Secure Managed Client

-

Storage Array User Guide

Machine Type 8332

Secure Manag ed Client - Sto rag e Array

User Guid e

Note

Before using this information and the product it supports, be sure to read the Safety and Warranty Guide that came with this

product.

First Edition (October 2008)

© Copyright Lenovo 2005, 2008. All rights reserved.

LENOVO products, data, computer software, and services have been developed exclusively at private expense and

are sold to governmental entities as commercial items as defined by 48 C.F.R. 2.101 with limited and restricted

rights to use, reproduction and disclosure.

LIMITED AND RESTRICTED RIGHTS NOTICE: If products, data, computer software, or services are delivered

pursuant a General Services Administration ″GSA″ contract, use, reproduction, or disclosure is subject to restrictions

set forth in Contract No. GS-35F-05925.

Contents

Introduction . . . . . . . . . . . . .v

Product contents, order options, and accessories . .v

Chapter 1. Important safety information 1

Chapter 2. Features . . . . . . . . . .3

Enclosure subsystem . . . . . . . . . . . .4

Enclosure chassis . . . . . . . . . . . . .5

Server board subdivision . . . . . . . . . .6

Server board I/O panel . . . . . . . . . .6

Front operator's panel . . . . . . . . . . .7

Rear panel . . . . . . . . . . . . . . .8

Power supply unit . . . . . . . . . . . .8

Power supply output connectors . . . . . . .9

Cooling fans . . . . . . . . . . . . . .9

Drive carrier module . . . . . . . . . . .10

Drive status indicator . . . . . . . . . .11

Anti-tamper locks . . . . . . . . . . .11

Chapter 3. Getting Started . . . . . .13

Planning your installation . . . . . . . . .13

Drive bay numbering convention . . . . . . .13

Enclosure installation prerequisites . . . . . .14

Preparation of site and host server . . . . . .14

Unpacking the enclosure system . . . . . .14

Planning and configuring your installation . . .15

Rack installation prerequisites . . . . . . .15

Installing the enclosure in a rack . . . . . . .16

Rail kit assembly . . . . . . . . . . .16

Enclosure installation . . . . . . . . . .16

Power cord connection . . . . . . . . . .17

Grounding checks . . . . . . . . . . .17

Chapter 4. Operation . . . . . . . . .19

Power on . . . . . . . . . . . . . . .19

Power supply unit LED . . . . . . . . .19

Front operator's panel LEDs and switches . . . .20

Starting the drives . . . . . . . . . . . .21

Disk drive LEDs . . . . . . . . . . . .21

Engaging the drive module anti-tamper locks . .21

BIOS settings . . . . . . . . . . . . . .22

Turning off . . . . . . . . . . . . . .22

Chapter 5. Troubleshooting and

problem solving . . . . . . . . . . .23

Initial start-up problems . . . . . . . . . .23

Faulty cords . . . . . . . . . . . . .23

Alarm sounds and power up . . . . . . .23

Computer doesn't recognize the subsystem . . .23

LEDs . . . . . . . . . . . . . . . .23

Power supply units . . . . . . . . . . .23

Front operator's panel . . . . . . . . . .24

Cooling fan LEDs . . . . . . . . . . .25

Drive carrier module LEDs . . . . . . . .25

Rear panel LED . . . . . . . . . . . .25

Server board LEDs . . . . . . . . . . .25

Audible alarms . . . . . . . . . . . . .26

Alarm interpretation . . . . . . . . . . .26

Troubleshooting . . . . . . . . . . . . .28

System faults . . . . . . . . . . . . .28

Power supply unit faults . . . . . . . . .28

Cooling fan faults . . . . . . . . . . .29

Thermal cooling . . . . . . . . . . . .29

Drive carrier module faults . . . . . . . . .30

Dealing with hardware faults . . . . . . . .30

Continuous operation during replacement . . . .31

Chapter 6. Notices . . . . . . . . . .33

Trademarks . . . . . . . . . . . . . .34

© Copyright Lenovo 2005, 2008 iii

iv User Guide

Introduction

The Secure Managed Client (SMC) - Storage Array is a 2U (rack space) disk drive

enclosure, currently housing 12 low-profile 2.54-cm (1-inch) high, 1.5/3.0 Gb/s,

8.89-cm (3.5-inch) form factor SATA disk drives. Each individual disk drive is field

replaceable.

This guide is written for system technicians who are responsible for setting up,

installing, and troubleshooting this storage system. This document provides a brief

overview of the features of this product, a list of accessories or other components

you may need, instructions on setting up the system, and troubleshooting

information.

Product contents, order options, and accessories

The SMC - Storage Array ships with the following items:

v Secure Managed Client (SMC) - Storage Array Setup Poster, in the product box

v AC power cord(s) (North America only)

v 50 Phillips head screws

v Resource CD

v Rail kit

v T10 TORX screwdriver

v 12 hard drive labels

information about which accessories and third-party hardware have been

For

tested and can be used with your storage system, and for ordering information for

Lenovo products, visit http://www.lenovo.com.

© Copyright Lenovo 2005, 2008 v

vi User Guide

Chapter 1. Important safety information

CAUTION:

Before using this manual, it is important that you read and understand all the

related safety information for this product. Refer to the Safety and Warranty Guide

that you received with this product for the latest safety information. Reading

and understanding this safety information reduces the risk of personal injury

and or damage to your product.

