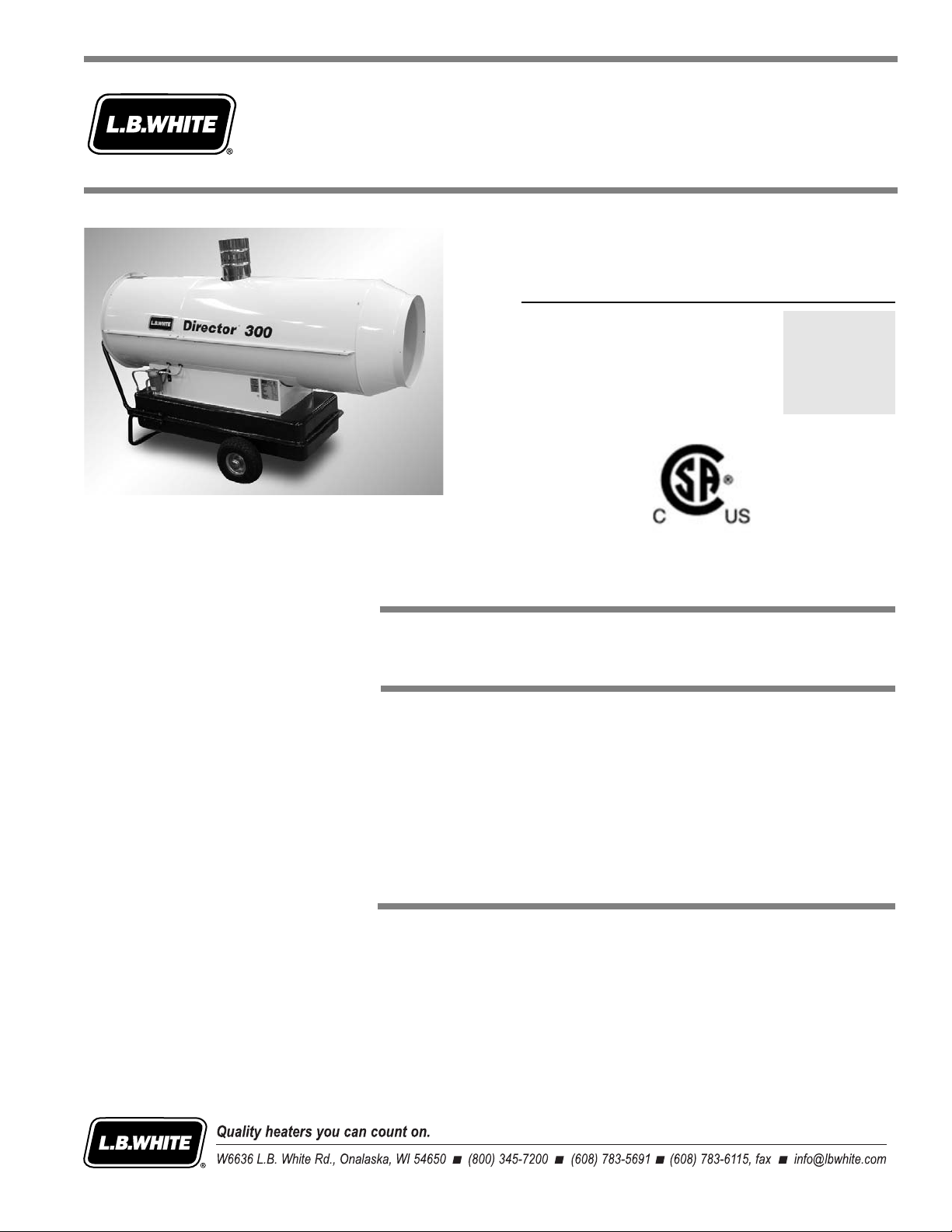

L.B. White 300 User Manual

Kerosene

#1, #2 Diesel/

Fuel Oil,

JP-8 or Jet A

Congratulations!

You have purchased the finest indirect fired construction heater available.

Your new L.B. White heater incorporates the benefits from the most experienced

manufacturer of heating products using state-of-the-art technology.

We, at L.B. White, thank you for your confidence in our products and

welcome any suggestions or comments you may have...call us, toll-free,

at (800) 345-7200.

