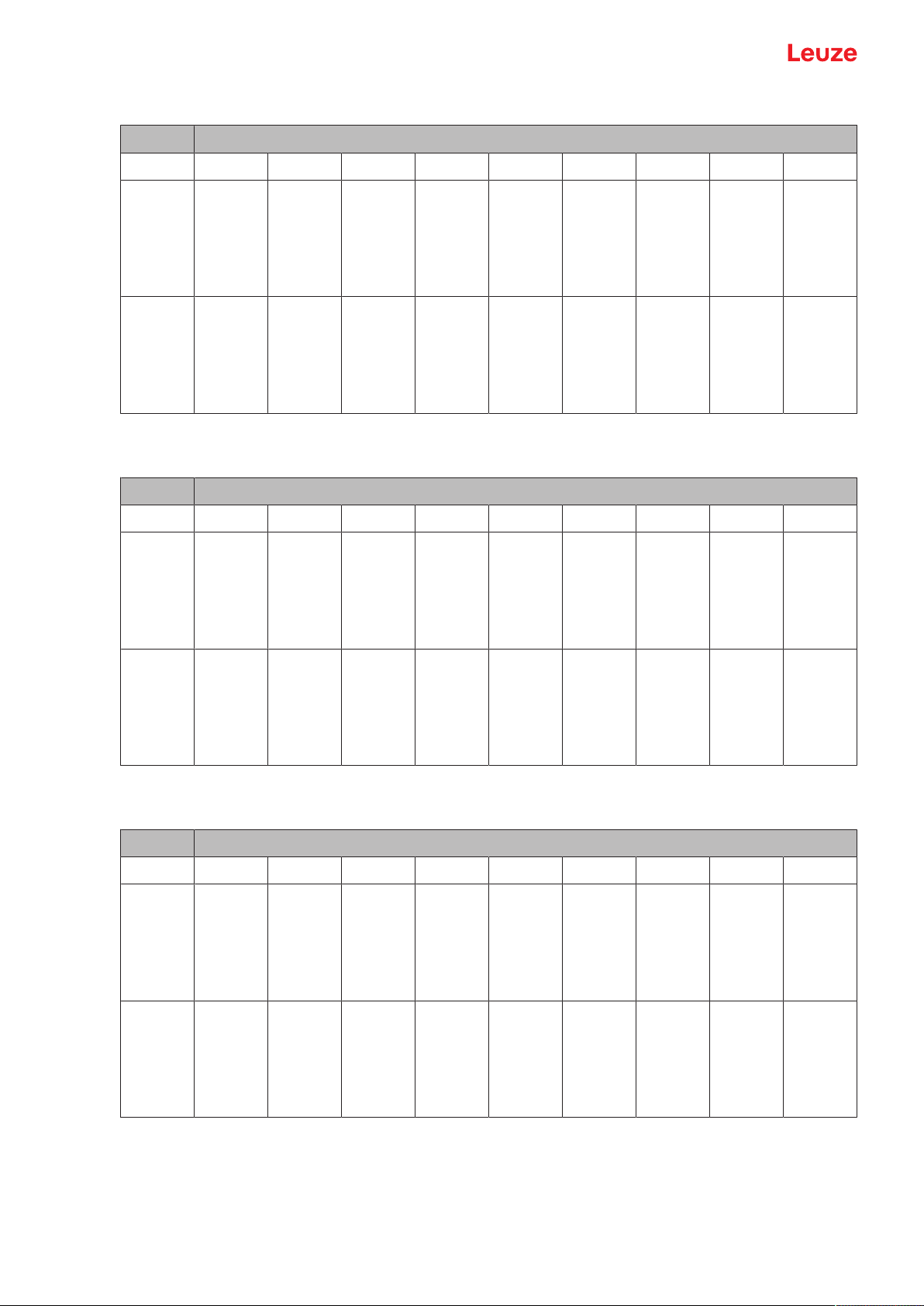

Level 1 Level 2 Level 3 Description Default

Input Input_Mode Function of the switching input on pin5 if the supply voltage

is applied.

No_Function No input function active

Teach Teach analog output and switching output X

Deactivation Switch off laser transmitter with +24V on the

switching input

Activation Switch on laser transmitter with +24V on the

switching input

Trigger_Rising The measurement value is only updated and

Trigger_Falling

output by an edge on input PIN 5.

Important: Activation or deactivation using IO-Link commands or process data (PDOut) only has an effect

if neither Deactivation nor Activation is set as the input function.

3.4.2

Output_SSC1 menu

The switching behavior of switching output SSC1 is set to pin4 in the Output_SSC1 menu.

NOTICE

Designation "SSC" corresponds to designation "Q" previously used for switching outputs.

Leuze electronic GmbH + Co. KG ODS 9 20

Page 21

Device description

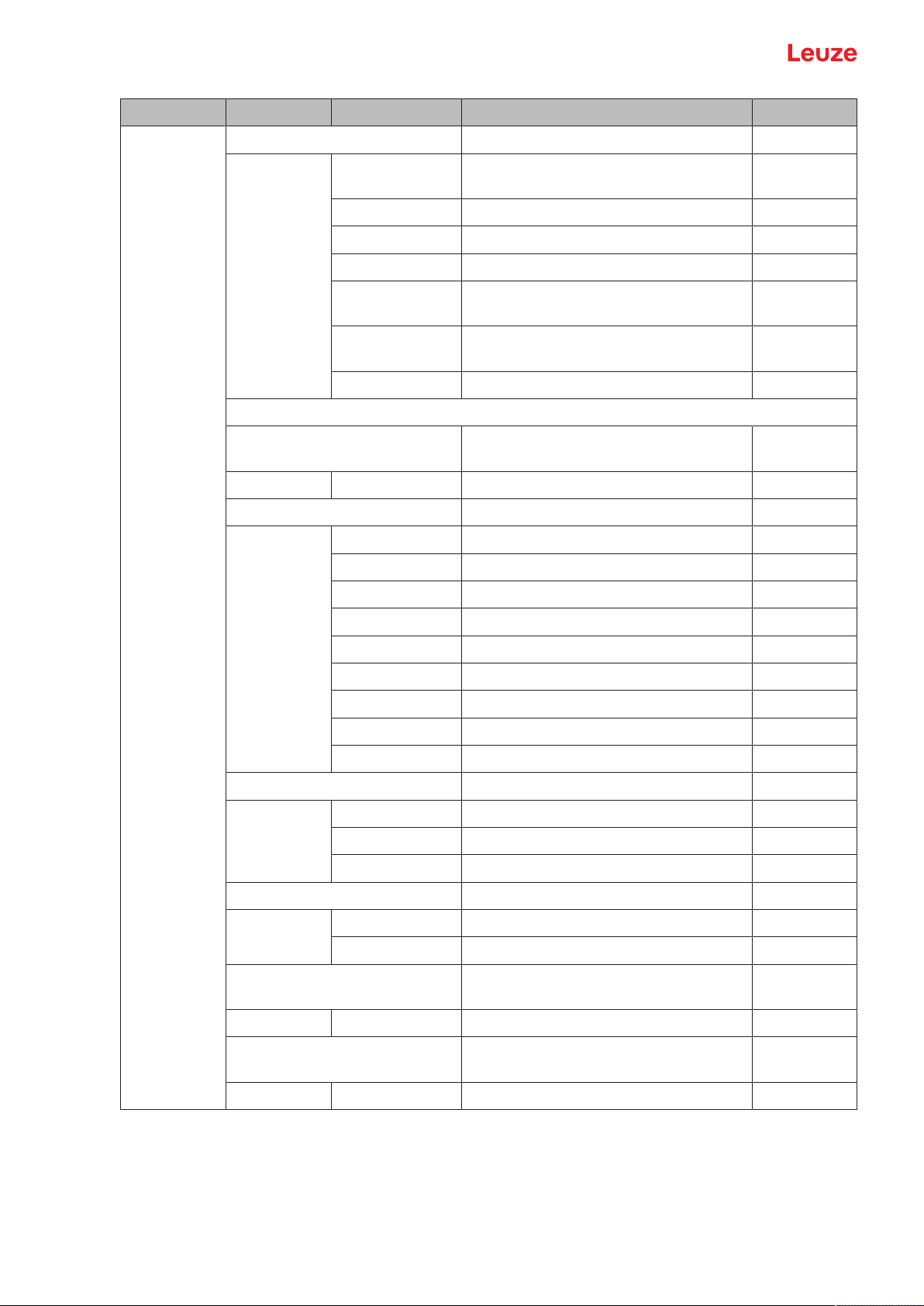

Level 1 Level 2 Level 3 Description Default

Output_SSC1

SSC1_SP1_(dist.) Upper switching point Depending on the

device range:

• 100mm: 75mm

• 200mm: 175mm

• 450mm: 250mm

• 650mm: 350mm

SSC1_SP2_(near) Lower switching point 50mm

Notice: For the limit values of the measurement range for your sensor, see chapter 12

"Technical data".

SSC1_Logic Behavior of the switching output if an

object is within the taught/configured

switching distance.

High_Active Switching output active (high) X

Low_Active Switching output not active (low)

SSC1_Mode see chapter 7.1.2 "Setting the

switching outputs"

Single_Point

One switching point on the object X

(Obj)

Window Switching window Window

3.4.3

Two_Point Two switching points on the object

Single_Point

(BG)

One switching point on the background (BG), also referred to as

background-teach. Switching

process for objects between background and sensor.

Deactivated Mode deactivated

SSC1_Hysteresis Hysteresis 10mm

Output_SSC2 menu

• ODS9LA6: The switching behavior of switching output SSC2 is set to pin5 in the Output_SSC2 menu.

• ODS9L6X: The switching behavior of switching output SSC2 is set to pin2 in the Output_SSC2 menu.

NOTICE

Ä The Output_SSC2 can only be used for sensors with a second switching output SSC2.

Ä Designation "SSC" corresponds to designation "Q" previously used for switching outputs.

