Page 1

Informati

onforthe

operato

r

EDK82MVXXX

Show/Hide Bookmarks

!N;,

of the machine/system

Ä!N;,ä

Global Drive

8200 motec

Frequency inverter

0.25 ... 7.5 kW

Page 2

This documentation applies to 8200 motec inverters as of version

Show/Hide Bookmarks

E82MV xxx _ x B001 XX Vx 2x

Type

Power

(e.g.551=55× 10

(e.g.752=75× 10

Voltage class

2 = 230 V

4 = 400 V/500 V

Hardware version

Software version

1

W = 0,55 kW)

2

W=7,5kW)

ã

2002 Lenze AG

This documentation contains all information the machine operator require in order

to operate the drive controller of the 8200 motec series installed in your

machine/system.

If you do not change the content, you are allowed to use the information in this

documentation for your purposes without contacting Lenze.

The information necessary for the project planning of a machine/system can be found in

the Mounting Instructions and Operating Instructions for the 8200 motec frequency

inverters. The Mounting Instructions are included in the scope of delivery, the Operating

Instructions can be ordered at your Lenze representative.

The downloading of the Lenze documentation can be made in the internet as an Adobe

Acrobat

file:

http://www.lenze.de

1.0 03/2002 TD14

Page 3

Safety information

Show/Hide Bookmarks

Lenze contr ollers

1 Safety information

1.1 General safety and application notes for Lenze controllers

(according to Low-Voltage Directive 73/23/EEC)

1. General

Lenze controllers (frequency inverters, servo inverters, DC controllers) can carry a voltage or parts of the controllers can rotate during operation. Surfaces can be hot.

If the required cover is removed, the controllers are used inappropriately or installed or operated incorrectly, severe damage to persons or material assets can occur.

For more information please see the documentation.

All operations concerning transport, installation, and commissioningas well as maintenance must be carried out by qualified, skilled personnel (IEC 364 and CENELEC HD

384 or DIN VDE 0100 and IEC report 664 or DIN VDE 0110 and national regulations for t he prevention of accidents must be observed).

According to this basic safety information qualified, skilled personnel are persons who are familiar with the assembly, installation, commissioning, and operation of the

product and who have the qualifications necessary for their occupation.

2. Intended use

Drive controllers are components which are designed for the installation into electrical systems or machinery. They are not to be used as domestic appliances, but only

for industrial purposes according to EN 61000-3-2. The documentation contains information about the compliance of the limit values with EN 61000-3-2.

When installing controllers into machines, commissioning of the drive controllers (i.e. the starting of operation as directed) is prohibited until it is proven that the machine

corresponds to the regulations of the EC Directive 98/37/EG (Machinery Directive); EN 60204 (VDE 0113) must be observed.

Commissioning (i.e. starti ng of operation as directed) is only allowed when there is compliance with t he EMC Directive (89/336/EEC).

The drive controllers meet the requirements of the Low-Voltage Directive 73/23/EEC. The harmonised standards EN 50178/DIN VDE 0160 a pply to t he controllers.

The technical data as well as the connection conditions can be obtained from the nameplate and the documentation. The instructions given must be strictly observed.

Warning: Controllers are products with restricted availability according to EN 61800-3. These products can cause interferences in residential premises. If controllers are

used in residential premises, corresponding measures are required.

3. Transport, storage

The notes on transport, storage and appropriate handling must be observed.

Climatic conditions according to EN 50178 apply.

4. Installation

The controllers must be installed and cooled according to the regulations given in the corresponding Instructions.

Ensure careful handling and avoid mechanical overload. Do not bend any components and do not change the insulation distances during transport and storage. Electronic

components and contacts must not be touched.

Controllers contain electrostatically sensitive components which can easily be damaged by inappropriate handling. Do not damage or destroy any electrical components

since this could mean hazards for your health!

5. Electrical connection

When working on live controllers, the valid national regulations for the prevention of accidents (e. g. VBG 4) must be observed.

The electrical installation must be carried out in compliance with the corresponding regulations (e.g. cable cross-sections, fuses, PE connection). Additional notes and

information can be obtained from the corresponding Instructions.

The Instructions contain notes concerning wiring according to EMC regulations (shielding, earthing, filters and cable routing). These notes must also be observed when

using CE-marked controllers. The compliance with limit values required by the EMC legislation is the responsibility of the manufacturer of the machine or system.

