Page 1

EDBCSXP064

.LKr

Ä.LKrä

Operating Instructions

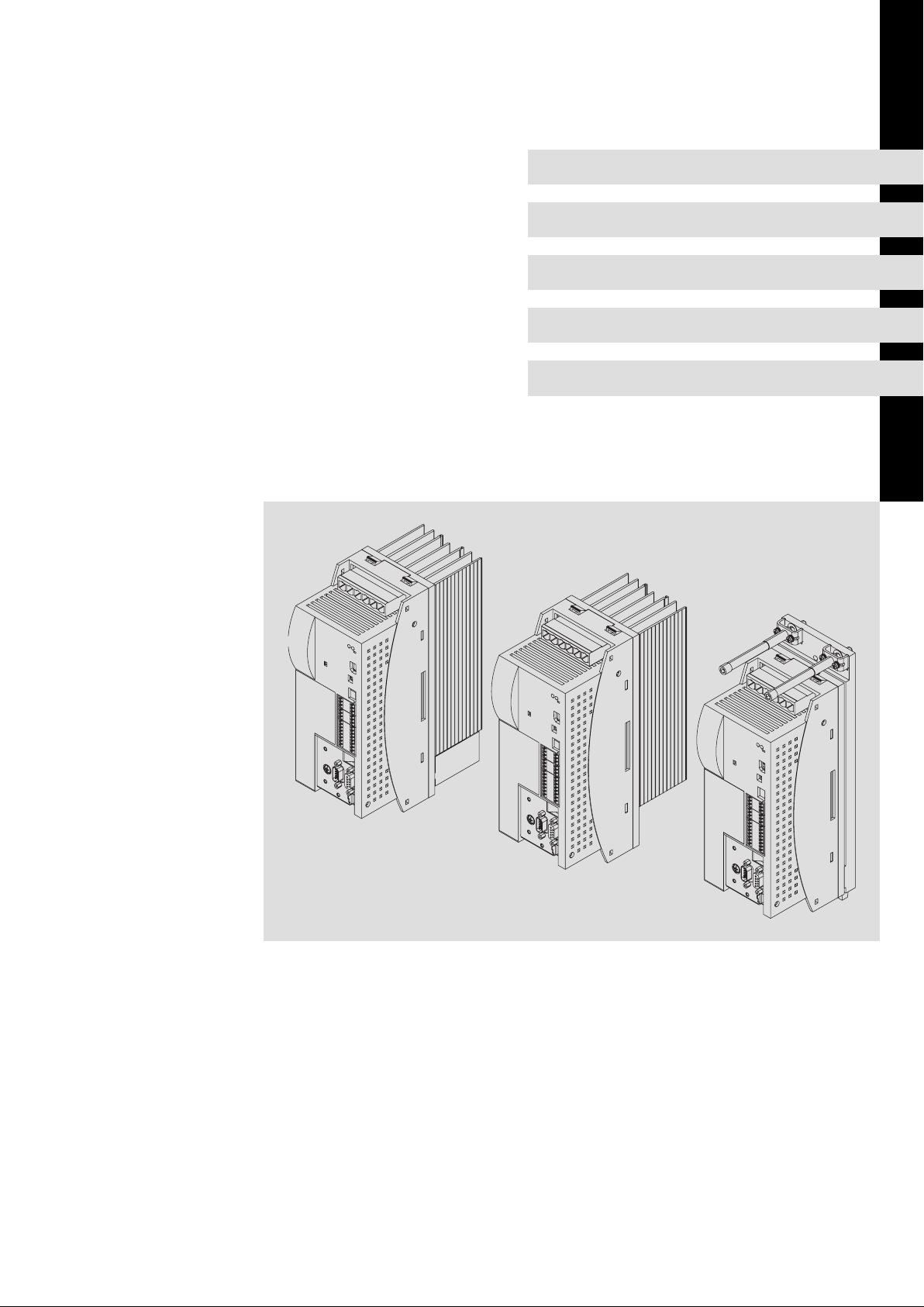

ECS

ECSEPxxx / ECSDPxxx / ECSCPxxx

Axis module ˘ "Posi & Shaft"

Page 2

Please read these instructions before you start working!

Follow the enclosed safety instructions.

This documentation is valid for ECSxP axis modules, application software "Posi & Shaft" from V1.3, and

operating software (B−SW) V7.0 or higher, as of version:

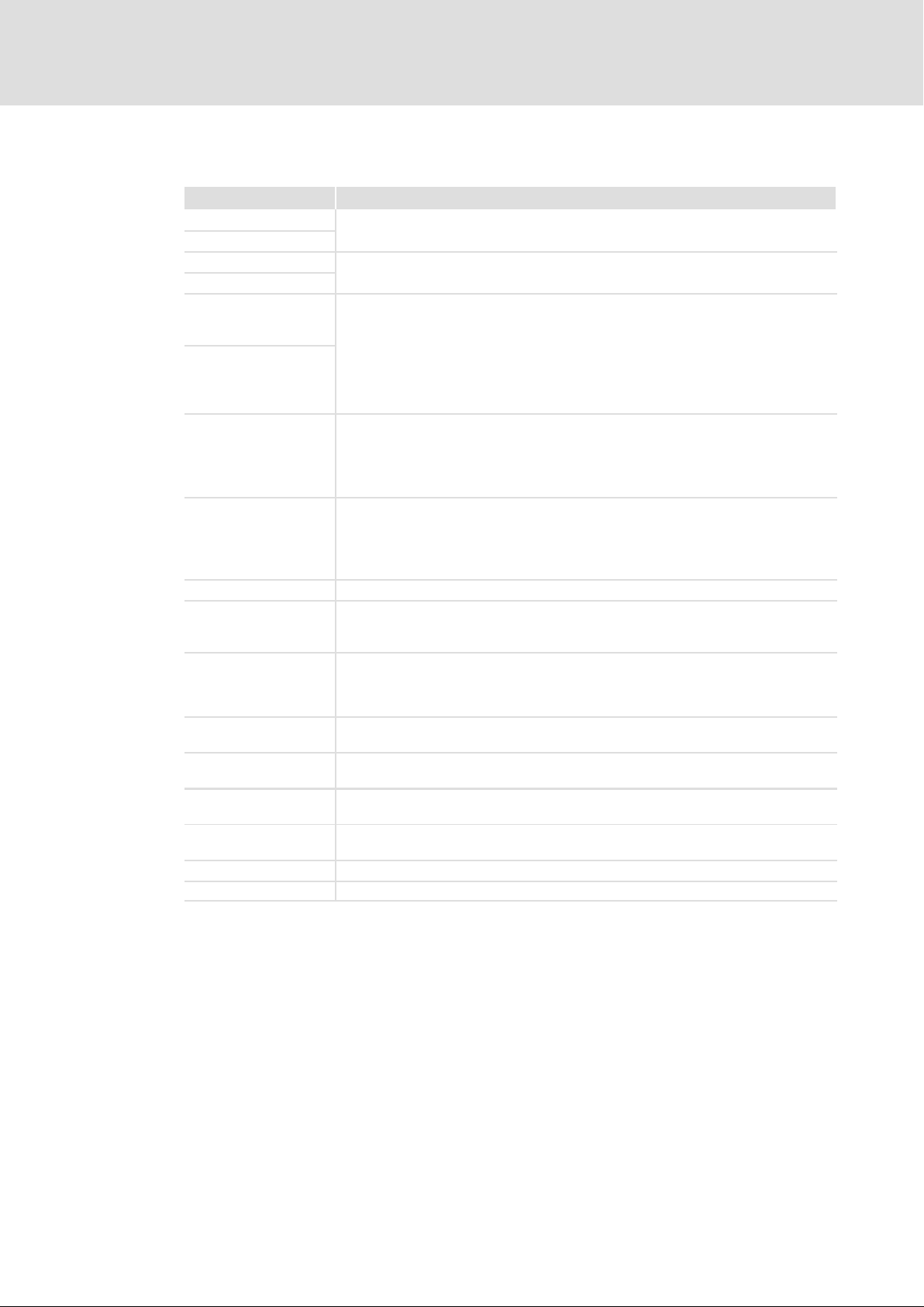

ECS x P xxx x 4 x xxx XX xx xx

Device type

Design

E = standard panel−mounted unit, IP20

D = push−through technique (thermally separated)

C = cold−plate technique

Application

P = "Posi & Shaft"

Peak current

004 = 4 A

008 = 8 A

016 = 16 A

Fieldbus interface

C = MotionBus/system bus (CAN)

032 = 32 A

048 = 48 A

064 = 64 A

ATTENTION

L ´appareil est sous tension

pendant 180s après la coupure

de la tension réseau

WARNING

Device is live up to 180s

after removing

mains voltage

Voltage class

4 = 400 V/500 V

Technical version

B = standard

V = coated

I = for IT systems, uncoated

K= for IT systems, coated

Variant

042 = Motion CiA402

Hardware version

1A or higher

Operating software version (B−SW)

7.0 or higher

0Fig. 0Tab. 0

© 2013 Lenze Drive Systems GmbH, Hans−Lenze−Straße 1, 31855 Aerzen

No part of this documentation may be reproduced or made accessible to third parties without written consent by Lenze Drive Systems GmbH.

All information given in this documentation has been selected carefully and complies with the hardware and software described.

Nevertheless, discrepancies cannot be ruled out. We do not take any responsibility or liability for any damage that may occur. Necessary corrections will be included in subsequent editions.

