Page 1

COPY

EP01E

13360071

EN

Operating Instructions

DE

Betriebsanleitung

FR

Instructions de Mise en Service

IT

Istruzioni di funzionamento

ES

Instrucciones de funcionamiento

epm001

EPM Programmer EEPM1RA

Page 2

© 2004 Lenze gmbH & C0 KG

No part of this documentation may be copied or made available to third parties without the explicit written approval

of Lenze GmbH & Co KG.

All information given in this documentation has been carefully selected and tested for compliance with the hardware

and software described. Nevertheless, discrepancies cannot be ruled out. We do not accept any responsibility nor

liability for damages that may occur. Any necessary corrections will be implemented in subsequent editions.

Page 3

Contents

1 Preface and general information ....................................................2

1.1 About these Operating Instructions .......................................................................2

1.2 Terminology used ..................................................................................................2

1.3 EPM Technology and Operation ............................................................................3

1.4 Pictographs used in these Operating Instructions ................................................3

1.5 Scope of delivery ...................................................................................................3

2 Technical data ..................................................................................4

2.1 General data and application conditions ..............................................................4

2.2 Electrical Data ........................................................................................................4

2.3 Dimensions ............................................................................................................5

3 Commissioning ................................................................................6

3.1 Battery Operation ...................................................................................................6

3.2 Changing Batteries ................................................................................................6

3.3 Operation with external power supply ...................................................................7

4 Operation ..........................................................................................8

4.1 Overview of operating elements ............................................................................8

4.2 Key Functions ........................................................................................................8

4.3 Switch on/off EPM Programmer .............................................................................9

4.4 Select Language ..................................................................................................10

4.5 Switch on/off display background illumination ....................................................10

4.6 Menu Overview ....................................................................................................11

4.7 Copy from one EPM to another EPM ...................................................................12

4.8 Copy a file stored in the Programmer to an EPM ................................................13

4.9 Edit the EPM ........................................................................................................14

4.10 Edit a file stored in the Programmer ....................................................................15

4.11 Create a new file ..................................................................................................16

4.12 Delete a file stored in the Programmer ................................................................17

4.13 Change EPM Programmer Internal Configuration ...............................................17

4.14 Contrast setting ....................................................................................................18

4.15 Display status messages .....................................................................................18

4.16 Enter/change password .......................................................................................19

5 Troubleshooting.............................................................................20

5.1 Error messages ....................................................................................................20

ENGLISH

1

Page 4

Preface and general information

1 Preface and general information

The EEPM1RA EPM programmer enables you to easily duplicate and archive the memory and configuration of inverter

drives and servo controllers that utilize the EPM feature.

The EEPM1RA EPM programmer enables you to:

• copy the contents of one EPM to another EPM,

• read out contents of EPMs and save them to a PC or the EPM programmer as files,

• edit files stored in the EPM programmer,

• store edited files under another file name and create new files,

• copy files stored in the EPM programmer into EPMs.

1.1 About these Operating Instructions

This documentation applies to the EPM Programmer as of version:

A B C

Type: EEPM1RA

L

Made in USA

EPM Programmer

A

Type EEPM1RA

B

Hardware version 1A

C

Software version 10

• These Operating Instructions are designed to ensure safe and trouble-free working with the EEPM1RA EPM

programmer.

• Before you start working with the EEPM1RA EPM programmer, please read the Operating Instructions carefully and

follow the notes.

• These Operating Instructions must always be kept as a complete legible document.

LISTED

CONT EQ

ND

5D81

6VDC 150mA min

Power Suppy

(FRIWO 7207/06 15 0791 MPP15)

For detailed nformation refer

to instruction manual EP01x

EEMP1RA 1A 10

xxxxx xx xx

epm010

1.2 Terminology used

Term Meaning in this document

Drive controller Lenze - AC Tech submicro frequency inverter

Servo controller Lenze - AC Tech SimpleServo, PositionServo

2

ENGLISH

Page 5

Preface and general information

1.3 EPM Technology and Operation

The EPM uses EEPROM technology housed in a removable plastic

casing for protection and ruggedness. A removable memory

structure, as provided by an EPM include:

• Programming a drive without power.

• Easily duplicate proven programs using the EPM Programmer.

• Reduce down-time and troubleshooting.

The EPM feature is included with several Lenze and AC Tech inverter

drive controllers and in the new SimpleServo products. Operation and

some functionality differ between the Drive and Servo product lines.

Drive Controllers

Servo Controllers

OEM Defaults

The EPM, when used in Inverter Drive Controllers, actually contains two sets of drive parameters. The USER memory is

the memory the drive typically uses for operation and is actually the drives operating memory that can be accessed and

changed from the front of the drive, a remote keypad or serial communications. The OEM Default values can only be written

by the EPM Programmer and cannot be altered through normal drive operation or programming. This provides a benefit

in that an OEM using the EPM Programmer to quickly copy the drive configuration, actually ships the drive with their own

“Factory Defaults”.

Lenze Servo Controllers are programmed using MotionView94 Software via serial link with a PC. Field reprogramming from the

front of the controller is not possible. As such, resetting to OEM defaults is impossible and this second memory set is not used.

1.4 Pictographs used in these Operating Instructions

Pictograph used Signal words

Stop! Warns of possible malfunctions of the EPM Programmer due to

EPM Color: Blue

EPM files can be stored in EPM Programmer

EPM Color: Blue (Model 94)

EPM files cannot be stored in EPM Programmer

electrostatic discharge (ESD)

epm011

1.5 Scope of delivery

Scope of delivery Important

• 1 EEPM1RA EPM programmer with 4 batteries (already

installed)

• 1 Operating Instructions

Tip! Designates a general and useful note. If observed, it will make using the

EPM Programmer easier.

After receipt of the delivery, check immediately whether

the items delivered match the accompanying papers.

Lenze does not accept any liability for deficiencies claimed

subsequently.

Claim

• visible transport damage immediately to the forwarder.

• visible deficiencies / incompleteness immediately to

your Lenze representative.

ENGLISH

3

Page 6

Technical data

2 Technical data

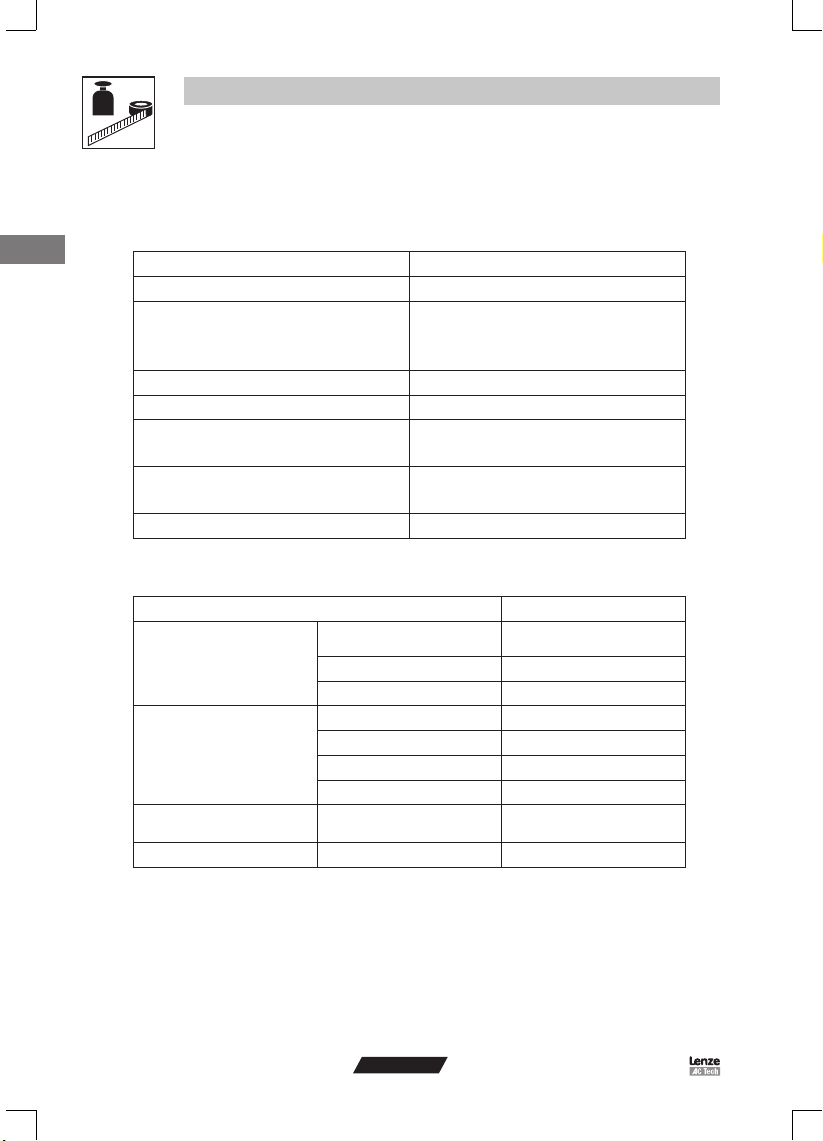

2.1 General data and application conditions

Field Values

Type of Protection IP20

Permissible temperature ratings Operation 0 … +50 °C

Humidity <85 %, without condensation

Weight 1.3 kg with batteries

Applied Standards Noise emission to EN 50081-2: 1993

Approvals UL 508C Underwriters Laboratories

Conformity CE EMC Directive (89/336/CEE)

2.2 Electrical Data

Field Values

DC Voltage Supply + 6 VDC, min. 150 mA

Internal Batteries 4 mono-cells (type D), 1.5 VDC each

External power supply unit + 6 VDC, 300 mA

Display Type LCD

Display format Text

Lines x characters 1 x 16

Contrast setting Via menu

Memory Data Memory up to 120 parameter files for inverter

Serial Interface DB9 Connector RS232

Transport -20 … +60 °C

Storage -20 … +60 °C

Noise immunity to EN 61000-6-2 : 1999

Power Conversion Equipment

drive controllers

4

ENGLISH

Page 7

2.3 Dimensions

4

Dimensions in mm

Technical data

105

COPY

155

76

epm001

ENGLISH

5

Page 8

Commissioning

3 Commissioning

3.1 Battery Operation

The EPM programmer is immediately ready for operation. It is delivered with 4 batteries

(1.5 V mono-cells).

