L.B. White I-34 User Manual

Owner’s Manual and Instructions

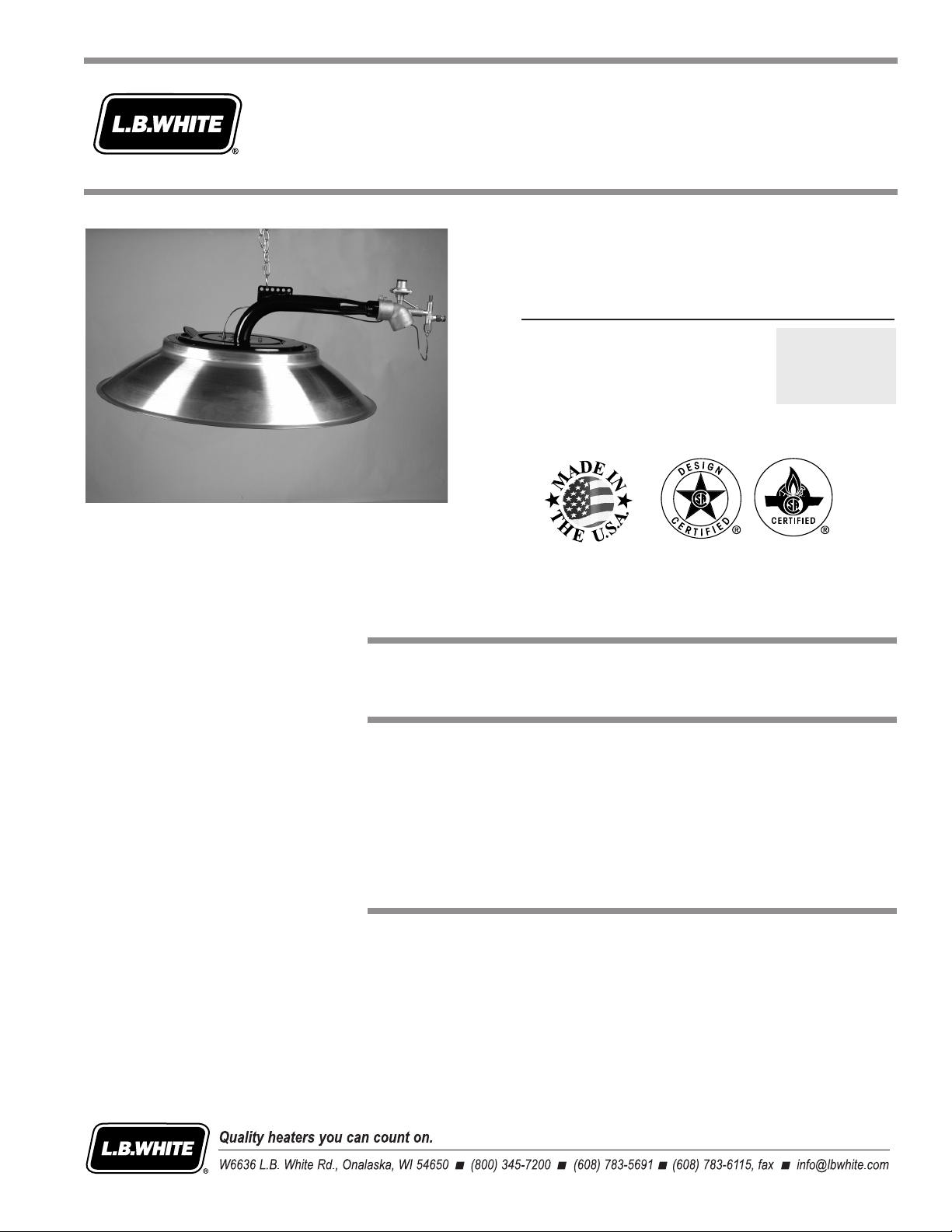

Modulating Infraconic

Agricultural Building Radiant Heaters

MODELS OUTPUT (Btuh) FUEL

Propane Vapor

I34 34,200

Withdrawal

or Natural Gas

Congratulations!

You have purchased the finest radiant heater available for the heating of livestock

in agricultural animal confinement buildings.

Your new L.B. White radiant heater incorporates the benefits from the most

experienced manufacturer of heating products using state-of-the-art technology.

We, at L.B. White, thank you for your confidence in our products and welcome any

suggestions or comments you may have...call us toll free at 1-800-345-7200.

ATTENTION ALL USERS

This heater has been tested and approved by CSA International in accordance with AGA

Requirements for Gas Fired Brooders No. 8-94 and Canadian Gas Association

Requirememts for Gas Fired Brooders, CAN1-2.20-M85, as a direct gas-fired radiant

heater with intended use for the heating of livestock in agricultural animal confinement

buildings. If you are considering using this product for any application other than its

intended use, then please contact your fuel gas supplier, or the L.B. White Co., Inc.