© Copyright Lenovo 2005, 2008 1

2 User Guide

Chapter 2. Features

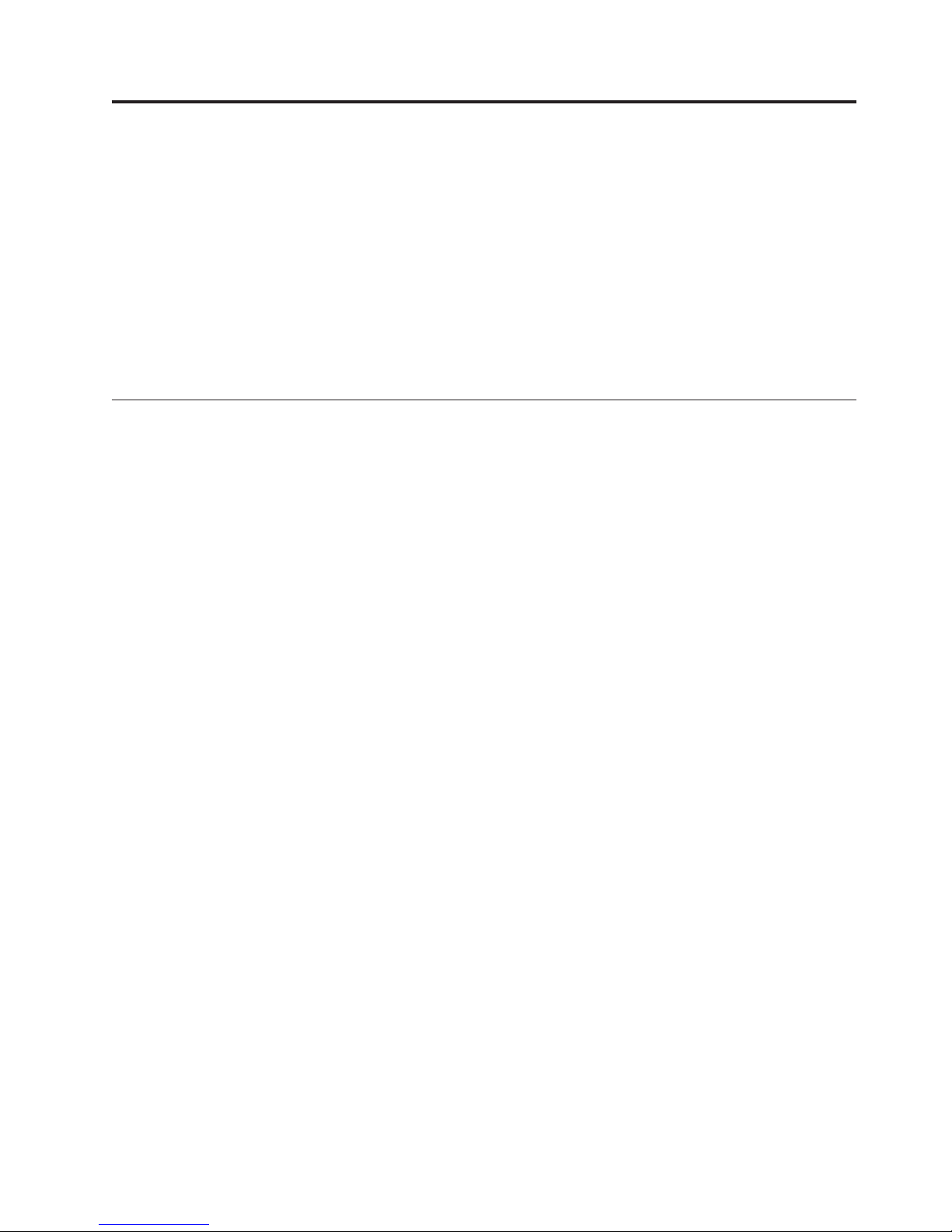

Figure 1 shows a front view of the Secure Managed Client (SMC) - Storage Array

while Figure 2 shows a rear view with the lid removed, showing those areas

accessible to service personnel only.

Figure 1. SMC - Storage Array front view

Figure 2. SMC - Storage Array rear view, showing service areas

1 SAS expander card

2 Power supply unit

3 Cooling fans (10)

4 Boot drive

5 Server board

6 PCI slots

© Copyright Lenovo 2005, 2008 3

Enclosure subsystem

The SMC - Storage Array design concept is based on an enclosure subsystem

together with a set of plug-in modules and (as supplied) consists of:

v An enclosure chassis with:

– A backplane PCB

– An enclosure management PCB

– A SAS expander PCB, to branch from 4 to 12 SAS ports, supporting SATA

tunnelling protocol

– A front operator's panel

– An integral rear panel, incorporating an enclosure ID LED

– A power supply mounting cage containing one 850-W plug-in power supply

unit (PSU)

Note:

A server subsystem comprising:

v

– An Intel Server Board S5000PSL with integral I/O panel

– An Intel RAID Controller SRCSATAWB

– A boot drive module

A cooling module containing 10 high-speed, single-rotor axial fans, which are

v

individually pluggable

v 12 SATA hard drives

A blanking plate must be installed over the empty upper bay.

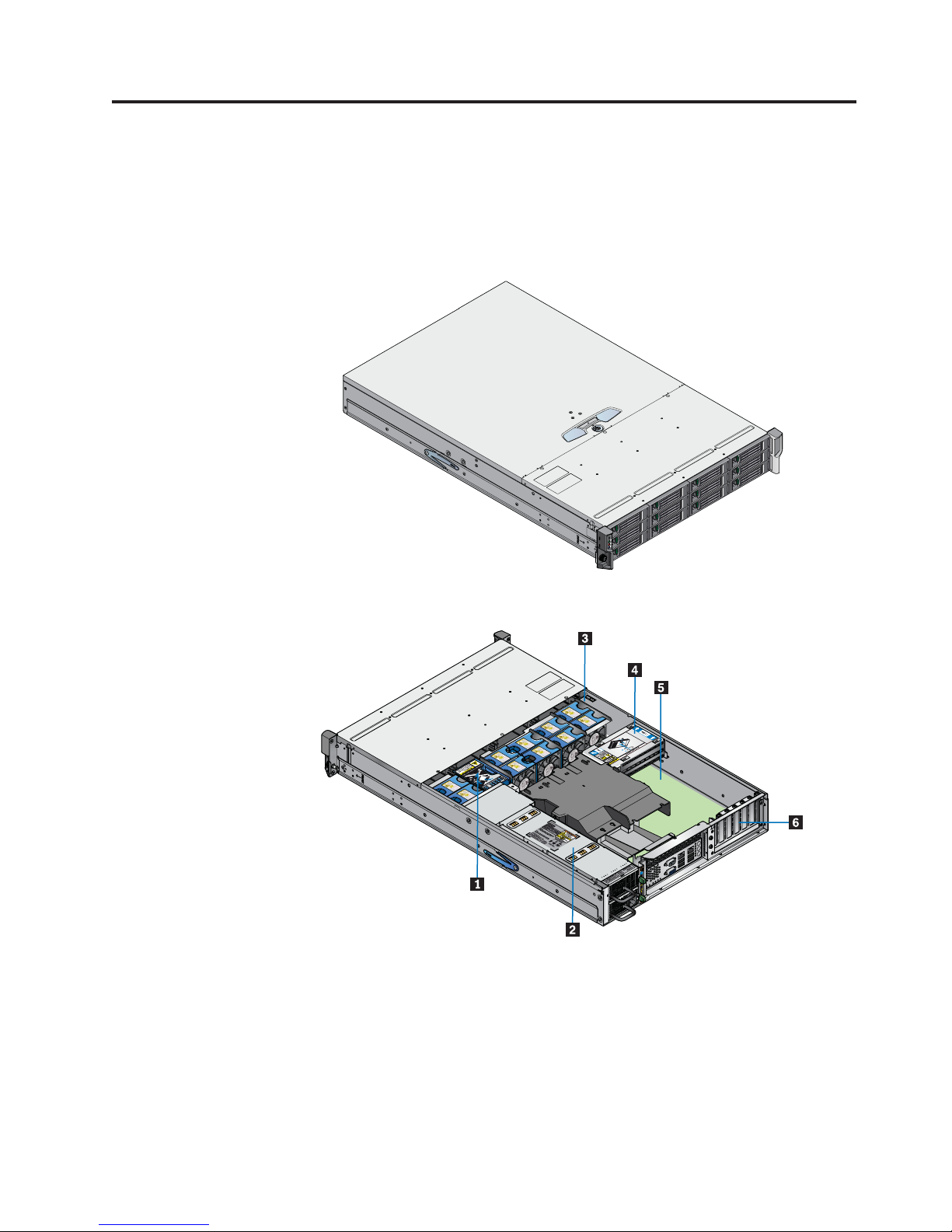

Figure 3. Enclosure subsystem rear view

1Empty power supply bay 11USB port 1

2PS2 mouse port 12USB port 3

3System status LED 13USB port 2

4MSB (POST LED) 14Video port

5Bit 1 (POST LED) 15LSB (POST LED)

