Page 1

LSIS 472i

Smart camera for compartment fine positioning

EN 2015/05 - 50129066

We reserve the right to

make technical changes

Original operating instructions

Page 2

© 2015

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

Leuze electronic LSIS 472i 2

Page 3

1 About this document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Used symbols and signal words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Foreseeable misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Competent persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Exemption of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Device overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.2 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.4 Device model with heating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Connection technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Indicators and operational controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3.1 LED indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.2 Control buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Functionality of the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Check programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Diagnostics – image transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4 Process sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Mounting with BT 56 mounting device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 Mounting with BT 59 mounting device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.4 BPS mounting with M4 fastening screws. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.2 PWR (supply voltage and switching inputs IO1 … IO4) . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.3 BUS OUT (RS 232 and switching outputs IO5 … IO8) . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.4 SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.1 Commissioning the device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.2 Mechanically aligning the device via the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.3 Teaching-in the position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.4 Parameter enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9 Extended configuration – Leuze electronic webConfig tool . . . . . . . . . . . . . . . . 29

9.1 Establishing an Ethernet connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.2 Start webConfig tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.3 Short description of the webConfig tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.3.1 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Leuze electronic LSIS 472i 3

Page 4

9.3.2 Configuration via the webConfig tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.3.3 Selecting the check program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.3.4 Configure compartment fine positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.3.5 Calibrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.3.6 Configuring image acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.3.7 Configuring the BLOB analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.3.8 Configuring the measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.3.9 Defining changeover of the check programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.3.10 Configuring the digital switching inputs/outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.3.11 Assigning digital switching outputs the measurement values . . . . . . . . . . . . . . . . . . . . 39

9.3.12 Activating display of the target/actual deviation in the display. . . . . . . . . . . . . . . . . . . . 41

9.3.13 Configuring the FTP output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.3.14 Configuring the Ethernet output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11 Care, maintenance and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

11.1 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

11.2 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

11.3 Disposing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

12 Service and support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

12.1 What to do should servicing be required? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

13 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

13.1 General specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

13.2 Dimensioned drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

14 Ordering information and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

14.1 Type overview LSIS 472i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

14.2 Cables-Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

14.3 Other accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

15 EC Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Leuze electronic LSIS 472i 4

Page 5

1 About this document

1.1 Used symbols and signal words

Table 1.1: Warning symbols and signal words

Symbol indicating dangers to persons

NOTICE Signal word for property damage

Indicates dangers that may result in property damage if the measures for danger avoidance are not followed.

Table 1.2: Other symbols

Symbol for tips

Text passages with this symbol provide you with further information.

About this document

Table 1.3: Terms and abbreviations

BLOB Binary Large Object

EN European standard

FE Functional earth

FOV Field of View of the smart camera

IO or I/O Input/Output

MAC address Media Access Control address; hardware address of a device in the network

PELV Protective Extra-Low Voltage; protective extra-low voltage with reliable discon-

HBS High-bay storage device

ROI Region of Interest; capture range of the smart camera

UL Underwriters Laboratories

Symbols for action steps

Text passages with this symbol instruct you to perform actions.

Hole or reflector for positioning

nection

Leuze electronic LSIS 472i 5

Page 6

2 Safety

The smart camera of the LSIS 472i series was developed, manufactured and tested in accordance with

the applicable safety standards. It corresponds to the state of the art. The LSIS 472i smart camera without

device heating is “UL LISTED” according to American and Canadian safety standards, i.e., satisfies the

requirements of Underwriters Laboratories Inc. (UL).

The variant with device heating is being prepared.

2.1 Intended use

The LSIS 472i smart camera for compartment fine positioning is designed for optical, contactless fine positioning of high-bay storage devices in conveyor and storage systems.

Positioning is performed using markings (hole or reflector) in the crossbeams.

NOTICE

Comply with conditions and regulations!

Observe the locally applicable legal regulations and the rules of the employer's liability insurance asso-

ciation.

2.2 Foreseeable misuse

Any use other than that defined under “Intended use” or which goes beyond that use is considered

improper use.

Safety

In particular, use of the device is not permitted in the following cases:

• Rooms with explosive atmospheres

• Circuits relevant to safety

• operation for medical purposes

NOTICE

Do not modify or otherwise interfere with the device.

Do not carry out modifications or otherwise interfere with the device.

The device must not be tampered with and must not be changed in any way.

The device must not be opened. There are no user-serviceable parts inside.

Repairs must only be performed by Leuze electronic GmbH + Co. KG.

2.3 Competent persons

Connection, mounting, commissioning and adjustment of the device must only be carried out by competent

persons.

Prerequisites for competent persons:

• They have a suitable technical education.

• They are familiar with the rules and regulations for occupational safety and safety at work.

• They are familiar with the technical description of the device.

• They have been instructed by the responsible person on the mounting and operation of the device.

Certified electricians

Electrical work must be carried out by a certified electrician.

Due to their technical training, knowledge and experience as well as their familiarity with relevant stan-

dards and regulations, certified electricians are able to perform work on electrical systems and independently detect possible dangers.

In Germany, certified electricians must fulfill the requirements of accident-prevention regulations BGV A3

(e.g. electrician foreman). In other countries, there are respective regulations that must be observed.

Leuze electronic LSIS 472i 6

Page 7

2.4 Exemption of liability

Leuze electronic GmbH + Co. KG is not liable in the following cases:

• The device is not being used properly.

• Reasonably foreseeable misuse is not taken into account.

• Mounting and electrical connection are not properly performed.

• Changes (e.g., constructional) are made to the device.

Safety

Leuze electronic LSIS 472i 7

Page 8

3 Device description

3.1 Device overview

3.1.1 General information

Device description

The LSIS 472i smart camera facilitates

and storage systems.

• Positioning is designed for a single- or double-deep pallet high-bay warehouse (

).

Far

• The device detects circular holes or reflectors in crossbeams in the rack construction and determines

the position deviation in the X- and Y-direction relative to the target position.

• The position deviation is output to the control via four digital outputs or via the interface.

• The device can be operated and configured by means of the integrated webConfig tool via the Ether-

net service interface.

The device consists of the following components:

•Camera

• Display and control panel

• Infrared lighting unit

• Evaluation unit with the following interfaces:

• Digital I/O

• Ethernet

•RS 232

The device can optionally be delivered with integrated heater.

fast and simple positioning of high-bay storage devices in conveyor

Rack Near, Rack

Leuze electronic LSIS 472i 8

Page 9

Device description

1

2

3

5

4

1 Display and control panel

2 Camera and lighting unit

3 M4 mounting thread

4 Electrical connections

5 Fastening groove

Figure 3.1: Device construction

Markings

The smart camera detects the following markings:

• Hole: dark marking on light background

• Reflector: light marking on dark background

Which markings (hole or reflector) need to be present in the crossbeam of the rack is dependent on the

working distance and the crossbeam:

Rack Near

•

•

Rack Far

3.1.2 Performance characteristics

: compartment fine positioning on hole or reflector

: compartment fine positioning on reflector

The most important performance characteristics of the smart camera:

• Positioning accuracy up to ± 2 mm

• Reading distance 250 mm to 1900 mm

• Integrated IR illumination (850 nm infrared LED)

• Integrated display with control panel for alignment and for fast teaching of the position marking (hole

or reflector).

• Measurement value output:

• 4 digital outputs

• Ethernet

Leuze electronic LSIS 472i 9

Page 10

• Optionally via MA 2xxi modular connection unit

3

2

1

• Interfaces:

• RS 232 and Ethernet TCP/IP

• PROFINET, PROFIBUS, CANopen, DeviceNet and EtherCat via MA 2xxi modular connection unit

• Alignment via display and webConfig tool

• Diagnostics in Process mode through image transfer via FTP transfer

• Optional model with heating for use to -35 °C

3.1.3 Accessories

Device description

Special accessories are available fo

smart camera:

• Ready-made connection and interconnection cables for M12 connectors

• Mounting devices for precise mounting

• Reflectors for

Rack Near

3.1.4 Device model with heating

The device is optionally available as a model with integrated heating

installed ex works.

The heating consists of two parts:

• Optics glass heating

• Housing heater

Features of the integrated heating:

• Extends the application range to -35 °C

• Supply voltage: 24 VDC ± 20 %

• Required conductor cross-section for the power supply: At least 0.75 mm

Thus, it is not possible to use ready-made cables.

