Page 1

EDB8200EN

Show/Hide Bookmarks

!NIi

Ä!NIiä

Operating Instructions

Lenze

Postfach 101352 ,31763 HAMELN

Typ

Id.-NR

Fert.-Nr

Serien-Nr.

Eingang1

Eingang2

hPRKMNNMJP

Global Drive

Frequency inverters

8200 series

Page 2

qЬЙлЙ lйЙк~нбеЦ fелнкмЕнбзел ~кЙ о~дбЗ Сзк нЬЙ UOuu ЕзенкзддЙкл зС нЬЙ оЙклбзелW

Show/Hide Bookmarks

33.820X- E- 1x. 1x (8201 - 8204)

33.8202- E- 1x. 1x -V002 reduced assembly depth (8202)

Type

Design:

B = Module

C=ColdPlate

E = Enclosure IP20

Hardware level and index

Software level and index

Variant

Explanation

кЙоблЙЗ

bЗбнбзе зСW MOLNMLNVVT MVLOMMO

Page 3

Contents

Show/Hide Bookmarks

1 Preface and general information 1-1...........................

1.1 About these Operating Instructions ... 1-1.......................

1.1.1 Terminology used 1-1...............................

1.1.2 What is new? 1-2..................................

1.2 Scope of delivery 1-2.....................................

1.3 Legal regulations 1-3.....................................

2 Safety information 2-1......................................

2.1 General safety information 2-1...............................

2.2 Layout of the safety information 2-3...........................

2.3 Residual hazards 2-4.....................................

3 Technical data 3-1.........................................

3.1 General data/application conditions 3-1.........................

3.2 Rated data (Operation with 150 % overload) 3-2...................

3.2.1 Types 8201 to 8204 3-2.............................

3.3 Fuses and cable cross-sections 3-4...........................

3.3.1 Single drives with 150 % overload 3-4....................

3.4 Dimensions 3-4.........................................

4 Installation 4-1............................................

4.1 Mechanical installation 4-1.................................

4.1.1 Important notes 4-1.................................

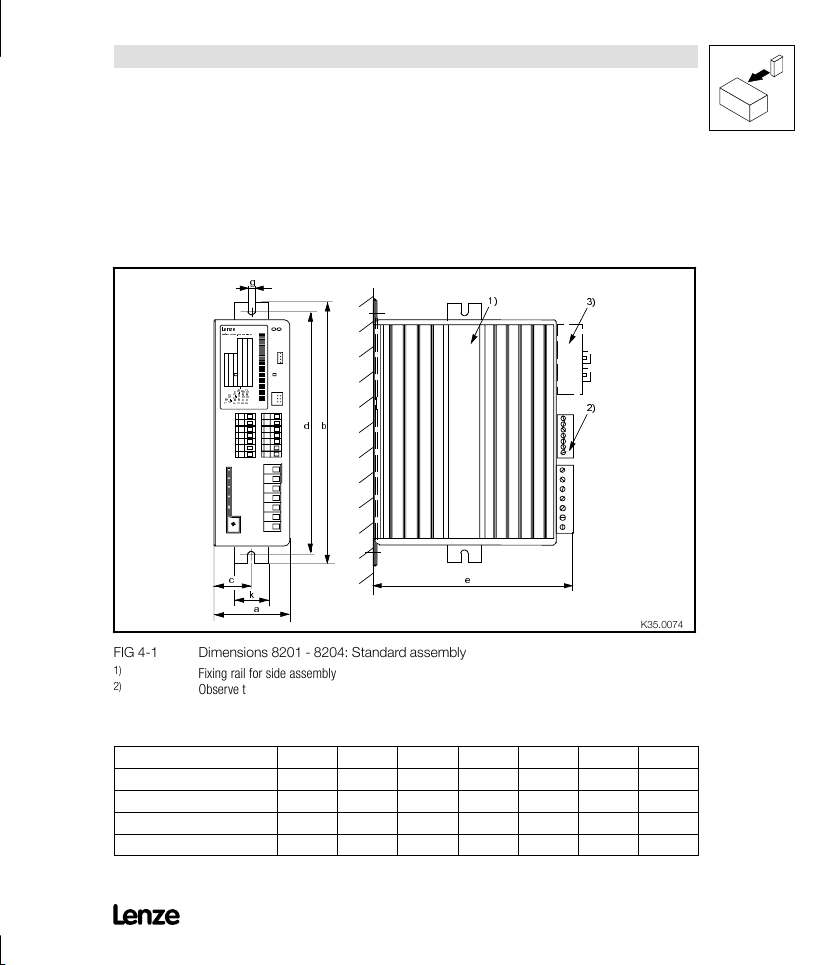

4.1.2 Standard assembly with fixing rails or fixing angles 4-3.........

4.1.2.1 Types 8201 to 8204 4-3......................

4.1.2.2 Type 8202-V002 (reduced assembly depth) 4-4.......

4.1.3 DIN-rail assembly 4-5...............................

4.2 Electrical installation 4-6...................................

4.2.1 Important notes 4-6.................................

4.2.2 Power connections 4-7..............................

4.2.2.1 Mains connection 4-7........................

4.2.2.2 Motor connection 4-7........................

4.2.2.3 Connection diagram 4-9.......................

4.2.3 Control connections 4-10..............................

4.2.3.1 Control cables 4-10...........................

4.2.3.2 Assignment of the control terminals 4-10............

4.2.3.3 Connection diagrams 4-12......................

4.3 Installation of a CE-typical drive system 4-13......................

UOMu_^MVMO i

Page 4

Contents

Show/Hide Bookmarks

5 Commissioning 5-1.........................................

5.1 Before you switch on 5-1..................................

5.2 Short set-up (Factory setting) 5-2.............................

5.2.1 Switch-on sequence 5-2.............................

5.2.2 Factory setting of the most important drive parameters 5-3......

5.3 Adapt machine data 5-4...................................

5.3.1 Determine speed range (fdmin, fdmax) 5-4.................

5.3.2 Adjustment of acceleration and deceleration times (Tir , T if) 5-6..

5.3.3 Setting of the current limit (Imax) 5-7.....................

5.4 Optimisation of the operating characteristic of the drive 5-8...........

5.4.1 Select the control mode 5-8...........................

5.4.1.1 Optimisation of V/f-characteristic control

5.4.1.2 Optimisation of V/f-characteristic control 5-13.........

6 During operation 6-1.......................................

7 Configuration 7-1..........................................

7.1 Basics 7-1............................................

7.2 Code table 7-2.........................................

8 Troubleshooting and fault elimination 8-1.......................

8.1 Troubleshooting 8-1......................................

8.1.1 Display at the controller 8-1...........................

8.1.2 Display at the operating module 8-1.....................

8.1.3 Maloperation of the drive 8-2..........................

8.2 Fault analysis using the history buffer 8-2.......................

8.3 Fault indications 8-3......................................

8.4 Reset of fault indications 8-5................................

9 Accessories (Overview) 9-1..................................

9.1 Accessories for all types 9-1................................

9.2 Software 9-2...........................................

9.3 Type-specific accessories 9-2...............................

10 Index 10-1................................................

with auto boost 5-11..........................

ii UOMu_^MVMO

Page 5

Preface and general information

Show/Hide Bookmarks

1 Preface and general information

1.1 About these Operating Instructions ...

D qЬЙлЙ lйЙк~нбеЦ fелнкмЕнбзел ЬЙдй узм нз ЕзееЙЕн ~еЗ лЙн мй

нЬЙ UOuu СкЙимЙеЕу беоЙкнЙкK qЬЙу Езен~бе л~СЙну беСзкг~нбзе

пЬбЕЬ гмлн ДЙ зДлЙкоЙЗK

D ^дд йЙклзел пЬз пзкв зе ~еЗ пбнЬ UOuu СкЙимЙеЕу беоЙкнЙкл

гмлн Ь~оЙ нЬЙ lйЙк~нбеЦ fелнкмЕнбзел ~о~бд~ДдЙ ~еЗ зДлЙкоЙ

~дд кЙдЙо~ен езнЙл ~еЗ белнкмЕнбзелK

D qЬЙ lйЙк~нбеЦ fелнкмЕнбзел гмлн ~дп~ул ДЙ бе ~ ЕзгйдЙнЙ ~еЗ

йЙкСЙЕнду кЙ~З~ДдЙ лн~нЙK

1.1.1 Terminology used

Ter m In the follo wing text used for

82XX Any frequency inverter of the series 8200, 8210, 8220, 8240

Controller 82XX frequency inverter

Drive system Drive systems with 82XX frequency inverters and other Lenze drive

components

UOMu_^MVMO 1-1

Page 6

Preface and general information

Show/Hide Bookmarks

1.1.2 What is new?

Material

no.

375134 05/10/1994 8200/8210 Short Instructions

375190 13/02/1995 8200/8210 Operating Instructions

398283 02/10/1997 replaces 375134

454072 09/2002 replaces 398283 D Chapter 4.2.3.2

Edition of Important Content

replaces 375190

1.2 Scope of delivery

Scope of delivery Important

D 1 82XX frequency inverter

D 1 Operating Instructions

D 1 accessory kit (components for

the mechanical and electric

installation)

D Contents only for 8200

D Complete revision of the contents

D Complete editorial revision

D Chapter 5.1

D Chapter 8.3

D Change of company name

After receipt of the delivery, check immediately whether

the scope of supply matches with the accompanying

papers. Lenze does not accept any liability for deficiencies

claimed subsequently.

Claim

D visible transport damage immediately to the forwarder.

D visible deficiencies/incompleteness immediately to your

Lenze representative.

1-2 UOMu_^MVMO

Page 7

Preface and general information

Labelling

Show/Hide Bookmarks

1.3 Legal regulations

Labelling

Application

as directed

Nameplate CE mark Manufacturer

Lenze controllers are

unambiguously designated by

the content of the nameplate

82XX frequency inverter

D must only be operated under the conditions prescribed in these Instructions.

D are components

- used for open and closed loop control of variable speed drives withasynchronous standard

motors, reluctance motors, PM-synchronous motors with asynchronous damping cage.

- used for installation into a machine.

- used for assembly together with other components to form a machine.

D are electric units for the installation into control cabinets or similar enclosed operating housing.

D comply with the requirements of the Low-Voltage Directive.

D are not machines for the purpose of the Machinery Directive.

D are not to be used as domestic appliances, but only for industrial purposes.

Drive systems with 82XX frequency inverters

D comply with the EMC Directive if they are installed according to the guidelines of CE-typical drive

systems.

D can be used

- on public and non-public mains.

- in industrial as well as residential and commercial premises.

D The user is responsible for the compliance of his application with the EC directives.

Any other use shall be deemed inappropriate!

Conforms to the EC Low Voltage

Directive

Lenze Drive Systems GmbH

Postfach 10 13 52

D-31763 Hameln

UOMu_^MVMO 1-3

Page 8

Preface and general information

Disposa

l

Show/Hide Bookmarks

Liability D The information, data and notes in these Operating Instructions met the state of the art at the time

Warranty D Warranty conditions: see Sales and Delivery Conditions of Lenze Drive Systems GmbH.

Disposal

of printing. Claims referring to drive systems which have already been supplied c annot be derived

from the information, illustrations, and descriptions given in these Operating Instructions.

D The specifications, processes, and circuitry described in these Operating Instructions are for

guidance only and must be adapted to your own specific application. Lenze does not take

responsibility for the suitability of the process and circuit proposals.

D The indications given in these Operating Instructions describe the features of the product without

warranting them.

D Lenze does not accept any liability for damage and operating interference caused by:

- disregarding these Instructions

- unauthorized modifications to the controller

- operating errors

- improper working on and with the controller

D Warranty claims must be made immediately after detecting defects or faults.

D The warranty is void in all cases where liability claims cannot be made.

Material recycle dispose

Metal D Plastic D Printed-board assemblies - D

1-4 UOMu_^MVMO

Page 9

Safety information

Show/Hide Bookmarks

2 Safety information

2.1 General safety information

Safety and application notes for controllers

EнзW iзпJsздн~ЦЙ aбкЙЕнбоЙ TPLOPLbb`F

1. General

During operation, drive controllers may have, according

to their type of protection, live, bare, in some cases also

movable or rotating parts as well as hot surfaces.

Non-authorized removal of the required cover,

inappropriate use, incorrect installation or operation,

creates the risk of severe injury to persons or damage to

material assets.

Further information can be obtained from the

documentation.

All operations concerning transport, installation, and

commissioning as well as maintenance must be carried

out by qualified, skilled personnel (IEC 364 and CENELEC

HD 384 or DIN V DE 0100 and IEC report 664 or DIN VDE

0110 and national regulations for the prevention of

accidents must be observed).

According to this basic safety information qualified

skilled personnel are persons who are familiar with the

erection, assembly, commissioning, and operation of the

product and who have the qualifications necessary for

their occupation.

2. Application as directed

Drive controllers are components which are designed for

installation in electrical systems or machinery.

When installing in machines, commissioning of the drive

controllers (i.e. the starting of operation as directed) is

prohibited until it is proven that the machine corresponds

to the regulations of the EC Directive 89/392/EEC

(Machinery Directive); EN 60204 must be observed.

Commissioning (i.e. starting of operation as directed) is

only allowed when there is compliance with the EMC

Directive (89/336/EEC).

The drive controllers meet the requirements of the Low

Voltage Directive 73/23/EEC. The harmonized standards

of the prEN 50178/ DIN VDE 0160 series together with

EN 60439-1/DIN VDE 0660 part 500 and EN 60146/DIN

VDE 0558 are applicable to drive controllers.

The technical data and information on the connection

conditions must be obtained from the nameplate and the

documentation and must be observed in all cases.

