Leuze BCL558i TECHNICAL DESCRIPTION

BCL558i

Bar code reader

en 01-2013/06 50123233

We reserve the right to

make technical changes

TECHNICAL DESCRIPTION

© 2013

Leuze electronic GmbH + Co. KG

In der Braike 1

D-73277 Owen - Teck / Germany

Phone: +49 7021 573-0

Fax: +49 7021 573-199

http://www.leuze.com

Leuze electronic BCL 558i

BCL 558i

ENIP

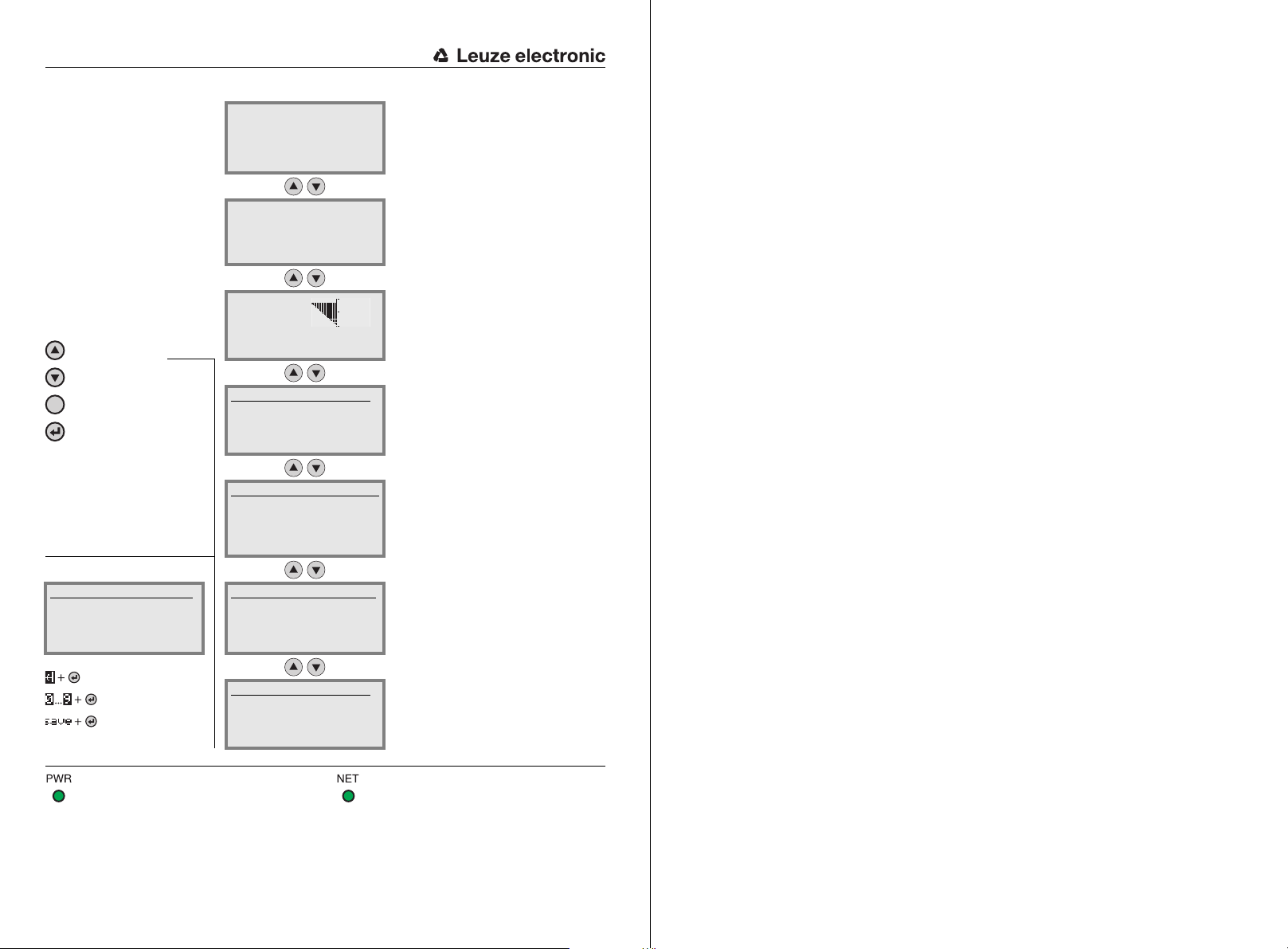

Navigate

upward/laterally

Navigate

downward/laterally

ESCAPE

leave

ENTER

confirm

Device buttons:

Delete character

Enter digit

Save input

The main menus

ESC

Input of values

12|

<-|0123456789 save

Standard --------- Unit

126 | |

BCL558i SF 102

Leuze electronic

GmbH & Co. KG

SW: V 1.4 HW:1

SN: 0704-081894 001

Network settings

Channel 1:

Addr: 192.168.60.101

Mask: 255.255.255.0

Gateway: 0.0.0.0

IO1 IO2 IO3

IO4 ATT ERR

12345678

Parameter

Parameter handling

Decoder table

Digital SWIO

EtherNet/IP

Language selection

o Deutsch

o English

o Español

o Français

o Italiano

Service

Diagnostics

Status messages

Device information - main menu

Information about

• Device type

• Software version

• Hardware version

• Serial number

Network settings - main menu

• Display of the network settings

See "EtherNet/IP" on page 99.

Bar code reading window - main

menu

Visualization of the read bar code information.

See "Indicators in the display" on page 86.

Parameter - main menu

Configuration of the bar code reader.

See "Parameter menu" on page 92.

Language selection - main menu

Selection of the display language.

See "Language selection menu" on

page 100.

Service - main menu

Scanner diagnosis and status messages.

See "Service menu" on page 100.

PWR LED NET LED

Off Device OFF Off No supply voltage/IP address

Flashes green Device ok, initialization phase Flashes green No Ethernet/IP communication

Green, continuous light Device OK Green, continuous light Bus communication ok

Orange, continuous light Service mode Flashes red Timeout

Flashes red Device ok, warning set Flashes red/green self test

Red, continuous light Device error Red, continuous light double IP address

Actions

o Start decoding

o Start alignment

o Start auto-setup

o Start teach-in

Actions - main menu

Various functions for scanner configuration

and manual operation.

See "Actions menu" on page 101.

Table of contents

1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Safety notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 General safety notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Safety standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Approved purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Working safely . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Fast commissioning / operating principle . . . . . . . . . . . . . . . . . . . 13

3.1 Mounting the BCL 558i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Device arrangement and selection of the mounting location . . . . . . . . . . . . . . . . . . . . 13

3.3 Electrical connection BCL 558i. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Starting the device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5 Further settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.6 Bar code reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1 About the bar code readers of the BCL 500i series. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2 Characteristics of the bar code readers of the BCL 500i series . . . . . . . . . . . . . . . . . . 21

4.3 Device construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.4 Reading techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4.1 Line scanner (single line). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4.2 Line scanner with oscillating mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4.3 Omnidirectional reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.5 Fieldbus systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.5.1 EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.5.2 Ethernet – star topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.5.3 Ethernet – linear topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.6 Heater. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.7 External parameter memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.8 autoReflAct. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.9 Reference codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.10 autoConfig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.1 General specifications of the bar code readers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Leuze electronic BCL 548i 1

Table of contents

5.1.1 Line scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.1.2 Oscillating-mirror scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5.1.3 Line scanner with deflection mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2 Heating models of the bar code readers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2.1 Line scanner with heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

5.2.2 Oscillating-mirror scanner with heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.2.3 Line scanner with deflection mirror and heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3 Dimensioned drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3.1 Line scanner with / without heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3.2 Deflection mirror scanner with / without heating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.3.3 Oscillating-mirror scanner with / without heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.4 Type overview BCL 558i. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.5 Reading field curves / optical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.6 Reading field curves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

