Page 1

***************************** HEADER ***************************************

;Title: Pick and Place example program

;Author: Lenze - AC Technology

;Description: This is a sample program showing a simple sequence that

; picks up a part, moves to a set position and drops the part

;**************************** I/O List ************************************

; Input A1 - not used

; Input A2 - not used

; Input A3 - Enable Input

; Input A4 - not used

; Input B1 - not used

; Input B2 - not used

; Input B3 - not used

; Input B4 - not used

; Input C1 - not used

; Input C2 - not used

; Input C3 - not used

; Input C4 - not used

; Output 1 - Pick Arm

; Output 2 - Gripper

; Output 3 - not used

; Output 4 - not used

;********************** Initialize and Set Variabl

UNITS = 1

ACCEL = 75

DECEL =75

MAXV = 10

;V1 =

;V2 =

;********************** Events *******************

;Set Events handling here

;********************** Main Program ************

RESET_DRIVE: ;Place holder fo

WAIT UNTIL IN_A3: ;Make sure tha

continuing

ENABLE

PROGRAM_START:

MOVEP 0 ;Move to Pick po

OUT1 = 1 ;Turn on output

WAIT TIME 1000 ;Delay 1 sec to

OUT2 = 1 ;Turn on output

WAIT TIME 1000 ;Delay 1 sec to

OUT1 = 0 ;Turn off output

MOVED -10 ;Move 10 REVs to

OUT1 = 1 ;Turn on output

WAIT TIME 1000 ;Delay 1 sec to

OUT2 = 0 ;Turn off output

WAIT TIME 1000 ;Delay 1 sec to

OUT1 = 0 ;Retract Pick ar

GOTO PROGRAM_START

END

;********************** Sub-Routines ***************

Enter Sub-Routine code here

;********************** Fault Handler Routine ***************

; Enter Fault Handler code here

ON FAULT

ENDFAULT

PositionServo

Programming Manual for PC-based MotionView

Page 2

Copyright ©2005 by AC Technology Corporation.

All rights reserved. No part of this manual may be reproduced or transmitted in any form without written permission from

AC Technology Corporation. The information and technical data in this manual are subject to change without notice.

AC Technology makes no warranty of any kind with respect to this material, including, but not limited to, the implied

warranties of its merchantability and fitness for a given purpose. AC Technology assumes no responsibility for any

errors that may appear in this manual and makes no commitment to update or to keep current the information in this

manual.

MotionView®, PositionServo®, and all related indicia are either registered trademarks or trademarks of Lenze AG in the

United States and other countries.

Page 3

Contents

1. Introduction ............................................................................................................................. 4

1.1 Definitions ..................................................................................................................................................4

1.2 Programming Flowchart .............................................................................................................................5

1.3 MotionView / MotionView Studio ...............................................................................................................6

1.3.1 Main Toolbar ............................................................................................................................6

1.3.2 Program Toolbar ......................................................................................................................8

1.3.3 MotionView Studio - Indexer Program .....................................................................................9

1.4 Programming Basics ................................................................................................................................10

1.5 Using Advanced Debugging Features .....................................................................................................17

1.6 Inputs and Outputs ..................................................................................................................................17

1.7 Events ...................................................................................................................................................... 22

1.8 Variables and Define Statement ..............................................................................................................23

1.9 IF/ELSE Statements ................................................................................................................................24

1.10 Motion ......................................................................................................................................................25

1.10.1 Drive Operating Modes ..........................................................................................................26

1.10.2 Point To Point Moves .............................................................................................................26

1.10.3 Segment Moves .....................................................................................................................27

1.10.4 Registration ............................................................................................................................28

1.10.5 S-Curve Acceleration ............................................................................................................. 29

1.10.6 Motion Queue ........................................................................................................................29

1.11 Subroutines and Loops ............................................................................................................................30

1.11.1 Subroutines ............................................................................................................................30

1.11.2 Loops .....................................................................................................................................31

2. Programming ........................................................................................................................ 32

2.1 Program Structure ...................................................................................................................................32

2.2 Variables .................................................................................................................................................. 34

2.3 Arithmetic Expressions ............................................................................................................................36

2.4 Logical Expressions and Operators ......................................................................................................... 36

2.4.1 Bitwise Operators ..................................................................................................................36

2.4.2 Boolean Operators ................................................................................................................. 37

2.5 Comparison Operators ............................................................................................................................37

2.6 System Variables and Flags ....................................................................................................................38

2.7 System Variables Storage Organization ..................................................................................................38

2.7.1 RAM File for User’s Data Storage .........................................................................................38

2.7.2 Memory Access Through Special System Variables .............................................................39

2.7.3 Memory Access Through MEMSET, MEMGET Statements .................................................40

2.8 System Variables and Flags Summary ....................................................................................................41

2.8.1 System Variables ...................................................................................................................41

2.8.2 System Flags .........................................................................................................................42

2.9 Control Structures .................................................................................................................................... 43

2.9.1 DO/UNTIL Structure ..............................................................................................................43

2.9.2 WHILE Structure ....................................................................................................................43

2.9.3 Subroutines ............................................................................................................................44

2.9.4 IF Structure ............................................................................................................................45

2.9.5 IF/ELSE Structure ..................................................................................................................45

2.9.6 WAIT Statement ....................................................................................................................46

2.9.7 GOTO Statement & Labels ....................................................................................................46

2.10 Scanned Event Statements ..................................................................................................................... 46

PM94P01C 1

Page 4

Contents

2.11 Motion ......................................................................................................................................................48

2.11.1 How Moves Work ...................................................................................................................48

2.11.2 Incremental (MOVED) and Absolute (MOVEP) Motion .........................................................48

2.11.3 Incremental (MOVED) Motion ................................................................................................49

2.11.4 Absolute (MOVEP) Move .......................................................................................................49

2.11.5 Registration (MOVEDR MOVEPR) Moves ............................................................................50

2.11.6 Segment Moves .....................................................................................................................50

2.11.7 MDV Segments ......................................................................................................................50

2.11.8 S-curve Acceleration ..............................................................................................................52

2.11.9 Motion SUSPEND/RESUME .................................................................................................52

2.11.10 Conditional Moves (MOVE WHILE/UNTIL) ...........................................................................52

2.11.11 Motion Queue and Statement Execution while in Motion ...................................................... 53

2.12 System Status Register (DSTATUS register) ..........................................................................................55

2.13 Fault Codes (DFAULTS register) ............................................................................................................. 56

2.14 Limitations and Restrictions .....................................................................................................................57

2.15 Homing ....................................................................................................................................................58

2.15.1 What is Homing? ................................................................................................................... 58

2.15.2 The Homing Function ............................................................................................................ 58

2.15.3 Home Offset ...........................................................................................................................59

2.15.4 Homing Velocity .....................................................................................................................59

2.15.5 Homing Acceleration ..............................................................................................................59

2.15.6 Homing Switch .......................................................................................................................59

2.15.7 Homing Start ..........................................................................................................................59

2.15.8 Homing Method ..................................................................................................................... 60

2.15.9 Homing Methods ....................................................................................................................61

2.15.9.1 Homing Method 1: Homing on the Negative Limit Switch ......................................................62

2.15.9.2 Homing Method 2: Homing on the Positive Limit Switch .......................................................62

2.15.9.3 Homing Method 3: Homing on the Positive Home Switch & Index Pulse ..............................63

2.15.9.4 Homing Method 4: Homing on the Positive Home Switch & Index Pulse ..............................63

2.15.9.5 Homing Method 5: Homing on the Negative Home Switch & Index Pulse ............................64

2.15.9.6 Homing Method 6: Homing on the Negative Home Switch & Index Pulse ............................64

2.15.9.7 Homing Method 7: Homing on the Home Switch & Index Pulse ............................................65

2.15.9.8 Homing Method 8: Homing on the Home Switch & Index Pulse ............................................66

2.15.9.9 Homing Method 9: Homing on the Home Switch & Index Pulse ............................................67

2.15.9.10 Homing Method 10: Homing on the Home Switch & Index Pulse .......................................... 68

2.15.9.11 Homing Method 11: Homing on the Home Switch & Index Pulse .......................................... 69

2.15.9.12 Homing Method 12: Homing on the Home Switch & Index Pulse .......................................... 70

2.15.9.13 Homing Method 13: Homing on the Home Switch & Index Pulse .......................................... 71

2.15.9.14 Homing Method 14: Homing on the Home Switch & Index Pulse .......................................... 72

2.15.9.15 Homing Method 17: Homing without an Index Pulse .............................................................73

2.15.9.16 Homing Method 18: Homing without an Index Pulse .............................................................74

2.15.9.17 Homing Method 19: Homing without an Index Pulse .............................................................75

2.15.9.18 Homing Method 21: Homing without an Index Pulse .............................................................76

2.15.9.19 Homing Method 23: Homing without an Index Pulse .............................................................77

2.15.9.20 Homing Method 25: Homing without an Index Pulse .............................................................78

2.15.9.21 Homing Method 27: Homing without an Index Pulse .............................................................79

2.15.9.22 Homing Method 29: Homing without an Index Pulse .............................................................80

2.15.9.23 Homing Method 33: Homing to an Index Pulse ..................................................................... 81

2.15.9.24 Homing Method 34: Homing to an Index Pulse ..................................................................... 81

2.15.9.25 Homing Method 35: Using Current Position as Home ...........................................................81

2.15.10 Homing Mode Operation example .........................................................................................82

3. Reference ............................................................................................................................. 83

3.1 Program Statement Glossary ..................................................................................................................83

3.2 Variable List ...........................................................................................................................................103

3.3 Quick Start Examples ............................................................................................................................117

3.3.1 Quick Start - External Torque/Velocity ................................................................................. 117

3.3.2 Quick Start - External Positioning ........................................................................................119

3.3.3 Quick Start - Internal Torque/Velocity ..................................................................................121

3.3.4 Quick Start - Internal Positioning ......................................................................................... 123

3.4 PositionServo Reference Diagrams .......................................................................................................124

PM94P01C2

Page 5

About These Instructions

This documentation applies to the programming of the PositionServo drive with model numbers ending in “EX”

and “RX”. This documentation should be used in conjunction with the PositionServo User Manual (Document

S94P01) that shipped with the drive. These documents should be read in their entirety as they contain important

technical data and describe the installation and operation of the drive.

Safety Warnings

Take note of these safety warnings and those in the PositionServo User Manual and related documentation.

WARNING! Hazard of unexpected motor starting!

When using MotionView, or otherwise remotely operating the PositionServo drive, the motor may

start unexpectedly, which may result in damage to equipment and/or injury to personnel. Make sure

the equipment is free to operate and that all guards and covers are in place to protect personnel.

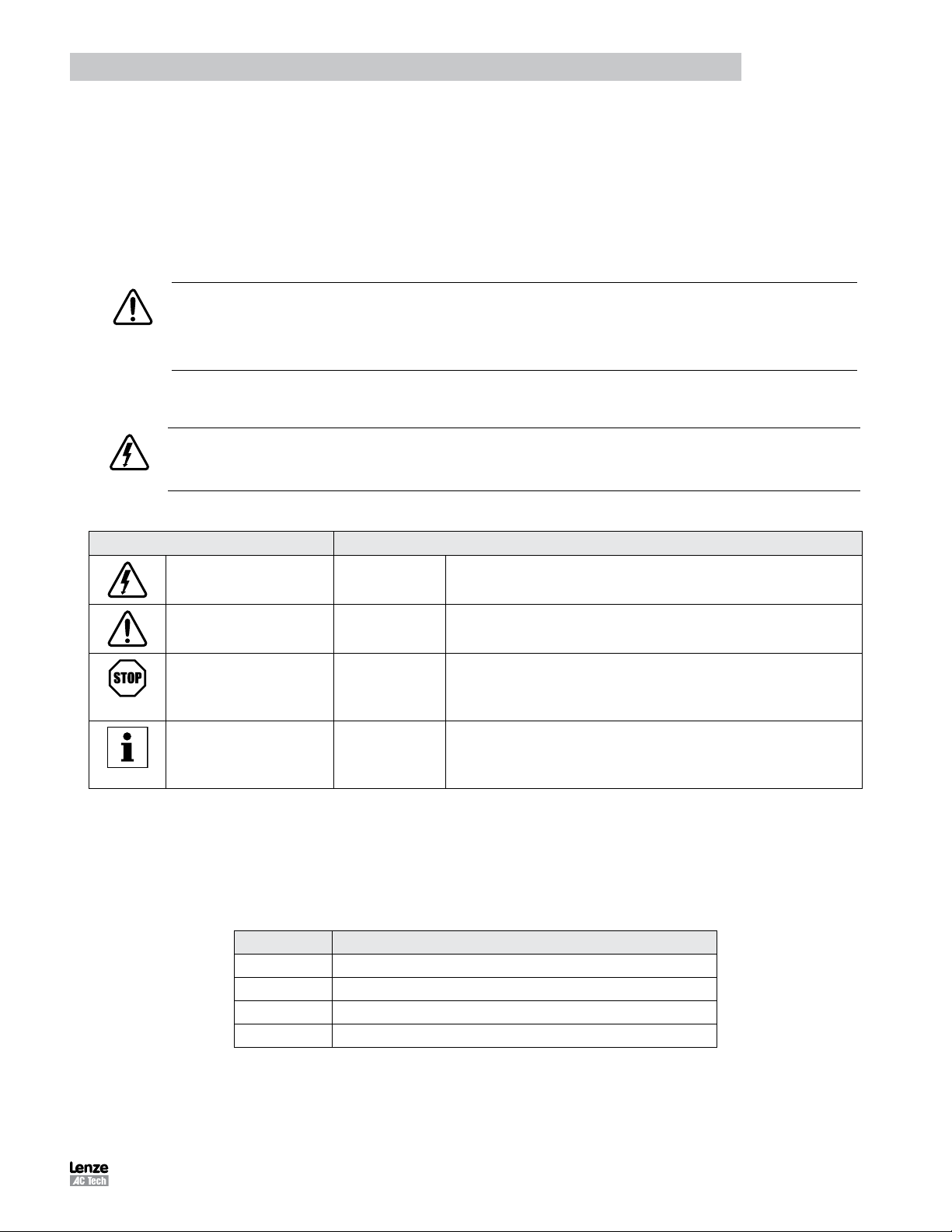

All safety information contained in these Programming Instructions is formatted with this layout including an icon,

signal word and description:

Signal Word! (Characterizes the severity of the danger)

Safety Information (describes the danger and informs on how to proceed)

