L.B. White FA-MCS User Manual

MODEL

FA-MCS

Owner's Manual and Instructions

SmartBox™Controller

For Use with

GUARDIAN

®

Electronic Ignition Forced Air Heaters

with Smart Sense

™

Automatic Variable Rate Heat

ATTENTION ALL USERS

The SmartBox™has been designed and developed by L.B.White Co. as a variable

rate heat controller for managing heat to demand within the animal confinement

facility. It works in conjuction with L.B.White Smart Sense™forced air heaters and an

existing room controller with on/off capability.

150-27951

Congratulations!

The SmartBox™incorporates the benefits from the most experienced manufacturer

of agricultural animal confinement building heating products using state-of-the-art

technology.

We, at L.B. White, thank you for your confidence in our products and

welcome any suggestions or comments you may have...call us, toll-free,

at 1-800-345-7200.

Patent Pending

SECTION PAGE

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Component Identification, Part Number, and Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Locating and Mounting the SmartBox

™

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Sensor Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Interconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

a. Power Supply to the SmartBox

™

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

b. Power to Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

c. Power to the Heater’s Smart Sense™Variable Rate Gas Control Valve . . . . . . . . . . . . . . . . . . . .7

d. Building Controller Heating Contacts to the SmartBox™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

e. SmartBox™Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Set-up and Programming the SmartBox™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Touch Pad Control and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Basic Room Control Typical Set- Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Temperature Control Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

A. Manual Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

B. Temperature Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Initial Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Initial SmartBox

™

Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Home Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Manual Mode or Temperature Curve Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Set Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Calibrating Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Defining the Temperature Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Set-up of Room Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Set-up of System Temperature Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Screen Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Maintenance/Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Service Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Touch Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Transformers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Programmable Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Signal Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Troubleshooting and Operation Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Replacement Parts and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Table of Contents

2

NEMA -4X

Dimensions ( L x W x H in.) 14 1/2 x 11 1/8 x 6

Inputs 120 /60 /1, 30 amps power required

Up to two 20k NTC temperature probes per zone

Outputs Two 25 amp 120 /60/1 relays for heater power

Two 0-15 vdc control signals for the variable rate gas control valves; 500 mA. per output

Net weight (lbs.) 11.5

SmartBox

™

3

Technical Specifications

Enclosure

Features

. The SmartBox™maintains precise temperature thereby

reducing fuel consumption and improving animal

productivity and health. It is offered in configurations for

controlling forced air heaters, for controlling radiant

heaters, and for controlling both forced air and radiant

heaters.

■ Operator interface touch pad.

-- Sets manual operation

-- Allows setting the clock at initial set-up

-- Activates and operates sensors

-- Provides for installing and changing the

temperature management curve.

■ Handles up to 10 temperature set points with up

to 225 days per period.

-- Linearly ramps from one set point temperature

to the next over the duration days for that

period

■ Two temperature control zones

-- Up to two temperature sensors for each zone

-- One zone can handle two heaters

a. Zone 1 and Zone 2 are forced air

heaters.

■ Heat Enable

-- Used with forced air heaters

-- Connected to the room controller in a

manner to allow operation only when the

room controller determines a need for

heat.

-- Minimizes interference between

the heating and ventilation

systems.

■ Indicator Lights

-- Heat Zone On: Green Light

-- Sensor Failure: Red Light

a. Identifies sensor malfunction.

b. If one sensor fails in a zone controlled

by two sensors, the remaining sensor

allows continued operation.

-- Cycle Complete: Amber Light

■ Control Reset Switch

-- Allows the producer to reset the controller back

to day 1 for the start of a new cycle.

-- Position the switch to OFF and then to ON to

reset.

This manual will instruct you in the installation and

operation of the SmartBox™. Have a qualified installer

review this manual with you so that you fully understand

the controller and how it functions.

When calling for technical service assistance, or for other

specific information, always have the model number and

serial number available.

Contact your local L. B. White distributor or the L. B. White

Co., Inc. for assistance, or if you have any questions about

the use of this product or its application.

The L. B. White Co., Inc. has a policy of continuous product

improvement. It reserves the right to change specifications

and design without notice.

