Page 1

Engineering tools

Engineer/

PLC Designer

Application Samples Inverter 8400/9400 _ _ _

Software Manual EN

Ä.OQjä

13464873

L

Page 2

Contents

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1 Document history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2 Conventions used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 Notes used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Preconditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 System requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 What is the PLC Designer? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Where can I receive a full version of the PLC Designer? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3.1 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

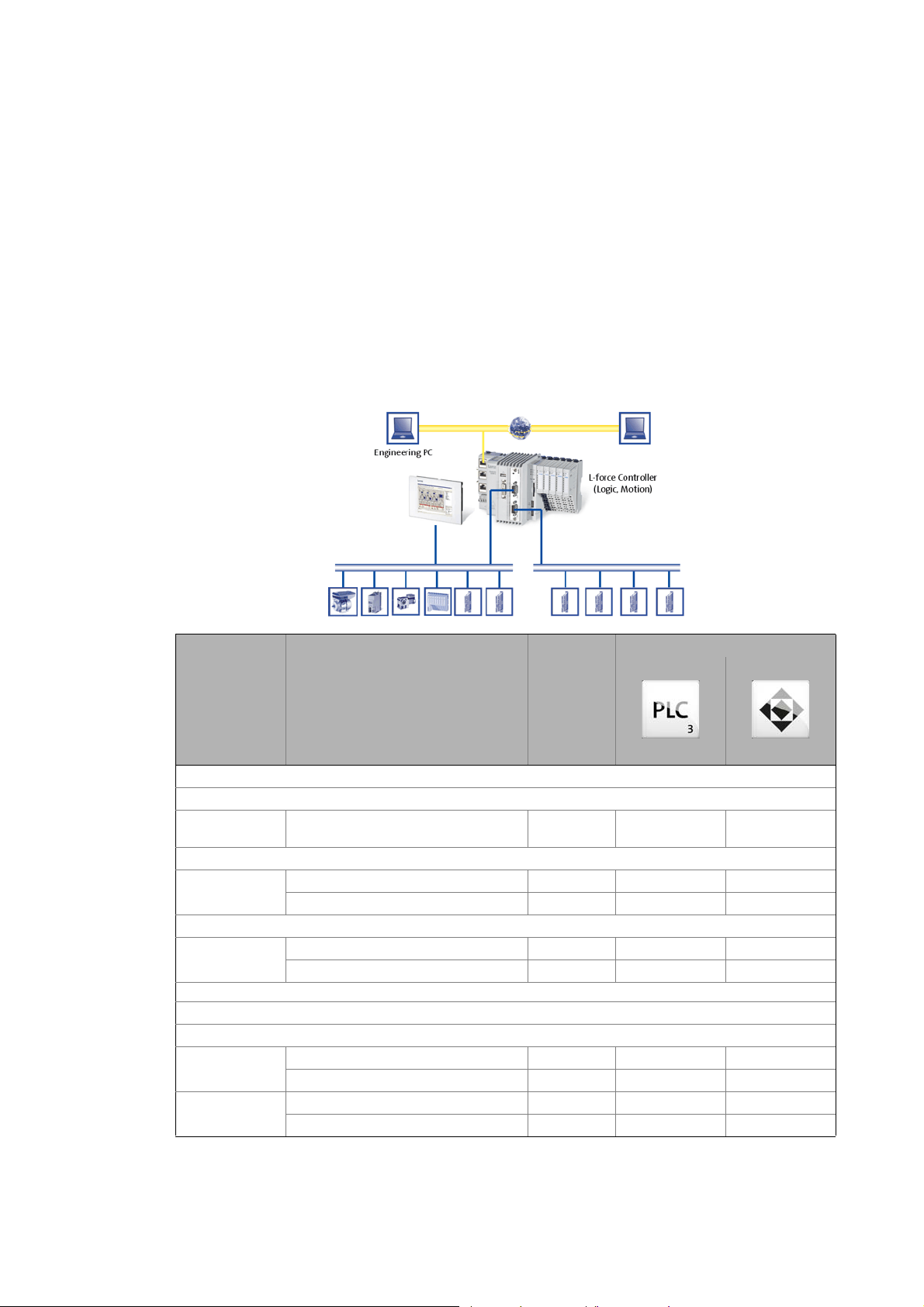

4 The Controller-based Automation system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 General system structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Wiring the hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.1 Setting up communication to the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.2 Compiling the project data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.3 Starting the sample project - Logging on to the control with the »PLC Designer«20

6 Which Lenze application samples (AppSamples) exist? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2.4 Downloading and starting the PLC program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.1 Controller-based Automation: Application samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Where do I find the sample projects? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3 How are the application samples called? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.4 Structure of the sample projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2 Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 3

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 Working with the sample projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1 Sample project with the "Actuator speed" application - Actuator Speed . . . . . . . . . . . . . 25

7.1.1 Components to be used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.1.2 Short overview of the functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.1.3 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.1.4 Open the »Engineer« project & go online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.1.5 Program structure in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.1.5.1 Control configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.1.5.2 Program organisation units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1.6 Operation via the visualisations in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . 33

7.1.6.1 Information/start page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1.6.2 Automatic mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.1.6.3 Manual mode ("Manual jog") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.1.6.4 Service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.1.6.5 Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2 Sample project with "Table positioning" application - TablePositioning. . . . . . . . . . . . . . 38

7.2.1 Components to be used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.2.2 Short overview of the functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2.3 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2.4 Open the »Engineer« project & go online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.2.5 Program structure in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2.5.1 Control configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2.5.2 Program organisation units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2.6 Operation via the visualisations in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . 45

7.2.6.1 Information/start page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.2.6.2 Automatic mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.2.6.3 Manual mode ("Manual jog") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.2.6.4 Service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.2.6.5 Homing mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.2.6.6 Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8 Extending sample projects - adding devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.1 Creating a control configuration - EtherCAT bus system . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.2 Create control configuration - bus system CAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.3 Setting of CAN parameters and PDO mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9 Overview of device descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.1 Inverter Drives 8400 BaseLine C - Actuator Speed ("speed actuating drive") . . . . . . . . . 62

9.1.1 Overview of indices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.2 Inverter Drives 8400 StateLine C - speed actuating drive. . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.2.1 Overview of indices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 3

Page 4

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.3 Inverter Drives 8400 HighLine C - table positioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

9.3.1 Overview of indices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

9.4 Inverter Drives 8400 TopLine C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.4.1 Overview of indices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

9.5 Servo Drives 9400 HighLine C speed actuating drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.5.1 Overview of indices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.6 Servo Drives 9400 HighLine C - table positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.7 Servo Drives 9400 HighLine C - torque actuating drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.8 Servo Drives 9400 HighLine C - electronic gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9.9 Servo Drives 9400 HighLine C - synchronism with mark synchronisation . . . . . . . . . . . 75

9.10 Servo Drives 9400 HighLine C - positioning sequence control . . . . . . . . . . . . . . . . . . . . . . 76

9.11 9400 regenerative power supply module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

9.12 Servo Drives 9400 HighLine C - "empty application" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

9.13 9400 HighLine C - Overview of indices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

9.14 Lenze generic drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

9.14.1 Overview of indices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

10 Overview: The libraries for controlling the inverters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.1 Overview - function libraries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.2 The L_LCB_LogicControlBasic library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.3 The L_DCO_DriveCommunication library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

10.4 The L_DAC_DataConversion library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11 The L_DAC_DataConversion library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

11.1 Overview of the functions and function blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

11.2 L_DAC_GetBitOfByte - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

11.3 L_DAC_GetBitOfDWord - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11.4 L_DAC_GetBitOfWord - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.5 L_DAC_ResetBitOfByte - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

11.6 L_DAC_ResetBitOfDWord - conversion block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

11.7 L_DAC_ResetBitOfWord - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

11.8 L_DAC_SetBitOfByte - bit operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

11.9 L_DAC_SetBitOfDWord - bit operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

11.10 L_DAC_SetBitOfWord - bit operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

11.11 L_DAC_BitsToByte - bit multiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

11.12 L_DAC_BitsToDWord - bit multiplexer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

11.13 L_DAC_BitsToWord - bit multiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4 Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 5

