Page 1

Instructions for Use

Leica LN22 – Liquid Nitrogen Freezing Device

V1.2, English – 10/2012

Order No.: 14 0373 80101 RevB

Always keep this manual near the instrument.

Read carefully prior to operating the instrument.

Leica LN22

Liquid nitrogen freezing

device

Page 2

Page 3

NOTE

The information contained in this documentation

represents the state of the art in science and

technology.

We are under no obligation to update the present

manual periodically and on an ongoing basis according to the latest technical developments, nor

to provide our customers with additional copies,

updates etc. of this manual.

For erroneous statements, drawings, technical

illustrations etc. contained in this manual we exclude liability as far as permissible according to

the national law applicable in each individual

case. In particular, no liability whatsoever is accepted for any financial loss or consequential

damage caused by or related to compliance with

statements or other information in this

manual.

Statements, drawings, illustrations and other information as regards contents or technical details of the present manual are not to be considered as warranted characteristics of our

products.

These are determined only by the contract provisions agreed between ourselves and our customers.

Leica reserves the right to change technical

specifications as well as manufacturing processes without prior notice. Only in this way is it possible to continuously improve the technology and

manufacturing techniques used in our products.

This document is protected under copyright

laws. Any copyrights of this document are retained by Leica Biosystems Nussloch GmbH.

Any reproduction of text and illustrations (or of

any parts thereof) by means of print, photocopy,

microfiche, web cam or other methods – including any electronic systems and media – requires

express prior permission in writing by Leica

Biosystems Nussloch GmbH.

© Leica Biosystems Nussloch GmbH

Published by:

Leica Biosystems Nussloch GmbH

Heidelberger Strasse 17 - 19

D-69226 Nussloch

Germany

Telephone: +49 (0) 62 24 143-0

Fax: +49 (0) 6224 143-2 68

Internet: http://www.LeicaBiosystems.com

Leica LN22

3

Page 4

Table of contents

1. Important information ................................................................................................................ 6

1.1 Symbols in the text and their meanings ................................................................................... 6

1.2 Intended use of instrument ........................................................................................................ 6

2. Safety ............................................................................................................................................ 7

2.1 Safety instructions ...................................................................................................................... 7

3. Instrument components and specifications ....................................................................... 15

3.1 Technical data ............................................................................................................................ 15

3.2 Overview and instrument components .................................................................................. 16

3.3 Standard delivery ...................................................................................................................... 17

4. Startup ........................................................................................................................................ 18

4.1 Installation site requirements.................................................................................................. 18

4.2 Unpacking ................................................................................................................................... 18

4.3 Preparing the microtome for attachment of the LN22 ......................................................... 19

4.4 Installing the cryochamber ...................................................................................................... 20

4.5 Connecting to mains ................................................................................................................. 21

4.5.1 Checking the voltage selector setting ................................................................................... 21

4.5.2 Changing the voltage selector setting and inserting the fuses ......................................... 22

4.5.3 Plugging in the connection cables ......................................................................................... 23

4.5.4 Grounding the Dewar ................................................................................................................ 23

4.5.5 Connecting the mains cable .................................................................................................... 24

4.6 Switching on the instrument.................................................................................................... 24

4.7 Control unit ................................................................................................................................. 25

4.8 Specimen holders...................................................................................................................... 27

4.8.1 Specimen holder for block embeddings ................................................................................ 27

4.8.2 Universal specimen holder and flat specimen holder ......................................................... 29

4.9 Knife holders .............................................................................................................................. 30

4.9.1 Knife holders for tungsten carbide knives............................................................................. 30

4.9.2 Glass knife, CryoDiamond knife, trimming knife Histo ......................................................... 30

4.10 Preparing the pumping system ............................................................................................... 33

4.11 Refrigerating .............................................................................................................................. 33

4.12 Refilling the Dewar vessel ....................................................................................................... 34

4.13 Heating up the chamber ........................................................................................................... 35

4

Instructions for Use V1.2, RevB – 10/2012

Page 5

Table of contents

5. Cleaning and maintenance .................................................................................................... 36

5.1 Cleaning ...................................................................................................................................... 36

5.2 Maintenance .............................................................................................................................. 39

5.2.1 General maintenance instructions ......................................................................................... 39

5.2.2 Exchanging the mains fuses .................................................................................................... 39

5.2.3 Exchanging the bulb .................................................................................................................. 40

5.2.4 Removal of the pump valves .................................................................................................... 41

6. Appendix .................................................................................................................................... 42

6.1 Ordering information ................................................................................................................. 42

7. Warranty and service .............................................................................................................. 43

Leica LN22

5

Page 6

1. Important information

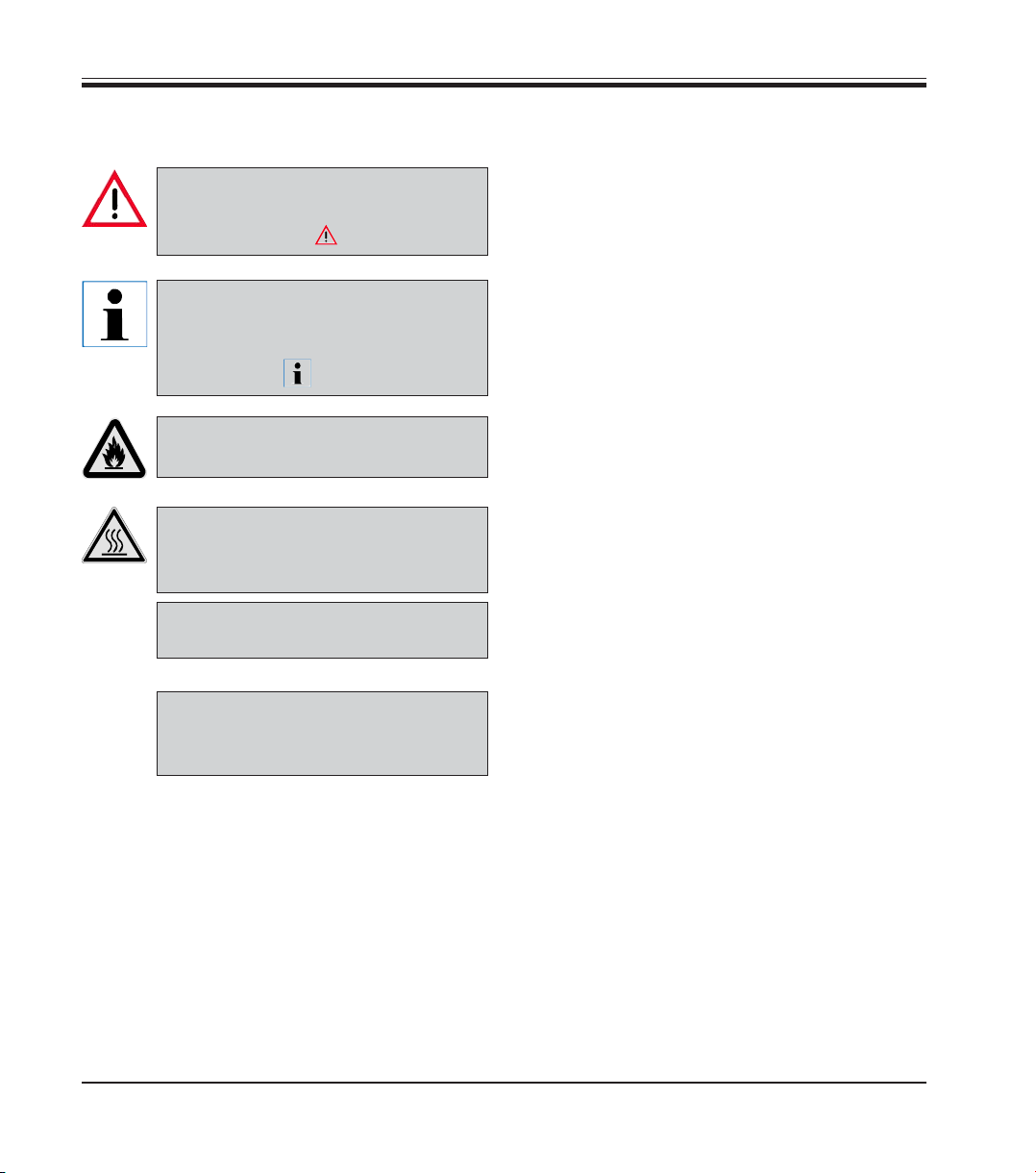

1.1 Symbols in the text and their meanings

Warnings

appear in a gray box and are marked by

a warning triangle .

