Page 1

r

r

r

r

Manual - Capacitive Sensor LCS

Safety Instructions and Functions and Features

• Please read the product description prior to set-up of the unit. Ensure that the product is suitable for your application without any restrictions.

• The unit conforms to the relevant regulations and EC directives.

• Improper or non-intended use may lead to malfunctions of the unit or to unwanted effects in your application.

• That is why installation, electrical connection, set-up, operation and maintenance of the unit must only be carried out by qualified personnel

authorized by the machine operator.

• The capacitive sensor detects without contact metals, almost all plastics, glass, ceramics, wood, paper, oils, greases, water and all hydrous

materials and indicates their presence by providing a switched signal.

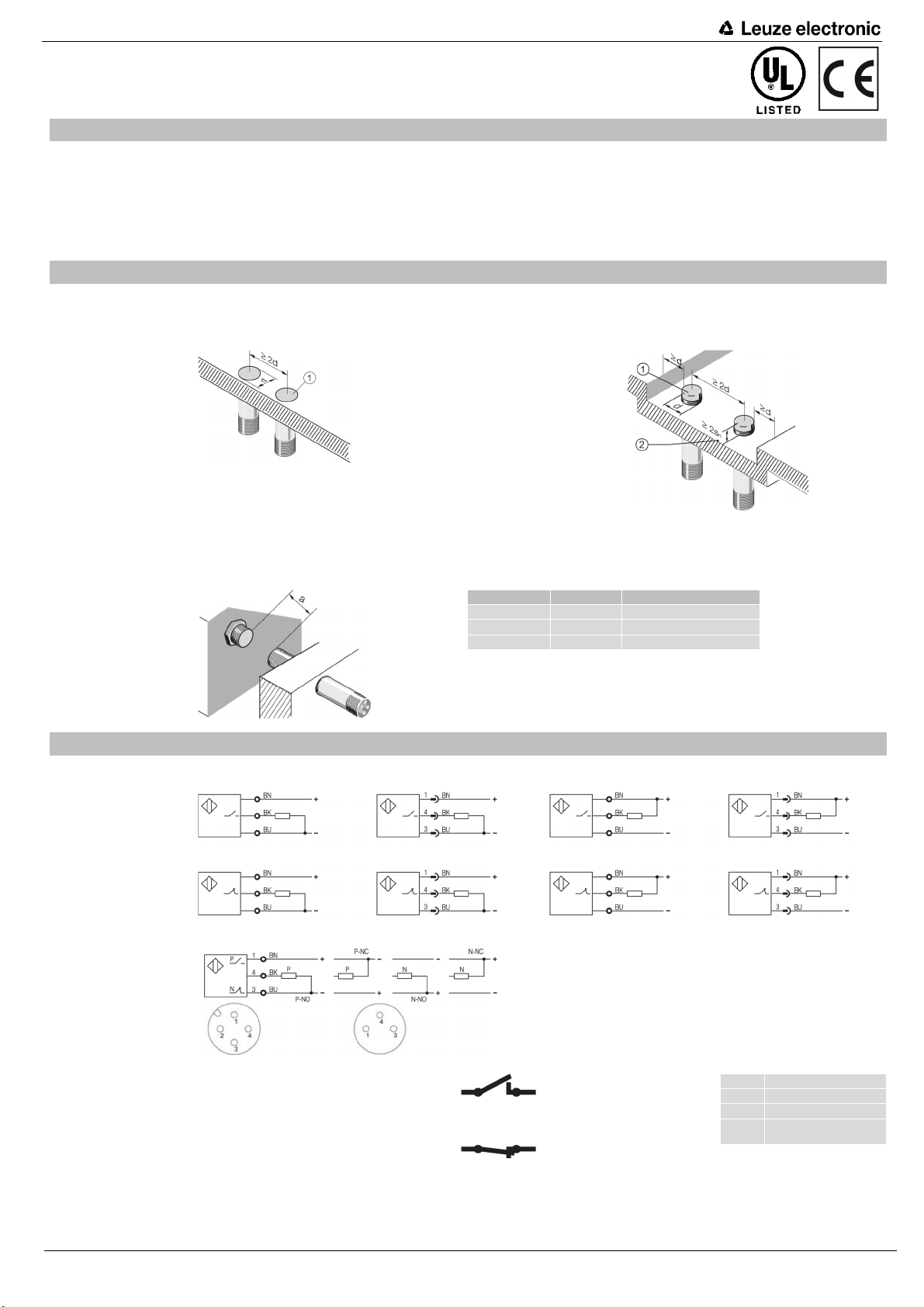

Mounting Restrictions

Flush-mount (shielded)

proximity switches

... can be installed with their sensing faces flush

to the metal.

The distance between two proximity switches

(in row mounting) must be ≥ 2d.

Non-flush-mount

(unshielded) proximity

switches

The sensing face must extend ≥ 2s

from the

n

metallic installation medium. The distance

between two proximity switches must be ≥ 2d

① Sensing ① Sensing

②Clea

Opposing installation of

2 sensors

Housing size Material Tightening torque

es a minimum distance of a ≥ 4d

... requi

between the sensing faces..

