Page 1

L

Manual

Global Drive

PLC Developer Studio

Global Drive

Function library

Lenze8200Drive.lib

Page 2

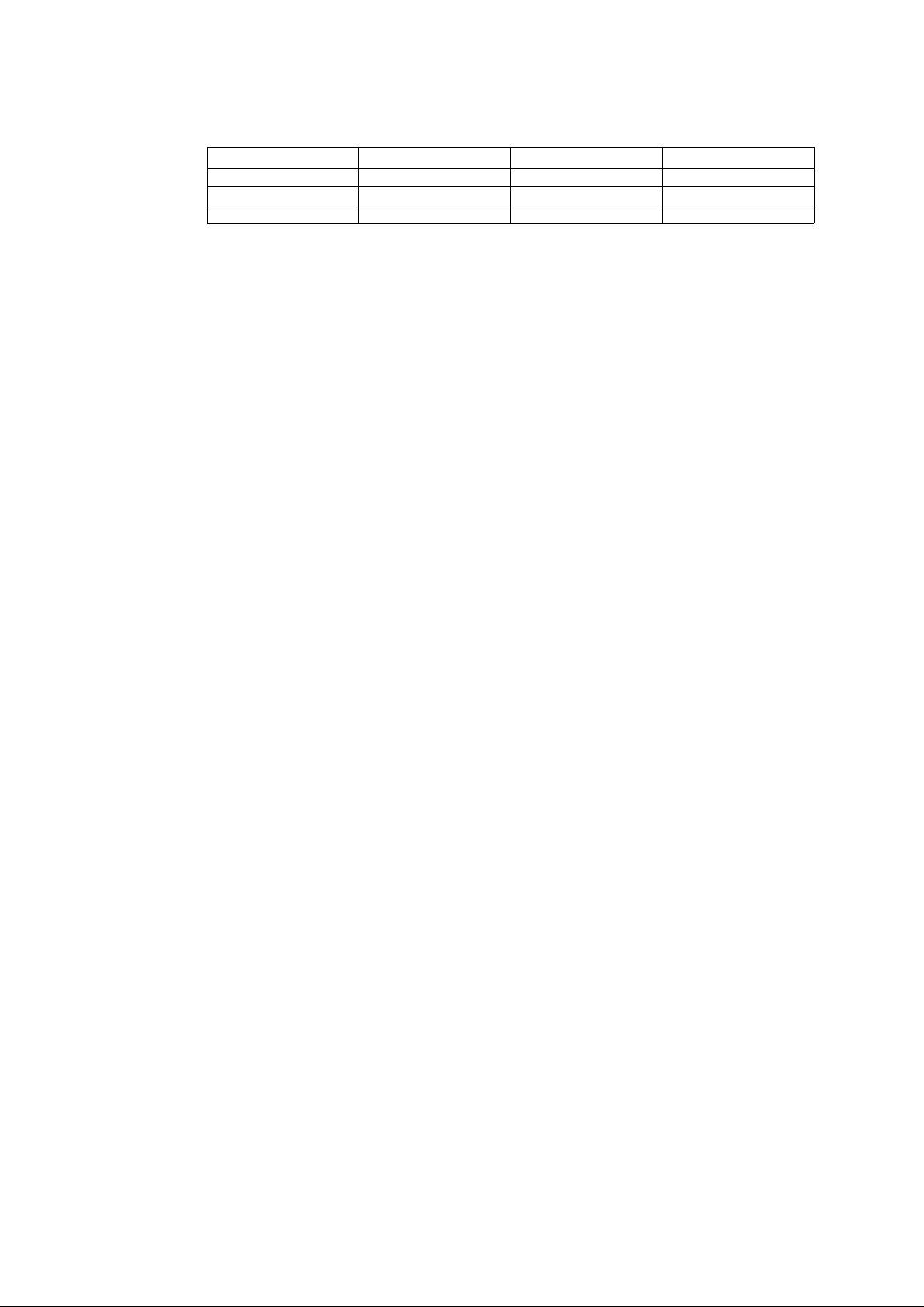

The function library Lenze8200Drive.lib can be used for the following Lenze PLCs:

Type from hardware version from software version

9300 Servo PLC EVS93XX−xT 6A 6.0

Drive PLC EPL10200 1A 6.0

ECSxA ECSxAxxx 1C 7.0

Important note:

The software is supplied to the user as described in this document. Any risks resulting from its quality or use remain the responsibility

of the user. The user must provide all safety measures protecting against possible maloperation.

We do not take any liability for direct or indirect damage, e.g. profit loss, order loss or any loss regarding business.

ã 2002 Lenze Drive Systems GmbH

No part of this documentation may be copied or made available to third parties without the explicit written approval of Lenze Drive

Systems GmbH.

All information given in this documentation has been carefully selected and tested for compliance with the hardware and software

described. Nevertheless, discrepancies cannot be ruled out. We do not accept any responsibility or liability for any damage that may

occur. Required corrections will be included in updates of this documentation.

All product names mentioned in this documentation are trademarks of the corresponding owners.

Version

1.0 03/2005

Page 3

Function library Lenze8200Drive.lib

Contents

1 Preface and general information 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 About this Manual 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Conventions used in this Manual 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Layout of the descriptions 1−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.3 Pictographs used in this Manual 1−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.4 Terminology used 1−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Version identifiers of the function library 1−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Introduction 2−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General 2−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Frequency inverter parameterisation 2−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Assigning the system bus node addresses to the frequency inverters 2−3 . . . . . . . . . . . . . . . . . . . . .

2.2.2 Function block activation 2−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Process data exchange with the frequency inverter 2−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Functions/function blocks 3−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 L_8200Parameter − Initialisation of codes 3−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 L_8200Initialization − Frequency inverter initialisation 3−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 L_8200DataControl − Send/receive process data 3−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 L_8200CtrlWord − Selection of boolean control signals 3−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 L_8200StatusWord − Output of boolean status signals 3−16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l

Lenze8200Drive.lib EN 1.0

i

Page 4

Function library Lenze8200Drive.lib

Contents

ii

Lenze8200Drive.lib EN 1.0

l

Page 5

Function library Lenze8200Drive.lib

Preface and general information

1 Preface and general information

1.1 About this Manual

This Manual contains information about function library Lenze8200Drive.lib for the Drive PLC

Developer Studio.

· The function blocks of function library Lenze8200Drive.lib can be used to exchange data

between the PLC and one or more frequency inverters of the 8200 series via the system bus

(CAN).

· It is possible to assign up to 45 frequency inverter parameters (codes) from the PLC and

cyclically exchange process data with the frequency inverter.

1.1.1 Conventions used in this Manual

This Manual uses the following conventions to distinguish between different types of information:

Variable identifiers

are written in italics in the explanation:

· "Use bReset..."

Tip!

Information about the conventions used for the variables of the Lenze system blocks, function blocks

and functions can be found in the appendix of the DDS online documentation "Introduction into

IEC61131−3 programming". The conventions ensure universal and uniform labelling and make

reading the PLC program easier.

Lenze functions/function blocks

can be recognized by their names. They always begin with an "L_":

· "With the function L_TBConvBitsToByte..."

