Page 1

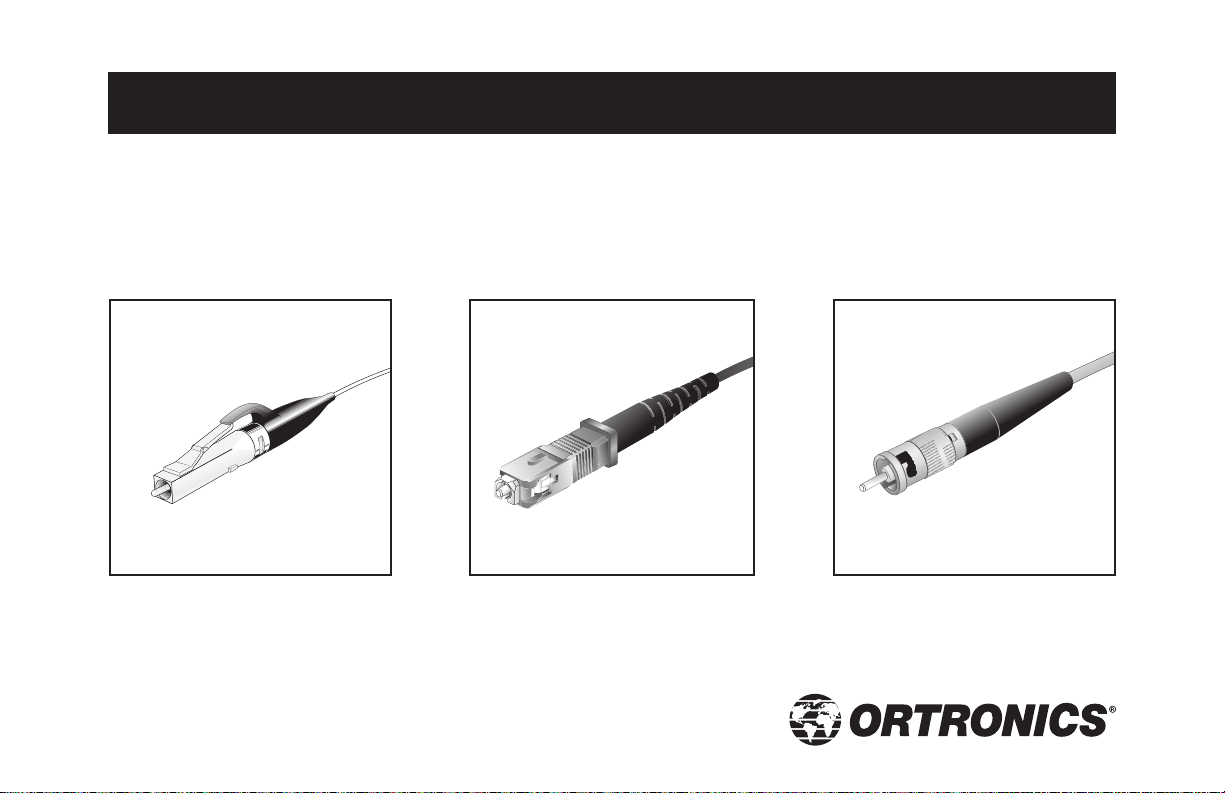

OptiMo

OR-71601671

®

LC, SC and ST Compatible Connectors

Installation Instructions

Page 2

OptiMo®Connector

Installation Instructions

OptiMo implies the OptiMo Multimode (50 µm & 62.5 µm) and Singlemode connectors

INST REV ECN DWN BY DATE CHK BY DATE APP BY DATE

Information subject to change without notice. Ortronics reserves

the right to make changes in product design or components as

progress in engineering or manufacturing may warrant.

OptiMo Connector Installation Instructions Page i

OptiMo®is a registered trademark of Ortronics/Legrand

Page 3

Table of contents

About this guide iv

Safety precautions v

Installation on 900 µm buffered fiber or loose tube with breakout kit 1

Installation on jacketed fiber 33

Cleaning procedures 64

Fiber Preparation Guide ANNEX

OptiMo Connector Installation Instructions Page iii

Page 4

About this guide

This guide contains assembly procedures for the OptiMo®Connector.

Before starting an installation, check to make sure that you have the required tools and materials outlined at the

start of the procedure.

Review each procedure to familiarize yourself with the graphic symbols and the actions required.

OR-71601671 Page iv

Page 5

Safety precautions

CAUTION:

• When installed on a live system, invisible laser radiation may be present.

Do not stare into connector endface or view directly with optical instruments.

• Wear safety glasses when working with optical fiber.

• Dispose of all scrap fiber in the waste bottle to avoid getting fiber slivers.

