L.B. White Oval 80 User Manual

Owner’s Manual and Instructions

Oval 80™ Radiant Poultry Heaters

View this manual online at www.lbwhite.com

MODEL |

OUTPUT (Btuh) |

FUEL |

|

|

|

AR080 |

80,000 |

Propane Vapor |

|

|

Withdrawal |

|

|

or |

|

|

Natural Gas |

|

Patent Pending |

|

|

|

SCAN THIS QR CODE

with your smartphone or visit http://goo.gl/yyKxJo

to view maintenance videos for L.B.White heaters.*

*Requires an app like QR Droid for Android or QR Reader for iPhone.

Congratulations!

You have purchased the finest radiant tube heater available for the heating of poultry confinement buildings.

Your new L.B. White radiant heater incorporates the benefits from the most experienced manufacturer of heating products using state-of-the-art technology.

We, at L.B. White, thank you for your confidence in our products and welcome any suggestions or comments you may have...contact us toll free at 1-800-345- 7200, or email us at customerservice@lbwhite.com.

ATTENTION ALL USERS

This heater has been tested and evaluated by L.B.White Co., Inc. as a direct gas fired radiant heater with intended use for the heating of poultry confinement buildings. If you are considering using this product for any application other than its intended use, then please contact your fuel gas supplier, or the L.B. White Co., Inc.

150-28792 REV.B

GENERAL HAZARD WARNING

■Failure to comply with the precautions and instructions provided with this heater, can result in:

—Death

—Serious bodily injury or burns

—Property damage or loss from fire or explosion

—Asphyxiation due to lack of adequate air supply or carbon monoxide poisoning

—Electrical shock

■Read this Owner’s Manual before installing or using this heater.

■Only properly-trained service people should repair or install this heater.

■Save this Owner’s Manual for future use and reference.

■Owner’s Manuals and replacement labels are available at no charge. See website, or for assistance, contact L.B. White at 1-800-345-7200.

WARNING

WARNING

■Proper gas supply pressure must be provided to the inlet of the heater.

■Refer to rating plate for proper gas supply pressure.

■Gas pressure in excess of the maximum inlet pressure specified at the heater inlet can cause fires or explosions.

■Fires or explosions can lead to serious injury, death, building damage or loss of livestock.

■Gas pressure below the minimum inlet pressure specified at the heater inlet may cause improper combustion.

■Improper combustion can lead to asphyxiation or carbon monoxide poisoning and therefore serious injury or death to humans and livestock.

WARNING

WARNING

Fire and Explosion Hazard

■Not for home or recreational vehicle use.

■Installation of this heater in a home or recreational vehicle may result in a fire or explosion.

■Fire or explosions can cause property damage or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other heater.

FOR YOUR SAFETY

If you smell gas:

1.Open windows.

2.Don't touch electrical switches.

3.Extinguish any open flame.

4.Immediately call your gas supplier.

WARNING

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death. Read the installation, operating and maintenance instructions thoroughly before installing or servicing

this equipment.

WARNING

WARNING

Fire and Explosion Hazard

■Keep solid combustibles a safe distance away from the heater.

■Solid combustibles include wood or paper products, feathers, straw, and dust.

■Do not use the heater in spaces which contain or may contain volatile or airborne combustibles.

■Volatile or airborne combustibles include gasoline, solvents, paint thinner, dust particles or unknown chemicals.

■Failure to follow these instructions may result in a fire or explosion.

■Fire or explosions can lead to property damage, personal injury or loss of life.

2

|

Table of Contents |

SECTION |

PAGE |

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . .3 |

Heater Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . .4 |

Safe Clearance to Combustibles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . .5 |

Temperature Sensor Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . .5 |

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . .6 |

Installation Instructions |

|

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . .8 |

Inlet Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . .8 |

Drawing Inlet Air From Attic . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . .8 |

Drawing Inlet Air Through Side Wall . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . .8 |

Initial Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .10 |

Hanging the Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .11 |

Installing Reflectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .12 |

Air Turbulation Strips & Vent Cap . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .13 |

Sediment Trap Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .13 |

Manual Shut Off Valve, Hose & Regulator Assembly . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .13 |

