LAVAZZA Blue LB 910 Compact Maintenance Manual For Technical Assistance

LB 910 Compact

MAINTENANCE MANUAL

FOR TECHNICAL ASSISTANCE

MANUAL CODE 10081945 / REL. 0.00 / FEBRUARY 2014

LB 910 Compact

Machine code

10080207

Manual code

10081945

Rel. 0.00

Edition 02/2014

© Copyright LAVAZZA S.p.A.

www.absoluteaftersales.it

Tel. 00 39.011.2348429

Fax 0039.011.23480466

technicalservice@lavazza.it

Maintenance manual for technical assistance

ABLE OF CONTENTS

T

1. GENERAL INFORMATION . . . . . . . . . . . . . . . . . . 1

1.1. Structure of the manual . . . . . . . . . . . . . . . . . . 1

.1.1. Scope and content . . . . . . . . . . . . . . . . . . . 1

1

1.1.2. Messages used . . . . . . . . . . . . . . . . . . . . . . 1

1.1.3. Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.4. Preservation . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2. Designated personnel . . . . . . . . . . . . . . . . . . . 1

1.3. Machine composition . . . . . . . . . . . . . . . . . . . . 2

1.3.1. Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.2. Identification data. . . . . . . . . . . . . . . . . . . . . 2

1.3.3. Overall dimensions and weight . . . . . . . . . . 2

1.3.4. Technical specifications . . . . . . . . . . . . . . . 2

1.3.5. External components . . . . . . . . . . . . . . . . . 2

1.3.6. Internal components . . . . . . . . . . . . . . . . . . 2

1.3.7. List of the accessories supplied with the

machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

7. DISASSEMBLY OF COMPONENTS . . . . . . . . . . . 6

.1. Disassembling the machine body . . . . . . . . . . 6

7

7.2. Disassembling the hydraulic supply unit . . . . . 8

7.3. Disassembling the on/off switch . . . . . . . . . . . 9

7.4. Disassembling the micro switch of handle

closure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.5. Disassembling the sensor of drawer

presence . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.6. Disassembling the boiler unit . . . . . . . . . . . . . 11

7.7. Disassembling thermal safety and temperature

detection systems . . . . . . . . . . . . . . . . . . . . . . 11

7.8. Disassembling the coffee brewing unit . . . . . . 12

7.9. Disassembling the electronic board . . . . . . . . 14

8. CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . 15

8.1. Programming coffee dose . . . . . . . . . . . . . . . 15

2. GENERAL SAFETY STANDARD . . . . . . . . . . . . . 3

2.1. Stop functions . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2. Safety devices . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3. Residual risks . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. HANDLING AND STORAGE . . . . . . . . . . . . . . . . 4

3.1. Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2. Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4. DISMANTLING AND DISPOSAL . . . . . . . . . . . . . 4

4.1. Instruction for end of life treatment . . . . . . . . . . 4

5. INSTALLATION AND START UP . . . . . . . . . . . . . 5

5.1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5.2. Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6. RECOMMENDED TOOLS . . . . . . . . . . . . . . . . . . 5

8.2. Programming . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.2.1. Unit release function . . . . . . . . . . . . . . . . . 15

8.2.2. Changing set temperature . . . . . . . . . . . . . 15

8.2.3 General reset function . . . . . . . . . . . . . . . . 16

8.3. Alarm messages . . . . . . . . . . . . . . . . . . . . . . 17

9. DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9.1. Electrical diagram . . . . . . . . . . . . . . . . . . . . . . 18

9.2. Hydraulic diagram . . . . . . . . . . . . . . . . . . . . . 19

10. INSPECTIONS AND MAINTENANCE . . . . . . . . 20

10.1. Weekly and daily cleaning . . . . . . . . . . . . . . . 20

10.2. Descaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . 22

11.1. Signalling and solutions to the most common

problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Manual code 10081945 / Rel. 0.00 / February 2014

Maintenance manual for technical assistance

. GENERAL INFORMATION

1

1.1. Structure of the manual

Before any operation is carried out on the machine,the

maintenance technician must carefully read the instruc-

ions contained in this publication. The undertaking of

t

any operation on the machine, without having read and

understood the contents of this manual is prohibited. If

there is any doubt about the correct interpretation of the

nstructions, contact Lavazza in order to obtain the ne-

i

cessary clarification.