150-23919

GENERAL HAZARD WARNING

■ Failure to comply with the precautions and instructions provided with this heater, can result in:

— Death

— Serious bodily injury or burns

— Property damage or loss from fire or explosion

— Asphyxiation due to lack of adequate air supply or carbon monoxide poisoning

— Electrical shock

■ Read this Owner’s Manual before installing or using this heater.

■ Only properly-trained service people should repair or install this heater.

■ Save this Owner’s Manual for future use and reference.

■ Owner’s Manuals and replacement labels are available at no charge. For assistance, contact

L.B. White at 1-800-345-7200.

WARNING

■ Proper gas supply pressure must be provided to the inlet of the heater.

■ Refer to rating plate for proper gas supply pressure.

■ Gas pressure in excess of the maximum inlet pressure specified at the heater inlet can cause

fires or explosions.

■ Fires or explosions can lead to serious injury, death, building damage or loss of livestock.

■ Gas pressure below the minimum inlet pressure specified at the heater inlet may cause

improper combustion.

■ Improper combustion can lead to asphyxiation or carbon monoxide poisoning and therefore

serious injury or death to humans and livestock.

WARNING

Fire and Explosion Hazard

■ Not for home or recreational vehicle use.

■ Installation of this heater in a home or

Fire and Explosion Hazard

■ Keep solid combustibles a safe distance

away from the heater.

WARNING

recreational vehicle may result in a fire or

explosion.

■ Fire or explosions can cause property

■ Solid combustibles include wood or paper

products, feathers, straw, and dust.

damage or loss of life.

■ Do not use the heater in spaces which

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of

this or any other heater.

contain or may contain volatile or airborne

combustibles.

■ Volatile or airborne combustibles include

gasoline, solvents, paint thinner, dust

particles or unknown chemicals.

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

■ Failure to follow these instructions may

result in a fire or explosion.

■ Fire or explosions can lead to property

damage, personal injury or loss of life.

4. Immediately call your gas supplier.

22

Table of Contents

SECTION

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Heater Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Gas Train Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Zone Control Panel Function and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Installing Dust Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Start-Up Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Shut-Down Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Cleaning Instructions

A. Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

B. Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Service Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Safety Gas Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Bypass Orifice (Individual Control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Thermostatic Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Burner Orifices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Main Burner Pressure Valve

A. Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

B. Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Thermocouple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Gas Pressure Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Heater Component Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Parts Identification

Parts Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Replacement Parts and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

PAGE

This owner's manual includes all options and accessories

commonly used on or with this heater. However, depending

on the configuration purchased, some options and

accessories may not be included.

When calling for technical service assistance, or for other

specific information, always have the model number and

serial number available.

This manual will instruct you in the operation and care of

your radiant heater. Have your qualified installer review this

manual with you so that you fully understand the heater and

how it functions.

General Information

The gas supply line installation, and the repair, installation

and servicing of the heater requires continuing expert

training and knowledge of gas heaters and should not be

attempted by anyone who is not so qualified. See page 6

for definition of the necessary qualifications.

Contact your local L. B. White distributor or the L. B. White

Co., Inc. for assistance, or if you have any questions about

the use of the heater or its application.

The L. B. White Co., Inc. has a policy of continuous product

improvement. It reserves the right to change specifications

and design without notice.

33

Radiant Heater Specifications

"B"

"A"

"C"

MMooddeell

SSPPEECCIIFFIICCAATTIIOONNSS

I34

Maximum Input (Btuh) 34,200

Ventilation Air to Support Combustion 400 CFM

Zone Control PROPANE GAS OR 5 PSIG

Full Output Pressure NATURAL GAS

Zone Control, PROPANE GAS OR 10 - 12 in. W.C.

Low Output Pressure NATURAL GAS

“A” 26-3/8 in.

Heater Dimensions

(See Fig. 1)

“B” 20-1/4 in.

“C” 10-5/8 in.

Net Weight 12 lbs.7 oz.

Fuel Consumption Per Hour

PROPANE GAS 1.58 lbs./hr.

NATURAL GAS 34.2 CFH

CHICKENS 2500-3800

Animal Coverage Per Heater (1)

TURKEYS 800-950

SWINE 300

Recommended Height Installation

For Livestock From Point of

Combustion Cone to Floor

CHICKENS 6 - 7 ft.

TURKEYS 4.5 ft.

SWINE 4 - 5 ft.

TOP OF HOOD TO CEILING 3 ft.

Minimum Safe Clearances to

Combustible Materials

POINT OF COMBUSTION 4.5 ft.

CONE TO FLOOR

SIDES 3 ft.

Animal Occupied Zone Temperature

POULTRY

Control Sensor Location (2)

SWINE

(1) There are other factors that will affect the quantity of animals

each heater can cover. These include building ventilation and control systems, building insulation, building size and population

density, etc. Consult your L.B. White dealer or call L.B. White for specific recommendations for your application.

(2) This is a typical sensor height range for poultry installations. The size and type of livestock being grown, heater spacing and height,

etc. will dictate sensor height. Care should always be taken to ensure that the sensor is sufficiently high as to not be damaged by

the animal during operation.

VERTICAL FROM FLOOR 6-12 in.

HORIZONTAL FROM BROODER 8-12 ft.

