L.B. White I-17 User Manual

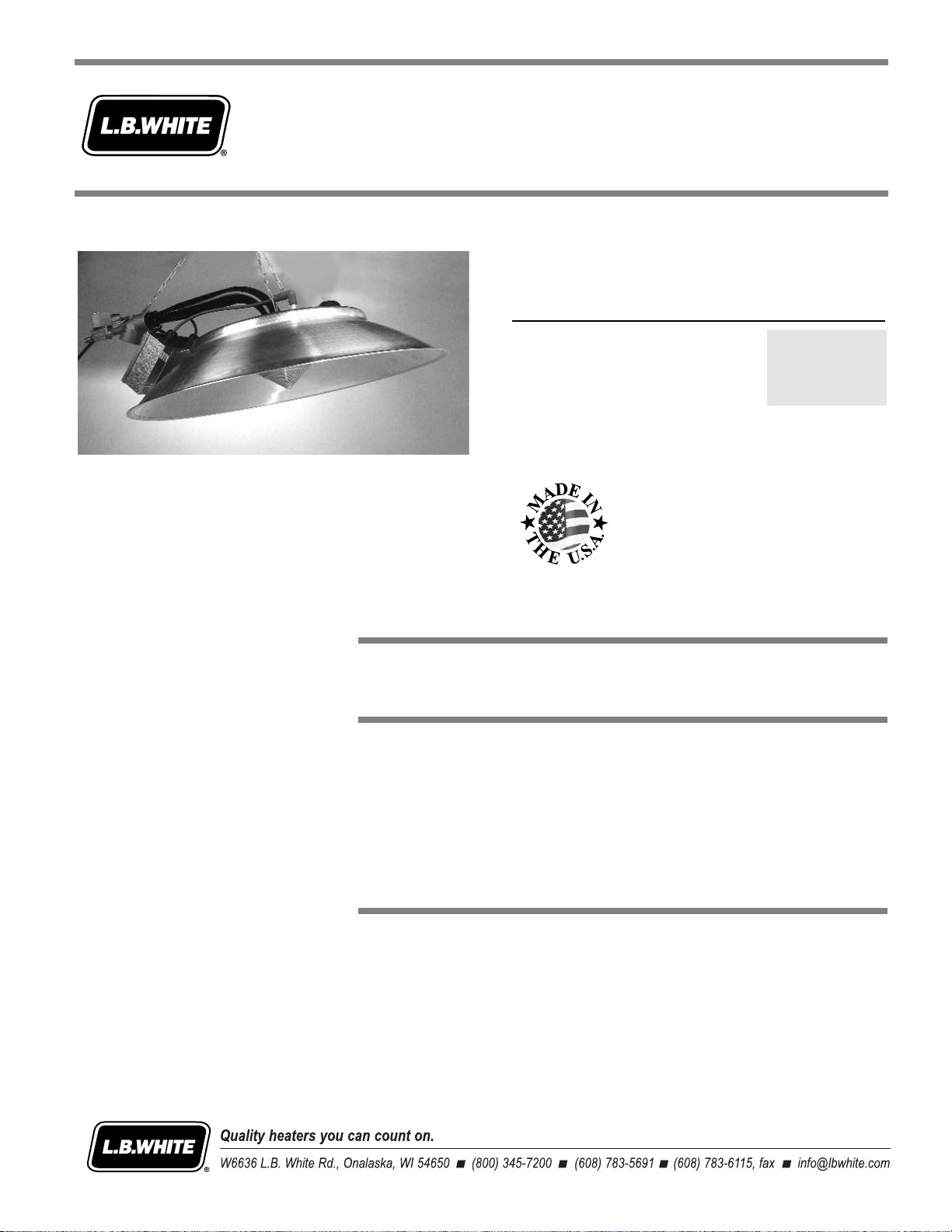

Congratulations!

You have purchased the finest radiant heater available for the heating of livestock

in agricultural animal confinement buildings.

Your new L.B. White radiant heater incorporates the benefits from the most

experienced manufacturer of heating products using state-of-the-art technology.

We, at L.B. White, thank you for your confidence in our products and welcome any

suggestions or comments you may have...call us toll free at 1-800-345-7200.

Owner’s Manual and Instructions

Spark Ignition Infraconic

Agricultural Building Radiant Heaters

ATTENTION ALL USERS

This heater has been tested and evaluated by L.B. White Co., Inc. as a direct gas-fired

radiant heater with intended use for the heating of livestock in agricultural animal

confinement buildings. If you are considering using this product for any application other

than its intended use, then please contact your fuel gas supplier, or the L.B. White Co., Inc.