6Serial port 16Bit 2 (POST LED)

7NIC port 1 (1 Gb) 17PS2 keyboard

8NIC port 2 (1 Gb) 18ID LED

92 dual-port Ethernet cards 19Power supply unit 1

10USB port 0

4 User Guide

Figure 4. Enclosure subsystem front view

1Front panel

2Drive bays

3Rack retaining screw

4Rack retaining screw

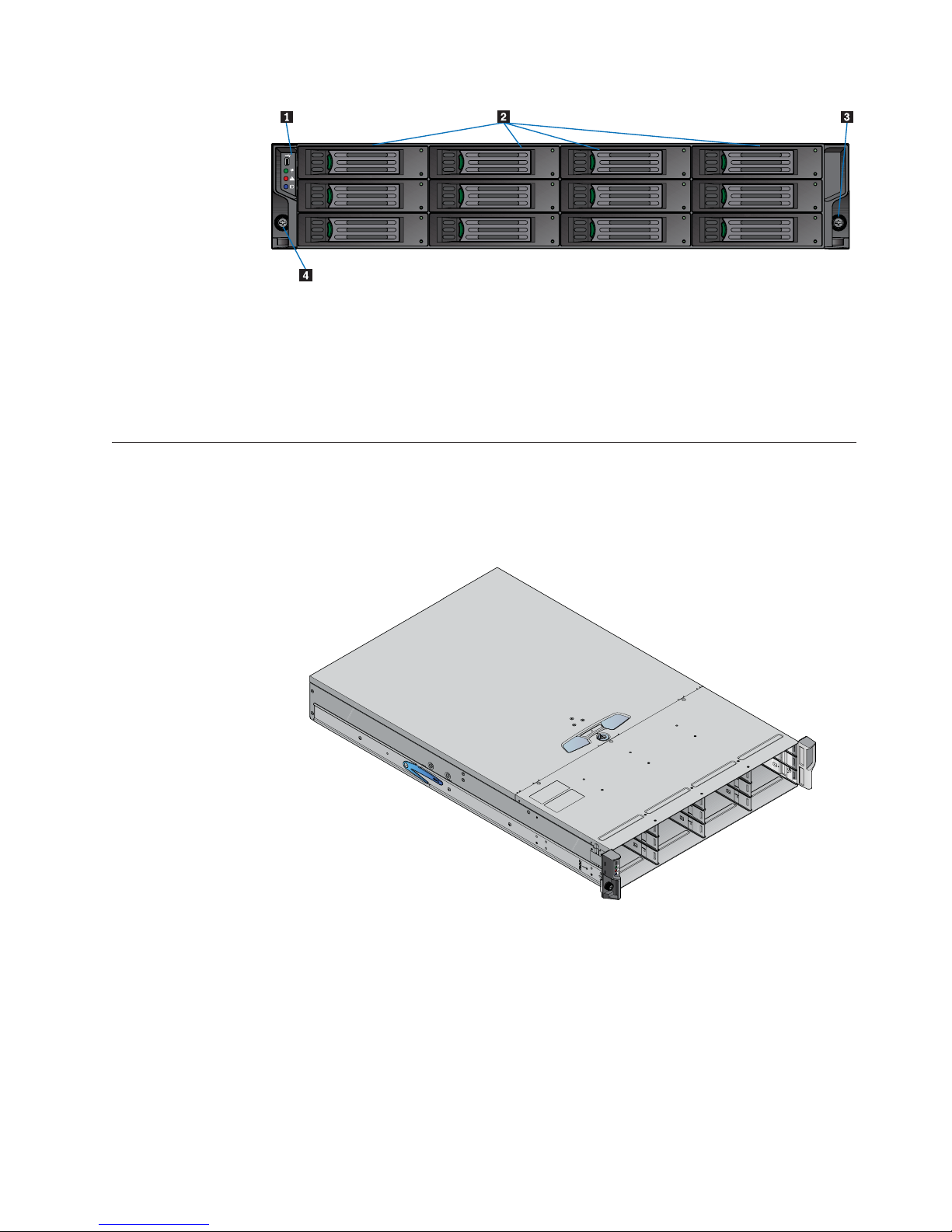

Enclosure chassis

The chassis is installed with 48.26-cm (19-inch) rack-mounting features, which

enable it to be installed to standard 48.26-cm (19-inch) racks. One chassis occupies

two units of rack space (3.5 inches or 8.89 cm high).

Figure 5. Enclosure chassis

The backplane PCB provides 12 direct dock SAS/SATA connectors to the drives

and acts as the connectivity hub of the enclosure, connecting to the enclosure

management PCB.

The ten cooling fans are connected to the system by the enclosure management

PCB.

There are 12 drive bays at the front of the enclosure. Each drive bay accommodates

a plug-in drive carrier module that can house one low-profile 2.54-cm (1-inch) high

Chapter 2. Features 5

8.89-cm (3.5-inch) form factor drive. In addition, two 6.35-cm (2.5-inch) boot drives

can be installed in the boot drive module.

A bay is defined as the space required to house a single 2.54-cm (1.0-inch)

Note:

high 8.89-cm (3.5-inch) disk drive in its carrier module (limitation of 1 TB

size).

At the rear, the chassis assembly accommodates one PSU and a server board

subsystem.

A top cover on the enclosure provides access to the cooling fans and the server

board subsystem.

The enclosure cover should only be removed by qualified service personnel

Note:

as it provides access to a service area. Upon replacement, the cover MUST

be secured by tightening the lock mechanism to the locked position with a

screwdriver.

Figure 6. Locking the enclosure cover

Server board subdivision

The server board subdivision consists of:

v An Intel Server Board S5000PSL

v Slots for up to six low-profile 1.905-cm (3/4-inch) PCI cards, installed in a

vertical orientation. The following PCBs are installed as standard configuration:

– An Intel RAID Controller SRCSATAWB, in the left-hand slot (when viewed

from the rear)