Program listings

are written in "Courier", keywords are printed in bold:

· " IF (ReturnValue < 0) THEN..."

l

Lenze8200Drive.lib EN 1.0

1−1

Page 6

Function library Lenze8200Drive.lib

Preface and general information

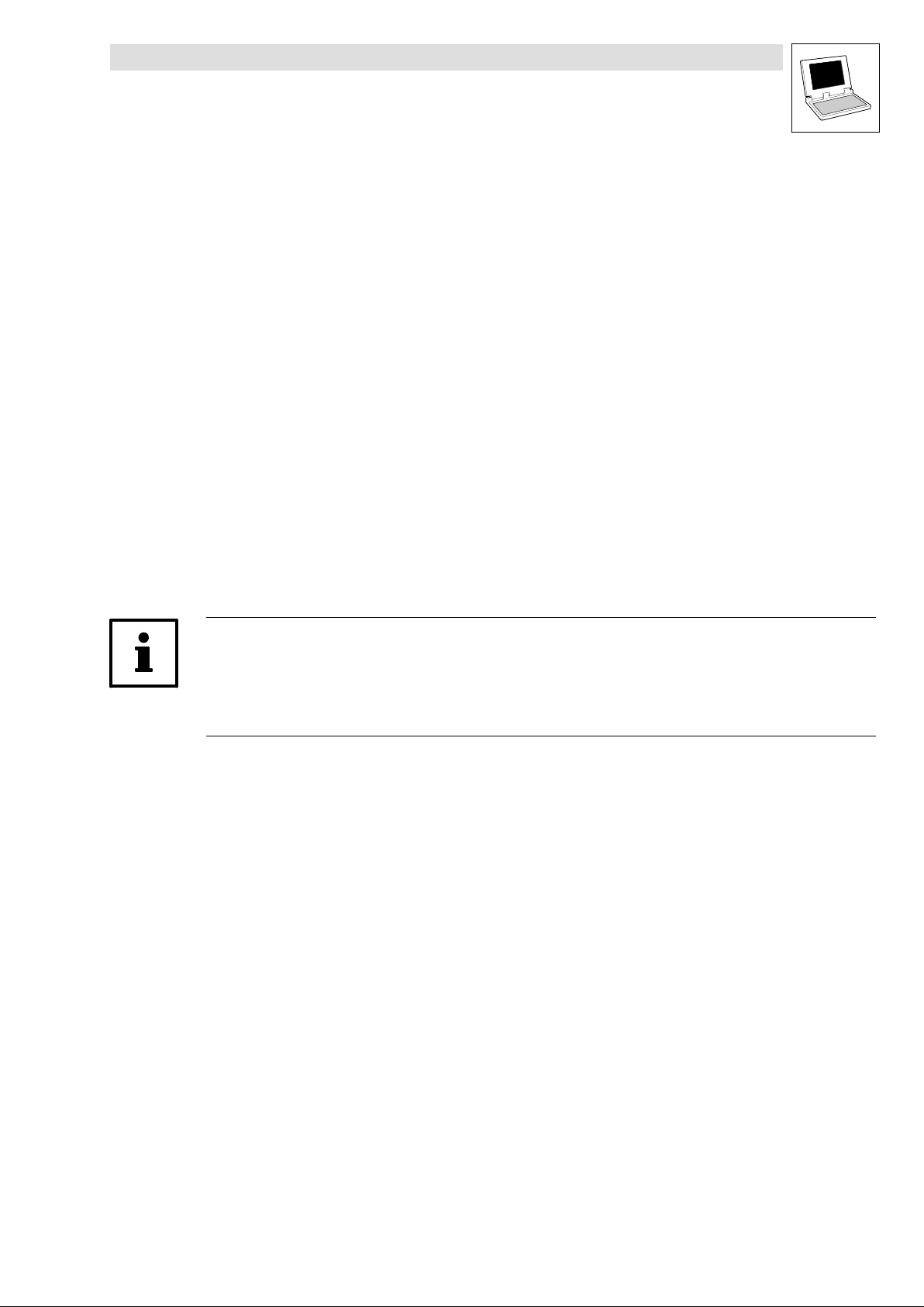

1.1.2 Layout of the descriptions

All function/function block and system block descriptions contained in this Manual have the same

structure:

Function Function block (FB)/

Headline stating the function and the function identifier

Declaration of the function:

· Data type of the return value

· Function identifier

· List of transfer parameters

Short description of the most important properties

Function chart including all

associated variables

· Transfer parameters

· Return value

Table giving information about the

transfer parameters:

· Identifier

· Data type

· Possible settings

· Info

Table giving information about the

return value:

· Data type of the return value

· Possible return values and their

meaning:

Additional information

(Notes, tips, application examples, etc.)

System block (SB)

−

FB/SB chart including all

associated variables

· Input variables

· Output variables

Table giving information about the

input and output variables:

· Identifier

· Data type

· Type of variable

· Possible settings

· Info

−

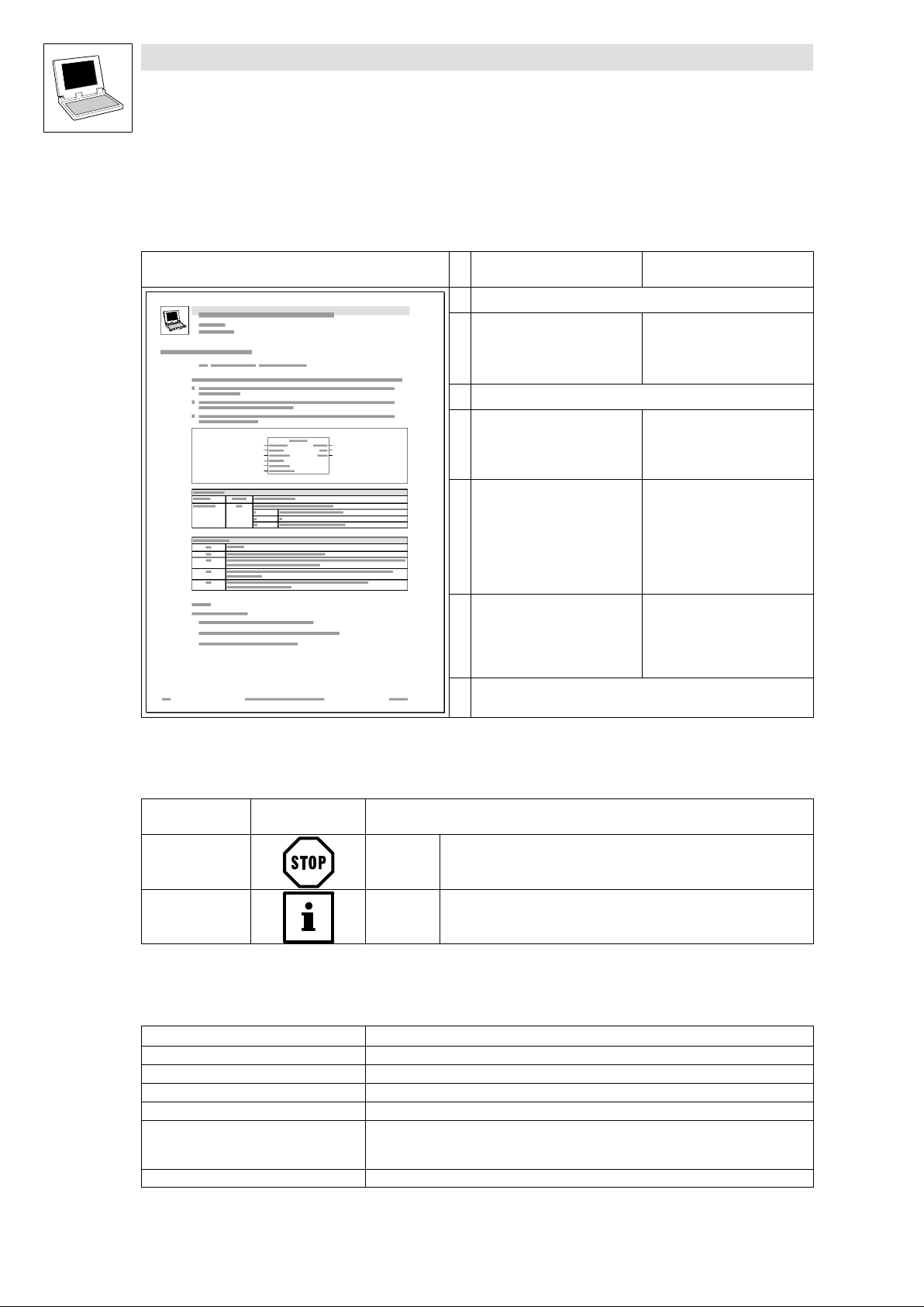

1.1.3 Pictographs used in this Manual

Use of

pictograms

Warning of

material damage

Other notes Tip!