Heater Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .14 |

Start-Up Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .15 |

Shut-Down Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .15 |

Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .16 |

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .17 |

Service Instructions |

|

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .17 |

Igniter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .18 |

Burner Orifice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .19 |

Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .19 |

Ignition Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .20 |

Air Differential Pressure Switch, Tubing, & Pressure Orifices . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .20 |

Gas Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .21 |

Motor and Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .22 |

Gas Pressure Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .22 |

Troubleshooting Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .24 |

Electrical Connection and Ladder Diagrams . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .28 |

Heater Component Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .29 |

Parts Identification |

|

Parts Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .30 |

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .31 |

Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .32 |

Replacement Parts and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . .32 |

This owner's manual includes all options and accessories commonly used on or with this heater. However, depending on the configuration purchased, some options and accessories may not be included.

When calling for technical service assistance, or for other specific information, always have the model number and serial number available.

This manual will instruct you in the operation and care of your radiant heater. Have your qualified installer review this manual with you so that you fully understand the heater and how it functions.

General Information

The gas supply line installation, and the repair, installation and servicing of the heater requires continuing expert training and knowledge of gas heaters and should not be attempted by anyone who is not so qualified. See page 6 for definition of the necessary qualifications.

Contact your local L. B. White distributor or the L.B. White Co., Inc. for assistance, or if you have any questions about the use of the heater or its application.

The L.B. White Co., Inc. has a policy of continuous product improvement. It reserves the right to change specifications and design without notice.

3

Heater Specifications

|

|

|

|

|

|

|

|

|

|

Model |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPECIFICATIONS |

|

|

|

|

|

|

AR080 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tube Length (ft.) |

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Input per Hour (BTUH) |

|

|

|

|

|

80,000 |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

Fuel Consumption |

L.P. GAS (lbs.) |

3.70 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

per Hour (Max.) |

NAT. GAS (cu. ft.) |

80 |

|

|||||

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inlet Gas Supply |

|

|

MAX. |

|

13.5 in. W.C., L.P. and Natural Gas |

|

||

|

|

|

Pressure Acceptable |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

at the Inlet of the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11.0 in. W.C., L.P. Gas |

|

|

|

|

|

Heater for Purpose of |

|

|

MIN. |

|

|

|||

|

|

|

|

|

|

7.0 in. W.C., Natural Gas |

|

||||

|

|

|

Input Adjustment |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

BurnerManifold |

|

|

|

|

|

|

10.0 in. W.C., L.P. Gas |

|

|

|

|

Pressure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4.0 in. W.C., Natural Gas |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ventilation Air Required |

|

|

|

|

|

140 CFM |

|

|

|

|

|

to Support Combustion |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Motor Characteristics |

|

|

|

|

|

|

Ball Bearing |

|

|

|

|

|

|

|

|

|

|

1/30 H.P., 3020 RPM, CW Rotation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electrical Supply (Volts/Hz/Phase) |