Owner's Manual and Instructions

Director

™

Construction Heater

150-28136

MODELS OUTPUT (Btuh) FUEL

CP300CKI 258,700

This heater has been tested and evaluated by C.S.A. International in accordance with

the requirements of Standard UL 733 and ANSI A10.10-1990, CAN/CSA B140.0-03

and CSA B140.8-1967 and is listed and approved as a ductable, indirect fired

Kerosene forced air construction heater with application for the temporary heating of

buildings under construction, alteration, or repair.

If you are considering using this heater for any application other than its intended use,

then please contact L.B. White Co.

GENERAL HAZARD WARNING

■ Failure to comply with the precautions and instructions provided with this heater, can result in:

— Death

— Serious bodily injury or burns

— Property damage or loss from fire or explosion

— Electrical shock

■ Read this Owner’s Manual before installing or using this product.

■ Only properly-trained service people should repair or install this heater.

■ Save this Owner’s Manual for future use and reference.

■ Owner’s Manuals and replacement labels are available at no charge. For assistance, contact

L.B. White at 800-345-7200.

WARNING

Fire and Explosion Hazard

■ Not for home or recreational vehicle use.

■ Installation of this heater in a home or

recreational vehicle may result in a fire or

explosion.

■ Fire or explosions can cause property

damage or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of

this or any other appliance.

2

WARNING

Fire and Explosion Hazard

■ Keep solid combustibles a safe distance

away from the heater.

■ Solid combustibles include wood, paper, or

plastic products, building materials and

dust.

■ Do not use the heater in spaces which

contain or may contain volatile or airborne

combustibles.

■ Volatile or airborne combustibles include

gasoline, solvents, paint thinner, dust

particles or unknown chemicals.

■ Failure to follow these instructions may

result in a fire or explosion.

■ Fire or explosions can lead to property

damage, personal injury or loss of life.

Table of Contents

3

General Information

This Owner's Manual includes all options and accessories

commonly used on this heater.

When calling for technical service assistance, or for other

specific information, always have model number,

configuration number and serial number available. This

information is contained on the dataplate.

This manual will instruct you in the operation and care of

your unit. Have your qualified installer review this manual

with you so that you fully understand the heater and how it

functions.

The installation, repair and servicing of the heater requires

continuing expert training and knowledge of gas heaters

and should not be attempted by anyone who is not so

qualified. See page 6 for definition of the necessary

qualifications.

Contact your local L.B. White distributor or the L.B. White

Co., Inc. for assistance, or if you have any questions about

the use of the equipment or its application.

The L.B. White Co., Inc. has a policy of continuous product

improvement. It reserves the right to change specifications

and design without notice.

SECTION

PAGE

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Heater Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Operation Instructions

Basics of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Fuels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Connecting Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Start-Up Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Shut-Down Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Re-set Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Cleaning and Storage Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Service Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Burner Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

High Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Setting for High Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Fan and Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Photocell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Igniters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Air Pressure Switch and Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Fuel Filter and Heating Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Electrical Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Heater Component Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Parts Identification

Parts Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24 & 25

Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Replacement Parts and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

