Page 1

Owner's Manual and Instructions

SmartBox™Controller

For Use with GUARDIAN®Electronic Ignition F orced Air Heaters

™

with Smart Sense

and Infraconic Manual or Spark Ignition Radiant Heaters

Automatic Variable Rate Heat

MODEL

COMBO-MCS

Patent Pending

Congratulations!

The SmartBox™incorporates the benefits from the most experienced manufacturer

of agricultural animal confinement building heating products using state-of-the-art

technology.

We,atL.B.White,thank you for your confidence in our products and

welcome any suggestions or comments you may have...call us, toll-free,

at 1-800-345-7200.

ATTENTION ALL USERS

The SmartBox™has been designed and developed by L.B.White Co. as a variable

rate heat controller for managing heat to demand within the animal confinement

facility. It works in conjuction with L.B.White Smart Sense™forced air and radiant

heaters and an existing room controller with on/off capability.

150-28782

Page 2

Table of Contents

SECTION PAGE

GeneralInformation ...................................................................3

Features ............................................................................3

TechnicalSpecifications ...............................................................3

ComponentIdentification,PartNumber,andFunction.......................................4

WiringDiagram.......................................................................5

Locating and Mounting the SmartBox

SensorLocation ......................................................................6

Interconnection ......................................................................7

Connecting the Electrical Power Supply to the SmartBox

ConnectingPowertotheHeaters ....................................................7

Wiring from the SmartBox

Connecting the Building Controller Heating Contacts to the SmartBox™....................8

Wiring the SmartBox™toRadiantHeaters .............................................8

Set-up and Programming the SmartBox

TouchPadControlandDisplay.......................................................9

BasicRoomControlTypicalSet-Up ...................................................9

TemperatureControlParameters.....................................................9

A.ManualOverride ............................................................9

B.TemperatureCurve ..........................................................9

InitialStart-Up ...................................................................10

Initial SmartBox

HomeScreens...................................................................10

ManualModeorTemperatureCurveSelection ........................................10

SetClock .......................................................................11

TemperatureSensors ............................................................11

CalibratingTemperatureSensors ...................................................12

DefiningtheTemperatureCurve ....................................................13

Set-upofRoomControl ...........................................................13

Set-upofSystemTemperatureCurve ................................................13

ScreenDisplays..................................................................14

Maintenance/Cleaning ...............................................................15

ServiceInstructions ..................................................................15

Fuses ..........................................................................15

Relays..........................................................................16

TouchPadDisplay ................................................................16

Transformers ....................................................................16

ProgrammableController ..........................................................17

ForcedAirSignalConditioner .......................................................17

RadiantSignalConditioner ........................................................18

TroubleshootingandOperationSequence................................................19

WarrantyPolicy .....................................................................23

ReplacementPartsandService ........................................................23

™

Set-Up ..........................................................10

™

...................................................5

™

................................7

™

to the Forced Air Heater’s Smart Sense™GasControlValve.......7

™

.................................................9

2

Page 3

Forced Air

Radiant

General Information

This manual will instruct you in the installation and

operation of the SmartBox™. Have a qualified installer

review this manual with you so that you fully understand

the controller and how it functions.

When calling for technical service assistance, or for other

specific information, always have the model number and

serial number available.

™

The SmartBox

reducing fuel consumption and improving animal

productivity and health. This configuration provides control

of both forced air and radiant heaters.

The SmartBox

temperature control of the forced air heaters. The

SmartBox™operates the radiant heaters independent

of the room controller

maintains precise temperature thereby

™

interfaces to the room controller for

■ Operator interface touch pad.

-- Sets manual operation

-- Allows setting the clock at initial set-up

-- Activates and operates sensors

-- Provides for installing and changing the

temperature management curve.

■ Handles up to 10 temperature set points with up to

225 days per period.

-- Linearly ramps from one set point temperature

to the next over the duration days for that

period

■ Separate temperature control zones

-- Up to four temperature sensors for forced air

heaters.

-- One separate sensor for radiant heaters

-- Zone 1 can handle two forced air heaters

-- Zone 2 interfaces with a proportional zone control

for either spark or manual ignition heaters.

-- Maximum capacity: 24, I-17 LP/NG

radiant heaters.

-- Zone control #s: Manual ignition 28564

Spark Ignition 28580

Contact your local L. B. White distributor or the L. B. White

Co., Inc. for assistance, or if you have any questions about

the use of this product or its application.

The L. B. White Co., Inc. has a policy of continuous product

improvement. It reserves the right to change specifications

and design without notice.

Features

■ Heat Enable

-- Used with Zone 1 (forced air heaters) only.

-- Connected to the room controller in a

manner to allow operation only when the

room controller determines a need for

heat.

-- Minimizes interference between

the heating and ventilation

systems.

■ Indicator Lights

-- Heat Zone On: Green Light

-- Sensor Failure: Red Light

a. Identifies sensor malfunction.

b. If one sensor fails in a zone controlled by

two sensors, the remaining sensor allows

continued operation.

-- Cycle Complete: Amber Light

■ Control Reset Switch

-- Allows the producer to reset the controller back to

day 1 for the start of a new cycle.

-- Position the switch to OFF and then to ON to

reset.

Technical Specifications

SmartBox

Enclosure

Dimensions(LxWxHin.) 141/2x111/8x6

Inputs 120 /60 /1, 30 amps power required

Up to two 20k NTC temperature probes per zone

Two 25 amp 120 /60/1 relays for heater power

F

Outputs

Net weight (lbs.) 11.5

: 0-15 vdc control signal for the variable rate gas control valves; 500 mA.

NEMA -4X

: 24 VDC PWM Control Signal, 900 mA

™

3

Page 4

Component Identification, Part Number, and Function

Fuse for Forced Air heaters: 572812

Fuse for Incoming Power and Radiant Brooders: 572918

Fuse holder with 1/4 in. male tabs:572809

Fuse holder with 3/16 male tabs: 572808

Green

26392

Amber

572813

Red:(571333

Forced Air Heaters : 572771

Radiant Brooders : 572913

Control Reset Switch (570456)

Powers up the SmartBox™for heating zone and allows the

producer to reset the control back to day 1 for start of new

cycle. Position from On to Off, then back to On.

Fuses

Used for protection of the programmable controller and the

variable rate gas control valves.

Fuse Holders

Secures the fuse into position within the electrical circuit.

Indicator Lights

: (

: (

) Indicates which heat zone is in operation

) Indicates heat cycle complete

) SmartBox™temperature sensor failure

Relays (572811)

Used for sending of power to the heaters in a specific heat

zone.

Sensor (572815) Not Illustrated

Used for monitoring temperature within the confinement

space. Interfaces to the programmable controller to allow

operation of the Smart Sense™variable rate gas control

valves.

Signal Conditioners

Used to process the electrical signal from the programmable

controller for operation of the variable rate gas control

valves.

Touch Pad / Display (572914)

Used for set up of the SmartBox™for system operation :

temperature , heating days, etc

Programmable Controller (572917)

Micro-processor used for the operation of the SmartBox

system and operation of the signal conditioners.

Transformers Used for reducing incoming 115 VAC to 24

™

VAC for powering of programmable controller and signal

conditioners.