115/60/1 |

|

||||||

|

|

|

Amp Draw |

|

|

|

|

STARTING |

1.16 |

|

|

|

|

|

(Starting Amps |

|

|

|

|

CONTINUOUS |

1.02 |

|

|

|

|

|

Include Igniter) |

|

|

|

|

|

|||

|

|

|

|

|

|

|

OPERATION |

|

|

|

|

|

|

|

Minimum Safe |

|

|

|

|

TOP |

|

1 ft. |

|

|

|

|

Distances of Heater |

|

|

|

|

SIDES |

|

2.5 ft. |

|

|

|

|

From Nearest |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

DISCHARGE END |

|

6 ft. |

|

|

|

|

|

Combustible Materials |

|

|

|

|

|

|||

|

|

|

(See Fig. 1 on page 5) |

|

|

|

|

BELOW RADIANT |

|

6 ft. |

|

|

|

|

|

|

|

|

|

||||

|

|

|

Temperature Sensor Location |

12-18 in. Above Litter and Approx. 10 Ft. Down from Burner Box |

|

||||||

|

|

|

(See Fig. 2 on page 5) |

|

|

|

|

|

|

||

4

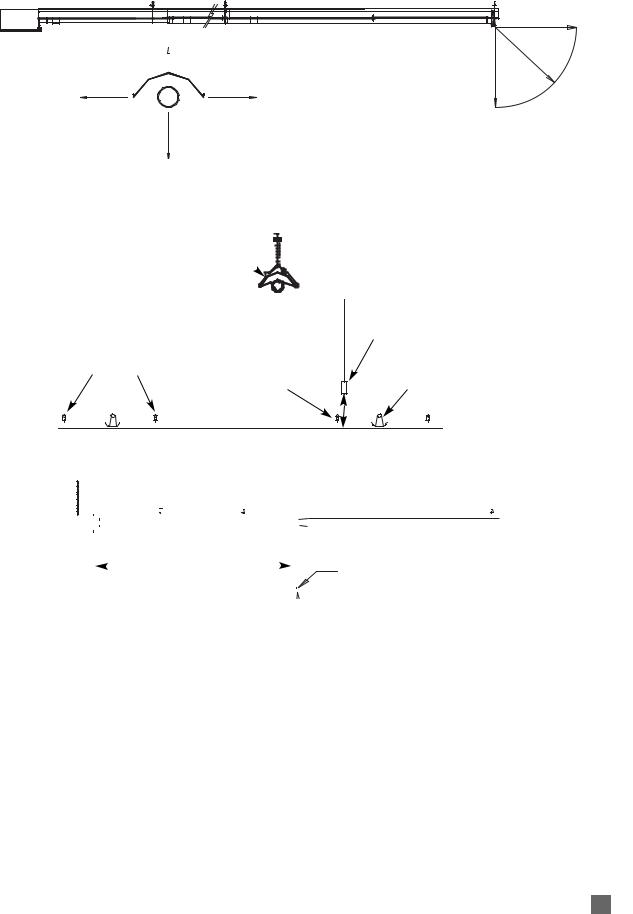

FIG. 1

SAFE CLEARANCES FROM COMBUSTIBLES

16 FTIN

16 FTIN

2.5 FT. |

2.56 FTFT. |

6 FT |

6 FT

6 FT

6 FT

6 FT

FIG. 2

TEMPERATURE SENSOR LOCATION

HEATER

|

SENSOR LOCATED TOWARD |

|

INSIDE WATER LINE AND 12-18 IN. |

|

R IN PROXIMITYSENSO |

|

ABOVE THE LITTER. |

WATER LINES |

INSIDETOWATERN I LINE |

|

|

INSIDE WATER LINE |

FEED LINE |

FEED LINE |

12-18 IN. |

LITTER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INSTALL SENSOR APPROXIMATELY |

|

SENSOR |

||||||

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

10 FT. DOWN FROM BURNER BOX |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INSIDE WATER LINE |

|

|

|

|

|||

5

Safety Precautions

WARNING

WARNING

Asphyxiation Hazard

■ Do not use this radiant heater for heating human living |

L.B. White Company to determine combustion air |

quarters. |

ventilation requirements of the heater. |

■ Do not use in unventilated areas. |

■ Lack of proper ventilation air will lead to carbon |

|

monoxide poisoning in humans leading to serious |

■ The flow of combustion and ventilation air must not be |

injury or death. Symptoms of carbon monoxide |

obstructed. |

poisoning can include headaches, dizziness and |

■ Proper ventilation must be provided to support the |

difficulty in breathing. |

|

|

combustion air requirements of the heater being used. |

■ Symptoms of improper ventilation affecting livestock |

■ Refer to the specification section of the Owner’s |

can be disease, lower feed conversion, or death. |

|

|

Manual, heater’s dataplate, or contact the |

|

FUEL GAS ODOR

Propane gas and natural gas has man-made odorant added specifically for detection of fuel gas leaks. If a gas leak occurs, you should be able to smell the fuel gas.

THAT’S YOUR SIGNAL TO GO INTO IMMEDIATE ACTION!

■Do not take any action that could ignite the fuel gas. Do not operate any electrical switches. Do not pull any power supply or extension cords. Do not light matches or any other source of flame. Do not use your telephone.

