Page 1

DB 12 B

Double Sheet Testing Unit

en 04-2014/06 50126538

We reserve the right to

make technical changes

TECHNICAL DESCRIPTION

Page 2

© 2014

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

Leuze electronic DB 12 B

Page 3

Table of contents

1 General information ........................................................................................................... 2

1.1 Explanation of symbols ........................................................................................................ 2

1.2 Declaration of conformity ..................................................................................................... 2

2 Safety notices..................................................................................................................... 3

2.1 Safety standards ..................................................................................................................3

2.2 Intended use ........................................................................................................................ 3

2.3 Areas of application ............................................................................................................. 3

2.4 Organisational measures .....................................................................................................3

3 Device overview .................................................................................................................4

4 Specifications..................................................................................................................... 6

5 Mounting the transmitter and receiver............................................................................. 8

6 Electrical connection ......................................................................................................... 9

7 Commissioning ................................................................................................................10

8 Operation - inputs and outputs....................................................................................... 14

9 Diagnosis in the case of error ........................................................................................ 15

10 Application-specific extension types............................................................................. 16

10.1 VDB 12 B/6.10P - Detection of splices on blister material ................................................. 16

10.2 VDB 12 B/6.11N - Automatic teach on first sheet .............................................................. 16

10.3 VDB 12B/6.12P - without teach button in the cover ........................................................... 16

Leuze electronic DB 12 B 1

Page 4

General information

For UL applications:

only for use in "Class 2" circuits according to NEC.

1 General information

1.1 Explanation of symbols

The symbols used in this technical description are explained below.

Attention!

This symbol appears before text passages which must absolutely be observed. Failure to

heed this information can lead to injuries to personnel or damage to the equipment.

Notice!

This symbol indicates text passages containing important information.

1.2 Declaration of conformity

The DB 12 B double sheet testing unit sensor system has been developed and manufactured in adherence with the applicable European standards and directives.

Notice!

The corresponding declaration of conformity can be requested from the manufacturer.

The manufacturer of the product, Leuze electronic GmbH + Co. KG in D-73277 Owen/Teck,

possesses a certified quality assurance system in accordance with ISO 9001.

2 DB 12 B Leuze electronic

Page 5

2 Safety notices

2.1 Safety standards

The DB 12 B double sheet testing unit has been developed subject to the applicable safety

standard EN 60947-5-2 (IEC 60947-5-2).

2.2 Intended use

The DB 12 B double sheet testing unit has been conceived as a monitoring device mainly

for paper working machines. It monitors incoming paper sheets at machines designed to

process single sheets. It is used to detect and signal double sheets in the sheet feeder

during operation.

Attention!

The DB 12 B is not a safety module acc. to EU machine guidelines.

The protection of machine and the device cannot be guaranteed if the device is operated in

a manner not corresponding to its intended use.

Access to or changes on the device, except where expressly described in this manual, are

not authorised.

2.3 Areas of application

Safety notices

Double sheets made of the following materials can be reliably detected by the DB 12 B:

• Paper

• Plastic

• Metal foils

For paper, the measurement range is 20g/m

cardboard).

2

(airmail paper) to 1200g/m2 (homogeneous

2.4 Organisational measures

All entries in this operating manual must be heeded, in particular those in the section "Safety

notices" and "Commissioning".

Keep this technical description in a safe place. It should be accessible at all times.

Safety regulations

Observe the locally applicable safety regulations.

Qualified personnel

Mounting, commissioning and maintenance of the device may only be carried out by qualified personnel.