Leuze electronic GmbH + Co. KG ODS 9 21

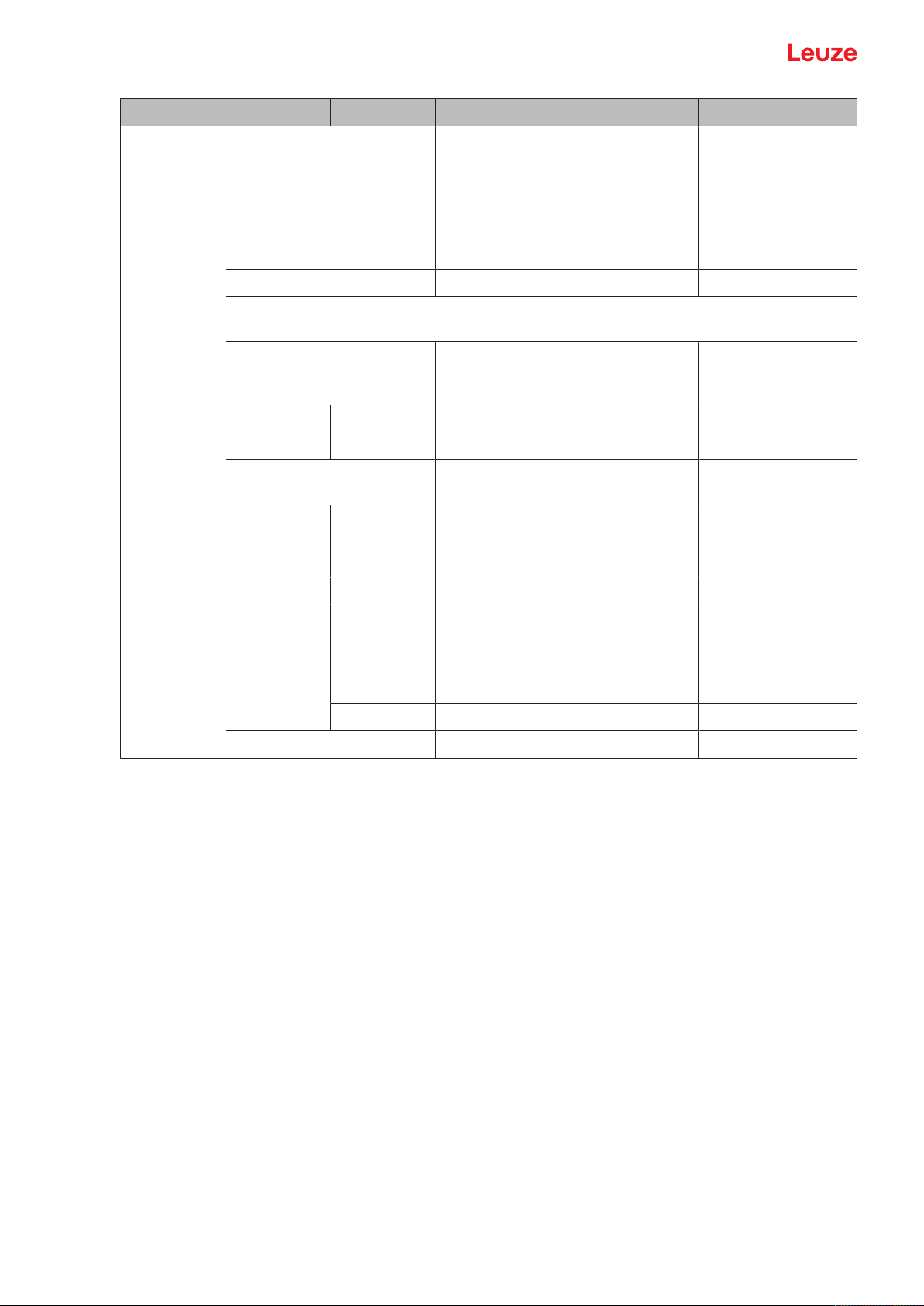

Page 22

Device description

Level 1 Level 2 Level 3 Description Default

Output_SSC2

SSC2_SP1_(dist) Upper switching point Depending on the

device range:

• 100mm: 75mm

• 200mm: 175mm

• 450mm: 250mm

• 650mm: 350mm

SSC2_SP2_(near) Lower switching point 50mm

Notice: For the limit values of the measurement range for your sensor, see chapter 12

"Technical data".

SSC2_Logic Behavior of the switching output if an

object is within the taught/configured

switching distance.

High_Active Switching output active (high) X

Low_Active Switching output not active (low)

SSC2_Mode see chapter 7.1.2 "Setting the

switching outputs"

Single_Point

One switching point on the object X

(Obj)

Window Switching window Window

Two_Point Two switching points on the object

Single_Point

(BG)

One switching point on the background (BG), also referred to as

background-teach. Switching

process for objects between background and sensor.

Deactivated Mode deactivated

SSC2_Hysteresis Hysteresis 10mm

Leuze electronic GmbH + Co. KG ODS 9 22

Page 23

Device description

3.4.4

Analog_Output menu

The characteristic output curve of the analog output is set to pin2 in the Analog Output menu.

NOTICE

The Analog Output menu is only available for sensors with analog output.

Level 1 Level 2 Level 3 Description Default

Analog output

Position_Max.Val. Distance measurement value for

maximum voltage / maximum current

Position_Min.Val. Distance measurement value for

Upper limit of the

measurement

range

50mm

minimum voltage / minimum current

Notice: For the limit values of the measurement range for your sensor, see chapter 12

"Technical data".

Analog Range Current/voltage range of the analog

output

4-20_mA X

1-10_V

0-10_V

3.4.5

Spreading the characteristic output curve

You can spread the characteristic output curve of the analog output according to your requirements.

Ä Select the current or voltage range of the analog output.

Ä Set the distance measurement value that corresponds to the lower limit of the measurement range

(4mA, 1V, 0V).

Ä Set the distance measurement value that corresponds to the upper limit of the measurement range

(20mA, 10V).

It is also possible to invert the working range of the analog output, i.e., the lower limit of the measurement

range is set to a larger value than the upper limit. This creates a descending characteristic output curve.

Serial Menu

In the Serial menu, the function of the serial interface is set to pin 2 and pin 5.

NOTICE

The Serial is only available for sensors with a serial interface.

Leuze electronic GmbH + Co. KG ODS 9 23

Page 24

Device description

Level 1 Level 2 Level 3 Description Default

Serial Serial_Function Format of the measurement value output

ASCII Measurement value output correspond-

X

ing to the device resolution

14_Bit 2 byte transfer

16_Bit 3 byte transfer

24_Bit 4 byte transfer

Decimal Transfer of the measurement value as

decimal number

Remote_Control Remote control operation of the ODS via

remote commands

Reserved

Note: For the device resolution for your sensor see chapter 12 "Technical data".

Device_Address Address under which the ODS is ad-

dressed

0…14 1

Transmiss._Rate Transmission rate of the serial interface

2400_Baud

4800_Baud

9600_Baud X

19200_Baud

28800_Baud

38400_Baud

57600_Baud

115200_Baud

230400_Baud

Parity Transfer of parity bit

None X

Odd

Even

Stop_Bit Number of stop bits

1 X

2

Termination_Byte If not equal to 0, the corresponding char-

acter is appended

0…255 0

Transmiss._Delay Delay of data transmission in millisec-

onds

0…255 0

Leuze electronic GmbH + Co. KG ODS 9 24

Page 25

Device description

3.4.6

Application menu

The measurement function of the sensor is set in the Application menu.

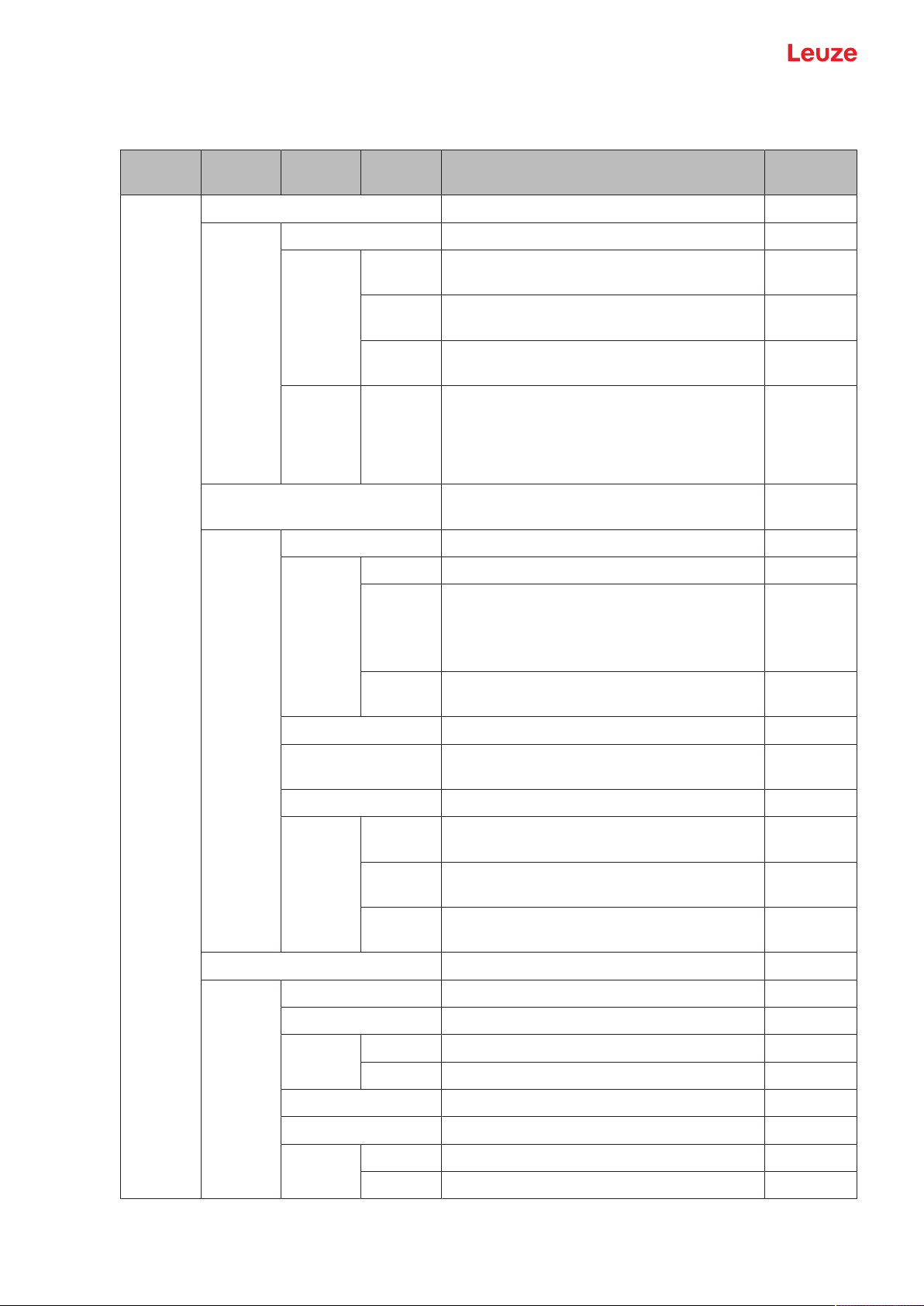

Level1 Level2 Level3 Selection

Description Default

level 3

Application

Process_Settings Measurement value processing

Measurem._Mode

Standard Multi-purpose function for many measure-

ment tasks

Precision Greater accuracy for less dynamic applica-

tions

Light_Sup-

Ambient light sensitivity

pression

LightSupp

r.Limit

2…32 Setting of the maximum number of measure-

ments for preventing the sensor from measuring for too long if the light is too bright

and, as a result, not outputting a measurement value.

Filter_Settings Filter for ascertaining and suppressing out-

liers

Filter_Type

X

32

None X

Averaging Floating average calculation taking 2…99

measurements into account

The response time increases with the number of measurements.

Spike_Su

ppression

Blocked central value filtering across buffer

sizes from 5…99 measurements

Average_Count Number of measurements used in averaging 10

Spike_Supp.Count Number of measurements used in outlier

suppression

Spike_Supp.Depth Adjustable filter depth for outlier suppression

Raw Averages approx. 75% of the central mea-

surement values

Medium Averages approx. 50% of the central mea-

surement values

Fine Averages approx. 25% of the central mea-

surement values

Dist.Correction Distance calibration

Offset 0mm

10

X

Gradient

Rising X

Falling

Preset_Position 0mm

Preset_Calc.

Inactive X

Execute

Leuze electronic GmbH + Co. KG ODS 9 25

Page 26

Device description

Measurement value processing and filtering is set according to the given requirements and the application

via the display or using the SensorStudio configuration software.

By changing the measurement value processing or filtering, the response time and accuracy can be increased.