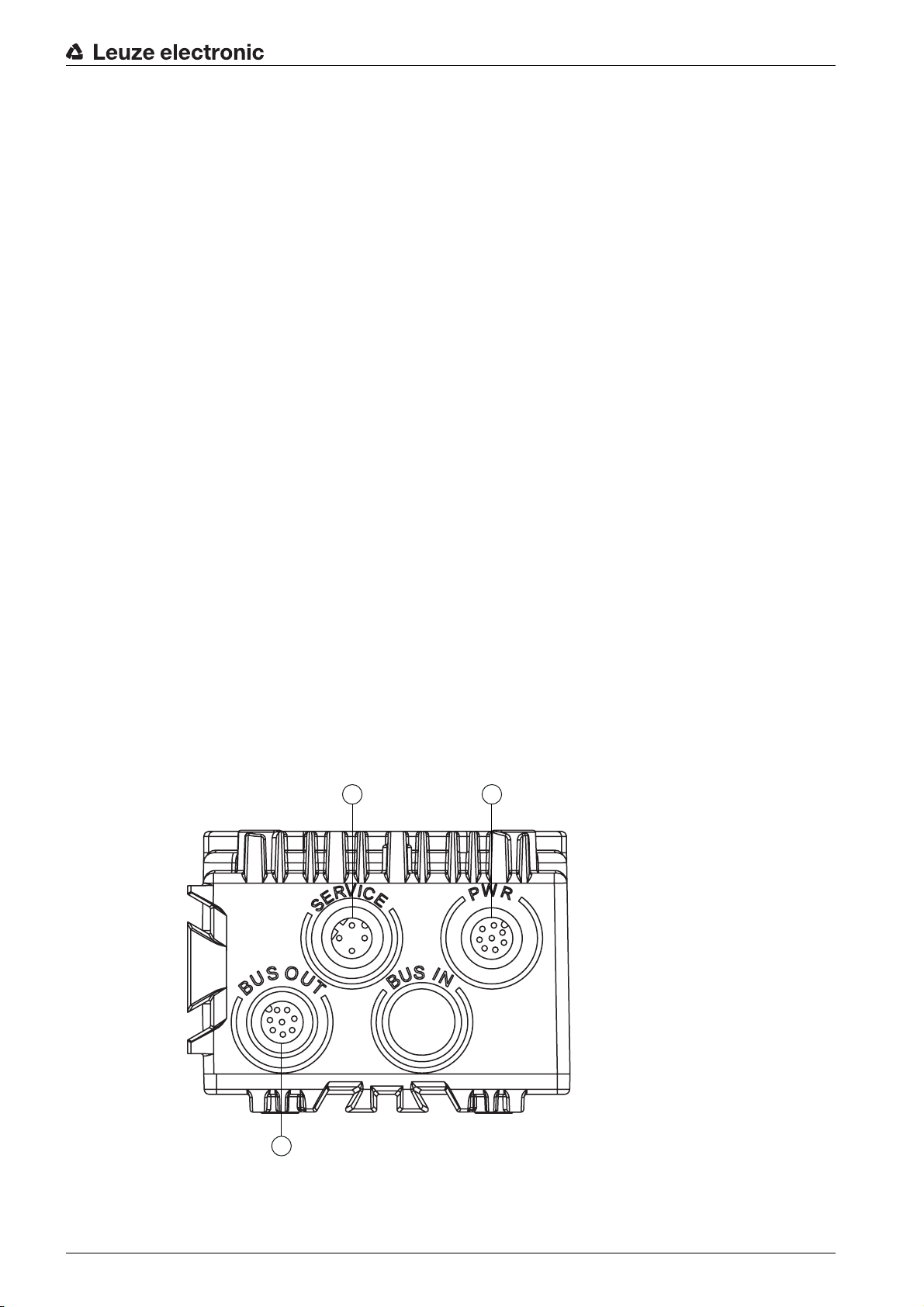

3.2 Connection technology

The device is connected using variously coded M12 connectors.

r the smart camera. The accessories are optimally matched to the

and

Rack Far

compartment depths

. In this case, heating is permanently

2

1 SERVICE: host and service interface (Ethernet); M12 socket (D-coded)

2 PWR: supply voltage (18 V … 30 VDC), IO1 … IO4; M12 plug (A-coded)

3 BUS OUT: RS 232 interface, IO5 … IO8; M12 socket (A-coded)

Figure 3.2: Electrical connections

Leuze electronic LSIS 472i 10

Page 11

Ready-made cables are available for all connections; see chapter 14.2 "Cables-Accessories".

2

1

3

4

5

6

NOTICE

Shielding connection

The shielding connection is done via the M12 connector housing

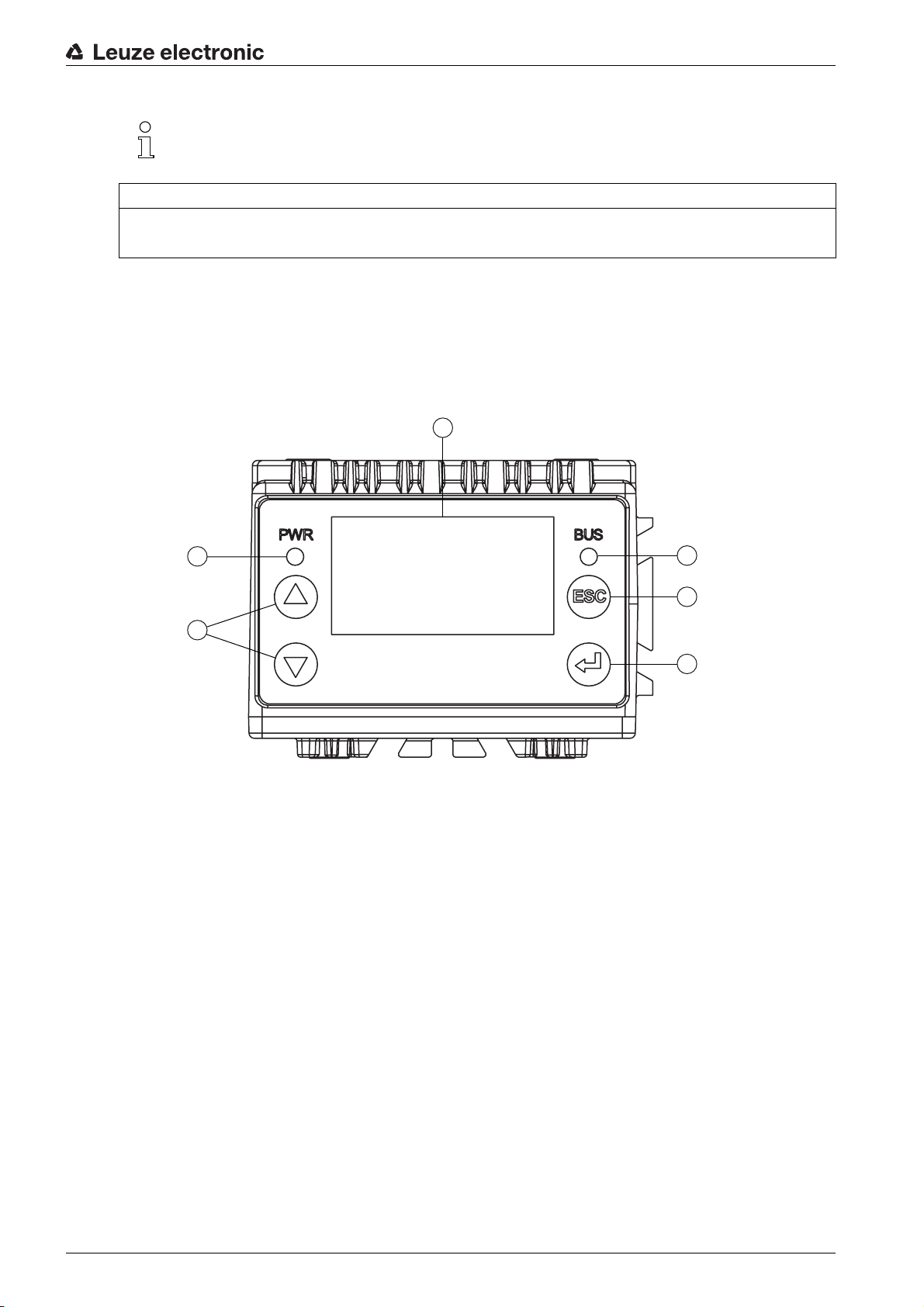

3.3 Indicators and operational controls

The device is equipped with the following indicators and operational controls:

