Page 1

SMVector RS-485 LECOM Communication Module

Communications Interface Reference Guide

Page 2

About these instructions

This documentation applies to the RS-485 / LECOM communications option for the SMVector inverter and should be

used in conjunction with the SMVector Operating Instructions (Document SV01) that shipped with the drive. These

documents should be read in their entirety as they contain important technical data and describe the installation and

operation of the drive and this option.

WARNING!

The information in this document is based on RS-485 LECOM Communication Module software version 1.20. If a

future revision of software contains differences in the register numbering or register definitions, drive operation

could be seriously affected. If drive parameter P494 does not display 1.20, then writing to any drive register over

the network MUST NOT BE ATTEMPTED as it would have the potential for unexpected consequences potentially

resulting in damage to the equipment or harm to personnel. Future releases of module software require that the

appropriate documentation be used for implementation.

NOTE

To use the LECOM option of the RS-485 communication module with the SMVector (0.33-10HP) requires standard

software version 3.0 or later. All SMVector 15HP (11kW) and higher models support the LECOM option on the

RS-485 communication module.

© 2008 Lenze AC Tech Corporation

No part of this documentation may be copied or made available to third parties without the explicit written approval of

Lenze AC Tech Corporation.

All information given in this documentation has been carefully selected and tested for compliance with the hardware

and software described. Nevertheless, discrepancies cannot be ruled out. We do not accept any responsibility nor

liability for damages that may occur. Any necessary corrections will be implemented in subsequent editions.

Page 3

Contents

1 Safety Information .....................................................................................................................................................2

1.1 General ........................................................................................................................................................................ 2

1.2 Application ................................................................................................................................................................... 2

1.3 Installation .................................................................................................................................................................... 2

1.4 Electrical Connection ....................................................................................................................................................2

1.5 Operation .....................................................................................................................................................................3

2 Introduction ...............................................................................................................................................................4

2.1 Module Specifications .................................................................................................................................................. 4

2.2 Module Identification Label ........................................................................................................................................... 4

3 Installation .................................................................................................................................................................5

3.1 Mechanical Installation .................................................................................................................................................5

3.2 RS-485 Terminal Block................................................................................................................................................. 6

3.3 Electrical Installation..................................................................................................................................................... 6

3.3.1 Cable Types ................................................................................................................................................. 6

3.3.2 Network Limitations ..................................................................................................................................... 6

3.3.3 Connections and Shielding ........................................................................................................................... 6

3.3.4 Network Termination ...................................................................................................................................7

4 Parameters for use with RS-485/LECOM ....................................................................................................................8

4.1 Drive Communication Parameters................................................................................................................................. 8

4.2 RS485 LECOM-Specific Parameters ............................................................................................................................. 9

5 LECOM Protocol Details ...........................................................................................................................................10

5.1 LECOM - A/B Protocol Description ..............................................................................................................................10

5.2 Controller address (AD1, AD2) ....................................................................................................................................10

5.3 Code Number (C1, C2) ................................................................................................................................................ 11

5.3.1 Standard Addressing.................................................................................................................................. 11

5.3.2 Addressing via Code Bank ......................................................................................................................... 11

5.3.3 Addressing via Input Selection ................................................................................................................... 12

5.3.4 Extended Addressing ................................................................................................................................. 12

5.4 Parameter Value (V1 to Vn) ......................................................................................................................................... 12

5.5 Block-Check Character (BCC) ..................................................................................................................................... 14

6 LECOM Message Details ..........................................................................................................................................15

6.1 Telegram Response .................................................................................................................................................... 15

6.2 Receive Telegram ....................................................................................................................................................... 15

6.3 Receive Telegram Response ....................................................................................................................................... 15

6.4 Send Telegram ........................................................................................................................................................... 16

6.4 Broadcast / Multicast .................................................................................................................................................. 17

7 Commissioning ........................................................................................................................................................18

7.1 Drive Monitoring ......................................................................................................................................................... 18

7.2 Drive Programming and Control .................................................................................................................................. 18

7.3 Network Watchdog Timer ........................................................................................................................................... 18

7.3.1 Watchdog Timer ........................................................................................................................................18

7.3.2 Watchdog Time-out Period (P425).............................................................................................................. 18

7.3.3 Watchdog Time-out Action (P426) .............................................................................................................. 18

8 Drive Registers ........................................................................................................................................................19

8.1 Configuration and Control Registers ............................................................................................................................ 19

8.1.1 C1050 (Network Controlled Digital Output) ................................................................................................. 22

8.1.2 C1055 (Network Controlled Analog Output) ................................................................................................ 22

8.1.3 C1099 (Parameter Version) ........................................................................................................................ 22

9 Programming Parameters ........................................................................................................................................23

9.1 Fault History (P500) .................................................................................................................................................... 23

9.2 Drive ID (P502) ........................................................................................................................................................... 24

9.3 Terminal and Protection Status (P530) ........................................................................................................................ 25

9.4 Keypad Status (P531) ................................................................................................................................................. 25

10 Troubleshooting and Fault Elimination ......................................................................................................................26

10.1 Faults ......................................................................................................................................................................... 26

10.2 Troubleshooting.......................................................................................................................................................... 26

CMVLC401A

1

Page 4

1 Safety Information

1.1 General

Some parts of Lenze controllers (frequency inverters, servo inverters, DC controllers) can be live, moving and rotating.

Some surfaces can be hot.

Non-authorized removal of the required cover, inappropriate use, and incorrect installation or operation creates the risk

of severe injury to personnel or damage to equipment.

All operations concerning transport, installation, and commissioning as well as maintenance must be carried out by

qualified, skilled personnel (IEC 364 and CENELEC HD 384 or DIN VDE 0100 and IEC report 664 or DIN VDE0110 and

national regulations for the prevention of accidents must be observed).

According to this basic safety information, qualified skilled personnel are persons who are familiar with the installation,

assembly, commissioning, and operation of the product and who have the qualifications necessary for their occupation.

1.2 Application

Drive controllers are components designed for installation in electrical systems or machinery. They are not to be used

as appliances. They are intended exclusively for professional and commercial purposes according to EN 61000-3-2.

The documentation includes information on compliance with EN 61000-3-2.

Safety Information

When installing the drive controllers in machines, commissioning (i.e. the starting of operation as directed) is prohibited

until it is proven that the machine complies with the regulations of the EC Directive 2006/42/EC (Machinery Directive);

EN 60204 must be observed.