3. Transport, storage

Notes on transport, storage and appropriate handling

must be observed.

Climatic conditions must be observed according to

prEN 50178.

4. Erection

The devices must be erected and cooled according to the

regulations of the corresponding documentation.

The drive controllers must be protected from

inappropriate loads. Particularly during transport and

handling, components must not be bent and/or isolating

distances must not be changed. Touching of electronic

components and contacts must be avoided.

UOMu_^MVMO 2-1

Page 10

Safety information

Show/Hide Bookmarks

Drive controllers contain electrostatically sensitive

components which can easily be damaged by

inappropriate handling. Electrical components must not

be damaged or destroyed mechanically (health risks are

possible!).

5. Electrical connection

When working on live drive controllers, the valid national

regulations for the prevention of accidents (e.g. VBG 4)

must be observed.

The electrical installation must be carried out according

to the appropriate regulations (e.g. cable cross-sections,

fuses, PE connection). More detailed information is

included in the documentation.

Notes concerning the installation in compliance with

EMC - such as screening, grounding, arrangement of

filters and laying of cables - are included in the

documentation of the drive controllers. These notes must

also be observed in all cases for drive controllers with

the CE mark. The compliance with the required limit

values demanded by the EMC legislation is the

responsibility of the manufacturer of the system or

machine.

6. Operation

Systems where drive controllers are installed must be

equipped, if necessary, with additional monitoring and

protective devices according to the valid safety

regulations, e.g. law on technical tools, regulations for

the prevention of accidents, etc. Modifications of the

drive controllers by the operating software are allowed.

After disconnecting the drive controllers from the supply

voltage, live parts of the controller and power

connections must not be touched immediately, because

of possibly charged capacitors. For this, observe the

corresponding labels on the drive controllers.

During operation, all covers and doors must be closed.

7. Maintenance and servicing

The manufacturer’s documentation must be observed.

This safety information must be kept!

The product-specific safety and application notes

in these Operating Instructions must also be

observed!

2-2 UOMu_^MVMO

Page 11

Safety information

Show/Hide Bookmarks

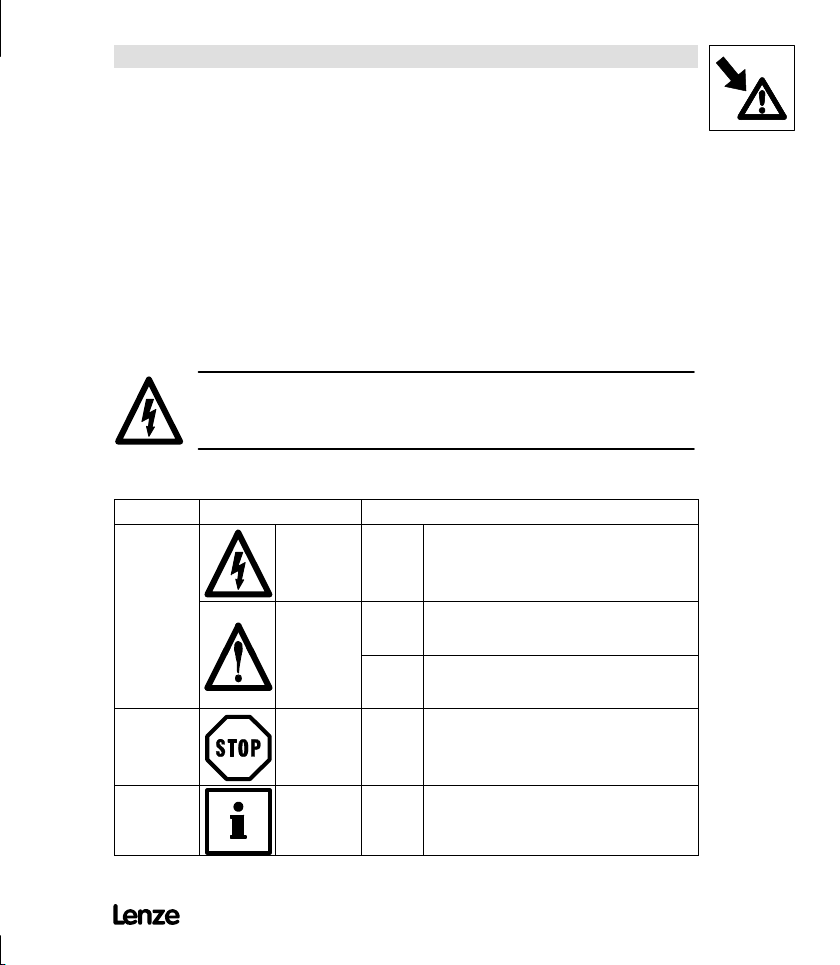

2.2 Layout of the safety information

D ^дд л~СЙну езнЙл Ь~оЙ ~ мебСзкг д~узмнW

J qЬЙ бЕзе ЕЬ~к~ЕнЙкбтЙл нЬЙ нуйЙ зС З~еЦЙкK

J qЬЙ лбЦе~д пзкЗ ЕЬ~к~ЕнЙкбтЙл нЬЙ лЙоЙкбну зС З~еЦЙкK

J qЬЙ езнЙ ЗЙлЕкбДЙл нЬЙ З~еЦЙк ~еЗ лмЦЦЙлнл Ьзп нз ~озбЗ

íÜÉ Ç~åÖÉêK

Signal word

kçíÉ

Icons used Signal words

Warning of

danger to

persons

Warning of

damage to

material

Other notes Note! This note designates general, useful notes.

Warning of

hazardous

electrical

voltage

Warning of a

general danger

Danger! Warns of impending danger.

Warning! Warns of potential, very hazardous situations.

Caution! Warns of potential, hazardous situations.

Stop! Warns of potential damage to material .

Consequences if disregarded:

Death or very severe injuries.

Possible consequences if disregarded:

Death or very severe injuries.

Possible consequences if disregarded:

Light or minor injuries.

Possible consequences if disregarded:

Damage of the controller/drive system or its

environment

If you observe it, handling of the controller/drive

system is made easier.

K

UOMu_^MVMO 2-3

Page 12

Safety information

Show/Hide Bookmarks

2.3 Residual hazards

Operator’s safety After mains disconnections, the power terminals U, V, W and +UG,-UGremain live for at

Protection of

devices

Overspeeds Drive systems can reach dangerous overspeeds (e. g. setting of inappropriately high field

least three minutes.

D Before working on the controller, check that no voltage is applied to the power terminals.

Cyclic connection and disconnection of the controller supply voltage at L1, L2, L3 or +U

may overload the internal input current load:

-U

G

D Allow at least 3 minutes between disconnection and reconnection.

frequencies):

D The controllers do not offer any protection against these operating conditions. Use

additional components for this.

,

G

2-4 UOMu_^MVMO

Page 13

Technical Data

Permissible

Show/Hide Bookmarks

3 Technical data

3.1 General data/application conditions

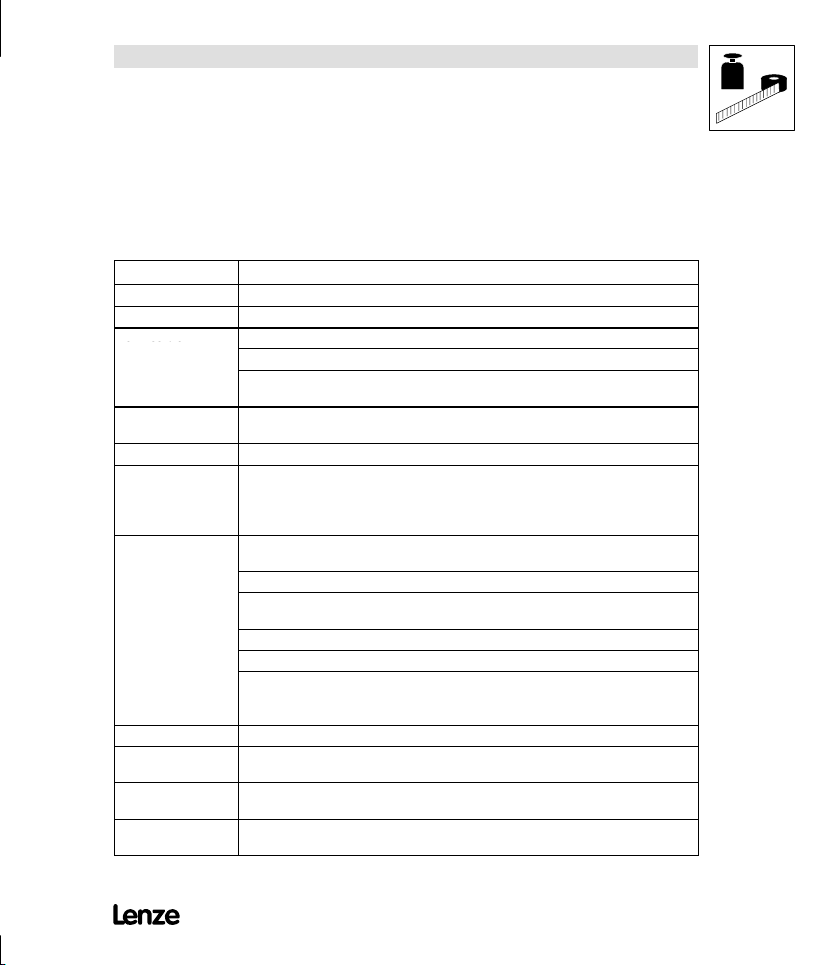

Field Values

Vibration resistance Germanischer Lloyd, general conditions

Humidity class Humidity class F without condensation (average relative humidity 85 %)

Permissible

temperature ranges

Permissible

installation height h

Degree of pollution VDE 0110 part 2 pollution degree 2

Noise emission Requirements acc. to EN 50081-2, EN 50082-1, IEC 22G-WG4 (Cv) 21

Noise immunity

Insulation strength Overvoltage category III according to VDE 0110

Packaging

(DIN 4180)

Type of protection IP20

Approvals CE: Low Voltage Directive

during transport of the controller: -25 °C ¼ +70 °C

during storage of the controller: -25 °C ¼ +55 °C

during operation of the controller: 0 °C ¼+40 °C

h ≤ 1000 m.a.m.s.l

1000 m a.m.s.l

Limit value class A to EN 55011 (industrial area) with mains filter

Limit value class B to EN 55022 (residential area) with mains filter and installation into

control cabinet

Limit values maintained usig mains filter

Requirements according to EN 50082-2, IEC 22G-WG4 (Cv) 21

Requirements Standard Severities

ESD EN61000-4-2 3, i.e. 8 kV with air discharge

RF interference(enclosure) EN61000-4-3 3, i.e. 10 V/m; 27¼1000 MHz

Burst EN61000-4-4 3/4, i.e. 2 kV/5 kHz

Surge

(Surge on mains cable)

< h ≤ 4000 m a.m.s.l

+40

°C ¼ +50 °C

EN 61000-4-5 3, i.e. 1.2/50 μs,

Dust packaging

NEMA 1: Protection against contact

without power derating

with power derating

without power derating

with power derating

6 kV with contact discharge

1 kV phase-phase,

2 kV phase-PE

Electromagnetic compatibility

UOMu_^MVMO 3-1

Page 14

Technical Data

Variantreducedassembl

y

otopoe(poeS

)

Show/Hide Bookmarks

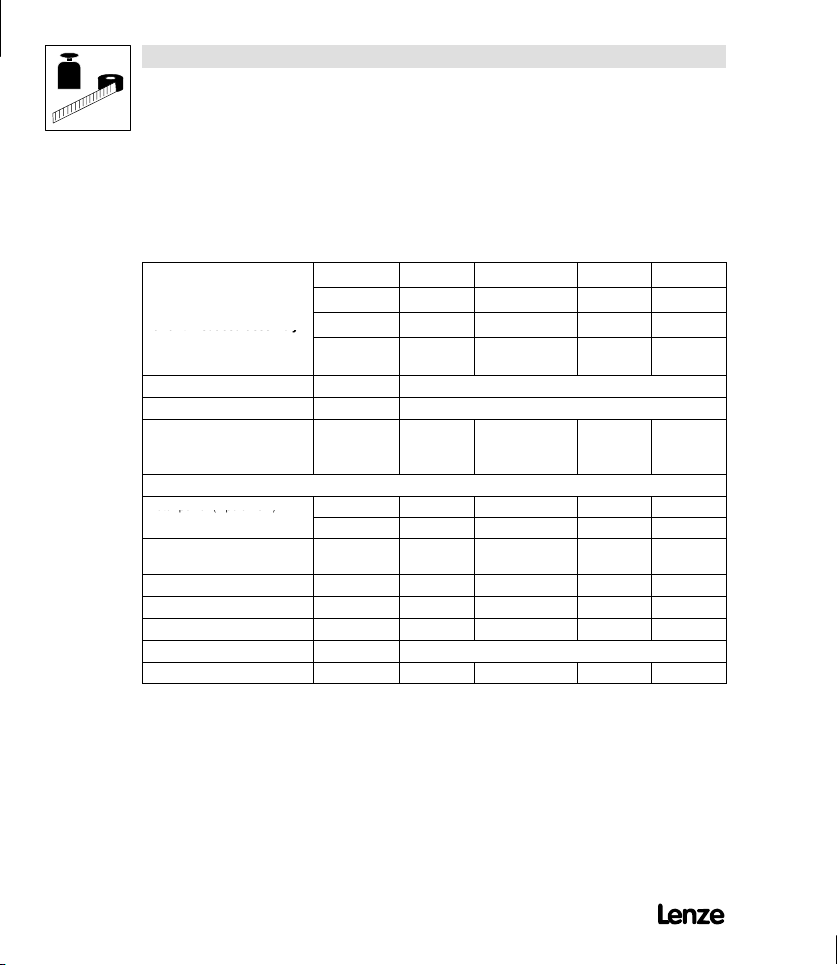

3.2 Rated data (Operation with 150 % overload)

3.2.1 Types 8201 to 8204

150 % overload Type 8201 8202 8203 8204

Order no. EVF8201-E EVF8202-E EVF8203-E EVF8204-E

Variant ”reduced assembly

depth”