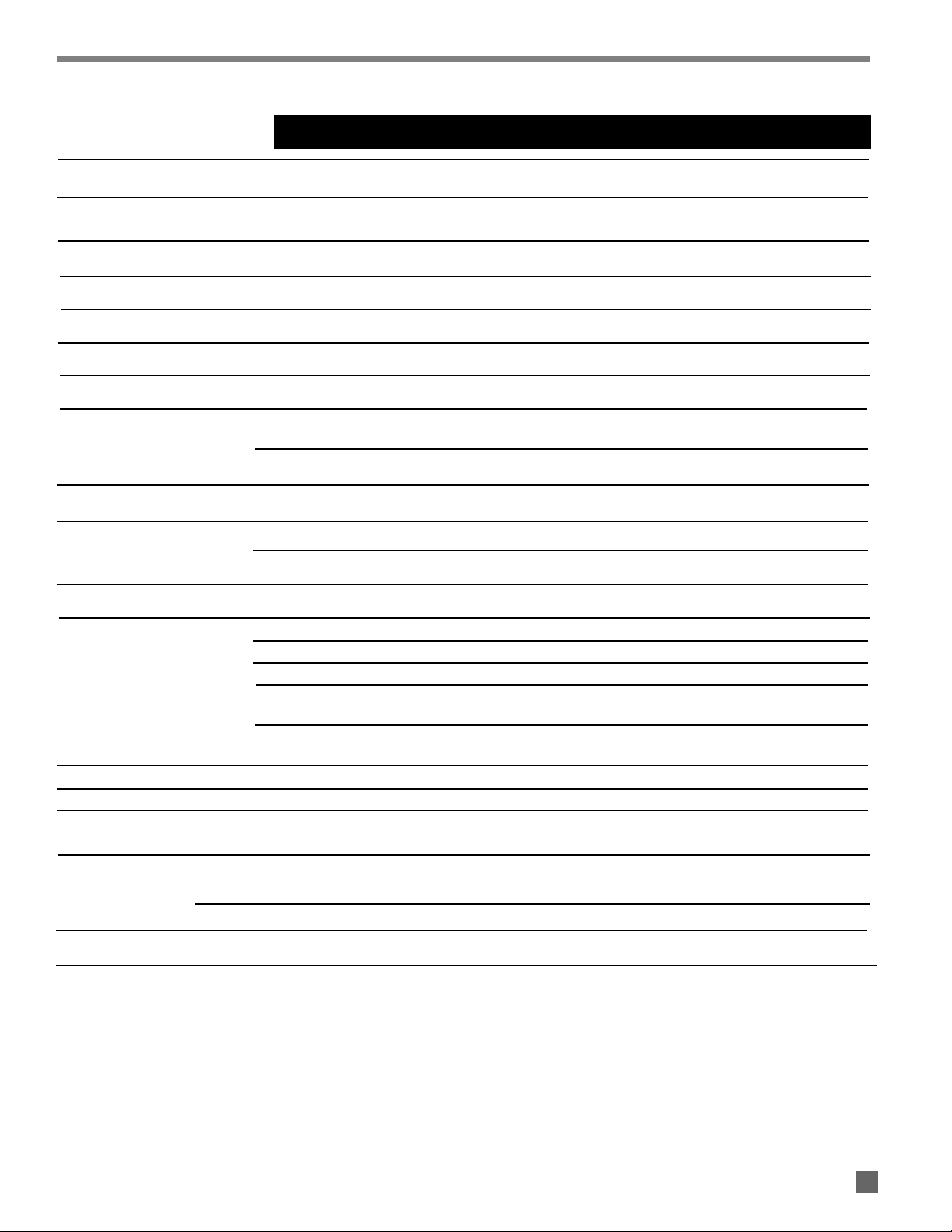

Duct Diameter and Maximum Length

Using 1 way Adapter 16 in. x 75 ft.

Using 2 way Adapter 2 - 12 in. x 35 ft

Model

Heater Specifications

4

Temperature Rise at 67F. 126 F.

SPECIFICATIONS

Fuel Type

Max Input (BTUH) 294,000

Net Output (BTUH) 258,700

Air Flow (Hot) CFM 2,500

Pump Pressure , (PSI) 232

Fuel Tank Capacity (gal.) / Fuel Consumption per Hour (gal.) 27.7/ 2.17

Motor Characteristics

Electrical Supply (Volts/Hz/Phase)

STARTING

Amp Draw

Dimensions (Inches)

L x W x H (w/o wheels )

Minimum Safe

Distances From

Nearest

Combustible

Materials

Net Weight (lbs.)

Shipping Weight (lbs.)

Minimum Ambient Temperature

in Which Heater May Be Used

CONTINUOUS

OPERATION

EXHAUST OUTLET TOP 8 FT

SIDES 3 ft. 10 in.

BACK 3 ft. 10 in.

BLOWER

OUTLET

BULK FUEL

STORAGE CONTAINER

Kerosene, #1 #2 Diesel/Fuel Oil, JP-8, Jet A

CP300CKI

Ball Bearing

1 H.P. / 1,750 RPM

115/60/1

28.4

6.5

65 x 22 1/4 x 34 1/2

10 ft.

