Page 1

Owner’s Manual and Instructions

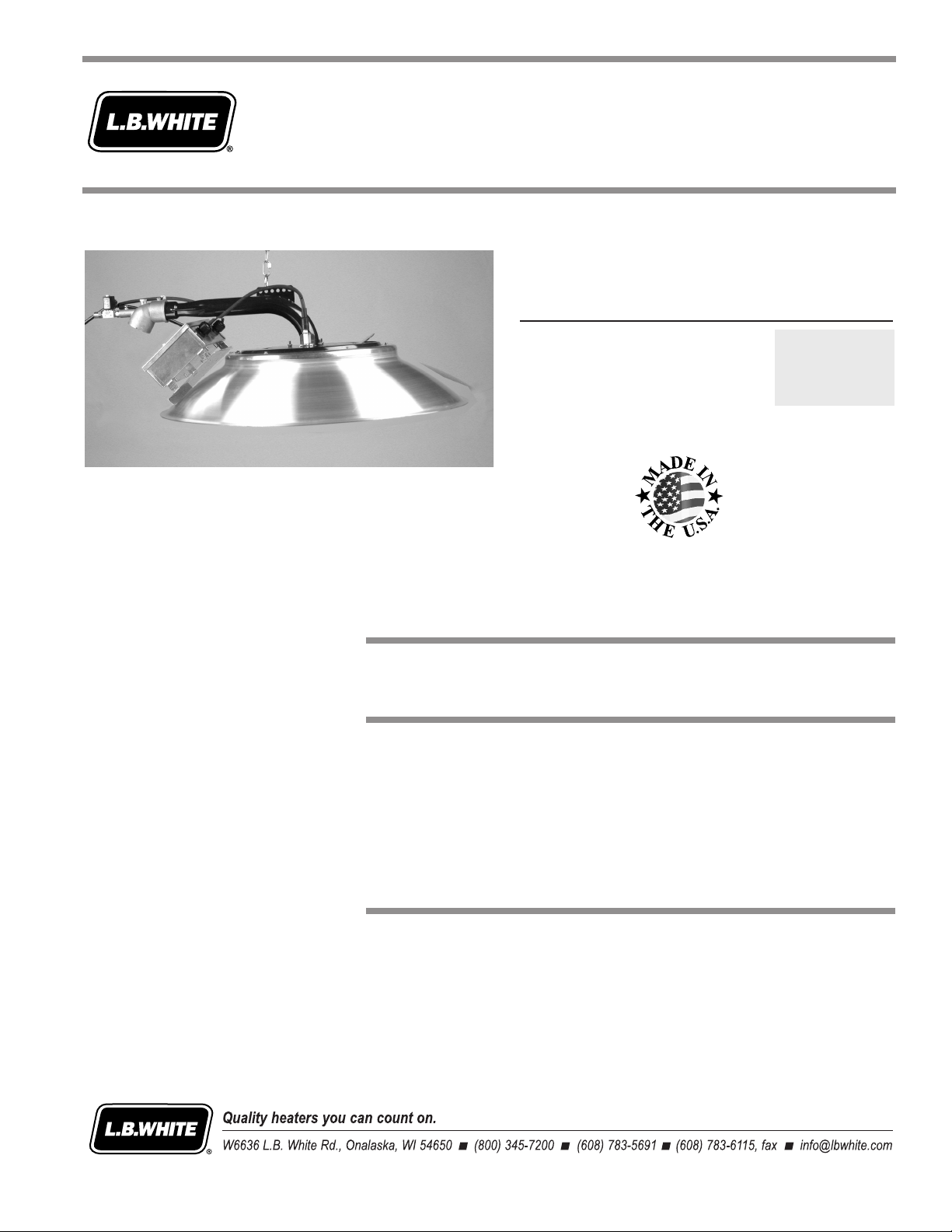

Spark Ignition Infraconic

Agricultural Building Radiant Heaters

MODELS OUTPUT (Btuh) FUEL

I34 34,200

Propane Vapor

Withdrawal

or Natural Gas

Congratulations!

You have purchased the finest radiant heater available for the heating of livestock

in agricultural animal confinement buildings.

Your new L.B. White radiant heater incorporates the benefits from the most

experienced manufacturer of heating products using state-of-the-art technology.

We, at L.B. White, thank you for your confidence in our products and welcome any

suggestions or comments you may have...call us toll free at 1-800-345-7200.

ATTENTION ALL USERS

This heater has been tested and evaluated by L.B. White Co., Inc. as a direct

gas-fired radiant heater with intended use for the heating of livestock in agricultural

animal confinement buildings. If you are considering using this product for any

application other than its intended use, then please contact your fuel gas supplier,

or the L.B. White Co., Inc.

150-23922-A

Page 2

Page 3

GENERAL HAZARD WARNING

■ Failure to comply with the precautions and instructions provided with this heater, can result in:

— Death

— Serious bodily injury or burns

— Property damage or loss from fire or explosion

— Asphyxiation due to lack of adequate air supply or carbon monoxide poisoning

— Electrical shock

■ Read this Owner’s Manual before installing or using this heater.

■ Only properly-trained service people should repair or install this heater.

■ Save this Owner’s Manual for future use and reference.

■ Owner’s Manuals and replacement labels are available at no charge. For assistance, contact

L.B. White at 1-800-345-7200.

WARNING

■ Proper gas supply pressure must be provided to the inlet of the heater.

■ Refer to rating plate for proper gas supply pressure.

■ Gas pressure in excess of the maximum inlet pressure specified at the heater inlet can cause

fires or explosions.

■ Fires or explosions can lead to serious injury, death, building damage or loss of livestock.

■ Gas pressure below the minimum inlet pressure specified at the heater inlet may cause

improper combustion.

■ Improper combustion can lead to asphyxiation or carbon monoxide poisoning and therefore

serious injury or death to humans and livestock.

WARNING

Fire and Explosion Hazard

■ Not for home or recreational vehicle use.

■ Installation of this heater in a home or

Fire and Explosion Hazard

■ Keep solid combustibles a safe distance

away from the heater.

WARNING

recreational vehicle may result in a fire or

explosion.

■ Fire or explosions can cause property

■ Solid combustibles include wood or paper

products, feathers, straw, and dust.

damage or loss of life.

■ Do not use the heater in spaces which

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of

this or any other heater.

contain or may contain volatile or airborne

combustibles.

■ Volatile or airborne combustibles include

gasoline, solvents, paint thinner, dust

particles or unknown chemicals.

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

■ Failure to follow these instructions may

result in a fire or explosion.

■ Fire or explosions can lead to property

damage, personal injury or loss of life.

4. Immediately call your gas supplier.

22

Page 4

Table of Contents

SECTION PAGE

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Heater Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Gas Train Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Zone Control Panel Function and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Installing Dust Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Start-Up Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Shut-Down Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Cleaning Instructions

A. Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

B. Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Service Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

On/Off Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Ignition Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Burner Orifice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

High Voltage Ignition Lead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Igniter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

High Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Gas Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Gas Pressure Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Electrical Connection and Ladder Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Heater Component Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Parts Identification

Parts Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Replacement Parts and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

General Information

This owner's manual includes all options and accessories

commonly used on or with this heater. However, depending

on the configuration purchased, some options and

accessories may not be included.

When calling for technical service assistance, or for other

specific information, always have the model number and

serial number available.

This manual will instruct you in the operation and care of

your radiant heater. Have your qualified installer review this

manual with you so that you fully understand the heater and

how it functions.

33

The gas supply line installation, and the repair, installation

and servicing of the heater requires continuing expert

training and knowledge of gas heaters and should not be

attempted by anyone who is not so qualified. See page 6

for definition of the necessary qualifications.

Contact your local L. B. White distributor or the L. B. White

Co., Inc. for assistance, or if you have any questions about

the use of the heater or its application.

The L. B. White Co., Inc. has a policy of continuous product

improvement. It reserves the right to change specifications

and design without notice.