Measurement value processing

Processing settings > Measure mode > Standard/Precision/Ambient light

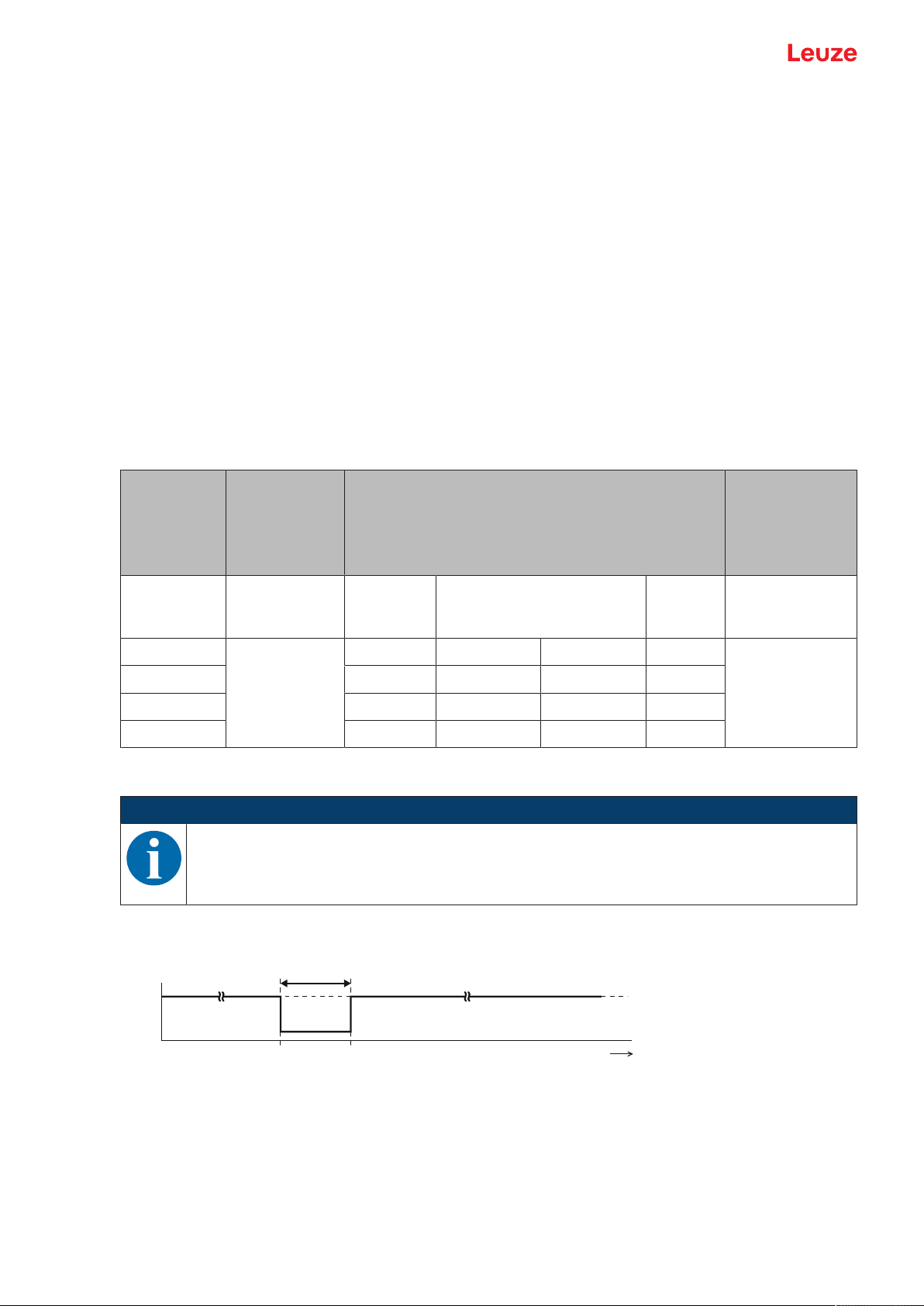

Tab.3.3: Measurement value processing

NOTICE

A higher response time presupposes the possibility of measuring an object for a longer period.

Accuracy Measurement

time / reload

Ambient light Varying diffuse

reflection

Standard + + + +

Precision ++ -- + +

Ambient light + -- ++ 0

Filter

Filter settings > Filter type > Averaging/outlier suppression

A floating average value is calculated over the number of set measurement values.

The measurement value noise decreases, i.e., measurement value fluctuations become smaller.

If the measurement value changes erratically, the output value moves linearly from the old measurement

value to the new measurement value over n measurements.

The higher the number of measurements is set, the higher the response time of the sensor. With dynamic

applications, averaging should be set to a very low number of measurement values or switched off altogether.

The time of measurement value updating is not affected by the filtering.

Outlier suppression

Filter settings > Degree of suppression > Coarse/Medium/Strong

Measurement results with excessively high or low measurement values (referred to as "outliers" or

"spikes") are suppressed or rejected according to the set filter depth.

• The user sets the number of measurements via the display or using the configuration software Sen-

sorStudio .

• The sensor performs the set number of measurements on the object, e.g. 100measurements.

Due to physical reasons, the measurement results are not all the same. The measurement values have a

scatter which corresponds to a normal distribution comprising a large number of similar measurement values and a small number of excessively high or low measurement values (outliers, spikes).

Leuze electronic GmbH + Co. KG ODS 9 26

Page 27

Device description

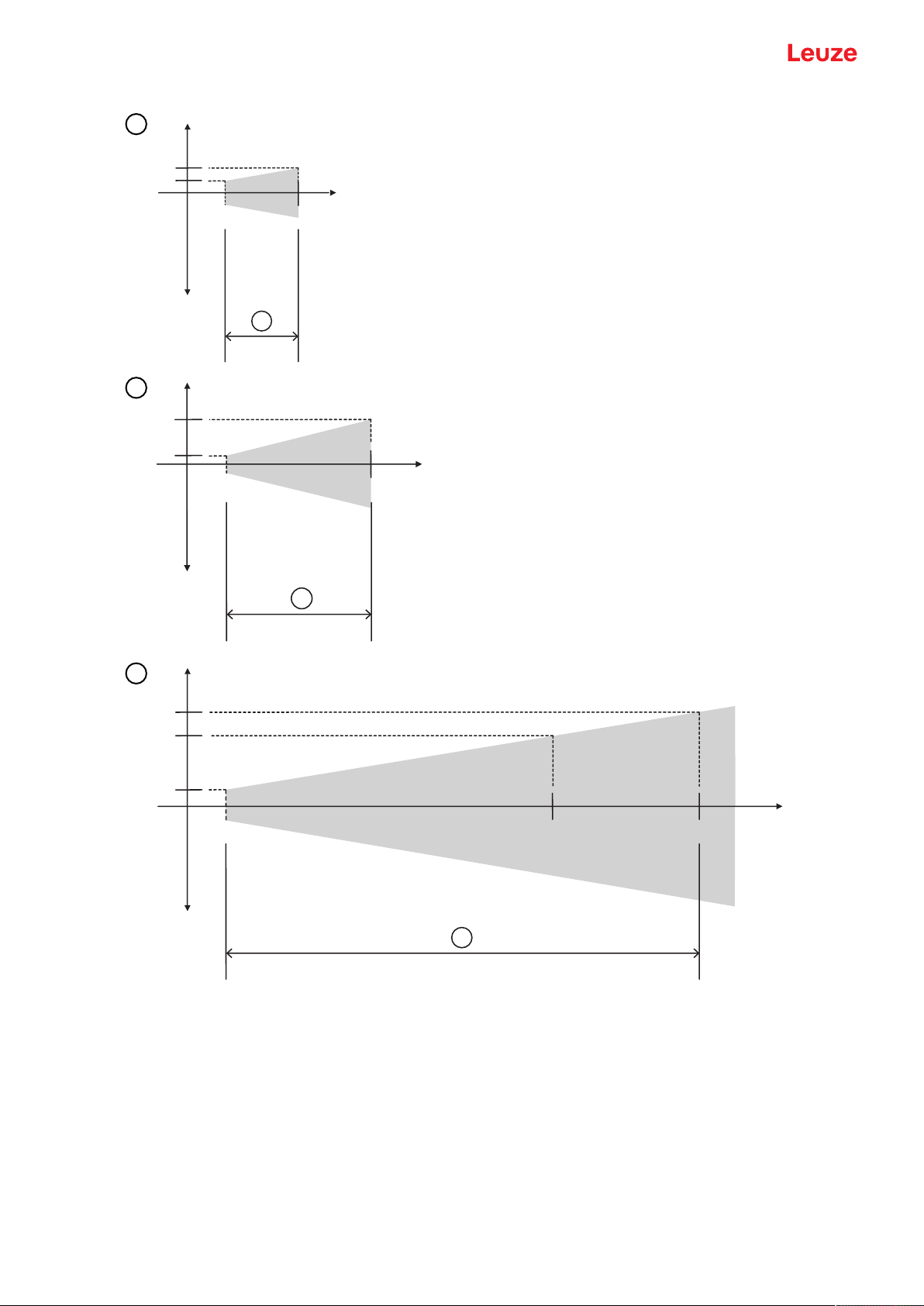

The suppression or rejection of the measurement value outliers is configured in the following levels using

the filter depth:

• Coarse: A large number of measurement values which do not occur with a high frequency are suppressed or rejected.

• Falling on one side: 12%

• Used center area, averaged: 76%

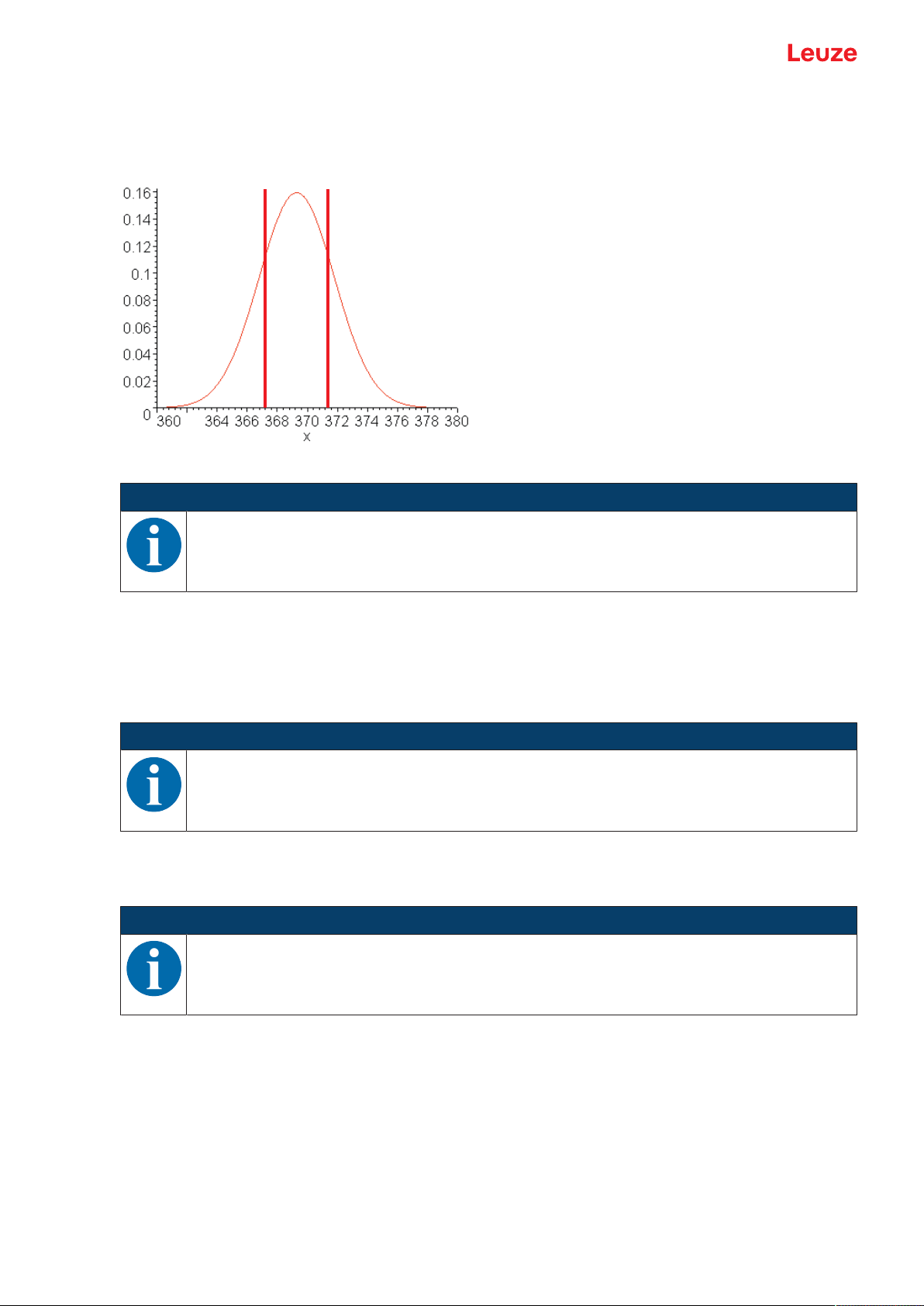

Fig.3.3: Coarse filter depth

• Medium

• Falling on one side: 24%

• Used center area, averaged: 52%

Fig.3.4: Medium filter depth

Leuze electronic GmbH + Co. KG ODS 9 27

Page 28

Device description

• Strong

• Falling on one side: 36%

• Used center area, averaged: 28%

Fig.3.5: Strong filter depth

NOTICE

In the case of dynamic applications with erratic changes in measurement distance, it is recommended to filter by setting the response time.

