LAVAZZA LB 2300, LB 2301, LB 2312, LB 2302, LB 2311 Maintenance Manual For Technical Assistance

LB 2300-2301-2302-2311-2312

MAINTENANCE MANUAL FOR

TECHNICAL ASSISTANCE

MAN UAL COD E 10083445 / REL. 0.00 / APRIL 20 10

L

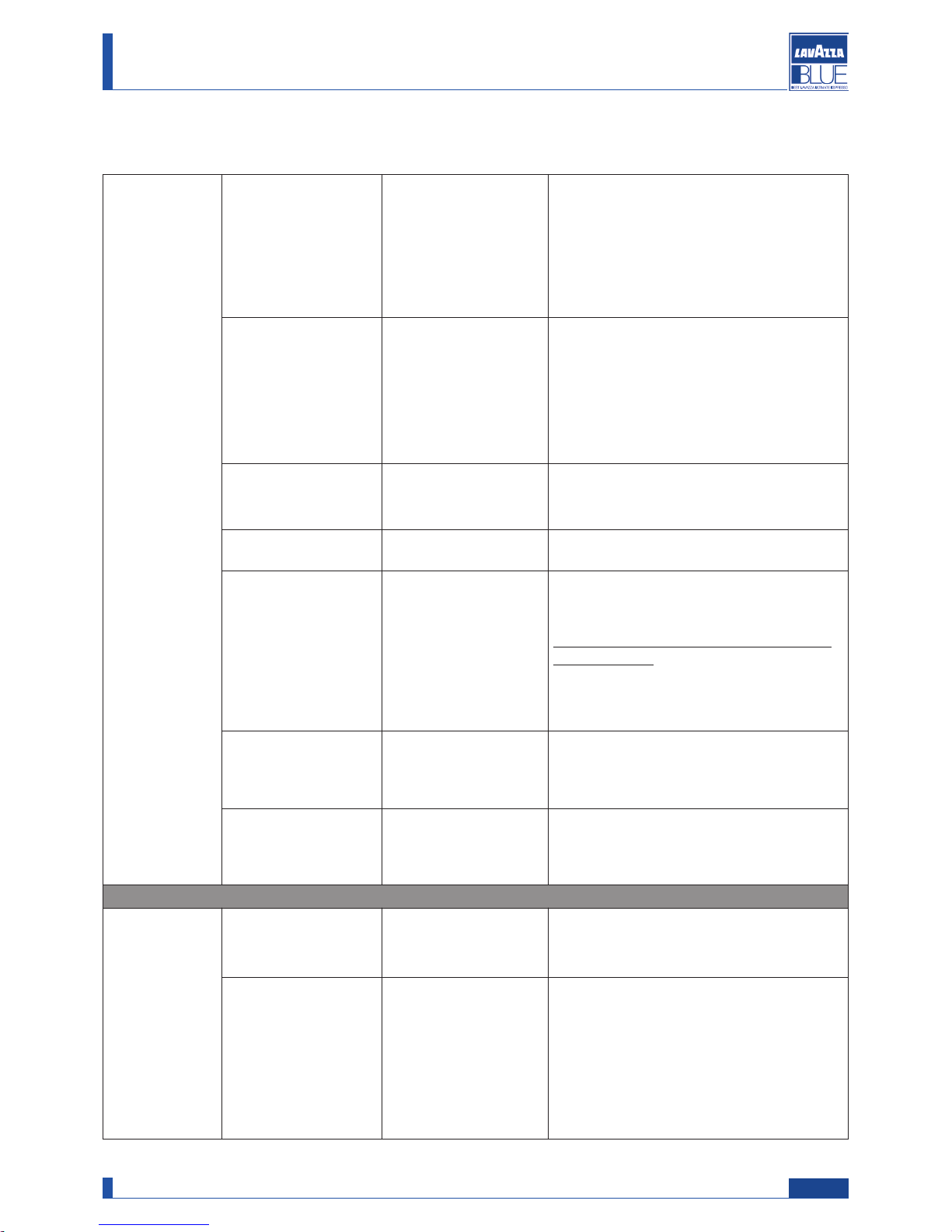

B 2300 Single cup 230 V

Machine code

10080606

LB 2301 Single cup

230 V Steam

Machine code

10080618

LB 2302 Double cup

230 V Steam

Machine code

10080712

LB 2311 Single cup

120 V Steam

Machine code

10080631

LB 2312 Double cup

120 V Steam

Machine code

10080632

Manual code

10083445

Rel. 0.00

Edition 04/2010

© Copyright LAVAZZA S.p.A.

Tel. 0 03 9. 01 1. 23 98429

Fax 003 9.01 1.23980466

technicalservi ce@la vazza .it

Certificated n° IT09/0445

Index

1. GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1. Designated personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2. Structure of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2.1. Scope and content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2.2. Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2.3. Preservation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2.4. Messages used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2.5. Machine composition . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.6. Internal components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.7. Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.8. Machine identification data . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.9. Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.10. Overall dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.11. List of the accessories supplied with the machine . . . . . 5

2. GENERAL SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1. Stop functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2. Safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3. Residual risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2. Mounting-Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3. Machine positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4. HANDLING AND STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1. Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2. Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5. DISMANTLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

I

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

I

6

. USER MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6

.1. Machine warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6

.2. Machine programming (service provider) . . . . . . . . . . . . 14

6

.3. Programming commands . . . . . . . . . . . . . . . . . . . . . . . . 15

6.4. Table of programming menu . . . . . . . . . . . . . . . . . . . . . . 16

6.5. Table of service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.6. Parameter change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.7 Exiting programming mode . . . . . . . . . . . . . . . . . . . . . . . .21

7. DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

7.1. Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.2. Hydraulic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.1. Test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.2 Access to test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.3. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9. OPERATIONAL LOGIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.1. Reset of used capsule drawer . . . . . . . . . . . . . . . . . . . . . 35

9.2. Reserve for product end . . . . . . . . . . . . . . . . . . . . . . . . . 35

10. RECOMMENDED TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

11. MOUNTING AND DISASSEMBLY OF THE MACHINE

COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

11.1. Upper body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11.2 GACO gasket replacement . . . . . . . . . . . . . . . . . . . . . . . 41

11.3. Power cord replacement . . . . . . . . . . . . . . . . . . . . . . . . . 42

11.4. Connector compartment . . . . . . . . . . . . . . . . . . . . . . . . . 43

11.5. Steam pipe disassembly . . . . . . . . . . . . . . . . . . . . . . . . . 44

11.6. Steam solenoid valve disassembly . . . . . . . . . . . . . . . . . 44

11.7. Cup warmer plate disassembly . . . . . . . . . . . . . . . . . . . . 46

11.8. Capsule release coil disassembly . . . . . . . . . . . . . . . . . . 47

II

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

III

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

1

1.9. Pump disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

1

1.10. Turbine disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1

1.11. Capsule release unit disassembly . . . . . . . . . . . . . . . . . . 50

1

1.12. Capacitive sensor disassembly . . . . . . . . . . . . . . . . . . . . 52

11.13. Transformer disassembly . . . . . . . . . . . . . . . . . . . . . . . . . 53

11.14. Coffee thermostat disassembly . . . . . . . . . . . . . . . . . . . . 55

11.15. Boiler disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

11.16. Gear motor disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . 57

11.17. Perforator filter disassembly . . . . . . . . . . . . . . . . . . . . . . . 58

11.18. POWER board disassembly . . . . . . . . . . . . . . . . . . . . . . . 63

11.19. CPU board disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.20. Keyboard board disassembly . . . . . . . . . . . . . . . . . . . . . . 64

11.21. Display disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

11.22. Assembly and removal of the OETIKER clamps . . . . . . . 66

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

Manual code 10083445 / Rel. 0.00 / April 2010

1. GENERAL INFORMATION

1.1. Designated personnel

The machine may be operated only by a qualified technician who has read this manual and, moreover who:

- is able to carry out repairs in case of serious malfunc

tion and who has read this manual and all the infor-

mation relative to safety;

- is able to understand the entire contents of the

manual and to correctly interpret the drawings and

diagrams;

- has knowledge of the appropriate hygiene, workplace safety, technology and security measures;

- has specific experience in the maintenance of vending machines;

- knows how to act in an emergency, where to find the

personal protective equipment and knows how to

use it.

Attention

Before any operation is carried out on the machine, the qualified technician must carefully read

the instructions contained in this publication.

If there is any doubt about the correct interpretation of

the instructions, contact the manufacturer to obtain the

necessary clarification.

1.2.2. Users

This manual is designed for technicians qualified for

the maintenance of the machine.