5.6.1 High Density (N) Optics: BCL 558i SN 100/102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.6.2 High Density (N) Optics: BCL 558i ON 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.6.3 Medium Density (M) Optics: BCL 558i SM 100/102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.6.4 Medium Density (M) Optics: BCL 558i OM 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.6.5 Low Density (F) Optics: BCL 558i SF 100/102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.6.6 Low Density (F) Optics: BCL 558i OF 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.6.7 Ultra Low Density (L) Optics: BCL 558i SL 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.6.8 Ultra Low Density (L) Optics: BCL 558i OL 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.7 Reading field curves for heating devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.7.1 High Density (N) Optics: BCL 558i SN 102 H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.7.2 High Density (N) Optics: BCL 558i SN 100 H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.7.3 High Density (N) Optics: BCL 558i ON 100 H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.7.4 Medium Density (M) Optics: BCL 558i SM 102 H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.7.5 Medium Density (M) Optics: BCL 558i SM 100 H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.7.6 Medium Density (M) Optics: BCL 558i OM 100 H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.7.7 Low Density (F) Optics: BCL 558i SF 102 H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.7.8 Low Density (F) Optics: BCL 558i SF 100 H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.7.9 Low Density (F) Optics: BCL 558i OF 100 H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.7.10 Ultra Low Density (L) Optics: BCL 558i SL 102 H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.7.11 Ultra Low Density (L) Optics: BCL 558i OL 100 H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6 Installation and mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.1 Storage, transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.2 Mounting the BCL 558i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.2.1 Fastening with M4 x 6 screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.2.2 BT 56 mounting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.2.3 BT 59 mounting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

2 BCL 548i Leuze electronic

Table of contents

6.3 Device arrangement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.3.1 Selecting a mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.3.2 Avoiding total reflection – Line scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.3.3 Avoiding total reflection – oscillating/deflection-mirror scanner. . . . . . . . . . . . . . . . . . . . 71

6.3.4 Mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.3.5 Devices with integrated heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.3.6 Possible read angles between BCL 558i and bar code . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.4 Attaching laser warning sign. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.5 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.1 Safety notices for the electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.2 Electrical connection of the BCL 558i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.2.1 PWR – Voltage supply and switching input/outputs 3 and 4 . . . . . . . . . . . . . . . . . . . . . . 77

7.2.2 SERVICE – USB interface (type A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.2.3 SW IN/OUT – Switching input/switching output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7.2.4 HOST / BUS IN for BCL 558i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7.2.5 BUS OUT for the BCL 558i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7.3 Ethernet topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.3.1 Ethernet wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.4 Cable lengths and shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8 Display and control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.1 Structure of the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.2 Status display and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.2.1 Indicators in the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.2.2 LED status indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.2.3 Control buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

8.3 Menu description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

8.3.1 The main menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

8.3.2 Parameter menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.3.3 Language selection menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8.3.4 Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8.3.5 Actions menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

8.4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

9 Leuze webConfig tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

9.1 Connecting the SERVICE USB interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

9.2 Installing the required software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

9.2.1 System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

9.2.2 Installing the USB driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Leuze electronic BCL 548i 3

Table of contents

9.3 Starting the webConfig tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

9.4 Short description of the webConfig tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

9.4.1 Module overview in the Configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

10 Commissioning and configuration . . . . . . . . . . . . . . . . . . . . . . . . 110

10.1 Measures to be performed prior to the initial commissioning . . . . . . . . . . . . . . . . . . .111

10.2 Starting the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

10.3 Setting the communication parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

10.3.1 Manually setting the IP address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

10.4 Configuration steps for a Rockwell control without EDS support . . . . . . . . . . . . . . . . 115

10.4.1 Integrating the hardware into the PLC using the generic Ethernet module. . . . . . . . . . . 115

10.5 Configuration steps for a Rockwell control with EDS support . . . . . . . . . . . . . . . . . . . 116

10.5.1 Integrating the hardware into the PLC and installing the EDS file . . . . . . . . . . . . . . . . . . 116

10.6 EDS file - general info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

10.7 Detailed EDS description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

10.7.1 Class 1 - Identity object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

10.7.2 Class 4 - Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

10.7.2.1 Input assembly...........................................................................................................................119

10.7.2.2 Output assembly........................................................................................................................122

10.7.2.3 Configuration assembly .............................................................................................................125

10.7.3 Class 103 - I/O status and control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

10.7.4 Class 106 - Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

10.7.5 Class 107 - Result data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

10.7.6 Class 108 - Entry data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

10.7.7 Class 109 - Device status and device control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

10.8 Configuration example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

10.8.1 Example 1 - activation & result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

10.8.2 Example 2 - activation & result & I/Os . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

10.8.3 Example 3 - activation & fragmented result. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

10.8.4 Example 4 - entry data & result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

10.9 Additional settings for the BCL 558i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

10.9.1 Decoding and processing the read data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

10.9.2 Control of the decoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

10.9.3 Control of the switching outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

10.10 Transmitting configuration data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

10.10.1 Via the webConfig tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

10.10.2 With the external parameter memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

11 Online commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

11.1 Overview of commands and parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

11.1.1 General 'online' commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

4 BCL 548i Leuze electronic

Table of contents

11.1.2 ’Online’ commands for system control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

11.1.3 ’Online’ commands for configuration of switching inputs/outputs . . . . . . . . . . . . . . . . . 164

11.1.4 ’Online’ commands for the parameter set operations . . . . . . . . . . . . . . . . . . . . . . . . . . 167

