LAVAZZA Blue LB 2000 Maintenance Manual

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

“LB 2000 OFFICE COFFEE SERVICE”

1 General information

2 General security standards

3 Transport and Storage

4 Disposal of the machine

5 Recommended tools

6 Disassembly of the machine

7 Test mode

8 Troubleshooting

9 Programming menu

10 Service menu

11 Power card

12 CPU card

13 Circuit diagram

14 Hydraulic diagram

15 Diagram of the RS232 circuit interface

General contents

Maintenance manual for

technical assistance

LB 2000

OFFICE COFFEE SERVICE

Machine code: 80602

Manual code: 83356

Edition: March 2005

Rel: 0.00

Tel. 0039.011.2398429

Fax 0039.011.23980466

E-mail: assistenzada@lavazza.it

TECHNICAL ASSISTANCE

© Copyright LUIGI LAVAZZA S.p.A

ESSEDI Manuali Tecnici - Torino (ITALY) • www.essedimanuali.it

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

“LB 2000 OFFICE COFFEE SERVICE”

Index

General Information

1.1 Designated personnel

1.2 Manual structure

1.2.1 Scope and content

1.2.2 Users

1.2.3 Preservation

1.2.4 Symbols used

1.1 Designated personnel

The tasks described in this manual may only be carried out by a qualified

technician who has read this manual and, moreover, who:

• has the appropriate credentials to carry out repairs in the case of serious

malfunction and who has read this manual and all the information relative to

safety;

• is able to understand the entire contents of the manual and to correctly interpret

the drawings and diagrams;

• has knowledge of the appropriate hygiene, workplace safety, technology and

security precautions;

• has specific experience in the maintenance of automatic dispensing equipment;

• knows how to act in an emergency, where to find the safety equipment and

knows how to use it correctly.

The use of the machine by personnel without these prerequisites is prohibited.

1.2 Structure of the manual

The technician must carefully read the information in this manual.

1.2.1 Scope and content

This manual can provide a qualified technician with all the information necessary

for the maintenance of the machine OCS base.

Before any operation is carried out on the machine, the qualified technician must

carefully read all the instructions contained in this publication.

If there is any doubt about the correct interpretation of the instructions, contact the

manufacturer to obtain the necessary clarification.

The undertaking of any operation on the machine, without having read and

understood the contents of this manual, is prohibited.

1.2.2 Users

The manual is designed for technicians qualified for the maintenance of the

machine.

It is prohibited for any unqualified person to follow the operations described in

this manual.

The manufacturer is not responsible for damage derived from the failure to follow

this rule.

1

1/2

General information

“LB 2000 OFFICE COFFEE SERVICE”

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

“LB 2000 OFFICE COFFEE SERVICE”

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

1.2.3 Preservation

In order to be able to guarantee the integrity and utility of this manual the following

guidelines should be observed:

• employ this manual in such a way that it remains undamaged and whole;

• do not for any reason, remove, tear, or write over any part of the manual;

• keep the manual in an area protected from humidity and heat, in such a way

that the quality and legibility of the publication are not compromised.

If this manual is damaged or lost, a new copy should be immediately requested

from the manufacturer or authorised distributor of the machine.

1.2.4 Symbols used

Attention!

Indicates a danger, possibly lethal, for the technician. In this case maximum

attention must be taken to act safely.

Caution!

Indicates a warning or directions about key functions or useful information.

Give full attention to text containing this warning.

Prohibited!

The presence of this symbol indicates that the operations should be halted as

they may cause danger for the user and persons in the vicinity.

1

2/2

General information

“LB 2000 OFFICE COFFEE SERVICE”

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

Index

General safety measures

2.1 Stop functions

• Read the entire manual carefully.

• Power connections should be made following the safety measures in the

country of use.

• The electric socket connecting the machine, should:

- conform to the type of plug installed on the machine;

- comply with the data provided on the plate on the bottom of the apparatus;

- be connected to an earthing device.

• The electric parts of the machine must not:

- enter into contact with any type of liquid - danger of electric shock and/or fire;

- be manipulated by humid or wet hands;

- be tampered with.

• It is forbidden:

- to use the machine near flammable substances and/or explosives

and/or in an atmosphere with any risk of fire;

- to use spare parts not advised by the manufacturer;

- carry out any type of technical modification not covered in the normal

procedures of diagnosis and repair;

- immerse the machine in any type of liquid;

- wash the automatic machine with a spray of water and/or petrol and/or

solvents of any type;

- repair the machine while under the influence of drugs, alcohol,

psychopharmaceuticals etc;

- repair the machine in an explosive environment or near high

concentrations of dust or oily substances in suspension in the air;

- to use the machine with other materials not suitable for the machine;

• Before carrying out any operation on the machine, ensure that the plug is

disconnected from the current and that the machine has cooled.

