Page 1

Page 2

ET46/fa

checked:

19.04.89

~I4B

33.0831

GB

page:

1

Table

1.

2.

3.

4.

5.

5.1

5.1.1

5.1.2

5.1.3

5.2

5.3

5.4 Selectiori of

5.5

5.6

5.7

5.8

5.9

5.10

5.11

5.12

5.13

5.14

5.15

of

conterits

Features

Specifications

Conriecting

Installation

Conriectirig

External

Using

Using master

Using

Controllerinhibit

Reversing

External

External TRIP

Switching

Standstill

‚Identical

Overload

TRIP

Frequencyoutput

I4ains

Motor

Connection

set-value

poteritioxrieter

current

temperature

indication

relay

connection

connection

diagram

instructions

instructions

adjustment

voltage

loop

and

brakirig

tixed

reset

of

the

iridication

freguency“ indication

of

braking

control

frequencies

switch

acceleration

resistor(s)

(speeds)

and

deceleration

ramp

page

2

2

3

4

4

4

4

4

4

5

5

6

7

7

7

8

8

9

9

10

10

11

11

6.

7.

7.1

7.2

7.3

8.

9.

10.

11.

12.

Display and

Modification

Keyboard

Furiotion

Description

Fault

Dimensionsand weights

Mains

Semiconductor

Braking

?.ad%o

1;ems

diagnosis

chokes

i::terfe~er~ce

:bers

supp1i~

operating

of

operation

code

of

the function

fuses

resistors

Ii

factory-set

suD~‘reE:i1Qn

and

panel

fuse

paraineters

code

holders

12

13

13

14

15

27

28

29

30

31

32

32

Page 3

ET4

The

6/fa

Lenze

checked:

inverter

19.04.89

series

standard three-phasemotors

1.

Features

-

Sinusaidal

-

Isolated

-

Contro3.

-

Power outputs

-

Set-value

acceleration

-

U/f

control

-

Fault

-

Tntegrated braking chopper

-

Reversirig

-

Preselection

-

Option boards

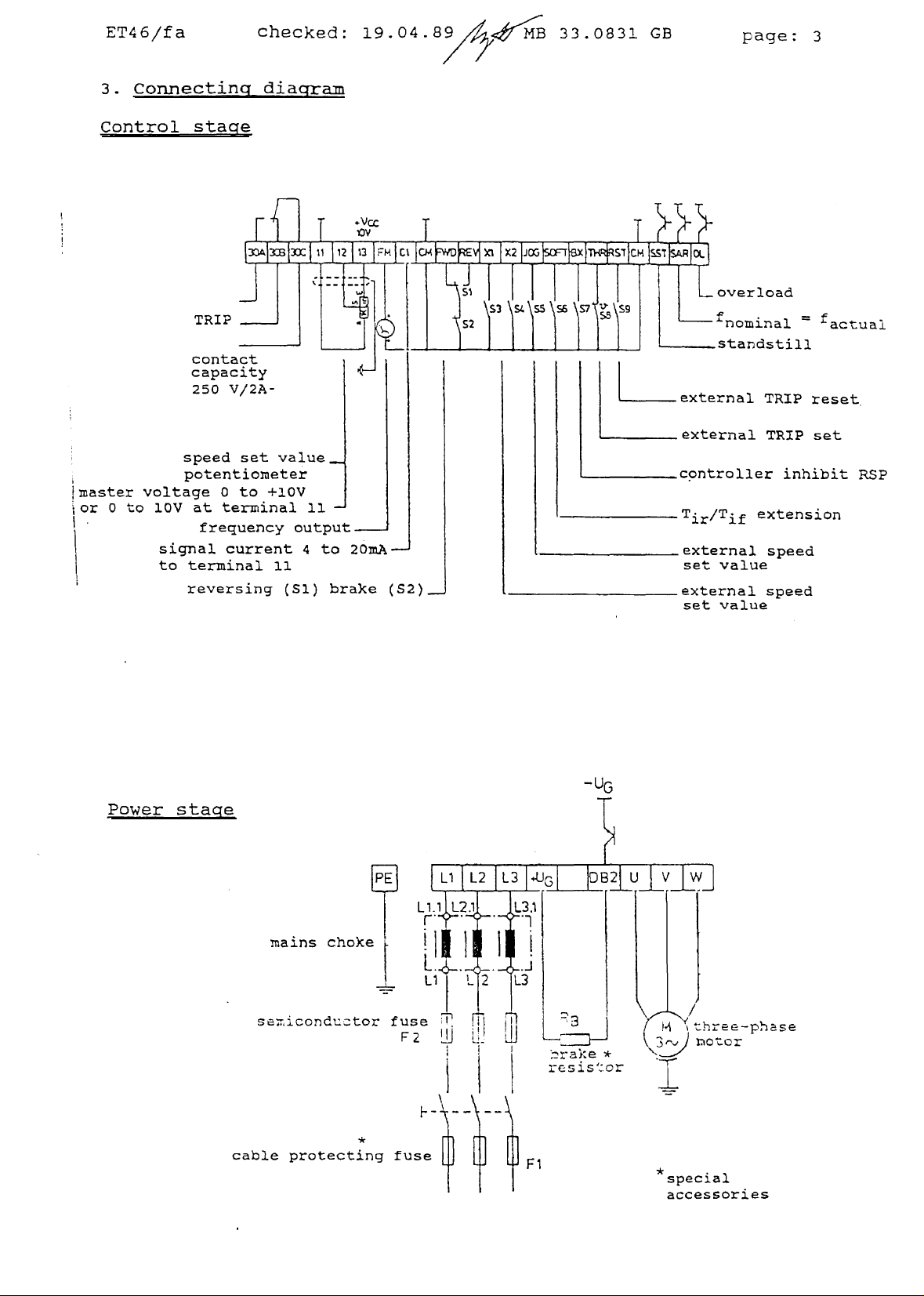

2.

Specifications

indication

pulse

contro3.

either

integrator

and

of

width

inputs

externally

are

short—

with

deceleration

system

4

fixed

can

be

inodulation

retrofitted

~MB

7800

comprises

of

powers from

or

via

and

earth-circuit

separately

ramp

including

speeds

33.0831

8

keyboard

prograininable

TRIP

GB

page:

frequency inverters

2.0 to

20

kW.

protected

indication

2

for

Ty~e

7811

7&12

7813

7814

7815

7816

7817

7818

O.vtput

power

S

/kVAetU

3.3

5.6 7.5

8

12

15

19

24 35 17

28 41

Output

voltage

/V

phase

0

..

lJ

Mains

vottage

50-60

Hz

U/

-

mains

/V

3x340

505V

4-Q%

Hains

current

at

norn.

power

hA

eff

4

10.5

3

16.5

21.5

.

27.5

Nomin.

Power

motor

power

at

p

/kWNPv/w

2.0

3.7

5.5 270

7.5 360

11

14

20

Loss

1=1

f=5OHz

100

180

510

640

760

8.60

Nca~in.

current

1

IA

5

8.5

112

118

1

23 35

29 44

37

43 64

Maxin~j¶~

current

1

13

18

27

55

max

7.5

Output

/A

frec~~ency

f/Hz

0.5

...

360Hz

2

...

240

Hz

maxifrLrn

ma

ter

vo?t

age!

master

current

ULN/V

0.

.+/-10V

4

..20

rnA

Ant~ient

teaperature

iL7~W

0

...