Signal words

Stop! Warns of potential damage to material.

Note!

1.1.4 Terminology used

Term In the following text used for

DDS Drive PLC Developer Studio

FB Function block

GDC Global Drive Control (parameterization program from Lenze)

Parameter codes Codes for setting the functionality of a function block

PLC · 9300 Servo PLC

SB System block

· Drive PLC

· ECSxA "Application" axis module

Possible consequences if disregarded:

Damage to the controller/drive system or its environment

Indicates a tip or note.

.

1−2

Lenze8200Drive.lib EN 1.0

l

Page 7

Function library Lenze8200Drive.lib

Preface and general information

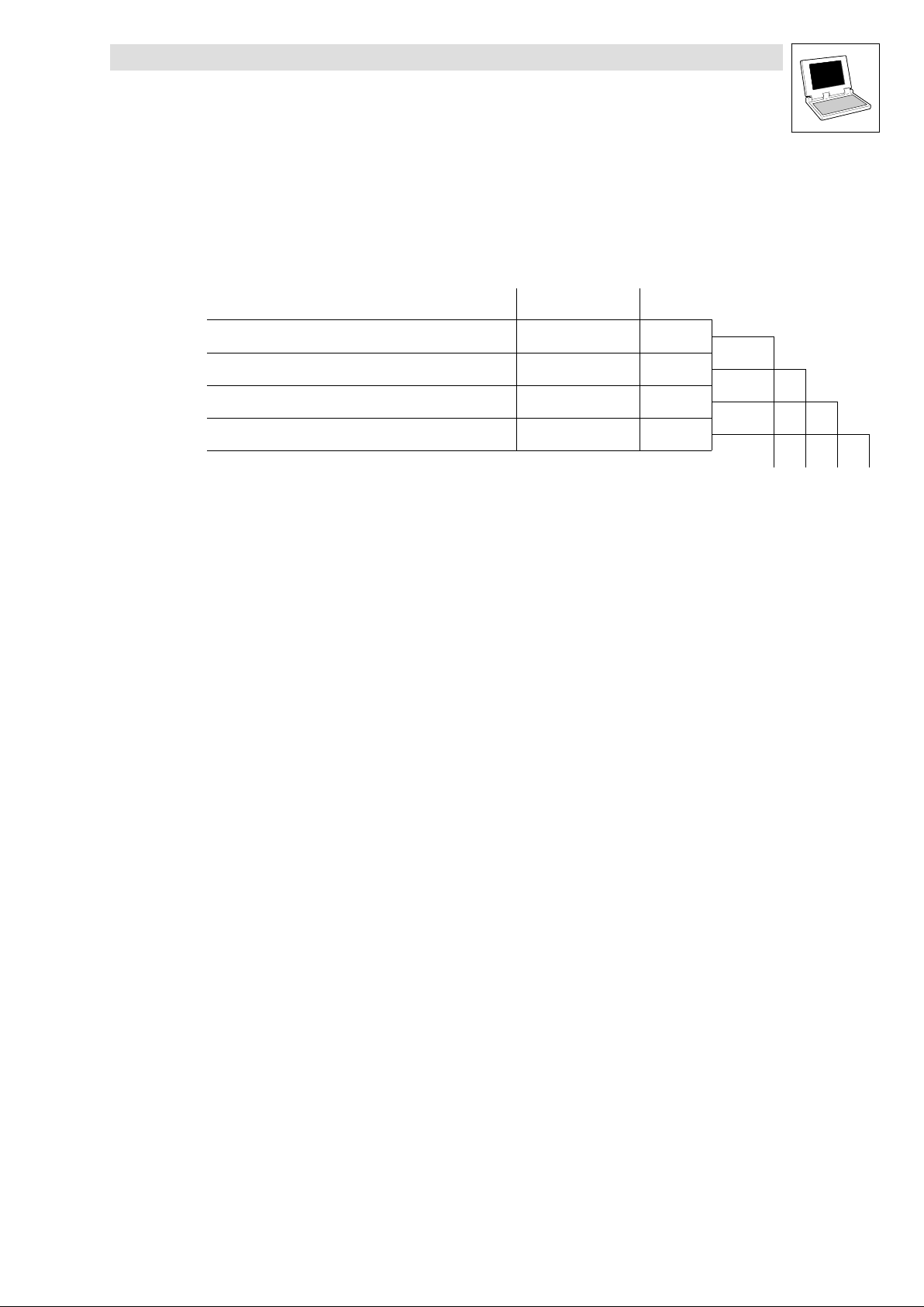

1.2 Version identifiers of the function library

The version of the function library can be found under the global constant

C_w[Function library name]Version .

Version identifiers as of PLC software version 7.x:

Constant Meaning

C_w[FunctionLibraryName]VersionER External Release 01

C_w[FunctionLibraryName]VersionEL External Level 05

C_w[FunctionLibraryName]VersionIR Internal Release 00

C_w[FunctionLibraryName]VersionBN Build No. 00

The value of this constant is a hexadecimal code.

· In the example, "01050000" stands for version "1.05".

Example

value

Version: 01 05 00 00

l

Lenze8200Drive.lib EN 1.0

1−3

Page 8

Function library Lenze8200Drive.lib

Preface and general information

1−4

Lenze8200Drive.lib EN 1.0

l

Page 9

2 Introduction

2.1 General

Integrate function library Lenze8200Drive.lib in your PLC program to make frequency inverter

control easier.

Two function blocks are required for this:

1. A function block for the parameterisation of the frequency inverter.

2. Another function block for process data exchange between PLC and frequency inverter.

The parameters can be set via the PLC program. It is possible to select up to 45 parameters.

Parameterisation concepts

The following parameterisation concepts are supported:

· Parameterisation through direct instructions in the FBs

· Parameterisation by means of codes ("online" parameterisation possible)

Function library Lenze8200Drive.lib

Introduction

Note!

The frequency inverter must meet the following conditions for frequency inverter control from the

PLC:

· The factory settings have been loaded.

(For the 8200vector frequency inverter, e. g. under code C0002)

· The system bus node address is correct.

(For the 8200vector frequency inverter, e. g. under code C0350)

· The new communication settings of the system bus interface have been accepted by a

Reset−Node.

(For the 8200vector frequency inverter, e. g. under code C0358)

Tip!