25

297

352

- 20ºF

5

Safety Precautions

1. Do not attempt to install, repair, or service this heater

unless you have continuing expert training and

knowledge of liquid fuel heaters.

Qualifications for service and installation of this

equipment are as follows:

To be a qualified liquid fuel heater service person, you

must have sufficient training and experience to handle

all aspects of indirect fired liquid fuel heater

installation, service and repair. This includes the task

of installation, troubleshooting, replacement of

defective parts and testing of the heater. You must be

able to place the heater into a continuing safe and

normal operating condition. You must completely

familiarize yourself with the heater by reading and

complying with the safety instructions, labels, Owner’s

Manual, etc., that is provided with each heater.

2. All installations and applications of L.B. White heaters

must meet all relevant local, state and national

codes. Included are electrical and safety codes. Your

local fuel supplier, a local licensed electrician, the

local fire department or similar government agencies,

or your insurance agent can help you determine code

requirements.

Refer to the following:

-- ANSI/NFPA 70, National Electrical Code.

-- ANSI A10.0, 1990 Latest Edition Safety

Requirements for Temporary and Portable Space

Heating Devices and Equipment Used in

Construction Industry.

3. The area surrounding the heater shall be kept clear

and free from combustible materials, gasoline, and

other flammable vapors and liquids.

4. We cannot anticipate every use which maybe made of

our heaters. Check with the local fire safety authority

if you have questions about applications.

5. For safety, this heater is equipped with fan and high

limit switches. Never operate the heater with any

safety device that has been bypassed. Do not

operate this heater unless these features are fully

functioning.

6. Do not locate fuel containers near the blower outlet of

the heater.

7. Do not block air intakes or discharge outlets of the

heater. Doing so may cause improper combustion or

damage to heater components leading to property

damage.

8. Check for fuel leaks and proper function upon heater

installation, when relocating, and after servicing.

9. This heater should be inspected for proper operation

by a qualified service person before each use, not

less than once per shift, and at least annually.

10. This heater is equipped with a three-prong

(grounding) plug for your protection against shock

hazard and must be plugged directly into a properly

grounded three-prong receptacle. Failure to use a

properly grounded receptacle can result in electrical

shock, personal injury, or death.

11. Read and understand all warnings. Keep this manual

for reference. It is your guide to safe and proper

operation of this heater.

12. Use only the recommended fuels to avoid risk of fire

or explosion. Never use gasoline, naptha, paint

thinners, alcohol, or other highly flammable fuels.

13. Fueling:

a) Personnel involved with fueling shall be

qualified and thoroughly familiar with the

manufacturer’s instructions and applicable

regulations regarding the safe fueling of heating

units.

b) Use only the type of fuel specified within the

manual.

c) All flame shall be extinguished and the heater

allowed to cool prior to fueling.

d) During fueling, all fuel lines and fuel-line

connections shall be inspected for leaks. Any leaks

shall be repaired prior to returning the heater to

service.

e) At no time shall more than one day’s supply of

heater fuel be stored inside a building in the vicinity

of the heater. Bulk fuel storage shall be outside

the structure.

f) All fuel storage shall be located a minimum of 25

feet from heaters, torches, welding equipment, and

similar sources of ignition (exception: the fuel

reservoir integral with the heater unit).

g) Whenever possible, fuel storage shall be confined

to areas where floor penetrations do not permit

fuel to drip onto or be ignited by a fire at lower

elevation.

h) Fuel storage shall be in accordance with the

authority having jurisdiction.

i) Fuel storage shall not be permitted within 10 ft. of

floor penetrations used for vertical access unless

separated from the penetration by full masonry

height walls.

14. Use only in areas free of flammable vapors or high

dust content.

15. Locate heater on a stable and level surface while hot

or operating.

16. Never start heater if fuel has accumulated in

combustion chamber.

17. Heater may start at any time when used with

thermostat.

1. Read all safety precautions and follow L. B. White

recommendations when installing this heater. If

during the installation or relocating of heater, you

suspect that a part is damaged or defective, call a

qualified service agency for repair or replacement.