Notes,

i.e. important user information, appear in

a gray box and are marked by an infor-

mation symbol .

Solvents and reagents that are flammable are identified by this symbol.

This warning symbol identifies surfaces

of the instrument that are hot during operation.

(5)

Numbers in parentheses refer to item

numbers in illustrations.

1.2 Intended use of instrument

The Leica LN22 is a liquid nitrogen freezing device to quickly and effortlessly change from sectioning at room temperature to freezing sectioning applications and vice versa.

Any other use of the instrument is

considered improper!

ENTER

6

Function keys that must be pressed on the

input screen are boldfaced in the text and

capitalized.

Instructions for Use V1.2, RevB – 10/2012

Page 7

Be sure to comply with the safety instructions and warnings provided in this chapter.

Be sure to read these instructions, even if you are already familiar with the operation and use

of other Leica products.

2.1 Safety instructions

2. Safety

These operating instructions contain important

information for the operational safety and maintenance of the device and are an important component of the device.

If additional requirements on accident

prevention and environmental protection exist in the country of operation,

this Instructions for Use must be supplemented by appropriate instructions

to ensure compliance with such requirements.

Device type

All information provided in this manual applies

only to the instrument type indicated on the cover

page.

An identification label with the serial number is

attached on the underside

of the control unit.

This instrument was built and tested in accordance with the safety regulations for electrical

measuring, control, regulating and laboratory

devices as specified below:

• EN 61010-1:2001,

• EN 61326: 1997+A1: 1998 +A2: 2001

.

The protective devices on both instrument and accessories must neither be

removed nor modified.

Only service personnel qualified by

Leica may repair the instrument and

access the instrument’s internal components.

Leica LN22

7

Page 8

2. Safety

Safety measures in cryopreparation

Provided that the safety measures outlined in the present chapter are

observed, using all safety devices of the instrument as described, there

is no significant accident risk involved in cryopreparation. For this reason, please make sure at all times when working with the LN22 system

that the few, but decisive, rules for safety listed in this chapter are followed.

When handling liquid nitrogen (LN

•LN2 is extremely cold and boils at -196°C. As a consequence, also nitrogen gas (GN2) escapes from boiling LN2 at a very low temperature.

Bear in mind, that LN2 and/or GN2 as well as objects which are in contact with LN2 / GN2 (pipe joints, valves, pipes, containers or stoppers)

can cause severe frost bite on skin and eyes.

• When evaporating, LN2 expands at a ratio of approximately 1 : 700,

i.e. 1 liter of liquid nitrogen produces almost 1 m3 of nitrogen gas

(GN2). Therefore, please make sure that the working area is kept well

ventilated when larger quantities of liquid nitrogen evaporate (e.g.

when pouring LN2 from one container into another). LN2 residues from

containers may only be emptied outdoors: Useful for disposing of liquid nitrogen is a gravel-filled container or pit, where LN2 will evaporate quickly and safely.

• Nitrogen gas (GN2) is odorless and has no taste so it cannot be distinguished from normal air when inhaled. GN2 is nontoxic as a substance. Still, a higher GN2 content (normal ratio: about 78 % GN2 to

21 % of oxygen) in the air will cause the oxygen level to diminish, thus

causing sudden fainting and deep unconsciousness without any preceding warning symptoms (such as numbness, dizziness).

In case of doubt about the oxygen level in the air it is advisable to use

a gas analyzer with an oxygen level indication range of 0 to 25 %.

There is danger when the oxygen level drops below 18 %.

), please bear in mind the following:

2

8

Instructions for Use V1.2, RevB – 10/2012

Page 9

2. Safety

If an unconscious person remains in such a low-oxygen environment,

death may occur.

In case of emergency immediately call a physician and an ambulance. If breathing stops, apply artificial respiration at once.

• For the reasons just explained, never place LN2 containers in closed

storage rooms. Due to defects because of improper handling (jolts,

mechanical damage) or simply by normal wear, the evaporation rate

of Dewar vessels may rise to several liters per day. In enclosed

spaces, this will cause a dangerous reduction of the oxygen level in

the air.

• Please remember that the LN22 system evaporates 2 to 3 liters of liq-

uid nitrogen per hour during normal operation. This quantity of liquid

corresponds to 2 to 3 m

area is kept well ventilated at all times and adhere to the precautionary measures described above.

• Be extremely careful when bringing objects at ambient temperature

into contact with LN

of gas will form around the object. This makes any significant transfer

of warmth impossible and so comparatively little LN2 will evaporate.

However, as soon as the object has cooled down sufficiently there

will often occur strong boiling and splashing of LN2 at a time when it

is no longer expected.