To ensure that the sensors are not mechanically destroyed during

installation, make sure that you comply with the following torque figures.

M12×1 V2A 40 Nm

M18×1 V2A 60 Nm

M30×1,5 V2A 90 Nm

Electrical Definitions

DC 3-/4-wire PNP (+) sourcing

Normally open

Cable/terminals

Connecto

NPN (–) sinking

Cable/terminals

Normally closed

PNP/NPN selectable (LCS-1Q40P-F20BNP-K020P)

NO/NC user selectable

(XDC - output)

Connecto

Switching function

N.O. (normally open): The sensor closes a circuit to the load when

a target is detected or the sensor is

operated. Contacts are open when the

Wire colors,

marking per

DIN IEC 60757

sensor is not operated and when there is no

external force on the actuator.

BN brown

BK black

BU blue

WH white

N.C. (normally closed): The sensor opens a circuit to the load when

a target is detected or the sensor is

operated. Contacts are closed when the

sensor is not operated and when there is no

external force on the actuator.

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen We reserve the right to make changes

• www.leuze.com Tel. +49 (0) 7021 573-0 04/2017 - 50136911 - 1/2

Page 2

r

Adjustment

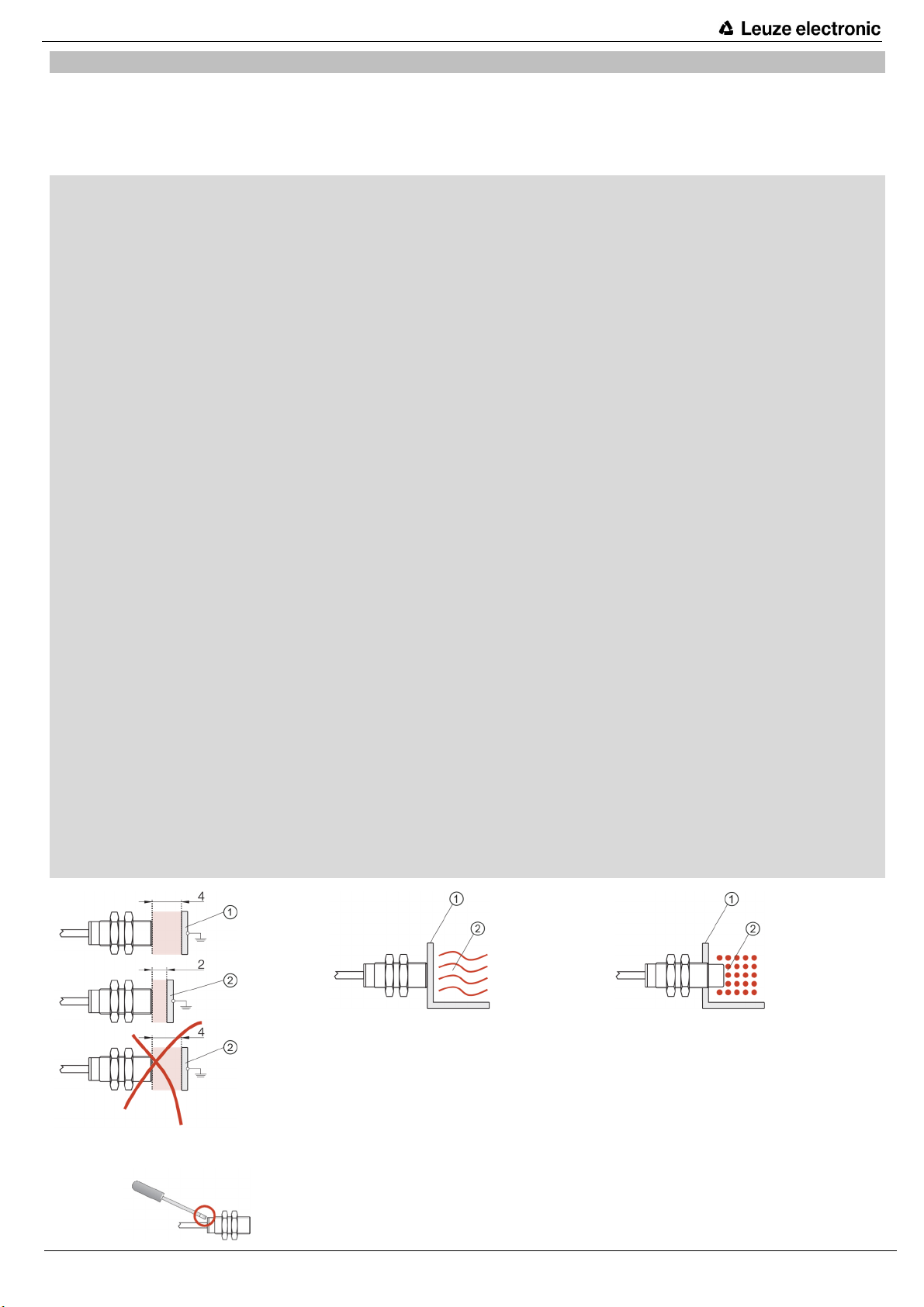

Flush (shielded) Sensors Non-Flush (unshielded) Sensors

Flush mountable sensors are normally being used for presence detection of objects or for indirect

point level detection of solids, powders or liquids. The following two setup routines help to assure

proper setup and operations. All LCS sensors allow sensitivity adjustment potentiometer.