OptiMo Connector Installation Instructions Page v

Page 6

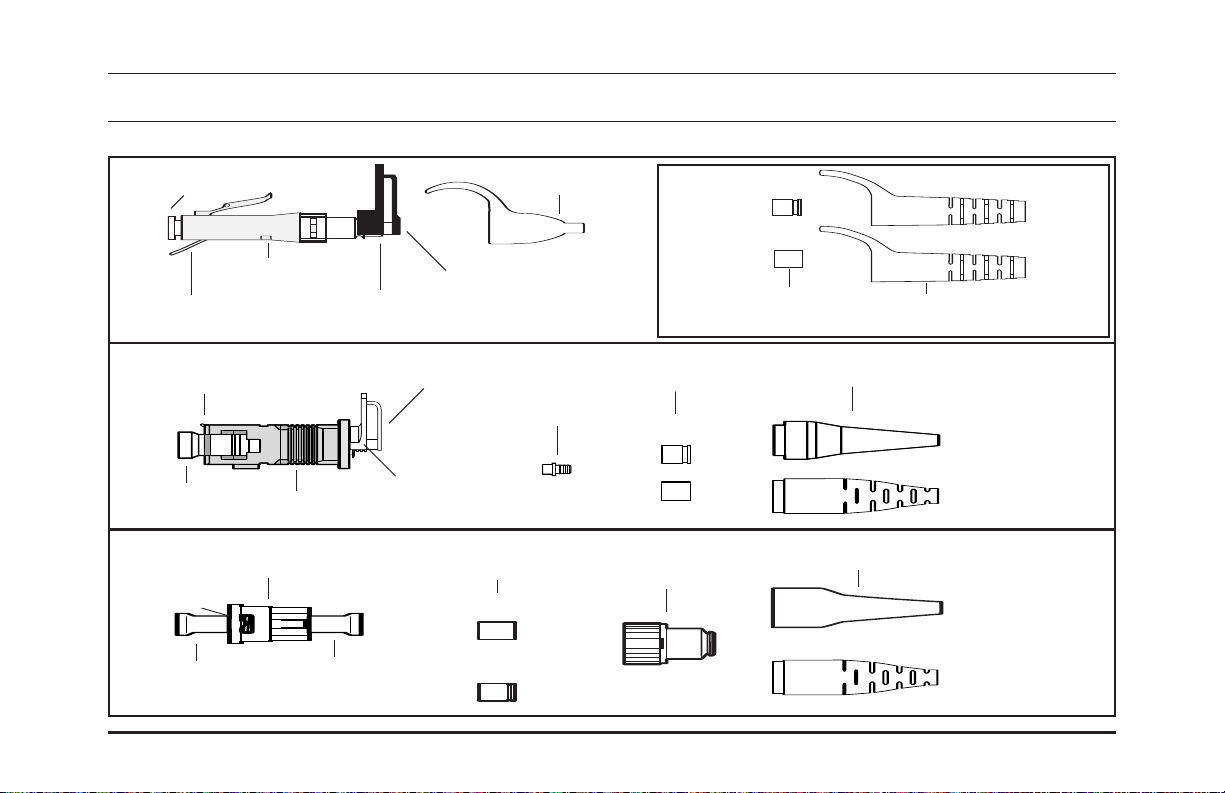

Connector components

LC

SC

ST

OR-71601671 Page vi

dust cap

connector body

Release wire

release wire

dust cap

connector body

front dust cap

disposable tool

connector body

rear dust cap

dust cap

disposable tool

900 µm strain relief boot

dust cap

Cord adapter

crimp sleeves

3.0 mm

2.4 mm

Accessories

crimp sleeves

2.4 mm

3.0 mm

rear housing

2.0 mm

3.0 mm

crimp sleeves

strain relief boots

strain relief boots

22 mmmm

33 mmmm

strain relief boots

900 µm

jacketed

900 µm

jacketed

2.0 mm

3.0 mm

Page 7

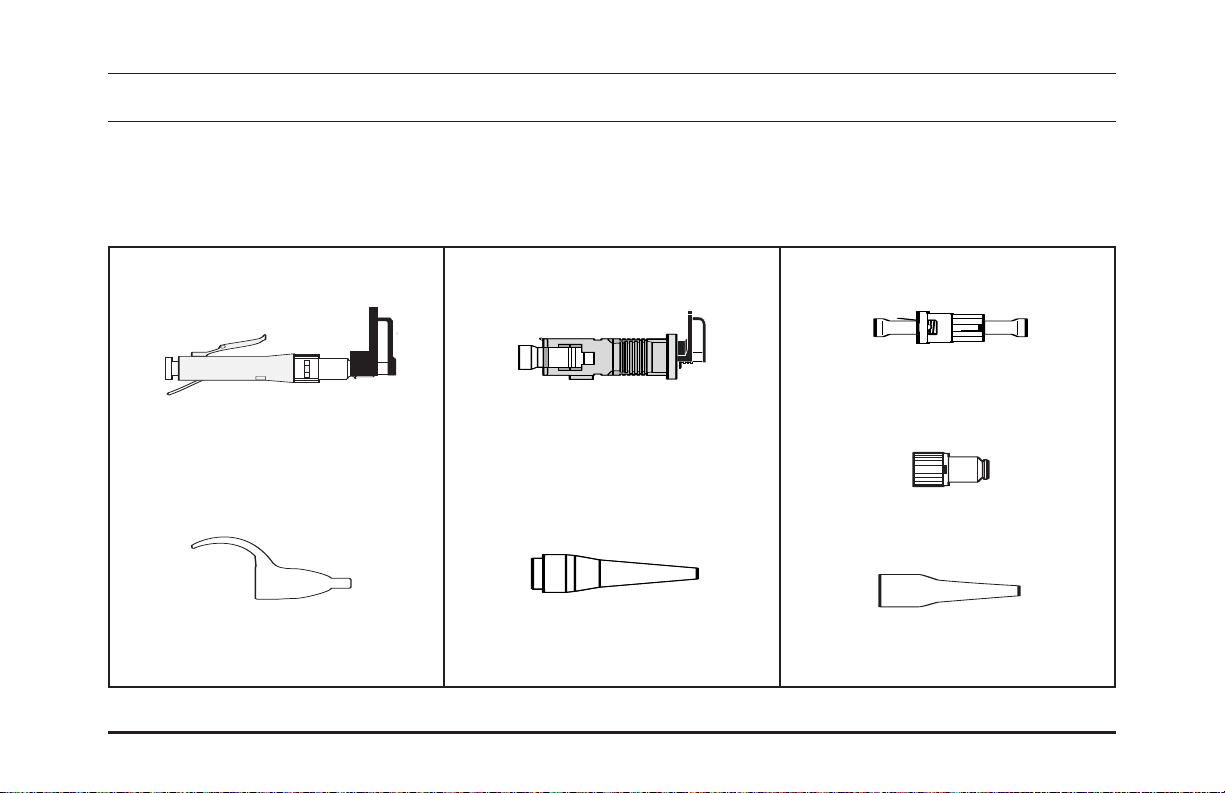

Connector installation tools

OR-71601671

OptiMo

®

LC, SC and ST Compatible Connectors

Installation Instructions

multihead adapter

table top base

OptiMo Connector Installation Instructions Page vii

universal installation tool

tool clamp

fiber cleaver

installation manual

universal stripper

scissors

ink marker

alcohol wipes

tweezers

crimping tool

microscope

fiber waste bottle

Page 8

Installation on 900 µm buffered fiber or loose tube with breakout kit

Open the bag and select the parts required for installation on 900 µm buffered fiber.

1

(Connector body and 900 µm strain relief boot.)

LC

connector body

900 µm strain relief boot

SC ST

connector body

900 µm strain relief boot

connector body with dust caps

rear housing

900 µm strain relief boot

Page 1OptiMo Connector Installation Instructions

Page 9

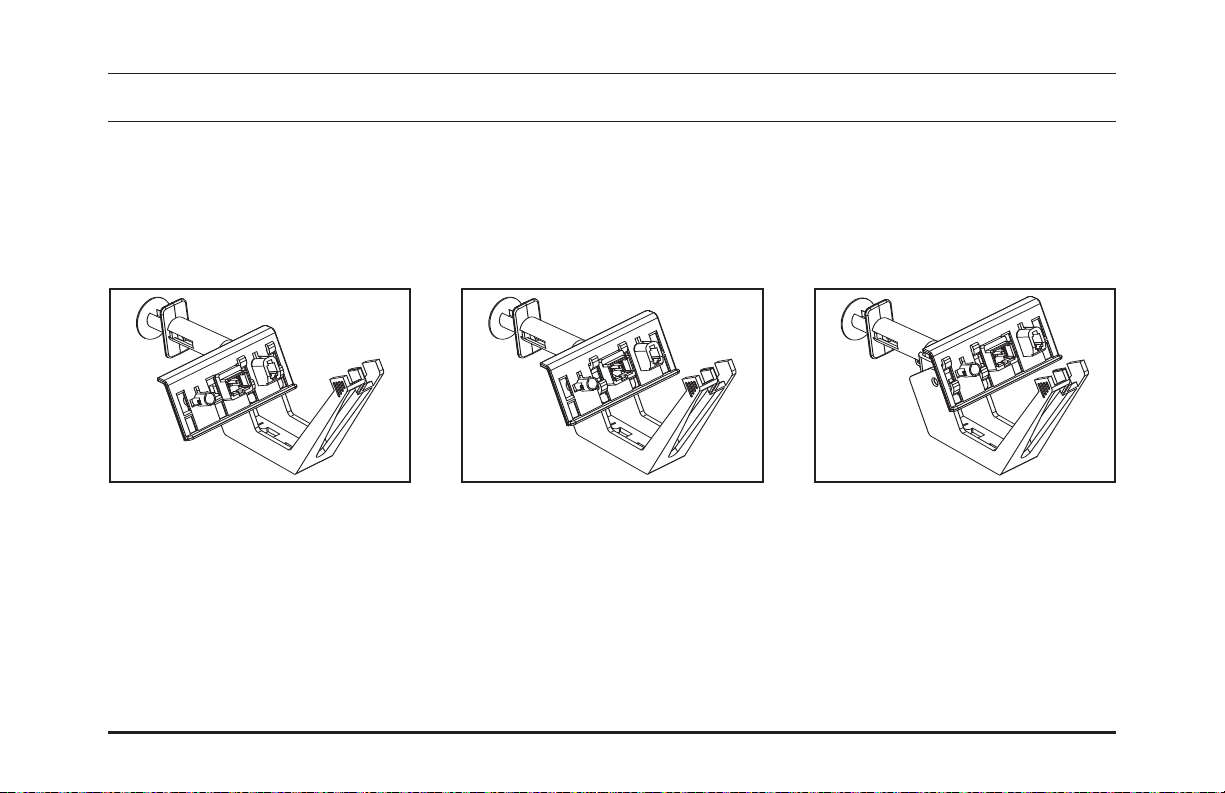

Installation on 900 µm buffered fiber or loose tube with breakout kit

a Install the installation tool on the C clamp as shown, then clamp to the table. The table top base can be

2

used as an alternative.

OR-71601671 Page 2

Page 10

Installation on 900 µm buffered fiber or loose tube with breakout kit

b Install the multihead adapter on the tool in the appropriate position as illustrated below.