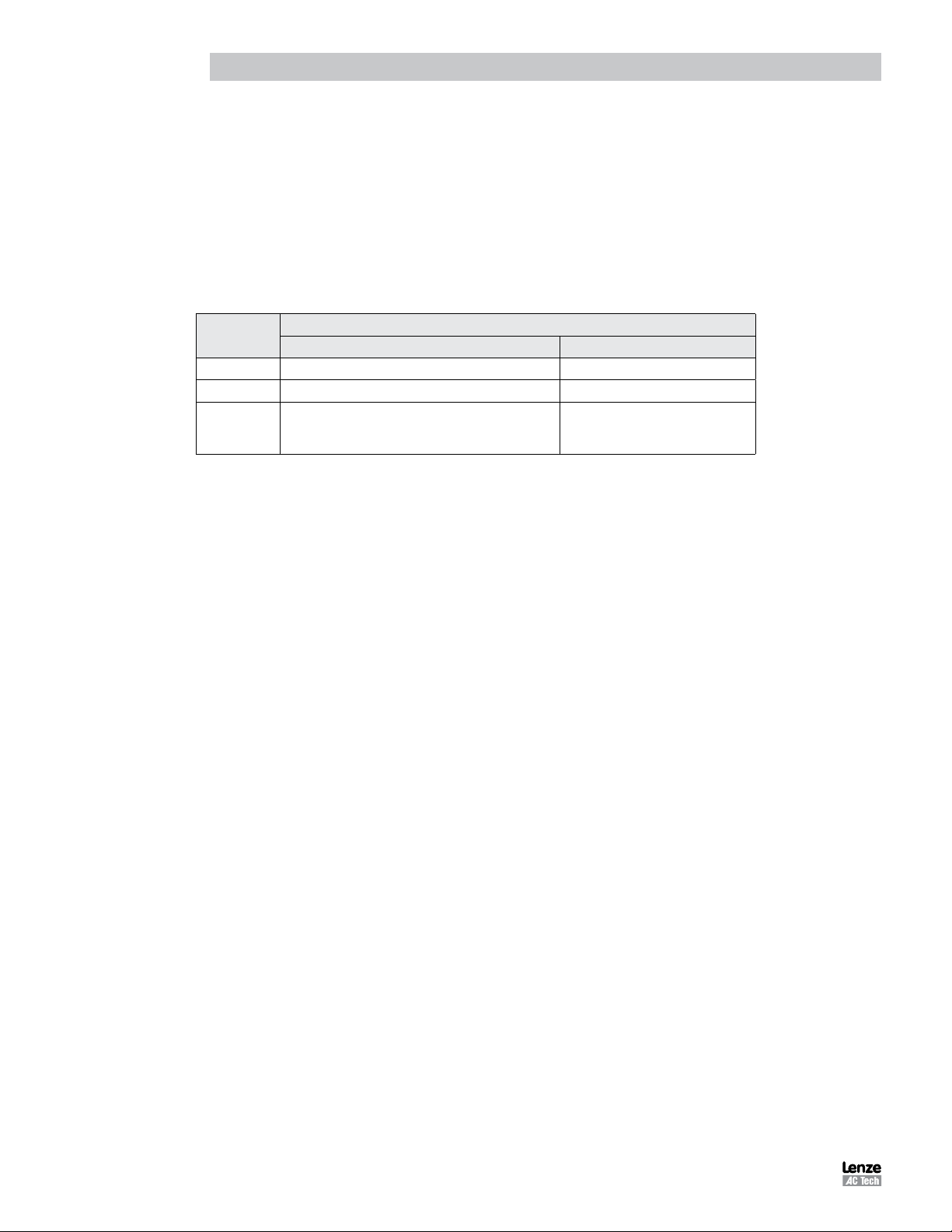

Table 1: Pictographs used in these Instructions

Icon

Warning of hazardous

electrical voltage

Warning of a general

danger

Warning of damage to

equipment

Signal Words

DANGER!

WARNING!

STOP!

Warns of impending danger.

Consequences if disregarded: Death or severe injuries.

Warns of potential, very hazardous situations.

Consequences if disregarded: Death or severe injuries.

Warns of potential damage to material and equipment.

Consequences if disregarded: Damage to the controller/

drive or its environment.

Information

NOTE

Designates a general, useful note.

If the note is observed then handling the controller/drive

system is made easier.

Related Documents

The documentation listed herein contains information relevant to the operation and programming of the Position

Servo drive with model numbers ending in “EX” and “RX”. To obtain the latest documentation, visit the Technical

Library at http://www.lenze-actech.com.

Table 2: Reference Documentation

Document # Description

S94P01 PositionServo User Manual

PM94P01 PositionServo Programming Manual

P94MOD01 Position Servo ModBus RTU over RS485, ModBus TCP/IP

P94CAN01 PositionServo CANopen Communications Reference Guide

PM94P01C 3

Page 6

Introduction

1. Introduction

1.1 Definitions

Included herein are definitions of several terms used throughout this programming manual and the PositionServo user

manual.

PositionServo: The PositionServo is a programmable digital drive/motion controller, that can be configured as a

stand alone programmable motion controller, or as a high performance torque and velocity drive for centralized control

systems. The PositionServo family of drives includes the 940 Encoder-based drive and the 941 Resolver-based drive.

MotionView: MotionView is a universal communication and configuration software that is utilized by the PositionServo

drive family. MotionView has an automatic self-configuration mechanism that recognizes what drive it is connected

to and configures the tool set accordingly. The MotionView platform is divided up into three sections or windows, the

“Parameter Tree Window”, the “Parameter View Window” and the “Message Window”. Refer to Section 1.3 for more

detail.

SimpleMotion Language (SML): SML is the programming language utilized by MotionView. The SML software provides

a very flexible development environment for creating solutions to motion applications. The software allows you to create

complex and intelligent motion moves, process I/O, perform complex logic decision making, do program branching,

utilize timed event processes, as well as a number of other functions found in PLC’s and high end motion controllers.

User Program (or Indexer Program): This is the SML program, developed by the user to describe the programmatic

behavior of the PositionServo drive. The User Program can be stored in a text file on your PC or in the PositionServo’s

EPM memory. The User Program needs to be compiled (translated) into binary form with the aid of the MotionView

Studio tools before the PositionServo can execute it.

MotionView Studio: MotionView Studio is the front end interface of the MotionView platform. It is a tool suite containing

all the software tools needed to program and debug a PositionServo. These tools include a full-screen text editor, a

program compiler, status and monitor utilities, an online oscilloscope and a debugger function that allows the user to

step through the program during program development.

WARNING!

• Hazard of unexpected motor starting! When using the MotionView software, or otherwise

remotely operating the PositionServo drive, the motor may start unexpectedly, which may result

in damage to equipment and/or injury to personnel. Make sure the equipment is free to operate

in this manner, and that all guards and covers are in place to protect personnel.

• Hazard of electrical shock! Circuit potentials are up to 480 VAC above earth ground. Avoid direct

contact with the printed circuit board or with circuit elements to prevent the risk of serious injury or

fatality. Disconnect incoming power and wait 60 seconds before servicing drive. Capacitors retain

charge after power is removed.

PM94P01C4

Page 7

Introduction

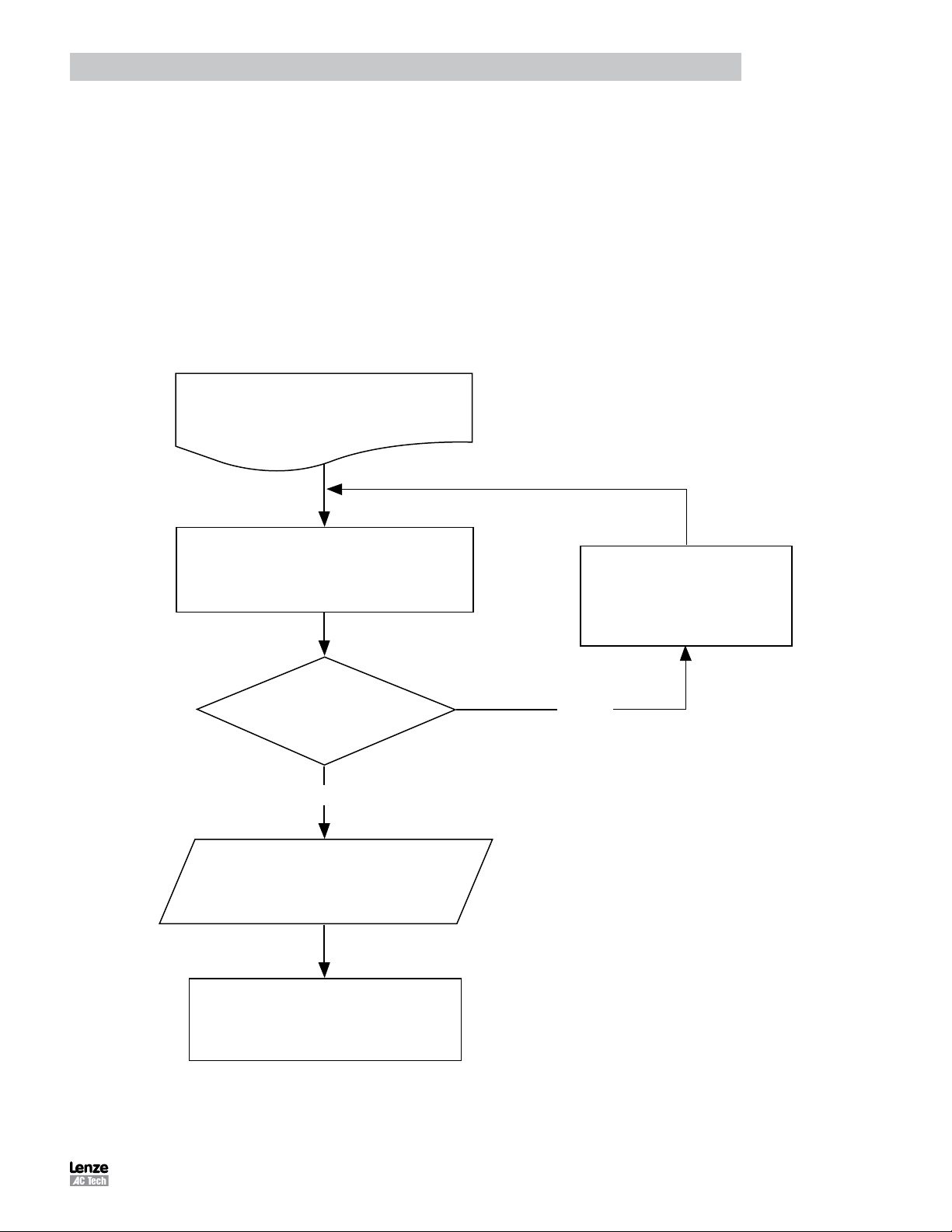

1.2 Programming Flowchart

MotionView utilizes a BASIC-like programming structure referred to as SimpleMotion Programming Language (SML).

SML is a quick and easy way to create powerful motion applications.

With SML the programmer describes his system’s logistics, motion, I/O processing and user interaction using the SML

structured code. The program structure includes a full set of arithmetic and logical operator programming statements,

that allow the user to command motion, process I/O and control program flow.

Before the PositionServo drive can execute the user’s program, the program must first be compiled (translated) into

binary machine code, and downloaded to the drive. Compiling the program is done by selecting the [Compile] button

from the toolbar. The user can also compile and download the program at the same time by selecting the [Compile

and Load] button from the toolbar. Once downloaded, the compiled program is stored in both the PositionServo’s EPM

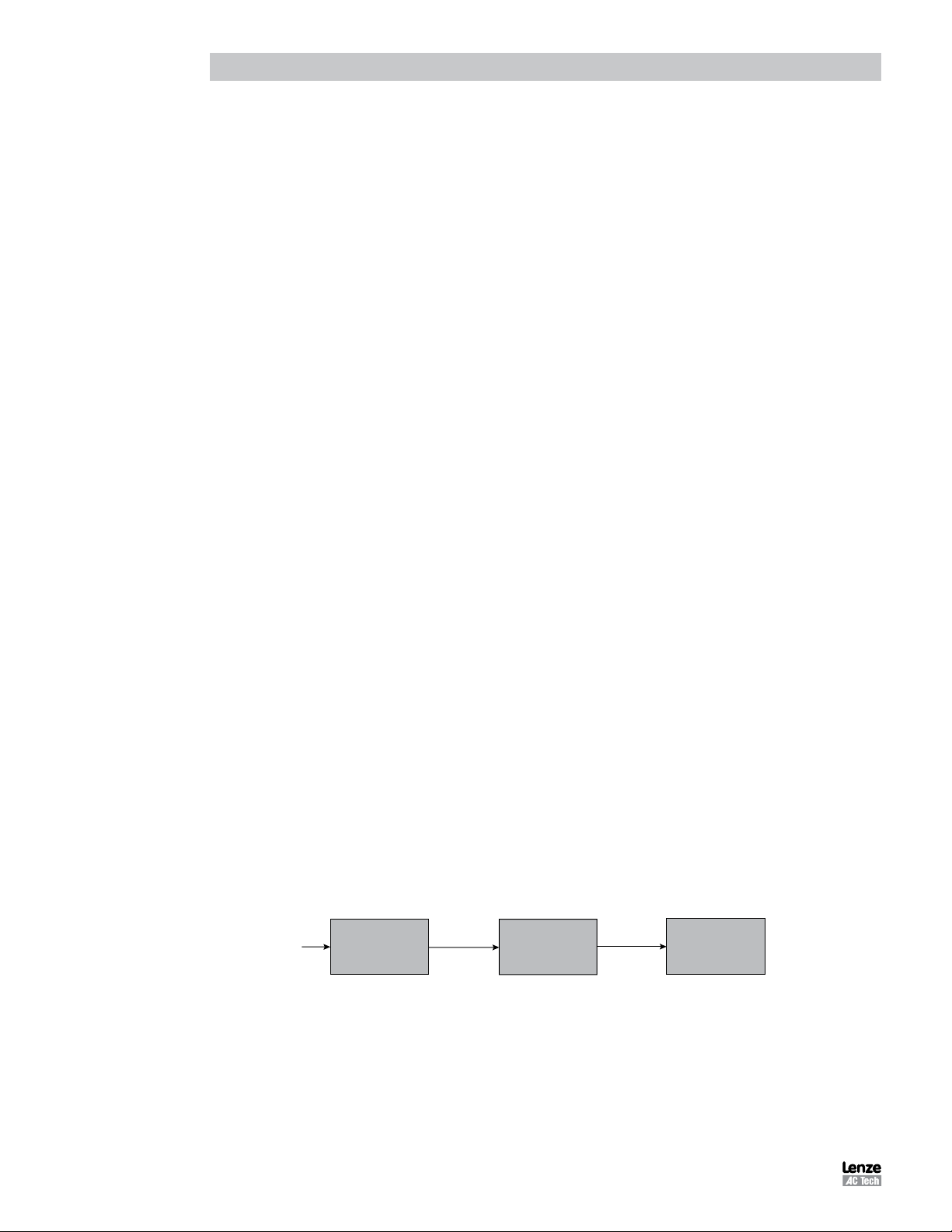

memory and the internal flash memory. Figure 1 illustrates the flow of the program preparation process.

Prepare User Program

COMPILER

Any Error?