3

of GN2/h. Therefore, make sure your work

. During the first few moments an insulating layer

2

9

Page 10

2. Safety

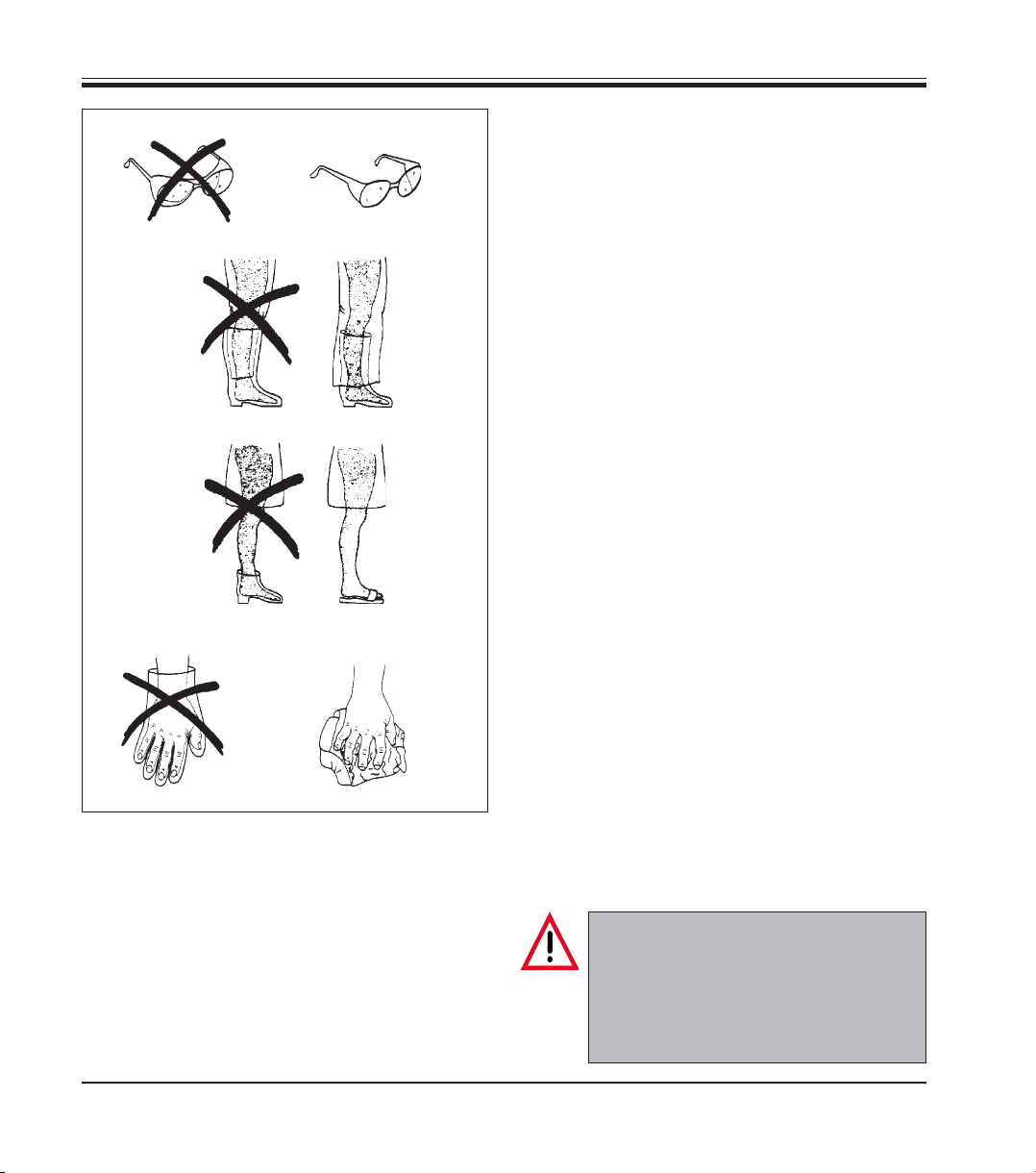

• There are clothing items and protective gear

with certain characteristics which you should

specifically avoid when working with LN2: Do

a

b

not wear closed safety goggles (a), boots (c),

shoes (e) and gloves (g) into which LN

splashes can enter, but from where they cannot escape. LN2 that has splashed into such

items will evaporate immediately inside the

item thus causing severe injuries, before the

item can be removed or taken off. Therefore,

always use safety goggles with side protec-

c

d

tion but which are open at the top and at the

bottom (b), so that LN2 splashes can escape

immediately. Wear boots only in combination

with long, loose-fitting (not tight!) pants that

fall over the boots (d) and completely cover

their upper opening. Only wear open slippers

(f) in the lab, no shoes or pumps that enclose

e

f

your feet entirely.

In combination with open slippers/sandals only

wear pants without cuffs, so that LN

will flow off freely. When pouring LN2 from one

container into another or when inserting the

Dewar pump into the Dewar, never wear safety

gloves! As an alternative to gloves you can use

an open flannel cloth (h) to protect your hands

gh

when touching cold components. Protective

gloves are useful when handling cold and dry

Fig. 1

objects, however they are not for work with LN2.

splashes

2

2

• If your skin is injured by splashing LN2, immediately rinse the affected skin area(s) thoroughly with lukewarm (body temperature!)

water. In case of serious injuries, immediately

see a dermatologist.

10

If LN2 splashes into your eyes, rinse the

eye immediately and thoroughly with

lukewarm water. If available in your lab,

use a special eye-rinsing device for that

purpose. After rinsing, immediately see

an ophthalmologist.

Instructions for Use V1.2, RevB – 10/2012

Page 11

Loosely fitted stopper

Fig. 2

2. Safety

• Once every three months check the actual evaporation rate of your

Dewar vessels and compare the measuring results to the evaporation

rates specified by the manufacturer. The evaporation rate of an undamaged metal Dewar is far less than 1 liter per day. Defective

Dewars with evaporation rates higher than that are a safety risk and

should be taken out of service or repaired.

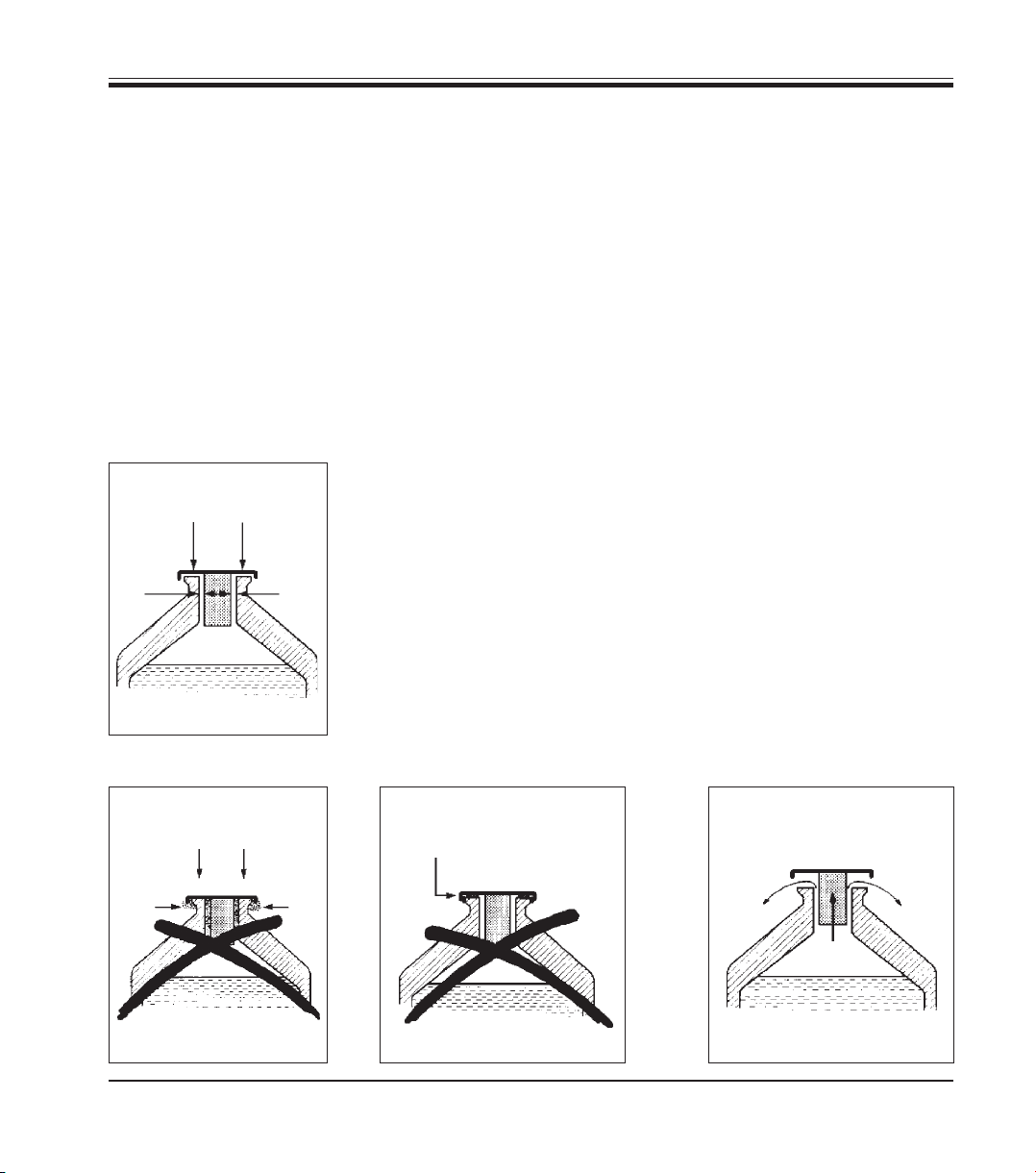

• Standard Dewar vessels, such as the metal Dewar of the LN22 system, are not pressure vessels, therefore make sure they are closed

only with a special Dewar topper (Fig. 2). These stoppers fit loosely

onto the Dewar neck and leave a sufficiently large gap to allow for

sudden evaporation of GN2. Check the stopper frequently to make

sure it will not be stuck to the Dewar neck by ice deposits (Fig. 3).