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

11.14 L_DAC_ByteToBits - bit demultiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

11.15 L_DAC_DWordToBits - bit demultiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

11.16 L_DAC_WordToBits - bit demultiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

11.17 L_DAC_2BytesToWord - type converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

11.18 L_DAC_2WordsToDWord - type converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

11.19 L_DAC_4BytesToDWord - type converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

11.20 L_DAC_DWordTo2Words - type converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

11.21 L_DAC_DWordTo4Bytes - type converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

11.22 L_DAC_WordTo2Bytes - type converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

12 The L_DCO_DriveCommunication library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

12.1 Overview of the functions and function blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

12.2 Enums. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

12.2.1 L_DCO_CommState . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

12.2.2 L_DCO_Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

12.3 Function blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

12.3.1 L_DCO_AXIS_REF_BASE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

12.3.2 L_DCO_ReadDriveParameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

12.3.3 L_DCO_ReadDriveParameterString . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

12.3.4 L_DCO_TransferDriveParameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

12.3.5 L_DCO_TransferData . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

12.3.6 L_DCO_WriteDriveParameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

12.4 Structures (Structs). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

12.4.1 L_DCO_SDOData . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

12.4.2 L_DCO_TransferData . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

12.5 Unions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

12.5.1 L_DCO_ConvertData. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

13 The L_LCB_LogicControlBasic library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

13.1 Overview of the functions and function blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

13.2 L_LCB_Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

13.3 L_LCB_AXIS_REF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

13.4 L_LCB_AXIS_REF_CAN (internal use) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

13.5 L_LCB_AXIS_REF_ETC (internal use) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

13.6 L_LCB_8400Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

13.7 L_LCB_9400Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

13.8 L_LCB_ActuatorSpeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

13.8.1 Assignment - input ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

13.8.2 Assignment - output ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 5

Page 6

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

13.9 L_LCB_TablePositioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

13.9.1 Assignment - input ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

13.9.2 Assignment - output ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

13.10 L_LCB_GenericDrive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

13.11 L_LCB_Norm_aToNorm_n - signal converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

13.12 L_LCB_Norm_nToNorm_a - signal converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

13.13 L_LCB_Norm_nToSpeed_s - signal converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

13.13.1 LCB_Axis_logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

13.14 L_LCB_Speed_nToNorm_r - signal converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

13.15 L_LCB_Speed_rToNorm_n - signal converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

13.16 L_LCB_Speed_sToNorm_n - signal converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

13.17 L_LCB_Speed_sToSpeed_v - signal converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

13.18 L_LCB_Speed_vToSpeed_s - signal converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

13.19 L_LCB_TaskCycle - read in task time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

13.20 L_LCB_GetAxisData - read out machine parameters from axis data . . . . . . . . . . . . . . . . 138

13.21 L_LCB_GetPosition - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

13.22 L_LCB_GetSpeed - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

13.23 L_LCB_SetAxisData - machine parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

13.24 L_LCB_SetPosition - position value conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

13.25 L_LCB_SetSpeed - speed value conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

13.26 L_LCB_AccToUnit - acceleration value conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

13.27 L_LCB_PosToUnit - position value conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

13.28 L_LCB_SpeedToUnit - speed value conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

13.29 L_LCB_UnitToAcc - acceleration value conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

13.30 L_LCB_UnitToPos - position value conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

13.31 L_LCB_UnitToSpeed - speed value conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

13.32 L_LCB_AXISMODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

13.33 L_LCB_LOGICDEVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

14 Automatically generated functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

14.1 GetBooleanProperty (automatically generated by »PLC Designer«). . . . . . . . . . . . . . . . . 151

14.2 GetCompany (automatically generated by »PLC Designer«). . . . . . . . . . . . . . . . . . . . . . . . 152

14.3 GetNumberProperty (automatically generated by »PLC Designer«). . . . . . . . . . . . . . . . . 152

14.4 GetTextProperty (automatically generated by »PLC Designer«) . . . . . . . . . . . . . . . . . . . . 153

14.5 GetTitle (automatically generated by »PLC Designer«). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

14.6 GetVersion (automatically generated by »PLC Designer«). . . . . . . . . . . . . . . . . . . . . . . . . . 154

6 Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 7

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

14.7 GetVersionProperty (automatically generated by »PLC Designer«) . . . . . . . . . . . . . . . . . 155

15 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Your opinion is important to us. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 7

Page 8

About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

This documentation describes the first commissioning steps of a Lenze automation system on the

basis of predefined sample projects. The automation system used consists of a PLC for the control

technology and drive components connected (via a bus system).

Read the mounting instructions accompanying the controller first before you start

working!

The mounting instructions include safety instructions which must be observed!

Note!

This documentation supplements the software manuals of the »PLC Designer« and

»Engineer«.

Tip!

Current information and tools regarding the Lenze products can be found in the download

area at: http://www.Lenze.com

This manual is part of the "Controller-based Automation" manual collection. The manual collection

consists of the documents:

Type of documentation Subject

System manuals System overview/example topologies

• Controller-based Automation

• Visualisation

Communication manuals Bus systems

• Controller-based Automation EtherCAT®

• Controller-based Automation CANopen®

• Controller-based Automation PROFIBUS®

• Controller-based Automation PROFINET®

Online helps/

software manuals

Lenze Engineering tools

• »PLC Designer«: Programming

• »Engineer«: Configuration of drives

• »VisiWinNET® Smart«: Visualisation

• »Backup & Restore«: Backing up/restoring data

8 Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 9

About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Further technical documentation on Lenze products

Further information on Lenze products which can be used in connection with Controller-based

Automation can be found in the following documentation:

Further information on Lenze products which can be used in connection with Controller-based

Automation can be found in the following documentation:

Mounting & wiring Icons

Mounting instructions

• Controller

• Communication cards (MC-xxx)

• I/O system 1000 (EPM-Sxxx)

•Inverter

•Communication modules

Using sample application/application template

Online help/software manuals

• i700 Application Sample

• Application samples

Inverter Drives 8400/Servo Drives 9400

• ApplicationTemplate

• ApplicationTemplate PackML

Parameterisation, configuration, commissioning

Online help/software manuals

• Controller

• i700 servo inverter

• Servo Drives 9400 HighLine/PLC/

regenerative power supply module

• Inverter Drives 8400 StateLine/HighLine/TopLine

• 1000 I/O system (EPM-Sxxx)

Online help/communication manuals

• Bus systems

•Communication modules

Printed documentation

Online help in the Lenze Engineering

tool/

software manuals and communication

manuals are provided as PDF files in

the download area of the Lenze

website.

Target group

This documentation addresses to all persons who plan, commission, and program a Lenze

automation system on the basis of the Lenze "ApplicationTemplate PackML" as part of the

"Controller-based Automation".

Screenshots/application examples

All screenshots in this documentation are application samples. Depending on the firmware version

of the Lenze devices and the software version of the engineering tools installed (here: »PLC

Designer«), the screenshots may differ from the real screen display.

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 9

Page 10

About this documentation

Document history

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

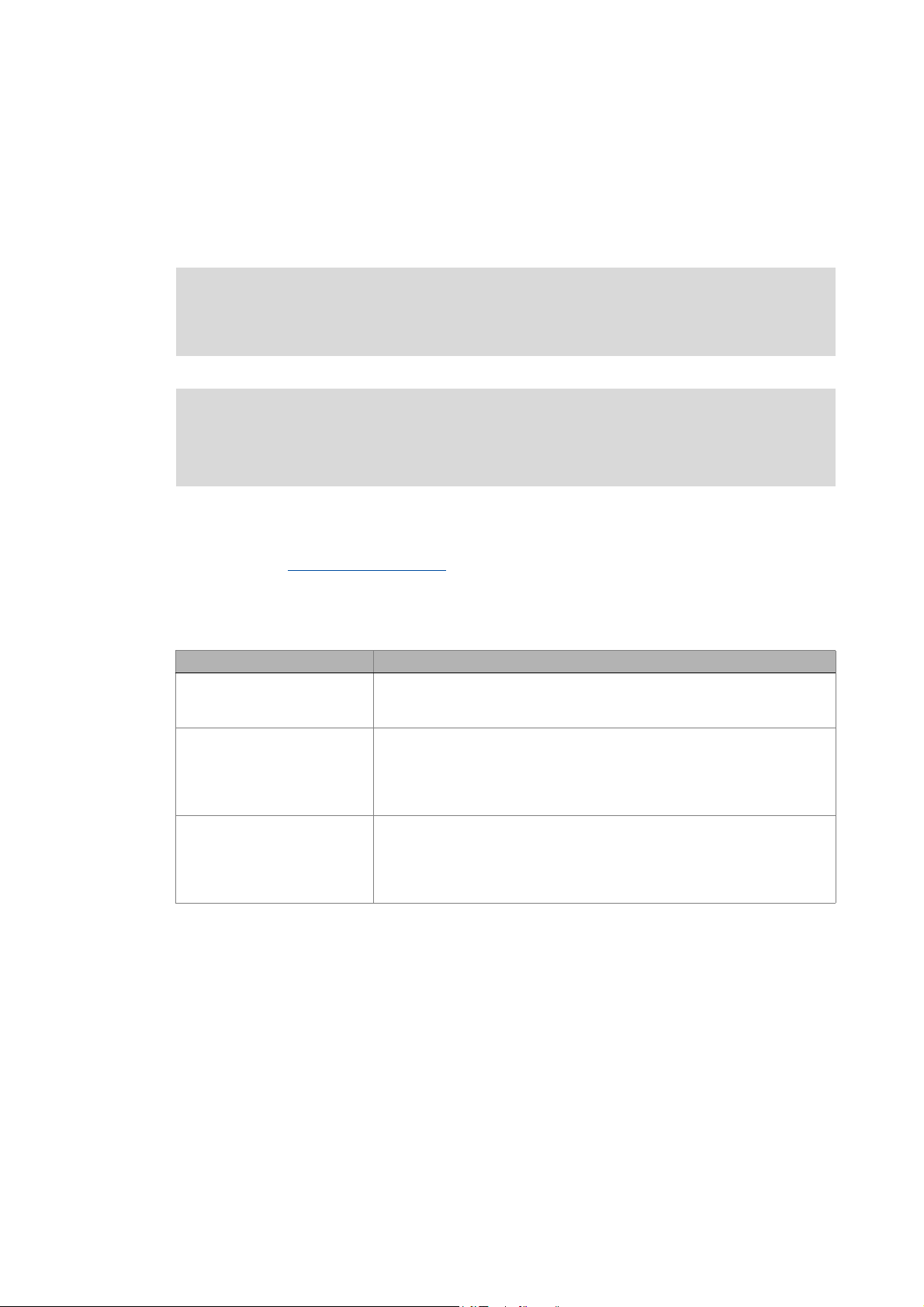

Information regarding the validity

The information in this documentation is valid for the following Lenze software:

Software From software version

»PLC Designer« 3.1.x

»Engineer« 2.13

1.1 Document history

Version Description

1.0 04/2011 TD11 First edition

1.1 05/2011 TD11 Updated version

• Device descriptions supplemented.

• L_LCB_LogicControlBasic library extended.

1.2 06/2012 TD11 Updated version

• Amended library L_LCB_LogicControlBasic: Amended by notes on the use of the

L_LCB_ActuatorSpeed, L_LCB_TablePositioning FBs.

1.3 06/2014 TD11 Updated version

• Completed version of the available Application Samples.

• Updated representation of the FBs.

10

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 11

About this documentation

Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.2 Conventions used

This documentation uses the following conventions to distinguish between different types of

information:

Type of information Writing Examples/notes

Spelling of numbers

Decimal separator Point The decimal point is always used.

For example: 1234.56

Text

Version information Blue text colour All information that applies to from a certain software

Program name » « »PLC Designer«...

Window italics The Message window... / the Options dialog box...

Variable names By setting bEnable to TRUE...

Control element bold The OK... button / The Copy... command / The Properties...

Sequence of menu

commands

Shortcut <bold> Use <F1> to open the online help.

Hyperlink Underlined

Icons

Page reference ( 11) Reference to further information: Page number in PDF file.