6. Operation

If necessary, systems including controllers must be equipped with additional monitoring and protection devices according to the applying safety regulations (e.g. regulation

for technical equipment, regulation for the prevention of accidents). The controller can be adapted to your application. Please observe the corresponding information given

in the Instructions.

After a controller has been disconnected from the voltage supply, all live components and power connections must not be touched immediately because capacitors can

still be charged. Please observe the corresponding stickers on the controller.

All protection covers and doors must be shut during operation.

Note for UL-approved systems with integrated controllers: UL warnings are notes which only apply to UL systems. The Instructions give UL-related information.

7. Safe standstill

The variant V004 of 9300 and 9300 vector, the variant Bx4x of 8200 vector controller and the axis controller ECSXA064 support the function ”Safe standstill”, protection

against unexpected start, according to the requirements of Annex I No. 1.2.7 of the EC Directive ”Machinery” 98/37/EG, DIN EN 954-1 category 3 and DINEN 1037. Please

observe the notes on the function ”Safe standstill” given in the corresponding Instructions.

8. Maintenance and service

Please observe the Instructions given by the manufacturer.

Please observe the product-specific safety and application notes in these Instructions.

l EDK82MVXXX EN 1.0

3

Page 4

Safety information

Show/Hide Bookmarks

Lenze low-voltage machinery

1.2 General safety and application notes for Lenze low-voltage machinery

(in conformity with the Low-Voltage Directive 73/23/EEC)

1. General

Low-voltage machines have dangerous, live and rotating parts as well as possibly hot surfaces. All operations serving transport, connection, commissioning and

maintenance are to be carried outbyskilled,responsible technical personnel (observe EN 50110-1(VDE0105-100);IEC60364). Improper handling can cause severe injuries

or damages.

Synchronous machines induce voltages at open terminals during operation.

2. Application as directed

These low-voltage machines are intended for industrial and commercial installations. They comply with the harmonized standards of the series EN 60034 (VDE O53O).

Their use in hazardous areas is prohibited unless they are expressly intended for such use (follow additional instructions).

The enclosures ≤IP23 are by no means intendedfor outdooruse. Air-cooled designsare ratedforambienttemperaturesbetween -15 °C and -10 °Cand+40°C and altitudes

≤ 1000 m a.m.s.l., from -20 °C to +40 °C without brake or with spring- operated brake, with separate ventilation or self ventilation, from -15 °C to +40 °C with permanent

magnet brake and from -10 °C to +40 °C with separate fan. Check indications on the nameplate and if they are different, observe them. The conditions on site must

correspond to all nameplate data.

Low-voltage machines are components for the installation into machines as defined in the Machinery Directive98/37/EC. Commissioning is prohibited until the conformity

of the end product with this Directive has been established (follow a.o. EN 60204-1).

The integrated brakes cannot be used as safety brakes. It cannot be ruled out that factorswhich cannot be influenced, such as oil ingression because of a defective A-side

shaft seal, cause a torque reduction.

3. Transport, storage

The forwarder must be informed directly after receipt of the goods about all damages or deficiencies; if necessary, commissioning must be stopped. Tighten screwed-in

ring bolts before transport. They are designed for the weight of the low-voltage machine, do not apply extra loads. If necessary, use suitable and adequately dimensioned

means of transport (e.g. rope guides).

Remove the shipping brace before commissioning. Reuse it for further transports. For storage of low-voltage machines ensure a dry, dust-free and low-vibration

(v

≤ 0.2 mm/s) environment (danger of bearing damage at rest). Measure the insulation resistance before commissioning. If the values are ≤ 1kΩ per volt of rated

rms

voltage, dry the winding.

4. Installation

Ensure an even surface, solid foot or flange mounting and exact alignment if a direct clutch is connected. Avoid resonances with the r otational frequency and double mains

frequency which maybe caused by the assembly. Turn rotor by hand, listen for unusual slipping noises.Check the direction of rotation when the clutchis not active (observe

section 5).

Use appropriate tools to mount or remove belt pulleys and clutches (heat generation!) and cover them with a touch guard. Impermissible belt tensions must be avoided

(technical list).

The machines are half-key balanced. The clutch must be half-key balanced, too. The visibly protruding part of the key must be removed.

If required, provide pipe connections. Mounting positions with shaft end at top must be protected with a cover which avoids the ingression of foreign particles into the fan.