12 Diagnostics and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 173

12.1 General causes of errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

12.2 Interface errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

13 Type overview and accessories . . . . . . . . . . . . . . . . . . . . . . . . . 175

13.1 Type key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

13.2 Type overview BCL 558i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

13.3 Accessory connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

13.4 Accessory USB cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

13.5 Accessory external parameter memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

13.6 Accessory mounting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

13.7 Accessory reflector for AutoReflAct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

13.8 Accessory ready-made cables for voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

13.8.1 Contact assignment of PWR connection cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

13.8.2 Specifications of the cables for voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

13.8.3 Order codes of the cables for voltage supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

13.9 Accessory ready-made cables for bus connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

13.9.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

13.9.2 Contact assignments M12 Ethernet connection cables KB ET… . . . . . . . . . . . . . . . . . 179

13.9.3 Specifications of the M 12 Ethernet connection cables KB ET… . . . . . . . . . . . . . . . . . . 179

13.9.4 Order codes for M 12 Ethernet connection cables KB ET…. . . . . . . . . . . . . . . . . . . . . . 180

14 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

14.1 General maintenance information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

14.2 Repairs, servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

14.3 Disassembling, packing, disposing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

15 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

15.1 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

15.2 ASCII character set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

15.3 Bar code samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

15.3.1 Module 0.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

15.3.2 Module 0.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Leuze electronic BCL 548i 5

Figures and tables

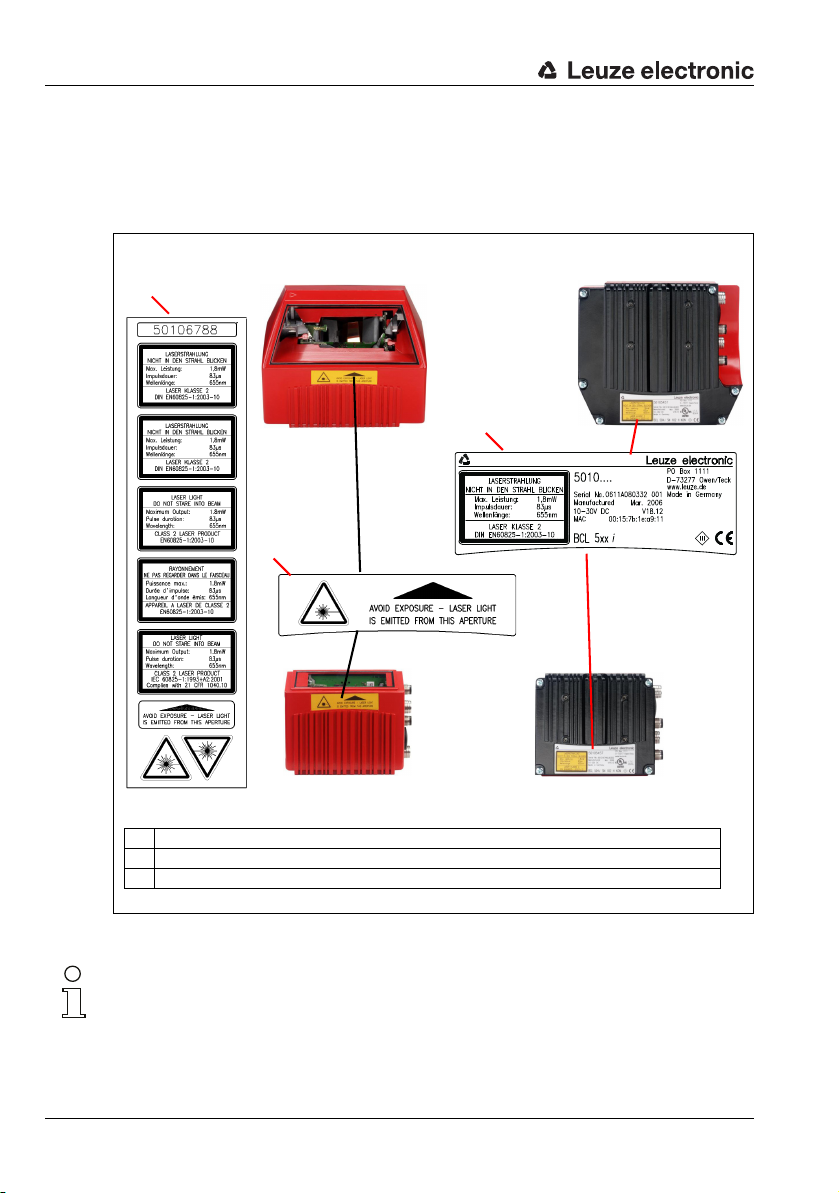

Figure 2.1: Attachment of the stick-on labels with warning notices at the BCL 558i................................ 12

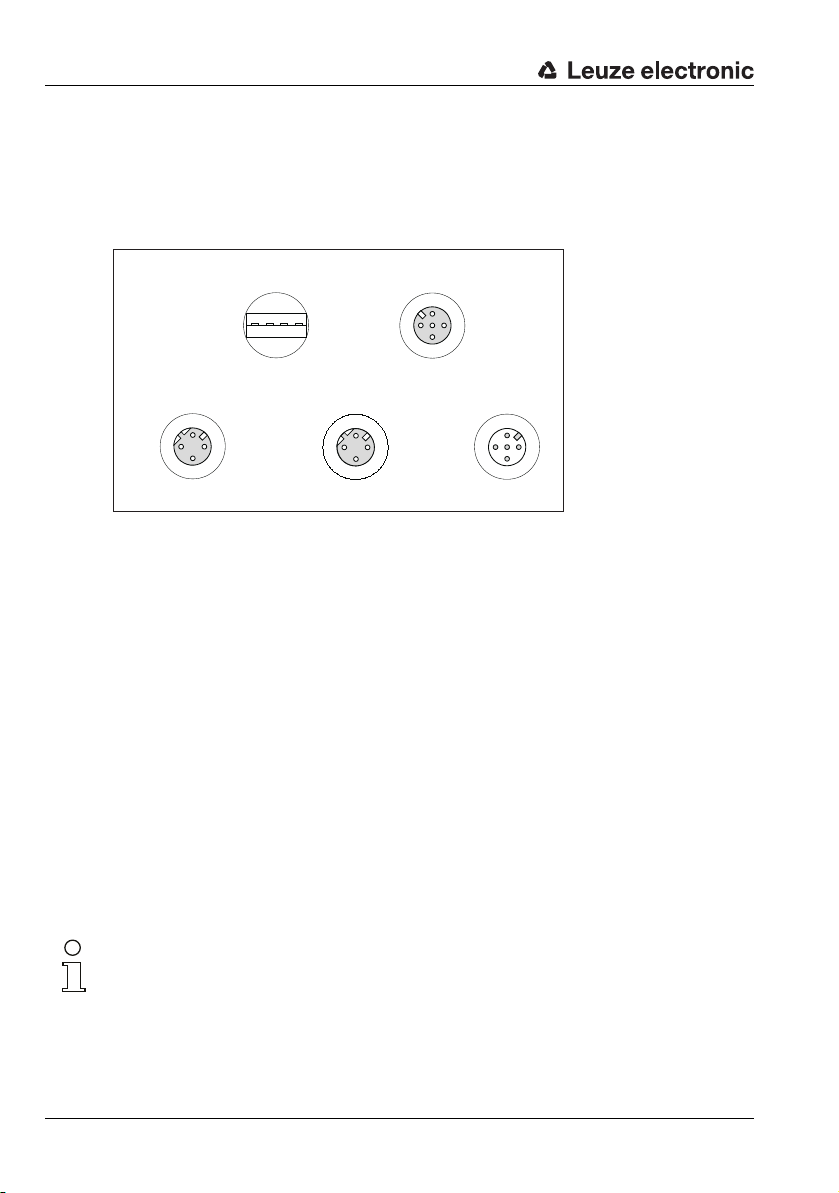

Figure 3.1: Connections of the BCL 558i................................................................................................. 14

Figure 3.2: Manually setting the IP address ............................................................................................ 16

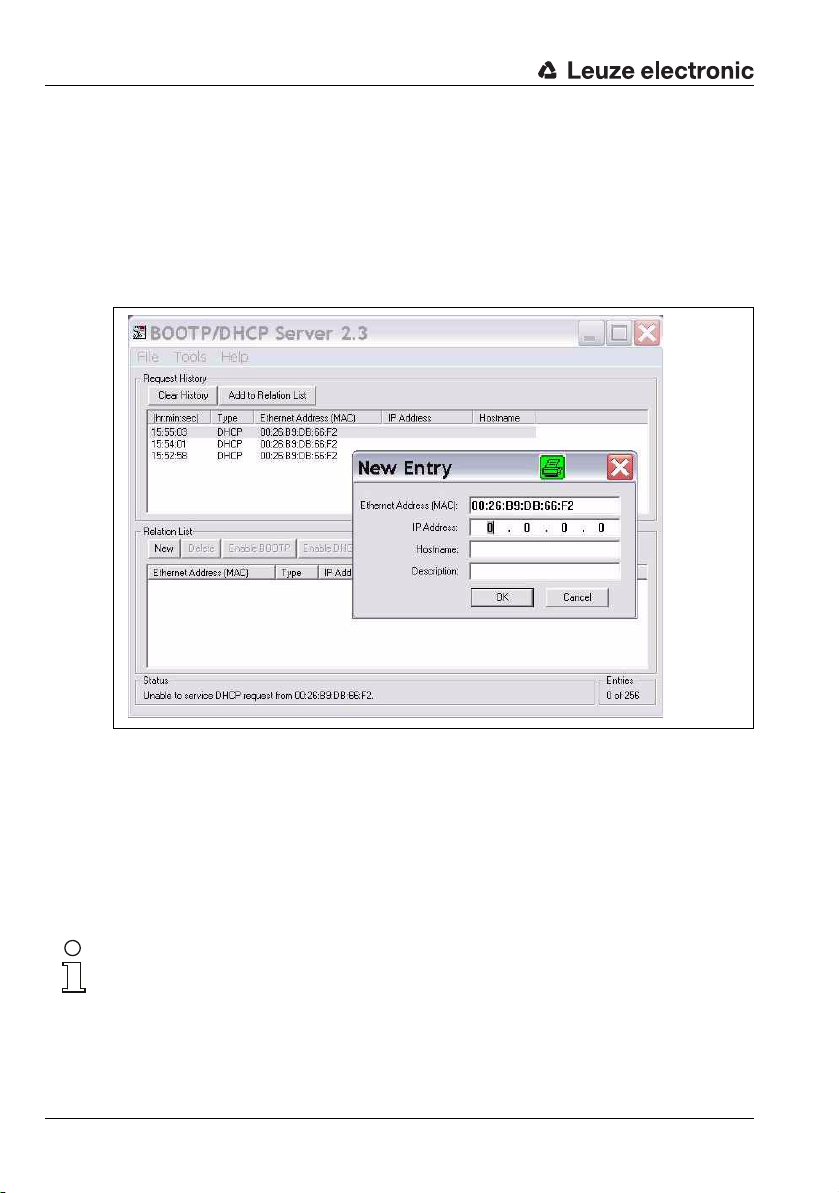

Figure 3.3: Generic Ethernet module....................................................................................................... 17