NO

Load compiled program

to PositionServo drive

Start Execution in

debugger environment

or at next power up

Fix program errors

YES

Figure 1: Program Preparation

PM94P01C 5

Page 8

Introduction

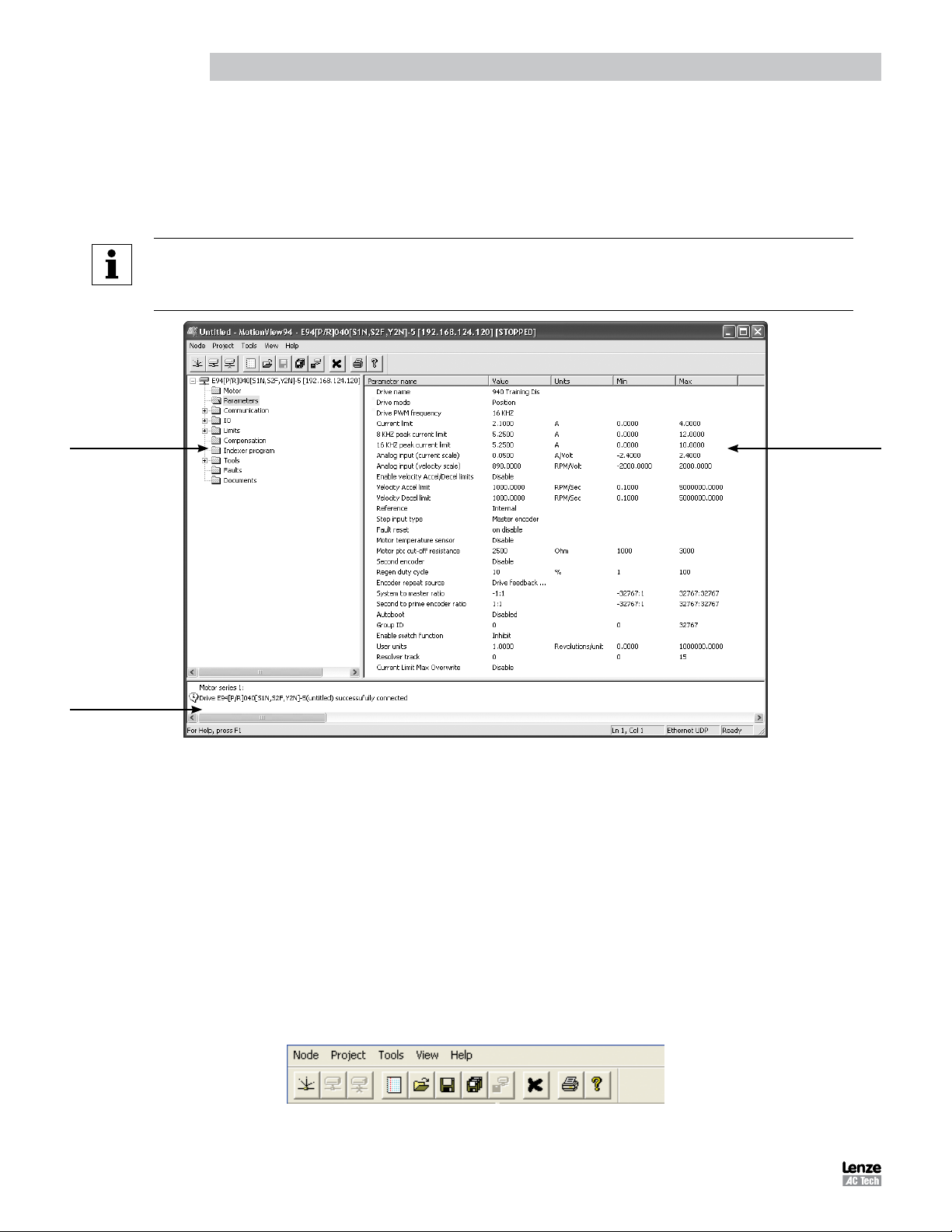

1.3 MotionView / MotionView Studio

There are two versions of MotionView Software: one which resides inside the drive’s memory, referred to as “MotionView

on Board” (MVOB); and one supplied as a PC-installed software package, referred to simply as MotionView. This

manual describes the PC-installed MotionView software for PositionServo drives with P/N ending in EX or RX. The

MotionView display is illustrated in Figure 2.

NOTE

For MotionView OnBoard (MVOB), refer to “PositionServo with MVOB Programming Manual”

document number PM94M01

Parameter Tree

Window

Message

Window

Figure 2: MotionView Parameters Display

MotionView is the universal programming software used to communicate with and configure the PositionServo drive. The

MotionView platform is segmented into three windows. The first window is the “Parameter Tree Window”. This window

is used much like Windows Explorer. The various parameter groups for the drive are represented here as folders or files.

Once the desired parameter group file is selected, all of the corresponding parameters within that parameter group will

appear in the second window, the “Parameter View Window”. The user can then enable, disable or edit drive features

or parameters in the Parameter View window. The third window is the “Message Window”. This window is located at the

bottom of the screen and will display communication status and errors.

Parameter View

Window

1.3.1 Main Toolbar

The functions of MotionView are accessible via the Main Toolbar as illustrated in Figure 3. If a function in a pull-down

menu or an icon is greyed out that denotes the function is unavailable. A function may be unavailable because a drive

is not physically connected to the network or the present set-up and operation of the drive prohibits access to that

function.

Figure 3: Main Menu and Toolbar

PM94P01C6

Page 9

Introduction

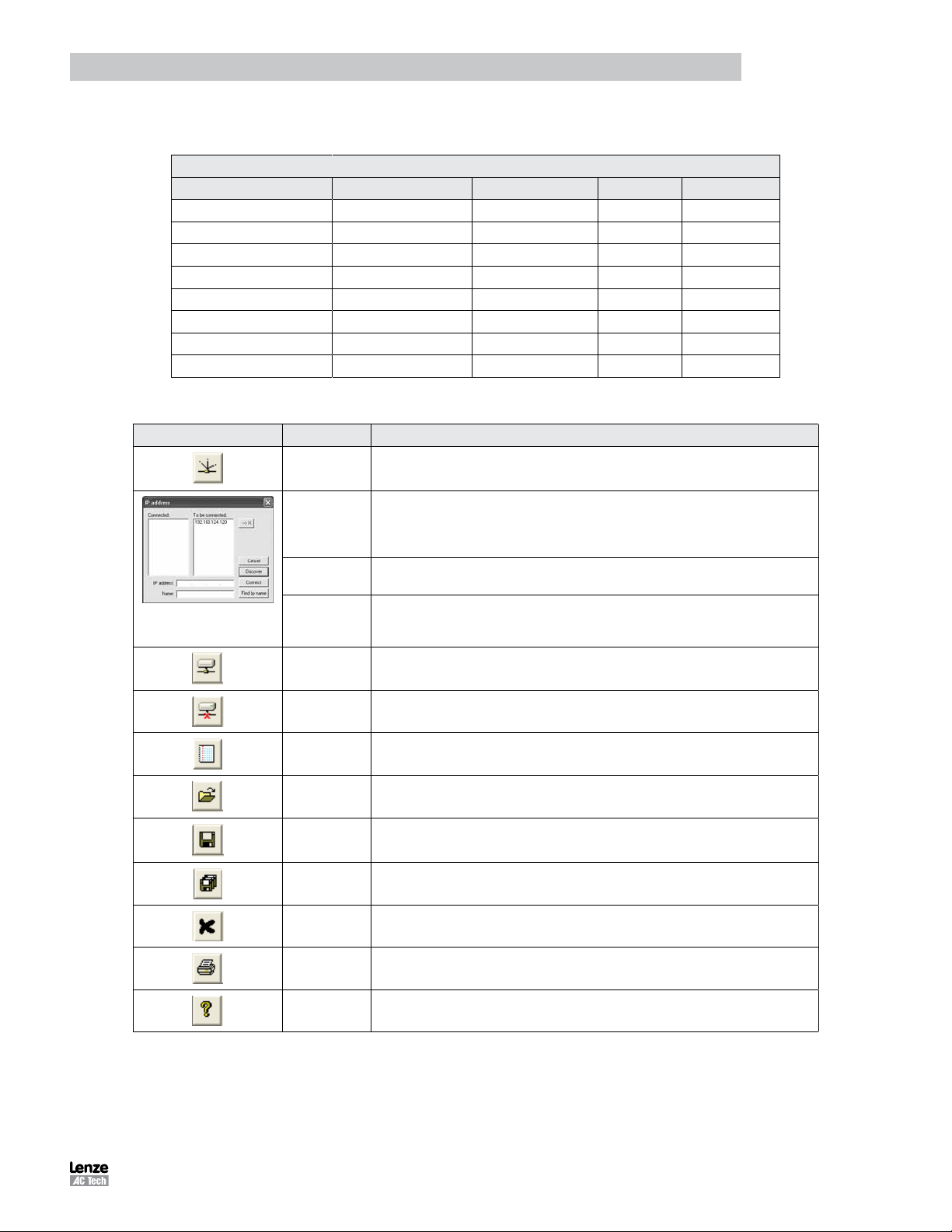

Table 3a: Main Menu Text Pull-Down Folders

Main Menu

Node Project Tools View Help

New configuration file New project Browse motor database Toolbar MotionView help

Open configuration file Open project Clear output window Status Bar Product manuals

Save configuration file Close project About MotionView

Load configuration file Save project Time stamp

Set all parameters to default Save all configuration files

Connect drive Options

Disconnect all coneected drives Connection setup

Remove node from project Recent file

Table 3b: Main Menu Icon Functions

Icon Function Description

Connect Build a connection list of the drive(s) to communicate with on the network. Build the

connection list by using any one of these three methods:

Discover [Discover] button discovers all drives on the network that are available for connectivity. Once

Connect If the IP address on the drive is known, enter it in the IP address dialog box and then select

Find by name If a drive has been assigned a specified “Drive Name”, enter this name in the Name dialog box

Connected Drive is connected as a node on the network.

Disconnect Terminate connection to the drive selected (backlit) in the Node Tree.

Add File Import a configuration file to the drive

Open File Recall & open any previously saved configuration files and connection parameters.

Save Save the configuration file and the connection parameters of the drive selected in Node Tree.

Save As Save the configuration file and the connection parameters of the drive selected in Node Tree.

Remove Node Remove a node from the network

drives have been discovered they are listed in the ‘Connect to drive’ list box. To connect one

or a number of drives highlight their IP address in this window and press the [Connect] button.

The ‘Ctrl’ key on your keyboard can be used to select multiple drives for connection.

[Connect] to access the drive.

and then select [Find by name]. The IP address should then appear in the “Connect To Drive”

list. The drive can now be connected by highlighting and pressing the [Connect] button.

Print Print a report for the currently selected drive, containing all parameter set-up and

Help Open MotionView Help folder (from original installation CD)

programming information.

PM94P01C 7

Page 10

Introduction

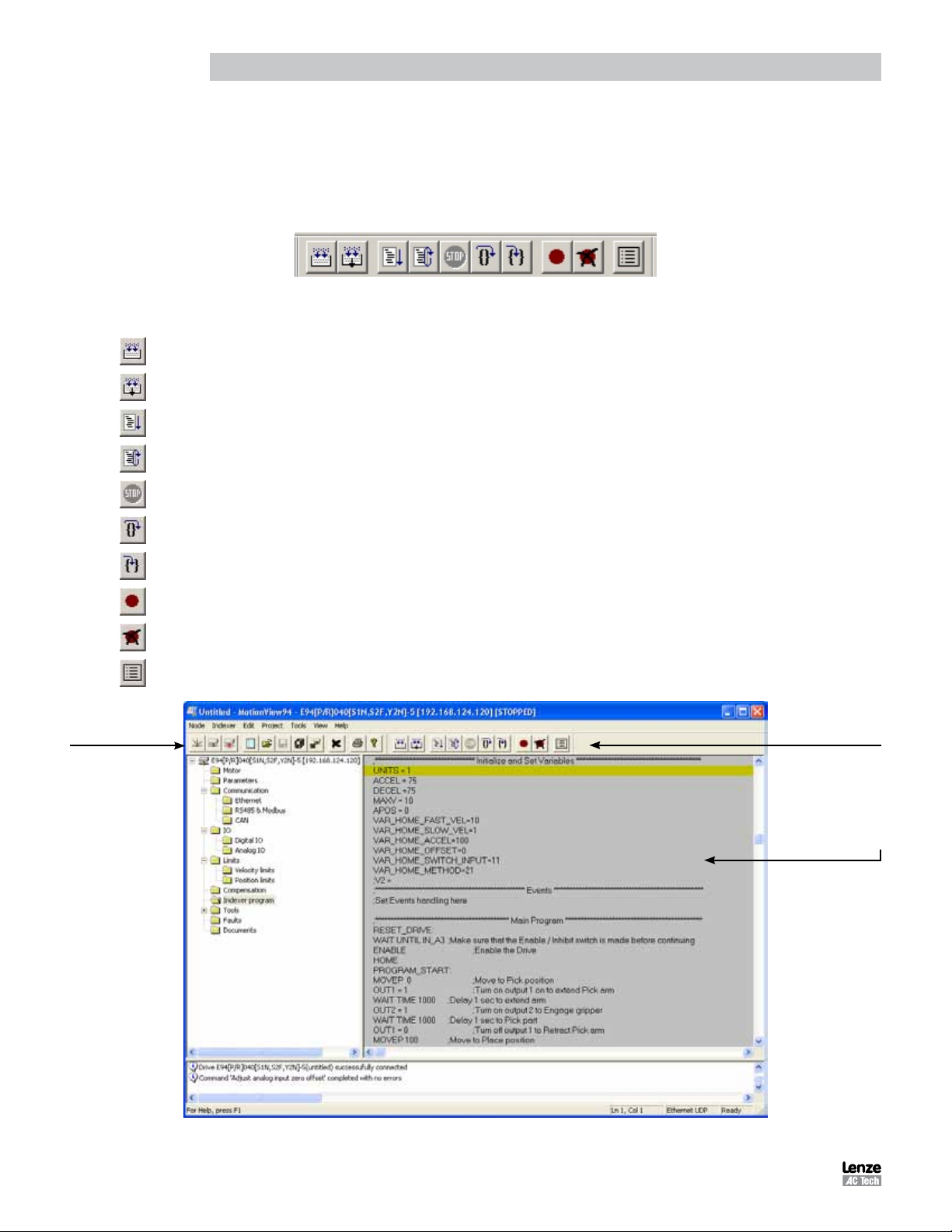

1.3.2 Program Toolbar

To view the Program Toolbar, click on the [Indexer Program] folder in the Node Tree. Click anywhere inside the gray

Indexer program in the right-hand parameter window to bring up the program toolbar. This paragraph contains a brief

description of the programming tools: Compile, Load with Source, Run, Reset, Stop, Step Over, Step Into, Set Breakpoint

and Remove Breakpoint. For detailed descriptions of the program toolbar functions refer to paragraphs 1.3.3 and 1.4.

Figure 4: Program Toolbar

Icon Function Description

Compile Check compilation of the indexer program currently in the List View window.

Compile & Load w/ Source Load program including source code to the PositionServo drive listed in Node Tree.

Run Start / Continue program execution.

Main

Toolbar

Reset

Stop

Step Over Execute each line of code in the program sequentially on each press on the [Step Over] button excluding subroutines.

Step Into Execute each line of code in the program sequentially on each press on the [Step Into] button, including subroutines.

Set Breakpoint Set breakpoint at current location of cursor in Indexer program.

Remove Breakpoint Remove breakpoint from current location of cursor in Indexer program.

Watch Window Display Parameter I/O window

Reset Drive. Disable drive, stop program execution, and return program processing to the beginning. Program will not

restart program execution automatically.

Stop program execution on completion of the current statement being executed. WARNING: Stop button does not

place the drive in a disable state or prevent execution of motion commands waiting on the motion stack.

Program

Toolbar

Program

User

Area

Figure 5: MotionView - Indexer Program Display

PM94P01C8

Page 11

Introduction

1.3.3 MotionView Studio - Indexer Program

The MotionView Studio provides a tool suite used by MotionView to enter, compile, load and debug the user program.