• Maintenance operations on the machine should be carried out by a single

person, if a second person must assist, this person should be advised of the

potential hazards relevant to the operation underway.

• In the case of fire use a carbon dioxide extinguisher (CO

2

). Do not use water

or powder extinguishers.

Attention!

During the repair of this machine, all the normal safety

standards should be observed to avoid accidents. Adopt all the measures

necessary to avoid accidents.

2.1 Stop functions

To stop the machine, use the main switch.

2

1/1

General safety measures

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

“LB 2000 OFFICE COFFEE SERVICE”

“LB 2000 OFFICE COFFEE SERVICE”

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

Index

Transport and storage

3.1 Transport

3.2 Storage

3.3 Accessories included

3.4 Assembly - positioning

3.5 Disposal of packaging

3.6 Electrical connections

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

“LB 2000 OFFICE COFFEE SERVICE”

3.1 Transport

During movement and transport, the machine must remain in a vertical position

according to the directions on the packaging. Carry out lifting and positioning with

care. Do not shake the machine.

Attention!

Ensure that nobody is in the vicinity when lifting and positioning of the load and,

in difficult conditions, make appropriate personnel available to help with the

placement.

3.2 Storage

The machine should be stored according to the following conditions:

- minimum temperature above 4°C.

- maximum temperature below 40°C.

- maximum humidity below 95%

The machine is packaged in cardboard and expanded polystyrene.

Attention!

Given the total weight of the package, it is prohibited to stack more than three

machines.

The machine should be stored, in its original packaging, in a dry and clean

place.

3.3 Accessories included

Manual: instructions for machine use.

Water hardness test: rapid test to determine the hardness of the water used to

make the beverages, this test used in order to set the value of the water hardness

on the machine.

Keys to access water tank: in order to inhibit access to non-authorised personnel.

3

1/3

Transport and storage

“LB 2000 OFFICE COFFEE SERVICE”

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

3.4 Assembly- positioning

Attention!

It is prohibited to set up the machine outside or in an environment where water

spray or steam is present.

The presence of magnetic fields near the machine will generate disturbances,

possibly causing malfunctions in the electronic controls of the machine.

With temperatures approaching 0°C there is the risk of freezing internal parts of

the machine which contain water. Do not use the machine under these conditions.

For the correct function of the apparatus the following advice is given:

• environmental temperature: 10°C ÷ 40°C ;

• maximum humidity: 90% ;

• the area must be ready for the installation of the machine;

• the place where the machine is installed is flat; solid and still; the surface

must not have an inclination of more than 2°;

• the area should be sufficiently illuminated, ventilated, hygienic and equipped with

a readily available power point.

Attention!

Sufficient space must be allowed to access the machine and the plug, to allow the

user to move freely and to be able to immediately leave the area in an

emergency.

3.5 Disposal of packaging

Upon opening the package it is recommended to divide the materials used for

packing by type and to dispose of these according to the standards of the country

of use.

We advise saving the package for possible movement or transport.

3.6 Electrical connections

Attention!

This procedure should only be carried out by a specialised technician or by the

manager.

This machine is designed to function with a single-phase voltage, detailed on the

identification plate.

3

2/3

Transport and storage

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

“LB 2000 OFFICE COFFEE SERVICE”

Before inserting the plug into the mains, ensure that the main switch is positioned

at “0”.

The electric connection of the machine is the responsibility of the manager.

The machine should be connected to the mains by the plug on the electric cable,

taking into consideration:

• the laws and technical standards in the place of installation;

• the data on the technical information plate found on the side of the machine.

Attention!

The power point should be easily accessible, so that the machine may be easily

disconnected from the electricity, when necessary.

Attention!

It is prohibited:

• to use extension cords of any type;

• to replace the original plug;

• to use adaptors.

3

3/3

Transport and storage

“LB 2000 OFFICE COFFEE SERVICE”

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

Index

Disposal of the machine

4.1 Disposal of the machine

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

“LB 2000 OFFICE COFFEE SERVICE”

4

1/1

Disposal of the machine

4 Disposal of the machine

Disposal of machine components, should be carried

out with respect for the environment, avoiding pollution of the soil, water and air.

Local legislation should be taken into consideration.

To make the machine unusable, remove the power cord.

Dispose of the machine at an appropriate collection centre.

Attention!

The battery in the electronic card should be removed from the equipment prior to

disposal.