Figure 4.1: Line scanner, line scanner with deflection mirror and oscillating-mirror scanner................... 20

Figure 4.2: Possible bar code orientation ................................................................................................ 22

Figure 4.3: Device construction .............................................................................................................. 23

Figure 4.4: Deflection principle for the line scanner ................................................................................ 24

Figure 4.5: Deflection principle for the line scanner with oscillating mirror add-on.................................. 25

Figure 4.6: Principle arrangement for omnidirectional reading ................................................................ 26

Figure 4.7: Ethernet with star topology ................................................................................................... 28

Figure 4.8: Ethernet with linear topology................................................................................................. 29

Figure 4.9: External parameter memory.................................................................................................. 30

Figure 4.10: Reflector arrangement for autoReflAct .................................................................................. 31

Table 5.1: Specifications of the BCL 558i line scanners without heating................................................ 33

Table 5.2: Specifications of the BCL 558i oscillating-mirror scanners without heating........................... 35

Table 5.3: Specifications of the BCL 558i deflection mirror scanners without heating............................ 36

Table 5.4: Specifications of the BCL 558i line scanners with heating..................................................... 37

Table 5.5: Specifications of the BCL 558i oscillating-mirror scanners with heating................................ 38

Table 5.6: Specifications of the BCL 558i deflection mirror scanners with heating................................. 39

Figure 5.1: Dimensioned drawing BCL 558i line scanner S…102 ........................................................... 40

Figure 5.2: Dimensioned drawing BCL 558i deflection-mirror scanner S…100....................................... 41

Figure 5.3: Dimensioned drawing BCL 558i oscillating-mirror scanner O…100 ...................................... 42

Table 5.7: Type overview BCL 558i ....................................................................................................... 43

Figure 5.4: The most important characteristics of a bar code .................................................................. 44

Figure 5.5: Zero position of the reading distance .................................................................................... 45

Table 5.8: Reading conditions ............................................................................................................... 45

Figure 5.6: "High Density" reading field curve for line scanner (with/without deflection mirror)............... 46

Figure 5.7: "High Density" reading field curve for oscillating-mirror scanners......................................... 47

Figure 5.8: Lateral "High Density" reading field curve for oscillating-mirror scanners ............................. 47

Figure 5.9: "Medium Density" reading field curve for line scanner (with/without deflection mirror) ......... 48

Figure 5.10: "Medium Density" reading field curve for oscillating-mirror scanners ................................... 49

Figure 5.11: Lateral "Medium Density" reading field curve for oscillating-mirror scanners........................ 49

Figure 5.12: "Low Density" reading field curve for line scanner (with/without deflection mirror) ............... 50

Figure 5.13: "Low Density" reading field curve for oscillating-mirror scanners ......................................... 51

Figure 5.14: Lateral "Low Density" reading field curve for oscillating-mirror scanners.............................. 51

Figure 5.15: "Ultra Low Density" reading field curve for line scanner without deflection mirror................. 52

Figure 5.16: "Ultra Low Density" reading field curve for oscillating-mirror scanners ................................. 53

Figure 5.17: Lateral "Ultra Low Density" reading field curve for oscillating-mirror scanners...................... 53

Figure 5.18: "High Density" reading field curve for line scanner with heating (without deflection mirror) .. 54

Figure 5.19: "High Density" reading field curve for line scanner with heating (with deflection mirror) ....... 55

Figure 5.20: "High Density" reading field curve for oscillating-mirror scanners with heating..................... 56

Figure 5.21: Lateral "High Density" reading field curve for oscillating-mirror scanners with heating ......... 56

Figure 5.22: "Medium Density" reading field curve for line scanner with heating (without deflection mirror) ... 57

Figure 5.23: "Medium Density" reading field curve for line scanner with heating (with deflection mirror).. 58

Figure 5.24: "Medium Density" reading field curve for oscillating-mirror scanners with heating ............... 59

Figure 5.25: Lateral "Medium Density" reading field curve for oscillating-mirror scanners with heating.... 59

Figure 5.26: "Low Density" reading field curve for line scanner with heating (without deflection mirror)... 60

6 BCL 558i Leuze electronic

Figures and tables

Figure 5.27: "Low Density" reading field curve for line scanner with heating (with deflection mirror) ........61

Figure 5.28: "Low Density" reading field curve for oscillating-mirror scanners with heating...................... 62

Figure 5.29: Lateral "Low Density" reading field curve for oscillating-mirror scanners with heating.......... 62

Figure 5.30: "Ultra Low Density" reading field curve for line scanner with heating (without deflection mirror). 63

Figure 5.31: "Ultra Low Density" reading field curve for oscillating-mirror scanners with heating .............64

Figure 5.32: Lateral "Ultra Low Density" reading field curve for oscillating-mirror scanners with heating.. 64

Figure 6.1: Device name plate BCL 558i ................................................................................................. 65

Figure 6.2: Fastening options using M 4x6 threaded holes....................................................................... 66

Figure 6.3: BT 56 mounting device ......................................................................................................... 67

Figure 6.4: Mounting example of BCL 558i with BT 56............................................................................68

Figure 6.5: BT 59 mounting device ......................................................................................................... 69

Figure 6.6: Total reflection – line scanner ...............................................................................................71

Figure 6.7: Total reflection – BCL 558i with oscillating/deflection mirror .................................................72

Figure 6.8: Reading angle for the line scanner ........................................................................................73

Figure 7.1: Location of the electrical connections.................................................................................... 74

Figure 7.2: Connections of the BCL 558i ................................................................................................. 76

Table 7.1: Pin assignment PWR ............................................................................................................. 77

Figure 7.3: Switching input connection diagram SWIO_3 and SWIO_4 ....................................................78

Figure 7.4: Switching output connection diagram SWIO_3 / SWIO_4....................................................... 78

Table 7.2: Pin assignments of SERVICE – USB interface......................................................................... 79

Table 7.3: Pin assignment SW IN/OUT ................................................................................................... 80

Figure 7.5: Switching input connection diagram SWIO_1 and SWIO_2 ....................................................80

Figure 7.6: Switching output connection diagram SWIO_1 / SWIO_2....................................................... 81

Table 7.4: Pin assignment HOST / BUS IN BCL 558i............................................................................... 82

Figure 7.7: HOST / BUS IN cable assignments on RJ-45..........................................................................82

Table 7.5: Pin assignment BUS OUT ......................................................................................................83

Figure 7.8: Ethernet with star topology.................................................................................................... 84

Figure 7.9: Ethernet with linear topology ................................................................................................. 84

Table 7.6: Cable lengths and shielding ..................................................................................................85

Figure 8.1: Structure of the control panel ................................................................................................ 86

Table 8.1: Parameter handling submenu ...............................................................................................92

Table 8.2: Decoder table submenu ........................................................................................................93

Table 8.3: Digital SWIO submenu........................................................................................................... 96

Table 8.4: EtherNet/IP submenu ............................................................................................................99

Figure 9.1: Connecting the SERVICE USB interface ................................................................................104

Figure 9.2: Device Manager with connected BCL 558i .......................................................................... 106

Figure 9.3: The start page of the webConfig tool ................................................................................... 107

Figure 9.4: Module overview in the webConfig tool ............................................................................... 108

Figure 10.1: Connections of the BCL 558i ............................................................................................... 111

Figure 10.2: Manually setting the IP address........................................................................................... 113