0C

40

Dimensions

HxL X

ljeight

~3~x240x235

•430x240x2.35

10

430x240x235

10.5

430x240x235

11kg

480x280x235

16

480x280x235

18.5

565x280x235

20.5

565X280X235

21.5

0

kg

kg

kg

kg

kg

kg

Page 4

ET4

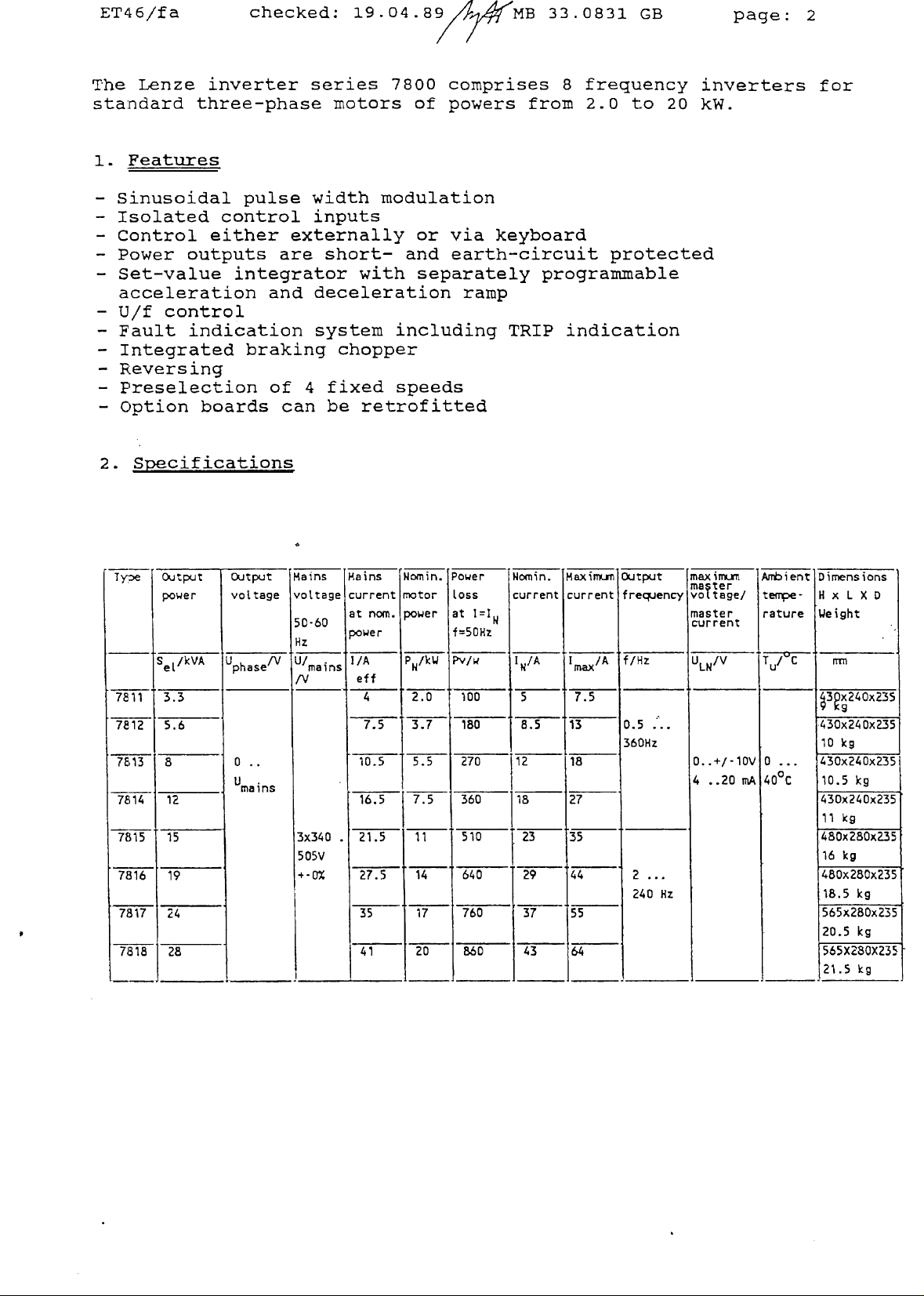

3.

Connecting

6/fa

checked:

diagram

19.04.89

33.0831

GB

page:

3

Control

Lmnaster

or0to

stage

TRIP

contact

capacity

250

speed

potentio~eter

voltage

10V

sigriaj.

to

0

at

teni-~inal

terDlirlal

reversing

V/2A-

set

value

to

+10V

current

11

(S1)

__

11

—

4

to 2OmA

brake

(S2)

overload

~nomina).

standstill

externaj.

external

controller

Tir/Tif

external speed

set

external

set

TRIP

TRiP

inhibit

extension

value

speed

value

=

reset

set

~actuai

RSP

Power

stage

muains

s~~ccndu~ztor

cable

protectingtuse

choke

-

UG

thret~—ph~se

I~otcr

*

special

accessories

Page 5

ET46/fa

4.

Installation

The

controller

at

the

±

:LOOin~

inaintain

bottom.

at

the

checked:

instructions

should

Ensure that

the top

flow

of

and

air

19.04.89

be

bottain,

maxrmmm ambient temperature

In

case of

rise

inust

fuses

5.

Connectinc~

5..l

and

only

(see

External

an

earth

improves

be

operated

paint

instructions

set—value

circuit

the

~nains

with

10./il.).

fitted

vertically

there

and

tI~xrough

must

fault,

current

specif

is

50

the

not

the

led

~4B

a

factor.

33.0831

with the

free

mm

heat sink

exceed

at

mains

space

the

0C.

40

choke

The

mains choke

GB page:

terminals

of

sides

and

7800

and

in

order

controller.

limits

the

inverter

sexni-conductor

4

located

to

The

current

series

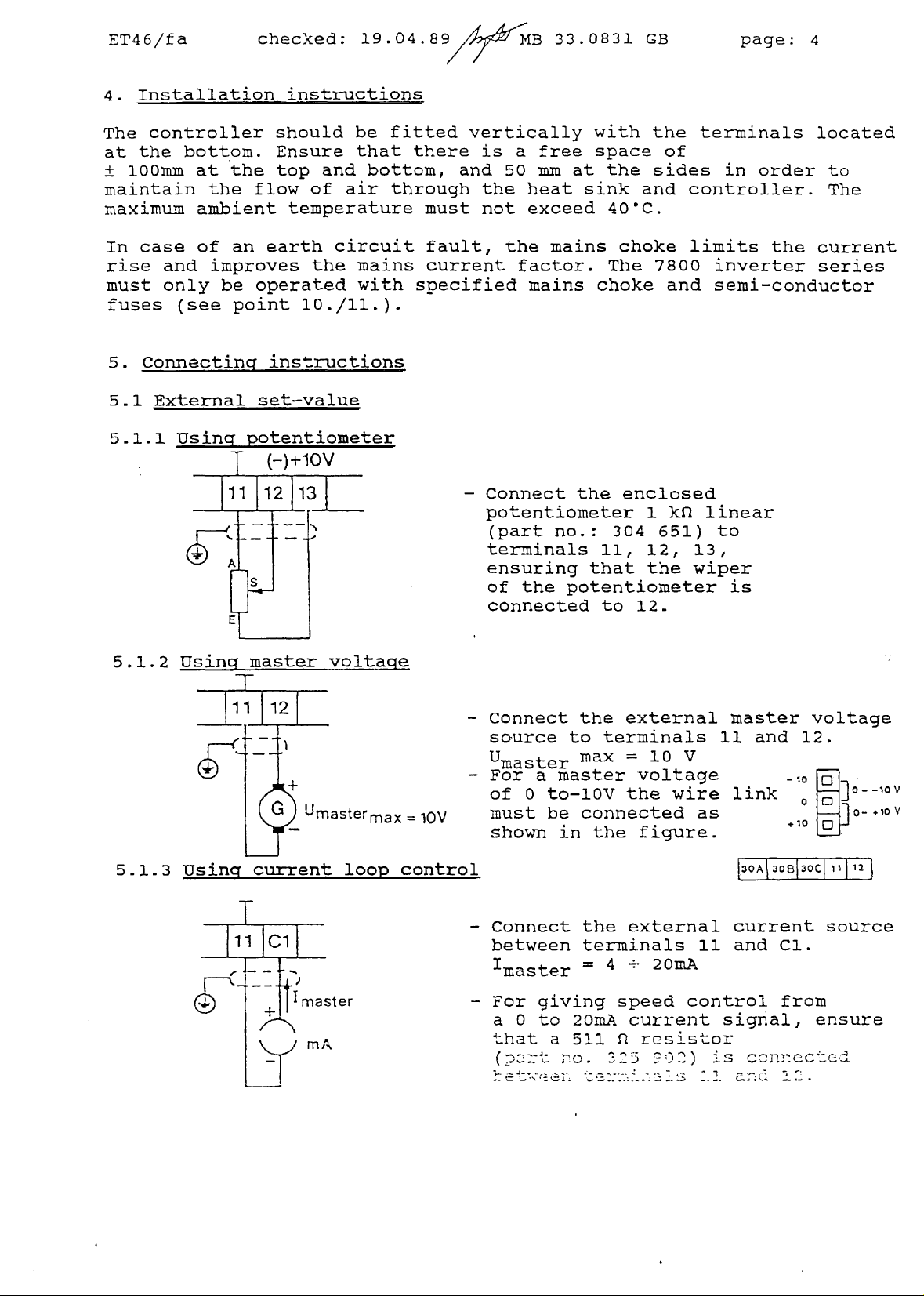

5..l.1

5.1.2

5..l..3

Usinc~

Usinq~

potentioxneter

(-)

+10V

UmastermaxiOV

current

loop

control

—

Corrnect

potentiometer

(part

no..:

terminals

ensuring

of

the

connected

—

Connect

source

Umaster

—

For

a master

of

0

to—lOV

must

shown

be

in

the

enclosed

1

kfl

304 651) to

11, 12,

that

the

potentiometer

to

l2~

the external

to

terminals

max

=

10

V

voltage

the

wire

connected

the

figure.

linear

13,

wiper

is

master

11

as

and

link

~f~B3Ocf12

voltage

12.