Leuze electronic DB 12 B 3

TNT 35/7-24V

Page 6

Device overview

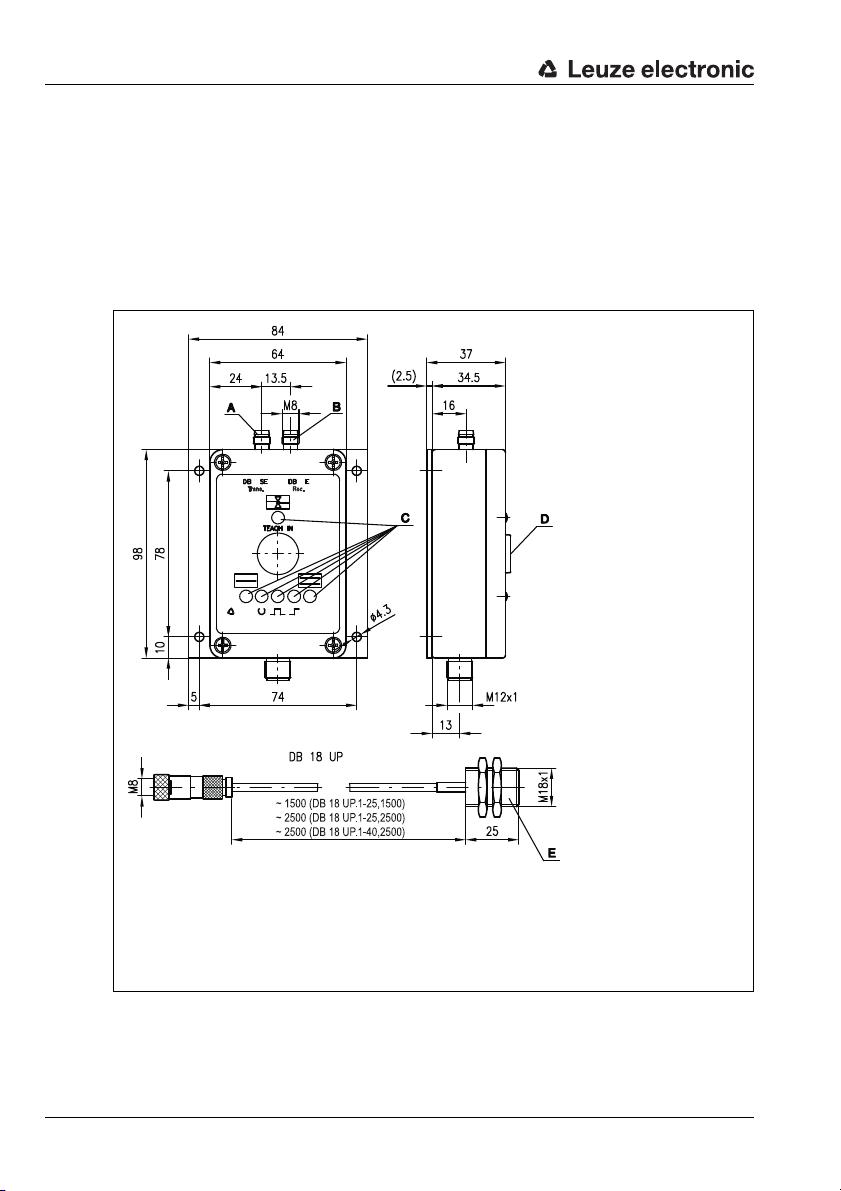

A M8 connector for transmitter DB 18 UP.1. …

B M8 connector for receiver DB 18 UP.1. …

C Indicator diodes

D Push button TEACH IN

E Alternative 42mm housing length (DB 18 UP.1-40, 2500)

3 Device overview

The ultrasonic double sheet testing system consists of a VDB 12 B… analysis amplifier and

a pair of DB 18 UP ultrasonic sensors.

It detects and checks primarily paper, plastic and metal foils which are guided in by feeders.

The device functions as a presence monitor by constantly applying a signal at the single

sheet output when an object is located between the sensors. It functions as a double sheet

testing unit by comparing each sheet with the stored reference value. A detected double

sheet is signalled at the double sheet output.

Figure 3.1: Device overview - dimensions

4 DB 12 B Leuze electronic

Page 7

Controls and indicators

A Green/yellow/red LED TEACH IN

B Ye l l o w L E D SINGLE SHEET

C Red LED DOUBLE SHEET

D Ye l l o w L E D READY

E Ye l l ow L ED TRIGGER IN

F Red LED TRIGGER OUT DOUBLE SHEET

T Push button TEACH IN

VDB 12 B/6.1P

VDB 12 B/6.1N

VDB 12 B/6P

VDB 12 B/6N

Device overview

Figure 3.2: Controls and indicators

Order guide

Designation Model Part No.