3.2 Changing Batteries

For battery operation you need four mono-cell (D size) with 1.5V each. In order to access the battery compartment, you

must open the housing of the EPM programmer.

Open the battery compartment of the EPM programmer

1. Remove the 5 screws on the bottom of the EPM programmer

2. Remove the EPM Programmer base plate carefully.

epm004

Insert the batteries into the battery compartment

1. Insert the batteries into the battery compartment as shown in figure above.

- Pay attention to the correct polarity of the batteries!

2. Replace the base plate carefully and secure the housing with the 5 screws.

6

epm007

ENGLISH

Page 9

Commissioning

A

Type EEPM1RA

For detaled nformation refer

to nstruction manual EP01x

EEMP1RA 1A 10

Made in USA

EPM Programmer

L

LSTED

IND

CONT EQ

5D81

xxxxx xx xx

6VDC 150mA min

Power Supply

FRIWO 720706 15 0791 MPP15)

3.3 Operation with external power supply

Stop!

• Avoid electrostatic discharges (ESD) at the connector for the voltage supply. EPM programmer malfunction

may occur.

• Take appropriate measures to avoid electrostatic conditions.

• Occasionally occurring malfunctions can normally be remedied by switching the EPM Programmer off and then

on again.

It is also possible to operate the EPM programmer with an external power supply.

Power supply output data:

• Output voltage: 6 VDC, stabilized

• Output current: 300 mA

Power supply connector plug details

For connections to the EPM programmer the power supply

unit requires an extra-low voltage plug with the following

+6 VDC

–

Connect the power supply unit

dimensions: 2.1 × 5.5 × 9.5 mm.

epm005

Plug the extra-low voltage plug of the power supply into the A connector at the back of the EPM Programmer

ENGLISH

epm006

7

Page 10

4 Operation

COPY

Operation

4.1 Overview of operating elements

epm001

4.2 Key Functions

Key Level Function

ON

OFF

Menu level: Select menu, quit submenu

MENU

Parameter level: Return to the main menu without saving changes

Menu level: Select submenu, execute menu command

ENTER

Parameter level: Select parameter to enter a value, accept a value entered

Menu level: Select submenu/file

Parameter level: Enter a higher value

Menu level: Select submenu/file

Parameter level: Enter a lower value

Switch on EPM programmer

Switch off EPM programmer

Display

MASTER PORT

Plug-in-station for EPM from which the data is to be read.

EPM Port

Plug-in-station for EPM memory chip on which the data is to

be written.

Operator Keypad

BACK

LIGHT

COPY

TO EPM

8

Switch on/off background illumination for the display

Copy data to EPM PORT

ENGLISH

Page 11

4.3 Switch on/off EPM Programmer

Switch-on with unprotected access (without password)

Press The display shows... Explanation

1.

ON

2.

3.

4.

Switch-on with protected access (with password)

Steps 1…4 as above ( Section 4.16, Enter/change password)

Press The display shows... Explanation

5.

6.

ENTER

EPM PROGRAMMER

INTERN CFG 400

MASTER CFG 400

MSTFILE#DEFAULTS

MASTER MISSING!

PASSWORD?? 000

PASSWORD?? xxxx

0

Operation

Shows the parameter version that the EPM

programmer is configured with (e.g. 400).

Shows the parameter version of the EPM (e.g. 400)

plugged into the MASTER PORT.

Shows the name of the parameter file (e.g.

DEFAULTS) stored in the EPM plugged into the

MASTER PORT.

This message is displayed, if no EPM is plugged

into the MASTER PORT.

The cursor is blinking in the display on the right.

Enter the password

If you do not enter a password, you have restricted

access to the main menus after confirmation (only

the menus CONTRAST, DISPLAY, and MASTER –>

EPM are available).

If you enter a wrong password, WRONG

PASSWORD will be displayed. If you press the

MENU key, you abort the process and get the

restricted access to the main menus.

using the buttons.

Tip!

• After the initialization, the main menu shown last is automatically called up.

• If you lose or forget your password, please contact your Lenze representative.

Switch-off

Press The display shows... Explanation

1.

OFF

Tip!

• The EPM programmer automatically turns off after 5 minutes, if no operation takes place during this time.

SHUTDOWN.. 5SEC

The shutdown process takes 5 seconds.

If you press any key within these 5 seconds, the

shutdown process is aborted

ENGLISH

9

Page 12

Operation

4.4 Select Language

You can choose between English, German, French, Italian and Spanish languages.

• The language change over can be carried out on the menu level and parameter level.

• The language set remains stored even after switching off the EPM Programmer.

Press The display shows... Explanation

1.

ON

Tip!

• Languages are a part of the product “Configuration File”. If, when changing the internal configuration (section

4.13), the new configuration file does not contain the selected language, English will be displayed.

4.5 Switch on/off display background illumination

Press The display shows... Explanation

1.

BACK

LIGHT

2.

BACK

LIGHT

Tip!

• If you operate the EPM programmer with a power supply unit, the background illumination will always be

switched on.

Press and hold the ON button. The languages will

scroll in 5 second intervals in the sequence: English,

German, French, Italian, Spanish. Release ON

button when desired language is displayed.

The background illumination is switched on.

The background illumination is switched off.

10

ENGLISH

Page 13

Operation

4.6 Menu Overview

After power is switched on and the initialization screens have been displayed, the primary functions of the EPM Programmer

are accessed by pressing the MENU button.

MASTER –> EPM

MENU

FILE –> EPM

MENU

EDIT EPM

MENU

EDIT FILE

MENU

CREATE NEW FILE

MENU

DELETE FILE

MENU

LOAD CFG EPM

MENU

DISPLAY CONTRAST

MENU

MISCELLANEOUS

MENU

Tip!

• When copying to an EPM using MASTER->EPM or FILE->EPM, all data on the target EPM will be overwritten.

SECTION 4.7

SECTION 4.8

SECTION 4.9 (servo config. only)

SECTION 4.10

SECTION 4.11

SECTION 4.12

SECTION 4.13

SECTION 4.14

SECTION 4.15

ENGLISH

11

Page 14

Operation

4.7 Copy from one EPM to another EPM

With this function it is possible to copy a parameter file directly from one EPM (a “Master”) to another EPM.

• Plug the EPM containing the parameter file you want to copy into the MASTER PORT.

• Plug the EPM, to which you want to copy the parameter file, into the EPM PORT.

Press The display shows... Explanation

1.

MENU

MASTER –> EPM

Press the key until the menu appears in the display.

2.

ENTER

3.

COPY

TO EPM

#DEFAULTS(400)>>

TRANSFERRING 0%

DAT=400 EPM=312

4.

ENTER

CONFIRM= [ENTER]

TRANSFERRING 100%

The name of the parameter file (e.g. DEFAULTS)

of the EPM in the MASTER PORT is displayed.

The parameter version of the file is shown in

parenthesis.

The parameter file is copied or..

...if the parameter version of the file does not

correspond with the parameter version of the EPM

in the EPM PORT,...

...a security check takes place concerning the

existing data on the EPM:

Press the ENTER key to overwrite the existing data.

Press the MENU key, if you want to abort the

process.

The parameter file will be copied.

#DEFAULTS(400)>>

5.

MENU

Tip!

• The file name on the MASTER EPM, is only displayed if the user parameters exactly match the OEM Default

parameters ( see Section 1.3, EPM Technology and Operation).

• If the user and OEM memory areas do NOT match, the name of the parameter file of the EPM in the MASTER

PORT will be displayed as #********(400)>>. This indicates that the user parameters have been changed

from the OEM defaults or the Factory Defaults.

• Copy from MASTER -> EPM will copy only the user parameter file from the MASTER and save this to both the

user and OEM memory locations of the EPM in the EPM PORT. The parameter file name of the new EPM will be

displayed as #????????(400)>>.

• Servo controllers do not store OEM defaults, so the parameter file name in the master will always be displayed

as ********(16384)>.

MASTER –> EPM

Returns to the main menu.

12

ENGLISH

Page 15

Operation

4.8 Copy a file stored in the Programmer to an EPM

With this function it is possible to copy a parameter file saved in the EPM programmer to an EPM.

• Plug the EPM, to which you want to copy the parameter file, into the EPM PORT.

Press The display shows... Explanation

1.

MENU

FILE –> EPM

Press the key until the menu appears in the display.

The stored name of a parameter file (e.g. DEFAULTS)

stored in the EPM programmer, is displayed.

The cursor is blinking in the display on the right.

Select the parameter file you want to copy (e.g.

ABC_ _ _ _ _).

The parameter file is copied or..

...if the parameter version of the file does not

correspond with the parameter version of the EPM

in the EPM PORT,...

...a security check takes place concerning the

existing data on the EPM:

Press the ENTER key to overwrite the existing data.

Press the MENU key, if you want to abort the

process.

The parameter file will be copied.

#DEFAULTS(400)>>

#DEFAULTS(400

)

#ABC_ _ _ _ _(400

TRANSFERRING 0%

>>

)

>>

2.

ENTER

3.

ENTER

4.

5.