Attention

The ATTENTION messages indicate a danger,

possibly lethal, for the technician. The operations

described after this message must be carried out

carefully and safely using the personal protective

equipment.

Warning

The WARNING messages are displayed before procedures that, if not observed, could cause damage

to the machine..

Warning

If this manual is damaged or lost, a new copy

should be immediately requested from the manufacturer or authorised distributor of the country

where the machine is used.

1.2.4. Messages used

Environment

The ENVIRONMENT messages are displayed before procedures that, if not observed, could cause

damage to the environment..

Attention

The use of the machine by personnel without the

prerequisites needed is prohibited.

1.2. Structure of the manual

The technician must carefully read the information in

this manual.

1.2.1. Scope and content

This manual can provide the technician with all the

information necessary for the maintenance of the

machine.

Attention

The undertaking of any operation on the machine,

without having read and understood the contents

of this manual is prohibited.

The manufacturer is not responsible for damage derived from the failure to follow this rule.

1

.2.3. Preservation

In order to be able to guarantee the integrity and utility

of this manual the following guidelines should be

observed:

- employ this manual in such a way that it remains

undamaged and whole;

- do not for any reason, remove, tear, or write over any

part of the manual;

- keep the manual in an area protected from humidity

and heat, in such a way that the quality and legibility

of the publication are not compromised.

Note

The NOTE messages show further information useful for the maintenance technician.

1

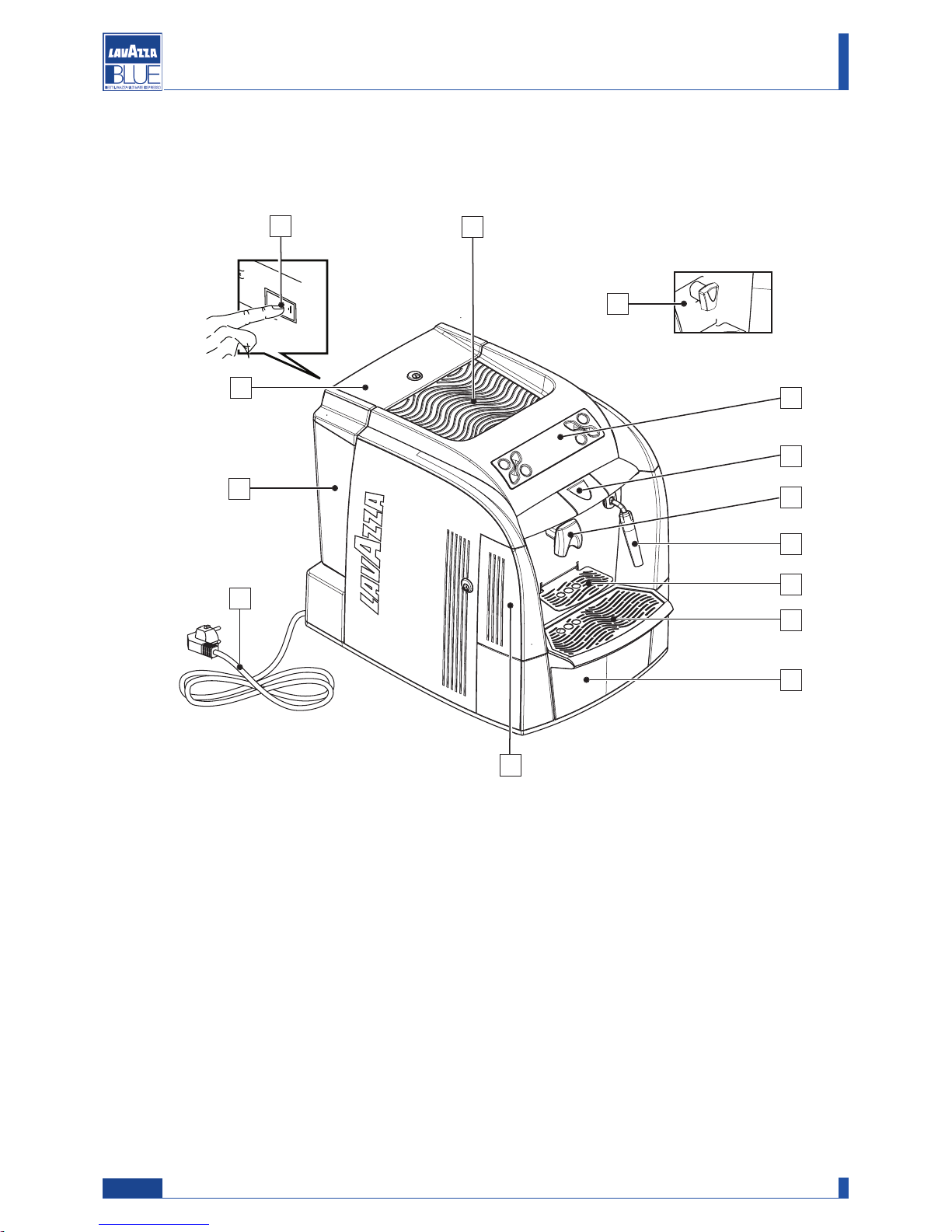

1.2.5. Machine composition

Note: if not expressly indicated in the text, the position numbers of the machine parts are referred to this figure.