~

master

—

Connect

between

‚master

-

For

a 0

that

(‚-x=~t

—

the

terminals

=

giving

to

2OmA

a

511

;o.

external

4 ~-

speed

current

fl

resistor

225

20mA

?D2)

current

11

and

control

signal,

is

c~nm-.ccted

-~

—.

source

Cl.

froln

ensure

Page 6

ET4

6/fa

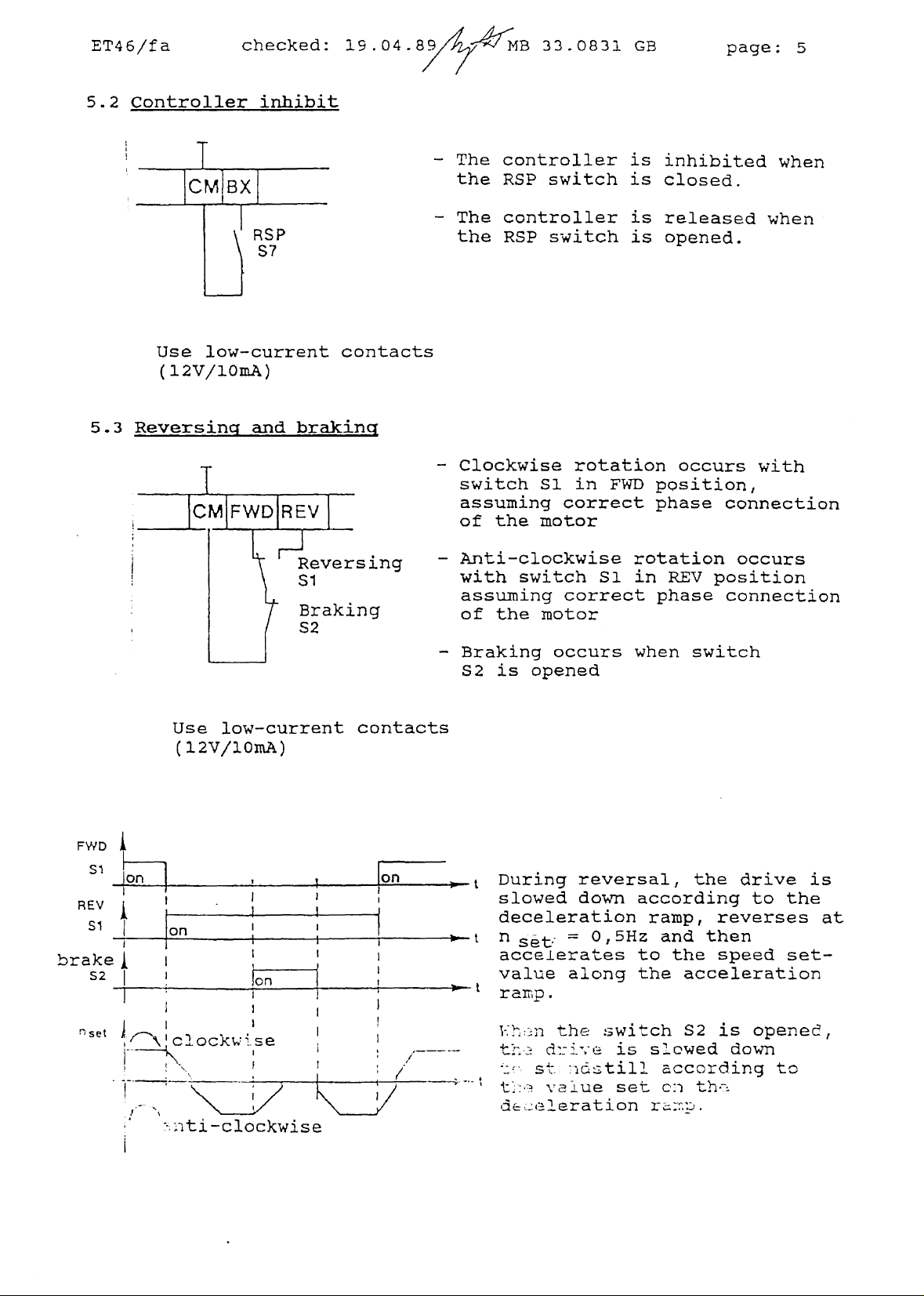

5.2

Controller

checked:

inhibit

RSP

S7

19.04.89

—

The

the

—

The

the RSP

IB

33.0831

controller

RSP

switch

controller

switch

GB

is

inhibited

is

closed.

is

releasedwhen

page:

is operied.

5

when

5.3

USe

low—current

(12V/lOinA)

Reversincr

Use

(12V/lOxnA)

and

low-current

contacts

braking

Reversing

s1

contacts

-

Clockwise

switch

51 in

assuming

of

the

motor

—

Ariti-clockwise

with

switch

assulning

of

the

motor

—

Braking

S2

is

occurs

opened

rotation

FWD

correct

51 in

correct

occurs

with

position,

phase

connection

rotation occurs

REV position

phase

connection

when switch

FWD

SI

-

-

-‚Pn

REV k

si

~

brakej

S2

T

~set ~‚~N‘c1ockw~se

—i-----I-------

fon

1

____

__________

-~

II

,

—‚

~ti-clockwise

Qn

on

—~--t

-1-

During

slowed

deceleration

n

set-

acceierates

value

reversal,

down

according

0,5Hz

to

alcing

the

the

raxop,

and

the

reverses

then

speed

acceleration

drive

to

is

the

at

set—

ramp.

~-2~3rl

—

t~

-~

~

tI--~

th&

~wi~ch S2 is

ci~:fy~iss.owed

-

- - ~L..1¶ ~

s~.

~Q~U1J!

v~1ue

set

down

accoroing

c:~

thr.

openec~,

Page 7

ET4

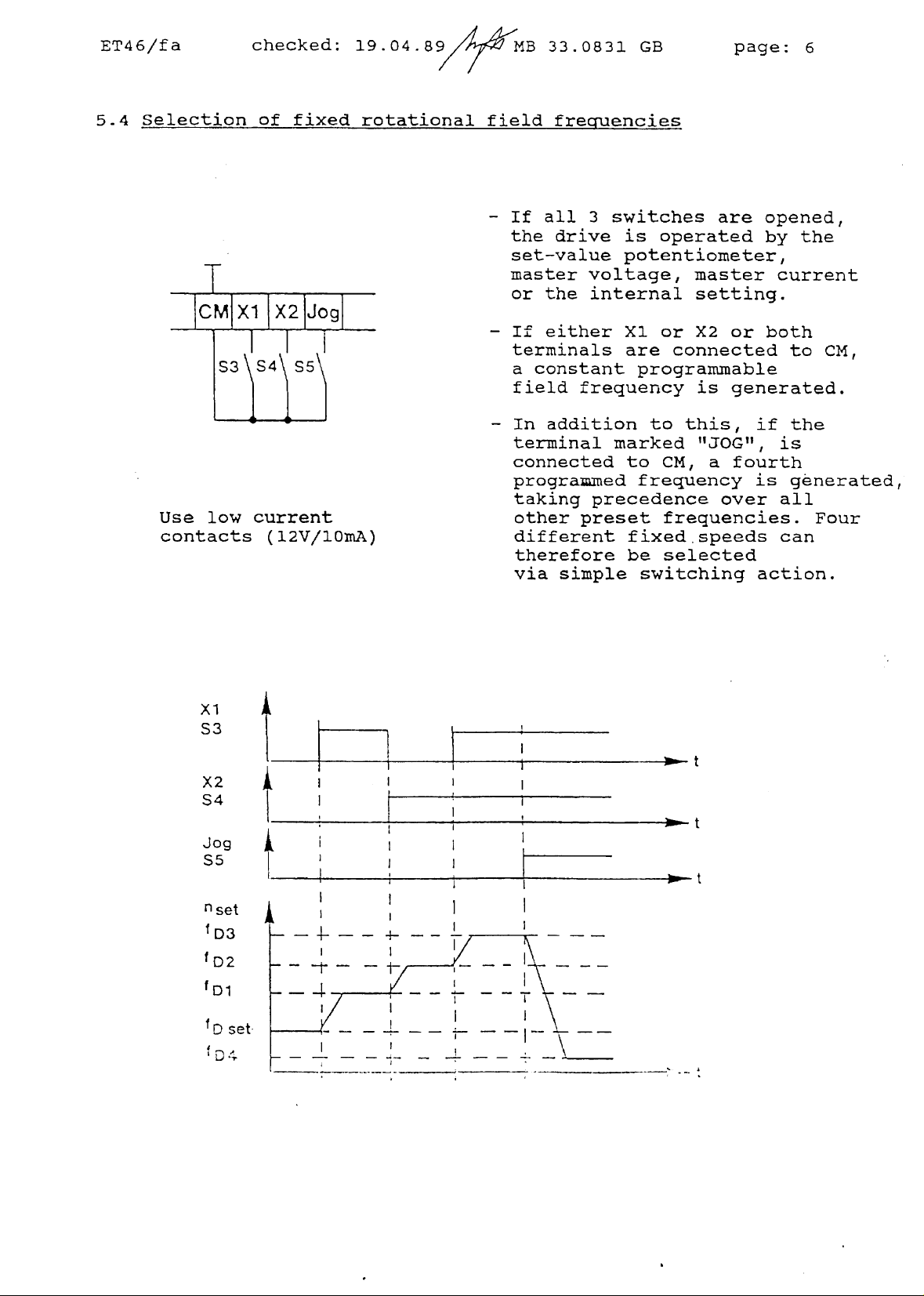

5..4

6/fa

Selection

T

CMIX1

Use

bwcurrent

contacts

checked:

of

fixed

X2

S3 S4 S5

(12V/lOmA)

Jogj

19.04.89

rotational

MB

33.0831

field

-

-

-

frecmencies

lt

all 3

the

drive

set—value

master

or

lt

terminals

a

constant

f

leid

In

terminal

connected

progra~medfreq~uency

taking

other

different

therefore

via

voltage,

the

internal

either Xl or

frequency

addition

preset

simple

GB

switches

is

potentiometer,

are

prograiiuuable

to

marked

to

precedence

fixedspeeds

be

switching

page:

are

operated

master

setting.