Free circulation of the cooling air must be ensured. The exhaust air - also the exhaust air of other machines next to the drive system - must not be immediately taken in

again.

5. Electrical connection

All operations must be carried outonly by qualified and skilled personnel when the low-voltagemachineis at standstill and whenthemachine is de-energized and protected

against unintentional restart. This also applies to auxiliary circuits (e.g. brake, encoder, separate fan).

Check safe isolation from the supply!

If the tolerances in EN 60034-1; IEC 34 (VDE 0530-1) - voltage ±5 %, frequency ±2 %, waveform, symmetry - are exceeded, more heat will be generated and the

electromagnetic compatibility will be influenced.

Observe the indications on the nameplate, operating notes, and the connection diagram in the terminal box.

The connection must ensure a continuous and safe electrical supply (no loose wire ends); use appropriate cable terminals. The connection to the PE conductor must be

safe. The plug-in connector must be screwed up tightly (to stop).

The clearances between bare, live parts and earth must not fall below: 8 mm at V

The terminal box must be clean and dry; foreign particles, dirt and moisture affect operation. All unused cable entries and the box itself must be sealed against dust and

water. For the trial run without output elements, lock the key. Check brake opera tion before the commissioning of low-voltage machines with brakes.

6. Operation

Vibration severities v

e.g. increased temperature, noise, vibration, find the cause and, if necessary, contact the manufacturer. Switch-off the machine in problematic situations.

If the drive is exposed to dirt, clean it regularly.

Do not switch-off the protection devices, not even for trial runs.

Integrated temperature sensors do not provide full protection. If necessary, limit the maximum current. Connect the function blocks to the option switch-off after several

seconds of operation at I > I

Shaft seals and bearings have a limited service life.

Regrease the bearings using the relubrication facility while the low-voltage machine is running. Observe the saponification number. If the grease drain hole is sealed with

a plug (IP54 drive end; I P23 drive end and non-drive end), remove the plug before commissioning. Seal the bore holes with grease. Replace the prelubricated bearings

(2Z-bearings) after approx. 10.000 h - 20.000 h, at the latest however after 3 - 4 years. Observe the manufacturer’s instructions.

≤ 3.5 mm/s (P

rms

≤ 15 kW) or 4.5 mm/s (P

rated

, especially if blocking may occur.

rated

> 15 kW) are acceptable when the clutch is activated. If deviations from normal operation occur,

rated

≤ 550 V, 10 mm at V

rated

≤ 725 V, 14 mm at V

rated

rated

≤ 1000 V.

4

EDK82MVXXX EN 1.0

l

Page 5

1.3 Residual hazards

Show/Hide Bookmarks

Safety information

Residual hazards, Layout of the safety instructions

Protection of

persons

• Before working on the motec or opening the housing, check that no voltage is appli ed. Wait for at least 3 minutes, since after mains switch-off

the power terminals U, V, W; BR0, BR1, BR2 and the pins of the FIF interface remain live.

– A fter you have opened the motec check whether the power terminals L1, L2, L3; U, V, W; BR0, BR1, BR2, relay outputs K 11, K12, K14 and

pins of the FIF interface are not live an y more.

– Even if the motec is separated from the mains, the relay outputs K11, K12, K14 can remain live!

• If you use the not fail-safe functi on “Selection of direction of rotation” via the digital signal DCTRL1- CW/CCW

(C0007 = -0- ... -13-, C0410/3 ≠ 255):

– I n the event of an open circuit or failure of the control voltage, the drive can change its direction of rotation.

• If you use the function ”Flying-restart circuit” (C0142 = -2-, -3-) with machines with a low moment of inertia and a minimum friction:

– A fter controller enable in standstill, the motor can start for a short time or change its direction of rotation for a short time.

• The motec heatsink temperature is > 60 °C:

– Direct skin contact with the heatsink results in burnings.

Controller

protection

• 8200 motec 3 ... 7,5 kW (E82MV302_4B, E82MV402_4B, E82MV552_4B, E82MV752_4B):

– Cyclic connection and disconnection of the controller supply voltage at L1, L2, L3 can exceed and destroy the input current limit!

– In case of cyclic mains switching over a longer period of time three minutes ha ve to pass between two starting operations!

• Depending on the controller settings, the co nnected motor can be overheated:

– at, for instance, longer DC-braking operations.