2

EDBCSXP064 EN 8.0

Page 3

ECSEA_003A

EDBCSXP064 EN 8.0

3

Page 4

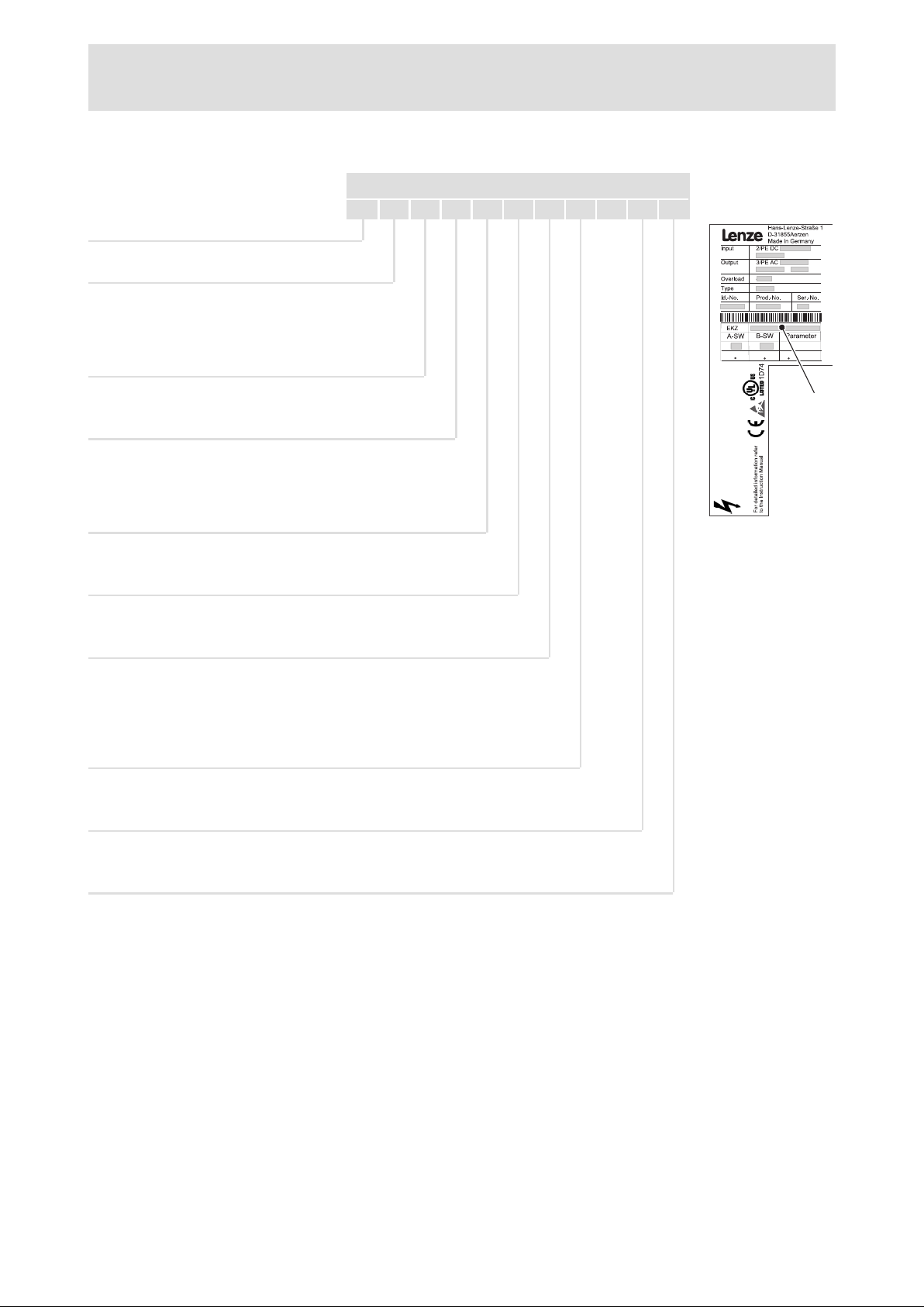

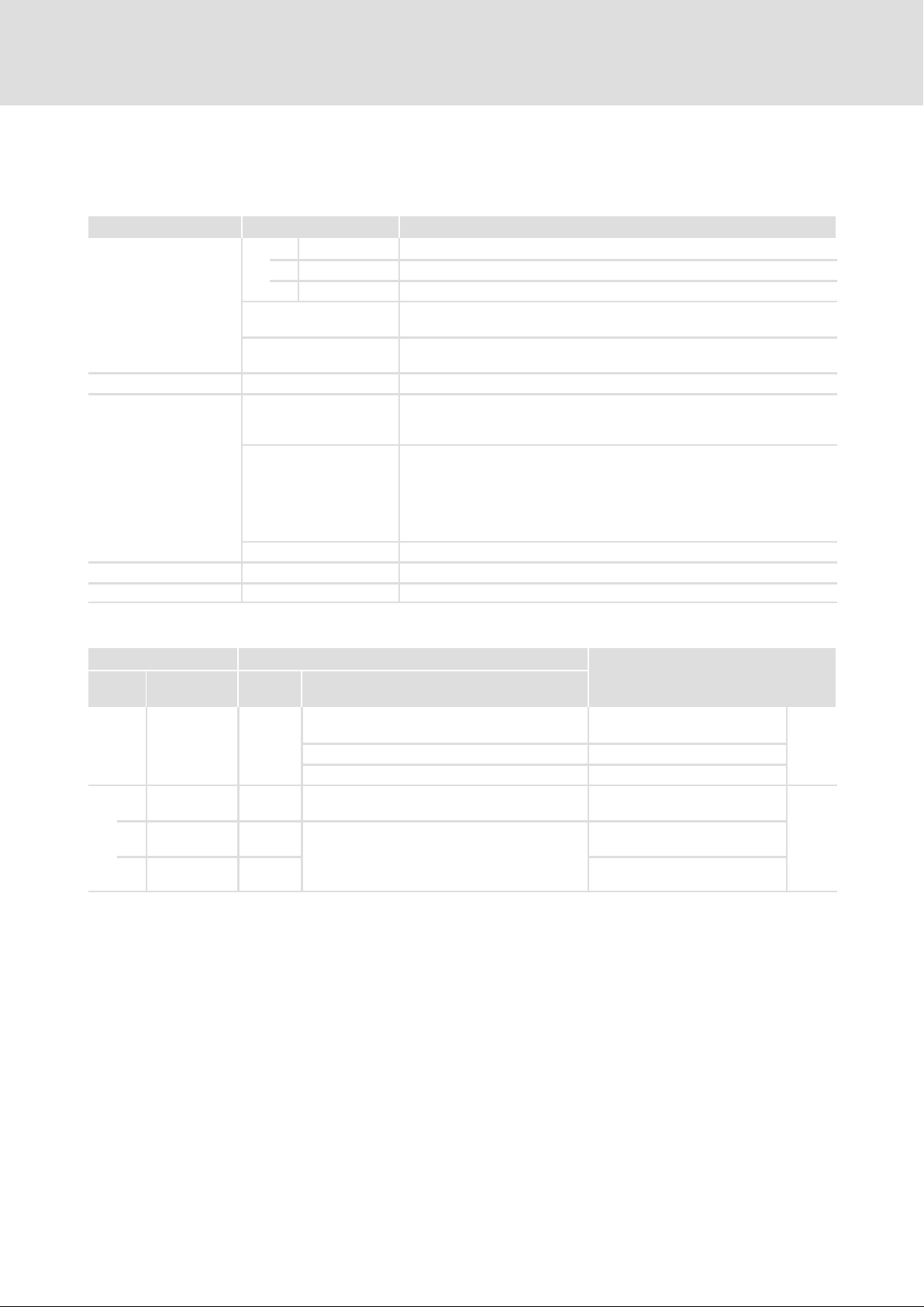

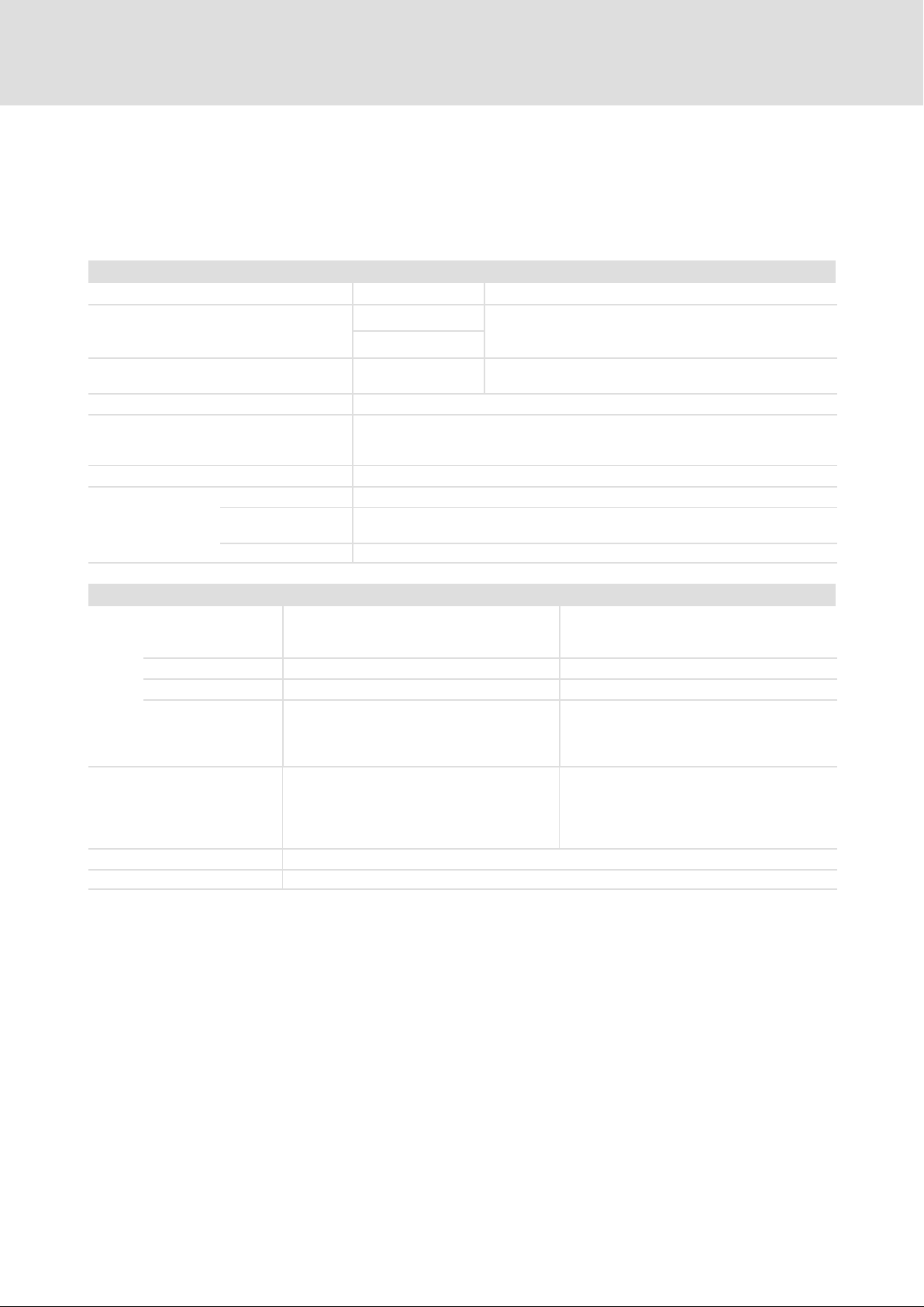

Scope of supply

Position Description Quantity

A ECSP... axis module 1

Accessory kit with fixing material corresponding to the design ():

l "E" − standard panel−mounted unit

l "D" − push−through technique

l "C" − cold−plate technique

Mounting Instructions 1

Drilling jig 1

Functional earth conductor (only ECSDP...) 1

Note!

The ECSZA000X0B connector set must be ordered separately.

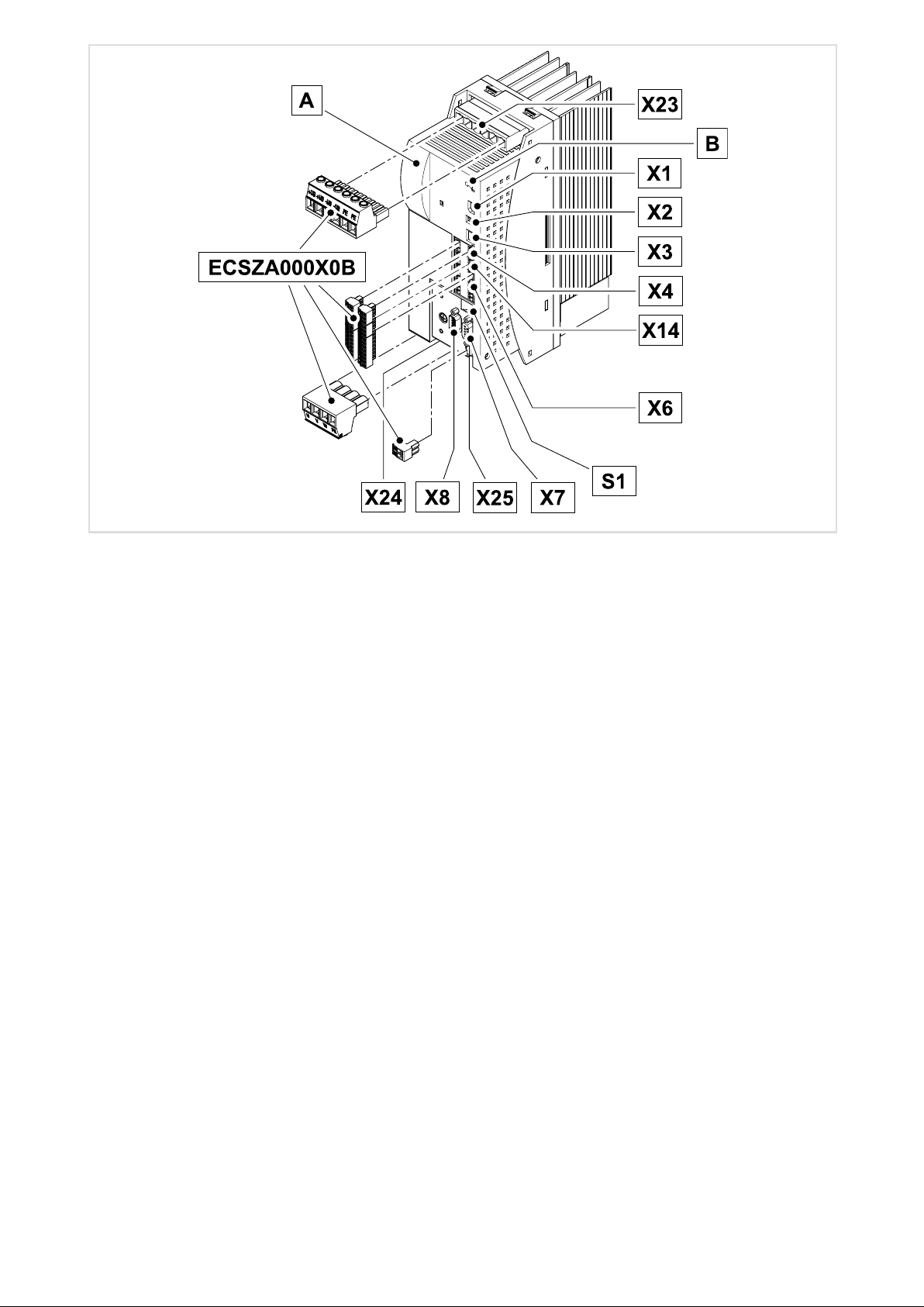

Connections and interfaces

Position Description Detailed

X23 Connections

l DC−bus voltage

l PE

B LEDs: Status and fault display

X1 Automation interface (AIF) for

l Communication module

l Operating module (keypad XT)

x2 PE connection of AIF

X3 Analog input configuration 69

X4 CAN connection

l MotionBus (CAN) / for ECSxA: System bus (CAN)

l Interface to the master control

X14 CAN−AUXconnection

l System bus (CAN)

l PC interface/HMI for parameter setting and diagnostics

X6 Connections

l Low−voltage supply

l Digital inputs and outputs

l Analog input

l "Safe torque off" (formerly "safe standstill")

S1 DIP switch

l CAN node address

l CAN baud rate

X7 Resolver connection 86

X8 Encoder connection

l Incremental encoder (TTL encoder)

l Sin/cos encoder

X25 Brake control connection 61

X24 Motor connection 60

54

79

260

80

64

68

69

70

266

87

1

information

Status displays

LED

Red Green

Off On Controller enabled, no fault

Off Blinking Controller inhibited (CINH), switch−on inhibit Code C0183

Blinking Off Fault/error (TRIP) active Code C0168/1

Blinking On Warning/FAIL−QSP active Code C0168/1

4

Operating state Check

EDBCSXP064 EN 8.0

Page 5

Contents i

1 Preface and general information 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 About these Operating Instructions 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Terminology used 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Code descriptions 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Features of the ECSxP axis module 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Scope of supply 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Legal regulations 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety and application notes for Lenze controllers 18 . . . . . . . . . . . . . . . . . .

