LAVAZZA LB2210 Instructions For Installation And Use Manual

Leer atentamente las siguientes instrucciones de uso antes de utilizar la máquina

MANUAL DE INSTALACIÓN Y DE USO

Lire attentivement ces instructions avant d’utiliser la machine.

MANUEL D’INSTALLATION ET D’UTILISATION

Read these instructions carefully before using the machine

INSTRUCTIONS FOR INSTALLATION AND USE

ESPAÑOL FRANÇAIS ENGLISH

COMMERCIAL USE

LB2210

Type SUP 026R/US

• 2 •

• 3 •

• 4 •

IMPORTANT SAFEGUARDS

When using electrical appliances, basic safety precautions should

always be followed to reduce the risk of fire, electric shock, and/or

injury to persons, including the following:

1 Read all instructions and information in this instruction book

and any other literature included in this carton referring to this

product before operating or using this appliance.

2 Do not touch hot surfaces. Use handles or knobs.

3 To protect against fire, electric shock and personal injury do not

immerse cord, plugs or appliance in water or other liquid.

4 Close supervision is necessary when any appliance is used by

or near children.

5 Unplug from outlet when not in use and before cleaning.

Allow to cool before putting on or taking off parts, and before

cleaning the appliance.

6 Do not operate any appliance with a damaged cord or plug or

after the appliance malfunctions or has been damaged in any

way. Return appliance to the nearest authorized service centre

for examination, repair or adjustment.

7 The use of accessory attachments not recommended by the

appliance manufacturer may result in fire, electric shock or

personal injury.

8 Do not use outdoors.

9 Do not let cord hang over edge of table or counter, or touch hot

surfaces.

10 Do not place on or near a hot gas or electric burner, or in a

heated oven.

11 Always turn appliance “OFF”, then plug cord into the wall

outlet. To disconnect, turn switch to “OFF”, then remove plug

from wall outlet.

12 Use extreme caution when using hot steam.

SAVE THESE INSTRUCTIONS

CAUTION

This appliance is for commercial use. Any servicing, other than

cleaning and user maintenance, should be performed by an

authorized service centre. Do not immerse base in water. To

reduce the risk of fire or electric shock, do not disassemble the

base. There are no user serviceable parts inside. Repair should be

done by authorized service personnel only.

1 Check voltage to be sure that the voltage indicated on the

nameplate agrees with your voltage.

2 Never use warm or hot water to fill the water tank. Use cold

water only.

3 Keep your hands and the cord away from hot parts of the

appliance during operation.

4 Never clean with scouring powders or hard implements. Simply

use a soft cloth dampened with water.

5 To avoid your coffee maker scaling up, use purified or bottled

water.

6 Risk of fire and electric shock. Replace only with manufacturer’s

cord set, part type SJO.

INSTRUCTIONS FOR THE POWER

SUPPLY CORD

A A short power-supply cord is provided to reduce risks of getting

tangled up or tripping over a longer cord.

B Longer extension cords are available and may be used if care

is exercised in their use.

C If a long extension cord is used:

1 the marked electrical rating of the extension cord should be at

least as great as the electrical rating of the appliance.

2 if the appliance is of the grounded type, the extension cord

should be a grounding type

3 the cable does not hang from the table to avoid the risk of

getting caught up in it.

• 5 •

ENGLISH

1 GENERAL INFORMATION

1 GENERAL INFORMATION

1.1 Intended use of the machine

1.1 Intended use of the machine

This machine is designed for automatic dispensing of:

- coffee and espresso brewed with LAVAZZA pods;

- hot drinks prepared using special LAVAZZA pods.

- steam for preparing hot drinks and cappuccino

This elegantly styled machine is designed for use in small offi ces and institu-

tions.

Important.Improper use shall result in forfeiture of all warranty rights

and release the Manufacturer from liability for injury or damage to persons and/or property.

The following are to be considered improper use:

- use for other than the intended purposes and/or employing methods

other than those described herein;

- any operation on the machine in contrast with the directions provided

herein;

- any use after machine components have been tampered with and/or

safety devices have been modifi ed;

- use of pods other than those supplied by LAVAZZA;

- outdoor installation of the machine.

In such cases the user shall be charged for any repair work on the machine.

1.2 To facilitate interpretation

1.2 To facilitate interpretation

Different types of symbols are used herein to highlight the different hazard levels or indicate who is authorised to perform an operation.

A warning triangle draws attention to all the instructions that are important for user safety. Please

carefully abide by these instructions to avoid seri-

ous injury!

Different symbols are used herein to indicate which operations are to be performed by each user.

User: a person who uses the machine to dispense beverages.

Users are NOT allowed to carry out operations restricted to

the Service Provider or specialised Technician. Should users

detect any machine malfunctioning and/or faults, they must

contact the Service Provider.

Service provider: firm or person in charge of normal machine installation,

start-up and stops, loading and internal and external cleaning.

On detecting a machine malfunctioning, the Service Provider

must request the assistance of a maintenance technician.

Technician: personnel qualified to perform special maintenance and serv-

icing on the machine.

The technician can carry out all the operations described

in this instruction book without requiring explicit authorisation.

This symbol is used to highlight information that is especially important for ensuring optimal use of the machine.

1.3 How to use these operating instructions

1.3 How to use these operating instructions

This instruction book is an integral part of the machine and should

be read carefully.

It contains information regarding the installation, maintenance and correct use of the machine. Always refer to this instruction book before undertaking any operation.

Keep these operating instructions in a safe place and make them available to

anyone else who should use the coffee machine. If the instruction book is lost

or in a deteriorated state, immediately request another copy from your service

provider. For further information or an explanation of problems not completely

1 GENERAL INFORMATION ....................................................5

1.1 Intended use of the machine ...................................................5

1.2 To facilitate interpretation ........................................................5

1.3 How to use these operating instructions ...............................5

1.4 Machine identifi cation ..............................................................6

1.5 Technical specifi cations ..........................................................6

1.6 Residual risks ...........................................................................6

2 SAFETY RULES .....................................................................6

3 KEY TO MACHINE COMPONENTS ......................................7

3.1 Description of control panel ....................................................7

4 USING THE MACHINE ...........................................................7

4.1 Switching on the machine .......................................................7

4.2 Selecting the display language ...............................................7

4.3 Using cups, mugs and glasses ...............................................7

4.4 Inserting pods ...........................................................................7

4.5 Coffee/beverage dispensing ....................................................8

4.6 “STOP” dispensing coffee/beverage ......................................8

4.7 Emptying the dreg drawer ......................................................8

4.8 Dispensing steam .....................................................................9

4.9 Using the coin mechanism (Optional) ....................................9

5 CLEANING .............................................................................9

6 DESCALING ...........................................................................9

7 MACHINE INDICATIONS AND WARNINGS ........................10

8 HANDLING AND STORAGE ................................................11

8.1 Handling ..................................................................................11

8.2 Storage ....................................................................................11

9 INSTALLATION ...................................................................11

9.1 Safety rules .............................................................................11

9.2. Stop functions ........................................................................ 11

9.3. List of accessories supplied .................................................11

9.4. Installation-Siting ................................................................... 11

9.5. Disposal of packing materials ...............................................12

9.6. Electrical connection ............................................................12

9.7 Setting the water hardness. ...................................................12

9.8 “Aqua Prima” Filter and fi lling the water tank .....................12

10 MACHINE PROGRAMMING ................................................14

10.1 Programming menu ................................................................14

10.2 Service menu ..........................................................................14

10.3 Programming commands ......................................................14

10.4 Description of programming menu .......................................15

10.5 Description of service menu .................................................15

10.6 Changing a parameter ............................................................16

10.7 Exiting the program mode .....................................................16

11 CLEANING ..........................................................................16

11.1 Frequency of cleaning ...........................................................16

11.2 Cleaning the water tank .........................................................16

11.3 Cleaning the dreg drawer ......................................................17

11.4 Cleaning the pod loading tray ...............................................17

11.5 Cleaning the steam wand ......................................................17

11.6 Descaling ................................................................................17

11.7 Brew group washing ..............................................................18

12 DISPOSAL ............................................................................18

• 6 •

or suffi ciently addressed in these instructions, contact the service provider.

1.4 Machine identifi cation

1.4 Machine identifi cation

The machine is identifi ed by the name of the model and the serial number

shown on the identifi cation plate.

The plate includes the following information:

• Manufacturer’s name

• CE marking

• machine model

• Serial no.

• year of manufacture

• several engineering specifi cations:

- voltage rating (V).

- frequency rating (Hz).

- electrical input (W).

Note: when submitting any type of request to the Service Provider,

always make reference to this plate and indicate the specifi c data

shown on it.

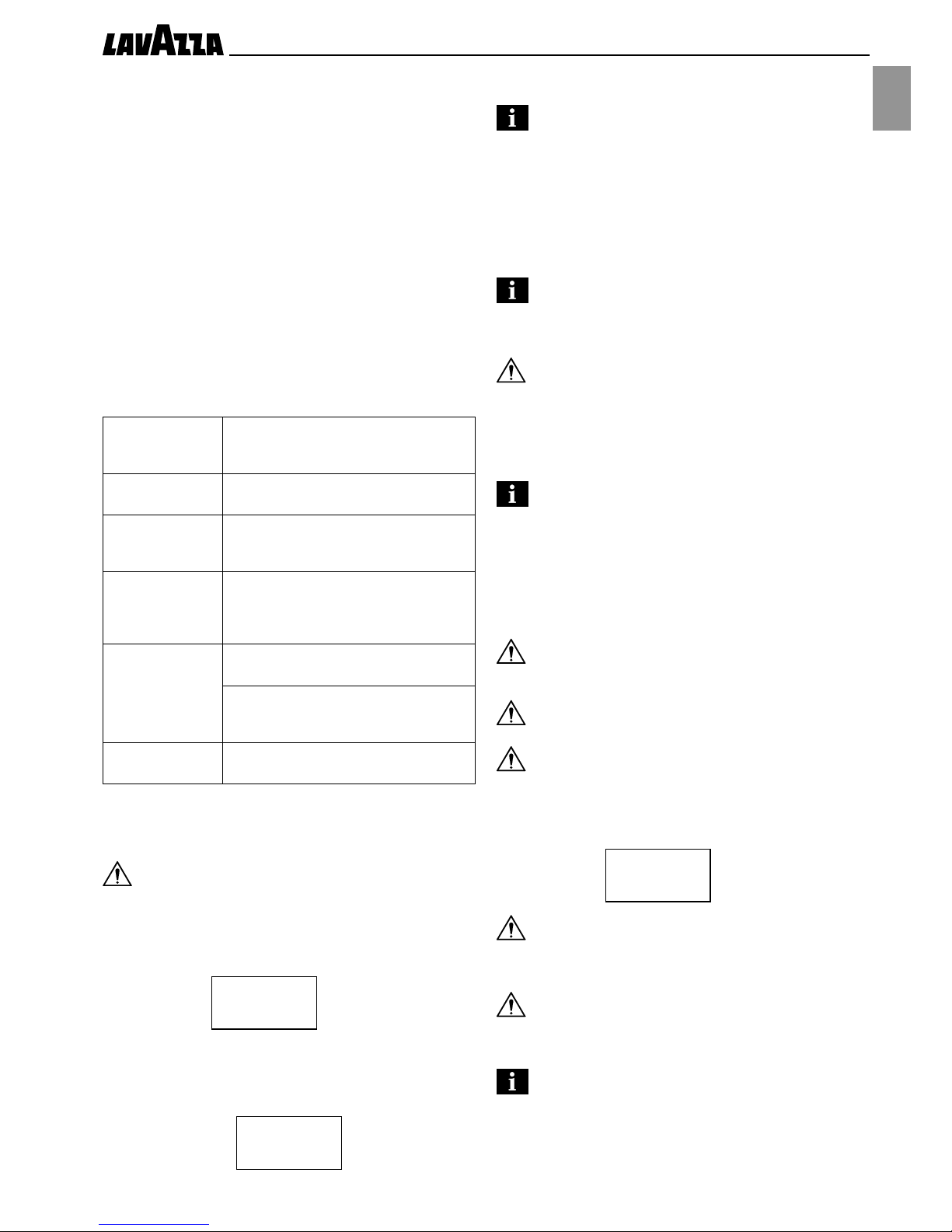

1.5 Technical specifi cations

1.5 Technical specifi cations

Voltage rating

See identifi cation plate on the bottom of the appliance

Power rating

See identifi cation plate on the bottom of the appliance

Power supply

See identifi cation plate on the bottom of the appliance

Casing material

Thermoplastic

Size (w x h x d)

327 x 391 x 473 (mm)

Weight

10,5 kg (approx.)