Page 5

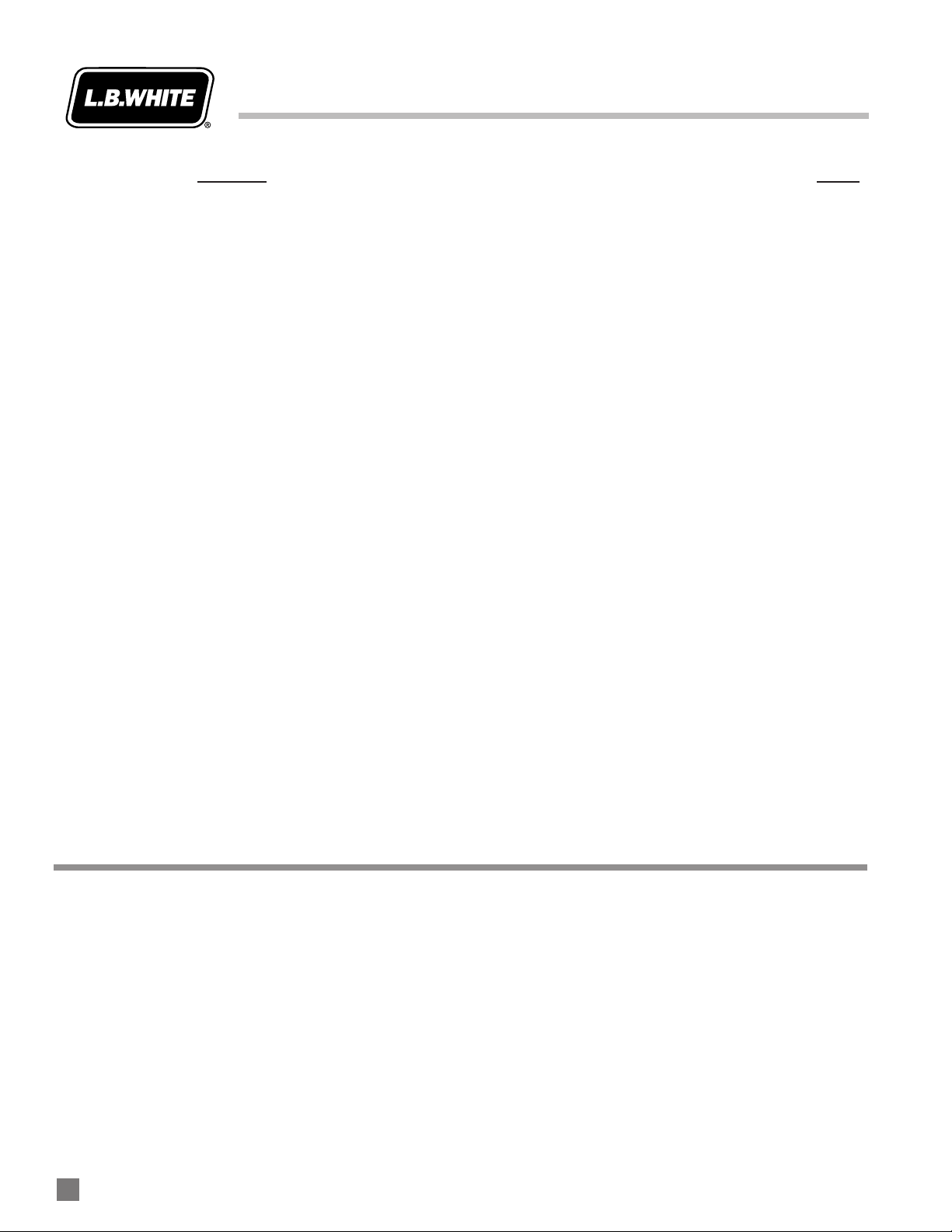

Radiant Heater Specifications

"B"

"A"

"C"

MMooddeell

SSPPEECCIIFFIICCAATTIIOONNSS

I34

Maximum Input (Btuh) 34,200

Ventilation Air to Support Combustion

FULL OUTPUT

Inlet Gas Supply Pressure at the Heater

(On/Off

Version)

ZONE

CONTROLLED

(Dual Solenoid

Version)

Burner Manifold Pressure at Maximum Pressure

MAX.

MIN.

MAX.

MIN.

400 CFM

5 psig

5 psig

5 psig

2.0 psig

5 psig

“A” 26-3/8 in.

Heater Dimensions

(See Fig. 1)

“B” 20 1/4 in.

“C” 10 3/8 in.

Net Weight 15 lbs. 8 oz.

Fuel Consumption Per Hour

Electrical Supply (Volts/HZ/Phase)

PROPANE GAS 1.58 lbs./hr.

NATURAL GAS

34.2 CFH

120/60/1

Amp Draw

CHICKENS 2500 - 3800

Animal Coverage Per Heater (1)

TURKEYS 800 - 950

SWINE 300

Recommended Height Installation

For Livestock From Point of

Combustion Cone to Floor

CHICKENS 6 - 7 ft.

TURKEYS 4.5 ft.

SWINE 4 - 5 ft.

TOP OF HOOD TO CEILING 3 ft.

Minimum Safe Clearances to

Combustible Materials

POINT OF COMBUSTION

CONE TO FLOOR

SIDES 3 ft.

Animal Occupied Zone Temperature

POULTRY

Control Sensor Location (2)

SWINE

(1) There are other factors that will affect the quantity of animals

(2) This is typical sensor placement range. The size and type of

each heater can cover. These include building ventilation and

control systems, building insulation, building size and population

density, etc. Consult your L. B. White dealer or call L. B. White for

specific recommendations for your application.

livestock being grown, heater spacing and height, etc. will dictate

sensor location. Care should always be taken to ensure that the

sensor is sufficiently high as to not be damaged by the animal

during operation.

0.5

4.5 ft.

VERTICAL FROM FLOOR 6-12 in.

HORIZONTAL FROM BROODER 8-12 ft.

VERTICAL FROM FLOOR Above Animal Height

HORIZONTAL FROM BROODER 4-8 ft.

FIG. 1

44

Page 6

Safety Precautions

Asphyxiation Hazard

■ Do not use this radiant heater for heating human living

quarters.

WWAARRNNIINNGG

L.B. White Company to determine combustion air

ventilation requirements of the heater.

■ Do not use in unventilated areas.

■ The flow of combustion and ventilation air must not be

obstructed.

■ Proper ventilation air must be provided to support the

combustion air requirements of the heater being used.

■ Refer to the spe c ification s ection of the Owner’s

Man u al , hea t e r’ s dat a pla te, or c on t ac t t he

■ Lack of proper ventilation air will lead to improper

combustion.

■ Improper combustion can lead to carbon monoxide

poisoning in humans leading to serious injury or death.

Symptoms of carbon monoxide poisoning can include

headaches, dizziness and difficulty in breathing.

■ Symptoms of improper combustion affecting livestock

can be disease, lower feed conversion, or death.

FUEL GAS ODOR

PPrrooppaannee ggaass aanndd nnaattuurraall ggaass hhaavvee mmaann--mmaaddee ooddoorraannttss aaddddeedd ssppeecciiffiiccaallllyy ffoorr ddeetteeccttiioonn ooff ffuueell ggaass lleeaakkss..

IIff aa ggaass lleeaakk ooccccuurrss,, yyoouu sshhoouulldd bbee aabbllee ttoo ssmmeellll tthhee ffuueell ggaass..

TTHHAATT’’SS YYOOUURR SSIIGGNNAALL TTOO GGOO IINNTTOO IIMMMMEEDDIIAATTEE AACCTTIIOONN!!

■ Do not take any action that could ignite the fuel gas. Do

not operate any electrical switches. Do not pull any

power supply or extension cords. Do not light matches

or a ny ot h er so u rce of fl a me. Do not us e you r

telephone.

■ Get everyone out of the building and away from the area

immediately.

■ Close all propane gas tank or cylinder fuel supply

valves, or the main fuel supply valve located at the

meter if you use natural gas.

■ Propane gas is heavier than air and may settle in low

areas. When you have reason to suspect a propane

leak, keep out of all low areas.

■ Natural gas is lighter than air and can collect around

rafters or ceilings.

■ Use your neighbor’s phone and call your fuel gas

supplier and your fire department. Do not re-enter the

building or area.

■ Stay out of the building and away from the area until

declared safe by the firefighters and your fuel gas

supplier.

FFIINNAALLLLYY ,,

■

firefighters check for escaped gas. Have them air out

the building and area before you return. Properly

trained service people must repair the leak, check for

further leakages, and then relight the heater for you.

le t the fuel gas service person a n d the

ODOR FADING -- NO ODOR DETECTED

SSoommee ppeeooppllee ccaannnnoott ssmmeellll wweellll.. SSoommee ppeeooppllee ccaannnnoott

■

ssmmeellll tthhee ooddoorr ooff tthhee mmaann--mmaaddee cchheemmiiccaall aaddddeedd ttoo

pprrooppaannee oorr nnaattuurraall ggaass.. YYoouu mmuusstt ddeetteerrmmiinnee iiff yyoouu ccaann

ssmmeellll tthhee ooddoorraanntt iinn tthheessee ffuueell ggaasseess..