COPY

TO EPM

DAT=400 EPM=312

CONFIRM= [ENTER]

6.

ENTER

TRANSFERRING 100%

#ABC_ _ _ _ _(400)>>

7.

MENU

FILE –> EPM

Returns to the main menu.

ENGLISH

13

Page 16

Operation

4.9 Edit the EPM

This menu item is only displayed when the EPM Programmer is configured for a Servo product.

With this function it is possible to edit PPP BAUDRATE, NETWORK ADDRESS, CAN NODE ID, and CAN BAUDRATE

for Model 94 Servo drives.

Press The display shows... Explanation

1.

MENU

EDIT EPM

Press the key until the menu appears in the display.

2.

ENTER

EPM INFO

********(16384)>

CAN NODE ID

NETWORK ADDRESS

NET ADDR 3

NET ADDR

NETWORK ADDRESS

EDIT EPM

1

5

ENTER

3.

4.

ENTER

ENTER

MENU

Tip!

• The EPM can only be edited if the configuration of the EPM Programmer and the parameter version of the EPM

are identical. See section 4.13 for changing the configuration of the EPM Programmer.

This request is briefly shown in the display.

The EPM parameter version is displayed.

Displays the parameters that can be edited

Select the parameter file you want to Edit

(NETWORK ADDRESS is shown as an example)

The cursor is blinking in the display on the right

Change the parameter

Stores the new value onto the EPM

Returns to the main menu.

14

ENGLISH

Page 17

Operation

4.10 Edit a file stored in the Programmer

With this function it is possible to edit an Inverter Drive controller parameter file stored in the EPM programmer.

Press The display shows... Explanation

1.

MENU

EDIT FILE

Press the key until the menu appears in the display.

2.

ENTER

3.

SELECT FILE

>#DEFAULTS (400

>#ABC_ _ _ _ _(400

<

)

)

<

4.

ENTER

:DATA FILE NAME

A

:MOP SAVED FREQ

B

or

:KEYPAD SPEED

B

:DIRECTION

C

X:PARAMETER

X

MENU

Tip!

• The parameter file DEFAULTS is write protected.

- If you want DEFAULTS to be the basis for editing, create a copy of this file (see section 4.11).

• A file can only be edited if the configuration of the EPM Programmer and the parameter version of the file

(shown in parenthesis) are identical. If these two are not the same, this will result in the error message

FILE VER INCOMP! See section 4.13 for changing the configuration of the EPM Programmer.

EDIT FILE

This request is briefly shown in the display.

The cursor is blinking in the display on the right.

The file name of a parameter file (e.g. DEFAULTS)

is displayed.

Select the parameter file you want to edit

(e.g. ABC_ _ _ _ _).

The cursor is blinking in the display on the left.

The first entry which can be edited is displayed (e.g.

DATA FILE NAME).

Press ENTER to edit the file name:

• Use buttons to change letters

• Use ENTER to move to next letter

• Pressing ENTER at the last character stores

the name, press MENU to abort

This parameter sets the initial run speed when the

speed source is either MOP or KEYPAD.

Press ENTER to access and

Selects default direction for the motor when

controlled by a remote keypad.

Sequence through the parameters available for the

configuration loaded into the programmer.

Press ENTER to edit the parameter:

• Use buttons to change selection or value

• Press ENTER to store the new value or press

MENU to abort

to adjust.

Returns to the main menu.

ENGLISH

15

Page 18

Operation

4.11 Create a new file

With this function you create a new parameter file in the EPM programmer. Data for your new file can be copied from the

following sources:

• Parameter files available on the EPM programmer.

• Parameter file from an EPM mounted in the MASTER PORT.

Press The display shows... Explanation

1.

MENU

CREATE NEW FILE

Press the key until the menu appears in the display.

2.

3.

4.

5.

6.

7.

8.

9.

10.

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER FILE NAME

NAME:=_ _ _ _ _ _ _

NAME:A_ _ _ _ _ _ _

NAME: A=_ _ _ _ _ _

NAME: ABC=_ _ _ _

NAME: ABC_ _ _ _

=

COPY DATA FROM..

1) FIL

E

SELECT FILE

>#DEFAULTS(400

>#ABC_ _ _ _ _(400

<

)

<

)

TRANSFERRING 100%

This request is briefly shown in the display

The cursor is positioned under the first character

of the file name.

A file name can consist of 8 characters maximum.

Use the buttons to select a value. To scroll

quickly to a value, keep the key pressed. The scroll

rate increases as you hold the button.

The cursor is positioned under the next character

of the file name.

Repeat step 3. until the desired name is entered.

Press ENTER until the cursor is positioned on the

eighth character position. If you re-press ENTER,

the file name is stored.

Press MENU at any time to abort the file creation

and return to the main menu.

The cursor is blinking in the display on the right.

Select a source (e.g FILE) whose parameters you

want to copy into your new file:

1) FILE

2) MASTER

(this message is not displayed when selecting

MASTER and steps 8 and 9 are skipped)

The cursor is blinking in the display on the right.

Select a parameter file you want to copy

(e.g. ABC_ _ _ _ _). Press the MENU key, if you

want to abort this proceedure.

The new file has been created.

16

FILE CREATED!

CREATE NEW FILE

ENGLISH

The EPM programmer automatically returns to the

main menu.

Page 19

4.12 Delete a file stored in the Programmer

With this function you delete the parameter files stored in the EPM Programmer

Press The display shows... Explanation

1.

MENU

DELETE FILE

Press the key until the menu appears in the display.

Operation

2.

ENTER

3.

4.

5.

ENTER

ENTER

SELECT FILE

>#DEFAULTS(400

>#ABC_ _ _ _ _(400

CONFIRM=[ENTER]

DELETING FILE…

<

)

)

<

This request is briefly shown in the display

The cursor is blinking in the display on the right.

Select the parameter file you want to delete (e.g.

ABC_ _ _ _ _).

Press the MENU key, if you want to abort the

process.

The parameter file is deleted.

FILE DELETED!

DELETE FILE

The EPM programmer automatically returns to the

main menu.

4.13 Change EPM Programmer Internal Configuration

With this function, you can change the type of files that the EPM Programmer can EDIT by downloading the proper

configuration for the file you will be working with from a “Configuration EPM” loaded in the MASTER PORT.

Press The display shows... Explanation

1.

MENU

2.

ENTER

LOAD CFG EPM

VERIFYING MASTER

CONFIRM=[ENTER]

3.

ENTER

4.

TRANSFERRING 0%...100%

WAIT-LOADING CFG

CFG LOADED!

LOAD CFG EPM

Press the key until the menu appears in the display.

The programmer verifies that the EPM in the

MASTER PORT is a valid Configuration EPM.

Press the ENTER button to confirm this action

The new configuration is loaded into the EPM

Programmer’s memory and verified.

Messages are displayed briefly then the EPM

programmer automatically returns to the main

menu.

Tip!

• Changing the EPM Programmer’s internal configuration is only required if you are going to EDIT an inverter drive

file stored in the EPM Programmer or EDIT a servo drive EPM. The Programmer must be configured for the

parameter version of the file.

• Configuration EPM’s can be purchased from Lenze, AC Tech or your local distributor.

• Configuration files can be downloaded into the EPM Programmer from your PC via RS232 connection using

TECHLINK software.

ENGLISH

17

Page 20

Operation

4.14 Contrast setting

With this function, you can adjust the viewing angle for the EPM Programmer display.

Press The display shows... Explanation

1.

ON

DISPLAY CONTRAST

Press the key until the menu appears in the display.

2.

ENTER

3.

ENTER

4.

5.

6.

ENTER

MENU

CONTRAST MEDIUM

CONTRAST MEDIU

CONTRAST XXXXX

CONTRAST LOW

DISPLAY CONTRAST

M

The currently set value is indicated (e.g. MEDIUM). .

The cursor is blinking in the display on the right.

Select the setting wanted:

CONTRAST LOW

CONTRAST MEDIUM

CONTRAST HIGH

The setting selected (e.g. LOW) is accepted. The

cursor stops blinking.

Returns to the main menu..

4.15 Display status messages

With this function, you can set the Programmer’s password and view other important information.

Press The display shows... Explanation

1.

MENU

2.

ENTER

3.

4.

5.

6.

7.

8.

MENU

MISCELLANEOUS

/W VERSION X.XX

S

INTERN CFG 400

ILES: 1

F

ATTERY: 5.8VDC

B

ASSWORD: 0000

P

MISCELLANEOUS

Press the key until the menu appears in the display.

Takes you to the submenu. The software version

(e.g. 1.00) of the EPM programmer is displayed.

With the you can select the status messages.

Shows the parameter version that the EPM

programmer is configured for (e.g.400).

Indicates the number of parameter files saved in the

EPM programmer.

Displays the current voltage level of the 4 internal

batteries. To guarantee safe operation, the battery

voltage must not fall below 3.6 VDC.

Displays the set password for the access protection

(Lenze setting: 0000), entering and changing the

password is described in the next section.

Returns to the main menu.

18

ENGLISH

Page 21

Operation

4.16 Enter/change password

When a password has been set, only the main menus can be accessed until the correct password has been entered.

• MASTER –> EPM

• DISPLAY CONTRAST

• MISCELLANEOUS (without the submenu PASSWORD).

Press The display shows... Explanation

1.

MENU

MISCELLANEOUS

Press the key until the menu appears in the display.

2.

ENTER

3.

4.

ENTER

5.

6.

7.

ENTER

MENU

/W VERSION X.XX

S

ASSWORD: 0000

P

PASSWORD: 000

PASSWORD: XXX

ASSWORD: XXXX

P

MISCELLANEOUS

0

X

Takes you to the submenu. The cursor is blinking in

the display on the left.