X2

or

connected

is

generated.

this,

„JOG“,

CM,

frequencies. Four

selected

a

over

lt

tourth

is

6

opened,

by

the

current

both

to

the

is

generated,

all

can

action.

CM,

xl

S3

X2

S4

Jog

$5

„set

D3

tD2

~D1

~D

D

set

4

lt

f.

1 1

~~~1

t

—

t

Page 8

ET4

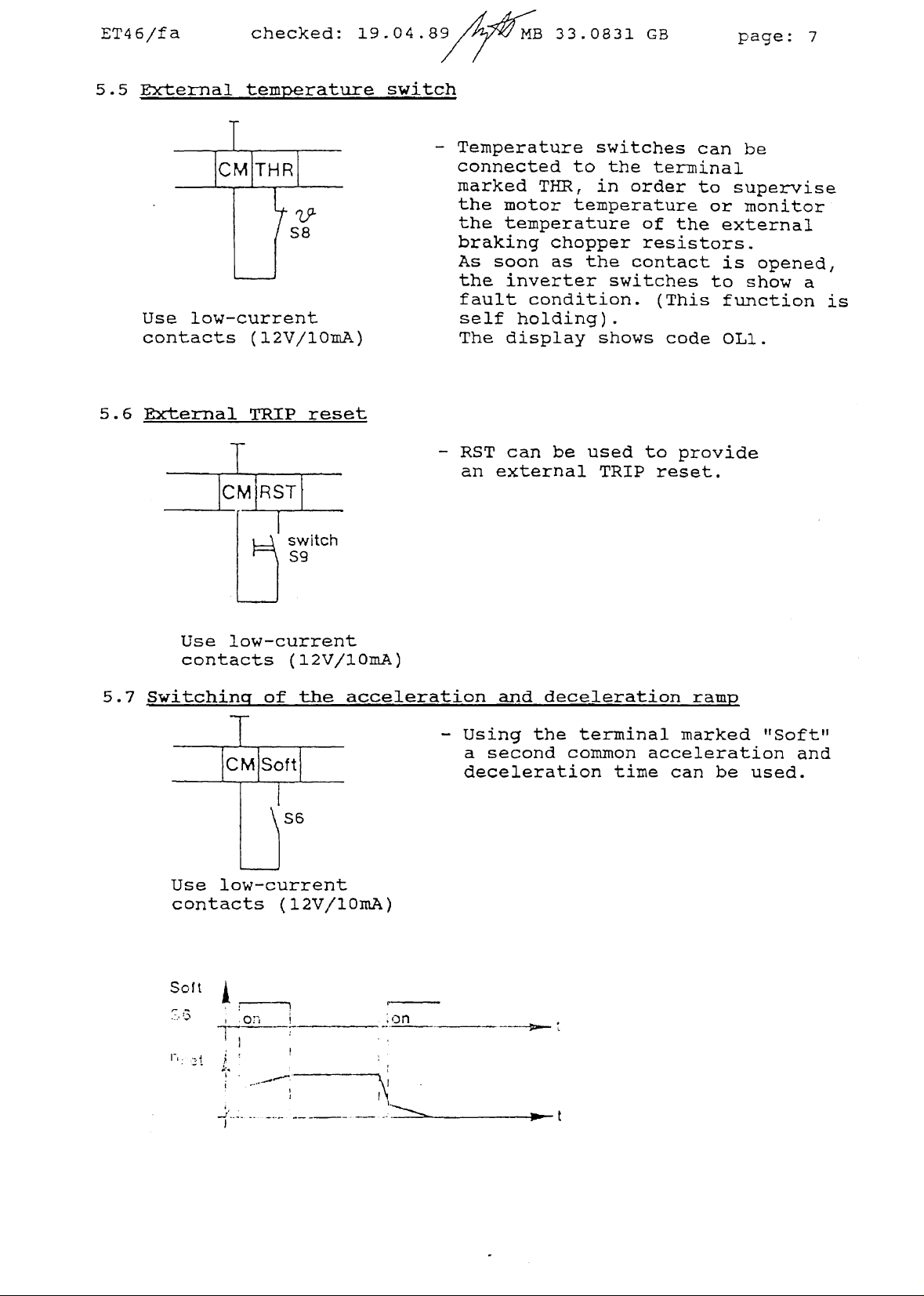

5.5

5.6

6/fa

External

Use

low-current

contacts

Bxternal

checked:

teniperature

79.

S8

(12V/lOmA)

TRIP

reset

T

CMjRSTj

19.04.89

switch

-

Temperature

connected

muarked

the

motor

the

temperature

braking

As

soon

the

inverter

fault

selt

The

display

-

RST

can

an

external

MB

33.0831

to

THIR,

chopper

as

condition.

holding).

be

GB

swltches

the

in

order

temperature

of

resistors.

the

contact

switches

shows

used

to

TRIP

page:

can

be

terminal

to supervise

or

monitor

the external

is

to

(This

f1lnction

code OLl.

provide

reset.

opened,

show

7

a

is

Use

5.7 Switchinq-

Use

low-current

contacts

low—current

contacts

So!

k

of

S6

(12V/lOm.A)

_______

switch

59

(12V/lOmA)

the

accelerationand

-

Using

a

second

deceleration

deceleration

the terminal

common

time

ramp

marked

acceleration

can

be

„Saft“

and

used.

1‘

Page 9

ET4

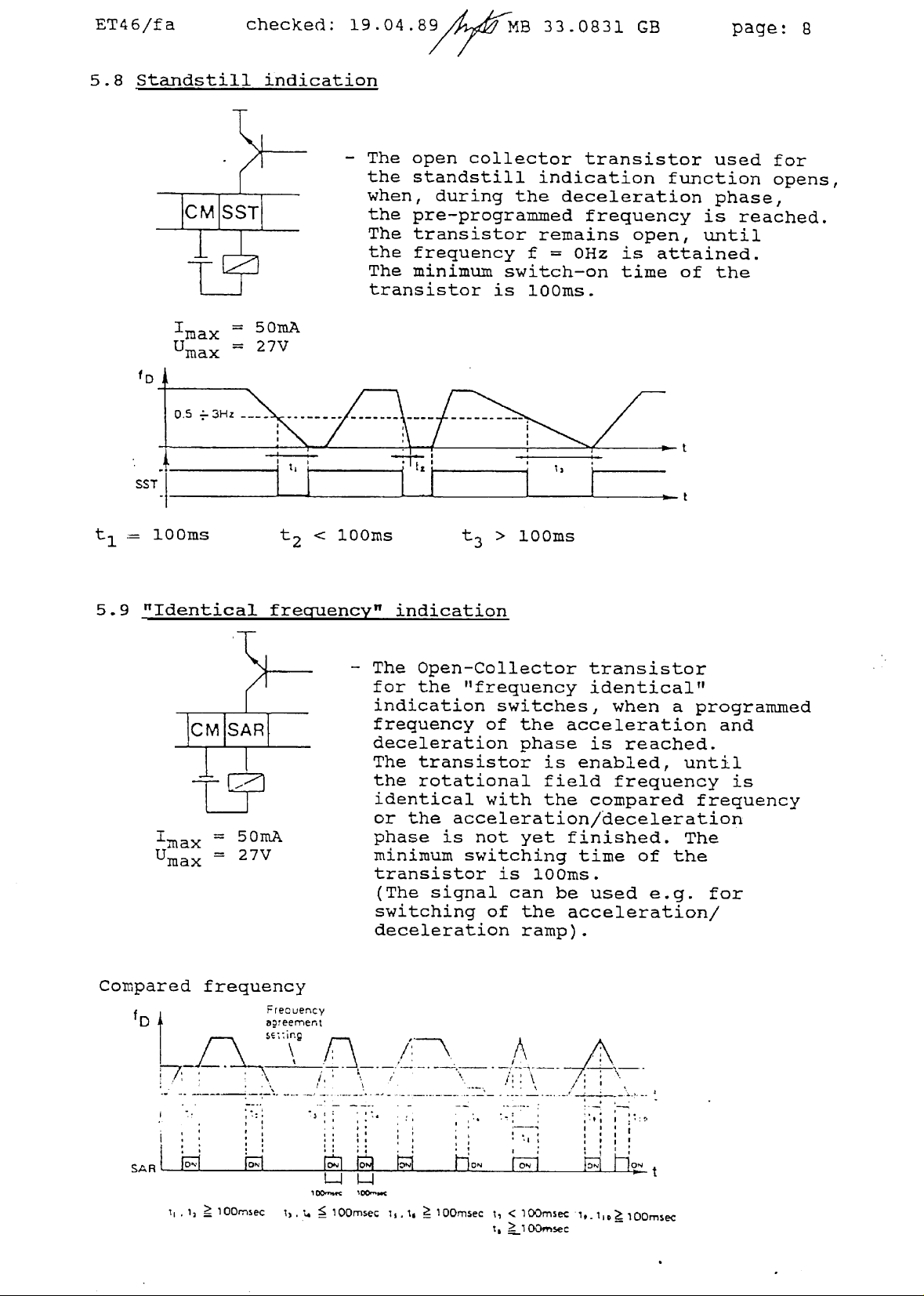

5.8

6/fa

Standstill

checked:

indication

19.04.8>t~/~14B

—

The

open

the

standstill

when,

the

The

the

The

during

pre—programmed

transistor

trequency

minimum

transistor

33.0831

collector

lndication function

the

remains

f

swltch-on

is

lOOms.

transistor

deceleration

frequency

=

0Hz

GB

open,

Is

attained.

tiine

of

page:

used

phase,

is

reached.

until

the

8

tor

opens,

5.9

‚max

Umax

SST

-=

lOOms

~Identical

‚max

Umax

=5OmA

=27V

=27V

<

lOOms

frecruency“

-

The

for the

indication switches,

freguency

deceleration phase

The

the

identical

or

phase

minimum

transistor

(The

switching

deceleration

t

3

>

indication

Open-Ccllector

„frequency

of

transistor

rotational

with the

the

acceleration/deceleration

is

not yet finished. The

switching

Is lOOms.

signal

ot

lOOms

the

is

field

can be

the

ramp).

transistor

identical“

when

a

programmed

acceleration

is

reached.

eriabled,

until

freguency

compared

tlme

of

used

treguericy

the

e.g.

aoceleratlon/

and

is

tor

Compared

1

1

SAR

frequency

.—

O~

-

re.

a~reemer~1

s~

O~.

uer~cy

ing

\

§S

O~

tOO.~c ~O0~‘mc

0

ON

O.~

~m~

1OOfV~sec

Page 10

ET4

6/fa

checked: 19.04.89 MB

33.0831

GB

page:

9

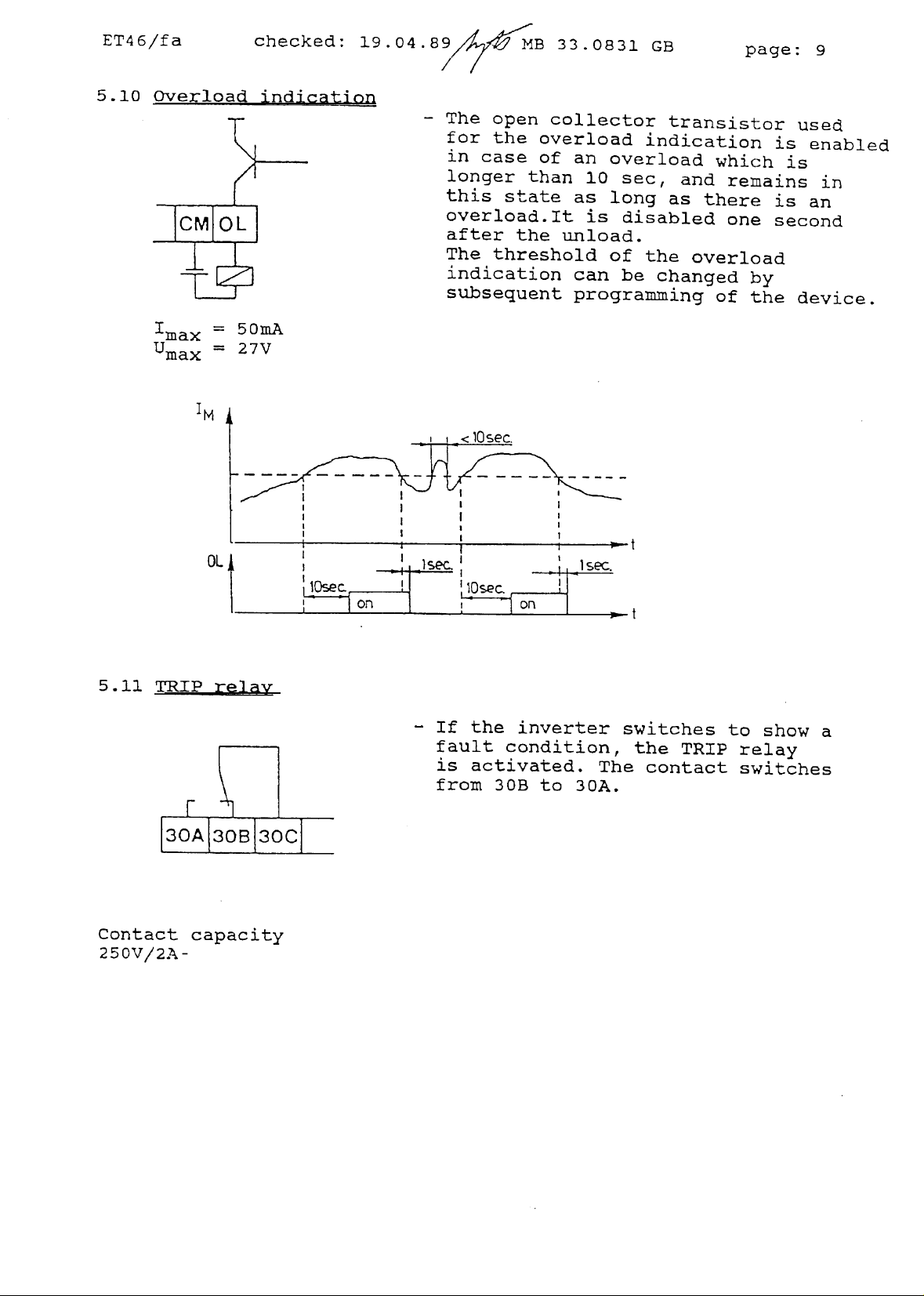

5.10

Qverload

indication

‚max SOmA

Umax

=27V

-

The

open

tor the

in

case

langer than

this

overload

of

state

collector

an

as

overload.It

after the unload.

The

threshold

indication

subseguent

can

programming

indication

overload

10 sec,

long

is

disabled

of

the

be

transistorused

is

as

and

which

remains

there

is

is

one second

overload

changed

ot

by

the

device.

enabled

in

an

5.11

TRIP

[3oA13

Coritact

250V/2A-

OL

relav

F

OB

1300

capacity

-

lt

the

fault

is

activated.

from

30B

inverter

condition,

The

to 30A.

switches

the

to

show

TRIP relay

contact switches

a

Page 11

ET46/f

a

checked:

19.04.89

MB

33.0831

GB

page:

10

5.12

a)

b

Frecruericv

Analogue

1

Digital

OMEM

885

out~ut

M

~7

C2H1-

4~1

5

-

An analogue

can

be

connected

which

or

0

0 —

is

—

10V tor

10V

used

Adjustment using

—

A

suitable

a

VSC

analogue meter,

-

A

digital

be

connected

~FM

~FM

Such

be a

=

=

=

a

322

display

24xfD

l2XfD

GXfD at

suitable

unit,

measuring

to

monitor:

0

+

tor

0

—

trlmmer

measuring

giving:

at

~D~{AX

at

tDI

fD~~<=200Hz

digital

part

instrument

(Ri

=

10km)

60HZ

120Hz

instrument

part

device

50Hz

4AX=lOOHz

no.

ADJ

no.

can

or

or

or

meter

326

is

326 893

also

60Hz

120Hz

240Hz

would

884

5.13

lt

3

minutes

Mains

PE

the

connection

L1

L2

motor

(e.g.

FU

7800

L3

must

jogging),

be

released

-

L1, L2,

340 to

-

Semiconductor

mains

tables

-

On-otf

limited

within

the

following

L3

505V

chokes

on

pages

mains

to

periods

three-phases

±

0%.

fuses

are

and

speclfied

30/31.

switching

once

circuit

in

every

of

less than

must

should

3

be

=

RFR

In

the

be

minutes.

used.

Kl~j~

K2(j

K44D

motor

K24J

Bx

Page 12

ET4

6/fa

checked:

19.04.89

MB

33.0831

GB

page:

II

5.14

‚~

screened

motor

(*)

levels

VDE

Motor

cable

three-phase

Valid

ot

0871.

corYnection

motor

tor

radio

industrial

interferencesuppression

lt necessary,

3

plants

please

—

Ihe

nominal

normally selected

corresponds

nominal

e.g.

—

lt

exceeds

voltage,

the

mains voltage

380V

460V

motor

motor

nominal

the

the inverte.r‘soutput

characteristic

grammed

turietion

—

Switching

as

code

of

permissible

described

and

factories

under polnt

in

consult the

motor

voltage

such

to

the

available

at

380V

at

460V

mains

voltage

nominal motor

can

be

described

urider

10.

the

phases

with

the

which

circuit

must

compliance

supplier.

that

mains

mains

pro—

is

5.13.

with

is

it

only

as

have

5.15

Connection

brake

resistor

of

braking

resistor(s

—

Application:

with

—

The

rator

DC

and

DC

operating

The

Fault

—

Using

vating

(See

excessive

as

The

1.sted

*

?or

current

large

energy

masses.

produced

rnode“

link

circuit

results

link

voltage

without

inverter

indication:

a

braking

the

tiinctlon

energy

heat.

~?D(~cified

in

the

settir.

see

Short

is

fed

in

an

sets

internal

code

brake