Cord length (mm)

1200

Water tank capacity

4 Litres

Dreg drawer capacity

25 pods

Pod type

Lavazza

Control panel

Front

Weighted sound pressure level A:

Lower than 70dB

Pump pressure

Max 1.5MPA (15.0 bars)

Operating conditions

Minimum temperature: above 10°C

Maximum temperature: below 40°C

Maximum humidity: below 95%

Safety devices

Boiler pressure safety valve

Termostato di sicurezza

Subject to engineering and manufacturing changes as warranted by technological developments.

Machine in conformity with European Directive 89/336/EEC (Italian Legislative

Decree 476 of 04/12/92) concerning electromagnetic compatibility.

1.6 Residual risks

1.6 Residual risks

The dispensing area has no guards to prevent accidental contact between

hands and coffee, hot drinks or steam.

2 SAFETY RULES

2 SAFETY RULES

Never place live parts in contact with water: danger of short circuit! Hot

water and steam can cause scalding!

Intended use

Intended use

This coffee machine is designed for commercial use .

Do not make any technical changes or use the machine for purposes other than

those stated since this would create serious hazards!

The machine may be used only by adults in full possession of their physical

and mental capacities.

Power supply

Power supply

The machine must be connected to mains power supply by the Service provider, in accordance with the electrical system specifi cations.

Power cord

Power cord

Never use the machine if the power cord is defective.

Immediately inform the service provider if the cord and/or plug show to be defective.

Do not pass the cord around corners, over sharp edges or over hot objects and

keep it away from oil. Do not use the power cord to carry or pull the machine.

Do not pull out the plug by yanking at the power cord or touch it with wet hands.

Do not let the power cord hang freely from tables or shelves.

Protecting others

Protecting others

Make sure that children are not allowed to play with the machine and/or with

packing materials.

Never direct the jet of steam toward yourself or others. Do not touch the steam

wand directly with your hands, always use the handles or knobs provided.

Danger of burns

Danger of burns

Avoid touching the steam wand and/or coffee/beverage brewing unit.

Space for use and maintenance

Space for use and maintenance

The machine must be installed by the service provider in accordance with the

safety regulations in force at the time of installation.

Only the service provider is authorised to move the machine.

Do not use the machine outdoors.

To prevent the casing from melting or being damaged, avoid bringing open

fl ames and/or very hot objects near the machine.

Do not use in places where the temperature may drop to a level equal to and/or

less than 0°C; if the machine has been exposed to such conditions notify the

service provider, who will have to carry out a safety check.

Cleaning

Cleaning

Before cleaning the machine, it is indispensable to put the main switch OFF (0)

and remove the plug from the socket. Then wait for the machine to cool down.

Never immerse the machine in water! It is strictly forbidden to attempt to access

internal machine parts.

Do not spray water onto the machine to clean it.

Storing the machine

Storing the machine

If the machine is to remain out of use for a long time, switch it off and unplug it.

Store it in a dry place out of children’s reach. Keep it protected from dust and

dirt.

Servicing / Maintenance

Servicing / Maintenance

In the event of a breakdown, fault or suspected damage after a fall, immediately

unplug the machine and notify the service provider or specialised technician.

Never attempt to operate a faulty machine.

• 7 •

ENGLISH

Only the service provider and/or a specialised technician are authorised to performing servicing and repairs.

Fire safety

Fire safety

In the event of a fi re, use carbon dioxide (CO2) extinguishers. Do not use water

or powder extinguishers.

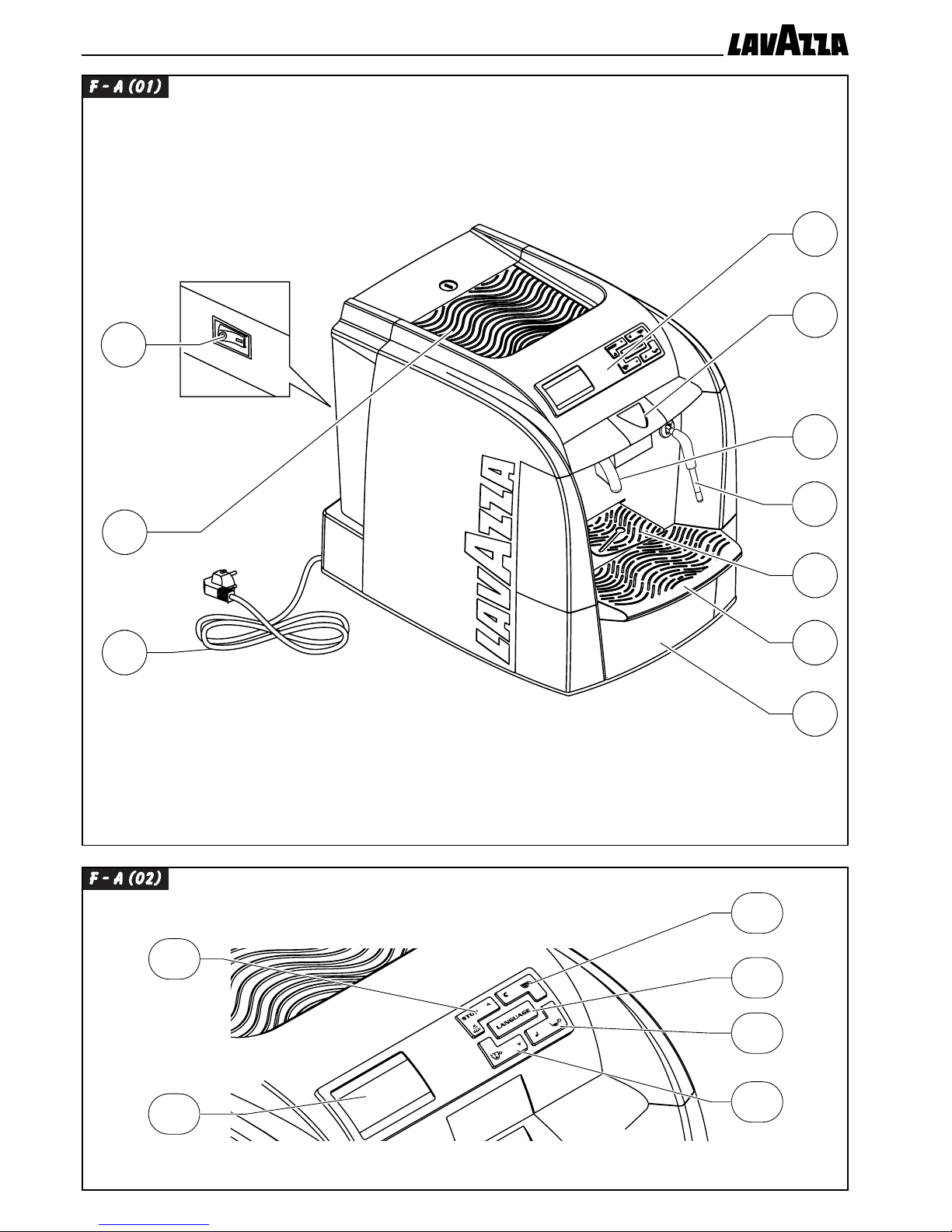

3 KEY TO MACHINE COMPONENTS (FIG.01)

3 KEY TO MACHINE COMPONENTS (FIG.01)

1 Control panel

2 Pod loading tray

3 Brew unit

4 Steam wand

5 Cup rest grill (small cups)

6 Cup rest grill (large cups)

7 Used pod drawer and drip tray

8 Power cord

9 Cup warmer always on

10 ON/OFF switch

3.1 Description of control panel (Fig.02)

3.1 Description of control panel (Fig.02)

11 Large coffee

button

When this button is pressed the machine will

brew a large coffee (quantity programmed by the

service provider).

12 “LANGUAGE”

button

It allows the user to display messages in the

desired language

13 Espresso

button

When this button is pressed the machine will brew

an espresso coffee (quantity programmed by the

service provider).

14 Manual dispensing

button

When this button is pressed the machine will dispense a quantity of product manually controlled

by the user (the user must stop the machine by

pressing the STOP button).

15 Button

1 - Steam

When you press this button the machine will instantly dispense steam

2 - Stop Pressing this button will stop fl ow when the machi-

ne is brewing coffee/other beverages or dispensing steam

16 LCD Display It displays the machine status and any alarms as well

as guiding the user in the operation of the machine.