■Get everyone out of the building and away from the area immediately.

■Close all propane (LP) gas tank or cylinder fuel supply valves, or the main fuel supply valve at the meter if you use natural gas.

■Propane gas is heavier than air and may settle in low areas. When you have reason to suspect a propane leak, keep out of all low areas.

■Natural gas is lighter than air and can collect around rafters or ceilings.

■Use your neighbor’s phone and call your fuel gas supplier and your fire department. Do not re-enter the building or area.

■Stay out of the building and away from the area until declared safe by the firefighters and your fuel gas supplier.

■FINALLY, let the fuel gas service person and the firefighters check for escaped gas. Have them air out the building and area before you return. Properly trained service people must repair the leak, check for further leakages, and then relight the heater for you.

ODOR FADING -- NO ODOR DETECTED

■Some people cannot smell well. Some people cannot smell the odor of the man-made chemical added to propane or natural gas. You must determine if you can smell the odorant in this fuel gas.

■Learn to recognize the odor of propane gas or natural gas. Local propane gas dealers will be more than happy to give you a “scratch and sniff” pamphlet. Use it to become familiar with the fuel gas odor.

■The odorant in propane gas and natural gas is colorless and the intensity of its odor can fade under some circumstances.

■If there is an underground leak, the movement of gas through the soil can filter the odorant.

■Propane gas odor may differ in intensity at different levels. Since propane gas is heavier than air, there may be more odor at lower levels.

■Smoking can decrease your ability to smell. Being

around an odor for a period of time can affect your ■ Always be sensitive to the slightest gas odor. If you

sensitivity to that particular odor. Odors present in animal confinement buildings can mask fuel gas odor.

continue to detect any gas odor, no matter how small, treat it as a serious leak. Immediately go into action as discussed previously.

ATTENTION -- CRITICAL POINTS TO REMEMBER!

■Propane gas and natural gas has a distinctive odor. Learn to recognize this odor. (Reference “Fuel Gas Odor” and “Odor Fading” sections above.

■If you have not been properly trained in repair and service of propane gas and natural gas fueled heaters, then do not attempt to light the heater, perform service or repairs, or make any adjustments to the heater on a propane gas

6 or fuel system.

■Even if you are not properly trained in the service and repair of radiant heaters, ALWAYS be consciously aware of the odors of propane gas and natural gas.

■A periodic “sniff test” around the heater or at the heater’s joints; i.e. hose, connections, etc., is a good safety practice under any conditions. If you smell even a small amount of gas, CONTACT YOUR FUEL GAS SUPPLIER IMMEDIATELY. DO NOT WAIT!

1.Do not attempt to install, repair, or service this heater or the gas supply line unless you have continuing expert training and knowledge of gas heaters.

Qualifications for service and installation of this equipment are as follows:

a.To be a qualified gas heater service person, you must have sufficient training and experience to handle all aspects of gas-fired heater installation, service and repair. This includes the task of installation, troubleshooting, replacement of defective parts and testing of the heater. You must be able to place the heater into a continuing safe and normal operating condition. You must completely familiarize yourself with each model heater by reading and complying with the safety instructions, labels, Owner’s Manual, etc., that is provided with each heater.

b.To be a qualified gas installation person, you must have sufficient training and experience to handle all aspects of installing, repairing and altering gas lines, including selecting and installing the proper equipment, and selecting proper pipe and tank size to be used. This must be done in accordance with all local, state and national codes as well as the manufacturer’s requirements.

2.All installations and applications of L.B. White heaters must meet all relevant local, state and national codes. Included are L.P. gas, electrical, and safety codes. Your local fuel gas supplier, a local licensed electrician, the local fire department or similar government agencies, or your insurance agent can help you determine code requirements.

--ANSI/NFPA 58, latest edition, Standard for Storage and Handling of Liquefied Petroleum Gas and/or

--ANSI Z223.1/NFPA 54, National Fuel Gas Code

--ANSI/NFPA 70, National Electrical Code.

3.Do not move, handle, or service heater while in operation or connected to a power or fuel supply.