Distance calibration "Distance correction"

Under the Distance correction menu item, you can influence the output of the measured distance value.

Gradient

If the gradient is changed from rising to falling, the measurement values decrease as the distance from the

object to the sensor increases. The distance information is output inverted.

NOTICE

Negative measurement values may result if the gradient is reversed.

Offset and Preset

Deviations that arise while mounting and attaching the sensor can be compensated for with the entries for

the Offset and Preset parameters.

NOTICE

Negative measurement values may occur if an offset is set.

The offset/preset calculation is available as a teach function. The assignment of the teach time frame can

be read out via IO-Link (see chapter 7 "Starting up the device").

Specify offset and preset

Under the Application > Dist.Correction menu item, you can influence the output of the measured distance value. The Offset and Preset parameters are used for correcting the measurement value by a fixed

amount.

Leuze electronic GmbH + Co. KG ODS 9 28

Page 29

Device description

Deviations that arise while mounting and attaching the sensor can be compensated for with the entries for

the Offset and Preset parameters.

• For the Offset parameter, a fixed value and sign are specified.

• For the Preset parameter, a nominal measurement value is specified; a measurement is then performed using an object located at the desired nominal distance. The Offset parameter is changed as a

result of this measurement.

Setting the offset

Ä Enter an offset value via the display:

Application > Dist.Correction > Offset

ð The set offset value is added to the measured distance value of the sensor.

Example:

• Measurement value of the ODS9: 1,500mm

• Entry offset-value: -100mm

• Output on the display and at the interface: 1400mm

NOTICE

If the calculation of the Offset parameter results in negative measurement values, zero is output

at the interface and on the display.

Preset presetting

Ä Enter a Preset value via the display or using the Sensor Studio configuration software (IO-Link):

Application > Distance correction > Preset position

Ä Position an object at the desired preset distance.

Ä Perform the preset measurement:

Application > Distance correction > Preset calculation > Execute

ð The offset value is automatically calculated from the measurement value and nominal measurement

value (preset value) and entered as the offset in the configuration.

Example:

• Entry: preset value 350mm

• Object distance: 300mm in front of the sensor

Trigger preset measurement

Distance correction > Preset calculation > Execute

An offset of +50 mm is automatically calculated and stored in the configuration.

• Object distance: 300mm

Output to display and interface: 350mm

• Object distance: 400mm

Output to display and interface: 450mm

Leuze electronic GmbH + Co. KG ODS 9 29

Page 30

Device description

3.4.7

Settings menu

You can set the display language and call up information about the sensor in the Settings menu.

Level 1 Level 2 Level 3 Description Default

Settings Language Setting of the display language

Note: If the display language is changed, this change only

becomes effective when the sensor is restarted.

English Display language English X

Deutsch Display language German

Display Display settings

Auto After pressing a control button, the display is

X

set to full brightness for approx. one minute.

The display is then dimmed slightly for five

minutes and then dimmed considerably.

Auto_Off The display (measurement value display) is

automatically switched off after approx.

sixminutes.

Off No measurement value display – the display

is only active in the menu after pressing a

control button.

On The display (measurement value display) is

always at full brightness.

Factory_Settings Reset to factory settings

Inactive The sensor is not reset to factory settings. X

Execute The sensor is reset to factory settings.

Password_Lock Locks access to the menu with the fixed password 165

Inactive Inactive X

Activated Active

Exit_behaviour Exit the configuration settings

Report_to_DS After making a change in the menu, the

X

change is taken over in the data memory after returning to measurement operation. The

DSUpload flag is set.

The "Data Storage" (DS) parameter memory

is updated.

Only_local_changes

The change is only temporary or local on the

device or no data memory is used.

The DSUpload flag is cleared.

Info Information on the sensor

Part_No. Leuze part number of the sensor

Serial_No. Sensor serial number

Firmware_Re-

Firmware version

vision

Leuze electronic GmbH + Co. KG ODS 9 30

Page 31

Device description

3.4.8

Ending configuration

With IO-Link data storage, the behavior upon ending the configuration settings can be changed in the following ways in the Settings menu.

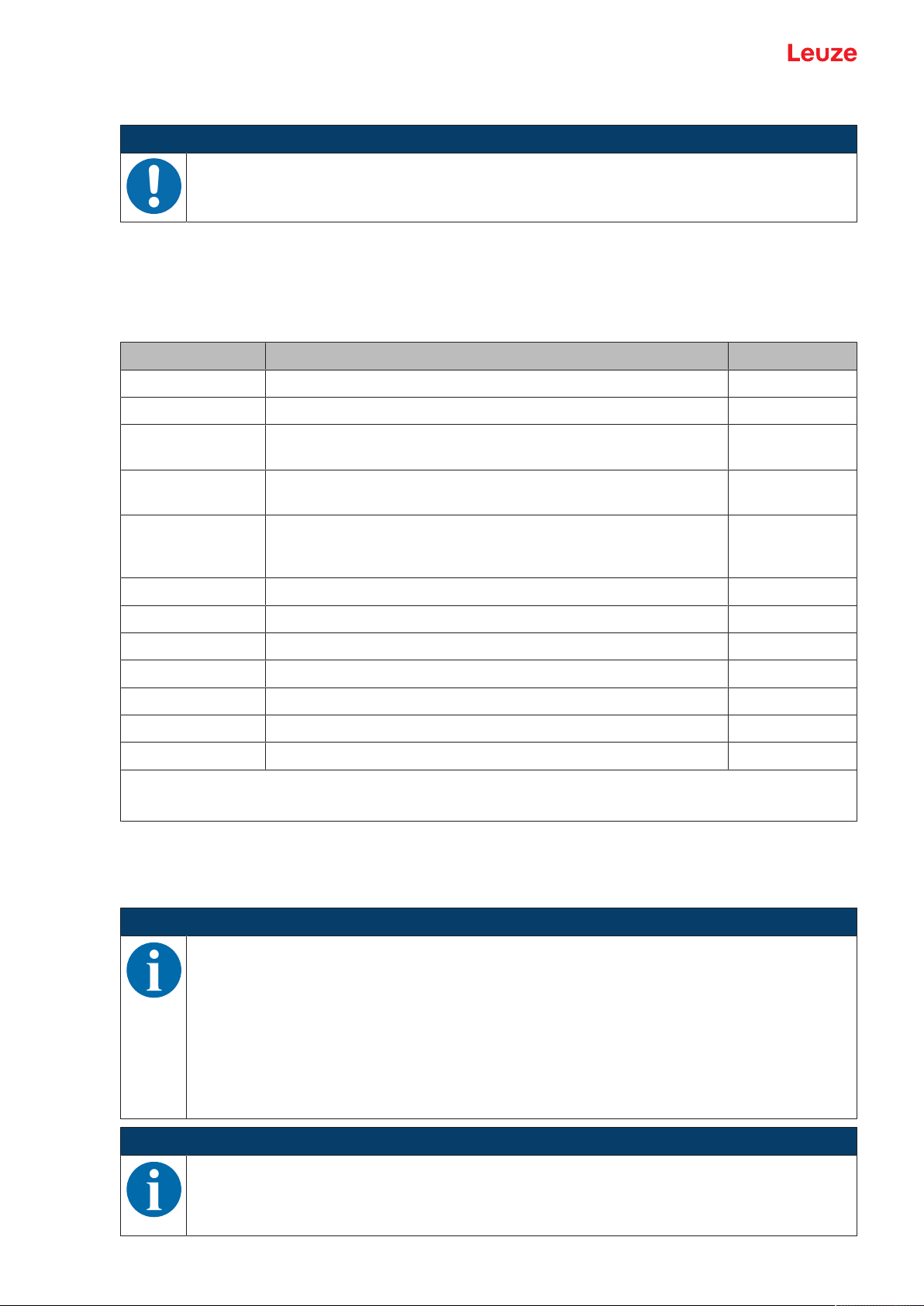

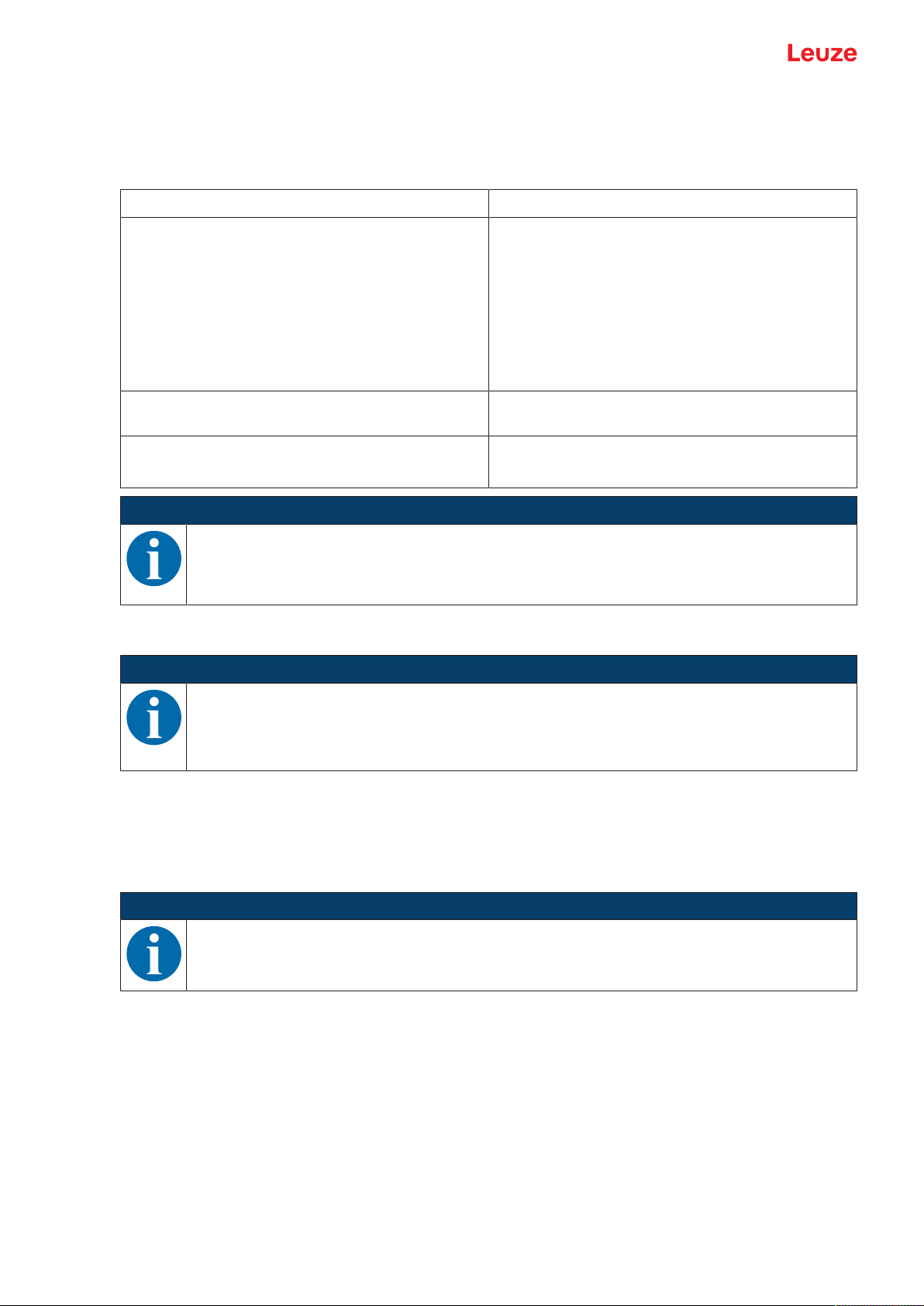

Tab.3.4: Settings > Exit behavior

Menu item Use Display of the menu item

Report to DS

(Report to DS)

Changes in the menu are taken

over in the data memory after

returning to measurement oper-

A change was performed and the data memory

updated.

ation. The DSUpload flag is set.