150-22721-A

MODELS OUTPUT (Btuh) FUEL

I17 17,100

I34 34,200

L.P. Vapor

Withdrawal

or Natural Gas

W

ARNING

Fire and Explosion Hazard

■ Not for home or recreational vehicle use.

■ Installation of this brooder in a home or

recreational vehicle may result in a fire or

explosion.

■ Fire or explosions can cause property

damage or loss of life.

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of

this or any other appliance.

WARNING

Fire and Explosion Hazard

■ Keep solid combustibles a safe distance

away from the brooder.

■ Solid combustibles include wood or paper

products, feathers, straw, and dust.

■ Do not use the brooder in spaces which

contain or may contain volatile or airborne

combustibles.

■ Volatile or airborne combustibles include

gasoline, solvents, paint thinner, dust

particles or unknown chemicals.

■ Failure to follow these instructions may

result in a fire or explosion.

■ Fire or explosions can lead to property

damage, personal injury or loss of life.

GENERAL HAZARD WARNING

■ Failure to comply with the precautions and instructions provided with this brooder, can result

in:

— Death

— Serious bodily injury or burns

— Property damage or loss from fire or explosion

— Asphyxiation due to lack of adequate air supply or carbon monoxide poisoning

— Electrical shock

■ Read this Owner’s Manual before installing or using this product.

■ Only properly-trained service people should repair or install this brooder.

■ Save this Owner’s Manual for future use and reference.

■ Owner’s Manuals and replacement labels are available at no charge. For assistance, contact

L.B. White at 800-345-7200.

W

ARNING

■ Proper gas supply pressure must be provided to the inlet of the brooder.

■ Refer to rating plate for proper gas supply pressure.

■ Gas pressure in excess of the maximum inlet pressure specified at the brooder inlet can cause

fires or explosions.

■ Fires or explosions can lead to serious injury, death, building damage or loss of livestock.

■ Gas pressure below the minimum inlet pressure specified at the brooder inlet may cause

improper combustion.

■ Improper combustion can lead to asphyxiation or carbon monoxide poisoning and therefore

serious injury or death to humans and livestock.

2

This owner's manual includes all options and accessories

commonly used on or with this heater. However, depending

on the configuration purchased, some options and

accessories may not be included.

When calling for technical service assistance, or for other

specific information, always have the model number and

serial number available.

This manual will instruct you in the operation and care of

your radiant heater. Have your qualified installer review this

manual with you so that you fully understand the heater and

how it functions.

The gas supply line installation, and the repair, installation

and servicing of the heater requires continuing expert

training and knowledge of gas heaters and should not be

attempted by anyone who is not so qualified. See page 6

for definition of the necessary qualifications.

Contact your local L. B. White distributor or the L. B. White

Co., Inc. for assistance, or if you have any questions about

the use of the heater or its application.

The L. B. White Co., Inc. has a policy of continuous product

improvement. It reserves the right to change specifications

and design without notice.

SECTION

PAGE

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Heater Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Gas Train Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Filter Kit Instructions

Installing Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Cleaning the Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Start-Up Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Shut-Down Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Service Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

On/Off Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Ignition Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Burner Orifice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

High Voltage Ignition Lead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Igniter/Flame Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Gas Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

High Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Gas Pressure Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Electrical Connection and Ladder Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Heater Component Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Parts Identification

Parts Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Replacement Parts and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Table of Contents