These capacitive sensors use a larger spherical

electrical field which is especially suited as level

detectors for liquids, granulates or powders.

Object Fluid Plastic

Presence Detection of Solid Objects

The following procedures are outlined for

setting a normally open capacitive sensor for

ideal sensing conditions:

1. Mount the sensor in the actual sensing

position

2. Set up the target for the worst case

condition. This means for a presence

detection application to move the object to

the farthest occurring position from the

sensor.

3. All LCS capacitive sensors are already

factory preset to their maximum

operational sensing range. The sensor has

to move closer to the target object, if the

farthest object position does not assure a

reliable switching. Alternatively, a larger

sensor with a larger sensing range can be

chosen.

4. The sensitivity can now be reduced by

turning the potentiometer CCW until the

sensor switches off. Increase now the

sensitivity

CW by 1/2 turn to set the sensor to its optimal

sensitivity setting.

Example:

In the following example, a shielded capacitive

sensor in a M12 tubular housing will be used to

detect a ceramic plate.

The sensor is factory preset to a maximum

rated switching distance sn of 4 mm to metal or

by approximation to your hand. When moving

the sensor towards the target object, the rated

switching distance sn to the ceramic plate has

been reduced to approx. 2 mm. This distance is

now the maximum permissible switching

distance for the ceramic plate.

Note:

To ensure that Leuze LCS capacitive sensors

work reliably within their technical specifications, they have a greater sensing distance

than the indicated maximum rated switching

distance sn in the datasheet. If the user decides

Point-Level Detection through Container Walls

Empty Setup (normally open)

1. Mount the sensor in the actual level sensing

position flush to the non-metallic container

wall.

2. All LCS capacitive sensors are already

factory preset to their maximum operational

sensing range. The sensor will initially trigger

on the container wall material.

3. The sensitivity has to be reduced by turning

the potentiometer CCW until the sensor

switches off. Increase now the sensitivity CW

by 1/2 turn to set the sensor to its optimal

sensitivity setting.

4. The sensor should switch on at 40% to 50%

sensing area coverage - readjust the

sensitivity CCW if the coverage is above

50% and CW if it is below 40%.

Full Setup (normally open)

1. Mount the sensor in the actual level sensing

position flush to the non-metallic container

wall.

2. All LCS capacitive sensors are already

factory preset to their maximum operational

sensing range. The sensor will initially switch

on to the container wall.

3. The sensitivity has to be reduced by turning

the potentiometer CCW until the sensor

switches off. Increase now the sensitivity CW

by 1/2 turn to set the sensor to its optimal

sensitivity setting.

4. The sensor should switch on at 40% - 50%

sensing area coverage - readjust the

sensitivity CCW if the coverage is above

50% and CW if it is below 40%.

Note:

The partition wall may only be made of glass or

plastic. A rule of thumb for the maximum

thickness of the wall yields a value of approx.

10 to 20% of the sensor‘s rated switching

distance, but max. 4 mm.

Direct Point-Level detection

Full Setup (normally open)

1. Mount the sensor in the actual level

sensing position with regards to the

minimum clearance guide line in our

mounting reference.

2. All LCS capacitive sensors are already

factory preset to their maximum

operational sensing range. The sensor will

initially switch on contact with the target

material.

3. The sensitivity has to be reduced by

turning the potentiometer CCW until the

sensor switches off. Now increase the

sensitivity CW by 1/2 turn to set the sensor

to its optimal sensitivity setting.

This setup procedure assures that the influence

of temperature and material build-up has been

reduced to a minimum. In some instances,the

target material creates extensive material buildup or has a very high relative dielectric constant

(conductivity) leading to uncontrollable

repetitive false triggering.

to adjust the sensor to a switching distance

greater than 2 mm for the above described

ceramic plate, the sensor will operate in an

unreliable mode. This entails a risk that temperature and other environmental factors or

electrical interferences may lead to unreliable

switching conditions.

CCW = counter-clockwise

CK = clockwise

① Metal

② Ceramic

① Wall thickness (max. 4 mm glass or plastic)

② Wate

① Wall

② Plastic granulate

Important: Different material properties and conditions have to be taken into consideration during

the calibration process. All Leuze LCS capacitive sensors are therefore equipped with highly

accurate trim potentiometers to adjust the device‘s sensitivity. Turning the potentiometer clockwise

(CW) increases the sensitivity, whereas counter-clockwise (CCW) turning reduces it.

Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen We reserve the right to make changes

• www.leuze.com Tel. +49 (0) 7021 573-0 04/2017 - 50136911 - 2/2

Loading...

Loading...