Only local changes

(only local changes)

The change is only temporary or

local on the device or no data

memory is used. The DSUpload

A change was made only locally on the device.

flag is cleared.

Central storage of configuration data

If the configuration setting is ended with subsequent adoption of the data in the data memory of a connected IO-Link master, the sensor does not need to be newly configured if a device is changed.

The sensor adopts the configuration from the data memory of the connected IO-Link master, provided that

the IO-Link master is capable of doing this and enabled accordingly.

Timeout

If the configuration setting is ended due to a timeout, the previously made changes are always reported by

default to the data memory (Data Storage, DS). If an IO-Link master is connected, the changes are transferred to its data memory. The status of the DSUpload flag is not changed.

If the DSUpload flag is not set and the changes are only stored locally, after reconnection the change is

overwritten by the configuration which is stored in the data memory of the connected IO-Link master.

NOTICE

If the sensor is not operated via an IO-Link master, these settings do not need to be made.

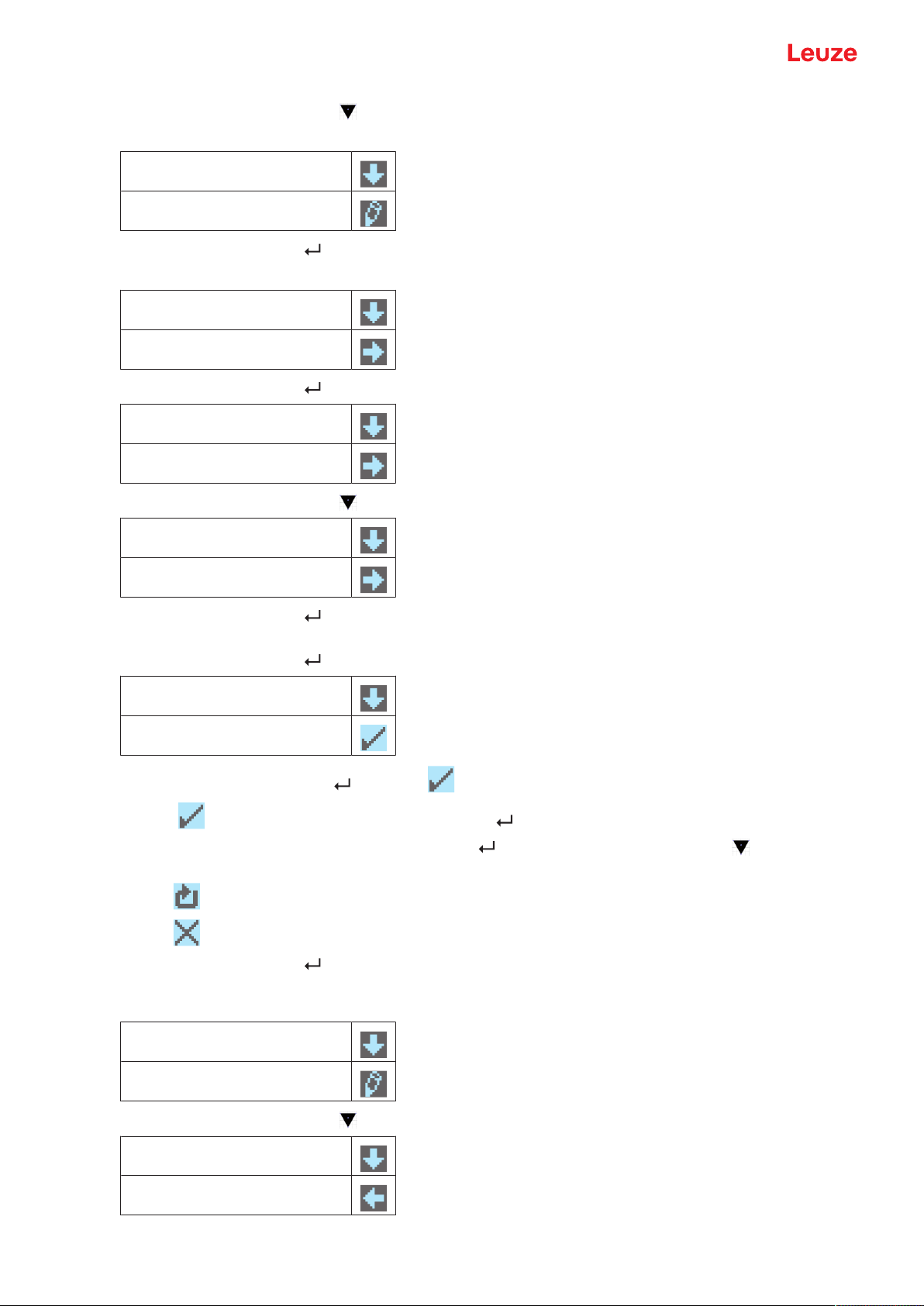

3.5 Configuration example

To illustrate menu operation, the setting of the lower switching point of switching output SSC1 to 100mm is

explained as an example.

Ä In process mode, press a control button to activate the menu display.

Input

Output SSC1

Ä Press the navigation button .

ð The display shows "Output SSC1" in the upper menu line.

Output SSC1

Output

Ä Press the enter button to select Output SSC1.

SSC1 SP1 (dist.)

00250mm

Leuze electronic GmbH + Co. KG ODS 9 31

Page 32

Device description

Ä Press the navigation button once.

ð The display shows "SSC1 SP2 (near)" in the upper menu line.

SSC1 SP2 (near)

00050mm

Ä Press the enter button to set the lower switching point.

ð The first digit of the switching point value is displayed with inverted colors.

SSC1 SP2 (near)

00050mm

Ä Press the enter button twice until the hundreds digit is inverted.

SSC1 SP2 (near).

00050mm

Ä Press the navigation button as many times as necessary to set the desired value “1”.

SSC1 SP2 (near)

00150mm

Ä Press the enter button to accept the set value.

Ä Repeat the setting for digit 5 until the complete value “00100” is set.

Press the enter button to move to the units digit.

SSC1 SP2 (near)

00100mm

After pressing the enter button again, the icon appears in the lower right part of the display.

• The icon indicates that the next time the enter button is pressed, the set value will be accepted.

• You can change the function of the enter button by pressing the navigation button several times.

The following icons are displayed in succession:

• : re-edit value

• : reject value

Ä Press the enter button to accept the set value 00100.

ð "SSC1 SP2 (near)" is displayed inverted in the display.

The newly set value “00100mm”, which is stored in non-volatile memory, appears in the display.

SSC1 SP2 (near)

00100mm

Ä Press the navigation button repeatedly until the←icon appears in the upper menu line.

←

SSC1 SP1 (dist.)

Leuze electronic GmbH + Co. KG ODS 9 32

Page 33

Device description

Ä Press the enter button to access the next-higher menu level.

Output SSC2

Analog output

Ä Press the enter button to exit the menu display and access process mode.

Quick exit

If you do not wish to make any further configuration settings, you can exit the menu via Quick exit and return to process mode.

225mm

NOTICE

The DSUpload upload flag is always set on quick exit. This means that parameter changes are

passed on to the connected IO-Link master.

Ä Press and hold down the enter button for at least 5 s – until the "Exit menu" message appears on

the display.

Ä Confirm with the enter button .

Leuze electronic GmbH + Co. KG ODS 9 33

Page 34

Applications

4 Applications

The laser distance sensor is designed for the following areas of application:

• Distance measurement

• Thickness measurement

• Positioning

• Diameter determination

• Fill level indicator

4.1 Wood width measurement

Fig.4.1: Application example: wood width measurement

Leuze electronic GmbH + Co. KG ODS 9 34

Page 35

Applications

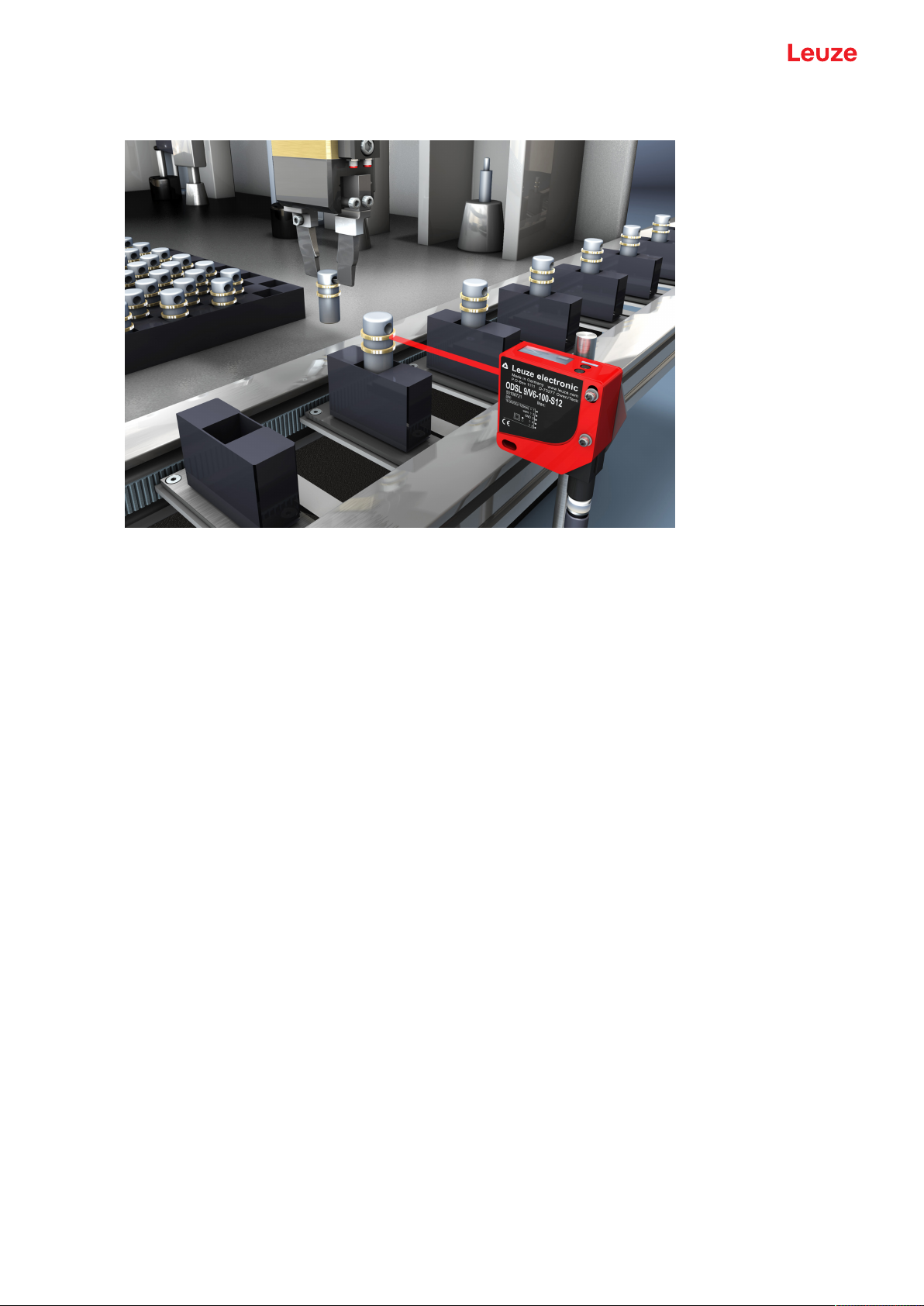

4.2 Assembly inspection

Fig.4.2: Application example: assembly inspection

Leuze electronic GmbH + Co. KG ODS 9 35

Page 36

Mounting

5 Mounting

The sensor can be mounted in the following ways:

• Mount using a mounting system

• BTU300M-D10: mounting on rod Ø 10mm

• BTU300M-D12: mounting on rod Ø 12mm

• BTU300M-D14: mounting on rod Ø 14mm

NOTICE

Observe during mounting!