VERTICAL FROM FLOOR Above Animal Height

HORIZONTAL FROM BROODER 4-8 ft.

FIG. 1

44

Asphyxiation Hazard

■ Do not use this radiant heater for heating human living

quarters.

Safety Precautions

WWAARRNNIINNGG

L.B. White Company to determine comb ustion air

ventilation requirements of the heater.

■ Do not use in unventilated areas.

■ The flow of combustion and ventilation air must not be

obstructed.

■ Proper ventilation air must be provided to support the

combustion air requirements of the heater being used.

■ Refer to the spe c ification s e ction of t he Owner’s

Man u al , hea t e r’ s d at a pl a te, o r con t ac t t he

PPrrooppaannee ggaass aanndd nnaattuurraall ggaass hhaavvee mmaann--mmaaddee ooddoorraannttss aaddddeedd ssppeecciiffiiccaallllyy ffoorr ddeetteeccttiioonn ooff ffuueell ggaass lleeaakkss..

■ Do not take any action that could ignite the fuel gas. Do

not operate any electrical switches. Do not pull any

power supply or extension cords. Do not light matches

or a ny ot h er so u rce of fl a me. Do not us e you r

telephone.

■ Get everyone out of the building and away from the area

immediately.

■ Close all propane gas tank or cylinder fuel supply

valves, or the main fuel supply valve located at the

meter if you use natural gas.

■ Propane gas is heavier than air and may settle in low

areas. When you have reason to suspect a propane

leak, keep out of all low areas.

■ Lack of proper ventilation air will lead to improper

combustion.

■ Improper combustion can lead to carbon monoxide

poisoning in humans leading to serious injury or death.

Symptoms of carbon monoxide poisoning can include

headaches, dizziness and difficulty in breathing.

■ Symptoms of improper combustion affecting livestock

can be disease, lower feed conversion, or death.

FUEL GAS ODOR

IIff aa ggaass lleeaakk ooccccuurrss,, yyoouu sshhoouulldd bbee aabbllee ttoo ssmmeellll tthhee ffuueell ggaass..

TTHHAATT’’SS YYOOUURR SSIIGGNNAALL TTOO GGOO IINNTTOO IIMMMMEEDDIIAATTEE AACCTTIIOONN!!

■ Natural gas is lighter than air and can collect around

rafters or ceilings.

■ Use your neighbor’s phone and call your fuel gas

supplier and your fire department. Do not re-enter the

building or area.

■ Stay out of the building and away from the area until

declared safe by the firefighters and your fuel gas

supplier.

FFIINNAALLLLYY,,

■

firefighters check for escaped gas. Have them air out

the building and area before you return. Properly

trained service people must repair the leak, check for

further leakages, and then relight the heater for you.

le t the fuel gas service person a n d the

SSoommee ppeeooppllee ccaannnnoott ssmmeellll wweellll.. SSoommee ppeeooppllee ccaannnnoott

■

ssmmeellll tthhee ooddoorr ooff tthhee mmaann--mmaaddee cchheemmiiccaall aaddddeedd ttoo

pprrooppaannee oorr nnaattuurraall ggaass.. YYoouu mmuusstt ddeetteerrmmiinnee iiff yyoouu ccaann

ssmmeellll tthhee ooddoorraanntt iinn tthheessee ffuueell ggaasseess..

■ Learn to recognize the odor of propane gas and natural

gas. Local propane gas dealers and your local natural

gas supplier (utility) will be more than happy to give you

a “scratch and snif f” pamphlet. Use it to become

familiar with the fuel gas odor.

■ Smoking can decrease your ability to smell. Being

around an odor for a period of time can affect your

sensitivity to that particular odor. Odors present in

animal confinement buildings can mask fuel gas odor.

ATTENTION -- CRITICAL POINTS TO REMEMBER!

■ Propane gas and natural gas have a distinctive odor.

Learn to recognize these odors. (Reference “Fuel Gas

Odor” and “Odor Fading” sections above.

■

If you have not been properly trained in repair and service

of propane gas and natural gas fueled heaters, then do

not attempt to light the heater, perform service or repairs,

or make any adjustments to the heater on a propane gas

or natural gas fuel system.

ODOR FADING -- NO ODOR DETECTED

TThhee ooddoorraanntt iinn pprrooppaannee ggaass aanndd nnaattuurraall ggaass iiss ccoolloorrlleessss

■

aanndd tthhee iinntteennss iittyy ooff iittss ooddoorr ccaann ffaaddee uunnddeerr ssoommee

cciirrccuummssttaanncceess..

■ If there is an underground leak, the movement of gas

through the soil can filter the odorant.

■ Propane gas odor may differ in intensity at different

levels. Since propane gas is heavier than air, there may

be more odor at lower levels.

AAllwwaayyss bbee sseennssiittiivvee ttoo tthhee sslliigghhtteesstt ggaass ooddoorr..

■

continue to detect any gas odor, no matter how small,

treat it as a serious leak. Immediately go into action as

discussed previously.

■ Even if you are not properly trained in the service and

repair of radiant heaters, ALWAYS be consciously aware

of the odors of propane gas and natural gas.