4 USING THE MACHINE

4 USING THE MACHINE

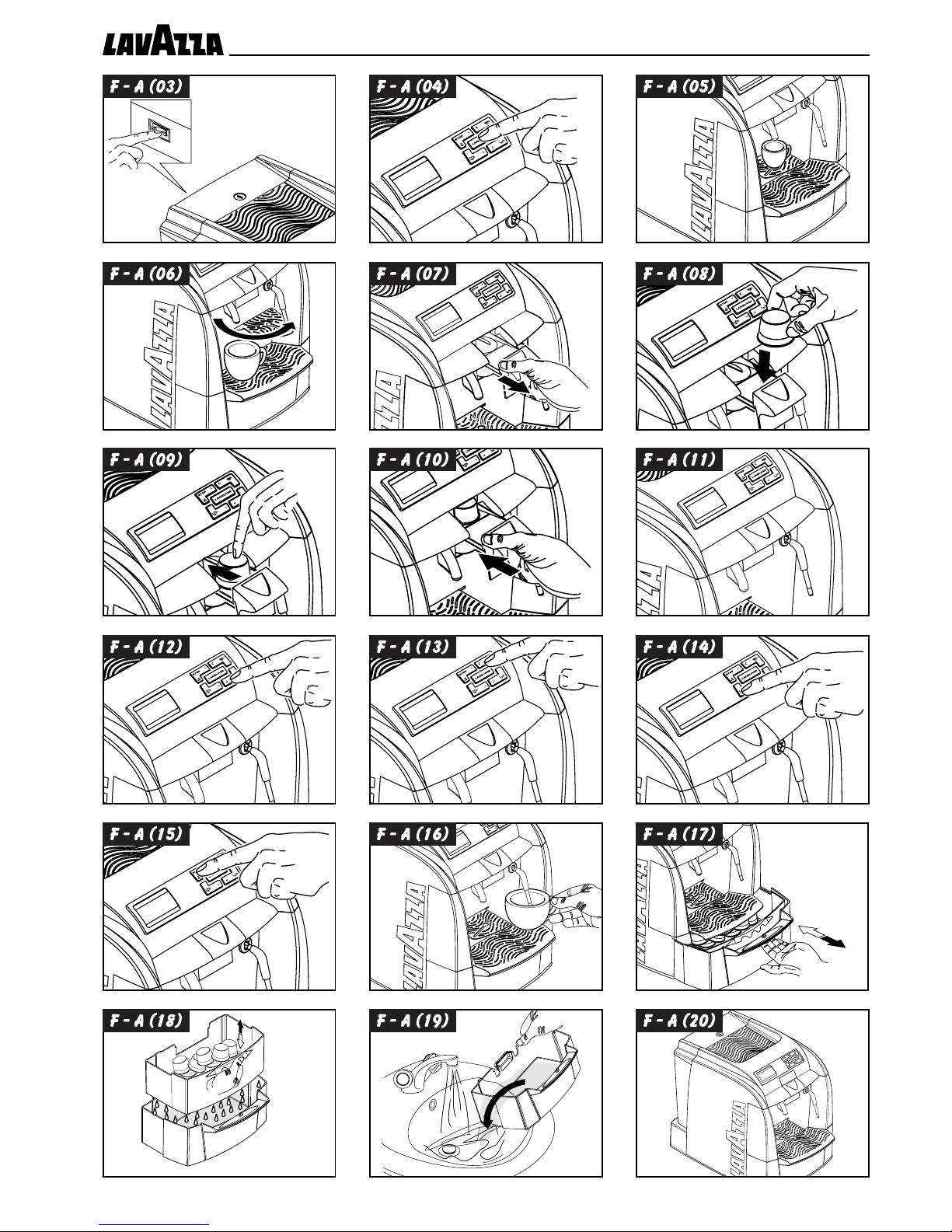

4.1 Switching on the machine

4.1 Switching on the machine

Warning! Only the service provider is authorised to make the connection to the mains power supply!

Before switching on the machine, make sure the plug is properly inserted in

the electric socket.

To switch on the machine, move the ON/OFF switch on the back to “I” (Fig.03).

The display will show:

10:30 11 Feb 04

Warming up

Wait please...

At this time the machine is warming up.

When the machine reaches the right temperature for brewing the beverage,

the display will show:

10:30 11 Feb 04

Ready

Insert pod

Now the machine is ready to dispense the beverage.

Note: if the machine is connected to a coin mechanism, in order to

brew coffee or other beverages the user must fi rst insert coins un-

til reaching the required amount. For further explanation see section 4.9.

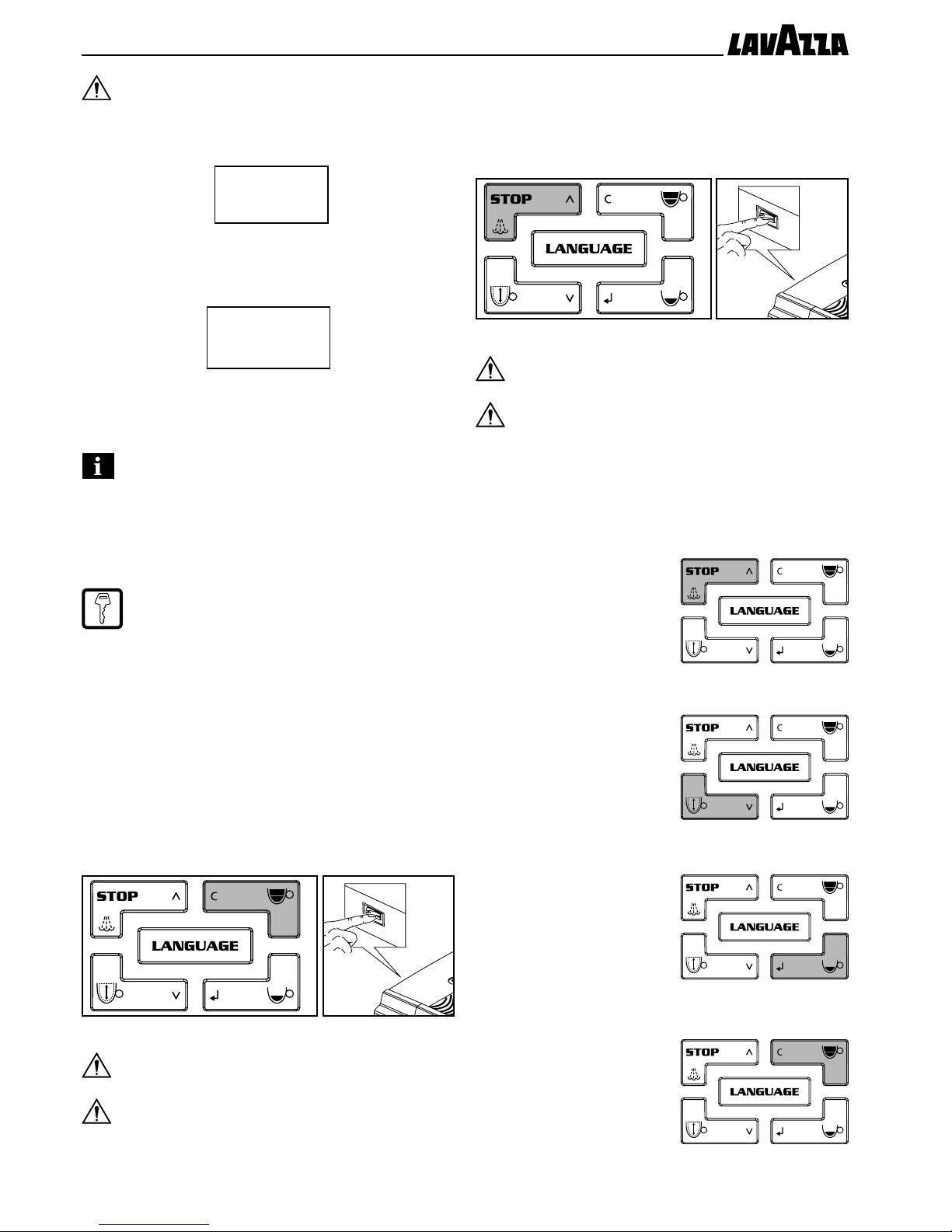

4.2 Selecting the display language (Fig.04)

4.2 Selecting the display language (Fig.04)

The machine has been designed to display messages in different languages.

To select the desired language, press the “LANGUAGE” button until the language you prefer appears on the display.

Note: the display language can be changed at any time during machine operation.

4.3 Using cups, mugs and glasses

4.3 Using cups, mugs and glasses

Warning! Do not use containers that stick out from the edge of the

grills they are resting on.

The machine is designed to correctly dispense beverages in small cups and/or

larger-sized containers.

The cups and/or mugs must be correctly positioned beneath the brew unit.

Note: if the cups and/or mugs are not correctly positioned beneath

the brew unit, the beverage may spill out of its container.

When dispensing in small cups, use the upper grill (Fig.05).

When dispensing in larger cups, mugs and/or glasses, use the lower grill, turning the upper grill counterclockwise by hand to move it out of the way (Fig.06).

4.4 Inserting pods

4.4 Inserting pods

Warning! To prepare the desired drinks, use only LAVAZZA pods

supplied directly by the service provider. Each pod is designed

and made to prepare a single serving.

Do not use pods other than those supplied by the service provider,

coffee beans, preground and/or freeze-dried coffee.

Do not reuse the same pod to prepare two or more drinks.

To insert a pod, it is necessary to open the loading tray.

To open the tray, pull it out all the way (Fig.07).

The display will show:

10:30 11 Feb 04

Insert pod

Close pod tray

Warning! Do not attempt to force it out beyond the limit.

Take a single pod by hand and place it on the outermost part of the slide (Fig.08).

Warning! The pod must be positioned as shown in the picture.

Gently push the pod into place inside the machine (Fig.09).

Note: the pod must be fi tted into place without using any further

tools; after being inserted, the pod may no longer be extracted.

When the pod is correctly positioned, close the tray (Fig.10).

• 8 •

The display will show:

10:30 11 Feb 04

Ready

Select product

.

Warning! If you meet with any resistance when closing the tray,

check the position of the pod.

It is forbidden to place fi ngers or any object other than a Lavazza

pod inside the tray.

At this point the pod has been inserted and the user is prompted to select the

desired drink.

4.5 Coffee/beverage dispensing

4.5 Coffee/beverage dispensing

Before dispensing a coffee/beverage make sure that:

1 The machine is warmed up;

2 the pod has been correctly positioned;

3 a cup suitable for the selected product is placed beneath the dispensing

tube.

4 the required amount has been inserted (machines with coin mechanism only).

Making espresso (Fig.12)

Press the espresso button. The machine will automatically brew the coffee. On

reaching the quantity programmed by the service provider, the machine will

automatically stop dispensing coffee.

Making a large coffee (Fig.13)

Press the large coffee button. The machine will automatically brew the coffee.

On reaching the quantity programmed by the service provider, the machine will

automatically stop dispensing coffee.

Manual dispensing (Fig.14)

Press the manual dispensing button. The machine will automatically start dispensing the selected product; the machine must be stopped by pressing the

“Stop” button.

Note: if the stop button is not pressed, coffee may overfl ow from

the cup; in any case, the machine will stop dispensing on reaching

the maximum quantity programmed by the manufacturer.

The machine will carry out a prebrewing cycle.

The display will show:

10:30 11 Feb 04

Prebrewing

Wait please...

Note: the fl ow of coffee can be shut off at any time by pressing the

“Stop “ button (see section 4.6).

10:30 11 Feb 04

Erogating Dose

Stop to end

On completion of the brewing operation

10:30 11 Feb 04

Done

Wait please...

the display will show:

The machine will automatically discharge the used pod into the dreg drawer

and be ready for the next brewing cycle.

4.6 “STOP” dispensing coffee/beverage (Fig.15)

4.6 “STOP” dispensing coffee/beverage (Fig.15)

The machine is programmed to automatically stop brewing coffee after it has

dispensed the quantity programmed by the service provider for “espresso and

large coffee”.

To stop the fl ow of coffee ahead of time, press the “STOP” button (Fig.15).

Warning! The fl ow must be manually stopped if the manual dis-

pensing function has been selected.

4.7 Emptying the dreg drawer

4.7 Emptying the dreg drawer

Note: the operator should perform the checking of coffee grounds.

Sometimes it is not necessary to empty the dreg drawer as it is

indicated in this section.

Note: the dreg drawer may be emptied only when the machine is

on.

Note: every time the dreg drawer is removed for more than 5 sec-

onds, the count of the capsules it contains is restarted.

When removing the dreg drawer, always empty the used capsules into an

appropriate container.

The machine will signal when the dreg drawer has fi lled to capacity.

The fi rst message warns the user that the dreg drawer must be emptied but the

machine will still allow coffee to be brewed; the display will show:

10:30 11 Feb 04

Ready

Empty dregdrawer

If the drawer is not emptied of used pods, after a few brewing cycles the machine will be disabled; in this case the display will show:

10:30 11 Feb 04

Empty dregdrawer

Before coffee can be brewed again, the dreg drawer must be emptied of used

pods (Fig17 - Fig.18).