Type 8202-V002

Order no. EVF8202-E- V002

3-2 UOMu_^MVMO

Mains voltage V

Alternative DC supply VDC[V] 270V 0% ≤ V

Mains current

4)

with mains filter/mains choke

without mains filter/mains choke

Data for mains operation with 1 AC / 230 V / 50 Hz/60 Hz; 270 ≤ V

Motor power (4 pole ASM)

at 9.2 kHz*

Output power U, V, W

at 9.2 kHz*

Output power +UG,-U

1)

G

Output current I

Max. output current for 60s

Motor voltage

3)

2)

[V] 190V 0% ≤ V

rated

I

[A]

mains

4.2

5.0

P

[kW] 0.37 0.75 1.5 2.2

rated

P

[hp] 0.5 1.0 2.0 2.9

rated

S

[kVA] 1.0 1.5 2.7 3.6

N9.2

≤ 260V 0% ; 45Hz¼65Hz 0%

rated

7.5

9.0

DC

DC

≤ 275V

≤ 360V 0%

12.5

15.0

PDC[kW] 0.0 0.0 0.0 0.0

[A] 2.6 4.0 7.0 9.5

rated

I

[A] 3.9 6.0 10.5 14.2

Nmax

VM[V] 0-3× V

/0Hz¼ 50Hz, if required up to 240Hz

mains

17.0

Power loss (Operation with IN) Pv[W] 30 50 70 100

-

Page 15

150 % overload 8204820382028201Type

Field

Analogsetpoin

t

Show/Hide Bookmarks

Variant ”reduced assembly

depth”

depth”

Technical Data

EVF8204-EEVF8203-EEVF8202-EEVF8201-EOrder no.

8202-V002TypeVariant ”reduced assembly

EVF8202-E- V002Order no.

Power derating [%/K]

[%/m]

Field

frequency

Resolution Absolute 0.05 Hz

Digital setpoint

selection

Analog setpoint

selection

Accuracy 0.05 Hz

Linearity 0.5 % (max. selected signal level, 5V or 10V)

Temperature

sensitivity

40 °C<T

1000 m a.m.s.l.

Offset 0.3 %

Weight m[kg] 1.0 1.3

Variant 1.0

1)

2)

3)

4)

This power can be additionally obtained when operating a matching motor

The currents apply to a periodical load cycle with 1 minute overcurrentwith the current mentioned here

and 2 minutes base load with 75% I

With mains choke/mains filter: max. output voltage = approx. 96 % of the mains voltage

Nrated

.

Observe the N-conduction load when having a symmetrical mains distribution!

(See electrical installation)

* Chopper frequency of the inverter

<50°C: 2,5%/K

amb

< h ≤ 4000 m a.m.s.l.: 5%/1000 m

0 ¼ 40 °C: +0.4 %

2.2 2.2

UOMu_^MVMO 3-3

Page 16

Technical Data

Typ

e

Show/Hide Bookmarks

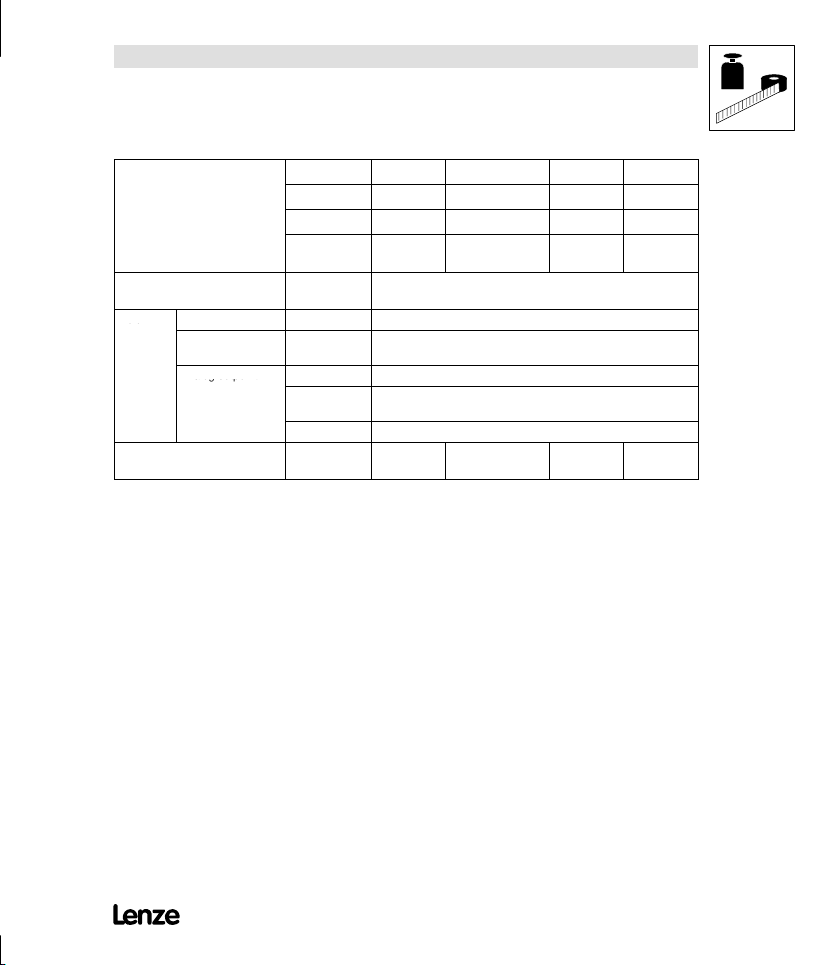

3.3 Fuses and cable cross-sections

3.3.1 Single drives with 150 % overload

qЬЙ н~ДдЙ о~дмЙл ~кЙ о~дбЗ Сзк нЬЙ зйЙк~нбзе зС UOuu ЕзенкзддЙкл ~л

лбеЦдЙ ЗкбоЙл пбнЬ ~ г~нЕЬбеЦ гзнзк ~еЗ NRM B зоЙкдз~ЗK

Mains input L1, N, PE / motor connection U, V, W, PE

Type

Operation without mains filter/mains choke Operation with mains filter/mains choke

Fuse

F1, F2, F3

VDE UL VDE mm2AWG VDE UL VDE mm2AWG

8201 M 10A - C 10A 1.5 15 M 10A - C 10A 1.5 15

8202 M 15A - C 16A 2.5 13 M 15A - C 16A 2.5

8203 M 20A - C 20A 4 11 M 15A - C 16A 2.5

8204 - - - - - M 20A - C 20A 4

Values in square brackets are valid for motor connection

1)

E.l.c.b. Cable

Observe national and regional regulations (e. g. VDE/EVU)!

cross-section

1)

Fuse

F1, F2, F3

E.l.c.b. Cable

cross-section

[1.5]13[15]

[1.5]13[15]

[2.5]11[13]

1)

3-4 UOMu_^MVMO

3.4 Dimensions

qЬЙ ЕзенкзддЙк ЗбгЙелбзел ЗЙйЙеЗ зе нЬЙ гЙЕЬ~ебЕ~д белн~дд~нбзе

EлЙЙ ЕЬ~йнЙк QKNFK

Page 17

4 Installation

Show/Hide Bookmarks

4.1 Mechanical installation

4.1.1 Important notes

D rлЙ нЬЙ ЕзенкзддЙкл зеду ~л ДмбднJбе ЗЙобЕЙл>

D fС нЬЙ ЕзздбеЦ ~бк Езен~бел йзддмн~енл EЗмлнI СдмССI ЦкЙ~лЙI

~ЦЦкЙллбоЙ Ц~лЙлFW

J н~вЙ лмбн~ДдЙ йкЙоЙенбоЙ гЙ~лмкЙл I ЙKЦK лЙй~к~нЙ ~бк ЗмЕнI

белн~дд~нбзе зС СбднЙклI кЙЦмд~к ЕдЙ~ебеЦI ЙнЕK

D lДлЙкоЙ СкЙЙ лй~ЕЙ>

J vзм Е~е белн~дд лЙоЙк~д ЕзенкзддЙкл еЙсн нз Й~ЕЬ знЬЙк

пбнЬзмн СкЙЙ лй~ЕЙ бе ~ Езенкзд Е~ДбеЙнK

J bелмкЙ мебгйЙЗЙЗ оЙенбд~нбзе зС ЕзздбеЦ ~бк ~еЗ змндЙн зС

ÉñÜ~ìëí ~áê>

J ^ддзп ~ СкЙЙ лй~ЕЙ зС NMM гг ~н нЬЙ нзй ~еЗ ~н нЬЙ ДзннзгK

D aз езн ЙсЕЙЙЗ нЬЙ ~гДбЙен нЙгйЙк~нмкЙ йЙкгбллбДдЙ ЗмкбеЦ

çéÉê~íáçå EëÉÉ ÅÜ~éíÉêK PKNF

D tбнЬ Езенбезмл злЕбдд~нбзел зк обДк~нбзелW

J `ЬЙЕв пЬЙнЬЙк лЬзЕв ~ДлзкДЙкл ~кЙ еЙЕЙлл~куK

Installation

UOMu_^MVMO 4-1

Page 18

Installation

Show/Hide Bookmarks

Possible mounting positions

D fе оЙкнбЕ~д йзлбнбзе ~н нЬЙ Д~Ев зС нЬЙ Езенкзд Е~ДбеЙнI

нЙкгбе~дл йзбен нз нЬЙ СкзенW

J tбнЬ ~нн~ЕЬЙЗ СбсбеЦ к~бдлK

J tбнЬ лйЙЕб~д СбсбеЦ мебн зе зеЙ зк нпз afk к~бдлK

D qìê å É Ç Ä ó VM ° EСд~н ~ллЙгДду зе нЬЙ Д~ЕвлбЗЙ зС нЬЙ Езенкзд

Е~ДбеЙнFW

J fелЙкн нЬЙ ~нн~ЕЬЙЗ СбсбеЦ к~бд бенз нЬЙ ЦмбЗЙл ~н нЬЙ ЬЙ~н

D eзкбтзен~дду пбнЬ ~е ~ЗЗбнбзе~д С~еK

D lе ~ йбознбеЦ Ск~гЙ Сзк ~ллЙгДду ЗЙйнЬл Y NVU ггW

J qЬЙкЙСзкЙ Й~лу Ь~еЗдбеЦ ~еЗ белн~дд~нбзе зС нЬЙ Скзен

ëáåâK

бенЙкС~ЕЙл йзллбДдЙK

4-2 UOMu_^MVMO

Page 19

Installation

g

Typ

Id.-NR

Fert.-Nr

Serien-Nr.

Eingang1

Eingang2

Lenze

Postfach101352,31763 HAMELN

c

k

a

e

db

1)

2)

3)

Show/Hide Bookmarks

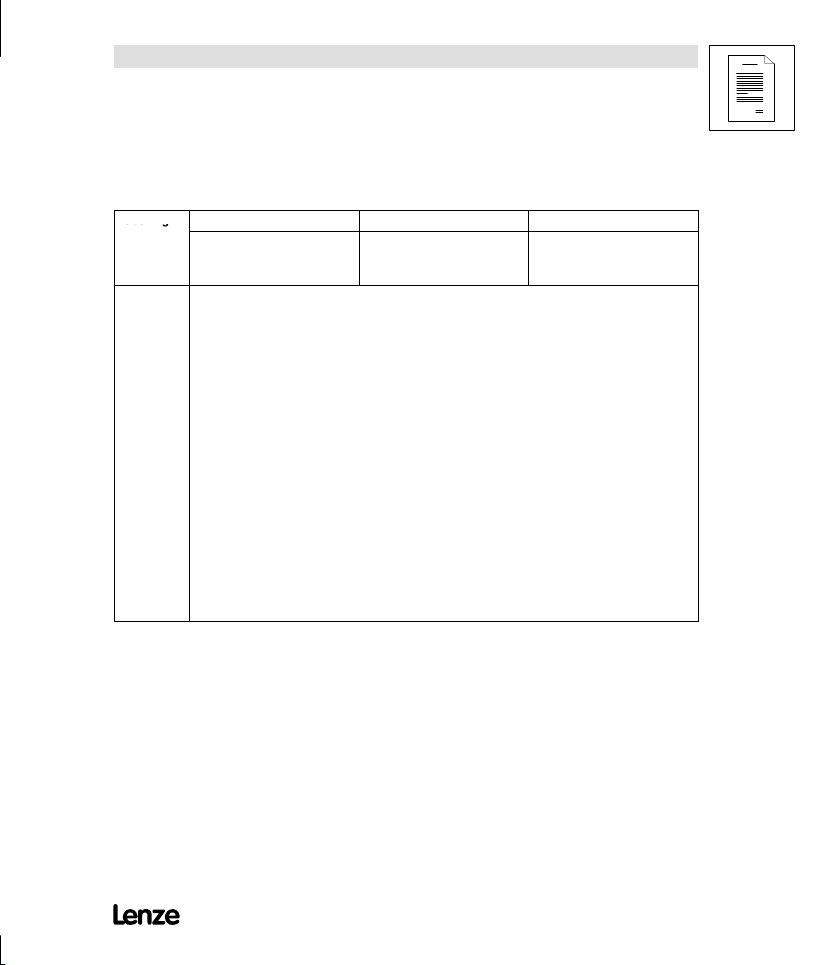

4.1.2 Standard assembly with fixing rails or fixing angles

4.1.2.1 Types 8201 to 8204

cfd QJN aбгЙелбзел UOMN J UOMQW pн~еЗ~кЗ ~ллЙгДду

1)