Displays the set password for the access protection

(Factory setting: 0000).

When the password is set to 0000, the access

protection is deactivated.

The cursor is blinking in the display on the right.

Enter a password. Any value between 0000 and

9999.

Use the

buttons to select a value. To scroll

quickly to a value, keep the key pressed. The scroll

rate increases as you hold the button.

The cursor is blinking in the display on the left.

The new password has been stored.

Returns to the main menu.

ENGLISH

19

Page 22

Troubleshooting and fault elimination

5 Troubleshooting

5.1 Error messages

Display Cause Remedy

CHANGE BATTERY!

FILE VER INCOMP!

READ ONLY FILE!

EPM DAMAGED!

EPM MISSING!

EPM TOO SMALL!

INTERNAL ERROR!

INVALID INT CFG

WRONG PASSWORD

The battery voltage is <3.6V (the

message is displayed after switching

on the EPM programmer.

The parameter file or servo EPM

you are attempting to edit has a

different parameter version than

the configuration file of the EPM

programmer.

You have tried to edit or delete the file

DEFAULTS.

The EPM in the EPM PORT is

defective.

The EPM is not placed correctly in the

EPM PORT.

There is no EPM in the EPM PORT to

which you are attempting to transfer

data or edit..

EPM in EPM PORT does not have

sufficient memory for the file you are

attempting to copy.

Internal device error. Please contact your Lenze

The configuration file of the EPM

programmer is invalid.

Attempting to reconfigure the

EPM programmer without a valid

configuration EPM.

The access protection is activated and

you have entered the wrong password

after switch-on.

Change the batteries

( See Section 3.2)

You can only edit a file if the

parameter version corresponds to

the configuration file of the EPM

programmer.

See Section 4.13 on changing the

programmers internal configuration.

The file DEFAULTS cannot be edited

or deleted.

Exchange the defective EPM.

Plug the EPM correctly in the PORT.

Press the menu key now to return to

the main menu.

Plug an EPM in the EPM PORT.

Replace the EPM in the EPM PORT

with an EPM that has a higher memory

capacity.

representative.

Please contact your Lenze

representative.

Insert a valid configuration EPM into

the MASTER PORT. See section 4.13.

Only if you enter the correct password

will you have full access to the main

menus.

If you press the MENU key, the

process is aborted and you have only

restricted access to the main menus.

(see Section 4.16 )

If you have forgotten your

password, please contact your Lenze

representative.

20

ENGLISH

Page 23

Troubleshooting and fault elimination

Display Cause Remedy

MASTER DAMAGED!

MASTER MISSING

INVALID MASTER!

NAME EXISTS!

MEMORY FULL

TRANSFER FAILED

INVALID OPTION!

INVALID EPM!

NO FILES

CFG EPM MISSING!

The EPM in the MASTER PORT is

defective.

The EPM is not placed correctly in the

MASTER PORT.

Seen on power-up if there is no EPM

in the MASTER PORT.

Programmer is trying to read data

from the MASTER PORT but cannot

detect an EPM in this PORT.

The EPM you are attempting to read in

the MASTER PORT is defective or has

no valid data.

The EPM in the MASTER PORT is a

Configuration EPM.

The file name you want to allocate to a

parameter file already exists.

The internal memory of the EPM

programmer is full.

Error in the data transmission to the

EPM PORT, because the memory chip

is defective, or is not placed correctly

in the PORT.

Attempted MASTER -> EPM transfer

when- the memory size of the

MASTER EPM is different from that

of the target.

Error in the data transmission to the

EPM PORT, because of an internal

error in the EPM programmer.

Attempted to CREATE a new file from

a servo drive EPM in the MASTER

PORT.

Attempted to EDIT a non-servo EPM

or a corrupted servo EPM.

Attempting to EDIT, DELETE or

CREATE a file, but there are no stored

files in the EPM Programmer.

Attempt to LOAD CFG EPM without

a valid configuration EPM in the

MASTER PORT.

Press the menu key to return to the

main menu.

Plug an EPM in the MASTER PORT.

The message does not indicate an

error but only serves as a note.

The message is only displayed for a

short time.

Information only.

Insert a valid EPM into the MASTER

PORT.

Press the menu key now to return to

the main menu.

Exchange the EPM in the MASTER

PORT.

A Configuration EPM cannot be

copied.

Select another file name.

It is not possible to save any more

parameter files.

If necessary, delete parameter files

you do not need anymore.

Exchange the defective EPM or plug

the EPM correctly in the PORT.

Replace the EPM in the EPM PORT

with an EPM of the same color as

the Master.

Please contact your Lenze

representative.

Only inverter drive EPM’s can be

saved as files in the EPM Programmer.

Replace the EPM in the EPM PORT

with a valid servo EPM.

Insert a configuration EPM into the

MASTER PORT.

ENGLISH

21

Page 24

Notes

22

ENGLISH

Page 25

Inhalt

1 Vorwort und allgemeine Informationen .........................................2

1.1 Informationen zu dieser Betriebsanleitung ............................................................2

1.2 Verwendete Terminologie ......................................................................................2

1.3 EPM-Technologie und -Betrieb ..............................................................................2

1.4 In der Betriebsanleitung verwendete Piktogramme ..............................................3

1.5 Lieferumfang ..........................................................................................................3

2 Technische Daten ............................................................................4

2.1 Allgemeine Daten und Anwendungsbedingungen ...............................................4

2.2 Elektrische Daten ...................................................................................................4

2.3 Abmessungen ........................................................................................................5

3 Inbetriebnahme ................................................................................6

3.1 Batteriebetrieb .......................................................................................................6

3.2 Austauschen der Batterien ....................................................................................6

3.3 Betrieb über eine externe Stromversorgung .........................................................7

4 Betrieb ..............................................................................................8

4.1 Übersicht über Betätigungselemente ....................................................................8

4.2 Tastenfunktionen ....................................................................................................8

4.3 Ein-/Ausschalten des EPM-Programmiergeräts.....................................................9

4.4 Auswählen der Sprache ......................................................................................10

4.5 Ein-/Ausschalten der Hintergrundbeleuchtung ...................................................10

4.6 Menüübersicht .....................................................................................................11

4.7 Kopieren von Daten zwischen verschiedenen EPMs ..........................................12

4.8 Kopieren einer im Programmiergerät gespeicherten Datei in ein EPM ...............13

4.9 Bearbeiten des EPM ............................................................................................14

4.10 Bearbeiten einer im Programmiergerät gespeicherten Datei ..............................15

4.11 Erstellen einer neuen Datei ..................................................................................16

4.12 Löschen einer im Programmiergerät gespeicherten Datei ..................................17

4.13 Ändern der internen Konfiguration des EPM-Programmiergeräts .......................17

4.14 Kontrasteinstellung ..............................................................................................18

4.15 Anzeigen von Statusmeldungen ..........................................................................18

4.16 Eingeben/Ändern des Passworts ........................................................................19

5 Problemlösungen...........................................................................20

5.1 Fehlermeldungen .................................................................................................20

DEUTSCH

1

Page 26

Vorwort und allgemeine Informationen

1 Vorwort und allgemeine Informationen

Das EEPM1RA EPM-Programmiergerät ermöglicht das problemlose Duplizieren und Archivieren des Speicherinhalts und

der Konfiguration von Umrichteransteuerungen und Servoreglern, die die EPM-Funktion verwenden.

Das EEPM1RA EPM-Programmiergerät bietet folgende Funktionen:

• Kopieren der Inhalte von einem EPM in ein anderes

• Auslesen der Inhalte von EPMs und Speichern der Inhalte in Dateiform auf einem PC oder in einem EPMProgrammiergerät

• Bearbeiten von im EPM-Programmiergerät gespeicherten Dateien

• Speichern bearbeiteter Dateien unter einem anderen Dateinamen und Erstellen neuer Dateien

• Kopieren von im EPM-Programmiergerät gespeicherten Dateien in EPMs

1.1 Informationen zu dieser Betriebsanleitung

Diese Dokumentation gilt für EPM-Programmiergeräte ab folgender Version:

A B C

Type: EEPM1RA

L

Made in USA

EPM Programmer

A

Typ EEPM1RA

B

Hardwareversion 1A

C

Softwareversion 10

• Diese Bedienungsanleitung soll ein sicheres und problemloses Arbeiten mit dem EEPM1RA EPM-Programmiergerät

ermöglichen.

• Bitte lesen Sie diese Bedienungsanleitung und befolgen Sie die Hinweise, bevor Sie das EEPM1RA EPMProgrammiergerät verwenden.

• Diese Bedienungsanleitung muss stets als vollständiges und lesbares Dokument aufbewahrt werden.

L STED

CONT EQ

IND

5D81

6VDC 150mA min

Power Supply

(FRIWO 7207/06 15 0791 MPP15)

For detailed nformation refer

to instruction manual EP01x

EEMP1RA 1A 10

xxxxx xx xx

epm010

1.2 Verwendete Terminologie

Begriff Bedeutung in diesem Dokument

Ansteuerungsregler Submikro-Frequenzumrichter von Lenze - AC Tech

Servoregler

Lenze - AC Tech SimpleServo, PositionServo

1.3 EPM-Technologie und -Betrieb

Das EPM verwendet die EEPROM-Technologie, die in einem abnehmbaren

Plastikgehäuse untergebracht ist, damit sie geschützt und weniger schadensanfällig

ist. Eine abnehmbare Speicherstruktur, wie sie ein EPM bietet, umfasst folgende

Funktionen:

• Programmieren einer Ansteuerungseinheit ohne Strom.

• Problemloses Duplizieren getesteter Programme mit dem EPMProgrammiergerät.