4.This heater may be installed in areas subject to washdown. This heater may only be washed on the external components. See Cleaning Instructions. Do not wash the interior of the burner box or the tubes. Use only compressed air, soft brush or dry cloth to clean the interior of the heater and it’s components. After external washdown, do not operate this heater until it is completely dry. In any event, do not operate the heater for at least one hour after external washdown.

5.For safety, this heater is equipped with an differential air pressure switch. Never operate this heater if this safety device has been bypassed. Do not operate this heater unless this feature is fully functioning.

6.The heater is designed to operate only with its access door closed and latched. Do not operate the heater with its burner box access door open.

7.Do not block air intakes or discharge outlets of the heater. Doing so may cause improper combustion or damage to heater components leading to property damage or animal loss.

8.The hose assembly shall be visually inspected on an annual basis. If it is evident there is excessive abrasion or wear, or if the hose is cut, it must be replaced prior to the heater being put into operation. The hose assembly shall be protected from animals, and contact with hot surfaces during use. The hose assembly shall be that specified by the manufacturer. See parts list.

9.Check for gas leaks and proper function upon heater installation and before building repopulation.

10.This heater should be inspected for proper operation by a qualified service person at least annually.

11.Always turn off the gas supply to the heater when not in use.

12.This heater is equipped with a three-prong (grounding) plug for your protection against shock hazard and must be plugged directly into a properly grounded three-prong receptacle. Failure to use a properly grounded receptacle can result in electrical shock, personal injury, or death.

13.Direct ignition heaters will make up to three trials for ignition. If ignition is not achieved, the control system will lock out the gas control valve. If gas is smelled after system lock out has occurred, immediately close all fuel supply valves. Do not relight until you are sure that all gas that may have accumulated has cleared away. In any event, do not relight for at least 5 minutes.

14.Use only approved gas hose or approved flexible connectors which are rated for use with propane or natural gas.

7

Installation Instructions

GENERAL

1.Read all safety precautions and follow L.B. White recommendations when installing this heater. If during the installation of the heater, you suspect that a part is damaged or defective, call a qualified service agency for repair or replacement.

2.A qualified service agency must check the heater upon installation and periodically. This shall consist of the following:

--Start up and shut down of the heaters to test for proper operation.

--Leak check all gas pipe joints and gas hose connections.

--Gas pressure checks.

--Ensuring the heater is properly positioned away from combustible materials.

WARNING

Combustion Hazard

■Provide a properly located and sized fresh air inlet for the heater.

--Refer to Inlet Air Requirements instructions.

■Failure to provide a fresh air inlet can lead to:

--Sooting causing building damage

--High carbon monoxide levels, causing serious injury or death to livestock and humans

--Overheating of the first 10 ft. tube, causing fires leading to building damage and injury to livestock and humans.

--Higher temperature differences over the length of the tubes, causing problems in temperature control and bird performance

3.Inlet Air Requirements:

This heater requires clean, fresh air from a normal, atmospheric pressure environment for proper operation and combustion. Contact L.B.White Company if you have any questions regarding the installation of this heater.

Inlet air may be drawn from the attic or through side walls under a protective eve. See Figs. 3 and 4.

--All inlet air seams and joints must be sealed

--Do not use any filters on the air inlet system

--The air inlet system must be kept as straight as possible. No more than 1 - 90º bend is allowed.

--Contact L.B.White Co. if you have any

questions regarding the installation of the heater

Inlet air for combustion must not be drawn from: ■ Inside the confinement room.

■ An attic or location where negative pressure (vacuum) affects the air draw of the heater’s fan. Examples include, but are not limited to: a. houses with attic soffit vent area smaller

than ridge cap vent area

b. heater air inlet located within 20 ft. of building ventilation fans

c. locations where wind and/or the elements can create a negative

pressure.