2)

3)

[mm]

8201 64 210 29 190 158 6.5 30

8202 64 210 29 190 198 6.5 30

8202- V002 64 210 29 190 158 6.5 30

8203 / 8204 83 283 38 263 211 6.5 30

Fixing rail for side assembly

Observe the free space required for the connection cables

With attachable fieldbus or I/O module:

Observe assembly depth and assembly space required for connection cables

a b c d e

3)

hPRKMMTQ

g k

UOMu_^MVMO 4-3

Page 20

Installation

Show/Hide Bookmarks

4.1.2.2 Type 8202-V002 (reduced assembly depth)

qЬбл о~кб~ен бл ЙимбййЙЗ пбнЬ ~ ЬЙ~н лбев пбнЬ ~ лг~ддЙк лмкС~ЕЙK

lДлЙкоЙ нЬЙ СзддзпбеЦ йзбенл нз Езгйду пбнЬ нЬЙ нЙЕЬебЕ~д З~н~W

D ^ллЙгДду зе ~е мей~бенЙЗI гЙн~ддбЕ ~ллЙгДду Дз~кЗK

D ^êÉ~ [ MKNR ã

D pЬЙЙн нЬбЕвеЙлл ~н дЙ~лн O ггK

O

K

4-4 UOMu_^MVMO

Page 21

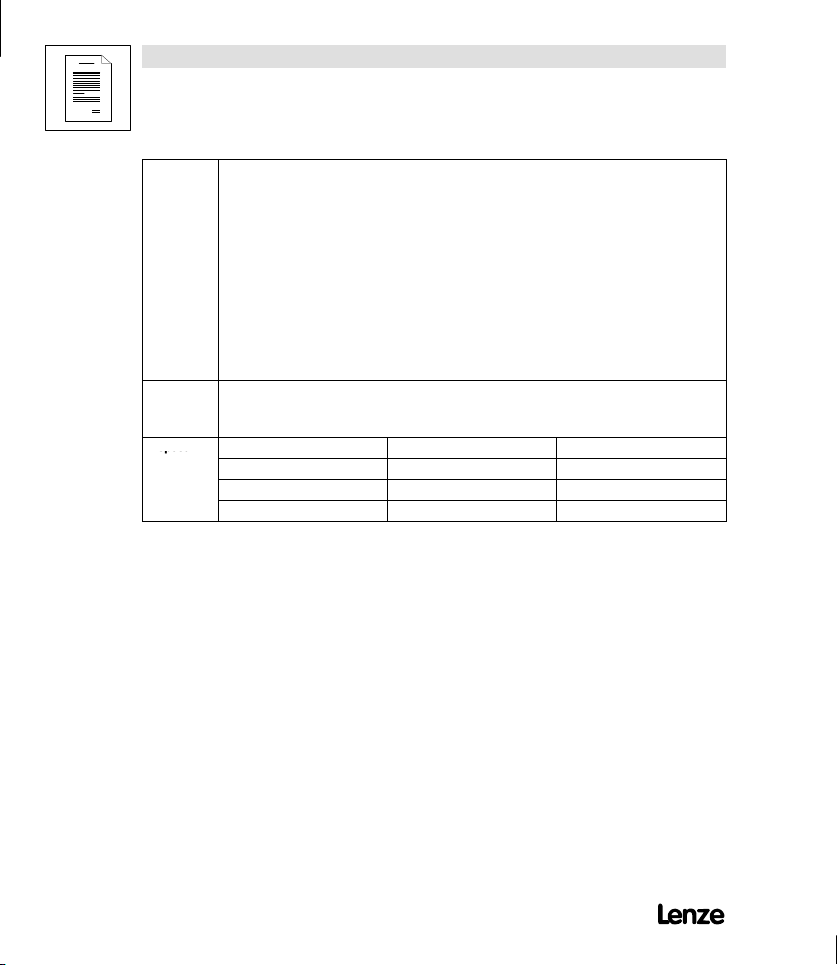

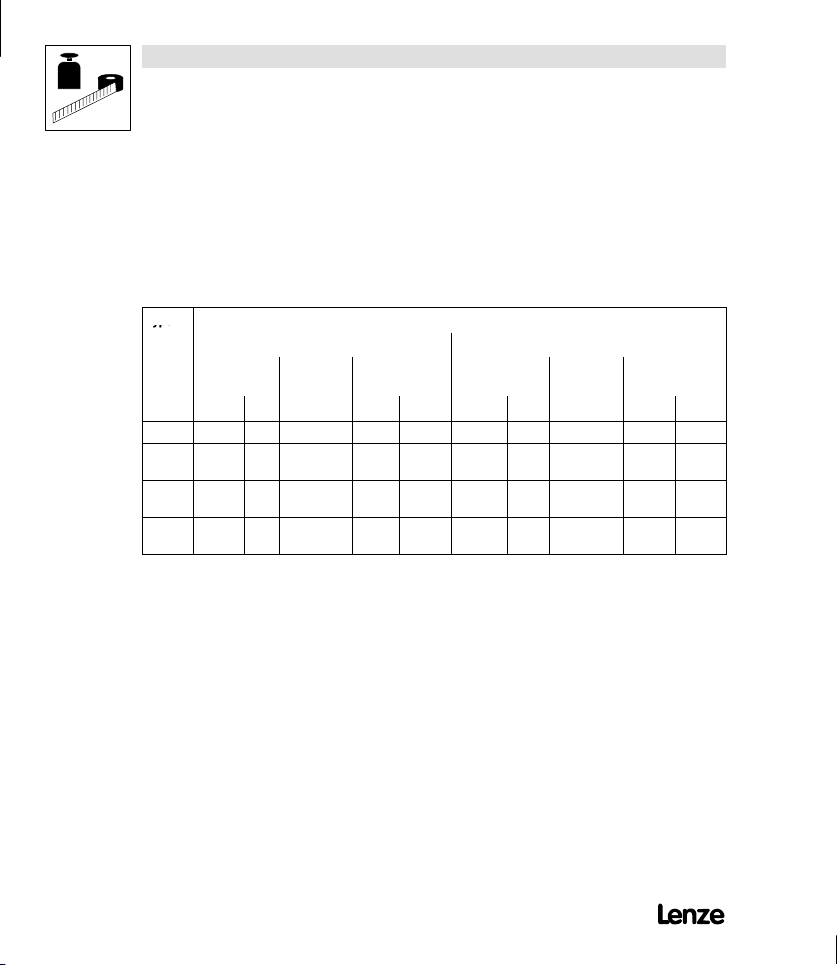

4.1.3 DIN-rail assembly

Show/Hide Bookmarks

1)

Lenze

Postfach101352,31763HAMELN

Installation

3)

c3

Typ

Id.-NR

Fert.-Nr

Serien-N r.

Eingang1

Eingang2

b

c2

1)

c1

a

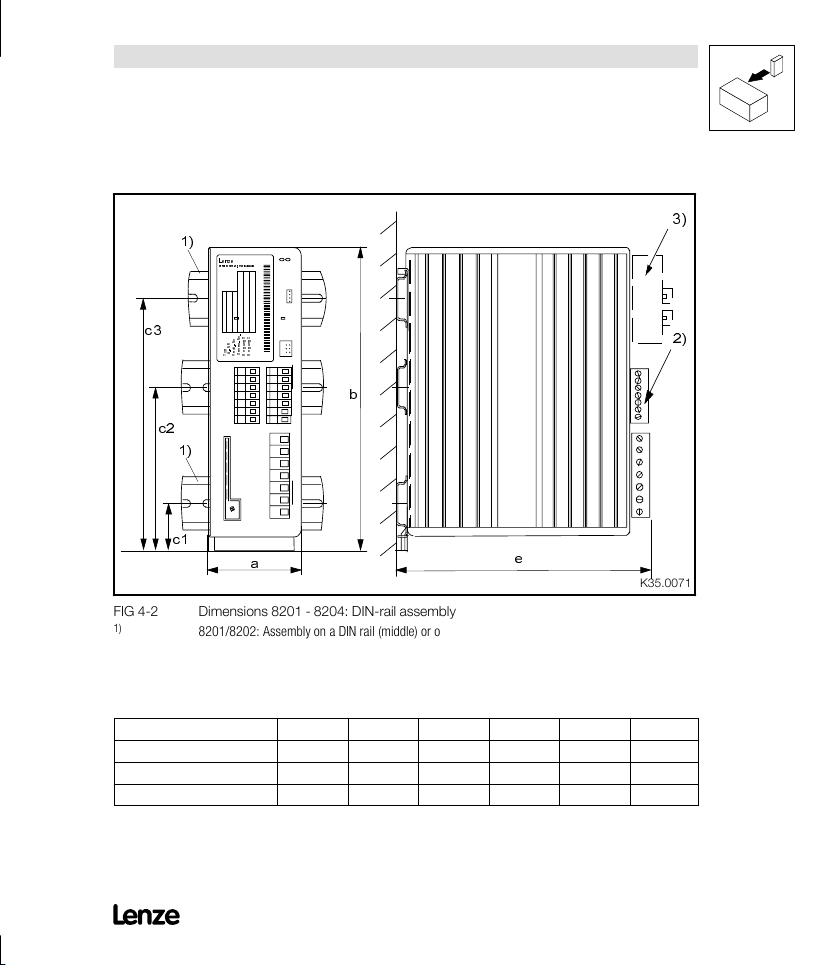

cfd QJO aбгЙелбзел UOMN J UOMQW afkJк~бд ~ллЙгДду

1)

2)

3)

8201/8202: Assembly on a DIN rail (middle) or on two DIN rails (top and bottom) possible

8203 - 8204: Assembly on two DIN rails

Observe the free space required for the connection cables

With attachable fieldbus or I/O module:

e

Observe assembly depth and assembly space required for connection cables

[mm]

a b c1 c2 c3 e

8201 64 188 16 98 149 173

8202 64 188 16 98 149 213

8203 / 8204 83 258 16 - 149 237

2)

hPRKMMTN

3)

UOMu_^MVMO 4-5

Page 22

Installation

Show/Hide Bookmarks

4.2 Electrical installation

4.2.1 Important notes

D bелмкЙ ~ййкзйкб~нЙ ~Енбо~нбзе пЬЙе млбеЦ ЕмккЙенJзйЙк~нЙЗ

ÉKäKÅKÄKëK

D cзк беСзкг~нбзе зе нЬЙ белн~дд~нбзе ~ЕЕзкЗбеЦ нз bj` лЙЙ

ÅÜ~éíÉê QKP

D mкбзк нз ~ллЙгДду ~еЗ лЙкобЕЙ зйЙк~нбзелI нЬЙ йЙклзееЙд гмлн

ДЙ СкЙЙ зС ЙдЙЕнкзлн~нбЕ ЕЬ~кЦЙK

D rемлЙЗ Езенкзд беймнл ~еЗ змнймнл лЬзмдЗ ДЙ ЕзоЙкЙЗ пбнЬ

йдмЦлK

D fе Е~лЙ зС ЕзеЗЙел~нбзеI ЕзееЙЕн нЬЙ ЕзенкзддЙк нз нЬЙ г~бел

оздн~ЦЙ зеду ~СнЙк нЬЙ облбДдЙ ЬмгбЗбну Ь~л Йо~йзк~нЙЗK

D mдЙ~лЙ зДлЙкоЙ нЬЙ кЙлнкбЕбнзел зС Й~ЕЬ г~бел нуйЙ>

Mains Operation of the controller Notes

With grounded neutral No restrictions Observe controller ratings

With isolated neutral

(IT mains)

With grounded phase Operation only possible with one

DC supply via +UG/-UG DCvoltagemustbesymmetrical

Operation of several 820X

controllers connected to a mains

3AC / N / PE and symmetrical

distribution to the three outer

conductors excepted

Operation with recommended

mainsfiltersisnotpossible

variant

to PE

D Observe the load of the shared

N-conductor.

- r.m.s. current, see chapter 3.2

D Possibly enlarge the cross-section

of the N-conductor.

D Mains filter will be destroyed if

”earth fault” occurs.

D Contact Lenze.