• Reduzieren von Stillstandszeiten und der für Problemlösungen benötigten Zeit.

Die EPM-Funktion ist in mehrere Umrichteransteuerungsregler von Lenze und AC Tech

sowie in die neuen SimpleServo-Produkte integriert. Der Betrieb und einige Funktionen

der Ansteuerungs- und der Servoproduktreihen unterscheiden sich jedoch.

2

DEUTSCH

epm011

Page 27

Vorwort und allgemeine Informationen

Ansteuerungsregler

Servoregler

OEM-Standardeinstellungen

Wenn das EPM in Umrichteransteuerungsreglern verwendet wird, enthält es eigentlich zwei Ansteuerungsparametersets. Den BENUTZER-Speicher, der von der Ansteuerung normalerweise für den Betrieb verwendet wird. Bei diesem

Speicher handelt es sich um den Betriebsspeicher der Ansteuerung, auf den über eine Remote-Tastatur oder eine

serielle Kommunikationsschnittstelle an der Vorderseite der Ansteuerung zugegriffen werden kann oder Änderungen

vorgenommen werden können. Die OEM-Standardwerte können nur vom EPM-Programmiergerät geschrieben und über

den normalen Ansteuerungsbetrieb bzw. die normale Programmierung nicht geändert werden. Dies bietet den Vorteil, dass

ein Originalhersteller (OEM), der das EPM-Programmiergerät für das schnelle Kopieren der Ansteuerungskonfiguration

verwendet, die Ansteuerung tatsächlich mit seinen eigenen „Werkseinstellungen“ versenden kann.

Servoregler von Lenze werden mithilfe der Software MotionView94 über die serielle Schnittstelle eines PCs programmiert.

Eine Umprogrammierung am Einsatzort über die Vorderseite des Reglers ist nicht möglich. Aus diesem Grund ist ein

Zurücksetzen auf die OEM-Standardeinstellungen nicht möglich und dieses zweite Speicherset wird nicht verwendet.

EPM-Farbe: Blau

EPM-Dateien können im EPM-Programmiergerät gespeichert werden.

EPM-Farbe: Blau (Model 94)

EPM-Dateien können nicht im EPM-Programmiergerät gespeichert werden.

1.4 In der Betriebsanleitung verwendete Piktogramme

Verwendetes

Piktogramm

Signalwörter

Stopp! Warnt vor möglichen Fehlfunktionen des EPM-Programmiergeräts

Tipp! Zeigt einen allgemeinen und nützlichen Hinweis an. Durch das

aufgrund elektrostatischer Entladungen.

Einhalten dieser Hinweise gestaltet sich die Bedienung des EPMProgrammiergeräts einfacher.

1.5 Lieferumfang

Lieferumfang Wichtig

• 1 EEPM1RA EPM-Programmiergerät mit 4 Batterien

(bereits eingelegt)

• 1 Bedienungsanleitung

Prüfen Sie nach Erhalt der Lieferung sofort, ob alle auf den

beiliegenden Unterlagen aufgeführten Objekte enhalten

sind. Lenze übernimmt keinerlei Haftung bei im Nachhinein

gemeldeten Mängeln.

Melden Sie

• sichtbare Schäden, die durch den Transport entstanden

sind, dem Transportunternehmen.

• sichtbare Mängel/unvollständige Lieferungen umgehend

Ihrem Lenze-Vertreter.

DEUTSCH

3

Page 28

Technische Daten

2 Technische Daten

2.1 Allgemeine Daten und Anwendungsbedingungen

Feld- Werte

Schutzart IP20

Zulässige Temperaturwerte Betrieb 0 … +50 °C

Transport -20 … +60 °C

Lagerung -20 … +60 °C

Luftfeuchtigkeit <85 %, ohne Kondensation

Gewicht 1,3 kg mit Batterien

Geltende Normen Störaussendung gemäß EN 50081-2: 1993

Störfestigkeit gemäß EN 61000-2: 1999

Zulassungen UL 508C Underwriters Laboratories

Umrichter

Konformität CE EMC-Direktive (89/336/CEE)

2.2 Elektrische Daten

Feld- Werte

DC-Spannungsquelle + 6 VDC, min. 150 mA

Interne Batterien 4 Monozellen (Typ D), je 1,5 VDC

Externe Stromversorgung + 6 VDC, 300 mA

Anzeige Typ LCD

Anzeigeformat Text

Zeilen x Zeichen 1 x 16

Kontrasteinstellung Über ein Menü

Speicher Datenspeicher bis zu 120 Parameterdateien bei

Serielle Schnittstelle DB9-Anschluss RS232

Umrichteransteuerungsreglern

4

DEUTSCH

Page 29

2.3 Abmessungen

4

Maße in mm

Technische Daten

105

COPY

155

76

DEUTSCH

5

Page 30

Inbetriebnahme

3 Inbetriebnahme

3.1 Batteriebetrieb

Das EPM-Programmiergerät ist sofort einsatzbereit. Im Lieferumfang sind 4 Batterien

(1,5-V-Monozellen) enthalten.

3.2 Austauschen der Batterien

Für den Batteriebetrieb benötigen Sie vier Monozellen (Typ D) mit je 1,5 V. Um die Batterien in das Batteriefach einlegen zu

können, müssen Sie das Gehäuse des EPM-Programmiergeräts öffnen.

Öffnen des Batteriefachs des EPM-Programmiergeräts:

1. Entfernen Sie die 5 Schrauben an der Unterseite des EPM-Programmiergeräts.

2. Entfernen Sie vorsichtig die Bodenplatte des EPM-Programmiergeräts.

Einlegen der Batterien in das Batteriefach:

1. Legen Sie die Batterien in das Batteriefach ein (siehe Abbildung oben).

- Achten Sie dabei auf die korrekte Polarität der Batterien!

2. Bringen Sie vorsichtig die Bodenplatte wieder an und sichern Sie das Gehäuse mit den 5 Schrauben.

6

epm007

epm004

DEUTSCH

Page 31

Inbetriebnahme

A

Type EEPM1RA

For detailed informaton refer

to instructon manual EP01x

EEMP1RA 1A 10

Made n USA

EPM Prog ammer

L

LISTED

IND

CONT EQ

5D81

xxxxx xx xx

6VDC 150mA min

Power Supply

(FRIWO 7207/06 150791 MPP15)

3.3 Betrieb über eine externe Stromversorgung

Stopp!

• Vermeiden Sie elektrostatische Entladungen am Anschluss der Spannungsquelle. Ansonsten kann es zu einer

Fehlfunktion des EPM-Programmiergeräts kommen.

• Treffen Sie entsprechende Vorkehrungen, um elektrostatische Entladungen zu vermeiden.

• Gelegentlich auftretende Fehlfunktionen können in der Regel behoben werden, indem Sie das EPMProgrammiergerät aus- und wieder einschalten.

Das EPM-Programmiergerät kann auch über eine externe Stromversorgung betrieben werden.

Ausgangsdaten des Netzgeräts:

• Ausgangsspannung: 6 VDC, stabilisiert

• Ausgangsstrom: 300 mA

Details zum Netzgerätestecker

Zum Anschließen an das EPM-Programmiergerät benötigt

das Netzgerät einen Kleinspannungsstecker mit folgenden

+6 VDC

Abmessungen: 2,1 x 5,5 x 9,5 mm.

–

Anschließen des Netzgeräts:

epm005

Stecken Sie den Kleinspannungsstecker des Netzgeräts am

Programmiergeräts ein.

DEUTSCH

Anschluss an der Rückseite des EPM-

A

epm006

7

Page 32

Betrieb

COPY

4 Betrieb

4.1 Übersicht über Betätigungselemente

Anzeige

MASTER PORT

Anschlussstation für ein EPM, von dem Daten gelesen

werden sollen.

EPM Port

Anschlussstation für einen EPM-Speicherchip, auf dem Daten

gespeichert werden sollen.

Bedientastatur

4.2 Tastenfunktionen

Taste Funktion

epm001

ON

OFF

Menüebene: Menü auswählen, Untermenü verlassen

MENU

Parameterebene: Zum Hauptmenü zurückwechseln, ohne Änderungen zu speichern

ENTER

TO EPM

Menüebene: Untermenü auswählen, Menübefehl ausführen

Parameterebene: Parameter für Werteingabe auswählen, eingegebene Werte akzeptieren

Menüebene: Untermenü/Datei auswählen

Parameterebene: Einen höheren Wert eingeben

Menüebene: Untermenü/Datei auswählen

Parameterebene: Einen niedrigeren Wert eingeben

BACK

LIGHT

COPY

8

EPM-Programmiergerät einschalten

EPM-Programmiergerät ausschalten

Ein-/Ausschalten der Hintergrundbeleuchtung für die Anzeige

Daten an den EPM-PORT übertragen

DEUTSCH

Page 33

Betrieb

4.3 Ein-/Ausschalten des EPM-Programmiergeräts

Einschalten ohne Passwortabfrage

Drücken Anzeige Erklärung

1.

ON

2.

3.

4.

Einschalten mit Passwortabfrage

Schritte 1…4 wie oben ( Abschnitt 4.16, Eingeben/Ändern des Passworts)

Drücken Anzeige Erklärung

5.

6.

ENTER

EPM-PROGRAMMER

INT.KONF 400

KONF MASTR 400

MSTFILE#DEFAULTS

MASTER FEHLT!

KENNWORT?? 0000

KENNWORT?? xxxx

Zeigt die Parameterversion an, mit der das EPMProgrammiergerät konfiguriert wurde (z. B. 400).

Zeigt die Parameterversion des EPM (z. B. 400) an,

das am MASTER PORT angeschlossen ist.

Zeigt den Namen der Parameterdatei (z. B.