Never close a Dewar vessel with stoppers that you have crafted

yourself (Fig. 4). Through exposure to shock or vibration (e.g. transport), a gas-tight closed Dewar vessel can release GN2 in an explosion-like fashion and burst in the process. In that case the entire LN

content (35 liters = 35m3 GN2) will evaporate at once (that may e.g.

happen inside a vehicle during transport). When a Dewar moves, thus

causing a sudden evaporation of LN

per will rise due to the gas pressure, thus opening a wide enough gap

for the GN2 to escape (Fig. 5). The small quantities of LN2 which may

escape as well in such situations do not have to be regarded as a significant safety risk.

, an appropriately designed stop-

2

2

Fig. 3

Ice deposits

Tightly fitted stopper

with seal

Fig. 4

GN

Fig. 5

2

GN

2

11

Page 12

2. Safety

• Never leave LN2 in open containers where it can exchange with the

room atmosphere. The boiling point of LN2 (-196°C) is lower than that

of liquid oxygen (-183°C). If a large LN2-surface is exposed to the air,

oxygen from the air is absorbed by the LN2 while nitrogen is released

into the air. LN2 with a high content of liquid oxygen has a bluish color.

In that case, caution is advised, since concentrated liquid oxygen is a

fire hazard.

• Make sure that your Dewar vessel is filled with no other substances

than LN2. If at the filling location also other gases are refilled, install a

warning sign there that clearly states: “Liquid nitrogen only”. Check

the color of the cryogen! Bluish color indicates a high oxygen con-

tent (see previous paragraph). If LN2 is stored during a prolonged

period of time, liquid oxygen will accumulate in the LN2 vessel, since

liquid oxygen has a higher boiling point (-183°C) than liquid LN2

(-196°C).

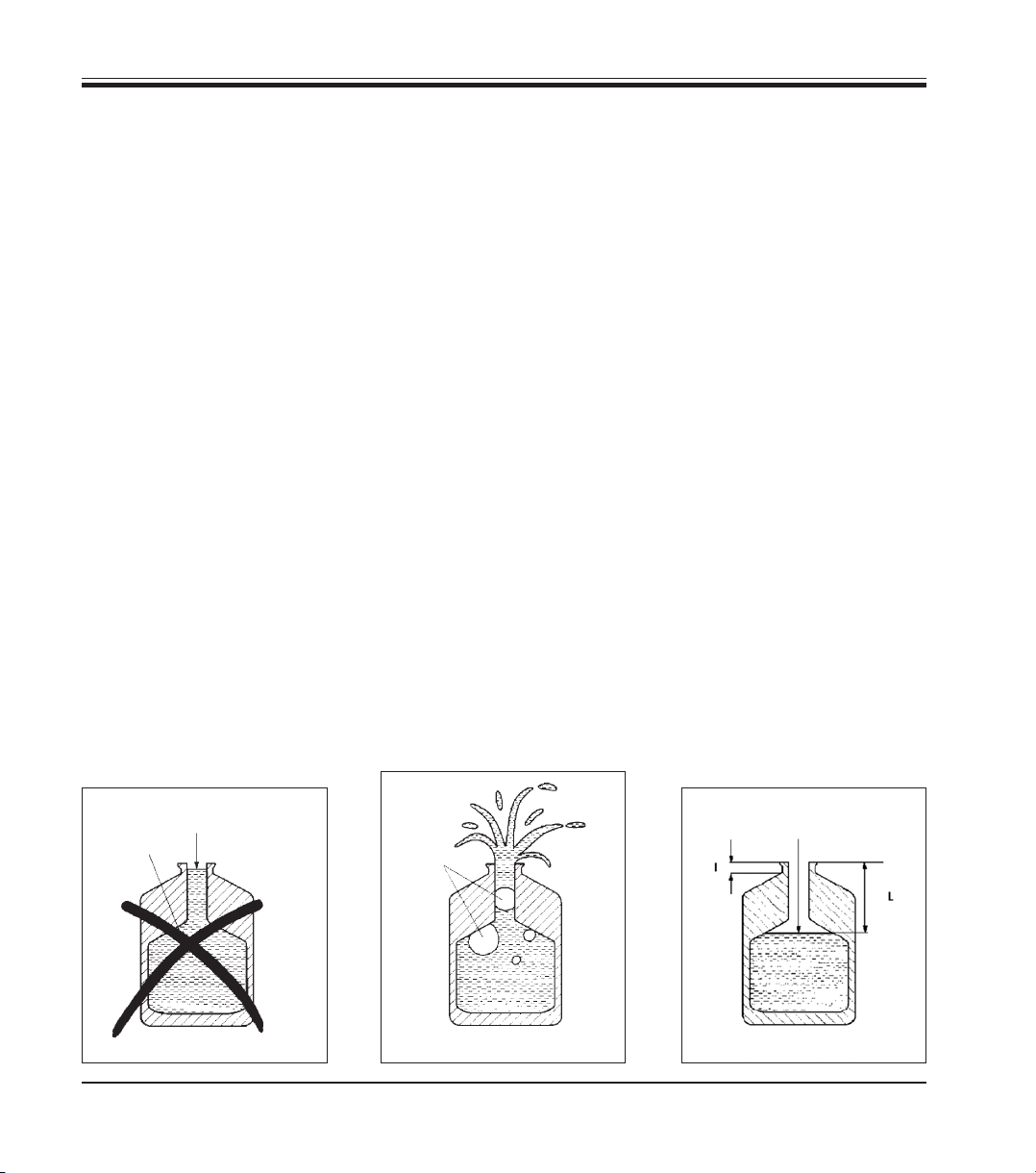

• Never fill a Dewar vessel up to the neck with LN2 (Fig. 6). In case of a

boiling delay, there is danger that the rapidly expanding gas bubbles

will force the LN

in the neck upwards causing it to splash (Fig. 7). For

2

this reason, always make sure that the LN2 surface level is below the

neck of the vessel (Fig. 8). Also bear in mind, that in most cases the

length ‘l’ of the outer insulation differs from the length ‘L’ of the actual

Dewar neck.

LN2 level

LN

2

Fig. 6 Fig. 7

12

GN

LN2 level

2

Fig. 8

Instructions for Use V1.2, RevB – 10/2012

Page 13

Warnings – Installation/Connection to mains

The room where the instrument is installed must either be well ventilated or be large enough to

avoid a dangerous decrease of the oxygen level in the air.

Please read chapter 2 ‘Safety instructions’ carefully!

Pay careful attention to chapter 3 - ‘Technical data’.

The voltage selector is preset to 230V in the factory.

Before connecting the instrument to the mains power, please check whether the factory setting

is identical with the local mains power in your lab!

The mains cable inlet is sealed with an adhesive tape that indicates the factory setting the instrument is delivered with.

Severe damage may be caused to the instrument when operating it at an incorrect voltage setting.

Do not change the voltage selector setting with the instrument being connected to the mains!

The Dewar must be externally grounded!

The instrument may only be connected to a grounded mains power outlet socket. To connect

the instrument only use one of the mains cables that are supplied together with the instrument!

2. Safety

Warnings – Maintenance

Only authorized and qualified service personnel may access the internal components of the instrument for service and repair!

Before opening the instrument, switch off the mains switch and pull the mains plug!

Before exchanging the fuses, switch off the mains switch and pull the mains plug!

When exchanging fuses, only replacement fuses with the same specification as the original

ones may be used. Refer to chapter 3 ‘Technical data’ for the correct specifications.

Before replacing the lamp, switch off the mains switch and pull the mains plug!

Leica LN22

13

Page 14

2. Safety

Warnings – working at the instrument

During operation, metal surfaces and components inside the cryochamber can reach temperatures from as low as -196°C up to as hot as +110°C!

Touching these extremely cold or hot parts can cause severe injury!

For that reason, for any type of manipulations inside the cryochamber you may use only the

special tools which come as part of the standard delivery and the use of which is described in

detail in the present manual.