Ä Make certain that the required environmental conditions (humidity, temperature) are main-

tained.

Ä Make certain that the optics cover of the sensor is not soiled, e.g., by leaking fluids, abrasion

from boxes or residues from packaging material.

Ä When mounting behind a cover: Make certain that the cutout in the cover is at least as large

as the lens cover of the sensor. Correct measurement cannot otherwise be ensured.

5.1 Mounting with mounting system

Mounting with a mounting system is intended for rod mounting. For ordering information, see chapter 13.3

"Other accessories".

Ä Mount the mounting system on the rod (system-side).

Ä Mount the sensor on the mounting system with M4 fastening screws (not included in delivery contents).

Max. tightening torque of the fastening screws: 1.4Nm

Leuze electronic GmbH + Co. KG ODS 9 36

Page 37

Electrical connection

Analog OUT

6 Electrical connection

6.1 Overview

The assignment of the electrical connections is dependent on the type of sensor that is used. The type designation of the sensor is specified on the name plate.

CAUTION

Safety notices!

Ä Before connecting the device, be sure that the supply voltage agrees with the value printed

on the name plate.

Ä Only allow competent persons to perform the electrical connection.

Ä Ensure that the functional earth (FE) is connected correctly.

Fault-free operation is only guaranteed if the functional earth is connected properly.

Ä If faults cannot be rectified, take the sensor out of operation. Protect the sensor from acci-

dentally being started.

NOTICE

Protective Extra Low Voltage (PELV)

Ä The sensor is designed in accordance with protection class III for supply with PELV (protec-

tive extra-low voltage with reliable disconnection).

NOTICE

Ä For all connections (connection cable, interconnection cable, etc.), use only the cables listed

in the accessories (see chapter 13.2 "Accessories – cables and connectors").

Ä Use shielded cables when using the analog interface. You can thereby prevent interference

caused by electromagnetic fields.