■ A periodic “snif f test” around the heater or at the

heater’s joints; i.e. hose, connections, etc., is a good

safety practice under any conditions. If you smell even

a small amou nt of gas, CONTACT YOUR FUEL GAS

SUPPLIER IMMEDIATELY. DO NOT WAIT!

If you

55

Safety Precautions

1. Do not attempt to install, repair or service this heater

or the gas supply line unless you have continuing

expert training and knowledge of gas heaters.

Qualifications for service and installation of this

equipment are as follows:

QUALIFICATIONS FOR

SERVICING AND INSTALLATION:

a. To be a qualified gas heater service person, you

must have be e n train e d in gas- f ired h e a ter

ser vi c in g , re pai r an d als o have s uf fi c ien t

experience to allow you to troubleshoot, replace

defective parts, and test heaters in order to get

them into a continuing safe and normal operation

condit i on. You m u s t complete l y f a milia r ize

yourself with each model heater by reading and

complying with the safety instructions, labels,

owner’s manual, etc. that is provided with each

heater.

b. To be a qualified gas installation person, you must

have sufficient training and experience to handle

all aspects of installing, repairing and altering gas

lines, including selecting and installing the proper

equipment, and selecting proper pipe size to be

used. This must be done in accordance with all

local, state and national codes as well as the

manufacturer’s requirements.

2. All installations or applications of L. B. White Co.,

Inc.’s radiant heater and associated zone control

panel should meet the requirements of local, state

and national L.P. gas and natural gas, electrical and

sa fety c o des. Your gas supplier, l o c al license d

electrician, local fire depar tment and government

agencies can help you determine these requirements.

In the abs e n c e of local co d e s , comply wit h the

following:

a. Installations in the U.S.A.:

-- ANSI/NFPA 58, latest edition, Standard for

Storage and Handling of Liquefied Petroleum

Gas and/or

-- ANSI Z223 .1/NFPA 54 , National Fuel Gas

Code

-- ANSI/NFPA 70, National Electrical Code.

b. Installations in Canada:

-- CAN1-B149.1 or CAN1-B149.2 Installation

Codes

-- CS A C 22.1 Pa r t 1 St an d ard Cana d ia n

Electrical Code. CSA C22.2 No.3, Electrical

Features of Fuel Burning Equipment.

3. If at any time you notice something unusual about the

ope r at i on o f y our h e ate r s uc h a s g as o do r,

overheating, flames other than in the combustion

cone area, etc., evacuate the area immediately and

call your fire department and your gas service agency.

Get assurances from the fire department that the

area is free of gas before you attempt to relight the

heater.

66

4. The components on the heater that call for hand

operation should work with hand pressure only. If

more force is required, have a qualified gas heater

service agency replace the complete part. Do not

attempt to repair.

5. This heater is intended for the heating of livestock in

agricultural animal confinement buildings only. The

heater shal l only be mounted insi de the animal

confinement building. It shall not be used for outside

heating applications.

6. Do not locate fuel gas containers or fuel supply hoses

anywhere within the heating zone of the heater.

7. Do not block air intakes or discharge outlets of the

heater. Doing so may cause improper combustion or

damage to the heater components leading to property

damage or animal loss.

8. Do not move, handle, or service the heater while in

operation or connected to fuel supply.

9. The hose assembly providing fuel to the heater must

be inspected on a regular basis. This should be done

at least once a year, or when the building is cleaned

out. If it is evident there is excessive abrasion or

wear, or if the hose is cut, it must be replaced prior to

heater being put into operation. The hose assembly

shall be protected from animals, building materials,

and contact with hot surfaces during use. The hose

assembly shall be that specified by the manufacturer.

See parts list.

10. Ch e ck fo r g as leaks a n d p ro per funct i o n upon

installation, before building repopulation and when

relocating.

11. If the gas flow is interrupted and the burner flame is

extinguished, immediately shut off the gas. Do not

relight the heater until you are sure that all of the gas

that may have accumulated through the heater has

cleared away. Do not relight the heater until at least

five minutes have passed.

12. If the heater is to be relocated, make sure that all gas

connections are capped and the gas supply is shut

off. All connection points must be leak checked after

disconnection and after reconnection.

WWAARRNNIINNGG

BBuurrnn HHaazzaarrdd

■ The heater’s combustion cones and canopy are

extremely hot during operation and shortly after

shutting down.

■ Always be aware of your proximity to the heater and

avoid contact with its hot surfaces during or shortly

after operation.

■ Failure to follow this warning can result in burns

leading to severe personal injury.

13. The grower shall inspect the heater before building

repopulation. Such inspection should consist of, but

is not limited to, the following points of action:

control panel to test for proper operation.

-- Leak check of all pipe joints and hose connections.

-- Insure proper clearance of heater to nea rest

combustible materials.

-- Check for general cleanliness. Clean if necessary.

-- Check for tightness of the gas hose connections.

