LBC Bakery Equipment LRO-2G Manual

Item No.

Project

Quantity

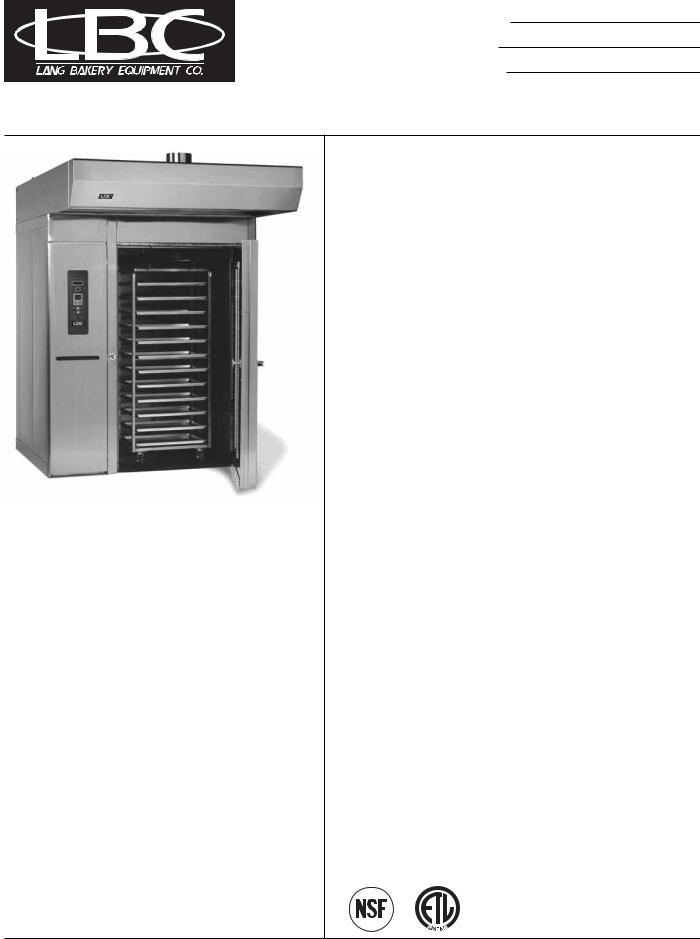

BakerSeries® Gas, Roll-In Rotating [Double] Rack Oven

Model: LRO-2G

Model LRO-2G

PAN/PRODUCTION CAPACITY GUIDE

Maximum Capacity |

LRO-2G |

18” x 26” Full-Sheet Pans* |

40 |

12” x 20” x 4” Hotel Pans** |

40 |

1 lb. Loaves of Bread |

200 |

1-1/2 lb. Loves of Bread |

150 |

*3” spacing

**6” spacing

SHORT/BID SPECIFICATION

Rack Oven shall be Lang Bakery Equipment Co. Model LRO-2G

290,000 BTU/hr. gas heated rotating double rack unit with: Vertiflow® stainless steel tube heat exchanger; gravity feed, waterfall type steam generation system, 5” thick compartment insulation and 0” combustible wall clearance; heavy duty rack lift and rotation

system; simple solid-state controls, with digital time-temperature readout, 10 hour cook cycle and five stage programming capability; an integrated ventilation hood meeting NFPA 96 and Type I & II UMC construction standards, plus all the features listed:

STANDARD PRODUCT WARRANTY

One year, parts & labor

CONSTRUCTION FEATURES

•Heavy duty 300 Series stainless steel interior and exterior

•VertiFlow® vertical stainless steel tube heat exchanger

•Cooking compartment insulated with 5” thick high-temp insulation

•Fully integrated ventilation hood assembly, with single point exhaust connection

•Automatic heavy duty rack lift and rotation system

•Cooking chamber illuminated by externally mounted florescent lamp

•Heavy duty door with single pane 9.75” X 57.5” viewing window

•Interior safety door release mechanism

•Accommodates two standard side-load, two end-load or one double side-load rack

PERFORMANCE FEATURES

•Heat Exchanger provides high heat transfer efficiency and quick temperature recovery

•VertiFlow System uses natural draft effect for air intake & exhaust, eliminating need for blowers, motors and airflow switches

•200-550˚F cooking temperature range

•Steam system uses large 520-lb. thermal mass gravity feed waterfall. No nozzles or orifices to clog.

•Rotating rack and even heat distribution ensure uniform baking and browning

•Self-adjusting slip clutch on rotating system protects operator and oven from damage and automatically stops rack in unloading position

INTEGRATED HOOD FEATURES AND PERFORMANCE

•Integrated hood meets NFPA 96 & Uniform Mechanical Code requirements for Type I & Type II Construction

•20 gauge stainless steel body

•Hood provides 5.9 square feet of effective filter area, with filter velocity of 120 FPM, .03” wc at 800 CFM

•Single point 8” round vent duct, velocity: 2,300 FPM at 800 CFM

CONTROL PACKAGE

•Rack lift & rotation system activates automatically, when door is closed

•Simple digital TIME & TEMP displays

•Programmable for temperature, time, steam, blower delay, vent, cycling steam and cycling blower

•Easy direct manual operation

•STOP, START, Vent & Fan touch pads

®

C |

US |

Sheet No. LSP-RR2 (rev. 10/05) |

|

|

LANG BAKERY EQUIPMENT COMPANY • 6500 Merrill Creek Parkway, Everett, WA 98203 TOLL FREE: 888-RACKOVN (888-722-5686) • FAX: 866-947-0122 • www.langbakery.com

Loading...

Loading...