8

Drawing Inlet Air From Attic

■ Use L.B.White air inlet kit 24950:

FIG. 3

ENSURE INLET CAP

IS UNBLOCKED BY

INSULATION

SMOOTH INLET TUBE, MAX. 2 |

12 IN. MIN. FROM |

FT. LENGTH, 4 IN. DIA. |

|

(FIT OVER CEILING FLANGE) |

INSIDE OF ROOF |

INLET CENTER |

12 IN. MIN. ABOVE |

|

30-40 IN. FROM |

||

INSULATION |

||

BURNER BOX |

||

|

CLAMPS

2 FT. RIGID TUBE

MINMIZE HORIZONTAL TRAVEL OF FLEX DUCT,

14 IN. MINIMUM

18 IN. MAXIMUM

CUT 4 1/4 in. HOLE THROUGH CEILING ADJACENT TO JOIST. SPREAD INSULATION AWAY AND FASTEN CEILING FLANGE TO JOIST.

CUT 4 1/4 in. HOLE THROUGH CEILING ADJACENT TO JOIST. SPREAD INSULATION AWAY AND FASTEN CEILING FLANGE TO JOIST.

FLEX TUBE CUT TO LENGTH

--DO NOT EXCEED 4 FT. MAX. LENGTH

--DO NOT KINK

CUT TUBE 6 IN. SHORTER IF

CEILING FLANGE IS CLOSER THAN 30 IN. FROM BURNER BOX.

ADD ADDITIONAL LENGTH OF 4 IN. RIGID TUBE (NOT INCLUDED) IF

CEILING FLANGE IS 40 IN. OR MORE FROM BURNER BOX.

Drawing Inlet Air Through Side Walls

FIG. 4 |

USE MINIMUM LENGTH OF 4 IN DIAMETER FLEX DUCT WHEN |

|

|

|

CONNECTING 4 IN.PVC TO BURNER BOX. |

|

|

|

AN ADAPTER CONNECTION FOR THE BURNER BOX TO THE 6 IN.PVC |

|

|

|

MUST BE OBTAINED THROUGH LOCAL SOURCE. |

|

|

|

INSTALL SUPPORTS EVERY 5 FT. TO |

||

|

PREVENT INLET SAGGING |

|

|

|

ROOF |

|

|

|

AIR |

|

|

|

INLET |

|

|

|

SECURE INLET TO WALL |

|

|

|

FOR INLET RUNS UP TO 20 FT., USE SMOOTH 4 IN. ID PVC |

|

|

|

FOR RUNS OVER 20 FT., USE 6 IN.ID. PVC |

WALL |

|

|

|

AIR INLET |

|

|

|

|

USE INLET CAP, |

|

|

|

24861 FOR 4 IN PVC |

|

|

|

CAN ALSO USE |

|

|

|

1/4 X 1/4 HARDWARE |

4. The heater is approved for indoor use only |

|

CLOTH FOR EITHER |

|

|

4 IN. OR 6 IN. PVC |

||

5. Heater installation must take into consideration proper hanging height to allow for clearance of catching machines, litter spreaders, and any other equipment used.

6. Ensure the heater installation does not interfere with water, gas, or electrical lines.

7. Position the gas hose to prevent any contact with the tubes, heat relectors, and burner box.

8.Ensure that all accessories that ship with the heater have been removed from shipping containers and installed. This pertains to gas hose, regulators, supports, hangers, etc.

9.This heater requires a regulated gas supply to its gas inlet :

--The regulator must be the proper design for the application.

--The regulator must control the inlet pressure to the heater within the range specified on the dataplate.

--Regulators mounted outside must be protected from adverse weather conditions.

--Regulators with pressure relief valves should be installed outside the building.

--Regulator installed inside should be vented outside.

--Local state and national codes apply to regulator installation. Refer to NFPA 54, National Fuel Gas Code, and NFPA 58, Standard for Storage and Handling of Liquified Petroleum Gas.

10.Always use pipe joint compound that is resistant to liquefied petroleum gas and natural gas.

11.Check all connections for gas leaks using approved gas leak detectors. Gas leak testing is performed as follows:

WARNING

Fire and Explosion Hazard

■Do not use open flame (matches, torches, candles, etc.) in checking for gas leaks.

■Use only approved leak detectors.

■Failure to follow this warning can lead to fires or explosions.

■Fires or explosions can lead to property damage, injury or death.

--Check all pipe connections, hose connections, fittings and adapters upstream of the gas control with approved gas leak detectors.