1 Control panel

2 Capsule loading tray

3 Steam/hot water pipe (according to the model)

4 Coffee dispensing spout (the dispensing spout allows brewing 1 or 2 coffees according to the model)

5 Cup support (small cups)

6 Cup support (mugs)

7 Used capsule drawer and drip tray

8 Service area access door

9 Power cord

10 Cup warmer plate (according to the model)

11 On/off switch

12 Water tank

13 Water tank lid

1

9

8

10

2

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

4

11

12

13

2

4

3

5

6

7

1.2.6. Internal components

1 Steam solenoid valve

2 Pressure relief valve

3 Power board

4 On/off switch

5 Safety fuses

6 Connection for power cord

7 IRDA for programming

8 RS232 connector for programming

9 Connector for payment systems

10 Coupling for water tank

11 Capacitive sensor

3

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

12 Gear motor

13 Pump

14 Boiler

15 Capsule release coil

16 CPU board

17 Noise filtera

18 Safety thermostats

19 Water solenoid valve

20 Flowmeter

12

13

1

3

5

4

6

7

8

9

16

1

5

14

11

1

15

17

18

19

20

2

10

WITH STEAM

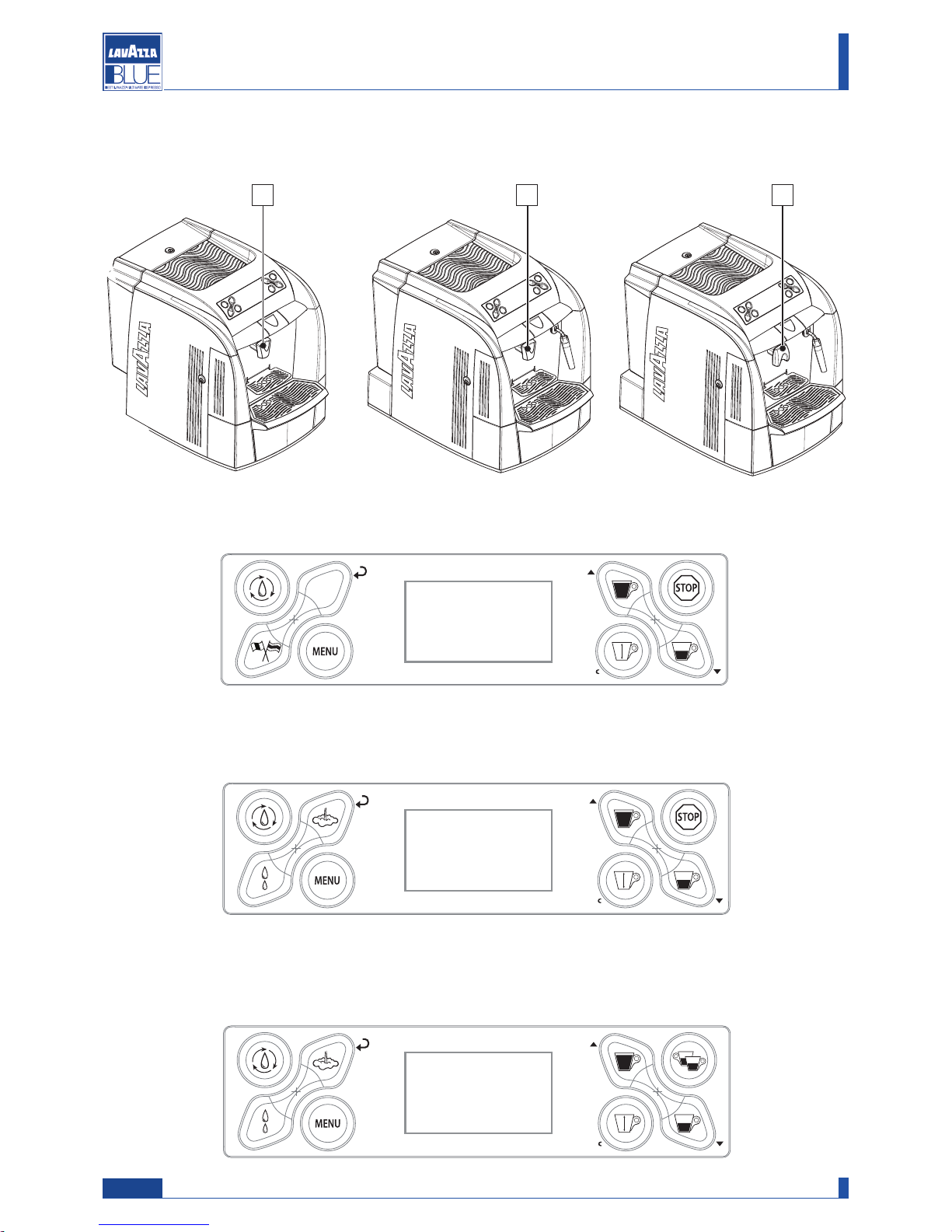

1.2.7. Range

4

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

Dispensing spout for 2 products (C)

Steam/hot water pipe

Dispensing spout for 1 product (B)

Steam/hot water pipe

Dispensing spout for 1 product (A)

DOUBLE CUP

WITH STEAM

SINGLE CUP

WITH STEAM

A

B

C

SINGLE CUP

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

5

1.2.8. Machine identification data

In the plate the following identification data of the

m

achine are indicated:

1.2.9. Technical specifications

Power supply voltage:

230 V~, 50 Hz

120 V~, 60 Hz

Power

Total: 1570 W

1100 W Coffee/hot water dispensing

470 W Additional for steam dispensing

Safety system:

Thermostat

Water level sensor:

Capacitive sensor

Pump:

Ulka brand with alternate piston and thermal

protector 100°C

48 W, 230V, 50 Hz, Type EP5 ca. 13-15 bar

Pressure relief valve:

Opens at 13-14 bar about

Water filter:

In the tank

Consumption:

During heating phase- about 6,8 A

Weight:

10,5 kg

Water tank capacity:

4 litres

Capsule container capacity:

Max. 20

-

Manufacturer;

- Machine name;

- Serial number;

- Power supply voltage (V) and frequency (Hz);

- Power consumption (W);

- Water mains pressure (MPa).

Note

In case of contact with authorized service centres,

please indicate the model and serial number.

391

327

473

O

perating conditions:

Minimum temperature: 10°C

Maximum temperature: below 40°

M

aximum humidity: below 95%

Brewing temperature:

about 73°C - 83°C

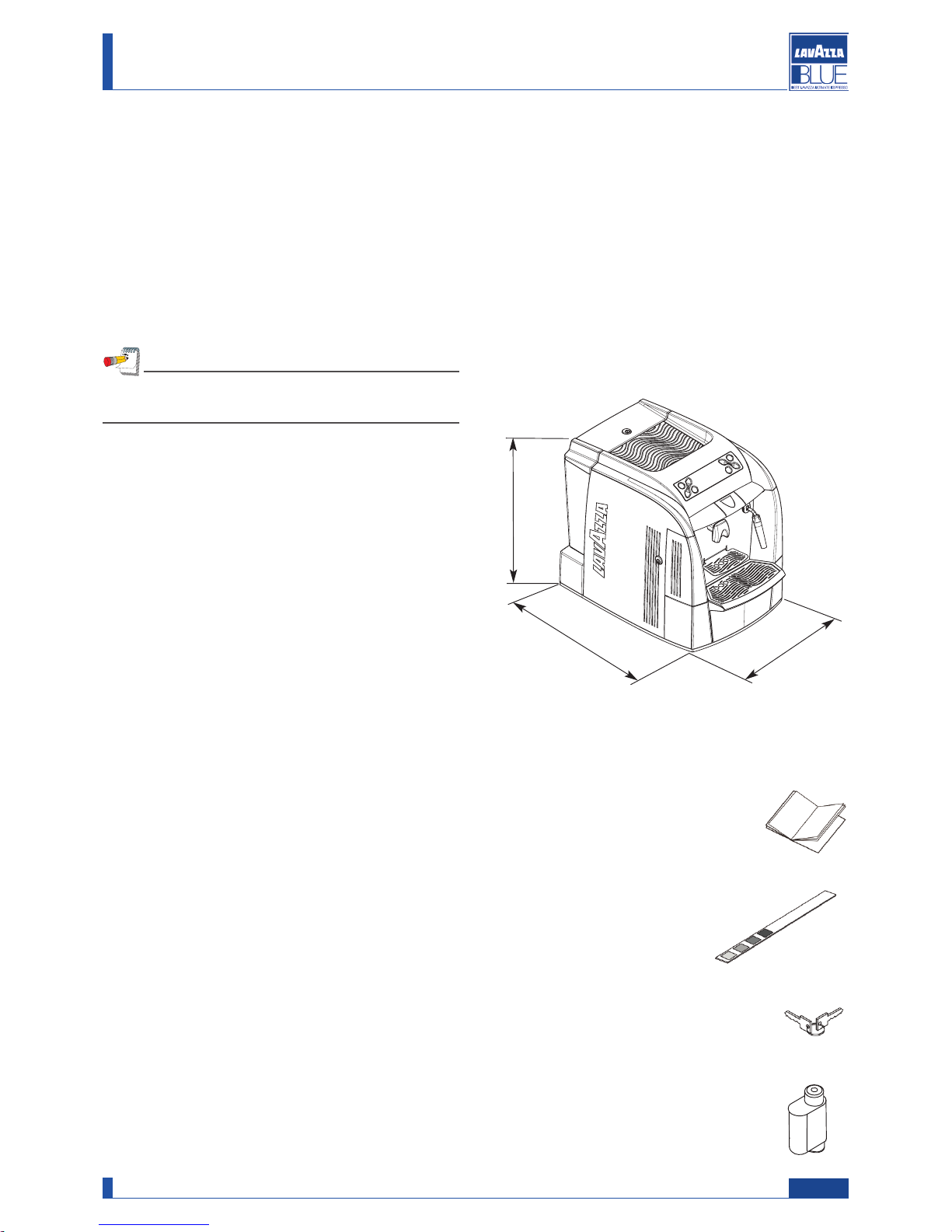

1.2.10. Overall dimensions

Deep: 473 mm

Width: 327 mm

Height: 391 mm

1.2.11. List of the accessories supplied with

the machine

Booklet: Instructions for using the

machine.

Water hardness test: Quick test to determine the hardness of the water used to prepare beverages; this is a very

important test to set the hardness of the water used by the

machine.

Key for water tank access: prevents

access to water tank by unauthorised personnel.

BRITA INTENZA filter

2. GENERAL SAFETY RULES

Attention

During the repair of the machine all the normal

safety protections, designed to avoid accidents

are disabled. Adopt all the measures necessary

to avoid accidents.

• Power connection should be made in compliance

with local standards in force.

• The electric socket connecting the machine should:

- conform to the type of plug installed on the machine;

- comply with the data provided on the plate placed on

the bottom of the apparatus;

- be connected to ground.

• The electric parts of the machine must not:

- enter into contact with any type of liquid: danger of

electric shock and/or fire;

- be manipulated by humid or wet hands;

- be tampered with.

• It is forbidden:

- To use the machine near flammable substances

and/or explosives and/or in an atmosphere with any

risk of fire;

- To use spare parts not advised by the manufacturer;

- Carry out any type of technical modification not covered in the normal procedures of diagnosis and repair.

• Before carrying out any operation on the machine

ensure that the plug is disconnected from the current

and that the machine has cooled.

• Maintenance operations on the machine should be

carried out by a single person; if a second person

must intervene, this person should be advised of the

potential hazards relevant to the operation underway.

• In case of fire use carbon dioxide (CO2) extinguishers. Do not use water or powder extinguishers.

Attention

Read the entire manual carefully and the follow

ing general safety rules..

2.1. Stop functions

To stop the machine turn the main switch to “0” (OFF).

2.2. Safety devices

Two Klixon thermostats with manual reset avoid any

overheating of the boiler.