Step-by-step instructions

version of the drive onwards are marked accordingly in this

documentation.

Example: This function extension is available from software

version V3.0!

tab / The Name ... input field

If the execution of a function requires several commands in

a row, the individual commands are separated by an arrow:

Select File

If a key combination is required for a command, a "+" is

placed between the key identifiers: With <Shift>+<ESC>...

Reference to further information: Hyperlink to further

information.

Step-by-step instructions are indicated by a pictograph.

Open to...

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 11

Page 12

About this documentation

Notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3 Notes used

The following signal words and symbols are used in this documentation to indicate dangers and

important information:

Safety instructions

Layout of the safety instructions:

Pictograph and signal word!

(characterise the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure trouble-free operation

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for easy handling

Reference to another document

12

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 13

Safety instructions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Safety instructions

Please observe the following safety instructions when you want to commission a controller or

system using the »Engineer«.

Read the documentation supplied with the controller or the individual components of

the system carefully before you start commissioning the devices with the »Engineer«!

The device documentation contains safety instructions which must be observed!

Danger!

According to today's scientific knowledge it is not possible to ensure absolute freedom

from defects of a software product.

If necessary, systems with built-in controllers must be provided with additional

monitoring and protective equipment complying with the relevant safety regulations

(e.g. law on technical equipment, regulations for the prevention of accidents) in each

case, so that an impermissible operating status does not endanger persons or facilities.

During commissioning persons must keep a safe distance from the motor or the

machine parts driven by the motor. Otherwise there is a risk of injury by the moving

machine parts.

Stop!

If you change parameters in the »Engineer« while the controller is connected online, the

changes will be directly accepted by the controller!

A wrong parameter setting can cause unpredictable motor movements. By an

unintended direction of rotation, a too high speed, or jerky operation, the driven

machine parts may be damaged!

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 13

Page 14

Preconditions

System requirements

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3 Preconditions

3.1 System requirements

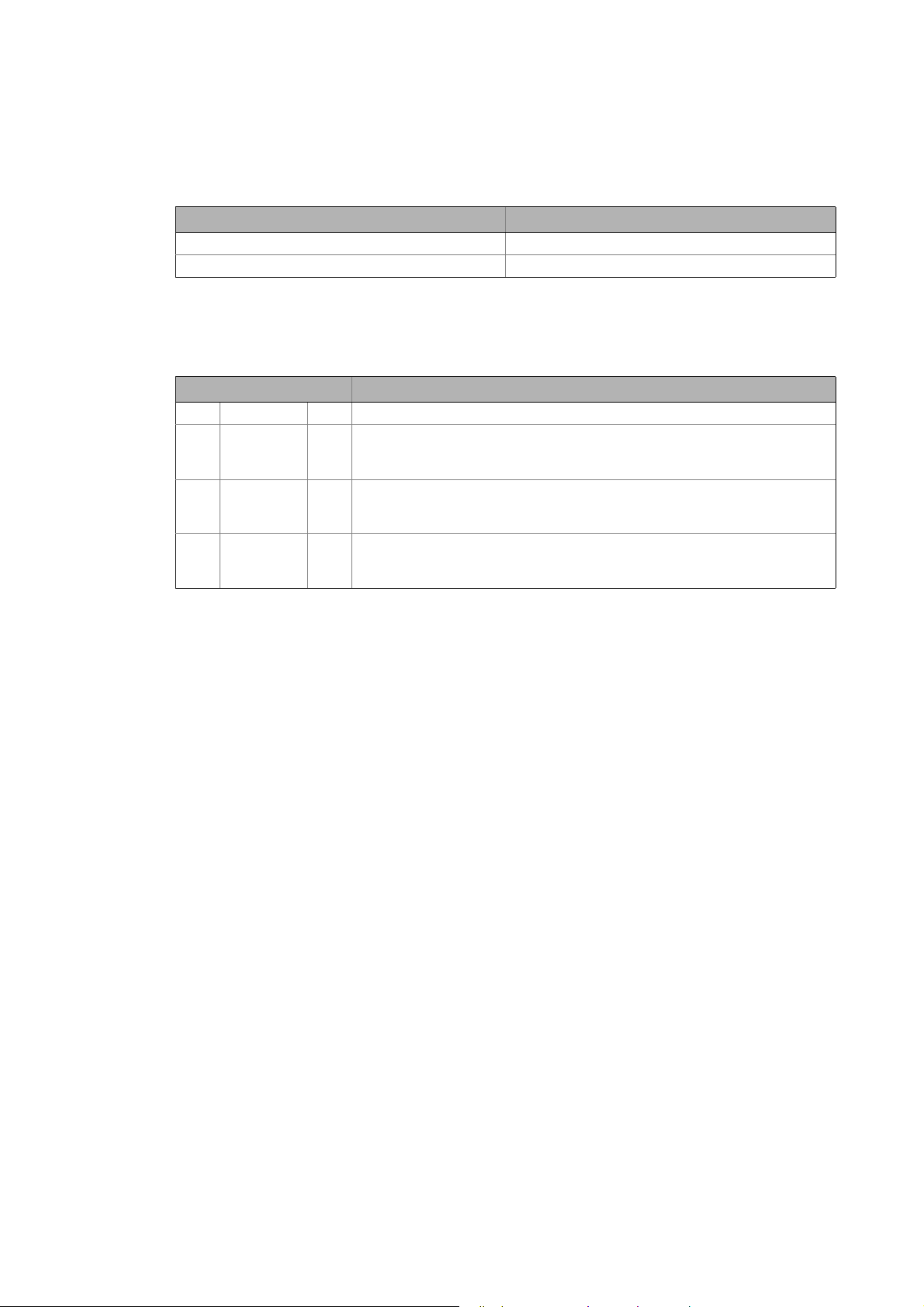

[3-1] Illustration example: System structure with a Controller 3200 C

Hardware PC/notebook PLC (Logic) from firmware V3.1

Operating system Windows XP Windows CE

Required Lenze software »PLC Designer« V3.1 Logic

Further requirements Depending on the respective sample

3.2 What is the PLC Designer?

The »PLC Designer« is a Lenze engineering tool for programming the PLC of Lenze Controllers. The

Controller is the central control component of the Lenze Controller-based Automation system.

Product features

• Five different editors for the programming languages standardised in the IEC 61131-3 and a

very efficient CFC Editor are available. They can be used to create your own programs or to

address the functions of the Logic & Motion runtime software.

• By means of the integrated visualisation the processes are shown, in order to obtain all

important pieces of information at a glance during commissioning.

Engineering PC Controller

application:

• CAN or EtherCAT bus system

• CAN or EtherCAT node

14

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 15

Preconditions

Where can I receive a full version of the PLC Designer?

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.3 Where can I receive a full version of the PLC Designer?

The »PLC Designer« is provided for download in the Lenze Application Knowledge Base (AKB) .

• The AKB is a product- and application-oriented collection of information provided by Lenze.

• Alternatively you can install the »PLC Designer« from the CD supplied with the Controller.

3.3.1 Installation

How to install the »PLC Designer«:

1. Select »PLC Designer« to save the full version as a packed ZIP file on your PC (Engineering

PC).

• Unpack the ZIP file PlcDesigner_V3.x.zip on your PC.

• The ZIP file contains an installation file.

or

Start the PLCDesigner_V3.x.exe installation file from the DC supplied with the Controller.

2. Start the EXE file and follow the installation instructions.

3. After the installation the »PLC Designer« can be started.

Further information and basics regarding the »PLC Designer« can be found in the

following documentation:

PLC Designer software manual

The manual is available on the CD supplied or on the Internet.

If the »PLC Designer« is already installed, carry out an update of the version available or install the

full version parallel to the version available.

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 15

Page 16

The Controller-based Automation system

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4 The Controller-based Automation system

Central control technology becomes more and more important in the field of automation

technology. Due to their scaling options and various combinations of visualisation and control on

one device, Industrial PCs provide clear advantages for many applications.

The Controllers are available with the following software programs:

• Controllers as control system

• Controllers as visualisation system (depending on the model, an additional panel may be

required)

• Controllers as component, optionally with operating system, without any further software

The Controller-based Automation system enables the central control of Logic and Motion systems.

Further information on parameter setting and configuration of the individual bus

systems can be found in the following bus system-specific communication manuals:

16 Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 17

The Controller-based Automation system

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Lenze supply specially matched system components:

• Controller as control and visualisation system

• The Controller is the central component in Controller-based Automation which uses the

runtime software to control the Logic and Motion functionalities.

• The controller communicates with the field devices via the fieldbus.

• Engineering tools for the Engineering PC

• The Engineering PC uses the Ethernet to communicate with the Controller.

• Use the various Engineering tools to configure and parameterise the system.

•Fieldbuses

•Field devices

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 17

Page 18

Commissioning

General system structure

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5 Commissioning

This chapter describes the commissioning of a sample project by means of examples. The following

requirements have to be met, so that the respective sample project can be used.