2

LC position SC position ST position

Page 3OptiMo Connector Installation Instructions

Page 11

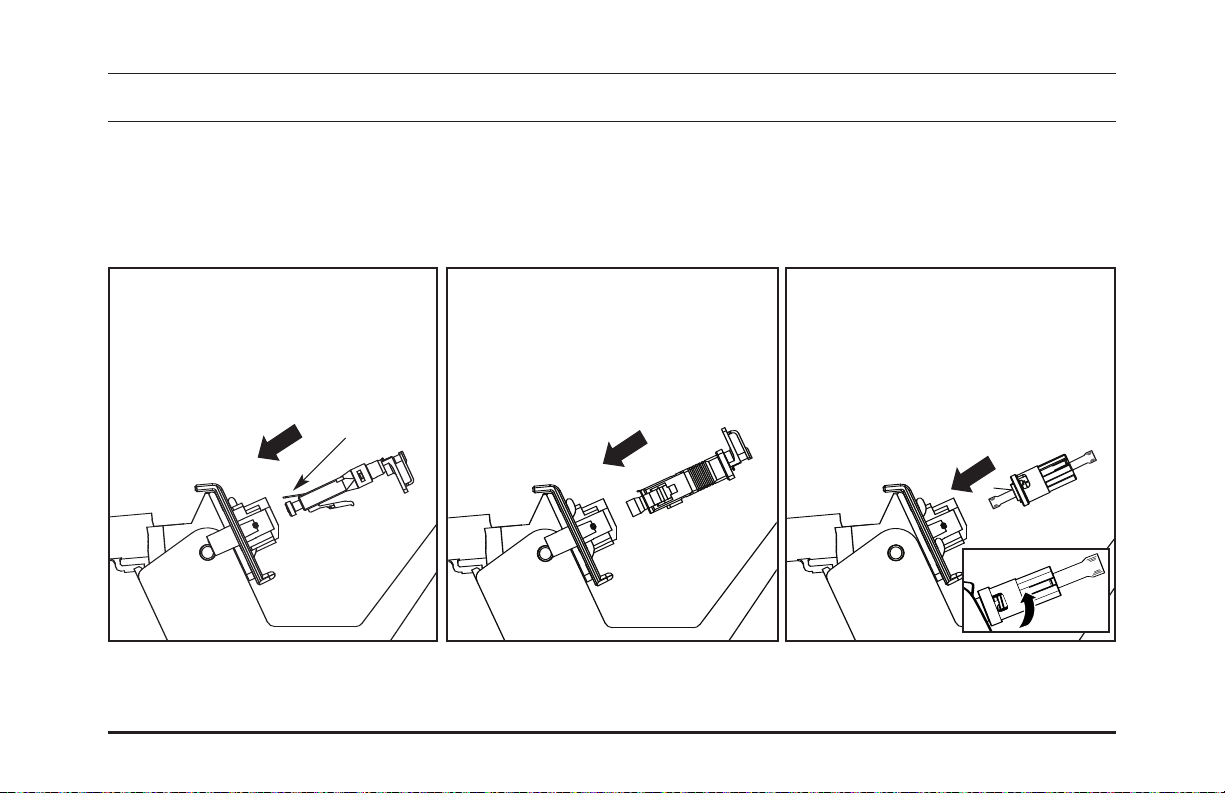

Installation on 900 µm buffered fiber or loose tube with breakout kit

Load the connector body into the installation tool, with the release wire up.

3

LC

Leave dust cap on. Leave dust cap on.

Release wire

OR-71601671 Page 4

SC ST

By pushing the housing into the

receptacle and turning 1/4 turn

clockwise, locking it in place.

Leave dust caps on.

Page 12

Installation on 900 µm buffered fiber

4

LC

Slide the boot down the fiber, narrow

end first, until it is out of the way.

SC ST

Slide the boot down the fiber, narrow

end first, until it is out of the way.

Slide the 900 µm strain relief boot onto

the rear housing until it locks in place.

(Holding the boot on it’s smaller end will

ease insertion.) Slide the rear housing

with boot down the fiber, narrow end

first, until it is out of the way.

Page 5OptiMo Connector Installation Instructions

Page 13

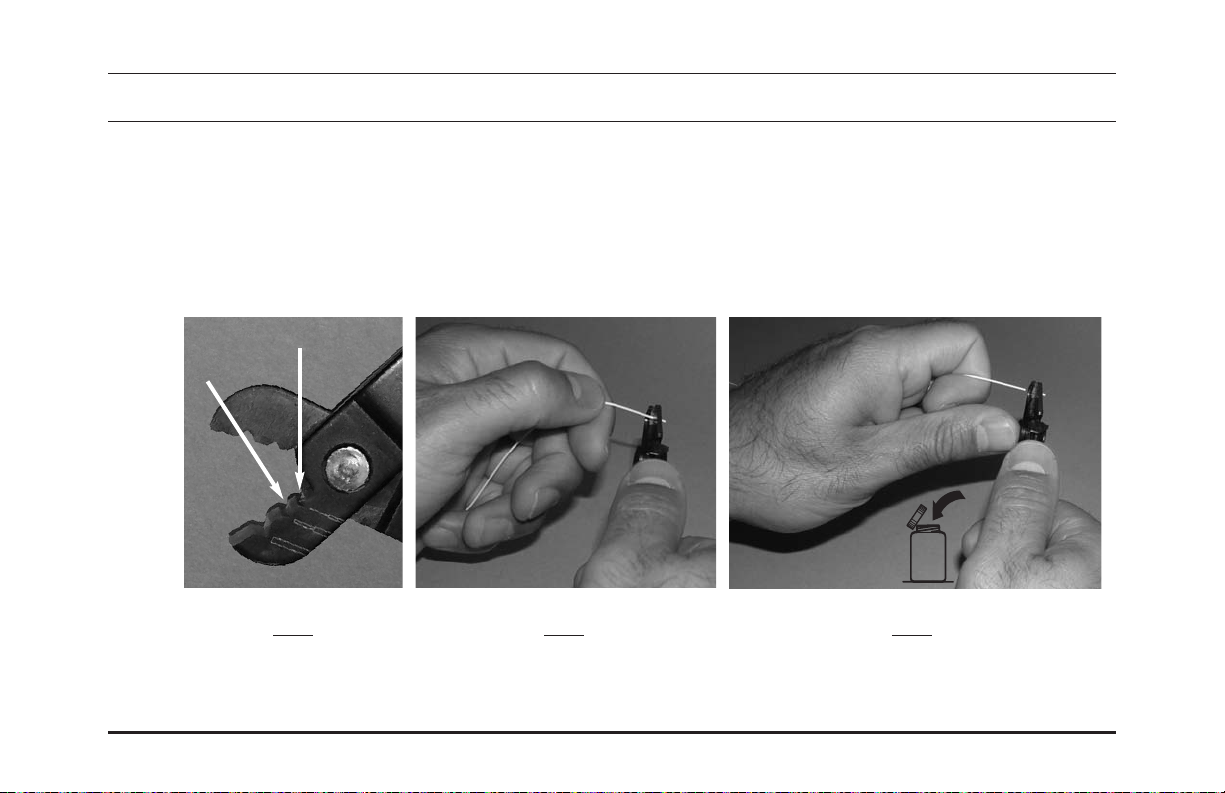

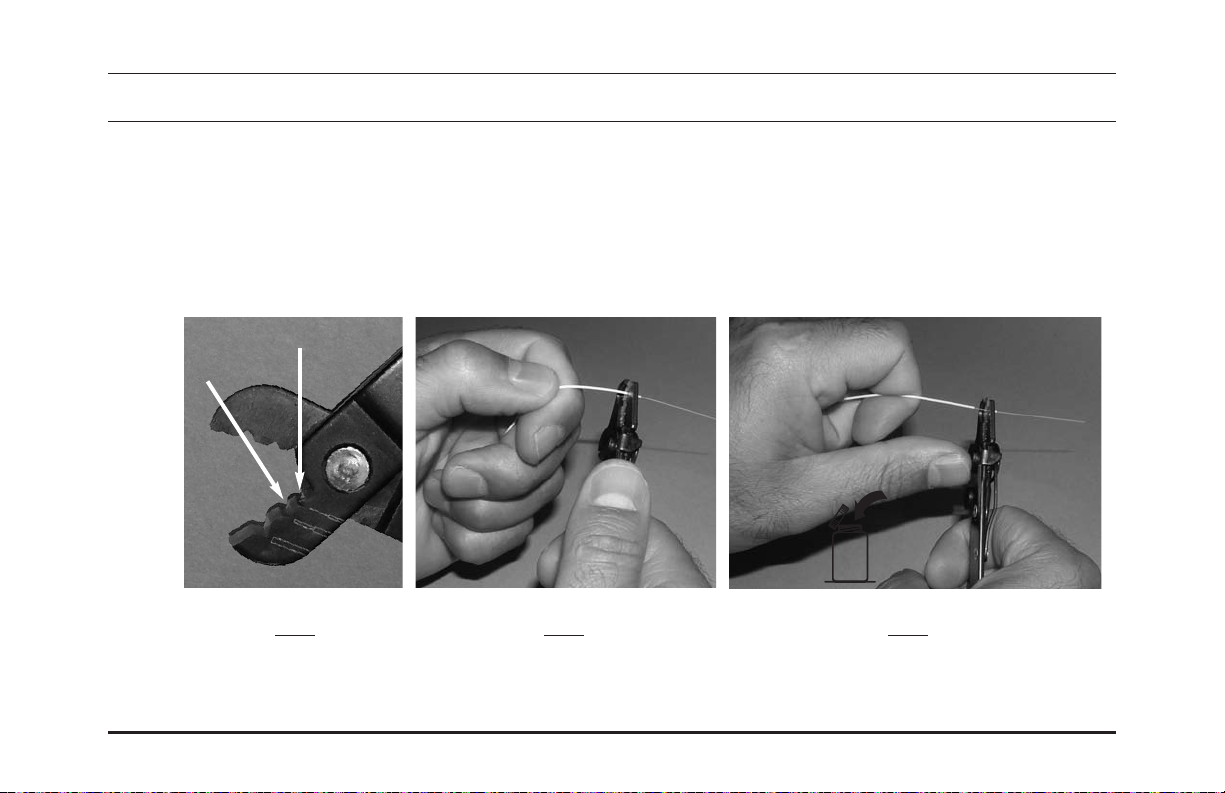

Installation: stripping 900 µm tight buffered fiber (if using loose tube with breakout kit, skip to step 11)

Strip approximately 40 mm of the 900 µm buffered fiber as shown below. Be sure to strip fiber in small

5

(5 mm) sections to avoid breaking it. Buffer end should be clean and square.

If unfamiliar with stripping optical fiber, it is advised to practice using a spare piece of fiber.

*

Make sure the fiber optic stripper tool you are using is in proper operating condition before attempting this step.

*

Use of a tool that is not in proper operating condition could cause the fiber to break.