General Information

Component Identification, Part Number, and Function

4

Control Reset Switch (570456)

Allows the producer to reset the control back to day 1 for

start of new cycle. Position from On to Off, then back to On.

Fuses (572812)

Used for protection of the electrical system of the

programmable controller and the heater’s variable rate gas

control valves.

Fuse Holders

Secures the fuse into position within the electrical circuit.

Fuse holder with 1/4 in. male tabs:572809

Fuse holder with 3/16 male tabs: 572808

Indicator Lights

Green: (26392)Zone 1 and Zone 2: Indicates which

heat zone is in operation

Amber: ( 572813) Indicates heat cycle complete

Red: (571333) SmartBox™temperature sensor failure

Programmable Controller (572814)

Micro-processor used for the operation of the SmartBox

™

system and operation of the signal conditioners.

Relays (572811)

Used for sending of power to the heaters in a specific heat

zone.

Sensor (572815) Not Illustrated

Used for monitoring temperature within the confinement

space. Interfaces to the programmable controller to allow

operation of the Smart Sense™variable rate gas control

valves.

Signal Conditioners (572771)

Used to process the electrical signal from the programmable

controller for operation of the variable rate gas control valves.

Touch Pad / Display (572914)

Used for set up of the SmartBox™for system operation :

temperature , heating days, etc

Transformers (570320)

Used for reducing incoming 115 VAC to 24 VAC for powering

of programmable controller and signal conditioners.