1.1.1. Scope and content

This manual contains all the information necessary for

the maintenance of the machine, safety instructions,

troubleshooting and diagrams.

All reproduction rights for the present manual are reserved to Luigi Lavazza S.p.A. The reproduction, even partial, of text or images is forbidden. Information contained

here cannot be transmitted to any third parties without

the prior written permission of Lavazza, which has the

exclusive rights to the property.

Lavazza reserves the right to modify features of equipments presented in this publication without prior notice;

it also declines any responsibilities for possible inaccurancies due to misprint.

It is recommended that the Internet site of the Lavazza

Technical Service be checked (at the following address

http://ts.inlavazza.it) to ensure that your manual is the

most recent version available and otherwise to download

an updated copy.

1.1.3. Users

This manual is designed for technicians qualified to

maintain the machine. Lavazza is not responsible for

damage derived from the failure to follow these rules.

1.1.4. Preservation

In order to be able to guarantee the integrity and utility of

his manual the following guidelines should be observed:

t

- employ this manual in such a way that it remains undamaged and whole;

- do not for any reason, remove, tear, or write over any

part of the manual;

- keep the manual in an area protected from humidity

and heat, in such a way that the quality and legibility of

the publication are not compromised;

- keep the manual close at hand for maintenance staff.

Warning

If this manual is damaged or lost, it is possible to

download another copy from the Lavazza Technical

Service site at the following address: http://ts.inlavazza.it.

1.2. Designated personnel

The machine may be operated only by a qualified technician who has read this manual and moreover who:

1.1.2. Messages used

Attention

ATTENTION messages indicate a danger, possibly

lethal, for the technician. The operations described

after this message must be carried out carefully and

safely using the personal protective equipment.

Warning

WARNING messages are displayed before procedures that, if not observed, could cause damage to the

machine.

Environment

ENVIRONMENT messages are displayed before procedures that, if not observed, could cause damage

to the environment.

NOTE

Messages show further information useful for the

maintenance technician.

- has specific experience in the maintenance of professional coffee machines;

- is able to carry out repairs in case of serious malfunction of the machine / machines shown in this manual;

- is able to understand the technical contents of the manual and to correctly interpret drawings and diagrams

and has knowledge of the safety information described

below;

- has knowledge of the appropriate hygiene, workplace

safety, technology and security measures;

- knows how to act in an emergency, where to find the

personal protective equipment and knows how to use

it.

Manual code 10081945 / Rel. 0.00 / February 2014

1

Maintenance manual for technical assistance

1.3. Machine composition

If not expressly indicated in the text, the position numbers of the machine components refer to figures in the

chapters 1.3.5. External components and 1.3.6 Internal

components.