14. A qualified service person shall inspect the heater

and its gas train at least on an annual basis. This

should consist of, but is not limited to, the following

points of action:

-- Start-up and shut down of the heaters and zone

1. Read all safety precautions and follow L. B. White

recommendations when installing this heater. If

during the installation or relocating of the heater, you

suspect that a part is damaged or defective, call a

qualified service agency for repair or replacement.

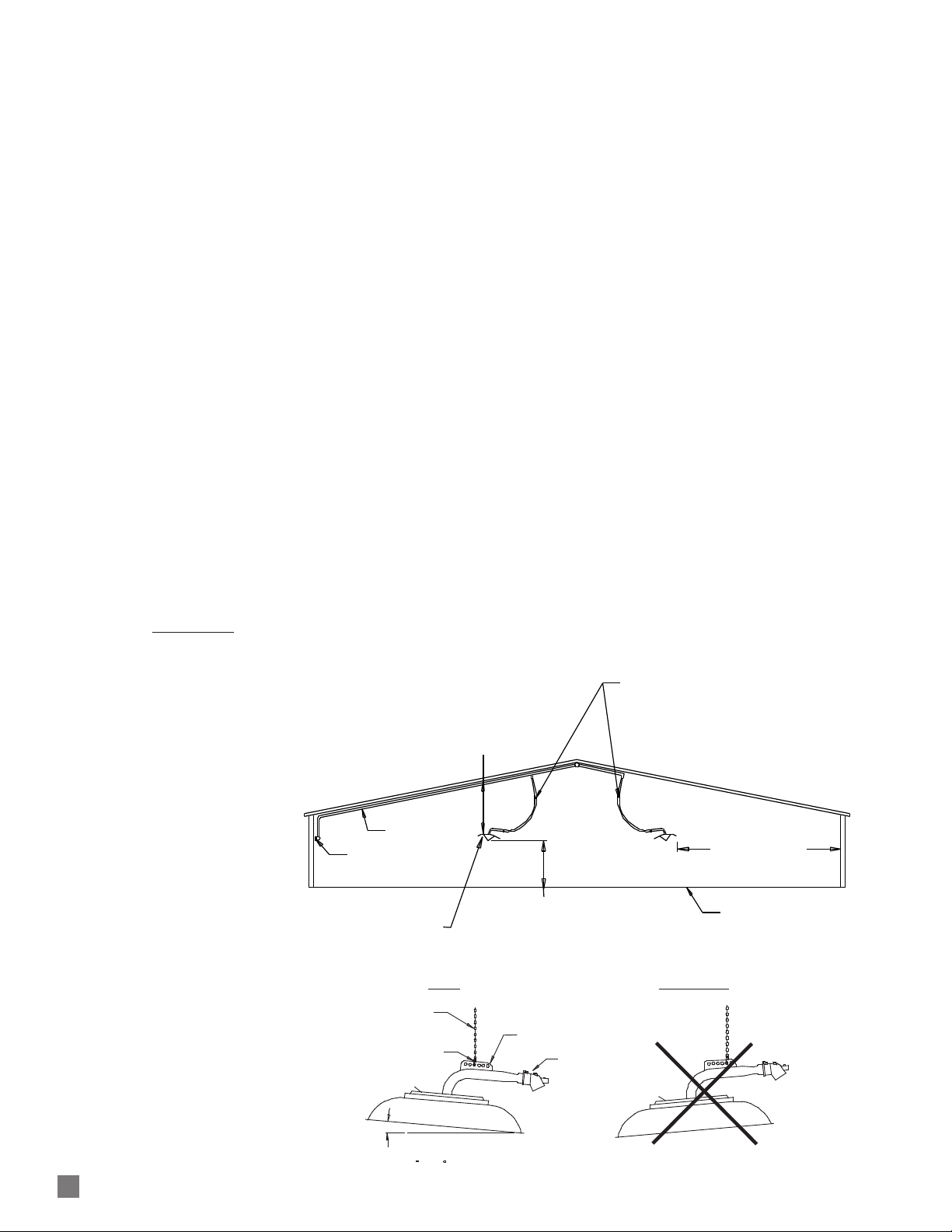

2. Position the heater properly before use in accordance

wi t h requ i r e m e n ts for comb u s t i b l e clearances,

ground clearance, tilt an gle, and to protect the

brooder from livestock. Refer to Fig. 2 as well as the

specification table on page 4 in this manual, for

information on installation and clearances.

-- Thorough cleaning of the exterior of the heater, its

inlet ventu r i , comb u s t i o n cones a nd f i lte r (if

applicable).

-- Thorough inspection of the heater’s component

parts for corrosion, stripped threads, etc. with

subsequent parts replacement as necessary.

-- Gas pressure checks.

15. Turn off the gas supply when the heater is not in use.

Installation Instructions

GENERAL

WWAARRNNIINNGG

FFiirree aanndd EExxpplloossiioonn HHaazzaarrdd

■ Do not use open flame (matches, torches, candles,

etc.) in checking for gas leaks.

■ Use only approved leak detectors.

■ Failure to follow this warning can lead to fires or

explosions.