General Information

3

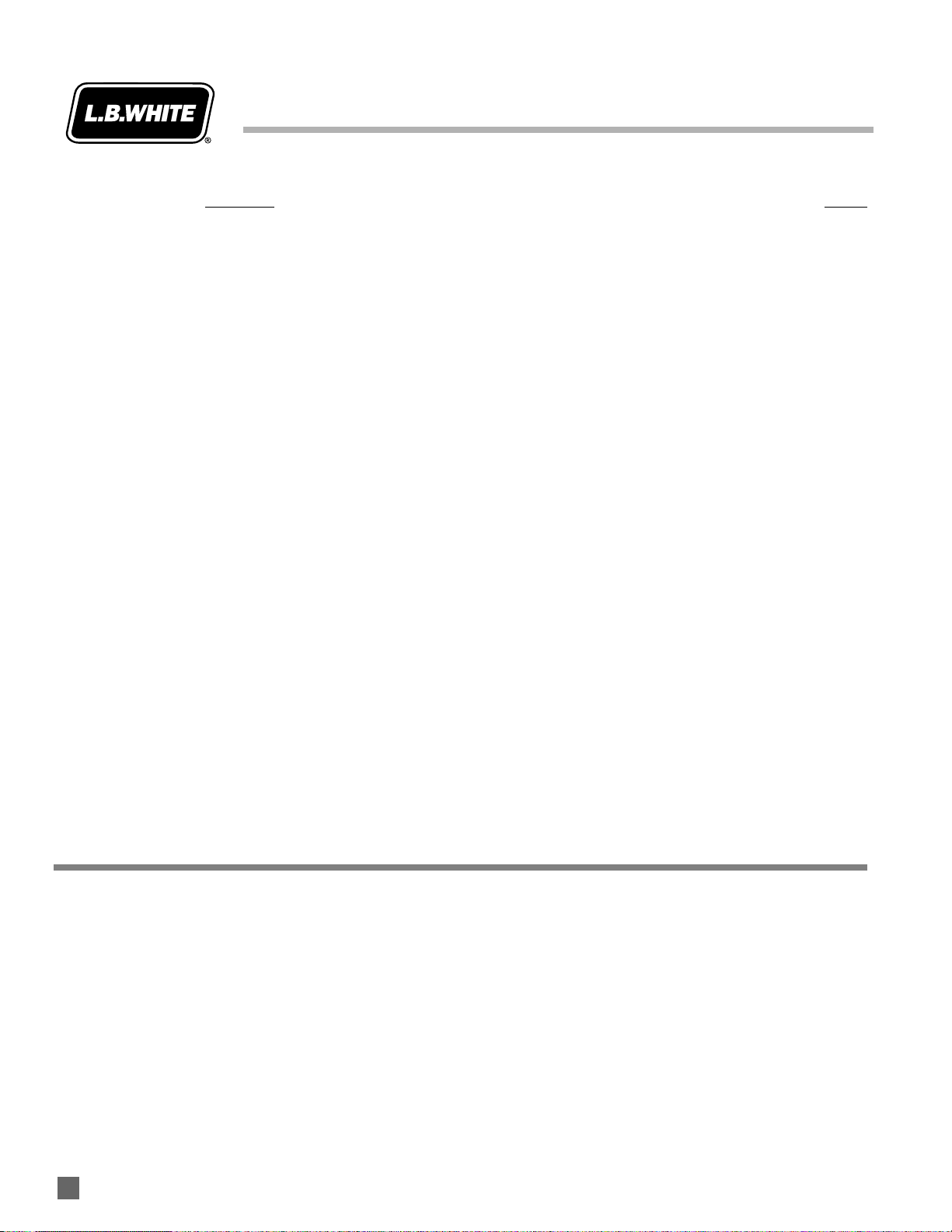

I17 I34

Maximum Input (Btuh) 17,100 34,200

Ventilation Air to Support Combustion

5 psig

5 psig

5 psig

2.5 psig

5 psig

“A” 16 7/8 in. 26 3/8 in.

“B” 17 in. 20 1/4 in.

“C” 8 3/4 in. 10 3/8 in.

Net Weight 8 lbs. 10 oz. 15 lbs. 8 oz.

L.P. GAS .80 lbs./hr. 1.58 lbs./hr.

NATURAL GAS

120/60/1

0.5

CHICKENS 1250 - 2000 2500 - 3800

TURKEYS 350 - 500 800 - 950

SWINE 125 300

CHICKENS 5 - 6 ft. 6 - 7 ft.

TURKEYS 4 ft. 4.5 ft.

SWINE 4 - 5 ft.

TOP OF HOOD TO CEILING 3 ft.

POINT OF COMBUSTION

CONE TO FLOOR

SIDES 3 ft.

POULTRY

SWINE

4

SPECIFICATIONS

Radiant Heater Specifications

FIG. 1

Heater Dimensions

(See Fig. 1)

Fuel Consumption Per Hour

Animal Coverage Per Heater (1)

Minimum Safe Clearances to

Combustible Materials

Recommended Height Installation

For Livestock From Point of

Combustion Cone to Floor

200 CFM

17.1 CFH

3.5 ft.

4.5 ft.

34.2 CFH

400 CFM

N/A - Not applicable.

(1) There are other factors that will affect the quantity of animals

each heater can cover. These include building ventilation and

control systems, building insulation, building size and population

density, etc. Consult your L. B. White dealer or call L. B. White for

specific recommendations for your application.

(2) This is typical sensor placement range. The size and type of

livestock being grown, heater spacing and height, etc. will dictate

sensor location. Care should always be taken to ensure that the

sensor is sufficiently high as to not be damaged by the animal

during operation.

"B"

"A"

"C"

Electrical Supply (Volts/HZ/Phase)

Amp Draw

Animal Occupied Zone Temperature

Control Sensor Location (2)

Inlet Gas Supply Pressure at the Heater

MAX.

MIN.

MAX.

MIN.

VERTICAL FROM FLOOR 6-12 in.

HORIZONTAL FROM BROODER 8-12 ft.