1.3.1. Models

LB 910 Compact

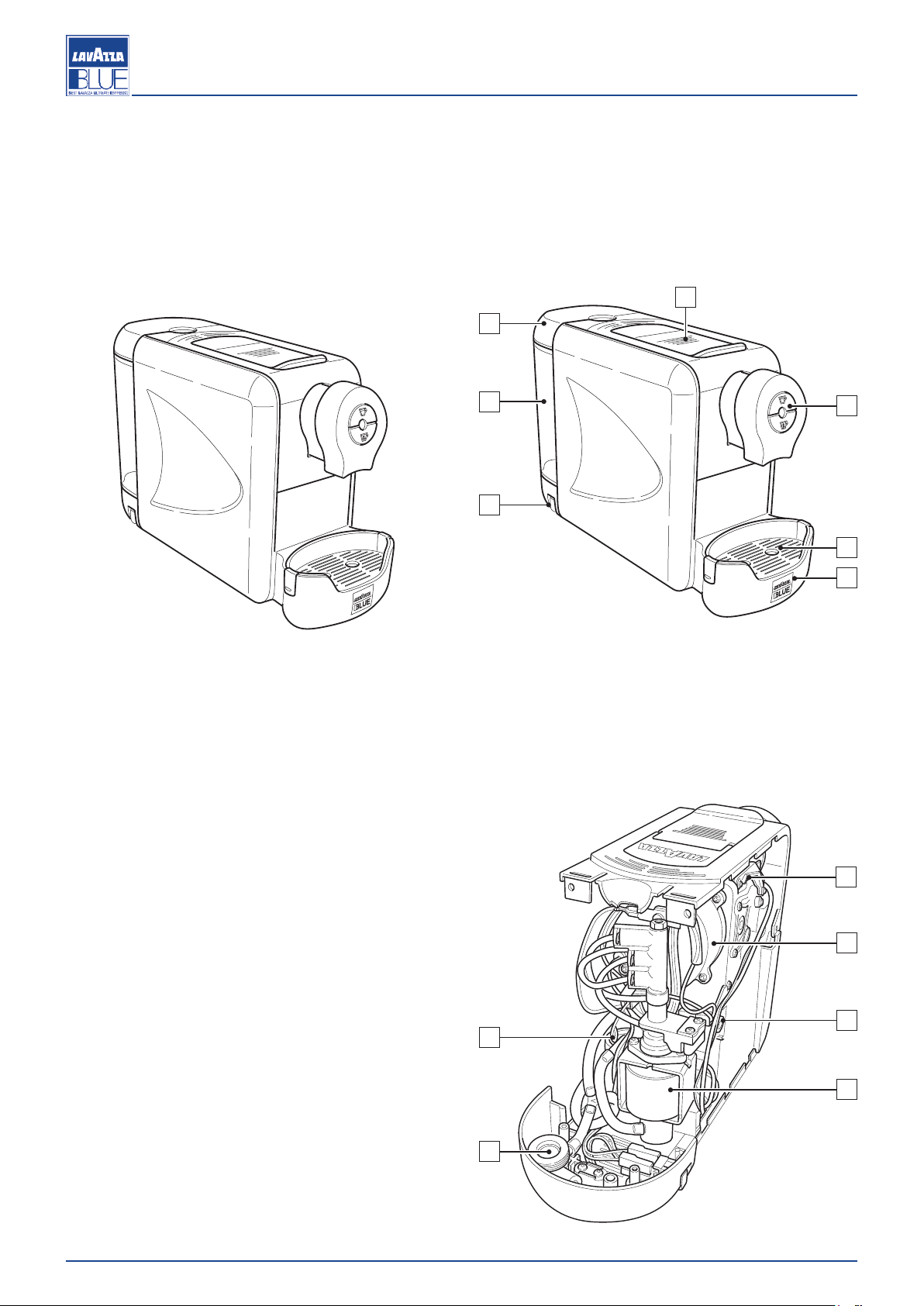

1.3.5. External components

1) Capsule loading handle

2) Water tank lid

3) Tank

4) On/off switch

5) Drip / used capsule tray

6) Cup support grid

7) Control panel

2

3

4

1

7

6

5

1.3.2. Identification data

In the plate the following data of the machine are indicated:

- manufacturer;

- machine model;

- serial number;

- product code Lavazza;

- production date;

- power supply voltage (V);

- power supply frequency (Hz);

- power consumption (W);

1.3.3. Overall dimensions and weight

Depth:

360 mm

Width:130 mm

Height:235 mm

Weight: 3,6 kg

1.3.4. Technical features

Power supply voltage: 220-240 V

Power supply frequency: 50/60 Hz

Power consumption: 1300 W

Water tank capacity: 1,2 litri

Boiler type: thermoblock

Control of water level: electronic control

Capsule container capacity: 8

1.3.6. Internal components

1) Coffee brewing unit

2) Boiler

3) Flowmeter

4) Pump unit

5) Tank coupling

6) Solenoid valve

1

2

6

3

4

5

2

Manual code 10081945 / Rel. 0.00 / February 2014

Maintenance manual for technical assistance

1.3.7. List of the accessories supplied with the ma-

chine

A) Instruction booklet for using the machine

2. GENERAL SAFETY STANDARD

Attention

Failure to comply with basic safety rules and precautions could cause accidents during machine

operation and maintenance. During the repair of the

machine all the measures necessary to prevent accident must be used.