v A boot drive module, which contains two 6.35-cm (2.5-inch) SATA boot drives

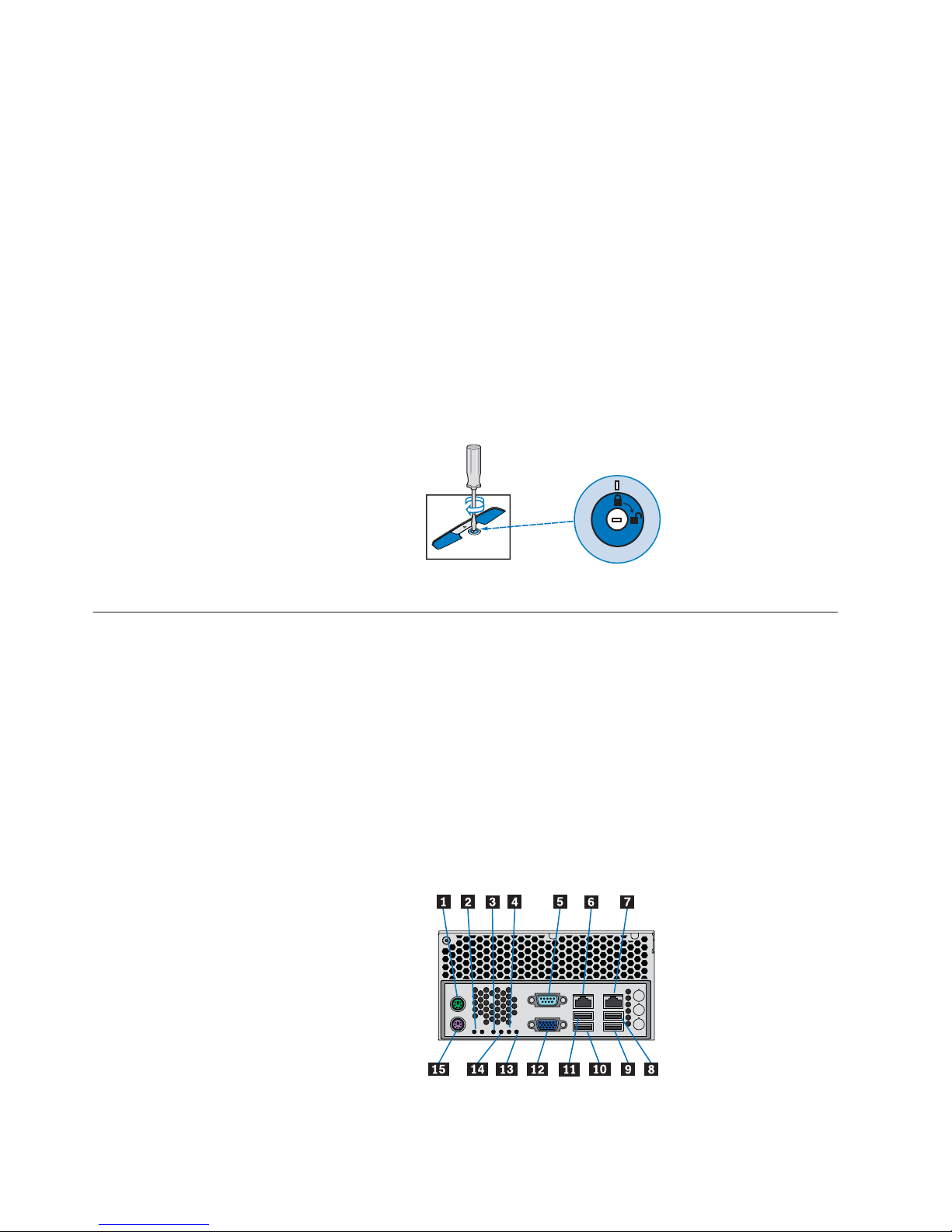

Server board I/O panel

The server board I/O panel consists of various connectors and LEDs.

Figure 7. Server board I/O panel connectors

6 User Guide

1PS2 mouse port 9Bit 2 (POST LED)

2System status LED 10LSB (POST LED)

3MSB (POST LED) 11Video port

4Bit 1 (POST LED) 12USB port 2

5Serial port 13USB port 3

6NIC port 1 (1 Gb) 14USB port 1

7NIC port 2 (1 Gb) 15USB port 0

8PS2 keyboard

Connectors

The following connectors are located on the server board I/O panel:

v PS2 mouse port

v PS2 keyboard port

v Serial port

v Video port

v Tw o RJ-45 ports - NICs 1 and 2 (1Gb each)

v Four USB ports: 0, 1, 2, and 3

Server board LEDs

Status LEDs: Diagnostic LEDs are located on the server board I/O panel to assist

in identifying failed and failing components. See “Server board LEDs” on page 25

for a summary of status LED states.

NIC LEDs: The NIC LEDs at the right and left of each NIC port provide

information on NIC status. See “I/O panel NIC LEDs” on page 25 for a summary

of NIC LED states.

Front operator's panel

A front operator ’s panel, consisting of a USB port, three LEDs and three

push-button switches, are located on the front of the enclosure.

The front operator’s panel is an integral part of the enclosure assembly and

Note:

is not field replaceable.

Figure 8. Front operator’s panel components

1USB port 5Power active LED

2Unit fault LED 6ID LED

Chapter 2. Features 7

Rear panel

3On/off switch 7Reset button (recessed)

4ID LED activation switch

Table 1. Functions of front operator's panel LEDs and switches

LED Push-button switch USB Port

Power Active (Green) Power On/Off Intended for service use only.

Unit Fault (Amber) Reset Button Intended for service use only.

Enclosure ID (Blue) Enclosure ID LED Activation Intended for service use only.

For a full description of LED and switch functions, see “Front operator's panel

LEDs and switches” on page 20.

A rear panel, consisting of a blue enclosure ID LED (see Figure 2 on page 3), is

located on the rear of the enclosure.

Note: The rear panel is an integral part of the enclosure assembly and is not field

replaceable.

Table 2. Rear Panel ID LED Status

Enclosure ID LED Blue (when activated) Activated by push button on

Power supply unit

AC-DC power is provided by a power supply with specific load capability,

mechanical packaging, and output connectors to suit this product.

A power supply mounting cage is installed in the rear of the enclosure as part of

the subsystem core product. The cage houses one individually hot pluggable

850-W AC power supply unit (PSU) with its own IEC inlet connector and failure

indicator.

the Front Operator's Panel,

or by system software.

Used to identify a server

from among several servers.

8 User Guide

Figure 9. Power supply unit

Power supply unit voltage operating ranges are nominally 100V - 240V AC,

selected automatically.

Power supply output connectors

Cooling fans

The PSU has an audible alarm to indicate a fault state and a bi-color (green/red)

LED to indicate PSU status.

The power supply output connectors provide the following outputs:

v P1 server board main power connector (1 x 24 pin)

v P2 processor power connector (8 pin)

v P3 12-V power connector

v P4 peripheral power connector (2 x 4 pin)

v P5 PSU1 connector (5 pin)

Ten high-speed single-rotor axial fans are housed in a cooling cage, located

centrally within the enclosure, between the drive bays and the server board, as

shown in Figure 2 on page 3. This ensures maximum airflow through the PSU and

minimizes noise.

Chapter 2. Features 9

Figure 10. Cooling fan

Airflow is front to rear with cooling air being drawn across the drives, through the

fans and pressurizing the rear of the enclosure. The pressurized rear allows the

PSU to draw the air that it requires; perforations at the rear of the chassis allow

cooling air to flow over the processor heatsinks, server board and PCI cards.

The cooling system must be operated with low-pressure rear exhaust installation

(back pressure created by rack doors and obstacles not to exceed 5 pascals [0.5mm

Water gauge]).

The cooling system provides sufficient capacity to ensure that drive maximum

temperatures have not exceeded at 35°C (95°F) with one failing fan at sea level.

The cooling cage contains ten individual high-speed single-rotor axial fans,

individually connected to and interfacing with the enclosure management PCB.

This interface provides power and speed control to the fans and returns speed

output from each fan to the management system.

Drive carrier module

The drive carrier module consists of a hard disk mounted in a drive carrier. Each

drive bay can house a single low-profile 2.54-cm (1.0-inch) high, 8.89-cm (3.5-inch)

form factor SATA disk drive in its drive carrier. The drive carrier has mounting

locations for SATA drives.