Transfer of frozen specimens may also only be done by means of the corresponding special

tools.

Always attach the specimen holder before inserting the knife holder!

The light has to be on as long as the knife is inside the cryochamber!

Exercise extreme caution when handling knives! The cutting edges are extremely sharp and

can cause severe injury!

Never try to catch a falling knife!

The knife may only be inserted into the knife holder shortly before sectioning and must be removed from the knife holder directly afterwards!

Cleaning

14

To insert the knife holder into the cryochamber, always use the corresponding manipulator

(part of standard delivery)!

The knife edge is exposed! Risk of injury!

Do not use acetone or xylene to clean the lacquered surfaces of the instrument.

Instructions for Use V1.2, RevB – 10/2012

Page 15

3. Instrument components and specifications

3.1 Technical data

General

Approvals: The device-specific approval symbols are located

on the underside of the control unit next to the

identification label.

Supply voltage: 100-240V/47-63Hz

Power draw: 250W

Room temperature: up to -150°C

Temperature stability: +/-1°C

Nitrogen consumption

in standby mode: approx. 1l/day

Dimensions and weight Control unit Cryochamber

Dimensions: inside outside

Width: 250mm 120mm 253mm

Depth: 340mm 100mm 172mm

Height: 120mm 130mm 171.5mm

Weight: 8.2kg 7.9kg

Fuses

Miniature fuses (5.0 x 20mm): 220-240V: 3.15 AT

100-120V: 6.3 AT

15

Page 16

3. Instrument components and specifications

3.2 Overview and instrument components

3

4

2

6

5

1 Cryochamber

2 Control unit

3 Liquid nitrogen

pump

1

4 Dewar vessel for

liquid nitrogen on

roller base

5 Connection cable

6LN

connection

2

hose

The liquid nitrogen freezing device LN22 quickly

converts a rotary microtome into a cryosectioning

system.

The LN22 attachment consists of a cryochamber,

which encloses the sectioning area, and which

is refrigerated by a permanent flow of liquid nitrogen, pumped from a Dewar vessel. The automatic pumping mechanism ensures a stable lowtemperature environment around the frozen

specimen and the knife. Separate temperature

control systems maintain stable temperatures of

both knife and specimen.

16

Fig. 9

The desired temperature setting for knife and

specimen are selected on the control unit. The

control unit, which continuously monitors and

regulates the selected temperature parameters

and controls the liquid nitrogen pumping system.

Actual temperatures of knife, specimen and

cryochamber are displayed on the control unit at

all times.

The cryochamber is mounted onto the microtome

base plate, thus being completely isolated from

the microtome feed and drive elements.

Instructions for Use V1.2, RevB – 10/2012

Page 17

3.3 Standard delivery

3. Instrument components and specifications

The Leica LN22 standard delivery includes:

• Basic instrument (cryochamber)

• Dewar,

• LN2 pump,

• Control unit

1 Knife holder for tungsten carbide knives ................................ 0378 25655

1 Tungsten carbide knife 40° ....................................................... 0216 08724

1 Round specimen holder 12 mm ................................................ 0378 25653

1 Tool for specimen holder manipulation .................................. 0378 26193

1 Tool for knife manipulation........................................................ 0378 26195

1 Tool set, replacement fuses, different mains cables

1 Set of power cords:

- 1 Power cord ,D’ .................................................................... 0411 13558

- 1 Power cord ‚USA-C-J‘ ....................................................... 0411 13559

- 1 Power cord ‚UK‘ .................................................................. 0411 27822

1 Instructions for Use - G/E/F/S ................................................... 0700 37117

Please compare the actually delivered parts with the parts list

and your order.

Should there be any discrepancies, please contact your local

Leica sales office immediately.

17

Page 18

4. Startup

4.1 Installation site requirements

- stable, vibration-free laboratory bench with horizontal and even stage

plate; practically vibration-free floor

- no direct insulation

- mains power supply within a range of approx. 1.5 meters

- no draft

- plain floor surface

- handwheel easily and comfortably accessible

- 10cm minimum distance between the instrument and walls and/or

other objects on all sides

The room must be well ventilated and large enough to avoid a dangerous decrease of the oxygen level in the air.

Carefully read the chapter on ‘Safety Instructions’!

4.2 Unpacking

18

The shipment consists of several cardboard boxes, which are all contained in one large box.

• Remove all packing material carefully.

If you find any damages, please contact your freight forwarder immediately.

Instructions for Use V1.2, RevB – 10/2012

Page 19

Fig. 10

4. Startup

4.3 Preparing the microtome for attachment of the LN22

• Move the microtome specimen cylinder to the

rear limit stop.

• Pivot the magnifier of microscope to the side.

• Remove knife holder basis and knife holder.

• Remove the specimen clamp.

• Unscrew the fixture for specimen clamps.

3

1a

• Lock handwheel (1) in 12-o’clock position (1a).

• Instead of the fixture for specimen clamps,

assemble the cryo specimen arm (3) with the

4 shorter screws (standard delivery) (2).

22

1

Fig. 11

• Rotate the handwheel to place the cryo speci-

men arm (3) at the low end of the cutting

stroke.

3

Leica LN22

Fig. 12

19

Page 20

4. Startup

4.4 Installing the cryochamber

2

• Place the cryochamber onto the guide rails (1)

on the microtome base plate and carefully insert the cryo specimen arm into the opening

(2) in the cryochamber while sliding the chamber towards the microtome.

• Push the cryochamber towards the microtome

until it reaches the limit stop and secure it in

3

1

Fig. 13

place with the clamping lever (3) on the right

side of the microtome base plate.

• Slide cold bridge (4) onto the cryo specimen

arm and secure with the screw.

4

20

Fig. 14

• Connect the cable (5) at the cryochamber connection.

Tube

connection

Connection

for control

unit

5

Fig. 15

Instructions for Use V1.2, RevB – 10/2012

Page 21

4.5 Connecting to mains

4.5.1 Checking the voltage selector setting

The voltage selector is preset to 230V in the factory.

Before connecting the instrument to the mains power, please

check whether the factory setting is identical with the local mains

power in your lab!

Severe damage may be caused to the instrument when operating it

at an incorrect voltage setting.

The voltage selector is located behind the cover of the voltage selector

housing (3) next to the mains switch (2) on the rear of the control unit.

The actual voltage setting can be seen in a small indication window (1) in

the cover (3). See the figure on the following page!

Check that the voltage selector setting that shows in the window

(1) is the appropriate one for the mains supply in your lab.

4. Startup

If the voltage shown in the indication window does not correspond to

your local mains supply, the voltage selector setting MUST be changed

to the appropriate values for your lab prior to connecting the instrument

to the mains supply.

21

Page 22

4. Startup

4.5.2 Changing the voltage selector setting and inserting the fuses

The voltage selector can be set to 120V and 230V.

Do not change the voltage selector setting with the instrument connected to the mains!

14

1

5

2

4

16

3

7

13

9

7

7

12

10

7

7

6

11

3

8

7

7

15

7

Fig. 16

22

Instructions for Use V1.2, RevB – 10/2012

Page 23

• Place the tip of the screwdriver into the small recess on the left of

cover (3) and push very carefully, using the screwdriver as a lever, to

remove the housing.

• Pull out the housing (3) together with the fuses (4) and the voltage

selector insert (2).

• Remove the voltage selector insert (2) from the housing (3).

• Insert 2 fuses (4) (both of the same specification) which are appropriate for the voltage in your lab (see instrument name plate for corresponding fuse value).

• Put the voltage selector insert (2) back into the housing (3), so that

the desired voltage shows in the indication window (16) of the housing.

• Reinsert the housing (3), together with voltage selector and fuses,

into the instrument and push lightly until it locks in place.

• Check whether the correct voltage now shows in window (16).

4.5.3 Plugging in the connection cables

• Connect the cryochamber (15) to the control unit (14) with cable (6)

and secure both plugs with screws (7).