Note: the dreg drawer will also contain liquid residues as a re-

sult of dripping after coffee or other beverages have been dispensed; the liquids and pods must be disposed of separately, as appropriate. (Fig.19).

The pod trap must be fi tted back into the dreg drawer before the

latter can be inserted in the machine.

After emptying the dreg drawer, fi t it back in place; the display will show:

10:30 11 Feb 04

Ready

Insert pod

The machine is now ready to make coffee.

Warning! The LAVAZZA pods used with the machine are singleserving pods to be used for the preparation of one drink only. Do

not use the same pod to prepare more than one drink.

Note: when pulling out the dreg drawer, do not grasp the lower

grill; this should remain in contact with the machine.

• 9 •

ENGLISH

4.8 Dispensing steam (Fig.16)

4.8 Dispensing steam (Fig.16)

Steam can be used to froth milk for cappuccino and also to heat

beverages.

Danger of scalding! The steam may be preceded by brief sprays

of hot water. The steam wand may reach high temperatures: avoid

touching it directly with your hands.

Before dispensing steam make sure that:

1 the machine has warmed up;

2 the steam wand is directed over the large cup rest grill.

Press the steam button (Fig.15) for a few seconds to discharge any water left

in the steam wand; shortly only steam will issue from the nozzle. The display

will show:

10:30 11 Feb 04

Steam

Stop to end

Press the button again (Fig.15) to stop fl ow.

Position a cup containing the beverage under the steam nozzle (Fig.16); press

the steam button (Fig.15).

When preparing cappuccino, use only cold milk for best results.

Move the cup slowly up and down in a circular fashion to heat and/or froth

evenly.

After heating/frothing for the desired amount of time, press the button (Fig. 15)

to shut off steam.

After this operation, wipe the steam wand clean with a damp cloth.

4.9 Using the coin mechanism (Optional)

4.9 Using the coin mechanism (Optional)

The coin mechanism is an optional component that can be installed only by a specialised technician.

If the machine is equipped with a coin mechanism, coins must be inserted in

order to dispense beverages.

the desired coffee/beverage.

Afterward the display will show:

10:30 11 Feb 04

Ready

Insert pod

At this point the user can brew coffee or another beverage as described in

section 4.4 and below.

Note: the manager establishes the amount to be inserted in the

coin box to brew coffee or other beverages. The amount inserted

can be shown on the display only if the coin mechanism features this option and/or the manager has enabled the function.

The functions of the coin mechanism are managed by the latter and do

not depend on the machine’s operation.

5 CLEANING

5 CLEANING

• Cleaning jobs may be carried out only when the machine is cold and discon-

nected from the power supply.

• Use a soft cloth dampened with water to clean the appliance.

• Do not immerse the machine in water nor place any of its components in a

dishwasher.

• Do not use sharp objects or harsh chemical products (solvents) for clean-

ing.

• Never dry the machine and/or its components in a microwave or conven-

tional oven.

6 DESCALING

6 DESCALING

Scale normally forms inside the appliance with use; when the machine needs

descaling, the display will show:

10:30 11 Feb 04

Ready

Please descale

In this case the machine can still be used normally to make coffee. Notify the

service provider, who will carry out a descaling treatment.

Note: only the service provider is authorised to descale the ma-

chine.

Note: no coins need to be inserted in order to dispense steam.

The display will show:

10:30 11 Feb 04

Ready

Insert credit

Only after the amount shown has been inserted will the user be able to select

• 10 •

7 MACHINE INDICATIONS AND WARNINGS

7 MACHINE INDICATIONS AND WARNINGS

This section describes all the messages the machine displays to the user and

which actions can and/or must be performed by the user.

Display Meaning Actions

The machine is ready to

brew coffee.

You can dispense a coffee/

beverage.

The machine is equipped

with a coin mechanism.

To brew a beverage, insert

the amount specifi ed for cof-

fee or other drinks.

The pod loading tray has

been opened.

Position a LAVAZZA pod in

the tray and close the tray.

Close the tray empty.

The tray has been closed

with a LAVAZZA pod inserted.

Dispense the beverage.

The machine is dispensing

steam.

Stop fl ow manually by press-

ing the STOP button.

The machine has started

the brewing cycle.

Wait until the machine automatically stops dispensing

the beverage.

Manually shut off fl ow by

pressing the STOP button.

The machine has fi nished

dispensing the beverage

and is being set in ideal

conditions for carrying out

the next brewing cycle.

The dreg drawer has been

removed from place.

Insert the dreg drawer.

The water tank is empty. Call the service provider,

who will fi ll the machine wa-

ter tank.

A machine fault has occurred.

Call the service provider.

The machine is warning

the user that the credit for

dispensing product is about

to run out.

Contact the service provider

and purchase new pods.

The supply of pods has run

out so no beverages can be

dispensed.

Contact the service provider

and purchase new pods.

The machine warns of the

need to carry out a descaling cycle but still allows beverages to be dispensed.

Call the service provider.

Display Meaning Actions

The machine warns of the

need to empty the dreg

drawer but still allows beverages to be dispensed. (If

enabled)

While the machine is

switched on but not working,

pull out the dreg drawer and

empty it of used pods.

The dreg drawer must be

emptied. (If enabled)

It is no longer possible to

dispense beverages.

(If enabled)

While the machine is

switched on but not working,

pull out the dreg drawer and

empty it of used pods.

Problems Causes Remedies

The machine does not

turn on

The machine is not

connected to the power

supply.

Contact the Service provider.

The ON/OFF switch has

not been pressed.

Turn on the machine by

pressing the ON/OFF switch.

The machine does not

work

No message on the

display.

Contact the Service provider.

10:30 11 Feb 04

Ready

Insert pod

10:30 11 Feb 04

Insert pod

Close pod tray

10:30 11 Feb 04

Ready

Select product

10:30 11 Feb 04

Erogating Dose

Stop to end

10:30 11 Feb 04

Done

Wait please...

10:30 11 Feb 04

Insert drawer

10:30 11 Feb 04

Fill with water

10:30 11 Feb 04

Out of service xx

Call service

10:30 11 Feb 04

Ready

Please descale

10:30 11 Feb 04

No credit

10:30 11 Feb 04

Ready

Empty dregdrawer

10:30 11 Feb 04

Empty dregdrawer

10:30 11 Feb 04

Credit Low

10:30 11 Feb 04

Ready

Insert credit

10:30 11 Feb 04

Steam

Stop to end

• 11 •

ENGLISH

8 HANDLING AND STORAGE

8 HANDLING AND STORAGE

All the operations described in section 8 must be performed exclusively by your service provider or a specialised technician,

who must organise all the operating sequences and use suitable

means to ensure strict compliance with current safety regulations.

8.1 Handling

8.1 Handling

During transport and handling, the machine must remain in an upright position

according to the indications shown on the packing container.

The machine must be lifted and positioned with care.

Do not shake it.

Make sure that no persons are standing within range of the load

during lifting and handling operations.

In diffi cult conditions, additional personnel should be assigned to over-

see the manoeuvres to be carried out.

8.2 Storage

8.2 Storage

The machine must be kept in the following storage conditions:

- minimum temperature: above 4°C.

- maximum temperature: below 40°C.

- maximum humidity: below 95%

The machine is packed in cardboard containers with expanded polystyrene.

Warning. Given the total weight of the packing container, it is for-

bidden to stack more than three machines. The machine must be

stored in its original packing in a NON-humid, NON-dusty place.

9 INSTALLATION

9 INSTALLATION

All the operations described in section 9 must be performed exclusively by your service provider or a specialised technician,

who must organise all the operating sequences and use suitable

means to ensure strict compliance with current safety regulations.

9.1 Safety rules

9.1 Safety rules

• Carefully read the entire instruction book.

• The connection to the mains power supply must be made in accordance

with the safety regulations in force in the user’s country.

• The machine must be connected to a socket which is:

- compatible with the type of plug installed on the machine;

- suitably sized to comply with the ratings shown on the machine identifi -

cation plate.

- effi ciently earthed.

• The power cord must not:

- come into contact with any type of liquid: danger of electric shocks and/

or fi re;

- be crushed and/or placed in contact with sharp surfaces;

- be used to move the machine;

- be used if damaged;

- be handled with damp or wet hands;

- be wound in a coil when the machine is being operated.

- be tampered with.

• It is forbidden to:

- Install the machine outdoors and other than as directed in Section 9.

- Use the machine in proximity to infl ammable and/or explosive substances.

- Leave plastic bags, polystyrene, nails etc. within children’s reach, as

they are sources of potential danger.

- Allow children to play near the machine.

- Use spare parts not recommended by the manufacturer.

- Make any technical changes to the machine.

- Immerse the machine in any type of liquid.

- Wash the machine with a spray of water.

- Use the machine in any manner other than as directed in this instruction

book.

- Install the machine on top of other appliances.

- Use the machine in an explosive or aggressive atmosphere or where

there is a high concentration of dust or oily substances suspended in

the air;

- Use the machine where there is a potential fi re hazard;

- Use the machine to dispense substances that are incompatible with the

characteristics of the machine itself;

• Before cleaning the machine, make sure it is unplugged. Do not wash it with

petrol and/or solvents of any kind.

• Do not place the machine near heating equipment (like stoves or radiators).

• In the event of a fi re, use carbon dioxide (CO

2

) extinguishers. Do not use

water or powder extinguishers.

9.2. Stop functions

9.2. Stop functions

The machine is stopped using the ON/OFF switch.