Radiant Brooders (UPPER): 572912

Forced Air Heaters (LOWER): 570230

FIG. 1 FIG. 2

TOUCH PAD

AND DISPLAY

RELAYS

TRANSFORMERS

PROGRAMMABLE

CONTROLLER

FUSES

RADIANT FORCED AIR

SIGNAL CONDITIONERS

4

Page 5

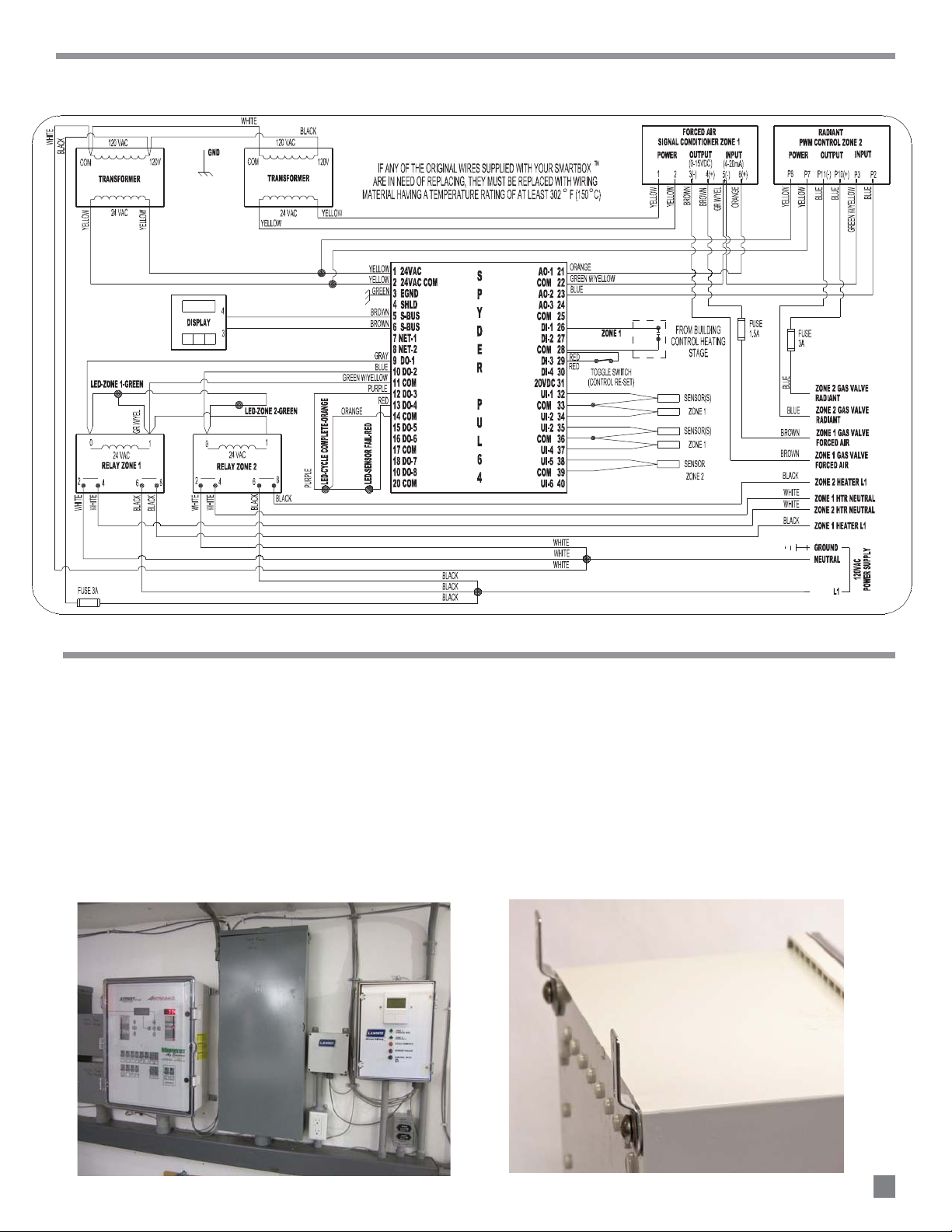

Location

Mounting

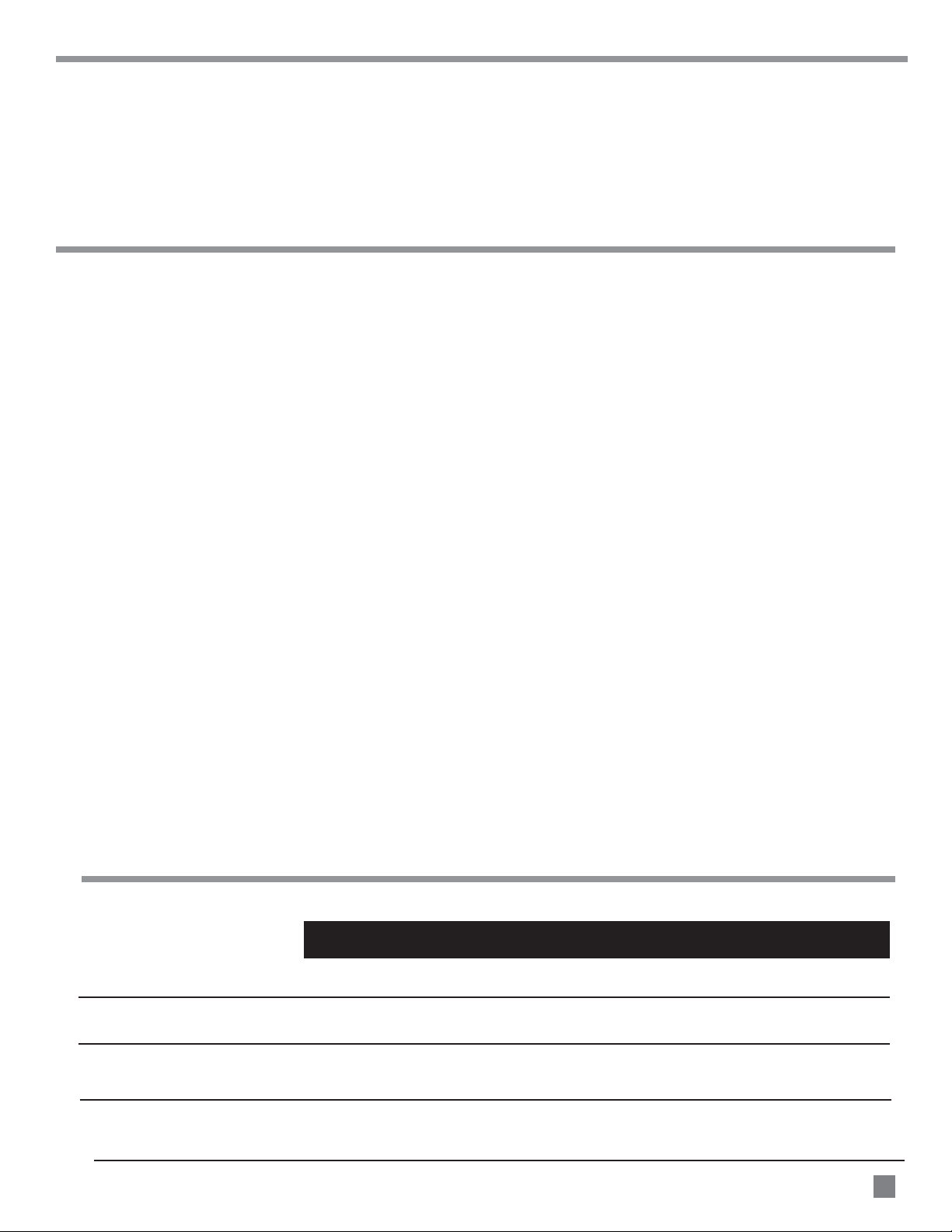

Wiring Diagram

L

-- Locate in a corridor or control room on the wall

adjacent to or close to the existing room controller.