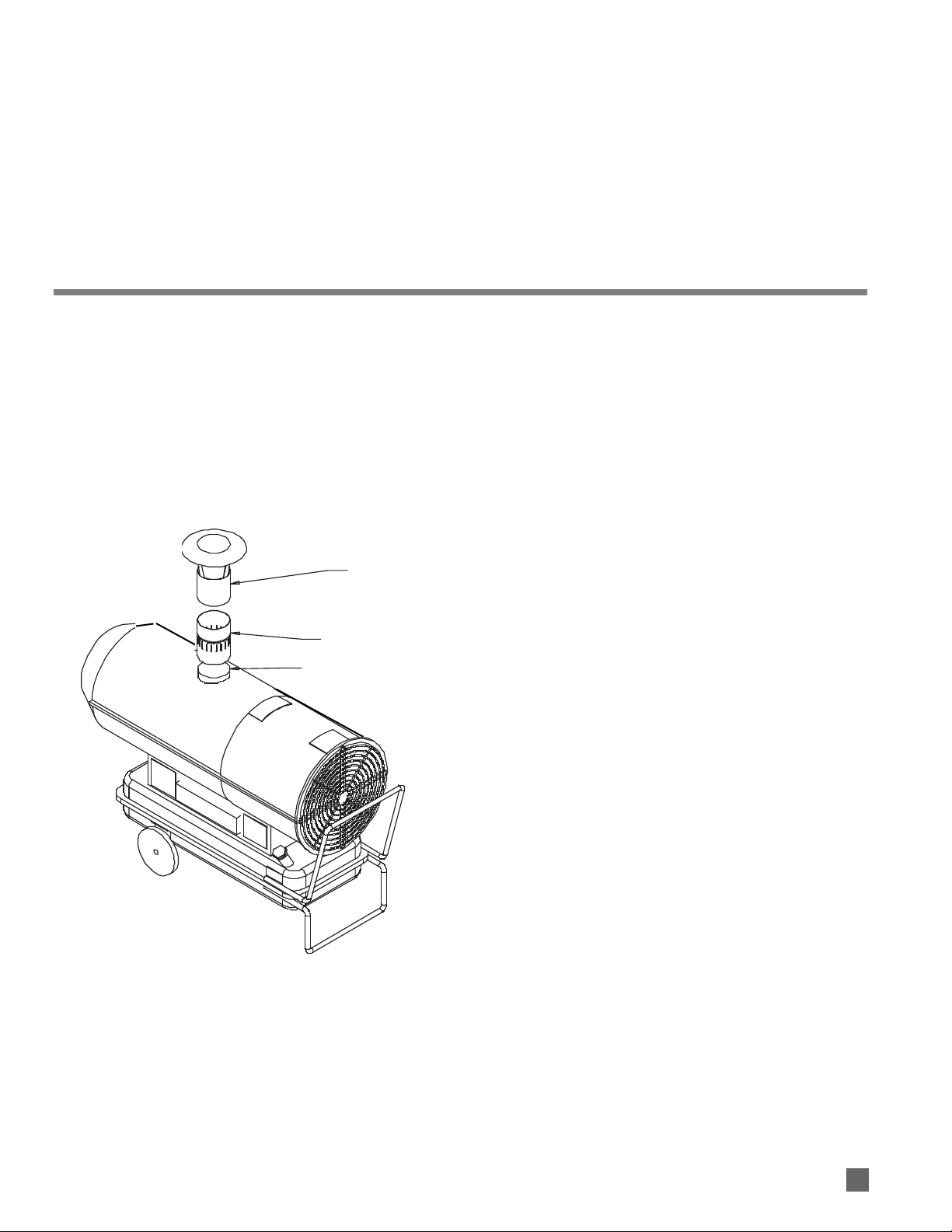

2. Install chimney, Part #24311 onto exhaust outlet.

Install raincap, Part #24223 (optional accessory)

onto chimney to protect against water entry when

heater is installed outside. See Fig. 1.

FIG. 1

3. This heater may be installed either indoors or

outdoors. For indoor installations, the heater must

be vented to outside. See Figs. 2 & 3 on page 7 for

chimney set-up and installation.

4. The heater may be ducted. Use only 20 ft. flexible

duct, part #24220, and duct adapter, part #26986.

Both parts are optional accessories. Do not use any

other length of duct, field fabricated ducts, or

adapters, stove pipes, etc. Locate the duct under

suitable wind barrier materials for jobsite

requirements.