Commissioning (i.e. starting drive as directed) is only allowed when there is compliance to the EMC Directive (2004/108/

EC).

The drive controllers meet the requirements of the Low Voltage Directive 2006/95/EC. The harmonised standards of the

series EN 50178/DIN VDE 0160 apply to the controllers.

The availability of controllers is restricted according to EN 61800-3. These products can cause radio interference

in residential areas. In the case of radio interference, special measures may be necessary for drive controllers.

1.3 Installation

Ensure proper handling and avoid excessive mechanical stress. Do not bend any components and do not change any

insulation distances during transport or handling. Do not touch any electronic components and contacts. Controllers

contain electrostatically sensitive components, which can easily be damaged by inappropriate handling. Do not damage

or destroy any electrical components since this might endanger your health! When installing the drive ensure optimal

airflow by observing all clearance distances in the drive's user manual. Do not expose the drive to excessive: vibration,

temperature, humidity, sunlight, dust, pollutants, corrosive chemicals or other hazardous environments.

1.4 Electrical Connection

When working on live drive controllers, applicable national regulations for the prevention of accidents (e.g. VBG 4) must

be observed.

The electrical installation must be carried out in accordance with the appropriate regulations (e.g. cable cross-sections,

fuses, PE connection). Additional information can be obtained from the regulatory documentation.

The regulatory documentation contains information about installation in compliance with EMC (shielding, grounding,

filters and cables). These notes must also be observed for CE-marked controllers. The manufacturer of the system or

machine is responsible for compliance with the required limit values demanded by EMC legislation.

2 CMVLC401A

Page 5

1.5 Operation

Systems including controllers must be equipped with additional monitoring and protection devices according to the

corresponding standards (e.g. technical equipment, regulations for prevention of accidents, etc.). You are allowed to

adapt the controller to your application as described in the documentation.

Safety Information

DANGER!

• After the controller has been disconnected from the supply voltage, do not touch the live components

and power connection until the capacitors have discharged. Please observe the corresponding

notes on the controller.

• Do not continuously cycle input power to the controller more than once every three minutes.

• Close all protective covers and doors during operation.

WARNING!

Network control permits automatic starting and stopping of the inverter drive. The system design must

incorporate adequate protection to prevent personnel from accessing moving equipment while power

is applied to the drive system.

Table 1: Pictographs used in these instructions

Pictograph Signal Word Meaning Consequences if Ignored

DANGER!

Warning of Hazardous

Electrical Voltage.

Reference to an imminent danger that may

result in death or serious personal injury if

the corresponding measures are not taken.

WARNING!

STOP!

NOTE

Impending or possible

danger for persons

Possible damage to

equipment

Useful tip: If observed, it will

make using the drive easier

Death or injury

Damage to drive system or its

surroundings

CMVLC401A

3

Page 6

2 Introduction

Right-hand Label:

This reference guide assumes that the reader has a working knowledge of the LECOM Protocol and familiarity with the

programming and operation of motion control equipment. This guide is intended as a reference only.

2.1 Module Specifications

Table 2 identifies the LECOM serial communication specifications. If the specification is fixed (non-adjustable) the value

is shown under “Range”, if the specification is selectable, the table identifies the Parameter and available range of

selections.

Typical communications between master and slave would be:

• Write commands from Master

− Run command

− Frequency Reference

− Modification of Drive operating parameters

Introduction

Table 2: LECOM Serial Communication

Description Type Range

Network Address Selectable P410 (1 - 99)

Baud Rate Selectable P411 (9600, 4800, 2400, 1200, 19200 bps)

Data Bits Fixed 7

Parity / Stop Bits Fixed Even/1

• Requests from Master

− Reporting of drive status

− Fault status (and fault history)