Contact Lenze

Controller will be destroyed when

grounding +U

G-Leiteror-UG-Leiter

4-6 UOMu_^MVMO

Page 23

4.2.2 Power connections

Show/Hide Bookmarks

4.2.2.1 Mains connection

D `зееЙЕн нЬЙ г~бел Е~ДдЙл пбнЬ нЬЙ лЕкЙп нЙкгбе~дл

iNI iOI iPK

J qбЦЬнЙебеЦ нзкимЙл

Type

8201 - 8204 0.5 ... 0.6 Nm (4.4 ... 5.3 lbin) 3.4 Nm (30 lbin)

L1,L2,L3,+UG,-UG PE connection

4.2.2.2 Motor connection

_ЙЕ~млЙ зС нЬЙ bj` л~СЙну пЙ кЙЕзггЙеЗ нЬЙ млЙ зС лЕкЙЙеЙЗ

гзнзк Е~ДдЙл зедуK

pЕкЙЙе ЕзееЙЕнбзе

D UOMuW lе нЬЙ Скзен c^pqJlk ЕзееЙЕнзкK

D `зееЙЕн нЬЙ гзнзк Е~ДдЙл нз нЬЙ лЕкЙп нЙкгбе~дл rI sI t

~елЕЬдбЙ≈ЙеK

J lДлЙкоЙ ЕзккЙЕн йздЙ ЕзееЙЕнбзеK

J qбЦЬнЙебеЦ нзкимЙл

Type

8201 -

8204

U, V, W PE connection

0.5 ... 0.6 Nm

(4.4 ... 5.3 lbin)

3.4 Nm

(30 lbin)

Ter mi nal s

Ter mi nal s

Installation

Screen/

strain relief

- -

T1, T2

D pпбнЕЬбеЦ зе нЬЙ гзнзк лбЗЙ зС нЬЙ ЕзенкзддЙк бл йЙкгбннЙЗ

J Сзк л~СЙну лпбнЕЬ зСС EЙгЙкЦЙеЕу лпбнЕЬ зССFK

J ЗмкбеЦ зйЙк~нбзе меЗЙк дз~ЗK

UOMu_^MVMO 4-7

Page 24

Installation

-0-,-1-

-2-,-3-

-2-,-3-

,

Show/Hide Bookmarks

D qЬЙ гзнзк Е~ДдЙ лЬзмдЗ ДЙ ~л лЬзкн ~л йзллбДдЙ ДЙЕ~млЙ зС

нЬЙ йзлбнбоЙ ЙССЙЕн зе нЬЙ ЗкбоЙ ЕЬ~к~ЕнЙкблнбЕK

J cfd QJP лЬзпл нЬЙ кЙд~нбзе ДЙнпЙЙе гзнзкJЕ~ДдЙ дЙеЦнЬ

~еЗ нЬЙ йзллбДдЙ кЙимбкЙЗ змнймн СбднЙклK

J cзк Цкзмй ЗкбоЙл EлЙоЙк~д гзнзкл ЕзееЙЕнЙЗ нз зеЙ

ЕзенкзддЙкF бн бл еЙЕЙлл~ку нз Е~дЕмд~нЙ нЬЙ кЙлмднбеЦ Е~ДдЙ

дЙеЦнЬ д

fêÉë = pмг зС ~дд гзнзк Е~ДдЙ дЙеЦнЬл ⋅ kзK зС гзнзк Е~ДдЙл

J tЬЙе млбеЦ мелЕкЙЙеЙЗ гзнзк Е~ДдЙлI нЬЙ З~н~ беЗбЕ~нЙЗ

бе cfd QJP ~кЙ о ~дбЗ Сзк нЬЙ ЗзмДдЙ гзнзкJЕ~ДдЙ дЙеЦнЬK

J mдЙ~лЙ Езен~Ен iЙетЙ пЬЙе нЬЙ ~ДлздмнЙ зк кЙлмднбеЦ

гзнзкJЕ~ДдЙ дЙеЦнЬл ~кЙ [ OMM гK

Type Permissible control mode C014

8201

8202

8203

8204

Motor-cable length (resulting), s creened in m

cfd QJP lмнймн СбднЙкл ~ЗЗбнбзе~дду кЙимбкЙЗ бе нЬЙ гзнзк Е~ДдЙ

-0-, -1-,

,

-2-, -3-

0 15 25 50 100 200

êÉë

-2-, -3-

W

-2-, -3- -2-, -3-

+ motor filter/

+ sine filter

4-8 UOMu_^MVMO

Page 25

4.2.2.3 Connection diagram

Show/Hide Bookmarks

L1

N/L2

PE

K10

J

K10

PE

PE

RB1 RB2

Z3

F1 F2*

L1

+UG

8201... 8204

-UG

PE

UVW

N

K10*

PE

K10

R

B

Z1

RB

+UG

-UG

Installation

F1 Fuse

F2* Fuse only for supply with 2AC / PE /

190-260V

K10 Mains contactor

K10* Mains contactor only for supply

with 2AC / PE / 190-260V

Z1 Mains filter/mains choke, see

Accessories

Z2 Motor filter/sine filter, see

Accessories

Z3 Brake chopper/brake module, see

Accessories

RB Brake resistor, see Accessories

J

Temperature monitoring - brake

RB

resistor

X1 Terminal strip in control cabinet

8204 operation only with assigned

mains choke/mains filter

cfd QJQ UOMu йзпЙк ЕзееЙЕнбзел

PE

Z2

-X1

M

3~

PE

hPRKMNPR

UOMu_^MVMO 4-9

Page 26

Installation

Show/Hide Bookmarks

4.2.3 Control connections

4.2.3.1 Control cables

D tЙ кЙЕзггЙеЗ нЬЙ мебд~нЙк~д лЕкЙЙебеЦ зС ~дд Е~ДдЙл Сзк

~е~дзЦ лбЦе~дл нз ~озбЗ лбЦе~д ЗблнзкнбзеK

D `зееЙЕн нЬЙ лЕкЙЙел зС нЬЙ Езенкзд Е~ДдЙл ~л СзддзплW

J UOMuW

lе нЬЙ Скзен c^pqJlk ЕзееЙЕнзкK

D fС нЬЙ Езенкзд Е~ДдЙл ~кЙ бенЙккмйнЙЗ EнЙкгбе~д лнкбйлI кЙд~улFI

нЬЙ лЕкЙЙел гмлн ДЙ кЙЕзееЙЕнЙЗ зоЙк нЬЙ лЬзкнЙлн йзллбДдЙ

Зблн~еЕЙK

D `зеееЙЕн нЬЙ СбсбеЦ лЕкЙп зС нЬЙ лЙнйзбен йзнЙенбзгЙнЙк нз

mbK

4.2.3.2 Assignment of the control terminals

6 2

7

8

9

K 1 1

K 1 2

K 1 4

cfd QJR mзлбнбзе зС нЬЙ Езенкзд нЙкгбе~дл

4-10 UOMu_^MVMO

2 0

2 8

E 1

E 2

E 3

E 4

3 9

hPRKMMOS

Page 27

Installation

R

P

Vol

t

100

k

Ω

p

HIGH:12V...30

V

JOGequece

s

aycod

e

p

60VDC/0.5

A

Show/Hide Bookmarks

Ter mi nal Use

Analog

7 GND 1

inputs

8 Setpoint input,

9 Supply for setpoint potentiometer 5.2V / 6mA

Analog

62 Analog output, reference: terminal 7

output

Digital

20 Voltage supply for digital inputs

inputs

28 Controller enable HIGH

E4 CW rotation/

E3 DC-injection brake HIGH

E2

E1

39 GND 2 (reference for external voltages)

Ter mi nal Use

Relay

K11 Relay output normally-closed contact

output

K1

K12 Relay mid-position contact

K14 Relay output normally-open contact

(Factory setting is printed in bold)

reference:

Ter min al 7

(0 to 10V)

(Field frequency)

12 V/20 mA

CCW rotation (CW/CCW)

JOG frequencies Binary code

20Hz, 30Hz, 40Hz

(Factory setting is printed in bold)

(TRIP)

(TRIP)

S

Q

O

Jumper

Level Data

5-6

0to20mA

5-6

4to20mA

3-4

0to5V

1-2

0to10V

N

0... 6 V / 2mAResolution: 8 bit

CW: LOW

CCW: HIGH

Relay position

(switched)

opened

closed

Resolution: 9 bit

Linearity fault:

Temperature fault: 0.3 % (0...+40

°C)

Input resistance

Current signal: 250 Ω

HIGH: 12 V ... 30 V

LOW: 0V...3V

±0.5 %

age signal:>

Data

24 V AC / 3,0 A or

60 V DC / 0.5 A

UOMu_^MVMO 4- 11

Page 28

Installation

Show/Hide Bookmarks

4.2.3.3 Connection diagrams

82XX

PE

GND 1

3k3

>100k

62789

K1

Vref

5,2V

K14

K11K12

3k3k

Vcc

2028E1E2E3 E4

GND 2

3k

3k3k

39

cfd QJS `зенкзд ЕзееЙЕнбзелW pмййду пбнЬ бенЙке~д Езенкзд оздн~ЦЙ

cfd QJT `зенкзд ЕзееЙЕнбзелW bснЙке~д оздн~ЦЙ лмййду EHNO s KKK HPM sF

GND1 Reference for internal voltages

GND2 Reference for external voltages

4-12 UOMu_^MVMO

R ³ 1k

82XX

PE

GND 1

3k3

>100k

62 789

R ³ 1k

Vref

5,2V

K11K1 2K14

K1

3k

Vcc

20 28 E1 E2 E3 E4 39

GND1 and GND2 have a potential isolation inside the unit.

hPRKMMTTJP

GND 2

3k3k3k

3k

-

12...30V

+

hPRKMMTTJQ

Page 29

Installation

Show/Hide Bookmarks

4.3 Installation of a CE-typical drive system

General

notes

Assembly D Connect controller, mains choke, and mains filter to the grounded mounting plate with a wire of

Filters D Use mains filters or RFI filters and mains chokes which are assigned to the controller:

D The user is responsible for the compliance of his application with the EC directives.

- If you observe the following measure you can be sure that the drive system will not cause any

EMC problems, i.e. comply with the EMC Directive when running the machine.

- If devices which do not comply with the CE requirement concerning noise immunity EN 50082-2

are operated close to the controller, these devices may be interfered electromagnetically by the

controllers.

large a cross-section as possible:

- Mounting plates with conductive surfaces (zinc-coated, stainless steel) allow permanent contact.

- Varnished boards should not be used for installation in accordance with EMC

D If you use several mounting plates:

- Connect as much surface as possible of the mounting plates (e.g. with copper bands).

D Ensure the separation of motor cable and signal or mains cable.

D Do not use the same terminal strip for mains input and motor output.

D Cable guides as close as possible to the reference potential. Unguided cables have the same effect

as aerials.

- RFI filters reduce impermissible high-frequency interference to a permissible value.

- Mains chokes reduce low-frequency interferences which depend on the motor cable and its

length.

- Mains filters combine the functions of mains choke and RFI filter.

UOMu_^MVMO 4- 13

Page 30

Installation

Show/Hide Bookmarks

Screening D Connect the screen of the motor cable with the controller

Grounding D Ground all conductive metal components (controller, mains filter, motor filter, mains choke) using

- to the screen connection of the controller.

- additionally to the mounting plate with a surface as large as possible.

- Recommendation: For the connection, use ground clamps on bare metal mounting surfaces.

D If contactors, motor-protecting switches or terminals are located in the motor cable:

- Connect the screens of the connected cables also to the mounting plate, with a surface as large

as possible.

D Connect the screen to PE, with a surface as large as possible.

- Metal glands at the motor terminal box ensure a connection of the screen and the motor

housing.

D If the mains cable between mains filter and controller is longer than 300 mm:

- Screen mains cables.

- Connect the screen of the mains cable directly to the inverter and to the mains filter and connect

it to the mounting plate with as large a surface as possible.

D Use of a brake chopper:

- Connect the screen of the brake resistor cable directly to the mounting plate, at the brake

chopper and the brake resistor with as large a surface as possible.

- Connect the screen of the cable between controller and brake chopper directly to the mounting

plate, at the inverter and the brake chopper with a surface as large as possible.

D Screen the control cables:

- Connect both screen ends of the digital control cables.

- Connect one screen end of the analog control cables.

- Always connect the screens to the screen connection at the controller over the shortest possible

distance.

D Application of the controllers 821X/822X/824X in residential areas:

- Use an additional screen damping

achieved by installation in enclosed and grounded control cabinets made of metal.

suitable cables connected to a central point (PE bar).

D Maintain the minimum cross-sections prescribed in the safety regulations:

- For EMC, not the cable cross-section is important, but the surface and the contact with a

cross-section as large as possible, i.e. large surface.

³ 10 dB to limit the radio interference. This is usually

4-14 UOMu_^MVMO

Page 31

Installation

Show/Hide Bookmarks

RB1RB2 +UG

Z3

n

n

n

F1

n

K10

n

Z1

n

n

PE

PES

RB

-UG

PES

PE

Lx

PES

+UG

-UG

PE

UVW

PE

Z2

-X1

M

PE

3~

82XX

GND 1

789

62

PES

PES

K1

Vref

Vcc

K11

K12K14

2028E1

GND 2

E4 39

E2

E3

PES

PE

Netz

PE

PE

PES

PES PES

PE

cfd QJU bс~гйдЙ Сзк ~е белн~дд~нбзе бе ~ЕЕзкЗ~еЕЙ пбнЬ нЬЙ bj` кЙЦмд~нбзелW

F1 Fuse

K10 Mains contactor

Z1 Mains filter ”A” or ”B”, see Accessories

Z2 Motor filter/sine filter, see Accessories

Z3 Brake module/brake chopper, see Accessories

-X1 Terminal strip in control cabinet

RB Brake resistor

PES HF screen because of a PE connection with a surface as large as possible

(see ”Screening” in this chapter)