See Fig.3.

-- This area should be dry and not exposed to water

washdown.

-- The temperature in this area must be between 32F

and 104F.

FIG. 3

Locating and Mounting

-- Use mounting tabs and screws provided with the

SmartBox™at all corners of the box back. See Fig.4.

-- Use proper hardware to secure the SmartBox

the wall surface

-- Provide sufficient clearance to allow complete

opening of the SmartBox™cover.

FIG. 4

™

to

5

Page 6

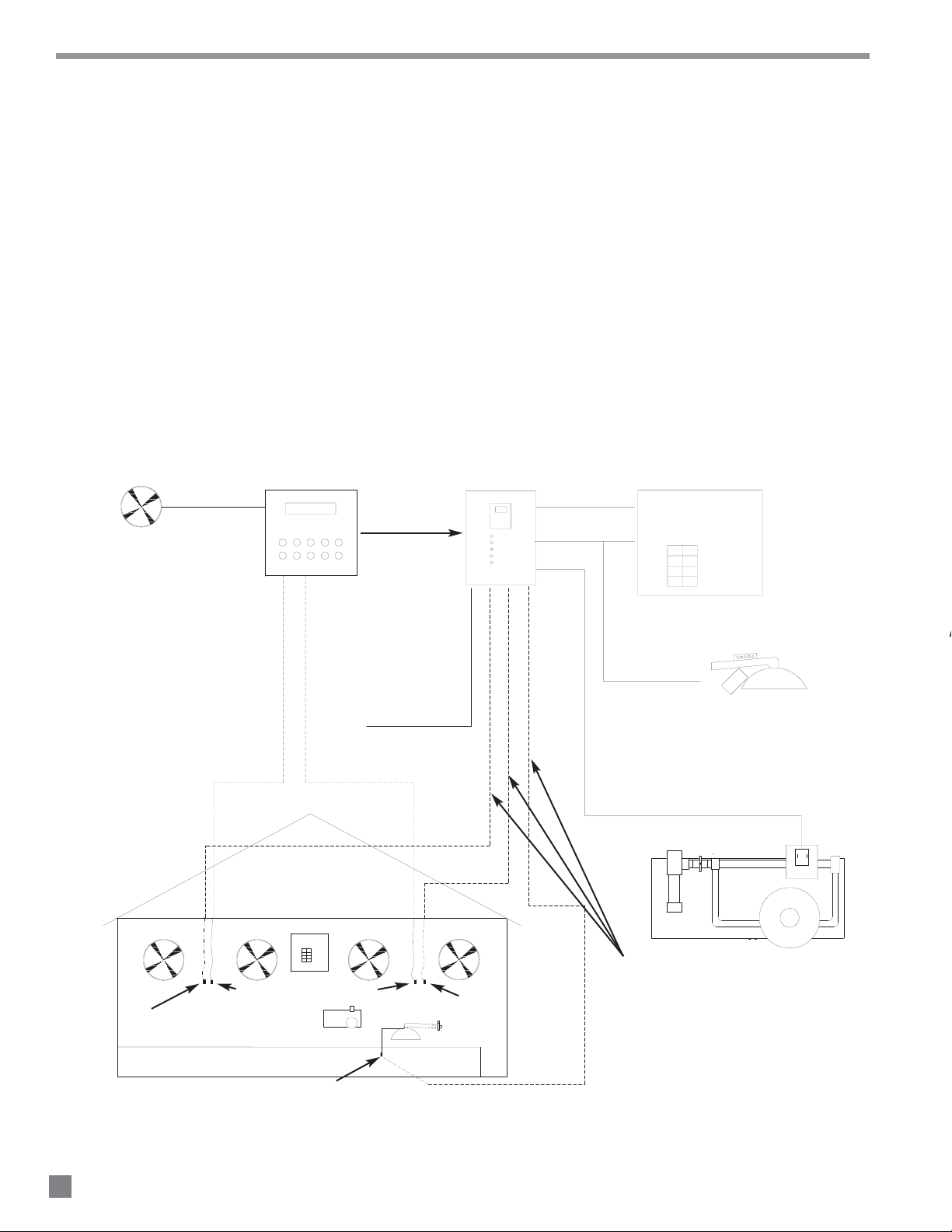

Sensor Location

Each SmartBox™ controls two zones of heat.:

-- Zone 1: Two forced air heaters

-- Zone 2: Radiant heaters

Use only the L.B.White SmartBox

™

sensors provided

wi th th e SmartBox™, or o rde r repl ace men ts as

needed. Do not use sensors from other controller

syst e ms as thes e a re not com p a tibl e w i th the

L.B.White SmartBox

™

.

See below for proper SmartBox™sensor location.

One SmartBox™sensor may be used for each zone of

heat. However two or more sensors are used for

optimum temperature management.

FIG. 5

FAN(S)

ROOM CONTROLLER

SmartBox™ SYSTEM DIAGRAM

FORCED AIR AND RADIANT HEATERS

ZONE1

ZONE2

CYCLE

SENSOR

RESET

™

120 VAC

POWER SUPPLY

SmartBox

ENABLE

GUARDIAN WITH

Smart Sense

™

SmartBox™ SENSOR(S) LOCATED WITHIN 6 IN. OF

EXISTING ROOM SENSOR AND AT SAME HEIGHT

GUARDIAN

GUARDIAN WITH

w/ SMARTSENSE™

™

Smart Sense

ROOM CONTROL SENSORS

ZONE PANEL

RADIANT SENSOR

120 VAC

POWER SUPPLY

SmartBox™ SENSOR(S) LOCATED WITHIN 6 IN. OF

EXISTING ROOM SENSOR AND AT SAME HEIGHT

120 VAC TO SPARK IGNITION

INFRACONICS ONLY (ZONE 2)

CONTROL SIGNAL TO ZONE PANEL VARIABLE RATE

SOLENOID VALVE (USE MINIMUM 18 GAUGE WIRING))