• Connect the cryo specimen arm with cable (8) to the cryochamber

(15) and secure both plugs with screws (7).

• Place the Dewar vessel (10) onto the roller base (11).

• Hang up the supporting device (12) for the LN2 pump (13), either in the

arched handle of the Dewar vessel or on the wall, using the supplied

dowels and screws.

• Place the LN2 pump onto the supporting device and connect the

pump cable (9) to the control unit; secure the plug with screws (7).

4. Startup

4.5.4 Grounding the Dewar

The Dewar must be externally grounded!

For safety reasons, metallic surfaces which contain electronic components have to be grounded. In

the absence of appropriate grounding, housing parts can be above the earth potential and thus dangerous when touched.

23

Page 24

4. Startup

4.5.5 Connecting the mains cable

• Before plugging in the mains cable, check whether the mains switch

(1, Fig. 16) on the rear side of the control unit (14, Fig. 16) is in ‘O’ (OFF)

position.

• From the set of mains cables, select the one with the plug that fits into

your wall outlet.

• Insert the connector plug of the mains cable into socket (5, Fig. 16).

• Plug the mains plug into the wall outlet.

The instrument is now ready for use.

4.6 Switching on the instrument

The instrument is delivered with various country-specific mains cables.

The instrument may only be connected to a grounded mains power

outlet socket. To connect the instrument, only use one of the mains

cables that are supplied together with the instrument!

• Switch on the mains switch at the rear of the

control unit (1, Fig. 16).

First, the software version will be displayed for a

few seconds. Then the actual temperature of

1

24

specimen (1, Fig. 18a), knife (2, Fig. 18b) and

chamber gas (3, Fig. 18c) is displayed.

Switching on the cryochamber illumination

The switch (1) for the cryochamber illumination is

located on the left side of the cryochamber.

The light has to be on as long as the knife

is inside the cryochamber!

Fig. 17

Instructions for Use V1.2, RevB – 10/2012

Page 25

4.7 Control unit

123

12

Fig. 18a

4. Startup

Fig. 18

‘TEMPERATURE’ control panel

• To indicate the selected temperature value,

press the + / - button (4) below the temperature indication briefly (less than four seconds).

4

• To alter the selected temperature value, press

the + / - button (4) for a longer period of time.

The temperature measuring unit (K, °C, °F) (12) is

changed via the software. See ‘Control panel OPERATION’ on how to actually change the temperature indication.

6

Leica LN22

Key combination:

5

Knife + specimen

+

‘MEMORY’ control panel

Parameters that are used often can be saved:

• To save these parameters, press STO (5) and

one of the 3 storage buttons (6, TA, TB, TC).

• To activate the individual saved parameters,

press the corresponding storage button (6, TA,

TB, TC).

Fig. 18b

25

Page 26

4. Startup

The selected temperature parameters are displayed for about 4 seconds. Then the display

switches back to actual temperature.

‘OPERATION’ control panel

Fig. 18c

10

789 11

The flow diagram indicates the LN2 filling level of Dewar vessel and

cryochamber (10). When the lowest filling level inside the Dewar is

reached, the pump is automatically switched off.

• To change the unit of measurement that is displayed (K, °C, °F) switch

on the control unit, immediately press the START button (11) and keep

it pressed down for at least 7 seconds.

• With the “+” button of the knife temperature indication (2), situated in

the ‘TEMPERATURE’ control panel, you can change between 1 (K),

2 (°C) and 3 (°F) (Fig.18a, 12).

With the LN

-STOP button (7), the LN2 pump can

2

be stopped at any time, e.g. for refilling the Dewar.

The STOP-Alarm button (8) is to switch off the

beep signal, which sounds either when the filling

level of the Dewar falls below 20% of full or when

the lowest LN2 level in the cryochamber is

reached.

Button H (9) activates chamber heating.

26

• To exit the selection mode press the H-button (9).

Instructions for Use V1.2, RevB – 10/2012

Page 27

4.8 Specimen holders

4 3

4. Startup

During operation metal surfaces and components inside the

cryochamber can reach temperatures from as low as -196°C up to

as hot as +110°C!

Touching these extremely cold or hot parts can cause severe injury!

For that reason, for any type of manipulations inside the

cryochamber you may use only the special tools which come as

part of the standard delivery and the use of which is described in

detail in the present manual. Transfer of frozen specimens may also

only be done by means of the corresponding special tools.

Always attach the specimen holder before inserting the knife

holder!

2

5

Fig. 19

Leica LN22

1 Freezing station

2 Cryo specimen arm

3 Clamping screw of the cold bridge

4 Cold bridge

5 Specimen holder

1

4.8.1 Specimen holder for block embeddings

• Put the specimen together with appropriate

embedding medium (e.g. 2.3 molar saccharose

solution) into the specimen holder.

OCT is very rarely suitable for these

low temperatures!

Fig. 20

27

Page 28

4. Startup

Fig. 21

• Lock the handwheel of the microtome in

12-o’clock position.

• Place the specimen holder into the freezing

station, as shown in.

4 3

2

Fig. 22

28

• Once the embedding medium is thoroughly frozen, use the special forceps with small radius

(20) to insert the specimen holders into the

cryo specimen arm (2) and tighten with the

clamping screw (3) of the cold bridge (4).

Extra Fine Screw Thread! Do not

tighten too much!

20

Instructions for Use V1.2, RevB – 10/2012

Page 29

4.8.2 Universal specimen holder and flat specimen holder

• Place the specimen into the specimen holder

6

5

Fig. 23

• Release handwheel lock.

• Place the specimen cylinder into the lowest possible position to ensure a fast freezing process.

• Once the desired temperature has been reached, bring the specimen

cylinder back in the upper limit position.

(5) and (6) slightly tighten screw (Use special

tool!)

• Use the special forceps with large radius to

insert the specimen holder into the cryo specimen arm and tighten loosely with screw (3) of

cold bridge (4).

4. Startup

Leica LN22

• Lock the handwheel.

• Tighten screw (6) in specimen holder (5).

• Loosen screw (3, Fig. 22) of cold bridge (4, Fig. 22) from the cryo

specimen arm, orient the specimen holder into the desired cutting

direction.

• Tighten screw (3) or cold bridge (4) thoroughly.

Extra Fine Screw Thread! Do not tighten too much!

29

Page 30

4. Startup

16 14 2 3

Fig. 24

13 12 6

4.9 Knife holders

4.9.1 Knife holders for tungsten carbide knives

1 Cryo specimen arm

2 Cold bridge

3 Clamping screw of the cold bridge

4 Specimen holder

1

4

8

7

5

10

9

11

15

5 Knife holder

6 Knife clamping screws

7 Knife holder clamping screw

8 Temperature sensor for cryochamber

temperature

9 Knife holder base

10 Clamping screw for knife holder base

11 Cryochamber base plate

12 Eccentric disc for lateral adjustment of

the knife holder

13 Freezing station

14 Bottom plate of LN2 trough

15 Cable loop

16 Clearance angle adjustment

Inserting the knife

30

Exercise extreme caution when handling knives! The cutting edges

are extremely sharp and can cause severe injury!

The knife may only be inserted into the knife holder shortly before

sectioning and must be removed from the knife holder directly afterwards!

The knife edge is exposed! Risk of injury!

Instructions for Use V1.2, RevB – 10/2012

Page 31

4

1

2

3

Fig. 25

Inserting the knife holder

4. Startup

• Move the specimen cylinder to the rear limit stop.

• Insert knife (1) in the center of knife holder (2); tighten clamping screws

(3). If the knife is moved to the left or right edge, tighten only the center

and left or right screw (place remaining screws and tighten slightly).

Always attach the specimen holder before inserting the knife

holder to avoid damaging the knife!

To insert the knife holder into the cryochamber, always use the appropriate manipulator, which comes as part of standard delivery!