• Two LED indicators

• Four control buttons

• Monochromatic display

Device description

1LED PWR

2 Navigation buttons

3LED BUS

4 Escape button

5 Enter button

6 Display

Figure 3.3: Indicators and operational controls

Leuze electronic LSIS 472i 11

Page 12

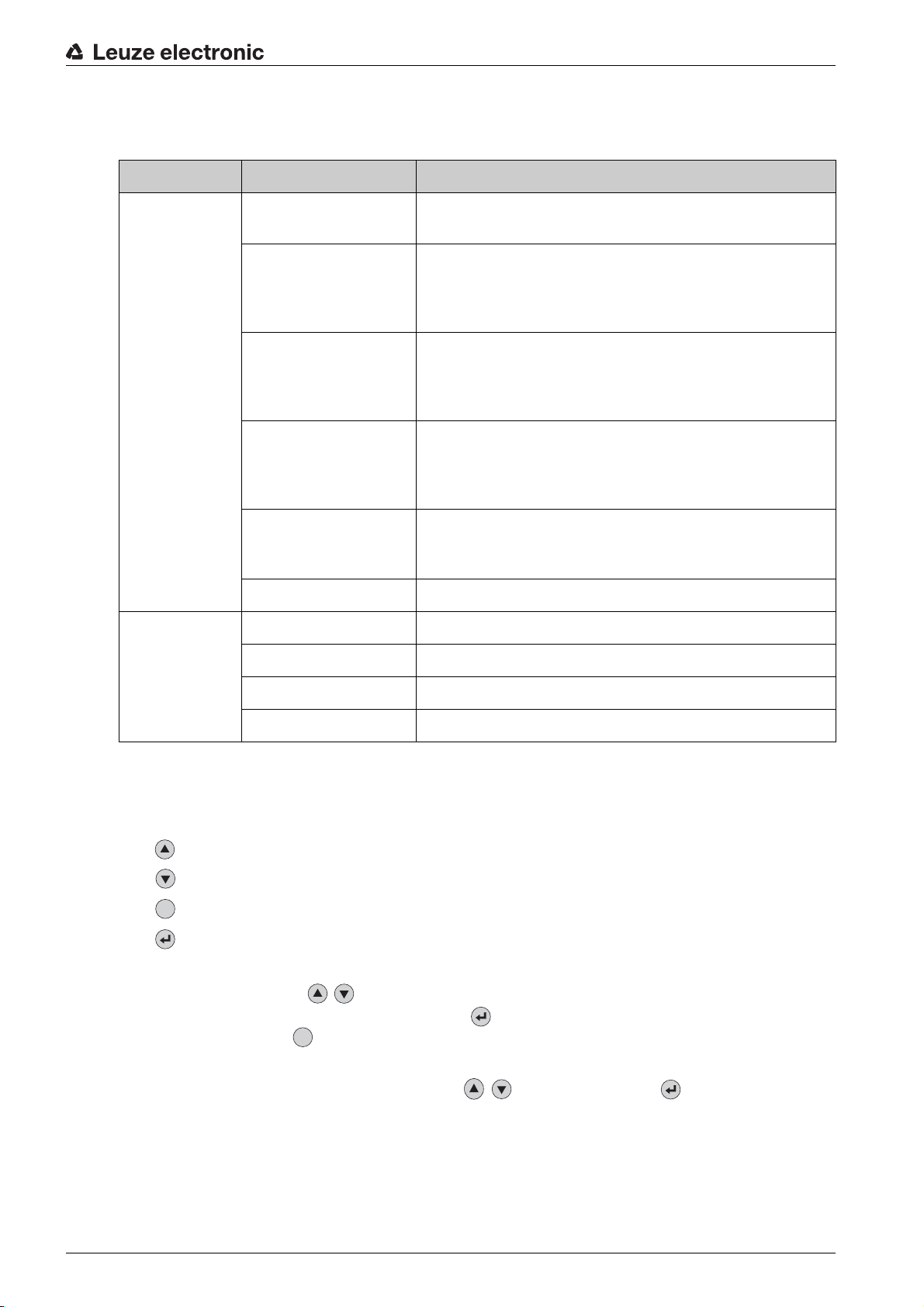

3.3.1 LED indicators

ESC

Table 3.1: Meaning of the LED indicators

LED Color, state Description

Device description

LED

PWR

LED

BUS

Off Device is switched off

• no supply voltage

Green, flashing Device is being initialized

• Supply voltage connected

• Self test running

• Initialization running

Green, continuous light Process mode

• Initialization finished

• Self test successfully finished

• Position display activated

Orange, continuous

light

Service mode

• Alignment via display

• Configuration via Ethernet service interface

• Configuration via the webConfig tool

Red, flashing Warning set

• Inspection mode

• Temporary operating fault

Red, continuous light Device error

Off No supply voltage

Green, flashing Bus initialization, a pulse

3.3.2 Control buttons

The display is controlled via the control buttons. You can call up var

control buttons (e.g., the IP address of the device) or make adjustments in the application; e.g., teach-in.

• - Scrolling through functions (upwards)

• - Scrolling through functions (downwards)

• – Escape button: exit the menu item, move up one menu level

• – Enter button: select function, confirm/enter value

Navigating within the menus

Use the navigation buttons to move through the menu.

Activate the desired selection with the enter button .

Press the escape button to move up one menu level.

Selecting options

Set the desired option with the navigation buttons and the enter button .

3.3.3 Display

Green, continuous light Device ready for communication

Red, flashing Communication error

ious pieces of information via the

ESC

Display functions

The following functions can be displayed and activated in the display:

• Device information

Leuze electronic LSIS 472i 12

Page 13

• Device type

1

SW:

•

•

•

• Status displays

• Status display of the switching inputs/outputs

• Display of warnings and errors

• Status information for the device interfaces

• Target/actual position deviation for X- and Y-coordinates in mm

•Statistics

Statistics data for the smart camera:

•

•

•

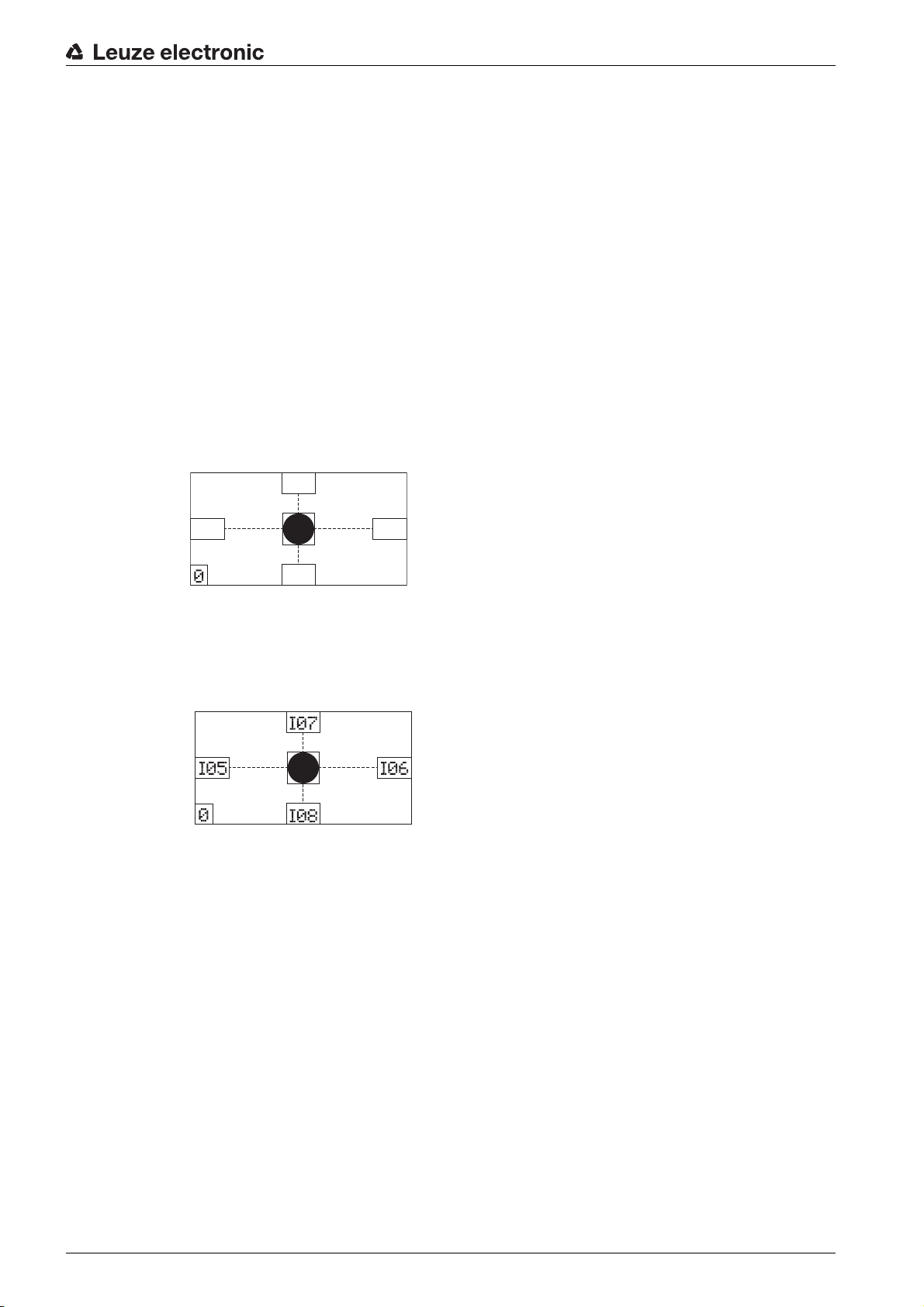

• Position display of the marking (hole or reflector)

Software version

HW:

Hardware version

SN:

Serial number

Tested

Number of check program runs since the last time the counter was reset

OK

Number of successful check program runs

NOK

Number of unsuccessful check program runs

Device description

1 Actual position of the marking within the capture range

Figure 3.4: Position display

• Parameter

•

Parameter handling

Lock and enable parameter entry on the display

Define password for enabling parameter entry

Reset parameters to factory settings

Display settings

•

Rotate the display 180°

Only possible with enabled parameter entry

Program selection

•

Activation of the check program via the display for compartment fine positioning:

Rack Far

•

Ethernet

Configuration of the host and service interface

• Language

Selection of the language used in the display:

German, English, Spanish, French, Italian

•Service

•

Status messages

Only for service purposes by Leuze electronic

Commissioning

•

Selection of the check program and position display for alignment; see chapter 8 "Commissioning"

Teaching-in of the position (teach); see chapter 8.3 "Teaching-in the position"

Rack Near

or

In Service mode, the device is decoupled from Process mode. Triggering via the switching inputs

Leuze electronic LSIS 472i 13

is not possible and the digital switching outputs are not set.

Page 14

Device description

Display during device start-up

During device start-up, a start-up display first appears which is briefly followed by the display with the

version information.

After the device starts up, the display shows the position display by default.

Leuze electronic LSIS 472i 14

Page 15

4 Functions

4.1 Functionality of the device

Compartment fine positioning is used for the detection of so-called hole positions (hole or reflector) that

are set into crossbeams of the high rack.

Functions

• Two different hole positions can be detected,

A check program is stored on the device for each detection position.

The distance between the rack profiles and the lens cover of the device can be specified for each

hole position.

• The control uses a signal that is constantly applied at digital switching inputs IO2 and IO3 to determine which check program is active; see chapter 4.4 "Process sequence".

4.2 Check programs

The

Rack Near

measuring tool in the check program are used for this purpose.

• With activation, compartment fine positioning for the

started or stopped via digital switching input I01.

Figure 4.1: Display of the detected hole position

• Digital switching outputs IO5 … IO8 signal whether the device is within the scan area for

Rack Far

or

whether the high-bay storage device is positioned too far to the left or right and/or too far up or down

relative to the hole position is displayed.

and

in relation to the hole position. Whether or not compartment fine positioning is correct or

Rack Far

Rack Near

check programs detect the respective hole position. A BLOB tool and a

and

Rack Far

Rack Near

or

Rack Far

.

check program is

Rack Near

Figure 4.2: Switching outputs IO5 … IO8 activated

Digital switching outputs IO5 … IO8 are permanently on as long as the control performs compartment fine positioning via the device.

• To compensate for the difference in position between loading position and unloading position of the

high-bay storage device, a shift of the coordinate origin is defined for the current check program by

entering an offset value.

On delivery, two check programs are set up in the device for

programs are optimized as follows:

Rack Near

•

Distance: 450 mm

Hole diameter: 15 mm

Rack Far

•

Distance: 1850 mm

Hole diameter: 15 mm

Leuze electronic LSIS 472i 15

Rack Near

and

Rack Far

. These check

Page 16

4.3 Diagnostics – image transfer

For diagnostics, the smart camera images can be stored (parallel to the check program procedure) in the

ring buffer.

• Saving the images in the ring buffer is started (IO4=1) and ended (IO4=0) via digital switching input

IO4.