table

ot

table

braking

in

the

ot

into

the

the

Inverter

iricrease

and current,

a

braking

TRIP.

OC

2

or OU.

resistor

or

braking

23)

causes

to be

the

an

dlssipated

resistor~

on

page

release

page

times

„gene

of

the

when

chopper.

acti—

chopper

the

~re

21.

21).

-

)

Page 13

ET4

6.

6/fa

Display

checked: 19.04.89

and

operating

unit

MB

33.0831

GB

page:

12

(

___

1

2

30/

—~;

lOj

Dl

31

4

50 ~0 80 ~Q)0O%

40

1

2O2E~

A

1

6

~

SET

5~

LEI

ST

D~

7

8

9

1.

Output

frequency).

2.

7-segioent

tor

parameters

3.

Selection

4.

Switching

during

code

5.

~ey

and

trequency

normal

normal

during

tor

storing

also

set—value

6.

Keys tor

trequency

the

keyboard.

7.

For stopping the

8.

For

starting

9.

Key tor TRIP

in

percent

display

operation,

during

key

key

tor

programming.

tor

operating

tor

motor current

output

or

operation

programlning mode.

new

parameters

tor

storing

is

entered via

parameter

the

setting

setting when

motor

the

motor

reset.

(related

to

the

tre~uency/current

alternatively, tor

mode

or

key

rotational

the

when

the

set

with internal control.

with

internal

or

program

display

tor

selection

in

the

tield

keyboard.

in

the

trequency

or

motor

program

trequency,

program

is

control.

maximum

the

mode.

Dt

mode

input

treguency

each

mode,

entered

(S2=0)

function

when

or

via

for

Page 14

ET46/fa

7.

Moditication

7.1

Keyboaxd

In

order

activates

the

„PRG“

tunction

the

„SHIFT“

this,

and

„SET“

lt

„

you

the

7

key.

want

tunction

modified

operating

the

swltch

checked:

operation

to

change

braking)

key,

code

the

is

key

data code

„.

lt

this

to

change

code

as

using

deslred,

mode by

S2,

the

19.04.89 MB

ot

the factory—set

the parameters,

so

that

inverter

displayed

the

desired tunction

can be

value

other

the

the

pressing

the

is

in the

chosen

is

paraxneters,

„SHIFT“

inverter

again the

inverter operates

parameters

open

display

switched

twa

lett

code

using

the desired

key.

lt

is

swltched

„PRG“

with

33.0831

the

is

switch

flashing.

to the

segments.

can

be

the

keys

new

parameter,

select the

all

parameters are

to

key.

the

new

GB

S2

By

program

selected.

marked

next

the

After

set

page:

(which

pressing

mode.

By

pressing

The

After

~1

1=11

~

press the

normal

re-closing

parameters.

13

~FTFi7T71

~9I§LLILI

1~z~

—

SHIFT

—

—

SET

—

Page 15

ET4

7.2

6/fa

Function

checked:

code

19.04.89 MB

33.0831

GB

page:

14

Function Fug~tion

Display

switchlng

3

setectabte

qiencies

superirrposed

first

first

second

and

after

on

fixed

pre-

(S3/S4)

acceteration

deceleration

corrrnon

deceleration

fre-

etectronic

motor

protect,on

Ii.increase

lJ/f

characterstic

(U/f

ecge

point+f~~)

chopper

f

1.increase

f.(bias>

MaximJn

3

freq~ency

Limit

freq~ency

imitation

frequency

with

Hz

Anp

Freq.1

Freq.2

Freq.3

fixed

freq.

time 05

tirr>e

acceleration

time-

(S6)

offset

with

offset

vatues

to

be

Date code

factory-set

code

vatue

see

page

00 00

Hz

15

17

18

19

19

20

20

21

21

01

01

input

input

in Hz

in Hz

02

03 30 30Hz

04

06

07 18

08

09 06

.

10

11 05

12

13

14

15

16

00

trnntation

at

150

01

without

Hz

limit

00 Hz

10

20 20 Hz

5

15 7.

16

01

00

00

00

00

00

00

—

10Hz

5Hz

5s

lOs

20s

100%

meditzii

0-50Hz

mediun

50Hz

0Hz

0Hz

150

exctuded

ration

ordertoavoid

externat

internEEtroLl

overcu‘rent

freq.~ency

inverter

idlingat< 2

brake chopper

DC

f

starting

Int./Ext.

set-vatue

U/f

characteristic

optioraL

autoii~tic

and

braking

<2

Hz

ecge

äiring

accete-

deceLerat>on

resonences

T7~o~~iF

FiJ~~ticu7~

warning

merker

signalatf.

Hz

operation

at

current

paint

functions

TRiP

Limit

externe

internat

at

18

reset after

mains ur~ervoLteoe

t.

in

17

18

19

20

21

22 00

inputinHz

00

01

02

03

inputinHz 50 50 Hz 24

00

00

00

01

00

23

01

02

02

24 01

25

26

27 00

28

01 01

OD

puinHz

50

00

with

out

externai.

Umin

controt

110%

0.5Hz

g~ak¶n

141%

externat.

50Hz

22

22/23

23

24

24

25

26

26

26

27

Page 16

ET46/ffa

7.3

Description

checked:

of

the

19.04.89

tiinction

code

M3

33.0831

GB

page:

15

Function

code

00

The display can be

thls

function

code.

Data code

00:

Display

01:

Display

By

pressing the

selected

Functiori

The

inverter

tield

as

made

frequencies, by

S3

and/or

inactive.

during

code

SHIFT-key,

operation.

01,

is

set

S4

are

S3

prograznined

ot

the

rotational

of

the

motor

either frequency

02,

03

to

one of

olosing

closed,

54

after mains

current

the

three

the

switches

any

other

trequency

[Hz] using

function

switch—on

fieid

prograininable

frequency

(R.~4.S.).

or

current

S3

and/or

set—value

setting

code

mains using

rotational

S4.

setting

tactory

setting

display

As soon

is

can

~e

closed

open

closed

Function

The

inverter

frequency

any

other

inactive.

Note:

At

maximum

field

03

treguencies

and

04

:Orexample

open

closed

closed

code

by

set-value

The

04

is

set

to a

closing

setting,

frequency

ffrequencies

which

are multiplied

-

Maximum

frequency:

(Function code

Prograxnined

(Function

Actual

flxed

code

fixed

fourth,

switch

S5.

as

is

set

higher

are

set

according

150Hz

10

data

fregency:

01,

02,

ffreguency:

programined

As

soon

well

in

Hz.

than

50

usirig

to

code

03

or

60Hz

01

02

03

as S5 is

as

switches

(Factory

or

tunction

the

04)