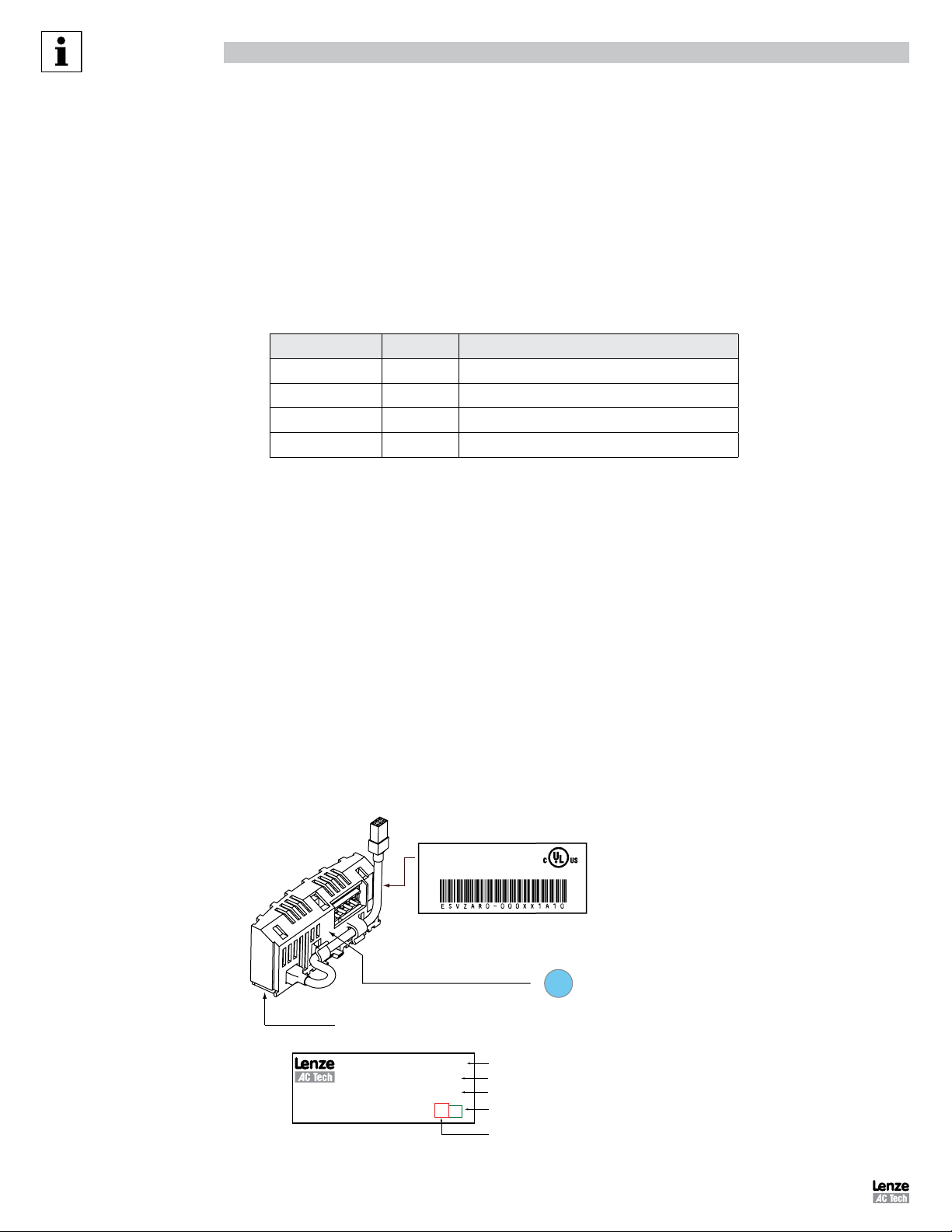

2.2 Module Identification Label

Figure 1 illustrates the labels on the SMV RS-485 communications module. The SMVector RS-485 module is identifiable by:

• Two labels affixed to either side of the module.

• The color coded identifier label in the center of the module.

COMM I/O ONLY

S/N: 123456789

Left-hand Label:

Module Data

SMV RS-485

TYPE: ESVZAR0

ID-NO: 12345678

ESVZAR0-000XX1A10

Ratings & Certifications

LISTED

Fieldbus Identifier:

R = RS-485 (Modbus RTU/LECOM)

R0

A

B

C

D

E

A: Fieldbus Protocol

B: Model Number

C: Lenze Order Number

D: Firmware Revision

E: Hardware Revision

Figure 1: RS-485 Module Labels

4 CMVLC401A

Page 7

3 Installation

3.1 Mechanical Installation

1. Ensure that for safety reasons the AC supply has been disconnected before opening the terminal cover.

2. Insert the RS-485 option module in the terminal cover and securely “click” into position as illustrated in Figure 2.

3. Wire the network cables to the connector provided, as detailed in paragraphs 3.2 (RS-485 Terminal Block) and 3.3

(Electrical Installation), and plug the connector into the option module.

4. Align terminal cover for re-fitting, connect the module umbilical cord to the drive then close the cover and secure,

as shown in Figure 3.

Installation

1 2 3 4 5

0.5 Nm/ 4.5 lb-in

<_ 2.8 mm

(12-22 AWG)

7mm

NEMA 1 (IP31) Models NEMA 4X (IP65) Models

Figure 2: Installing the RS-485 Communications Module

NEMA 1 (IP31) Models NEMA 4X (IP65) Models

Figure 3: Re-installing the Terminal Cover

CMVLC401A

5

Page 8

3.2 RS-485 Terminal Block

For a LECOM network, wire the RS-485 connector as detailed in Table 3.

Terminal Description Important RS-485 Connector

1 Earth ground / shield For reliable communication make sure terminal is

2 TXA If controller is located at either end of the network,

3 No connection

4 TXB

5 No connection

Protection against contact

• All terminals have basic isolation (single insulating distance)

• Protection against contact can only be ensured by additional measures (i.e. double insulation)

3.3 Electrical Installation

Installation

Table 3: RS-485 Pin Designation

connected to the LECOM network GND/common. If

only two wires are used (TXA and TXB) in the network,

connect Terminal 1 to chassis/earth ground.

a terminating resistor (120ohm typical) should be

connected across TXA and TXB

5

4

3

2

1

3.3.1 Cable Types

For RS-485 LECOM-B networks, use a quality shielded twisted pair cable. The use of low quality cable will result in

excess signal attenuation and data loss.

3.3.2 Network Limitations

There are several limiting factors that must be taken into consideration when building an RS-485 LECOM network:

• LECOM-B networks are limited to: 31 devices (w/o repeaters); 90 w/ repeaters).

• Topology: Without repeaters: line; with repeaters: line or tree.

• Maximum total network length is 1200 m depending on the baud rate and cable used.

• Minimum of 1 meter of cable between nodes.

3.3.3 Connections and Shielding

To ensure good system noise immunity all networks cables should be correctly grounded:

• Minimum grounding recommendation: ground the network cable once in every cubical.

• Ideal grounding recommendation: ground the network cable on or as near to each drive as possible.

• For wiring of cable to the connector plug the unscreened cable cores should be kept as short as possible;

recommended maximum of 20mm. The shield connection of terminal 1 should also be wired to earth (PE).

2

1

Connect to

drive earth

(PE)

Figure 4: Connector Wiring Diagram

6 CMVLC401A

3 4

5

20mm

max

Page 9

3.3.4 Network Termination

For an RS-485 network it is essential to install the specified termination resistors (120W), i.e. one at both ends of a network

segment. Failure to do so will result in signals being reflected back along the cable which will cause data corruption.

An external 120W 1/4W resistor can be connected as shown in Figure 5.

Installation

2

1

3 4

5

Connect to

drive earth

(PE)

120Ω

1/4W

Figure 5: Network Termination Resistor

20mm

max

CMVLC401A

7

Page 10

Commissioning

4 Parameters for use with RS-485/LECOM

4.1 Drive Communication Parameters

The parameters listed in Table 5 are always present on the drive, even if there is no communication module installed.

Table 5: Drive Communication Parameters

Code Possible Settings

No. Name Default Selection

P400

Network Protocol 0 Not Active

1 Remote Keypad

2 Modbus RTU

7 LECOM-B

P401

Module Revision 01.0.0 Display reads 01.x.x where:

01 = RS485/Remote Keypad Module

x.x = Module Revision

P402

Module Status 0 0 Not Initialized Read only

1 Initialization: Module to EPM

2 Initialization: EPM to Module

3 Online the communications between the drive

4 Failed Initialization Error

5 Time-out Error

6 Initialization Failed

7 Initialization Error

P403

Module Reset 0 0 No Action

1 Reset Module parameter values to

default.

P404

Module Time-out

Action

3 0 Ignore • Action to be taken in the event of an

1 STOP (refer to

2 Quick Stop

3 Fault (

P405

Network Fault 0 0 No Fault Read only, see P425 and P426

1 Network Time-out,

P406

Proprietary Module specific Read only

NOTE:

If this parameter returns a value of 16, the software version in this SMVector drive

does not support the LECOM functionality. Contact factory technical support.