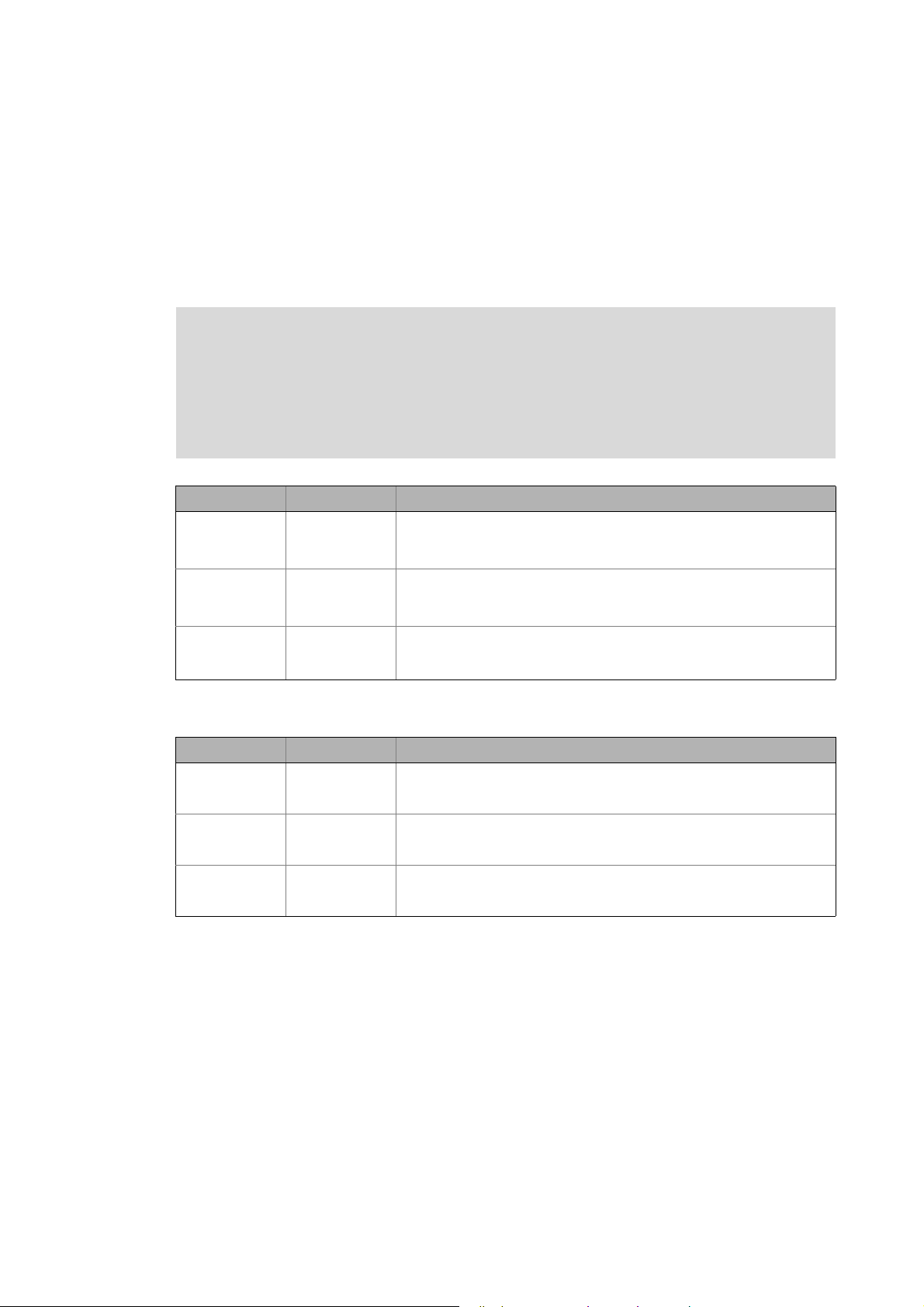

5.1 General system structure

The Lenze project examples are based on the following system structure.

• The Controller is the central control component of the system configuration.

• The sample projects are available for the following bus systems: CAN/EtherCAT.

[5-1] System structure with a Controller (Logic)

5.2 Wiring the hardware

Before you can work with the project, the hardware has to be connected to each other. The sample

projects are configured so that the motors rotate if a controller is used as fieldbus node.

• Connect the desired Controller with the fieldbus nodes.

• Connect the devices (controllers, motors) with the corresponding voltage supply

Further information on the electrical connections can be found in the documentation

supplied. Please read the mounting instructions supplied with the controller first before

you start working!

The mounting instructions include safety instructions which must be observed!

• Connect the components with a suitable fieldbus cable.

18

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 19

Commissioning

Wiring the hardware

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

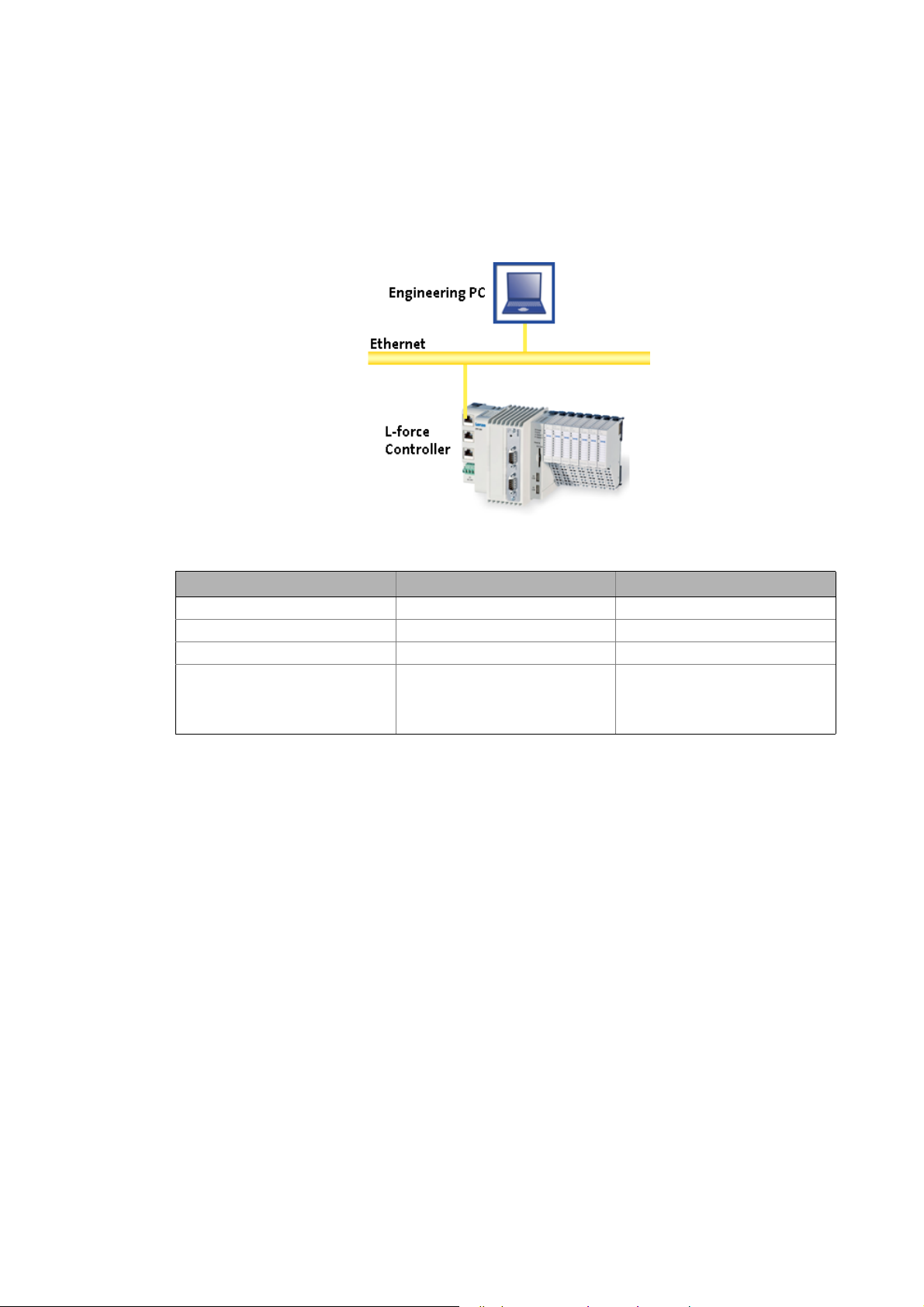

5.2.1 Setting up communication to the Controller

• Connect the Engineering PC with the controller via a network cable, as the »PLC Designer«

accesses the controller via Ethernet.

• Make the IP settings with the »PLC Designer«.

How to check the communication settings:

1. Go to the Device view and double-click the desired L-force Controller.

2. Make the desired settings on the Communication settings tab.

•Click the Add gateway button to insert a gateway.

• Enter the desired IP address of the L-force Controller.

[5-2] Example: Entering the IP address of the L-force Controller

3. Click OK to add the controller as gateway.

4. By double-clicking the desired channel (or clicking the Set active path button) set the

channel selected in the device tree below the gateway as active path for control.

• Thus, all communication actions directly refer to this channel.

• The currently active path is represented in bold in the list and "(active)" is attached:

5. A device represented in italics is set as momentarily active path but has not been found by

the last network scan.

Note!

• During initial commissioning, observe the following predefined IP addresses:

• Engineering PC: 192.168.5.100

• Controller: 192.168.5.99

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 19

Page 20

Commissioning

Wiring the hardware

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Further information can be found in the following documentation:

• Controller - Parameter setting & configuration

5.2.2 Compiling the project data

To compile the project data, select the BuildCompile menu command or press the <F11> function

key.

• If errors have occurred during the compilation process, you can locate and eliminate them by

means of the »PLC Designer«error messages.

Then compile the project data again.

• If no errors have occurred during the compilation process, save the »PLC Designer«project in the

project folder.

5.2.3 Starting the sample project - Logging on to the control with the »PLC Designer«

First transmit the sample project to the PLC device and start it then. To log the »PLC Designer« on to

the control system, select the OnlineLogin menu command.

• For this, the PLC program must be error-free.

• With login, the PLC program is loaded in the control system.

5.2.4 Downloading and starting the PLC program

• If the PLC program has not been loaded yet onto the Controller, select the OnlineLoad menu

command.

• Select the OnlineRun menu command to start the PLC program.

Tip!

Install the PLC program as "boot project" in order to load it automatically after a device

is restarted.

How to install the project as boot project:

1. Open the Online menu in the menu bar

2. Select the Create boot project for L-force Controller command.

20

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 21

Which Lenze application samples (AppSamples) exist?

Controller-based Automation: Application samples

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6 Which Lenze application samples (AppSamples) exist?

The ready-configured sample projects are to facilitate the work with the Lenze products for

you. They include established system configurations representing typical application

cases. The objective is to obtain an executable Lenze automation system by using low

effort.

Depending on the application case, the sample projects can be optionally extended, and

thus they have to be adapted to the requirements in each case.