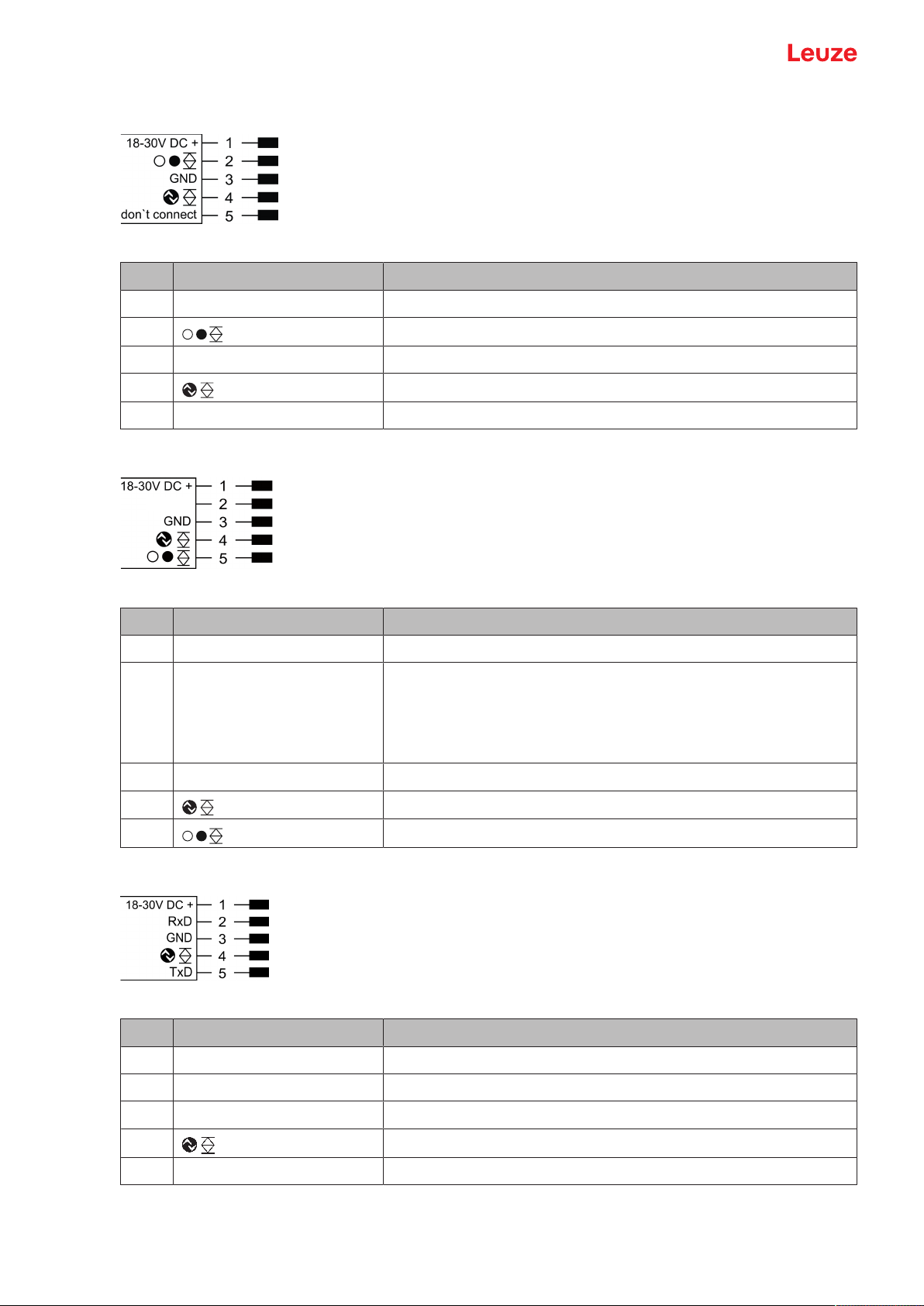

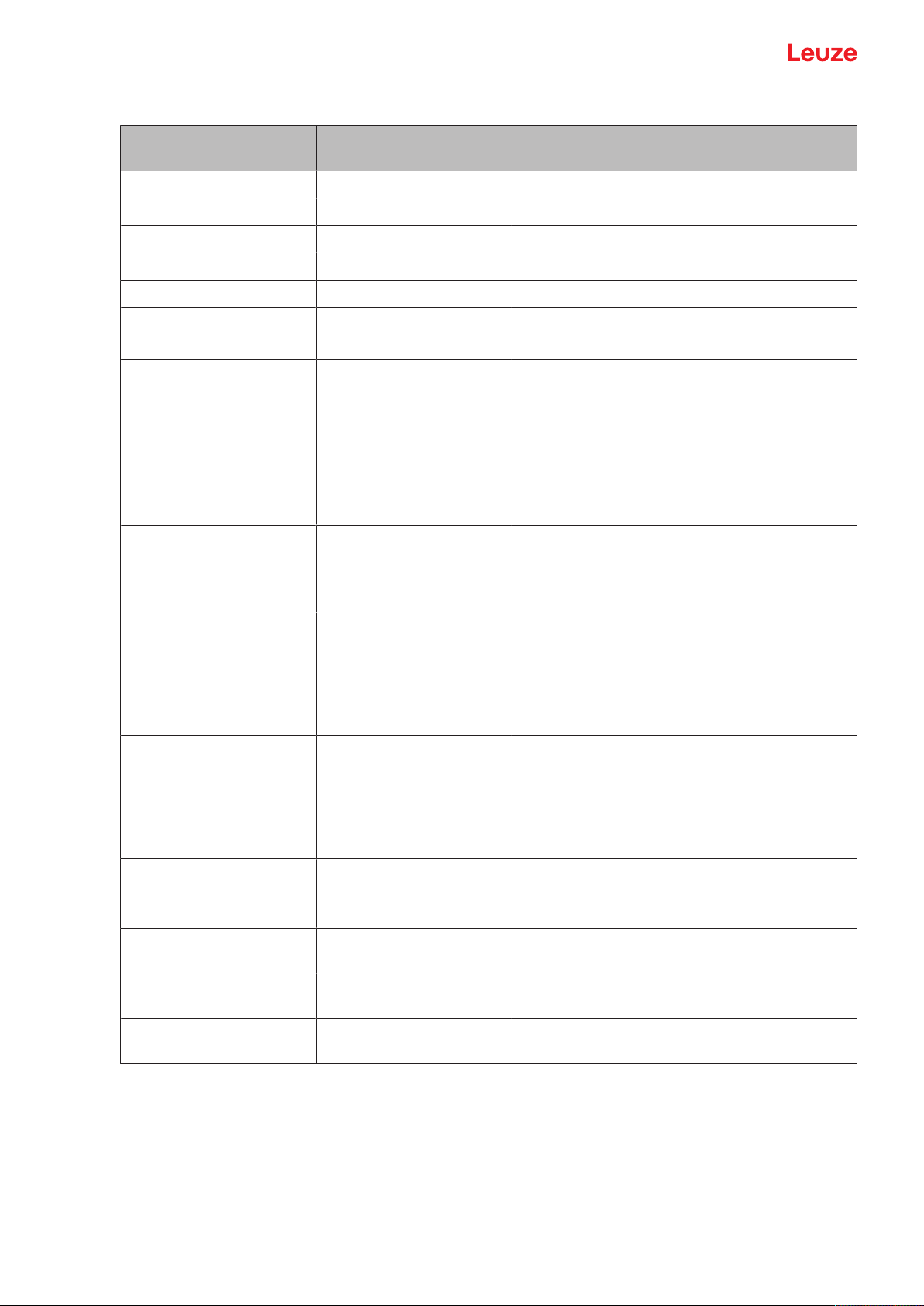

6.2 Pin assignment

Pin assignment ODS9L2.8/LAK-…-M12

Fig.6.1: Pin assignment

Pin Designation Assignment

1 18-30VDC+ Supply voltage

2 Analog OUT Configurable analog output

• Current: 4mA…20mA

• Voltage: 1V…10V, 0V…10V

Factory setting: Current

3 GND Functional earth

4 IO-Link / switching output1, push-pull

5 IN Function of the switching input

Leuze electronic GmbH + Co. KG ODS 9 37

Page 38

Electrical connection

Analog OUT

Pin assignment ODS9L2.8/L6X-…-M12

Fig.6.2: Pin assignment

Pin Designation Assignment

1 18-30VDC+ Supply voltage

2 Switching output2, push-pull

3 GND Functional earth

4 IO-Link / switching output1, push-pull

5 don’t connect don’t connect

Pin assignment ODS9L2.8/LA6-…-M12

Fig.6.3: Pin assignment

Pin Designation Assignment

1 18-30VDC+ Supply voltage

2 Analog OUT Configurable analog output

• Current: 4mA…20mA

• Voltage: 1V…10V, 0V…10V

Factory setting: Current

3 GND Functional earth

4 IO-Link / switching output1, push-pull

5 Switching output2, push-pull

Pin assignment ODS9L2.8/LFH-…-M12

Fig.6.4: Pin assignment

Pin Designation Assignment

1 18-30VDC+ Supply voltage

2 RxD Signal RxD of the RS232 serial interface

3 GND Functional earth

4 IO-Link / switching output1, push-pull

5 TxD Signal TxD of the RS232 serial interface

Leuze electronic GmbH + Co. KG ODS 9 38

Page 39

Electrical connection

Pin assignment ODS9L2.8/LQZ-…-M12

Fig.6.5: Pin assignment

Pin Designation Assignment

1 18-30VDC+ Supply voltage

2 D– Signal D– of the RS485 serial interface

3 GND Functional earth

4 Switching output

5 D+ Signal D+ of the RS485 serial interface

Leuze electronic GmbH + Co. KG ODS 9 39

Page 40

Starting up the device

7 Starting up the device

7.1 Teaching and configuring output functions

7.1.1

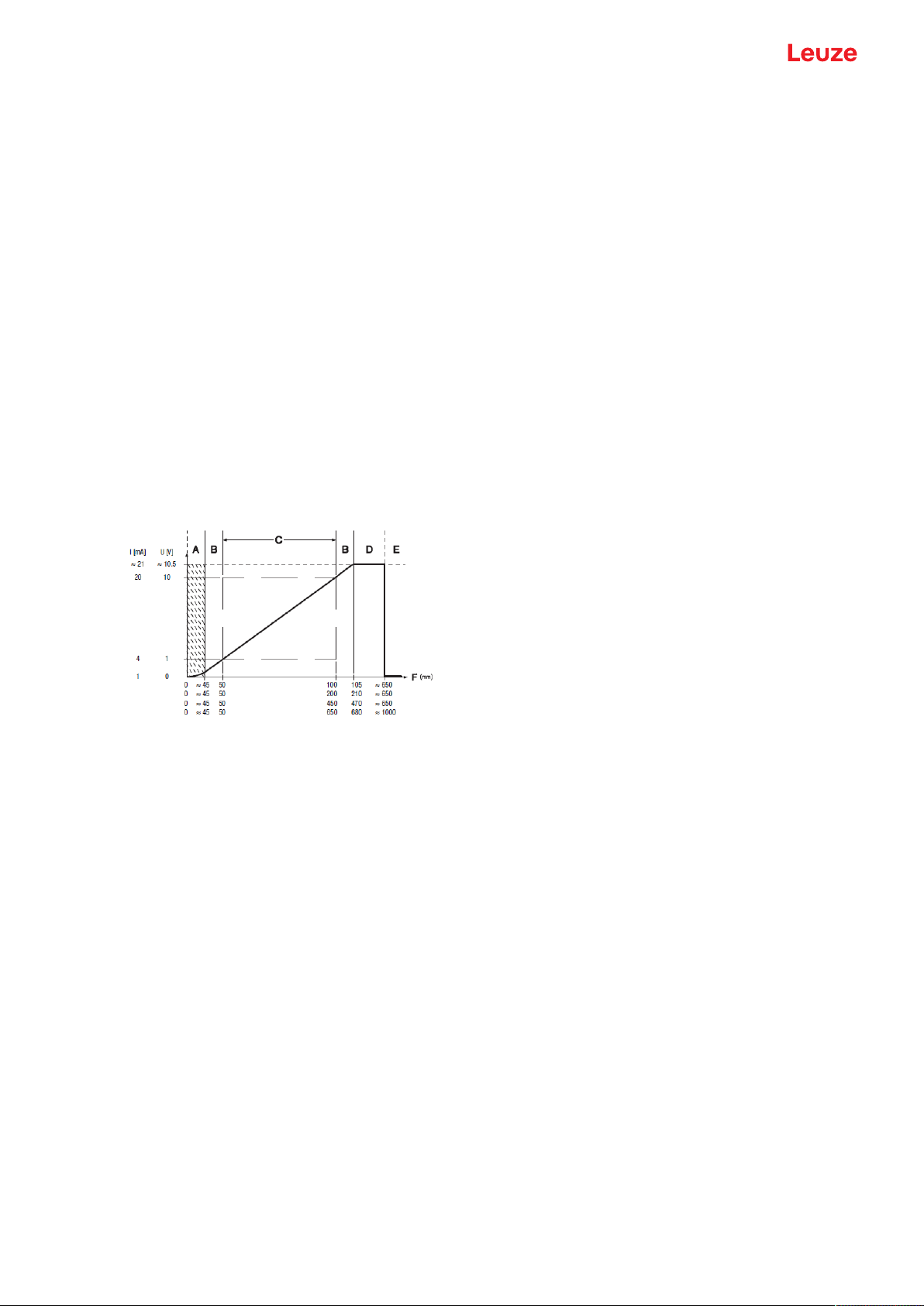

Setting the analog output

The sensors are equipped with an analog output with linear response within the respective measurement

range.

Above and below the measurement range linearity is not obtained. If a signal is present, the output values

can be used to determine whether the measurement range is exceeded or not met.

In order to achieve the highest resolution possible, set the range of the analog output as small as the application allows. The characteristic output curve can be configured as rising or falling, e.g. for fill level applications.

The output can be switched to current or voltage with the following ranges:

• 4…20mA

• 1…10V

• 0…10V

To configure the analog output, the two distance values Position Min. Val. and Position Max. Val. are specified at which the respective minimum or maximum analog value is output.

Measurement range C is assigned ex works (see figure), e.g., 50…100mm for device types -100.

A Area not defined

B Linearity not defined

C Measurement range

D Object present

E No object detected (characteristic curve behavior configurable via IO-Link)

F Measurement distance

Fig.7.1: Characteristic curve of analog output ODS9L2.8/LA…-M12

Setting the analog output

You can set the characteristic output curve for the analog output as follows:

• Directly changing the parameters:

• On the device via the OLED display and the control buttons (see chapter 3.4 "Configuration / menu

structure")

• Via the SensorStudio configuration software (see chapter 8 "Connecting to a PC – SensorStudio").

• Teach-in / teach:

• Via IO-Link (see chapter 7.1.5 "Teaching the output functions via the IO-Link system commands"),

especially using the SensorStudio configuration software (see chapter 8 "Connecting to a PC –

SensorStudio").

• Via the multifunction input with set Teach input function (see chapter 7.1.4 "Teaching the output

functions via the multifunction input").

Leuze electronic GmbH + Co. KG ODS 9 40

Page 41

Starting up the device

OFF

ON

OFF

ON

1

2

4

3

3

7.1.2

Setting the switching outputs

All sensors are equipped with at least one SSC1 switching output. LA6 model sensors are provided with a

second SSC2 switching output.

For each switching output you can configure the following parameters:

• Upper and lower switching point

• Switching hysteresis

• Switching logic

• Light switching (high active)

• Dark switching (low active)

• Switching point mode

NOTICE

The output state in the hysteresis area is not uniquely defined!

The output state in the hysteresis area is dependent on the previous situation.

If the output in the hysteresis area is permanently set to high active, a short detection failure (no

signal, e.g., due to a target that is marginally dark) results in a change to permanently low active

(dark switching).

1 Light switching

2 Dark switching

3 Hysteresis

4 Measurement distance

Fig.7.2: Switching output configuration

The switching outputs can be set via the OLED display and the control buttons (see chapter 3.5 "Configuration example"), but also via the multifunction input on pin 5 and via IO-Link system commands.

NOTICE

For sensor models with multifunction input, there is only one physically present switching output

that can be taught in.

Leuze electronic GmbH + Co. KG ODS 9 41

Page 42

Starting up the device

1

3

2

3

4

5

6

1

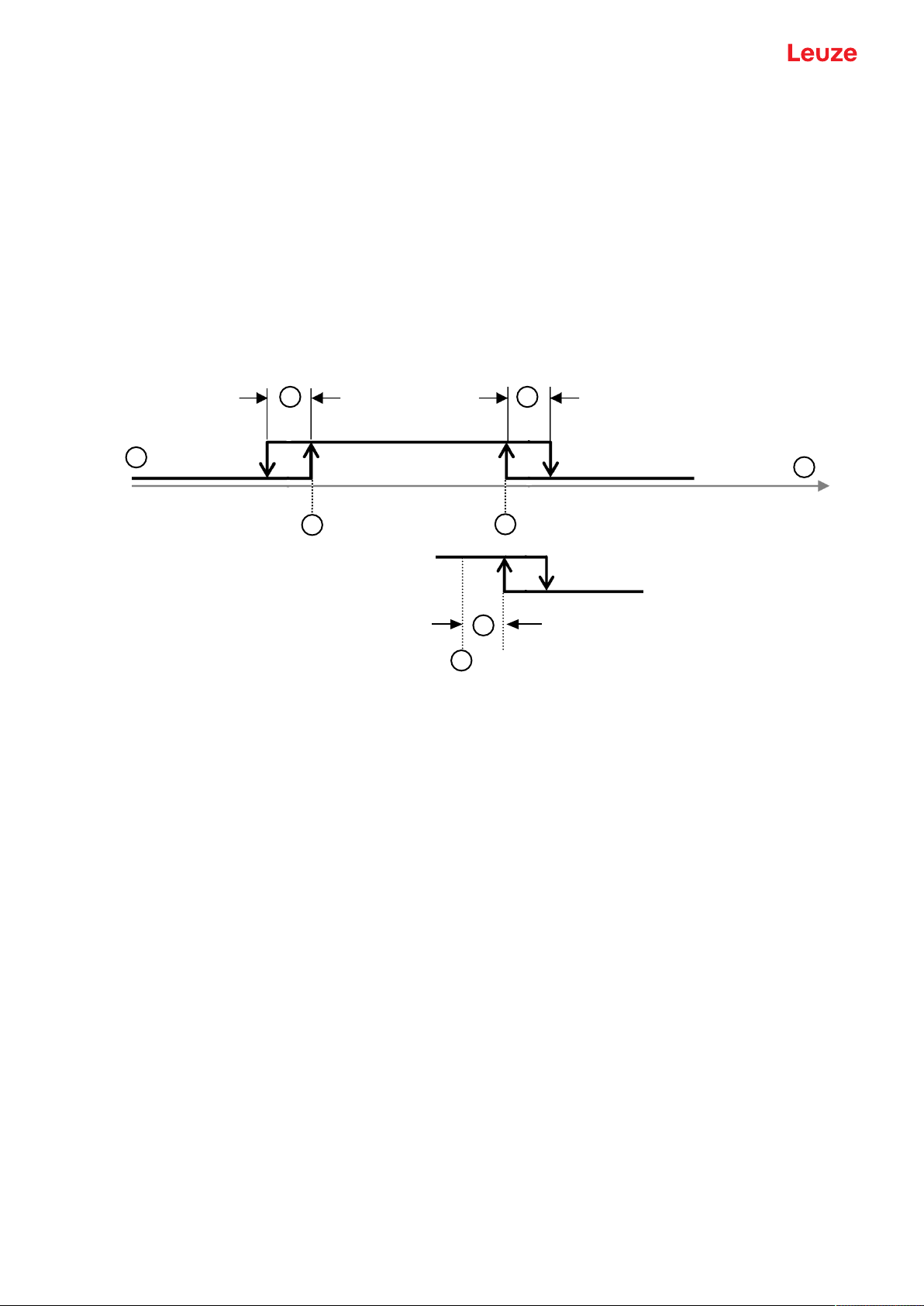

Configuring switching point modes

The following switching point modes can also be configured. These are structured according to the switching profiles of the Smart Sensor Profile specification.