To view and develop the user program, select the [Indexer Program] folder in the Parameter (Node) Tree window. Once

selected the program toolbar is displayed. The program displayed in the View window is uploaded from the drive when

the connection is made between MotionView and the drive. This upload is always performed regardless of program

running state. Click anywhere in the Parameter View Window to edit the Indexer program.

Common Programming Actions

Load User program from the PC to MotionView

- Select [Indexer Program] in the Node Tree.

- Select [Import] on the program toolbar.

Select the program to import from the PC folder where it is located. This procedure loads the program from the

file to the editor window. It doesn’t load the program to the drive’s memory.

Compile program and Load to the drive

- Select [Indexer Program] in the Node Tree.

- Select [Compile & Load W Source] on the program toolbar to to compile the program and load the source

code and the compiled binary file to the PositionServo drive. The original source code contained in the drive can

be viewed whenever the drive is accessed through MotionView and the Indexer Program folder is opened.

- Select [Compile] to check syntax errors without loading the program to drive. If the compiler finds any syntax

error, compilation stops. Errors are reported in bottom portion of the screen in Message window.

Save User program from MotionView to PC.

- Select [Indexer Program] in the Node Tree.

- Select [Export] ] on the program toolbar.

The program will be saved to the Windows “My Documents” folder by default.

Run User program in drive.

- Select [Indexer Program] in the Node Tree.

- Select [Run] on the program toolbar.

If the program is already running, then first select [Reset] or [Stop] to stop the program.

Step Through the User program.

- Select [Indexer Program] in the Node Tree.

- Select [Step] or [Step over] on the program toolbar.

If [Step] is selected, the drive will execute the program one step at a time including subroutines. If [Step Over] is

selected, the drive will execute the program one step at a time excluding subroutines. The program statement

under execution will be highlighted. If the program is running, it will have to be either stopped or reset.

Set Breakpoint(s) in the program

- Select [Indexer Program] in the Node Tree.

- Place the cursor at the point in the program where the program will stop.

- Select [Set Breakpoint] or [Remove Breakpoint] on the program toolbar.

A convenient way to debug a user program is to insert breakpoints at critical junctions throughout the program.

These breakpoints stop the drive from executing the program, but do not disable the drive and the position

variables. Once the program has stopped, the user can continue to run the program, step through the program

or reset the program.

PM94P01C 9

Page 12

Introduction

Stop program execution

- Select [Indexer Program] in the Node Tree.

- Select [Stop] on the program toolbar.

The program will stop after completing the current statement. Select [Run] to resume the program from the

same point.

IMPORTANT!

The [Stop] button only stops the execution of the program code.

It does not stop motion or disable the drive.

Restart Program execution

- Select [Indexer Program] in the Node Tree.

- Select [Reset] on the program toolbar.

The program will be reset and the drive will be disabled. Variables within the drive are not cleared (reset) when

program execution is reset. It is important that any variables used by the programmer are set to safe values at

the start of the user program.

1.4 Programming Basics

The user program consists of statements which when executed will not only initiate motion moves but also process

the drives I/O and make decisions based on drive parameters. Before motion can be initiated, certain drive and I/O

parameters must be configured. To configure these parameters perform the following procedure.

Parameter setup

Select [Parameter] folder in the Node Tree window and set the following parameters.

Set the “Drive” to “Position”:

- Select [Drive mode] from the Parameter View Window.

- Select [Position], [Velocity], or [Torque] from the drop down menu depending on the mode the drive is to be

operated in. In order to execute the examples contained in this section of the manual the drive will need to be

in [Position] mode.

Set the [Reference] to [Internal]:

- Select [Reference] from the Parameter View Window.

- Select [Internal] from the pull down menu to select the user program as the source of the Torque, Velocity, or

Position Reference.

Set the [Enable switch function] to [Inhibit]:

- Select [Enable switch function] from the Parameter View Window.

- Select [Inhibit] from the menu to allow the user program control of the enable / disable status of the drive.

Input A3 will now act as a hardware inhibit.

I/O Configuration

Input A3 is the Inhibit/Enable special purpose input. Refer to the PS User Manual (S94P01) for more information. Before

executing any motion related statements, the drive must be enabled by executing “ENABLE” statement. “ENABLE”

statement can only be accepted if input A3 is made. If at any time while drive is enabled A3 deactivates then the fault

“F36” (“Drive Disabled”) will result. This is a hardware safety feature.

PM94P01C10

Page 13

Introduction

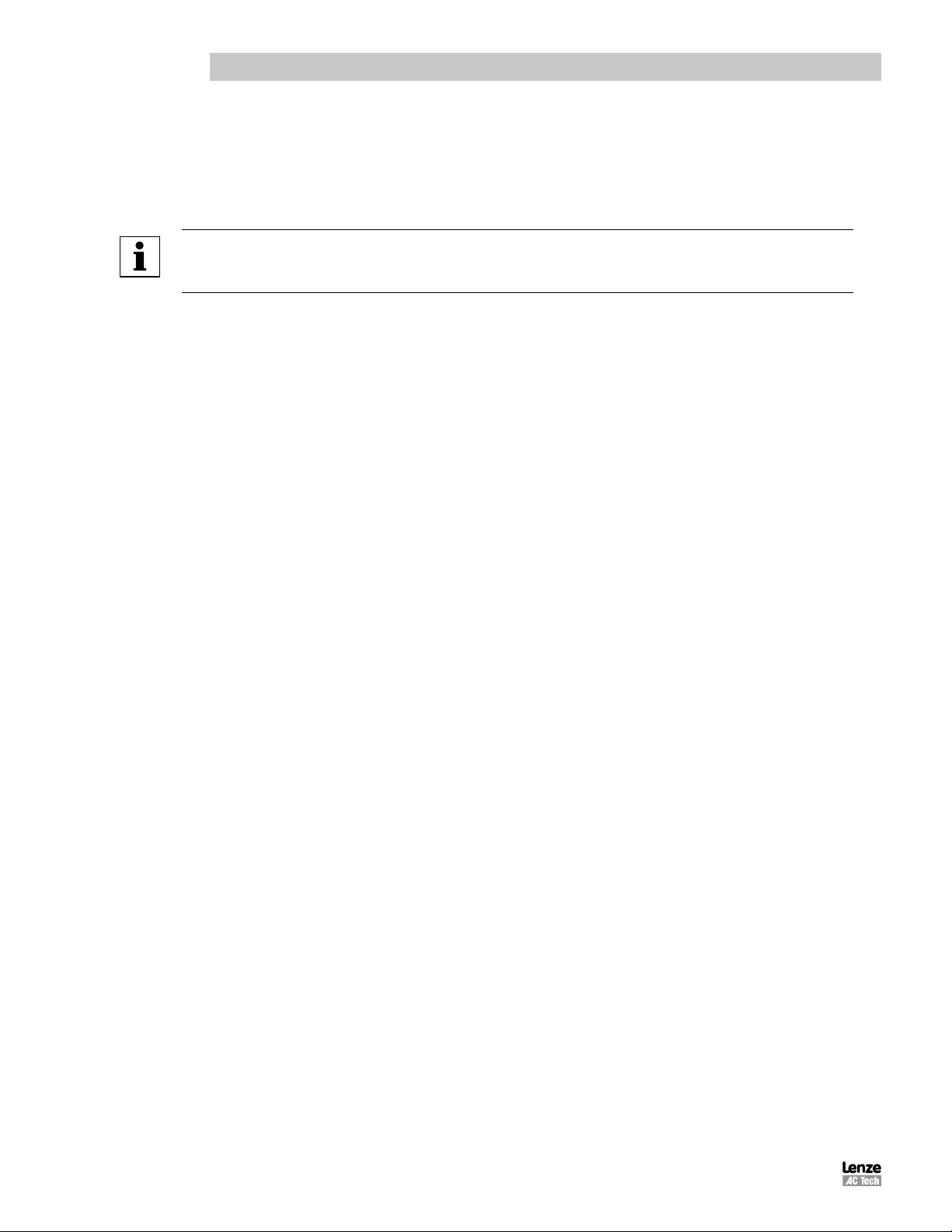

Basic Motion Program

Select [Indexer program] from the Node Tree. The Parameter View window will display the current User Program stored in the

drive. Note that if there is no valid program in the drive’s memory the program area will be empty.

WARNING!

This program will cause motion. The motor should be disconnected from the application (free to rotate)

or if a motor is connected, the shaft must be free to spin 10 revs forward and reverse from the location of

the shaft at power up. Also, the machine must be capable of 10 RPS and an accel / decel of 5 RPSS.

In the program area, clear any existing program and replace it with the following program:

UNITS=1

ACCEL = 5

DECEL = 5

MAXV = 10

ENABLE

MOVED 10

MOVEDISTANCE -10

END

After the text has been entered into the program

area, select the [Compile] icon from the toolbar. After

compilation is done, a “Compilation Error” message

should appear:

Click [OK] to dismiss the “Compliation error” dialog box. The cause of the compilation error will be displayed in the

Message window, located at the bottom of the MotionView OnBoard window. MotionView will also highlight the program

line where the error occurred.

UNITS=1

ACCEL = 5

DECEL = 5

MAXV = 10 ;

ENABLE

MOVED 10 ;

MOVEDISTANCE -10

END

The problem in this example is that “MOVEDISTANCE” is not a valid command. Change the text “MOVEDISTANCE”

to “MOVED”.

UNITS=1

ACCEL = 5

DECEL = 5

ENABLE

MOVED 10

MOVED -10

END

After editing the program, select the [Compile]

icon from the program toolbar. After compilation

is done, the “Compilation Complete” message box

should appear.

PM94P01C 11

Page 14

Introduction

The program has now been compiled without errors. Select [Compile & Load W Source] to load the program to the

drive’s memory. Click [OK] to dismiss the dialog box.

To Run the program, input A3 must be active to remove the hardware inhibit. Select the [Run] icon

on the program toolbar. The drive will start to execute the User Program. The motor will spin 10

revolutions in the CCW direction and then 10 revolutions in the CW direction. After all the code has

been executed, the program will stop and the drive will stay enabled.

To Restart the program, select the [Reset] icon on the program toolbar. This will disable the drive

and reset the program to execute from the start. The program does not run itself automatically. To

run the program again, select the [Run] icon on the toolbar.

Program Layout

When developing a program, structure is very important. It is recommended that the program be divided up into the

following 7 segments:

Header: The header defines the title of the program, who wrote the program and description of what

the program does. It may also include a date and revision number.

I/O List: The I/O list describes what the inputs and outputs of the drive are used for. For example input A1

might be used as a Start Switch.

Init & Set Var: Initialize and Set Variables defines the drives settings and system variables. For example

here is where acceleration, deceleration and max speed might be set.

Events: An Event is a small program that runs independently of the main program. This section is

used to define the Events.

Main Program: The Main Program is the area where the process of the drive is defined.

Sub-Routines: This is the area where any and all sub-routines should reside. These routines will be called

out from the Main Program with a GOSUB command.

Fault Handler: This is the area where the Fault Handler code resides. If the Fault handler is utilized this code

will be executed when the drive generates a fault.

The following is an example of a Pick and Place program divided up into the above segments.

***************************** HEADER **************************************

;Title: Pick and Place example program

;Author: Lenze - AC Technology

;Description: This is a sample program showing a simple sequence that

; picks up a part, moves to a set position and places the part

;**************************** I/O List ************************************

; Input A1 - not used

; Input A2 - not used

; Input A3 - Enable Input

; Input A4 - not used

; Input B1 - not used

; Input B2 - not used

; Input B3 - not used

; Input B4 - not used

; Input C1 - not used

; Input C2 - not used

; Input C3 - not used

; Input C4 - not used

; Output 1 - Pick Arm

; Output 2 - Gripper

; Output 3 - not used

; Output 4 - not used

PM94P01C12

Page 15

Introduction

;********************** Initialize and Set Variables ***********************

UNITS = 1

ACCEL = 75

DECEL =75

MAXV = 10

;V1 =

;V2 =

;********************** Events *********************************************

;Set Events handling here

;No events are currently defined in this program

;********************** Main Program **************************************

RESET_DRIVE: ;Place holder for Fault Handler Routine

WAIT UNTIL IN_A3: ;Make sure that the Enable input is made before continuing

ENABLE ;Enable output from drive to motor

PROGRAM_START: ;Place holder for main program loop

MOVEP 0 ;Move to Pick position

OUT1 = 1 ;Turn on output 1 to extend Pick arm

WAIT TIME 1000 ;Delay 1 sec to extend arm

OUT2 = 1 ;Turn on output 2 to Engage gripper

WAIT TIME 1000 ;Delay 1 sec to Pick part

OUT1 = 0 ;Turn off output 1 to Retract Pick arm

MOVED -10 ;Move 10 REVs to Place position

OUT1 = 1 ;Turn on output 1 to extend Pick arm

WAIT TIME 1000 ;Delay 1 sec to extend arm

OUT2 = 0 ;Turn off output 2 to Disengage gripper

WAIT TIME 1000 ;Delay 1 sec to Place part

OUT1 = 0 ;Retract Pick arm

GOTO PROGRAM_START ;Loop back and continuous execute main program loop

END

;********************** Sub-Routines ***************************************

;Enter Sub-Routine code here

;********************** Fault Handler Routine ********************

;Enter Fault Handler code here

ON FAULT

;No Fault Handler is currently defined in this program

ENDFAULT

Saving Configuration File to PC

The “Configuration File” consists of all the parameter settings for the drive, as well as the User Program. Once you are

done setting up the drive’s parameters and have written your User Program, you can save these setting to your computer.

To save the settings, select [Save All] from the Main toolbar. Then simply assign your program a name, (e.g. Basic

Motion), and click [Save] in the dialog box. The configuration file has a “.dcf” extension and by default will be saved to the

“My Documents” folder.

Loading Configuration File to the Drive

There are times when it is desired to import (or export) the program to another drive. Other times the program was

prepared off-line. In both scenarios, the program or configuration file needs to be loaded from the PC to the drive. To

load the configuration file to the drive, select [Load Configuration] from the Main toolbar. Then simply select the

program you want to load and click [Open] in the dialog box. MotionView will first compile the selected program. Once

compiled, the [Compilation Complete] dialog box should appear. Click [OK] to dismiss this dialog box. MotionView will

then load the selected file to the drive. When done, a “Parameters Successfully Loaded” or similar message will be

displayed in the Message Window.

PM94P01C 13

Page 16

Introduction

Motion source (Reference)

The PositionServo can be set up to operate in one of three modes: Torque, Velocity, or Position. The drive must

be given a command before it can initiate any motion. The source for commanding this motion is referred to as the

“Reference”. With the PositionServo you have two ways of commanding motion, or two types of References. When

the drive’s command signal is from an external source, for example a PLC or Motion Controller, it is referred to as an

External Reference. When the drive is being given its command from the User program or through one of the system

variables it is referred to as an Internal Reference.

Table 4: Setting the Reference

“Reference” Parameter Setting

Mode External Internal

Torque

Velocity

Position

User Program (Trajectory generator output)

Units

All motion statements in the drive work with User units. The statement on the first line of the test program, UNITS=1,

sets the relationship between User units and motor revolutions. For example, if UNITS=0.5 the motor will turn 1/2 of

a revolution when commanded to move 1 Unit. When the UNITS variable is set to zero, the motor will operate with

encoder counts as User units.

Analog input AIN1 System variable “IREF”

Analog input AIN1 System variable “IREF”

Step/Direction Inputs

Master Encoder Pulse Train Inputs

User Program/Interface

(Trajectory generator)

Time base

Time base is always in seconds i.e. all time-related values are set in USER UNITS/SEC.