2.3. Residual risks

In this chapter are illustrated the risks that the user may

incur in if he doesn’t comply with the specific safety

rules (as described in this booklet).

The appliance must be connected to ground

If it is not done, the appliance can become a source of

dangerous electrical discharges as it is no longer able

to discharge electricity to earth.

Do not use running water for washing

The use of pressurised water directly on the machine

can seriously damage electrical appliances. Never use

water jets to wash any part of the appliance.

Be careful with the hot water pipe

During use the hot water pipe may overheat, thus

becoming a source of danger. Handle this part carefully. Never direct steam or hot water jets directly on

parts of the body.

Do not work on the machine when it is powered

Before carry out any maintenance or repair on the

machine you must turn it off by means of the main network switch, or better yet, disconnecting the connection terminals in the network. Never remove any body

panels when the machine is supplied with electrical

power.

Note

The machines described in this publication, are

designed in compliance with the specific European

standards in force and therefore have measures of

protection in all the potentially hazardous parts.

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

Manual code 10083445 / Rel. 0.00 / April 2010

6

Use of the appliance

This espresso coffee machine is an appliance for prof

essional use only. Any other type of use is considered

incorrect and therefore dangerous. Never allow children or incapacitated persons to use the machine..

Attention

Non-observance of the above rules can cause

serious harm to people, property or animals.

Never operate the electronic components when

the machine is still supplied with electrical power.

Shut off the machine completely by unplugging it

from the mains before carrying out any operation.

Warning

Do not use any containers that are not suitable for

foodstuffs.

Attention

Burn danger – During hot water and steam

dispensing, do not direct the jets toward others

or yourself. Grasp the pipe, exclusively on the

relevant protectors (12 and 17).

Attention

Any operation taken by the technician on the electronics of the machine when the machine is powered, automatically invalidates any guarantee.

The technician should know that the machine is

electrically connected and act accordingly.

3. INSTALLATION

3.1. Unpacking

O

pen the packaging, taking care not to damage it.

Remove the machine protections and the equipment

contained in the package.

Take the machine out.

Warning

It is prohibited to install the machine outside or in

places where water or steam jets are used.

Warning

The presence of magnetic fields or proximity with

electric machines which generate disturbances,

may cause malfunctions in the electronic control of

the machine.

Warning

With temperatures approaching 0°C there is the risk

of freezing internal parts of the machine which contain water. Do not use the machine under these conditions.

3.2. Mounting-Positioning

For the correct operation of the machine, the following

advice is given:

- environmental temperature: 10°C ÷ 40°C;

- maximum humidity: 90%;

- the area must be ready for the installation of the

machine;

- the place where the machine is installed should be

flat, solid and still; the surface must not have an incli-

nation of more than 2°;

- the area should be sufficiently illuminated, ventilated,

hygienic and equipped with a readily available power

outlet.

Attention

Sufficient space must be allowed to access the

machine and the plug, to allow the user to move

freely and to be able to immediately leave the

area in an emergency.

7

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

Manual code 10083445 / Rel. 0.00 / April 2010

3.3. Machine positioning

Warning

Check that the surface prepared for the machine

installation, has dimensions and sturdiness suitable

to safely support the machine.

N

ote

For a correct ergonomic use of the machine, place

it on a working surface not lower than one meter

from the floor.

4. HANDLING AND STORAGE

4.1. Handling

During handling and transport, the machine must

remain in a vertical position according to the directions

on the packaging. Carry out lifting and positioning with

care. Do not shake the machine.

4.2. Storage

The machine should be stored according to the following conditions:

- minimum temperature: above 4°C;

- maximum temperature: below 40°C;

- maximum humidity: below 95%.

The machine is packaged in cardboard and polystyrene.

5. DISMANTLING

E

nvironment

Disposal of machine components after dismantling,

should be carried out with respect for the environment, avoiding pollution of the soil, water and air.

Any operation should comply with local legislation

in force.