• A maximum of 14 images are stored in the ring buffer, with the oldest images being overwritten once

the buffer is full.

14 images in the ring buffer correspond to approx. 500 ms of positioning.

The images can be transferred to an FTP server via FTP for diagnostics:

• To transfer the images, an M12 Ethernet connection cable must be connected between the smart

camera and a PC or laptop as FTP server.

Alternatively, the smart camera can be connected to a network in which the FTP server can be

accessed.

• Data transmission via FTP:

• The FTP access data must be entered in the webConfig tool.

• Data transmission via FTP must be activated in the webConfig tool.

The images are not transferred from the ring buffer until after the trigger signal (IO1=0) has been

reset.

• Upon conclusion of diagnostics, data transmission via FTP must be deactivated in the webConfig

tool.

The M12 Ethernet connection cable can be removed after completing diagnostics.

• The FTP access data can be stored in the smart camera for later diagnostics.

• Details on the settings in the webConfig tool: see chapter 9 "Extended configuration –

Leuze electronic webConfig tool".

Functions

4.4 Process sequence

Prerequisite: The high-bay storage device knows the hole positions for

NOTICE

Incoming signals are ignored while changing the check programs!

While the check programs are being changed internally, additional incoming signals are ignored,

including the trigger signals.

The internal changeover of the check programs lasts up to 300 ms.

• Shortly before reaching the target position (capture range), a permanently applied signal at switching

inputs IO2 and IO3 specifies the check program for the device.

Program 1: IO2=0 and IO3=0, corresponds to

Program 2: IO2=0 and IO3=1, corresponds to

• The control activates the test procedure, i.e., compartment fine positioning, by setting switching input

IO1=1.

Tool evaluation, i.e., execution of the check program, is started beginning at this point in time. Digital

switching outputs IO5 … IO8 are output statically as long as the specified hole position is detected in

the respective tool.

• At the end of check program execution, a check for the presence of the activation signal (IO1=1) is

performed.

If the activation signal is still present, the check program is immediately executed again.

• If the activation signal (IO1) is reset while a check program is being executed (IO1=0), this check

continues to run. Switching outputs IO5 … IO8 are then set to 0.

• If switching output IO5 … IO8=1 and the high-bay storage device has reached the target position,

loading or unloading is started.

• Parallel to the test procedure, switching input IO4 can be used to start (IO4=1) or end (IO4=0) the

saving of images in the ring buffer. The user can thereby separate the check program procedure

from the image.

Rack Near

Rack Far

Rack Near

and

Rack Far

.

Leuze electronic LSIS 472i 16

Page 17

Functions

1

2

3

4

5

6

t

t

t

t

7

7 78

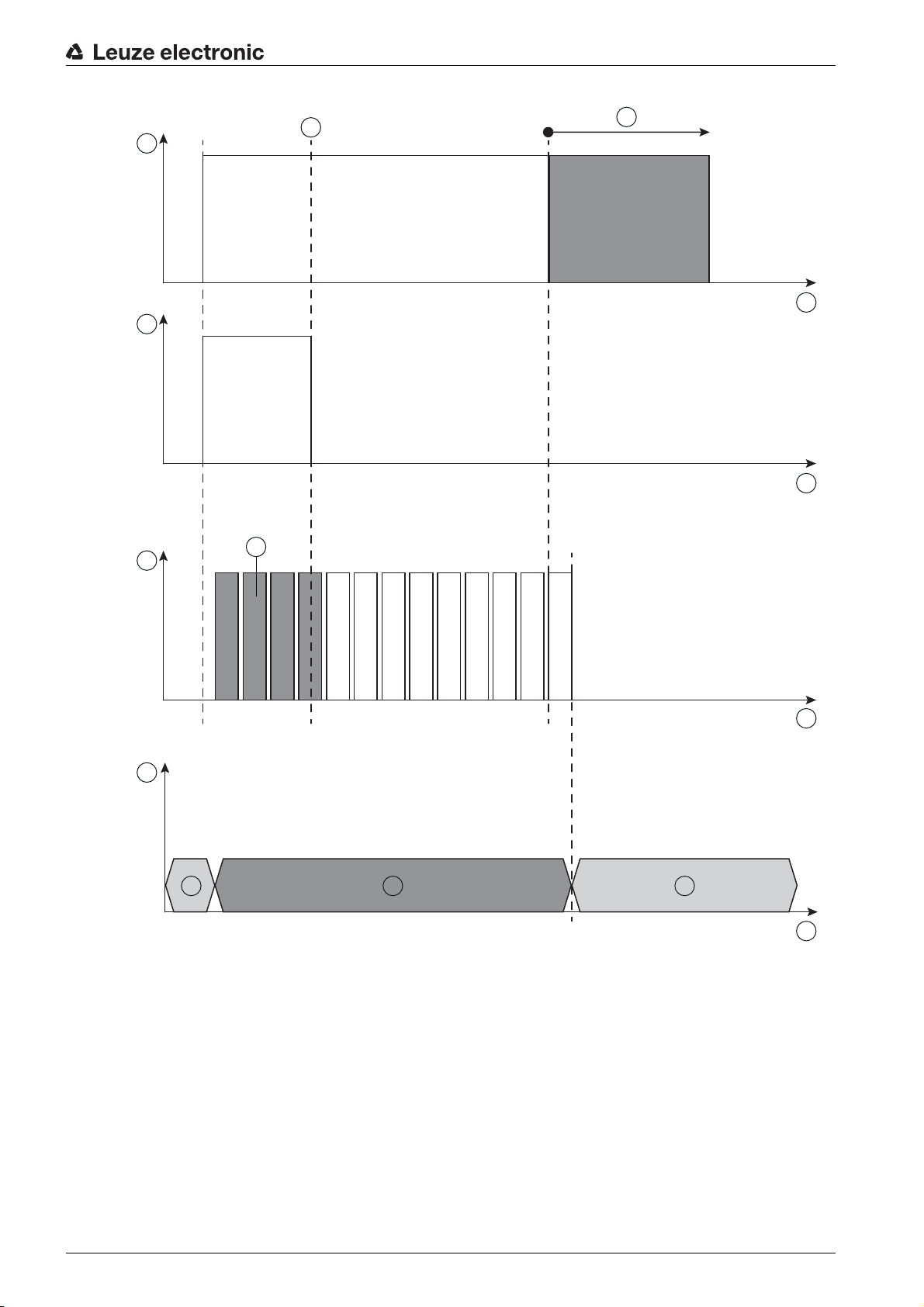

Figure 4.3: Process sequence

Leuze electronic LSIS 472i 17

1 Activation: IO1

2 Image acquisition in ring buffer: IO4

3 Program runs

4 State IO5 … IO8

5 IO5 … IO8 stable

6 Image transfer via FTP

7(3) Images that are written in the ring buffer

7(4) IO5 … IO8: output inactive (low)

8 IO5 … IO8: output active (high), tool result

Page 18

5 Applications

Following rough positioning, the LSIS 472i smart camera is used for the optical, contactless, compartment

fine positioning of a high-bay storage device in X- and Y-direction. It is possible to use just one camera in

single-deep and double-deep pallet high-bay warehouses.

Applications

Figure 5.1: Compartment fine positioning of a high-bay storage device in a double-deep pallet high-bay

warehouse

Leuze electronic LSIS 472i 18

Page 19

6 Mounting

The device can be mounted in the following ways:

• Mounting using a mounting device on the fastening grooves on the rear of the device or on the narrow side of the device.

• BT 56: Mounting on a rod

• BT 59: Wall mounting

• Mounting via M4 mounting thread:

• on the rear side of the device

• on the front side of the device

• on the narrow side of the device

6.1 Installation instructions

NOTICE

Observe during mounting!

Make certain that the required environmental conditions (humidity, temperature) are maintained.

Affix the markings for compartment fine positioning according to the working distance:

Rack Near

Rack Far

Make certain that the area behind a hole is not obstructed.

With closed profiles, only reflectors may be used as markings.

There must not be a light source behind a hole.

Avoid glossy, reflective surfaces behind the holes.

The surface surrounding a hole must reflect diffusely, i.e., no glossy surfaces.

Avoid interfering contours in the camera's field of view, e.g., stamped numbers.

Make certain that there is only one marking (hole or reflector) in the capture range of the smart camera.

Screw heads with identical diameter must not be located in the capture range of the smart camera.

Make certain that the lens cover of the smart camera is oriented parallel to the marking (hole or reflec-

tor).

Make certain that the marking (hole or reflector) is located as close to the middle of the capture range

of the smart camera as possible.

Make certain that the camera window is not soiled, e.g., by leaking fluids, abrasion from boxes or res-

idues from packaging material.

: hole or reflector

: reflector only

Mounting

6.2 Mounting with BT 56 mounting device

Mounting with a BT 56 mounting device is intended for rod mounting. For ordering information, see

chapter 14.3.

Mount the BT 56 on the rod with the clamp profile (system-side).

Mount the device with its fastening grooves on the clamping jaws of the BT 56 with limit stop at end.

Secure the device with the M6 screw terminal.

Maximum tightening torque for the M6 screw terminal: 8 Nm

6.3 Mounting with BT 59 mounting device

Mounting with a BT 59 mounting device is intended for wall mounting. For ordering information, see

chapter 14.3.

Mount the BT 59 mounting device on the system side with M8 fastening screws (included in delivery

contents).

Mount the device with its fastening grooves on the clamping jaws of the BT 59 with limit stop at end.

Secure the device with the M6 screw terminal.

Leuze electronic LSIS 472i 19

Page 20

Maximum tightening torque for the M6 screw terminal: 8 Nm

6.4 BPS mounting with M4 fastening screws

Mount the device on the system with M4 fastening screws (not included in delivery contents).

Max. tightening torque of the fastening screws: 2 Nm

Location and thread depth of the mounting thread: see figure 13.1

Mounting

Leuze electronic LSIS 472i 20

Page 21

7 Electrical connection

3

2

1

7.1 Overview

The electrical connection of the device is performed using M12 connectors.