Each disk drive is enclosed in a sheet steel carrier which provides excellent thermal

conduction, radio frequency and electro-magnetic induction protection, as well as

affords the drive with maximum physical protection.

The front cap of the drive carrier supports an ergonomic handle, which provides

the following functions:

v Camming of drive carrier into and out of drive bays.

v Positive "spring loading" of the drive/backpane connector.

10 User Guide

Figure 11 . Driver carrier module

Drive status indicator

Disk drive status, under ESI processor control, is monitored by two LEDs (a green

LED and an amber LED) mounted on the front cap of each drive carrier module.

See “Disk drive LEDs” on page 21 for a description of LED states.

Figure 12. Drive status LEDs and components

1Green LED

2Amber LED

3Torque screw

4Drive lock indicator opening

Anti-tamper locks

Anti-tamper locks are installed in each drive carrier handle and are accessed with a

TORX screwdriver through the small cutout in the latch section of the handle.

When activated, the locks disable the normal "pinch" latch action of the drive

carrier handle. A drive is locked when the red lock symbol appears in the indicator

opening.

Chapter 2. Features 11

12 User Guide

Chapter 3. Getting Started

In this chapter, you are shown how to plan and install your Secure Managed Client

(SMC) - Storage Array into an industry standard 48.26-cm (19-inch) rack cabinet.

CAUTION:

When connecting the SMC - Storage Array, use only the power cords supplied or

power cords that match the specification quoted in the Safety and Warranty Guide.

Planning your installation

Before installing the SMC - Storage Array, familiarize yourself with the

configuration requirements listed in the following table.

CAUTION:

Installation procedures should be performed by trained personnel only.

Table 3. Configuration requirements

Module Location

Drive bays All drive bays must be installed with either

a drive carrier module or a dummy drive

carrier module. No bays should be left

empty. A minimum of 1 drive must be

installed.

Power supply One PSU can be installed. A blanking plate

must be installed to cover the empty (top)

slot.

Cooling fans Ten fans, housed in a cooling cage, are

located centrally within the enclosure

between the drive bays and the server

board.

PCI cards Up to six PCI cards can be installed in a

vertical orientation. Currently, only the two

outer card slots are used in the standard

configuration, installed with an Intel® RAID

Controller SRCSAS144E and an Intel

®

Intelligent AXXRIBBU1 Battery Backup Unit.

When not in use, the four empty PCI slots

must be installed with blanking plates.

Drive bay numbering convention

The drive bay numbering convention is as follows.

© Copyright Lenovo 2005, 2008 13

Figure 13. Drive bay numbering

The SMC - Storage Array subsystem is housed in a 4 x 3 enclosure (four drive bays

wide by three bays high). The top bays are numbered 1 to 4 from left to right, as

viewed from the front. Drive carrier module locations are identified from a matrix

of the top and side numbers.

Enclosure installation prerequisites

The SMC - Storage Array is delivered fully populated with 12 drive carrier

modules pre-installed.

Notes:

1. The SMC - Storage Array with all its component parts installed is too heavy for

a single person to easily install into a rack cabinet.

2. Ensure that you have fitted and checked a suitable anti-static wrist or ankle

strap and observe all conventional ESD precautions when handling modules

and components. Avoid contact with backplane, server board and PCI card

components and module connectors, or other parts. See the Safety and Warranty

Guide for additional information on static electricity prevention.

Preparation of site and host server

Before beginning, make sure that the site where you intend to set up and use your

SMC - Storage Array has standard AC power available from an independent

source or a rack power distribution unit with a universal power supply (UPS).

Unpacking the enclosure system

The package contents and unpacking procedure are outlined in the following

figure.

14 User Guide

Figure 14. Unpacking the SMC - Storage Array

Planning and configuring your installation

Refer to “Planning your installation” on page 13 for information on overall system

configuration requirements.

Refer to the Secure Managed Client (SMC) - Storage Array Setup Poster that shipped

with your system for instructions on installing the processors, drives, and memory.

Rack installation prerequisites

The SMC - Storage Array is designed for installation into an industry standard

48.26-cm (19-inch) cabinet capable of holding the unit.

v Minimum depth: 70.76 cm (27.83 inches) from rack posts to maximum extremity

of enclosure (excludes rear cabling).

v Weight: up to 30 kg (66.20 lb), dependent upon configuration, per enclosure.

v A minimum gap of 2.54-cm (1-inch) clearance is required between the rack cover

and front of drawer. A 5.08 cm (2-inch) rear clearance between rear of drawer

and rear of rack is recommended to maintain correct airflow around the

enclosure.

v The rack should present a maximum back pressure of 0.5 mm (5 pascals) water

gauge.

Chapter 3. Getting Started 15

CAUTION:

Operation of the enclosure system with any modules missing will disrupt the

airflow and the drives will not receive sufficient cooling. It is essential that all

openings are filled before operating the unit.

Installing the enclosure in a rack

A set of rack-mounting rails is provided with the system for installing the SMC Storage Array in a 48.26-cm (19-inch) rack cabinet. These rails have been designed

and tested to handle the maximum weight of the enclosure and to ensure that

multiple enclosures may be installed without loss of space within the rack. Use of

other mounting hardware may cause some loss of rack space.

Contact your supplier to ensure suitable mount rails are available for the rack you

are using.

Rail kit assembly

Refer to the Rail Kit Installation Guide for instructions on assembling the rail kit.

Figure 15. Rack mount rail kit

1Rear rack post

2Clamping screws

3Rack bracket ASM

4Front rack post

5Slide screw (4)

6Slide washer (4)

Enclosure installation

To install the enclosure, do the following:

1. Check for damage.

2. Lift enclosure and align with front rails.

3. Carefully insert enclosure slides into rack rails and push fully home.

4. Tighten rear screws.

5. Withdraw enclosure until it reaches hard stops (approximately 400 mm).

6. Tighten front screws.

16 User Guide

7. Return enclosure to fully home position and attach to rack using captive

fasteners on front flanges.

Rack rails have features to restrict complete enclosure withdrawal while still

Note:

allowing access to the cooling fans. If it becomes necessary to completely

remove the system, pull the enclosure out until it stops then rotate the

latches, shown in Figure 15 (right hand up, left hand down), to completely

remove the enclosure from the rack.

Power cord connection

CAUTION:

The power connection must always be disconnected prior to removal of a PSU

from the enclosure.

To connect the power cord, do the following:

1. Observe all safety and ESD precautions listed in the Safety and Warranty Guide.

2. Attach a power cord for the installed PSU. The Power On LED (see 1 in

Figure 16) for the PSU will blink green when AC main power is present. The

Power On LED will illuminate a constant green when power to the PSU is

turned on.

Figure 16. Connecting power cords

Grounding checks

The SMC - Storage Array must only be connected to a power source that has a

safety electrical earth connection.

CAUTION:

If more than one enclosure is installed in a rack, the earth connection to the rack

is even more important, because the rack will have a high “earth leakage

current” (“touch current”).

Before powering on, the earth connection to the rack must be checked by an

electrical engineer who is qualified in local and National electrical standards.