USE 18 GAUGE WIRE FROM THE

SmartBox™TO EACH TEMPERATURE SENSOR

LOCATION. UP TO 4-FORCED AIR AND

1 RADIANT ZONE

6

Page 7

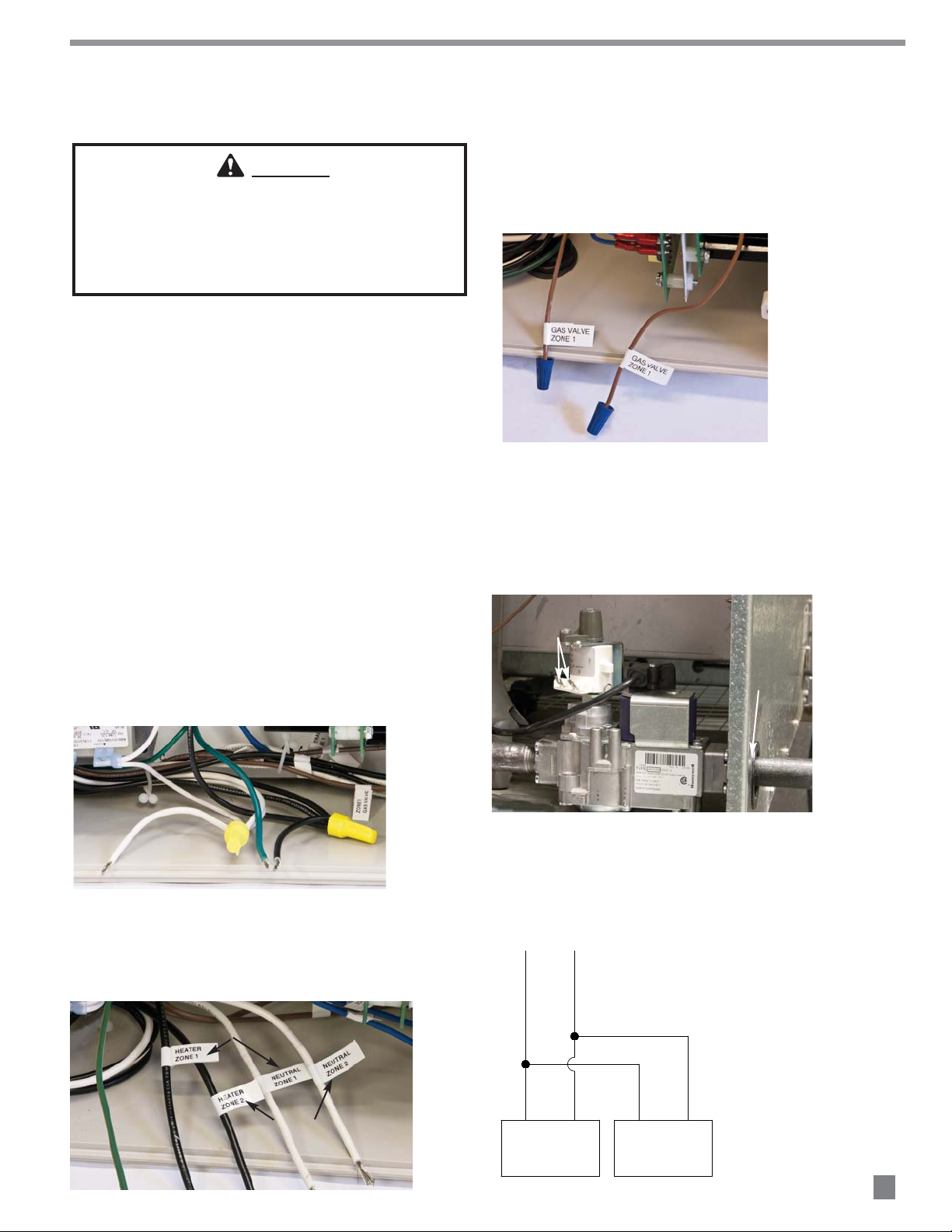

A

All wiring must be done by a qualified electrician in

accordance with local, state, and national electrical

codes.

Do not drill holes

at the top of the control box.

Install the appropriate sized water tight connectors.

Connecting the 120 VAC Power Supply to the SmartBox™.

Connecting 120 VAC Power to the Heaters

Wiring from SmartBox™to the forced air heater’s Smart

Sense™ variable rate gas control valve

WARNING

Electrical Shock Hazard

■

■ Disconnect the electrical supply before installation of

the SmartBox

™

.

■ Failure to follow this warning may result in personal

injury or death.

■ Unlatch the control box cover, and open the control

panel.

■ Select locations on either the side or the bottom where

a wiring access holes may be drilled.

■

Interconnection

a. Connect the Smart Sense™ gas control valve wiring

for Zone 1 at the brown SmartBox

shown in Fig.8.

FIG. 8

™ leads as

■ Use customer supplied minimum 18 gauge conductor

and the appropriate wiring terminals for connecting the

Smart Box™ to the heater’s variable gas control valve,

to the room controller contacts, and the temperature

sensors.

■ Refer to the following instructions for wiring

connections. Refer to the white flags on the

SmartBox™leads for interconnections.

Connect to hot, neutral, and ground leads as shown in

Fig.6.

FIG. 6

b. Route the wiring from these leads through the

gas inlet hole at the heater’s case. See Fig.9.

c. Attach 1/4 in. insulated female terminals to

these wires and connect to either terminal on

the valve. See Fig. 9.

FIG. 9

CONNECT WIRING TO TERMINALS

( NOT POLARITY SENSITIVE)

ROUTE WIRING

THROUGH HOLE

d. See Fig.10 for typical connections. Each SmartBox™

zone can control two heaters.

FIG. 10

Connect leads in SmartBox™to heating Zones 1 and 2.

See Fig.7.

FIG. 7

FORCED AIR

USED FOR SPARK IGNITION

RADIANT HEATERS ONLY. DO

NOT USE FOR MANUAL IGNITION

RADIANT HEATERS

WIRING FROM Smart Box™ To FORCED AIR Smart Sense™

VARIABLE RATE GAS CONTROL VALVE

VALV E

VOLTS TO VALVE

HEATER 1

GAS VALVE

HEATER 2

GAS VALVE

7

Page 8

C

Connecting the building controller’s heating contacts to the

SmartBox™(for contact closure) for Zone 1 forced air heaters.

(Zone 2 is for radiant heaters and operates independent of

the room controller. This does not require contact closure

wiring)

These are

not powered contacts.

Wiring from SmartBox™to the radiant heaters.

Connecting the SmartBox™temperature sensors

(Zone 1 has 4 sensors, Zone 2 has 1 sensor)

See page 6 for sensor location.

Use onl y the L.B. White SmartBox™se nsors, part

num ber 572815, provided with the SmartBox™, or

order replacements as needed. Do not use sensors

from room controllers as these are not compatible with

the L.B.White SmartBox

™

.

FIG. 13

Connect to the red leads as shown in Fig.11.

-- Remove the wiring from the heat contacts (one for

each zone) in the room controller.

-- Connect these same contacts to the SmartBox

Enable wiring Zone 1, and to common Zone 1.

- This allows each SmartBox™ zone

to operate within the temperature

parameters of the room controller.

FIG. 11

™

FIG. 14

COMBO SmartBox

PROPORTIONAL CONTROL VALVE

CONNECTOR BLOCK

2

1

™

-

+

BLUE

BLUE

GROUND

■ The SmartBox™ operates the variable rate proportional

solenoid control used for the radiant heaters, and

operates independent from the room controller.

■ Separate installation and operation instructions

accompany the appropriate control for manual igntion

or spark ignition radiant heaters.

■ See Fig.12 for connection of the SmartBox™ to the

proportional control valve for radiant heaters. Fig13

identifies the proportional valve and Fig.14 illustrates a

typical connection from the SmartBox

™ to the valve.

FIG. 12

Connect 18 gauge (minimum) wiring between the gray

leads as shown in Fig.14 and the SmartBox™sensor.

Solder the connection between the SmartBox™ sensor

and the conductor. Wrap this connection with electrical

tape.

FIG. 14

8

Page 9

Set Up and Programming

TOUCH PAD CONTROL AND DISPLAY

BASIC ROOM CONTROL-TYPICAL SET-UP

As an Example:

Note: The actual average room temperature is what will

become the Set-point for the variable rate

forc

ed air heating.

TEMPERATURE CONTROL PARAMETERS

A. Manual Mode

Note:

B. Temperature Curve:

The touch pad control is an interface device used to

program and operate the control. See Fig. 16 as an

example.

FIG. 16

SOFT KEYS

DOWN UP

■ The following can be programmed from the touch pad:

-- Setting for manual operation.

-- Setting the clock at initial start-up or resetting in the

event of a power failure of more than 24 hours.

-- Enabling or disabling room sensors

-- Correlating the SmartBox

controller sensors

-- Setting the initial temperature set points for each

zone.

-- Setting the initial temperature curve, if one is used.

-- With the system in operation, temperature and day

points can be edited to make changes as needed.

™

sensors to room

■ There are up and down keys to adjust parameters.

■ There are three soft keys used to access and program

entries:

-- Designation for the function of each soft key is

indicated at the bottom of the display screen

within the three boxes. Designations change

depending on operating mode.