2.2 Thermal motor monitoring 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Forced ventilated or naturally ventilated motors 23 . . . . . . . . . . . . . . . . . .

2.2.2 Self−ventilated motors 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Residual hazards 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Safety instructions for the installation according to UL 28 . . . . . . . . . . . . . . . . . . . . .

2.5 Notes used 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Technical data 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 General data and operating conditions 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Rated data 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Current characteristics 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Increased continuous current depending on the control factor 34 . . . . . . .

3.3.2 Device protection by current derating 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Mechanical installation 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Important notes 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Mounting with fixing rails (standard installation) 39 . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Dimensions 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Mounting steps 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Mounting with thermal separation (push−through technique) 41 . . . . . . . . . . . . . . .

4.3.1 Dimensions 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Mounting steps 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Mounting in cold−plate design 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Dimensions 46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Mounting steps 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDBCSXP064 EN 8.0

5

Page 6

Contentsi

5 Electrical installation 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Installation according to EMC (installation of a CE−typical drive system) 48 . . . . . . .

5.2 Power terminals 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Connection to the DC bus (+UG, −UG) 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Connection plan for mimimum wiring with internal

brake resistor 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Connection plan for mimimum wiring with external

brake resistor 58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Motor connection 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.5 Motor holding brake connection 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.6 Connection of an ECSxK... capacitor module (optional) 63 . . . . . . . . . . . . . .

5.3 Control terminals 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Digital inputs and outputs 68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Analog input 69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Safe torque off 70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Automation interface (AIF) 79 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Wiring of system bus (CAN) 80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Wiring of the feedback system 85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.1 Resolver connection 86 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.2 Encoder connection 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.3 Digital frequency input/output (encoder simulation) 90 . . . . . . . . . . . . . . .

6 Commissioning 92 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Basic terms of positioning 92 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Positioning 92 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Touch probe positioning 93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.3 Positioning profile 94 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.4 Positioning profile mode 95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.5 Additional functions of the positioning profile (C3096/x) 96 . . . . . . . . . . .

6.1.6 Positioning profile parameters 97 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.7 Setting of manual jog (inching mode) 101 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.8 Homing 101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.9 Measuring system for positioning 102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.10 Machine parameters 103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.11 Electrical shaft ("EShaft") 107 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.12 Device structure and interfaces to the higher−level control 108 . . . . . . . . . .

6.2 State control of the positioning drive 110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Operating states 111 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 Conditions for state change (transitions) 113 . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Before you start 115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

EDBCSXP064 EN 8.0

Page 7

Contents i

6.4 Commissioning steps (overview) 116 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 Basic settings with GDC 117 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 Set reference 119 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.3 Setting of manual jog (inching mode) 121 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.4 Setting of homing 122 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.5 Setting absolute positioning/relative continuous positioning 123 . . . . . . . .

6.5 Loading the Lenze setting 125 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 Setting of mains data 126 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.1 Selecting the function of the charging current limitation 126 . . . . . . . . . . .

6.6.2 Setting the voltage thresholds 127 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 Entry of motor data for Lenze motors 128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8 Holding brake configuration 130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9 Setting of the feedback system for position and speed control 132 . . . . . . . . . . . . . . .

6.9.1 Resolver as position and speed encoder 133 . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.2 Resolver as absolute value encoder 135 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.3 TTL/SinCos encoder as position and speed encoder 136 . . . . . . . . . . . . . . . .

6.9.4 TTL/SinCos encoder as position encoder and resolver as

speed encoder 140 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.5 Absolute value encoder as position and speed encoder 145 . . . . . . . . . . . . .

6.9.6 Absolute value encoder as position encoder and resolver as

speed encoder 150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10 Select control interface (operating mode) 155 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.11 Process data to the axis module (control word Ctrl1 and setpoints) 158 . . . . . . . . . .

6.11.1 Control word Ctrl1 159 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.11.2 Setpoint data words to the controller

(VelDirect, PosDirect, rx_par1..3) 160 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12 Process data from the axis module (status words and actual values) 161 . . . . . . . . .

6.12.1 Status word 1 (Stat1), status word 2 (Stat2) 161 . . . . . . . . . . . . . . . . . . . . . . .

6.12.2 Device status 163 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.3 Monitor data words from the controller (tx_par1 und tx_par2) 164 . . . . . .

6.13 Entry of machine parameters 165 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.14 Configuring the digital inputs and outputs 168 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.14.1 Digital inputs for operation with continuous positioning axis 170 . . . . . . . .

6.14.2 Digital inputs for operation with linear positioning axis 171 . . . . . . . . . . . .

6.14.3 Setting the polarity of digital inputs and outputs 172 . . . . . . . . . . . . . . . . . .

6.15 Setting of manual control parameters 173 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.15.1 Manual control to software limit position 175 . . . . . . . . . . . . . . . . . . . . . . . .

6.15.2 Manual control to hardware limit switch 175 . . . . . . . . . . . . . . . . . . . . . . . .

6.15.3 Retracting from hardware limit switches 176 . . . . . . . . . . . . . . . . . . . . . . . . .

EDBCSXP064 EN 8.0

7

Page 8

Contentsi

6.16 Setting of homing parameters 177 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.16.1 Setting homing modes 179 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.16.2 Shifting the zero position with regard to the home position

(offsets C3011, C3012) 187 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.16.3 Example: Reference search with linear positioning axis 188 . . . . . . . . . . . .

6.16.4 Example: Reference search with continuous positioning axis 189 . . . . . . . .

6.17 Setting the positioning profile 191 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.17.1 Selecting a positioning profile mode 191 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.17.2 "Point−to−point" positioning 193 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.17.3 Touch probe positioning 194 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.17.4 Continuous constant travel 195 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.17.5 Electrical shaft ("E−shaft") per digital frequency, MotionBs (CAN) or

EtherCAT 196 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.17.6 Homing 197 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.17.7 Direct positioning 198 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.17.8 Positioning sequence for controller optimisation 200 . . . . . . . . . . . . . . . . . .

6.17.9 Setting of positioning profile parameters 201 . . . . . . . . . . . . . . . . . . . . . . . . .

6.17.10 Setting the profile parameter jerk time for S−shaped ramps 202 . . . . . . . . .

6.17.11 Additional functions of the positioning profile (C3096/x) 204 . . . . . . . . . . .

6.17.12 Activating the speed override 205 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.17.13 Activating the torque limitation after positioning 208 . . . . . . . . . . . . . . . . . .

6.17.14 Activating the profile continuation function 209 . . . . . . . . . . . . . . . . . . . . . .

6.17.15 Activate immediate profile change during positioning

(Direct Change) 210 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.18 Configuring the electrical shaft ("E−Shaft") 211 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.18.1 Setting the stretch factor (C3097 / C3098) 212 . . . . . . . . . . . . . . . . . . . . . . .

6.18.2 Electrical shaft via classical digital frequency coupling

(digital frequency input X8) 215 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

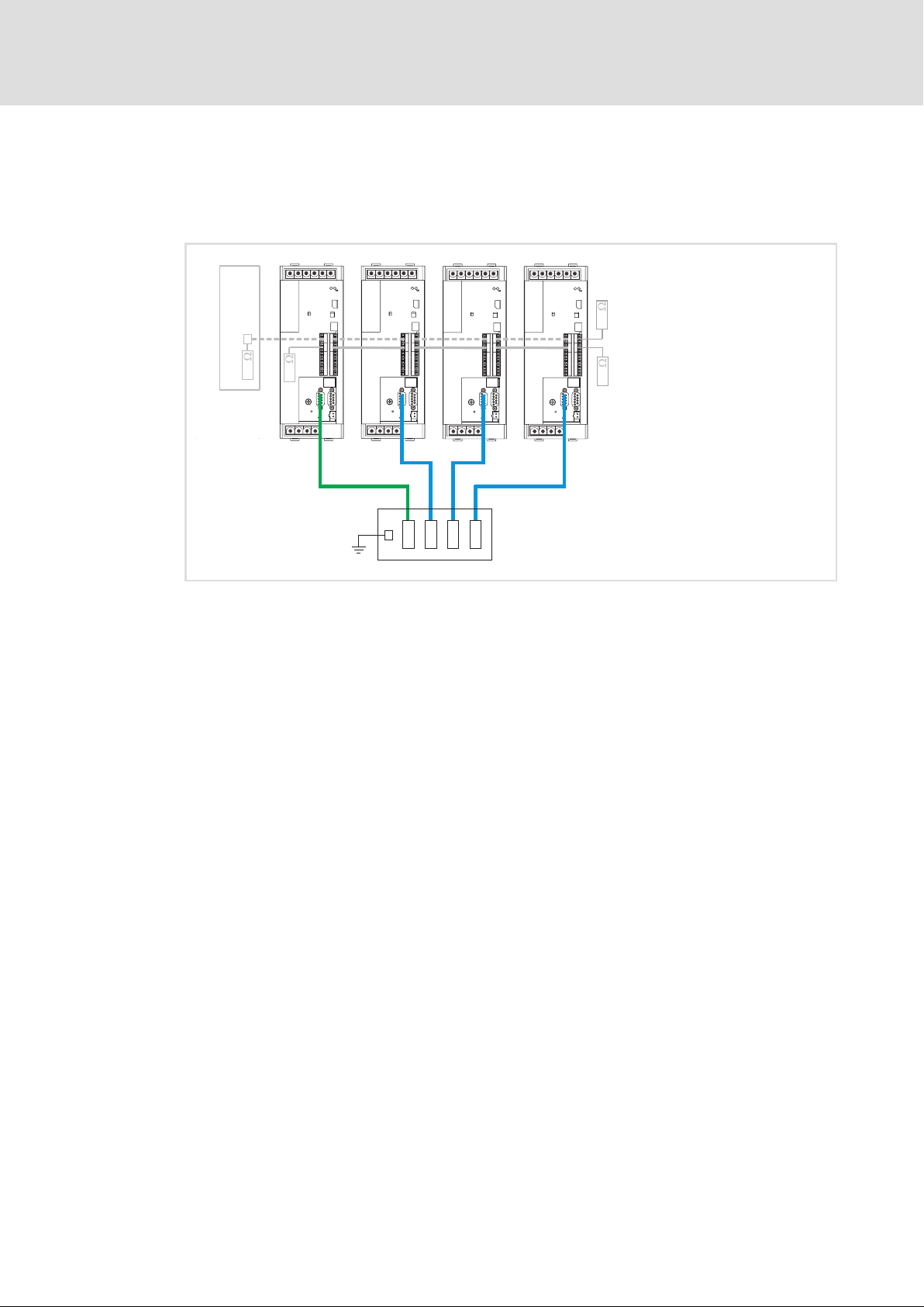

6.18.3 Electrical shaft via MotionBus (CAN) with ECSxP as

electrical shaft master 217 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.18.4 Electrical shaft via MotionBus (CAN) with PLC as

electrical shaft master 220 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.18.5 Electrical shaft via EtherCAT with PLC as electrical shaft master 224 . . . . . .

6.19 Starting positioning profiles (ProfEnable, profile number) 226 . . . . . . . . . . . . . . . . . .

6.19.1 Start of positioning profile via the "ProfEnable" control bit 227 . . . . . . . . .

6.19.2 Start of positioning profile by selecting a new profile number

"PNoSet_x" 228 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.20 Setting the target position window (InTarget) 229 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.21 Defining the window for standstill message 231 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.22 Defining the dwell time 232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.23 Following error monitoring (C3030, C3031) 233 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.24 E−Shaft: Speed−dependent angular trimming 235 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.25 Software limit positions, limitation of the travel range 237 . . . . . . . . . . . . . . . . . . . . .

8

EDBCSXP064 EN 8.0

Page 9

Contents i

6.26 Evaluation of hardware limit switches 240 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.27 Controller enable (CINH = 0) 241 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.28 Quick stop (QSP) 243 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.29 Operation with motors from other manufacturers 244 . . . . . . . . . . . . . . . . . . . . . . . .

6.29.1 Entering motor data manually 244 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.29.2 Checking the direction of rotation of the motor feedback system 246 . . . .

6.29.3 Adjusting current controller 247 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.29.4 Effecting rotor position adjustment 249 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.30 Optimising the drive behaviour after start 252 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.30.1 Speed controller adjustment 252 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.30.2 Adjustment of field controller and field weakening controller 254 . . . . . . .

6.30.3 Resolver adjustment 257 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Parameter setting 258 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 General information 258 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Parameter setting with "Global Drive Control" (GDC) 259 . . . . . . . . . . . . . . . . . . . . . .

7.3 Parameter setting with the XT EMZ9371BC keypad 260 . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Connecting the keypad 260 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.2 Description of the display elements 261 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.3 Description of the function keys 263 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.4 Changing and saving parameters 264 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Configuration 265 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Configuring MotionBus/system bus (CAN) 266 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1 Setting CAN node address and baud rate 266 . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2 Individual addressing 271 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.3 Defining boot−up master in the drive system 273 . . . . . . . . . . . . . . . . . . . . . .

8.1.4 Setting of boot−up time/cycle time 274 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.5 Executing a reset node 276 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.6 Guiding angle selection and synchronisation via MotionBus (CAN) 277 . . .