■ Learn to recognize the odor of propane gas and natural

gas. Local propane gas dealers and your local natural

gas supplier (utility) will be more than happy to give you

a “scratch and snif f” pamphlet. Use it to become

familiar with the fuel gas odor.

■ Smoking can decrease your ability to smell. Being

around an odor for a period of time can affect your

sensitivity to that particular odor. Odors present in

animal confinement buildings can mask fuel gas odor.

TThhee ooddoorraanntt iinn pprrooppaannee ggaass aanndd nnaattuurraall ggaass iiss ccoolloorrlleessss

■

aanndd tthhee iinntteennssiittyy ooff iittss ooddoorr ccaann ffaaddee uunnddeerr ssoommee

cciirrccuummssttaanncceess..

■ If there is an underground leak, the movement of gas

through the soil can filter the odorant.

■ Propane gas odor may differ in intensity at different

levels. Since propane gas is heavier than air, there may

be more odor at lower levels.

AAllwwaayyss bbee sseennssiittiivvee ttoo tthhee sslliigghhtteesstt ggaass ooddoorr..

■

continue to detect any gas odor, no matter how small,

treat it as a serious leak. Immediately go into action as

discussed previously.

ATTENTION -- CRITICAL POINTS TO REMEMBER!

■ Propane gas and natural gas have a distinctive odor.

Learn to recognize these odors. (Reference “Fuel Gas

Odor” and “Odor Fading” sections above.

■

If you have not been properly trained in repair and service

of propane gas and natural gas fueled heaters, then do

not attempt to light the heater, perform service or repairs,

or make any adjustments to the heater on a propane (LP)

gas or natural gas fuel system.

55

■ Even if you are not properly trained in the service and

repair of radiant heaters, ALWAYS be consciously aware

of the odors of propane gas and natural gas.

■ A periodic “snif f test” around the heater or at the

heater’s joints; i.e. hose, connections, etc., is a good

safety practice under any conditions. If you smell even

a small amou nt of gas, CONTACT YOUR FUEL G AS

SUPPLIER IMMEDIATELY. DO NOT WAIT!

If you

Page 7

Safety Precautions

1. Do not attempt to install, repair or service this heater

or the gas supply line unless you have continuing

expert training and knowledge of gas heaters.

Qualifications for ser vice and installation of this

equipment are as follows:

QUALIFICATIONS FOR

SERVICING AND INSTALLATION:

a. To be a qualified gas heater service person, you

must have been tra i n ed in gas- f i red heater

ser vi c in g , rep a ir a n d als o have su f f i ci e nt

experience to allow you to troubleshoot, replace

defective parts, and test heaters in order to get

them into a continuing safe and normal operation

conditio n . You must co m p l ete ly familia r i z e

yourself with each model heater by reading and

complying with the safety instructions, labels,

owner’s manual, etc. that is provided with each

heater.

b. To be a qualified gas installation person, you must

have sufficient training and experience to handle

all aspects of installing, repairing and altering gas

lines, including selecting and installing the proper

equipment, and selecting proper pipe size to be

used. This must be done in accordance with all

local, state and national codes as well as the

manufacturer’s requirements.

5. This heater is intended for the heating of livestock in

agricultural animal confinement buildings only. The

heater shall only be mounted inside the animal

confinement building. It shall not be used for outside

heating applications.

6. Do not locate fuel gas containers or fuel supply hoses

anywhere within the heating zone of the heater.

7. Do not block the air intake, burner venturi tube or

burner cone area. Doing so may cause improper

combustion or damage to the heater components,

leading to property damage or animal loss.

8. Do not move, handle, or service the heater while in

operation or connected to fuel supply.

9. The hose assembly must be inspected on a regular

basis. This should be done at least once a year, or

when the building is cleaned out. If it is evident there

is excessive abrasion or wear, or if the hose is cut, it

must be replaced prior to heater b eing put into

operation. The hose assembly shall be protected

from animals, building materials, and contact with

hot surfaces during use. The hose assembly shall be

that specified by the manufacturer. See parts list.

10. Ch e c k for ga s leaks and proper func t i o n u pon

installation, before building repopulation and when

relocating.

2. All installations or applications of L. B. White Co.,

Inc.’s radiant heater and associated zone control

panel should meet the requirements of local, state

and national L.P. gas and natural gas, electrical and

sa fety codes. Yo ur gas s upplier, l ocal lic ensed

electrician, local fire department and government

agencies can help you determine these requirements.

In the absen c e of loca l codes, co mply with the

following:

-- ANSI/NFPA 58, latest edition, Standard for

Storage and Handling of Liquefied Petroleum

Gas and/or

-- ANSI Z223.1/NFPA 54, National Fuel Gas

Code

-- ANSI/NFPA 70, National Electrical Code.

3. If at any time you notice something unusual about the

ope r at i on of you r h e ate r s u ch as ga s o dor,

overheating, flames other than in the combustion

cone area, etc., evacuate the area immediately and

ca l l you r f i re depar t m e n t and you r gas ser v i c e

agency. Get assurances from the fire department

that the area is free of gas before you attempt to

relight the heater.

4. The components on the heater that call for hand

operation should work with hand pressure only. If

more force is required, have a qualified gas heater

service agency replace the complete part. Do not

attempt to repair.

11. If the gas flow is interrupted and the burner flame is

extinguished, immediately shut off the gas. Do not

relight the heater until you are sure that all of the gas

that may have accumulated through the heater has

cleared away. Do not relight the heater until at least

five minutes have passed.

12. If the heater is to be relocated, make sure that all gas

connections are capped and the gas supply is shut

off. All connection points must be leak checked after

disconnection and after reconnection.

WWAARRNNIINNGG

BBuurrnn HHaazzaarrdd

■ The heater’s combustion cones and canopy are

extremely hot during operation and shortly after

shutting down.

■ Always be aware of your proximity to the heater and

avoid contact with its hot surfaces during or shortly

after operation.

■ Failure to follow this warning can result in burns

leading to severe personal injury.

13. The grower shall inspect the heater before building

repopulation. Such inspection should consist of, but

is not limited to, the following points of action:

66

Page 8

-- Ins u re p r ope r cle a ra n ce o f he a ter to nea r es t

combustible materials.

-- Check for general cleanliness. Clean if necessary.

-- Check for tightness of the gas hose connections.

14. A qualified service person shall inspect the heater

and its gas train at least on an annual basis. This

should consist of, but is not limited to, the following

points of action:

-- Leak check of all pipe joints and hose connections.

-- Thorough cleaning of the exterior of the heater, its

inlet ventur i , comb u s t i o n con e s and filter (if

applicable).

-- Thorough inspection of the heater’s component

parts for corrosion, stripped threads, etc. with

subsequent parts replacement as necessary.

-- Gas pressure checks.

-- Start-up and shut down of the heaters and zone

control panel to test for proper operation.

Installation Instructions

GENERAL

1. Read all safety precautions and follow L. B. White

recommendations when installing this heater. If

during the installation or relocating of the heater, you

suspect that a part is damaged or defective, call a

qualified service agency for repair or replacement.

2. On initial installation and before use, position the

heater properly regarding clearance to combustible

materials and ground clearance to protect the heater

from livestock. Refer to the specification table on

page 4 as well as Figure 2 for installation information

for proper hanging and clearances.

3. The h e ater m a y b e con n ecte d t o an ap p ro v e d

electrical supply and operated from off to full heat

outp u t by util i zing t h e bui l d ing’ s e nvironm e nt

controller. In this type of installation, 5 psig must be

plumbed directly to each radiant heater for proper

combustion.

4. For installations requiring two stage heating, a zone

control panel is available which, when interfaced with

the building’s environment controller, will provide

from half to full heat output. Refer to page 10 of this

manual for more information relative to the control

panel.

5. Position the gas hose outside of the hot zone directly

above the heater. Position the gas hose to avoid any

opportunity for contact with the hot canopy surface of

the heater. Refer to Fig. 2.

6. Insure that all accessories that ship with the heater

have been removed from inside of heater’s shipping

container and installed. This pertains to gas hose,

regulators, etc.

7. The heater’s gas regulator (with pressure relief valve)

should be installed outside of building. Typically any

regulators inside the buildings must be properly

vented to the outside. However, local, state and

national codes always apply to regulator installation.