Enable/Disable/Inhibit drive

Set “Enable switch function” to “Run”.

When the “Enable switch function” parameter is set to Run, and the Input A3 is made, the drive will be enabled. Likewise,

toggling input A3 to the off state will disable the drive.

- Select “Parameter” from the Parameter Tree Window.

- Select “Enable switch function” from the Parameter View Window.

- Select “Run” from the popup menu. This setting is primarily used when operating without any user’s program

in torque or velocity mode or as position follower with Step&Direction/Master Encoder reference.

Set “Enable switch function” to “Inhibit”.

In the example of the Enable switch function being set to Run the decision on when to enable and disable the drive is

determined by an external device, PLC or motion controller. The PositionServo’s User Program allows the programmer

to take that decision and incorporate it into the drive’s program. The drive will execute the User Program whether the

drive is enabled or disabled, however if a motion statement is executed while the drive is disabled, the F36 fault will

occur. When the “Enable switch function” parameter is set to Inhibit, and Input A3 is on, the drive will be disabled and

remain disabled until the ENABLE statement is executed by the User Program.

- Select “Parameter” from the Parameter Tree Window.

- Select “Enable switch function” from the Parameter View Window.

- Select “Inhibit” from the popup menu.

PM94P01C14

Page 17

Introduction

Faults

When a fault condition has been detected by the drive, the following actions will occur:

- Drive will Immediately be placed in a Disabled Condition.

- Motion Stack will be flushed of any Motion Commands

- Execution of the user program will be terminated and program control will be handed over to the Fault Handler

section. If no Fault handler is described then program execution will terminate. See fault handler section.

- A fault code defining the nature of the drive trip will be written to the DFAULTS system variable and can be

accessed by the fault handler. Refer to section 2.13 for a list of fault codes.

- The fault code will will be displayed on the drive display.

- Dedicated “Ready” output will turn off.

- Any Output with assigned special function “Fault” will turn on.

- Any Output with assigned special function “ready/enabled” will turn off.

- The “enable” status indicator on the drive display will turn off indicating drive in disabled state.

Clearing a fault condition can be done in one of the following ways:

- Select the [Reset] button from the toolbar.

- Execute the RESUME statement at the end of the Fault Handler routine (see Fault Handler

example).

- Send “Reset” command over the Host Interface.

- Cycle power (hard reset).

Fault Handler

The Fault Handler is a code segment that will be executed when the drive is experiencing a fault. The fault handler allows

the programmer to analyze the type of fault and define a recovery process for the drive and permits the continuation of

program execution. While the drive is executing the Fault Handler Routine the drive is disabled and therefore will not

be able to detect any additional faults that might occur. Fault handler code should be treated as the drive’s first reaction

on fault. While it executes, the drive will not respond to any I/O, interface commands etc. Therefore the user should

use the fault handler to manipulate time critical and safety related I/O and variables and then exit the Fault Handler

Routine by executing a “RESUME” statement for a full stop after statement. The Resume statement permits program

execution to leave the fault handler and resume back in the main program section of the user code. Use the Resume

statement to jump back to a section of the main program that designates the recovery process for the fault. Waiting

in Fault handler for I/O state change or for interface command is not allowed. Do that in the code where you point the

“RESUME” statement.

Without Fault Handler

To simulate a fault, restart the Pick and Place example program. While the program is running, switch the ENABLE

input IN_A3 to the off state. This will cause the drive to generate an F_36 fault (Drive Disabled) and put the drive

into Fault Mode. While the drive is in Fault Mode, any digital output currently active will remain active and any output

deactivated will remain deactivated, excluding the dedicated ready output and any output that has been assigned

special functionality. The program execution will stop and any motion moves will be terminated. In this example the Pick

and Place arm may not be in a desired location when the program goes into the fault mode.

PM94P01C 15

Page 18

Introduction

With Fault Handler

Add the following code to the end of your sample program. While the program is running, switch the ENABLE input

IN_A3, to the off state. This will cause the drive to generate an F_36 fault (Drive Disabled) and put the drive into a Fault

Mode. From this point the Fault Handler Routine will take over.

F_PROCESS:

WAIT UNTIL IN_A4==1 ;Wait until reset switch is made

WAIT UNTIL IN_A4==0 ;and then released before

GOTO RESET_DRIVE ;returning to the beginning of the program

END

;*********************** Sub-Routines **************************************

Enter Sub-Routines here;

;*********************** Fault Handler Routine *****************************

ON FAULT ;Statement starts fault handler routine

;Motion stopped, drive disabled, and events no longer

;scanned while executing the fault handler routine.

OUT2 = 0 ;Output 1 off to Disengage gripper.

;This will drop the part in the gripper

OUT1 = 0 ;Retract Pick arm to make sure it is up and out of the way

RESUME F_PROCESS ;program restarts from label F_PROCESS

ENDFAULT ;fault handler MUST end with this statement

NOTE

The following statements can not be used inside the Fault Handler Routine:

- ENABLE

- WAIT

- MOVE

- MOVED

- MOVEP

- MOVEDR

- MOVEPR

- MDV

- MOTION SUSPEND

- MOTION RESUME

- GOTO, GOSUB

- JUMP

- ENABLE

- VELOCITY ON/OFF

Refer to section 2.1 for additional details and the Language Reference section for the statement

“ON FAULT/ENDFAULT”.

PM94P01C16

Page 19

Introduction

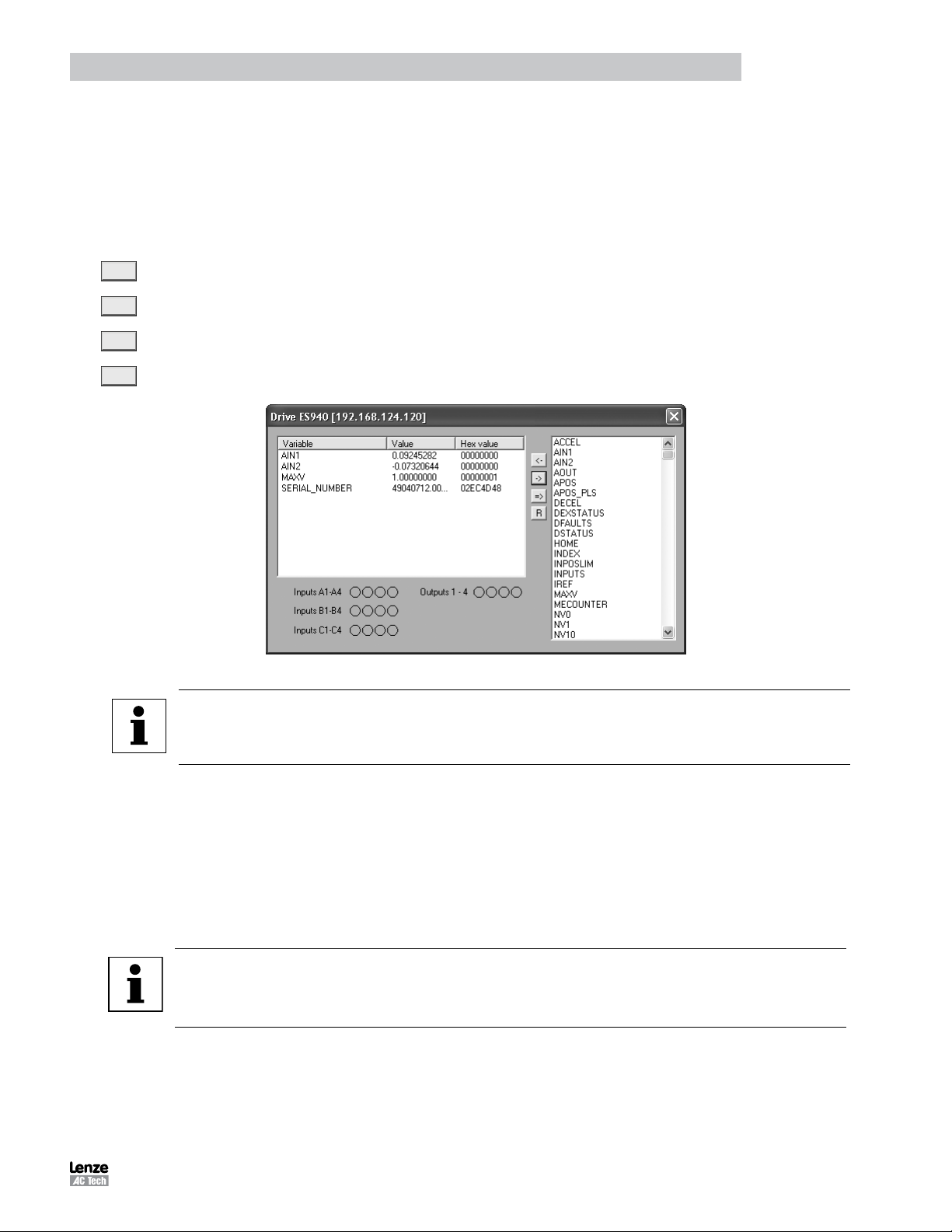

1.5 Using Advanced Debugging Features

To debug a program or view the I/O, open the Diagnostic window by clicking on the [Tools] in the Parmeter (Node)

Tree list then click on the [Parameter & I/O View] button. The Diagnostic window will open. This window allows the

programmer to monitor and set variables, and to view status of drive digital inputs and outputs.

Click on a variable in the variable list on the right-hand side to select that parameter

< -

- >

= >

R

Use the left arrow button to add variables after selecting a variable.

Use the right arrow button to remove variables after selecting a variable.

Use the double right arrow button to remove all variables in left-hand Diagnostic window.

Use the [R] (Refresh) button to refresh variable values.

Figure 6: Variable Diagnostic Display

NOTE

Write-only variables cannot be read. Attempts to either display a write-only variable in the diagnostic

window or to read a write-only variable via network communications can show erroneous data.

1.6 Inputs and Outputs

Analog Input and Output

- The PositionServo has two analog inputs. These analog inputs are utilized by the drive as System Variables and

are labeled “AIN1” and “AIN2”. Their values can be directly read by the User Program or via a Host Interface.

Their value can range from -10 to +10 and correlates to ±10 volts analog input.

- The PositionServo has one analog output. This analog output is utilized by the drive as a System Variable and

is labeled “AOUT”. It can be directly written by the User Program or via a Host Interface. Its value can range

from -10 to +10 which correlates to ± 10 volts analog input.

NOTE

If an analog output is assigned to any special function from MotionView, writing to AOUT from the

User Program will not change its value. If an analog output is set to “Not assigned” then it can be

controlled by writing to the AOUT variable.

PM94P01C 17

Page 20

Introduction

Digital Inputs

- The PositionServo has twelve digital inputs that are utilized by the drive for decision making in the User Program.

Example uses: travel limit switches, proximity sensors, push buttons and hand shaking with other devices.

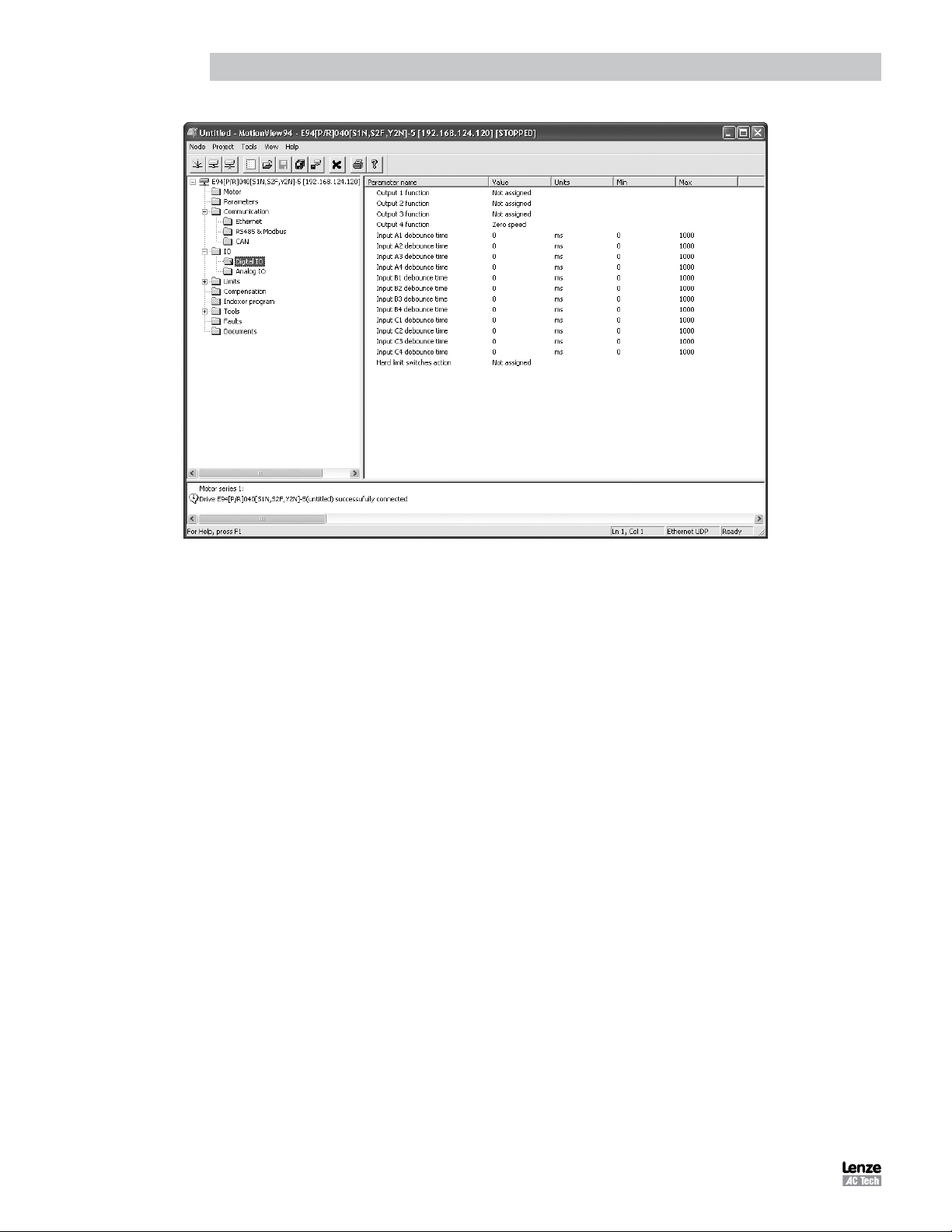

- Each input can be assigned an individual debounce time via MotionView. From the Parameter Tree, select [IO].

Then select the [Digital Input] folder. The debounce times will be displayed in the Parameter View Window.

Debounce times can be set between 0 and 1000 ms (1ms = 0.001 sec). Debounce times can also be set via

variables in the user program.

- The twelve inputs are separated into three groups: A, B and C. Each group has four inputs and share one

common: Acom, Bcom and Ccom respectfully. The inputs are labeled individually as IN_A1 - IN_A4, IN_B1

- IN_B4 and IN_C1 - IN_C4.