■ Fires or explosions can lead to proper ty damage,

personal injury or death.

performed as follows:

3. Position the gas hose outside of the hot zone directly

above the heater to avoid any contact with the hot

canopy surface of the heater. Refer to Fig. 2.

4. Insure that all accessories that ship with heater have

be en removed fro m inside o f heater ’ s shipping

container and installed. This pertains to gas hose,

regulators, etc.

5. The heater’s gas regulator (with pressure relief valve)

sho u ld be ins t al l ed ou ts i de of b u il d in g . A ny

regulators inside the buildings must be properly

vented to the outside. Local, state and national codes

always apply to regulator installation. Natural gas

regulators with a vent limiting device may be mounted

indoors without venting to outdoors.

6. Any regula tor mounted outside the building be

pro tec ted aga i n s t t h e w e a t h er, par ticularly ice

fo rm a ti o n. Ic e fo rma t io n ca n lead to

overpressurization of the regulator and subsequent

gas leaks. See codes covering proper protection.

7. Always use pipe joint compound that is resistant to

liquefied petroleum gas and natural gas.

8. Check all connections for gas leaks using approved

gas l e ak d e tec t o rs . G as l e ak te s tin g is

-- Check all pipe connections, hose connections,

fittings and adapters upstream of the gas

control with approved gas leak detectors.

-- In the event a gas leak is detected, check the

co mponents involved for cle a nliness a nd

proper application of pipe compound before

further tightening.

-- Furthermore tighten the gas connections as

necessary to stop the leak.

-- After all connections are checked and any

leaks are stopped, turn on the main burner.

-- Stand clear while the main burner ignites to

prevent injury caused from hidden leaks that

could cause flashback.

-- With the main burner in operation, check all

connections, hose connections, fittings and

joints as well as the gas control valve inlet and

outlet connections with approved gas leak

detectors.

-- If a leak is detected, check the components

involved for cleanliness in the thread areas

and proper application of pipe compound

before further tightening.