8

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

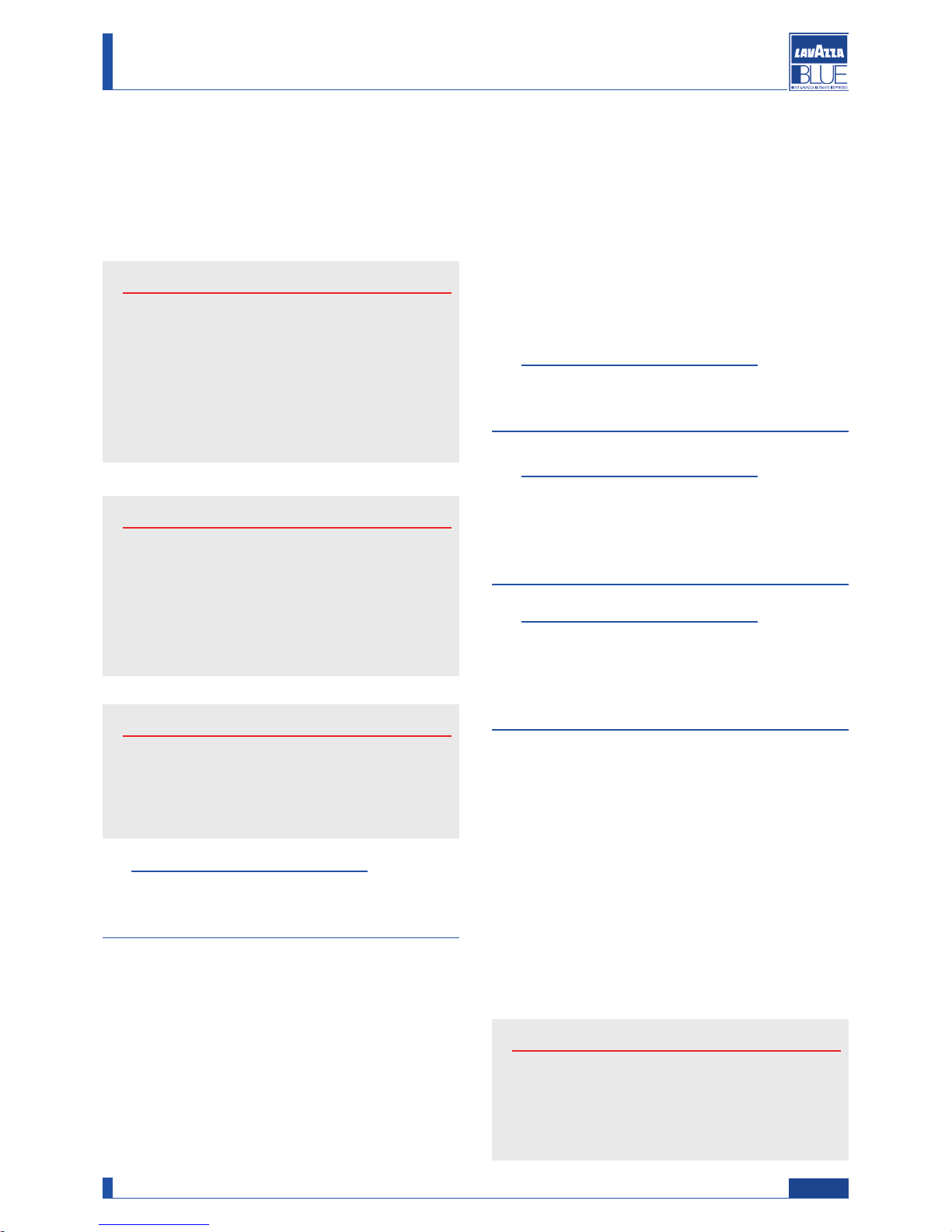

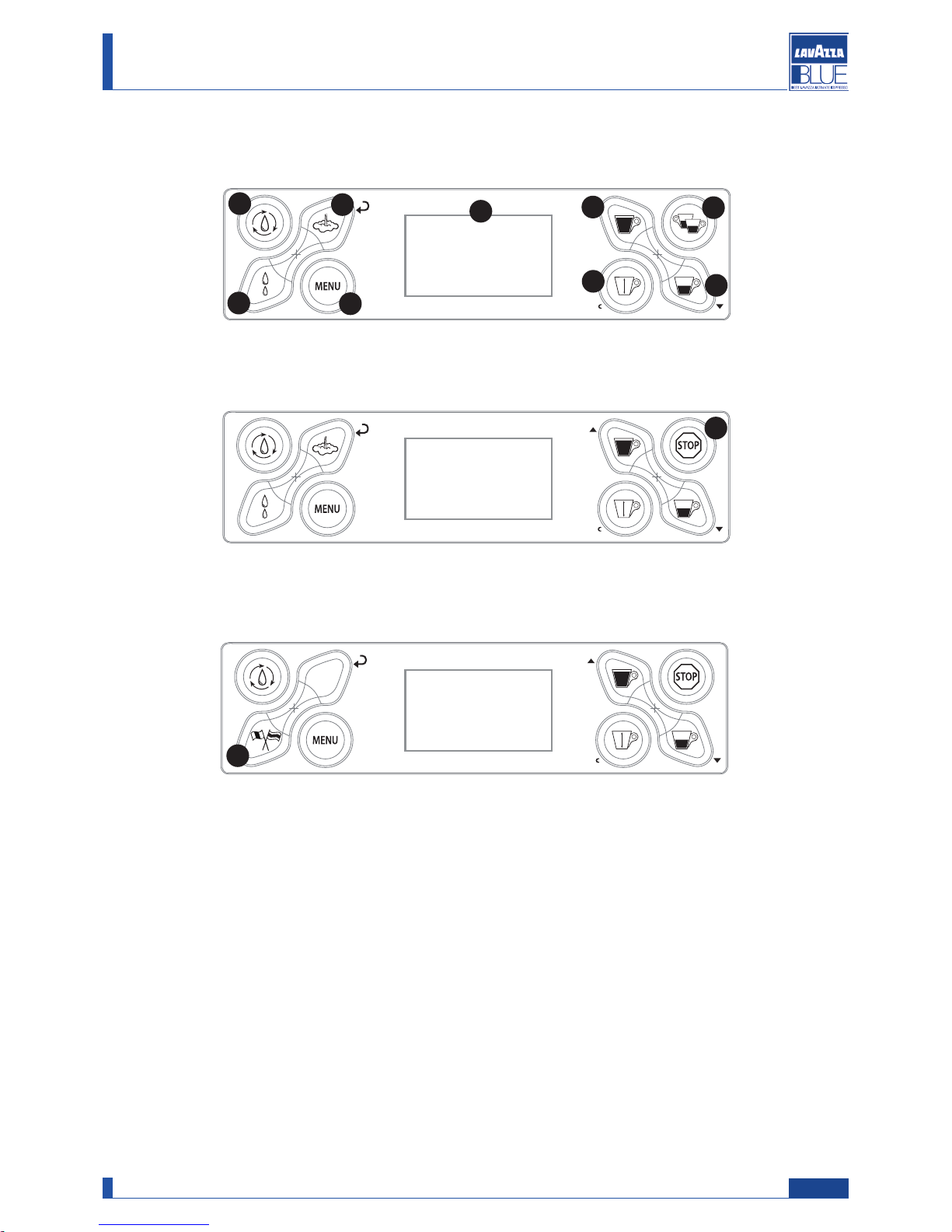

6. USER MENU

WITH STEAM

DOUBLE CUP

WITH STEAM

SINGLE CUP

WITH STEAM

SINGLE CUP

77

88

99

66

1100

1111

22

11

44

33

55

9

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

Press the MENU button (8) to access the QUICK MENU that allows the following operations:

- Change the language

- Activate/deactivate the cup warmer (according to the model)

- Wash the brew unit

- Set the rinse cycles

- Descale the machine

- Activate/deactivate the stand-by mode (to activate the energy saving mode)

BUTTON DESCRIPTION

0

1) Hot water dispensing

Press this button for 1 second and the machine immediately dispenses hot water.

0

2) Steam dispensing

Press this button for 1 second and the machine immediately dispenses steam.

03) Manual dispensing

button

Press this button to dispense a quantity of product that the user can manually

control (the user must stop the dispensing by pressing again the button).

04) Long coffee button

Press this button and the machine dispenses a long coffee (dose programmed by

the service provider).

05) Espresso button

Press this button and the machine dispenses an espresso coffee (dose programmed by the service provider).

06) Double espresso Press this button and the machine dispenses a double espresso.

07) Rinse Press this button for 1 second to carry out a rinse cycle of the internal circuits.

08) MENU Press this button for 1 second to display the user menu.

09) LCD display

Displays the machine status and alarm signals, and guides the user to operate the

machine.

10) Stop Press this button to stop coffee or steam/hot water dispensing.

11) Language Press this button for 1 second to display messages in the desired language.

10

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

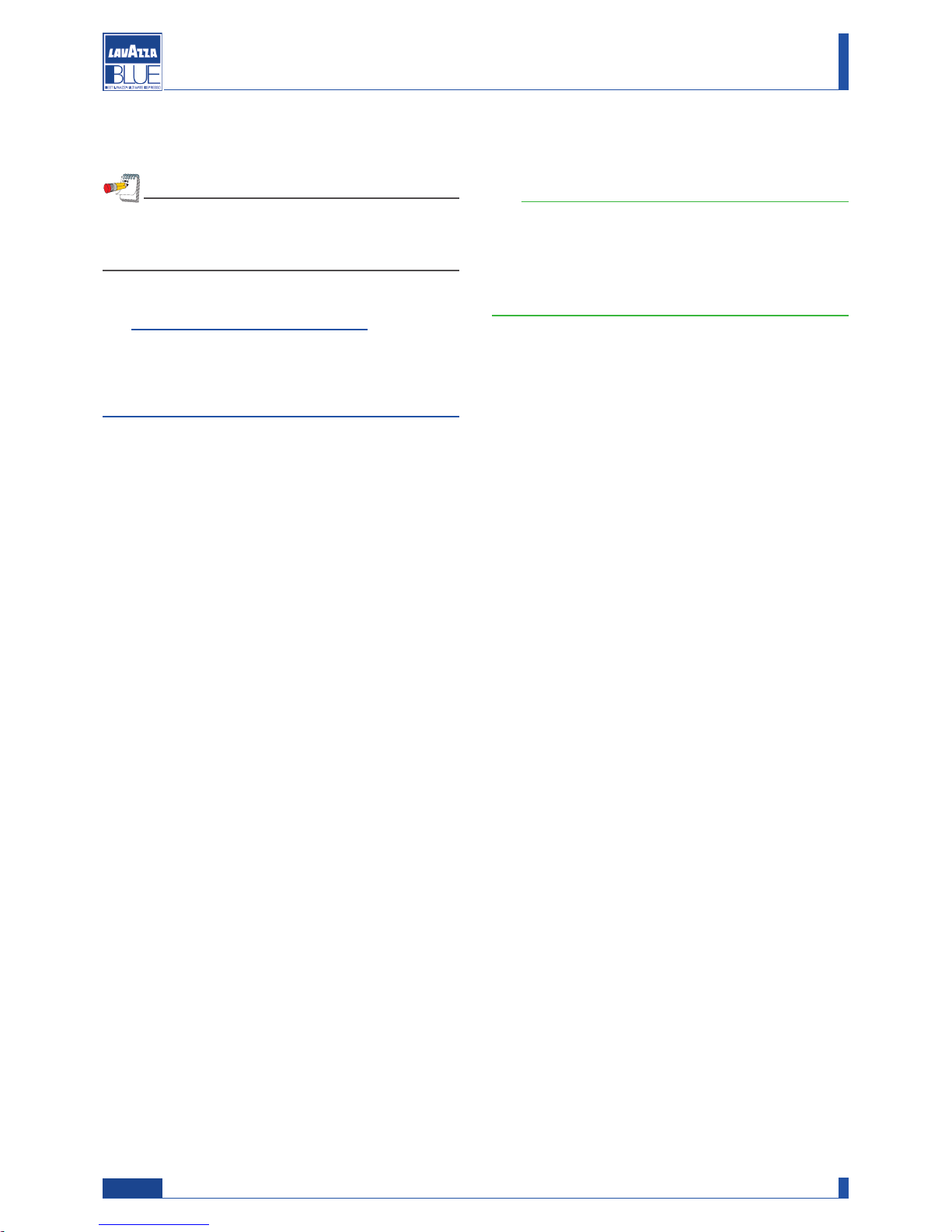

BUTTON DESCRIPTION

0

2) Enter/Confirm Press the button to select the function or confirm the command.

06) Page UP

Press the button to change function or parameter.

08) ESC Press the button to exit the function.

09) Page DOWN Press the button to change function or parameter.