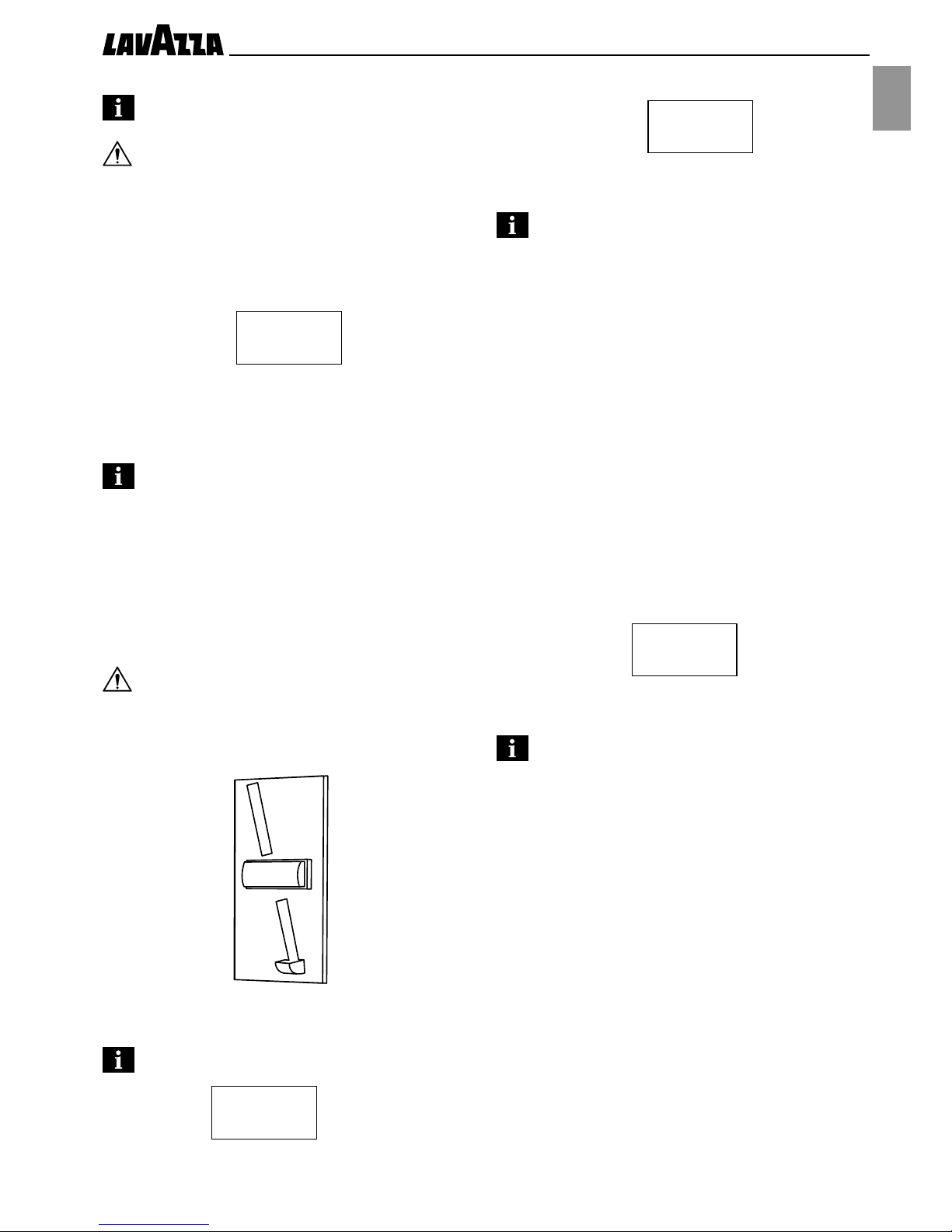

9.3. List of accessories supplied

9.3. List of accessories supplied

Manual: Instructions for operating the machine.

Water hardness test: quick test for determining the actual hardness of the

water used to prepare beverages; this test is of fundamental importance for

setting the water hardness in the machine.

Key for accessing water tank: it is used to prevent unauthorised personnel

from accessing the water tank.

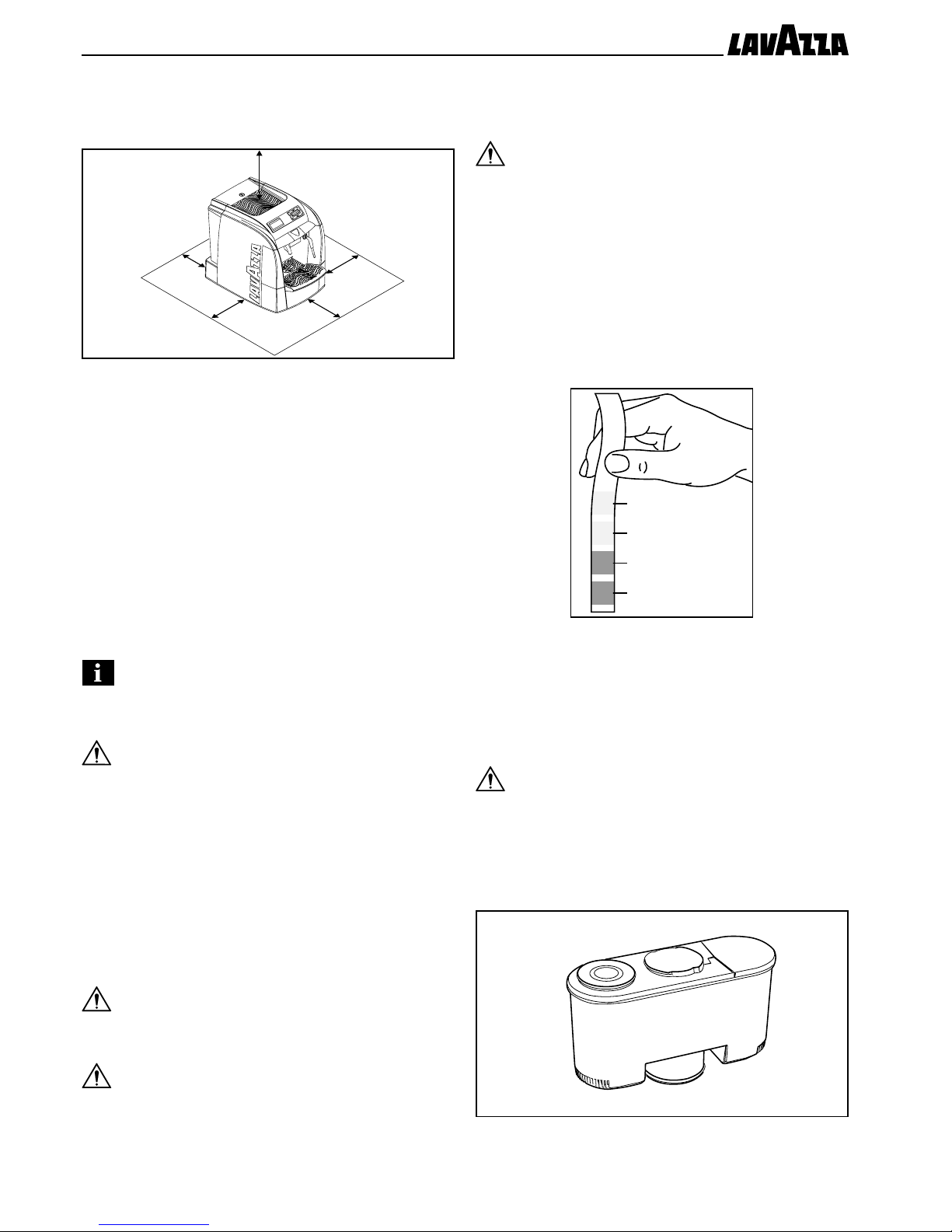

“Aqua Prima” Filter: for perfect coffee, water is no less essential than the right

roast level. It has to be clear and fresh.

9.4. Installation-Siting

9.4. Installation-Siting

It is forbidden to install the machine outdoors or in places where

jets of water or steam are used.

The presence of magnetic fi elds or vicinity of electrical equipment

that generates disturbance may cause the machine electronic con-

trol system to malfunction.

Important. As temperatures approach 0°C, the internal parts containing water are subject to freezing. Do not use the machine in

such conditions.

To ensure that the machine works properly and effi ciently, the following condi-

tions are recommended:

• ambient temperature: 10°C ÷ 40°C

• maximum humidity: 90%.

• the site should be duly prepared for installation of the machine;

• the machine should rest on a level, solid and fi rm surface; the surface the

machine rests on should incline by no more than 2°;

• the machine should be installed in an adequately lit, ventilated, hygienic

location and the electric socket should be within easy reach.

Adequate clearance must be provided to allow users to freely access the machine and plug and leave the area immediately in case

of need.