15. Turn off the gas supply when the heater is not in use.

8. Any reg u l a tor mounted outside the building be

pro tec ted ag a i n st the weather, pa r ticula r l y i c e

fo rm a ti o n. Ic e fo rm a ti o n can le a d to

overpressurization of the regulator and subsequent

gas leaks. See codes covering proper protection.

9. Always use pipe joint compound that is resistant to

liquefied petroleum gas and natural gas.

10. Check all connections for gas leaks using approved

gas leak detectors. Gas leak testing is performed as

follows:

WWAARRNNIINNGG

FFiirree aanndd EExxpplloossiioonn HHaazzaarrdd

■ Do not use open flame (matches, torches, candles,

etc.) in checking for gas leaks.

■ Use only approved leak detectors.

■ Failure to follow this warning can lead to fires or

explosions.

■ Fires or explosions can lead to property damage, injury

or death.

-- Check all pipe connections, hose connections,

fittings and adapters upstream of the gas

control with approved gas leak detectors.

-- In the event a gas leak is detected, check the

co mponents involved for cle anliness a nd

proper application of pipe compound before

further tightening.

-- Furthermore tighten the gas connections as

necessary to stop the leak.

-- After all connections are checked and any

leaks are stopped, turn on the main burner.

-- Stand clear while the main burner ignites to

prevent injury caused from hidden leaks that

could cause flashback.

77

Page 9

INSTALLATION LAYOUT G

FOR SAFE CLEARANCES

I17 & I34 - 3 FT. MINIMUMG

BROODER TOP TO CEILING

POSITION THE GAS HOSE AND ELECTRICAL POWER CORDG

OUTSIDE OF THE HOT ZONE DIRECTLY ABOVE THE HEATER.G

POSITION THE GAS HOSE AND POWER CORD TO AVOID G

ANY OPPORTUNITY FOR CONTACT WITH THE HOT CANOPYG

SURFACE OF THE HEATER.

MINIMUM 3 FT. CLEARANCEG

TO COMBUSTIBLES

FLOOR

I17 - 3.5 FT. MINIMUMG

I34 - 4.5 FT. MINIMUMG

POINT OF COMBUSTION G

CONE TO FLOORG

G

HANG THE HEATER WITH THE G

CONTROL END 1 TO 5 DEGREES DOWN G

FROM HORIZONTAL (SEE BELOW)

CONTROL PANEL

GAS PIPING

-- With the main burner in operation, check all

THIS NOT THIS

CONTROL END

KEYRING

STEEL CABLE

HANGING

CONTROL END

OR CHAIN

BRACKET

OF HEATER

MUST BE 1 TO 5 DOWN

FROM HORIZONTAL

connections, hose connections, fittings and

joints as well as the gas control valve inlet and

outlet connections with approved gas leak

detectors.

-- If a leak is detected, check the components

involved for cleanliness in the thread areas and

proper application of pipe compound before

further tightening.

-- Tighten the gas connection as necessary to

stop the leak.

-- If necessary, replace the parts or components

involved if the leak cannot be stopped.

-- Ensure all gas leaks have been identified and

repaired before proceeding.

11. A qualified service agency must check for proper

operating ga s pressures upon insta llation of the

heaters.

12. It is extremely important to use the proper gas supply

line to assure prope r functioning of the heaters.

Typically, 1/2 in. ID black iron pipe is used to convey

the gas to the heaters. However, always consult your

fuel gas supplier, or the L. B. White Co., Inc. for proper

line sizing and installation.

13. Infraconic heaters require a regulated gas supply to

the gas inlet. Exceeding the gas inlet pressure rating

can r e sult in po o r per form a nce a n d unr e lia b le

ope r at i on . Refer t o pa g e 4 o f thi s ma n ual f o r

information on gas pressu res r elating to specific

models.

14. The heater is designed for either L.P. vapor withdrawal

or natural gas, depending on model number. Do not

use t h is h e ater i n a n LPG l i qui d w it h dr a w a l

system. Do not permit LPG in liquid form to enter the

heater at any time.

15. T h e c o rro s ive at m osp her e p r ese nt i n a nim a l

confinement buildings can cause component failure or

heater malfunction. The heater should be periodically

insp e c ted and c l eane d in acc o rd ance with t h e

Maintenance and Cleaning Instructions in this manual.

Make sure that livestock is protected by a back up

alarm system that limits high and low temperatures

and also activates appropriate alarms.

16. Take time to understand how to operate and maintain

the heater using the owner’s manual. Make sure you

know how to shut off the gas supply to the building

and to the in dividu al hea ters. Conta ct yo ur gas

supplier if you have any questions.

17. Any defects found in performing any of the service

procedures must be eliminated and defective parts

replaced immed iatel y. Retest t he hea ter b efor e

placing it back into service.

AATTTTEENNTTIIOONN

FIG. 2

■ Model I34 heaters use an

integral hanging bracket with

key ring for hanging the heater.

■ Attach only steel cable or chain

to the key ring. Do not use

combustible hanging materials

such as ropes, lines, etc.

■ The installer must make sure

that the heater is hung so

control end of heater is

positioned 1º to 5º down from

horizontal after gas supply

hose is attached.This allows

proper venting of heater and

eliminates potential heat

damage to optional dust filter.

■ Repositioning of factory

installed key ring into hanging

bracket may be required.

■ Refer to following illustrations.

3 FT. MINIMUM

BROODER TOP TO CEILING

4.5 FT. MINIMUM

POINT OF COMBUSTION

CONE TO FLOOR

88

Page 10

BUSHING

RIGID END G

OF HOSE

TO GASG

SUPPLY

VALVE, SHUT-OFF

CONNECT HOSE TO GASG

INLET, TIGHTEN SECURELY

STANDARD HOSE

GAS TRAIN ASSEMBLY

1/8 NPT FITTING KIT, PART #23406

AB

NUT

STEM

- ASSEMBLE FITTING

FITTING ASSEMBLY

CONTROL VALVEG

INLET

- ATTACH FITTING TO GAS INLETG

& TIGHTEN SECURELY.G

- CONNECT APPROVED GAS HOSE ASSEMBLYG

WITH APPROPRIATE CONNECTIONS TO 1/8 NPT G

FITTING.

A

B

C

HOSE & QUICK COUPLING KIT

COLLAR

MALE END

COUPLING

VALVEG

SHUT-OFF

TO

GA

S

G

SUP

PL

Y

BUSHING

NIPPLE

DUST CAP

- ASSEMBLE COUPLING KIT, PART #21335,G

& TIGHTEN COMPONENTS SECURELY.G

- CONNECT TO GAS SUPPLY.

- PULL BACK COUPLING COLLAR.G

- FIRMLY PUSH MALE HOSE ENDG

INTO COUPLINGG

- RELEASE COLLAR. ENSUREG

MALE HOSE END IS SECURELYG

LOCKED INTO COUPLING.

CONNECT HOSE TO GAS INLET G

& TIGHTEN SECURELY

This heater is supplied with one of the following gas train

assemblies. Refer to the appropriate illustrations.

FIG. 3

FIG. 4

FIG. 5

99

Page 11

INJECTOR BODY TABS

FILTER ADAPTER

PART #23931

BEADED CABLE TIE

DUST FILTER

PART #23953

ZONE CONTROL PANEL

FILTER SLEEVE

PART #20421

FUNCTION AND INSTALLATION

(Optional)

With proper (5 PSIG) gas pressure supplied, spark ignition

heaters will operate in the standard ON/OFF mode when

electrically connected to a building environment controller or

thermostat

If you require two stages of heat for greater temperature

control, a two stage solenoid operated zone panel must be

installed. This panel incorporates solenoids to control the

first and second stage heating levels as well as a pressure

regulator to set the firing rate of the first stage. Use of this

panel requi r e s a t w o s t age therm o s t at or a buildi n g

controller capable of controlling the heat in two stages.

When energized by a building controller or thermostat, the

zone panel’s first stage solenoid opens providing 2 PSIG,

controlled by the regulator on the zone control panel, to the

heater. This represents approximately half the heater’s full

output. If this level of heating does not satisfy the demand,

the building controller or thermostat will call for the second

stage of heating, full output, by energizing the second stage

solenoid. This provides 5 PSIG to the heater.

As the heat demand is satisfied, the building controller or

thermostat will reduce the firing rate by closing the second

stage solenoid and lastly the first stage solenoid if heat is no

longer needed.