• SinglePoint Object mode (SinglePtObj): single switching point taught on an object

• Window: window mode

• TwoPoint: two-point mode

• SinglePoint Background mode (SinglePtBG): single switching point taught against a background

SinglePoint Object mode (SinglePtObj)

When teaching setpoint SP1 before of after, the object (Obj) is targeted, i.e., with SP1, the SSC is still active. The SSC becomes inactive only after SP1.

1 Setpoint SP1

2 Measurement range minimum

3 Hysteresis

4 Signal response

5 Sensor/SSC

6 Reserve if >0

Fig.7.3: SinglePoint Object switching point mode

• Only setpoint SP1 (not SP2) is used for calculating the switching edges. The lower switching edges are

always at the lower limit value.

• Reserve and hysteresis run from the upper switching point into the distance, so that the switching output has reliably (i.e., with reserve) switched on after the teach event (provided it is light switching high

active).

Leuze electronic GmbH + Co. KG ODS 9 42

Page 43

Starting up the device

1

3

4

3

2

5

6

7

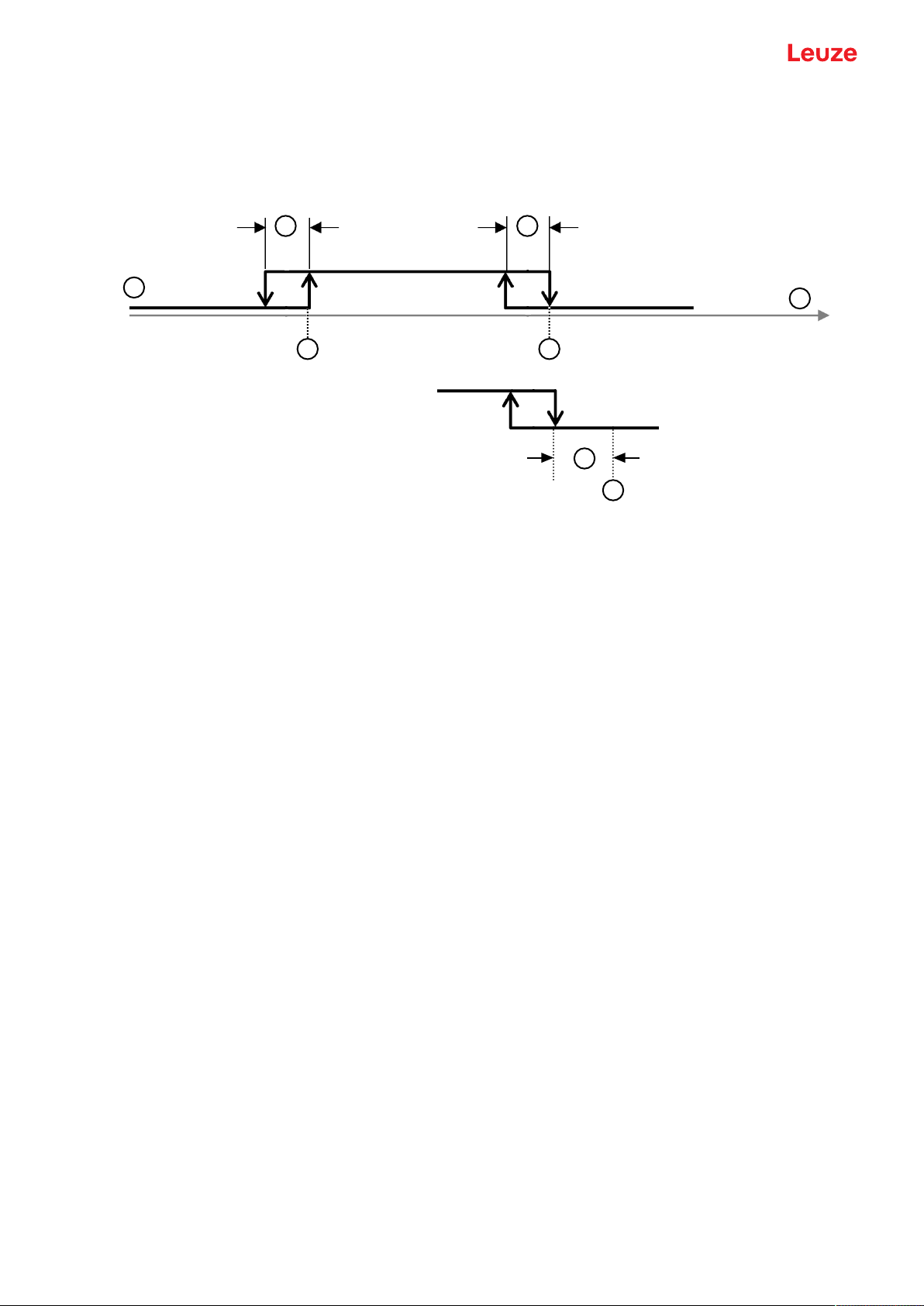

Window – window mode

Teach point is midway between the equidistantly shifted setpoints S2 (near) and SP1 (far)

1 Setpoint SP1 (far)

2 Setpoint SP2 (near)

3 Hysteresis

4 Teach point

5 Sensor/SSC

6 Signal response

7 Window

Fig.7.4: Switching point mode window

• Hysteresis runs to the outside.

• Reserve is not used.

Leuze electronic GmbH + Co. KG ODS 9 43

Page 44

Starting up the device

12

3

5

6

7

4

TwoPoint – two-point mode

• Closer than setpoint SP2, the output is set to high active (as with the Single Point modes).

• The "far" hysteresis area lies between setpoint SP2 and setpoint SP1; the Hysteresis parameter is not

used here.

• After setpoint SP1, the output is set to low active.

1 Setpoint SP1

2 Setpoint SP2

3 Hysteresis "near"

4 Hysteresis "far"

5 Sensor/SSC

6 Signal response

7 Measurement range minimum

Fig.7.5: TwoPoint switching point mode

NOTICE

The Hysteresis parameter is used for the switch-on/switch-off edges at the start of the measurement range.

Ä If setpoint SP2 is too close to the switch-on edge, the assigned switching edge is shifted into

the distance by the distance of the Hysteresis parameter.

Ä If, afterwards, setpoint SP1 is closer than the shifted edge, the edge assigned to setpoint

SP1 is placed on the shifted SP2 edge. The two far switching edges then decrease together.

NOTICE

The output state in the hysteresis area is not uniquely defined!

The output state in the hysteresis area is dependent on the previous situation.

If the output in the hysteresis area is permanently set to high active, a short detection failure (no

signal, e.g., due to a target that is marginally dark) results in a change to permanently low active

(dark switching).

Leuze electronic GmbH + Co. KG ODS 9 44

Page 45

Starting up the device

12

3 3

4

5

1

6

SinglePoint Background mode (SinglePtBG)

When teaching setpoint SP1 before of after, the background (BG) is targeted, i.e., with setpoint SP1, the

SSC must no longer be active. The SSC is only active before setpoint SP1.

1 Setpoint SP1

2 Measurement range minimum

3 Hysteresis

4 Signal response

5 Sensor/SSC

6 Reserve if >0

Fig.7.6: SinglePoint BG switching point mode

• Only setpoint SP1 (not SP2) is used for calculating the switching edges. The lower switching edges are

always at the lower limit value.

• Reserve and hysteresis run from the upper switching point into the near range, so that the switching

output has reliably (i.e., with reserve) switched off after the teach event (provided it is light switching

high active).

Leuze electronic GmbH + Co. KG ODS 9 45

Page 46

Starting up the device

0V

T

t

+24V

7.1.3

Teach-in / teach

Teaching offers the possibility to adjust certain parameters based on the current measurement situation.

Focus here is primarily on settings that affect the output functions, i.e., analog output and the switching output(s).

The teaching action is triggered in the following ways:

• Via the multifunction input when setting the input function to Teach (see chapter 7.1.4 "Teaching the

output functions via the multifunction input")

• Via IO-Link system commands (see chapter 7.1.5 "Teaching the output functions via the IO-Link system commands")

• Special teach via the device menu (OLED display and control buttons)

When completed, each successful teach returns a so-called teach point (TP), which is formed by averaging

multiple individual measurements.

• Prerequisite for successfully teaching is a minimum number of valid measurement values. Objects that

are marginally dark and/or distant objects can increase the teach time.

• The teachable areas are limited by model.

• A teach point may only be located within the measurement range described in the table in order for an

assignment to the respective, likewise limited parameters to be possible.

Device Outside of the

operating

range (-)

(Out of Range

(-))

(measurement value shown on the display)

Operating range [mm]

Outside of the

operating range

(+)

(Out of

Range(+))

7.1.4

Limited accuracy

…-100-… Directly under-

…-200-… 47.00 50.00 200.00 220.00

neath

47.00 50.00 100.00 110.00 Directly above

Measuring range Limited

accuracy

…-450-… 47.0 50.0 450.0 500.00

…-650-… 47.0 50.0 650.0 700.00

Teaching the output functions via the multifunction input

NOTICE

The information in this chapter only applies for devices that are equipped with a multifunction input on pin 5 (ODS9…/LAK-…).

To teach, a teach signal is applied to the multifunction input (pin 5). The duration of the teach signal (low

level on the teach input) determines the teach-in function.

T Duration of the teach signal

Fig.7.7: Plot of the teach signal

To teach, proceed as follows:

Ä In the Configuration menu, activate the input function Teach (Default)

Input > Input mode > Teach

Leuze electronic GmbH + Co. KG ODS 9 46

Page 47

Starting up the device

Ä Position the measurement object at the desired distance.

NOTICE

The teachable area must be located within the measurement range of the sensor.

Ä Apply the teach signal to the multifunction input (pin 5).

• The duration T of the low level at the teach input determines the teach-in function.

• The teach functions assigned to the time frames are preset and can be queried via IO-Link.

Tab.7.1: Default assignment of the teach functions

Duration T [ms] Teach function Function no.

20…80 Object teach of switching output SSC1 14

120…180 Window teach (Window) of switching output SSC1 15

220…280 Analog teach of the distance value for the smallest analog value

6

(4mA, 1V, 0V) on pin 2

320…380 Analog teach of the distance value for the largest analog value

7

(20mA, 10V) on pin 2

420…480 Preset-Offset calculation:

8

determination of an offset value so that the preset Preset value is

output as measurement value.

520…580 Background-Teach_SSC1 16

620…680 Setpoint1-Teach SP1_SSC1 12

720…780 Setpoint2-Teach SP2_SSC1 13

820…880 Alternative setpoint1-Teach SP1a_SSC1 17

920…980 Logic of SSC1 to 0 "light switching" Light_SSC1 19

1020…1080 Logic of SSC1 to 1 "dark switching" Dark_SSC1 20

1120…1180 Toggle logic of SSC1 "light/dark switching" 18

Corresponding IO-Link object:

Index 140, teach level assignment (Wire Function Array)

Ä Detection and averaging of measurement values for forming the teach point TP begins with the rising

edge of the input signal.

The parameter or parameters assigned to the time frame for the teach signal is/are updated based on

the teach point.