– at longer operation of self-ventilated motors at low speed.

Overspeeds • Drives can reach dangerous overspeeds (e.g. setting of inappropriately high field frequencies):

– The controllers do not offer any protection against these operating conditions. For this, use additional components.

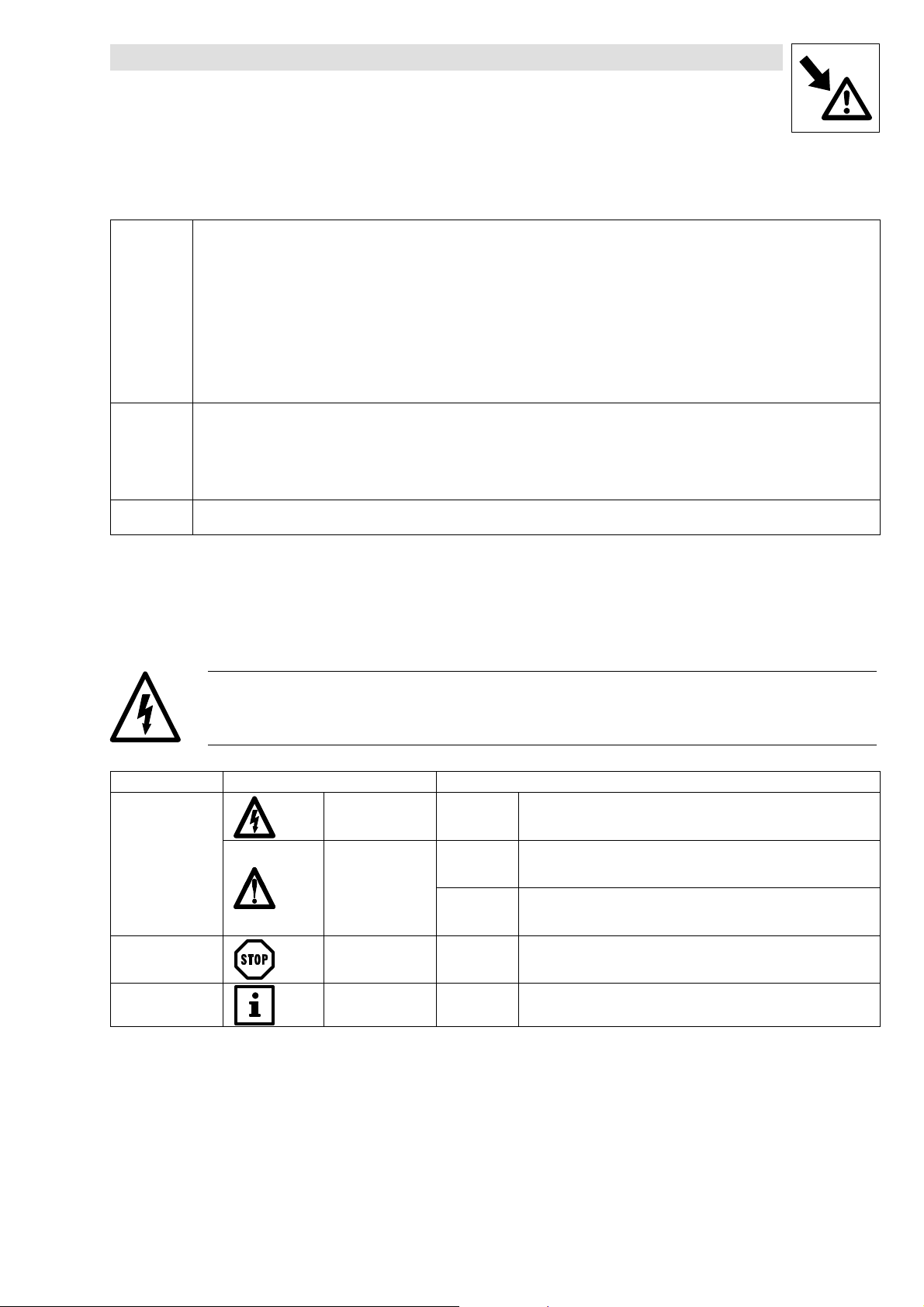

1.4 Layout of the safety information

All safety information given in these Operating Instructions have the same layout:

Signal word (characterises the severity of danger)

Note (describes the danger and gives information how to avoid it)

Icons used Signal words

Warning of danger

to persons

Warning of damage

to material

More information Tip! Designates a general, useful note.