Electrical connection

1 SERVICE: host and service interface (Ethernet); M12-socket (D-coded)

2 PWR: supply voltage (18 V … 30 VDC), IO1 … IO4; M12 plug (A-coded)

3 BUS OUT: RS 232 interface, IO5 … IO8; M12 socket (A-coded)

Figure 7.1: Position and designation of the M12 connections

For all connections (connection cable, interconnection cable, etc.), use only the cables listed in

the accessories (see chapter 14.2 "Cables-Accessories").

CAUTION

Safety Notices!

Before connecting the device please ensure that the supply voltage matches the value printed on the

nameplate.

Only allow competent persons to perform the electrical connection.

The shielding connection is done via the M12 connector housing.

Ensure that the functional earth (FE) is connected correctly.

Fault-free operation is only guaranteed if the functional earth is connected properly.

All electrical disturbances (EMC couplings) are discharged via the functional earth connection.

If faults cannot be rectified, take the device out of operation. Protect the device from accidentally being

started.

NOTICE

UL applications

For UL applications, use is only permitted in class 2 circuits in accordance with the NEC (National Elec-

tric Code).

Leuze electronic LSIS 472i 21

Page 22

NOTICE

FE

1

2

3

4

5

6

7

8

Protective Extra-Low Voltage (PELV)

The smart camera of the LSIS 4xxi series is designed in accordance with safety class III for supply by

PELV (protective extra-low voltage with reliable disconnection).

NOTICE

Degree of protection IP 65 / IP 67

Degree of protection IP 65 / IP 67 is only achieved with screwed-on connectors.

Connect the supply voltage (18 V … 30 VDC) to the PWR connection.

Connect switching inputs IO1 … IO4 to the PWR connection.

Connect switching outputs IO5 … IO8 to the BUS OUT connection.

Connect your RS 232 process interface to the BUS OUT connection.

Connect the Ethernet cable for configuration and diagnostics to the SERVICE connection.

7.2 PWR (supply voltage and switching inputs IO1 … IO4)

8-pin M12 plug (A-coded)

Electrical connection

Figure 7.2: Pin assignment of the PWR connection

Table 7.1: PWR pin assignment

Pin Designation Assignment

1 VIN Positive supply voltage +18 … +30 VDC

2 IO1 Switching input 1

• Activation - program start

• Function: reading gate start/stop

3 GND Negative supply voltage 0 VDC

4 IO2 Switching input 2

• Program selection 1

5 IO3 Switching input 3

• Program selection 2

6 IO4 Switching input 4

• Error image memory active

• Start: write images in ring buffer

7 NC Not connected

8 FE Functional earth

(Thread for M12

connector plug)

FE Connection cable shield

The shield of the connection cable is on the thread of

the M12 connector plug.

The thread of the M12 connector plug is part of the

metallic housing. The housing is at the potential of

Connection cables: see table 14.2

Leuze electronic LSIS 472i 22

the functional earth via pin 8.

Page 23

NOTICE

Maximum input current

The maximum input current of the switching inputs is 8 mA.

7.3 BUS OUT (RS 232 and switching outputs IO5 … IO8)

8-pin M12 socket (A-coded)

7

8

1

6

5

Electrical connection

2

3

FE

4

Figure 7.3: Pin assignment of the BUS OUT connection

Table 7.2: BUS OUT pin assignment

Pin Designation Assignment

1 IO5 Configurable switching output 1

Compartment fine positioning (-X)

2 IO6 Configurable switching output 2

Compartment fine positioning (+X)

3 GND Negative supply voltage 0 VDC

4 IO7 Configurable switching output 3

Compartment fine positioning (+Y)

5 IO8 Configurable switching output 4

Compartment fine positioning (-Y)

6 Rx Rx signal (RS 232)

7 Tx Tx signal (RS 232)

8 FE Functional earth

(Thread for M12

connector plug)

FE Connection cable shield

The shield of the connection cable is on the thread of

the M12 connector plug.

The thread of the M12 connector plug is part of the

metallic housing. The housing is at the potential of

the functional earth via pin 8.

Connection cables: see table 14.2

NOTICE

Maximum loading of the switching outputs

Do not load the switching outputs with more than 60 mA at +18 … +30 VDC.

The switching outputs are protected against short-circuit, overcurrent, overvoltage, excess temperature and transients.

NOTICE

Maximum cable length 10 m

Operation of the RS 232 interface is only permissible with shielded cables with maximum cable length

of 10 m.

Leuze electronic LSIS 472i 23

Page 24

7.4 SERVICE

3

4

1

2

2

1

3

4

1

8

4-pin M12 socket (D-coded)

Figure 7.4: Pin assignment of the SERVICE connection

Table 7.3: SERVICE pin assignment

Pin Designation Assignment

1 TD+ Transmit Data +

2 RD+ Receive Data +

3 TD- Transmit Data -

Electrical connection

(Thread for M12

connector plug)

FE Connection cable shield

The shield of the connection cable is on the thread of

the M12 connector plug.

The thread of the M12 connector plug is part of the

metallic housing. The housing is at the same potential as functional earth.

Connection cables: see table 14.2

Ethernet cable assignment

Figure 7.5: Cable assignments - SERVICE on RJ-45

Designed as shielded cable, max. length 100 m.

Pin (M12) Designation Pin/core color (RJ-45)

1 TD+ 1/yellow

2 RD+ 3/white

3 TD- 2/orange

4 RD- 6/blue

NOTICE

Self-configured cables for Ethernet connection!

The depicted core colors apply only for interconnection cables from Leuze electronic.

The depicted core colors are not compliant with EIA/TIA 568A and EIA/TIA 568B.

Ensure adequate shielding.

The entire interconnection cable must be shielded and earthed.

Leuze electronic LSIS 472i 24

The RD+/RD- and TD+/TD- wires must be stranded in pairs.

Use CAT 5 cable for the connection.

Page 25

8 Commissioning

Basic operation of the device is via a multi-language display and control buttons or via the webConfig

configuration tool.

For faster commissioning, the most important parameters for compartment fine positioning are set on a

connected PC/laptop via a configuration dialog in the webConfig tool.

Commissioning includes the mechanical alignment of the smart camera and the teaching-in of the position

via the display and control buttons as well as calibration, i.e., calibration of distance and marking size, via

the webConfig tool.

8.1 Commissioning the device

Electrically connect the smart camera and apply the supply voltage.

The smart camera starts up and the position display appears on the display.

Connect the smart camera to a PC/laptop and start the webConfig tool; see chapter 9 "Extended

configuration – Leuze electronic webConfig tool".

Make the settings for your application with the webConfig tool; see chapter 9.3.4 "Configure compart-

ment fine positioning".

Disconnect the smart camera from the PC/laptop and from the power source.

Mount the smart camera in your application; see chapter 6 "Mounting".

Electrically connect the smart camera in your application; see chapter 7 "Electrical connection".

Connect the supply voltage.

Mechanically align the smart camera with the marking via the display and control buttons; see

chapter 8.2 "Mechanically aligning the device via the display".

Commissioning

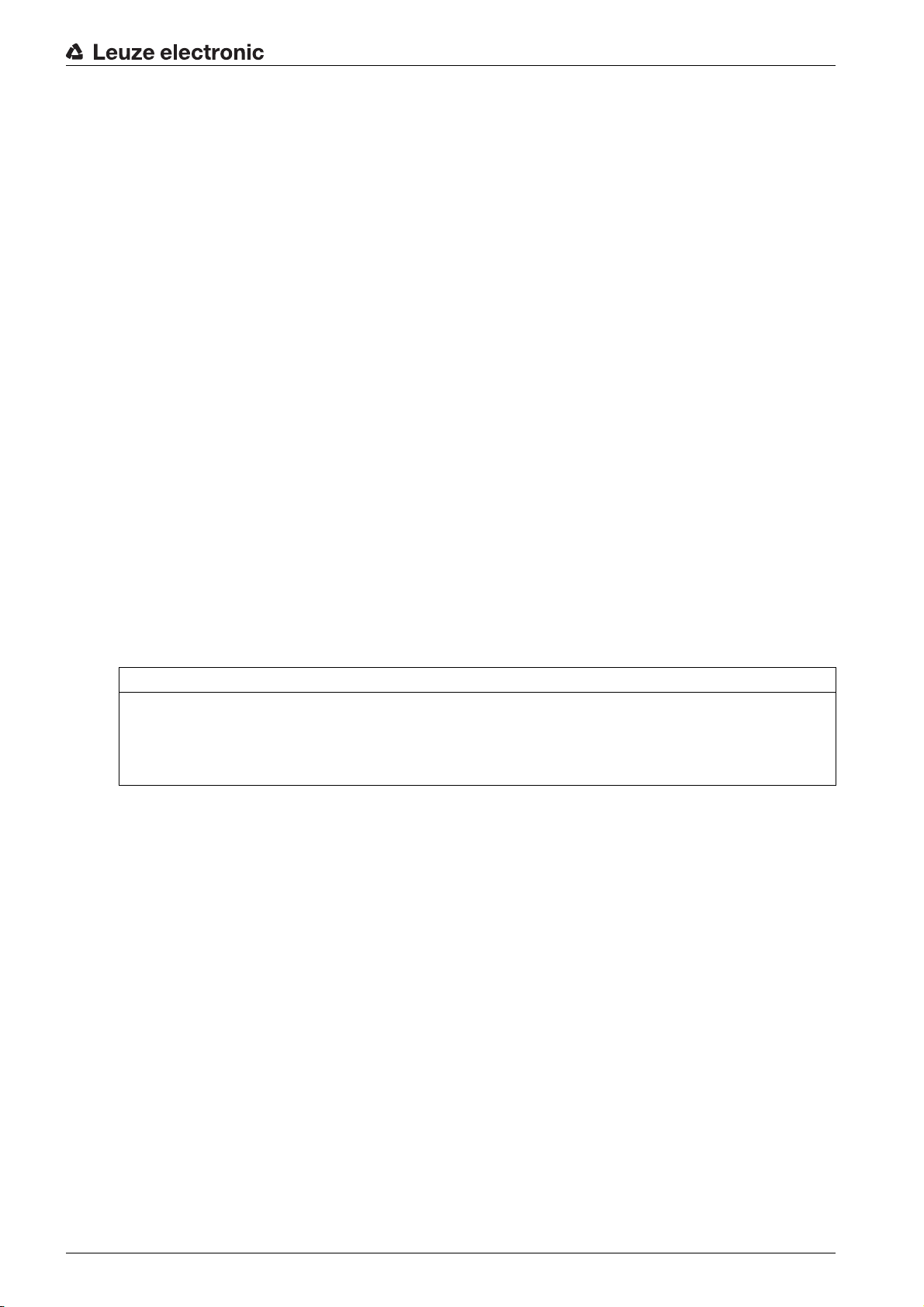

NOTICE

Adjusting compartment fine positioning with the webConfig tool!