Two stage zone panels are available in high or medium

capacity configurations and will control the following quantity

of heaters depending on fuel type.

Solenoid Zone Control System

Medium High

Model and Capacity Capacity

Heat Output Fuel Panel Panel

Quantity Quantity

I34 L. P. Gas 7 20

(34,200 BTUH) Natural Gas 4 20

All zone control pan els mus t have an adjustabl e high

pressure regulator installed upstream of the inlet of the

panel. This regulator may be purchased from PSI as an

optional accessory. The regulator must be capable of

handli n g a m aximum i n l et press u r e of 10 p si, whil e

supplying an outlet pressure of 5 psi nominal.

Separate installation instructions accompany each zone

panel.

IMPORTANT

This filter kit is designed to provide additional dust filtration

capability and capacity for Infraconic heaters when installed

in severely dusty environments.

1. Attach filter sleeve to injector body. The injector body

tabs fit into the slots on the sleeve. Rotate the sleeve

to lock it onto the injector body.

2. Position the filter onto the sleeve. Ensure all sleeve

holes are covered by the filter.

FIG. 6

INSTALLING DUST FILTER

3. Securely attach the filter to the sleeve using the

beaded cable tie.

4. Ensure filter does not sag or touch heater’s canopy.

FILTER SLEEVE

FILTER

1100

Page 12

Start-Up Instructions

ON/OFF SWITCH

ON

Follow steps 1-5 on initial start up after heater installation

by a qualified gas heater service person. For normal

startup, simply turn the building thermostat above room

temperature.

1. Connect the heater to an approved electrical supply

and building’s temperature control system.

2. Open all gas supply valves to the heater and check

for gas leaks at all connections using approved leak

detectors.

3. Energize the building’s temperature control system to

provide power to the heater.

4. Position the ON/OFF switch on the heater’s control

box to ON. See Fig. 7. The igniter will spark and

ignition will occur.

5. Set the building’s temperature control to desired

temperature.

■ It is normal for air to be trapped in the gas line on new

installations.

■ The heater may attempt more than one ignition trial

before air is purged from the line and ignition occurs.

purposes of controlling the timing of the ignition process of

the heater as well as monitoring the safety functions. The

control module is located in a control box at the gas inlet

end of the heater. On a call for heat, the igniter will spark

and the gas control valve will open shortly afterward. The

igniter will continue to spark for approximately 10 seconds.

Flame sense, as monitored by the ignition control, will keep

the gas valve open and main burner in operation until

proper temperature is achieved.

The ignition control module will make up to 3 trials for

ignition. There will be a 15 second time span between each

ignition trial. If ignition is not achieved after the third trial, a

15 minute wait period will occur. After the 15 minute time

span has elapsed, the heater will make three more trials for

ignition. This process will continue as long as there is a call

for heat from the building’s temperature control system.

FIG. 7

This heater includes a spark ignition control module for

Shut-Down Instructions

The building’s environmental temperature control system

will shut the heater down after proper temperature has been

achieved.

If heater is to be shut down for cleaning, maintenance or

service:

1. Shut off all gas supply valves to the heaters.

2. Allow heaters to burn off fuel gas remaining in the

gas supply line.

3. Position the ON/OFF switch to OFF.

4. Disconnect the heater from its electrical supply.

1111

Page 13

AIR NOZZLE

Cleaning Instructions

It is important to clean the heater and the optional dust

filter on a regular basis to maintain proper combustion and

to eliminate future problems.

wwaatteerr oorr ootthheerr lliiqquuiiddss..

The frequency of cleaning w i l l vary depen d i n g u p on

livestock being raised and overall ventilation of the building.

Problems associated with lack of cleaning typically are:

DDoo nnoott cclleeaann tthhee hheeaatteerr wwiitthh

■ Black soot on inside of canopy.

■ Gas backflashing in venturi tube or injector body.

■ Burner flame appearing beyond outer cone.

AA.. HHEEAATTEERR

CLEANING WITH BACKPACK BLOWERS

AND HEATER BLOWER

Blower Part No. 21170

For general cleaning when the heaters do not have heavy

accumulations of dust or dirt, use either a backpack type of

blower or the heater blower.

Foll ow the same procedures for cleaning as listed for

“Cleaning with Compressed Air”.

If the dust and dirt cannot be removed effectively using the

backpack blower or heater blower, then clean the heater

using the Compressed Air cleaning method which follows.

CLEANING WITH COMPRESSED AIR

5. Inspect the cones and venturi tube to make sure

these areas are clean.

6. Return the heater to its normal hanging position and

relight the heater.

FIG. 8

BB.. FFIILLTTEERR

11.. DDuurriinngg CCoonnttiinnuueedd HHeeaatteerr UUssee

- Remove filter and shake off dust.

- Do not squeeze or tap filter while filter is installed on

heater. Doing so will allow dust to be blown into venturi

tube or combustion cones.

22.. AA ff tt eerr CC oonntt iinnuu eedd HHee aatt ee rr UUssee oorr BB eeff oorr ee BBuu ii llddiinngg

RReeppooppuullaattiioonn

1. Turn off the gas supply to the heater and let the

heater cool down.

2. Direct the air at the combustion cones, working your

way around entire surface of cone assembly.

See Fig. 8.

3. Blow air through air inlet opening in the injector body

to bl ow bac k ou t an y lo o se n ed dus t th roug h

combustion cones.

4. Repeat Steps 2 and 3 until the cones and the venturi

tube are no longer emitting dust.

- Remove filter and shake off dust.

- Use compressed air or standard water faucet pressure

to clean it.

- Do not use high pressure water, air, or a washing

machine as filter material damage may occur.

- If water is used, squeeze out excess water from filter

before installation.

- Let filter dry before lighting heater.

1122

Page 14

Maintenance Instructions

1. Have your gas supplier check all gas piping annually

for leaks or restrictions in gas lines. Also, at this time

have your gas supplier clean out the sediment trap on

the zone control panel of any debris that may have

accumulated.

TThhee hheeaatteerr’’ss ssuurrrroouunnddiinngg aarreeaa sshhaallll bbee kkeepptt cclleeaarr aanndd

2.

ffrreeee ffrroomm ccoommbbuussttiibbllee mmaatteerriiaallss,, ggaassoolliinnee,, aanndd ootthheerr

ffllaammmmaabbllee vvaappoorrss aanndd lliiqquuiiddss..

3. Regulators can wear out and function improperly.

Have your gas supplier check the date codes on all

regulators installed and check delivery pressures to

the appliance to make sure that the regulator is

suitable for continued use.

4. Regulators must be periodically inspected to make

sure the regulator vents are not blocked. Debris,

insects, insect nests, snow, or ice on a regulator can

block vents an d cause excess pre s s ure at the

appliance.

5. For safety as well as for optimum performance at the

heater, it is necessary to keep the inside and the

outsi d e of the h e ater fre e o f dust , d ir t o r any

combustible material. If any operational component

show s si g ns o f ru s t or c or r o si o n, r e pl a ce t he

component immediately.

6. If any warning or instruction labels, dataplates, etc.

bec o me l o st o r h ard to r ead , r ep l ac e t hem

immediately. Do not operate the heater until you

have all instructions and can read and understand

them.

7. Check overall condition of heater for cracked or

damaged components, loose screws or bolts, etc.

Replace any suspect components.

8. Check all hose and tubing assemblies for cracks,

abrasions or ruptures. Replace any hoses that are

suspect.

If it becomes apparent that a dark spot has formed part way

up on the inner combustion cone or a build up of debris is

occurring in the bottom of the in n e r c o ne, it will be

necessary to clean out the combustion cone assembly.

Refer to “Cleaning Instructions”.

Service Instructions

GENERAL

WWAARRNNIINNGG

BBuurrnn HHaazzaarrdd

■ Heater surfaces are extrememly hot for a period of

time after the heater has been shut down.

■ Allow the heater to cool before performing service,

maintenance, or cleaning.

■ Failure to follow this warning will result in burns

causing injury.

WWAARRNNIINNGG

FFiirree aanndd EExxpplloossiioonn HHaazzaarrdd

■ Do not disassemble or attempt to repair any heater

components or gas train components.

■ All component parts must be replaced if defects are

found.

■ Failure to follow this warning will result in fire or

explosions, causing property damage, injury, or death.

1. Clo s e th e fu e l su p pl y val v e to th e he a ter a n d

disconnect the hea ter’ s elec trical supp ly before

servicing unless it is necessary to have the valve open

and electrical supply connected for your service

procedure.