900 µm "V" opening

250 µm "V" opening

Fiber waste

Fig. 1 Fig. 2 Fig. 3

Step 1. (Fig. 1) Insert fiber into Step 2. (Fig. 2) Close the tool Step 3. (Fig. 3) Draw the tool along the fiber

250 µm "V" opening of the tool. squarely around the fiber. using thumb pressure while keeping the tool

perpendicular to the fiber.

OR-71601671

Page 6

Page 14

Installation: stripping 900 µm tight buffered fiber (if using loose tube with breakout kit, skip to step 11)

Strip approximately 40 mm of the 900 µm buffered fiber. Be sure to strip fiber in small (5 mm) sections to

6

avoid breaking it. Buffer end should be clean and square. After stripping, measure and mark the buffer

from its end as illustrated below.

If unfamiliar with stripping optical fiber, it is advised to practice using a spare piece of fiber.

*

LC

15 mm

SC

11 mm

ST

9 mm

OptiMo Connector Installation Instructions

Fiber waste

Page 7

Page 15

Installation on 900 µm buffered fiber

Carefully clean the bare fiber with a folded alcohol wipe or alcohol soaked lint-free paper. Use two or

7

three passes. Avoid touching the bare fiber, or laying it down on the table, after it has been cleaned.

OR-71601671

Page 8

Page 16

Pre-Set Cleaver Installation on 900 µm tight buffered fiber (if using an adjustable cleaver, skip to step 8b)

a Cleave the fiber 7 mm from the end of the buffer. Be sure to read and understand the procedure

8

included with your cleaver that is provided with your Ortronics®Field Installation Kit prior to

attempting this step. (The procedure can be downloaded from the Ortronics web site at

http://www.legrand.us/ortronics/technicalresources/instruction%20manuals.aspx)

If unfamiliar with cleaving, it is advised to practice using a spare piece of fiber. Generally, a light touch is all that is

*

required to score the fiber. The fiber buffer must rest against the stop.

Alternative cleavers which produce a 7 mm bare fiber length may be used.

+0.5

-0.0

*

Fiber waste

OptiMo Connector Installation Instructions

Page 9

Page 17

Adjustable Cleaver Installation on 900 µm tight buffered fiber

b Cleave the fiber 7 mm from the end of the buffer. Be sure to read and understand the procedure

8

included with your cleaver that is provided with your Ortronics®Field Installation Kit prior to

attempting this step. (The procedure can be downloaded from the Ortronics web site at

http://www.legrand.us/ortronics/technicalresources/instruction%20manuals.aspx)

*

*

OR-71601671

If unfamiliar with cleaving, it is advised to practice using a spare piece of fiber. Generally, a light touch is all that is

required to score the fiber. The fiber buffer must be set to produce a 7 mm bare fiber length.

Alternative cleavers which produce a 7 mm bare fiber length may be used.

+0.5

-0.0

Fiber waste

+0.5

-0.0

Page 10

Page 18

Installation on 900 µm buffered fiber

Cleave the fiber 7 mm from the end of the buffer. Be sure to read and understand the operating

9

instructions included with the cleaver. Using tweezers, discard waste fiber into the proper waste container.

If unfamiliar with cleaving, it is advised to practice using a spare piece of fiber. Generally, a light touch is all that is

*

required to score the fiber. The fiber buffer must rest against the stop.

Alternative cleavers which produce a 7 mm bare fiber length may be used.

+0.5

-0.0

*

OptiMo Connector Installation Instructions

Fiber waste

Page 11

Page 19

Installation on 900 µm buffered fiber

Use the microscope to check the quality of the cleave. Pointing the microscope at a white surface will

10

provide a brighter image.

Note: If the Ortronics®Precision Cleave Tool (OR-60300189) is used, cleave inspection with a microscope is not required.

*

Turn microscope over and place fiber on stage.

1

1

Make sure fiber position is as illustrated.

2

2

OR-71601671

Page 12

Page 20

Installation on 900 µm buffered fiber

Close stage and check fiber. It is recommended to rotate the fiber 900-180

3

3

Note: Batteries are not required.

0

to verify from different angles.

Unacceptable cleaves

Acceptable cleave

*

If the cleave is unacceptable, then the fiber must be re-prepared starting from step 5. If fiber or fiber endface

appear dirty clean it as in step 6.

Once this step is successfully completed, proceed to step 11

OptiMo Connector Installation Instructions

Page 13

Page 21

Installation: stripping 900 µm loose tube fiber with breakout kit(if using tight buffered, go to step 5)

Strip the 900 µm tube as shown below such that the distance from the end of the tube to the end of the

11

250 µm "V" opening

fiber is approximately 40 mm. Tube end should be clean and square.

If unfamiliar with cleaving, it is advised to practice using a spare piece of fiber.

*

Make sure the fiber optic stripper tool you are using is in proper operating condition before attempting this step.

*

Use of a tool that is not in proper operating condition could cause the fiber to break.

900 µm "V" opening

Fiber waste

Fig. 1 Fig. 2 Fig. 3

Step 1. (Fig. 1) Insert fiber into Step 2. (Fig. 2) Close the tool Step 3. (Fig. 3) Draw the tool along the fiber

900 µm "V" opening of the tool. squarely around the fiber. using thumb pressure while keeping the tool

perpendicular to the fiber.

OR-71601671

Page 14

Page 22

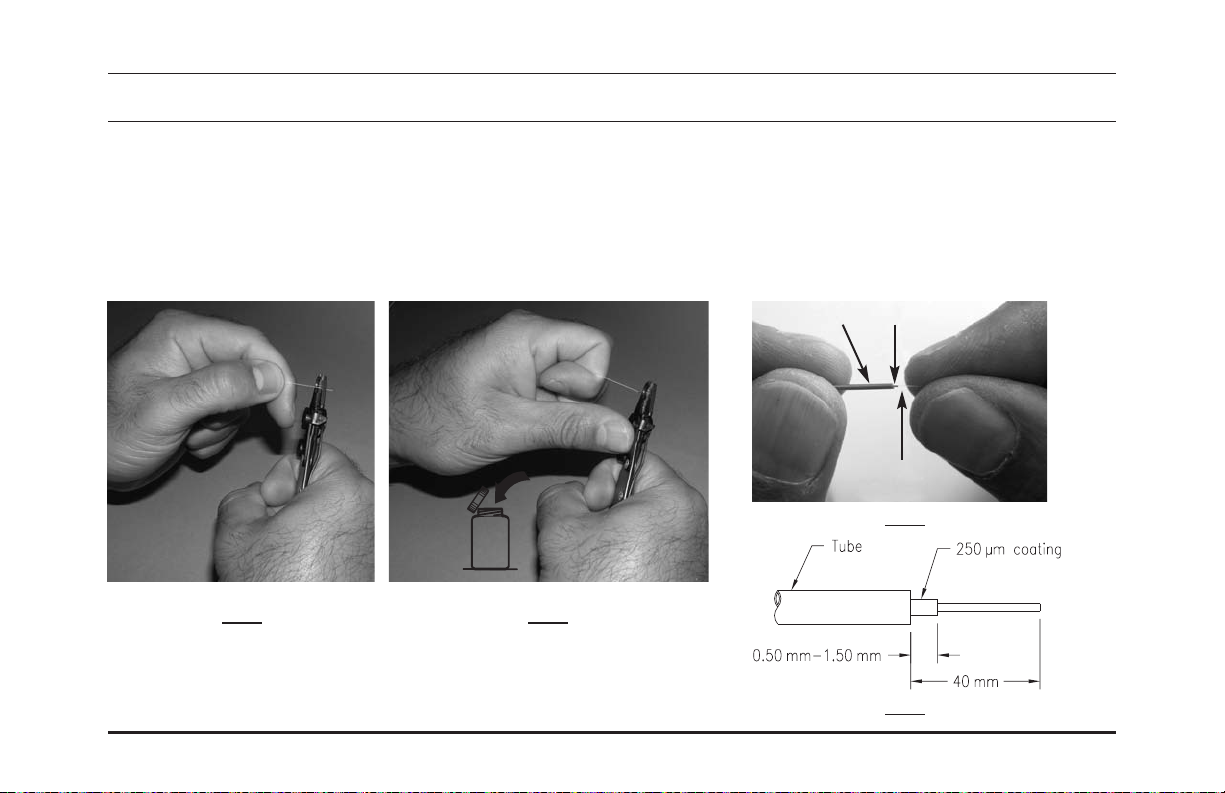

Installation: stripping 900 µm loose tube fiber with breakout kit

Using your fingers, carefully grip the end of the 250 µm coated fiber as shown, and gently push the fiber

12

back into the tube as far as it will go without bending.

OptiMo Connector Installation Instructions

Tube

250 µm coated fiber

Page 15

Page 23

Installation: stripping 900 µm loose tube fiber with breakout kit

Position the fiber stripper at the end of the tube, and proceed to remove the 250 µm coating in one even

13

stripping motion as shown in Figures 1 and 2 below. 250 µm coating end should be clean and square.