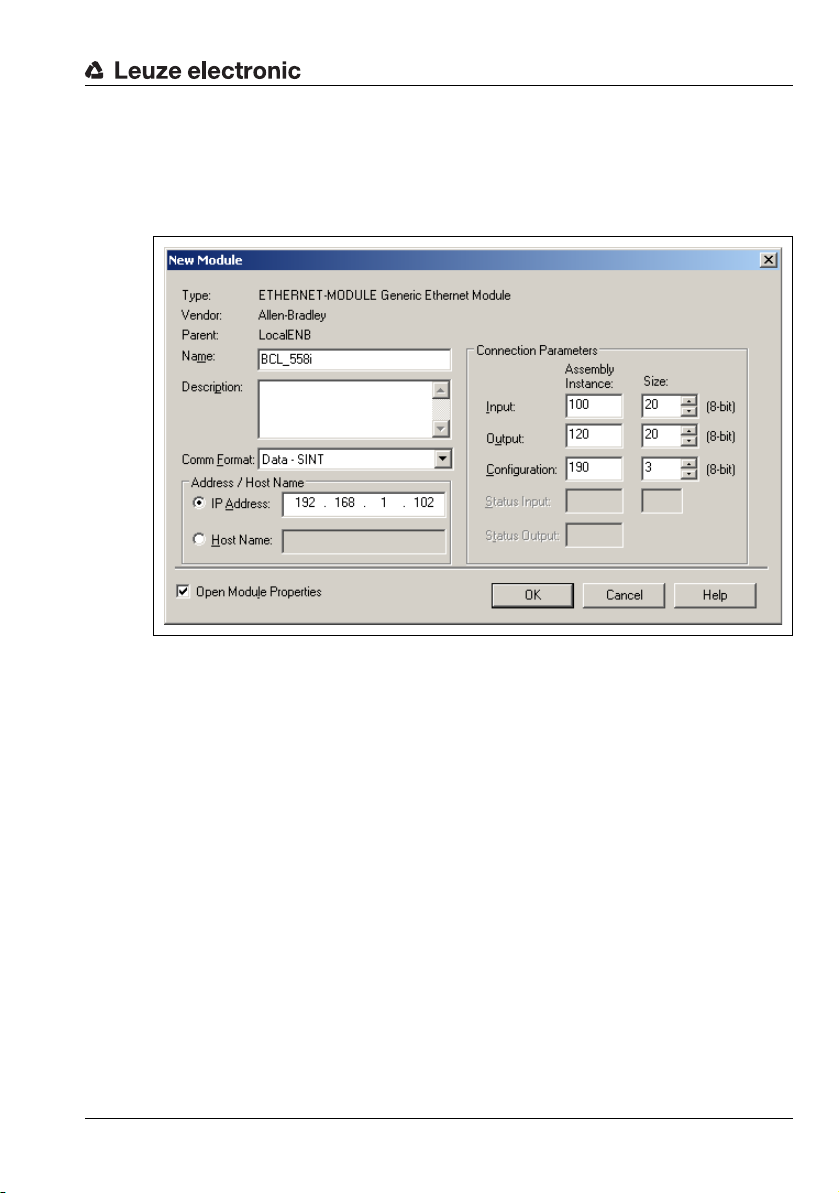

Figure 10.3: Generic Ethernet module.....................................................................................................115

Figure 10.4: New module........................................................................................................................ 116

Figure 10.5: Connection between Data acceptance/Data rejection/Error code attributes.......................... 133

Figure 10.6: Configuration of example 1 - module definition with generic module...................................137

Figure 10.7: Configuration of example 1 - module definition with the EDS file .........................................137

Figure 10.8: Data exchange sequence diagram - example 1 ................................................................... 139

Figure 10.9: Configuration of example 2 - module definition with generic module...................................140

Figure 10.10: Configuration of example 2 - module definition with the EDS file.........................................140

Leuze electronic BCL 558i 7

Figures and tables

Figure 10.11: Data exchange sequence diagram - example 2................................................................... 142

Figure 10.12: Configuration of example 3 - module definition with generic module................................... 143

Figure 10.13: Configuration of example 3 - module definition with the EDS file......................................... 143

Figure 10.14: Data exchange sequence diagram - example 3................................................................... 145

Figure 10.15: Configuration of example 4 - module definition with generic module................................... 146

Figure 10.16: Configuration of example 4 - module definition with the EDS file......................................... 146

Figure 10.17: Data exchange sequence diagram - example 4................................................................... 148

Figure 10.18: Storing configuration data in the webConfig tool ................................................................. 152

Figure 10.19: Installing the external parameter memory ........................................................................... 153

Figure 10.20: BCL 558i with installed parameter memory ........................................................................ 153

Table 12.1: General causes of errors ..................................................................................................... 173

Table 12.2: Interface error..................................................................................................................... 173

Table 13.1: Type key ............................................................................................................................. 175

Table 13.2: Type overview BCL 558i ..................................................................................................... 176

Table 13.3: Connectors for the BCL 558i ............................................................................................... 177

Table 13.4: Cable for the BCL 558i........................................................................................................ 177

Table 13.5: External parameter memory for the BCL 558i ..................................................................... 177

Table 13.6: Mounting devices for the BCL 558i ..................................................................................... 177

Table 13.7: Reflector for the BCL 558i................................................................................................... 178

Table 13.8: PWR cables for the BCL 558i .............................................................................................. 178

Figure 13.1: Cable structure of Industrial Ethernet connection cable ....................................................... 179

Table 13.9: Bus connection cables for the BCL 558i .............................................................................. 180

Figure 15.1: Bar code sample labels (module 0.3) .................................................................................. 187

Figure 15.2: Bar code sample labels (module 0.5) .................................................................................. 188

8 BCL 558i Leuze electronic

1 General information

U

L

US

C

LISTED

1.1 Explanation of symbols

The symbols used in this technical description are explained below.

Attention!

This symbol precedes text messages which must strictly be observed. Failure to comply with

this information results in injuries to personnel or damage to the equipment.

Attention Laser!

This symbol warns of possible danger caused by hazardous laser radiation.

Notice!

This symbol indicates text passages containing important information.

1.2 Declaration of conformity

The bar code readers of the BCL 500i series have been developed and manufactured in

accordance with the applicable European standards and directives.

The BCL 500i series is "UL LISTED" according to American and Canadian safety standards,

and fulfills the requirements of Underwriter Laboratories Inc. (UL).

Notice!

You can find the Declaration of Conformity of the devices in the appendix of the manual on

page 182.

The manufacturer of the product, Leuze electronic GmbH & Co. KG in D-73277 Owen,

possesses a certified quality assurance system in accordance with ISO 9001.

Leuze electronic BCL 558i 9

TNT 35/7-24V

2 Safety notices

2.1 General safety notices

Documentation

All entries in this technical description must be heeded, in particular the present chapter

"Safety notices". Keep this technical description in a safe place. It should be available at all

times.

Safety regulations

Observe the locally applicable regulations and the rules of the employer's liability insurance

association.

Repair

Repairs must only be carried out by the manufacturer or an authorized representative.

2.2 Safety standards

The bar code readers of the BCL 500i series were developed, manufactured and tested in

accordance with the applicable safety standards. They correspond to the state of the art.

2.3 Approved purpose

Attention!

The protection of personnel and the device cannot be guaranteed if the device is operated

in a manner not complying with its intended use.

Bar code readers of the BCL 500i series are conceived as stationary, high-speed scanners

with integrated decoders for all current bar codes used for automatic object detection.

In particular, unauthorized uses include:

• In rooms with explosive atmospheres

• Operation for medical purposes

Areas of application

The bar code readers of the BCL 500i series are especially designed for the following areas

of application:

• Storage and conveying technologies, in particular for object identification on fastmoving conveyor belts

• Pallet transportation applications

• Automobile sector

• Omnidirectional reading

10 BCL 558i Leuze electronic

2.4 Working safely

Attention!

Access to or changes on the device, except where expressly described in this operating

manual, are not authorized.