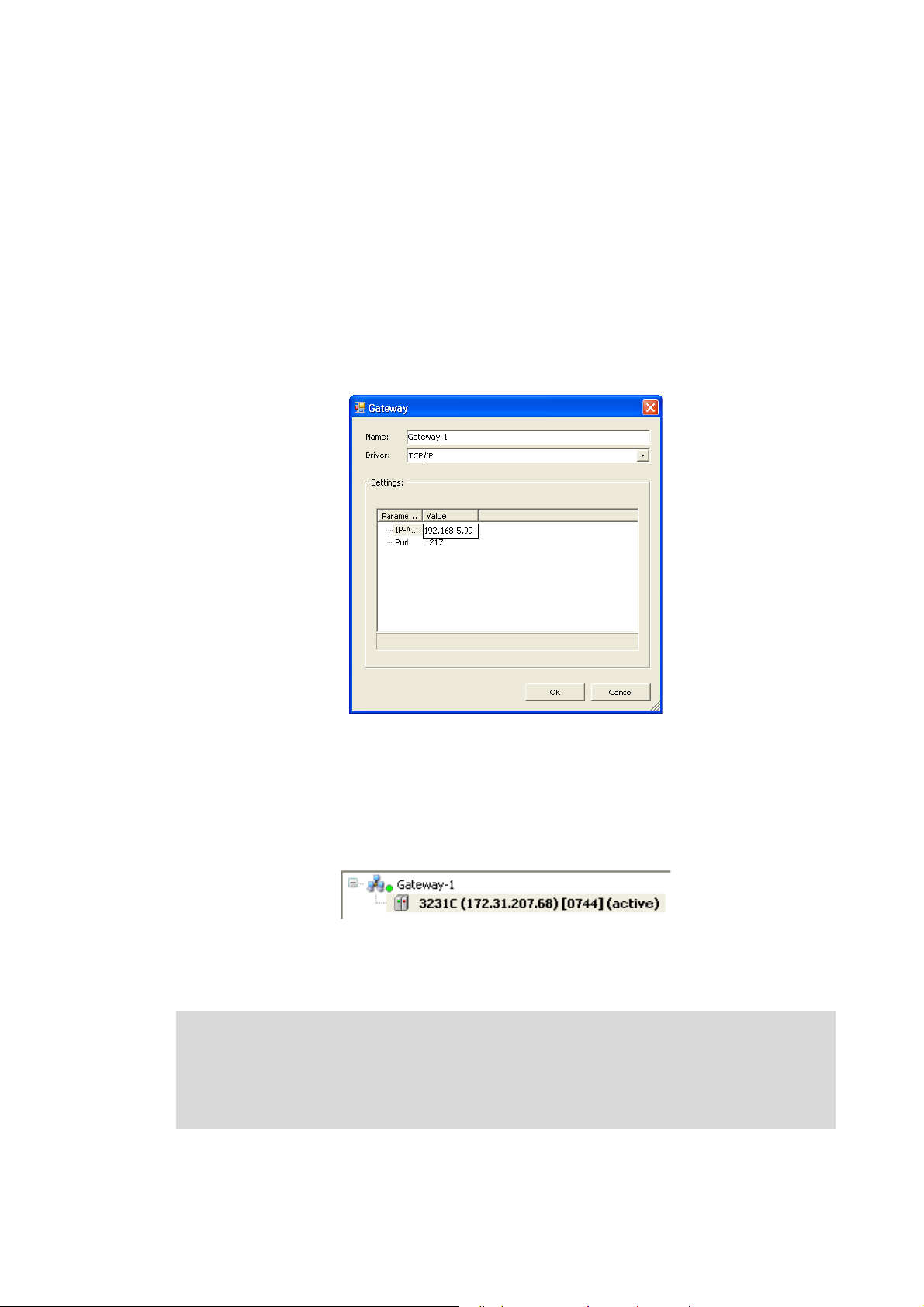

6.1 Controller-based Automation: Application samples

Product/device

application

Inverter Drives 8400

Baseline

Actuating drive

speed

Stateline

Actuating drive

speed

HighLine

Table

positioning

Servo Drives 9400

HighLine

Actuating drive

speed

Table

positioning

Project name Available for

bus system

LAS_40_INTF_Can_84BL_Speed_0100 CAN

LAS_40_INTF_Can_84SL_Speed_0200 CAN

LAS_40_INTF_ETC_84SL_Speed_0100 EtherCAT

LAS_40_INTF_Can_84HL_TabPos_0200 CAN

LAS_40_INTF_ETC_84HL_TabPos_0100 EtherCAT

LAS_40_INTF_Can_94HL_Speed_0200 CAN

LAS_40_INTF_ETC_94HL_Speed_0100 EtherCAT

LAS_40_INTF_Can_94HL_TabPos_0200 CAN

LAS_40_INTF_ETC_94HL_TabPos_0100 EtherCAT

Lenze Engineering tool

»PLC Designer«

V3.x

»Engineer«

V2.x

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 21

Page 22

Which Lenze application samples (AppSamples) exist?

Where do I find the sample projects?

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.2 Where do I find the sample projects?

After a successful »PLC Designer« installation, the sample projects can be found under:

(All) ProgramsLenzeAppSamples

6.3 How are the application samples called?

LAS_<Sortierschlüssel>_<Kategorie>_<Bussystem>_<Antriebsregler>_<Version>

Example: LAS_40_INTF_Can_84SL_Speed_xxx

Sort key/category

Sort key Category Description

40 INTF Application samples with interface function (interface connection) for

connecting Lenze controllers.

Differentiation of the bus systems

The sample projects are preconfigured for different bus systems.

Bus system Description

CAN CAN projects contain the "_Can" code in the file name.

EtherCAT EtherCAT projects contain the "_ETC" code in the file name.

6.4 Structure of the sample projects

Tip!

The »Engineer« sample projects are archived in ZIP format to allow you to send

them for instance by e-mail.

The »Engineer« supports project saving (FileSave archive) and project opening

(FileOpen archive) in ZIP format.

Each sample project consists of:

– Ready-made projects in the »Engineer«

– program code and visualisation in the »PLC Designer«. The following modes are

possible: automatic, manual (manual jog), service, homing (optional).

22

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 23

Working with the sample projects

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 Working with the sample projects

The ready-configured sample projects are to facilitate the work with the Lenze components for you.

They include established system configurations representing typical application cases. The

objective is to obtain an executable Lenze automation system by using low effort.

Depending on the application case, the sample projects can be optionally extended, and thus they

have to be adapted to the requirements in each case.

Where do I find the sample projects?

After a successful installation of the Lenze sample projects they can be found under:

ProgramsLenzeAppSamples

The sample projects are preconfigured for different bus systems.

• CAN projects contain the "_Can" code in the file name

• EtherCAT projects contain the "_ETC" code in the file name

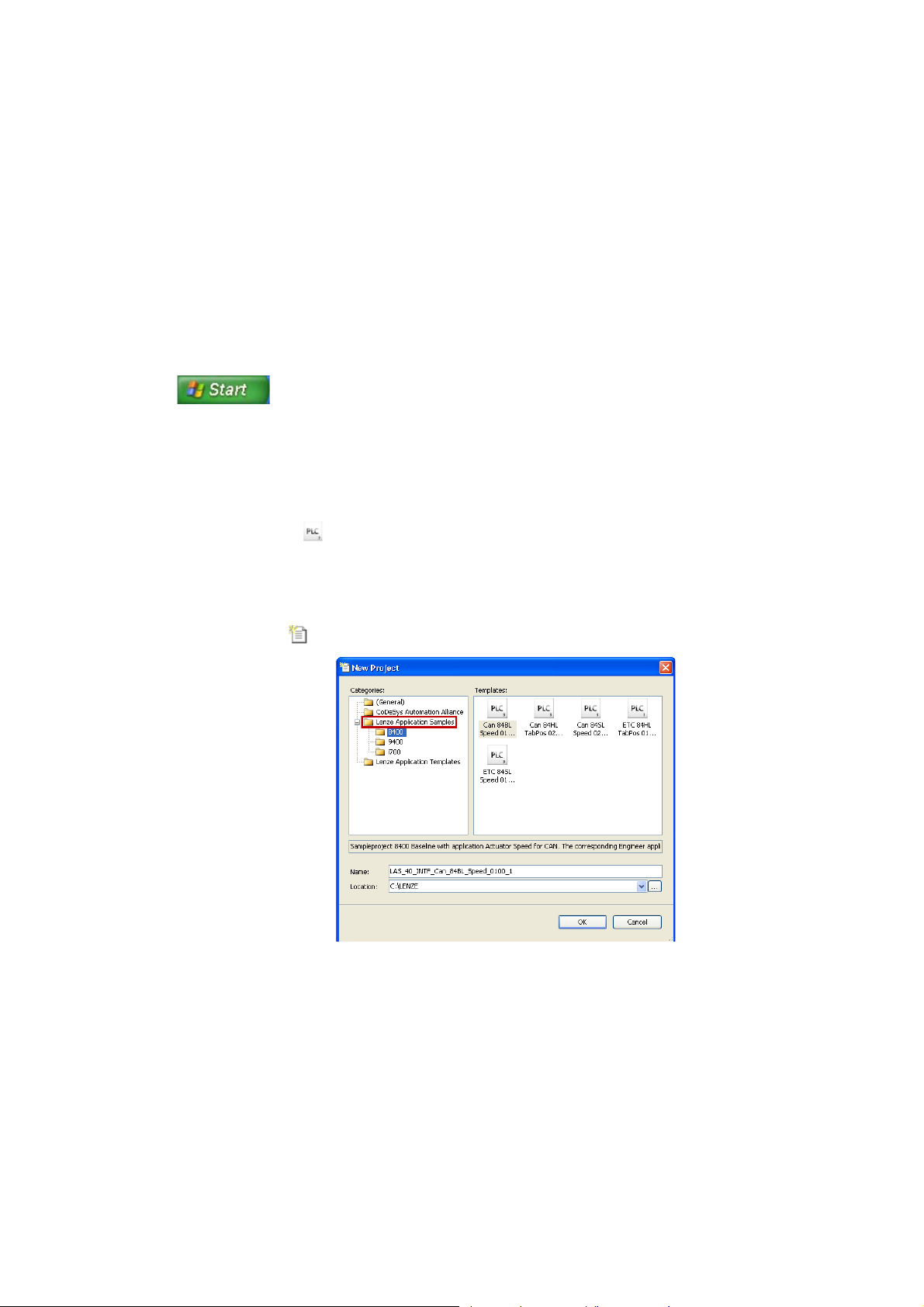

From »PLC Designer« V3.3 the Application Samples are available as predefined »PLC Designer«

projects (*.project, ) when a new project is created.