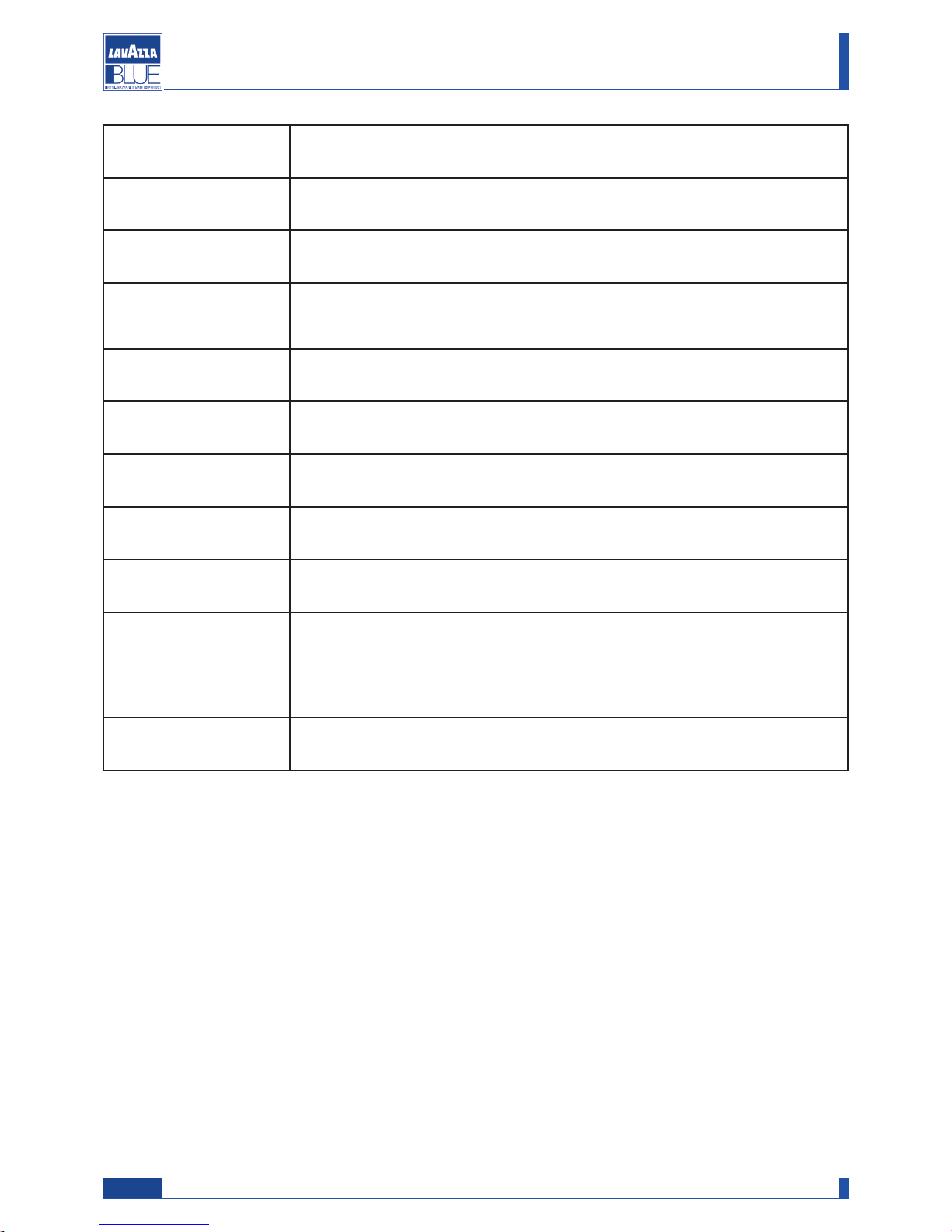

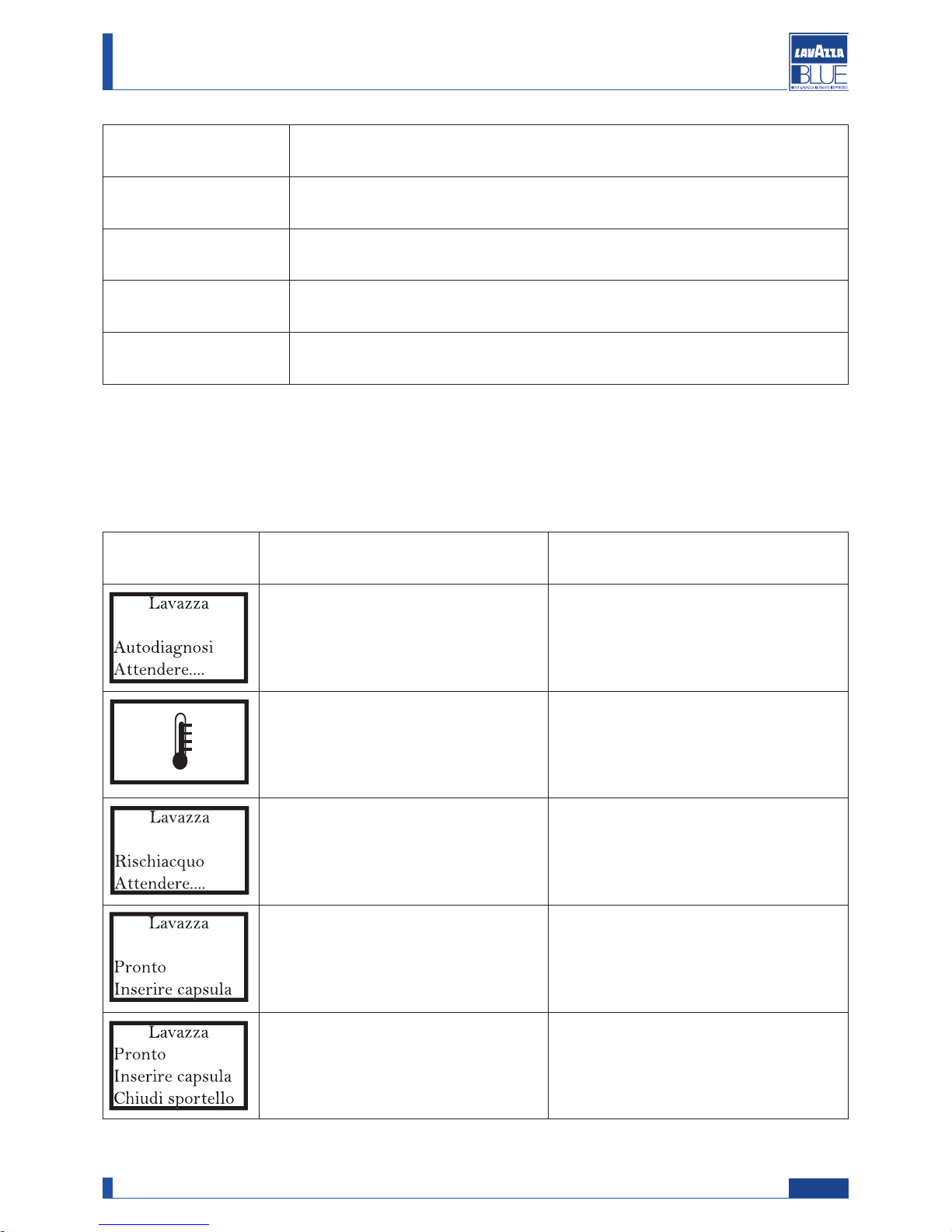

DISPLAY MEANING ACTIONS

The machine is checking the components. Wait for the check to conclude automatically.

The machine is warming up Wait for this step to conclude automatically.

The machine is performing the circuit

rinse cycle with fresh water.

Wait for the rinse cycle to end automatically.

The machine is ready to brew coffee. It is possible to dispense the coffee/product.

The capsule loading tray has been opened.

Place a capsule in the tray and close it.

Close the tray without the capsule.