The main safety precautions that should be used when

operating the machine are described below. Lavazza

does not foresee every possible situation that could be

potentially dangerous. Warnings in this manual are not

exhaustive. If tools, procedures, working methods or techniques not expressly recommended are used, make

sure that there is no risk of personal injury or injury for

other people.

Adjustments, specifications and illustrations in this manual are based on information available at the moment

of the editing and therefore can change anytime. These

modifications affect maintenance operations to be carried out. Ensure that the updated version of the present

manual is being used.

Power connection must be made in compliance with the

CEI EN 60335-1 and local safety standards in force.

vered in the normal procedures of diagnosis and repair.

In case of fire, use carbon dioxide (CO

) extinguishers.

2

Do not use water or powder extinguishers.

If an operation or intervention not foreseen should be

carried out, following a different procedure than that indicated in the manual, please contact Lavazza technical

service before starting.

Structural damage, modifications, tampering, alterations

or improper repairs could compromise the safety of the

machine.

2.1. Stop functions

To turn the machine off, press the on/off switch.

2.2. Safety devices

The machine/s described in this publication, are designed in compliance with the specific standards in force

(CEI EN 60335-1) and therefore have measures of protection in all the potentially hazardous parts.

Pump thermal protector: it serves to stop the machine

when the pump reaches a temperature of 120° due to

insufficient or lack of water. To restart the machine wait

4 or 5 minutes for it to cool down.

Thermal fuses: they serve to stop the machine operation if the boiler is overheated.

A Fuse on the power board.

The electric socket connecting the machine must:

- conform with the type of plug installed on the machine,

if it is present;

- be sized in order to comply with the data provided on

the plate on the bottom of the appliance;

- be connected to ground system, efficient and in accordance with the law.

Before carrying out any operation on the machine ensure that the plug is disconnected from the current and

that the machine is cool.

In order to avoid any electric shocks, electrical parts and

surrounding components must not :

- enter into contact with any type of liquid;

- be manipulated by humid or wet hands;

- be tampered with.

It is forbidden:

- to use the machine near flammable substances and/or

explosives and/or in an atmosphere with any risk of

fire;

- to use unoriginal spare parts (not advised by the manufacturer);

- to carry out any type of technical modification not co-

Attention

Do not change, eliminate or by-pass the safety devices in order to not cause serious risks to health

and safety.

2.3. Residual risks

The careful hazardous analysis performed, has allowed

most of the risks connected with operating and maintenance machine conditions to be eliminated. Lavazza reminds the user that the instructions, procedures and

recommendations contained in this manual should be

strictly followed, and comply with the safety rules in

force, including the use of provided protection devices,

both integrated in the machine and individual.

This chapter illustrates the risks that the user may incur

if he does not comply with the specific safety rules as

described in this booklet.

- Do not work on the machine when it is powered.

Before carry out any operations on the machine, disconnect it from the electrical network.

- Do not use water jets for washing any part of the appliance because running water can seriously damage

Manual code 10081945 / Rel. 0.00 / February 2014

3

Maintenance manual for technical assistance

electrical and electronic components.

- Never work on the hydraulic system and boiler before

having emptied them and checking that no pressure is

n the system.

i

- This machine is an appliance for espresso coffee dispensing. Any other type of use is considered incor-

ect and therefore dangerous.

r

Attention

Non-observance of the above rules can cause serious harm to people, property or animals.

3. HANDLING AND STORAGE

3.1. Handling

During handling the machine must be treated according

to the rules in force concerning health and safety on working places.