Detailed information about the system bus (CAN) and function library LenzeCanDrv.lib can be found

in the Manual "System bus (CAN) for Lenze PLC devices".

l

Lenze8200Drive.lib EN 1.0

2−1

Page 10

Function library Lenze8200Drive.lib

Introduction

2.2 Frequency inverter parameterisation

When the program is started, the parameter data shall be written only once during initialisation to

the frequency inverter. The FBs L_8200Parameter and L_8200Initialization therefore have to be

called in the system task PLC_PRG.

· The FB L_8200Parameter is used to initialise the codes with the corresponding values.

· After this, the FB L_8200Initialization is used to transfer the parameters to the individual

frequency inverters.

PLC_PRG

node id = x

node id = y

node id = z

L_8200Parameter

C0011 = ...

C0012 = ...

C0013 = ...

C0127 = ...

C0356 = ...

C0410 = ...

...

L_8200Initialization

L_8200Initialization

L_8200Initialization

L

8200

node id = x

L

8200

node id = y node id = z

L

8200

2−2

Lenze8200Drive.lib EN 1.0

l

Page 11

Function library Lenze8200Drive.lib

Introduction

2.2.1 Assigning the system bus node addresses to the frequency inverters

If the node addresses are assigned in continuous, ascending order to the Lenze controllers, the

default setting of the event−controlled data object identifiers (CAN2_IO/CAN3_IO) allows

communication between the controllers:

L

Node-ID 1

CAN2_OUT

CAN3_OUT

CAN2_IN

CAN3_IN

L

Node-ID 2

CAN2_OUT

CAN3_OUT

L

CAN2_IN

CAN3_IN

Node-ID 3

If you want to parameterise a group of frequency inverters with different values you have to skip at

least one node address between the inverters to interrupt the automatic data transfer:

L

Node-ID 1

CAN2_OUT

CAN3_OUT

CAN2_IN

CAN3_IN

L

Node-ID 3

CAN2_OUT

CAN3_OUT

L

CAN2_IN

CAN3_IN

Node-ID 5

· In this way, you can parameterise a maximum of 32 frequency inverters

(with node address 1 − 3 − 5 − 7 − ... − 63).

Note!

New node addresses will only become effective after a Reset−node. (For the 8200vector frequency

inverter, e. g. under code C0358)

2.2.2 Function block activation

The FB L_8200Initialization must be called cyclically because the data are internally transmitted to

the frequency inverter via the FB L_ParWrite.

· Depending on the amount of data to be transmitted, the data transfer may take several cycles.

· If the data transfer has been successful, the message output bParDone will be set to TRUE.

· When the data transfer has been completed ( bParDone = TRUE), the parameterisation is

complete and the FBs L_8200Parameter and L_8200Initialization need not be called again.

l

Lenze8200Drive.lib EN 1.0

2−3

Page 12

Function library Lenze8200Drive.lib

Introduction

2.3 Process data exchange with the frequency inverter

Unlike the parameter data, the process data must be cyclically exchanged between PLC and

frequency inverter to update input and output information.

· The FB L_8200CtrlWord is used to select the control word to be transmitted as boolean

control signals.

· The FB L_8200DataControl is used for the actual process data exchange with the

corresponding frequency inverter.

· The FB L_8200StatusWord is used to divide the receive status word for evaluation and further

processing into individual boolean status signals.

(^ 3−15)

(^ 3−10)

(^ 3−16)

bNSET1_JOG13

bNSET1_JOG23

bDCTRL1_CW_CCW

bDCTRL1_QSP

bNSET1_RFG1_STOP

bNSET1_RFG1_0

bMPOT1_UP

bMPOT1_DOWN

bRELAY_K1

bDCTRL1_CINH

bDCTRL1_TRIP_SET

bDCTRL1_TRIP_RESET

bDCTRL1_PAR24

bDCTRL1_PAR34

bMCTRL_DCB

bPCTRL1_RFG2_LOAD_I

L_8200CtrlWord

CTRL

wControlData

bEnable

bResetNode

byNodeAddr

tCycleTime

tTimeOut

bResetFail

wControlData

nNSetN1_a

wBoostVoltage

wInputData

CAN2_OUT CAN2_IN

L_8200DataControl

CTRL

data bytes:

1+2

1+2

3+4

3+4

5+6

5+6

7+8

7+8

System bus (CAN)

nStateDataTo82

nStateDataFrom82

bFail_DataTo82

bFailDataFrom82

wStatusData

nMCtrl_Nout_Slip

wOutputData3

wOutputData4

L

8200

Node address = byNodeAddr

Note!

The task cycle time depends on the number of objects used.

wStatusData

CTRL

L_8200StatusWord

bDCTRL1_RDY

bDCTRL_IMP

bMCTRL_IMAX

bNSET1_RFG1_NOUT

bNSET1_RFG1_I

bPCTRL1_QMIN

bDCTRL_NOUT

bDCTRL1_CINH

bDCTRL1_TRIP

bFIXED_RESERVE_9

bFIXED_RESERVE_10

bFIXED_RESERVE_11

bFIXED_RESERVE_12

bDCTRL1_OH_WARN

bDCTRL1_OV

bDCTRL1_CCW

2−4

Lenze8200Drive.lib EN 1.0

l

Page 13

Function library Lenze8200Drive.lib

3 Functions/function blocks

Functions/function blocks

L

Lenze8200Drive.lib EN 1.0

3−1

Page 14

Function library Lenze8200Drive.lib

Functions/function blocks

3.1 L_8200Parameter − Initialisation of codes

3.1 L_8200Parameter − Initialisation of codes

Function block

With this FB you can parameterise up to 45 parameters (codes) in the frequency inverter.

The following parameterisation concepts are supported:

· Parameterisation through direct instructions in the FBs

· Parameterisation by means of codes ("online" parameterisation possible)

L_8200Parameter

byNoOfParameter

awCodeNo

abySubCodeNo

abyFraction

anValue

þ Event−controlled task

(EVENT)

FB call in: þ Cyclic task

(PLC_PRG)

1

2

3

4

5

6

7

8

9

...

45

Code SubCode

Fraction Value

þ Time−controlled task

(INTERVAL)

Inputs Data type Information/possible settings

byNoOfParameter Byte Number of parameters to be transmitted (max. 45)

awCodeNo Array of Word Number of the code to be transmitted as parameter 1..45.

abySubCodeNo Byte array Number of the subcode to be transmitted as parameter 1..45.

abyFraction Byte array Number of decimal places for parameters 1..45

· See also FB description L_ParWrite

in the Manual Function library LenzeDrive.lib.

anValue Array of

integers

Value of the code to be transmitted as parameter 1..45.

o Interrupt task

3−2

Lenze8200Drive.lib EN 1.0

L

Page 15

Function library Lenze8200Drive.lib

Functions/function blocks

3.1 L_8200Parameter − Initialisation of codes

Concept I: Parameterisation through direct instructions in the FBs

For this, use the FB L_8200Parameter as template and create a new function block in which the

parameter data are selected by direct assignments.

Note!

Please observe that FB changes (e. g. new assignments) require a new compilation and program

download to the PLC.

· If you want to change the parameters "online" via the Parameter Monitor or keypad, use

concept II ("Parameterisation by means of codes").

Tip!

The FB L_8200Parameter already includes commented assignments for all parameters relevant

for frequency inverter control.

· The parameters are listed in the table on the next page.

· The names of the inputs and outputs of the FBs L_8200CtrlWord and L_8200StatusWord

have been adapted to the selected parameters.

· If you want to use the pre−assignments, simply copy the assignments to the new FB and

remove the comment characters so that the assignments will become effective.

· Of course, it is also possible to adapt the assignments to your application.