DEFAULTS) an, die im am MASTER PORT

angeschlossenen EPM gespeichert ist.

Diese Meldung wird angezeigt, wenn am MASTER

PORT kein EPM angeschlossen ist.

Der Cursor in der Anzeige auf der rechten Seite

blinkt. Geben Sie das Passwort

Schaltflächen ein.

Wenn Sie kein Passwort eingeben, haben Sie nach

der Bestätigung nur eingeschränkten Zugriff auf die

Hauptmenüs (nur die Menüs KONTRAST, ANZEIGE

und MASTER –> EPM sind verfügbar).

Wenn das eingegebene Passwort nicht korrekt

ist, wird die Meldung KENNWORT FALSCH

angezeigt. Wenn Sie die Taste MENÜ drücken,

wird der Vorgang abgebrochen und Sie erhalten

eingeschränkten Zugriff auf die Hauptmenüs.

mithilfe der

Tipp!

• Nach der Initialisierung wird automatisch das zuletzt angezeigte Hauptmenü aufgerufen.

• Sollten Sie Ihr Passwort verlieren oder vergessen, wenden Sie sich bitte an Ihren Lenze-Vertreter.

Ausschalten

Drücken Anzeige Erklärung

1.

Tipp!

• Das EPM-Programmiergerät schaltet sich nach 5 Minuten automatisch aus, falls innerhalb dieses Zeitraums

keine Aktion durchgeführt wird.

ABSCHALTEN.. 5SEK.

DEUTSCH

Das Herunterfahren dauert 5 Sekunden.

Wenn Sie innerhalb dieser 5 Sekunden auf

eine beliebige Taste drücken, wird der Vorgang

abgebrochen.

9

Page 34

Betrieb

4.4 Auswählen der Sprache

Wählen Sie zwischen den Sprachen Englisch, Deutsch, Französisch, Italienisch, und Spanisch.

• Die Sprachänderung kann sowohl auf Menü- als auch auf Parameterebene durchgeführt werden.

• Die eingestellte Sprache wird auch nach dem Ausschalten des EPM-Programmiergeräts gespeichert.

Drücken Anzeige Erklärung

1.

ON

Tipp!

• Sprachen sind ein Teil des Produkts “Konfigurationsdatei”. Wenn bei Änderung der internen Konfiguration

(Abschnitt 4.13) die neue Konfigurationsdatei nicht die ausgewählte Sprache enthält, wird Englisch angezeigt.

4.5 Ein-/Ausschalten der Hintergrundbeleuchtung

Drücken Anzeige Erklärung

1.

BACK

LIGHT

2.

BACK

LIGHT

Drücken und halten Sie die Taste EIN. Die Sprachen

werden in Intervallen von 5 Sekunden in folgender

Reihenfolge angezeigt:

Französisch, Italienisch, und Spanisch.. Lassen

Sie die Taste EIN los, wenn die gewünschte Sprache

angezeigt wird.

Die Hintergrundbeleuchtung wird eingeschaltet.

Die Hintergrundbeleuchtung wird ausgeschaltet.

Englisch, Deutsch,

10

Tipp!

• Wenn Sie das EPM-Programmiergerät über ein Netzgerät betreiben, ist die Hintergrundbeleuchtung immer

eingeschaltet.

DEUTSCH

Page 35

Betrieb

4.6 Menüübersicht

Nachdem das Gerät eingeschaltet und die Initialisierungsbildschirme angezeigt wurden, können die primären Funktionen

des EPM-Programmiergeräts durch Drücken der Taste MENÜ aufgerufen werden.

MASTER –> EPM

MENU

DATEI –> EPM

MENU

AUSGABE EPM

MENU

AUSGABE DATEI

MENU

NEUE DATEI

MENU

DATEI LÖSCHEN

MENU

CFG EPM LADEN

MENU

KONTRAST ANZEIGE

MENU

SONSTIGES

MENU

Tipp!

• Wenn Sie eine Datei mithilfe der Funktionen MASTER->EPM oder DATEI->EPM in ein EPM kopieren, werden

alle Daten auf dem Ziel-EPM überschrieben.

ABSCHNITT 4.7

ABSCHNITT 4.8

ABSCHNITT 4.9 (nur Servokonfiguration)

ABSCHNITT 4.10

ABSCHNITT 4.11

ABSCHNITT 4.12

ABSCHNITT 4.13

ABSCHNITT 4.14

ABSCHNITT 4.15

DEUTSCH

11

Page 36

Betrieb

4.7 Kopieren von Daten zwischen verschiedenen EPMs

Mit dieser Funktion kann eine Parameterdatei direkt von einem EPM (einem „Master“) in ein anderes EPM kopiert werden.

• Schließen Sie das EPM mit der zu kopierenden Parameterdatei am MASTER PORT an.

• Schließen Sie das EPM, in das die Parameterdatei kopiert werden soll, am EPM PORT an.

Drücken Anzeige Erklärung

1.

MENU

MASTER –> EPM

Drücken Sie die Taste, bis das Menü angezeigt wird.

2.

ENTER

3.

COPY

TO EPM

#DEFAULTS(400)>>

ÜBERTRAGEN 0%

DAT=400 EPM=312

4.

ENTER

EINGABE=[ENTER]

ÜBERTRAGEN 100%

Der Name der Parameterdatei (z. B. DEFAULTS)

des am MASTER PORT angeschlossenen EPM wird

angezeigt. Die Parameterversion der Datei wird in

Klammern angezeigt.

Die Parameterdatei wird kopiert oder ...

... falls die Parameterversion der Datei nicht

der Parameterversion des am EPM PORT

angeschlossenen EPM entspricht, ...

... wird eine Sicherheitsüberprüfung bezüglich der

im EPM vorhandenen Daten durchgeführt:

Drücken Sie die Taste ENTER, um die vorhandenen

Daten zu überschreiben.

Drücken Sie die Taste MENU, um den Vorgang

abzubrechen.

Die Parameterdatei wird kopiert.

#DEFAULTS(400)>>

5.

MENU

Tipp!

• Der Dateiname des MASTER EPM wird nur angezeigt, wenn die Benutzerparameter exakt den OEMStandardparametern entsprechen ( siehe Abschnitt 1.3, EPM-Technologie und -Betrieb).

• Wenn die Benutzer- und die OEM-Speicherbereiche nicht übereinstimmen, wird der Name der Parameterdatei

des am MASTER PORT angeschlossenen EPM angezeigt mit #********(400)>>. Dadurch wird angezeigt,

dass die Benutzerparameter nicht mehr den OEM- bzw. den Werkseinstellungen entsprechen.

• Mit MASTER -> EPM wird nur die Datei mit den Benutzerparametern vom MASTER kopiert und sowohl im

Benutzer- als auch im OEM-Speicher des am EPM PORT angeschlossenen EPM gespeichert. Der Name der

Parameterdatei des neuen EPM wird angezeigt mit #????????(400)>>.

• Servoregler speichern keine OEM-Standardwerte. Aus diesem Grund wird der Name der Parameterdatei immer

angezeigt mit ********(16384)>.

MASTER –> EPM

Wechselt zurück zum Hauptmenü.

12

DEUTSCH

Page 37

Betrieb

4.8 Kopieren einer im Programmiergerät gespeicherten Datei in

ein EPM

Mit dieser Funktion kann eine im EPM-Programmiergerät gespeicherte Parameterdatei in ein EPM kopiert werden.

• Schließen Sie das EPM, in das die Parameterdatei kopiert werden soll, am EPM PORT an.

Drücken Anzeige Erklärung

1.

MENU

DATEI –> EPM

Drücken Sie die Taste, bis das Menü angezeigt wird.

Der gespeicherte Name einer im EPMProgrammiergerät gespeicherten Parameterdatei

(z. B. DEFAULTS) wird angezeigt.

Der Cursor in der Anzeige auf der rechten Seite

blinkt.

Wählen Sie die Parameterdatei, die kopiert werden

soll (z. B. ABC_ _ _ _ _).

Die Parameterdatei wird kopiert oder ...

... falls die Parameterversion der Datei nicht

der Parameterversion des am EPM PORT

angeschlossenen EPM entspricht, ...

... wird eine Sicherheitsüberprüfung bezüglich der

im EPM vorhandenen Daten durchgeführt:

Drücken Sie die Taste ENTER, um die vorhandenen

Daten zu überschreiben.

Drücken Sie die Taste MENU, um den Vorgang

abzubrechen.

Die Parameterdatei wird kopiert.

#DEFAULTS(400)>>

#DEFAULTS(400

#ABC_____(400

)

)

ÜBERTRAGEN 0%

>>

>>

2.

ENTER

3.

ENTER

4.

5.

COPY

TO EPM

DAT=400 EPM=312

EINGABE=[ENTER]

6.

ENTER

ÜBERTRAGEN 100%

#ABC_ _ _ _ _(400)>>

7.

MENU

DATEI –> EPM

Wechselt zurück zum Hauptmenü.

DEUTSCH

13

Page 38

Betrieb

4.9 Bearbeiten des EPM

Dieser Menüpunkt wird nur angezeigt, wenn das EPM-Programmiergerät für ein Servoprodukt konfiguriert wurde.

Mit dieser Funktion können für Servoansteuerungen des Models 94 folgende Einstellungen bearbeitet werden: PPP

BAUDRATE, NETWORK ADDRESS, CAN NODE ID, und CAN BAUDRATE.

Drücken Anzeige Erklärung

1.

MENU

AUSGABE EPM

Drücken Sie die Taste, bis das Menü angezeigt wird.

2.

ENTER

INFO EPM

********(16384)>

CAN NODE ID

NETWORK ADDRESS

NET ADDR 3

NET ADDR

NETWORK ADDRESS

AUSGABE EPM

1

5

ENTER

3.