PROGRAMMABLE

CONTROLLER

FUSES

RELAY

RELAY

TRANSFORMER

TRANSFORMER

SIGNAL

CONDITIONERS

TOUCH PAD

AND DISPLAY

FIG. 1

FIG. 2

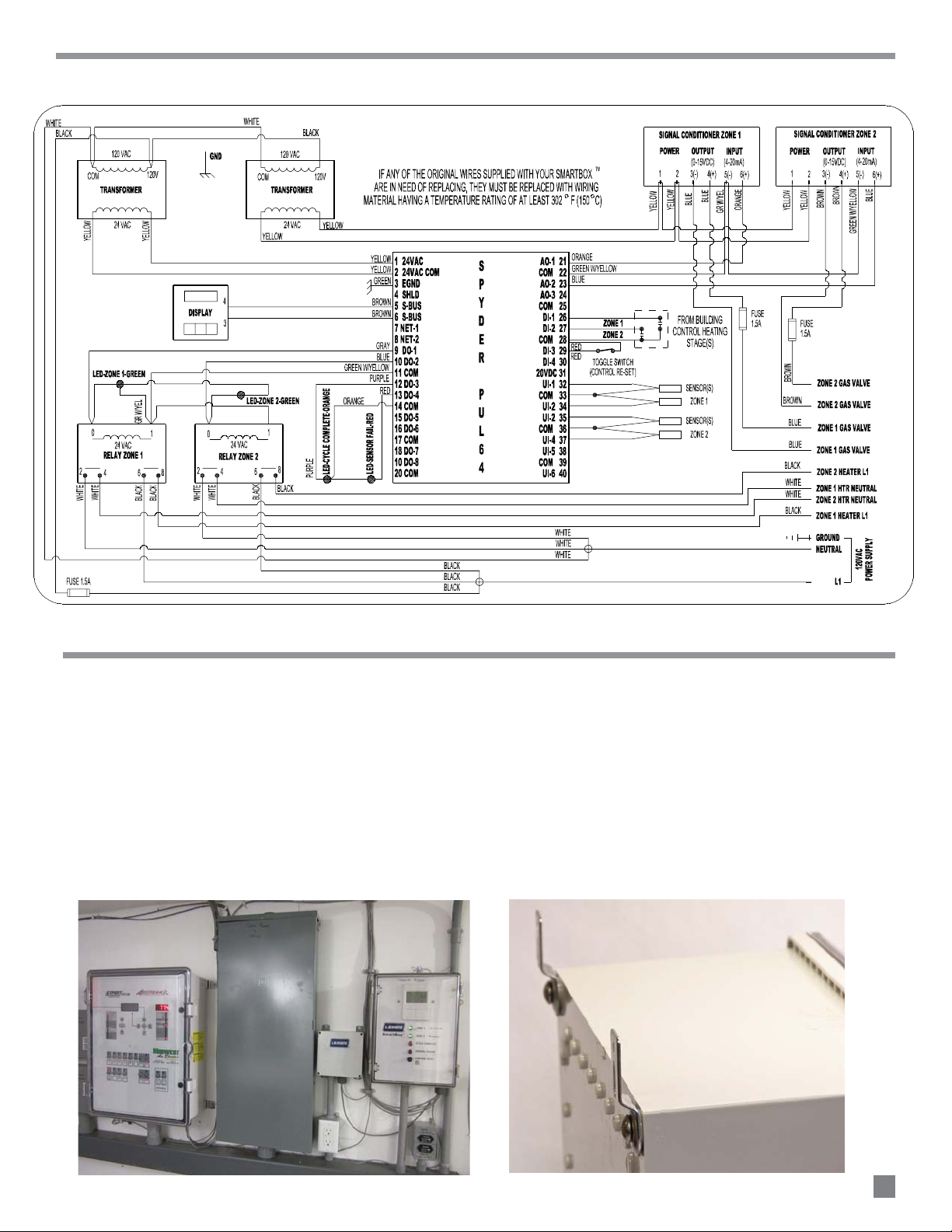

Locating and Mounting

Location

-- Locate in a corridor or control room on the wall

adjacent to or close to the existing room controller.

See Fig.3.

-- This area should be dry and not exposed to water

washdown.

-- The temperature in this area must be between 32F

and 104F.

FIG. 3

Mounting

-- Use mounting tabs and screws provided with the

SmartBox™at all corners of the box back. See Fig.4.

-- Use proper hardware to secure the SmartBox™to

the wall surface

-- Provide sufficient clearance to allow complete

opening of the SmartBox™cover.