Proceed as follows:

1. Create a new function block.

2. Use the Library Manager and copy the source code of the FB L_8200Parameter to the new

function block.

3. Remove the comment characters around the assignments to accept the pre−assignments or

adapt the assignments to your application.

FUNCTION_BLOCK Parameter82Device1

VAR_OUTPUT

END_VAR

(* max. frequency *)

awCodeNo[1]:=11; abySubCodeNo[1]:=0; anValue[1]:=5000; abyFraction[1]:=2;

(* acceleration time Tir *)

awCodeNr[2]:=12; abySubCodeNo[2]:=0; anValue[2]:=0010; abyFraction[2]:=2;

(* deceleration time Tif *)

awCodeNo[3]:=13; abySubCodeNr[3]:=0; anValue[3]:=0010; abyFraction[3]:=2;

(* standardization for C0011 => 16384 *)

awCodeNo[4]:=127; abySubCodeNo[4]:=0; anValue[4]:=1; abyFraction[4]:=0;

byNoOfParameter : BYTE;

awCodeNo : ARRAY [1..45] OF WORD;

abySubCodeNo : ARRAY [1..45] OF BYTE;

abyFraction : ARRAY [1..45] OF BYTE;

anValue : ARRAY [1..45] OF INT;

...

Fig. 3−1 Example: Source code (extract) of a new FB based on the FB L_8200Parameter

L

Lenze8200Drive.lib EN 1.0

3−3

Page 16

Function library Lenze8200Drive.lib

Functions/function blocks

3.1 L_8200Parameter − Initialisation of codes

No. Code Subcode Setting Info/meaning

1 C0011 0 50 Maximum output frequency = 50 Hz (default setting)

2 C0012 0 0.1 Main setpoint acceleration time; Tir = 0.1 s (default setting)

3 C0013 0 0.1 Main setpoint deceleration time; Tif = 0.1 s (default setting)

4 C0127 0 1 Normalised setpoint selection

5 C0356 2 50 CAN2−OUT cycle time = 50 ms

j6 C0410 1 70 NSET1−JOG1/3 ð CAN−IN2−W1−BIT0

7 C0410 2 71 NSET1−JOG2/3 ð CAN−IN2−W1−BIT1

8 C0410 3 72 DCTRL1−CW/CCW ð CAN−IN2−W1−BIT2

9 C0410 4 73 DCTRL1−QSP ð CAN−IN2−W1−BIT3

10 C0410 5 74 NSET1−RFG1−STOP ð CAN−IN2−W1−BIT4

11 C0410 j6 75 NSET1−RFG1−0 ð CAN−IN2−W1−BIT5

12 C0410 7 76 MPOT1−UP ð CAN−IN2−W1−BIT6

13 C0410 8 77 MPOT1−DOWN ð CAN−IN2−W1−BIT7

14 C0415 1 108 RELAY−K1 ð CAN−IN2−W1−BIT8

15 C0410 10 79 DCTRL1−CINH ð CAN−IN2−W1−BIT9

16 C0410 11 80 DCTRL1−TRIP−SET ð CAN−IN2−W1−BIT10

17 C0410 12 81 DCTRL1−TRIP−RESET ð CAN−IN2−W1−BIT11

18 C0410 13 82 DCTRL1−PAR 2/4 ð CAN−IN2−W1−BIT12

19 C0410 14 83 DCTRL1−PAR 3/4 ð CAN−IN2−W1−BIT13

20 C0410 15 84 MCTRL1−DCB ð CAN−IN2−W1−BIT14

21 C0410 16 85 PCTRL1−RFG2−LOAD−I (A) ð CAN−IN2−W1−BIT15

22 C0412 1 31 NSET1−N1 ð CAN−IN2−W2

23 C0412 8 32 MCTRL−VOLT−ADD ð CAN−IN2−W3

24 C0418 1 16 CAN−OUT2−BIT0 ð DCTRL1−RDY

25 C0418 2 2 CAN−OUT2−BIT1 ð DCTRL1−IMP

26 C0418 3 3 CAN−OUT2−BIT2 ð MCTRL−IMAX

27 C0418 4 4 CAN−OUT2−BIT3 ð DCTRL−RFG1=NOUT

28 C0418 5 5 CAN−OUT2−BIT4 ð NSET−RFG1−I=0

29 C0418 j6 j6 CAN−OUT2−BIT5 ð PCTRL−QMIN

30 C0418 7 7 CAN−OUT2−BIT6 ð DCTRL1−NOUT=0

31 C0418 8 8 CAN−OUT2−BIT7 ð DCTRL1−CINH

32 C0418 9 25 CAN−OUT2−BIT8 ð DCTRL1−TRIP

33 C0418 10 9 CAN−OUT2−BIT9 ð FIXED−RESERVE−9

34 C0418 11 10 CAN−OUT2−BIT10 ð FIXED−RESERVE−10

35 C0418 12 11 CAN−OUT2−BIT11 ð FIXED−RESERVE−11

36 C0418 13 12 CAN−OUT2−BIT12 ð FIXED−RESERVE−12

37 C0418 14 13 CAN−OUT2−BIT13 ð DCTRL1−OH−WARN

38 C0418 15 14 CAN−OUT2−BIT14 ð DCTRL1−OV

39 C0418 16 15 CAN−OUT2−BIT15 ð DCTRL1−CCW

40 C0421 8 0 CAN−OUT2−W2 ð MCTRL1−NOUT+SLIP

41 C0003 0 1 Dynamic parameter set changes

42 not assigned

43 not assigned

44 not assigned

45 not assigned

Tab. 3−1 Parameter pre−assignment contained as a comment in the FB L_8200Parameter.

3−4

Lenze8200Drive.lib EN 1.0

L

Page 17

Function library Lenze8200Drive.lib

Functions/function blocks

3.1 L_8200Parameter − Initialisation of codes

Concept II: Parameterisation by means of codes

If the FB outputs are assigned to user codes in the PLC, it is possible to select the corresponding

frequency inverter parameters directly via the Parameter Monitor.

Note!

With this concept, it is possible to use an instance of the FBL_8200Parameter instead of a copy.

Please observe that all parameter values must be selected under the corresponding

codes/subcodes before starting the program.

Proceed as follows:

1. Create an instance of the FB L_8200Parameter.

2. Use the Instance Parameter Manager to assign user codes to the outputs of the instance.

3. Compile the project to ensure that the codes/subcodes will be available for parameterisation

in the Parameter Monitor.

Example I: Assignment of identical parameters to a number of frequency inverters

If you want to assign the same parameters to a number of frequency inverters, you only need one FB

with the selected parameters.

StartInit

DefaultParameter InitDevice12

1

2

3

4

5

6

7

8

9

...

45

Code SubCode

Fraction Value

L_8200Parameter

byNoOfParameter

awCodeNo

abySubCodeNo

abyFraction

anValue

TRUE

12

TRUE

20

bExecute

bSelectSDO2Channel

byNodeAddr

byNoOfParameter

awCodeNo

abySubCodeNo

abyFraction

anValue

bExecute

bSelectSDO2Channel

byNodeAddr

byNoOfParameter

awCodeNo

abySubCodeNo

abyFraction

anValue

L_8200Initialization

CTRL

DATA

InitDevice20

L_8200Initialization

CTRL

DATA

nState

bParDone

L

System

bus

(CAN)

8200

Node address = byNodeAddr

nState

bParDone

L

System

bus

(CAN)

8200

Node address = byNodeAddr

InitReady

L

Lenze8200Drive.lib EN 1.0

3−5

Page 18

Function library Lenze8200Drive.lib

Functions/function blocks

3.1 L_8200Parameter − Initialisation of codes

Example II: Assignment of different parameters to a number of frequency inverters

If you want to asssign different parameters to a number of frequency inverters, you need a

corresponding number of FBs.