8.1.7 Axis synchronisation (CAN synchronisation) 278 . . . . . . . . . . . . . . . . . . . . . .

8.1.8 Monitoring of the synchronisation (sync time slot) 281 . . . . . . . . . . . . . . . . .

8.1.9 Axis synchronisation via CAN 282 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.10 Axis synchronisation via terminal X6/DI1 283 . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Node guarding 284 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Diagnostics codes 286 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.1 CAN bus status (C0359/C2459) 286 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.2 CAN telegram counter (C0360/2460) 287 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.3 CAN bus load (C0361/2461) 288 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Remote parameterisation (gateway function) 289 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDBCSXP064 EN 8.0

9

Page 10

Contentsi

9 Monitoring functions 291 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Fault responses 292 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Overview of monitoring functions 293 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Configuring monitoring functions 297 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.1 Monitoring times for process data input objects 297 . . . . . . . . . . . . . . . . . . .

9.3.2 Time−out monitoring for activated remote parameterisation 299 . . . . . . . .

9.3.3 Short circuit monitoring (OC1) 300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.4 Earth fault monitoring (OC2) 300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.5 Motor temperature monitoring (OH3, OH7) 301 . . . . . . . . . . . . . . . . . . . . . .

9.3.6 Heatsink temperature monitoring (OH, OH4) 303 . . . . . . . . . . . . . . . . . . . . .

9.3.7 Monitoring of internal device temperature (OH1, OH5) 304 . . . . . . . . . . . . .

9.3.8 Function monitoring of thermal sensors (H10, H11) 305 . . . . . . . . . . . . . . . .

9.3.9 Current load of controller (I x t monitoring: OC5, OC7) 306 . . . . . . . . . . . . . .

9.3.10 Current load of motor (I2 x t monitoring: OC6, OC8) 309 . . . . . . . . . . . . . . . .

9.3.11 DC−bus voltage monitoring (OU, LU) 313 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.12 Voltage supply monitoring − control electronics (U15) 316 . . . . . . . . . . . . . .

9.3.13 Motor phase failure monitoring (LP1) 316 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.14 Monitoring of the resolver cable (Sd2) 317 . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.15 Motor temperature sensor monitoring (Sd6) 318 . . . . . . . . . . . . . . . . . . . . . .

9.3.16 Monitoring of the absolute value encoder initialisation (Sd7) 319 . . . . . . . .

9.3.17 Sin/cos signal monitoring (Sd8) 320 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.18 Monitoring of the speed system deviation (nErr) 321 . . . . . . . . . . . . . . . . . . .

9.3.19 Monitoring of max. system speed (NMAX) 322 . . . . . . . . . . . . . . . . . . . . . . . .

9.3.20 Monitoring of the rotor position adjustment (PL) 323 . . . . . . . . . . . . . . . . . .

10 Diagnostics 324 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Diagnostics with Global Drive Control (GDC) 324 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Diagnostics with Global Drive Oscilloscope (GDO) 326 . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.1 GDO buttons 327 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.2 Diagnostics with GDO 328 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Diagnostics with the XT EMZ9371BC keypad 333 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 Diagnostics with PCAN−View 334 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.1 Monitoring of telegram traffic on the CAN bus 334 . . . . . . . . . . . . . . . . . . . .

10.4.2 Setting all CAN nodes to the "Operational" status 336 . . . . . . . . . . . . . . . . .

10

EDBCSXP064 EN 8.0

Page 11

Contents i

11 Troubleshooting and fault elimination 337 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Fault analysis 337 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1.1 Fault analysis via the LED display 337 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1.2 Fault analysis with keypad XT EMZ9371BC 337 . . . . . . . . . . . . . . . . . . . . . . .

11.1.3 Fault analysis with the history buffer 338 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1.4 Fault analysis via LECOM status words (C0150/C0155) 340 . . . . . . . . . . . . .

11.2 Malfunction of the drive 342 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Fault messages 343 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.1 Causes and remedies 343 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.2 Reset fault messages (TRIP−RESET) 352 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Appendix 353 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 Code table 353 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 General information about the system bus (CAN) 411 . . . . . . . . . . . . . . . . . . . . . . . . .

12.3 Communication with MotionBus/system bus (CAN) 412 . . . . . . . . . . . . . . . . . . . . . . .

12.3.1 Structure of the CAN data telegram 412 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3.2 Communication phases of the CAN network (NMT) 414 . . . . . . . . . . . . . . . .

12.3.3 Process data transfer 417 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3.4 Parameter data transfer 423 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3.5 Addressing of the parameter and process data objects 429 . . . . . . . . . . . . .

12.4 Overview of accessories 431 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4.1 Connector sets 431 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4.2 Shield mounting kit 431 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4.3 Components for operation and communication 432 . . . . . . . . . . . . . . . . . . .

12.4.4 Brake resistor 433 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4.5 Mains fuses 435 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4.6 Mains chokes 436 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4.7 RFI filters 437 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 Index 438 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDBCSXP064 EN 8.0

11

Page 12

1

Preface and general information

About these Operating Instructions

1 Preface and general information

1.1 About these Operating Instructions

These Operating Instructions will assist you in connecting and commissioning the ECSxP...

axis modules.

They contain safety instructions which must be observed!

All persons working on and with the ECSxP... axis modules must have the Operating

Instructions available and must observe the information and notes relevant for their work.

The Operating Instructions must always be in a complete and perfectly readable state.

12

EDBCSXP064 EN 8.0

Page 13

1.1.1 Terminology used

Term In the following text used for

Power supply module

ECSxE...

Capacitor module

ECSxK...

Axis module

Controller

Standard device

ECSxS...

ECSxP...

ECSxM...

ECSxA ...

Drive system ECS drive system consisting of:

24 V supply

Low−voltage supply

AIF Automation InterFace

System bus (CAN) Lenze standard bus system based on CANopen for

MotionBus (CAN) The "MotionBus (CAN)" term expresses the functionality of the CAN interface X4 in

DDS Drive PLC Developer Studio

GDC Global Drive Control

GDO Global Drive Oscilloscope

Cxxxx Code Cxxxx (e.g. C0351)

Cxxxx/y Subcode y of code Cxxxx (e. g. C0470/3 = subcode 3 of code C0470)

Xk/y Terminal y on terminal strip Xk (e.g. X6/B+ = terminal B+ on terminal strip X6)

Preface and general information

About these Operating Instructions

Terminology used

ECSxE... power supply module

ECSxK... capacitor module

Axis module of the ECS series

l ECSxS... − "Speed and Torque"

l ECSxP... − "Posi and Shaft"

l ECSxM... − "Motion"

l ECSxA... − "Application"

l ECSxE... power supply module

l Axis module ECSxS... / ECSxP... / ECSxM... / ECSxA...

l ECSxK series capacitor module (optional)

l further Lenze drive components (accessories)

Voltage supply

l of the control card, voltage range 20 ... 30 V DC (±0 V)

l of the "safe torque off" function (formerly "safe standstill"), voltage range

18 ... 30 V DC (±0 V)

l of the motor holding brake, voltage range 23 ... 30 V DC (±0 V)

l communication with a higher−level host system (PLC) or further controllers.

l parameter setting and diagnostics.

case of ECSxS/P/M... axis modules, where communication takes place using a

higher−level host system (PLC) or further controllers exclusively via the X4 interface.

Interface X14 (CAN−AUX) is exclusively used for parameter setting and diagnostics.

(Lenze software for PLC programming acc. to IEC 61131)

(Lenze software for parameter setting and diagnostics)

(additional diagnostic tool of the GDC)

Parameters which serve to parameterise or monitor the controller.

1

EDBCSXP064 EN 8.0

13

Page 14

1

Preface and general information

About these Operating Instructions

Code descriptions

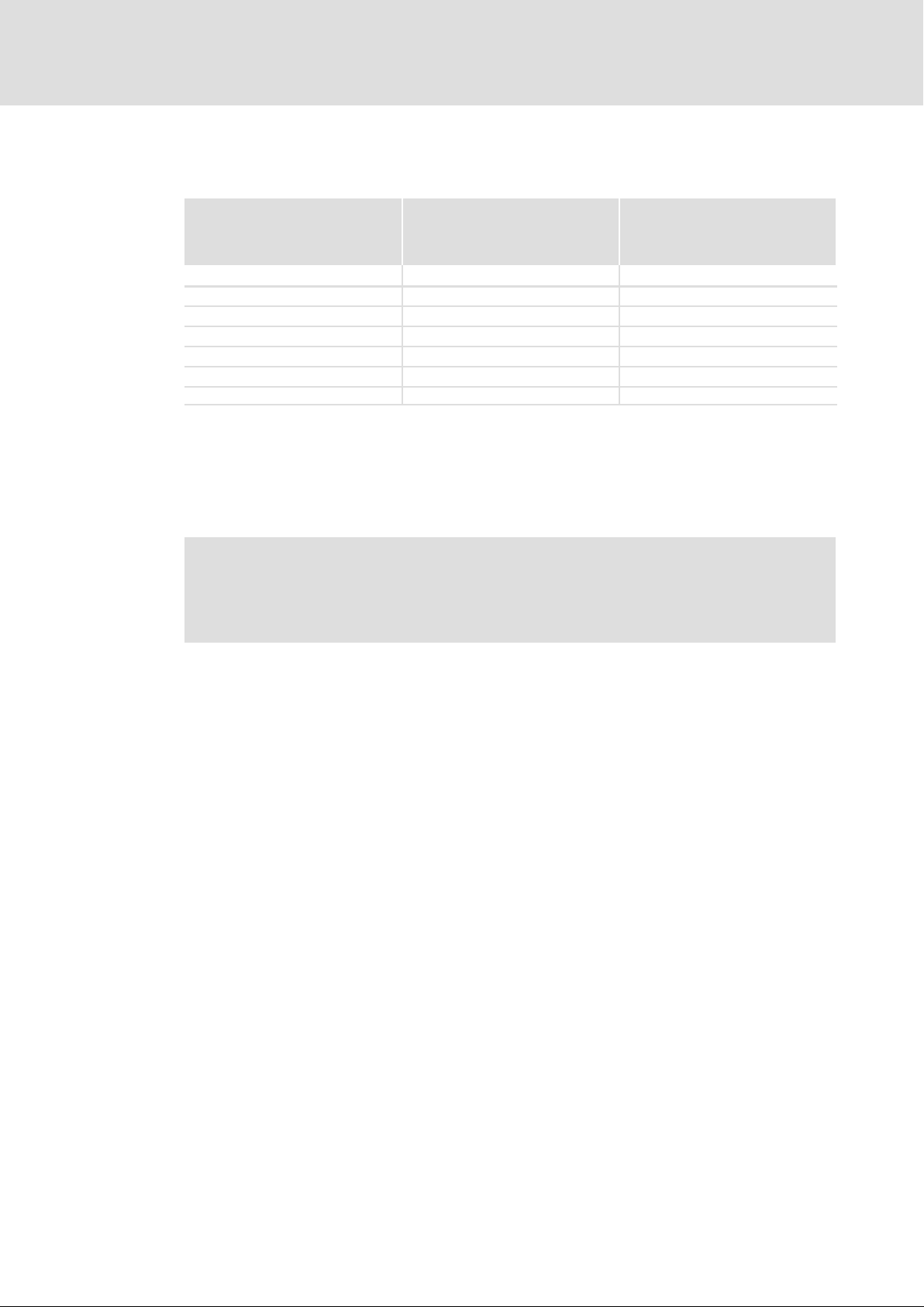

1.1.2 Code descriptions

Lenze codes are described in the form of tables with the following structure:

Column Abbreviation Meaning

No.

Name LCD display of the keypad XT EMZ9371BC

Lenze/{Appl.}

Selection 1 {%} 99 minimum value {unit} maximum value

IMPORTANT Short code description

Cxxxx

1 Subcode 1 of Cxxxx

2 Subcode 2 of Cxxxx

Cxxxx Changed input value of the code or subcode is accepted after pressing

[Cxxxx] Changed input value of the code or subcode is accepted after pressing

x Lenze setting:

{xxx...} Different application initialisation value

à The "Important" column contains further information

Code no. Cxxxx

.

when the controller is inhibited.

l Value at the time of delivery or after loading the Lenze setting using

C0002.

l Value at the time of delivery

l After loading the Lenze setting using C0002, the application

initialisation value is overwritten with the Lenze setting.

l The application initialisation values can be restored by loading the

application software with "Global Drive Loader" (GDL).

Example

Code Possible settings IMPORTANT

No. Designation Lenze/

{Appl.}

C0003 Par save 0

C1192 Selection of resistance

1 Char.: OHM 1000

2 Char.: OHM 2225 PTC characteristic:

Selection

Non−volatile saving of parameter

set

0 No response

1 Save parameter set

characteristic for PTC

0 {1 W} 30000 PTC characteristic:

{0}

resistance R1 at T1

resistance R2 at T2

14

EDBCSXP064 EN 8.0

Page 15

1.2 Features of the ECSxP axis module

ƒ Safety function "safe torque off" (formerly "safe standstill")

ƒ 15 separate positioning profile can be stored:

– Positioning in a finite travel range (absolute measuring system)

– Continuous positioning in one direction (incremental dimensioning system), e.g.

for cut−to−length cutters

– Touch probe positioning (mark sensor)

– "Electrical shaft" with classic digital frequency coupling or via CAN

ƒ Additional profile functions:

– Speed override via analog input or per process data communication (PDO) via CAN

or fieldbus module at the automation interface (AIF)

– Stretch factor for the "electrical shaft" function

– Torque limitation after positioning

– Profile continuation after profile stop

– Immediate profile change during positioning(direct change)

Preface and general information

Features of the ECSxP

1

ƒ Homing, 14 different modes

ƒ Manual jog

ƒ Brake logic activatable

ƒ Software based monitoring of the travel range and of the hardware limit switch

ƒ Process coordination by higher−level host system (PLC)

ƒ Double CAN ON BORD

– MotionBus (CAN):

Interface X4 "CAN" (PDO1, Sync−based) for communicating with a higher−level

host system (PLC) or further controllers.