How to proceed:

1. Creating a new project:

• File New project

•Select category Lenze Application Samples.

• Open the desired Application Sample.

Tip!

The »Engineer« sample projects are archived in ZIP format to allow you to send them for

instance by e-mail.

The »Engineer« supports project saving (FileSave archive) and project opening

(FileOpen archive) in ZIP format.

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 23

Page 24

Working with the sample projects

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Structure of the sample projects

• Each sample project consists of:

• ready-made project data in the »Engineer«

• program code and visualisation in the »PLC Designer«. The following modes are possible:

automatic, manual (manual jog), service, homing (optional).

24 Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 25

Working with the sample projects

Sample project with the "Actuator speed" application - Actuator Speed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.1 Sample project with the "Actuator speed" application - Actuator Speed

Further information on the device-independent function libraries can be found in the

following section:

The L_LCB_LogicControlBasic library

The L_DCO_DriveCommunication library ( 100)

General procedure

( 113)

How to commission the controller:

1. Commission the controller. Commissioning

2. Load the desired project (depending on the desired bus system) to the controller using the

»Engineer«. Open the »Engineer« project & go online

3. Open the desired sample project in the »PLC Designer«. Program structure in the »PLC

Designer« ( 29)

4. Load the project to the Controller and go online.

( 26)

( 27)

7.1.1 Components to be used

[7-1] System configuration with L-force Controller CAN master (ID=0, connection to CAN1) and Lenze 8400 (CAN node ID=5)

Control supported field devices (bus system)

Hardware L-force Controller 8400 BaseLine (CAN)

8400 StateLine (CAN, EtherCAT)

9400 HighLine (CAN, EtherCAT)

Operating system From version Logic 3.1.x Firmware version is device-

Required Lenze software »PLC Designer« from version 3.1

»Engineer« from version 2.12

Further requirements • CAN master ID = 127

• Connection to interface CAN 1

• Logic CAN 500kB

dependent

-

• CAN node ID = 5

• EtherCAT station ID = 1001

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 25

Page 26

Working with the sample projects

Sample project with the "Actuator speed" application - Actuator Speed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.1.2 Short overview of the functions

Mode Description

Automatic In the automatic mode a sequence runs over an infinite loop.

Selection:

•Travel for three seconds at speed1,

•then for five seconds at speed2,

• Start with speed1 again.

Manual In manual mode, the controller can be actuated manually by setting the

Service The service mode serves to adjust the controller.

7.1.3 Commissioning

individual control bits (Jog1, Jog2, QSP, ErrorReset...). Like this, the controller

can be controlled manually, e.g. for cleaning or changing the tools.

Selection:

• Travel positive for one second,

•Stop for one second,

• Travel negative for one second.

Read the mounting instructions accompanying the controller first before you start

working!

The mounting instructions contain safety instructions that must be observed!

1. Wire the power connections

• Use the mounting instructions supplied with the controller to correctly use the power

connections according to the requirements of your device.

2. Wire the control terminals

3. Connect USB diagnostic adapter.

4. Switch on the voltage supply of the controller.

• Connect mains voltage.

When the green LED "DRV-RDY" is blinking and the red LED "DRV-ERR" is off, the controller is ready

to start and you can continue with the commissioning.

26

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 27

Working with the sample projects

Sample project with the "Actuator speed" application - Actuator Speed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.1.4 Open the »Engineer« project & go online

Detailed information on the general handling of the »Engineer« can be found in the

online help for the »Engineer«, which you can call with [F1].

How to open the sample project in the »Engineer«:

1. Start »Engineer«.

2. Open the desired sample project using the FileOpen archive command.

3. Insert the desired motor in the configuration:

• Highlight controller, select the desired motor with the command Insert a component on the

Motors tab

• By clicking Complete, insert the selection in the »Engineer« project.

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 27

Page 28

Working with the sample projects

Sample project with the "Actuator speed" application - Actuator Speed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

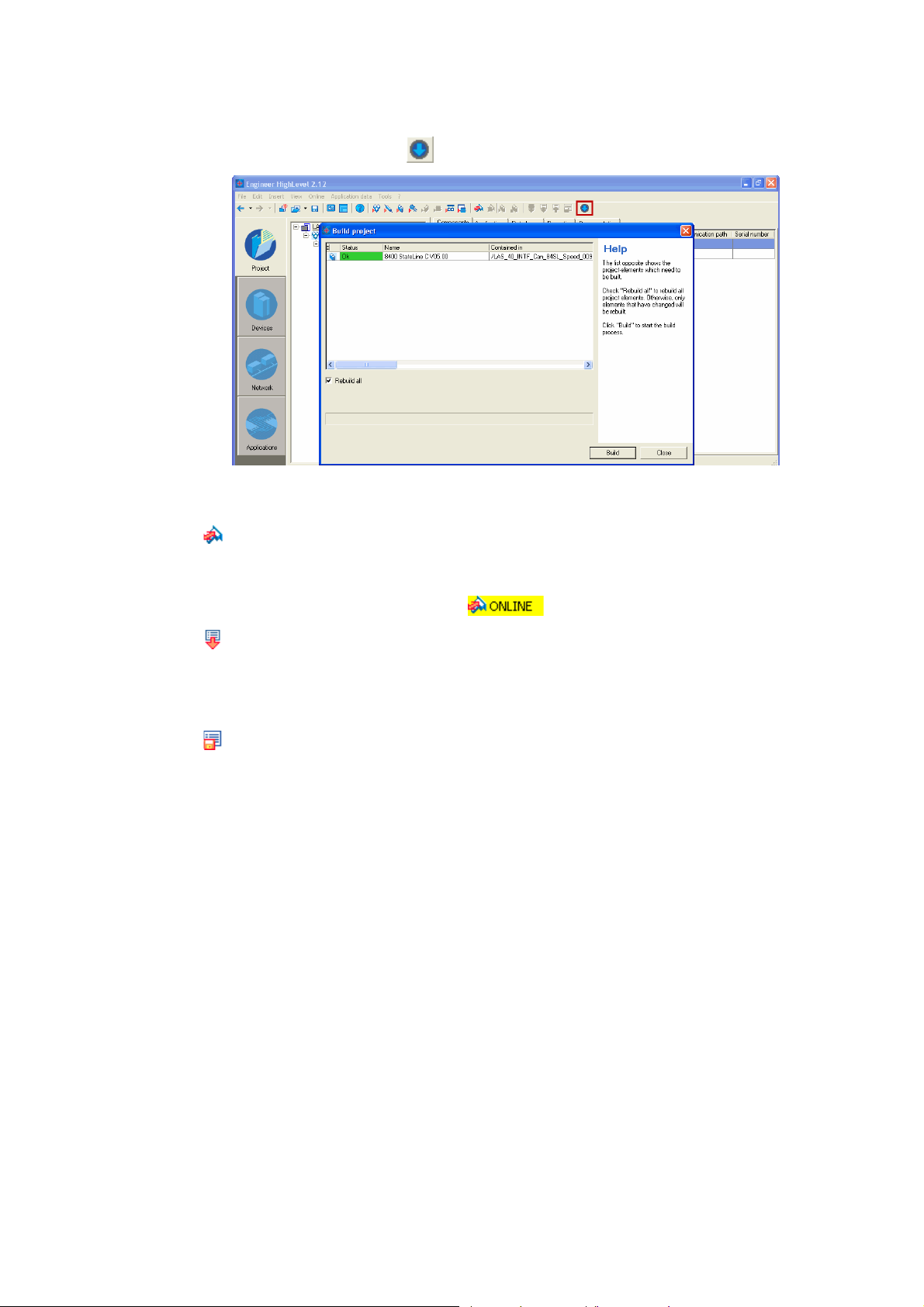

4. Update the project by clicking :

• Select the option Rebuild all

•Click the Build button to update the project.

5. Going online

• After a connection to the controller has been established successfully, the following status is

displayed in the Status line:

6. Download parameter set

• This command has the effect that the application and the parameter settings of the

»Engineer« project overwrite the parameter settings in the controller.

7. Optional: Adapt desired communication settings (for instance network address, baud rate).

8. Store parameter set

9. Mains switching to accept the communication settings to the device.

28

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 29

Working with the sample projects

Sample project with the "Actuator speed" application - Actuator Speed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.1.5 Program structure in the »PLC Designer«

How to proceed:

1. Open the desired sample project (CAN or EtherCAT) in the »PLC Designer«.

2. Load the project to the Controller and Go online.

7.1.5.1 Control configuration

CAN

• The CAN master (ID = 127) is the control section of the system configuration

• The controller (CAN node ID = 5) is attached below the CAN master.

• Below the controller, the axis data are available in the form of an additional node.

• One PDO for CAN-Input and one PDO for CAN-Output is used, respectively.

• The transmission mode is sync-controlled (10 ms)

You can find further details on the extension of the control configuration with CAN and EtherCAT in

the following section: Extending sample projects - adding devices

( 51)

EtherCAT

• The EtherCAT master is the control section of the system configuration

• The controller (station ID = 1001) is attached below the EtherCAT master.

• Below the controller, the axis data are available in the form of an additional node.