To align via the display and the control buttons, the current configuration for compartment fine posi-

tioning must be set with the webConfig tool and be stored in the device; see chapter 9 "Extended

configuration – Leuze electronic webConfig tool".

Teach-in the position of the smart camera; see chapter 8.3 "Teaching-in the position".

Connect a PC/laptop to the smart camera and start the webConfig tool; see chapter 9 "Extended

configuration – Leuze electronic webConfig tool".

Calibrate the device for the current check program with the webConfig tool; see chapter 9.3.5 "Calibrat-

ing".

8.2 Mechanically aligning the device via the display

Prerequisites:

• The smart camera is correctly mounted; see chapter 6 "Mounting".

The smart camera is correctly connected; see chapter 7 "Electrical connection".

The application data is set via the webConfig tool; see chapter 9.3.4 "Configure compartment fine

positioning".

• The lens cover of the smart camera is aligned parallel to the marking (hole or reflector).

• The marking (hole or reflector) is located as close to the middle of the capture range of the smart

camera as possible.

Use the navigation buttons to move through the menu. Activate the desired selection with

the enter button .

Press the navigation button three times.

Press the enter button to activate

Select

Select the check program for alignment (

Leuze electronic LSIS 472i 25

Commissioning

.

Service

mode.

Rack Near

or

Rack Far

).

Page 26

Commissioning

1

2

34

1

1 Actual position of the marking

2 Status signaling of switching outputs IO5 … IO8

3 Capture range

4 Display of the active check program

Rack Near

0 for

1 for

Rack Far

Figure 8.1: Indicators in the display

• A semicircle visible in the position display indicates that the marking is in the field of view of the

device but not in the capture range.

Turn the device towards the semicircle.

1

1 Marking indicator outside of capture range

Figure 8.2: Marking in the field of view, but not in the capture range

• A black dot in the position display indicates that the marking is in the capture range of the device.

The device is not yet optimally aligned.

1 Marking indicator in the capture range

Figure 8.3: Marking in the capture range

• If the marking is not in the field of view of the device (no marking indicator), the device must be

mechanically repositioned.

Align the device until the marking indicator (black dot) is exactly in the square in the middle of the dis-

play.

Leuze electronic LSIS 472i 26

Page 27

1

ESC

1 Marking indicator

Figure 8.4: Device aligned with the marking

Commissioning

Press the escape button to exit

If necessary, teach-in the position for fine adjustment; see chapter 8.3.

Calibrate the device for the current check program with the webConfig tool; see chapter 9.3.5 "Calibrat-

ing".

8.3 Teaching-in the position

For fine adjustment and, alternatively, for exact mechanical alignment via the

user can teach-in the position of the device via the display.

While teaching-in the position (teach), a position correction of the coordinate system of the capture range

is performed.

Teaching-in of the position is performed separately for each distance.

Reteaching of the position is not performed for a different hole geometry or for different exposure/

focal settings.

NOTICE

Align the device before teaching-in the position!

The device must be roughly aligned before teaching-in the position.

The capture range must not exit the field of view.

For the

as the capture range.

Rack Near

distance, the teach range is nearly zero since the field of view is almost the same

Service

mode.

Commissioning

menu, the

Use the navigation buttons to move through the menu. Activate the desired selection with

the enter button .

To teach the position for the current alignment, the marking (hole or reflector) must be located within the

capture range; see figure 8.3.

Service

In

Select the distance for teaching-in (

Select the

Select

If the

Teach-in

mode, select

Teach-in

Teach-in

.

Commissioning

menu.

menu option is crossed out in the

.

Rack Near

or

Rack Far

Teach-in

).

menu, teaching-in of the position is not possible.

Mechanically realign the device; see chapter 8.2 "Mechanically aligning the device via the display".

Possible causes:

• The marking is not in the capture range of the device.

• The limits of the new capture range ascertained by teaching in are not completely in the field of view.

Exit the

To do this, press the Escape button .

Leuze electronic LSIS 472i 27

Commissioning

menu.

ESC

Page 28

The capture range with the new coordinate origin ascertained by teaching in must be completely

ESC

in the field of view.

Calibrate the device for the current check program with the webConfig tool; see chapter 9.3.5 "Calibrat-

ing".

8.4 Parameter enable

During process mode parameters can only be viewed. If parameters are to be changed and for configuration settings via the display, parameter enabling must be activated.

Parameter enabling is activated by default.

If parameter enabling is deactivated, you must activate parameter enabling for the configuration settings

via the display.

Use the navigation buttons to move through the menu. Activate the desired selection with

the enter button .

Commissioning

In the

Parameter

Select the

Select the

menu, select the

Parameter enable

ON

option and press the enter button .

Parameter handling

option.

option.

The PWR LED illuminates orange. The device is in Service mode and you can set the configuration parameters via the display.

Press the Escape button to enter the main menu.

Leuze electronic LSIS 472i 28

Page 29

Extended configuration – Leuze electronic webConfig tool

IP

00:15:7B:20:00:15

DDLS 508i MAC

Name

9 Extended configuration – Leuze electronic webConfig tool

The smart camera can be operated and configured by means of the integrated webConfig tool via the

Ethernet service interface.

With the Leuze electronic webConfig tool, an operating-system independent, web-technology based,

graphical user interface is available for the configuration.

The webConfig tool can be run on any Internet-ready PC. The webConfig tool uses HTTP as communication protocol and the client-side restriction to standard technologies (HTML, JavaScript and AJAX) that are

supported by modern browsers.

The webConfig tool is offered in the following languages:

German, English, French, Italian, Spanish

9.1 Establishing an Ethernet connection

The Ethernet connection is used as the host interface and for configuring the device via a PC with a

browser.

In order for the PC and the smart camera to communicate with one another, both devices must

be on the same subnet and have different network addresses.

Address Link Label

The “Address Link Label” is an additional stick-on label that is affixed to the device.

Figure 9.1: Example of an “Address Link Label”; the device type varies depending on series

• The “Address Link Label” contains the MAC address (Media Access Control address) of the device

and offers the possibility to enter the IP address and the device name by hand.

The area of the “Address Link Label” on which the MAC address is printed can be separated from the

remainder of the stick-on label if necessary by means of the perforation.

• To use, the “Address Link Label” is peeled from the device and can be affixed in the installation and

layout diagrams to designate the device.

• Once affixed in the documents, the “Address Link Label” establishes a unique reference between

mounting location, MAC address or device, as well as the corresponding control program.

The time-consuming searching, reading, and manually writing down of the MAC addresses of all

devices installed in the system are eliminated.

Each device with Ethernet interface is uniquely identified via the MAC address assigned during

production. The MAC address is also listed on the name plate of the device.

If multiple devices are commissioned in a system, the MAC address of each installed device

must be correctly assigned, e.g., during programming of the control.

Connecting smart camera to a PC/laptop without network

Check the network address of the smart camera.

Leuze electronic LSIS 472i 29

On the display, select

Note the values for

Set the network address on the PC/laptop (example for Windows7).

Status > Network settings

Addr

and

Mask

.

.

Page 30

Log in as administrator.

Select

Select

Select

Set the

Start > Control Panel > Network and Internet > Network and Sharing Center

LAN connection

Internet Protocol Version 4 (TCP/IPv4)

IP address

The IP address of the PC/laptop must not be identical to the IP address of the smart camera.

Example: IP address of the smart camera: 192.168.060.101

IP address of the PC/laptop: 192.168.060.111

Set the subnet mask of the PC/laptop to the same value as on the smart camera.

Example: 255.255.255.0

Confirm all of the settings dialogs with [OK] or [Close].

Connect the SERVICE interface of the smart camera directly to the LAN port of your PC/laptop.

9.2 Start webConfig tool

Prerequisite: IP address and subnet mask for the LAN connection with the device are set correctly.

Connect the operating voltage to the device.

Connect the SERVICE interface of the device to the PC.

The connection to the SERVICE interface of the device is made via the LAN port of the PC.

Start the webConfig tool via your PC's Internet browser with IP address 192.168.60.101 or with the IP

address set by you.

192.168.60.101 is the standard Leuze electronic service address for communication with the smart

camera of the LSIS 4xxi series.

The webConfig start page is displayed on your PC.

and right-click to open the

of the PC/laptop.

Extended configuration – Leuze electronic webConfig tool

.

Properties

dialog.

and click on the [Properties] button.

Changing the operating mode (

Process

-

Service

) (upper left)

Figure 9.2: The start page of the webConfig tool

The user interface of the webConfig tool is largely self-explanatory.

The webConfig tool is completely contained in the firmware of the device.

The pages and functions of the webConfig tool may appear and be displayed differently depend-

ing on the firmware version.

Leuze electronic LSIS 472i 30

Page 31

Clearing browser history

The cache of the Internet browser is to be cleared if different device types or devices with different firmware

were connected to the webConfig tool.

Delete cookies and temporary Internet and website data from the browser cache before starting the

webConfig tool.

Example for Internet Explorer 10:

Tools > Delete browsing history > [Delete]

Note limit of Firefox sessions for version 17.0 and higher

If the limited number of Firefox sessions is exceeded, it may no longer be possible to address the device

via the webConfig tool.