Safety regulations

Observe the locally applicable legal regulations and the rules of the employer's liability

insurance association.

Qualified personnel

Mounting, commissioning and maintenance of the device must only be carried out by

qualified personnel.

Electrical work must be carried out by a certified electrician.

Attention, laser radiation!

If you look into the beam path over a longer time period, the retina of your eye may

be damaged!

Never look directly into the beam path!

Do not point the laser beam of the BCL 558i at persons!

When mounting and aligning the BCL 558i, avoid reflections of the laser beam off

reflective surfaces!

The BCL 558i bar code readers comply with safety standards EN 60825-1 for a class

2 product. They also comply with the U.S. 21 CFR 1040.10 regulations for a class II

laser product except for deviations pursuant to Laser Notice No. 50, dated July 26,

2001.

Radiant Energy: The BCL 558i uses a low power visible laser diode. The emitted wavelength is 655nm. The average laser power is less than 1mW in accordance with the

definition of class 2 lasers.

Adjustments: Do not attempt any adjustments to or alterations of this product.

Do not remove the protective housing of the bar code reader. There are no userserviceable parts inside.

The scanner window is the only aperture through which light may be observed on this

product. A failure of the scanner motor, while the laser diode continues to emit a laser

beam, may cause emission levels to exceed those for safe operation. The bar code

reader has safeguards to prevent this occurrence. If, however, a stationary beam is

emitted, the failing bar code reader should be disconnected from its power source

immediately.

TNT 35/7-24V

CAUTION: Use of controls or adjustments or performance of procedures other than

specified herein may result in hazardous light exposure.

Leuze electronic BCL 558i 11

The use of optical instruments or devices in combination with the device increases

A

B

BCL 558i

Line scanner

BCL 558i

with oscillating/deflection mirror

C

A Included stick-on labels

B Aperture label

C Name plate

the danger of eye damage!

The housing of the BCL 558i is provided with warning notices B and C above and next

to the reading window as shown in the following figure:

Figure 2.1: Attachment of the stick-on labels with warning notices at the BCL 558i

Notice!

It is important that you attach the stick-on labels supplied to the device (A in figure 2.1)! If

the signs would be covered due to the installation situation of the BCL 558i, attach them

instead in the immediate vicinity of the BCL 558i in such a way that it is not necessary to

look into the laser beam when reading the notices.

12 BCL 558i Leuze electronic

3 Fast commissioning / operating principle

Below you will find a short description for the initial commissioning of the BCL 558i. Detailed

explanations for all listed points can be found throughout this technical description.

3.1 Mounting the BCL 558i

The BCL 558i bar code readers can be mounted in 3 different ways:

• Using two M4x6 screws on the rear of the device or using four M4x6 screws on the

bottom of the device.

• Using a BT 56 mounting device on the two fastening grooves.

3.2 Device arrangement and selection of the mounting location

In order to select the right mounting location, several factors must be considered:

• Size, orientation, and position tolerance of the bar codes on the objects to be

scanned.

• The reading field of the BCL 558i in relation to the bar code module width.

• The resulting minimum and maximum reading distance from the respective reading

field (see chapter 5.5 "Reading field curves / optical data").

• The permissible cable lengths between the BCL 558i and the host system depending

on which interface is used.

• The correct time for data output. The BCL 558i should be positioned in such a way

that, taking into consideration the time required for data processing and the conveyor

belt speed, there is sufficient time to e.g. initiate sorting operations on the basis of the

read data.

• The display and control panel should be very visible and accessible.

• For configuring and commissioning with the webConfig tool, the USB interface should

be easily accessible.

For specific information, please refer to chapter 4.4.

Notice!

The beam exits the BCL 558i as follows for the respective devices:

- line scanner parallel to the housing base

- oscillating mirror and deflection mirror perpendicular to the housing base

The black areas in figure 6.1 are the housing base. The best read results are obtained when:

• The BCL 558i is mounted in such a way that the scanning beam is incident on the bar

code at an angle of inclination greater than ±10° … 15° to vertical.

• The reading distance lies in the middle area of the reading field.

• The bar code labels are of good print quality and have good contrast ratios.

• You do not use high-gloss labels.

• There is no direct sunlight.

Leuze electronic BCL 558i 13

TNT 35/7-24V

3.3 Electrical connection BCL 558i

SW IN/OUT

VOUT

1

2

3

4

SWIO_1

SWIO_2

GND

FE

5

HOST / BUS IN

TD+

1

2

3

4

RD+

RD-

TD-

SERVICE

2134

GND D+ D-

U

B

PWR

SWIO_4

SWIO_3

3

2

1

4

5

GND VIN

FE

BUS OUT

TD+

1

2

3

4

RD+

RD-

TD-

USB socket

Type A

M12 socket

(A-coded)

M12 socket

(D-coded)

M12 socket

(D-coded)

M12 plug

(A-coded)

The BCL 558i is equipped with four M 12 plugs/sockets which are A- and D-coded, and an

USB socket of Type A.

Figure 3.1: Connections of the BCL 558i

Voltage supply and switching inputs/outputs

The voltage supply (10 … 30 VDC) is connected at the PWR M12 connector.

Available at both the PWR M12 connector as well as at the SW IN/OUT M12 socket are

four freely programmable switching inputs/outputs for custom adaptation to the respective application. Detailed information on this topic can be found in chapter 7.2.

Standalone operation in Ethernet network

During stand-alone operation of the BCL 558i, the host interface of the superior system is

connected to HOST/BUS IN. Thus, a star structure (Ethernet structure) is possible. Please

be certain to select the correct protocol for the connected components.

Network operation in Ethernet network

In network operation, the superior system (PC/PLC) is connected to the host interface of

the BCL 558i. With the aid of the "switch" integrated in the BCL 558i, the bus connection

to the next participant, e.g. another BCL 558i, can occur directly via the BUS OUT socket!

Notice!

The BCL 558i does not have its own built-in DHCP server. Please make certain that each

participant in the Ethernet has its own unique IP address. This can be set by a DHCP server

in the primary system or through manual address assignment.

14 BCL 558i Leuze electronic

3.4 Starting the device

Connect the supply voltage +10 … 30VDC (typ. +24 VDC); the BCL 558i starts up and

the bar code reading window appears on the display:

As a first step, you need to set the communication parameters of the BCL 558i.

You can make the necessary settings via the display or via the webConfig tool. Provided

here is only a brief description of the settings via the webConfig tool; detailed information

can be found in chapter 10.

ENIP

3.4.1 BCL 558i on EtherNet/IP

Commissioning on the EtherNet/IP is performed according to the following scheme:

1. Address assignment

• automatic via DHCP, BootP or

• manual via webConfig (with a USB connection)

2. Configuration of the participant depending on the version of the control software:

• either with the generic Ethernet module or

• installation of the EDS file

3. Transferring the data to the control

4. Adapting the device parameters via webConfig

5. Use explicit messaging services

Notice!

On delivery, the automatic address assignment via DHCP server is defined as the standard

setting of the BCL 558i and the IP address is set to 0.0.0.0.

The BCL 558i can be configured in the planning tool/control using the EDS file (Electronic

Data Sheet) if the control supports this. PLC software RSLogix 5000 from Rockwell offers

EDS support for EtherNet/IP from software version 20.00 and up.

Without PLC support of the EDS integration, the settings are made via the generic Ethernet

module. In this case, the respective configuration must be entered and adapted manually

for each device. The parameter download from the control to the BCL 558i is performed

during every establishment of connection. Since the parameters are stored centrally in the

control, this helps during device exchange.

By default, parameter enabling is deactivated and you

cannot change any settings. If you wish to carry out the

configuration via the display, you must activate parameter

enabling. Further information can be found in chapter

"Parameter enabling" on page 103.

TNT 35/7-24V

Leuze electronic BCL 558i 15

3.4.2 Manually setting the IP address

If your system does not include a DHCP server or if the IP addresses of the devices are to

be set permanently, proceed as follows:

• Have the network administrator specify the data for IP address, net mask and gateway address of the BCL 558i.