■ The SmartBox

controller that has an on/off heat control in order to

provide variable rate heating for the forced air heaters.

The SmartBox

of the room controller.

™

interfaces with an existing room

™

operates radiant heaters independently

■ There is a desired room air temperature -not to be

exceeded- typically called:

-- DRT (Daily Required Temperature) or

-- Set Point

■ The typical swine room control will operate a minimum

ventilation fan plus additional stages of ventilation.

-- If DRT /Set Point is exceeded by room temperature

the ventilation fan will increase in speed to full

output.

-- At some point, if this increased airflow is not

sufficient to cool the room back to the desired

DRT/Set Point, then additional stages of

ventilation are activated.

■ To avoid the situation of heaters causing room air

temperature to increase above the DRT/Set Point

thereby causing increased ventilation to remove the

heated air, the settings for heat “on” and “off” are set

to avoid overshoot and the accompanying waste of fuel.

-- DRT/Set Point is 82 F

-- Heater “on” offset is -3F: heater comes on at 79F.

-- Heater “off” differential is -1F, the heater goes off at

81F. This is below the DRT/set point and intended to

minimize overshoot.

With settings given such as in the previous example:

-- You will typically see 5-6 degrees variation in room

temperature. This variation will be eliminated with

variable heat control.

-- The actual average room temperature due to heating

is about 2F lower than the stated DRT/Set-point

temperature, in this example 80F.

■ There are two ways of utilizing the temperature control:

the operator based on appearance and performance of

the animal.

room controller temperature setting and the SmartBox

temperature setting must be aligned.

curve of temperature vs. days that is used to adjust the

room temperature environment as the animal ages.

: Temperature is adjusted as needed by

To operate in the manual mode, the

there is a defined temperature

™

9

Page 10

I

INITIAL START-UP

INITIAL SET-UP

The following instructions guide you through a step by step

process for setting the various paramete

rs.

HOME SCREENS

MANUAL MODE OR TEMPERATURE CURVE SELECTION

■ Connect to a 120 VAC power supply. Set the reset switch

to the ON position. It will take about 30 seconds for the

touch pad to display the following screen.

FIG. 17

-- Display # 2 shows the actual room temperature for each

zone plus the day in the temperature curve cycle. See

Fig.20.

FIG. 20

FORCED AIR TEMP.

RADIANT TEMP.

If at any time during set-up you want to start over, press the

up/down keys and the center soft key simultaneously to get

back to the Home Screen. Press the right soft key

PARAMETERS, then press right soft key NEXT to scroll to the

area you want to change.

■ Simultaneously press the up/down keys and center soft

key. The following screen is displayed. See Fig.18.

FIG. 18

FORCED AIR TEMP.

RADIANT TEMP.

■ Press right soft key NEXT.

-- Display # 3 shows Set Point for both heating zones

and schedule day. See Fig.21.

FIG. 21

■ Once you have decided which display you want, press the

left soft key DONE to get back to the Home Screen

selection.

■ To continue from the Home Screen, press the right soft key

PARAMETERS. The following screen will be displayed.

■ To access Home Screens, press left soft key SET HOME

SCREEN. See Fig.18.

■ There are three home screen displays:

-- Display #1 shows schedule day. See

Fig.19. Then press right soft key NEXT.

FIG. 19

10

FIG. 22

■ This is the manual temperature override selection,

allowing you to set and hold a specific temperature.

Once the selection has been made, the SmartBox™

will hold this temperature.

Page 11

■ Press the center soft key EDIT. The following screen will be

ENABLE (Manual Mode)

Zone 1 is now in manual override. After ensuring

the room controller and Smart Box

™

set points are

aligned, no further action is needed.

DISABLE (Operating on Temperature Curve)

to operate within the

temperature curve.

--

SET CLOCK (To run the temperature curve the clock must be

set)

TEMPERATURE SENSORS

displayed.

FIG. 23

Press the right soft key NEXT to continue. The screen

shown in Fig.26 will be displayed.

FIG. 26

■ Using the up/down keys, select either “‘ENA” to enable the

manual override or “dSA” to disable the override.

E

-- If enable is selected, press the right soft

key NEXT and then up/down keys to set the

temperature that will be maintained by the

SmartBox

-- Once the temperature has been selected , press the

left soft key DONE.

--

™ . See Fig.24.

FIG. 24

■ Press the right soft key NEXT to continue set-up. The

screen shown in Fig.27 will be displayed.

FIG. 27

■ Press the center soft key EDIT to set the clock.

-- Starting with the Month, use the up/down keys to

select Month, day, year, hour, (Note; AM or PM) and

Minutes.

-- Press left soft key DONE to return to SET CLK.

■ Press the right soft key NEXT to continue set-up.

FIG. 25

-- Selecting disable deactivates the manual override,

allowing the SmartBox

-- Press the right soft key NEXT. The following screen

will be displayed. Complete the same enabling

or disabling process for Zone 2 as you previously did

for Zone 1.

™

■ The following screen is displayed. There are four

temperature sensors for Zone 1(forced air) and one

temperature sensor for Zone 2 (radiant). This screen gives

you the option for either using all sensor for the forced air

zones, or the single radiant sensor. YOU MUST USE AT

LEAST ONE SENSOR.

FIG. 28

11

Page 12

■ Press the center soft key EDIT.

CALIBRATING TEMPERATURE SENSORS

■ Press the up/down keys to enable (ENA) or disabled (dSA)

Zone 1 Temperature Sensor 1. See Fig. 29. Make the

same selections for sensors 2 through 4 for Zone 1.

FIG. 29

■ Once all have been selected for Zone 1, Temperature

Sensor 1 through 4, , press the right soft key NEXT to

access Zone 2, Temperature Sensor 1. Enable the sensor

using the up/down keys. When completed, press the left

soft key DONE.

■ To continue set-up, press right soft key NEXT. The following

screen is displayed.

-- Before making any adjustments, you must allow the

temperature between the room controller sensors

and the SmartBox

-- Once temperatures have stabilized, use the up/down

keys to enter room temperature sensor offset.

■ Press the right soft key NEXT to set temperature offset for

Zone 1, Temperature Sensors 1 through 4. Complete

the same process for Zone 2, Temperature Sensor 1.

Use the up/down keys accordingly.

-- Example: If the room controller reads 70 F and the

SmartBox

by pressing the up key.

■ Press the leftsoft key DONE, then press NEXT. The

following screen is displayed

™ reads 69 F, set the offset temperature 1F

™ sensors to stabilize.

FIG. 32

C

This selection allows correlation between the room

controller’s sensors and the SmartBox™ sensors.

FIG. 30

■ Press the center soft key EDIT. The following screen is

displayed.

FIG. 31

■ Press the center soft key EDIT to view the heat load

percent in Zone 1. See Fig. 33. To view Zone 2, press right

center soft key NEXT

FIG. 33

■ Press the up/down keys and center soft key

simultaneously to exit the set-up mode and to return you

back to the Home Screen. Now determine your

temperature curve.

12

Page 13

D

DEFINING THE TEMPERATURE CURVE

Period DRT Day SmartBox™Set Point

Forced Air Radiant

1 76 F 1 74 F 88 F

2 76 F 7 74 F 85 F

3 76 F 21 74 F 74 F *

4 72 F 35 70 F 60 F

5 70 F

48 68 F 60 F

6 68 F 65 66 F 60 F

7 66 F 70 64 F 60 F

8 64 F 80 62 F 60 F

9 62 F 120 60 F 60 F

10 62 F

180 60 F 60 F

* Typically the radiant heaters will shut off

after 2-3 weeks o

f operation.