20:~iz

04:

rotational

setting

60Hz,

the

codes

maximum

data code

10

Hz

20

Hz

30

Hz

ffield

closed,

53

and

S4

is

5

rotational

01,

02,

freguencies.

20)

are

Hz).

Page 17

ET

46/fa

checked: 19.04.89

MB

33.0831

GB

page:

16

Furction

The

tirst

cominon

tollowing

code

051

acceleration

acceleration

table:

06

and

and

07

and

deceleraticn

deceleration

tue

tiiue,

are

as

coded

well

as

the

according

second

to

the

lt

the

times

apply.

deceleration

At

maximum

deceleration

are

multiplied.

Factory

-

first

—

first

—

second

switch

lt

tue

SG

is

S6 is

becomes

opened,

trequencies

times

setting:

acceleration

listed

tue

deceleration time

conunori

time

20s

then

higher

the

clcsed,

eftective.

than

above

7.5s

lOs

first

the

50

and

acceleration and

second

or

the

programmable

60

coiamon

Hz,

the

deceleration

acceleration

acceleration

fixed

ffreguencies

and

and

Page 18

ET4

6/fa

checked:

19.04.89

MB

33.0831

GB

page:

17

Function code

When

tive

using

this

tunction

dimensioned

only

drives.

valid

tor

The

table.

Date

cc~de

00

not

08

tunction

can

tor

the

tour-pole

data

01

1

100

c

0>

E

be

inverter

code

02 03

95 90

50

40

30

code

adapted

a

built—in electronic

to

smaller

size.

The

motors,

protective

motors and cannot be used

to

be

set

can

be

tound

0-4

05

06

07 08 09

85

80

75

70 65 60

which

ttinction

in

the

101

11112 13 14

55150145

motor

are

tor

group

tollowing

40 35 30

protec—

not

is

151

The

protective

lower

at

nominal

switch-ott

appears

treguenoles

trequency.

times.

as

the

0

20

0

1.~

10

tunction

(speeds).

When

tault

30

inveder

considers

The

100

current

the

reduced

characterlstic

Lower trequencies result

the

protective

tunction

condition.

150

motor

shows

in

is released,

{O/)

shorter

cooling

the

at

operation

0L2

Page 19

ET4

6/ta

checked:19.04.89

MB

33.0831

GB

page:

18

Function

At

voltage-treguency

16

different

istlcs

through

with

code

0

and

to

linear

15

voltage-trequency

Umains

09

U

.

characteristics

lni~i~e

allcw

(U/t)

motor

tor

edge

is

underexcited,

a

voltage

points

can

increase

increase.

ot 50

be

entered.

whilst

in

Hz or

Using

characteristics

the

lowerspeed

60

Hz,

character

range

-

2

lt

of

(0

the

the

to

U/t

motor

15)

00:

06:

15:

edge

is

have

minimum

normal

maximum

pointis

no

langer

a

linear

Umin

Umin

Umin

hlgher

possible.

than

60

Then,

Hz,

an

all

voltage—trequency increase.

increase

increase

lncrease

50

or

underexcitement

characteristics

Page 20

ET4

6/fa

checked:

19.04.89 MB 33.0831 GB

page:

19

Functlon

The

following

code

5

~

~

50Hz

‚

10

U/t characteristics can

QO

5

50Hz

01

6

6

6

60Hz

1

02 03

1

1

1

‚

1 1

50Hz

05 06

3ZOHz

12

~

~

~

0Hz

1

1

‚

‚

1

~•

1

1

1 1

1 1

eo

1

1 1

60Hz

12

‚1S~Hz

360Hz

~

~7L

10

1

1

.

1

1

1

be

I

1

T2~—~z

1

1

100Hz

.1

1

1

programxned:

~

~

~

~

~*-~ ~2Vt—tz

07

1

1

1

1

1

120Hz

15

2

2

2

lt

the

multiple

tiioes

03,

The

using

as

04

U/ff

tunction

via data

Funotion

The

chopper

order

to

‚i5OHz

16

17

1

330Hz3EO-~z

maximum treguency

ot

50

Hz

orGO

well

and

edge

code

code

avoid

as

the

„SAR“

point

code

18.

11

trequency

machine

the

fixedtrequenciesot tiinction

output

can

26,

can

180Hz

11

5

ot

Hz,the

~

1

1

~i7L

S0Hz93H

the

acceleration

si~Tial,

be

treely

when

choosing the last

be set

resonances.

2001-tz

18

2~Hz

chosen

are

selected

to 10

2~.0Hz

characterlstic

arid

deceleration

code

multiplied

between

accordingly.

50

characteristic

ditterent

values

Hz

is

a

01,

and

in

02,

99

Hz

00 09

dotc

code

foctc~y

dato

code

seting

5

Page 21

E‘I‘4

6/ta

checked:

19.04.89

MB

33.0831

GB

page:

20

Function

Using

to

62.5

When

range

codes

tunction

%

the

set-value

is

not

ot

Function code

Ioata

code

00

01

~Tirnitat

Lin

Using

to

When the

range

ion

X

37.5

100

~

tunetion

%

of

set—value

is

not

12.

13

code

the

12

maximum

is

ettective

12

~02 ~03

04 06 07 08 09

1

95

192.5

90 87.5

code

the

maximum

is

ettective

the

tield

adjusted

due

13

the

adjusted

due

upper

to

85

82.5

lower

field

to

tield

frequency

using

this

programined

80

77.5

tield

freguency

using

this

programined

trequency

set

vla

a

potentiometer,

can

tunction

„null“ range.

10 11 12 13 14 15

75

72.5

70 67.5 65

frequency

set

via

a

potentio~ieter,

can

ffi.tnctiori

„null“ range.

be

the

1

62.51

be

the

limited

code

upper

limited

code

lower

10.

10.

Function

Data code

Limitation

in

%

code

00

0

01

2.5

13

02

~D[

03

04 05 06

5

7.5

10

12.5

15

07

17.5

08

20

1ö9

j22.5

10 11 12 13

25

27.5

30

32.5

-

35

15

t37•5

%

set

vo)ue

[Y0)

Page 22

ET4

6/fa

checked:

19.04.89

MB

33.0831

GB

page:

21

Functlon

code

Using the

maximum

frequency

proqrainned

in an

in

inetteotive

a

higher

14

tunction

at the

resolution

code

which

14 a

is

inverter.

range

ot

ot

minimum

set

This

via

speed

tunction

prograinining

the set-value

speed

adjustment.

ot

0%

to

75%

code

does

10,

not

can

potentiometer,

ot

result

but

the

be

only

Function code

The

tunction

Hz

in orderto

Data

Data code

15

code

protect

code

15

allows

the

FIT:

01

:

tor

an

motor

treguency

no

freguency

1.

1000/.

output

and

machine.

limitation

limtation

vo!ue

IO/o)

fre~uency

at

150

limitation

Hz

at

150

Page 23

ET4

6/ta