Sensor pair M18 x 25 mm, cable length 1.5m DB 18 UP.1-25,1500 501 09014

Sensor pair M18 x 25 mm, cable length 2.5m DB 18 UP.1-25,2500 501 08998

Sensor pair M18 x 42 mm, cable length 2.5m DB 18 UP.1-40,2500 501 08997

Amplifier (positive logic) VDB 12 B/6P 501 04021

Amplifier (negative logic) VDB 12 B/6N 501 04402

Amplifier with TRIGGER input (positive logic) VDB 12 B/6.1P 501 04038

Amplifier with TRIGGER input (negative logic) VDB 12 B/6.1N 501 04403

Accessories

Designation Model Part No.

Cable 5m, PVC, 5-pin, with M12 connectors K-D M12A-5P-5m-PVC 501 04557

Cable 5m, PUR, 8-pin, with M12 connectors K-D M12A-8P-5m-PUR 501 04590

Leuze electronic DB 12 B 5

TNT 35/7-24V

Page 8

Specifications

4 Specifications

Technical data for sensor DB 18 UP

Sensor data

Operating range 20 … 60mm

Converter frequency 200kHz ±2%

Ultrasonic lobe approx. 12°

Mechanical data

Housing nickel-faced brass

Weight 30g

Connection type 1.5/2.5m cable with M8 connector,

Technical data for analysis amplifier VDB 12 B/…

Timing

Switching frequency 200Hz

Input pulse min. 5 ms

Delay before start-up ≤ 300ms

Electrical data

Operating voltage U

Residual ripple ≤ 15% of U

Open-circuit current ≤ 75mA

Switching output …/6… 2 push-pull switching outputs

Function all types

Signal voltage high/low ≥ (UB- 2V) / ≤ 2V

Output current max. 100mA per output

TEACH-/TRIGGER input R

TEACH-/TRIGGER IN active/not active5)…/…P (PNP): ≥ 10V / ≤ 2V or not connected

TRIGGER IN pulse duration ≥ 1ms

TEACH-/TRIGGER IN duration max. 100ms

TEACH IN delay

Indicators

all models:

LED green A double sheet testing unit ready

LED A yellow teach-in process

LED A red flashing error (see chapter 9)

LED yellow B single sheet detected

LED red C double sheet detected

only …/6.1…:

LED yellow D ready for function READY

LED yellow E inquiry signal TRIGGER IN

LED red F double sheet triggered TRIGGER OUT

Mechanical data

Housing aluminium, black powder-coated

Weight 400g

Connection type M12 connector,

6)

3-pin, bending radius r > 25mm

1)

B

…/6.1… 4 push-pull switching outputs 1

all types

only …/6.1…

only …/6.1…

18 … 30VDC (incl. residual ripple)

B

single sheet detected, or ≥ 1 sheet

double sheet detected, or ≥ 2 sheets

double sheet triggered

double sheet testing unit ready to operate

=10kΩ

in

…/…N (NPN): ≤ 2V / ≥ 10V or not connected

approx. 300ms

…/6…:5-pin

…/6.1…:8-pin

2)

3)

4)

6 DB 12 B Leuze electronic

Page 9

Specifications

Environmental data

Ambient temp. (operation/storage) 0 °C … +50°C / -40°C … +70 °C

Protective circuit

VDE safety class III

Protection class IP 65

Standards applied EN 60947-5-2

Certifications UL 508, C22.2 No.14-13

1) For UL applications: only for use in "Class 2" circuits according to NEC.

2) Function: …/…P = active high (+24V); inactive low (0V),

The push-pull switching outputs must not be connected in parallel

3) Is set during low/high transition (…/…P) or high/low transition (…/…N) of the TRIGGER IN

input and reset when the measurement field becomes vacant; trigger delay

response time from edge until switching of the switching output is

4) Is set when the operating voltage is applied if the receiving level is adequate as well as

after the teach event if the calibration was successful.

5) Setting the Teach IN input disables the TEACH IN button (see page 10)

6) Only applies for automatic calibration during sheet movement (automatic teach)

7) 1=transient protection, 2=polarity reversal protection, 3=short circuit protection

8) These proximity switches shall be used with UL Listed Cable assemblies rated 30V,

0.5A min, in the field installation, or equivalent (categories: CYJV/CYJV7 or PVVA/PVVA7)

7)

…/…N = active low (0V); inactive high (+24V).