– System bus (CAN):

Interface X14 "CAN−AUX" for parameter setting and diagnostics

ƒ Selectable control interfaces (via code C4010):

– MotionBus (CAN)

– System bus (CAN−AUX)

– Fieldbus via the automation interface (AIF)

– Via codes per parameter data channel

ƒ Supported feedback systems:

– Resolver with and without position storage

– Encoder (incremental encoder (TTL encoder), sin/cos encoder)

EDBCSXP064 EN 8.0

ƒ Commissioning, parameter setting and diagnostics with the Lenze parameter

setting and operating program "Global Drive Control" (GDC) or the XT EMZ9371BC

keypad

15

Page 16

1

1.3 Scope of supply

Preface and general information

Scope of supply

The scope of supply of the ECSxP... axis module includes:

ƒ Standard device

ƒ Accessory kit with fixings according to the design:

– "E" − panel−mounted device

– "D" − push−through technique

– "C" − cold−plate technique

ƒ Mounting Instructions

ƒ Drilling jig

ƒ Functional earth conductor (only ECSDP...)

Accessories

The appendix includes information on the following accessories: ( 431).

ƒ Connector sets for

– power supply modules: ECSZE000X0B

– capacitor modules: ECSZK000X0B

– axis modules: ECSZA000X0B

ƒ ECSZS000X0B001 shield mounting kit (EMC accessories)

ƒ Components for operation and communication

ƒ Brake resistors

ƒ Mains fuses

ƒ Mains chokes

ƒ RFI filters

Tip!

Information and auxiliary devices related to the Lenze products can be found

in the download area at

http://www.Lenze.com

16

EDBCSXP064 EN 8.0

Page 17

1.4 Legal regulations

Preface and general information

Legal regulations

1

Identification

Application as

directed

Liability l The information, data and notes in these Instructions met the state of the art at the time of printing. Claims

Warranty l Terms of warranty: See terms of sales and delivery of Lenze Drive Systems GmbH.

Nameplate CE designation Manufacturer

Lenze controllers are

unambiguously designated by the

contents of the nameplate.

ECSxP... axis modules

l must only be operated under the conditions prescribed in these Instructions.

l are components

– for open and closed loop control of variable speed drives with PM synchronous motors and asynchronous

motors.

– for installation into a machine

– for assembly with other components to form a machine.

l are electrical equipment for the installation in control cabinets or similar closed operating areas.

l comply with the protective requirements of the EC Low−Voltage Directive.

l are not machines for the purpose of the EC Machinery Directive.

l are not to be used as domestic appliances, but for industrial purposes only.

Drive systems with ECSxP... axis modules

l comply with the EC Directive "Electromagnetic compatibility" if they are installed according to the guidelines

of CE−typical drive systems.

l can be used

– at public and non−public mains.

– in industrial premises.

l The user is responsible for the compliance of his application with the EC directives.

Any other use shall be deemed inappropriate!

on modifications referring to axis modules and components which have already been supplied cannot be

derived from the information, illustrations and descriptions given in these Instructions.

l The specifications, processes, and circuitry described in these Instructions are for guidance only and must be

adapted to your own specific application. Lenze does not take responsibility for the suitability of the process

and circuit proposals.

l Lenze does not accept any liability for damages and failures caused by:

– Disregarding the Operating Instructions

– Unauthorised modifications to the axis module

– Operating errors

– Improper working on and with the axis module

l Warranty claims must be made to Lenze immediately after detecting the deficiency or fault.

l The warranty is void in all cases where liability claims cannot be made.

Conforms to the EC Low−Voltage

Directive

Lenze Automation GmbH

Grünstraße 36

D−40667 Meerbusch

EDBCSXP064 EN 8.0

17

Page 18

2

Safety instructions

General safety and application notes for Lenze controllers

2 Safety instructions

2.1 General safety and application notes for Lenze controllers

(in accordance with Low−Voltage Directive 2006/95/EC)

For your personal safety

Disregarding the following safety measures can lead to severe injury to persons and

damage to material assets:

ƒ Only use the product as directed.

ƒ Never commission the product in the event of visible damage.

ƒ Never commission the product before assembly has been completed.

ƒ Do not carry out any technical changes on the product.

ƒ Only use the accessories approved for the product.

ƒ Only use original spare parts from Lenze.

ƒ Observe all regulations for the prevention of accidents, directives and laws

applicable on site.

ƒ Transport, installation, commissioning and maintenance work must only be carried

out by qualified personnel.

– Observe IEC 364 and CENELEC HD 384 or DIN VDE 0100 and IEC report 664 or

DIN VDE 0110 and all national regulations for the prevention of accidents.

– According to this basic safety information, qualified, skilled personnel are persons

who are familiar with the assembly, installation, commissioning, and operation of

the product and who have the qualifications necessary for their occupation.

ƒ Observe all specifications in this documentation.

– This is the condition for safe and trouble−free operation and the achievement of

the specified product features.

– The procedural notes and circuit details described in this documentation are only

proposals. It is up to the user to check whether they can be transferred to the

particular applications. Lenze Automation GmbH does not accept any liability for

the suitability of the procedures and circuit proposals described.

ƒ Depending on their degree of protection, some parts of the Lenze controllers

(frequency inverters, servo inverters, DC speed controllers) and their accessory

components can be live, moving and rotating during operation. Surfaces can be hot.

– Non−authorised removal of the required cover, inappropriate use, incorrect

installation or operation, creates the risk of severe injury to persons or damage to

material assets.

– For more information, please see the documentation.

18

ƒ High amounts of energy are produced in the controller. Therefore it is required to

wear personal protective equipment (body protection, headgear, eye protection, ear

protection, hand guard).

EDBCSXP064 EN 8.0

Page 19

Safety instructions

General safety and application notes for Lenze controllers

Application as directed

Controllers are components which are designed for installation in electrical systems or

machines. They are not to be used as domestic appliances, but only for industrial purposes

according to EN 61000−3−2.

When controllers are installed into machines, commissioning (i.e. starting of the operation

as directed) is prohibited until it is proven that the machine complies with the regulations

of the EC Directive 2006/42/EC (Machinery Directive); EN 60204 must be observed.

Commissioning (i.e. starting of the operation as directed) is only allowed when there is

compliance with the EMC Directive (2004/108/EC).

The controllers meet the requirements of the Low−Voltage Directive 2006/95/EC. The

harmonised standard EN 61800−5−1 applies to the controllers.

The technical data and supply conditions can be obtained from the nameplate and the

documentation. They must be strictly observed.

Warning: Controllers are products which can be installed in drive systems of category C2

according to EN 61800−3. These products can cause radio interferences in residential areas.

In this case, special measures can be necessary.

2

Transport, storage

Please observe the notes on transport, storage, and appropriate handling.

Observe the climatic conditions according to the technical data.

Installation

The controllers must be installed and cooled according to the instructions given in the

corresponding documentation.

The ambient air must not exceed degree of pollution 2 according to EN 61800−5−1.

Ensure proper handling and avoid excessive mechanical stress. Do not bend any

components and do not change any insulation distances during transport or handling. Do

not touch any electronic components and contacts.

Controllers contain electrostatic sensitive devices which can easily be damaged by

inappropriate handling. Do not damage or destroy any electrical components since this

might endanger your health!

EDBCSXP064 EN 8.0

19

Page 20

2

Safety instructions

General safety and application notes for Lenze controllers

Electrical connection

When working on live controllers, observe the applicable national regulations for the

prevention of accidents (e.g. VBG 4).

The electrical installation must be carried out according to the appropriate regulations

(e.g. cable cross−sections, fuses, PE connection). Additional information can be obtained

from the documentation.

This documentation contains information on installation in compliance with EMC

(shielding, earthing, filter, and cables). These notes must also be observed for CE−marked

controllers. The manufacturer of the system is responsible for compliance with the limit

values demanded by EMC legislation. The controllers must be installed in housings (e.g.

control cabinets) to meet the limit values for radio interferences valid at the site of

installation. The housings must enable an EMC−compliant installation. Observe in

particular that e.g. the control cabinet doors have a circumferential metal connection to

the housing. Reduce housing openings and cutouts to a minimum.

Lenze controllers may cause a DC current in the PE conductor. If a residual current device

(RCD) is used for protection against direct or indirect contact for a controller with

three−phase supply, only a residual current device (RCD) of type B is permissible on the

supply side of the controller. If the controller has a single−phase supply, a residual current

device (RCD) of type A is also permissible. Apart from using a residual current device (RCD),

other protective measures can be taken as well, e.g. electrical isolation by double or

reinforced insulation or isolation from the supply system by means of a transformer.

Operation

If necessary, systems including controllers must be equipped with additional monitoring

and protection devices according to the valid safety regulations (e.g. law on technical

equipment, regulations for the prevention of accidents). The controllers can be adapted to

your application. Please observe the corresponding information given in the

documentation.

After the controller has been disconnected from the supply voltage, all live components

and power terminals must not be touched immediately because capacitors can still be

charged. Please observe the corresponding stickers on the controller.

All protection covers and doors must be shut during operation.

Notes for UL−approved systems with integrated controllers: UL warnings are notes that

only apply to UL systems. The documentation contains special UL notes.

20

EDBCSXP064 EN 8.0

Page 21

Safety instructions

General safety and application notes for Lenze controllers

Safety functions

Certain controller versions support safety functions (e.g. "Safe torque off", formerly "Safe

standstill") according to the requirements of the EC Directive 2006/42/EC (Machinery

Directive). The notes on the integrated safety system provided in this documentation must

be observed.

Maintenance and servicing

The controllers do not require any maintenance if the prescribed operating conditions are

observed.

Disposal

Recycle metal and plastic materials. Ensure professional disposal of assembled PCBs.

The product−specific safety and application notes given in these instructions must be

observed!

2

EDBCSXP064 EN 8.0

21

Page 22

2

Safety instructions

Thermal motor monitoring

2.2 Thermal motor monitoring

Note!

2

ƒ I

x t monitoring is based on a mathematical model which calculates a

thermal motor load from the detected motor currents.

ƒ The calculated motor load is saved when the mains is switched.

ƒ The function is UL−certified, i.e. no additional protective measures are

required for the motor in UL−approved systems.

ƒ However, I

the motor load could not be detected as for instance changed cooling

conditions (e.g. interrupted or too warm cooling air flow).

2

x t load of the motor is displayed in C0066.

Die I

The thermal loading capacity of the motor is expressed by the thermal motor time

constant (t, C0128). Find the value in the rated motor data or contact the manufacturer of

the motor.

2

The I

x t monitoring has been designed such that it will be activated after 179 s in the

event of a motor with a thermal motor time constant of 5 minutes (Lenze setting C0128),

a motor current of 1.5 x I

Two adjustable trigger thresholds provide for different responses.

2

x t monitoring is no full motor protection as other influences on

N

and a trigger threshold of 100 %.

ƒ Adjustable response OC8 (TRIP, warning, off).

– The trigger threshold is set in C0127.

– The response is set in C0606.

– The response OC8, for instance, can be used for an advance warning.

ƒ Fixed response OC6−TRIP.

– The trigger threshold is set in C0120.

Behaviour of the I2 x t monitoring Condition

The I2 x t monitoring is deactivated.

C0066 is set = 0 % and

MCTRL−LOAD−I2XT is set = 0.00 %.

I2 x t monitoring is stopped.

The current value in C0066 and at the

MCTRL−LOAD−I2XT output is frozen.

I2 x t monitoring is deactivated.

The motor load is displayed in C0066.

When C0120 = 0 % and C0127 = 0 %, set controller

inhibit.

When C0120 = 0 % and C0127 = 0 %, set controller

enable.

Set C0606 = 3 (off) and C0127 > 0 %.

Note!

An error message OC6 or OC8 can only be reset if the I2 x t load falls below the

set trigger threshold by 5 %.

