Leuze GSX14E Product Flyer

GSX14E:

World’s first combined fork sensor

Detect any label type with a single sensor

The GSX14E fork sensor from our new product range of fork sensors is the world’s first sensor of its kind and combines the

two detection methods of ultrasonics and light in a single housing. It thus merges the advantages of the two methods and reliably,

quickly, and position-accurately detects all types of labels, regardless of their material and characteristics.

Advantages for you at a glance

— The reliable detection of labels made from a wide range of

materials and various characteristics ensures high machine

throughput and prevents downtime

— No reconfiguring of the sensor is required when switching

label rolls. Shorter setup times result in higher production

volumes

— The sensor is set up quickly by simply teaching in the

label-carrier combination with the teach button.

Only one mounting position is required for all objects

— Reliable operation even in case of contamination and

variations in terms of label / carrier materials through

automatic readjustment of the switching threshold

— IO-Link for easy integration of additional functions in the

machine control, e.g., simple format changeover when

changing rolls via recipe management, remote teaching of

the sensor, or locking of the buttons

Detection principle Ultrasonic + optical

Switching frequency

Response time

Operation 2 buttons

Teach options EasyTeach, static teach

IO-Link

Housing dimensions

(L × W × H)

Housing material Metal, galvanically nickel-plated

Mouth width/depth 4 mm / 80 mm

Ultrasonic: ~2 kHz

Optical: ~9 kHz

Ultrasonic: <0.2 ms

Optical: <0.05 ms

V1.1 (SmartSensorProfile, COM3)

96 × 22 × 46.9 mm

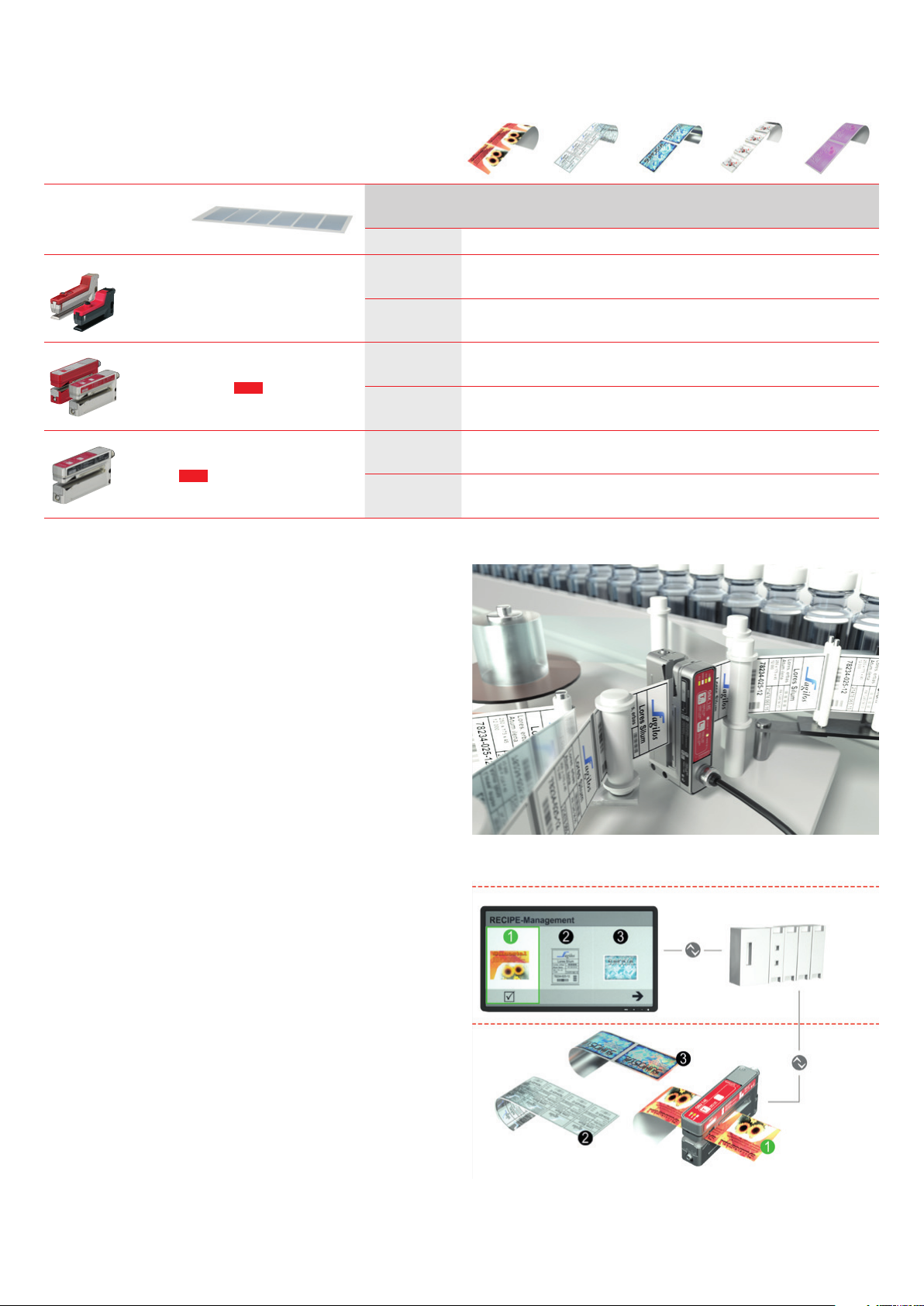

New and extensive fork sensor product range for your application

Which sensor is right for which label-carrier combination?

Label

Base material

Not transparent

GS63B, GS61 Optical

Transparent

Not transparent

GSU12, (I)GSU14E

GSX14E

NEW

NEW Ultrasonics

Transparent

Not transparent

Ultrasonic

+ optical

Transparent

The new all-round carefree GSX14E fork sensor

— Universal use for the detection of all types of label materials,

even inhomogeneous cavitated BOPP material

— Perfect for labeling machines that are operated with

changing label types

— A single sensor replaces multiple fork sensors of different

types

— Space-saving, less effort required, and reduced costs for

mounting, commissioning, and label changeovers

Not

transparent

Transparent Metalized Booklet

• • • •

• • • •

• • • •

• • • •

• • • • •

• • • • •

Cavitated

BOPP

Confi guration and recipe management made easy

for fork sensors thanks to IO-Link

— Quick and easy remote teaching or locking of the buttons via

IO-Link interface

— Convenient format changeover to a different label type by

uploading the respective parameter set including teach value

to the forked sensor

— No setup time and no re-teaching of the forked sensor when

changing rolls

— Easy format change by selecting the appropriate parameter

set for the corresponding label format

— Convenient selection of the parameter set directly via the

HMI (Human Machine Interface)

PLC / HMI

Sensor

Loading...

Loading...