FIG. 4

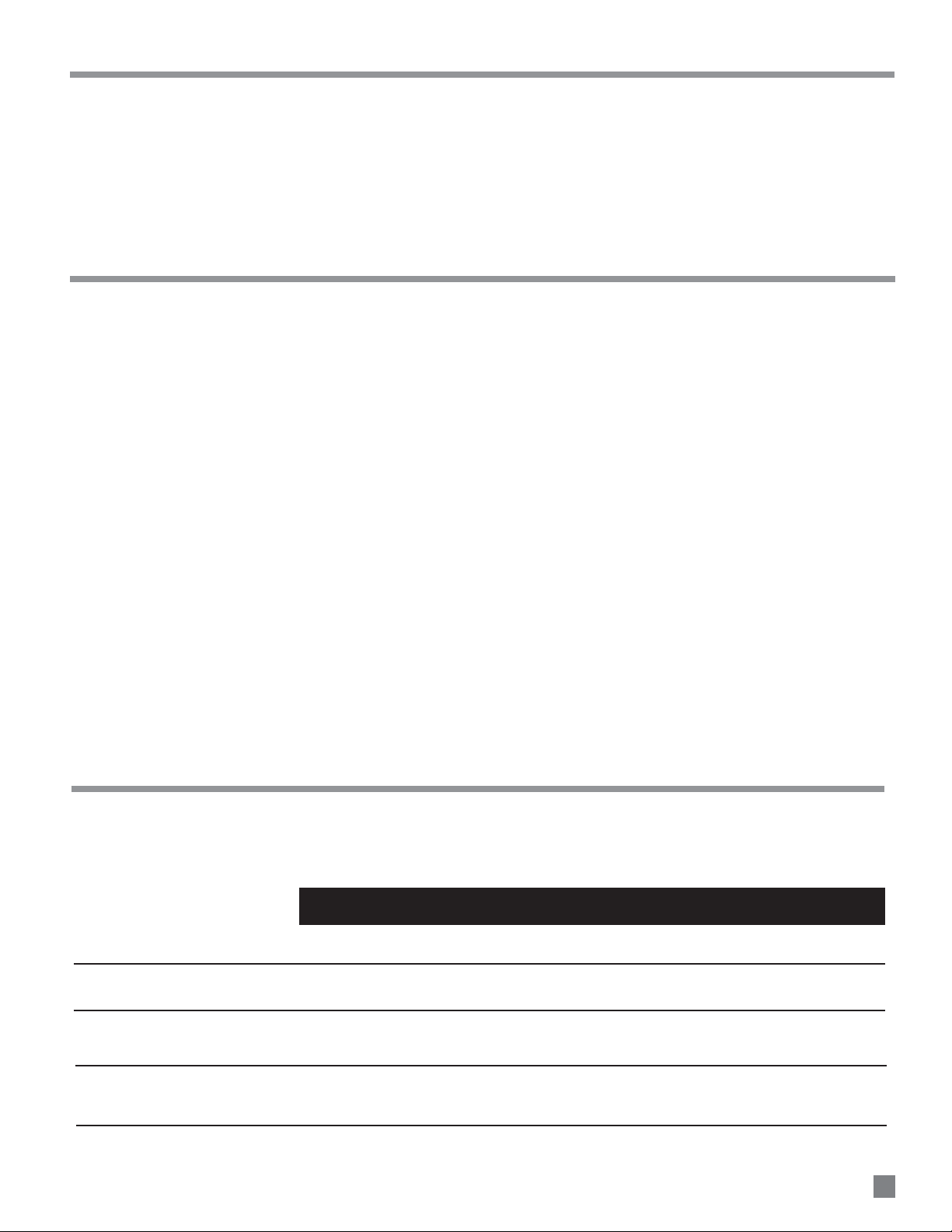

Wiring Diagram

5

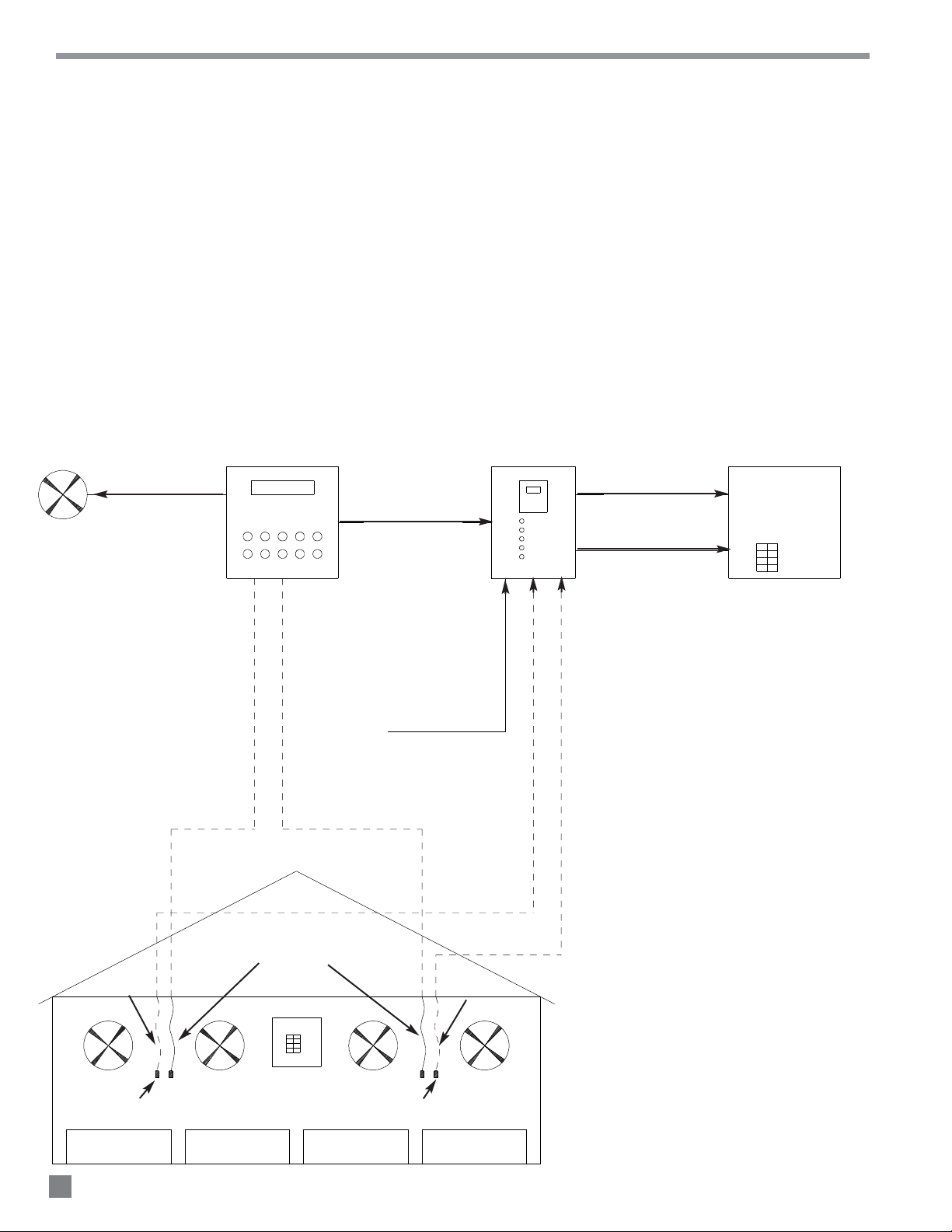

Sensor Location

Each SmartBox™ controls two zones of heat, two heaters

per zone . One SmartBox™sensor may be used for each

zone of heat. however two sensors are used for optimum

temperature management..

Use only the L.B.White SmartBox™sensors provided with

the SmartBox™, or order replacements as needed. Do

not use sensors from other controller systems as these

are not compatible with the L.B.White SmartBox™.

See below for proper SmartBox™sensor location.

FANS

ENVIRONMENT

CONTROLLER

L.B. WHITE

SmartBox

™

ENABLE

CONTROL SIGNAL

TO GAS VALVE

115 VAC TO HEATER

115 VAC

INCOMING

POWER

SmartBox

™

SENSORS

EXISTING ROOM

SENSORS

GUARDIAN

HEATER(S) WITH

Smart Sense

™

GUARDIAN WITH Smart Sense

™

FIG. 5

SmartBox

™

SENSORS

SmartBox

™

SENSORS ARE LOCATED WITHIN 6 IN. OF EXISTING ROOM SENSORS, AND AT THE SAME HEIGHT.

6

*

*

*

SOLDER AND WRAP WITH

ELECTRICAL TAPE THE CONNECTION

BETWEEN THE SmartBox™SENSOR

AND THE 2 WIRE CONDUCTOR LEADING

BACK TO THE SmartBox

™

■

All wiring must be done by a qualified electrician in

accordance with local, state, and national electrical

codes.

Initial Preparation

■ Unlatch the control box cover, and open the control

panel.

■ Select locations on either the side or the bottom where

a wiring access holes may be drilled. Do not drill holes

at the top of the control box.

■ Install the appropriate sized water tight connectors.

■ Use customer supplied minimum 18 gauge conductor

and the appropriate wiring terminals for connecting the

Smart Box™ to the heater’s variable gas control valve,

to the room controller contacts, and the temperature

sensors.

■ Refer to sections A through E for connection

instructions. Refer to the white flag labeling on

SmartBox™leads for interconnections.