Using your fingers, carefully grip the bare fiber close to the 250 µm coating as shown in Fig. 3 below, and

gently push the fiber back into the tube as far as it will go. The 250 µm coating must always be visible

when the fiber is lightly pushed into the tube. There must be 0.50 mm–1.50 mm of 250 µm coating

extending beyond the tube as shown in Fig. 4 below.

250 µm coating

tube

fiber

Fig. 3

Fiber waste

Fig. 1 Fig. 2

Step 1. (Fig. 1) Insert fiber into the Step 2. (Fig. 2) Draw the tool along the

250 µm "V" opening of the tool fiber using thumb pressure while keeping

(shown in previous page). Close the tool perpendicular to the fiber.

the tool squarely around the fiber.

Fig. 4

OR-71601671

Page 16

Page 24

Installation: marking the 900 µm loose tube fiber with breakout kit

Place a mark 15 mm from the end of the tube, as shown below.

14

Tube

OptiMo Connector Installation Instructions

Mark

250 µm coating

15 mm

Page 17

Page 25

Installation: cleaning 900 µm loose tube fiber with breakout kit

Carefully clean the bare fiber with a folded alcohol wipe or alcohol soaked lint-free paper. Use two or

15

three passes. Use care not to remove the mark on the tube in the process. Avoid touching the bare fiber,

or laying it down on the table, after it has been cleaned.

OR-71601671

Page 18

Page 26

Pre-Set Cleaver Installation on 900 µm loose tube fiber(if using an adjustable cleaver, skip to step 16b)

a Cleave the fiber 7.0 mm–7.5 mm from the end of the 250 µm coating (not from the end of the tube).

16

Be sure to read and understand the procedure included with your cleaver that is provided with

your Ortronics®Field Installation Kit prior to attempting this step. (The procedure can be

downloaded from the Ortronics web site at

http://www.legrand.us/ortronics/technicalresources/instruction%20manuals.aspx)

If unfamiliar with cleaving, it is advised to practice using a spare piece of fiber. Generally, a light touch is all that is

*

required to score the fiber. The 250 µm coating must rest against the stop.

Alternative cleavers which produce a 7 mm bare fiber length may be used.

*

After cleaving, there must still be 0.50 mm–1.50 mm of 250 µm coating extending beyond the tube as shown. If required,

*

using your fingers, carefully grip the bare fiber close to the 250 µm coating as shown in Fig. 3 of step 13, and gently push

the fiber back into the tube as far as it will go. The 250 µm coating must always be visible when the fiber is lightly pushed

into the tube.

+0.5

-0.0

OptiMo Connector Installation Instructions

Fiber waste

Page 19

Page 27

Adjustable Cleaver Installation on 900 µm loose tube fiber

b Cleave the fiber 7.0 mm–7.5 mm from the end of the 250 µm coating (not from the end of the tube). Be

16

sure to read and understand the procedure included with your cleaver that is provided with your

Ortronics®Field Installation Kit prior to attempting this step. (The procedure can be downloaded from

the Ortronics web site at http://www.legrand.us/ortronics/technicalresources/instruction%20manuals.aspx)

*

*

*

OR-71601671

If unfamiliar with cleaving, it is advised to practice using a spare piece of fiber. Generally, a light touch is all that is

required to score the fiber. The 250 µm coating must be set to produce a 7 mm bare fiber length.

Alternative cleavers which produce a 7 mm bare fiber length may be used.

After cleaving, there must still be 0.50 mm–1.50 mm of 250 µm coating extending beyond the tube as shown. If

required, using your fingers, carefully grip the bare fiber close to the 250 µm coating as shown in Fig. 3 of step 13,

and gently push the fiber back into the tube as far as it will go. The 250 µm coating must always be visible when the

fiber is lightly pushed into the tube.

Fiber waste

+0.5

-0.0

+0.5

-0.0

Page 20

Page 28

Installation: cleave inspection of 900 µm loose tube fiber

Use the microscope to check the quality of the

17

OptiMo Connector Installation Instructions

cleave. Pointing the microscope at a white

surface will provide a brighter image. If the

cleave is unacceptable, then the fiber must be

re-prepared starting from step 11. If fiber or

fiber end-face appears dirty, reclean fiber as in

step 15.

1

Turn microscope over and place fiber on stage.

2

Make sure fiber position is as illustrated.

3

Close stage and check fiber.

4

Slowly adjust focus knob until fiber profile is clear.

5

It is recommended to rotate the fiber 90˚ - 180˚ to

verify different angles

Note: Batteries are not required.

*

If the Ortronics®Precision Cleave Tool

(OR-60300189) is used, cleave inspection

with a microscope is not required.

3

1

2

Unacceptable cleaves

Acceptable cleave

Page 21

Page 29

Installation on 900 µm tight buffered fiber or loose tube with breakout kit

Break dust cap from the disposable tool. Discard.

18

OR-71601671

Page 22

Page 30

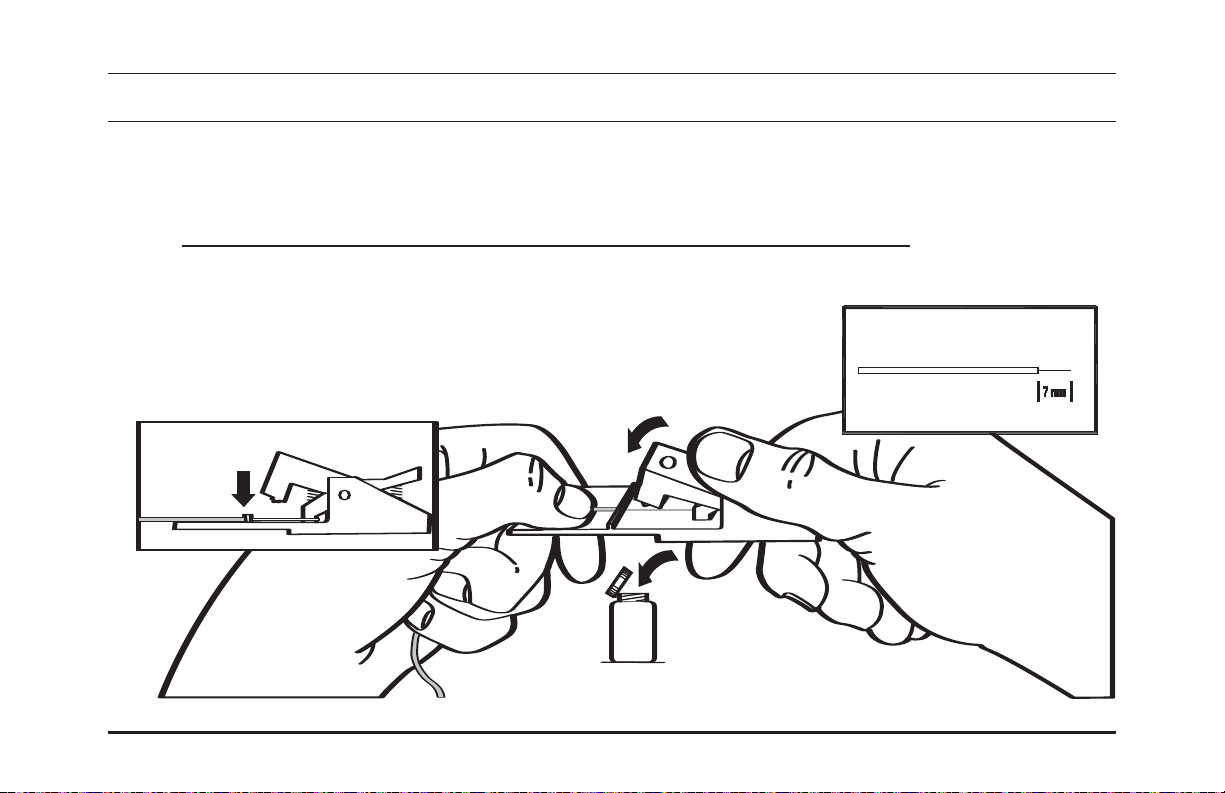

Installation on 900 µm tight buffered fiber or loose tube with breakout kit

Carefully insert the bare fiber into the stem of the connector until you feel the end of the fiber touch the

19

fiber stub inside the connector. Gently rotating the fiber between your thumb and forefinger may ease

insertion. DO NOT rotate or remove the fiber once fully inserted into the connector. When fully inserted,

the pen mark on the buffer should be near the edge of the connector stem. Clamp the fiber into the

installation tool clamp as shown in Fig. 1. In order to ensure that the fiber end face being installed

maintains contact with the fiber end face inside the connector during subsequent handling, there MUST

BE a bow of approximately 15 mm–20 mm (0.6 in.–0.75 in.) as illustrated.

OptiMo Connector Installation Instructions

Pen mark

Installation Tool

Fiber Clamp

15 mm–20 mm

(0.6 in.–0.75 in.)

Figure 1

Page 23

Page 31

Installation on 900 µm tight buffered fiber or loose tube with breakout kit

Depress the installation tool plunger. Ensure it hooks the release wire, then slowly release the plunger.