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 29

Page 30

Working with the sample projects

Sample project with the "Actuator speed" application - Actuator Speed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

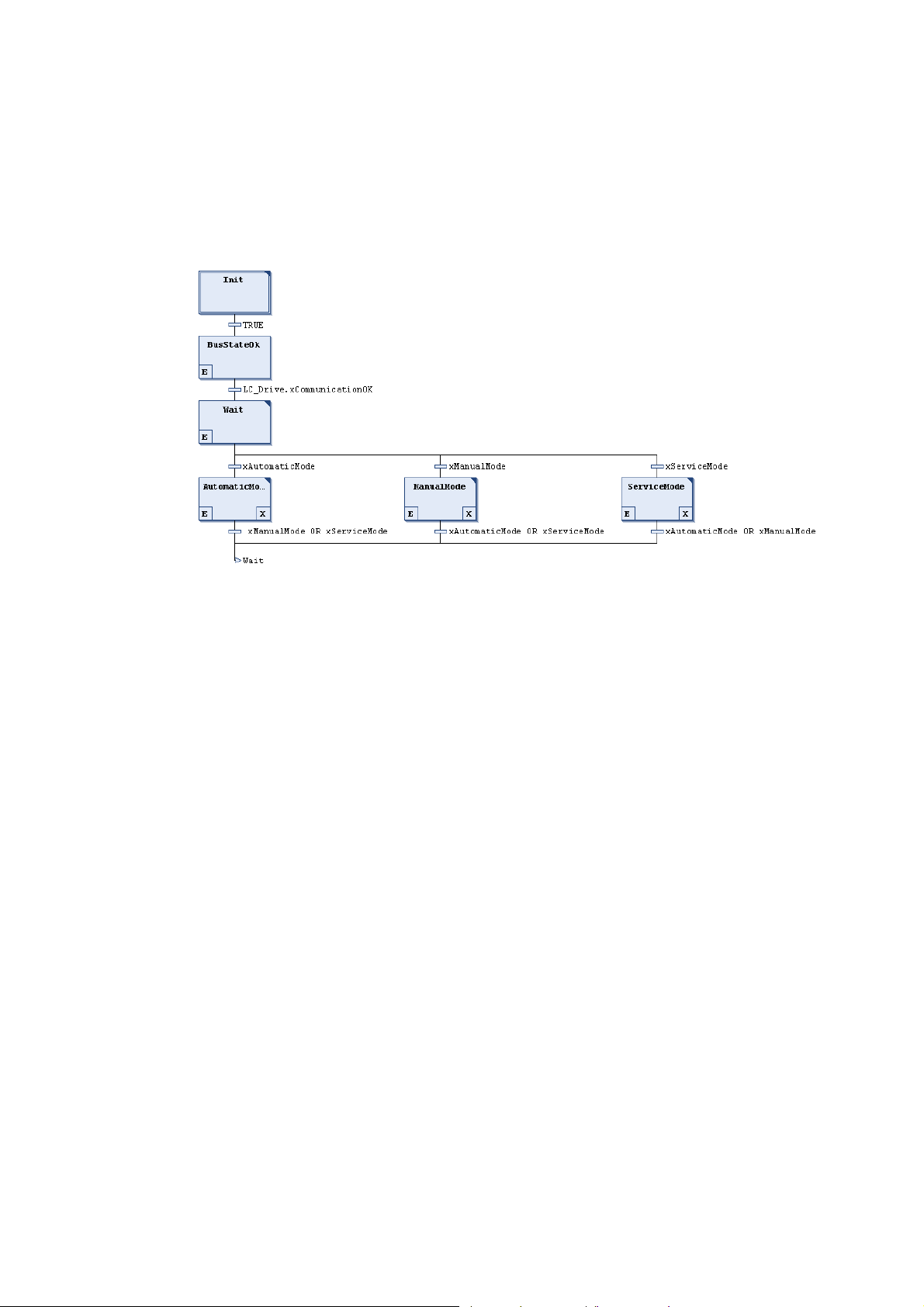

7.1.5.2 Program organisation units

"Main" program

• The "Main (PRG)" program is the basic program for processing the program sequences:

initialisation of the controller and selection of the different modes.

[7-2] Main (PRG)

30

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 31

Working with the sample projects

Sample project with the "Actuator speed" application - Actuator Speed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

"Drive" program

• The "Drive (PRG)" program actuates the controller using the function block

L_LCB_ActuatorSpeed.

• The connection of the AXIS_REF-instance(LC_Drive) provides a connection to the control

configuration.

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 31

Page 32

Working with the sample projects

Sample project with the "Actuator speed" application - Actuator Speed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

"PLC_PRG" program

• The "PLC_PRG (PRG)" program contains all program calls.

32

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 33

Working with the sample projects

Sample project with the "Actuator speed" application - Actuator Speed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.1.6 Operation via the visualisations in the »PLC Designer«

7.1.6.1 Information/start page

[7-3] Visualisation start page of the sample project Lenze 8400 HighLine - Actuator Speed

Select mode Information/start page Status

Parameter

selection

• Via the buttons in area , the mode (automatic, manual, service) can be selected.

•In area , SDO services (read/write parameters) for the controller can be selected.

• The button in area refers to the start page which displays the version identifier of the project

and the libraries in area .

• Dialog box shows the status of the machine.

• Control field shows the bus communication status.

Version identifier Status

Note!

If a bus communication error occurs, the control and drive controller are to be restarted,

since the sample application does not support an automatic reset of bus

communication.

• Control field Error indicates the error message status.

• Error in the application

• Error in the controller

•The Error Reset button resets the error messages.

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 33

Page 34

Working with the sample projects

Sample project with the "Actuator speed" application - Actuator Speed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.1.6.2 Automatic mode

Select mode Stop button Actual speed Status

Start button Status Status

• Button selects the automatic mode.

• Button starts the motion profile.

• Button inhibits the motion profile.

•Display field indicates the status of the mode.

•Display field shows the current speed (Speed Value variable).

• Dialog box indicates the machine status.

• Control field shows the bus communication status.

Note!

If a bus communication error occurs, the control and drive controller are to be restarted,

since the sample application does not support an automatic reset of bus

communication.

• Control field Error indicates the error message status.

• Error in the application

• Error in the controller

•The Error Reset button resets the error messages.

7.1.6.3 Manual mode ("Manual jog")

The controller can be actuated manually via the visualisation of the L_LCB_ActuatorSpeed block.

34

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 35

Working with the sample projects

Sample project with the "Actuator speed" application - Actuator Speed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Select mode Control panel Activate control via visualisation

• Button selects the manual (manual jog) mode.

• In the control and status panel the FB for actuating the controller is visualised.

Note: Activate button to be able to operate the controller via the visualisation.

• Enable the controller via the xDriveEnable FB input to be able to define setpoints manually.

Note: Click the xDriveSetQsp button to activate quick stop.

For more information on the FB, please see the following section:L_LCB_ActuatorSpeed

( 120)

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 35

Page 36

Working with the sample projects

Sample project with the "Actuator speed" application - Actuator Speed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.1.6.4 Service mode

Select mode Stop button Status of the service mode

Start button Activate clockwise

rotation (CW)

• Button selects the service mode.

• Button starts the motion profile.

• Button inhibits the motion profile.

• Button sets clockwise rotation (clockwise rotating direction of the motor).

•Display field indicates the status of the mode.

•Display field indicates the current speed (variable Actual Value).

•Display field shows the currently set speed setpoint.

• Possible setpoint data for the motion profile: 0 ... 100%.

• Dialog box shows the status of the machine.

• Control field shows the bus communication status.

Actual speed Setpoint speed

Note!

If a bus communication error occurs, the control and drive controller are to be restarted,

since the sample application does not support an automatic reset of bus

communication.

36

• Control field Error indicates the error message status.

• Error in the application

• Error in the controller

•The Error Reset button resets the error messages.

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 37

Working with the sample projects

Sample project with the "Actuator speed" application - Actuator Speed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.1.6.5 Parameter

The Parameter button selects the visualisation of the parameter FBs.

• The mode selected last remains active.

• You can use the FBs to...

• read individual parameters

• write individual parameters

Read parameters Write parameters

•Area shows the FB for reading parameters.

For more information on the FB, please see the following section:

L_DCO_ReadDriveParameter

•Area shows the FB for writing a parameter table.

Further information on the FB can be found in the following section:

L_DCO_WriteDriveParameter

( 105)

( 110)

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 37

Page 38

Working with the sample projects

Sample project with "Table positioning" application - TablePositioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.2 Sample project with "Table positioning" application - TablePositioning

Further information on the function libraries used in this project can be found in the

following section:

The L_LCB_LogicControlBasic library

The L_DCO_DriveCommunication library ( 100)

L_LCB_TablePositioning ( 124)

General procedure

How to commission the controller:

1. Commission the controller. Commissioning

2. Load the desired project (depending on the desired bus system) to the controller using the

»Engineer. Open the »Engineer« project & go online

3. Open the desired sample project in the »PLC Designer« Program structure in the »PLC

Designer« ( 42)