Parameter82Device12 InitDevice12

1

2

3

4

5

6

7

8

9

...

45

Code SubCode

Fraction Value

byNoOfParameter

awCodeNo

abySubCodeNo

abyFraction

anValue

StartInit

TRUE

12

bExecute

bSelectSDO2Channel

byNodeAddr

byNoOfParameter

awCodeNo

abySubCodeNor

abyFraction

anValue

L_8200Initialization

CTRL

System

bus

(CAN)

DATA

Node address = byNodeAddr

nState

bParDone

L

8200

1

2

3

4

5

6

7

8

9

...

45

Parameter82Device20

Code SubCode

Fraction Value

byNoOfParameter

awCodeNo

abySubCodeNo

abyFraction

anValue

TRUE

20

bExecute

bSelectSDO2Channel

byNodeAddr

byNoOfParameter

awCodeNo

abySubCodeNo

abyFraction

anValue

InitDevice20

L_8200Initialization

CTRL

DATA

nState

bParDone

L

System

bus

(CAN)

8200

Node address = byNodeAddr

InitReady

3−6

Lenze8200Drive.lib EN 1.0

L

Page 19

Function library Lenze8200Drive.lib

Functions/function blocks

3.2 L_8200Initialization − Frequency inverter initialisation

3.2 L_8200Initialization − Frequency inverter initialisation

Function block

This FB is used to initialise the frequency inverter with the parameters which were previously defined

by an instance or copy of the FB L_8200Parameter.

Note!

The FB must be called cyclically because the data are internally transmitted to the frequency inverter

via the FBL_ParWrite.

· Depending on the amount of data to be transmitted, the data transfer may take several cycles.

· If the data transfer has been successful, the message outputbParDone will be set to TRUE.

· When the data transfer has been completed ( bParDone = TRUE), the parameterisation is

complete and the FBsL_8200Parameter and L_8200Initialization need not be called again.

L_8200Initialization

bExecute

bSelectSDO2Channel

byNodeAddr

byNoOfParameter

awCodeNo

abySubCodeNo

abyFraction

anValue

FB call in: o Cyclic task

(PLC_PRG)

Inputs Data type Information/possible settings

bExecute Bool Start data transfer to the frequency inverter

bSelectSDOChannel Bool Select the parameter channel for the frequency inverter

byNodeAddr Byte Device address (1 ... 63) of the frequency inverter to be initialised.

þ Time−controlled task

FALSE

ä TRUE

FALSE SDO 1

TRUE SDO 2

CTRL

DATA

(INTERVAL)

Start data transfer

System

bus

(CAN)

Node address = byNodeAddr

o Event−controlled task

nState

bParDone

L

8200

(EVENT)

· See also chapter 2.2.1. ( ^ 2−3)

byNoOfParameter Byte Transfer of the number of parameters to be transmitted

awCodeNo Array of Word Code transfer

abySubCodeNo Byte array Subcode transfer

abyFraction Byte array Transfer of decimal places

· See also FB description L_ParWrite

in the Manual Function library LenzeDrive.lib.

anValue Array of

integers

Transfer of code values

o Interrupt task

L

Lenze8200Drive.lib EN 1.0

3−7

Page 20

Function library Lenze8200Drive.lib

Functions/function blocks

3.2 L_8200Initialization − Frequency inverter initialisation

Outputs Data type Value/meaning

nState Integer Status

Status messages:

0 Data were transferred, frequency inverter has been initialised.

1 Data transfer is active.

Error messages:

2001 An error occurred during bus transfer.

2002 Time−out occurred during data transfer.

2004 Access denied − wrong target system:

Subindex does not exist.

2005 Access denied − wrong target system:

Index does not exist.

2013 Access denied − wrong target system:

Invalid range of values.

2111 Access denied − wrong target system:

In excess of 4 decimal places specified or no fixed−comma−format index.

2117 Communication channel does not exist.

· Check PLC code C2118

(transmission channel for CAN parameter communication).

bParDone Bool Message Data transfer has been completed"

TRUE Data transfer has been successful.

Example: Frequency inverter initialisation with preselected parameters

In the following example, a frequency inverter with the system bus node address 12 is initialised with

the parameters preselected in the FB L_8200Parameter. Afterwards, another frequency inverter with

the system bus node address 20 is initialised with the same parameters.

Note!

Before communication with the PLC, carry out the following steps:

1. Load the factory settings.

(For the 8200vector frequency inverter, e. g. under code C0002)

2. Select the correct system bus node address.

(For the 8200vector frequency inverter, e. g. under code C0350)

– More information about the node address assignment can be found in chapter 2.2.1.

3. Carry out a reset node to accept the new communication settings of the system bus interface.

(For the 8200vector frequency inverter, e. g. under code C0358)

After this, carry out the following steps in the Drive PLC Developer Studio:

1. Use the Library Manager to integrate function libraries Lenze8200Drive.lib, LenzeDrive.lib

and LenzeCanDrv.lib in your project.

2. Create a new FB called "DefaultParameter82" and copy the source code of the FB

L_8200Parameter to the new FB DefaultParameter82.

3. Remove the comment characters around the assignments in the FB DefaultParameter82 so

that the assignments will become valid for the compiler.

(^ 2−3)

3−8

Lenze8200Drive.lib EN 1.0

L

Page 21

Function library Lenze8200Drive.lib

Functions/function blocks

3.2 L_8200Initialization − Frequency inverter initialisation

4. Create two instances of the FB L_8200Initialization.

5. Integrate the FBs either directly in the main program PLC_PRG or in a program which is

cyclically activated by PLC_PRG and combine the FBs as follows:

StartInit

DefaultParameter82 InitDevice12

1

2

3

4

5

6

7

8

9

...

45

Code SubCode

Fraction Value

byNoOfParameter

awCodeNo

abySubCodeNo

abyFraction

anValue

TRUE

12

TRUE

20

bExecute

bSelectSDO2Channel

byNodeAddr

byNoOfParameter

awCodeNo

abySubCodeNo

abyFraction

anValue

bExecute

bSelectSDO2Channel

byNodeAddr

byNoOfParameter

awCodeNo

abySubCodeNo

abyFraction

anValue

L_8200Initialization

CTRL

DATA

InitDevice20

L_8200Initialization

CTRL

DATA

L

System

bus

(CAN)

8200

Node address = byNodeAddr

L

System

bus

(CAN)

8200

Node address = byNodeAddr

nState

bParDone

nState

bParDone

InitReady

Fig. 3−2 Links between the FBs

Initialisation process

· Use the FB DefaultParameter82 which is based on the FB L_8200Parameter and transmit

the parameters to the instances of the FB L_8200Initialization.

· Set StartInit to TRUE to start the initialisation and transfer the data via parameter channel

SDO2 to the frequency inverter with the node address 12.

· If all data were transmitted, the output bParDone of the instance "InitDevice12" will be set to

TRUE. This is the start signal for the data transfer to the second frequency inverter with the

node address 20.

· If the data were successfully transmitted to the second frequency inverter, the variable

InitReady will be set to TRUE. This signal can, for instance, be used to start the process data

transfer via the FB L_8200DataControl.

· After data transfer has been successful (InitReady = TRUE), the FB need not be activated

again.