5. When installed indoors, proper ventilation air must be

supplied to support the combustion of the heater.

Refer to Pg. 4 of this Owner’s Manual, or heater’s

dataplate for ventilation air requirements.

6. Insure all heater accessories have been installed.

7. The heater must be installed so as not to interfere

with or obstruct normal exits, emergency exits, doors

and walkways.

8. Railing, fencing or suitable substitute materials must

be used to keep the heating equipment from any

people using and visiting the structure.

9. The unit shall be located so that rain, ice, or snow

drainage from the structure does not affect

equipment operation. The heater must be mounted

above any pooled or standing water. A surrounding

trench is recommended to drain any rain, ice or snow

away from the unit.

10. The ground and surrounding terrain must be cleared

of any combustible vegetation and other combustible

materials when the heater is used.

11. Eventually, like all electrical/mechanical devices, the

thermostat can fail. Thermostat failure may result in

an underheating condition. The thermostat should be

tested to make sure it turns the heater on and off

within a temperature differential of ±3°F.

12. Take time to understand how to operate and maintain

the heater by using this Owner’s Manual. Make sure

you know how to shut off the power supply to the

heater.

13. Any defects found in performing any of the service or

maintenance procedures must be eliminated and

defective parts replaced immediately. The heater

must be retested by properly qualified service

personnel before placing the heater back into use.

EXTENSION CORD WIRE SIZE REQUIREMENTS

FOR DIRECTOR 300

■ 6 to 100 ft. long, use 14 AWG rated cord

■ 101 to 200 ft. long, use 12 AWG rated cord

■ 201 to 300 ft. long, use 10 AWG rated cord

18. When heater is moved or stored, it must be in a level

position or fuel spillage may occur.

19. Never move, handle, refuel, or service a hot,

operating, or plugged-in heater.

20. Never attach duct work to rear of heater.

21. Follow all local codes if connecting the heater to an

external fuel source.

22. Heaters used in the vicinity of tarpaulins, canvas, or

similar enclosure materials shall be located in safe

distance from such materials. The recommended

minimum safe distance is 10 ft. It is further

recommended that these enclosure materials be of a

fire retardant nature. These enclosure materials

shall be securely fastened to prevent them from

igniting or from upsetting the heater due to wind

action.

23. Unplug heater when not in use.

24. When the heater is used in an enclosed or partially

enclosed permanent or temporary structure, tests for

the presence of carbon monoxide shall be made

within one hour after the start of each shift, and at

least four hours thereafter. Immediate, more

frequent testing may be dictated by job conditions.