Warning of hazardous

electrical voltage

Warning of a general

danger

Danger! Warns of impending danger.

Consequences if disregarded:

Death or most severe injuries

Warning! Warns of potential, very hazardous situations.

Possible consequences if disregarded:

Death or most severe injuries

Caution! Warns of potential, hazardous situations.

Possible consequences if disregarded:

Light or minor injuries

Stop! Warns of potential damage to material.

Possible consequences if disregarded:

Damage of the controller/drive system or its environment

If you observe it, handling of the controller/drive system is made easier.

l

EDK82MVXXX EN 1.0

5

Page 6

Parameter setting

Changespossiblewhen

Show/Hide Bookmarks

Parameter setting using the keypad

2 Parameter setting

2.1 Parameter setting using the keypad

The keypad is available as accessory. A full description can be obtained from the information

included in the keypad delivery.

0 Function keys

1 Status display

2 Bargraph display

3 Function bar 1

4 Function bar 2

5 Parameter set

6 Code number

7 Subcode number

8 Parameter value with unit

Changes possible when

lamp is blinking

2.1.1 Menu structure

All parameters for controller setting or monitoring are saved incodes under the menus User and all.

The codes have numbers 6 and are abbreviated in the text with a ”C” before the number. Some

codes store the parameters in numerical “subcodes” 7 to ensure that parameter setting is clearly

structured (example: C0517 menu User).

• The menu User

– is active after every mains switching or keypad attachment during operation.

– contains all codes for a standard application with linear V/f characteristic control (Lenze

setting).

– can be modified as required under C0517.

• The menu all

– contains all codes.

– shows a list of all codes in ascending order.

• The change between User and all and how to change parameters in the codes is described

on the following pages.

6

EDK82MVXXX EN 1.0

l

Page 7

Parameter setting

C0034Setpointselectionrange

0

C0007Fixedconfigurationofdigitalinputs0

Show/Hide Bookmarks

Parameter setting using the keypad

2.1.2 The menu U

r - The 10 most important drive parameters

UUUsssseeeerrr

After mains switching or plugging in the keypad during operation, the 10 codes defined to be the

most important in the user menu User (Code C0517) are available immediately.

In default setting the menu contains User all codes required for a standard application with linear V/f

characteristic control.

Code Name Lenze setting

C0050 Output frequency Display: Output frequency without slip compensation

C0034 Setpoint selection range -0-

C0007 Fixed configuration of digital inputs -0-

C0010 Minimum output frequency 0.00 Hz

C0011 Maximum output frequency 50.00 Hz

C0012 Acceleration time main setpoint 5.00 sec

C0013 Deceleration time main setpoint 5.00 sec

C0015 V/f rated frequency 50.00 Hz

C0016 U

C0002 Parameter set transfer/reset seecodetable

boost depending on the inverter type

min

Standard I/O X3/8: 0 ... 5 V / 0 ... 10 V / 0 ... 20 mA

Application I/O

E4 E3 E2 E1

CW/CCW DCB JOG2/3 JOG1/3

CW/CCW rotation DC-injection brake

X3/1U: 0 ... 5 V / 0 ... 10 V

X3/2U: 0 ... 5 V / 0 ... 10 V

Tip!

Use C0002” Parameter set transfer” to easily transfer configurations from one controller to theother

or to reset the controller to Lenze settings.