SET-UP OF ROOM CONTROL

SET-UP OF SYSTEM TEMPERATURE CURVE

■ The SmartBox™has the capacity for 10 time and

temperature control periods.

-- An example is the following:

Note: For each Period, the Days must be equal to or

greater than the previous period.

Example: Period 3 cannot start at Day 6.

-- Determine the 10 temperature/day period curve.

-- Enter the temperature curve.(See the previous table

example)

-- Set heat “on” offset to -3F (73F)

-- Set the heat “off” differential to 3F (76F), same as the

DRT

- The SmartBox

temperature exceeds DRT or Set-point.

- This allows the SmartBox

operate in the range of 73F to 76F.

™

will turn heating off before

™

to be enabled to

FIG. 35

■ To enter the temperature, press the center soft key EDIT.

The following screen is displayed.

FIG. 36

■ Use the up/down keys to set the Start Temperature for

Zone 1. Press the right soft key NEXT and use the up/down

keys to set Zone 2 Start Temperature.

■ Press the left soft key DONE.

■ Press the up/down keys and the center soft key

simultaneously to enter the set-up mode. The following

screen is displayed.

FIG. 34

■ Press the right soft key PARAMETERS.

■ Continue to press the right soft key NEXT to arrive at the

Temperature Curve Input section. See Fig.35.

■ Press the right soft key NEXT. The following screen is

displayed.

FIG. 37

■ Press the center soft key EDIT. The following screen is

displayed.

FIG. 38

13

Page 14

■ Press the up/down keys to set the Period 2 day as

Set up is complete.

SCREEN DISPLAYS

*

*

* Percentage of operation of variable rate gas control valves

determined with the Temperature Curve.

■ Press the right soft key NEXT. The following screen is

displayed. Enter the desired set point for Period 2 Zone 1

using the up/down keys.

FIG. 39

■ Press the right soft key NEXT and enter the set point for

Period 2 Zone 2 using the up/down keys.

■ Press the left hand soft key DONE.

■ Repeat this this same process for Periods 3 through 10,

setting the number of days and set points.

■ Press the left soft key DONE.

■ Simultaneously press the middle soft key and up/down

S

keys to return to the Home Screen.

-- Z1 OR EN (Zone 1 Override Enabled)

-- Z1 TSP OR ( Zone 1 Temperature Set Point Override)

-- Z1 OR ENA or dSA (Zone 1 enabled or disabled)

-- Z2 OR EN (Zone 2 Overide Enabled)

-- Z2 TSP OR (Zone 2 Temperature Set Point Override)

-- STRT DAY (Start Day)

-- Time

-- SCHD DAY (Schedule Day)

-- ACT Period (Actual Period)

-- RMNG HRS (Remaining Hours)

-- Z1 ACTSP (Zone 1 Actual Set point)

-- Z2 ACTSP (Zone 2 Actual Set Point)

-- Z1 T1, T2,T3 etc (Zone 1 Temperature Sensor 1, etc.)

-- Z2 T1 ( Zone 2 Temperature Sensor 1)

-- Z1 T Avg (Zone 1 Temperature Sensor Average)

-- Z2 T Avg (Zone 2 Temperature Sensor Average)

-- SCHED ER (Schedule Error)

-- HTG STS (Heating Status)

-- Z1 Htg Ld (Zone 1 Heating Load Forced Air)

-- Z2 Htg Ld (Zone 2 Heating Load Radiant)

-- P1 T SP(Period 1 through 10 Temperature Set Point)

-- P-1 Z11 (Set Point for Period 1,Zone 1)

-- P-1 Z-2 (Set Point for Period 2 Zone 2)

-- P2 Day (Period 2 Day through Period 10 Day)

-- Sen Dis (Sensor Disabled)

-- Z1 T1 through T4 (Zone 1 Temperature Sensor 1-4

Disabled)

-- Z 2 T2 (Zone 2 Temperature Sensor 2 Disabled)

-- TMP OF SET( Temperature off set)

-- OF ST T1 (or T2) (Off set Temperature Sensor 1 or 2)

-- Status

-- Set Clk (Set Clock)

-- Month

-- Day

-- Year

-- Hour

-- Minutes

14

Page 15

Maintenance/Cleaning Instructions

Don’t use water or chemicals when cleaning.

WARNING

Electrical Shock Hazard

Fuse A

Fuse B

Fuse C:

WARNING

Electrical Shock Hazard

1. Ensure all water tight connectors on the SmartBox

are securely tightened. Check the interior of the box

for any water/condensation which might have

entered. Replace the connector if necessary.

3. Peridically check all wiring, associated terminals, and

™

electrical components within the controller for

corrosion, frayed or cut insulation, tight connections,

etc. Repair or replace as necessary.

2. Periodically check the SmartBox

fits tightly around the cabinet, and that the cover

gasket is in good condition. (No cuts, nicks etc. ).

™

to ensure its cover

■ Do not disassemble or attempt to repair any

components of the SmartBox™.

■ All component parts must be replaced if defects are

found.

■ Failure to follow this warning will result in shock,

causing injury, or death.

4. Use a soft rag to clean the exterior to prevent

dust/dirt from entering the box when opening for

D

service.

Service Instructions

1. Open the box cover and loosen the panel screws for

access to control components.

2 Disconnect the appropriate electrical leads and

remove the mounting screws for the component being

replaced.

3. For reassembly, reverse the service procedure.

Ensure all electrical connections are tight.

4. The SmartBox

checking components, you will need a volt ohm meter

cable of measuring these voltages.

™

operates on AC and DC volts. When

■ Disconnect the electrical supply before servicing the

SmartBox™.

■ Failure to follow this warning may result in electrical

shock, causing personal injury or death.

There are three 250V fuses in the box. See Fig.40.

incoming power supply.

signal conditioner to the variable rate gas solenoid

on the zone panel.

signal conditioner to the variable rate Smart Sense™

gas control valve.

: 3.0 amp fuse connected to the 120 VAC

: 3.0 amp fuse connected from the radiant

1.5 amp fuse connected from the forced air

5. DO NOT overtighten the small wiring connection

screws used on the programmable controller or the

touch pad display. Overtightening will strip threads.

Snug the screws in.

FUSES

FIG. 40

A B C

15

Page 16

Terminal Function

RELAYS

Upper transfo mer

Lower transformer

Both transformers must supply 24VAC for complete

system operation.

Two relays are mounted in the SmartBox™, each

responsible for supplying power to a maximum of

two heaters.

Upper relay: Supplies power to Zone 2 heaters.

Lower relay: Supplies power to Zone 1 heaters.

Refer to Fig. 41 and following table for connection of

wiring and voltage checks.

The relays have numbers adjacent to the male 1/4

in. male connectors for reference.

T

2 Power supply neutral

4 Neutral for heater

6 120 VAC power to heater

8 120 VAC power to relay

0 Ground for relay

1 24 VAC input for relay coil

TOUCH PAD /DISPLAY

closure (sends 115 VAC from

terminal 8 to terminal 6)

FIG. 41

ZONE 2 RELAY

2

0

4

6

1

8

ZONE 1 RELAY

2

0

4

6

1

8

The touch pad/display allows the user to set up the

SmartBox

™

for system operation, heating days,

temperature, etc.

In the event the pad is being programmed and

erratic displays are observed, or no display, the

display pad must be replaced.

Loosen the small screws securing the brown leads

to the back of the touch pad. See Fig.42.

Remove the sheet metal screws adjacent to the

front of the touch pad.