• 12 •

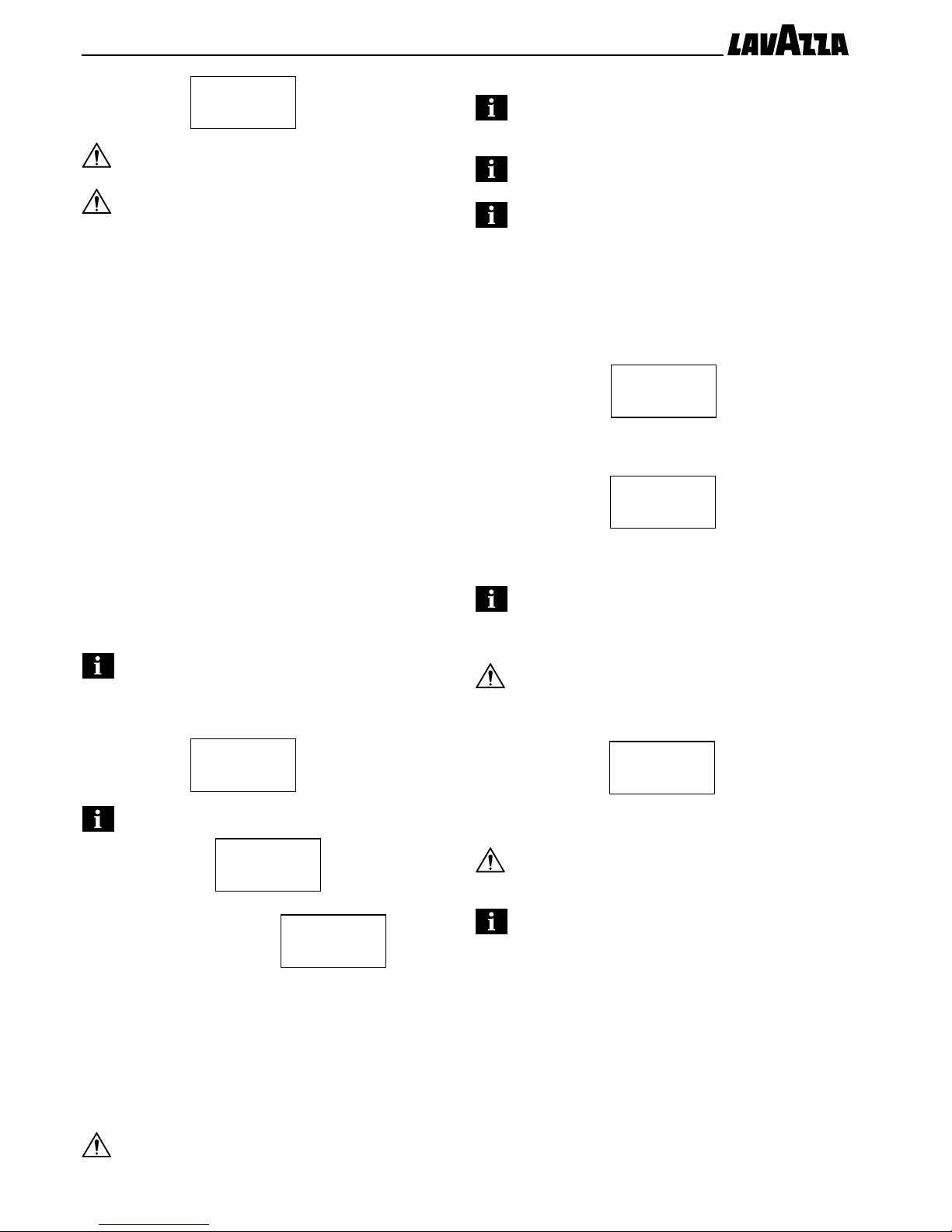

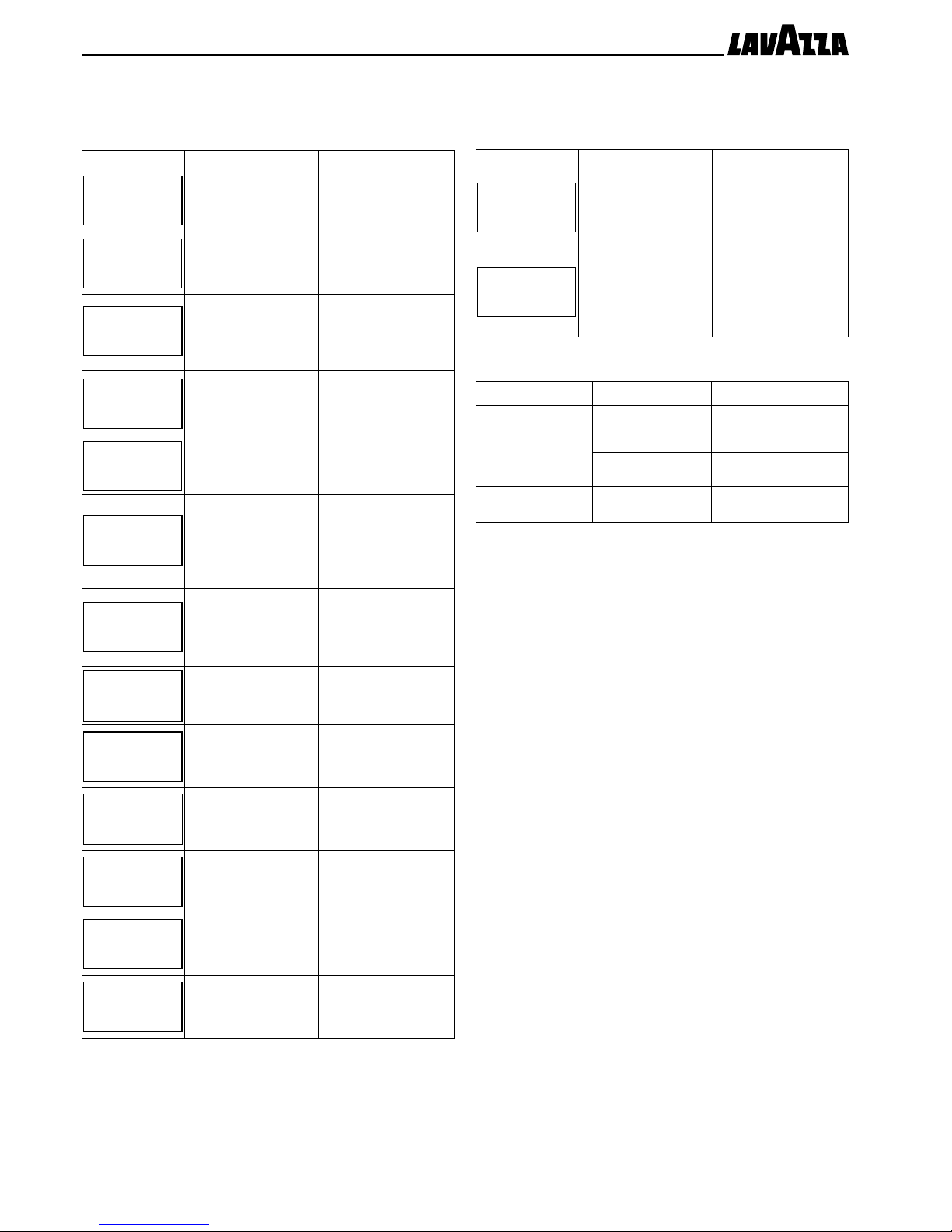

The illustration shows the minimum spaces for accessing:

• the control panel on the front

• the components that may require servicing in case of machine malfunctioning.

200

200

100

200

400

After positioning the packing container near the installation site, proceed as

follows:

• make sure that the original packing container is closed and intact and has

not been tampered with during transport;

• open the packing;

• check the condition and model of the packed machine;

• check the contents of the bag of accessories enclosed with the machine

(see “9.3 List of accessories supplied”);

• remove the machine from its original packing container;

• free it from any remaining packing materials;

• then lift the machine and position it in the site prepared beforehand.

9.5. Disposal of packing materials

9.5. Disposal of packing materials

After the packing container has been opened, the packing materials should be

segregated according to type and disposed of in accordance with the regulations in force in the user’s country.

We recommend keeping the packing container for future conveyance

or transport.

9.6. Electrical connection

9.6. Electrical connection

This job may be performed only by specialised technical personnel

or by the service provider.

The machine is designed to work with single-phase voltage: the voltage rating

is shown on the identifi cation plate (1.4 Machine identifi cation).

Before plugging in the machine, make sure that the ON/OFF switch is positioned on “0”.

The Service provider makes and is responsible for the electrical connection of

the machine.

The machine must be connected to the power supply line via the plug installed

on the power cord, bearing in mind:

• The laws and technical standards in force at the time of installation;

• The technical data shown on the plate on the side of the machine.

Warning: The electrical socket to which the machine is connected

must be situated within convenient reach of users, so that they can

easily disconnect the machine from the mains power line when necessary.

It is forbidden to:

• Use extension cords of any type.

• Replace the original plug.

• Use adaptors.

9.7 Setting the water hardness.

9.7 Setting the water hardness.

This function allows you to set the degree of water hardness so that the machine will signal the need for a descaling treatment at the right time.

Warning. To make this setting, carefully read the directions provided in section 10.

The hardness of tap water may vary depending on the region.

For this reason, the appliance can be set according to the water hardness in the

place where it is to be used, expressed on a scale of 0 to 4.

The appliance is factory set on a standard value (hardness 1).

The setting should be adjusted according to the level of hardness of the water

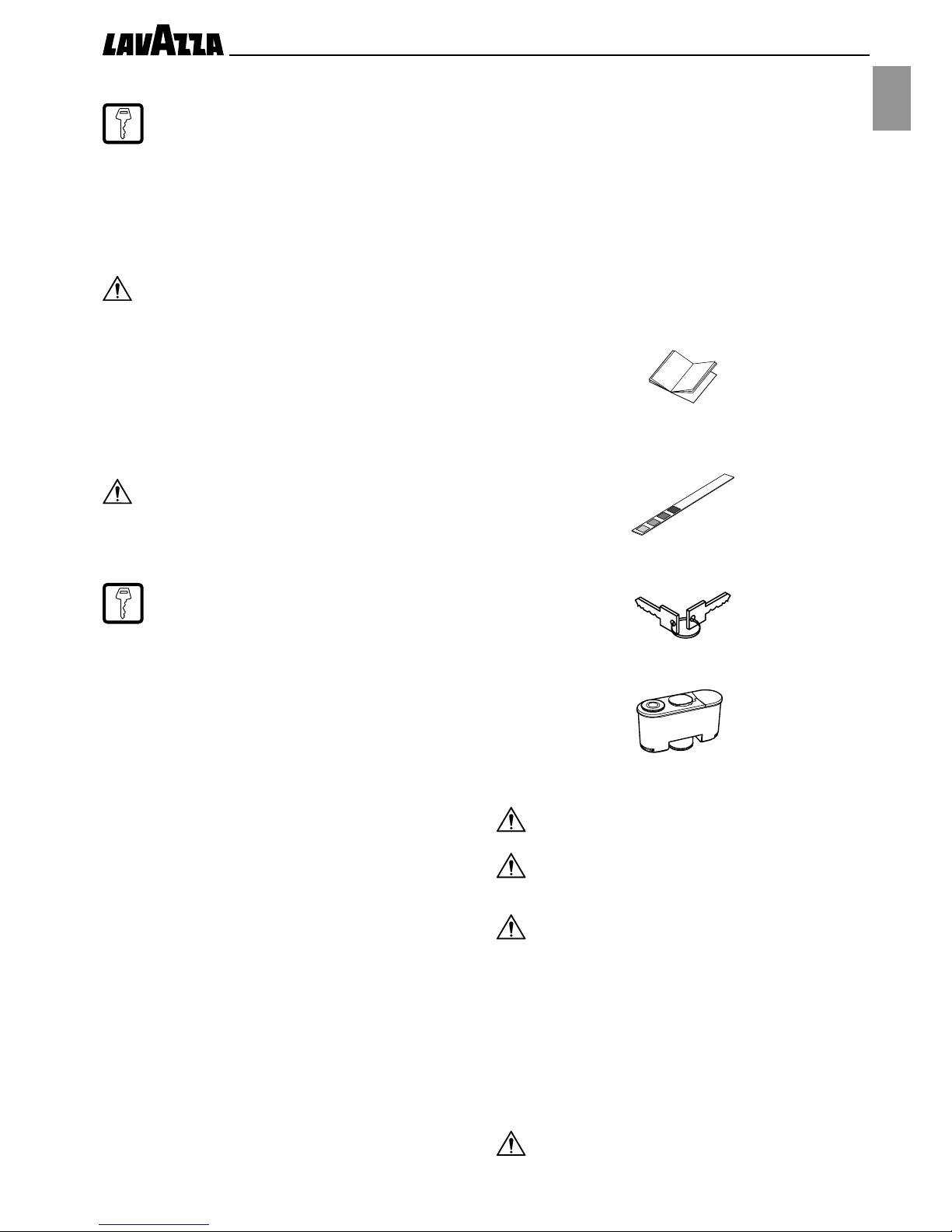

supply, which can be measured using the strip provided with the machine.

Briefl y dip (1 second) the strip provided in water and shake it gently.

After one minute the test results can be read on the strip.

Sehr weiches Wasser

Weiches Wasser

Mittleres Wasser

Hartes Wasser

Durezza 4

Durezza 3

Durezza 2

Durezza 1

HARDNESS 4 (hard)

HARDNESS 3 (medium)

HARDNESS 2 (soft)

HARDNESS 1 (very soft)

HARDNESS 0 (descale control disabled)

After completing the test, set the corresponding value on the machine.

WARNING: before operating the coffee machine, you must install

the Aqua Prima fi lter, supplied with, inside the water tank.

9.8 “Aqua Prima” Filter and fi lling the water tank

9.8 “Aqua Prima” Filter and fi lling the water tank

Properly check the water hardness level and install the “Aqua Prima” fi lter.

For perfect coffee, water is no less essential than the right roast level.

It has to be clear and fresh.

Thanks to its revolutionary system, the “Aqua Prima” fi lter purifi es tap water,

eliminating all harmful substances without holding back important minerals.

Dimensions in mm

Hardness 4

Hardness 3

Hardness 2

Hardness 1

• 13 •

ENGLISH

The “Aqua Prima” fi lter must be replaced when the machine sig-

nals to do so.

Before descaling, the “Aqua Prima” fi lter must be removed from

the water tank.

In order to ensure a correct use of the “Aqua Prima” fi lter, please observe the

following recommendations:

1. Store the “Aqua prima” fi lter in a cool place away from the sun, at a tem-

perature between +5°C and +40°C;

2. Use in areas with temperature not higher than 60°C.

3. It is advisable to wash the “Aqua prima” fi lter if the machine has been inac-

tive for 3 days or more;

4. Replace fi lter if the machine has been inactive for 20 days or more;

5. To preserve a fi lter that has already been opened, place in a plastic airtight

bag and store in the refrigerator; do not store in freezer, as this will alter the

properties of the fi lter;

6. Before using the fi lter, place in the water tank for 30 minutes;

7. Once removed from its package, do not store fi lter in the open air;

8. The fi lter must be replaced within 90 days after it has been removed from its

package, or after it has fi ltered 60 litres of drinking water.