checked:

19.04.89

MB

33.0831

GB

page:

22

Function

In

order

codes

to

deceleratlon,

ot

1

Hz

each

in

Hz.

16, 17, 18

avoid

due

can be

0

machine

to

the

output

programxned

resonances

freguency,

in.

during

The

acceleration

3

trequency

parameter

No

ot

set

volue

and

notches

variables

tactorysetting

trequency

notches

are

Furiction

The

control

fu.nction

-

Data code

The

tunctions

-

the

The

set

Data

The

„P.UN“

motor

via

code

furictions

connections;

The

motor

field

code

code

19

mode

19,

and

00

are controlled

and

„Stop“

voltage depends

function

01

are

the

voltage

trequency

vla

codes

also

„RUN“

is

and

the

motor

keyboard

keys

09

controlled

and

set

the

necessary

voltage

or

terminals.

via

the

an

the

keyboard

on

the

and

10.

„Stap“

depending

control

can be set uslng

(Factory setting

terminal

are

block

not

rotational tield

via

the

terminal

keys

on

are

the

rotational

not

etfective.

torque.

connectians;

ettective.

frequency

block

00).

as

voltage control

range

Page 24

ET4

6/ta

-

Data

The

„PJJN“

set

ration

code

tunctions

and

automatically

and

tunction code

checked:

02

are

also

„Stop“

keys

in

deceleration

9

is set.

UM

=100%

19.04.89

controlled

are

not

the

stationary

a

motor voltage ot

MB

33.0831

via

the

etteative.

operation.

GB

terminal

The

motor voltage

the

fD

page:

block;

During

accele

data code

8

23

the

is

-

and

-

Data

The

The

The

code

funotions

terminals

motor voltage

rotational

Function

The

opto—coupler

using

ta

tunction

the

following

Data code

Inverter

1_put

current

code

aut—

03

tield

20

(%)

„RUN“

Xl, X2,

trequency

output

code

table.

and „Stop“

„Jog“

is

set

automatically

„012‘

20.

The

00 01

non

active

are

and

as

can

„Satt“

described

be

threshold

110

controlled

da

depending

not

via

have

the

on

under data code

activated

current

in

can

case

be

02 03 04

120

130 140

keyboard.

any

fuziction.

the

ot

overload

set

according

00.

-T

05

150

Page 25

ET46/fa

checked: 19.04.89 MB

33.0831

GB page:

24

Function code

This

rotational

functian

field

trequencies

least

(Factory

Function

The

freguency

the

least

tollowing

Data

Inverter

100

insec.

setting

code

opto-coupler

duririg

programmed

100

msec.

table.

code

autput

treguency

21

allows

are

22

frequency

[Hz]

tor

a

comparison

trequency

ideritical,

The

compared

is

50 Hz).

output

the deceleration

The

compared

and

the

T‘SST“

(0

to

treguency

freguency

a

programmed

output

Is

activated

phase

3

Hz).

between

„SAR“

is

set

lt

is

smaller

The

output

is

set

the

momentary

trequency.

is

activated

in

Hz.

the

rotational

than or

is

active

accordlng

lt

the

tor at

to the

two

field

equal

tor ~t

to

Function

Function

code

code

deceleration

Data code

23

23

phase.

00

01

~

determines

:

lt

the

to

<

2

This data

inverter

chopper.

lt

the

tO <

~~iith

2Hz,

DC

the

motor‘s mode

rotational tield

Hz,

the

motor

code

is to

must

be

ratational

the

motor

injectian

idles.

be

operated

tield

is

current.

at

operation

trequency

selected,

with

trequency

braked

down

it

the

has

the

braking

has

to

in

the

reduced

reduced

standstill

Page 26

ET4

6/ta

checked:

19.04.89

MB

33.0831

GB

page:

25

Function

This

phase.

the

Inverter

demand

current

code

function

lt

the

of

value.

resuned.

the

24

allows

motor

output

motor

At this

rD

1malcr

tor

limiting

current

is

trec~uency

is

smaller

point,

the

motor

higher

is

held constant until the

than

the

than the preset

the

acceleration phase

current

inverter‘s

in

the

starting

maximum

current

current

preset maximum

is

once

f

again

The

be

exceeded

The

the

data

code

starting

current

coded

input

following

tor the

during the

maximum

(%)

=

nominal inverter current A

ot

the

table:

maximum

starting

inverter

starting

inverter

phase, can

out~ut

current

output

be

current

is

achieved according

current,

calculated

A ~

which must

as

follows:

100

%

to

not

Page 27

ET4

6/ta

checked:

19.04.89

I4B

33.0831

GB

page:

26

Function

Using

used,

Da~a

the

is

code

Function

lt

the

U/t

edge

code.

code

ffunction

25

code 25

determined.

00

Frequency

External

1.)

using

2.)

using

3.)

using

code

26

characteristic

paint

can be set between

the

type

setting via the

trequency

set-value

master-valtage

master-current

18

has

beeri

ot

set—value setting

keyboard

setting:

potentiometer

value

value

selected

50

Hz and

0

4

using functlon code

99

to

to

Hz

„7/\“

10

V

20

iaA

using

to

/DC

/DC

this

be

10,

tunction

thE

Umo~or

The

values

Function

The

tunctian

are

code 27

code

display (option

select

data

code

50Hz 99Hz

set

in

Hz.

27

is

p~ovlded

7804). lt

00.

(2nd

this

second

display

Factory

tor

using

display

= data code

a

second,

is

02).

setting

external

not

used,

=

50Hz

Page 28

ET4

6/fa

checked: 19.04.89

MB

33.0831

GB

page:

27

Function code

The tunction

inverter

The

trequency inverter

to

the

after

after

main

L1,

FWD(REV)

motor

speed

speed

subsequent

accelerates

ramp.

28

code

s

L2,L3

ot

to

28

allows

a

short—time

adapts

the idling

reconnection

its

set—value,

tor

an

inains

its

motor

ot

automatic

tailure.

rotatlonal

and then connects the motor

the

xnains.

connection

tield

The

trequency

drive

tollowing the set acceleration

ot

then

the

Data

8.

Fault diaqnosis