6.1. Machine warnings

11

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

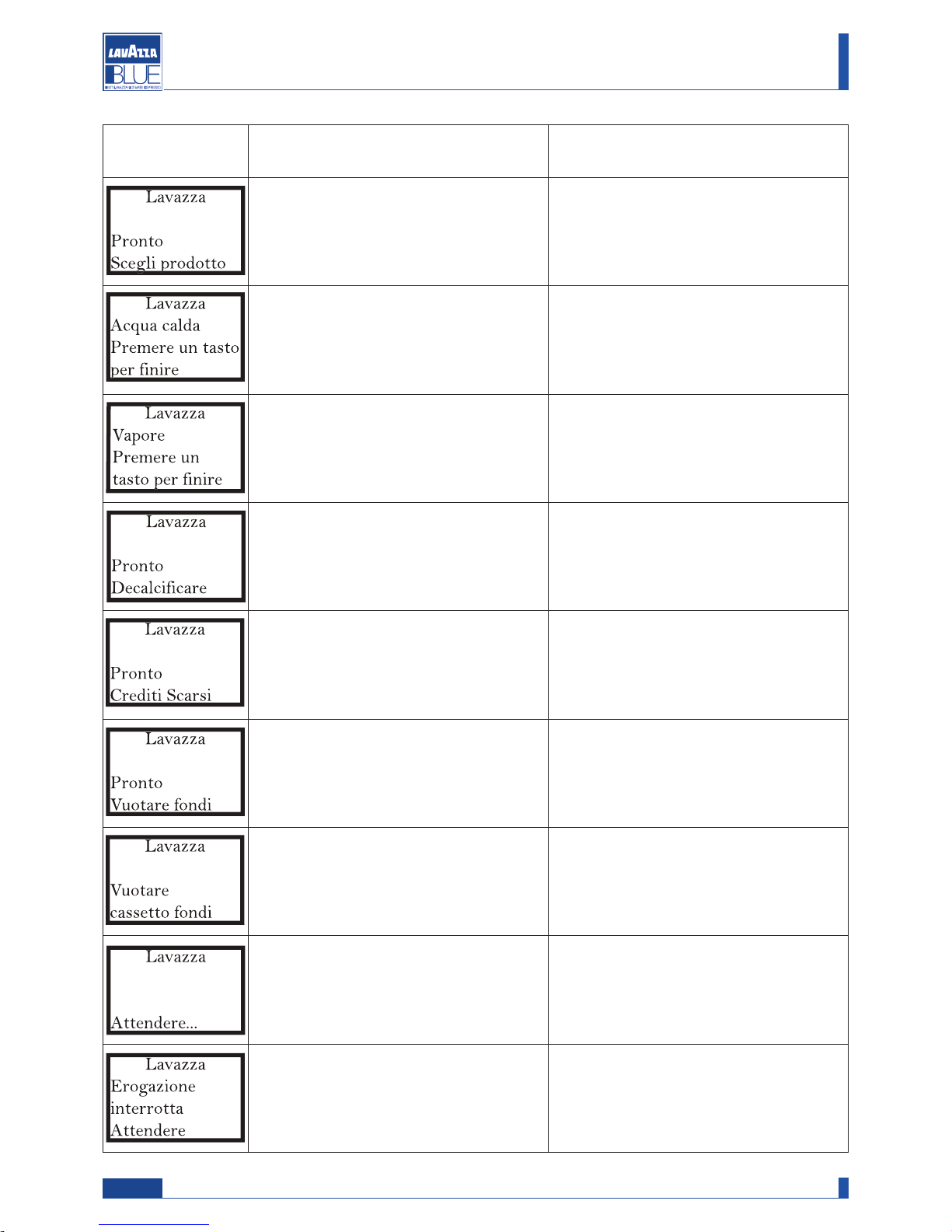

DISPLAY MEANING ACTIONS

The tray has been closed with a capsule

inside.

Dispense the product.

The machine is dispensing hot water.

Stop the dispensing by pressing the hot

water button.

The machine is dispensing steam.

Stop the dispensing by pressing the steam

button.

The machine signals that a descaling cycle

has to be carried out.

Start the descaling cycle.

The machine is alerting the user that credits for product brewing have almost run

out.

Request assistance from the service provider to acquire new credits.

Indicates that the used capsule drawer

should be emptied, though further products

can still be dispensed.

With the machine stopped and switched

on, remove the used capsule drawer and

empty it.

Indicates that the used capsule drawer

must be emptied because further products

may not be dispensed.

With the machine stopped and switched

on, remove the used capsule drawer and

empty it.

The used capsule drawer has been removed following a machine warning.

Empty the used capsule drawer and wait

for the following message "insert drawer"

to appear.

The machine has interrupted the brewing

cycle.

An alarm signal has been triggered, stopping the brewing cycle.

Contact the service provider, if necessary.

12

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

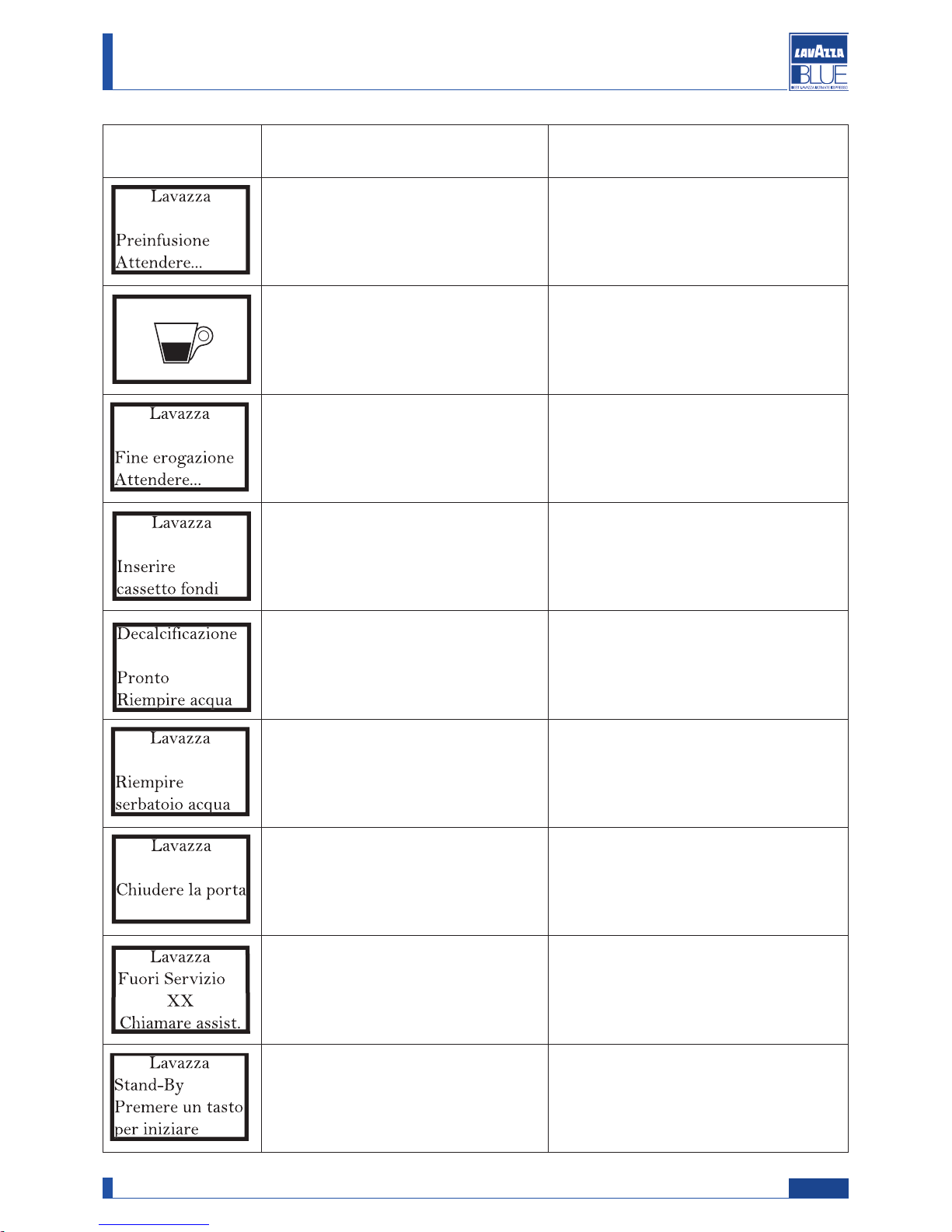

DISPLAY MEANING ACTIONS

The machine is performing the pre-infusion cycle and stops brewing the product.

Wait for the product brewing to restart automatically.

The machine has started the product brewing cycle.

Wait for the brewing automatically or

manually to end.

End brewing, the machine is being returned to the ideal conditions for the next

brewing cycle.

The used capsule drawer has been

removed from its seat.

Insert the used capsule drawer.

The machine alerts that the water tank

should be filled though further product

can still be dispensed.

Fill the water tank.

The water tank is empty. Fill the water tank.

The front service door is open.

Close the door. If the door is closed and

the warning persists, request assistance.

There is a machine malfunction. Refer to the notes on chap. 8.3.

The machine is in energy saving mode.

Press any button or open the capsule loading tray to activate the machine.

13

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

DISPLAY MEANING ACTIONS

The machine is filling the hydraulic circuit.

Wait for this operation to be successfully

completed.

The descaling filter must be replaced.

Request assistance from the service provider.

6.2. Machine programming (service provider)

To access the programming menu carry out the following:

Turn the machine off using the on/off switch.

Turn the machine on using the on/off switch and while

the hourglass shows up, keep pressed the steam button

until the menu appears.