Chapter 3. Getting Started 17

18 User Guide

Chapter 4. Operation

Before powering on the Secure Managed Client (SMC) - Storage Array ensure that

all modules are firmly seated in their correct bays.

Power on

Apply AC main power to power on the enclosure.

The power active LED on the front operator ’s panel will light up green once

power is activated. The disk drive motors will also start running.

CAUTION:

Do not operate the SMC - Storage Array until the ambient temperature is within

the specified operating range. If the drives have been recently installed, ensure

they have had time to acclimate before operating them.

Notes:

1. If main power is lost for any reason, upon restoration of power, the enclosure

will re-start automatically.

2. See “Front operator's panel LEDs and switches” on page 20 for details on Front

Operator’s Panel LEDs and related fault conditions.

Power supply unit LED

The PSU has a bi-color red/green LED.

v When the PSU is connected to a main supply, the LED will flash green.

v When the PSU is switched on, the LED will illuminate a constant green.

v If a fault occurs, the LED will illuminate a constant red.

v If an over-current, under-voltage or over-voltage protection condition occurs, the

LED will flash red.

Figure 17. Power supply unit LEDs

© Copyright Lenovo 2005, 2008 19

1POST LED

Front operator's panel LEDs and switches

The front operator’s panel LED fault and status conditions are defined in Table 4.

Functions of the push-button switches are defined in Table 5.

Figure 18. Front operator’s panel components

1USB port

2Power active LED

3Unit fault LED

4ID LED

5On/off switch

6Reset button (recessed)

7ID LED activation switch

Table 4. Front operator's panel LED states

LED Status

Power active Constant green: good or positive indication

Unit fault Constant amber: fault present

Enclosure ID Blue: only when activated

Table 5. Front operator's panel switch functions

Push-button

switch Definition

On/Off Function of this button is dependent on the enclosure status.

Enclosure connected to power source but not operating.

Press button to activate and commence boot process.

Enclosure operating: Depress button for <4 seconds to turn off

the enclosure.

System reset Resets the enclosure hardware and firmware.

This button is recessed and is activated with a ball-point pen or similar

implement.

Enclosure ID Each press of this button causes the state of the blue ID LED on the Front

Operator's Panel and rear panel to change.

20 User Guide

Starting the drives

Unless otherwise selected during installation, all drives in the enclosure should

automatically start their motors during power on. If this does not occur then one

of the following conditions may exist:

v There may be a power problem (an alarm and power fault indication would

normally be present).

v The drive motors will spin up in a delayed sequence.

Disk drive LEDs

Each drive carrier module has two LEDs, an upper (green) LED and a lower

(amber) LED.

v During normal operation, the green LED will be on and will flicker to indicate

drive activity. It will also be on when no drive is present. It is off when the drive

is not spun up.

v During normal operation, the amber LED will be:

– Off if no drive is present

– Off as the drive operates

– On if a drive fault exists

Engaging the drive module anti-tamper locks

An anti-tamper lock is installed in each drive carrier handle and can be accessed

through the small cutout in the latch section of the handle with a TORX

screwdriver. A lock symbol displays in the small opening beside the torque screw

when the drive is locked.

Activating an anti-tamper lock

To activate an anti-tamper lock, do the following:

1. Carefully insert the TORX screwdriver provided into the cutout in the handle

(see 1 in Figure 19).

2. Rotate the screwdriver in a clockwise direction until the lock symbol is visible

in the opening beside the key see 2 in Figure 19).

Note: Do not turn the lock more than half a turn; otherwise, the drive carrier

may be damaged.

3. Remove the screwdriver.

Figure 19. Activating an anti-tamper lock

Note: A drive carrier cannot be installed if its anti-tamper lock is activated outside

the enclosure.

Deactivating an anti-tamper lock

To deactivate an anti-tamper lock, do the following:

Chapter 4. Operation 21

BIOS settings

1. Carefully insert the TORX screwdriver provided into the cutout in the handle

(see 1 in Figure 20).

2. Rotate the screwdriver in an anti-clockwise direction until the lock symbol is no

longer visible in the opening beside the key (see 2 in Figure 20).

Do not turn the lock more than half a turn; otherwise, the drive carrier

Note:

may be damaged.

3. Remove the screwdriver.

Figure 20. Deactivating an anti-tamper lock

To install the AMI StorTrends iTX software, verify the following BIOS settings:

1. Disable the Onboard SATA Controller option to install onto the boot drive. This

option is present in the ATA Controller Configuration settings under the

Advanced tab.

2. Enable the LSI MPT SAS Controller option, which is present in the Mass

Storage Controller Configuration settings under the Advanced tab.

3. If you add DIMMS to increase system memory, the default BIOS option limits

the memory visible to the operating system to 2.50GB. To make more memory

visible to the operating system, modify the Memory Mapped I/O Start Address

option, which is present in the PCI Configuration settings under the Advanced

tab.

4. To boot from the network using PXE boot, enable the option Onboard NIC

ROM option, which is also present in the PCI Configuration settings. The

device boot order registers this change after you save the changes and reboot.

5. To boot from the boot drive attached to the LSI MPT SAS controller, change the

hard disk order under the Boot Options tab. Set ID01 LUN0 as the first disk,

followed by the PCI RAID adapter. If you need to enable the network boot,

select IBA GE as the first boot device.

6. To boot from the boot drive attached to the LSI MPT SAS controller, set ID01

LUN0 as the second boot option under the Boot Options tab.

The drives need to be connected to the blue S ATA slots on the server

Note:

Turning off

To turn off the enclosure, either:

v Turn off the PSU installed in the enclosure by pressing the power push-button

on the front operator's panel for approximately three seconds,

OR

v Remove AC main at the power source

22 User Guide

board for installation.

Chapter 5. Troubleshooting and problem solving

The Secure Managed Client (SMC) - Storage Array includes an enclosure services

processor and associated monitoring and control logic to enable it to diagnose

problems within the enclosure’s power, cooling and drive systems.

The sensors for power and cooling conditions are housed within the PSUs and

cooling fans. There is independent monitoring for each unit.

Initial start-up problems

The following problems may occur on initial start up:

Faulty cords

First check that you have wired up the subsystem correctly. Call your supplier for

replacement if:

v Cords are missing or damaged.

v Plugs are incorrect.

v Cords are too short.

LEDs

Alarm sounds and power up

See “Audible alarms” on page 26 for details.

Computer doesn't recognize the subsystem

1. Check that the interface cables from the SMC - Storage Array to the host

computer are installed correctly.

2. Check that the LEDs on all installed drive carrier modules are illuminated

(amber).

Note: Drive LEDs will not be lit during drive spin up.

3. Check that drive carrier modules have been correctly installed.

A green LED is always used for good or positive indication. A flashing

green/amber LED is used for non-critical conditions. With the exception of the

drive carrier module LED, which is lit amber under Normal conditions (see “Drive

carrier module faults” on page 30), a continuous red or amber LED indicates the

presence of a critical fault within the module.

Power supply units

The power supply unit provides a single external bi-color LED to indicate the

status of the power supply. When AC is applied to the PSU and standby voltages

are available, the LED will blink green. The LED will be solid on green to indicate

that all power outputs are available. The LED will be on solid amber to indicate

that the power supply has failed (shut down due to over current, shut down due

to over temperature, or a predictive failure).