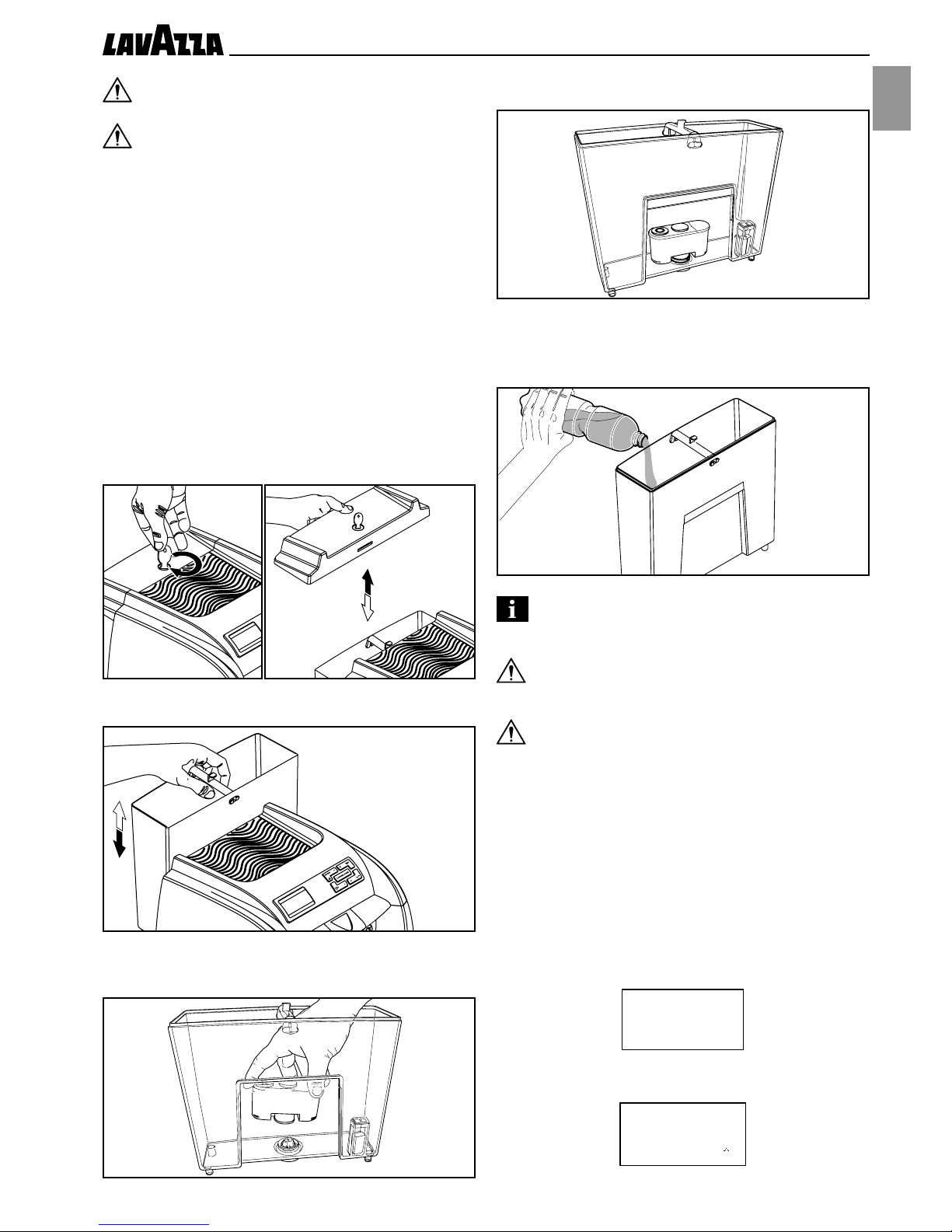

To install the “Aqua Prima” fi lter, proceed as follows:

1 using the key supplied with the machine, open the lid of the water tank and

lift it off.

2 Lift out the tank using the handle provided.

3 take the “Aqua Prima” fi lter from its package and insert it into the tank; posi-

tion the reference mark so that it corresponds to the slot;

4 insert fi lter and push fully as you make light oscillating movements;

5 fi ll the water tank with fresh drinking water and correctly place the tank back

in the machine.

Note: before using the fi lter, leave it immersed in water for about

30 minutes, for its activation.

Warning! The tank may be fi lled only with fresh drinking water. Hot

or carbonated water or other liquids will damage the machine.

When fi lling the tank, never exceed the maximum level.

After fi lling the water tank, set it back in place, taking care to position it

correctly; in this manner the valve situated at the bottom will open and allow

the machine to work properly.

Replace the lid on the water tank.

Lock the lid in place using the key provided.

6 go to the programming menu section 10.1 and enable the fi lter replacement

control (2.6. Filter warning);

Go to the service menu as directed in section 10.2 and display the fi lter activa-

tion menu.

5.

Enable filter

Using the appropriate controls, select “Yes” to perform fi lter activation.

5.

Enable filter

Yes

• 14 •

10.2 Service menu

10.2 Service menu

To access the service menu, proceed as follows:

1 Turn off the machine by pressing the ON/OFF switch,

2 Press the “STOP” button and simultaneously turn the machine back on by

pressing the ON/OFF switch.

Section 10.5 lists all the functions available in this menu.

The menu must be PASSWORD protected.

The PASSWORD must be set during the machine initialisation

phase to prevent access of unauthorised personnel.

10.3 Programming commands

10.3 Programming commands

When you access the machine programming or service menu, the keys take

on different functions.

“Page up/edit”

This key enables you to:

1 browse the pages of a menu;

2 change parameters once they

have been made editable with

the ENTER key.

“Page down/edit”

This key enables you to:

1 browse the pages of a menu;

2 change parameters once they have

been made editable with the ENTER

key.

“Select/confi rm” (ENTER)

This key enables you to:

1 select the function displayed;

2 make a parameter/value editable;

3 confi rm a parameter/value once it

has been made editable.

“ESC”

This key can be pressed to exit without

saving changes to the edited or selected parameter.

Note: the activation cycle cannot and must not be interrupted.

The machine brings the brew group to the working position and dispenses

water from the coffee spout. The display will show:

Enable filter

in progress

Wait please ...

The machine dispenses a preset quantity of water for correct activation of

the new “Aqua Prima” filter.

When the cycle is complete, the display will show:

5.

Enable filter

Exit the service menu. The machine will go back into the normal operating

mode.

Empty the dreg drawer of the fi lter rinse water.

Note: set machine to the water hardness value which is immediately below the measured value. If 3 squares changed in colour,

then the value to be set is 2.

Now the machine is ready to dispense drinks.

10 MACHINE PROGRAMMING

10 MACHINE PROGRAMMING

All the operations described in section 10 must be performed

exclusively by your service provider or a specialised technician,

who must organise all the operating sequences and use suitable

means to ensure strict compliance with current safety regulations.

The specialised technician or service provider can change some machine operating parameters according to the personal needs of users.

There are two menus that can be used:

1 Programming menu;

2 Service menu.

10.1 Programming menu

10.1 Programming menu

To access the programming menu, proceed as follows:

1 Turn off the machine by pressing the ON/OFF switch,

2 Press the “large coffee” button and simultaneously turn the machine back

on by pressing the ON/OFF switch.

Section 10.4 lists all the functions available in this menu.

The menu must be PASSWORD protected.

The PASSWORD must be set during the machine initialisation

phase to prevent access of unauthorised personnel.

• 15 •

ENGLISH

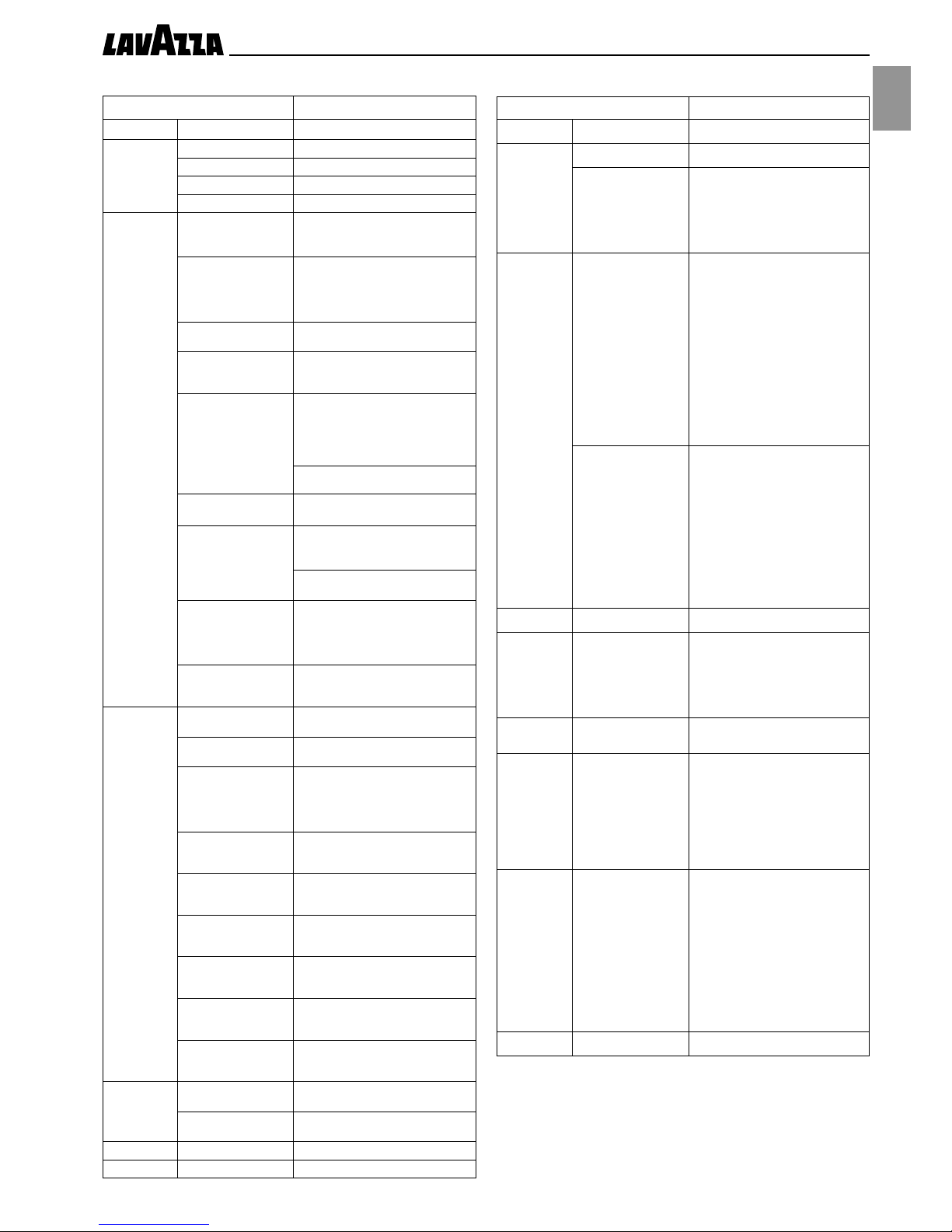

10.4 Description of programming menu

10.4 Description of programming menu

10.5 Description of service menu

10.5 Description of service menu

Menu

Menu

Notes

Notes

Password Required only if other than 0.

1. Identifi cation 1.1. Machine code Machine identifi cation code.

1.2. Model Read only.

1.3. Version Read only.

1.4. Asset Number Service provider identifi cation code.

2. Setup 2.1. Temperatures

2.1.1. Std. temperature

Default: 100°C

Operating temperature when machine is

“warmed up”.

2.2. Programme doses

2.2.1. Dose water short

Default: 165

2.2.2. Dose water long

Default: 275

Qty. small drink (it is a numerical parameter

without any physical equivalent, e.g. cc).

Qty. large drink (it is a numerical parameter

without any physical equivalent e.g. cc).

2.3. Prebrewing

Default: Medium

Prebrewing time.

2.4. Ventilate

Default: No

Enables/disables rinse cycle when machine is

switched on (this function will only be performed

when the machine is cold).