P498

Missed Messages

Drive to Module

P499

Missed Messages

Module to Drive

n )

11 )

IMPORTANT

Read only

and module are working properly.

Module type mismatch (

Protocol Selection mismatch (

0 )

0 )

Returns module parameters 401…499 to

the default values shown in this manual.

SPI Time-out.

• SPI Time-out is fixed at 200ms.

F

Read only

Read only

8 CMVLC401A

Page 11

4.2 RS485 LECOM-Specific Parameters

The parameters listed in Table 6 are only present in the drive if there is an RS485 communication module installed,

P400 = 7 and the module is online (P402 = 3).

Commissioning

Table 6: RS485 LECOM-Specific Parameters

Code Possible Settings

No. Name Default Selection

P410

P411

Network address 1 1 99 The values 00, 10, 20, 30 … 90 must not

Network

Baud Rate

0 0 9600 bps

1 4800 bps

2 2400 bps

3 1200 bps

4 19200 bps

P420

Network Control

Level

0 0 Monitor Only P420 =2, 3: setpoint control using code

1 Parameter Programming

2 Programming and Setpoint Control

3 Full Control

4 Full Control (Special)

P424

P425

Network Powerup

Start Status

Network Message

0 0 Quick Stop

1 Controller Inhibit

50 0 {ms} 65000

time-out

P426

Network Message

time-out action

0 0 No action

1 Controller Inhibit

2 Quick Stop

3 Trip Fault, F.nF1

P427

Valid Network

0 0 {messages} 9999 • Read-only

messages

Received

P494

Communication

Module software

version

P495

Internal Code • Read only

IMPORTANT

be used since they are reserved for group

addressing (see section 6.4).

number C0046 or C1061.

P420 = 3, 4: drive control using code

numbers C0040 and/or C0135

P420 = 4: setting C0140 = 0 results in

Quick Stop

Stop commands (QUICK STOP, INHIBIT)

will always be accepted.

• When number of messages exceed

9999, counter resets and resumes

counting from 0.

• Read only

• Format: x.yz

• Alternating Display: xxx-; -yy

CMVLC401A

9

Page 12

Commissioning

5 LECOM Protocol Details

5.1 LECOM - A/B Protocol Description

The LECOM-A/B protocol is used to exchange data between SMV controllers and a host. The LECOM-A/B protocol is

based on DIN 66019, ISO 1745 and ANSI X3.28 (category 2.5 and A2, A4). These standards are similar to each other

and describe the control mode of a transmission section of a transmission system.

The host (the master) can communicate with a slave (SMV controller) in three modes:

• RECEIVE (refer to 6.2)

• SEND (refer to 6.3)

• BROADCAST/MULTICAST (refer to 6.4)

The controllers communicate by means of the ASCII code:

0 1 2 3 4 5 6 7 8 9 0 B C D I F

0 NUL SOH STX ETX EOT ENQ ACK BEL BS TAB LF VT FF CR SO SI

1 DLE DC1 DC2 DC3 DC4 NAK SYN ETB CAN EM SUB ESC FS GS RS US

2 space ! “ # $ % & ‘ ( ) * + , - . /

3 0 1 2 3 4 5 6 7 8 9 : ; < - > ?

4 @ A B C D E F G H I J K L M N O

5 P Q R S T U V W X Y Z [ \ ] ^ _

6 ‘ a b c d e f g h i j k I m n o

7 p q r s t u v w x y z { I } ~ DEL

Example:

“EOT” = 02

Character “ 1” = 31

= 2

hex

= 49

hex

dec

dec

5.2 Controller address (AD1, AD2)

One or more bus devices (slaves) can be selected by means of the controller address, which is 2 bytes (AD1, AD2) long.

The LECOM-A/B protocol supports the broadcast telegrams, i.e. a telegram is sent to a group or all other bus devices.

For this, controller addresses are reserved (refer to BROADCAST, 6.4). Controller addresses have the following structure:

The abbreviations have the following meanings:

AD1 ASCII ten-digit of the slave address (0 ... 9; 30 ... 39

AD2 ASCII one-digit of the slave address (0 ... 9; 30 ... 39

AD1 AD2

)

hex

hex

)

10 CMVLC401A

Page 13

5.3 Code Number (C1, C2)

5.3.1 Standard Addressing

The meaning of the code numbers and the assigned parameters can be obtained from the code table (in section 9) and

the SMV Operating Instructions Manual (SV01, section10). When transmitting data, the code number is coded as follows:

The following calculation determines the two ASCII digits from the code number (value range: 0 ... 6229) (value range:

48

...127

dec

dec

):

C1 = INTEGER((REMAINDER(code number/790)Y10)+48

C2 = REMAINDER(REMAINDER(code number/790)/10) + INTEGER(code number/790) x 10 + 48

The INTEGER is the digit before the decimal point, the REMAINDER is an integer.

Example: 13/5 = 2 remainder 3

INTEGER(13/5) = 2

REMAINDER(13/5) = 3

Example: Convert code number 1002 in ASCII code C1 and C2:

C1

= INTEGER((REMAINDER(1002/790/10) + 48 = INTEGER(212/10) + 48 =

ASCII

21 + 48 = 69 = 45hex = “E”

C2

= REMAINDER(REMAINDER(1002/790)/10) + INTEGER(1002/790) x 10 + 48 =

ASCII

REMAINDER(212/10) + 1 x 10 + 48 = 2 + 10 + 48 = 60 = 3C

Commissioning

dec

ASCII

= “<”

hex

dec

ASCII

The code number C1002 is converted into the ASCII string “E<”, if they are transmitted to the controller by a host.

5.3.2 Addressing via Code Bank

With previous LECOM-A/B drivers, only code numbers in the range from 0 to 255 could have been addressed, since

these drivers used only one byte as code number. To achieve the addressing of the wider code-number range with

these drivers, use the code banking. The code-number range 0...255 is displayed as a window over the whole codenumber range. This is controlled via the code C0249 (code bank). Code C0249 can always be accessed via number

249, independent of the currently set code bank.

NOTE

Code banking is only active when the standard addressing is being used. If the selected code numbers are

higher than 255, the code-number range increases correspondingly. Only the corresponding code-number

offset is selected by means of the code bank.

Table 7: Code Bank Assignment

Code bank Code offset Code-number range

0 0 0 - 255

1 250 250 - 505

2 500 500 - 755

3 750 750 - 1005

4 1000 1000 - 1255

5 1250 1250 - 1505

6 1500 1500 - 1755

7 1750 1750 - 2005

Example:

Set the code bank INTEGER(1002/250) =4 in C0249 to address the code number 1002. C1002 is then accessed via

the code number C02.