77

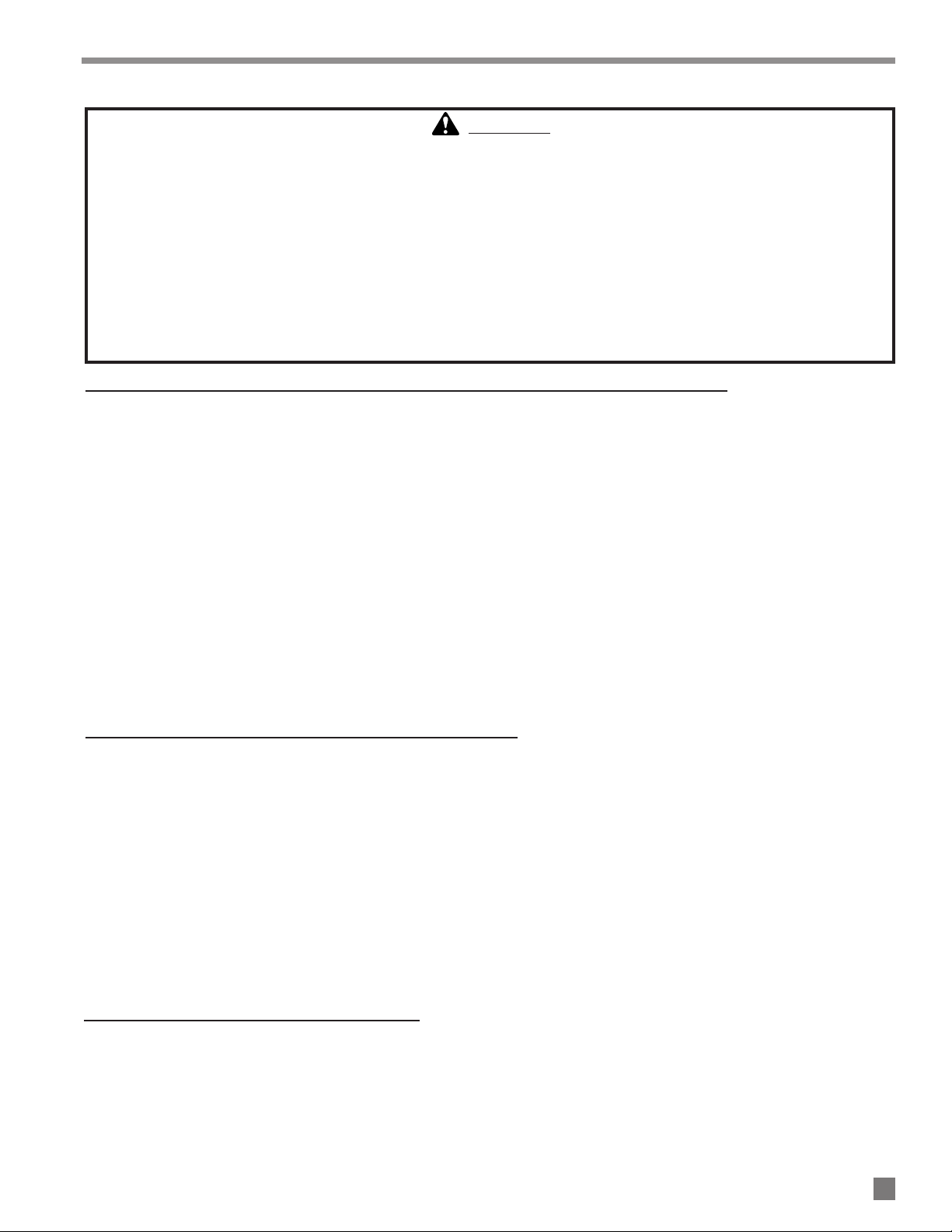

INSTALLATION LAYOUT

FOR SAFE CLEARANCES

I17 & I34 - 3 FT. MINIMUM

BROODER TOP TO CEILING

POSITION THE GAS HOSE AND ELECTRICAL POWER CORD

OUTSIDE OF THE HOT ZONE DIRECTLY ABOVE THE HEATER.

POSITION THE GAS HOSE AND POWER CORD TO AVOID

ANY OPPORTUNITY FOR CONTACT WITH THE HOT CANOPY

SURFACE OF THE HEATER.

MINIMUM 3 FT. CLEARANCE

TO COMBUSTIBLES

FLOOR

I17 - 3.5 FT. MINIMUM

I34 - 4.5 FT. MINIMUM

POINT OF COMBUSTION

CONE TO FLOOR

HANG THE HEATER WITH THE

CONTROL END 1 TO 5 DEGREES DOWN

FROM HORIZONTAL (SEE BELOW)

CONTROL PANEL

GAS PIPING

-- Tighten the gas connection as necessary to

THIS NOT THIS

CONTROL END

KEYRING

STEEL CABLE

HANGING

CONTROL END

OR CHAIN

BRACKET

OF HEATER

MUST BE 1 TO 5 DOWN

FROM HORIZONTAL

stop the leak.

-- If necessary, replace the parts or components

involved if the leak cannot be stopped.

-- Ensure all gas leaks have been identified and

repaired before proceeding.

9. A qualified service agency must check for proper

operating gas pressures upon installation of the

heaters.

10. Use the proper gas supply line to assure proper

functioning of the heaters. Typically, 3/4 in. ID black

iron pipe is used to supply gas to the inlet of the zone

control panel with 1/2 in. ID black iron pipe used to

convey the gas to the heaters. However, always

consult your fuel gas supplier, or the L. B. White Co.,

Inc. for proper line sizing and installation.

11. Infraconic heaters require a regulated gas supply to

the gas inlet. Exceeding the gas inlet pressure rating

can r esult in poor performance and unreli a b l e

operati o n . R e fer to pa g e 4 o f t his manu a l fo r

information on gas pressures relating to specific

models.

heater at any time.

13. T h e co r ros i ve at m os p he r e pr e sen t in an im a l

confinement buildings can cause component failure

or hea t e r malf u ncti o n. The h e ater sh o uld be

periodically inspected and cleaned in accordance

with the Maintenance and Cleaning Instructions in

this manual. Make sure that livestock is protected by

a back up alarm system that limits high and low

temperatures and also activates appropriate alarms.

14. Ta ke t i me to und e rs t an d how to o p er a te a n d

maintain the heater using the owner’s manual. Make

sure you know how to shut off the gas supply to the

building and to the individual heaters. Contact your

gas supplier if you have any questions.

15. Any defects found in performing any of the service

procedures must be eliminated and defective parts

replaced immediately. Retest the heater before

placing it back into service.

12. The heater is designed for either L.P. vapor withdrawal or natural gas, depending on model number.

Do not use this heater in an LPG liquid withdrawal

system. Do not permit LPG in liquid form to enter the

ATTENTION

FIG. 2

■ Model I34 heaters use an

integral hanging bracket with

key ring for hanging the heater.

■ Attach only steel cable or chain

to the key ring. Do not use

combustible hanging materials

BROODER TOP TO CEILING

such as ropes, lines, etc.

■ The installer must make sure

that the heater is hung so

control end of heater is

positioned 1º to 5º down from

horizontal after gas supply

hose is attached.This allows

proper venting of heater and

eliminates potential heat

damage to optional dust filter.

■ Repositioning of factory

installed key ring into hanging

bracket may be required.

■ Refer to following illustrations.

3 FT. MINIMUM

POSITION THE GAS HOSE OUTSIDE OF THE HOT ZONE

DIRECTLY ABOVE THE HEATER. POSITION THE GAS HOSE TO

AVOID ANY OPPORTUNITY FOR CONTACT WITH THE HOT

CANOPY SURFACE OF THE HEATER.