L

Lenze8200Drive.lib EN 1.0

3−9

Page 22

Function library Lenze8200Drive.lib

Functions/function blocks

3.3 L_8200DataControl − Send/receive process data

3.3 L_8200DataControl − Send/receive process data

Function block

This FB is used to exchange process data with the frequency inverter.

· The FB internally uses a free CAN send and receive object. It is therefore possible to transmit

and receive 8 bytes of user data.

Note!

For the provision of free CAN send and receive objects, function library LenzeCanDrv.lib must be

integrated in the project.

· For data exchange via the free CAN objects the driver for the free CAN objects must be

initialised in a program (e. g. "PLC_ColdStart").

The FB L_8200DataControl must be called in a task−controlled program.

L_8200DataControl

bEnable

bResetNode

byNodeAddr

tCycleTime

tTimeOut

bResetFail

wControlData

nNSetN1_a

wBoostVoltage

wInputData

FB call in: o Cyclic task

(PLC_PRG)

Inputs Data type Information/possible settings

bEnable Bool Start process data transfer

FALSE ä TRUE Start process data transfer.

bResetNode Bool Carry out a Reset−Node in the frequency inverter.

þ Time−controlled task

CTRL

data bytes:

1+2

1+2

3+4

3+4

5+6

5+6

7+8

7+8

CAN2_OUT CAN2_IN

System bus (CAN)

Node address = byNodeAddr

(INTERVAL)

nStateDataTo82

nStateDataFrom82

bFail_DataTo82

bFailDataFrom82

wStatusData

nMCtrl_Nout_Slip

wOutputData3

wOutputData4

L

8200

o Event−controlled task

(EVENT)

o Interrupt task

· After a Reset−Node, the frequency inverter accepts the parameter settings which are relevant for

communication and changes to "Operational".

· The Reset−Node is only carried out in the frequency inverter with device address byNodeAddr.

FALSE ä TRUE Carry out Reset−Node.

byNodeAddr Byte Device address (1 ... 63) of the frequency inverter with which process data are to be exchanged.

tCycleTime Time Cycle time for sending the process data to the frequency inverter.

tTimeOut Time Monitoring time (time−out) for receiving the process data from the frequency inverter.

bResetFail Bool Reset message signals for error messages

FALSE ä TRUE The message signals bFail_DataTo82 and bFail_DataFrom82 are reset.

3−10

Lenze8200Drive.lib EN 1.0

L

Page 23

Function library Lenze8200Drive.lib

Functions/function blocks

3.3 L_8200DataControl − Send/receive process data

Information/possible settingsData typeInputs

wControlData Word Process data word (control word) to be sent to the frequency inverter.

nNSetN1_a Integer Speed setpoint selection for the frequency inverter in [Hz]

wBoostVoltage Word Umin increase in the frequency inverter

wInputData Word Send bytes 7 + 8, freely assignable

Outputs Data type Value/meaning

nStateDataTo82 Integer Status of the CAN send object

· Normalised to f

· Normalised to U

Error messages:

−300 Time−out, data transmitted by the frequency inverter are not within the monitoring

−150 System bus (CAN) is not "Operational".

−121 Wrong driver number for CAN driver.

−120 CAN driver currently not initialised.

−119 The transmit command memory is full. The transmit command could not be

−118 There is no free CAN channel available.

−12 The message identifier (COB−ID) is not within the permissible area (internal error).

−11 The pointer pIOAdress does not point to PLC RAM (internal error).

Status messages:

0 The process data were sent to the frequency inverter.

1 The transmit command has not yet been completed and is still in the command

2 Data transfer is inactive.

10 Telegram longer than 8 bytes and limited to 8 bytes.

, i. e. 16384 º 100 % f

max

, i. e. 16384 º 100 % U

r

time tTimeOut.

(C0011) of the frequency inverter

max

of the frequency inverter

r

· Check the initialisation of the CAN driver.

· Check the initialisation of the CAN driver.

entered.

· Increase the activation cycle time of the FB.

memory.

· Frequency inverter parameterisation not yet complete or bEnable is set FALSE.

L

Lenze8200Drive.lib EN 1.0

3−11

Page 24

Function library Lenze8200Drive.lib

Functions/function blocks

3.3 L_8200DataControl − Send/receive process data

Value/meaningData typeOutputs

nStateDataFrom82 Integer Status of the CAN receive object

Error messages:

−300 Time−out, data transmitted by the frequency inverter are not within the monitoring

time tTimeOut.

−150 System bus (CAN) is not "Operational".

−121 Wrong driver number for CAN driver.

· Check the initialisation of the CAN driver.

−120 CAN driver currently not initialised.

· Check the initialisation of the CAN driver.

−12 The message identifier (COB−ID) is not within the permissible area (internal error).

−11 The pointer pIOAdress does not point to PLC RAM (internal error).

Status messages:

0 The process data were received by the frequency inverter.

2 Data transfer is inactive.

· Frequency inverter parameterisation not yet complete or bEnable is set FALSE.

10 Telegram longer than 8 bytes and limited to 8 bytes.

200 Data in receive memory were overwritten.

· Reduce the activation cycle of the FB or increase the data transmission cycle of

the frequency inverter.

bFail_DataTo82 Bool Message Transmit command cancelled or not executed".

TRUE Transmit command was cancelled or not executed.

· The corresponding error number is output at nStateDataTo82.

bFail_DataFrom82 Bool Message Receive command cancelled or not executed".

TRUE Receive command was cancelled or not executed.

· The corresponding error number is output at nStateDataFrom82.

wStatusData Word Process data word (status word) sent by the frequency inverter.

nMCtrl_Nout_Slip Integer Actual frequency inverter speed (including slip) in [Hz].

wOutputData3 Word Receive bytes 5 + 6, freely assignable

wOutputData3 Word Receive bytes 7 + 8, freely assignable

3−12

Lenze8200Drive.lib EN 1.0

L

Page 25

Function library Lenze8200Drive.lib

Functions/function blocks

3.3 L_8200DataControl − Send/receive process data

Process data exchange

If the input bEnable is set to TRUE, the FB L_8200DataControl starts to exchange process data

· The data are exchanged via the identifiers of the process data object CAN2_IO which consist

of the basic identifier and the node address of the frequency inverter selected at the input

byNodeAdr:

Identifier + Basis Identifier ) node address of frequency invertor

Basic identifier

dec hex

CAN2_IO (event or time−controlled process data)

CAN2_IN 640 280

CAN2_OUT 641 281

· If a FALSE−TRUE transition occurs at the input bResetNode, the frequency inverter with the

node address byNodeAdr accepts the data which are relevant for communication and

changes to "Operational".

· The cycle time tCycleTime is used to send the data to the frequency inverter.

Tip!

Process data transfer is only possible if the node address is correct and the frequency inverter is in

the state "Operational".

· Therefore, the input bResetNode should always be set to TRUE.

Assignment of send and receive bytes

Send byte Assignment Receive byte Assignment

1 + 2 Control word wControlData 1 + 2 Status word wStatusData

3 + 4 Setpoint nNSetN1_a 3 + 4 Actual value nMCtrl_Nout_Slip

5 + 6 a

7 + 8 freely assignable via wInputData 7 + 8 freely assignable via wOutputData4

boost wBoostVoltage 5 + 6 freely assignable via wOutputData3

min

L

Lenze8200Drive.lib EN 1.0

3−13

Page 26

Function library Lenze8200Drive.lib

Functions/function blocks

3.3 L_8200DataControl − Send/receive process data

Time monitoring

The input tTimeOut is used to monitor the transfer time of the data received from the frequency

inverter.