CMVLC401A

11

Page 14

5.3.3 Addressing via Input Selection

Simple LECOM-A/B drivers, which only use the standard addressing, cannot address subcodes. The input selection

C0248 has been developed to offer the possibility of addressing the subcodes. When using the standard addressing,

the value entered in C0248 is always considered as the subcode. The code C0248 can always be accessed via number

248, independent of the currently set code bank and the sub code used.

Example:

Enter value 1 in C0248 to address the JOG value 1 in subcode 1. Now subelement 1 is always addressed when accessing

C39.

NOTE

After a sub element has been accessed through C0248, C0248 should be reset to 0 to avoid the addressing

of a subelement “by accident” when accessing another code.

5.3.4 Extended Addressing

Another possibility is the direct addressing of parameters by means of expanded addressing.

The abbreviations have the following meanings:

Commissioning

! CH1 CH2 CH3 CH4 SC1 SC2

! The ASCII character “!” = 21

CH1 to CH4 Code number in hexadecimal code: each character corresponds to a nibble of the code numbers (CH1

is the highest, CH4 is the lowest nibble).

SC1, SC2 Subcode number in hexadecimal code: each character corresponds to a nibble of the code number

word (SC1 is the highest and SC2 the lowest nibble).

The following characters can be displayed in the ASCII code:

ASCII 0 1 2 3 4 5 6 7 8 9 A B C D E F

Dec 48 49 50 51 52 53 54 55 56 57 65 66 67 68 69 70

Hex 30 31 32 33 34 35 36 37 38 39 41 42 43 44 45 46

A code number range from 0 to 65535 can be addressed by means of these characters. A maximum of 255 subelements

(field elements) can be accessed via one subcode number of each code. Example: 1002 = “!03EA00”

5.4 Parameter Value (V1 to Vn)

Parameter values can be transmitted in four different formats with the following structures:

• ASCII decimal format (VD)

- VK1 VK2 VK3 VK4 VK5 VK6 . NK1 NK2 NK3 NK4

• ASCII hexadecimal format (VH)

H VH1 VH2 VH3 VH4 VH5 VH6 VH7 VH8

hex

= 33

shows that the expanded addressing is used

dec

• String format (VS)

S VS1 VS2 VS3 VS4 VS5 VS6 ... VS240

• Octet string format for data blocks (VO)

O VO1 VO2 VO3 VO4 VO5 VO6 ... VO240

12 CMVLC401A

Page 15

Commissioning

The abbreviations have the following meanings:

VK1 to VK6 Integers

. Decimal point (if required)

NK1 to NK4 Decimal codes (if required)

“H” (48hex) Character [H], transfer of parameter values in the ASCII hexadecimal format

VH1 to VH8 1 to 8 hexadecimal characters each [0 to 9; A to F]

“S” (53hex) Character [S], transfer of parameter values in the string format

VS1 to VS240 1 to 12 visible ASCII characters each (no control characters)

“O” (4Fhex) Character [0], transfer of parameter values in the octet string format

VO1 to VO240 Data block in hexadecimal code; each character corresponds to a nibble of the data block

Parameter value in the ASCII decimal format (110)

The ASCII decimal format (VD) is most often used. The values consist of the following:

1 leading negative sign (if required)

6 digits before the decimal point (VK1 to VK6)

1 decimal point (if required)

4 digits after the decimal point (NK1 to NK4) (if required)

Values from -214748.3648 to 214748.3647 can be displayed.

NOTE

In the ASCII decimal format (VD), the decimal point must not be transmitted if the value does not have digits

after the decimal point.

Parameter value in ASCII hexadecimal format (VH)

The LECOM-A/B protocol supports the transmission of hexadecimal parameter values with a length of:

• 2 characters (byte value)

• 4 characters (word/integer value)

• 8 characters (double word/long integer)

In the ASCII hexadecimal format, VH1 is the most significant and VH8 the least significant hexadecimal character.

Parameter value in the string format (VS)

By means of the string format (VS) of the protocol it is possible to transmit strings with a maximum of 20 characters in

both directions.

The SMV inverter can only send the string parameters (e. g. C200).

CMVLC401A

13

Page 16

Parameter values in the octet string format (VO)

The LECOM-A/B protocol includes the octet string format (VO) with which it is possible to transfer data blocks.

The character sequence corresponds to the filing in the memory (ascending order), i.e. the character transmitted first

is the data block nibble with the lowest address. The data structure of the data block corresponds to the Intel-memory

format with the following definition:

BYTE: 1st high nibble

2nd low nibble

WORD: 1st high BYTE

2nd low BYTE

DWORD: 1st high WORD

2nd low WORD

5.5 Block-Check Character (BCC)

The block-check character (BCC) is used to store the transmitted data and is generated according to DIN 66219 (chapter 3).

Because of the program, the block-check character is generated by an XOR link from the following digits of the SEND

telegram:

Commissioning

• it starts with the character directly after the STX control character

• it ends directly after the ETX control character

- BCC can accept the value 00 ... FF

EOT AD1 AD2 STX C1 C2 V1 O Vn ETX BCC

hex

.

BCC

or with expanded addressing:

STX “!” CH1 CH2 O SC2 ETX BCC

BCC

14 CMVLC401A

Page 17

6 LECOM Message Details

6.1 Telegram Response

The SMV controller must return an acknowledgement to the host. The only exceptions to this are when a broadcast

telegram is received or when the controller address is not correct. These telegrams do not require an acknowledgement.

The SMV controller sends two types of acknowledgements:

• Negative acknowledgement (NAK = 15hex), if:

− a fault (e.g. parity fault) was detected in one or more characters, including the character ENQ

− an invalid command or variable address has been recognized

− the variable value is not within the permissible range

• Otherwise, Positive acknowledgement (ACK = 06hex)

6.2 Receive Telegram

The command RECEIVE is to request parameter values of the SMV controllers. The code numbers of the requested

parameter are transmitted via the RECEIVE telegram using the following structure:

EOT AD1 AD2 C1 C2 ENQ

Commissioning

The abbreviations have the following meanings:

EOT (04

) End of the (previous) transmission

hex

AD1, AD2 Logic unit address of the slave to be addressed Slaves

C1, C2 Code number (two ASCII characters) or extended addressing

ENQ (05

) Station request

hex

6.3 Receive Telegram Response

The SMV controller addressed via a RECEIVE telegram generates one of the following responses:

• The controller could decode the request and is now sending the requested parameter value to the host.