Do not use the refresh functions of the Internet browser:

[Shift] [F5] or [Shift] + mouse click

9.3 Short description of the webConfig tool

The menus and dialog boxes of the webConfig tool are intuitive to operate and offer help texts and tool tips.

9.3.1 Operating modes

Extended configuration – Leuze electronic webConfig tool

For configurations with th

•

Process

The device is connected to the control.

• The process communication to the control is activated.

• The switching inputs/outputs are activated.

• The configuration cannot be changed.

PROCESS

•

CONFIGURATION

•

•

Service

• The process communication to the control is interrupted.

• The switching inputs/outputs are deactivated.

• The configuration can be changed.

PROCESS

•

CONFIGURATION

•

9.3.2 Configuration via the we

Use webConfig tool to set u

Select the check program; see chapter 9.3.3.

Configure compartment fine positioning for fast commissioning; see chapter 9.3.4.

Calibrate the device; see chapter 9.3.5.

Configure the image acquisition; see chapter 9.3.6.

Define the changeover of the check programs; see chapter 9.3.9.

Configure the BLOB analysis; see chapter 9.3.7.

Configure the measurement; see chapter 9.3.8.

Configure the digital switching input/outputs; see chapter 9.3.10.

Assign measurement values to the digital switching outputs; see chapter 9.3.11.

Activate the marking display on the display; see chapter 9.3.12.

Configure the output via an FTP connection; see chapter 9.3.13.

Configure the output via an Ethernet connection; see chapter 9.3.14.

function available.

function not available.

e webConfig tool, you can switch between the following operating modes:

function not available.

function available.

bConfig tool

p the device:

Leuze electronic LSIS 472i 31

Page 32

NOTICE

Configuration changes only in the

Changes made using the

mode.

9.3.3 Selecting the check program

Service

operating mode!

CONFIGURATION

Extended configuration – Leuze electronic webConfig tool

function can only be performed in the

Service

operating

There is a check program stored on the device for the detection

positions.

Select

The

CONFIGURATION > PROGRAMS

Overview of Check Programs

.

dialog is displayed.

of both the

Rack Near

and

Rack Far

hole

Figure 9.3:

Select the check program that you would like to activate (

Table 9.1: Overview of digital inputs for check programs

Digital input IO2 Digital input IO3 Selection ID Check program

000

101

0 1 2 Not defined

1 1 3 Not defined

9.3.4 Configure compartment fine positioning

To commission more quickly, you can

and

Near

Alternatively, you can make the configuration settings for compartment fine positioning manually; see

chapter 9.3.6.

Overview of Check Programs

Rack Far

The configuration for compartment fine positioning for faster commissioning is only available if

the device is directly connected to the PC/laptop.

) via a configuration dialog.

Rack Near

or

Rack Far

).

Rack Near

Rack Far

set the most important parameters for the check programs (

Rack

Leuze electronic LSIS 472i 32

Page 33

Extended configuration – Leuze electronic webConfig tool

Select

Click on the [Configure compartment fine positioning] button.

CONFIGURATION > PROGRAMS

.

Figure 9.4:

Enter the type and diameter of the marking.

Enter the distance between rack profile and lens cover of the device.

Enter the positioning accuracy for the active check program.

The positioning accuracy is determined over a rectangular positioning area depending on the diameter

of the marking. If the device sees the marking within this area, positioning of the high-bay storage device

is concluded (I05 … IO8 = 1).

Example:

• Diameter of the marking: 15 mm

Positioning accuracy X: 5 mm

Positioning accuracy Y: 5 mm

If the device sees the marking within an area of 25 mm x 25 mm around the center of the marking, all

switching outputs switch to 1.

Enter the offset values for the active check program.

The offset can be used to enter a deviation of the positioning relative to the middle of the marking, e.g.,

to take into account the difference in positioning between loading position and unloading position of the

high-bay storage device.

Confirm all entries with [OK].

Configure compartment fine positioning

For a single-depth warehouse, enter the same distance under

dialog

Rack Near

and

Rack Far

.

9.3.5 Calibrating

During device calibration, the measurement distance is calibrated with the diameter of the marking.

Select

Select the active check program (

Select

The

Leuze electronic LSIS 472i 33

CONFIGURATION > PROGRAMS

Rack Near

.

or

Rack Far

CONFIGURATION > PROGRAM > Tools > Calibration

Tool configuration – Calibration

dialog is displayed.

).

.

Page 34

Extended configuration – Leuze electronic webConfig tool

Figure 9.5:

NOTICE

Recalibration required if the measurement distance changes!

If the distance for the check program (

tion must be adjusted.

Calibrate via the point detectors if necessary.

Enter the diameter of the marking (hole or reflector) in the selection list [Calibration block length].

Click on the [Accept values] button.

Setting the offset

For the current check program, you can set additional distances (offsets) for the positioning. By means of

the offset value, it is possible to detect, e.g., the position difference between loading position and unloading

position of the high-bay storage device.

• If the offset values are 0, the smart camera positions the high-bay storage device exactly on the

marking.

• If offset values are set, the control signals a corresponding position deviation.

Example: with offset Y = 20 mm, the high-bay storage device is positioned 20 mm below the marking.

Tool configuration – Calibration

dialog

Rack Near

The offset is not visualized in the image.

or

Rack Far

) changes in the application, the calibra-

Select

Select the active check program (

Select

The

Leuze electronic LSIS 472i 34

CONFIGURATION > PROGRAMS

Rack Near

CONFIGURATION > PROGRAM > Tools > Calibration > Offset

Tool configuration – Offset

dialog is displayed.

.

or

Rack Far

).

.

Page 35

Extended configuration – Leuze electronic webConfig tool

Figure 9.6:

9.3.6 Configuring image acquisition

As an alternative to configuring compartment fine positioning for faster commissioning (see chapter 9.3.4),

you can make the configuration settings for compartment fine positioning manually.

Select

Select the active check program (

Select

The

Image acquisition – Attributes

Tool configuration – Offset

CONFIGURATION > PROGRAMS

CONFIGURATION > PROGRAM > Tools > Image acquisition

dialog

.

Rack Near

dialog is displayed.

or

Rack Far

).

.

Figure 9.7:

Set the image acquisition attributes according to the requirements of the application.

Leuze electronic LSIS 472i 35

Image acquisition – Attributes

dialog

Page 36

NOTICE

Adjust exposure time and focus if the distance is changed!

If the distance for the check program (

time and focus must be checked or adjusted.

When adjusting the focus, the same value must be set for the

grams.

For two compartments with different distances, use the mathematical average of the distances as the

focal distance.

9.3.7 Configuring the BLOB analysis

Extended configuration – Leuze electronic webConfig tool

Rack Near

or

Rack Far

) changes in the application, the exposure

Rack Near

and

Rack Far

check pro-

The centroid of the marking for the display in the image is ascertained v

Select

Select the active check program (

BLOB segmentation

Select

The

CONFIGURATION > PROGRAMS

Rack Near

.

or

Rack Far

).

CONFIGURATION > PROGRAM > Tools > BLOB > Segmentation

BLOB segmentation

dialog is displayed.

ia the BLOB analysis.

.

Figure 9.8:

Set the attributes for BLOB segmentation according to the requirements of the application.

Under

Hole:

Reflector:

BLOB attributes

Select

The

BLOB prefiltering

Leuze electronic LSIS 472i 36

BLOB segmentation

The display for the marking must lie completely in the capture range (blue frame).

Binarization

, set the type of marking:

Dark objects

Bright objects

CONFIGURATION > PROGRAM > Tools > BLOB > Attributes

dialog is displayed.

dialog

.

Page 37

Extended configuration – Leuze electronic webConfig tool

Figure 9.9:

Area

Shape factor

Centroid X, Centroid Y

9.3.8 Configuring the measurement

Select

Select the active check program (

Select

The

Measurement - Testing

BLOB prefiltering

attribute: adjust the NOMINAL limit values if the geometry of the marking has changed.

attribute: adjust the NOMINAL limit values if the geometry of the marking has changed.

attributes: the limits of the centroid values must not be changed.

CONFIGURATION > PROGRAMS

CONFIGURATION > PROGRAM > Tools > Measurement > Testing

dialog

.

Rack Near

dialog is displayed.

or

Rack Far

).

.

Figure 9.10:

Define the limits for the measurement.

Leuze electronic LSIS 472i 37

Measurement - Testing

dialog

Page 38

Extended configuration – Leuze electronic webConfig tool

The MINIMUM values for

Maximum Y

NOTICE

Adjust limit values if the tolerance areas are changed!

If the tolerance areas change in the application, the limit values in the

must be checked and adjusted if necessary.

The minimum value for this application is 2 mm.

9.3.9 Defining changeover of the check programs

In Process mode, you can switch between the

Select

The

CONFIGURATION OF DIGITAL I/OS

correspond to the limits for the positioning accuracy X and Y.

CONFIGURATION > DEVICE > Digital I/Os > General parameters

Minimum Y

and

dialog is displayed.

Maximum X

Rack Near

and the MAXIMUM values for

Measurement - Evaluation

and

Rack Far

check programs.

.

Minimum X

dialog

and

Figure 9.11:

Activate the

inputs IO2 and IO3.

The signals for program selection on the inputs must currently be applied.

• If the signals are removed at the inputs while the

the device interprets this as a “logical low” pending signal and activates the check program with

selection ID 0 (

•If the

performed via a “program change” input.

Define the

The delay time defines the time that the input signals must be applied to the device before a change to

an edge results in a change of check program. The delay time protects against faulty activations since

it takes up to 300 ms for the check program to changeover.

For technical reasons, it is not possible to implement an immediate changeover (delay time = 0 ms). If

the delay time is set to 0 ms, the functionality is deactivated. This corresponds to unselecting the

matic program change

9.3.10 Configuring the digital sw

The digital switching inputs/outputs are configured for the active check pr

ration dialog.