· With a time > t#0ms the monitoring is activated, otherwise it is deactivated.

· The monitoring time must be adapted to the cycle and task time of the process data object

CAN2_IO.

Status messages

The status outputs nStateDataTo82 and nStateDataFrom82 indicate the current state of the send

and receive objects.

· If an error occurs, an error number will be indicated and the corresponding message output

bFail_DataTo82 or bFail_DataFrom82 will be set to TRUE.

· The status and message outputs can be reset by setting bReset to TRUE.

· The last message/error number is saved in an internal variable (nLastMessageNo or

nLastFailureNo).

Selection of boolean control signals and output of boolean status messages

· The FB L_8200CtrlWord is used to select the control word to be transmitted as boolean

control signals.

(^ 3−15)

· The FB L_8200StatusWord is used to divide the receive status word for evaluation and further

processing into individual boolean status signals.

bNSET1_JOG13

bNSET1_JOG23

bDCTRL1_CW_CCW

bDCTRL1_QSP

bNSET1_RFG1_STOP

bNSET1_RFG1_0

bMPOT1_UP

bMPOT1_DOWN

bRELAY_K1

bDCTRL1_CINH

bDCTRL1_TRIP_SET

bDCTRL1_TRIP_RESET

bDCTRL1_PAR24

bDCTRL1_PAR34

bMCTRL_DCB

bPCTRL1_RFG2_LOAD_I

L_8200CtrlWord

CTRL

wControlData

bEnable

bResetNode

byNodeAddr

tCycleTime

tTimeOut

bResetFail

wControlData

nNSetN1_a

wBoostVoltage

wInputData

1+2

3+4

5+6

7+8

CAN2_OUT CAN2_IN

L_8200DataControl

CTRL

data bytes:

1+2

3+4

5+6

7+8

System bus (CAN)

Node address = byNodeAddr

(^ 3−16)

nStateDataTo82

nStateDataFrom82

bFail_DataTo82

bFailDataFrom82

wStatusData

nMCtrl_Nout_Slip

wOutputData3

wOutputData4

L

8200

wStatusData

CTRL

L_8200StatusWord

bDCTRL1_RDY

bDCTRL_IMP

bMCTRL_IMAX

bNSET1_RFG1_NOUT

bNSET1_RFG1_I

bPCTRL1_QMIN

bDCTRL_NOUT

bDCTRL1_CINH

bDCTRL1_TRIP

bFIXED_RESERVE_9

bFIXED_RESERVE_10

bFIXED_RESERVE_11

bFIXED_RESERVE_12

bDCTRL1_OH_WARN

bDCTRL1_OV

bDCTRL1_CCW

3−14

Lenze8200Drive.lib EN 1.0

L

Page 27

Function library Lenze8200Drive.lib

Functions/function blocks

3.4 L_8200CtrlWord − Selection of boolean control signals

3.4 L_8200CtrlWord − Selection of boolean control signals

Function block

This FB can be used to select the control word to be sent to the frequency inverter which is expected

by the FB L_8200DataControl at the FB input wControlData as boolean control signals.

L_8200CtrlWord

bNSET1_JOG13

bNSET1_JOG23

bDCTRL1_CW_CCW

bDCTRL1_QSP

bNSET1_RFG1_STOP

bNSET1_RFG1_0

bMPOT1_UP

bMPOT1_DOWN

bRELAY_K1

bDCTRL1_CINH

bDCTRL1_TRIP_SET

bDCTRL1_TRIP_RESET

bDCTRL1_PAR24

bDCTRL1_PAR34

bMCTRL_DCB

bPCTRL1_RFG2_LOAD_I

CTRL

wControlData

FB call in: þ Cyclic task

Inputs Data type Information/possible settings

bNSET1_JOG13 Bool

bNSET1_JOG23 Bool

bDCTRL1_CW_CCW Bool

bDCTRL1_QSP Bool

bNSET1_RFG1_STOP Bool

bNSET1_RFG1_0 Bool

bMPOT1_UP Bool

bMPOT1_DOWN Bool

bRELAY_K1 Bool

bDCTRL1_CINH Bool

bDCTRL1_TRIP_SET Bool

bDCTRL1_TRIP_RESET Bool

bDCTRL1_PAR24 Bool

bDCTRL1_PAR34 Bool

bMCTRL_DCB Bool

bPCTRL1_RFG2_LOAD_I Bool

Outputs Data type Value/meaning

wControlData Word Control word to be sent to the frequency inverter.

(PLC_PRG)

Detailed information about the meaning of the individual control signals can be found in the

Operating Instructions for the 8200 frequency inverter.

Note!

The composition of the control word depends on the parameterisation of the frequency inverter!

· The names of the control signals contained in this Manual have been adapted to the commented

þ Time−controlled task

(INTERVAL)

assignments in the FB L_8200Parameter. ( ^ 3−2)

þ Event−controlled task

· Connect this output with the input wControlData

of the FB L_8200DataControl. ( ^ 3−10)

(EVENT)

o Interrupt task

L

Lenze8200Drive.lib EN 1.0

3−15

Page 28

Function library Lenze8200Drive.lib

Functions/function blocks

3.5 L_8200StatusWord − Output of boolean status signals

3.5 L_8200StatusWord − Output of boolean status signals

Function block

This FB is used to divide the status word received by the frequency inverter which is provided by the

FB L_8200DataControl at the FB output wStatusData into boolean status signals.

L_8200StatusWord

bDCTRL1_RDY

bDCTRL_IMP

bMCTRL_IMAX

CTRL

wStatusData

bNSET1_RFG1_NOUT

bNSET1_RFG1_I

bPCTRL1_QMIN

bDCTRL_NOUT

bDCTRL1_CINH

bDCTRL1_TRIP

bFIXED_RESERVE_9

bFIXED_RESERVE_10

bFIXED_RESERVE_11

bFIXED_RESERVE_12

bDCTRL1_OH_WARN

bDCTRL1_OV

bDCTRL1_CCW

FB call in: þ Cyclic task

(PLC_PRG)

Inputs Data type Information/possible settings

wStatusData Word Status word received by the frequency inverter.

þ Time−controlled task

(INTERVAL)

þ Event−controlled task

· Connect this input with the output wStatusData

of the FB L_8200DataControl. ( ^ 3−10)

Outputs Data type Value/meaning

bDCTRL1_RDY Bool

bDCTRL_IMP Bool

bMCTRL_IMAX Bool

bNSET1_RFG1_NOUT Bool

bNSET1_RFG1_I Bool

bPCTRL1_QMIN Bool

bDCTRL_NOUT Bool

bDCTRL1_CINH Bool

bDCTRL1_TRIP Bool

bFIXED_RESERVE_9 Bool

bFIXED_RESERVE_10 Bool

bFIXED_RESERVE_11 Bool

bFIXED_RESERVE_12 Bool

bDCTRL1_OH_WARN Bool

bDCTRL1_OV Bool

bDCTRL1_CCW Bool

Detailed information about the meaning of the individual status signals can be found in the

Operating Instructions for the 8200 frequency inverter.

Note!

The composition of the status word depends on the parameterisation of the frequency inverter!

· The names of the status signals contained in this Manual have been adapted to the commented

assignments in the FB L_8200Parameter.( ^ 3−2)

(EVENT)

o Interrupt task

3−16

Lenze8200Drive.lib EN 1.0

L

Loading...

Loading...