STX C1 C2 V1 O Vn ETX BCC

• The controller could decode the request, however, a check-sum fault (parity fault) occurred during transmission.

STX C1 C2 ? ETX BCC

• The controller could not process the request because the requested code number does not exist.

STX C1 C2 EOT

The abbreviations have the following meanings:

STX (02

) Start of text

hex

C1, C2 Code number (two ASCII characters) or extended addressing

V1 to Vn Parameter value (n ASCII characters)

ETX (03

BCC Block-check character (00 ... FF

? (3F

EOT (04

) End of text

hex

) ASCII character “?”

hex

) End of the (previous) transmission

hex

hex

)

Structure and meaning of the block-check character (BCC) are described in the corresponding paragraph of the chapter

SEND.

CMVLC401A

15

Page 18

Commissioning

Example 1

The current speed setpoint (code number C46) is to be read with the bus address 01 at the controller. The host sends

the following RECEIVE telegram

EOT 0 1 4 6 ENQ

The controller can respond in three different ways:

STX 4 6 3 5

Valid request: The current value of the parameter C46 is 35.4 (Hz) or

STX 4 6 ? ETX BCC

Invalid request: A check-sum fault (parity fault) occurred during data transmission or

STX 4 6 EOT

Invalid request: Parameter C46 does not exist in this controller.

6.4 Send Telegram

The command SEND is used to transmit data from the master to the slave. The master then sends a telegram with the

following structure:

EOT AD1 AD2 STX C1 C2 V1 O Vn ETX BCC

The abbreviations have the following meanings:

EOT (04

) End of the (previous) transmission

hex

AD1, AD2 Logic unit address of the slave to be addressed Slaves

STX (02

) Start of text

hex

C1, C2 Code number (two ASCII characters)

V1 to Vn Parameter value (n ASCII characters)

.

4 ETX BCC

ETX (03

BCC Block-check character (00 ... FF

) End of text

hex

hex

)

In the text section of the telegram, which is embedded between the control characters STX and ETX, the code number

(C1. C2) and the corresponding parameter value (V1 to Vn) are transmitted to the slave.

Example for a SEND telegram:

The maximum speed (code number C1103) is to be set to the value 95.2 Hz via the bus address 34 at the controller.

The host must send the following SEND telegram:

EOT 3 4 STX 0 1 9 5 . 2 ETX BCC

The controller can respond with one of two acknowledgements:

ACK

The command was processed correctly. The current value of the parameter C1103 is 95.2 Hz or

NAK

The request could not be processed correctly. The value of parameter C1103 has not been changed.

16 CMVLC401A

Page 19

6.4 Broadcast / Multicast

In a bus network, the command BROADCAST is to address all devices or a group of devices (multicast) at the same

time. The structure of the BROADCAST telegram is similar to the structure of the SEND telegram. The only exception is

that it does not return an acknowledgement.

The devices can be selected via their controller addresses. The controller addresses listed in Table 8 are reserved for

a BROADCAST telegram.

Commissioning

Table 8: Controller Addresses for Broadcast Telegram

Controller address

(reserved)

00 all “0” “0”

10 11 to 19 “1” “0”

20 21 to 29 “2” “0”

30 31 to 39 “3” “0”

40 41 to 49 “4” “0”

50 51 to 59 “5” “0”

60 61 to 69 “6” “0”

70 71 to 79 “7” “0”

80 81 to 89 “8” “0”

90 91 to 99 “9” “0”

Controller address

of groups

ASCII character

AD1 AD2

Example for a BROADCAST telegram:

All controllers are to be stopped when setting controller enable (code number C40 = 0).

The host sends the following BROADCAST telegram:

EOT 0 0 STX 4 0 0 ETX BCC

The controllers do not return an acknowledgement.

Monitoring of the slave response:

The master monitors the selected slave. The slave must return a response within a defined time. Under the following

circumstances the slave does not return a response to the master (time out):

• The controller address could not be recognized

• The transmission path is faulty

• A BROADCAST telegram had been sent.

• The hardware does not work properly

If the master does not receive a response within a defined period of time, the transmission is tried again. The number

of repetitions is limited.

The monitoring time in the master should be approx. twice as long as the maximum response time.

Transmission faults

After a transmission fault, the master can read C0068 and evaluate the communication error in bit 4... 7.

CMVLC401A

17

Page 20

7 Commissioning

7.1 Drive Monitoring

The network can always read drive parameters as long as the LECOM communications are enabled (i.e. P400 = 7) and

configured properly (see P410-411). For monitor only operation, set P420 = 0.

7.2 Drive Programming and Control

Network Control must be enabled for the network to program drive parameters or take control of a drive. This is done by:

1. Setting P121…P124 equal to 09 (NET ENABLE) and asserting the corresponding TB-13x terminal

2. Setting P100 to 00, 01, 03, 04 or 06. Network control cannot be enabled when P100 is set to 02 (REMOTE KEYPAD

ONLY) or 05 (TERMINAL STRIP/REMOTE KEYPAD).

3. Setting P420 to 01, 02 or 03.

7.3 Network Watchdog Timer

7.3.1 Watchdog Timer

The SMV is equipped with a Serial Link “Watchdog Timer”. If the Watchdog Timer is enabled, the Master MUST

PERIODICALLY COMMUNICATE with the drive or the timer will timeout.

Commissioning

Watchdog timer setup is performed by using parameters P425 and P426 (LECOM codes C1425 and C1426).

7.3.2 Watchdog Time-out Period (P425)

The maximum amount of time that should be allowed to pass between network messages to a specific drive will vary from

one network to the next. Therefore, we have made the watchdog time-out period user settable via Drive Programming

Parameter P425 (refer to section 4.2 for details).

NOTE

To prevent erroneous timeout trips, make sure the time set in parameter P425 (C1425) is appropriate for

particular network - default value of 50ms might be to restrictive!

7.3.3 Watchdog Time-out Action (P426)

The appropriate action to be taken when a watchdog time-out occurs will also vary from one application to the next.

Therefore, we have provided four user selectable time-out actions which can be set via Drive Programming Parameter

P426.

The selections are:

0) No action Watchdog timer is disabled.

1) Controller inhibit If the drive doesn’t receive valid communication for period longer than the time specified in

parameter P425 (C1425), it will coast to stop and drive display will show inhibit state ‘Stop’.