--In the event a gas leak is detected, check the components involved for cleanliness and proper application of pipe compound before further tightening.

--Tighten the gas connections as necessary to stop the leak.

--After all connections are checked and any leaks are stopped, turn on the main burner.

--Stand clear while the main burner ignites to prevent injury caused from hidden leaks that could cause flashback.

--With the main burner in operation, check all connections, hose connections, fittings and joints as well as the gas control valve inlet and outlet connections with approved gas leak detectors.

--If a leak is detected, check the components involved for cleanliness in the thread areas and proper application of pipe compound before further tightening.

--Tighten the gas connection as necessary to stop the leak.

--If necessary, replace the parts or components involved if the leak cannot be stopped.

--Ensure all gas leaks have been identified and repaired before proceeding.

12.Install a sediment trap at the gas valve inlet to prevent foreign materials (pipe compound, pipe chips and scale) from entering the gas valve. Debris blown into the gas valve may cause that valve to malfunction resulting in a serious gas leak that could result in a possible fire or explosion causing loss of products, building or even life. A properly installed sediment trap will keep foreign materials from entering the gas valve and protect the safe functioning of that important safety component.

13.Any heater connected to a piping system must have an accessible, approved manual shut off valve installed within six feet (6 ft.) of the heater it serves.

14.Install the proper gas supply line to assure proper functioning of the heaters. Consult your fuel gas supplier, or the L.B. White Co., Inc. for proper line sizing and installation.

15.Light according to instructions on heater or within Owner’s Manual.

16.The heater is designed for L.P. vapor withdrawal or natural gas only. Do not use this heater in a propane liquid withdrawal system. Do not permit propane in liquid form to enter the heater at any time.

17.The corrosive atmosphere present in animal confinement buildings can cause component failure or heater malfunction. The heater should be periodically inspected and cleaned in accordance with the Maintenance and Cleaning Instructions in this manual. Make sure that livestock is protected by a back up alarm system that limits high and low temperatures and also activates appropriate alarms.

18.Take time to understand how to operate and maintain the heater using the owner’s manual. Make sure you know how to shut off the gas supply to the building and to the heater. Contact your gas supplier if you have any questions.

19.Any defects found in performing any of the service procedures must be eliminated and defective parts replaced immediately. Retest the heater before placing it back into service.

20.Do not exceed input rating stamped on the dataplate of the heater. Do not exceed the burner manifold pressure stated on the dataplate. Do not use an orifice size different than specified for the specific input rating of this heater, fuel type configuration and altitude.

9

INITIAL SETUP

1.Plan the installation. Determine location for the heater to optimize its heat pattern, keeping in mind cooler regions in the house (end walls, and curtains) and clearances to combustibles.

2.Hang the burner box. See Fig. 5. Maintain clearances to combustibles as shown in Fig. 1.

3.From the burner box chain, measure the distances shown in Fig. 6. Aligning to the center of the burner box discharge, hang chains at these points, using open eye hooks.

FIG. 5

JOIST

OPEN EYE HOOKS

IN LINE WITH

EYE BOLTS ON

BURNER BOX

TIGHTEN HOOKS SECURELY

OPEN EYE BOLT |

|

11 FTIN. |

AIR INLET |

|

|

BURNER |

|

DISCHARGE |

|

FIG. 6

|

BURNERBURNERBOXBOX |

HANGING CHAINSHANGING CHA |

||||

A |

B |

C |

D |

|

E |

|

|

|

HANGING CHAIN DISTANCES |

||||

|

TRUSS |

HEATER |

A - B B - C C - D D - E |

|||

|

CENTERS |

LENGTH |

(FT) |

(FT) |

(FT) |

(FT) |

|

4 FOOT |

20 FOOT |

4 |

4 |

124 |

88 |

|

50 FOOT |

4 |

||||

|

5 FOOT |

FOOT |

55 |

5 |

105 |

105 |

|

5020 FOOT |

|||||

|

10 FOOT |

2050FOOTFOOT |

55** |

5 |

105* |

105 |

* A SUPPORT MUST BE CREATED BETWEEN THE TRUSS

10

Loading...

Loading...