22

EDBCSXP064 EN 8.0

Page 23

Forced ventilated or naturally ventilated motors

2.2.1 Forced ventilated or naturally ventilated motors

Parameter setting

2

The following codes can be set for I

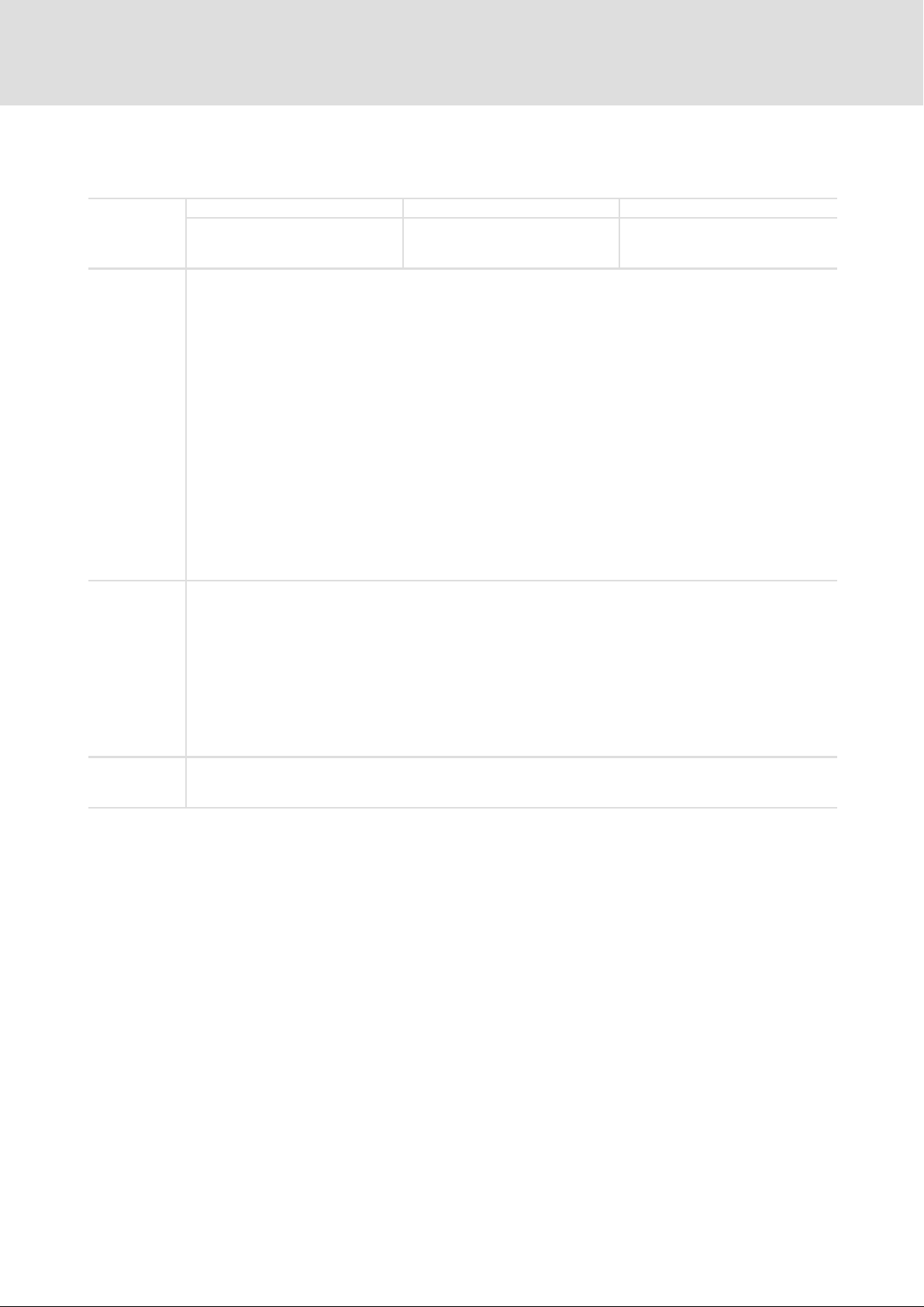

Code Meaning Value range Lenze setting

C0066 Display of the I2 x t load of the motor 0 ... 250 % −

C0120 Threshold: Triggering of error "OC6" 0 ... 120 % 0 %

C0127 Threshold: Triggering of error "OC8" 0 ... 120 % 0 %

C0128 Thermal motor time constant 0.1 ... 50.0 min 5.0 min

C0606 Response to error "OC8" TRIP, warning, off Warning

x t monitoring:

Calculate release time and I2 x t load

Formula for release time Information

t +*(t) ln

ȡ

ȧ

ȧ

Ȣ

1 *

I

ȣ

z ) 1

I

Mot

ǒ

Ǔ

I

N

2

100

ȧ

ȧ

Ȥ

Mot

I

r

t Thermal motor time constant (C0128)

z Threshold value in C0120 (OC6) or C0127 (OC8)

Actual motor current (C0054)

Rated motor current (C0088)

Safety instructions

Thermal motor monitoring

2

Formulae for I2 x t load Information

L(t) Chronological sequence of the I2 x t load of the motor

2

I

Mot

ǒ

L(t) +

If the controller is inhibited, the I2 x t load is reduced:

Ǔ

100% ǒ1 * e

I

N

L(t) + L

Start

Ǹ

e

*t

t

t

*

t

I

Ǔ

Mot

Ir Rated motor current (C0088)

t Thermal motor time constant (C0128)

L

Start

(Display: C0066)

Actual motor current (C0054)

I2 x t load before controller inhibit

If an error is triggered, the value corresponds to the

threshold value set in C0120 (OC6) or

C0127 (OC8).

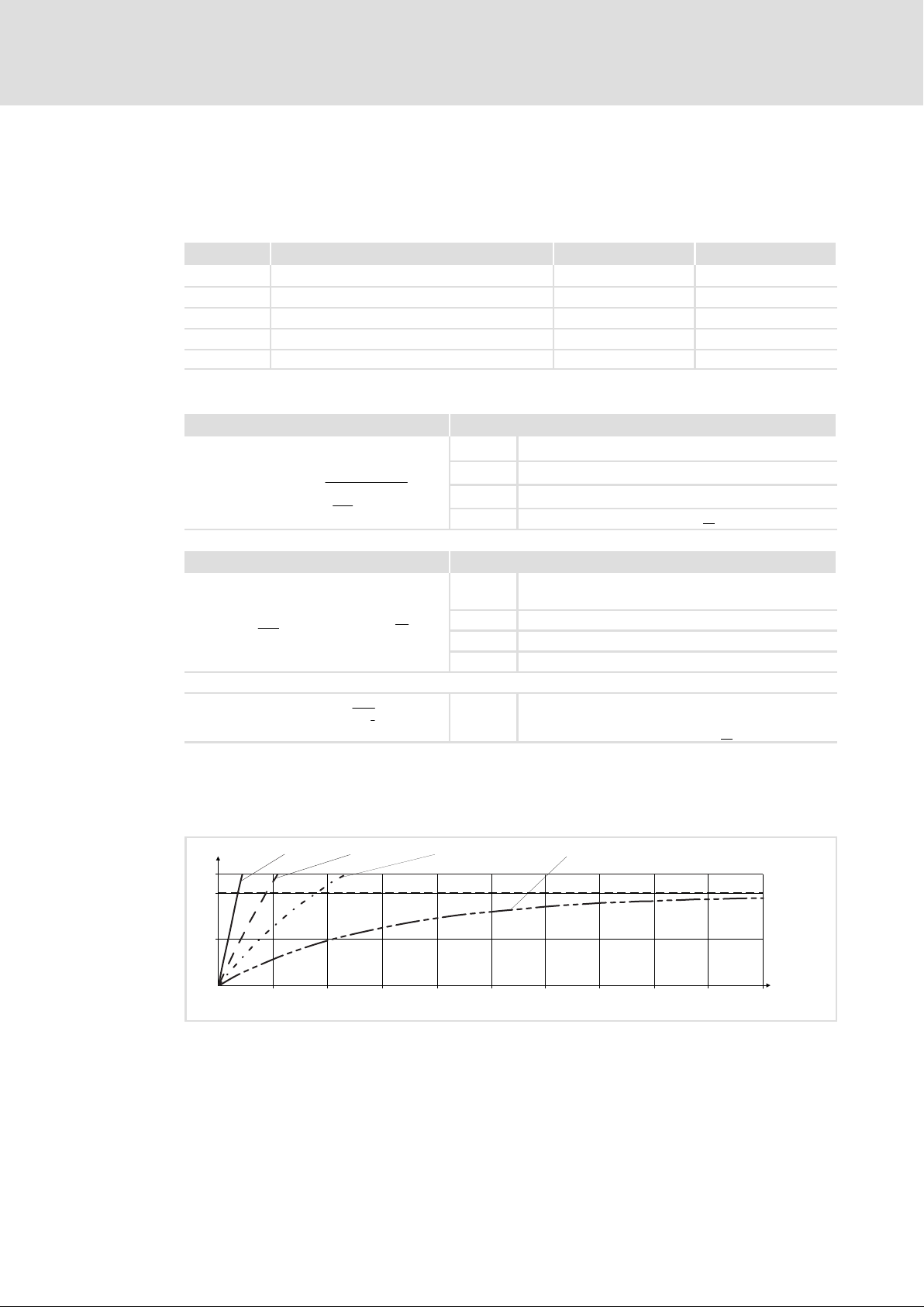

Read release time in the diagram

Diagram for detecting the release times for a motor with a thermal motor time constant

of 5 minutes (Lenze setting C0128):

L [%]

120

100

50

0

Fig. 2−1 I2 × t−monitoring: Release times for different motor currents and trigger thresholds

I = 3 × I

Mot N

0 100 200 300 400 500 600 700 800 900

I

Mot

I

r

LI

T Time

I = 2 × I

Mot N

Actual motor current (C0054)

Rated motor current (C0088)

2

x t load of the motor (display: C0066)

I = 1.5 × I

Mot N

I = 1 × I

Mot N

t [s]

1000

9300STD105

EDBCSXP064 EN 8.0

23

Page 24

2

Safety instructions

Thermal motor monitoring

Self−ventilated motors

2.2.2 Self−ventilated motors

Due to the construction, self−ventilated standard motors are exposed to an increased heat

generation in the lower speed range compared to forced ventilated motors.

Warnings!

For complying with the UL 508C standard, you have to set the

speed−dependent evaluation of the permissible torque via code C0129/x.

Parameter setting

The following codes can be set for I

Code Meaning Value range Lenze setting

C0066 Display of the I2 x t load of the motor 0 ... 250 % −

C0120 Threshold: Triggering of error "OC6" 0 ... 120 % 0 %

C0127 Threshold: Triggering of error "OC8" 0 ... 120 % 0 %

C0128 Thermal motor time constant 0.1 ... 50.0 min 5.0 min

C0606 Response to error "OC8" TRIP, warning, off Warning

C0129/1 S1 torque characteristic I1/I

C0129/2 S1 torque characteristics n2/n

2

x t monitoring:

rated

rated

10 ... 200 % 100 %

10 ... 200 % 40 %

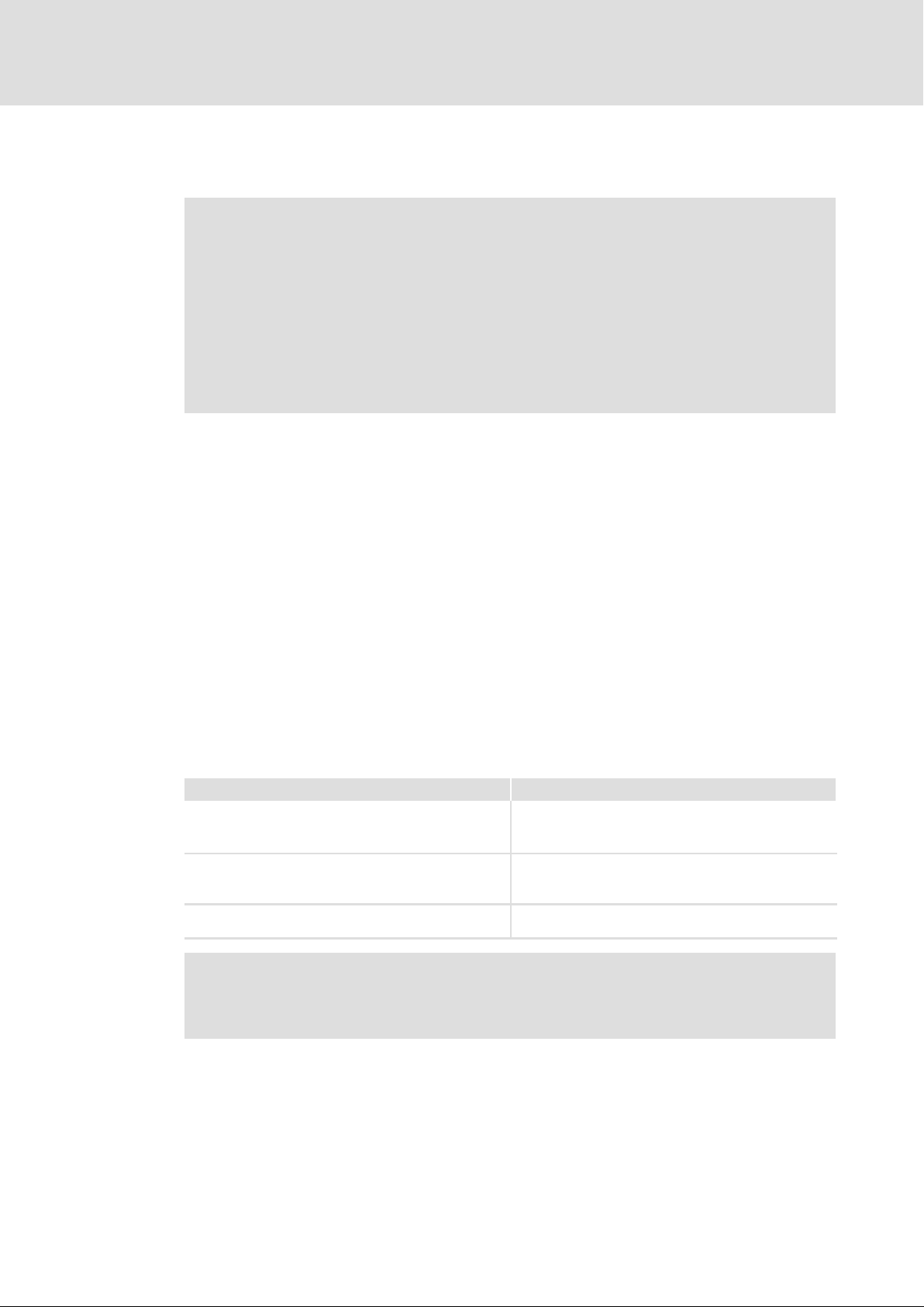

Effect of code C0129/x

I / I

N

1.1

1.0

3

0.9

0.8

0.7

0.6

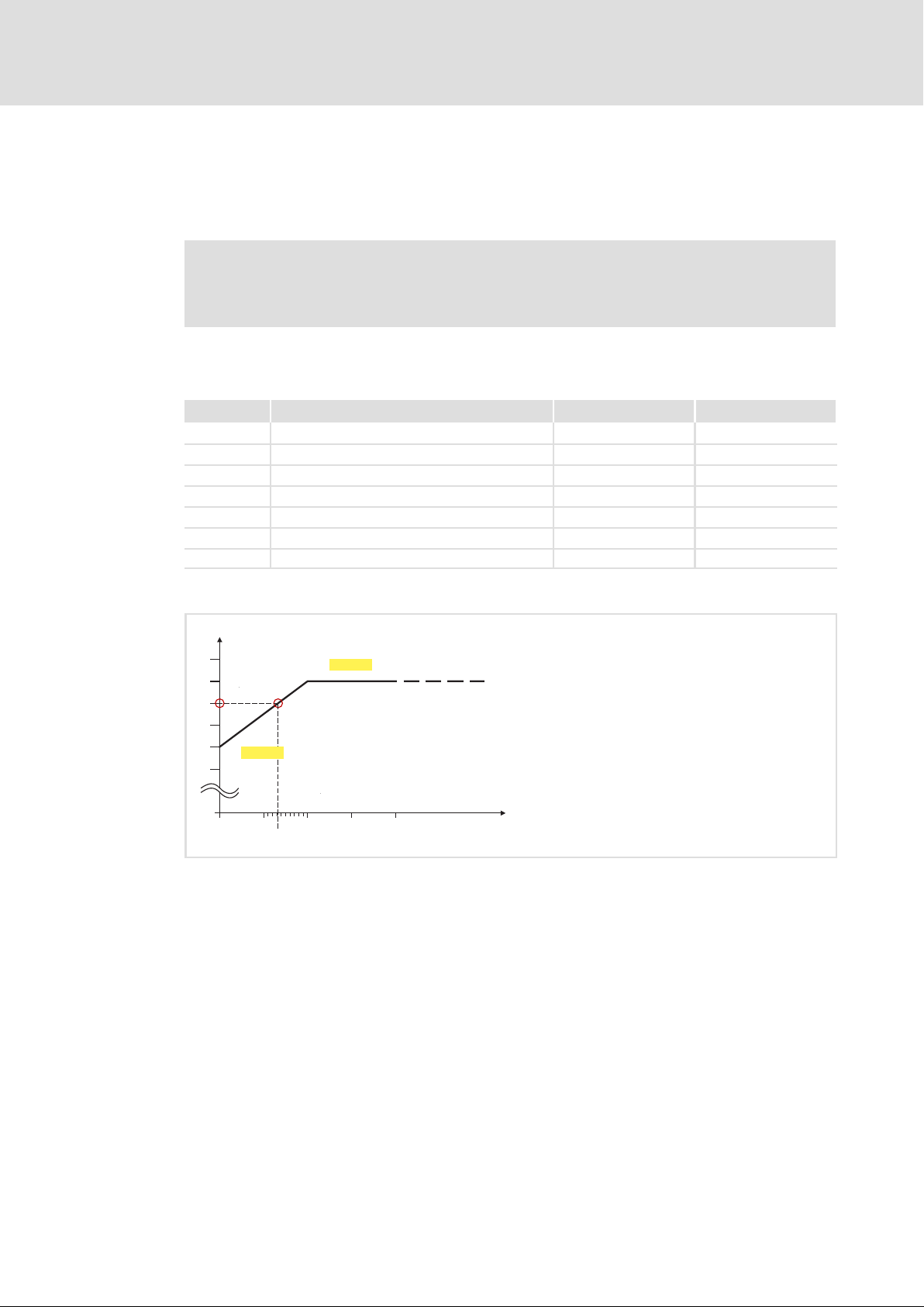

Fig. 2−2 Working point in the range of characteristic lowering

0

0

0 0.1

C0129/1

0.132

C0129/2

1

2

0.2 0.3 0.4

n / n

N

9300STD350

The lowered speed / torque characteristic (Fig. 2−2) reduces the permissible thermal load

of self−ventilated standard motors. The characteristic is a line the definition of which

requires two points:

ƒ Point : Definition with C0129/1

This value also enables an increase of the maximally permissible load.

ƒ Point : Definition with C0129/2

With increasing speeds, the maximally permissible load remains unchanged

(I

Mot

= I

rated

).

In Fig. 2−2, the motor speed and the corresponding permissible motor torque () can be

read for each working point (on the characteristic () ... ). can also be calculated

using the values in C0129/1and C0129/2 (evaluation coefficient "y", 25).

24

EDBCSXP064 EN 8.0

Page 25

Thermal motor monitoring

Calculate release time and I2 x t load

Calculate the release time and the I

2

x t load of the motor considering the values in

C0129/1 and C0129/2(evaluation coefficient "y").

Formulae for release time Information

T Release time of the I2 x t monitoring

ȡ

I

Mot

ǒ

y I

n

Ǹ

e

z ) 1

Ǔ

N

n

) C0129ń1

N

*

T +*(t) ln

ȧ

ȧ

1 *

Ȣ

100% * C0129ń1

y +

Formulae for I2 x t load Information

If the controller is inhibited, the I2 x t load is reduced:

L(t) +

C0129ń2

I

Mot

ǒ

y I

L(t) + L

2

Ǔ

100% ǒ1 * e

N

Start

2

100

t

t

ȣ

t Thermal motor time constant (C0128)

In Function: Natural logarithm

ȧ

ȧ

I

Mot

Ȥ

I

r

z Threshold value in C0120 (OC6) or C0127 (OC8)

y Evaluation coefficient

n

rated

L(t) Chronological sequence of the I2 x t load of the motor

y Evaluation coefficient

*t

Ǔ

t

I

Mot

Ir Rated motor current (C0088)

t Thermal motor time constant (C0128)

L

Start

Actual motor current (C0054)

Rated motor current (C0088)

Rated speed (C0087)

(Display: C0066)

Actual motor current (C0054)

I2 x t load before controller inhibit

If an error is triggered, the value corresponds to the

threshold value set in C0120 (OC6) or

Safety instructions

Self−ventilated motors

C0127 (OC8).

2

EDBCSXP064 EN 8.0

25

Page 26

2

2.3 Residual hazards

Safety instructions

Residual hazards

Protection of persons

ƒ Before working on the axis module, check that no voltage is applied to the power

terminals, because

– the power terminals +UG, −UG, U, V and W remain live for at least 3 minutes after

mains switch−off.

– the power terminals +UG, −UG, U, V and W remain live when the motor is stopped.

ƒ The heatsink has an operating temperature of > 70 °C:

– Direct skin contact with the heatsink results in burns.

ƒ The discharge current to PE is > 3.5 mA AC or. > 10 mA DC.

– EN 61800−5−1 requires a fixed installation.

– The PE connection must comply with EN 61800−5−1.

– Comply with the further requirements of EN 61800−5−1 for high discharge

currents!

Device protection

ƒ All pluggable connection terminals must only be connected or disconnected when

no voltage is applied!

ƒ The power terminals +UG, −UG, U, V, W and PE are not protected against polarity

reversal.

– When wiring, observe the polarity of the power terminals!

ƒ Power must not be converted until all devices of the power system are ready for

operation. Otherwise, the input current limitation may be destroyed.

Frequent mains switching (e.g. inching mode via mains contactor) can overload and

destroy the input current limitation of the axis module, if

ƒ the axis module is supplied via the ECSxE supply module and the input current

limitation is activated depending on the DC−bus voltage (C0175 = 1 or 2).

ƒ the axis module is not supplied via a supply module delivered by Lenze.

ƒ the low−voltage supply (24 V) is switched off.

For this reason allow a break of at least three minutes between two starting operations!

Use the safety function ˜Safe torque off˜ (STO) for frequent disconnections for safety

reasons.

26

EDBCSXP064 EN 8.0

Page 27

Safety instructions

Residual hazards

Motor protection

ƒ Only use motors with a minimum insulation resistance of û = 1.5 kV,

min. du/dt = 5 kV/ms.

– Lenze motors meet these requirements.

ƒ When using motors with an unknown insulation resistance, please contact your

motor supplier.

ƒ Some settings of the axis module lead to an overheating of the connected motor,

e.g. longer operation of self−ventilated motors with low speeds.

ƒ Use PTC thermistors or thermostats with PTC characteristic for motor temperature

monitoring.

2

EDBCSXP064 EN 8.0

27

Page 28

2

Safety instructions

Safety instructions for the installation according to UL

2.4 Safety instructions for the installation according to UL

Warnings!

General markings:

ƒ Use 60/75 °C or 75 °C copper wire only.

ƒ Maximum ambient temperature 55 °C, with reduced output current.

Markings provided for the supply units:

ƒ Suitable for use on a circuit capable of delivering not more than 5000 rms

symmetrical amperes, 480 V max, when protected by K5 or H Fuses

(400/480 V devices).

ƒ Alternate − Circuit breakers (either inverse−time, instantaneous trip types or

combination motor controller type E) may be used in lieu of above fuses

when it is shown that the let−through energy (i

) of the inverse−time current−limiting circuit breaker will be less

p

current (I

than that of the non−semiconductor type K5 fuses with which the drive has

been tested.

ƒ Alternate − An inverse−time circuit breaker may be used, sized upon the

input rating of the drive, multiplied by 300 %.

Markings provided for the inverter units:

ƒ The inverter units shall be used with supply units which are provided with

overvoltage devices or systems in accordance with UL840 2nd ed., Table 5.1.

ƒ The devices are provided with integral overload and integral thermal

protection for the motor.

ƒ The devices are not provided with overspeed protection.

2

t) and peak let−through

Terminal tightening torque of lb−in (Nm)

Terminal lb−in Nm

X 21, X 22, X 23, X 24 10.6 ... 13.3 1.2 ... 1.5

X4, X6, X14 1.95 ... 2.2 0.22 ... 0.25

X 25 4.4 ... 7.1 0.5 ... 0.8

Wiring diagram AWG

Terminal AWG

X 21, X 22, X 23, X 24 12 ... 8

X4, X6, X14 28 ... 16

X 25 24 ... 12

28

EDBCSXP064 EN 8.0

Page 29

2.5 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

Danger!

Danger!

Stop!

Safety instructions

Notes used

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

2

Application notes

Pictograph and signal word Meaning

Note!

Tip!

Special safety instructions and application notes for UL and UR

Pictograph and signal word Meaning

Warnings!

Warnings!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

Safety or application note for the operation of a UL−approved

device in UL−approved systems.

Possibly the drive system is not operated in compliance with UL

if the corresponding measures are not taken.

Safety or application note for the operation of a UR−approved

device in UL−approved systems.

Possibly the drive system is not operated in compliance with UL

if the corresponding measures are not taken.

EDBCSXP064 EN 8.0

29

Page 30

3

Technical data

General data and operating conditions

3 Technical data

3.1 General data and operating conditions

Standards and operating conditions

Conformity CE Low−Voltage Directive (2006/95/EG)

Approvals

Max. permissible

Motor cable length

Packaging (EN ISO 4180) Shipping package

Installation l Installation into IP20 control cabinet

Mounting position vertically suspended

Free space

shielded 50 m For rated mains voltage and switching frequency of 8 kHz

above ³ 65 mm

below ³ 65 mm

to the sides can be mounted directly side by side without any clearance

UL 508C

CSA 22.2 No. 14

l For the "safe torque off" function (formerly "safe standstill"): mounting in IP54

control cabinet

With ECSZS000X0B shield mounting kit: > 195 mm

Power Conversion Equipment

Underwriter Laboratories (File No. E132659)

for USA and Canada

Environmental conditions

Climate 3k3 in accordance with IEC/EN 60721−3−3

Condensation, splash water and ice formation

not permissible.