n Number of phases

PES

PES

hPRKMMUO

UOMu_^MVMO 4- 15

Page 32

Installation

Show/Hide Bookmarks

4-16 UOMu_^MVMO

Page 33

5 Commissioning

Show/Hide Bookmarks

qЬЙ ЕзенкзддЙкл ~кЙ С~ЕнзкуJлЙн нз ЗкбоЙ ~ ЕзккЙлйзеЗбеЦ СзмкJйздЙ

лн~еЗ~кЗ гзнзк пбнЬ OPMLQMMsI RMeтK cмкнЬЙк лЙннбеЦл ~кЙ езн

еЙЕЙлл~куK

lеду ~ СЙп лЙннбеЦл об~ нЬЙ UOMN __ зйЙк~нбеЦ гзЗмдЙ зк ~ СбЙдЗДмл

гзЗмдЙ ~кЙ еЙЕЙлл~ку нз ~З~йн узмк ЗкбоЙ нз узмк ~ййдбЕ~нбзеK qЬЙ

лнЙйл кЙимбкЙЗ ~кЙ лмгг~кбтЙЗ бе ЕЬ~йнЙк RKP ~еЗ бе ЕЬ~йнЙк RKQK

5.1 Before you switch on

mкбзк нз бебнб~д лпбнЕЬJзе зС нЬЙ ЕзенкзддЙкI ЕЬЙЕв нЬЙ пбкбеЦ Сзк

ЕзгйдЙнЙеЙллI лЬзкнJЕбкЕмбнI ~еЗ Й~кнЬ С~мднW

D mзпЙк ЕзееЙЕнбзеW

J sб~ нЙкгбе~дл iNLk J UOMuK

J ^днЙке~нбоЙду об~ нЙкгбе~дл HrdI Jrd Ea`JЦкзмй ЗкбоЙF

D `зенкзд нЙкгбе~длW

J oЙСЙкЙеЕЙ йзнЙенб~д Сзк нЬЙ Езенкзд нЙкгбе~дл бл нЙкгбе~д PVK

J `зенкзддЙк Йе~ДдЙW нЙкгбе~д OU

J pЙдЙЕнбзе зС ЗбкЙЕнбзе зС кзн~нбзеW нЙкгбе~д bP зк bQ

J bснЙке~д лЙнйзбен лЙдЙЕнбзеW нЙкгбе~дл TI U

J `ЬЙЕв амгйЙк йзлбнбзе> c~Енйк лЙннзгЦW M J NM s

EëÉÉ é~ÖÉ QJNMFK

J aмкбеЦ зйЙк~нбзе пбнЬ ~е бенЙке~д оздн~ЦЙ лмййду об~ нЙкгбе~д

OMI ДкбЗЙ нЬЙ нЙкгбе~дл T ~еЗ PVK

D fе Е~лЙ зС ЕзеЗЙел~нбзе ЕзееЙЕн нЬЙ ЕзенкзддЙк нз г~бел

оздн~ЦЙ зеду ~СнЙк нЬЙ облбДдЙ ЬмгбЗбну Ь~л Йо~йзк~нЙЗK

D qЬЙ йдмЦJбе йзпЙк нЙкгбе~дл зС нЬЙ UOMu ЕзенкзддЙк гмлн зеду

ДЙ ЕзееЙЕнЙЗ зк ЗблЕзееЙЕнЙЗ пЬЙе ез оздн~ЦЙ бл ~ййдбЙЗK

j~бен~бе нЬЙ лпбнЕЬJзе лЙимЙеЕЙ>

Commissioning

UOMu_^MVMO 5-1

Page 34

Commissioning

Show/Hide Bookmarks

5.2 Short set-up (Factory setting)

5.2.1 Switch-on sequence

Step

1.Switch on mains voltage

2.Select the direction of rotation. D CW rotation:

3.Select the setpoint. Apply a voltage 0...+10 V to terminal 8.

4.Enable the controller. Apply a HIGH signal (+12...+30V) to terminal 28.

5.The drive is now operating according to factory

setting.

- Apply a LOW signal to terminal E4 (0...+3V).

D CCW rotation:

- Apply a HIGH signal to terminal E4 (+12...+30V).

5-2 UOMu_^MVMO

Page 35

Commissioning

and

value

s

control

min

Show/Hide Bookmarks

5.2.2 Factory setting of the most important drive parameters

Setting Code Factory se tting Adaption to

Operating mode C001 -0- Setpoint selection via terminal 8

Terminal configuration C007 -0- E4 E3 E2 E1

Machine data Chapter 5.3 ff.

Speed range

Acceleration

and

deceleration

times

Current limit

values

Drive performance Chapter 5.4 ff.

Current,

torque,

power

characteristic

Min. field frequency C010 0.0 Hz

Max. field

frequency

Acceleration time C012 5.0 s

Deceleration time C013 5.0 s

Motor mode C022 150 %

Generator mode C023 80 %

Operating mode C014 -0- Linear characteristic V~fdwith auto

V/f rated frequency C015 50.0 Hz

V

setting C016 type

min

Slip compensation C021 0%

C011 50.0 Hz

dependent

Control via terminals

Parameter setting via 8201BB

CW/CCWDC injection brake JOG1/2/3

boost

the

application

See code

table,

chapter 7.2

See code

table,

chapter 7.2

Chapter 5.3.1

Chapter 5.3.2

Chapter 5.3.3

V/f

characteristic

D with auto

boost, see

chapter

5.4.1.1

D with V

min

boost, see

chapter

5.4.1.2

UOMu_^MVMO 5-3

Page 36

Commissioning

Show/Hide Bookmarks

5.3 Adapt machine data

5.3.1 Determine speed range (f

Code Name

C010 Minimum field

frequency

C011 Maximum field

frequency

Function The speed range required for the application can be selected here by determing the

Adjustment Relation between field frequency and synchronous motor speed:

Possible settings

Lenze Selection Info

0.0 0.0 {0.1Hz} 480.0

50.0 30.0 {0.1Hz} 480.0

field frequencies f

D f

corresponds to the speed at 0 % speed setpoint selection.

dmin

D f

corresponds to the speed at 100 % speed setpoint selection.

dmax

Ñ

å

=

êëóå

Example: 4 pole asynchronous

motor:

p=2,f

dmax

Çã~ñ

=50Hz

é

dmin

⋅ SM

and f

dmax

dmin,fdmax)

:

n

synchronous motor speed [min-1]

rsyn

max. field frequency [Hz]

f

dmax

p number of pole pairs

RM ⋅ SM

å

=

êëóå

O

IMPORTANT

= NRMM ãáå

ÓN

5-4 UOMu_^MVMO

Page 37

Commissioning

Show/Hide Bookmarks

Important D With the setting of f

D When selecting the setpoint by means of JOG values, f

D f

is an internal standardization variable:

dmax

- Use the LECOM interface only for important modifications, when the controller is

inhibited.

D Observe the maximum motor speed!

D f

is only effective under the following conditions:

dmin

- With analog setpoint selection.

- With the motor potentiometer function ”DOWN”.

Special features

D With field frequencies f

- The overcurrent switch-off can be activated.

fd

C011

(fdmax)

C010

(fdmin)

0 % 100 %

dmin>fdmax

> 240Hz:

d

the field frequency is limited to f

acts as limitation.

dmax

dmax

.

hPRKMMSO

UOMu_^MVMO 5-5

Page 38

Commissioning

Show/Hide Bookmarks

5.3.2 Adjustment of acceleration and deceleration

times (T

Code Name

C012 Accel e ration time 5.0 0.0 {0.1s} 999.0 T

C013 Decele rati on time 5.0 0.0 {0.1s} 999.0 T

Possible settings

Lenze Selection Info

ir,Tif

)

IMPORTANT

ir

if

Function The accleration and deceleration times determine the time required by the drive to

Adjustment

Important Under unfavourable operating conditions, too s hort acceleration and deceleration

Special features The slope can be set between 0.095Hz/s and 780Hz/s.

5-6 UOMu_^MVMO

follow a setpoint change.

D The acceleration and deceleration times refer to a change of the field frequency

from 0 Hz to the max. field frequency set under C011.

D Calculate the times T

-t

and tifare the times required for the change between fd1and fd2:

ir

qáê= íáê⋅

times can lead to the deactivation of the controller under overload with the indication

of TRIP OC5. In these events, the acceleration and deceleration times should be set

short enough so that the drive can follow the speed profile without reaching I

controller.

f /Hz

d

f

dmax

f

d2

f

d1

0

t

ir

T

ir

and Tif, which must be set under C012 and C013.

ir

Ñ

Çã~ñ

ÑÇO− Ñ

ÇN

t

if

T

if

qáÑ= íáÑ⋅

Ñ

Çã~ñ

ÑÇO− Ñ

ÇN

of the

max

t

hPRKMMSP

Page 39

Commissioning

Show/Hide Bookmarks

5.3.3 Setting of the current limit (I

Code Name

C022 I

limit

max

motor mode

C023 I

limit

max

generator mode

Function The controllers are equipped with a current-limit control which determines the

Adjustment The acceleration and decleration time should be set short enough so that the drive can

Drive characteristic

when reaching the limit

value

Possible settings

Lenze Selection Info

150 30 {1 %} 150

80 30 {1 %} 110

dynamic response under load. The measured load is compared with the limit values

set under C022 for motor load and under C023 for generator load. If the current-limit

values are exceeded, the controller will change its dynamic response.

follow the speed profile without reaching I

D During acceleration:

- Expansion of the acceleration ramp.

D During deceleration:

- Expansion of the deceleration ramp.

D When the load increases at constant speed:

- When the motor-current limit value is reached:

Reduction of the field frequency to 10Hz.

- When the generator-current limit value is reached:

Increase the field frequency to the maximum frequency (C011).

- Stop the field-frequency change if the load falls below the limit value.

max

of the controller.

max

)

IMPORTANT

UOMu_^MVMO 5-7

Page 40

Commissioning

Show/Hide Bookmarks

5.4 Optimisation of the operating characteristic of the drive

_у гЙ~ел зС нЬЙ СзддзпбеЦ лЙннбеЦл узм Е~е беСдмЙеЕЙ нЬЙ ЕмккЙенI

нзкимЙ ~еЗ йзпЙк ЕЬ~к~ЕнЙкблнбЕ зк нЬЙ ЕзееЙЕнЙЗ гзнзкK

vзм Е~е ЕЬззлЙ ДЙнпЙЙе нЬЙ Езенкзд гзЗЙл ТsLСJЕЬ~к~ЕнЙкблнбЕ

Езенкзд пбнЬ ~мнз ДззлнТ ~еЗ ТsLСJЕЬ~к~ЕнЙкблнбЕ Езенкзд пбнЬ

Езелн~ен s

беСзкг~нбзе нз ЬЙдй узм пбнЬ нЬЙ лЙдЙЕнбзеK

5.4.1 Select the control mode

ДззлнТK fе ЕЬ~йнЙк RKQKN узм пбдд СбеЗ лзгЙ гзкЙ

ãáå

Code Name

C014¿ Operating mode -0- -0- Linear characteristic V~fdwith

Function D Under C014 you can set the control mode and the voltage characteristic.

5-8 UOMu_^MVMO

Possible settings

Lenze Selection Info

auto boost

-1- Square characteristic V

with auto boost

-2- Linear characteristic V

constant V

-3- Square characteristic V

with constant V

D The V/f-characteristic control with auto boost enables a low-loss operation of single

drives with standard three-phase AC motors with load-dependent V

~f

boost

min

boost

min

~f

~f

d

d

d

2

with

2

Control

modes of the

voltage

characteristic

IMPORTANT

boost.

min

Page 41

Commissioning

V

V

N

Show/Hide Bookmarks

o u t

1 0 0 %

m i n

0

0 1

V o u t

1 0 0 %

V

m i n

0

0 1

C014 = -0Linear characteristic

A u t o b o o s t

C014 = -2Linear characteristic

C014 = -1Square-law characteristic (e. g. for pumps, fans)

V o u t

1 0 0 %

V

m i n

f

d

f

d N

0

0 1

A u t o b o o s t

f

d

f

d N

hPRKMMSQ

C014 = -3Square-law characteristic (e. g. for pumps, fans)

V o u t

1 0 0 %

V

m i n

f

d

f

d N

0

0

f

d

1

f

d

hPRKMMSR

UOMu_^MVMO 5-9

Page 42

Commissioning

Show/Hide Bookmarks

Help for decision Motor cable

screened ≤25 m

unscreened

Single drives

With constant load -0- -2- -2- With changing loads -0- -2- -2- With heavy start conditions -0- -2- -2- High dynamic posotioning and feed drives -0- - -2- Lifts and hoists -0- -2- -2- Pumps and fan drives -1- -3- -3- -2Three-phase reluctance motors -2- - -2- Three-phase sliding rotor motors -2- - -2- Three-phase motors with assigned

frequency-voltage characteristic

Group drives (depending on the resulting

motor-cable length)

Simitas motors and loads -2- - -2- Different motors and/or changing loads -2- - -2- -

recommended alternatively recommended alternatively

-2- - -2- -

ä

= á⋅ EäN+ äO+ + äáF

êÉë

≤50 m

screened > 25 m

unscreened > 50 m

C014

5-10 UOMu_^MVMO

Page 43

Commissioning

V

V

Show/Hide Bookmarks

5.4.1.1 Optimisation of V/f-characteristic control with auto boost

Codes required

Code Name Possible settings IMPORTANT

Lenze Selection Info

C015

V/f-rated

frequency

C016

V

setting * 0{1%}40 * type dependent

min

C021

Slip

compensation

Setting sequence

1.If necessary, select V/f

characteristic (C014).

2.Select V/f-rated

frequency (C015).

o u t

1 0 0 %

50.0 30.0 {0.1Hz} 960.0

0 0{1%}12

D The V/f-rated frequency determines the slope of the V/f characteristic and has

considerable influence on the current, torque and power performance of the motor.

D An internal mains voltage compensation compensates deviations in the mains

during operation. They therefore do not have to be considered for the setting of

C015.

Adjustment

Calculate the frequency to be set under C015

`MNRxeòz =

C014 = -0Linear characteristic

OPMs

s

к~нЙЗ гзнзк

⋅ к~нЙЗ гзнзк СкЙимЙеЕуxeтz

xsz

C014 = -1Square-law characteristic (e. g. for pumps, fans)

V o u t

1 0 0 %

m i n

A u t o b o o s t

0

0 1

V

m i n

f

d

f

d N

0

0 1

A u t o b o o s t

f

d

f

d N

hPRKMMSQ

UOMu_^MVMO 5- 11

Page 44

Commissioning

Setspcopesato

Show/Hide Bookmarks

3.Set the Vmin boost

(C016).