2) Quick Stop If the drive doesn’t receive valid communication for period longer than the time specified in

parameter P425 (C1425), it will ramp to stop and drive display will show stop state ‘Stop’.

3) Trip fault ‘F.nF1’ If the drive doesn’t receive valid communication for period longer than the time specified in

parameter P425 (C1425), it trips with fault ‘F.nF1’.

WARNING!

Disabling the watchdog timer may cause injury to personnel and/or damage to equipment. The watchdog

timer should only be disabled during configuration or diagnosis to prevent nuisance timeout trips.

18 CMVLC401A

Page 21

8 Drive Registers

8.1 Configuration and Control Registers

Registers #1 through #1099 are reserved for registers that are only available over the network and cannot be accessed

via the drive’s local keypad.

Commissioning

Table 9: Configuration & Control Registers

Code

Number

C0040 Controller Inhibit 0 0 Controller inhibited

C0043 Fault Reset 0 0 No Action

C0046 Frequency Setpoint 0.0 … 500.0 Hz Read only

C0050 Actual Output

C0068 Operating Status Bit

Parameter Name Default Range of Adjustment Important

The controller can also be enabled

Frequency

Word

1 Controller enabled

1 Reset Fault

0.0 … 500.0 Hz Read only

Bit Description Read only

0-3 The 10th digit of the LECOM fault number is

displayed. Example:

TRIP OH = 5 (LECOM no. = 50)

4-7 Last communication error

0 = No fault

1 = Check sum error

2 = Protocol frame error

3 = Reserved

4 = Invalid code number

5 = Invalid variable

6 = No access permission

7 = Telegram processing interrupted by a new

telegram

15 = General fault

8 Control via LECOM enabled

9 Actual frequency above threshold C17

10 Direction of rotation

0 = CW

1 = CCW

11 Power stage transistors energized

12 Quick STOP active

13 Current Limit

14 Setpoint frequency reached

15 Fault occurred

LECOM Format = VH

with the control word C0135

The fault can also be reset with

the control word C0135

CMVLC401A

19

Page 22

Commissioning

Code

Number

C0135 Controller Control

C0140 Frequency Setpoint

Parameter Name Default Range of Adjustment Important

Word

Command

Bit Description

0-1 JOG1, JOG2, JOG3

0 = C0046 active

1 = JOG1 (C0037) active

2 = JOG2 (C0038) active

3 = JOG3 (C0039) active

2 Rotation command

0 = CW

1 = CCW

3 Quick Stop

0 = QSP not active

1 = QSP active

4-8 Reserved

9 Controller inhibit

0 = No controller inhibit

1 = Controller inhibit

10 Reserved

11 Trip fault reset

0 -> 1

Edge from 0 to 1 causes TRIP reset

12-13 Reserved

14 DC Brake (DC injection brake)

0 = DCB not active

1 = DCB active

15 Reserved

LECOM Format = VH

0.0 Hz 0.0 … 500.0 Hz

20 CMVLC401A

Page 23

Commissioning

Code

Number

C0150 Controller Status

Parameter Name Default Range of Adjustment Important

Word

Bit Description Read only

0 Reserved

1 Power stage transistors energized

2 Current Limit reached

3 Reserved

4 Setpoint Frequency reached

5 Actual frequency above threshold C17

6 Actual frequency == 0Hz

7 Controller inhibit

0 = No controller inhibit

1 = Controller inhibit

8 - 11 Controller status

0 = No error

1 = Error

12 Overtemperature fault

13 DC Bus overvoltage

14 Direction of rotation

0 = CW

1 = CCW

15 Read for operation

0 = fault (not ready for operation)

1 = no fault (ready for operation)

LECOM Format = VH

CMVLC401A

21

Page 24

Commissioning

Code

Number

C0200 Software

C0201 Software

C1050 Network Controlled

C1055 Network Controlled

C1060 Keypad Speed

C1061 Network Speed

C1070 Keypad PID

C1071 Network PID

C1072 Actual PID setpoint 0.0 -99.9 … 3100.0 Read only

C1073 PID Setpoint

C1074 PID Feedback 0.0 -99.9 … 3100.0 Read only

C1080 Keypad Torque

C1081 Network Torque

C1099 Parameter Version Refer to section 8.1.3

Parameter Name Default Range of Adjustment Important

Identification

Generation Date

Digital Output

(TB14) + Relay

Analog Output

Command

Command

Setpoint Command

Setpoint Command

Command

Command

Command

Software identification string:

example “33SSSMD-M_14000”

LECOM Format = VS

Software generation date:

example “2008-10-18”

LECOM Format = VS

0 = de-energized

1 = energized

bit 9: TB-14 state

bit 10: Relay state

other bits are not used

0.0% 0.0 … 100.0 Refer to section 8.1.2

20.0 Hz P102 … P103

0.0 Hz P102 … P103

0.0 -99.9 … 3100.0 Read only

0.0 -99.9 … 3100.0 Read-only

0.0 -99.9 … 3100.0 Read only

100% 0.0 … 400.0

0% 0.0 … 400.0

Read only

Read only

Refer to section 8.1.1

8.1.1 C1050 (Network Controlled Digital Output)

To control the state of the relay or digital output (TB14), Drive Programming Parameter P140 and/or P142 must be set

to 25 (Network Controlled).

8.1.2 C1055 (Network Controlled Analog Output)

To control the state of the analog output (TB30), Drive Programming Parameter P150 must be set to 09 (Network

Controlled).

8.1.3 C1099 (Parameter Version)

The Parameter Version identifies the parameter set for the current version of software. If the Parameter version is

different between two drives, it could indicate that a register has been added or deleted, a register’s min/max limits

have changed, a register’s function has been changed, or a register’s default value has been changed.

22 CMVLC401A

Page 25

9 Programming Parameters

There is an offset of 1000 between the Drive Programming Parameter numbers and the code numbers used in the

LECOM messages. For example, if you want to read Drive Programming Parameter P103 (Maximum Frequency) over

the LECOM network, you would read code number 1103.