During handling and transport, the machine must remain

in a vertical position according to the directions and symbols on the packaging. Carry out lifting and positioning

with care. Do not shake the machine. For occasional

transport use the original packaging, which will contain

and protect the machine.

delivered to an authorised local recycling centre of

WEEE. Collecting the components of the machine in

properly separated fractions will enable recycling, treatment and environmentally friendly disposal and contri-

ute to avoiding possible adverse effects on the

b

environment and on health and favours the re-use

and/or re-cycling of materials which make up the machine.

Environment

INFORMATION FOR USERS OF PROFESSIONAL APPLIANCES. The separate collection of this appliance, at the end of its life, is organised and

managed by the producer. The user who wants to dispose of this appliance must contact the producer

and follow the system to collect the appliance separately at the end of its useful life.

Environment

INFORMATION FOR USERS OF HOUSEHOLD APPLIANCES. At the end of the useful life of the appliance, the user must send it to a WEEE waste

collection centre or to the retailer when purchasing

a new similar appliance, on a one-to one basis. In

both cases make the machine unusable cutting the

power cord.

3.2. Storage

The machine should be stored according to the following

conditions:

- minimum temperature: above 5 °C;

- maximum temperature: below 45 °C;

- maximum humidity: below 80%.

The machine is packaged in cardboard and polystyrene.

Check the maximum number of containers that can be

stacked on the packaging.

4. DISMANTLING AND DISPOSAL

4.1. Instruction for end of life treatment

This product conforms to art. 13 of the Decree Law No.

151 of July 25th, 2005, “Implementation of Directives

2002/95/EC, 2002/96/CE and 2003/108/CE, regarding

the restriction of the use of certain hazardous substances in electrical and electronic equipment and disposal

of waste electrical and electronic equipment”.

The crossed-out wheeled bin symbol displayed

on the appliance and/or the packaging indicates

that at the end of its life, the product should not

be treated as a generic household waste but should be

An appropriate separate collection of the appliance for

re-cycling and disposal compatible with the environment

contributes to preventing any possible negative effects

on the environment and health and favours the re-use

and/or recycling of materials which make up the machine.

Unlawful disposal of this product involves the application of administrative sanctions in compliance with Legislative Decree no. 152/2006 and subsequent

modifications.

5. INSTALLATION AND START UP

5.1. Unpacking

Open the packaging, taking care not to damage it. Remove the machine protections and the equipment contained in the package. Take the machine out.

Warning

Do not extract the machine by holding the bag.

4

Manual code 10081945 / Rel. 0.00 / February 2014

Maintenance manual for technical assistance

nvironment

E

omponents of the packing must be separated ac-

C

cording to the materials with which they are composed and disposed of according to the waste

collection and disposal regulation in force.

5.2. Positioning

or a correct ergonomic use of the machine, place it on

F

a stable and perfectly horizontal surface, away from

water source, flames and heat. The area should be sufficiently illuminated, ventilated, hygienic, not corrosive

and/or explosive and equipped with a power outlet readily reached with the supplied power cord. Also make

sure that the place where the machine is installed has dimensions and sturdiness suitable to safely support it.

For the correct operation of the machine the following

advice is given:

- room temperature: 15 °C ÷ 35 °C;

- maximum humidity: 60 %;