Installation Instructions

6

CHIMNEY

EXHAUST OUTLET

CHIMNEY

EXHAUST OUTLET

RAIN CAP

7

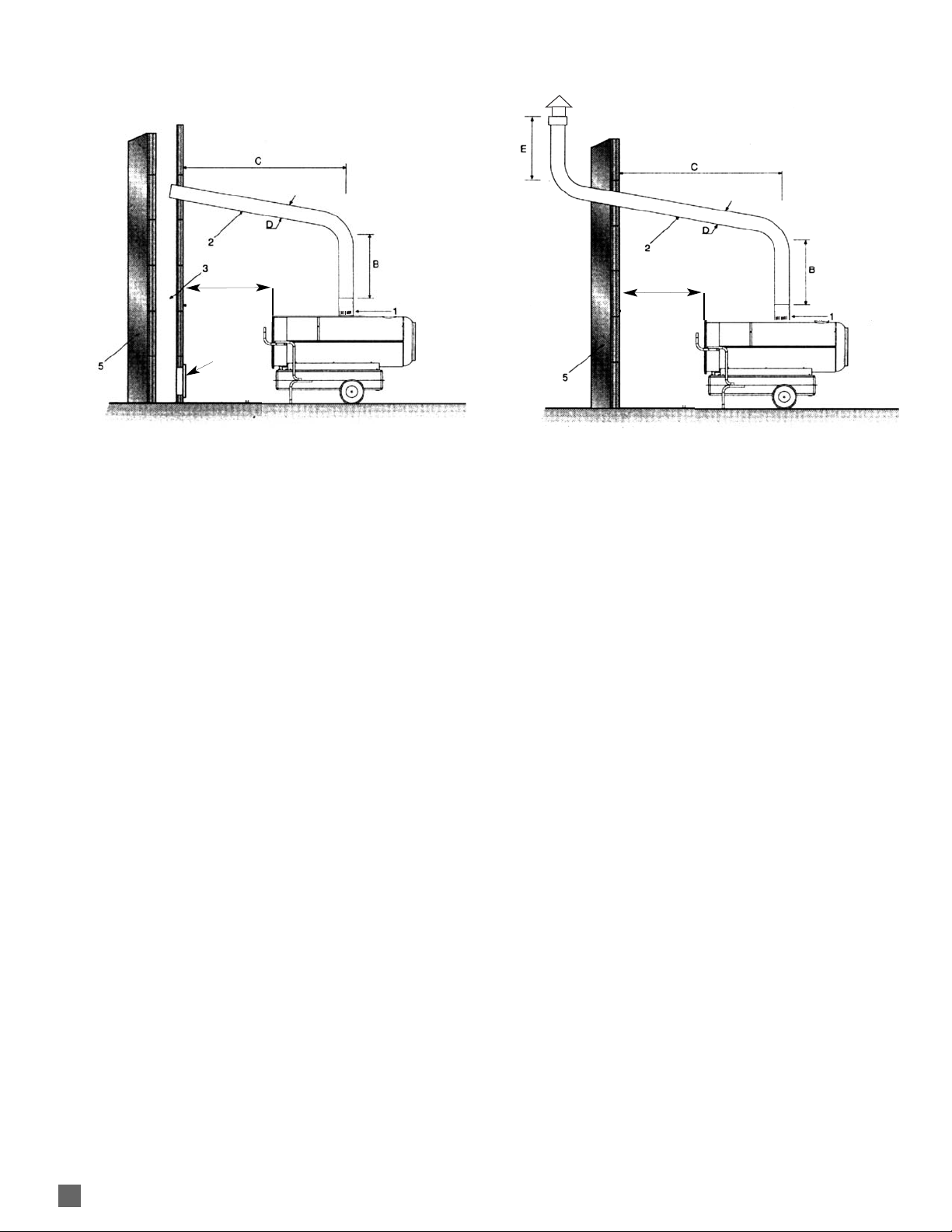

FIG. 3 VENTING TO OUTSIDE THROUGH WALL

FIG. 2 VENTING TO EXISTING CHIMNEY

A) Minimal 3 ft.

B) Minimal 3 ft.

C) The shortest

D) The same or bigger than the stacks outlet

diameter

E) Minimal 3 ft.

1) Anti-wind device provided

with the heater

2) Horizontal crossing with minimal upside angle pitch of 5º

3) Chimney 8 in. x 8 in. of minimal inside measure

4) Chimney anti-explosion flap door

5) External seating wall

Note: The above information is a recommendation only. Have

your installation checked by local authority.

A

A

4

8

THE FUEL SYSTEM

The motor turns the fuel pump. The fuel pump pulls fuel

from the fuel tank. The fuel pump pushes fuel through a

filter and a solenoid valve and out the burner head nozzle.

A fine mist of fuel is sprayed into the combustion chamber.

THE AIR SYSTEM

The motor turns the fan while at the same time operating

the pump. The fan creates air pressure, closing the air

pressure switch, which delivers power to the solenoid for

supply of fuel to the burner nozzle.

Additionally, the fan is also responsible for pushing the air

into and around the combustion chamber. This air is

heated and provides a stream of clean, dry, hot air.

THE IGNITION SYSTEM

The electronic ignitor sends voltage to the spark plug. The

spark plug ignites the fuel and air mixture.

THE FLAME-OUT CONTROL SYSTEM

This system causes the heater to shut down if the flame

goes out. It also allows the fan to continue running after

normal shutdown of heater. This cools the combustion

chamber.

Operation Instructions

BASICS OF OPERATION

Heavier fuels such as #1, #2 Diesel, JP-8, opr Jet A may be

used. Using heavier fuels other than kersoene may result in

in:

■ Clogged fuel filter and nozzle

■ Carbon build-up on spark plug

■ Dark smoke from stack

■ The need of non-toxic anti-icer in fuel during very

cold weather.