Batteries should be disposed of in a safe manner.

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

“LB 2000 OFFICE COFFEE SERVICE”

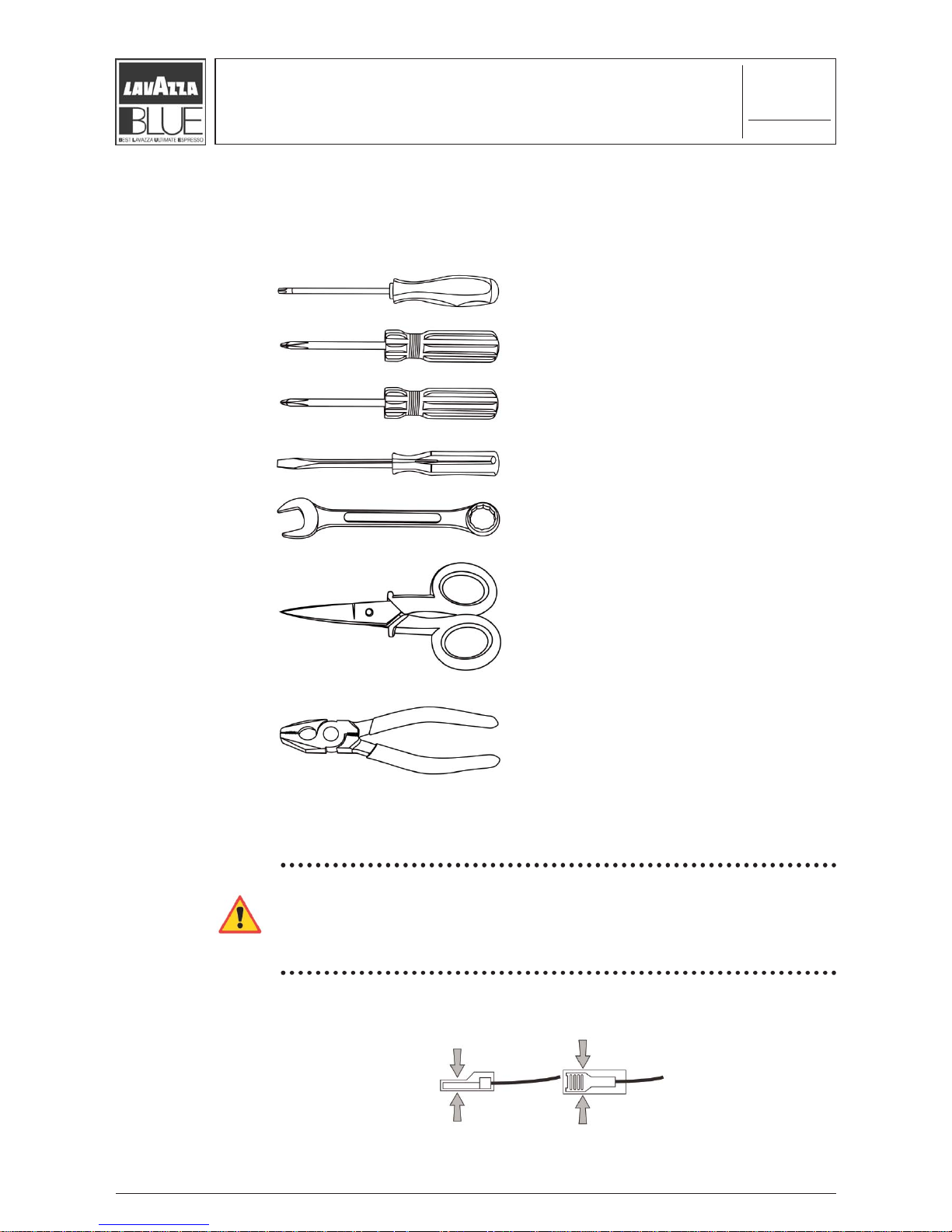

5

1/1

Recommended tools

In order to maintain the apparatus the following tools should be available:

Screwdriver Torx T10

Philips-head screwdriver PH1

Philips-head screwdriver PH2

Screwdriver 0.8 x 4 x 80

Spanner 10 mm

Scissors with insulation

Standard pliers

Attention!

All the mechanical connections and cables use antislip safety fastons.

If there is a faston cover squeeze the plastic as indicated in the figure and

pull.