20

Discard the release wire.

Release wire

OR-71601671

Page 24

Page 32

Installation on 900 µm buffered fiber

21

LC SC

Break dust cap from disposable tool and

discard it.

Break dust cap from disposable tool and

discard it.

ST

Remove rear dust cap from connector

body. Discard.

Page 25OptiMo Connector Installation Instructions

Page 33

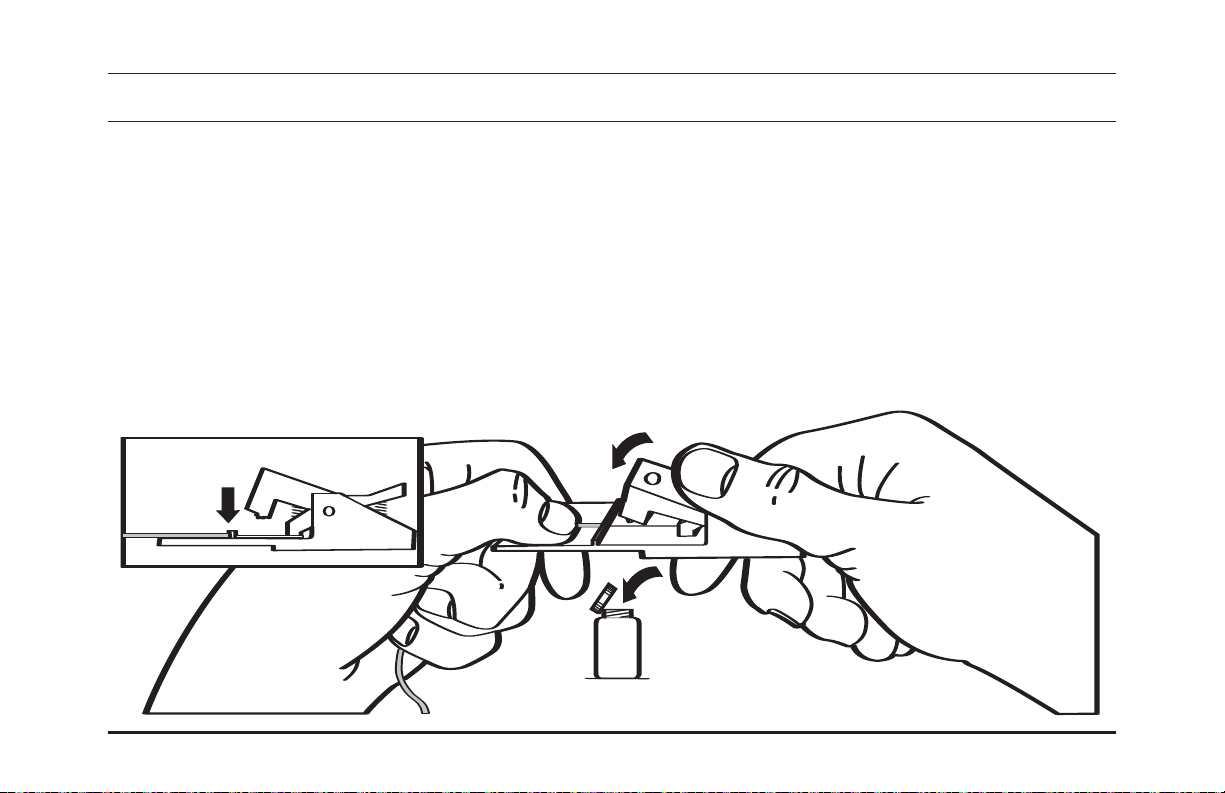

Installation on 900 µm tight buffered fiber or loose tube with breakout kit

Carefully insert the bare fiber into the stem of the connector until you feel the end of the fiber touch the

22

fiber stub inside the connector. Gently rotating the fiber between your thumb and forefinger may ease

insertion. DO NOT rotate or remove the fiber once fully inserted into the connector. When fully inserted,

the pen mark on the buffer should be near the edge of the connector stem. Clamp the fiber into the

installation tool clamp as shown in Fig. 1. In order to ensure that the fiber end face being installed

maintains contact with the fiber end face inside the connector during subsequent handling, there MUST

BE a bow of approximately 15 mm–20 mm (0.6 in.–0.75 in.) as illustrated.

Pen mark

Installation Tool

Fiber Clamp

15 mm–20 mm

(0.6 in.–0.75 in.)

Figure 1

Page 26OR-71601671

Page 34

Installation on 900 µm buffered fiber

Carefully insert the bare fiber into the stem of the connector until you feel the fibers

23

make contact. Gently twisting the fiber may ease insertion. Do not twist or remove

the fiber once it is fully inserted. When fully inserted, the pen mark on the buffer

should be near the edge of the stem of the connector. Clamp the fiber into the clamp

of the installation tool. There must be a bow of approximately 15mm-20mm (0.6in-

0.75in) as illustrated in the fiber in order to maintain a contact between the end faces

of the fibers.

LC SC ST

Pen mark

clamp

OptiMo Connector Installation Instructions

Pen mark

Pen mark

Page 27

Page 35

Installation on 900 µm buffered fiber

Depress the installation tool plunger. Ensure it hooks the release wire, then slowly release the plunger.

24

LC SC

Release wire

OR-71601671

ST

Release wire Release wire

Page 28

Page 36

Installation on 900 µm buffered fiber

Unclamp the fiber. Carefully remove the connector from the installation tool. Hold the crimping tool

25

horizontally and close it partially. Load the connector into the first and smallest die (.068 hex) of the

crimping tool as shown with the disposable tool tab pointing at the crimping tool handle. The smallest

diameter hex face is against the disposable tool tab. Crimp firmly until tool release latch opens.

Make sure that the crimp tool you are using is in proper operating condition before attempting this step. Also make sure that the tool is set to the

*

settings shown in the Technical Bulletin—OptiMo®Field Installable Connectors document that is provided with your Ortronics®Field Installation Kit.

(The document can be downloaded from the Ortronics web site at http://www.legrand.us/ortronics/technicalresources/instruction%20manuals.aspx)

LC SC ST

Buffer crimp area

OptiMo Connector Installation Instructions

Buffer crimp area

Buffer crimp area

Page 29

Page 37

Installation on 900 µm buffered fiber

a

26

LC SC ST

Remove disposable tool and discard it.

Holding the boot by its collar, align the anti

snag with the latch of the LC connector,

slide it onto the rear of the connector until

its step reaches the connector body. The

installation is now completed.

Be sure to clean the connector as described

*

in the “Cleaning Procedures” section before

using the connector.

Grab the disposable tool as shown. Pull

until a click is heard. Remove the tool and

discard it.

Align and press the rear housing with boot

into the front housing until a click is heard.

The installation is now complete.

Be sure to clean the connector as described

*

in the “Cleaning Procedures” section before

using the connector.

OR-71601671

Page 30

Page 38

SC

26

Installation on 900 µm buffered fiber

b Holding the boot by its collar, slide it onto the rear of the connector until its step reaches the

connector body. The installation is now completed.

Be sure to clean the connector as described in the “Cleaning Procedures” section before using the connector

*

(See page 64).

SC only

OptiMo Connector Installation Instructions

Page 31

Page 39

Notes

OR-71601671 Page 32

Page 40

Installation on jacketed fiber

1

LC

Open the connector bag and the accessories

bag. Select the appropriate parts required for

installation on 2.0mm or 3.0mm jacketed

fiber. (Connector body, crimp sleeve and

strain relief boot)

connector body

Accessories

2.0 mm

3.0 mm

crimp sleeves

OptiMo Connector Installation Instructions

22 mm mm

33 mm mm

strain relief boots

2.0 mm

3.0 mm

SC

1a) Before you start an installation on jacketed

fiber, you need to determine the installation

method (there are two) and the parts you are

going to need. You simply have to determine the

outer diameter of the cable jacket you are

installing the connector on.

connector body

2.4 mm

3mm strain relief boots

Cord adapter

3.0 mm

crimp sleeves

ST

Open Open the bag of materials and take out the

connector body and the rear housing. In order to

select the crimp sleeve, you need to first

determine the outer diameter of the cable jacket

you are installing. The appropriate crimp sleeve

for a cord, size from 2.0 mm to 2.4 mm is the 2.4

mm sleeve. For a cord size from 2.5 mm to

3.0 mm, use the 3.0 mm crimp sleeve.

connector body

crimp sleeves

3.0 mm

2.4 mm

rear housing

3mm strain relief boots

Page 33

Page 41

Installation on jacketed fiber

a Install the installation tool on the C clamp as shown, then clamp to the table. The table top base can be

2

used as an alternative.

OR-71601671 Page 34

Page 42

Installation on jacketed fiber

b Install the multihead adapter on the tool in the appropriate position as illustrated below.

2

LC position SC position ST position

Page 35OptiMo Connector Installation Instructions

Page 43

Installation on jacketed fiber

Load the connector body into the installation tool, with the release wire up.