Use a KEROSENE ONLY storage container. Be sure storage

container is clean. Foreign matter such as rust, dirt, or

water will cause flame-out control to shut down heater.

Foreign matter may also require you to clean fuel system

often.

FUELS

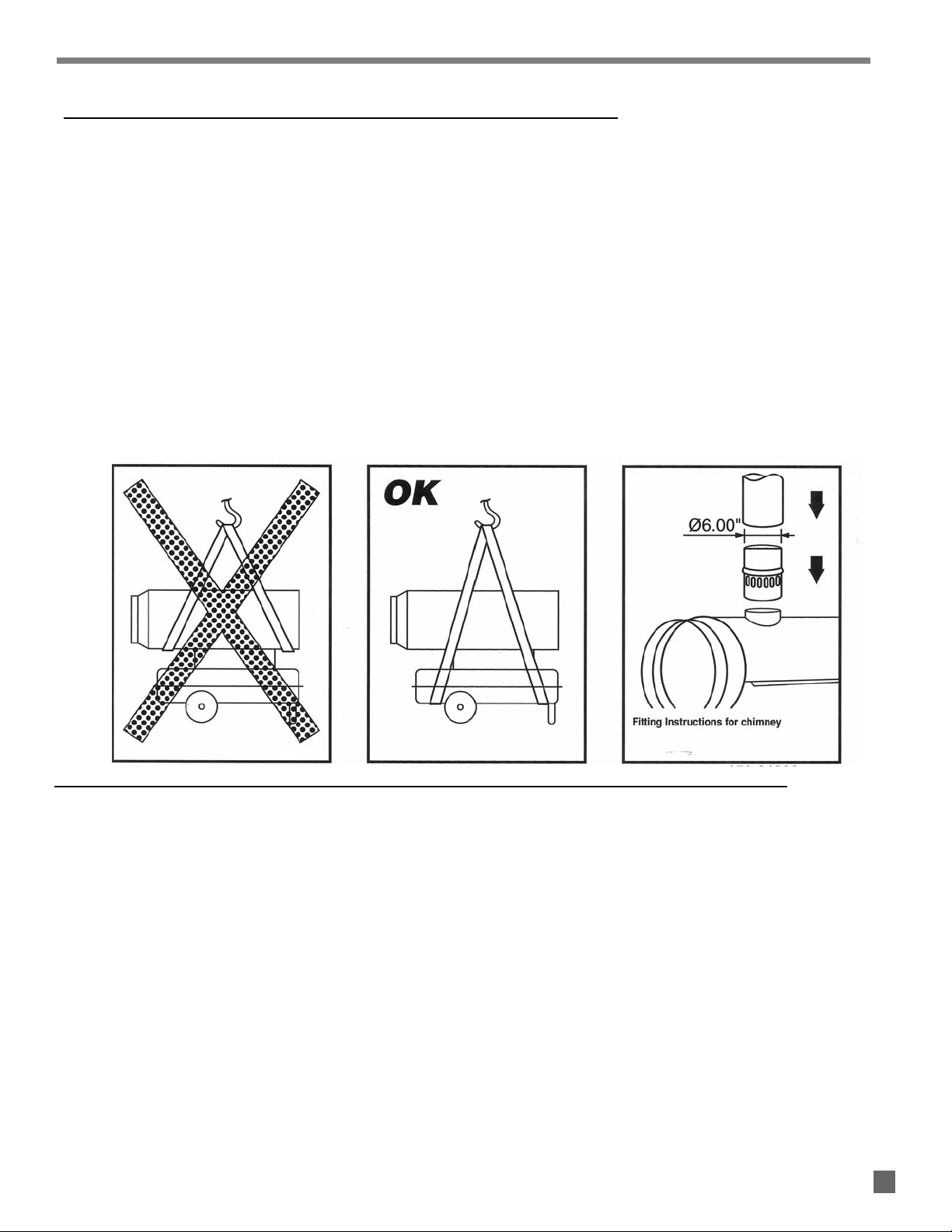

FIG. 4 Handling instructions

Loading...

Loading...