2. In servicing some components, it may be necessary to

remove optional filter kit.

3. Remove the control box cover for access to ignition

control,high limit switch, and on/off switch.

4. Fo r r eassembly, r eve r s e t he respective ser vice

procedure. Ensure gas connections are tightened

securely.

5. Af ter servicing, star t the heater to ensure proper

operation and check for gas leaks.

CClleeaann tthhee hheeaatteerr’’ss oorriiffiicceess wwiitthh ccoommpprreesssseedd aaiirr oorr aa

6.

ssoofftt,, ddrryy rraagg.. DDoo nnoott uussee ffiilleess,, ddrriillllss,, bbrrooaacchheess,, eettcc.. ttoo

cclleeaann tthhee oorriiffiiccee hhoolleess.. DDooiinngg ssoo wwiillll eennllaarrggee tthhee hhoollee,,

ccaauussiinngg ccoommbbuussttiioonn oorr iiggnniittiioonn pprroobblleemmss.. RReeppllaaccee tthhee

oorriiffiiccee iiff iitt ccaannnnoott bbee cclleeaanneedd pprrooppeerrllyy..

1133

Page 15

IGNITION LEAD

IGNITION CONTROLG

MOUNTING SCREWS

ADAPTER

INLET

BUSHING

GROUND LEAD

VALVE GROUNDING ANDG

ATTACHMENT SCREW

G

ADAPTER

VENTURI G

NECK

BURNER ORIFICE

GAS CONTROLG

VALVE

BOOT

SWITCH

ON/OFF SWITCH

1. Disconnect the electrical leads from the ON/OFF

switch.

2. Remove the rubber boot from the ON/OFF switch.

See Fig. 9. Remove the switch from the control box.

■ Handle the module at the edges of the board

■ Do not touch or allow any contact to the module

components, otherwise damage may occur.

1. Disconne ct all elect rical leads from th e igni tion

control terminals.

FIG. 9

IGNITION MODULE

FIG. 10

2. Disconnect high voltage ignition lead.

3. Remove ignition control module mounting screws.

See Fig. 10.

1. Remove valve grounding and attachment screw.

2. Remove injector body with gas control from venturi

tube.

3. Using a 6 mm hex nut driver, remove the orifice.

4. Clean the orifice hole. Reinstall orifice into the orifice

body. Do not overtighten the orifice as overtightening

can strip the threads in the injector body.

BURNER ORIFICE

FIG. 11

INJECTOR

BODY

1144

Page 16

NUTS

SCREWS

IGNITOR W/ BRACKET

DISCONNECT FROM

IGNITOR LEAD

LOOSEN NUT

B

A

C

HIGH VOLTAGE IGNITION LEAD

GAPPING TOOL

.100

.125

.175

.100

.125

.175

1. Disconnect the igniter lead from ignition module.

2. Loosen the water tight connector nut. See Fig. 12.

Pull the ignition lead through this connection.

3. Disconnect the high voltage ignition lead from the

ignitor. See Fig. 12.

4. Remove the connector nut from the ignition cable.

This nut will be used on the replacement ignition

cable.

5. Although the ignition lead is self locating, ensure it is

positioned away from the venturi tube and the lead

boot is covering the ignitor terminal.

IGNITER

1 Disconnect the ignition lead from the ignitor. Remove

ignitor mounting screws. See Fig. 13.

Fig. 13

FIG. 12

LOOSEN WATER

TIGHT NUT

DISCONNECT

LEAD FROM

IGNITION

CONTROL

FIG. 14a

DISCONNECT

LEAD FROM

IGNITOR

TERMINAL

IGNITOR

TERMINAL

2. Remove the igniter from the heater. Clean the rod with

steel wool or emery cloth.

3. The rod and its insulating ceramic body must be rigid

within its mounting flange. If the rod or its body are

capable of movement, the igniter will not be properly

positioned to the combustion cone. The igniter must

then be replaced.

AAddjjuussttiinngg IIggnniittoorr GGaapp

Ignitor gap may need to be adjusted if spark is still weak

or non-existent after the ignitor has been either cleaned

or replaced. Refer to the following instructions.

a. Ensure the three burner plate nuts are securely

tightened. See Fig 14a.

1155

b. Use gapping tool, part # 23967, to set the gap to .175

inches. See Fig.14b.

FIG. 14b

GAPPING TOOL

c. Insert tool at opening between inner and outer

combustion cone tips.

Page 17

TERMINAL

MOUNTING LEG

RESET BUTTON

SENSING SURFACE

FLAME

d. Position the tool between inner cone and ignitor

INNER

CONE

T

OOL

.175 GAP BETWEEN

ELECTRODE AND CONE

tip. See Fig. 14c.

FIG. 14c

e. If the gap exceeds the minimum to maximum

tolerances of the tool, reset the gap:

-- loosen igniter mounting screws.

-- reposition the igniter assembly until the

gap is within the proper tolerances.

f. Tighten the igniter mounting screws.

■ This heater is equipped with a manual reset high limit

switch. Its purpose is to disconnect the electrical

supply to the ignition control board in the event of an

overheat condition.

■ An overheat condition is normally caused by:

-- Excessive fuel gas pressure.

-- Heater not being routinely cleaned.

-- Heater not properly hung. (See page 8.)

The high limit switch should be tested a minimum of once

a year or anytime the heater is taken down for servicing.

Refer to the following testing instructions.

WWAARRNNIINNGG

FFiirree HHaazzaarrdd

■ Do not operate the heater with the high limit switch

bypassed.

■ Operating the heater with a bypassed high limit switch

may lead to overheating, possibly resulting in a fire,

with subsequent damage to the heater and building,

or loss of livestock.

HIGH LIMIT SWITCH

2. Apply a small flame only to the sensing portion on the

back of the switch.

hhoouussiinngg ooff tthhee sswwiittcchh wwhheenn ccoonndduuccttiinngg tthhiiss tteesstt..

4. Within a minute, you should hear a pop coming from

the switch, indicating the contacts of the switch have

opened.

5. Allow the switch cool down before firmly pressing the

reset button.

6. Check for electrical continuity across the switch

terminals.

7. Reinstall the switch back into the heater.

FIG. 15

BBee ccaarreeffuull nnoott ttoo mmeelltt tthhee ppllaassttiicc

1. Remove the high limit switch from the control box.

1166

Page 18

FUEL SUPPLY VALVEG

(OPEN THIS VALVE TO USEG

PRESSURE GAUGE)

G

TEST KIT HOSE

PRESSURE GAUGE KITG

20736

GAS SUPPLY HOSE

GAS CONTROL VALVE

OPEN

G

ADAPTER

INLET

BUSHING

GROUND LEAD

VALVE GROUNDING ANDG

ATTACHMENT SCREW

INJECTOR G

BODY

ADAPTER

GAS CONTROL G

VALVE

GAS CONTROL VALVE

1. Brush or blow off any dust in vicinity of gas control

valve.

2. Disconnect the gas hose and remove control box

cover.

3. Loosen water tight connector nut at the control box

for the power supply leads of the control valve.

4. Disconnect the valve’s electrical leads from the

ignition module.

5. Remove the connector nut from the valve leads.

6. Loosen the valve ground and attachment screw at the

injector body.

GAS PRESSURE CHECKS

AA.. PPrreeppaarraattiioonn

1. Obtain an L.B. White pressure gauge test kit -

Part # 20736.

2. Disconnect the heater from the electrical supply and

close the fuel supply valve to the heater.

3. Brush or blow off any dust and dirt on or in the vicinity

of the gas control valve.

4. Disconnect the gas hose from the heater.

BB.. GGaauuggee IInnssttaallllaattiioonn

1. Connect the pressure test kit between the heater and

gas supply hose. See Fig. 17. Insure both gas shutoff valves on the test kit are in the closed position

when connecting the kit to the heater and gas supply.

2. Reconnect the heater to its electrical supply and open

the main fuel supply valve to the heater.

7. Remove bushing with hose adapter from control valve

inlet. See Fig. 16.

8. Secure the gas valve adapter at the outlet of the gas

control. Remove the control valve from adapter.

FIG. 16

CC.. RReeaaddiinngg PPrreessssuurreess

1. With the heater operating, the pressure gauge should

read the pressure specified on the dataplate.

2. Does the reading on the gauge of the test kit agree

with that specified on the dataplate? If so, then no

further checking or adjustment is required. Proceed

to Section D.