Selection of fixed setpoints

l EDK82MVXXX EN 1.0

7

Page 8

Parameter setting

p

Show/Hide Bookmarks

Parameter setting using the keypad

2.1.3 Change between the menus U

USEr

j gfkih PS

mno

qr

Hi

j gfkih PS

Lo

mno

qr

Hi

j gfkih PS

~5 s

bcd e

j gfkih PS

mno

p

qr

0050

Hi

Lo

000

5

z

wx

y

z

wx

y

a

1

000

Hz

s

vtu

s

vtu

mno

Hi

Lo

j gfkih PS

mno

qr

Hi

Lo

z

wx

y

Lo

mno

qr

Hi

j gfkih PS

Lo

mno

qr

Hi

j gfkih PS

Lo

mno

qr

Hi

j gfkih PS

Lo

mno

qr

Hi

bcd e

j gfkih PS

Lo

000

mno

p

qr

Hi

bcd e

j gfkih PS

Lo

000

mno

p

qr

0007

Hi

bcd e

j gfkih PS

Lo

000

p

qr

0034

bcd e

000

p

0050

000

s

vtu

bcd e

000

p

bcd e

000

p

001 1

001 0

a

000

Hz

r and A

UUUSSSSEEEErrr

bcd e

p

bcd e

000

p

001 6

bcd e

000

p

001 5

bcd e

000

p

001 3

001 2

a

000

Hz

a

000

Hz

a

1

000

Hz

a

1

000

Hz

1

0002

a

000

a

000

Hz

a

1

000

Hz

1

1

Hz

a

000

Hz

1

1

a

000

Hz

1

1

AAALLLLLLL

L

z

wx

y

z

s

t

wx

y

u

v

j gfkih PS

mno

qr

Hi

Lo

vtu

wx

s

mno

Hi

Lo

z

y

j gfkih PS

mno

qr

Hi

Lo

j gfkih PS

mno

qr

Hi

Lo

bcd e

j gfkih PS

p

qr

0002

bcd e

000

p

0001

000

s

vtu

j gfkih PS

mno

qr

Hi

Lo

bcd e

p

001 0

000

bcd e

p

0007

000

a

000

Hz

a

1

000

Hz

ALL

1

bcd e

p

0988

000

a

1

000

Hz

a

1

000

Hz

a

000

Hz

1

z

s

t

wx

y

u

v

bcd e

j gfkih PS

mno

p

qr

Hi

Lo

0050

suer

a

000

Hz

z

s

wx

y

vtu

1

z

s

wx

y

vtu

z

s

t

wx

y

u

v

bcd e

j gfkih PS

mno

p

qr

Hi

Lo

0050

AL L

a

000

Hz

1

2.1.4 Parameter change in menus

Step Keys Display Note Example

1. Controller inhibit

Set parameters

2.

3.

4.

s dc

wx f

z XXXX

x k

001

5.

6.

7.

8.

yz XXX

x i 5.00 s

yz XXXXX

v STOre

w

9. Restart the ”loop” at 2. to set other parameters.

Only necessary if you want to change codes marked with “[ ]” in

the code table, e. g. [C0002].

All other parameters can be changed during operation.

Select code

For codes without subcodes: Jump to i (and then 6.)

Select subcode

Set parameters

Acknowledge entry if p blinking

Acknowledge entry if p is not blinking; v is not active

0012

1.00 s

8200vec075

Reduce C0012

(acceleration time)

from 5.00 s to 1.00 s

8

EDK82MVXXX EN 1.0

l

Page 9

Troubleshooting and fault elimination

Motordoesno

t

rotatesmoothl

y

Current

consumptionof

i

dentif

icat

i

Show/Hide Bookmarks

Maloperation of the drive

3 Troubleshooting and fault elimination

3.1 Maloperation of the drive

Fault Cause Remedy

Motor does n ot

rotate

Motor does n ot

rotate smoothly

Current

consumption of

motor too high

Motor rotates,

setpoints are

“0”

Motor

parameter

stops with error

LP1

Unacceptable

drive response

with vector

control

DC-bus voltage too low

(Red LED is blinking every 0.4 s;

keypad display

Controller inhibited

(Green LED is blinking, keypad display:

Automatic start inhibited (C0142 = 0 or 2) LOW-HIGH edge at X3/28

DC injection brake active (DCB) Deactivate DC-injection brake

Mechanical motor brake is not released Manual or electrical release of mechanical motor brake

Quick stop (QSP) active (keypad display: c) Remove quick stop

Setpoint = 0 Setpoint selection

JOG setpoint activated and JOG frequency = 0 JOG setpoint selection (C0037 ... C0039)

Active fault Eliminate fault

Wrong parameter set active Change to correct parameter set via terminal

Control mode C0014 = -4-, -5-, but no motor parameter identificatio n Motor parameter identification (C0148)

Under C0410 several functions, which exclude each other, are assigned to the

same signal source.