• Set the IP address manually via the BootP/DHCP server tool and deactivate the

DHCP operation in the BCL 558i. The BCL 558i automatically adopts these settings.

A restart is not required.

Figure 3.2: Manually setting the IP address

Alternatively, you can set the IP address manually via the webConfig tool. Proceed as

follows:

• Have the network administrator specify the data for IP address, net mask and

gateway address of the BCL 558i.

• Connect the BCL 558i to your computer using the service cable.

• Set these values on the BCL 558i. Via webConfig:

Configuration -> Communication -> Ethernet interface.

Notice!

If the IP address is set via the webConfig tool, then it becomes active after transfer to the

device. A restart is not required.

16 BCL 558i Leuze electronic

3.4.3 Configure the participant

Configuration with the generic Ethernet module

In the RSLogix 5000 configuration tool (up to software version 20.00), a so-called generic

Ethernet module is created under the Communication path for the BCL 558i.

Figure 3.3: Generic Ethernet module

The input mask for the generic module describes the following parameters to be set:

• The name of the participant (can be selected freely; e.g. BCL 558i)

• The format of I/O data (data - SINT = 8 bits)

• The IP address of the participant

• The address and length of the input assembly (instance 100, instance 101 or instance

102; min 1 byte - up to max. 266 bytes for the default input assembly of the read

results)

• The address and length of the output assembly (instance 120, instance 121 or

instance 122; min 1 byte - up to max. 263 bytes for the default output assembly)

• The address and length of the configuration assembly (instance 190; 3 bytes)

For the exact description of the assemblies for input/output and configuration, please refer

to chapter 10.

TNT 35/7-24V

Leuze electronic BCL 558i 17

Configuration of the participant using the EDS file

From software version 20.00 and up, proceed as follows in the RSLogix 5000 configuration

tool to create the BCL 558i as an EtherNet/IP participant in your system:

• First, load the EDS file for the device via EDS wizard into the PLC database.

Notice!

You can find the EDS file at: www.leuze.com.

• After it has downloaded, select the device from the device list.

• Open the input dialog for setting the address and additional parameters by

double-clicking on the device symbol and make the desired entries here.

• Finally, transmit the values to the control via download.

3.4.4 Transferring the data to the control (RSLogix 5000 specific)

• Activate online mode

• Select the Ethernet communication port

• Select the processor onto which the project is to be transferred

• Set the control to PROG

• Start the download

• Set the control to RUN

3.5 Further settings

After the basic configuration of the operating mode and the communication parameters, you

need to carry out further settings:

• Decoding and processing the read data

Define at least one code type with the desired settings.

• Via webConfig:

Configuration -> Decoder

• Control of the decoding

Configure the connected switching inputs according to your requirements. To do

this, first set the I/O mode to Input and then configure the switching behavior:

• Via webConfig:

Configuration -> Device -> Switching inputs/outputs

• Control of the switching outputs

Configure the connected switching outputs according to your requirements. To do

this, first set the I/O mode to Output and then configure the switching behavior:

• Via webConfig:

Configuration -> Device -> Switching inputs/outputs

18 BCL 558i Leuze electronic

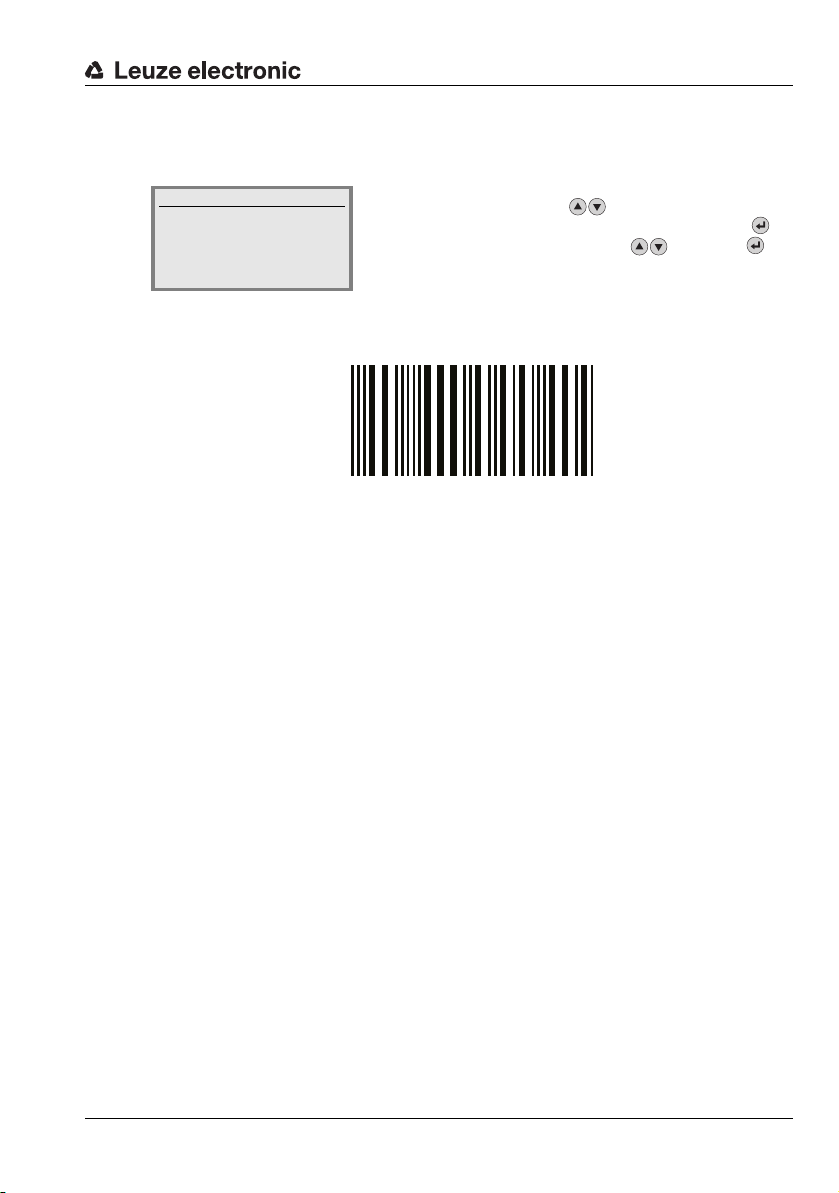

3.6 Bar code reading

Modul 0,5

6677889900

With the aid of the "Action menu", you can instruct the BCL 558i to read a bar code.

Actions

o Start decoding

o Start alignment

o Start auto-setup

o Start teach-in

To test, you can use the following bar code in the 2/5 Interleaved format. The bar code

module here is 0.5:

The read information appears in the display and is simultaneously passed on to the superior

system (PLC or PC).

Please check the incoming data of the bar code information there.

Alternatively, you can connect a photoelectric sensor or a 24 V DC switching signal to the

SW IN/OUT socket for read activation. To do this, however, you must appropriately

configure the switching input (see chapter 7.2.3 "SW IN/OUT – Switching input/switching

output").

In the main menu, use the buttons to select the

Actions menu item. Activate the Actions menu with .

Then select Start decoding with and press

again to start the bar code reading operation.

Leuze electronic BCL 558i 19

TNT 35/7-24V

4 Device description

Line scanner

Oscillating-mirror scanner /

Line scanner with deflection mirror

4.1 About the bar code readers of the BCL 500i series

Bar code readers of the BCL 500i series are high-speed scanners with integrated decoder

for all commonly used bar codes, e.g. 2/5 Interleaved, Code 39, Code 128, EAN 8/13 etc.,

as well as codes from the GS1 DataBar family.

Bar code readers of the BCL 500i series are available in various optics models as well as

line scanners, line scanners with deflection mirrors, oscillating mirrors and also optionally

as heated models.

Notice!

Please note: the BCL 558i line scanner with deflection mirror (perpendicular beam

exit) is currently not available.