3

LC

Leave dust cap on.

Release wire

OR-71601671 Page 36

SC

Leave dust cap on.

ST

By pushing the housing into the

receptacle and turning 1/4 turn

clockwise, locking it in place.

Leave dust caps on.

Page 44

Installation on jacketed fiber

4

LC

Slide the boot down the fiber, narrow

end first, until it is out of the way.

SC

Slide the boot down the fiber, narrow

end first, until it is out of the way.

ST

Slide the strain relief boot onto the rear

housing until it locks in place. (Holding

the boot on its smaller end will ease

insertion.) Slide the rear housing with

boot, narrow end first.

Page 37OptiMo Connector Installation Instructions

Page 45

Installation on jacketed fiber

Using the universal stripper as shown cut squarely and remove 50 mm of the outer jacket from the end of

5

the cord. The jacket must be cut cleanly and square.

Fiber waste

OR-71601671 Page 38

Page 46

Installation on jacketed fiber

Insert the crimp sleeve down the fiber approx. 30 mm from the edge of the jacket, hold the Kevlar with

6

the crimp sleeve.

LC

SC

ST

3 mm

2 mm

3 mm

2.4 mm

3 mm

2.4 mm

Page 39OptiMo Connector Installation Instructions

Page 47

LC

7

Installation on jacketed fiber

Make sure all the slack fiber is pushed back inside the jacket. First mark the buffer at the end of the

jacket. Then mark it again at 16 mm.

LC

16 mm

OR-71601671 Page 40

Page 48

SC

Installation on jacketed fiber

a For 2.0 mm to smaller than 2.4 mm cord

8

Make sure all the slack fiber is pushed back inside the

jacket. First mark the buffer at the end of the jacket.

Mark it again at 6 mm and 17 mm.

6 mm

17 mm

b For 2.4 mm to 3.0 mm cord

8

Make sure all the slack fiber is pushed back inside the

jacket. Insert the cord adapter as shown. First mark

the buffer at the end of the cord adapter. Mark it again

at 4 mm and 15 mm.

SC

4 mm

15 mm

Page 41OptiMo Connector Installation Instructions

Page 49

ST

9

Installation on jacketed fiber

Make sure all the slack fiber is pushed back inside the jacket. First mark the buffer at the end of the

jacket. Then mark it again at 11 mm.

ST

11 mm

OR-71601671 Page 42

Page 50

Installation on jacketed fiber

Hold the fiber on the exposed buffer section. Strip the fiber to the mark. Be

10

sure to strip the buffer from the fiber in small (5 mm) sections to avoid breaking

the fiber.

LC

SC

For 2.0 mm to smaller than 2.4 mm cord

16 mm

For 2.4 mm to 3.0 mm cord

If unfamiliar with stripping optical fiber, it is advised to practice using a spare piece of fiber.

17 mm

15 mm

ST

*

11 mm

Page 43OptiMo Connector Installation Instructions

Page 51

Installation on jacketed fiber

Carefully clean the bare fiber with a folded alcohol wipe or alcohol soaked lint-free paper. Use two or

11

three passes. Avoid touching the bare fiber, or laying it down on the table, after it has been cleaned.

OR-71601671 Page 44

Page 52

Pre-Set Cleaver Installation on jacketed fiber

a Cleave the fiber 7 mm from the end of the buffer. Be sure to read and understand the procedure

12

included with your cleaver that is provided with your Ortronics®Field Installation Kit prior to

attempting this step. (The procedure can be downloaded from the Ortronics web site at

http://www.legrand.us/ortronics/technicalresources/instruction%20manuals.aspx)

If unfamiliar with cleaving, it is advised to practice using a spare piece of fiber. Generally, a light touch is all that is

*

required to score the fiber. The fiber buffer must rest against the stop.

Alternative cleavers which produce a 7 mm bare fiber length may be used.

+0.5

-0.0

*

Fiber waste

Page 45OptiMo Connector Installation Instructions

Page 53

Adjustable Cleaver Installation on jacketed fiber

b Cleave the fiber 7 mm from the end of the buffer. Be sure to read and understand the procedure

12

included with your cleaver that is provided with your Ortronics®Field Installation Kit prior to

attempting this step. (The procedure can be downloaded from the Ortronics web site at

http://www.legrand.us/ortronics/technicalresources/instruction%20manuals.aspx)

If unfamiliar with cleaving, it is advised to practice using a spare piece of fiber. Generally, a light touch is all that is

*

required to score the fiber. The fiber buffer must be set to produce a 7 mm bare fiber length.

Alternative cleavers which produce a 7 mm bare fiber length may be used.

+0.5

-0.0

*

+0.5

-0.0

Fiber waste

OR-71601671 Page 46

Page 54

Installation on jacketed fiber using preset cleaver

Press the buffer into place on the cleaver, and cleave the fiber 7 mm from the end of the buffer. Be sure

13

to read and understand the operating instructions included with the cleaver. Using tweezers, discard

waste fiber into the proper waste container.

If unfamiliar with cleaving, it is advised to practice using a spare piece of fiber. Generally, a light touch is all that is required to

*

score the fiber. The fiber buffer must rest against the stop.

Alternative cleavers which produce a 7 mm bare fiber length may be used.

*

+0.5

-0.0

Fiber waste

OptiMo Connector Installation Instructions

Page 47

Page 55

Installation on jacketed fiber

Use the microscope to check the quality of the cleave. Pointing the microscope at a white surface will

14

provide a brighter image.

Note: If the Ortronics®Precision Cleave Tool (OR-60300189) is used, cleave inspection with a microscope is not required.

*

1

Turn microscope over and place fiber on stage.

1

2

Make sure fiber position is as illustrated.

2

OR-71601671 Page 48

Page 56

Installation on jacketed fiber

Close stage and check fiber. It is recommended to rotate the fiber 900-180

3

3

Note: Batteries are not required.

*

If the cleave is unacceptable, then the fiber must be re-prepared starting from step 5. If fiber or fiber endface appear

dirty, clean it as in step 11.

0

to verify from different angles.

Unacceptable cleaves

Acceptable cleave

Page 49OptiMo Connector Installation Instructions

Page 57

Installation on jacketed fiber

15

LC SC

Break dust cap from disposable tool and

discard it.

OR-71601671 Page 50

Break dust cap from disposable tool and

discard it.

ST

Remove rear dust cap from connector

body. Discard.

Page 58

Max. 1mm

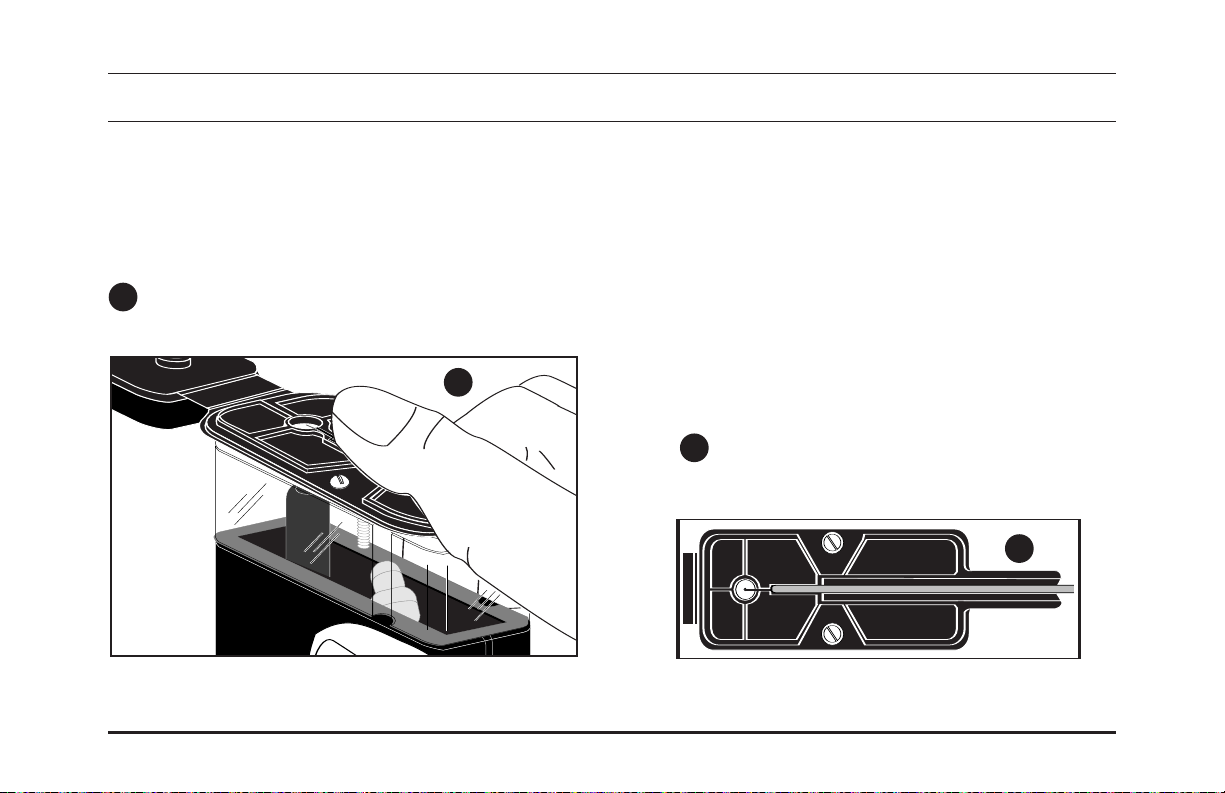

Installation on jacketed fiber

Carefully insert the bare fiber into the stem of the connector until you feel the fibers

16

make contact. Gently twisting the fiber may ease insertion. Do not twist or remove the

fiber once it is fully inserted. When fully inserted, the pen mark on the buffer should

be near the edge of the stem of the connector. Clamp the fiber into the clamp of the

installation tool. Must be a bow of approximately 15mm-20mm to maintain a contact

between the end faces of the fibers.