Use internal voltage source X3/20 for function modules Standard-I/O, INTERBUS,

PROFIBUS-DP or LECOM-B (RS485):

Bridge between X3/7 and X3/39 is missing

Defective motor cable Check motor cable

Maximum current too low (C0022, C0023) Adaptation to application

Motor underexcited or overexcited Check parameter setting (C0015, C0016, C0014)

C0084, C0087, C0088, C0089, C0090, C0091 and/or C0092 are not adapted to

the motor data

Setting of C0016 too high Correct setting

Setting of C0015 to o low Correct setting

C0084, C0087, C0088, C0089, C0090, C0091 and/or C0092 are not adapted to

the motor data

With the function j of the keypad a setpoint has been selected. Set the setpoint to ”0” by C0140 = 0

Motor too small compared with rated power

on

DC brake active via terminal

various Vector control optimisation

LU)

c)

Check mains voltage

Remove the controller inhibit, controller inhibit can be set

through several sources

If necessary, correct start condition (C0142)

Correct configuration in C0410

Jumper terminals

Manual adaptation or identification of motor parameters

(C0148)

Manual adaptation or identification of motor parameters

(C0148)

l EDK82MVXXX EN 1.0

9

Page 10

Troubleshooting and fault elimination

ccr

y

min

L

U

g

Show/Hide Bookmarks

Error messages

3.2 LEDs at the controller (operating status display)

LED Operating status

green red

on off Controller enabled

on on Mains switched on and automatic start inhibited

blinking off Controller inhibited

off blinking every second Fault active, check under C0161

off blinking every 0.4 seconds Undervoltage switch-off

fast blinking off Motor parameter identification

3.3 Fault messages at the keypad or in the parameter setting program Global Drive Control

Display Fault Cause Remedy

Keypad PC

noer

ccr

a

ce0

a

ce1

a

ce2

a

ce3

a

ce4

a

ce5

a

ce6

a

EEr

a

H05

a

id1

a

LP1

a

LP1

LU

c

1)

0 No fault - -

71 System fault

61 Communication error to A I F Transmission of control commands via AIF is

62 Communciation error at

CAN-IN1 with sync control

Strong interferences on control cables Shield control cables

Ground or earth loops in the wiring

interfered

CAN-IN1 object receives faulty data or

communication interrupted

Plug the communication module firmly into the hand

terminal

• Plug-in connection for bus module ó Check FIF

• Check transmitter

• Increase monitoring time under C0357/1 if necessary

63 Communication error to

CAN-IN2

CAN-IN2 object receives faulty data or

communication is interrupted

• Plug-in connection for bus module ó Check FIF

• Check transmitter

• Increase monitoring time under C0357/2 if necessary

64 Communication error to

CAN-IN1 with event or time

control

65 BUS-OFF

(many communication errors

occurred)

CAN-IN1 object receives faulty data or

communication interrupted

Controller has received too many faulty telegrams

via system bus and has been disconnected from the

bus

• Plug-in connection for bus module ó Check FIF

• Check transmitter

• Increase monitoring time under C0357/3 if necessary

• Check whether the bus terminator is available

• Check screen contact of the cables

• Check PE connection

• Check the bus load, if necessary, reduce the baud rate

66 CAN Time-Out

67 Function module system bus

(CAN) is set to ”Warning” or

”BUS-OFF”

(only generated if C0128 = 1)

91 External error (TRIP-SET) A digital signal used for the function TRIP set has

105 Internal fault Contact Lenze

140 Faulty parameter identification Motor not connected Connect motor

32 Error in motor phase

(only generated if C0597 = 1)

182 Error in motor phase

(only generated if C0597 = 2)

1030 DC-bus undervoltage

With remote parameter setting via system bus

(C0370):

Slave does not respond. Communication monitoring

time exceeded

OperationwithmoduleonFIF:

Internal error

CAN controller sends ”Warning” or ”BUS-OFF” • Check whether the bus is terminated

• Check wiring of the system bus

• Check system bus configuration

Contact Lenze

• Check screen contact of the cables

• Check PE connection

• Check the bus load, if necessary, reduce the baud rate

been activated.