4.5 FT. MINIMUM

POINT OF COMBUSTION

CONE TO FLOOR

88

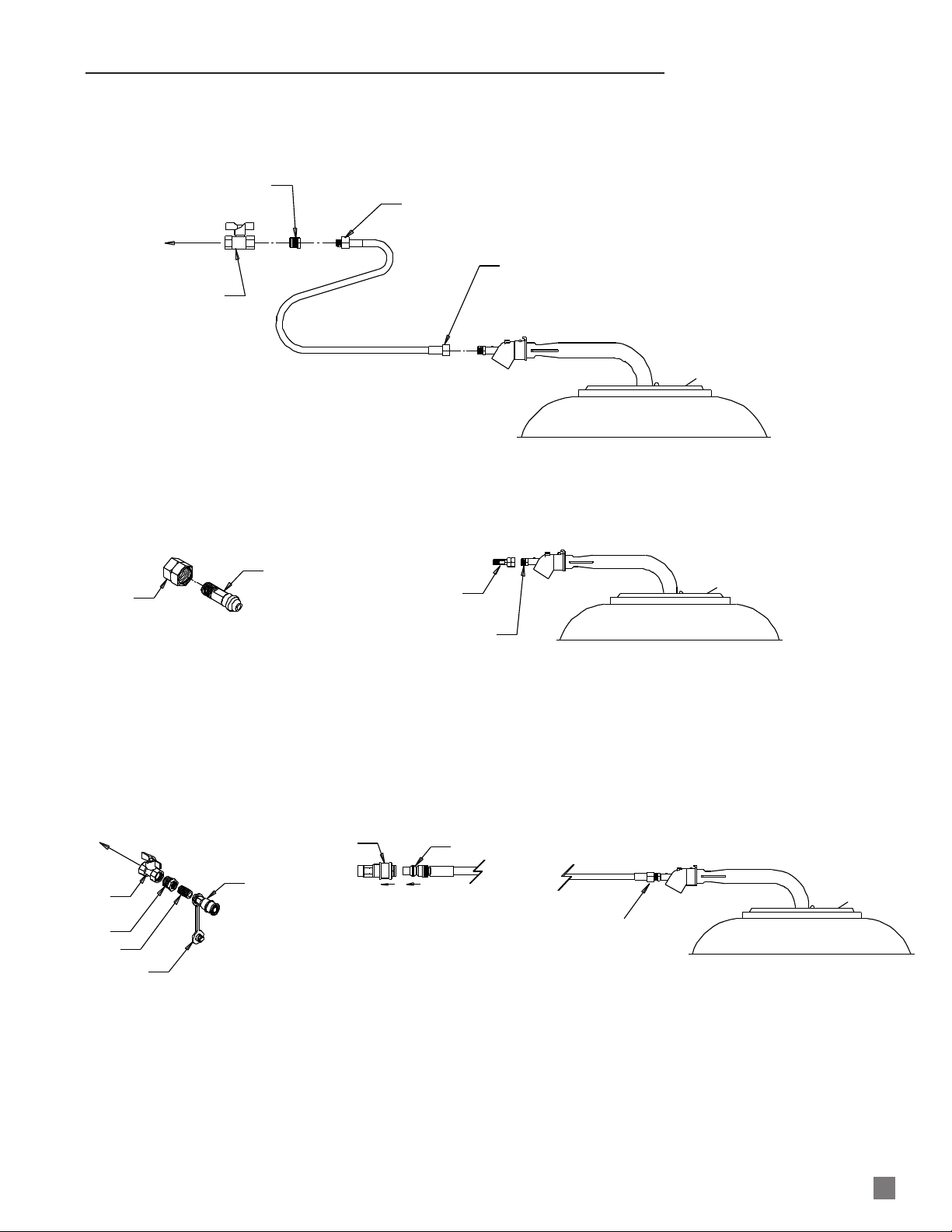

A

BC

HOSE & QUICK COUPLING KIT

COLLAR

MALE END

COUPLING

VALVE

SHUT-OFF

T

O

G

A

S

SU

PPL

Y

BUSHING

NIPPLE

DUST CAP

- ASSEMBLE COUPLING KIT

COMPONENTS & TIGHTEN

SECURELY.

- CONNECT TO GAS SUPPLY.

- PULL BACK COUPLING COLLAR.

- FIRMLY PUSH MALE HOSE END

INTO COUPLING

- RELEASE COLLAR. ENSURE

MALE HOSE END IS SECURELY

LOCKED INTO COUPLING.

CONNECT HOSE TO

GAS CONTROL INLET

& TIGHTEN SECURELY

BUSHING

RIGID END

OF HOSE

TO GAS

SUPPLY

VALVE, SHUT-OFF

CONNECT HOSE TO CONTROL VALVE

INLET, TIGHTEN SECURELY

STANDARD HOSE

Your heater is supplied with one of the following gas train

1/8 NPT FITTING KIT, PART #23406

AB

NUT

STEM

- ASSEMBLE FITTING

FITTING ASSEMBLY

CONTROL VALVE

INLET

- ATTACH FITTING TO CONTROL VALVE INLET

& TIGHTEN SECURELY.

- CONNECT APPROVED GAS HOSE ASSEMBLY

WITH APPROPRIATE CONNECTIONS TO 1/8 NPT

FITTING.

assemblies. Refer to the appropriate illustrations.

FIG. 3

FIG. 4

GAS TRAIN ASSEMBLY

FIG. 5

99