• Place knife holder (2) using manipulator (4) diagonally from above

onto knife holder base (9, Fig. 24). Always use the manipulator in or-

der to avoid injury.

• Set the desired clearance angle (see Fig. 24).

Adjusting the clearance angle

The clearance angle is adjusted with the no. 3 Allen key, through the

drillings (16, Fig. 24) in the clearance angle adjusting on the left of the

knife holder.

Limit stop = 2° effective clearance angle 1st scale mark: 5°

2nd scale mark: 10°

3rd scale mark: 15°

• Fasten knife holder (5, Fig. 24) in knife holder base (9, Fig. 24) with

screws (6, Fig. 24).

• Once the selected temperature has been reached, retighten the

screws (7, Fig. 24), on the knife holder (5, Fig. 24), and on the knife

holder base (10, Fig. 24) as well as the knife clamping screws

(6, Fig. 24).

31

Page 32

4. Startup

Adjusting the knife holder laterally:

• Release the clamping screws (10, Fig. 24) of the knife holder base

(9, Fig. 24).

• Displace the knife holder laterally via the eccentric disc (12, Fig. 24).

Changing the knives inside the cryochamber

• Prior to changing knives, move the cryo specimen arm (1, Fig. 24) first

to the rear limit stop and next to the lower limit position.

• Lock the handwheel.

• Using special forceps (Fig. 26) knives can be exchanged inside the

cryochamber at very low temperatures.

Fig. 26

4.9.2 Glass knife, CryoDiamond knife, trimming knife Histo

• Insert the cryo-diamond (8) or glass knife in the knife holder (9); tighten

clamping screws (10).

• See ‘Knife holder for tungsten carbide knives’ on how to proceed.

The trimming knife kit can be used to trim lateral specimen edges parallel

before sectioning with glass or diamond knives.

8

10

Fig. 27

10

Manipulator

9

Fig. 28

32

• It is possible to exchanges the knives inside the cryochamber at very

low temperatures using the standard forceps. Prior to exchanging

the knives, displace the cryo specimen arm to the rear limit stop.

• Lock the handwheel.

Instructions for Use V1.2, RevB – 10/2012

Page 33

4.10 Preparing the pumping system

Use caution when handling liquid nitrogen!

Prior to filling the Dewar vessel with LN2, please refer to the safety

instructions in chapter 2.

• Slowly lower the pump into the Dewar vessel if the liquid boils over

and LN2 escapes from the Dewar, lift the pump partly back out until

the boiling over stops, then continue to lower the pump carefully until

it is completely immersed into the Dewar.

2

1

1

2

The LN2 connecting pipe consists of an outer insulation tube (1) with a

polyamide filling tube (2) inside.

a

• Connect the polyamide tube (2) to the cryochamber (Fig. 29 a), and

press the insulation tube (1) completely into the corresponding opening in the cryochamber wall.

4. Startup

3

• Place the Dewar vessel close.

• Open the protective lid (3) and connect the other end of the polya-

b

Fig. 29

mide tube to the pump (Fig. 29b).

The polyamide and insulation tube are both delivered overlength and can

be shortened according to the needs at the installation site. Always

make sure, however, that both ends of the polyamide tube are covered

entirely by the outer insulation tube.

4.11 Refrigerating

• Before starting with your cryopreparation work, set the desired tem-

perature values for specimen and knife.

• Start the pump by pressing the START button (11, Fig. 18c).

• Move the cryospecimen arm to the lowest position to ensure the

quickest possible refrigeration time.

The reservoir in the cryochamber is filled up with LN2. Once the appropriate level is reached, the filling

level is maintained constant by means of a level sensor which controls the LN2 pump. When the specimen temperature has reached the selected value, the motorized sectioning function of the microtome

33

Page 34

4. Startup

can be started to help reach a stable specimen temperature through the

regular immersion of the cold bridge of the cryo specimen arm into the

liquid nitrogen. The LED above the START button flashes until the knife

temperature has reached the preselected value.

If you want to change the temperature during a work session, e.g. from

-70°C to -120°C, it is recommendable to press the START button once

again as this ensures that the new temperature is reached as fast as

possible, since otherwise the instrument will approach the new temperature value only very slowly.

The cryochamber of the LN22 liquid nitrogen freezing device is an open

chamber system, which can be covered with a lid when relative air humidity is high or during breaks. It is advisable to cover the chamber during the refrigeration process and reopen it before starting to section. An

appropriate plastic lid for the chamber comes as part of standard delivery.

While not in operation or while collecting the specimens, always

move the cryo specimen arm to the lowest position to maintain the

selected specimen temperature at a constant level.

4.12 Refilling the Dewar vessel

Use caution when handling liquid nitrogen!

Please refer to the safety instructions in chapter 2.

The 25 liter Dewar vessel contains enough liquid

nitrogen to work without interruption for more

than 8 hours. We advise you to leave the pump in

the Dewar until the nitrogen content is exhausted.

The liquid nitrogen consumption of the pump while

not in use is less than 1 liter / day.

The Dewar can be filled in two different ways:

34

Press the LN

STOP button (7, Fig. 18c) and wait a

2

few minutes until the pump tubing has thawed and

can thus be bent without difficulty:

Do NOT remove the LN

connecting tube from the

2

pump. This way you avoid formation of condensation water inside the upper pump valve.

1. Slightly lift the pump and refill the Dewar from

a LN

storage tank without removing the pump

2

entirely.

Instructions for Use V1.2, RevB – 10/2012

Page 35

4. Startup

2. Remove the pump from the Dewar, cover the

pump immediately with the yellow protection

cap, place it on the corresponding supporting

device and refill the Dewar. Before the pump

is re-immersed into the Dewar it has to be thoroughly dry.

This second method is very time-consuming

and can take up to several hours. To simplify

the process the use of a second Dewar vessel is recommended. Once a Dewar is empty,

immediately place it into the second (full)

Dewar.

4.13 Heating up the chamber

During operation, metal surfaces and components inside the

cryochamber can reach temperatures from as low as -196°C up to

as hot as +110°C! Touching these extremely cold or respectively

hot parts can cause severe injury!

For that reason, for any type of manipulations inside the

cryochamber you may use only the special tools which come as

part of the standard delivery and the use of which is described in

detail in the present manual.

Transfer of frozen specimens may also only be done by means of

the corresponding special tools.

The pump must always be held in UPRIGHT position to prevent melt water and

humid air from entering the pump valve.

After taking the pump out of the Dewar, immediately cover the Dewar and cover the pump with

the yellow protective cap.

Humidity will cause icing of the pump valves during the following refrigeration process thus interfering with the pumping process. Pumping trouble is easy to recognize: in spite of the pumping

motor being activated, no nitrogen will be pumped

from the Dewar. To eliminate this problem, please

proceed as described in chapter 5.2.4.

• Remove specimens and cryo-tools from the

cryochamber.

• Remove sectioning waste since it will fuse

during heating.

• Press button (H) on the control unit (9, Fig. 18c).

After pressing button (H) the temperature of both

knife and specimen holder will rise quickly to approximately +100°C. After about 45 minutes the

heating process is completed.

Leica LN22

At that point, any residual water inside the chamber should have been evaporated.

The control unit automatically switches off the

heating function once a certain chamber temperature has been reached. This means that the

instrument can be left in the H-mode overnight.

The pump can remain in the Dewar vessel due to

its low liquid nitrogen consumption while not in

operation.

• To restart the instrument, simply press the

START button (11, Fig. 18c).

35

Page 36

5. Cleaning and maintenance

5.1 Cleaning

The cryochamber should be cleaned in regular intervals, especially

when large quantities of sectioning debris have been produced during a

work session.

Since sectioning debris (especially very soft rubber samples, such as

bitumen) melts during the chamber heating process, we advise you to

clean the chamber prior to the heating process (however, after all remaining LN

perature) with a vacuum cleaner or similar tool.