• Failure of one/several motor phase(s)

• Motor current too low

Check external encoder

• Check motor cables

• V

boost

min

• Connect motor with corresponding power or adapt

motor under C0599

Mains voltage too low Check mains voltage

DC-bus voltage too low Check supply module

400 V controller connected to 240 V mains Connect the controller to the appropriate mains voltage

10

EDK82MVXXX EN 1.0

l

Page 11

Display RemedyCauseFault

a

OC2

a

OC6

(

)

O

H

p

a

(yg

(yg

O

U

g

Show/Hide Bookmarks

Keypad PC

OC1

1)

11 short-circuit

a

OC2

12 Earth fault

a

OC3

a

OC4

a

OC5

a

OC6

13 Overload inverter during

acceleration or short circuit

14 Overload controller during

deceleration

15 Controller overload in

stationary operation

16 Motor overload (I2x t overload)

a

OH

50 Heatsink temperature > +85°CAmbient temperature T

a

OH

e

OH3

a

OH4

- Heatsink temperature > +80

°C

53 PTC monitoring (TRIP)

(only generated if C0119 = 1

or 4)

54 Controller overtemperature Controller inside too hot • Reduce controller load

a

OH51

OU

203 PTC monitoring

(only generated if C0119 = 2

or 5)

1020 DC-bus overvoltage

c

Pr

a

Pr1

a

Pr2

a

Pr3

a

Pr4

a

Pr5

75 Faulty parameter transfer when

using the keypad

72 Faulty transmission of PAR1

when using the keypad

73 Faulty transmission of PAR2

when using the keypad

77 Faulty transmission of PAR3

when using the keypad

78 Faulty transmission of PAR4

when using the keypad

79 Internal fault Contact Lenze

a

Pt5

a

81 Time error during parameter

set transfer

Troubleshooting and fault elimination

Error messages

short-circuit • Find reason for short circuit; check motor cables

Excessive capacitive charging current of the motor

cable

Grounded motor phase Check motor, check motor cable

Excessive capacitive charging current of the motor

cable

Acceleration time (C0012) too short • Increase acceleration time

Defective motor cable Check wiring

Interturn fault in the motor Check motor

Deceleration time too short (C0013) • Allow longer deceleration time

Long and frequent overload periods Check drive selection

Motor thermally overloaded by for instance

• impermissible continuous current • Check drive selection

• frequent or too long acceleration processes • Check setting under C0120

>+60°C • Allow controller to cool down and ensure better

amb

Heat sink very dirty Clean heat sink

Impermissible high current or frequent and long

acceleration processes

Motor too hot because of impermissibly high

current or frequent and long acceleration processes

PTC not connected Connect PTC or switch-off monitoring (C0585=3)

Motor too hot because of impermissibly high

current or frequent and long acceleration processes

PTC not connected Connect PTC or switch-off monitoring (C0585=3)

Mains voltage too high Check voltage supply

Braking operation • Prolong deceleration times.

Earth leakage on the motor side Check motor cable and motor for earth fault (disconnect

All parameter sets are faulty

PAR1 is faulty.

PAR2 is faulty.

PAR3 is faulty.

PAR4 is faulty.

Data flow interrupted by keypad or PC, e. g. keypad

disconnected during data transmission.

• Check brake resistor

Use shorter/low-capacity motor cables

Use shorter/low-capacity motor cables

Earth fault detection can be deactivated for checking

• Check drive selection

• Check the external brake resistor selection

ventilation

• Check ambient temperature

• Check drive selection

• Check load, if necessary replac e sluggish, defective

bearings

Check drive selection

• Improve cooling

• Check fan in the controller

Check drive selection

• For operation with external brake resistor:

– Check dimensioning, supply and connection of brake resistor

– Increase the deceleration times

motor from inverter)

It is absolutely necessary to repeat the data transfer or

load the factory setting before the controller is enabled.

It is absolutely necessary to repeat the data transfer or

load the factory setting before the controller is enabled.

l

EDK82MVXXX EN 1.0

11

Page 12

Display RemedyCauseFault

Show/Hide Bookmarks

Keypad PC

rSt

a

sd5

a

1)

76 Faulty auto-TRIP reset More than 8 fault messages in 10 minutes Depends on the fault message

85 Open wire at analog input

(setpoint range 4 ... 20 mA)

1)

Troubleshooting and fault elimination

Error messages

Current at analog input < 4 mA Close circuit at analog input

LECOM error number

12

EDK82MVXXX EN 1.0

l

Page 13

Page 14

Page 15

Page 16

Lenze Drives GmbH, Postfach 10 13 52, D-31763 Hameln

Standort: Hans-Lenze-Straße 1, D-31855 Aerzen,

Telefon +49

Telefax Service +49

E-Mail: Lenze@Lenze.de · Internet:

Printed in Germany 04/10

(0) 51 54 / 82-0, Telefax +49 (0) 51 54 / 82-21 11

(0) 51 54 / 82-11 12

http://www.Lenze.com

Loading...

Loading...