Site altitude 0 ... 4000 m amsl

Pollution EN 61800−5−1, UL840: Degree of pollution 2

Vibration resistance Acceleration resistant up to 0.7 g (Germanischer Lloyd, general conditions)

Storage IEC/EN 60721−3−1 1K3 (−25 ... + 55 °C)

Transport IEC/EN 60721−3−2 2K3 (−25 ... +70 °C)

Operation IEC/EN 60721−3−3 3K3 (0 ... + 55 °C)

l Atmospheric pressure: 86 ... 106 kPa

l Above +40 °C: reduce the rated output

current by 2 %/°C.

l Reduce rated output current by

5 %/1000 m above 1000 m amsl.

l Over 2000 m amsl: Use is only permitted in

environments with overvoltage category II

30

EDBCSXP064 EN 8.0

Page 31

Technical data

General data and operating conditions

General electrical data

EMC Compliance with the requirements acc. to EN 61800−3

Noise emission Compliance with the limit class C2 acc. to EN 61800−3

(achieved by using collective filters typical for the application)

Noise immunity

Insulation resistance EN 61800−5−1, UL840: Overvoltage category III

Discharge current to PE

(Acc. to EN 61800−5−1)

Enclosure IP20 for

Protective measures against l Short circuit in power terminals

Protective insulation of control circuits Protective separation from the mains

1)

Noise immunity in the above−mentioned severities must be guaranteed by the control cabinet! The user

must check the compliance with the severities!

Requirements acc. to EN 61800−3

Requirement Standard Severity

1)

ESD

Conducted high frequency EN 61000−4−6 10 V; 0.15 ... 80 MHz

RF interference (housing) EN 61000−4−3 3, i. e. 10 V/m;

Burst EN 61000−4−4 3/4, i. e. 2 kV/5 kHz

Surge (surge voltage on mains

cable)

> 3.5 mA AC

l Standard installation (built−in unit)

l Cold−plate technique

l Mounting with thermal separation (push−through technique), IP54 on heatsink side

– Motor terminal has a limited protection against short circuit (after short circuit

detection, the error message must be reset.)

l Short circuit in auxiliary circuits

– Digital outputs: Short−circuit−proof

– Bus and encoder systems: Limited protection against short circuit (if necessary,

monitoring functions can be switched off, in this case, error messages must be

reset:)

l Earth fault (earth−fault protected during operation, limited earth−fault protection

on mains power−up)

l Overvoltage

l Motor stalling

l Motor overtemperature (input for KTY, I

Double/reinforced insulation acc. to EN 61800−5−1

EN 61000−4−2 3, i. e.

EN 61000−4−5 3, i. e. 1.2/50 ms

2

x t monitoring)

3

l 8 kV for air discharge

l 6 kV for contact discharge

80 ... 1000 MHz

l 1 kV phase/phase

l 2 kV phase/PE

EDBCSXP064 EN 8.0

31

Page 32

3

Technical data

Rated data

3.2 Rated data

Rated data Type

ECSx004 ECSx008 ECSx016

Output power 400 V mains S

Data for operation with upstream power supply module

on mains voltage

DC−bus voltage V

DC−bus current I

Rated output current at 4 kHz

(causes a heatsink temperature of 70°C at an ambient

temperature of 20°C)

Rated output current at 8 kHz (at an ambient

temperature of 20°C it causes a heatsink temperature

of 70°C)

Max. output current

(acceleration current)

Continuous current at standstill

(holding current at 90°C, 4 kHz)

Short−time standstill current

(holding current at 90 °C, 4 kHz)

Short−time standstill current

(holding current at 70 °C, 4 kHz)

Short−time standstill current

(holding current at 70 °C, 8 kHz)

Power loss (operation with rated

current at 4 kHz / 8 kHz)

Max. output frequency f

Mass m [kg] approx. 2.4

1)

2)

2)

2)

Total

Inside the device 13.3 17.3 20.7

Heatsink 14.0 29.0 64.0

1)

If the heatsink temperature reaches 70°C, the switching frequency automatically changes to 4 kHz.

2)

The indicated temperature is the measured heatsink temperature (C0061).

Application software:

[kVA] 1.3 2.6 5.3

rated

V

[V] 400 480 400 480 400 480

mains

[V] 15 ... 770

DC−bus

[A] 2.5 2.0 4.9 3.9 9.8 7.8

DC−bus

Ir [A] 2.0 1.6 4.0 3.2 8.0 6.4

Ir [A] 1.4 1.1 2.7 2.2 5.3 4.2

I

[A] 4.0 8.0 16.0

max

I

0,eff 4 kHz

I

0,eff 4 kHz

I

0,eff 4 kHz

I

0,eff 8 kHz

S = Speed & Torque P = Posi & Shaft

M = Motion A = Application

[A] 2.0 1.6 4.0 3.2 8.0 6.4

[A] 2.3 4.6 9.1

[A] 3.0 6.0 12.0

[A] 1.5 3.0 6.0

27.3 46.3 84.7

P

[W]

loss

[Hz] 600

out

Axis module

32

EDBCSXP064 EN 8.0

Page 33

Technical data

Rated data

3

Rated data Type

ECSx032 ECSx048 ECSx064

Output power 400 V mains S

Data for operation with upstream power supply module

on mains voltage

DC−bus voltage V

DC−bus current I

Rated output current at 4 kHz

(causes a heatsink temperature of 70°C at an ambient

temperature of 20°C)

Rated output current at 8 kHz (at an ambient

temperature of 20°C it causes a heatsink temperature

of 70°C)

Max. output current

(acceleration current)

Continuous current at standstill

(holding current at 90°C, 4 kHz)

Short−time standstill current

(holding current at 90 °C, 4 kHz)

Short−time standstill current

(holding current at 70 °C, 4 kHz)

Short−time standstill current

(holding current at 70 °C, 8 kHz)

Power loss (operation with rated

current at 4 kHz / 8 kHz)

Max. output frequency f

Mass m [kg] approx. 2.4 approx. 3.3

1)

2)

2)

2)

2)

Total

Inside the device 27.5 34.5 41.0

Heatsink 117.0 132.0 158.0

1)

If the heatsink temperature reaches 70°C, the switching frequency automatically changes to 4 kHz.

2)

The indicated temperature is the measured heatsink temperature (C0061).

Application software:

[kVA] 8.3 11.2 13.2

rated

U

[V] 400 480 400 480 400 480

mains

[V] 15 ... 770

DC−bus

[A] 15.6 12.5 20.9 16.8 24.5 19.6

DC−bus

Ir [A] 12.7 10.2 17.0 13.6 20.0 16.0

Ir [A] 8.5 6.8 11.3 9.0 13.3 10.6

I

[A] 32.0 48.0 64.0

max

I

0,eff 4 kHz

I

0,eff 4 kHz

I

0,eff 4 kHz

I

0,eff 8 kHz

S = Speed & Torque P = Posi & Shaft

M = Motion A = Application

[A] 16.0 12.8 23.0 18.4 27.0 21.6

[A] 18.1 27.2 36.3

[A] 24.0 36.0 48.0

[A] 12.1 18.1 24.2

144.5 166.5 199.0

P

[W]

loss

[Hz] 600

out

Axis module

EDBCSXP064 EN 8.0

33

Page 34

3

Technical data

Current characteristics

Increased continuous current depending on the control factor

3.3 Current characteristics

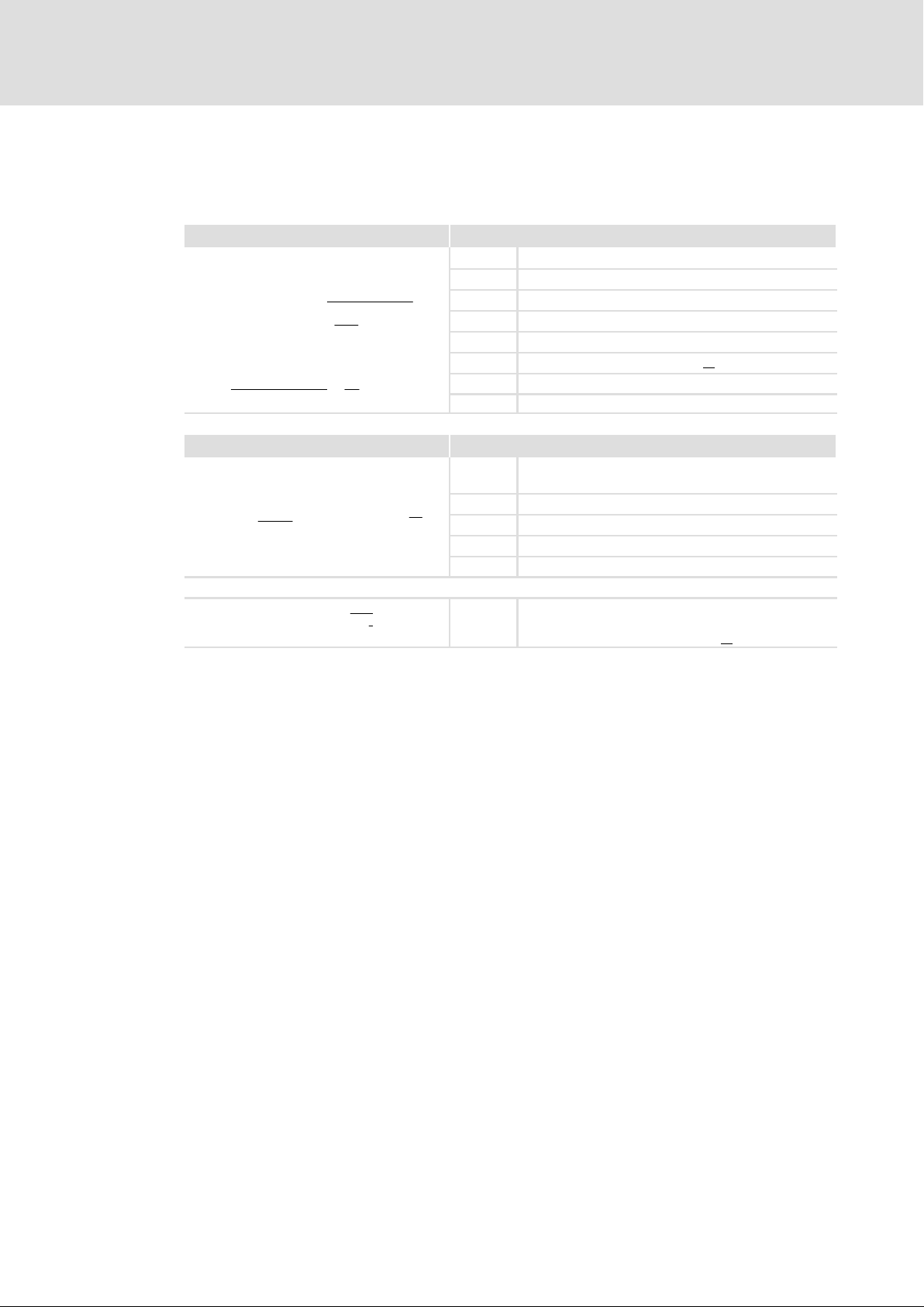

3.3.1 Increased continuous current depending on the control factor

In the lower speed range ˘ the motor does not need the full motor voltage ˘ particularly

the more powerful ECS axis modules can be permanently operated with increased output

current (cp. continuous current I

I [A]

I [A]

0

30.0

27.0

25.0

23.0

20.0

16.0

15.0

10.0

8.0

5.0

4.0

2.0

0.0

0 % 50 %

Fig. 3−1 Continuous device current, depending on the output voltage for U

I

r

U

Mot_n

U

Mot_max

Rated output current of the axis module

Actual controller output voltage

0.9 x current mains voltage

32).

0,eff

ECSxS/P/M/A064

ECSxS/P/M/A048

ECSxS/P/M/A032

ECSxS/P/M/A016

ECSxS/P/M/A008

ECSxS/P/M/A004

I [A]

N

20.0

17.0

12.7

U/U

Mot

£ 400 V at 4 kHz

mains

8.0

4.0

2.0

100 %

max

ECSXA002

The permissible continuous current depends on the control factor of the power output

stages, approximately on the ratio of the motor voltage output in the operating point

(U

the components involved at rated load and a control margin, U

) to the maximum possible output voltage (U

Mot_n

Mot_max

). Due to voltage drops across

Mot_max

can be estimated

with 90 % of the mains voltage.

Tip!

The operating threshold of the device utilisation monitoring (I x t) function is

automatically adapted to the continuous device current which changes

depending on the output voltage (see fig.).

34

EDBCSXP064 EN 8.0

Page 35

Technical data

Current characteristics

Increased continuous current depending on the control factor

The following table shows the connections between mains voltage, DC−bus voltage and

motor voltage:

3

Mains voltage

]

[U

mains

3 x 230 V AC 310 V DC 3 x 205 V AC

3 x 380 V AC 510 V DC 3 x 340 V AC

3 x 400 V AC 540 V DC 3 x 360 V AC

3 x 415 V AC 560 V DC 3 x 370 V AC

3 x 460 V AC 620 V DC 3 x 415 V AC

3 x 480 V AC 650 V DC 3 x 435 V AC

3 x 528 V AC 712 V DC 3 x 475 V AC

DC−bus voltage

= U

[U

DC

mains

x 1.35]

Output voltage (motor voltage)

nominally achievable for 100 %

modulation

[U

mot

= 0.66 x UDC]

For steady−state operation in generator mode with increased DC−bus voltage or supply

from a closed−loop DC−voltage source, interpolate accordingly between the values given in

the table.

The increased rated currents are valid for the entire voltage range specified at switching

frequencies of 4 kHz and 8 kHz.

Note!

If in this connection a heatsink temperature of > 70 °C is reached, the drive