© Copyright Lenovo 2005, 2008 23

Table 6. Power supply unit LED states

Condition LED state

No AC power to all PSUs Off

Power supply direct current (DC) outputs

Green

ON and OK

No AC power to this PSU only Amber

AC present / only standby outputs Blink Green

Power supply failure (includes over voltage,

Amber

over temperature)

Voltage regulator module (VRM) failure

Blink green

(cage related)

240VA limit (cage related) Blink green

Current limit Amber

Front operator's panel

The front operator’s panel displays the aggregated status of all the modules. Front

operator’s panel LED states are defined in Table 4 on page 20.

Note: The front operator’s panel is supplied as an integral part of the enclosure

core product and is not user replaceable.

Figure 21. Front operator’s panel LEDs

1Power active LED

2Unit fault LED

3Enclosure ID LED

Table 7. Ops panel LED states

LEDs Normal Operation Fault condition

Power active Constant green: good or

positive indication

Unit fault Off Constant amber: fault present

Enclosure ID Blue: only when activated Blue: only when activated

24 User Guide

Cooling fan LEDs

An amber LED incorporated in each cooling fan monitors its status. Constant On

indicates a fault condition. .

Drive carrier module LEDs

Disk drive status is monitored by a green LED and an amber LED mounted on the

front of each drive carrier module. The conditions for each LED are defined in

“Drive carrier module faults” on page 30.

Rear panel LED

Table 8. Rear panel status LED

Enclosure ID LED Blue (when activated) Activated by push button on

the front operator's panel, or

by system software. Used to

identify a server from among

several servers.

Server board LEDs

Server board LEDs consist of I/O panel status LEDs and I/O panel NIC LEDs.

I/O panel status LEDs

The server board I/O panel contains a number of diagnostic LEDs, whose

functions are summarized in the following table. Refer to your server board

documentation for full details of each LED state.

Table 9. Server board status LEDs

LED Color Function

System status LED

v Green

v Off

v Alternating green/amber

v Amber

v Green blink

v Amber blink

v System OK

v AC power off

v System not ready

v Critical fault

v System degraded

v Non-fatal alarm, system

likely to fail

4 x power-on self test (POST)

LEDs

Off

*Amber

System running normally

The POST LEDs toggle

between red, green, amber,

and Off at boot up.

*(Lit amber only if a

failure occurs)

I/O panel NIC LEDs

The Network Interface Controller (NIC) LED states are summarized in the

following table. Refer to your server board documentation for full details of each

state.

Chapter 5. Troubleshooting and problem solving 25

Audible alarms

Table 10. NIC LEDs

LED LED state Description

Left Off No network connection is in

place

Solid green Active network connection is

in place

Blinking green Transmit / receive activity is

occurring

Right Off 10 Mbps connection (if left

LED is on or blinking)

Solid green 100 Mbps connection

Solid amber 1000 Mbps connection

The PSUs incorporate audible alarms, which indicate when a fault state is present.

A Voltage Out Of Range condition will activate the audible alarm.

The audible alarm can be muted by pressing the Enclosure ID button on the front

operator’s panel.

Alarm interpretation

The following table summarizes the various interpretations when combining LED

states and audible alarms. Use this table to help understand a pattern of lights and

beeps. Each light/beep is taken in turn and shows linked items, so some of the

data is duplicated in several places to make ease of search better.

Note: There will be no beep if the enclosure is muted.

Table 11. Light and buzzer interpretations

LED/buzzer State Related Meaning Action

Front operator's panel

fault light

Off - No warnings or

worse

Slow blink (0.5

seconds on, 3.5

seconds off)

Slow beep (half

second beep every

8 seconds). No fan/

drive lights lit

Warning state usually approaching

temperature

threshold.

constant. No beep if

muted.

Slow beep. Fan light

constant. No beep if

Fan broken or out of

tolerance.

muted.

Slow beep. Fan light

Drive fault Replace drive

constant. No beep if

muted.

None - all OK

Check ambient

temperature and

increase if too cold or

decrease if too hot. If

this does not work,

check for fan failure

that has a broken

light, too.

Replace lit fan.

26 User Guide

Table 11. Light and buzzer interpretations (continued)

LED/buzzer State Related Meaning Action

Fast blink (alternating

every half second)

Faster beep (1.5

seconds beep, 0.5

seconds silence). No

fan light constant.

No beep if muted.

Critical state - usually

temperature near

edge of operating

range

Check ambient

temperature and

increase if too cold or

decrease if too hot

immediately. If this

does not work, check

for a fan failure that

also has a broken

light.

Faster beep, more

than one fan light

Fans broken or out of

tolerance.

Replace fans

immediately.

on or a single PSU

fan light on. No

beep if muted.

Constant on Constant - no fan

lights lit constant

Failure state temperature in range

where damage could

occur

Check ambient

temperature and

increase if too cold or

decrease if too hot

immediately. If this

does not work check

for fan failure that

has a broken light,

too.

Constant - multiple

fan lights lit constant

Fans broken or out of

tolerance

Replace fans

immediately. Decrease

ambient temperature

Fan light Constant on Varying levels of

beep and chassis

Fan broken or out of

tolerance.

Replace fans

immediately.

fault light setting.

No beep if muted.

Drive light (amber) Constant on Varying levels of

beep and chassis

Drive faulty Replace drive

fault - usually slow

beep and slow flash.

No beep if muted.

Front operator's panel

Flashing Ops panel ident on

ID LED

Buzzer Off Front operator's panel

No issues

fault LED off

Off Front operator's panel

fault LED flashing or

constant

Intermittent short

beep (0.5 second beep

every 32 seconds)

Various front

operator's panel fault

light flash states

Muted See Table 4 on page

20 for interpretation

of lights and remedy.

Fault has occurred

and system is muted

but in remind mode

Check fault status

using ops panel fault

LED settings and

remedy.

Slow beep (half

second beep every 8

seconds)

Front operator's panel

fault LED slow blink

(0.5 seconds on, 3.5

Warning mode See Table 4 on page

20.

seconds off)

Chapter 5. Troubleshooting and problem solving 27

Table 11. Light and buzzer interpretations (continued)

LED/buzzer State Related Meaning Action

Faster beep (1.5

seconds beep, 0.5

second silence)

Front operator's panel

fault LED fast blink

(alternating every half

Critical mode See Table 13.

second)

Constant beep Front operator's panel

fault LED constant on

Failure mode See Table 4 on page

20.

Troubleshooting

The following sections describe common problems, with possible solutions, which

can occur with your Secure Managed Client (SMC) - Storage Array.

For details on how to remove and replace a module see the Hardware Installation

and Replacement Guide.

System faults

Table 12. System faults

Symptom Cause Action

1. Audible alarm sounds 1. Internal fault detected (failure of

an internal communications path)

1. Check for other amber LED

indications of the power supply

units. If there is a PSU error

present there may be a

communication problem with that

PSU. Remove and then re-install

the PSU. If the problem persists

then change the PSU.

Power supply unit faults

Table 13. Power supply unit faults

Symptom Cause Action

1. Front operator's panel unit fault

LED amber

2. Audible alarm sounding

1. Any power fault

2. A thermal condition which could

cause PSU overheating

1. Check that the AC main

connection to PSU is live

2. Disconnect the PSU from main

power and remove the PSU from

the power supply cage. Re-install.