Figure 4.1: Line scanner, line scanner with deflection mirror and oscillating-mirror scanner

The extensive options for device configuration via display or software enable adaptation to

a multitude of reading tasks. Due to the large reading distance combined with the great

depth of field and a very compact construction, the device is ideally suited for package and

20 BCL 558i Leuze electronic

pallet transportation systems. In general, the bar code readers of the BCL 500i series are

designed for the conveyor and storage technology market.

The interfaces (RS 232, RS 485 and RS 422) integrated in the various device models and

the fieldbus systems (PROFIBUS DP, PROFINET-IO, Ethernet TCP/IP / UDP and

EtherNet/IP) of the BCL 500i series bar code readers offer optimum connection to the superior host system.

4.2 Characteristics of the bar code readers of the BCL 500i series

Performance features:

• Integrated fieldbus connectivity = i -> Plug-and-Play fieldbus coupling and easy

networking

• Numerous interface variants facilitate connection to the superior systems

• RS 232, RS 422 as well as with integrated multiNet plus master

• RS 485 and multiNet plus slave

alternatively, various fieldbus systems, such as

•PROFIBUS DP

•PROFINET-IO

• Ethernet TCP/IP and UDP

• EtherNet/IP

• Integrated code fragment technology (CRT) enables the identification of soiled or damaged bar codes

• Maximum depth of field and reading distances from 200 mm to 2400mm

• Large optical opening angle and, thus, large reading field width

• High scanning rate from 800 - 1200 scans/s for fast reading tasks

• Intuitive, backlit, multi-language display with user-friendly menu navigation

•Integrated USB 1.1 service interface

• Adjustment of all device parameters with a web browser

• Connection options for an external parameter memory

• Easy alignment- and diagnosis functions

• M 12 connections with Ultra-Lock™ technology

• Four freely programmable switching inputs/outputs for the activation or signaling of

states

• Automatic monitoring of the read quality with autoControl

• Automatic recognition and setting of the bar code type using autoConfig

• Reference code comparison

• Optional heating models to -35°C

• Heavy-duty housing of protection class IP 65

Notice!

Information on technical data and characteristics can be found in chapter 5.

TNT 35/7-24V

General information

The integrated fieldbus connectivity = i contained in the bar code readers of the BCL 500i

series facilitates the use of identification systems which function without connector unit or

gateways. The integrated fieldbus interface considerably simplifies handling. The Plug-andPlay concept enables easy networking and very simple commissioning: Directly connect the

respective fieldbus and all configuration is performed with no additional software.

For decoding bar codes, the bar code readers of the BCL 500i series make available the

proven CRT decoder with code fragment technology:

Leuze electronic BCL 558i 21

The proven code fragment technology (CRT) enables bar code readers of the BCL 500i

series to read bar codes with a small bar height, as well as bar codes with a damaged or

soiled print image.

With the aid of the CRT decoder, bar codes can also be read without problem in other

demanding situations, such as with a large tilt angle (azimuth angle or even twist angle).

Figure 4.2: Possible bar code orientation

The BCL 558i can be operated and configured using the integrated webConfig tool via the

USB service interface; alternatively, the bar code readers can be adjusted using configuration commands via the host/service interface.

The BCL 558i needs a suitable activation to start a read process as soon as an object is in

the reading field. This opens a time window ("reading gate") in the BCL 558i for the read

process during which the bar code reader has time to detect and decode a bar code.

In the basic setting, triggering takes place through an external reading cycle signal.

Alternative activation options include online commands via the host interface and the

autoReflAct function.

Through the read operation, the BCL 558i collects additional useful pieces of data for diagnosis which can also be transmitted to the host. The quality of the read operation can be

inspected using the alignment mode which is integrated in the webConfig tool.

A multi-language display with buttons is used to operate the BCL 558i as well as for visualization purposes. Two LEDs provide additional optical information on the current operating

state of the device.

The four freely configurable switching inputs/outputs "SWIO 1 … SWIO 4" can be assigned

various functions and control e.g. activation of the BCL 558i or external devices, such as a

PLC.

System, warning and error messages provide assistance in setup/troubleshooting during

commissioning and read operation.

22 BCL 558i Leuze electronic

4.3 Device construction

USB interface

M12 connection

technology

Reading window

Dovetail mounting and

4 mounting threads

Dovetail mounting and

2 mounting threads

Display, LEDs

and buttons

Figure 4.3: Device construction

Leuze electronic BCL 558i 23

TNT 35/7-24V

4.4 Reading techniques

4.4.1 Line scanner (single line)

A line (scan line) scans the label. Due to the opt. opening angle, the reading field width is

dependent on the read distance. Through the movement of the object, the entire bar code

is automatically transported through the scan line.

The integrated code fragment technology permits twisting of the bar code (tilt angle) within

certain limits. These are dependent on the transport speed, the scanning rate of the scanner

and the bar code properties.

Areas of application of the line scanner

The line scanner is used:

• when the bars of the bar code are printed in the conveying direction ('ladder arrangement').

• with bar codes having very short bar lengths.

• when the ladder code is turned out of the vertical position (tilt angle).

• when the scanning distance is large.

Figure 4.4: Deflection principle for the line scanner

24 BCL 558i Leuze electronic

4.4.2 Line scanner with oscillating mirror

The oscillating mirror deflects the scan line additionally to both sides across the scan direction at a randomly adjustable oscillation frequency. In this way, the BCL 558i can also scan

larger areas or spaces for bar codes. The reading field height (and the scan line length useful

for evaluation) depends on the reading distance due to the optical beam width of the oscillating mirror.

Areas of application of the line scanner with oscillating mirror

For line scanners with oscillating mirror, oscillation frequency, start/stop position etc. are

adjustable. It is used:

• when the position of the label is not fixed, e.g. on pallets – various labels can, thus,

be detected at various positions.

• when the bars of the bar code are printed perpendicular to the conveying direction

('picket fence arrangement').

• when reading stationary objects.

• when the bar code is turned out of the horizontal position.

• when the scanning distance is large.

• when a large reading field (reading window) has to be covered.

Figure 4.5: Deflection principle for the line scanner with oscillating mirror add-on

Leuze electronic BCL 558i 25

TNT 35/7-24V

4.4.3 Omnidirectional reading

In order to read arbitrarily oriented bar codes on an object, at least 2 bar code readers are

necessary. If the bar code is not printed over-square, i.e. bar length > code length, bar code

readers with integrated code fragment technology are necessary.

Figure 4.6: Principle arrangement for omnidirectional reading

26 BCL 558i Leuze electronic

4.5 Fieldbus systems

Various product variants of the BCL 500i series are available for connecting to different

fieldbus systems such as PROFIBUS DP, PROFINET-IO, Ethernet and EtherNet/IP.

4.5.1 EtherNet/IP

The BCL 558i is designed as an EtherNet/IP device (acc. to IEEE 802.3) with a standard

baud rate of 10/100 Mbit. EtherNet/IP makes use of the Common Industrial Protocol (CIP)

as an application layer for the user. The functionality of the device is defined via parameter

sets which are clustered in objects, classes and instances. These are contained in an EDS

file which, depending on the version of the control software, can be used to configure and

integrate the BCL 558i into the system. A fixed MAC ID is assigned to each BCL 558i by the

manufacturer; this ID cannot be changed.

The BCL 558i automatically supports the transmission rates of 10 Mbit/s (10Base T) and

100 Mbit/s (100Base TX), as well as auto-negotiation and auto-crossover.

The electrical connection of the supply voltage, the interface and the switching inputs/

outputs on the BCL 558i is performed via several M12 connectors.

Additional information on the electrical connection can be found in chapter 7.

The BCL 558i supports the following protocols and services:

• EtherNet/IP

•DHCP

•HTTP

•ARP

•PING

• Telnet

• BootP

Notice!

The BCL 558i communicates via the Common Industrial Protocol (CIP).

CIP Safety, CIP Sync and CIP Motion are not supported by the BCL 558i.

Further information on commissioning can be found in chapter 10.

Leuze electronic BCL 558i 27

TNT 35/7-24V

Loading...

Loading...