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

“LB 2000 OFFICE COFFEE SERVICE”

Index

Disassembly of the machine

6.1 Disassembly of the body

6.2 Disassembly of the GACO rubber gasket

6.3 Replacement of the electrical cord

6.4 Disassembly of the CPU card

6.4.1 Replacement of the silicone keyboard

6.4.2 Replacement of the display

6.5 Disassembly of the POWER card

6.6 Disassembly of the capsule release coil

6.7 Disassembly of the pump

6.8 Disassembly of the volume metering device

6.9 Disassembly of the capsule release unit

6.10 Disassembly of the water tank support

6.11 Disassembly of the transformer

6.12 Disassembly of the resettable thermostat

6.13 Disassembly of the boiler

6.14 Disassembly of the gear motor

6.15 Disassembly of the filter perforator

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

“LB 2000 OFFICE COFFEE SERVICE”

6

1/28

Machine disassembly

6 Machine disassembly

This chapter describes the correct procedure to follow to access the parts

installed in the machine in order

to check and possibly replace them.

Attention!

Before beginning any procedures carefully read the directions

in the Safety Measures.

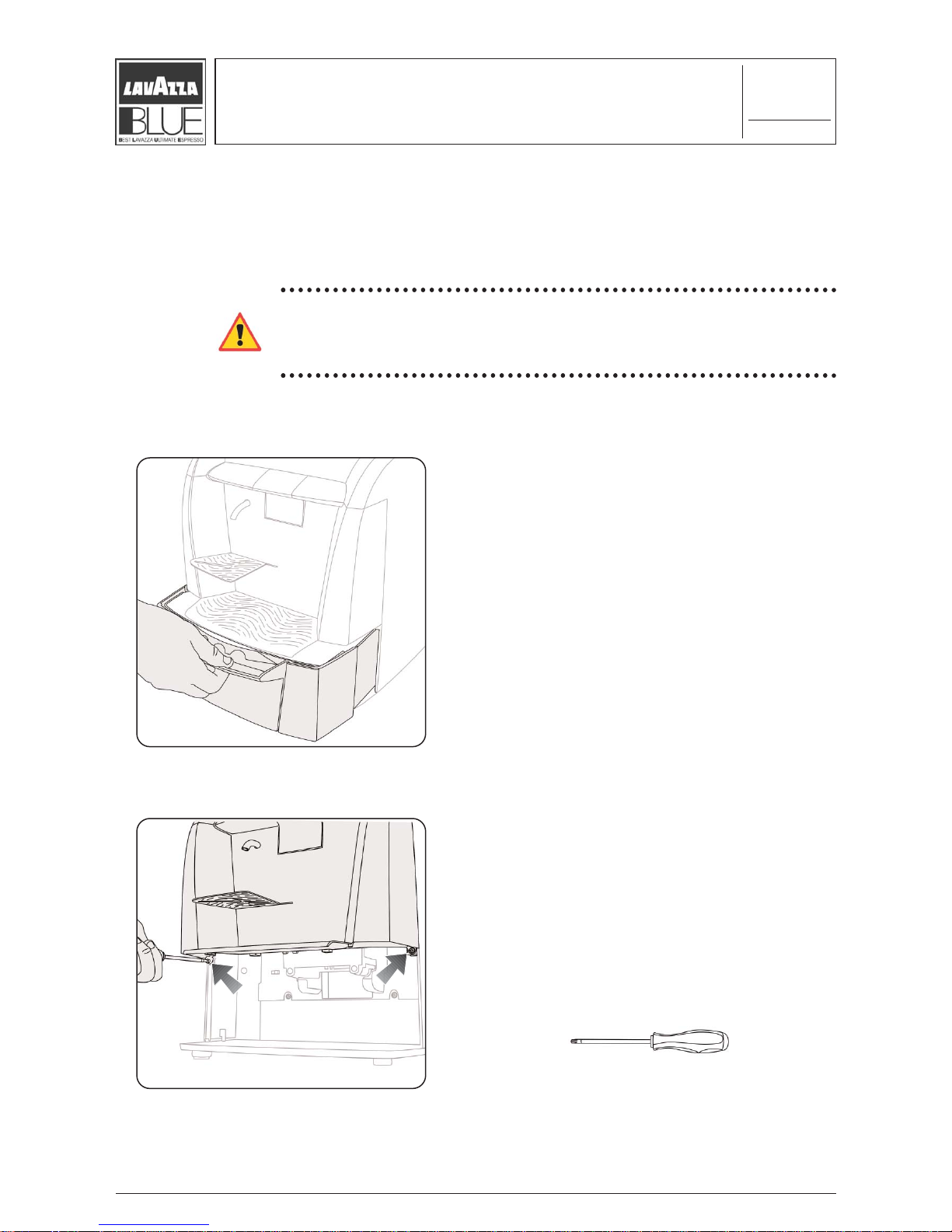

6.1 Disassembly of the body

Remove the drip collection tank; collect and

dispose of any used capsules; empty out any

remaining liquid.