4.

ENTER

ENTER

MENU

Tipp!

• Das EPM kann nur bearbeitet werden, wenn die Konfiguration des EPM-Programmiergeräts und die

Parameterversion des EPM identisch sind. Siehe Abschnitt 4.13 für Informationen zur Änderung der

Konfiguration des EPM-Programmiergeräts.

Diese Anfrage wird kurz angezeigt.

Die Version des EPM-Parameters wird angezeigt.

Zeigt die Parameter an, die bearbeitet werden

können.

Wählen Sie die Parameterdatei, die bearbeitet

werden soll.

(NETZWERKADRESSE wird als Beispiel angezeigt)

Der Cursor in der Anzeige auf der rechten Seite

blinkt.

Ändern Sie den Parameter.

Speichert den neuen Wert im EPM.

Wechselt zurück zum Hauptmenü.

14

DEUTSCH

Page 39

Betrieb

4.10 Bearbeiten einer im Programmiergerät gespeicherten Datei

Mit dieser Funktion kann eine im EPM-Programmiergerät gespeicherte Parameterdatei eines Umrichteransteuerungsreglers

bearbeitet werden.

Drücken Anzeige Erklärung

1.

MENU

AUSGABE DATEI

Drücken Sie die Taste, bis das Menü angezeigt wird.

DATEI WÄHLEN

>#DEFAULTS(400

>#ABC_____(400

:DATEINAME

A

:MOTOR POT FREQ

B

oder

:KEYPAD SPEED

B

:DREHRICHTUNG

C

X:PARAMETER

X

AUSGABE DATEI

2.

ENTER

3.

4.

ENTER

MENU

Diese Anfrage wird kurz angezeigt.

Der Cursor in der Anzeige auf der rechten Seite blinkt.

<

)

Der Dateiname einer Parameterdatei (z. B. DEFAULTS) wird angezeigt.

Wählen Sie die Parameterdatei, die bearbeitet werden soll.

<

)

(z. B. ABC_ _ _ _ _).

Der Cursor in der Anzeige auf der linken Seite blinkt.

Der erste bearbeitbare Eintrag wird angezeigt (z. B. DATEINAME).

Drücken Sie EINGABE, um den Dateinamen zu bearbeiten:

• Verwenden Sie die Tasten , um Buchstaben zu ändern.

• Verwenden Sie EINGABE, um zum nächsten Buchstaben zu

wechseln.

• Durch Drücken der Taste EINGABE beim letzten Zeichen wird

der Name gespeichert. Drücken Sie MENÜ, um die Aktion

abzubrechen.

Dieser Parameter legt die anfängliche Laufdrehzahl fest, wenn es sich bei

der Drehzahlquelle entweder um POT oder TASTATUR handelt.

Drücken Sie ENTER, um auf den Wert zuzugreifen, und

ihn zu bearbeiten.

Wählt die Standardrichtung des Motors, wenn dieser über eine

Remote-Tastatur gesteuert wird.

Abfolge der Parameter, die für die Konfiguration zur Verfügung

stehen, die in das Programmiergerät geladen werden soll.

Drücken Sie ENTER, um den Parameter zu bearbeiten:

• Verwenden Sie die Tasten , um die Auswahl oder den

Wert zu ändern.

• Drücken Sie ENTER, um den neuen Wert zu speichern, oder

MENÜ, um den Vorgang abzubrechen.

Wechselt zurück zum Hauptmenü.

, um

Tipp!

• Die Parameterdatei DEFAULTS ist schreibgeschützt.

- Wenn die Datei DEFAULTS bearbeitet werden soll, erstellen Sie eine Kopie dieser Datei (siehe Abschnitt 4.11).

• Eine Datei kann nur bearbeitet werden, wenn die Konfiguration des EPM-Programmiergeräts und die

Parameterversion der Datei (in Klammern angegeben) identisch sind. Wenn diese beiden Konfigurationen nicht

übereinstimmen, wird folgende Fehlermeldung angezeigt:

DATEIVER FALSEHI.! Siehe Abschnitt 4.13 für Informationen zur Änderung der Konfiguration des EPMProgrammiergeräts.

DEUTSCH

15

Page 40

Betrieb

4.11 Erstellen einer neuen Datei

Mit dieser Funktion erstellen Sie eine neue Parameterdatei im EPM-Programmiergerät. Daten für die neue Datei können aus

folgenden Quellen kopiert werden:

• Aus Parameterdateien, die im EPM-Programmiergerät zur Verfügung stehen.

• Aus einer Parameterdatei eines EPM, das am MASTER PORT angeschlossen ist.

Drücken Anzeige Erklärung

1.

MENU

2.

ENTER

NEUE DATEI

DATEINAME EING

Drücken Sie die Taste, bis das Menü angezeigt wird.

Diese Anfrage wird kurz angezeigt.

3.

4.

5.

6.

7.

8.

9.

10.

ENTER

ENTER

ENTER

ENTER

NAME:=_ _ _ _ _ _ _

NAME:A_ _ _ _ _ _ _

NAME: A=_ _ _ _ _ _

NAME: ABC=_ _ _ _

NAME: ABC_ _ _ _

KOPIERE DATEN V.

1) DATE

DATEI WÄHLEN

>#DEFAULT(400

>#ABC_____(400

ÜBERTRAGEN 100%

DATEI ERZEUGT!

Der Cursor wird unter dem ersten Zeichen des Dateinamens

positioniert.

Ein Dateiname darf maximal aus 8 Zeichen bestehen.

Verwenden Sie die Tasten , um einen Wert auszuwählen.

Um schnell zu einem Wert zu blättern, halten Sie die Taste

gedrückt. Während Sie die Taste gedrückt halten, erhöht sich

die Blättergeschwindigkeit.

Der Cursor wird unter dem nächsten Zeichen des Dateinamens

positioniert.

Wiederholen Sie Schritt 3, bis der gewünschte Name

eingegeben wurde.

Drücken Sie so lange auf ENTER, bis sich der Cursor unter

=

der achten Zeichenposition befindet. Wenn Sie jetzt erneut auf

ENTER drücken, wird der Dateiname gespeichert.

Sie können jederzeit auf die Taste MENU drücken, um die

Dateierstellung abzubrechen und zum Hauptmenü zurückzuwechseln.

I

)

Der Cursor in der Anzeige auf der rechten Seite blinkt.

Wählen Sie eine Quelle (z. B. DATEI), deren Parameter Sie in die

neue Datei kopieren möchten:

1) DATEI

2) MASTER

(Diese Meldung wird nicht angezeigt, wenn die Auswahl

von MASTER und die Durchführung der Schritte 8 und 9

übersprungen wird.)

Der Cursor in der Anzeige auf der rechten Seite blinkt.

<

Wählen Sie eine Parameterdatei, die kopiert werden soll

<

)

(z. B. ABC_ _ _ _ _). Drücken Sie die Taste MENU, um diesen

Vorgang abzubrechen.

Die neue Datei wurde erstellt.

16

NEUE DATEI

DEUTSCH

Das EPM-Programmiergerät wechselt automatisch zurück zum

Hauptmenü.

Page 41

Betrieb

4.12 Löschen einer im Programmiergerät gespeicherten Datei

Mit dieser Funktion löschen Sie die im EPM-Programmiergerät gespeicherten Dateien.

Drücken

1.

MENU

Anzeige Erklärung

DATEI LÖSCHEN

Drücken Sie die Taste, bis das Menü angezeigt wird.

2.

ENTER

3.

4.

5.

ENTER

ENTER

DATEI WÄHLEN

>#DEFAULTS(400

>#ABC_ _ _ _ _(400

EINGABE=[ENTER]

LÖSCHE DATEI

)

Diese Anfrage wird kurz angezeigt.

Der Cursor in der Anzeige auf der rechten Seite blinkt.

<

Wählen Sie die Parameterdatei, die gelöscht werden soll

<

)

(z. B. ABC_ _ _ _ _).

Drücken Sie die Taste MENU, um den Vorgang

abzubrechen.

Die Parameterdatei wurde gelöscht.

DATEI GELÖSCHT!

DATEI LÖSCHEN

Das EPM-Programmiergerät wechselt automatisch zurück

zum Hauptmenü.

4.13 Ändern der internen Konfiguration des EPM-Programmiergeräts

Mit dieser Funktion können Sie den Dateityp ändern, den das EPM-Programmiergerät bearbeiten kann, indem Sie von einem

am MASTER PORT angeschlossenen „Konfigurations-EPM“ die entsprechende Konfiguration für die Datei herunterladen,

mit der gearbeitet werden soll.

Drücken Anzeige Erklärung

1.

MENU

2.

ENTER

CFG EPM LADEN

PRÜFE MASTER

EINGABE=[ENTER]

3.

ENTER

4.

ÜBERTRAGEN 0%...100%

WARTEN-LADE KONF

KONF GELADEN!

CFG EPM LADEN

Drücken Sie die Taste, bis das Menü angezeigt wird.

Das Programmiergerät überprüft, ob es sich bei dem

am MASTER PORT angeschlossenen EPM um ein

gültiges Konfigurations-EPM handelt.

Drücken Sie die Taste ENTER, um diese Aktion zu

bestätigen.

Die neue Konfiguration wird in den Speicher des

EPM-Programmiergeräts geladen und überprüft.

Die Meldungen werden kurz angezeigt und

anschließend wechselt das EPM-Programmiergerät

automatisch zurück zum Hauptmenü.

Tipp!