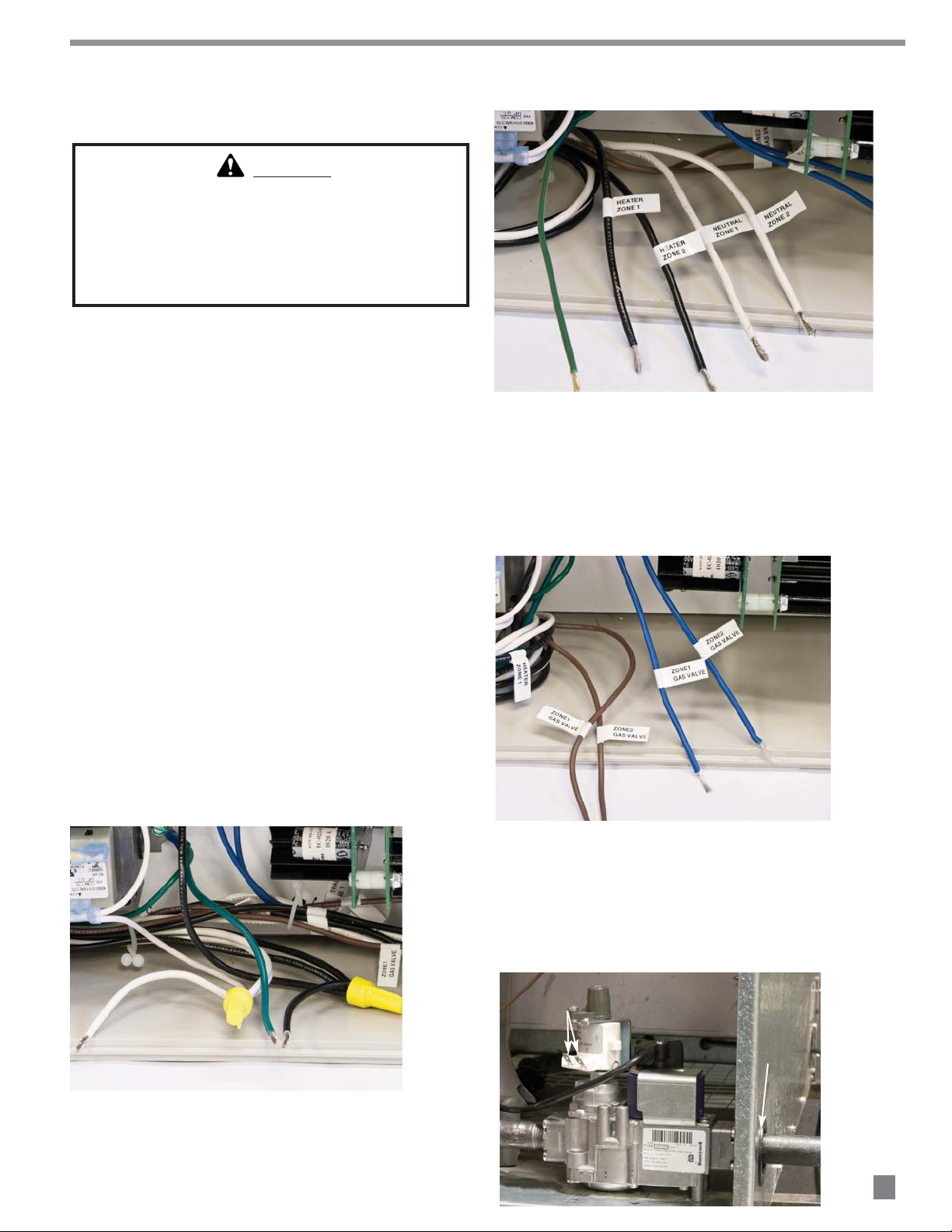

Connection

A. Connecting the Electrical Power Supply to the SmartBox™.

Connect to hot, neutral, and ground leads as shown in

Fig.6.

FIG. 6

B. Connecting Power to the Heaters

Connect leads in SmartBox™to heating Zones 1 and 2.

See Fig.7.

FIG. 7

C. Wiring from SmartBox™to the heater’s Smart Sense

™

variable rate gas control valve

a. Connect Smart Sense™ gas control valve wiring

for Zones 1 and 2 at SmartBox™ leads as

shown in Fig.8.

FIG. 8

b. Route the wiring from these leads through the

gas inlet hole at the heater’s case. See Fig.9.

c. Attach 1/4 in. insulated female terminals to

these wires and connect to either terminal on

the valve. See Fig. 9.

FIG. 9

7

Interconnection

ROUTE WIRING

THROUGH HOLE

CONNECT WIRING TO TERMINALS

( NOT POLARITY SENSITIVE)

WARNING

Electrical Shock Hazard

■ Disconnect the electrical supply before installiation of

the SmartBox

™

.

■ Failure to follow this warning may result in personal

injury or death.

Loading...

Loading...