VERTICAL FROM FLOOR Above Animal Height

HORIZONTAL FROM BROODER 4-8 ft.

MMooddeell

FULL OUTPUT

(On/Off

Version)

ZONE

CONTROLLED

(Dual Solenoid

Version)

Burner Manifold Pressure at Maximum Pressure

LP ggas aand nnatural ggas hhave mman-mmade oodorants aadded sspecifically ffor ddetection oof ffuel ggas lleaks.

If aa ggas lleak ooccurs, yyou sshould bbe aable tto ssmell tthe ffuel ggas.

THAT’S YYOUR SSIGNAL TTO GGO IINTO IIMMEDIATE AACTION!

■ Do not take any action that could ignite the fuel gas. Do

not operate any electrical switches. Do not pull any

power supply or extension cords. Do not light matches

or any other source of flame. Do not use your

telephone.

■ Get everyone out of the building and away from the area

immediately.

■ Close all propane (LP) gas tank or cylinder fuel supply

valves, or the main fuel supply valve located at the

meter if you use natural gas.

■ Propane (LP) gas is heavier than air and may settle in

low areas. When you have reason to suspect a propane

leak, keep out of all low areas.

■ Natural gas is lighter than air and can collect around

rafters or ceilings.

■ Use your neighbor’s phone and call your fuel gas

supplier and your fire department. Do not re-enter the

building or area.

■ Stay out of the building and away from the area until

declared safe by the firefighters and your fuel gas

supplier.

■

FI NALL Y,

let the fuel gas service person and the

firefighters check for escaped gas. Have them air out

the building and area before you return. Properly

trained service people must repair the leak, check for

further leakages, and then relight the heater for you.

WARNING

■ Do not use this radiant heater for heating human living

quarters.

■ Do not use in unventilated areas.

■ The flow of combustion and ventilation air must not be

obstructed.

■ Proper ventilation air must be provided to support the

combustion air requirements of the heater being used.

■ Refer to the specification section of the Owner’s

Manual, heater’s dataplate, or contact the

L.B. White Company to determine combustion air

ventilation requirements of the heater.

■ Lack of proper ventilation air will lead to improper

combustion.

■ Improper combustion can lead to carbon monoxide

poisoning in humans leading to serious injury or death.

Symptoms of carbon monoxide poisoning can include

headaches, dizziness and difficulty in breathing.

■ Symptoms of improper combustion affecting livestock

can be disease, lower feed conversion, or death.

Asphyxiation Hazard

■

Some ppeople ccannot ssmell wwell. SSome ppeople ccannot

smell tthe oodor oof tthe mman-mmade cchemical aadded tto

propane ((LP) oor nnatural ggas. YYou mmust ddetermine iif yyou

can ssmell tthe oodorant iin tthese ffuel ggases.

■ Learn to recognize the odor of propane (LP) gas and

natural gas. Local propane (LP) gas dealers and your

local natural gas supplier (utility) will be more than

happy to give you a “scratch and sniff” pamphlet. Use it

to become familiar with the fuel gas odor.

■ Smoking can decrease your ability to smell. Being

around an odor for a period of time can affect your

sensitivity to that particular odor. Odors present in

animal confinement buildings can mask fuel gas odor.

■

The oodorant iin ppropane ((LP) ggas aand nnatural ggas iis

colorless aand tthe iintensity oof iits oodor ccan ffade uunder

some ccircumstances.

■ If there is an underground leak, the movement of gas

through the soil can filter the odorant.

■ Propane (LP) gas odor may differ in intensity at different

levels. Since propane (LP) gas is heavier than air, there

may be more odor at lower levels.

■

Always bbe ssensitive tto tthe sslightest ggas oodor.

If you

continue to detect any gas odor, no matter how small,

treat it as a serious leak. Immediately go into action as

discussed previously.

Safety Precautions

FUEL GAS ODOR

ODOR FADING -- NO ODOR DETECTED

ATTENTION -- CRITICAL POINTS TO REMEMBER!

■ Propane (LP) gas and natural gas have a distinctive

odor. Learn to recognize these odors. (Reference “Fuel

Gas Odor” and “Odor Fading” sections above.

■

If you have not been properly trained in repair and service

of propane (LP) gas and natural gas fueled heaters, then

do not attempt to light the heater, perform service or

repairs, or make any adjustments to the heater on a

propane (LP) gas or natural gas fuel system.

■ Even if you are not properly trained in the service and

repair of radiant heaters, ALWAYS be consciously aware

of the odors of propane (LP) gas and natural gas.

■ A periodic “sniff test” around the heater or at the

heater’s joints; i.e. hose, connections, etc., is a good

safety practice under any conditions. If you smell even

a small amount of gas, CONTACT YOUR FUEL GAS

SUPPLIER IMMEDIATELY. DO NOT WAIT!