Attention

These menus are PASSWORD protected.

14

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

Attention

The chosen PASSWORD (default 0000), should be changed during the first machine start up in such away

to prevent unauthorised access.

It is possible to change the password using either the service or the programming menu.

Programming menu Access to the programming menu (the password is requested)

Service menu Access to the service menu (the password is requested)

Exit Exits the programming menu

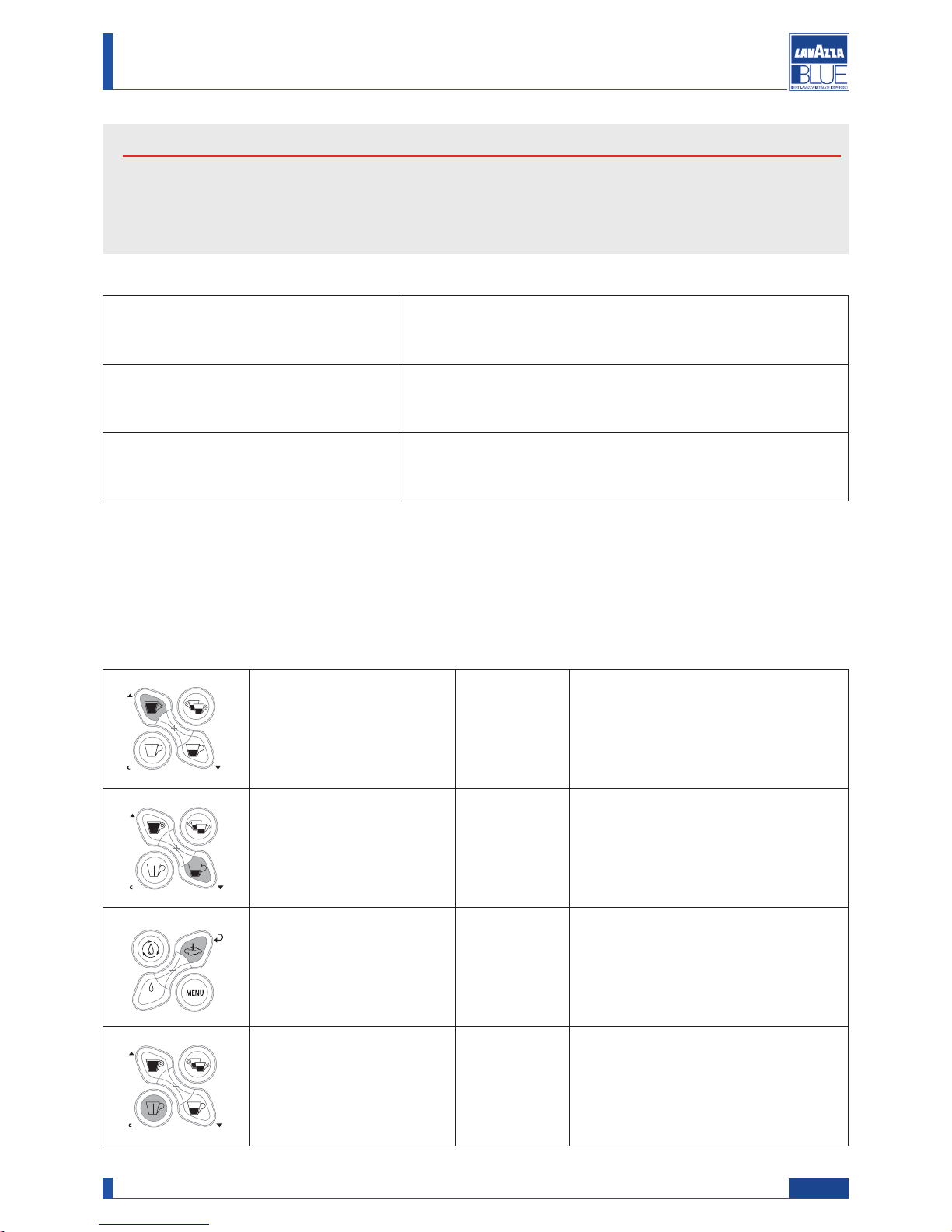

“Page up/change” button

This button

allows :

- Scrolling the pages within a menu

- Changing the parameters when they

are made editable using the “OK”

button

“Page down/change” button

This button

allows :

- Scrolling the pages within a menu

- Changing the parameters when they

are made editable using the “OK”

button

“OK” (ENTER) button

This button

allows :

- Selecting the displayed function

- Making changeable a parameter/value

- Confirm the parameter/value when it

is made editable

“ESC” button

This button

allows :

Exiting without changing the edited or

selected parameter.

6.3. Programming commands

The buttons of the control panel have different functions when the programming or service menu are entered.

15

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

1. Programming menu Press ENTER to access the programming menu

Password Enter password

Set value

Default: 0000

Enter the previously stored password (4 digits)

for accessing the password function

1.1.

Identification

1.1.1. Admin/affiliate PIN

Default 00000

Identifies the Service Provider or Administratorʼs

code: Numerical value between 0 and 65535

1.1.2. Model (Read only) Identifies the machine model.

1.1.3. Version

(Read only) Identifies the version of the machineʼs software.

1.1.4. Point of sale

Default 00000

Identifies the point of sale: Numerical value between 0 and 65535. Enter the selected number.

This number will then be

displayed.

1.2.

Setup

1.2.1.

Standard temperature

Default: 100°C

Boiler operating temperature (in degrees centigrade) when the machine is ready to be used.

Range: 90° - 105°.

1.2.2.Progr.dose

1.2.2.1.Short prod.dose

Default: 140

Quantity for espresso coffee (this is a numerical

parameter with no physical correspondent, e.g. cc).

1.2.2.2.Long prod. Dose

Default 173

Quantity for long coffee (this is a numerical parameter with no physical correspondent, e.g. cc).

1.2.2.3.Free prod.dose

Default 615

Maximum amount of manually dispensed product

(this is a numerical parameter with no physical correspondent, e.g. cc).

1.2.2.2.Double dose

prod.dose

Default 210

Quantity for double espresso coffee (this is a

numerical parameter with no physical correspondent, e.g. cc).

1.2.3.Pre-infusion

Default: Media

Pre-infusion time

No, Short, Medium, Long

1.2.4.Filter coffee

Default: No

“Yes” enables the filter coffee function. Filter

coffee can only be brewed by pressing “ESC”.

The filter operation is not available.

1.2.5.

Descaling

1.2.5.1. Water hardness

Default: 3

Values 0-4. “0” disables descaling checks. With

hardness 1, 2, 3 and 4, descaling checks are

activated and an alarm signal will appear after

240, 180, 120 or 60 litres of water that have

been treated. (Values from 5 to 9 will not be

accepted)

1.2.5.2. Descal.warning

Default: Yes

“Yes” enables display of the descaling alarm

signal.

1.2.6.

Filter warning

Default: No

“Yes” enables display of the filter replacement

alarm signal. When enabled, the alarm signal

appears after approximately 60 litres of water

have been treated, or in any event after 60 days.

6.4. Table of programming menu

16

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

1.2.

Setup

1.2.7.Credits 1.2.7.1.Credit check

(Read only)

Yes: the machine checks the remaining credits.

N

o: The machine does not check remaining credit.

1.2.7.2.Credit warning

Default: Yes

“Yes” enables

- display of the credit alarm signal when the

preset minimum number of credits is reached;

- display of the "no credit" alarm signal

when the credits have been run out

1.2.7.3.Load credits

Default: 000

Number of credits added.

Value: 0-255

1.2.8.Language

Default: Italian

Select language

1.2.9.Grounds delay

Default: 5

Time, in seconds, after which the machine

resets used capsule counter (with the used

capsule drawer removed)

this delay applies only if the relevant alarm

signal is shown.

After this time the warning or the alarm

signal is cancelled.

Values: 0 - 255 seconds

1.2.10. Contrast

Default: 35

To set the display contrast

Values: 20 - 50

1.2.11 Brightness

Default: 150

To set the display brightness

Values: 30 - 255

1.3. Stand-by

1.3.1. Activate?

Default: No

“Yes” enables energy saving mode.

1.3.2.

Stand-by delay

Default: 60

- When the machine is in standby mode, it

switches off automatically after the defined

time has elapsed following the last use.

- When the machine is in standby mode, the

boiler temperature is reduced after the defined time has elapsed

Values: 5 - 240 Minutes

17

Manual code 10083445 / Rel. 0.00 / April 2010

Maintenance manual for technical assistance LB 2300-2301-2302-2311-2312

Loading...

Loading...