3. If the pressure does not agree with that specified on

the dataplate, then the regulator controlling gas

pressure to the heaters requires adjustment.

DD.. CCoommpplleettiioonn

1. On c e gas pressu r e has been c o nf irmed and/or

properly set, close the fuel supply valve to the heater

and allow the heater to burn off any gas remaining in

the gas supply hose.

2. Disconnect the heater from its electrical supply.

3. Open only the gas shut-off on the test kit which is

4. Light the heater.

FIG. 17

1177

connected to gas supply.

3. Remove the gauge kit and reconnect the gas hose

and electrical supply to the heater. Tighten securely.

4. Ope n t h e f u el su p pl y va l ves an d se t bu i ld i ng

controller to desired temperature.

Page 19

Troubleshooting Guide

READ THIS ENTIRE SECTION BEFORE

BEGINNING TO TROUBLESHOOT PROBLEMS.

The following troubleshooting flow charts provide systematic

procedures for isolating heater problems. The charts are

intended for use by a QUALIFIED GAS HEATER SERVICE

PERSON.

BBEEEENN PPRROOPPEERRLLYY TTRRAAIINNEEDD..

TEST EQUIPMENT REQUIRED

The following pieces of test equipment will be required to

troubleshoot this system with minimal time and effort.

•• DDiiggiittaall MMuullttiimmeetteerr

•• PPrreessssuurree GGaauuggee

pressures to the heaters.

IINNIITTIIAALL PPRREEPPAARRAATTIIOONN

-- Inspect the heater for damage.

-- Clean the heater as necessary.

DDOO NNOOTT SSEERRVVIICCEE TTHHEE HHEEAATTEERR UUNNLLEESSSS YYOOUU HHAAVVEE

- For measuring voltage.

- (Part No. 20736) For checking inlet

WWAARRNNIINNGG

EElleeccttrriiccaall SShhoocckk aanndd BBuurrnn HHaazzaarrdd

■ Troubleshooting this system may require operating the

heater with the burner on. Use extreme caution when

working on the heater.

■ Failure to follow this warning may result in electrical

shock or burns causing severe injury.

HHeeaatteerr PPrroobblleemmss PPaaggee

1.Heater does not light................................................19

2.Heater lights, but will not stay lit ............................20

3.Heater backflashes gas through air inlet. ..............20

Components should be replaced only after each step has

been completed and replacement is suggested in the flow

chart. Refer to the “Servicing” sections as necessary to

ob t a i n information on d i s a ssembly and replace m e n t

procedures of the component once the problem is identified

by the flow chart.

OPERATION SEQUENCE:

••

A call for heat occurs from building thermostat.

••

Line voltage is sent from building’s temperature control

to heater’s ON/OFF switch.

••

Switch sends power to ignition control through high

limit switch.

-- Ignition control module begins ignition trial sequence

-- Ignition control sends high voltage to igniter

electrode

-- Igniter sparks

-- Gas control solenoid opens

••

Ignition occurs

-- Igniter continues to spark for 10 seconds until

flame proving occurs

-- Ignition spark is shut off

-- Gas control solenoid stays open

••

Ground warms to desired temperature

-- Building thermostat is satisfied

-- Heater shuts down

••

Process is repeated on a call for heat

IGNITION FAILURE SEQUENCE:

••

Ignition control will make three ignition trials

-- Each trial lasts 10 seconds

-- 15 seconds time span between each trial

••

If ignition control does not establish flame sense within

ignition trial:

-- Ignition spark shuts off

-- Gas valve closes

••

After three ignition trials, ignition control will wait for 15

minutes before retrying for ignition.

••

This process will be repeated continually until the

ignition problem is solved.

••

To manually reset the ignition control:

-- Unplug the heater and plug it back in

OR

-- Turn the building temperature control to off and

then back on.

OR

-- Turn ON/OFF switch on heater off. Wait 5

seconds, then turn back on.

1188

Page 20

Yes

Inner

Combustion

Cone , Venturi

Tube or Main

Burner Orifice

are Plugged with

Dirt. Clean the

Heater.

No

to ON?

Is ON/OFF Switch

on Heater Positioned

Position the

Switch to ON.

Yes

Yes

Is an

Audible Click

Valve is Supplied

Heard When Solenoid

No

Is Proper

Switch?

Voltage Being

Cord to On/Off

Sent through Power

Resistance.

Power Cord for

Check Leads of

Replace Power

Cord if Necessary.

Yes

Yes

Is Proper

Gas Control Valve

Voltage Supplied to

Is

Heater Power

Proper Voltage

Supplied to Zone

Control Panel and

No

Cord?

Yes

environment control

thermostat is working

properly and calling for

- Check Circuit Breakers

- Make sure building

Provide Proper Voltage.

heat

Yes

No

Is Proper

To Heater?

Gas Pressure

Supplied to Zone

Control Panel and

Pressure.

Provide Proper

Does Igniter Spark?

Yes

No

Voltage?

Valve

Replace Gas Solenoid

No

on Heater?

Control.

Replace Ignition

No

Defects, Cleanliness, and

Proper Gap.

A. Check Igniter for

Connections and No Cuts

Verify Resistance of Lead.

Replace if Necessary.

are Good, Replace

Ignition Control.

B. Check Ignition Lead.

C. If Igniter and Ignition Lead

1199

Yes

Is High

Voltage to Ignition

Limit Switch Sending

No

Valves Open?

Are All Fuel Supply

Open All Fuel Supply Valves

PPrroobblleemm 11

HHeeaatteerr

DDooeess

NNoott LLiigghhtt

Yes

Is

Proper Voltage

being sent from

ON/OFF Switch to

No

Control?

Check for Tripped High

Limit Switch. Reset the

Tripping.

Determine Cause of

High Limit Switch and

No

Switch?

High Limit

Defective.

Check for Voltage

Leads Between

and Resistance of

Switch and Electrical

Control. Replace if

Switches and Ignition

Page 21

or Main Burner Orifice

are Plugged with Dirt.

Yes

Inner Combustion Cone

components.

Clean these

Yes

Is

Flame Sense

Connected and in

Ground Lead Properly

Yes

Is Heater’s

Reasonably

Venturi Tube

No

Good Condition?

Check the Lead for:

Resistance

- Corroded Terminal

- Loose Connections

- Continuity/

Repair or Replace as

Is Igniter Clean?

?

No

Clean

Necessary.

No

Clean its Electrode.

Remove Igniter and

Clean the Heater.

Yes

?

No

Clean

Dust Filter

Is Heater’s

Reasonably

the Filter.

Remove and Clean

Replace Combustion Cone.

Yes

Yes

21088

Part Number

Combustion Cone Kits

Clean these

Components.

Yes

Tighten the Nuts

Yes

Plate.or Gasket

Replace the Burner

Yes

Plate Notch.

Weld Seam in Burner

Position the Inner Cone

No

No

Is Proper

to the Heater?

Pressure Supplied

Supply Proper Pressure

and Check for Blockages

Necessary.

in Gas Hose. Refill

L.P. Gas Containers if

Is Inner

Cone Seam

Damaged or

Fractured or is Tip

No

Are

Missing?

Injector

Body, Burner

Tube, or Inner Cone

Orifice,Filter, Venturi

Partially Plugged with

No

Dirt?

Assembly

Are Burner

No

Nuts Loose?

Gasket

Is the Burner

Plate or Burner

No

Notch?

Aligned to

Cracked?

Weld Seam

Burner Plate

Is Inner Cone

Yes

Yes

No

Is High

Condition?

Lead in Good

Voltage Ignition

Verify Continuity Value of

HHeeaatteerr

LLiigghhttss bbuutt

wwiillll nnoott

PPrroobblleemm 22

SSttaayy LLiitt

Replace if Necessary.

Connections, and No Cuts.

Lead. Verify Lead has Good

Is Proper

Gas Pressure

Being Supplied to

PPrroobblleemm 33

HHeeaatteerr

No

the Heater?

Gas Pressure.

Check for Proper

BBaacckkffllaasshheess

GGaass TThhrroouugghh

AAiirr IInnlleett..

Read 5 PSIG.

High Heat Should

Proper Pressure at

2200

Page 22

Electrical Connection and Ladder Diagram

CAUTION: REFER TO THE HEATER'S ELECTRICAL CONNECTION

DIAGRAM WHEN SERVICING TO AVOID WIRING ERRORS AND HEATER

MALFUNCTION. CHECK FOR PROPER OPERATION AFTER SERVICING.