lt the

is

given

code:

inverters

in

FIJ

the

Display

Err

Err

Oc

QC

OC

GMJ

LU

OL

CL

:

Funotion

04

sets

:

Function

TRIP,

tollowing

1

3

1

2

3

1

7

inactive

active

the type

table.

Type

0-perating

ot

tault

fault

Controller

Overcurrent

Overcurrent

Overcurrent

Overvo

ltage

Undervoltage

Inverter

external

(ezterrial

Motor

overtemperature

temDerature

TRL?

ov‘~rloir~

ot

fault

tailure

during

during

at

constant

release)

is

displayed.

acceleration

deceleration

speed

„TI-flV‘

switch

S8

or

The

coding

The

or

displays

earth

OCl,

circult

of

0C2

the

and

motor

0C3

may

also

terminals

indicate

U, V,

a

short—circuit

W.

Page 29

ET4

6/ta

9.

Diniensions

-

Front

checked:

and

view

weicrhts

19.04.89

MB

33.0831

GB

page:

28

Fig.

-

1.

Side view

Fig.

Fig.

4

1.2

~1-~

2

Fig.

1.2

Fig.

3

280

5

135

—

fixinq‘

Fig.

L=~1~.

—

lower

Fig.

5

156

235

6

~Lij

10

hole

oaniel

Fig.

4

II

cable

Fig.

~1

6

F-1

:~.

holes

7

12

Fig.

~2O

~27J

8

Fig.

9

~26

ri

~34j

Page 30

ET4

6/fa

checked:

19.04.89

MB

33.0831

GB

page:

29

Type

7811-

7812

7813

7814

7815 2,5,6,11

7816

7817

7818

10.

Mains chokes

Type

-

7811

3x

Fig.

1,4,6,7,9

1,4,6,7,10

1,4,6,8,10

1,4,6,8,10

2,5,6,11

3,5,6,11

3,5,6,11

Choke

A

7

3x

No.

jPart

TnH -

2.5

322 293 SA

Weight

9

10

10,5

11

16

18,5

20,5

21,5

abc

m~

1 irrt

11201

61

(kg)

Dimensions

d e

iiia

im~

um

84

45

130 105

f

km

flyn nillumrrm

73

6.0

n

11

7812

7813

7814/7815

7816 3x 35

7817/7818

3x

3x

•

3x

3x 45

12

3x

17

3x

25

3x

3,~

3x

‚1;

1.6

1.2

1.2

0.880

0.750

325 294 SA 11501 70 90

322 149

322

307 342 SA 180 90

307 343

hAI

124

148

jSA

150175

1SA ~180 85 163

66 110

140

163

—

54

155

130816.0

53

162 11080f

60

180 135

74

225~167

69j216

166)

0~

5.O

95j5.0

120~6.3

120 6.3

11

10

11

11

11

;

Page 31

ET4

6/fa

11.

Semiconductor

checked:

fuses and

19.04.89

tuse

MB

holders

33.0831

GB

page:

30

Type

7811

7812

7813

7814

7815

7816

7817

7818

Fuse

Fig.

2

2

2

2

2

1

1

1

holders

part

332

721

332

721

332

721

332

721

332

721

329

807

329

807

329

807

na.

Fuses

Type

FF

12A

FF

20A

FF

25A 307 959

FF

32A

FF

40A

FF

50A

FF

63A

FF

BOA

Part

307

305 321

307

305 240

329

329

329

na.

960

943

893

894

895

Fig.

Fig.

1

2

0

0

Page 32

ET4

12.

6/fa

Brake

checked:

resistors

19.04.89

MB 33.0831

GB

page:

31

Inverter

type/no«~inaI

power

7811/2KW

7812/3.7KV

7813/5.5KV

7814/7.5KW

7815/11

7816/14

7817p7

7818/20

Rl:1

KV

KW

K~J

KW

ZWS

ZWS

R3:

RSO

resistor

cpantity/

type

2xRI

1xR2

4xR1

1xR3

1xR3

2 x

R3

2xR3

2xR3

100

250W

50

x

W

,

,

373,

corbnection

arrangement

in

series

.

2inR.2x

in

parallel

.

-

in

paralleL

in

paralLel.

in

paraLlel

100

fl±10%

f2±10%

100

68

fl,

total

resistance

0-

•

200

100

100

63

68

34

34

34

±5%,lkW

total

power

200W

250W

400W

lkW

lkW

2kW

2kW

•

2kW

1_part

part

part

reLease

current/motor

protection

relay

0.8A

1.OA

1.5>,

3.5>,

3.5>,

7.OA

7.OA

7.OA

na.

309

no.

no.

309

333

163

164

113

Fig.1

Fig.2

Fig..3

Fig.

0

Fig.

1

‚165

:2

0 0

~3.2

1

3

11.5

0

1

18

_______

373

332

71q

1

Fig.

2

F1

421

451

Page 33

ET4

6/fa

Cautic‘n

In

case

When

burn-out.

USlflg

of

mains

resistors

Theretore

checked:

overvoltagethe

19.04.89

without

only

bemperature surveillance

approaching

is

recom~ended

flreproot hous

lt

the

external

an

page

overload.

overvoltage,

20

seconds.

13.

Radio

lt

is

permissible

ference

operation

provided

dass

CENELEC

local

B

regulations.

350C

may

occur

that the resistors be

Ing.

brake

11,

the

TRIP

Since

interferencesuppression

the

the

inverter must

suppression

rooms,

that

are

HD

not

344).

commercial premises

the

exceeded.

The

resistor

indication

interterence

to

use the

in

limit

units

overload

resistars

devices

at

the

is

be

controllers

electrical

values

(See

according

CISPR

should

MB

33.0831 GB

braking

with

must

surfaces

chopper

protection

integrated

be

lnstalled.

of

the.

additionally

connected according

„OLl“

niay

is

displayed

have

disconnected

been

caused

from the

wlthout

systems

or

publicatiens

only be used

within

industrial

to

VDIE

in

page:

niay

be

the

0871/6.78,

reslstor(s)may

er

external

Since

brake

installed

to

in

case

by

radio

inter

connected

plants,

11,

compliance

32

actlvated.

temperatures

resistors,

the

into

diagram

a

ot

mains

mains within

-

with

lt

In

order

sensitive

cantrol

ensure

interrupted.

and

connection

resistance

14.

15.

that the

be

placed

Part nmnbers

Ite~ns

to

iniprove

equipment,

cables should

screening

lt

should

directly

requires

and

si~p~

as

Inverter

part

Inverter

part

led

large

no. 329 167 329

na.

the

electromag~etic

e.g.

special

be

screened.

also

an

a

7811

7815

329 171

a

PLC,

is

effeotive

begin

the

attention;

cross—section

the motor

as

motor

7812 7813

7816

329

Apply

lt

dose

terminal

lt

1681

172j

compatibiuity

cables

the

screen

should

to

board.

should

as

possible.

329 169

7817 7818

329 173

the

U, V,

not

device

have

329 170

329 174

to

be

The

as

7814

(ENG)

W and

both

opened

as

earth

bw

of

the

ends.

or

possible

chassis

a

Ta

:-~c::~ücc1

•

-•

•

jiue

l4ains

chokes,

descriptf

an

potentiometer

semiconductor

1 k~72/1W.

fuses

and

fuse

halders

must

be

ordered

separately.

!

Loading...

Loading...