5

1. Do not attempt to install, repair or service this heater

or the gas supply line unless you have continuing

expert training and knowledge of gas heaters.

Qualifications for service and installation of this

equipment are as follows:

QUALIFICATIONS FOR

SERVICING AND INSTALLATION:

a. To be a qualified gas heater service person, you

must have been trained in gas-fired heater

servicing, repair and also have sufficient

experience to allow you to troubleshoot, replace

defective parts, and test heaters in order to get

them into a continuing safe and normal operation

condition. You must completely familiarize

yourself with each model heater by reading and

complying with the safety instructions, labels,

owner’s manual, etc. that is provided with each

heater.

b. To be a qualified gas installation person, you must

have sufficient training and experience to handle

all aspects of installing, repairing and altering gas

lines, including selecting and installing the proper

equipment, and selecting proper pipe size to be

used. This must be done in accordance with all

local, state and national codes as well as the

manufacturer’s requirements.

2. All installations or applications of L. B. White Co.,

Inc.’s radiant heater and associated zone control

panel should meet the requirements of local, state

and national L.P. gas and natural gas, electrical and

safety codes. Your gas supplier, local licensed

electrician, local fire department and government

agencies can help you determine these requirements.

In the absence of local codes, comply with the

following:

-- ANSI/NFPA 58, latest edition, Standard for

Storage and Handling of Liquefied Petroleum

Gas and/or

-- ANSI Z223.1/NFPA 54, National Fuel Gas

Code

-- ANSI/NFPA 70, National Electrical Code.

3. If at any time you notice something unusual about the

operation of your heater such as gas odor,

overheating, flames other than in the combustion

cone area, etc., evacuate the area immediately and

call your fire department and your gas service

agency. Get assurances from the fire department

that the area is free of gas before you attempt to

relight the heater.

4. The components on the heater that call for hand

operation should work with hand pressure only. If

more force is required, have a qualified gas heater

service agency replace the complete part. Do not

attempt to repair.

5. This heater is intended for the heating of livestock in

agricultural animal confinement buildings only. The

heater shall only be mounted inside the animal

confinement building. It shall not be used for outside

heating applications.

6. Do not locate fuel gas containers or fuel supply hoses

anywhere within the heating zone of the heater.

7. Do not block the air intake, burner venturi tube or

burner cone area. Doing so may cause improper

combustion or damage to the heater components,

leading to property damage or animal loss.

8. Do not move, handle, or service the heater while in

operation or connected to fuel supply.

9. The hose assembly providing fuel to the heater must

be inspected on a regular basis. This should be done

at least once a year, or when the building is cleaned

out. If it is evident there is excessive abrasion or

wear, or if the hose is cut, it must be replaced prior to

heater being put into operation. The hose assembly

shall be protected from animals, building materials,

and contact with hot surfaces during use. The hose

assembly shall be that specified by the manufacturer.

See parts list.

10. Check for gas leaks and proper function upon

installation, before building repopulation and when

relocating.

11. If the gas flow is interrupted and the burner flame is

extinguished, immediately shut off the gas. Do not

relight the heater until you are sure that all of the gas

that may have accumulated through the brooder has

cleared away. Do not relight the heater until at least

five minutes have passed.

12. If the heater is to be relocated, make sure that all gas

connections are capped and the gas supply is shut

off. All connection points must be leak checked after

disconnection and after reconnection.

13. The grower shall inspect the heater before building

repopulation. Such inspection should consist of, but

is not limited to, the following points of action:

6

WARNING

Burn HHazard

Can ccause pproperty ddamage, ssevere iinjury oor ddeath.

■ The heater’s combustion cones and canopy are

extremely hot during operation and shortly after

shutting down.

■ Always be aware of your proximity to the heater and

avoid contact with its hot surfaces during or shortly

after operation.

■ Failure to follow this warning can result in burns

leading to severe personal injury.

Safety Precautions

1. Read all safety precautions and follow L. B. White

recommendations when installing this heater. If

during the installation or relocating of the heater, you

suspect that a part is damaged or defective, call a

qualified service agency for repair or replacement.

2. On initial installation and before use, position the

brooder properly regarding clearance to combustible

materials and ground clearance to protect the

brooder from livestock. Hang the brooder with the

control end 1 to 5 degrees down from horizontal.

This is necessary to protect the filter and control

enclosure from heat damage as well as providing

proper venting to ensure good combustion. Refer to

the specification table on page 4 as well as Figure 2

for installation information for proper hanging and

clearances.

3. Position the gas hose outside of the hot zone directly

above the heater. Position the gas hose to avoid any

opportunity for contact with the hot canopy surface of

the heater. Refer to Fig. 2.