2

1

Do not use acetone or xylene to clean the lacquered surfaces of the

instrument.

has evaporated / the chamber has reached ambient tem-

2

For cleaning, proceed as follows:

• Remove knife, knife holder, specimen holder

and cold bridge.

• Displace the cryo specimen arm to the rear

limit stop and lower end position.

• Release the clamping lever (1) on the microtome base plate.

• Carefully pull the chamber forward towards

yourself until the cryo specimen arm (2) is outside the chamber.

Fig. 30

• Retighten the clamping lever (1) on the microtome base plate.

36

10

• To remove the knife holder system (9), detach

both screws (10).

• Remove both screws together with the corresponding washers, using forceps.

10

9

Fig. 31

Instructions for Use V1.2, RevB – 10/2012

Page 37

5. Cleaning and maintenance

17

Fig. 32

9

111712 15

• Carefully pull out the cable loop (15) far enough

so that the knife holder base can be placed

upright on the bottom plate of the

cryochamber (11).

• Remove the eccentric disc (12).

• Detach the 3 screws (17) of the cryochamber

17

bottom plate.

• Remove cryochamber bottom plate (11) and

knife holder base (9).

• Store the knife holder base on the chamber

wall.

• Use the manipulator to remove the bottom

plate (14) of the LN

trough.

2

Fig. 33

Fig. 34

Leica LN22

11

914

• Vacuum sectioning debris that sticks to cham-

ber walls and bottom or remove it with benzine.

Caution: flammable!

21

• All removable parts can be cleaned in an ul-

trasonic bath.

37

Page 38

5. Cleaning and maintenance

Fig. 35

• Loosely attach the chamber bottom plate (11)

to the knife holder base (9) with screws

(10, Fig. 31).

• Reinsert the bottom plate (14) of the LN

trough

2

into the chamber using the manipulator.

• Use one of your hands to hold the cable loop

on the chamber bottom while inserting the

knife holder base together with the base plate

with your other hand. Pay careful attention

that the cable loop is not crushed between

bolts (21, Fig. 35) and the chamber bottom

plate.

• Unscrew knife holder base (9) again, place on

edge in the chamber, fasten the chamber bottom plate (11) with the screws (17).

• Place eccentric disk (12) in the recess of the

bottom plate.

Fig. 36

17

Fig. 37

38

9

111712 15

• Insert the two screws with the washers in the

drillings (10) and screw the knife holder base

(9) onto the bottom plate.

17

10

17

Fig. 38

Instructions for Use V1.2, RevB – 10/2012

17

Page 39

5.2 Maintenance

5.2.1 General maintenance instructions

Only authorized Leica service engineers may open the instrument

for maintenance and repair work!

Before opening the instrument, switch off the mains switch and pull

the mains plug!

The instrument is practically maintenance-free. However, to ensure

smooth and trouble-free operation of the instrument over a long period

of time, we recommend the following preventive maintenance steps:

• Have the instrument inspected once a year by an authorized Leica

Technical Service engineer.

• Ask for a Service Contract after the warranty period expires.

For details, please contact your local Leica sales office.

• Never attempt any repairs on the instrument yourself since this will

invalidate the warranty.

5.2.2 Exchanging the mains fuses

5. Cleaning and maintenance

14

Fig. 39

Leica LN22

Before exchanging the fuses, switch the instrument off and pull the

mains plug!

When exchanging fuses, only use replacement fuses with the same

specification as the original ones. Refer to chapter 3 ‘Technical

data’ for the correct specifications.

116

The mains fuses are located in the voltage selector housing (3).

• Remove the voltage selector housing (3) as

2

4

described in chapter 5.5.2.

• Remove the fuses (4) and insert new fuses of

the same technical specification.

• Reinsert the housing together with the insert

(2) and the fuses into the corresponding opening in the instrument housing and push lightly

16

to lock it in place.

• Check again whether the correct voltage

3

shows in the indication window (16).

39

Page 40

5. Cleaning and maintenance

5.2.3 Exchanging the bulb

2

1

Fig. 40

Before replacing the lamp, switch off the mains switch and pull the

mains plug!

The bulb of the chamber illumination is located

behind a cover on the left side of the cryochamber.

• Remove the two screws (1) of the cover (2)

with 2.5 screwdriver.

40

• Carefully pull out the cover (2) together with

the cable attached to it on the inside just

3

enough to be able to reach the lamp.

• Remove the lamp (3) and insert a new lamp of

the same specification.

• Put the cover (2) back in its place and secure

with the screws (1).

2

Fig. 41

Instructions for Use V1.2, RevB – 10/2012

Page 41

5.2.4 Removal of the pump valves

2

5. Cleaning and maintenance

The two lower pump valves (1) and (2) can be easily disassembled for

thorough drying. Valve (2) is located above valve (1).

1

3

• For disassembly, support the valves (1) and (2) valve block at the pipe

end with an Allen key no. 3 at the screw (3) and unscrew the brass

valves with a screwdriver.

• Dry the valves on a heating panel.

• Before reinstallation, check whether the ball moves inside the valve

Fig. 42

by shaking it.

41

Page 42

6. Appendix

6.1 Ordering information

Knife holders

Knife holder for triangle glass knife and diamond knife .............................................................. 0378 26169

Knife holder for tungsten carbide knives ....................................................................................... 0378 25655

Knives

Tungsten carbide knife 40°, 30mm .................................................................................................. 0216 08724

Tungsten carbide knife 50°, 30mm .................................................................................................. 0216 08728

Trimming knife (usable only together with adapter 0378 26875) ................................................ 0216 25654

Holder for trimming knife .................................................................................................................. 0378 26875

Cryo-diamond knife, 4mm, 45°, with truff ....................................................................................... 0366 26427

Cryo-diamond knife, 4mm, 45°, without truff ................................................................................. 0366 26428

Cryo-diamond knife, 6mm, 45°, with truff ....................................................................................... 0366 26431

Cryo-diamond knife, 6mm, 45°, without truff ................................................................................. 0366 26432

Specimen holders

EM Universal specimen holder, for RM 21 series and RM 22 series ........................................ 0356 10868

EM Flat specimen holder .................................................................................................................. 0355 10405

Special wrench for EM specimen holder 0356 10868 and 0355 10405....................................... 0356 10869

Round specimen holder for round specimen blocks, dia. 12mm ............................................... 0378 25653

Accessories

Ionization device ............................................................................................................................upon request

Holding pliers for tungsten carbide knives ................................................................................... 0378 26195

Holding pliers for round specimen holder, dia. 6 and 12mm ....................................................... 0378 26193

Holding pliers for EM specimen holder .......................................................................................... 0378 26194

Spare halogen bulb for backlighting system ................................................................................. 0378 32400

Instructions for Use V1.1 – 06/2006 (German, English, French, Spanish).................................. 0700 37117

42

Instructions for Use V1.2, RevB – 10/2012

Page 43

Warranty

Service information

7. Warranty and service

Leica Biosystems Nussloch GmbH guarantees that the contractual

product delivered has been subjected to a comprehensive quality control procedure based on the Leica in-house testing standards, and that

the product is faultless and complies with all technical specifications

and/or agreed characteristics warranted.

The scope of the warranty is based on the content of the concluded

agreement. The warranty terms of your Leica sales organization or the

organization from which you have purchased the contractual product

shall apply exclusively.

If you are in need of technical customer service or spare parts, please

contact your Leica representative or the Leica dealer where you purchased the unit.

Please provide the following information:

• Model name and serial number of the instrument.

• Location of the instrument and name of the person to contact.

• Reason for the service call.

• Delivery date

Decommissioning and disposal

The instrument or parts of the instrument must be disposed of in compliance with the local laws.

Leica LN22

43

Page 44

Notes

44

Instructions for Use V1.2, RevB – 10/2012

Loading...

Loading...