4.Set slip compensation

(C021).

Load-dependentboost of the motor voltage in the field-frequency range below the

V/f-rated frequency. C016 acts as gain factor of the auto-boost function.

Adjustment

In general, an adjustment is not necessary. An optimisation can be advantageous:

For drives with very high starting torques:

A Operate the motor under load.

B Select the frequency setpoint.

C Increase V

Too high settings of V

TRIP ”Overcurrent” (OCx).

until the required motor current (torque) occurs.

min

can lead to a positive-feedback effect which activates the

min

For drives with square load torques (fans, pumps):

A Operate the motor under load.

B Select the frequency setpoint.

C Adapt V

until the motor is running steadily and smoothly over the whole fre-

min

quency range.

Too high settings of V

extensive motor temperature.

can activate the TRIP ”Overcurrent” (OCx) and lead to an

min

For drives with special motors:

A Operate the motor under load.

B Select the frequency setpoint.

C Increase V

Too high settings of V

TRIP ”Overcurrent” (OCx).

until the required motor current (torque) occurs.

min

can lead to a positive-feedback effect which activates the

min

D Check the current consumption during idle-running when no load is applied

Rough setting by means of the motor data:

ë =

å

êëóå

å

ê

êëóå

⋅ NMMB

å

êëóå

⋅ SM

Ñ

Çê

=

é

s Slip constant (C021)

synchronous motor speed [min-1]

n

rsyn

rated speed to motor nameplate [min-1]

n

r

rated frequency to motor nameplate [Hz]

f

dr

p Number of pole pairs

− å

Precise setting:

Change C021 under constant load until the speed is near the synchronous speed.

If C021 is set to too high values, the drive may become instable (overcompensation).

5-12 UOMu_^MVMO

Page 45

Commissioning

N

Show/Hide Bookmarks

5.4.1.2 Optimisation of V/f-characteristic control

Codes required

Code Name

C015

V/f-rated

frequency

C016

V

setting * 0{1%}40 * type dependent

min

C021

Slip

compensation

Setting sequence

1.If necessary, select V/f

characteristic (C014).

Possible settings

Lenze Selection Info

50.0 30.0 {0.1Hz} 960.0

0 0{1%}12

IMPORTANT

2.Select V/f-rated

frequency (C015).

V o u t

1 0 0 %

V

m i n

0

0 1

D The V/f-rated frequency determines the slope of the V/f characteristic and has

considerable influence on the current, torque and power performance of the motor.

D An internal mains voltage compensation compensates deviations in the mains

during operation. They therefore do not have to be considered for the setting of

C015.

Adjustment

Calculate the frequency to be set under C015

`MNRxeòz =

C014 = -2Linear characteristic

OPMs

s

к~нЙЗ гзнзк

f

⋅ к~нЙЗ гзнзк СкЙимЙеЕу xeтz

xsz

C014 = -3Square-law characteristic (e. g. for pumps, fans)

V o u t

1 0 0 %

V

m i n

f

d N

0

d

0

f

d

1

f

d

UOMu_^MVMO 5- 13

hPRKMMSR

Page 46

Commissioning

Setspcopesato

Show/Hide Bookmarks

3.Set the Vmin boost

(C016).

4.Set slip compensation

(C021).

D Load-independentboost of the motor voltage for field frequencies below the

U/f-rated frequency. You can thus optimize the torque performance of the inverter

drive.

D It is absolutely necessary to adapt the asynchronous motor used, since otherwise,

the motor can be destroyed by overtemperatue:

Adjustment

Please note the thermal characteristic of the connected motor under small field

frequencies:

D Usually, standard asynchronous motors with insulation class B can be operated for a

short time with rated current and frequencies between 0Hz

D Please ask the motor manufacturer for the exact setting values for the motor

current.

A Operate the motor in idle running with a slip frequency of f

-P

≤7.5 kW: fd≈5Hz

mot

-P

>7.5 kW: fd≈2Hz

mot

B Increase V

- Motor in short-term operation at 0Hz

with self-ventilated motors: I

with forced-ventilated motors: I

- Motor in permanent opera tion at 0Hz ≤f

with self-ventilated motors I

with forced-ventilated motors: I

until you reach the following motor current:

min

≤fd≤ 25Hz:

motor

motor

d

motor

motor

≤ 25Hz:

≤ I

N motor

≤ I

N motor

≤ 0.8 ¡I

≤ I

≤ fd≤25Hz.

≈:

d

N motor

N motor

Rough setting by means of the motor data:

ë =

å

êëóå

å

ê

êëóå

⋅ NMMB

å

êëóå

⋅ SM

Ñ

Çê

=

é

s Slip constant (C021)

synchronous motor speed [min-1]

n

rsyn

rated speed to motor nameplate [min-1]

n

r

f

rated frequency to motor nameplate [Hz]

dr

p Number of pole pairs

− å

Precise setting:

Change C021 under constant load until the speed is near the synchronous speed.

If C021 is set to too high values, the drive may become instable (overcompensation).

5-14 UOMu_^MVMO

Page 47

6 During operation

Show/Hide Bookmarks

D oЙйд~ЕЙ ЗЙСЙЕнбоЙ СмлЙл пбнЬ нЬЙ йкЙлЕкбДЙЗ нуйЙ зеду пЬЙе

ез оздн~ЦЙ бл ~ййдбЙЗK

qЬЙкЙ ~кЙ ез СмлЙл бе нЬЙ ЕзенкзддЙкK

D `уЕдбЕ г~бел лпбнЕЬбеЦW

J aз езн лпбнЕЬ зе нЬЙ ЕзенкзддЙк гзкЙ нЬ~е ЙоЙку P гбемнЙлI

знЬЙкпблЙ нЬЙ бенЙке~д бебнб~дJЕмккЙен дбгбн~нбзе Е~е ДЙ

зоЙкдз~ЗЙЗK

D pпбнЕЬбеЦ зе нЬЙ гзнзк лбЗЙW

J mЙкгбллбДдЙ Сзк ЙгЙкЦЙеЕу лпбнЕЬJзССK

J jзебнзкбеЦ гЙлл~ЦЙл Е~е ДЙ ~Енбо~нЙЗ пЬЙе лпбнЕЬбеЦ нЬЙ

гзнзк пЬЙе нЬЙ ЕзенкзддЙк бл Йе~ДдЙЗK

D qЬЙ йдмЦJбе ЕзееЙЕнбзе нЙкгбе~дл зС нЬЙ UOMu ЕзенкзддЙкл гмлн

зеду ДЙ ЕзееЙЕнЙЗ зк ЗблЕзееЙЕнЙЗ пЬЙе ез оздн~ЦЙ бл

~ййдбЙЗK

D aЙйЙеЗбеЦ зе нЬЙ ЕзенкзддЙк лЙннбеЦлI нЬЙ ЕзееЙЕнЙЗ гзнзк

Е~е ДЙ зоЙкЬЙ~нЙЗW

J cзк белн~еЕЙI дзеЦЙк a`JДк~вбеЦ зйЙк~нбзелK

J iзеЦЙк зйЙк~нбзе зС лЙдСJоЙенбд~нЙЗ гзнзкл ~н дзп лйЙЙЗK

D qЬЙ ЕзенкзддЙкл ЦЙеЙк~нЙ ~е змнймн СкЙимЙеЕу зС мй нз QUM eт

пЬЙе лЙннбеЦ бн ЕзккЙлйзеЗбеЦдуW

J fС ~е бе~ййкзйкб~нЙ гзнзк бл ЕзееЙЕнЙЗI ~ Ь~т~кЗзмл

зоЙклйЙЙЗ г~у зЕЕмкK

J tбнЬ СкЙимЙеЕбЙл [OQM eтI UOMu ЕзенкзддЙкл Е~е ~Енбо~нЙ

нЬЙ зоЙкJЕмккЙен лпбнЕЬJзССK

During operation

UOMu_^MVMO 6-1

Page 48

During operation

Show/Hide Bookmarks

D fС узм млЙ нЬЙ СмеЕнбзе `tL``t EлЙдЙЕнбзе зС нЬЙ ЗбкЙЕнбзе зС

кзн~нбзеF пбнЬ нЬЙ ЕзеСбЦмк~нбзе `MMT Z JMJ нз JNPJW

J qЬЙ ЗкбоЙ Е~е кЙоЙклЙ нЬЙ ЗбкЙЕнбзе зС кзн~нбзе бе нЬЙ ЙоЙен

зС ~ ЕзенкздJоздн~ЦЙ С~бдмкЙ зк ~ Е~ДдЙ ДкЙ~вK

D fС узм млЙ нЬЙ СмеЕнбзе ТcдубеЦJкЙлн~кн ЕбкЕмбнТ E`NQO Z JOJI JPJF

пбнЬ г~ЕЬбеЙл пбнЬ дзп беЙкнб~ нзкимЙ ~еЗ СкбЕнбзеW

J qЬЙ гзнзк Е~е лн~кн Сзк ~ лЬзкн нбгЙ зк кЙоЙклЙ нЬЙ ЗбкЙЕнбзе

зС кзн~нбзе Сзк ~ лЬзкн нбгЙ ~СнЙк Йе~ДдбеЦ нЬЙ ЕзенкзддЙк

пЬЙе нЬЙ гзнзк бл бе лн~еЗлнбддK

6-2 UOMu_^MVMO

Page 49

7 Configuration

Show/Hide Bookmarks

7.1 Basics

D qЬЙ ЕзеСбЦмк~нбзе зС нЬЙ ЕзенкзддЙк бл млЙЗ нз ~З~йн нЬЙ ЗкбоЙ

нз узмк ~ййдбЕ~нбзелK

D cзк нЬблI узм Ь~оЙ нЬЙ СзддзпбеЦ СмеЕнбзел ~о~бд~ДдЙW

J lйЙк~нбеЦ СмеЕнбзел

J `зенкзд СмеЕнбзе

J aблйд~у СмеЕнбзел

J jзебнзкбеЦ СмеЕнбзел

D qЬЙ йзллбДдЙ СмеЕнбзе лЙннбеЦл ~кЙ зкЦ~ебтЙЗ бе ЕзЗЙлW

J `зЗЙл ~кЙ емгЙкбЕ~дду лзкнЙЗI лн~кнбеЦ Скзг нЬЙ ЕзЗЙ пбнЬ

нЬЙ лг~ддЙлн емгДЙк нз нЬЙ зеЙ пбнЬ нЬЙ ЬбЦЬЙлн емгДЙкK ^дд

ЕзЗЙл лн~кн пбнЬ ~ Т `ТK

J qЬЙу ~кЙ дблнЙЗ бе нЬЙ ЕзЗЙ н~ДдЙK

J b~ЕЬ ЕзЗЙ йкзобЗЙл й~к~гЙнЙкл пЬбЕЬ Е~е ДЙ млЙЗ нз

~Замлн ~еЗ зйнбгбтЙ узмк ЗкбоЙK

D qЬЙ ЕзеСбЦмк~нбзе зС нЬЙ ЕзенкзддЙк Е~е ДЙ ЙенЙкЙЗ Ду гЙ~ел

зС нЬЙ вЙуй~З зС нЬЙ UOMN__ зйЙк~нбеЦ гзЗмдЙ зк Ду гЙ~ел

зС ~ СбЙдЗДмл об~ нЬЙ лЙкб~д бенЙкС~ЕЙK

J qЬЙ зйЙк~нбеЦ гзЗмдЙ ~еЗ СбЙдЗДмл гзЗмдЙл ~кЙ ~о~бд~ДдЙ

~л ~ЕЕЙллзкбЙлK

D qЬЙ ЕЬ~еЦбеЦ зС й~к~гЙнЙкл Ду гЙ~ел зС нЬЙ зйЙк~нбеЦ

гзЗмдЙ зк СбЙдЗДмл гзЗмдЙл бл ЗЙлЕкбДЙЗ

J бе нЬЙ lйЙк~нбеЦ fелнкмЕнбзел зС нЬЙ гзЗмдЙлK

J бе нЬЙ j~ем~дK

D ^дд СмеЕнбзел зС нЬЙ ЕзенкзддЙк ~кЙ ЗЙлЕкбДЙЗ лЬзкнду бе нЬЙ ЕзЗЙ

н~ДдЙK ^ ЗЙн~бдЙЗ ЗЙлЕкбйнбзе Е~е ДЙ зДн~беЙЗ Скзг нЬЙ

j~ем~дK

Configuration

UOMu_^MVMO 7-1

Page 50

Configuration

Show/Hide Bookmarks

7.2 Code table

How to read the code table:

Column Abbreviation Meaning

Code C013 Code C013

D The parameter of the code can be different in PAR1 and

PAR2.

D The parameter value is accepted immediately (ONLINE).

Name

Lenze Fac tory setting of the code

Selection 1{1%}99Minimum value {smallest step/unit} maximum value

Info - Meaning of the code

IMPORTANT - Additional, important explanations of the code

7-2 UOMu_^MVMO

C009* D The parameter value of the code is always the same in

C001¿ D The parameter value of the code will be accepted after

[C002] D The parameter value of the code will be accepted after

* The column ”Important” contains further information

PAR1 and PAR2, but is always displayed in PAR1.

pressing SH+PRG.

pressing SH+PRG but only if the controller is inhibited.

Name of the code.

820X

Unit-specific setting possibilites (here for 820X).

Without unit designation the code is valid for all unit types.