LC SC

ST

Max. 2 mm

Pen mark

Page 51OptiMo Connector Installation Instructions

Page 59

Installation on jacketed fiber

Depress the installation tool plunger. Ensure it hooks the release wire, then slowly release the plunger.

17

LC

Release wire Release wire

OR-71601671 Page 52

SC

ST

Release wire

Page 60

LC

18

*

Installation on jacketed fiber

Unclamp the cord. Carefully remove the connector from the installation tool. Hold the crimping tool

vertically and rest the crimping tool against the disposable tool tab to ensure it is aligned properly. The

disposable tool must be rotated in order for it’s tab to be pointing at the crimp tool handle. Using the first

and smallesr die (,068 hex) on the crimping tool, strongly crimp the stem on the buffer at the “buffer

crimp area”, making sure neither the jacket nor any aramid yarn is in the way. The smallest diameter hex

face is against the disposable tool tab.

Make sure that the crimp tool you are using is in proper operating condition before attempting this step. Also make sure that the tool is set to the

settings shown in the Technical Bulletin—OptiMo®Field Installable Connectors document that is provided with your Ortronics®Field Installation Kit.

(The document can be downloaded from the Ortronics web site at http://www.legrand.us/ortronics/technicalresources/instruction%20manuals.aspx)

Buffer crimp area

Page 53OptiMo Connector Installation Instructions

Page 61

LC

19

Installation on jacketed fiber

Remove disposable tool and discard it. Gently pull the Kevlar towards the connector to make sure there is

no slack. Slide the crimp sleeve over the Kevlar. Spread the Kevlar evenly around the connector.

Carefully remove the connector from the installation tool. Ensure the crimp sleeve is against the rear of

the connector and strongly crimp the crimp sleeve using the middle die (.128 hex) of the crimping tool.

Now you can cut excess aramid yarn.

OR-71601671 Page 54

Page 62

LC

20

*

Installation on jacketed fiber

Holding the boot by its collar, align the anti snag with the latch of the LC connector, slide it onto the rear

of the connector until its step reaches the connector body. The installation is now completed.

Be sure to clean the connector as described in the “Cleaning Procedures” section before using the connector (See page 64).

Page 55OptiMo Connector Installation Instructions

Page 63

SC

21

*

Installation on jacketed fiber

Rest the crimping tool against the disposable tool tab to ensure it is aligned properly. The disposable tool

must be rotated in order for it’s tab to be pointing at the crimp tool handle. Using the first and smallest

die (.068 hex) on the crimping tool, strongly crimp the stem on the buffer at the “buffer crimp area”,

making sure neither the jacket nor any aramid yarn is in the way. The smallest diameter hex face is

against the disposable tool tab.

Make sure that the crimp tool you are using is in proper operating condition before attempting this step. Also make sure that the tool is set to the

settings shown in the Technical Bulletin—OptiMo®Field Installable Connectors document that is provided with your Ortronics®Field Installation Kit.

(The document can be downloaded from the Ortronics web site at http://www.legrand.us/ortronics/technicalresources/instruction%20manuals.aspx)

Buffer crimp area

OR-71601671 Page 56

Page 64

SC

22

Installation on jacketed fiber

Grab the disposable tool as shown. Pull in order to expose approximately 8 mm of the sliding part and

until a click is heard. During this operation, if you are using the cord adaptor, hold it carefully and

facilitate its mating with the sliding part. Remove the tool and discard it.

Page 57OptiMo Connector Installation Instructions

Page 65

SC

23

Installation on jacketed fiber

Slide the crimp sleeve farther down the fiber to release the aramid yarn. Gently pull the aramid yarn

towards the connector to make sure there is no slack. Slide the crimp sleeve over the aramid yarn.

Spread the aramid yarn evenly around the connector. Carefully remove the connector from the

installation tool. Ensure the crimp sleeve is against the rear of the connector and strongly crimp the

crimp sleeve using the middle die (.128 hex) of the crimping tool. Now you can cut excess aramid yarn.

OR-71601671 Page 58

Page 66

SC

24

*

Installation on jacketed fiber

Holding the boot on its ribbed section, slide it onto the rear of the connector until it snaps in place. The

installation is now complete.

Be sure to clean the connector as described in the “Cleaning Procedures” section before using the connector (See page 64).

Page 59OptiMo Connector Installation Instructions

Page 67

ST

25

*

Installation on jacketed fiber

Disengage coupling nut by pushing and rotating the connector body 1/4 turn counterclockwise in order to

unlock the connector from the installation tool. Rest the crimping tool against the connector body to

ensure it is aligned properly. Using the first and smallest die (.068 hex) on the crimping tool, crimp

strongly the stem on the buffer at the “buffer crimp area”, making sure neither the jacket nor any aramid

yarn is in the way. The smallest diameter hex face is against the rear of the connector.

Make sure that the crimp tool you are using is in proper operating condition before attempting this step. Also make sure that the tool is set to the

settings shown in the Technical Bulletin—OptiMo®Field Installable Connectors document that is provided with your Ortronics®Field Installation Kit.

(The document can be downloaded from the Ortronics web site at http://www.legrand.us/ortronics/technicalresources/instruction%20manuals.aspx)

Buffer crimp area

OR-71601671 Page 60

Page 68

ST

26

Installation on jacketed fiber

Reinsert the connector in the installation tool and lock it in place. Turn the connector body housing 1/8

turn counterclockwise so the housing is resting as shown.

1

/8turn

Page 61OptiMo Connector Installation Instructions

Page 69

ST

27

Installation on jacketed fiber

Slide the crimp sleeve farther down the fiber to release the aramid yarn. Gently cut the aramid yarn

ensuring that it reaches the end of the connector body. Spread the aramid yarn evenly around the stem

of the connector. Slide the crimp sleeve down the fiber toward the connector. Ensure the crimp sleeve is

against the retaining ring at the rear of the connector body and strongly crimp the crimp sleeve using the

middle die (.128 hex) of the crimping tool.

OR-71601671 Page 62

Page 70

ST

28

*

Installation on jacketed fiber

Unclamp the cord. Align and press the rear housing with boot into the front housing until a click is heard.

Remove the connector from the installation tool. The installation is now complete.

Be sure to clean the connector as described in the “Cleaning Procedures” section before using the connector.

Page 63OptiMo Connector Installation Instructions

Page 71

Cleaning procedures

1. Wipe completely around the connector ferrule a few times with a lint-free alcohol soaked wipe. Then wipe

across the end of the ferrule.

2. Repeat step 1 with a dry wipe.

3. Blow compressed gas across the end of the ferrule (optional but recommended).

Do not allow ferrule to touch anything before inserting into coupling.

*

Preferred alcohol is ethanol but isopropyl alcohol may be used.

*

A dry cleaning tape system may also be used.

*

OR-71601671 Page 64

Page 72

Notes

OptiMo Connector Installation Instructions

Page 65

Page 73

Fiber Preparation Guide

OptiMo®LC Fiber Preparation Guide (for Multimode and Singlemode)

900 µm buffered fiber

NOT TO SCALE

*Reproductions of the above guide generated from this PDF may not be to scale.

OptiMo LC Connector Installation Instructions

Jacketed fiber

Page 74

Fiber Preparation Guide

OptiMo®SC Fiber Preparation Guide (for Multimode and Singlemode)

900 µm buffered fiber

Smaller than 2.4 mm cord

NOT TO SCALE

*Reproductions of the above guide generated from this PDF may not be to scale.

OptiMo SC Connector Installation Instructions

2.4 mm cord or larger

Page 75

Fiber Preparation Guide

OptiMo®ST-Type Fiber Preparation Guide (for Multimode and Singlemode)

900 µm buffered fiber

NOT TO SCALE

*Reproductions of the above guide generated from this PDF may not be to scale.

OptiMo ST Connector Installation Instructions

Jacketed fiber

Page 76

OptiMo

high performance

fiber optic solutions

®

http://www.legrand.us/ortronics

800-934-5432

Loading...

Loading...