4. Insure that all accessories that ship with the heater

have been removed from inside of heater’s shipping

container and installed. This pertains to gas hose,

regulators, etc.

5. The heater’s gas regulator (with pressure relief valve)

should be installed outside of building. Typically any

regulators inside the buildings must be properly

vented to the outside. However, local, state and

national codes always apply to regulator installation.

6. It is extremely important that any regulator outside

the building be protected against the weather,

particularly ice formation. Ice formation can lead to

overpressurization of the regulator and subsequent

gas leaks. See codes covering proper protection.

7. Always use pipe joint compound that is resistant to

liquefied petroleum gas and natural gas.

8. Check all connections for gas leaks using approved

gas leak detectors. Gas leak testing is performed as

follows:

-- Check all pipe connections, hose connections,

fittings and adapters upstream of the gas

control with approved gas leak detectors.

-- In the event a gas leak is detected, check the

components involved for cleanliness and

proper application of pipe compound before

further tightening.

-- Furthermore tighten the gas connections as

necessary to stop the leak.

-- After all connections are checked and any

leaks are stopped, turn on the main burner.

-- Stand clear while the main burner ignites to

prevent injury caused from hidden leaks that

could cause flashback.

-- With the main burner in operation, check all

connections, hose connections, fittings and

joints as well as the gas control valve inlet and

outlet connections with approved gas leak

detectors.

7

Installation Instructions

GENERAL

-- Insure proper clearance of heater to nearest

combustible materials.

-- Check for general cleanliness. Clean if necessary.

-- Check for tightness of the gas hose connections.

14. A qualified service person shall inspect the heater

and its gas train on at least an annual basis. This

should consist of, but is not limited to, the following

points of action:

-- Start-up and shut down of the heaters and zone

control panel to test for proper operation.

-- Leak check of all pipe joints and hose connections.

-- Thorough cleaning of the exterior of the heater, its

inlet venturi, combustion cones and filter (if

applicable).

-- Thorough inspection of the heater’s component

parts for corrosion, stripped threads, etc. with

subsequent parts replacement as necessary.

-- Gas pressure checks.

15. Turn off the gas supply when the heater is not in use.

WARNING

Fire oor eexplosion hhazard.

Can ccause pproperty ddamage, ssevere iinjury oor ddeath.

To avoid dangerous accumulation of fuel gas, turn off

the gas supply at the heater service valve before

starting installation, and perform gas leak test after

completion of installation.

WARNING

Fire aand EExplosion HHazard

■ Do not use open flame (matches, torches, candles,

etc.) in checking for gas leaks.

■ Use only approved leak detectors.

■ Failure to follow this warning can lead to fires or

explosions.

■ Fires or explosions can lead to property damage,

personal injury or loss of life.