TRANSFORMERS

There are two transformers with 120 VAC input

voltages.

controller and to the radiant heater signal

conditioner.

signal conditioner for use in operating the variable

rate gas control valves.

- 24 VAC to the programmable

- 24 VAC output to the forced air

FIG. 42

FIG. 43

UPPER TRANSFORMER

LOWER TRANSFORMER

16

Page 17

The controller requires 24 VAC for operation which can

Replacement

or

If transferring the blocks with wiring intact, refer to the

following:

LED BLINK RATE

STATUS

be checked at the terminals shown in Fig 44.

(Without 24 VAC, the controller will not operate the

SmartBox

™

)

FIG. 44

LED

24 VAC INPUT FROM UPPER TRANSFORMER

The controller also includes an LED which provides

operation status. When power is applied, the LED may

appear in one of the conditions given in the following

table:

:

OFF Not applicable No power to controller,

ON ON steady

Not blinking

Very slow blink

(continuous)

Slow blink

(continuous)

1 second ON

1 second OFF

0.5 second ON

0.5 second OFF

low voltage, or controller

damaged

Controller is receiving

power but its internal

processor has

malfunctioned.

Normal operation

Sensor failure

PROGRAMMABLE CONTROLLER

a. Remove all individual wires from the terminal

blocks and reconnect to the replacement

controller

b.Remove the terminal blocks with the wiring intact

from original controller and transfer the blocks to

the replacement controller

a. Use a thin bladed screw driver to evenly raise the

block from its alignment pins on the replacement

controller.

b.Insert the screwdriver blade no more than 1/8 in. to

prevent damage to the alignment pins.

c. Insert the screwdriver blade at one end of the

terminal block and rotate the blade about 1/4

turn.

d. Move to the other end of the terminal block and

do the same. See Fig.45. Repeat the process until

the block is evenly raised about 1/4 in. from the

alignment pins.

e. Once the block has been elevated, grasp the

block at its center and carefully pull the block

straight up.

f. Complete these same steps for removal of the

blocks with wiring from the original controller.

g. Remove respective blocks from replacement

controller using this process.

h.Transfer the blocks with wiring to the replacement:

-- Position the block onto the respective

alignment pins.

-- Press straight down to firmly seat the

block.

-- Repeat the process for all blocks.

FIG. 45

This signal conditioners receives 24 VAC from the

lower transformer in the SmartBox

™

, in addition to

a 4-20 mA input signal from the programmable

controller.

The conditioner sends anywhere from 0-15 VDC to

the heater’s variable rate Smart Sense™gas

control for operation, based upon the 4-20 mA

signal supplied from the programmable controller.

See Fig.46 for reference to terminals on the

conditioner when checking voltage and connection

of wiring.

FORCED AIR SIGNAL CONDITIONER

FIG.46

24 VAC INPUT

FROM LOWER

TRANSFORMER

0-15 VDC OUTPUT

TO GAS CONTROL

4-20 mA INPUT

FROM CONTROLLER

17

Page 18

RADIANT SIGNAL CONDITIONER

This conditioner receives 24 VAC from the upper

transformer in the SmartBox™, in addition to a

4-20 mA input signal from the programmable

controller.

The conditioner then sends control signal of 0-15

VDC to the zone control panel’s variable rate

solenoid valve for operation, based upon the 4-20

mA signal supplied from the programmable

controller.

See Fig.47 for reference to terminals on the

conditioner when checking voltage and connection

of wiring.

NOT USED

4-20 mA INPUT

ROM CONTROLLER

F

GROUND

24 VAC INPUT

FROM UPPER

TRANSFORMER

FIG.47

0-15 VDC OUTPUT TO THE

PROPORTIONAL GAS

SOLENOID VALVE

18

Page 19

DO NO T SERVICE UNL ESS Y OU HAV E BEE N

PROPERLY TRAINED.

Use the green LED on the programmable c ontroller for

assistance in troubleshooting if problems occur. A blink

pattern of 1 second ON, 1 second OFF indicates normal

operation.

• Digital Multimeter

Problems Page

Sequence of Operation

spark iggnition radiant

heaters only

Troubleshooting Instructions

WARNING

Electrical Shock Hazard

READ THIS ENTIRE SECTION BEFORE

BEGINNING TO TROUBLESHOOT PROBLEMS.

■ Troubleshooting this system may require operating the

unit with line voltage present. Use extreme caution

when working on the SmartBox

™

.

■ Failure to follow this warning may result in personal

injury or death.

The troubleshooting flow charts on the following pages

provide systematic procedures for isolating problems. The

charts are intended for use by a QUALIFIED SERVICE

D

PERSON.

Components should be replaced only after each step has

been completed.

The troubleshooting flow charts pertain to forced air, and

radiant heaters, (spark and manual ignition). Unless

otherwise noted, the troubleshooting is the same for all

heaters, regardless if forced air or radiant.

TEST EQUIPMENT REQUIRED

- for measuring AC and DC voltage and

resistance.

INITIAL PREPARATION

■ Check all internal wiring for loose connections and

worn/damaged insulation.

a. 120 VAC is supplied to SmartBox™.

b. Call for heat occurs from building controller.

c. Building controller closes heating contacts

enabling SmartBox

operation.

d. 120 VAC is sent to both transformers and to both

relays.

e. Upper transformer reduces 120 VAC to 24 VAC which

is sent to the programmable controller and radiant

heat signal conditioner.

-- Green LED on blinks 1 second ON, 1 second

Off (Normal operation)

f. Lower transformer reduces the 120 VAC to 24VAC

and sends it to the forced air signal conditioners.

g. Programmable controller sends 24 VAC to both

relays.

-- 24 VAC is used to close the relay coil.

-- Relays send out 120 VAC for power supply to

heaters.

h. Programmable controller sends out 4-20 mA signal to

the signal conditioners.

i. Signal conditioners use the 4-20 mA signal to change

the received 24VAC into 0-15 VDC output (forced air)

and 0-24 VDC (radiant).

-- Forced air signal conditioner sends the 0-15

VDC to the forced air heater’s variable rate

gas control

-- Radiant signal conditioner sends the 0-24

VDC to the proportional solenoid valve.

j. Ignition of gas occurs at a specific rate.

-- Room warms to desired temperature.

k. Building controller and SmartBox

simultaneously to monitor temperature until heat

demand is satisfied.

™

operation for forced air heater

-- Forced air or

-- Heaters start the ignition cycle

™

work

Green LED on controller is steady ON

. . . . . . . . . . . . . .20

Green LED on controller is OFF. No display at touch

pad, indicator lights are out, heaters do not operate

. .20

Green LED on controller is blinking 0.5 seconds ON,

0.5 seconds OFF. Red sensor failure light is on . . . . .21

Forced air or spark ignition heaters do not start, but

zone light is ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Zone 1 forced air or Zone 2 radiant heaters do not

start. Zone 1 or 2 LED os OFF, but touch pad is

functional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Heaters start and operate properly, but zone

LED is off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Heaters in zone start, but heat output does not

change is response to SmartBox

™

setting . . . . . . . . . .22

SmartBox™ Zone 1 (forced air) does not operate

concurrently with room controller . . . . . . . . . . . . . . . .22

19

Page 20

Green LED on

programmable

controller is

steady ON

Green LED on

programmable

controller is

OFF.

No display at

touch pad, all

indicator lights

are off.

Heaters d

o not

operate.

Problem 2

Yes

Problem 1

Is

upper transformer

delivering 24 VAC to

Yes

Is upper

transformer

Yes

controller?

programmable

power fuse?

receiving 120

VAC from main

No

Verify 24 VAC between the two

yellow leads, (Terminals 10 and 6)

of the transformer. If absent,

No

needed.