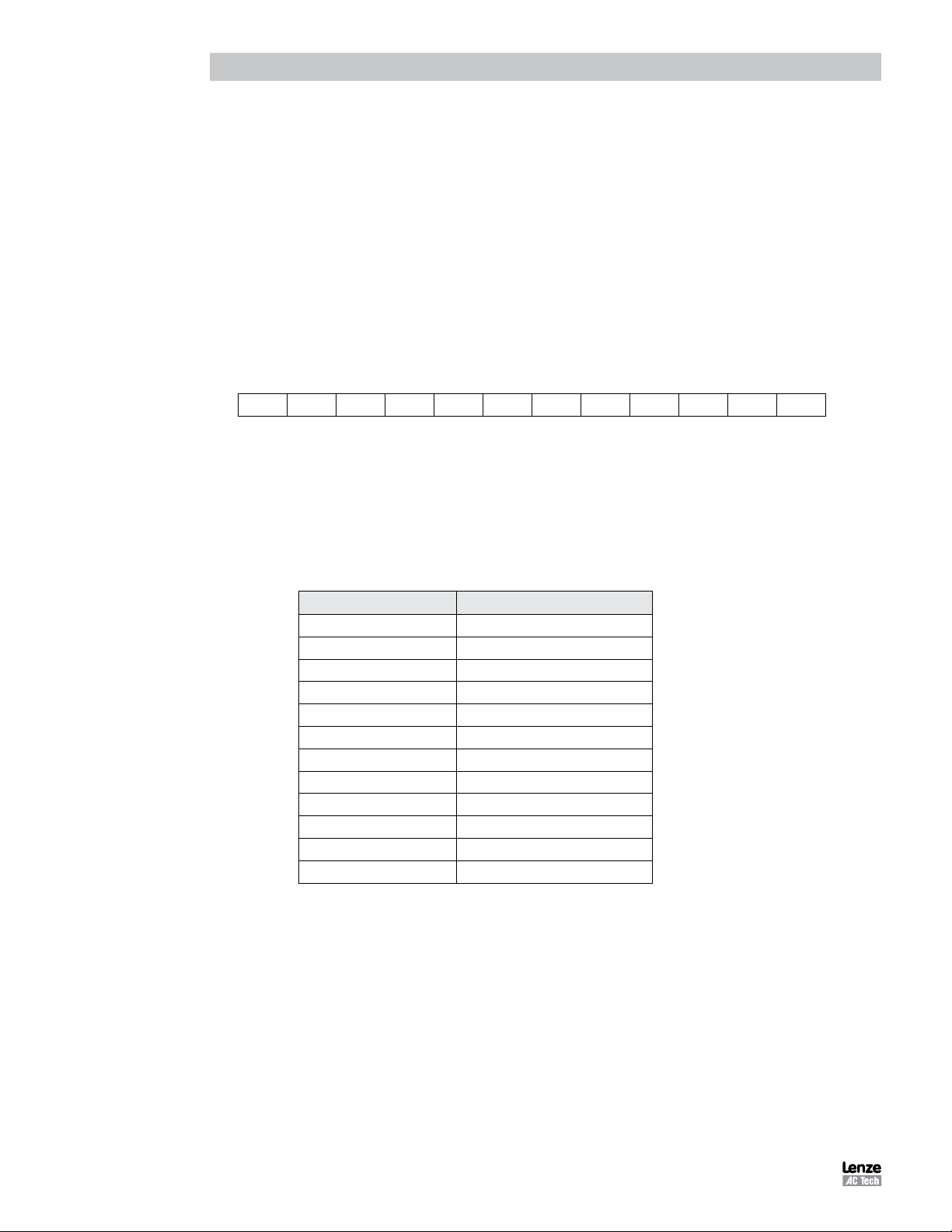

- In addition to monitoring each input individually, the status of all twelve inputs can be represented as one binary

number. Each input corresponds to 1 bit in the INPUTS system variable. Use the following format:

System

Variable

INPUTS

Bit # 11 10 9 8 7 6 5 4 3 2 1 0

Input

Name

C4 C3 C2 C1 B4 B3 B2 B1 A4 A3 A2 A1

- Some inputs can have additional special functionality such as Travel Limit switch, Enable input, and Registration

input. Configuration of these inputs is done from MotionView or through variables in the user program. Input

special functionality is summarized in the table below and in the following sections. The current status of the

drive’s inputs is available to the programmer through dedicated System Flags or as bits of the System Variable

INPUTS. Table 5 summarizes the special functions for the inputs.

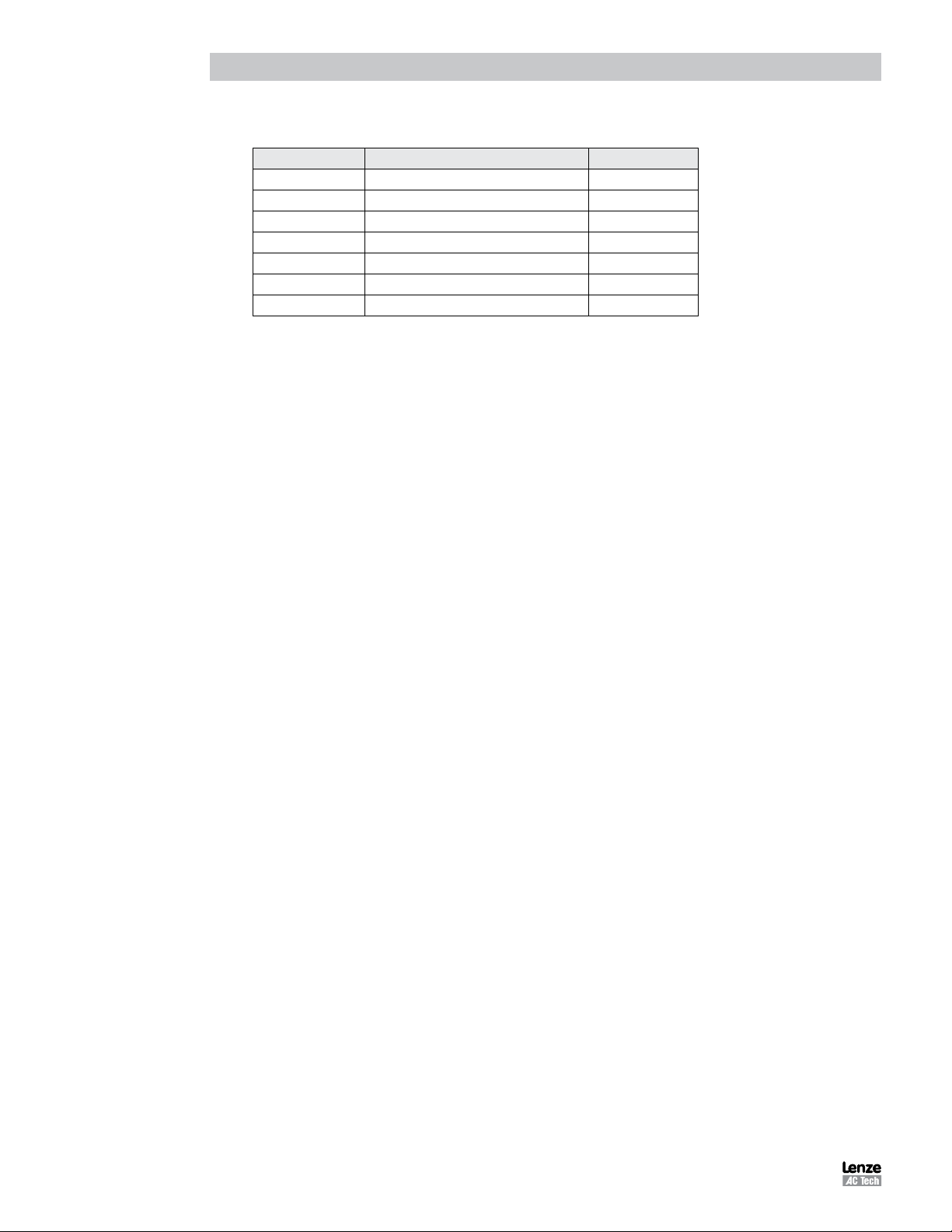

Table 5: Input Functions

Input Special Function

Input A1 negative limit switch

Input A2 positive limit switch

Input A3 Inhibit/Enable input

Input A4 N/A

Input B1 N/A

Input B2 N/A

Input B3 N/A

Input B4 N/A

Input C1 N/A

Input C2 N/A

Input C3 Registration sensor input

Input C4 N/A

PM94P01C18

Page 21

Introduction

Read Digital Inputs

The Pick and Place example program has been modified below to utilize the “WAIT UNTIL” inputs statements in place

of the “WAIT TIME” statements. IN_A1 and IN_A4 will be used as proximity sensors to detect when the pick and place

arm is extended and when it is retracted. When the arm is extended, IN_A1 will be in an ON state and will equal “1”.

When the arm is retracted, IN_A4 will be in an ON state and will equal “1”.

;********************* Main Program ****************************************

RESET_DRIVE: ;Place holder for Fault Handler Routine

WAIT UNTIL IN_A3 ;Make sure that the Enable input is made before continuing

ENABLE

PROGRAM_START:

WAIT UNTIL IN_A4==1 ;Make sure Arm is retracted

MOVEP 0 ;Move to Pick position

OUT1 = 1 ;Turn on output 1 to extend Pick arm

WAIT UNTIL IN_A1==1 ; Arm extend

OUT2 = 1 ;Turn on output 2 to Engage gripper

WAIT TIME 1000 ;Delay 1 sec to Pick part

OUT1 = 0 ;Turn off output 1 to Retract Pick arm

WAIT UNTIL IN_A4==1 ;Make sure Arm is retracted

MOVED -10 ;Move 10 REVs to Place position

OUT1 = 1 ;Turn on output 1 on to extend Pick arm

WAIT UNTIL IN_A1==1 ; Arm is extended

OUT2 = 0 ;Turn off output 2 to Disengage gripper

WAIT TIME 1000 ;Delay 1 sec to Place part

OUT1 = 0 ;Retract Pick arm

WAIT UNTIL IN_A4==1 ;Arm is retracted

GOTO PROGRAM_START

END

Once the above modifications have been made, export the program to file and save it as “Pick and Place with I/O”, then

compile, download and test the program.

ASSIGN & INDEX - Using inputs to generate predefined indexes

“INDEX” is a variable on the drive that can be configured to represent a certain group of inputs as a binary number.

“ASSIGN” is the command that designates which inputs are utilized and how they are configured.

Below the Pick and Place program has been modified to utilize this “INDEX” function. The previous example program

simply picked up a part and moved it to a place location. For demonstration purposes we will add seven different place

locations. These locations will be referred to as Bins. What Bin the part is placed in will be determined by the state of

three inputs, B1, B2 and B3.

Bin 1 - Input B1 is made

Bin 2 - Input B2 is made

Bin 3 - Inputs B1 and B2 are made

Bin 4 - Input B3 is made

Bin 5 - Inputs B1 and B3 are made

Bin 6 - Inputs B2 and B3 are made

Bin 7 - Inputs B1, B2 and B3 are made

The “ASSIGN” command is used to assign the individual input to a bit in the “INDEX” variable. ASSIGN INPUT <input

name> AS BIT <bit #>

;*********************** Initialize and Set Variables *******************

ASSIGN INPUT IN_B1 AS BIT 0 ;Assign the Variable INDEX to equal 1 when IN_B1 is made

ASSIGN INPUT IN_B2 AS BIT 1 ;Assign the Variable INDEX to equal 2 when IN_B2 is made

ASSIGN INPUT IN_B3 AS BIT 2 ;Assign the Variable INDEX to equal 4 when IN_B4 is made

PM94P01C 19

Page 22

Introduction

Table 6: Bin Location, Inputs & Index Values

Bin Location Input State INDEX Value

Bin 1 Input B1 is made 1

Bin 2 Input B2 is made 2

Bin 3 Inputs B1 and B2 are made 3

Bin 4 Input B3 is made 4

Bin 5 Inputs B1 and B3 are made 5

Bin 6 Inputs B2 and B3 are made 6

Bin 7 Inputs B1, B2 and B3 are made 7

The Main program has been modified to change the end place position based on the value of the “INDEX” variable.

;************************** Main Program **********************************

ENABLE

PROGRAM_START:

WAIT UNTIL IN_A4==1 ;Make sure Arm is retracted

MOVEP 0 ;Move to (ABS) to Pick position

OUT1 = 1 ;Turn on output 1 to extend Pick arm

WAIT UNTIL IN_A1==1 ;Arm extends

OUT2 = 1 ;Turn on output 2 to Engage gripper

WAIT TIME 1000 ;Delay 1 sec to Pick part

OUT1 = 0 ;Turn off output 1 to Retract Pick arm

WAIT UNTIL IN_A4==0 ;Make sure Arm is retracted

IF INDEX==1 ;In this area we use the If statement to

GOTO BIN_1 ;check and see what state inputs B1, B2 & B3

ENDIF ;are in.

IF INDEX==2 ; INDEX = 1 when input B1 is made

GOTO BIN_2 ; INDEX = 2 when input B2 is made

ENDIF ; INDEX = 3 when input B1 & B2 are made.

. ; INDEX = 4 when input B3 is made

. ; INDEX = 5 when input B1 & B3 are made.

. ; INDEX = 6 when input B2 & B3 are made.

IF INDEX==7 ; INDEX = 7 when input B1, B2 & B3 are made

GOTO BIN_7 ;We can now direct the program to one of seven

ENDIF ;locations based on three inputs.