Page 51

Configuration

CodeNam

e

IMPORTANT

Show/Hide Bookmarks

Code Name

C001¿Operating mode -0- -0- Setpoint selection via term. 8

[C002]*Parameter set -0- F unction executed

C004¿Switch-on

display

Possible settings

Lenze Selection Info

Control via terminals

Parameter setting via 8201BB

-1- Setpoint selection via 8201BB or via

LECOM

Control via terminals

Parameter setting via 8201BB

-2- Setpoint selection via term. 8

Control via terminals

Parameter setting via LECOM

-3- Setpoint selection via LECOM

Control via LECOM

Parameter setting via LECOM

-1- Overwrite PAR1 with factory setting

-2- Overwrite PAR2 with factory setting

-3- Overwrite PAR1 and PAR2 with the data

of the operating module

-4- Overwrite PAR1 with the data of the

operating module

-5- Overwrite PAR2 with the data of the

operating module

-6- Transmit PAR1 and PAR2 to the

-0- -0- Field frequency f

operating module

-1- Controller load

-2- Motor current

d

IMPORTANT

UOMu_^MVMO 7-3

Page 52

Configuration

Show/Hide Bookmarks

Code IMPORTANTPossible settingsNameCode IMPORTANT

Name

InfoSelectionLenze

[C007]*Ter min al

configuration

C008¿Function relayK1-1- -0- Ready for operation

-0- E4 E3 E2 E1

-0- CW/CCWDC brake JOG1/2/3

-1- CW/CCW PAR JOG1/2/3

-2- CW/CCWQSP JOG1/2/3

-3- CW/CCWPAR DC brake JOG1

-4- CW/CCW QSP PAR JOG1

-5- CW/CCWDC brake Trip set JOG1

-6- CW/CCW PAR Trip set JOG1

-7- CW/CCW PAR DC brake Trip set

-8- CW/CCW QSP PAR Trip set

-9- CW/CCW QSP Trip set JOG1

-10- CW/CCWTrip set UP DOWN

-11- CW/CCWDC brake UP DOWN

-12- CW/CCW PAR UP DOWN

-13- CW/CCWQSP UP DOWN

-14- CCW/QSPCW/QSPDC brake JOG1

-15- CCW/QSPCW/QSP PAR JOG1

-16- CCW/QSPCW/QSPJOG1/2/3

-17- CCW/QSPCW/QSP PAR

-18- CCW/QSPCW/QSP PAR Trip set

-19- CCW/QSPCW/QSPDC brake Trip set

-20- CCW/QSPCW/QSP Trip set JOG1

-21- CCW/QSPCW/QSP UP DOWN

-22- CCW/QSPCW/QSP UP JOG1

-1- TRIP fault message

-2- Motor is running

-3- Motor is running / CW rotation

-4- Motor is running / CCW rotation

-5- Field frequency f

-6- f

dset

-7- Q

min

-8- I

max

-9- Overtemperature (

-10- TRIP or Q

reached

reached

reached

min

d

or IMP

=0

J

max

DC brake

-10 °C)

D CW = CW

rotation

D CCW =

CCW

rotation

D DC brake =

DC

injection

brake

D PAR =

Change of

parameter

sets

D JOG = JOG

frequency

D QSP =

Quick stop

D Tri p- Set =

External

fault

D UP/DOWN

= Motor

potentiomet

er functions

7-4 UOMu_^MVMO

Page 53

Configuration

Show/Hide Bookmarks

Code IMPORTANTPossible settingsNameCode IMPORTANT

Name

InfoSelectionLenze

C009* Device address 1 1 {1} 99 Only for

C010 Minimum field

frequency

C011 Maximum field

frequency

0.0 0.0 {0.1Hz} 480.0

820X 50.0 30.0 {0.1Hz} 480.0

821X 50.0 7.5 {0.1Hz} 480.0

30.0 {0.1Hz} 480.0

(Software 2x)

(Software 1x)

822X/824X 50.0 7.5 {0.1Hz} 480.0

LECOM

applications

C012 Acceleration

C013 Deceleration

C014¿Operating mode

C015

time

time

821X/822X

V/f-rated

frequency

5.0 0.0 {0.1s} 999.0

5.0 0.0 {0.1s} 999.0

820X -0- -0- Linear characteristic V~fdwith auto

-4- -4- Motor-current control

/ 824X

boost

-1- Square characteristic V

boost

-2- Linear characteristic V~fdwith constant

boost

V

min

-3- Square characteristic V

constant V

min

boost

~f

~f

d

d

820X 50.0 30.0 {0.1Hz} 960.0

821X 50.0 7.5 {0.1Hz} 960.0

30.0 {0.1Hz} 960.0

822X/824X 50.0 7.5 {0.1Hz} 960.0

2

with auto

2

with

(Software 2x)

(Software 1x)

UOMu_^MVMO 7-5

Page 54

Configuration

C01

6

¿

Show/Hide Bookmarks

Code IMPORTANTPossible settingsNameCode IMPORTANT

Name

InfoSelectionLenze

C016

V

setting

min

820X * 0{1%} 40 * depends on

821X/822X

C017 Threshold Q

C018

Chopper

¿

frequency

821X/822X/824X-1- -0- 4 kHz

C019

Threshold auto

DC brake

821X/822X/824X0.1 0.1 {0.1Hz} 5.0

C021

Slip

compensation

822X/824X 0 0{1%} 20

C022 I

C023 I

limit motor

max

mode

limit

max

generator mode

0 0{1%} 40

/ 824X

0.0 0.0 {0.1Hz} 480.0

min

-1- 8 kHz

-2- 12 kHz

-3- 16 kHz

-4- 12 kHz noise optimized

-5- 16 kHz noise optimized

820X 0 0{1%} 12

821X 0 0{1%} 20

0{1%} 12

150 30 {1 %} 150

80 30 {1 %} 110

(Software 2x)

(Software 1x)

the unit

7-6 UOMu_^MVMO

C034¿Master current -0- -0- 0 to 20mA /

C036 Voltage for DC

brake

C037 JOG value 1 20 0 {1Hz} 480

* 0{1%} 40 * depends on

0to5V/0to10V

-1- 4 to 20mA

the unit

Page 55

Configuration

transferrin

g

Show/Hide Bookmarks

Code IMPORTANTPossible settingsNameCode IMPORTANT

Name

InfoSelectionLenze

C038 JOG value 2 30 0 {1Hz} 480

C039 JOG value 3 40 0 {1Hz} 480

C050* Output

frequency

C052* Motor voltage Only display

C054* Motor current Only display

C056* Controller load Only display

C061* Heat sink

temperature

C079

Oscillation

damping

822X/824X 5 0 {1} 80

C088 Rated motor

current

821X/822X/824

C091 Motor cos j

821X/822X/824

C093*

Type Only display

822X/824X 822X

*

0.0 ... 1.2 ¡ rated output current

X

*

0.4 {0.1} 1.0

X

820X 820X

821X 821X

Only display

Only display

Is not

transferred

when

transferring

parameters

via the

operating

module.

* depends on

the unit

* depends on

the unit

UOMu_^MVMO 7-7

Page 56

Configuration

Show/Hide Bookmarks

Code IMPORTANTPossible settingsNameCode IMPORTANT

Name

InfoSelectionLenze

C099*

Software version Only display

820X 82 1x (Software 1x)

821X 82 2x (Software 2x)

82 1x (Software 1x)

822X/824X 82 1x (Software 1x)

C105 Deceleration

time quick stop

821X/822X/824

C106

Holding time for

autom. DC

injection brake

821X/822X

C108*

Gain (C111)

822X/824X 128 0 {1} 255

Monitor signal -0- -0- Field frequency

C111

¿

5.00 0.00 {0.01s} 999.00

X

820X 0.00 0.00 {0.01s} 50.00

0.02 0.00 {0.01s} 999.00

824X

820X 220 0 {1} 255

821X 128 0 {1} 255

-1- Controller load

-2- Motor current

-3- DC-bus voltage

7-8 UOMu_^MVMO

Page 57

Configuration

Show/Hide Bookmarks

Code IMPORTANTPossible settingsNameCode IMPORTANT

Name

InfoSelectionLenze

C117¿Function relay

K2

822X/824X

C119¿Function PTC

822X/824X

2

C120

I

¡ t switch off

822X/824X 0 0 {1 %} 100

C125¿*LECOM baud

rate

C142¿Start condition -1- -0- Automatic start inhibited, flying-restart

-0- -0- Ready for operation

-1- TRIP fault message

-2- Motor is running

-3- Motor is running / CW rotation

-4- Motor is running / CCW rotation

-5- Field frequency f

reached

-6- f

dSet

-7- Q

reached

min

-8- I

reached

max

-9- Overtemperature (

-10- TRIP or Q

-11- PTC warning

=0

d

J

max

or IMP

min

-0- -0- PTC input inactive

-1- PTC input active,

TRIP and IMP (pulse inhibit) are set

-2- PTC input active, warning

-0- -0- 9600 baud

-1- 4800 baud

-2- 2400 baud

-3- 1200 baud

-4- 19200 baud

circuit inactive

-1- Automatic start, if term. 28 HIGH,

flying-restart circuit not active

-2- Automatic start inhibited, flying-restart

circuit active

-3- Automatic start, if term. 28 HIGH,

flying-restart circuit active

-10°C)

Only for

LECOM

applications

UOMu_^MVMO 7-9

Page 58

Configuration

¿

Show/Hide Bookmarks

Code IMPORTANTPossible settingsNameCode IMPORTANT

Name

InfoSelectionLenze

C144

Chopper-frequency

¿

reduction

821X/822X/824X-1- -0- No chopper-frequency reduction

C161* Current fault Only display

C162* Last fault Only display

C163* Last but one

fault

C164* Last but two

fault

C170¿TRIP-reset

selection

C171 Delay for

Auto-TRIP-Reset

C178* Operating time Only display

C179* Mains switch-on

time

C377 Gain Zk-voltage

detection

822X/824X

C500*

Display factor

application

datum

numerator

821X/822X/824X2000 1 {1} 25000

-1- Automatic chopper-frequency lowering

when

J

-10°C

max

-0- TRIP-reset by pressing the STP key or

LOW signal at ctrl. enable

-1- Auto-TRIP-Reset

0 0{1s} 60

Only display

Only display

Only display

Should only

be changed

by the Lenze

Service!

7-10 UOMu_^MVMO

C501*

Display factor

for process

variable

denominator

821X/822X/824X10 1 {1} 25000

Page 59

Troubleshooting and fault elimination

Show/Hide Bookmarks

8 Troubleshooting and fault elimination

D c~мднл ~кЙ бггЙЗб~нЙду беЗбЕ~нЙЗ об~ нЬЙ Зблйд~у зк лн~нмл

беСзкг~нбзе EЕЬ~йнЙк UKNFK

D qЬЙ С~мдн Е~е ДЙ ~е~дулЙЗ Ду млбеЦ нЬЙ Ьблнзку ДмССЙк EЕЬ~йнЙк

UKOF ~еЗ нЬЙ дблн бе ЕЬ~йнЙк UKPK qЬЙ дблн ЬЙдйл узм пбнЬ нЬЙ

Йдбгбе~нбзе зС С~мднлK

8.1 Troubleshooting

8.1.1 Display at the controller

aмкбеЦ зйЙк~нбзе пбнЬзмн ~е зйЙк~нбеЦ гзЗмдЙI нЬЙ зйЙк~нбеЦ лн~нЙ

зС нЬЙ ЕзенкзддЙк бл Зблйд~уЙЗ зе нпз ibaл ~н нЬЙ Скзен зС нЬЙ мебнK

LED Operating status

green red

on off Controller enabled

on on Mains switched on and automatic start inhibited (AS_LC)

blinking off Controller inhibited

off blinking every second Fault message, check under C161

off blinking every 0.4 seconds Undervoltage switch-off

off off Programming mode

8.1.2 Display at the operating module

pн~нмл беЗбЕ~нбзел бе нЬЙ Зблйд~у беЗбЕ~нЙ нЬЙ ЕзенкзддЙк лн~нмлK

Display Meaning

OV Overvoltage

UV Undervoltage

IMAX Set current limit exceeded

TEMP Heat sink temperature near switch-off

UOMu_^MVMO 8-1

Page 60

Troubleshooting and fault elimination

acknowledge

d

d

ina”higher”

l

y

Show/Hide Bookmarks

8.1.3 Maloperation of the drive

Maloperation Possible causes

Motor does not rotate D DC-bus voltage too low

Motor does not rotate

smoothly

Current consumption of

motor too high

8.2 Fault analysis using the history buffer

qЬЙ Ьблнзку ДмССЙк бл млЙЗ нз нк~ЕЙ С~мднлK qЬЙ С~мдн гЙлл~ЦЙл ~кЙ

лнзкЙЗ бе нЬЙ Ьблнзку ДмССЙк бе нЬЙ зкЗЙк зС нЬЙбк зЕЕмккЙеЕЙK

qЬЙ Ьблнзку ДмССЙк Ь~л Q гЙгзку дзЕ~нбзел пЬбЕЬ Е~е ДЙ ~ЗЗкЙллЙЗ

об~ ЕзЗЙлK

Structure of the history buffer

Code C0168 Entry Note

C161 Memory locations 1 Active fault

C162 Memory location 2 Last fault

C163 Memory location 3 Last but one fault

C164 Memory location 4

(red LED is blinking every 0.4 s; message LU is displayed)

D Controller inhibited

(green LED is blinking, display of the operating module: OFF,

STOP or AS_LC)

D Setpoint = 0

D DC braking active

D Quick-stop function active

D JOG setpoint activated and JOG frequency = 0

D Fault is indicated (see chapter 8.3 )

D Mechanical motor brake is not released

D Defective motor cable

D Maximum current C022 and C023 too low

D Motor underexcited or overexcited (check parameter setting)

D Setting of C016 too high

D Setting of C015 too low

D C088 and C091 are not adapted to the motor data.

If the fault is no longer active or has been