WARNING: THIS HEATER MAY START AT ANY TIME

HIGH VOLTAGE IGNITER LEAD

IGNITER

RED RED

GROUND

WHITE

RED

GREEN

BLACK

RED

GROUND

BLACK

BLACK

GREEN

WHITE

SPARK

IGNITION

CONTROL

NOTE: POWER CORD IS

CONNECTED TO

THERMOSTAT OR

BUILDING ENVIRONMENTAL

CONTROL SYSTEM

ELECTRICAL CONNECTION DIAGRAM

N2

N3

GND

L1

MV

ON/OFF

SWITCH

POWER

CORD

GAS

CONTROL

VALVE

GROUND

SPARK

IGNITION

CONTROL

ELECTRICAL LADDER DIAGRAM

N2

N3

GND

L1

MV

ON/OFF

SWITCH

L1

GROUND

IGNITER

SOLENOID

NEUTRAL

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE HEATER

MUST BE REPLACED, IT MUST BE REPLACED WITH WIRING MATERIAL

HAVING A TEMPERATURE RATING OF AT LEAST 302°F (150°C)

HIGH

LIMIT

SWITCH

HIGH LIMIT

SWITCH

150-22824-A

2211

Page 23

Heater Component Function

Burner Orifice

Metering device used to feed gas to combustion cones at a

specific flow rate.

Canopy

Reflective aluminum heat shield for heater.

Double Combustion Chamber

Made of special alloy steel. This is where combustion of gas

occurs, providing radiant heat used in the warming process.

Consists of small inner cone and large outer cone

Gas Control Valve

Component that houses electromagnet which is energized by

voltage and therefore opens or closes to supply or shut off

the flow of gas to the burner.

Gas Hose

Flexible connector used to convey gas from gas supply line

to inlet of heater.

High Limit Switch

Safety device wired into the heater’s electrical supply which

is used to open the electrical circuit to the ignition control

module in the event of an overheat condition.

Igniter/Sensor

Electrical ignition device used on automatic ignition control

systems. Ignites gas by spark. The igniter also serves as a

flame sensor on this heater to prove flame after ignition

Ignition Control Module

Electronic device which controls the ignition sequence and

operation of the heater.

Injector Body

Allows combustion air to be drawn in to injector tube with

gas flow for combustion.

Manual Shut Off Valve

It’s purpose is to shut off gas flow to the appliance if

maintenance or service are required, or if an emergency

situation occurs. When the handle on the manual valve is

turned parallel to gas flow, the valve is completely open

delivering full gas supply to the appliance. Turning handle

perpendicular (90°) to gas flow shuts off gas flow.

On/Off Switch

Simple electrical device used to connect or disconnect

incoming voltage at the ignition control box on the heater.

Venturi Tube

Tubular steel neck connecting the gas control valve and

burner orifices to the combustion cones. Gas is fed to the

combustion cones through the injector tube.

2222

Page 24

Parts Identification

2

4

35

34

36

37

33

32

30

27

26

25

29

28

31

14

17

18

39

8

10

4

13

11

40

3

6

9

16

20

19

2

7

21

1A

31A

31B

1B

42

38

41

23

PARTS SCHEMATIC

2233

Page 25

PARTS LIST

Item Description Part Number

1A Inner Cone 09557

1B Outer Cone 09556

Combustion Cone Kit with Gasket 21088

2 Gasket 09560

3 Plate, Burner 22212-04

4 Igniter Kit 24050

6 Spacer 09568

7 Screw 10-32 x 1 1/2 23636

8 Nut 10-32 09578

10 Key Ring 09620

13 Lead, Igniter w/ Boot 23989

14 Connector, Liquid Tight 08948

16 Control, Direct Spark Ignition 22715

17 Switch, On/Off 22714

18 Boot, On/Off Switch 09916

19 Bracket, Control Box 24047

20 Control Box Cover w/ Gasket 23986

21 Control Box Bottom 23985

22 Bushing 01544

23 Adapter, Hose 23789

24 Valve, Gas Control w/ Electrical Leads 23729

and Screen

25 Orifice, Burner Propane Gas 26702

Natural Gas 26701

26 Injector Body w/ Air Register Plate Propane Gas 20672

Natural Gas 21559

27 Retaining Screw for Injector Tube 09572

28 Adapter 1/8 NPT x 1/8 BSP 23707

29 Lead, Black, On/Off Switch to Ignition Control 22610

30 Hose, Gas 1/4 in. x 6 ft. Rigid x Swivel, Poultry 20495

1/4 in. x 10 ft. Rigid x Swivel, Poultry 20496

1/4 in. x 12 ft. Rigid x Swivel, Poultry 20497

1/4 in. x 6 ft. Swivel Both Ends, Swine 20499

1/4 in. x 10 ft. Swivel Both Ends, Swine 20242

1/4 in. x 15 ft. Swivel Both Ends, Swine 20500

31 Filter Kit 20428

31A Sleeve 20421

31B Filter 23953

32 Plug 20358

33 Cord, Power 22704

34 Screw, Igniter Mounting 06658

35 Tube, Injector 09597

36 Lock Nut 08948

37 Screw, Injector Body 09575

38 Screw, Direct Spark Ignition 02330

39 High Limit Switch, Manual Reset 23148

40 Screw, High Limit Switch 22783

41 Gasket, Liquid Tight 22565

42 Wire, High Limit Switch 22610

43 Quick Coupling Kit, Female Coupling and Shut-Off (Not Illustrated) 21335

Consisting Of:

Shut-Off Valve 05548

Nipple, 1/4 in. Close 01142

Coupling, Quick Disconnect 21328

Bushing, 1/2 x 1/4 01519

44 Kit,1/8 NPT Fitting ( Not Illustrated) 23406

2244

Page 26

Warranty Policy

EQUIPMENT

L.B. White Co., Inc. warrants that the component parts of its

equ i pme n t a r e fr e e fr o m de f e cts in ma teri a l a n d

workm anshi p, when properly ins talle d, operated, and

mainta i n ed in accorda n c e with th e I n s tallat i o n and

Maintena n c e I nstruc t i ons, safety g u i d es and lab e l s

contained with each unit. If,

ddaattee ooff ppuurrcchhaassee bbyy tthhee eenndd uusseerr

to be defective, L.B. White Co., Inc. will at its option, repair

or replace the defective part or equipment, with a new part

or equipment, F.O.B., Onalaska, Wisconsin.

wwiitthhiinn 1122 mmoonntthhss ffrroomm tthhee

, any component is found

PARTS

L. B . White Co. , Inc. war r a nts that r e placement pa r ts

purchased from the company and used on the appropriate

L. B. White equipment are free from defects both in material

and workmanship for

bbyy tthhee eenndd uusseerr

found defective within 12 months of the date code marked

on the part. If the defect occurs more than 12 months later

than the date code but within 12 months from the date of

purchase by the end user, a copy of a bill of sale will be

required to establish warranty qualification.

The warranty set for th above is the exclusive warranty

provided by L.B. White, and all other warranties, including

any implied warranties or merchantability or fitness for a

particular purpose, are expressly disclaimed. In the event

any implied warranty is not hereby effectively disclaimed

due to operation of law, such implied warranty is limited in

1122 mmoonntthhss ffrroomm tthhee ddaattee ooff ppuurrcchhaassee

. Warranty is automatic if a component is

A warranty card on file at L.B. White will automatically

qu alify a unit an d its compone n t par t s fo r warranty

consideration. If a warranty card is not on file, a copy of the

bil l of sa le wi l l be requ i red to est abl i sh war r an t y

qualification. If neither is available, the warranty period will

be 12 months from date of shipment from L B. White.

duration to the duration of the applicable warranty stated

above. The remedies set forth above are the sole and

exclusive remedies available hereunder. L.B. White will not

be liable for any incidental or consequential damages

directly or indirectly related to the sale, handling or use of

the equipment, and in any event L.B. White's liability in

connection with the equipment, including for claims based

on negligence or strict liability, is limited to the purchase

price.

Some regions do not allow limitations on how long an

implied warranty lasts, so the above limitation may not

apply to you. Some regions do not allow the exclusion or

limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This

warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Replacement Parts and Service

Contact your local L.B. White dealer for replacement parts

and se r vi c e or ca l l the L. B . Whi te Compa n y, In c . at

1-800-345-7200 for assistance. Be sure that you have your

heater model number when calling.

2255

Loading...

Loading...