1,2,3

1) 8)

≤ 1ms

≤ 1ms, i.e.,

Leuze electronic DB 12 B 7

TNT 35/7-24V

Page 10

Mounting the transmitter and receiver

A Receiver

B Angle of inclination

C Sheet material

D Transmitter

Sheet material Recomm. angle of inclination B

0° 15° … 25° 25° … 35°

Standard paper up to 150g/m² X X X

Cardboard X X

Plastics X

A Receiver

B Machine direction

C Sheet material

D Transmitter

5 Mounting the transmitter and receiver

The transmitter and receiver (DB 18 UP) are identical in construction and are to be mounted

according to the table in figure 5.1 at an angle which varies depending on the sheet material.

A larger angle of inclination increases the flutter range; e.g. with a 35° pitch, flutter is permissible within 50% of the measurement field. The distance between transmitter and receiver

must be at least 20mm and can be max. 60mm.

Ensure that alignment is exact (± 1°). If the alignment does not run along the axis, the

working range is reduced.

Notice!

When aligning the transmitter and receiver, take care to ensure the most exact alignment

possible. See "Alignment mode" on page 10. To ensure proper function, the sensors must

be inclined by the angle "B" towards the vertical.

Figure 5.1: Mounting the transmitter and receiver

Figure 5.2: Recommended configuration for maximum functionality

8 DB 12 B Leuze electronic

Page 11

6 Electrical connection

Connect the transmitter and receiver at the appropriate M8 connectors of the VDB 12 B…

analysis amplifier.

Connect the analysis amplifier acc. to connection diagram (figure 6.1).

Figure 6.1: Connection diagrams VDB 12 B…

Circuit logic

VDB 12B/…P -> positive logic

VDB 12B/…N -> negative logic

Electrical connection

Leuze electronic DB 12 B 9

TNT 35/7-24V

Page 12

Commissioning

7 Commissioning

Notice!

If the indicators flash during the initial commissioning, a calibration must first be performed

on a single sheet.

First apply operating voltage. An alignment mode is available for commissioning. This can

be used to check the alignment of the transmitter and receiver.

Alignment mode

Press the TEACH IN button

for > 5s and < 10 s

LEDs and flash synchronously at 3 Hz

LED green:

LED yellow:

LED red: Alignment bad

Notice!

After exiting alignment mode, it is absolutely necessary to perform a calibration.

Calibrating on the material to be detected

For reliable detection of double layers of the medium being processed, it is always necessary to perform a calibration on a single sheet of the medium.

Calibration of the material to be detected can be performed by either pressing the TEACH IN

button on the analysis amplifier for 0.3s to 5s or by means of a control command at the

Teach IN input (pin 5).

Alignment OKExit:

Alignment

critical

press the TEACH IN button < 5s

Align transmitter and receiver until

LED is green.

Only then is it possible to exit alignment mode!

Extraordinary exiting of alignment

mode is possible only by means of

Power OFF!

Align transmitter and receiver until

LED is green.

Only then is it possible to exit alignment mode!

Extraordinary exiting of alignment

mode is possible only by means of

Power OFF!

Notice!

Setting the Teach IN input (pin 5) disables the TEACH IN button. As soon as a signal is applied once via the Teach IN input for the purpose of calibration, the TEACH IN button remains inactive (disabled) until the next Power On.

10 DB 12 B Leuze electronic

Page 13

Commissioning

During the calibration process, LED illuminates yellow.

If the calibration was successful, LED illuminates green and LEDs and yellow.

The single sheet and ready outputs are activated. The reference value remains stored until

the next calibration process.

If the calibration process was not successful, LED flashes red and LEDs and

illuminate red. The double sheet and TRIGGER OUT outputs (double sheet triggered) are

activated.

Notice!

Causes of unsuccessful calibration include e.g.:

• More than 1 sheet between the sensors.

• Unsuitable sheet material, e.g. due to lamination or coating, too thin, too thick, or air

pockets present.

• Pitch to sensors too low.

For devices VDB 12 B/6.1N and VDB 12 B/6.1P with trigger input Trigger IN (pin 6), it is

recommended that the device be configured in such a way that, for Trigger IN, the threshold

signals be adapted so that the amplifier always operates in the optimum range (1., standard

mode). This mode is especially recommended when the material consistency changes

during operation (moisture, density, …).