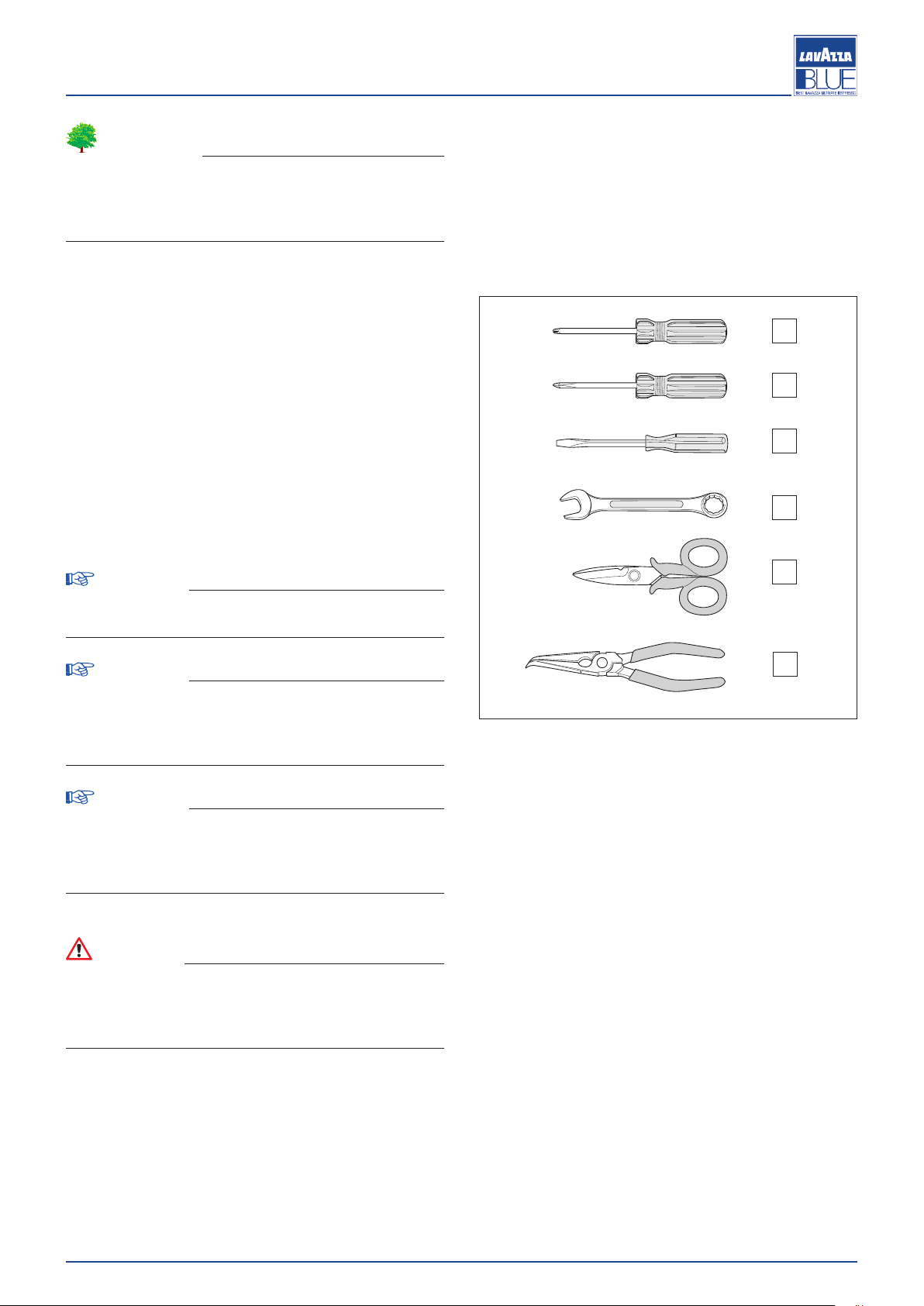

. RECOMMENDED TOOLS

6

A) Foolproof Torx T15 and T20 screwdrivers

) Cross head screwdriver

B

C) Flat head screwdriver

D) Combination wrench (12 mm)

E) Insulated scissor

) Long nose pliers

F

A

B

C

D

Warning

The machine is not suitable for outdoor installation,

and should not be exposed to weather.

Warning

The presence of magnetic fields or proximity of electric machines which generate disturbances, may

cause malfunctions in the electronic control of the

machine.

Warning

With temperatures approaching 0°C there is the risk

of freezing internal parts of the machine which contain water. Do not use the machine under these conditions.

Attention

Sufficient space must be allowed to access the machine and the plug, to allow the user to move freely

and to be able to immediately leave the area in an

emergency.

E

F

Manual code 10081945 / Rel. 0.00 / February 2014

5

Loading...

Loading...