2.5. Descale

2.5.1. Water hardness

Default: 1

2.5.2. Descal. warning

Default: Yes

Range: 0-4 - Water hardness setting to

determine the quantity of water after which the

machine will signal a descaling alarm.

0 = disables the descale control function.

Enables/Disables display of descaling alarm.

2.6. Filter warning

Default: No

Enables/Disables display of an alarm message

indicating that the fi lter needs replacing.

2.7. Credits

2.7.1. Credit control

Default: No

2.7.2. Credits warning

Default: No

Enable/Disable the dispensing control via credit

management.

Enable/Disable the display of alarms “Credit

low” and “No credit”

2.8. Payment method

2.8.1. Enable system

Default: No

2.8.2. Display credit

Default: No

Enables/Disables brewing/dispensing by

means of an external coin mechanism.

Enables/Disables display of the amount inserted in the coin box.

2.9 Grounds control

Default: Yes

It enables/disables the machine to brew without

checking the number of used pods in the dump

box.

3. Save energy 3.1. Stand-by enabled

Default: No

Enables/disables stand-by function.

3.2. Ritardo stand-by

Default: 10

Elapsed time in minutes since last use before machine switches off when in the Stand-by time band.

3.3. Monday

3.3.1. Switch on time

Default: 08.00

3.3.2. Switch off time

Default: 20.00

It enables you to program the machine ON/OFF

times for Monday.

3.4. Tuesday

3.4.1. Switch on time

3.4.2. Switch off time

It enables you to program the machine ON/OFF

times for Tuesday.

3.5. Wednesday

3.5.1. Switch on time

3.5.2. Switch off time

It enables you to program the machine ON/OFF

times for Wednesday.

3.6. Thursday

3.6.1. Switch on time

3.6.2. Switch off time

It enables you to program the machine ON/OFF

times for Thursday.

3.7. Friday

3.7.1. Switch on time

3.7.2. Switch off time

It enables you to program the machine ON/OFF

times for Friday.

3.8. Saturday

3.8.1. Switch on time

3.8.2. Switch off time

It enables you to program the machine ON/OFF

times for Saturday.

3.9. Sunday

3.9.1. Switch on time

3.9.2. Switch off time

It enables you to program the machine ON/OFF

times for Sunday.

4. Security 4.1. Password

Default: 000000

sets the password for accessing the

programming menu (6 digits)

4.2. Service password

Default: 0000

sets the password for accessing the service

menu (4 digits)

5. Reset to default selecting “Yes” will restore all default settings

6. Exit Press ENTER to quit.

Menu

Menu

Notes

Notes

Password Required only if other than 0

1. Date & Time 1.1. Time Sets the current time

1.2. Date

1.2.1. Day

1.2.2. Month

1.2.3. Year

1.2.4. Day of the week

2. Audit 2.1. Total from reset

2.1.1. Total from reset

2.1.2. P1 from reset

2.1.3. P2 from reset

2.1.4. P3 from reset

2.1.5. Last Reset

2.1.6 Reset Audit

Number of total products since last reset

Number of type 1 products (espresso) since

last reset

Number of type 2 products (long coffee) since

last reset

Number of type 3 products (free cycle) since

last reset

Read only - Date and time of last reset

Selecting “Yes” will clear all partial counters

2.2. Total from init

2.2.1. Total from init

2.2.2. P1 from init

2.2.3. P2 from init

2.2.4. Pr3 from init

2.2.5. Last init

Number of product totals since the beginning

of the machine’s life

Number of type 1 products (espresso) since

the beginning of the machine’s life

Number of type 2 products (long coffee) since

the beginning of the machine’s life

Number of type 3 products (free cycle) since

the beginning of the machine’s life

Read only - Date and time of last initialization

3. Brew unit wash Washing of the brew group is performed

4. Descale 4.1. Qty till descale

4.2. Final descale

4.3. Do it now

Remaining quantity of water to be dispensed

before having to perform next decalcifi ca-

tion (expressed in litres).

Date and time of last descaling.

Pressing “Enter” will launch a descaling cycle.

5. Enable fi lter

The new fi lter installed in the machine

undergoes a rinse cycle.

6. Errors 6.1. Error log

6.1.1. Display of errors

with up/down keys

6.2. Reset log

6.3. Errors reset

The last N errors can be displayed: index 0

= error of oldest date. May be accessed

only if there is at least one error.

Selecting “Yes” will delete the list of the last

errors.

Selecting “Yes” will cancel any Out-of-Service

conditions that do not automatically reset.

7. Credits 7.1. Add credits

0

7.2. Zero credits

Default: No

7.3. Alarm level

0

The value indicates the number of credits that

are to be added to those already in the

machine.

Select “Yes” to zero all credits in the machine.

The value indicates the quantity of residual

credits below which the message “Credit

low” is displayed

Note: the message is only displayed if

enabled.

8. Exit Press ENTER to quit.

• 16 •

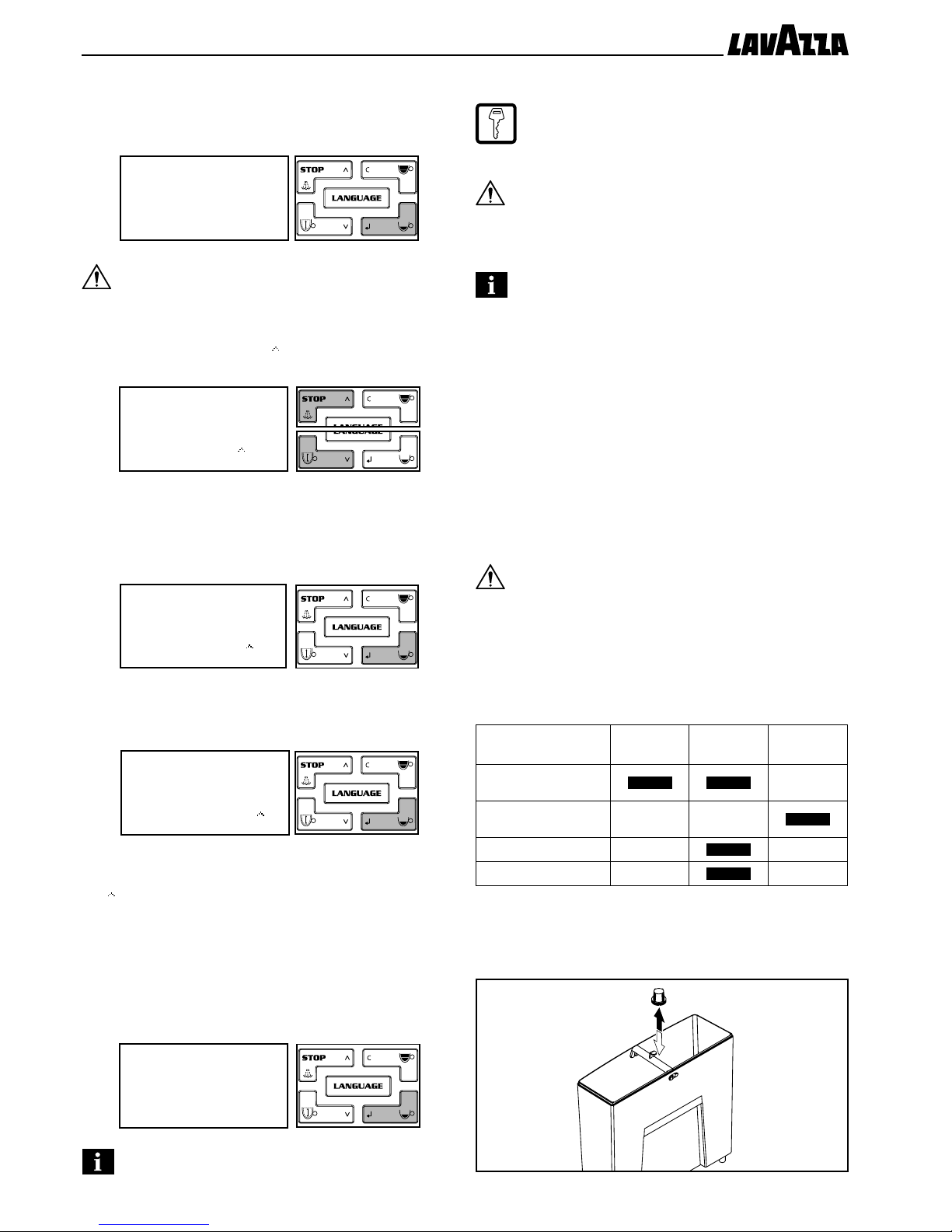

10.6 Changing a parameter

10.6 Changing a parameter

All editable parameters can be very easily changed.

When the page containing the value you wish to change is displayed, press “Enter”.

2.1.2

Std temperature

100

Warning! When you change a machine operating parameter, you

should be aware that you are changing an operating parameter set

by the manufacturer for the purpose of ensuring optimal machine performance.

The value will become editable and the “

” symbol will appear beneath the digit

to be changed.

2.1.2

Std temperature

100

Press the up/down keys to change the value.

When the desired value is displayed, press “ENTER” to confi rm.

The value will be memorised and the next digit will become available for editing.

2.1.2

Std temperature

100

When the desired value is displayed, press “ENTER”.

The value will be memorised and the next digit will become available for editing.

2.1.2

Std temperature

100

When the desired value is displayed, press “ENTER”.

The “

” symbol will disappear and the settings will take effect only when you

exit the program mode.

10.7 Exiting the program mode

10.7 Exiting the program mode

To quit the program mode, the following page must be displayed.

When the message appears on the display, press “ENTER”.

8

Exit

The number contained in the screen to exit the program mode can

vary according to the selected menu.

11 CLEANING

11 CLEANING

All the operations described in section 11 must be performed

exclusively by your service provider or a specialised technician,

who must organise all the operating sequences and use suitable

means to ensure strict compliance with current safety regulations.

Warning. Before undertaking any maintenance and/or cleaning jobs,

switch off the machine, unplug it and wait for it to cool down.

To ensure that the machine delivers optimal performance and dispenses drinks

of the best quality, carefully abide by the instructions contained herein.

Unless otherwise specifi ed, non-removable components and the

machine itself should be cleaned only with cold or lukewarm water

using non-abrasive sponges and damp cloths (do not attempt to clean

exposed electrical parts in this manner).

• Do not use any detergent or solvent which could impair the machine’s form

or functionality.

• Do not immerse the machine in water or other liquids: this will damage the

machine.

• Do not wash any of the machine components in a dishwasher.

• Always dry machine components by hand, without placing them in a con-

ventional or microwave oven.

• Do not spray water directly onto the machine.

• All the parts requiring cleaning are easily accessible so no tools are need-

ed.

• Regular maintenance and cleaning will preserve the machine and keep it

performing effi ciently for a longer time as well as ensuring compliance with

basic standards of hygiene.

Important. The machine should undergo maintenance at the frequencies shown in the routine maintenance table in section 11.1

of this instruction book.

11.1 Frequency of cleaning

11.1 Frequency of cleaning

To ensure that the appliance performs effi ciently, it is recommended to carry out

the cleaning and maintenance operations described in the table below.

Operation to be performed

When

signalled

At every

refill

After

2 refill

Empty out clean the dreg

drawer.

Clean the pod loading

slide.

Clean the water tank.

Steam wand

11.2 Cleaning the water tank

11.2 Cleaning the water tank

The water tank must be cleaned every time it is to be refi lled.

Loading...

Loading...