The VDB 12 B analysis amplifier can be operated in 3 different operating modes (teach

modes):

1. Standard mode:

Teach with intelligent transmitter/receiver control for covering a wide spectrum of

materials. Automatic signal adaptation (averaging) during operation for VDB 12 B/

6.1….

2. Automatic teach:

300ms after sheet detection by the ultrasonic sensors, teach-in occurs automatically.

In this operating mode, manual or external teaching is not necessary. Automatic signal adaptation (averaging) possible during operation for VDB 12 B/6.1…. Another

automatic teach-in is carried out when the ultrasonic path is clear for more than 2s.

3. Fixed switching threshold:

This operating mode is recommended when the process does not permit manual or

external teaching. In this operating mode, the variety of materials to be detected is

limited.

TNT 35/7-24V

Leuze electronic DB 12 B 11

Page 14

Commissioning

Selecting the operating mode (teach mode)

Press the TEACH IN button

for >10s and <15s

1. LED green:

2. LED red:

3. LED off:

Attention!

After selecting the operating mode (teach mode), a calibration must be performed!

LEDs and flash alternately at 3 Hz

Manual teach

(standard mode)

Automatic teach on

the first sheet

Permanently stored

switching threshold

To select and exit:

press the TEACH IN button > 3s

(LED yellow)

To advance to next:

press the TEACH-IN button

<3s

To select and exit:

press the TEACH IN button > 3s

(LED yellow)

To advance to next:

press the TEACH-IN button

<3s

To select and exit:

press the TEACH IN button > 3s

(LED yellow)

To advance to next:

press the TEACH-IN button

<3s

Adapting the averaging calculation (VDB 12 B/6.1… only)

For device variants VDB 12 B/6.1… with trigger input, it is possible to adapt the signals

during running control operation (operating mode 1, standard mode).

Signal adaptation is performed by averaging measurement values which are detected at the

respective Trigger IN. A lower value, e.g. 4, means that an average value is calculated from

4 trigger IN measurement values; a higher value, e.g. 128, means that an average value is

calculated from 128 trigger-in measurement values. Signal adaptation occurs every time the

set number of trigger pulses is reached.

Signal adaptation (averaging) is also possible in operating mode 2, automatic teach.

Attention!

After changing the averaging, recalibration must be performed!

12 DB 12 B Leuze electronic

Page 15

Commissioning

Press the TEACH IN button

for > 15s and < 20s

LED flashes red, LED illuminates yellow.

The other LEDs display the current configured average value

Average value

via

off =

no signal

adaptation

LED LED LED

off off off

4 values

(trigger pulses)

on off off

8 values

(trigger pulses)

off on off

16 values

(trigger pulses,

default)

on on off

32 values

(trigger pulses)

off off on

64 values

(trigger pulses)

on off on

128 values

(trigger pulses)

off on on

No change back on on on

To select and exit:

press the TEACH IN button > 3s

(LED briefly green)

To advance to next:

press the TEACH-IN button < 3s.

To select and exit:

press the TEACH IN button > 3s

(LED briefly green)

To advance to next:

press the TEACH-IN button < 3s.

To select and exit:

press the TEACH IN button > 3s

(LED briefly green)

To advance to next:

press the TEACH-IN button < 3s.

To select and exit:

press the TEACH IN button > 3s

(LED briefly green)

To advance to next:

press the TEACH-IN button < 3s.

To select and exit:

press the TEACH IN button > 3s

(LED briefly green)

To advance to next:

press the TEACH-IN button < 3s.

To select and exit:

press the TEACH IN button > 3s

(LED briefly green)

To advance to next:

press the TEACH-IN button < 3s.

To select and exit:

press the TEACH IN button > 3s

(LED briefly green)

To advance to next:

press the TEACH-IN button < 3s.

To select and exit:

press the TEACH IN button > 3s

(LED briefly green)

TNT 35/7-24V

Attention!

After changing the averaging, recalibration must be performed!

Leuze electronic DB 12 B 13

Page 16

Operation - inputs and outputs

8 Operation - inputs and outputs

The evaluation unit VDB 12 B/6P or VDB 12 B/6N continuously signals the situation occurring between the sensors to two outputs.

The single sheet output (pin 2) is activated as long as one or more sheets are located in

the measurement field.