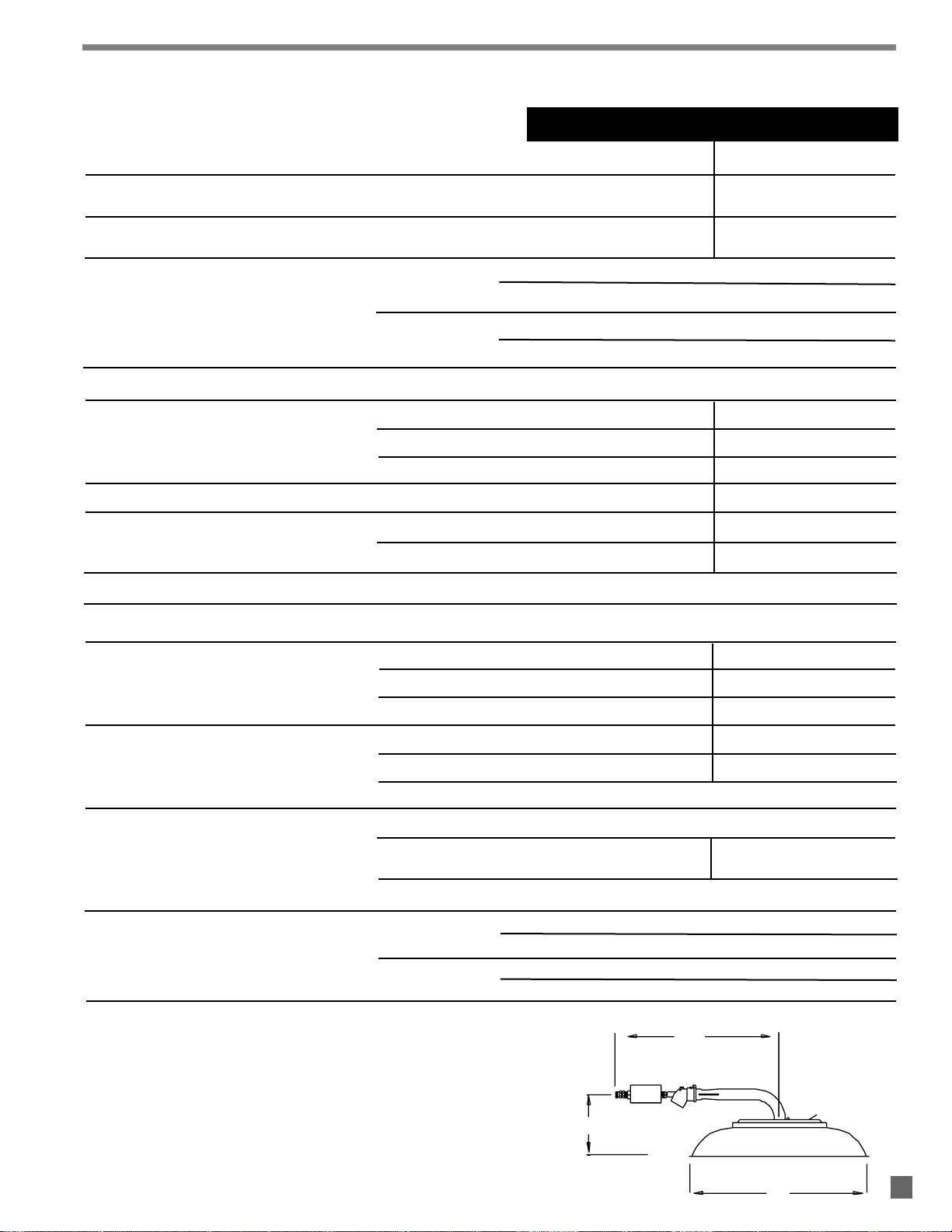

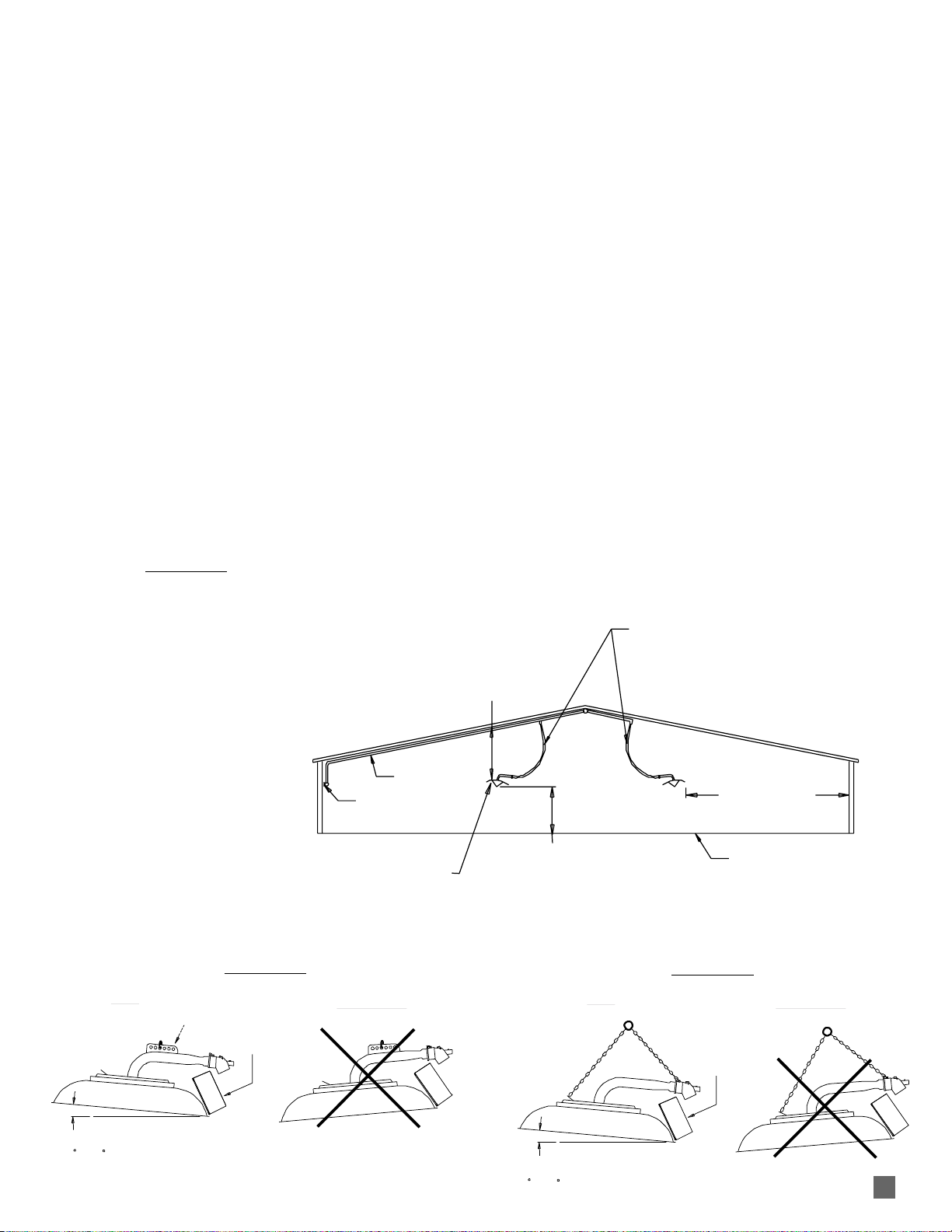

INSTALLATION LAYOUT

FOR SAFE CLEARANCES

I17 & I34 - 3 FT. MINIMUM

BROODER TOP TO CEILING

POSITION THE GAS HOSE AND ELECTRICAL POWER CORD

OUTSIDE OF THE HOT ZONE DIRECTLY ABOVE THE HEATER.

POSITION THE GAS HOSE AND POWER CORD TO AVOID

ANY OPPORTUNITY FOR CONTACT WITH THE HOT CANOPY

SURFACE OF THE HEATER.

MINIMUM 3 FT. CLEARANCE

TO COMBUSTIBLES

FLOOR

I17 - 3.5 FT. MINIMUM

I34 - 4.5 FT. MINIMUM

POINT OF COMBUSTION

CONE TO FLOOR

HANG THE HEATER WITH THE

CONTROL END 1 TO 5 DEGREES DOWN

FROM HORIZONTAL (SEE BELOW)

CONTROL PANEL

GAS PIPING

-- If a leak is detected, check the components

involved for cleanliness in the thread areas and

proper application of pipe compound before

further tightening.

-- Tighten the gas connection as necessary to

stop the leak.

-- If necessary, replace the parts or components

involved if the leak cannot be stopped.

-- Ensure all gas leaks have been identified and

repaired before proceeding.

9. A qualified service agency must check for proper

operating gas pressures upon installation of the

heaters.

10. It is extremely important to use the proper gas supply

line to assure proper functioning of the heaters.

Typically, 1/2 in. ID black iron pipe is used to convey

the gas to the heaters. However, always consult your

fuel gas supplier, or the L. B. White Co., Inc. for proper

line sizing and installation.

11. Infraconic heaters require a regulated gas supply to

the gas inlet of the product. Exceeding the gas inlet

pressure rating can result in poor performance and

unreliable operation. Refer to page 4 of this manual

for information on gas pressures relating to specific

models.

12. The heater is designed for either L.P. vapor withdrawal