4. Load the project to the Controller and go online.

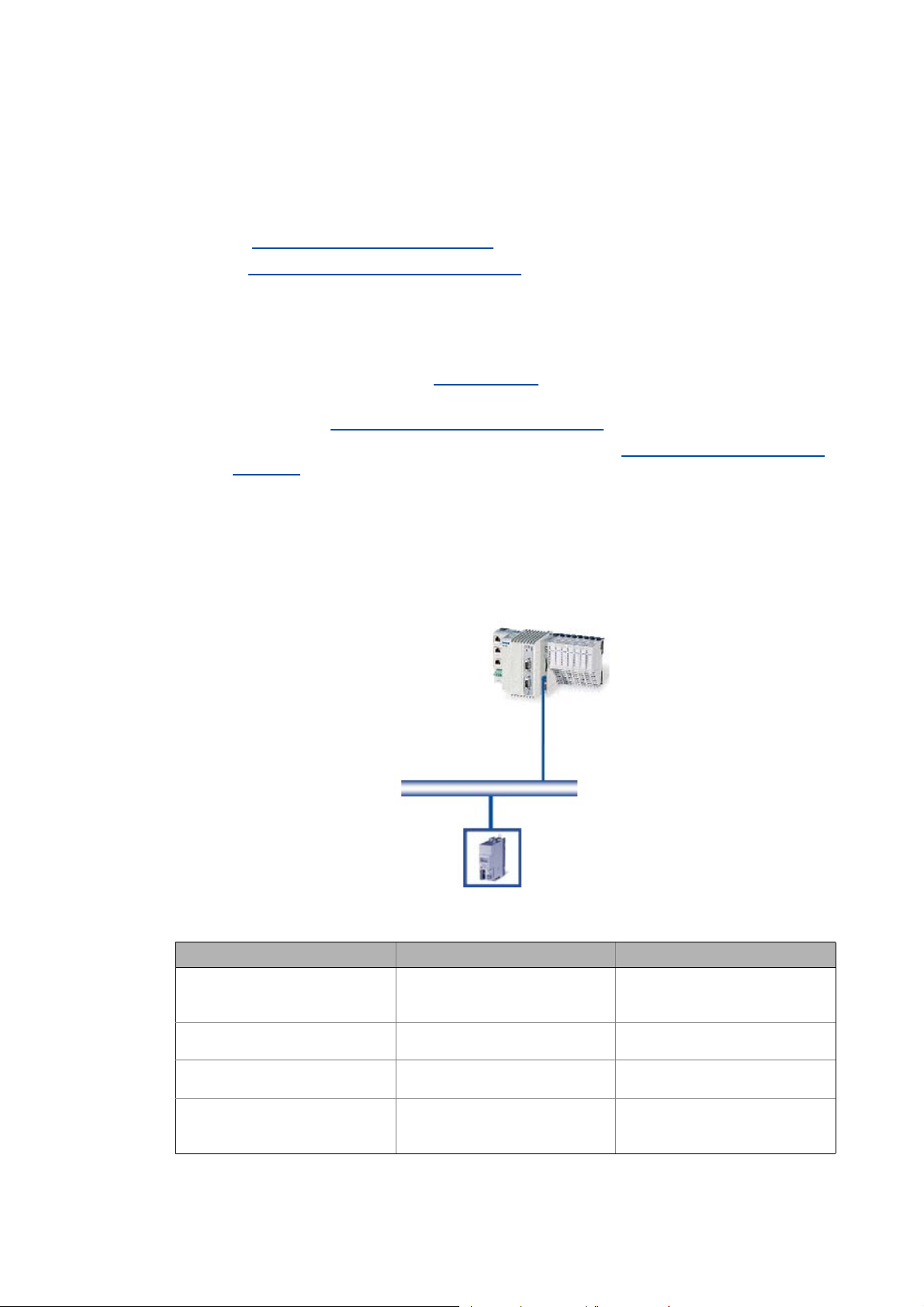

7.2.1 Components to be used

( 39)

( 40)

[7-4] System configuration with Controller (ID=0, connection to CAN1) and 8400 HighLine (CAN node ID=5)

Control supported field devices (bus system)

Hardware L-force Controller 8400 HighLine CAN (CAN, EtherCAT)

Operating system From version Logic 3.1.x Firmware version is device-

Required Lenze software »PLC Designer« from version 3

»Engineer« from version 2.12

Further requirements • CAN master ID = 127

• Connection to interface CAN 1

• Logic CAN 500kB

38

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

9400 HighLine CAN (CAN, EtherCAT)

dependent

-

• CAN node ID = 5

• EtherCAT station ID = 1001

Page 39

Working with the sample projects

Sample project with "Table positioning" application - TablePositioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.2.2 Short overview of the functions

Mode Description

Automatic In the automatic mode a sequence runs over an infinite loop.

Selection:

When the drive has been referenced...

1.travel to position 1,

2.travel to position 2,

3.restart at (1.).

Manual In manual mode, the controller can be manually actuated by setting the

Service The service mode serves to adjust the controller.

Homing In homing mode, the drive is referenced.

single control bits (xManualPos, xManualNeg, xDriveSetQsp, xResetError).

Like this, the controller can be controlled manually, e.g. for cleaning or

changing the tools.

Selection:

• Travel positive for one second,

•Stop for one second,

• Travel negative for one second.

• Either the home position is set directly, or a homing is started.

7.2.3 Commissioning

Read the mounting instructions accompanying the controller first before you start

working!

The mounting instructions contain safety instructions that must be observed!

1. Wire the power connections

• Use the mounting instructions supplied with the controller to correctly use the power

connections according to the requirements of your device.

2. Wire the control terminals

3. Connect USB diagnostic adapter.

4. Switch on the voltage supply of the controller.

• Connect mains voltage.

When the green LED "DRV-RDY" is blinking and the red LED "DRV-ERR" is off, the controller is ready

to start and you can continue with the commissioning.

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 39

Page 40

Working with the sample projects

Sample project with "Table positioning" application - TablePositioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.2.4 Open the »Engineer« project & go online

Detailed information on the general handling of the »Engineer« can be found in the

online help for the »Engineer«, which you can call with [F1].

How to open the sample project in the »Engineer«:

1. Start »Engineer«.

2. Open the desired project (CAN or EtherCAT) using the FileOpen archive command.

3. Insert the desired motor in the configuration:

• Highlight controller, select the desired motor with the command Insert a component on the

Motors tab

• By clicking Complete, insert the selection in the »Engineer« project.

40

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 41

Working with the sample projects

Sample project with "Table positioning" application - TablePositioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4. Update the project by clicking :

• Select the option Rebuild all

•Click the Build button to update the project.

5. Going online

• After a connection to the controller has been established successfully, the following status is

displayed in the Status line:

6. Download parameter set

• This command has the effect that the application and the parameter settings of the

»Engineer« project overwrite the parameter settings in the controller.

7. Optional: Adapt desired communication settings (for instance network address, baud rate).

8. Store parameter set

9. Mains switching to accept the communication settings to the device.

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 41

Page 42

Working with the sample projects

Sample project with "Table positioning" application - TablePositioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.2.5 Program structure in the »PLC Designer«

How to proceed:

1. Open the desired sample project (CAN or EtherCAT) in the »PLC Designer«.

2. Load the project to the Controller and Go online.

7.2.5.1 Control configuration

CAN

• The CAN master (ID = 127) is the control section of the system configuration

• The controller (CAN node ID = 5) is attached below the CAN master.

• Below the controller, the axis data are available in the form of an additional node.

• Two PDOs for CAN-Input and CAN-Output are used, respectively.

• The transmission mode is sync-controlled (10 ms).

You can find further details on the extension of the control configuration with CAN and EtherCAT in

the following section: Extending sample projects - adding devices

( 51)

EtherCAT

• The EtherCAT master is the control section of the system configuration

• The controller (station ID = 1001) is attached below the EtherCAT master.

• Below the controller, the axis data are available in the form of an additional node.

7.2.5.2 Program organisation units

"Main" program

• The "Main (PRG)" program is the basic program for processing the program sequences:

initialisation of the controller and selection of the different modes.

[7-5] Example: Main (PRG)

42

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 43

Working with the sample projects

Sample project with "Table positioning" application - TablePositioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

"Drive" program

• The "DRIVE (PRG)" program actuates the controller using the function block

L_LCB_TablePositioning an.

• The machine constants are provided in a conditioned manner by means of the

L_LCB_SetAxisData block.

• The connection of the AXIS_REF-instance(LC_Drive) provides a connection to the control

configuration.

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 43

Page 44

Working with the sample projects

Sample project with "Table positioning" application - TablePositioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

"PLC_PRG" program

• The "PLC_PRG (PRG)" program contains all program calls.

44

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 45

Working with the sample projects

Sample project with "Table positioning" application - TablePositioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.2.6 Operation via the visualisations in the »PLC Designer«

7.2.6.1 Information/start page

[7-6] Example: Visualisation start page of the sample project Lenze 8400 HighLine - TablePositioning

Select mode Manufacturer information Status

Parameter

selection

• Via the buttons in area , the mode (automatic, manual, service, homing) can be selected.

•In area , SDO services (read/write parameters) for the controller can be selected.

• The button in area refers to the start page which displays the version identifier of the project

and the libraries in area .

• Dialog box shows the status of the machine.

• Control field shows the bus communication status.

Information/home page Status

Note!

If a bus communication error occurs, the control and drive controller are to be restarted,

since the sample application does not support an automatic reset of bus

communication.

• Control field Error indicates the error message status.

• Error in the application

• Error in the controller

•The Error Reset button resets the error messages.

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 45

Page 46

Working with the sample projects

Sample project with "Table positioning" application - TablePositioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.2.6.2 Automatic mode

Select mode Stop button Current profile

Start button Mode status Set position

• Button selects the automatic mode.

• Button starts the motion profile.

• Button inhibits the motion profile.

•Display field indicates the status of the mode.

•Display field indicates the current profile number.

•Display field indicates the set position.

number

46

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 47

Working with the sample projects

Sample project with "Table positioning" application - TablePositioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.2.6.3 Manual mode ("Manual jog")

The controller can be actuated manually via the visualisation of the L_LCB_TablePositioning block.

Select mode Control/status panel Activate control via visualisation

• Button selects the manual (manual jog) mode.

• The control and status panel contains the FB for actuating the controller.

• The controller can be actuated manually via the visualisation of the L_LCB_TablePositioning

block.

Note: Activate button to be able to operate the controller via the visualisation.

• Enable the controller via the xDriveEnable FB input to be able to define setpoints manually.

Note: Click the xDriveSetQsp button to activate quick stop.

Further information on the FB can be found in the following section:

L_LCB_TablePositioning

•Area visualises the FB for reading out the errors from the controller.

Further information on the FB can be found in the following section:

L_DCO_ReadDriveParameter

( 120)

( 105)

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 47

Page 48

Working with the sample projects

Sample project with "Table positioning" application - TablePositioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.2.6.4 Service mode

Select mode Stop button Status of the service mode

Start button Activate clockwise

rotation

• Button selects the service mode.

• Button starts the motion profile.

• Button inhibits the motion profile.

• Button selects clockwise rotation (clockwise rotating direction of the motor).

•Display field indicates the status of the mode.

•Display field indicates the current speed (variable Speed Value).

• Dialog box shows the status of the machine.

• Control field shows the bus communication status.

Actual speed

Note!

If a bus communication error occurs, the control and drive controller are to be restarted,

since the sample application does not support an automatic reset of bus

communication.

• Control field Error indicates the error message status.

• Error in the application

• Error in the controller

•The Error Reset button resets the error messages.

48

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014

Page 49

Working with the sample projects

Sample project with "Table positioning" application - TablePositioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.2.6.5 Homing mode

Select mode Stop button Status of the service mode

Start button Activate clockwise

rotation

• Button selects the homing mode.

• The active standard setting in the controller is homing mode 12 (travel to negative limit

switch / digital input 3)

• Button starts the homing.

• Button stops homing.

• Button sets the home position.

• Button resets the home position.

• Set reference / Pos Act = 0 unit

• Dialog box shows the homing status.

Actual speed

Lenze · Commissioning of Lenze drives · 1.3 EN - 06/2014 49

Page 50

Working with the sample projects