9.1 Fault History (P500)

Value Display Fault Message

0 No Fault

1 TMP Output Fault

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

F.OF

F.OF1

F.AF

F.rF

F.HF

F.LF

F.PF

F.GF

F.IL

F.dbF

F.SF

F.EF

F.CF

F.UF

F.cF

F.F1

F.F2

F.F3

F.F5

F.F5

F.F6

F.F7

F.F8

F.F9

F.bF

F.F12

F.JF

F.AL

F.F4

F.F0

F.FoL

F.F11

F.ntF

F.Fnr

F.nF1

Commissioning

Output (Transistor) Fault

Ground Fault

High Drive Temperature

Flying Start Fault

High DC Bus Voltage

Low DC Bus Voltage

Motor Thermal Overload

OEM Fault

Illegal Setup

Dynamic Brake Over Temperature

Single Phase Fault

External Fault

Control Fault

Start Error (Power loss)

Incompatibility Fault

Internal Fault 1 (EPM)

Internal Fault 2

Internal Fault 3

Internal Fault 5 (stack overflow)

Internal Fault 5 (stack underflow)

Internal Fault 6

Internal Fault 7

Internal Fault 8

Internal Fault 9

Personality Fault

Internal Fault (AD Offset)

Internal Fault (Remote Keypad Lost)

Assertion Level switched during Operation Fault

Internal Fault 4 (FGD Missing)

Internal Fault 0 (PW Missing)

Follower Lost

ISO Comm Fault

Internal Fault (Module Communication (SPI) Timeout)

Internal Fault (FNR: Invalid Message Received)

Network Time-out

CMVLC401A

23

Page 26

9.2 Drive ID (P502)

This register returns an index value that is associated with the voltage and power rating of the drive. Table 10 lists the

drive configuration by Index number.

Commissioning

Table 10: Drive ID

Index Input Voltage Power Rating

8 240 VAC, Single-Phase 0.33 HP (0.25 kW)

12

13 2 HP (1.5 kW)

14 3 HP (2.2 kW)

21

23 1 HP (0.75 kW)

24 1.5 HP (1.1 kW)

25 2 HP (1.5 kW)

26 3 HP (2.2 kW)

28 5 HP (4 kW)

29 7.5 HP (5.5 kW)

30 10 HP (7.5 kW)

31 15 HP (11 kW)

32 20 HP (15 kW)

42

44 1 HP (0.75 kW)

45 1.5 HP (1.1 kW)

46 2 HP (1.5 kW)

47 3 HP (2.2 kW)

49 5 HP (4 kW)

50 7.5 HP (5.5 kW)

51 10 HP (7.5 kW)

52 15 HP (11 kW)

53 20 HP (15 kW)

54 25 HP (18.5 kW)

55 30 HP (22 kW)

69

71 2 HP (1.5 kW)

72 3 HP (2.2 kW)

74 5 HP (4 kW)

75 7.5 HP (5.5 kW)

76 10 HP (7.5 kW)

77 15 HP (11 kW)

78 20 HP (15 kW)

79 25 HP (18.5 kW)

80 30 HP (22 kW)

91

92 0.5 HP (0.37 kW)

94 1 HP (0.75 kW)

240 VAC

Single or Three-Phase

240 VAC

Three-Phase

480 VAC

Three-Phase

600 VAC

Three-Phase

120 or 240 VAC

Single-Phase

1.5 HP (1.1 kW)

0.5 HP (0.37 kW)

0.5 HP (0.37 kW)

1 HP (0.75 kW)

0.33 HP (0.25 kW)

All unused Index values are reserved for future use

24 CMVLC401A

Page 27

9.3 Terminal and Protection Status (P530)

When a read command is issued over the LECOM network to Programming Parameter P530 (code number 1530), the

Terminal and Protection Status data returned can be interpreted as follows:

Commissioning

0 TB-13D Input Status

1 reserved 9 TB-14 Output Status

2 Protection Status 10 Relay Output Status

3 Fast Current Limit Status 11 Charge Relay State

4 Input TB-1 Status 12 Assertion Level Switch State

Data Low Byte

5 reserved 13 reserved

6 TB-13A Input Status 14 reserved

7 TB-13B Input Status 15 reserved

9.4 Keypad Status (P531)

When a read command is issued over the LECOM network to Programming Parameter P531 (code number 1531), the

Keypad Status data returned can be interpreted as follows:

0 UP Push-button State

1 DOWN Push-button State 9 DOWN Push-button State

2 MODE Push-button State 10 MODE Push-button State

3 FWD/REV Push-button State 11 FWD/REV Push-button State

8 TB-13C Input Status

Data High Byte

8 UP Push-button State

4

Data Low Byte

5

LOCAL Drive Keypad

6

STOP Push-button State 12

STOP

START Push-button State 13

RUN

CTRL Push-button 14

CTRL

Data High Byte

REMOTE Keypad

CTRL

7 Unused 15 Unused

STOP Push-button State

STOP

START Push-button State

RUN

CTRL Push-button

CMVLC401A

25

Page 28

Troubleshooting and Fault Elimination

10 Troubleshooting and Fault Elimination

10.1 Faults

Table 11 lists the faults common to the LECOM communications module.

Fault Code Fault Cause Remedy

Module to Drive

f

communication time out

F 1

10.2 Troubleshooting

Table 12 lists some common LECOM communications problems and possible corrective action.

Symptom Possible Cause Remedy

No communication

from the drive

Network Time-out Fault Drive under NETWORK control

Module is not initialized properly • Verify the module connection

Incorrect LECOM settings • Use P403 to reset LECOM parameters.

Improper wiring • Check wiring between the LECOM Network and

Table 11: Faults

Connection between drive and

module is not made.

and network communications

have been lost.

Table 12: Troubleshooting

• Check P400 and P402

• Verify P410 and P411

communication module.

• Ensure that terminal block is properly seated.

• Check connection between module and drive.

Check cable and connection

between module and drive

See parameters P425, P426

LECOM write

commands are

ignored or return

exceptions.

Drive stops without

obvious reason

“Network Enabled” terminal is either

open or not configured.

Network Control Level set to monitor only

(P420 = 0)

LECOM message monitoring time-out

occurred. The timeout reaction is set to

Quick stop or Inhibit.

Configure one of the input terminals (P121 ... P124)

to “Network Enabled” function (selection 9) and close

the corresponding contact.

Set P420 = 1, 2, 3 or 4

Modify the setting of time-out time (P425) or the

reaction to the time-out (P426).

26 CMVLC401A

Page 29

Lenze AC Tech Corporation

630 Douglas Street • Uxbridge, MA 01569 • USA

Sales: (508) 278-9100 • Service (508) 217-9100

www.lenzeamericas.com

Document

CMVLC401A-en1

Loading...

Loading...