or natural gas, depending on model number. Do not

use this heater in an LPG liquid withdrawal

system. Do not permit LPG in liquid form to enter the

heater at any time.

13. The corrosive atmosphere present in animal

confinement buildings can cause component failure or

heater malfunction. The heater should be periodically

inspected and cleaned in accordance with the

Maintenance and Cleaning Instructions in this manual.

Make sure that livestock is protected by a back up

alarm system that limits high and low temperatures

and also activates appropriate alarms.

14. Take time to understand how to operate and maintain

the heater using the owner’s manual. Make sure you

know how to shut off the gas supply to the building

and to the individual heaters. Contact your gas

supplier if you have any questions.

15. Any defects found in performing any of the service

procedures must be eliminated and defective parts

replaced immediately. Retest the heater before

placing it back into service.

FIG. 2

AATTTTEENNTTIIOONN

■ Model I17 heaters utilize an

integral chain hanging bracket

located on the heater’s venturi

tube. Model I34 heaters use

chain hanging clips.

■ Regardless of hanging system,

the installer must make sure

that the heater is installed so

control end of heater is

positioned 1º to 5º down from

horizontal after gas supply hose

is attached.

■ Repositioning of factory

installed key ring into hanging

bracket (for I17) or adjustment

of chain for I34 may be

required.

■ Refer to following illustrations.

MMOODDEELL II1177

MMOODDEELL II3344

8

THIS

HANGING

BRACKET

CONTROL END

OF HEATER

NOT THIS

THIS

CONTROL END

OF HEATER

NOT THIS

CONTROL END MUST BE

1 TO 5 DOWN FROM

HORIZONTAL

CONTROL END MUST BE

1 TO 5 DOWN FROM

HORIZONTAL

Loading...

Loading...