If problem persists, replace PSU.

3. Reduce the ambient temperature

28 User Guide

Cooling fan faults

Table 14. Cooling fan faults

Symptom Cause Action

1. Front panel fault LED amber

2. Audible alarm sounding

3. Fan LED is illuminated

1. Any power fault

2. A fan failure

1. Check to ensure DC power to

cooling fans is correct and that

the LED is not illuminated

2. Disconnect the PSU from main

power and remove the faulty fan

from the system. Re-install. If

problem persists, replace PSU.

3. Reduce the ambient temperature

Thermal cooling

The Secure Managed Client (SMC) - Storage Array uses extensive thermal

monitoring to ensure component temperatures are kept low and acoustic noise is

minimized. Airflow is from front to rear of the enclosure.

Table 15. Thermal cooling

Symptom Cause Action

If the ambient air is cool

(below 25°C or 77°F) and the

fans are observed to increase

in speed then some restriction

on airflow may be causing an

additional internal temperature

rise.

Note: This is not a fault condition.

The first stage in the thermal

control process is for the fans

to automatically increase in

speed when a thermal threshold

is reached. This may be caused

by higher ambient temperatures

in the local environment and may

be perfectly normal.

Note: This threshold changes

according to the number of drives

and power supplies installed.

1. Check the installation for any

airflow restrictions at either the

front or rear of the enclosure. A

minimum gap of 2.5 cm (1 inch)

at the front and 5 cm (2 inches) at

the rear is recommended.

2. Check for restrictions due to dust

build up; clean as appropriate.

3. Check for excessive re-circulation

of heated air from rear to front.

Use in a fully enclosed rack

installation is not recommended.

4. Check that all blank modules are

in place.

5. Reduce the ambient temperature.

Chapter 5. Troubleshooting and problem solving 29

Table 15. Thermal cooling (continued)

Symptom Cause Action

1. Front operator's panel unit fault

LED amber.

2. An amber LED is lit on one or

more PSUs.

If the internal temperature

measured in the airflow

through the enclosure

exceeds a pre-set threshold,

a thermal alarm sound.

1. Check to ensure that local

ambient environment temperature

is below the upper 35°C (95°F)

specification.

2. Check the installation for any

airflow restrictions at either the

front or rear of the enclosure. A

minimum gap of 2.5 cm (1 inch)

at the front and 5 cm (2 inches)

mm at the rear is recommended.

3. Check for restrictions due to dust

build up; clean as appropriate.

4. Check for excessive re-circulation

of heated air from rear to front.

Use in a fully enclosed rack

installation is not recommended.

5. If possible, turn off the enclosure

and investigate the problem

before continuing.

Drive carrier module faults

Each Drive Carrier module has two LEDs: an upper (green) LED and a lower

(amber) LED.

v Under normal operation, the green LED is on and will flicker as the drive

operates

v Under normal operation, the amber LED will be:

– Off if there is no drive present

– Off as the drive operates

– On if a drive fault is present

Dealing with hardware faults

Ensure that you have obtained a replacement module of the same type before

removing any faulty module.

v If the subsystem is powered up and you remove any module, replace it

immediately. If the subsystem is used with modules or module blanks missing

for more than a few minutes, the enclosure can overheat, causing power failure

and data loss. Such use will invalidate the warranty.

v Replace a faulty drive with a drive of the same type and equal or greater

capacity.

v Refer to your vendor-supplied documentation when using storage software for

handling drive-related hardware faults.

v All drive bays must be installed with a drive carrier module in order to

maintain a balanced airflow.

v All the supplied plug-in power supply units, electronics modules and blank

modules must be in place for the air to flow correctly around the cabinet

30 User Guide

CAUTION:

Observe all conventional ESD precautions when handling modules and

components. Avoid contact with backplane components and module connectors,

etc.

The top cover of the enclosure covers a service area which should be

Note:

accessed only by qualified service personnel. When the cover is replaced it

must be secured by turning the lock mechanism to the locked position.

Continuous operation during replacement

Depending on how the enclosure system is set up, if a disk unit fails, it can

normally be replaced without interrupting the use of the system.

Chapter 5. Troubleshooting and problem solving 31

32 User Guide

Chapter 6. Notices

Lenovo may not offer the products, services, or features discussed in this

document in all countries. Consult your local Lenovo representative for

information on the products and services currently available in your area. Any

reference to an Lenovo product, program, or service is not intended to state or

imply that only that Lenovo product, program, or service may be used. Any

functionally equivalent product, program, or service that does not infringe any

Lenovo intellectual property right may be used instead. However, it is the user’s

responsibility to evaluate and verify the operation of any other product, program,

or service.

Lenovo may have patents or pending patent applications covering subject matter

described in this document. The furnishing of this document does not give you

any license to these patents. You can send license inquiries, in writing, to:

Lenovo (United States), Inc

1009 Think Place

Building One

Morrisville, NC 27560

USA

Attention: Lenovo Director of Licensing

LENOVO GROUP LTD. PROVIDES THIS PUBLICATION “AS IS” WITHOUT

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, THE IMPLIED WARRANTIES OF NON-INFRINGEMENT,

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some

jurisdictions do not allow disclaimer of express or implied warranties in certain

transactions, therefore, this statement may not apply to you.

This information could include technical inaccuracies or typographical errors.

Changes are periodically made to the information herein; these changes will be

incorporated in new editions of the publication. Lenovo may make improvements

and/or changes in the product(s) and/or the program(s) described in this

publication at any time without notice.

The products described in this document are not intended for use in implantation

or other life support applications where malfunction may result in injury or death

to persons. The information contained in this document does not affect or change

Lenovo product specifications or warranties. Nothing in this document shall

operate as an express or implied license or indemnity under the intellectual

property rights of Lenovo or third parties. All information contained in this

document was obtained in specific environments and is presented as an

illustration. The result obtained in other operating environments may vary.

Lenovo may use or distribute any of the information you supply in any way it

believes appropriate without incurring any obligation to you.

Any references in this publication to non-Lenovo We b sites are provided for

convenience only and do not in any manner serve as an endorsement of those Web

sites. The materials at those We b sites are not part of the materials for this Lenovo

product, and use of those Web sites is at your own risk.

© Copyright Lenovo 2005, 2008 33

Trademarks

Any performance data contained herein was determined in a controlled

environment. Therefore, the result in other operating environments may vary

significantly. Some measurements may have been made on development-level

systems and there is no guarantee that these measurements will be the same on

generally available systems. Furthermore, some measurements may have been

estimated through extrapolation. Actual results may vary. Users of this document

should verify the applicable data for their specific environment.

The following terms are trademarks of Lenovo in the United States, other

countries, or both:

Lenovo

the Lenovo logo

Microsoft, Windows, Windows Vista, and Active Directory are trademarks or

registered trademarks of Microsoft Corporation in the United States, other

countries, or both.

Other company, product, or service names may be trademarks or service marks of

others.

34 User Guide

Part Number: 45K1342

Printed in USA

(1P) P/N: 45K1342

Loading...

Loading...