Defective electrical wire or

connection. Repair or replace as

replace the transformer.

OFF and then

™

Cycle the power to the

Smart Box

controller.

steady ON, replace the

ON. If the LED remains

™

fuse in Smart Box

Is main power supply

delivering 120 VAC to

Yes

?

™

Is 120 VAC

delivered to

Smart Box

transformers?

No

No

Check breakers in building.

continuity.

by checking voltage to

and from fuse or check

Replace the fuse. Verify

Check power outlet for

Check power cord for tight

defects, corrosion, etc.

connections and continuity.

No

controller?

18 VDC from

Is touch pad receiving

controller.

controller terminals 5 and 6 (brown). If

Check for 18VDC at the programmable

present at the programmable controller,

VDC is absent, trace the wires back to the

Check across brown wires at touch pad. If 18

repair or replace wiring between the touch

pad and the programmable controller. If

absent, replace the programmable controller.

20

G

Page 21

Green LED on

programmable

controller is

blinking 0.5

seconds ON,

0.5 seconds

OFF

Red sensor

failure light is

o

n.

Problem 3

Forced air or spark

ignition radiant

heaters do not start,

zone light is ON.

Problem 4

Zone 1 forced air or

Zone 2 radiant

heaters do not start,

Zone 1 or 2 LED is

OFF. Touch pad

display is fun

ctional

Problem 5

OFF and then

™

Cycle the power to the

ON. If the LED remains in

SmartBox

this blink pattern, replace

the programmable controller.

Yes

No

Have sensors

continuity across

been checked for

the sensor leads?

Yes

sensor.

oberved, replace the

Check continuity across

sensor leads. Reading

overload or infinity is

20 k ohm. If a reading of

should be in the range of

for troubleshooting.

not functioning, there is a

at the heater but heater is

If 120 VAC is being received

fault in the heater. Refer to

the heater’s Owner’s Manual

Yes

Is 120 VAC

delivered at

heaters?

No

Yes

heaters?

out 120 VAC to

Is relay sending

Yes

Repair or replace.

outlets, and electrical

connections to the heater.

Check power supply wiring ,

No

relay is not sending 120 VAC,

from programmable controller.

If 24 VAC is present at relay, but

Ensure relay is receiving 24 VAC

replace the relay.

controller is defective.

If good, the programmable

check wiring and connections.

from programmable controller,

If 24 VAC is not received at relay

tight at

connectors

Are all sensor

secure and water

?

™

in the

SmartBox

appropriate leads

sensor leads.

™

No

corrosion, etc.

Verify proper connection of zone

Ensure good, tight connections, no

sensors to SmartBox

Press right soft key VIEW to determine

No

supply?

VAC power

power from 120

Is relay receiving

needed.

Check electrical connections,

wiring, etc. Repair or replace as

tripped circuit breaker, defective

FORCED AIR HEATERS ONLY

Verify room controller is calling for heat

which sensor (T1 or T2) is inoperative.

the touch pad.

FORCED AIR AND RADIANT: Verify

temperature set-point for the zone, using

21

Page 22

Heaters start but

heat ouptut does

not change in

response to

SmartBox

™

setting.

Problem 7

Radiant heaters:

Forced Air Heaters:

Radiant Heaters

Forced Air

Radiant:

SmartBox

™

Zone 1

(forced air) does not

operate concurrently

with room controller.

Problem 8

Heaters start

and operate

properly, but

zone light is

OFF

Problem 6

Check for

gas supply

blockages in

Yes

proportional valve

receiving 1-15 VDC

the radiant heater’s

Is the Smart Sense™

forced air gas valve or

Yes

™

continuity?

the SmartBox

Have the variable

been checked for

rate output fuses of

from fuse?

No

for the specific heater to a

™

higher temperature (at least 10F) over room

temperature.

A. Set the SmartBox

No

defective, replace.

Check the fuses. If

Measure across terminals at

: Loosen the proportional gas

valve to obtain reading

B. Verify increase in VDC to gas valve.

valve’s housing screw and pull back the connector

block sufficiently to allow voltage meter probes to

be inserted at the valve terminals.

: Terminals 3 and 4 (brown wires)

Terminals 10 and 11 (blue wires).

C. If no increase in VDC (should be 13-15 VDC) at

gas control, then check the output at the

respective signal conditioner terminals:

If 13-15 VDC is measured at output but not at

valve, check all wiring and terminals between

the signal conditioner and variable rate valve.

D. If no reading is given at the output of the forced

air or radiant signal conditioner, then the signal

conditioner for that zone of heaters is defective

and must be replaced.

LED.

absent, repair wiring

between controller and

If present replace LED. If

Verify 24 VDC to zone LED.

controller and LED.

between programmable

Zone LED is defective or

poor electrical connecton

™

sensors

Are SmartBox

Yes

Are sensors

Yes

sensors?

same height as

the room control

positioned to the

properly?

positioned

No

No

Reposition the sensors. Refer

cold spots, etc.

away from drafts, air inlets,

Ensure all sensors are located

to sensor location

instructions in this manual.

Ensure the

radiant sensor bracket is

installed and that the sensor

to 3/16 in. from the end of

is located properly within its

housing. It should be 1/8 in.

and inside the sensor housing.

and the

™

Check temperature curve for

both the SmartBox

room controller. Verify the

temperatures match.

22

Page 23

Warranty Policy

L.B. White Co., Inc. warrants that the component parts are

free from defects in material and workmanship, when

properly installed, operated, and maintained in accordance

with the Installation and Maintenance Instructions, safety

guides and labels contained with each unit. If, within 12

months from the date of purchase by the end user, any

component is found to be defective, L.B. White Co., Inc. will

at its option, repair or replace the defective part or heater,

with a new part or heater, F.O.B., Onalaska, Wisconsin.

L.B. White Co., Inc. warrants that replacement parts

purchased from the company and used on the appropriate

L. B. White equipment are free from defects both in material

and workmanship for 12 months from the date of

purchase by the end user. Warranty is automatic if a

component is found defective within 12 months of the date

code marked on the part. If the defect occurs more than 12

months later than the date code but within 12 months from

the date of purchase by the end user, a copy of a bill of sale

will be required to establish warranty qualification.

The warranty set forth above is the exclusive warranty

provided by L.B. White, and all other warranties, including

any implied warranties or merchantability or fitness for a

particular purpose, are expressly disclaimed. In the event

any implied warranty is not hereby effectively disclaimed

due to operation of law, such implied warranty is limited in

Smart Box

A warranty card on file at L.B. White will automatically

qualify a unit and its component parts for warranty

consideration. If a warranty card is not on file, a copy of the

bill of sale will be required to establish warranty

qualification. If neither is available, the warranty period will

be 12 months from date of shipment from L B. White.

™

Parts

duration to the duration of the applicable warranty stated

above. The remedies set forth above are the sole and

exclusive remedies available hereunder. L.B. White will not

be liable for any incidental or consequential damages

directly or indirectly related to the sale, handling or use of

the equipment, and in any event L.B. White's liability in

connection with the equipment, including for claims based

on negligence or strict liability, is limited to the purchase

price.

Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to you.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty

gives you specific legal rights, and you may also have other

rights which vary from state to state.

Contact your local L.B. White dealer for replacement parts

and service or call the L.B. White Co., Inc. at 1-800-345-7200

for assistance. Be sure that you have your model number

and serial number when calling.

Replacement Parts and Service

23

Loading...

Loading...