BIN_1: ;Set up for Bin 1

MOVEP 10 ;Move to Bin 1 location

GOTO PLACE_PART ;Jump to place part routine

BIN_2: ;Set up for Bin 2

MOVEP 20 ;Move to Bin 2 location

GOTO PLACE_PART ;Jump to place part routine

BIN_7: ;Set up for Bin 7

MOVEP 70 ;Move to Bin 7 location

GOTO PLACE_PART ;Jump to place part routine

PLACE_PART:

OUT1 = 1 ;Turn on output 1 to extend Pick arm

WAIT UNTIL IN_A4 == 1 ;Arm extends

OUT2 = 0 ;Turn off output 2 to Disengage gripper

WAIT TIME 1000 ;Delay 1 sec to Place part

OUT1 = 0 ;Retract Pick arm

WAIT UNTIL IN_A4 == 0 ;Arm is retracted

GOTO PROGRAM_START

END

PM94P01C20

Page 23

Introduction

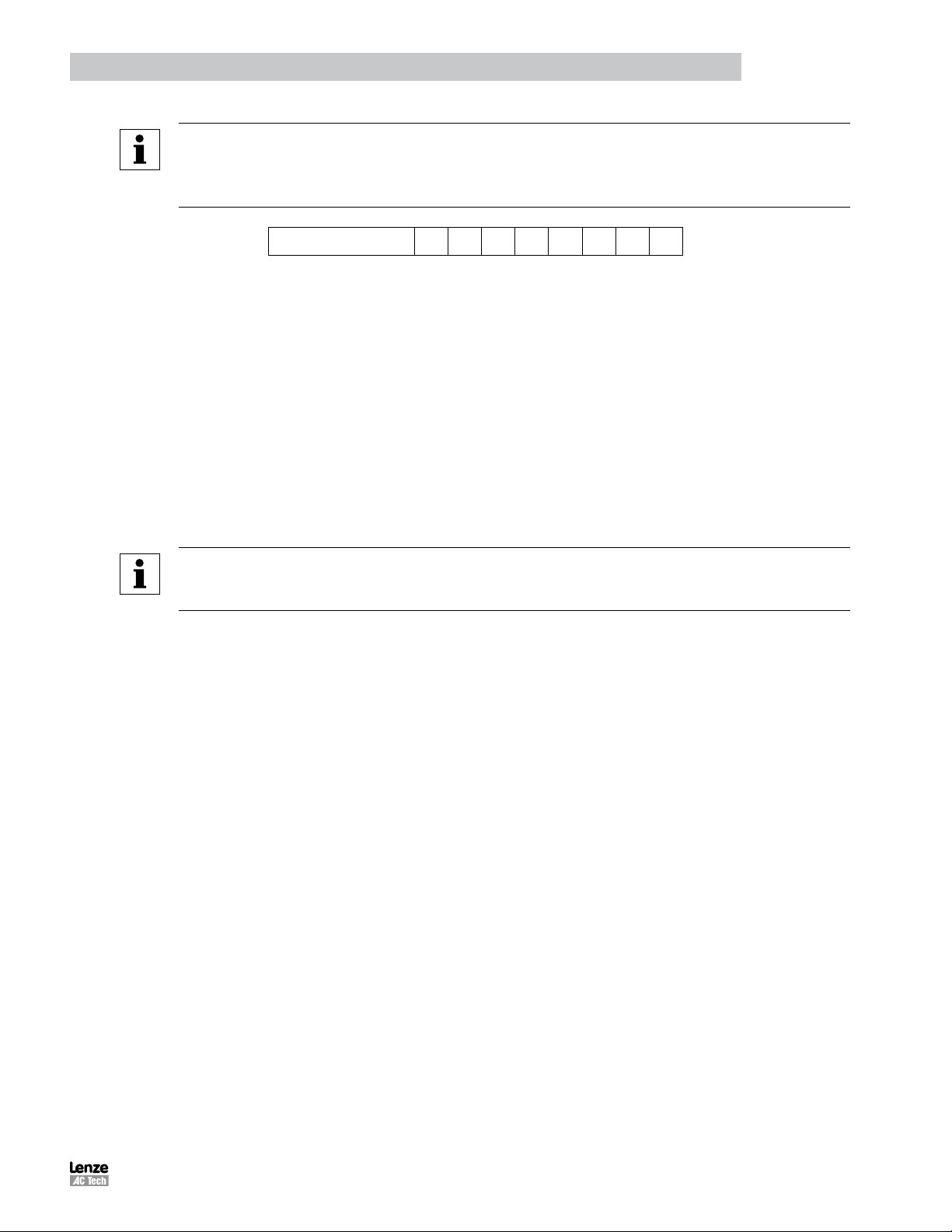

NOTE

Any one of the 12 inputs can be assigned as a bit position within the INDEX variable. Only bits 0

through 7 can be used with the INDEX variable. Bits 8-31 are not used and are always set to 0.

Unassigned bits in the INDEX variable are set to 0.

BITS 8-31 (not used) A1 0 A2 A4 0 0 0 0

Limit Switch Input Functions

Inputs A1 and A2 can be configured as special purpose inputs from the [Digital IO] folder in MotionView. They can be set to

one of three settings:

- The “Not assigned” setting designates the inputs as general purpose inputs which can be utilized by the User

Program.

- The “Fault” setting will configure A1 and A2 as Hard Limit Switches. When either input is made the drive will

be disabled, the motor will come to an uncontrolled stop, and the drive will generate a fault. If the negative limit

switch is activated, the drive will display an F-33 fault. If the positive limit switch is activated the drive will display

an F32 fault.

- The “Stop and fault” setting will configure A1 and A2 as End of Travel limit switches. When either input is

made the drive will initiate a rapid stop before disabling the drive and generating an F34 or F35 fault (refer to

section 2.15 for details). The speed of the deceleration will be set by the value stored in the “QDECEL” System

Variable.

NOTE

The “Stop and Fault” function is available in position mode only, (“Drive mode” is set to “Position”).

In all other cases, the Stop and Fault function will act the same as the Fault function.

To set this parameter, select the [IO] folder from the Parameter Tree. Then select the [Digital IO] folder. From the

Parameter View Window, use the pull-down menu next to [Hard Limit Switches Action] to select the status: Not

Assigned, Fault or Stop and Fault.

Digital Outputs Control

- The PositionServo has 5 digital outputs. The “RDY” or READY output is dedicated and will only come on when

the drive is enabled, i.e. in RUN mode. The other outputs are labeled OUT1 - OUT4.

- Outputs can be configured as Special Purpose Outputs. If an output is configured as a Special Purpose Output

it will activate when the state assigned to it becomes true. For example, if an output is assigned the function

“Zero speed”, the assigned output will come on when the motor is not in motion. To configure an output as a

Special Purpose Output, select the [IO] folder from the Parameter Tree. Then select the [Digital IO] folder. From

the Parameter View Window, select the “Output function” parameter you wish to set (1, 2, 3 or 4).

- Outputs that are configured as “Not assigned” can be activated either via the User Program or from a host

interface. If an output is assigned as a Special Purpose Output, neither the user program nor the host interface

can overwrite its status.

- The Systems Variable “OUTPUTS” is a read/write variable that allows the User Program, or host interface,

to monitor and set the status of all four outputs. Each output allocates 1 bit in the OUTPUTS variable. For

example, if you set this variable equal to 15 in the User Program,i.e. 1111 in binary format, then all 4 outputs

will be turned on.

- The example below summarizes the output functions and corresponding System Flags. To set the output, write

any non-0 value (TRUE) to its flag. To clear the output, write a 0 value (FALSE) to its flag. You can also use

flags in an expression. If an expression is evaluated as TRUE then the output will be turned ON. Otherwise, it

will be turned OFF.

OUT1 = 1 ;turn OUT1 ON

OUT2 = 10 ;any value but 0 turns output ON

OUT3 = 0 ;turn OUT3 OFF

OUT2 = APOS>3 && APOS<10 ;ON when position within window, otherwise OFF

PM94P01C 21

Page 24

Introduction

Figure 7: Digital IO Folder

1.7 Events

A Scanned Event is a small program that runs independently of the main program. An event statement establishes a

condition that is scanned on a regular basis. Once established, the scanned event can be enabled and disabled in the

main program. If condition becomes true and EVENT is enabled, the code placed between EVENT and ENDEVENT

executes. Scanned events are used to trigger the actions independently of the main program.

In the following example the Event “SPRAY_GUNS_ON” will be setup to turn Output 3 on when the drive’s position

becomes greater than 25. Note: the event will be triggered only at the instant when the drive position becomes greater

than 25. It will not continue to execute while the position is greater than 25. (i.e. the event is triggered by the transition

in logic from false to true). Note also that main program doesn’t need to be interrupted to perform this action.

;*********************** EVENT SETUP ***************************************

EVENT SPRAY_GUNS_ON APOS>25 ;Event will trigger as position passes 25 in pos dir.

OUT3=1 ;Turn on the spray guns (out 3 on)

ENDEVENT ;End event

;***************************************************************************

Enter the Event code in the EVENT SETUP section of the program. To Setup an Event, the “EVENT” command must

be entered. This is followed by the Event Name “SPRAY_GUNS_ON” and the triggering mechanism, “APOS>25”.

After that a sequence of programming statements can be entered once the event is triggered. In our case, we will turn

on output 3. To end the Event, the “ENDEVENT” command must be used. Events can be activated (turned on) and

deactivated (turned off) throughout the program. To turn on an Event, the “EVENT” command is entered, followed by the

Event Name “SPRAY_GUNS_ON”. This is completed by the desired state of the Event, “ON” or “OFF”. Refer to Section

2.10 for more on Scanned Events.

;***************************************************************************

EVENT SPRAY_GUNS_ON ON ;Enable ‘spray guns on’ event

;***************************************************************************

Two Scanned Events have been added to the Pick and Place program below to trigger a spray gun on and off. The

Event will be triggered after the part has been picked up and is passing in front of the spray guns (position greater than

25). Once the part is in position, output 3 is turned on to activate the spray guns. When the part has passed by the spray

guns, (position greater than 75), output 3 is turned off, deactivating the spray guns.

PM94P01C22

Page 25

Introduction

;*********************** Events ********************************************

EVENT SPRAY_GUNS_ON APOS>25 ;Event will trigger as position passes 25 in pos dir.

OUT3=1 ;Turn on the spray guns (out 3 on)

ENDEVENT ;End event

EVENT SPRAY_GUNS_OFF APOS>75 ;Event will trigger as position passes 75 in pos dir.

OUT3=0 ;Turn off the spray guns (out 3 off)

ENDEVENT ;End event

;*********************** Main Program **************************************

PROGRAM_START: ;Place holder for main program loop

ENABLE ;Enable output from drive to motor

EVENT SPRAY_GUNS_ON ON ;Enable ‘spray guns on’ event

EVENT SPRAY_GUNS_OFF ON ;Enable ‘spray guns off’ event

WAIT UNTIL IN_A4==1 ;Make sure Arm is retracted

MOVEP 0 ;Move to Pick position

OUT1 = 1 ;Turn on output 1 to extend Pick arm

WAIT UNTIL IN_A1==1 ;Arm extends

OUT2 = 1 ;Turn on output 2 to Engage gripper

WAIT TIME 1000 ;Delay 1 sec to Pick part

OUT1 = 0 ;Turn off output 1 to Retract Pick arm

WAIT UNTIL IN_A4==1 ;Make sure Arm is retracted

MOVEP 100 ;Move to Place position

OUT1 = 1 ;Turn on output 1 to extend Pick arm

WAIT UNTIL IN_A1==1 ;Arm extends

OUT2 = 0 ;Turn off output 2 to Disengage gripper

WAIT TIME 1000 ;Delay 1 sec to Place part

OUT1 = 0 ;Retract Pick arm

WAIT UNTIL IN_A4==1 ;Arm is retracted

GOTO PROGRAM_START ;Loop back and continuously execute main program loop

END

1.8 Variables and Define Statement

In the previous program for the pick and place machine constants were used for position limits to trigger the event and

turn the spray gun ON and OFF. If limits must be calculated based on some parameters unknown before the program

runs (like home origin, material width, etc.), then use the User Variables. The PositionServo provides 32 User Variables

V0-V31 and 32 User Network Variables NV0-NV31. In the program below, the limit APOS (actual position) is compared

to V1 for an ON event and V2 for an OFF event. The necessary limit values could be calculated earlier in the program

or supplied by an HMI or host PC.

The DEFINE statement can be used to assign a name to a constant, variable or drive Input/Output. In the program below,

constants 1 and 0 are defined as Output_On and Output_Off. DEFINE is a pseudo statement, i.e it is not executed by

the program interpreter, but rather substitutes expressions in the subsequent program at the time of compilation.

DEFINE Value2 2

DEFINE Value10 10

V1 = Value2+Value10 ; result is 12

V1 = 2+10 ; does exactly same as above, the result is 12

PM94P01C 23

Page 26

Introduction

;*********************** Initialize and Set Variables **********************

UNITS = 1 ;Define units for program, 1=revolution of motor shaft

ACCEL = 5 ;Set acceleration rate for motion command

DECEL = 5 ;Set deceleration rate for motion command

MAXV = 10 ;Maximum velocity for motion commands

V1 = 25 ;Set Variable V1 equal to 25

V2 = 75 ;Set Variable V2 equal to 75

DEFINE Output_On 1 ;Define Name for output On

DEFINE Output_Off 0 ;Define Name for output Off

;*********************** EVENTS *******************************************

EVENT SPRAY_GUNS_ON APOS > V1 ;Event will trigger as position passes 25 in pos dir.

OUT3= Output_On ;Turn on the spray guns (out 3 on)

ENDEVENT ;End event

EVENT SPRAY_GUNS_OFF APOS > V2 ;Event will trigger as position passes 75 in pos dir.

OUT3= Output_Off ;Turn off the spray guns (out 3 off)

ENDEVENT ;End even

;*********************** Main Program *************************************

PROGRAM_START: ;Place holder for main program loop

ENABLE ;Enable output from drive to motor

EVENT SPRAY_GUNS_ON ON ;Enable the ‘spray guns on’ event

EVENT SPRAY_GUNS_OFF ON ;Enable the ‘spray guns off’ event

WAIT UNTIL IN_A4==1 ;Ensure Arm is retracted before running the program

MOVEP 0 ;Move to position 0 to pick part

OUT1 = Output_On ;Turn on output 1 to extend Pick arm

WAIT UNTIL IN_A1==1 ;Check input to make sure Arm is extended

OUT2 = Output_On ;Turn on output 2 to Engage gripper

WAIT TIME 1000 ;Delay 1 sec to Pick part

OUT1 = Output_Off ;Turn off output 1 to Retract Pick arm

WAIT UNTIL IN_A4==1 ;Check input to make sure Arm is retracted

MOVED 100 ;Move to Place position

OUT1 = Output_On ;Turn on output 1 to extend Pick arm

WAIT UNTIL IN_A1==1 ;Check input to make sure Arm is extended

OUT2 = Output_Off ;Turn off output 2 to Disengage gripper

WAIT TIME 1000 ;Delay 1 sec to Place part

OUT1 = Output_Off ;Retract Pick arm

WAIT UNTIL IN_A4==1 ;Check input to make sure Arm is retracted

GOTO PROGRAM_START ;Loop back and continuously execute main program loop

END

1.9 IF/ELSE Statements

An IF/ELSE statement allows the user to execute one or more statements conditionally. The programmer can use an

IF or IF/ELSE construct:

Single IF example:

This example increments a counter, Variable “V1”, until the Variable, “V1”, is greater than 10.

Again:

V1=V1+1

IF V1>10

V1=0

ENDIF

GOTO Again

END

PM94P01C24

Page 27

Introduction

Position Feedback

IF/ELSE example:

This example checks the value of Variable V1. If V1 is greater than 3, then V2 is set to 1. If V1 is not greater than 3,

then V2 is set to 0.

IF V1>3

V2=1

ELSE

V2=0

ENDIF

Whether you are using an IF or IF/ELSE statement the construct must end with ENDIF keyword.