Leuze electronic LSIS 472i 38

CONFIGURATION OF DIGITAL I/OS

Automatic program change

Near Rack

).

Automatic program change

checkbox for changing the check programs via digital switching

checkbox is not selected, the check program confirmation must be

Delay time - program selection input

checkbox.

itching inputs/outputs

dialog

Automatic program change

.

checkbox is selected,

ogram via the

DEVICE

Auto

configu-

-

Page 39

Extended configuration – Leuze electronic webConfig tool

Select

Select the active check program (

Select

The

CONFIGURATION > PROGRAMS

CONFIGURATION > DEVICE > Digital I/Os

CONFIGURATION OF DIGITAL I/OS

.

Rack Near

or

dialog is displayed.

Rack Far

.

).

Figure 9.12:

Set the configuration of the digital switching inputs/outputs according to the requirements of the appli-

cation.

Table 9.2: Factory settings of the digital switching inputs/outputs

IO port IO mode Function

IO1 Input Activation - program start

IO2 Input Program selection 1

IO3 Input Program selection 2

IO4 Input Error image memory active

IO5 … IO8 Output Programmable 1 … 4

9.3.11 Assigning digital switching outputs the measurement values

Check-program-specific assignment of tool results to the programmable digital switching outputs.

Select

Select the active check program (

Select

The

TOOL CONFIGURATION - Digital I/O

CONFIGURATION OF DIGITAL I/OS

Reading gate start/stop

Start writing images to ring buffer

Outputs for compartment fine positioning

CONFIGURATION > PROGRAMS

.

Rack Near

CONFIGURATION > PROGRAM > Tools > Output > Digital I/O

dialog is displayed.

or

Rack Far

dialog

).

.

Leuze electronic LSIS 472i 39

Page 40

Extended configuration – Leuze electronic webConfig tool

Figure 9.13:

TOOL CONFIGURATION - Digital I/O

dialog

For each switching output, select the desired measurement value that is to be output via the switching

output.

Click on the [Save changes] button.

The smart camera makes available digital switching outputs -X, +X, -Y, +Y. In addition, the status of these

switching outputs appears on the display.

The target position is located within a rectangular tolerance area. Depending on the X deviations and Y

deviations, the switching outputs are switched as follows.

•IO5=-X

• IO6=+X

• IO7=+Y

•IO8=-Y

Leuze electronic LSIS 472i 40

Page 41

Extended configuration – Leuze electronic webConfig tool

Figure 9.14: Switching of the switching outputs

9.3.12 Activating display of the target/actual deviation in the display

In order for the target/actual deviation for the marking to be shown in the display, the output must be activated via the Ethernet interface.

Select

Select the active check program (

Select

The

CONFIGURATION > PROGRAMS

Rack Near

.

or

Rack Far

CONFIGURATION > PROGRAM > Tools > Output > Display

TOOL CONFIGURATION - Display

dialog is displayed.

).

.

Leuze electronic LSIS 472i 41

Page 42

Extended configuration – Leuze electronic webConfig tool

Figure 9.15:

Select the

Click on the [Save changes] button.

9.3.13 Configuring the FTP output

Check-program-specific output of test results on the Ethernet interface via the FTP protocol.

Select

The

FTP CLIENT

TOOL CONFIGURATION - Display

Output activated

CONFIGURATION > DEVICE > Communication > FTP client

dialog is displayed.

dialog

checkbox.

.

Figure 9.16:

Leuze electronic LSIS 472i 42

FTP CLIENT

dialog

Page 43

Extended configuration – Leuze electronic webConfig tool

Make the following entries:

•

IP address:

•

Port number:

Standard setting: port 21

User name:

•

•

Password:

Select the

Select the

Settings for the FTP connection

NOTICE

Ensure availability of the FTP server

Ensure the availability of your FTP server. If no FTP connection can be established, the device outputs

warning messages repeatedly.

IP address of the FTP server with which the connection is to be established.

port number of the FTP server with which the connection is to be established.

freely selectable user name. The device logs into the FTP server with this user name.

only necessary if required by the FTP server for login.

Fault image output at reading gate end

FTP activated

checkbox.

checkbox.

Select

Select the active check program (

Select

The

CONFIGURATION > PROGRAMS

CONFIGURATION > PROGRAM > Tools > Output > FTP

TOOL CONFIGURATION - FTP

.

Rack Near

dialog is displayed.

or

Rack Far

).

.

Figure 9.17:

Select the

Click on the [Settings] button.

Leuze electronic LSIS 472i 43

TOOL CONFIGURATION - FTP

Output activated

checkbox.

dialog

Page 44

Extended configuration – Leuze electronic webConfig tool

Figure 9.18: Settings for FTP output

Make the following settings:

•

Activate image transfer:

•

Image name:

The image name must not contain any space characters.

Image filing:

•

Click on the [Save changes] button.

9.3.14 Configuring the Ethernet output

Check-program-specific output of test results on the Ethernet interface via the Ethernet protocol.

Select

The

CONFIGURATION > DEVICE > Communication > Process - Ethernet

CONFIGURATION OF ETHERNET COMMUNICATION

assign an image name, e.g., “HBS1_rack1”.

select the

select the two checkboxes.

with time stamp

option.

.

dialog is displayed.

Leuze electronic LSIS 472i 44

Page 45

Extended configuration – Leuze electronic webConfig tool

Figure 9.19:

Make the following settings in the

• Select the

•Select

If you select

Settings for the Ethernet output of target/actual value deviation

Select

Select the active check program (

Select

The

TOOL CONFIGURATION - Ethernet

CONFIGURATION OF ETHERNET COMMUNICATION

TCP/IP PROCESS DATA

Activated

Mode: Server

Client

CONFIGURATION > PROGRAM

checkbox.

or

Client

.

mode, you must configure host communication.

.

Rack Near

or

Rack Far

).

CONFIGURATION > PROGRAM > Tools > Output > Ethernet

dialog is displayed.

dialog

dialog:

.

Figure 9.20:

Select the

Leuze electronic LSIS 472i 45

TOOL CONFIGURATION - Ethernet

Output activated

checkbox.

dialog

Page 46

Extended configuration – Leuze electronic webConfig tool

In the drop-down lists, select

Drag the

Click on the [Save changes ]button.

Point 1 X

These settings are stored as standard settings.

and

Tool: Near measurement

Point 1 Y

functions into the

and

Measurement: Minimum

Output for tool result OK or NOK

.

field.

Leuze electronic LSIS 472i 46

Page 47

10 Troubleshooting

Error signaling via LED

Table 10.1: Meaning of the LED indicators

Faults Possible error causes Measures

PWR LED

Troubleshooting

Off

Orange, continuous light

Red, continuous light

Red, flashing Warning set Query diagnostic data and carry out the result-

BUS LED

Off

Red, flashing Communication error Check interface

• No supply voltage connected to

the device

• Hardware error

Device in Service mode Reset Service mode via webConfig or display

Internal device error Contact Leuze electronic customer ser-

• No supply voltage connected to

the device

• Hardware error

• Check supply voltage

• Contact Leuze electronic customer service(see chapter 12)

vice(see chapter 12)

ing measures

• Check supply voltage

• Contact Leuze electronic customer service(see chapter 12)

Leuze electronic LSIS 472i 47

Page 48

11 Care, maintenance and disposal

11.1 Cleaning

If there is dust on the device:

Clean the device with a soft cloth; use a cleaning agent (commercially available glass cleaner) if nec-

essary.

NOTICE

Do not use aggressive cleaning agents!

Do not use aggressive cleaning agents such as thinner or acetone for cleaning the device.

Use of improper cleaning agents can damage the lens cover.

11.2 Servicing

The device does not normally require any maintenance by the operator.

Repairs to the device must only be carried out by the manufacturer.

For repairs, contact your responsible Leuze electronic subsidiary or Leuze electronic customer service

(see chapter 12 "Service and support").

Care, maintenance and disposal

11.3 Disposing

For disposal observe the applicable national regulations regarding electronic components.

Leuze electronic LSIS 472i 48

Page 49

12 Service and support

24-hour on-call service at:

+49 (0) 7021 573 - 0

Service hotline:

+49 (0) 7021 573 - 123

Monday to Friday 8.00 a.m. to 5.00 p.m. (UTC+1)

E-mail:

service.identify@leuze.de

Repair service and returns:

Procedure and Internet form can be found at

www.leuze.com/repair

Return address for repairs:

Service center

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen / Germany

Service and support

12.1 What to do should servicing be required?

NOTICE

Please use this chapter as a master copy should servicing be required!

Enter the contact information and fax this form together with your service order to the fax number given

below.

Customer data (please complete)

Device type:

Serial number:

Firmware:

Display messages:

LED states:

Error description:

Company:

Contact person/department:

Phone (direct):

Fax:

Street/No:

ZIP code/City:

Country:

Leuze Service fax number:

+49 7021 573 - 199

Leuze electronic LSIS 472i 49

Page 50

13 Technical data

13.1 General specifications

Table 13.1: Optics

Light source Infrared LED, strobed operation

Wavelength 850 nm

Image sensor Global shutter CMOS

Number of pixels 752 x 480

Focal length 16 mm

Electronic shutter speeds 54 µs … 20 µs

Technical data

Exempt group (in acc. with EN 62471)

Read distance From 250 mm (

Up to 1900 mm (

Field of view X - Y From 74 x 48 mm (

Up to 545 x 348 mm (

Near Rack

Far Rack

Near Rack

Far Rack

)

)

, 250 mm distance)

, 1900 mm distance)

Marking size (round) Diameter 10 mm … 20 mm

Near Rack

Far Rack

: minimum marking size 10 mm

: minimum marking size 13 mm

Table 13.2: Electrical equipment

Operating voltage U

B

18 …30 VDC

PELV, Class 2 / SELV

Power consumption 8 W maximum

Switching inputs 4 digital switching inputs, protected against polarity rever-

sal

18 …30 VDC, depending on supply voltage

Switching outputs 4 digital switching outputs, freely programmable function