• Eine Änderung der internen Konfiguration des EPM-Programmiergeräts ist nur dann erforderlich, wenn Sie eine

im EPM-Programmiergerät gespeicherte Umrichteransteuerungsdatei oder ein EPM für eine Servoansteuerung

bearbeiten. Das Programmiergerät muss für die Parameterversion der Datei konfiguriert sein.

• Konfigurations-EPMs sind bei Lenze, AC Tech oder Ihrem örtlichen Händler erhältlich.

• Konfigurationsdateien können von Ihrem PC über einen RS232-Anschluss mithilfe der TECHLINK-Software in

das EPM-Programmiergerät heruntergeladen werden.

DEUTSCH

17

Page 42

Betrieb

4.14 Kontrasteinstellung

Mit dieser Funktion können Sie den Betrachtungswinkel für die Anzeige des EPM-Programmiergeräts einstellen.

Drücken Anzeige Erklärung

1.

ON

KONTRAST ANZEIGE

Drücken Sie die Taste, bis das Menü angezeigt wird.

KONTRAST MITTEL

KONTRAST MITTE

KONTRAST XXXXX

KONTRAST NIEDRIG

KONTRAST ANZEIGE

2.

ENTER

3.

ENTER

4.

5.

ENTER

6.

MENU

Der derzeit eingestellte Wert wird angezeigt (z. B. MITTEL).

Der Cursor in der Anzeige auf der rechten Seite blinkt.

L

Wählen Sie die gewünschte Einstellung:

KONTRAST NIEDRIG

KONTRAST MITTEL

KONTRAST HOCH

Die ausgewählte Einstellung (z. B. NIEDRIG) wird akzeptiert.

Der Cursor hört auf zu blinken.

Wechselt zurück zum Hauptmenü.

4.15 Anzeigen von Statusmeldungen

Mit dieser Funktion können Sie das Passwort für das Programmiergerät festlegen und andere wichtige

Informationen anzeigen.

Drücken

1.

MENU

2.

ENTER

3.

4.

5.

6.

7.

8.

MENU

Anzeige Erklärung

SONSTIGES

/W VERSION X.XX

S

INT. KONF 400

ATEIEN: 1

D

ATTERIE: 5;8 VDC

B

ENNWORT: 0000

K

SONSTIGES

Drücken Sie die Taste, bis das Menü angezeigt wird.

Ruft das Untermenü auf. Die Softwareversion (z. B. 1.00) des

EPM-Programmiergeräts wird angezeigt.

Mit denTasten können Sie die Statusmeldungen

auswählen.

Zeigt die Parameterversion an, für die das EPMProgrammiergerät konfiguriert wurde (z. B. 400).

Zeigt die Anzahl der im EPM-Programmiergerät gespeicherten

Parameterdateien an.

Zeigt den derzeitigen Spannungsstand der 4 internen

Batterien an. Um einen sicheren Betrieb gewährleisten zu

können, darf die Batteriespannung nicht unter 3,6 VDC fallen.

Zeigt das für den geschützten Zugriff festgelegte Passwort

an (Lenze-Einstellung: 0000). Das Eingeben und Ändern des

Passworts ist im nächsten Abschnitt beschrieben.

Wechselt zurück zum Hauptmenü.

18

DEUTSCH

Page 43

Betrieb

4.16 Eingeben/Ändern des Passworts

Wenn ein Passwort festgelegt wurde, kann ohne Eingabe des korrekten Passworts nur auf die Hauptmenüs

zugegriffen werden.

• MASTER –> EPM

• ANZEIGEKONTRAST

• SONSTIGES (ohne das Untermenü KENNWORT)

Drücken Anzeige Erklärung

1.

MENU

SONSTIGES

Drücken Sie die Taste, bis das Menü angezeigt wird.

2.

ENTER

3.

4.

ENTER

5.

6.

7.

ENTER

MENU

/W VERSION X.XX

S

ENNWORT: 0000

K

KENNWORT: 000

KENNWORT: XXX

ENNWORT: XXXX

K

SONSTIGES

0

X

Ruft das Untermenü auf. Der Cursor in der Anzeige

auf der linken Seite blinkt.

Zeigt das für den geschützten Zugriff festgelegte

Passwort an (Werkseinstellung: 0000).

Wenn als Passwort 0000 festgelegt wird, ist der

geschützte Zugriff deaktiviert.

Der Cursor in der Anzeige auf der rechten Seite

blinkt.

Geben Sie ein Passwort ein. Sie können jeden Wert

zwischen 0000 und 9999 eingeben.

Verwenden Sie die Tasten

auszuwählen. Um schnell zu einem Wert zu

blättern, halten Sie die Taste gedrückt. Während

Sie die Taste gedrückt halten, erhöht sich die

Blättergeschwindigkeit.

Der Cursor in der Anzeige auf der linken Seite blinkt.

Das neue Passwort wurde gespeichert.

Wechselt zurück zum Hauptmenü.

, um einen Wert

DEUTSCH

19

Page 44

Problemlösungen

5 Problemlösungen

5.1 Fehlermeldungen

Anzeige Ursache Lösung

BATT. WECHSELN!

DATEIVER FALSCH!

DATEI SCHREIBG.!

EPM DEFEKT!

INT KONF UNGÜLTIG

EPM ZU KLEIN!

INTERNER FEHLER!

UNGÜLTIGE INT. KFG.

KENNWORT FALSCH

Die Batteriespannung ist <3,6 V (Meldung

wird nach dem Einschalten des EPMProgrammiergeräts angezeigt).

Die Parameterdatei oder das Servo-EPM,

das bearbeitet werden soll, hat eine andere

Parameterversion als die Konfigurationsdatei

des EPM-Programmiergeräts.

Sie haben versucht, die Datei DEFAULTS zu

bearbeiten oder zu löschen.

Das EPM am EPM PORT ist defekt. Wechseln Sie das defekte EPM aus.

Das EPM ist nicht korrekt am EPM PORT

angeschlossen.

Am EPM PORT, an den Sie Daten transferieren

oder den Sie bearbeiten möchten, ist kein EPM

angeschlossen.

Das EPM am EPM PORT verfügt nicht über

ausreichend Speicher für die Datei, die Sie

kopieren möchten.

Ein interner Gerätefehler ist aufgetreten. Wenden Sie sich an Ihren Lenze-Vertreter.

Die Konfigurationsdatei des EPMProgrammiergeräts ist ungültig.

Es wurde versucht, das EPM-Programmiergerät

ohne gültiges Konfigurations-EPM zu

rekonfigurieren.

Der geschützte Zugriff ist aktiviert und Sie

haben nach dem Einschalten ein falsches

Passwort eingegeben.

Neue Batterien einlegen

(siehe Abschnitt 3.2)

Sie können eine Datei nur dann

bearbeiten, wenn die Parameterversion

der Konfigurationsdatei des EPMProgrammiergeräts entspricht.

Siehe Abschnitt 4.13 bezüglich des

Änderns der internen Konfiguration des

Programmiergeräts.

Die Datei DEFAULTS kann weder

bearbeitet noch gelöscht werden.

Schließen Sie das EPM korrekt am

PORT an.

Drücken Sie die Taste MENÜ, um ins

Hauptmenü zurückzuwechseln.

Schließen Sie ein EPM am EPM PORT an.

Tauschen Sie das EPM am EPM

PORT gegen ein EPM mit höherer

Speicherkapazität aus.

Wenden Sie sich an Ihren Lenze-Vertreter.

Schließen Sie ein gültiges KonfigurationsEPM am MASTER PORT an. Siehe

Abschnitt 4.13.

Nur wenn Sie das korrekte Passwort

eingeben, haben Sie vollen Zugriff auf die

Hauptmenüs.

Wenn Sie die Taste MENU drücken,

wird der Vorgang abgebrochen und Sie

haben nur eingeschränkten Zugriff auf die

Hauptmenüs (siehe Abschnitt 4.16).

Wenn Sie das Passwort vergessen haben,

wenden Sie sich an Ihren Lenze-Vertreter.

20

DEUTSCH

Page 45

Problemlösungen

Anzeige Ursache Lösung

MASTER DEFEKT!

MASTER FEHLT

MASTER UNGÜLTIG!

NAME VORHANDEN!

SPEICHER VOLL

ÜBERTRAG.FEHLER

UNGÜLTIGE OPTION!

UNGÜLTIG EPM!

KEINE DATEIEN

KONF EPM FEHLT!

Das EPM am MASTER PORT ist defekt. Drücken Sie die Taste MENÜ, um ins

Das EPM ist nicht korrekt am MASTER PORT

angeschlossen.

Diese Meldung wird beim Einschalten

angezeigt, wenn am MASTER PORT kein EPM

angeschlossen ist.

Das Programmiergerät möchte Daten über den

MASTER PORT abrufen, kann an diesem PORT

jedoch kein EPM erkennen.

Das am MASTER PORT angeschlossene EPM,

von dem Sie Daten abrufen möchten, ist defekt

oder verfügt über keine gültigen Daten.

Das EPM am MASTER PORT ist ein

Konfigurations-EPM.

Der Name, den Sie einer Parameterdatei

zuweisen möchten, existiert bereits.

Der interne Speicher des EPMProgrammiergeräts ist voll.

Bei der Datenübertragung zum EPM PORT ist

ein Fehler aufgetreten, weil der Speicherchip

defekt oder das EPM nicht korrekt am PORT

angeschlossen ist.

Ein MASTER -> EPM-Transfer wurde versucht,

wobei sich die Speichergröße des MASTER

EPM von der des Ziels unterscheidet.

Bei der Datenübertragung zum EPM PORT

ist aufgrund eines internen Fehlers im EPMProgrammiergerät ein Fehler aufgetreten.

Es wurde versucht, eine neue Datei von

einem am MASTER PORT angeschlossenen

Servoansteuerungs-EPM zu erstellen.