1.10 Motion

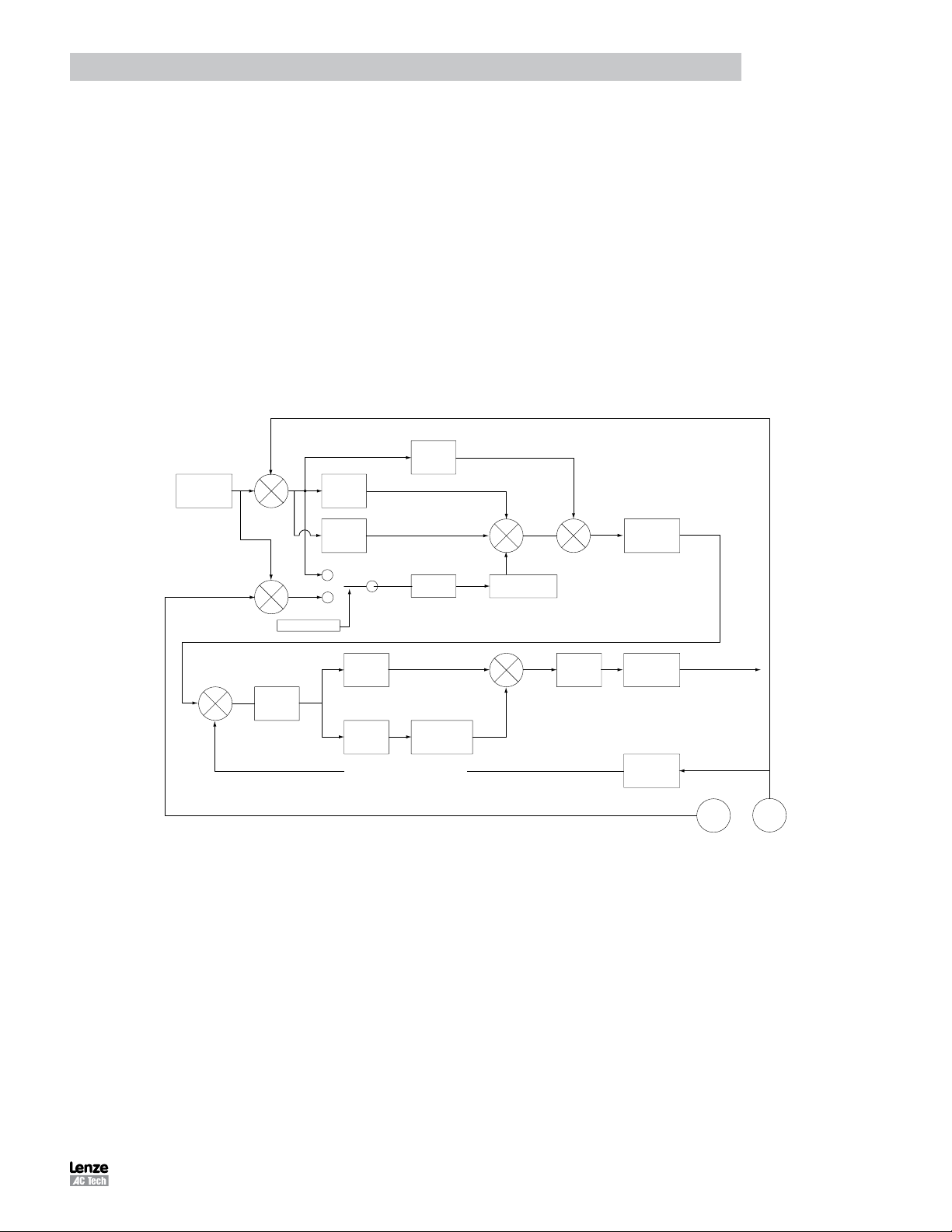

Figure 8 illustrates the Position and Velocity regulator of the PositionServo drive.

Kff is automatically calculated

Kff term

I term

+

+

I term Limit and

unti wind-up

+

+

+

Biquad

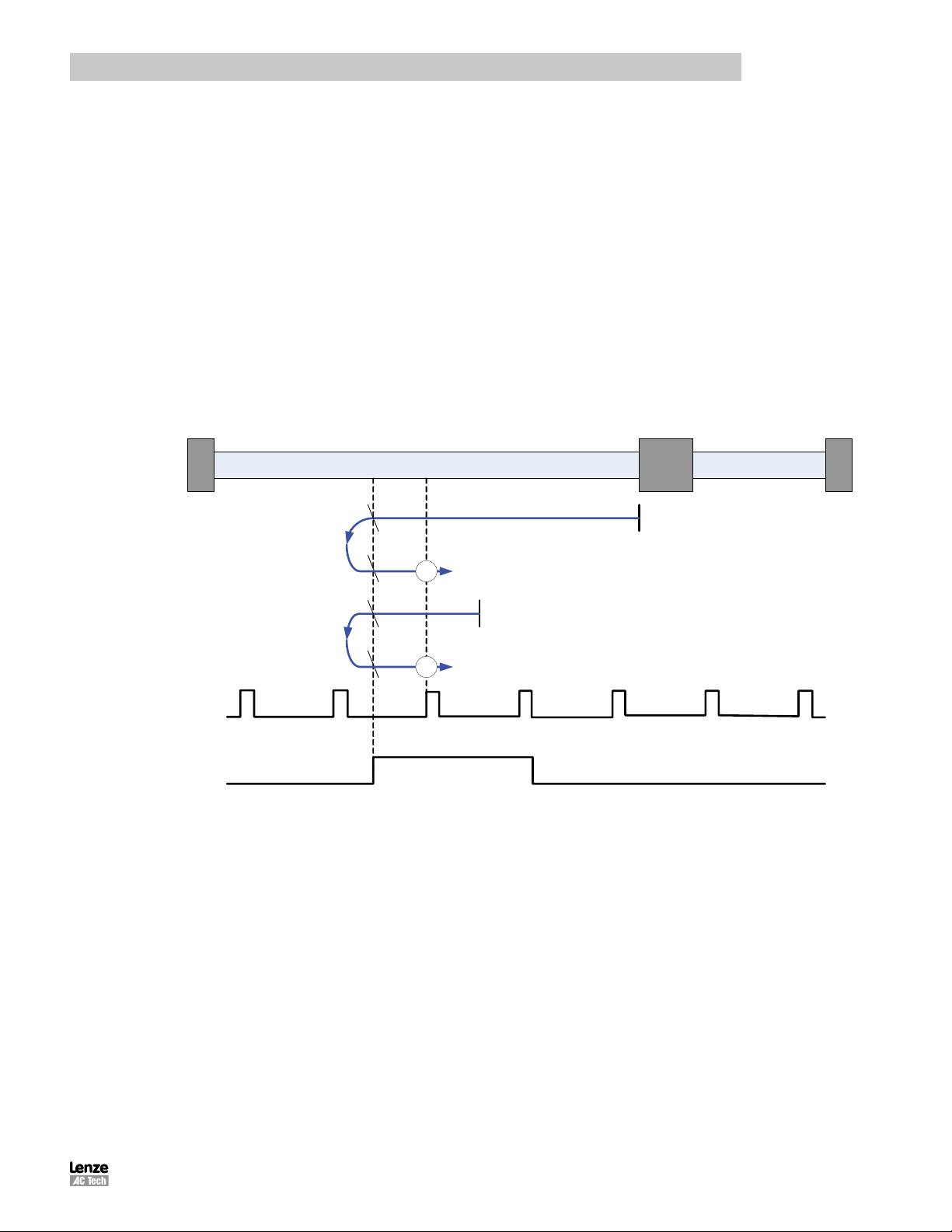

Convergence

Filter

Position

Command

+

+

-

-

P term

D term

=0

=1

#41 Second Encoder

To Torque Amplifier

Current Command

Secondary

Encoder

Primary

Encoder

Velocity Command

+

-

Velocity

Window

P term

D term

Mechanical Velocity Feedback

I term Limit and

unti wind-up

+

+

Current

Limiter

Biquad

Convergence

Filter

Velocity

Estimator

Figure 8: PositionServo Position and Velocity Regulator’s Diagram

The “Position Command”, as shown in the regulator’s diagram (Figure 9), is produced by a Trajectory Generator.

The Trajectory Generator processes the motion commands produced by the User’s program to calculate the position

increment or decrement, also referred to as the “index” value, for every servo loop. This calculated target (or theoretical)

position is then supplied to the Regulator input.

The main purpose of the Regulator is to set the motors position to match the target position created by the Trajectory

Generator. This is done by comparing the input from the Trajectory Generator with the position feedback from the

encoder or resolver, to control the torque and velocity of the motor. Of course there will always be some error in the

position following. Such error is referred to as “Position Error” and is expressed as follows:

Position Error = Target Position - Actual Position

When the actual Position Error exceeds a certain threshold value a “Position Error limit”, fault (F_PE) will be generated.

The Position Error limit and Position Error time can be set under the Node Tree “Limits”/ “Position Limits” in MotionView.

The Position Error time specifies how long the actual position error can exceed the Position Error limit before the fault

is generated.

PM94P01C 25

Page 28

Introduction

T

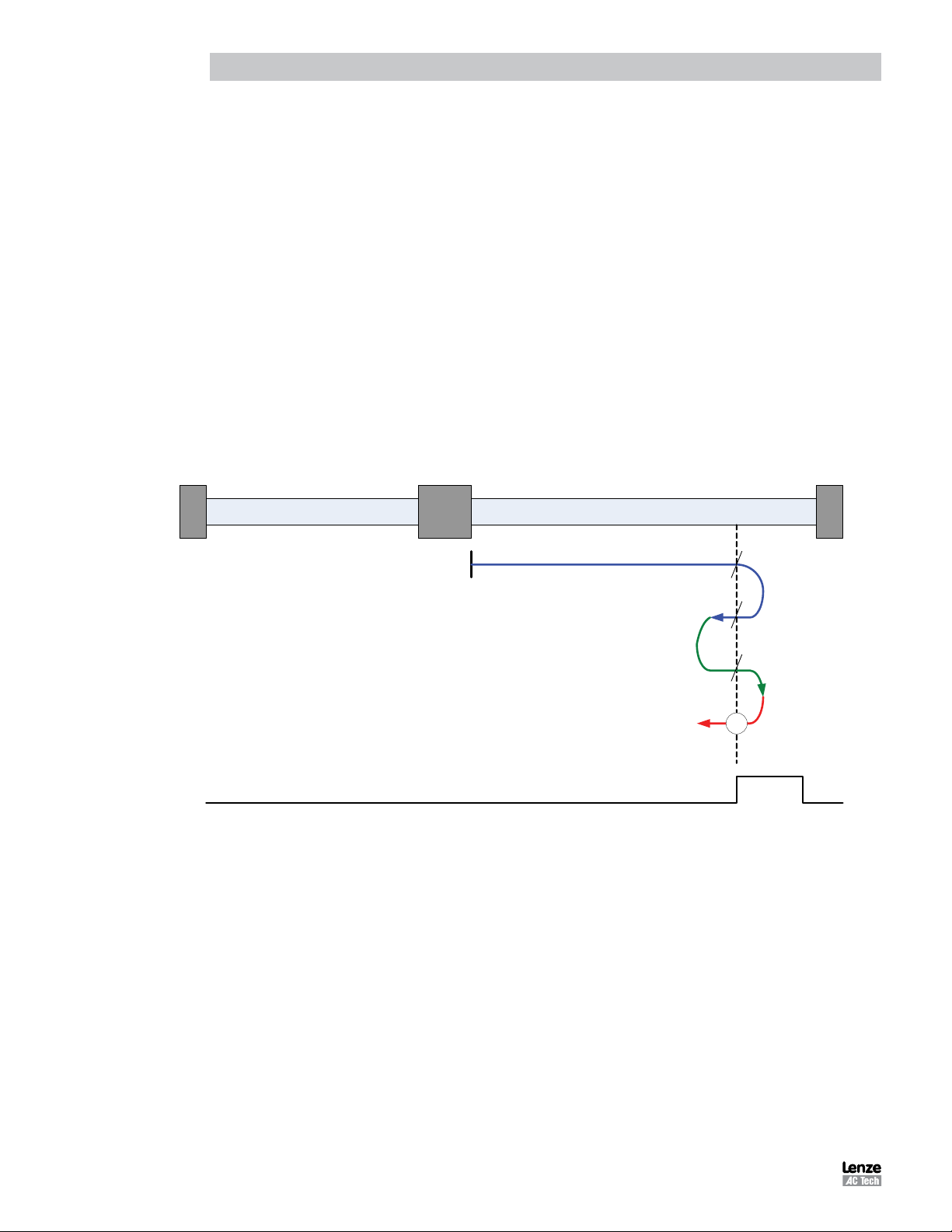

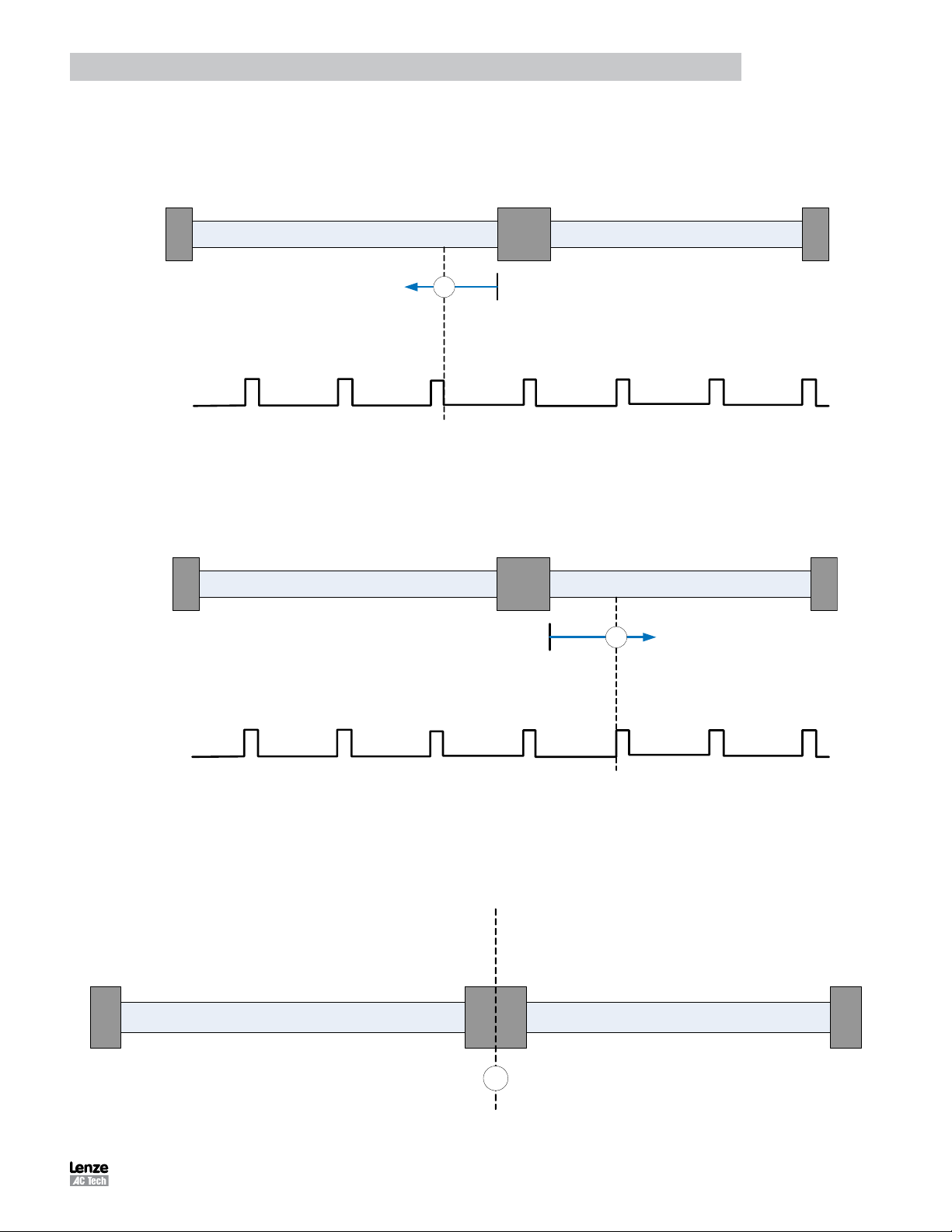

1.10.1 Drive Operating Modes

There are three modes of operation for the PositionServo: Torque, Velocity and Position. Torque and Velocity modes

are generally used when the command reference is from an external device, (Ain). Position mode is used when the

command comes from the drives User Program, or from an external device, encoder or a step and direction pulse.

Setting the drive’s mode is done from the [Parameter] folder in MotionView. To command motion from the user program