The double sheet output (pin 4) is activated as long as two or more sheets are located in

the measurement field.

Notice!

For reliable operation, it is essential that calibration be performed on the material to be

detected. See "Calibrating on the material to be detected" on page 10.

Also available on the VDB 12 B/6.1… evaluation units are a Trigger IN query input, a

Trigger OUT double sheet output stored at the query time, as well as a ready output.

If a double sheet is detected on the ascending edge (VDB 12 B/6.1P) or on the falling edge

(VDB 12 B/6.1N) of the query, the Trigger OUT output is set. This remains set until the ultrasonic path is cleared.

The ready output is set if the receiving level is sufficient when operating voltage is supplied.

It remains set until the next calibration, provided a calibration has already been successfully

completed.

The reference value remains stored even after a voltage interruption.

14 DB 12 B Leuze electronic

Page 17

9 Diagnosis in the case of error

Attention!

In the event of an error, the ready output is not active and LED is switched off!

The device LEDs indicate the following error states:

LEDLEDLEDLEDLED Meaning Cause Remedy

red

red

red

red

red

yellow

flashing

(6Hz)

rapid

yellow

flashing

red red

red

flashing

(6Hz)

red

flashing

(6Hz)

rapid

red

flashing

red

flashing

(6Hz)

flashing

(6Hz)

flashing

(6Hz)

flashing

(6Hz)

flashing

(3Hz)

Diagnosis in the case of error

Double-sheet

control not calibrated

No single sheet

detected during

calibration

Amplifier

detects insufficient

input signal

when device

switched on

Amplifier

detects excessively high noise

level when

device switched

on

Current at

output too high

Fatal

memory error

No sheet

inserted or double sheet

inserted

Sheet between

the sensors or

sensors not

connected

Extreme

background

noise

Short circuit

Defect

Perform

calibration

Calibrate on single sheet

Remove sheet

and acknowledge with the

TEACH IN button

Dampen background noises,

e.g. using foam

Switch off voltage, check wiring

Have repaired

by Leuze electronic

Leuze electronic DB 12 B 15

TNT 35/7-24V

Page 18

Application-specific extension types

10 Application-specific extension types

The amplifier types described below are used for the adaptation to specific applications.

They are used instead of the standard amplifier types.

10.1 VDB 12 B/6.10P - Detection of splices on blister material

This amplifier corresponds to the VDB 12B/6P with regard to the technical and electrical

data. The software is adapted for splice detection on plastic rolls (blister material). That is,

the system is more sensitive for the detection of two layers (splices). This does however

require the reduction of the flutter range to a maximum of 2mm.

The function of the push-pull switching outputs is inverted. That is, the PNP outputs for

single and double sheets are activated if there is no material between the sensors.

After applying the supply voltage, the check of operational readiness is deactivated because

at switching on, material may be present between the sensors in the application.

Designation Model Part No.

Amplifier (positive logic) for splice detection VDB 12 B/6.10P 501 07312

10.2 VDB 12 B/6.11N - Automatic teach on first sheet

This amplifier corresponds to the VDB 12B/6N with regard to the technical and electrical

data. At delivery, the amplifier is preconfigured to the operating mode "automatic teach on

first sheet".

This customer-specific configuration features what is called FAST TEACH-IN in the "automatic teach on first sheet" teach mode. The reaction time (TEACH-IN delay) is 1ms. A new

automatic teach-in is carried out if the ultrasonic path is clear for more than 2s.

The detection range covers papers between 40g/m² and 450g/m².

Designation Model Part No.

Amplifier (negative logic) for automatic teach VDB 12 B/6.11N 501 07511

10.3 VDB 12B/6.12P - without teach button in the cover

This amplifier corresponds to the VDB 12B/6P with regard to technical and electrical data as

well as the software. The devices are delivered with "manual teach" operating mode.

The calibration on the material to be detected is performed using pin 5 on the M 12

connector.

Designation Model Part No.

Amplifier (positive logic) without teach button in the cover VDB 12 B/6.12P 501 09781

Notice!

To enter alignment mode, the 2-pin pin strip directly on the PCB can be bridged for longer

than 5s. Afterwards, alignment can be carried out as described in chapter 7.

16 DB 12 B Leuze electronic

Loading...

Loading...