Using an appropriate screwdriver undo the

screws that secure the front panel to the body

of the machine.

Note: the screws can be removed

with a normal Torx safety screwdriver.

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

“LB 2000 OFFICE COFFEE SERVICE”

6

2/28

Machine disassembly

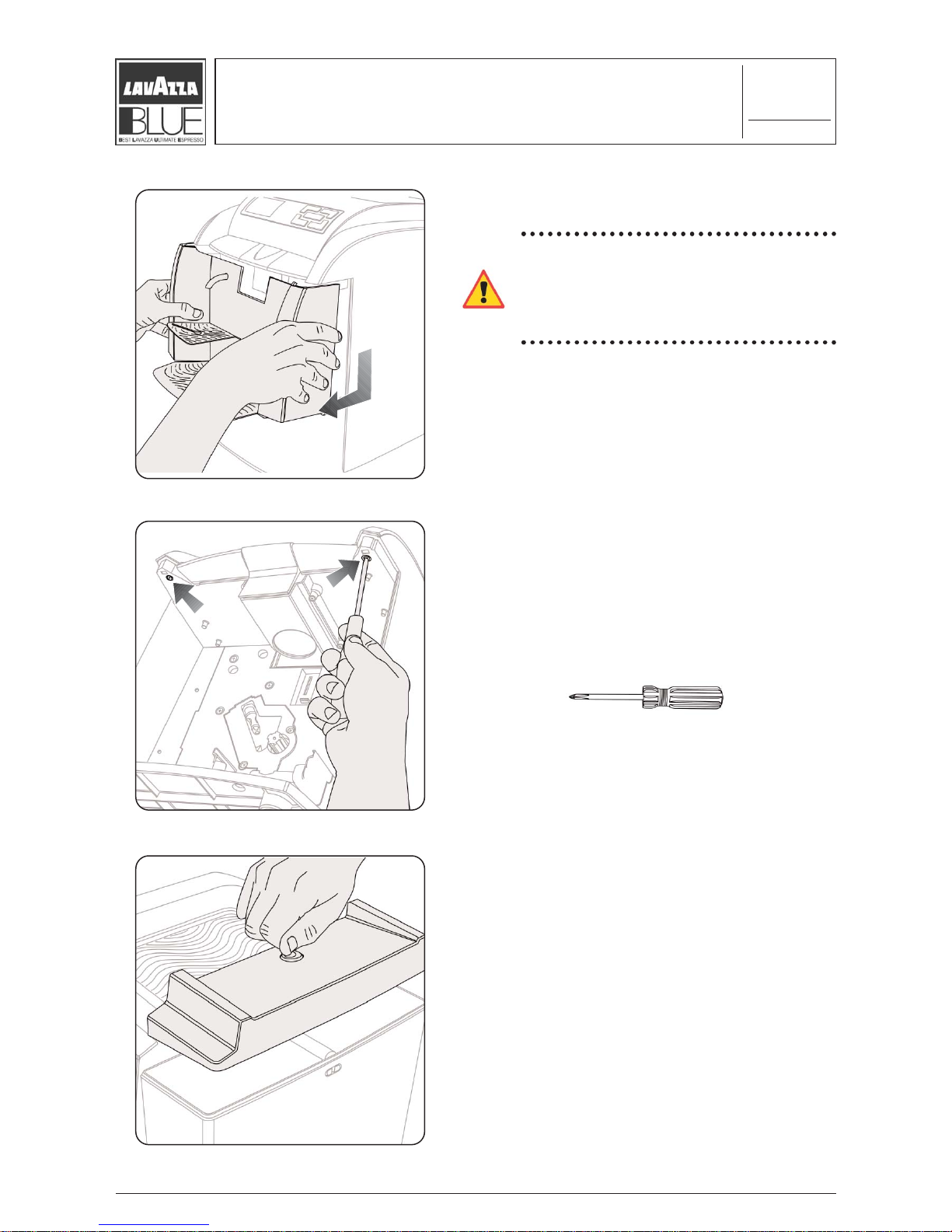

Attention!

This operation should be carried out

carefully, the panel may be damaged if it is

removed in an incorrect fashion.

Grasp the front panel as demonstrated in the

figure and remove it by pulling first lightly

downwards and then outwards.

Undo the 2 screws which hold the cover of

the upper plate of the machine.

With the spanner remove the cover of the

water tank.

“LB 2000 OFFICE COFFEE SERVICE”

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

6

3/28

Machine disassembly

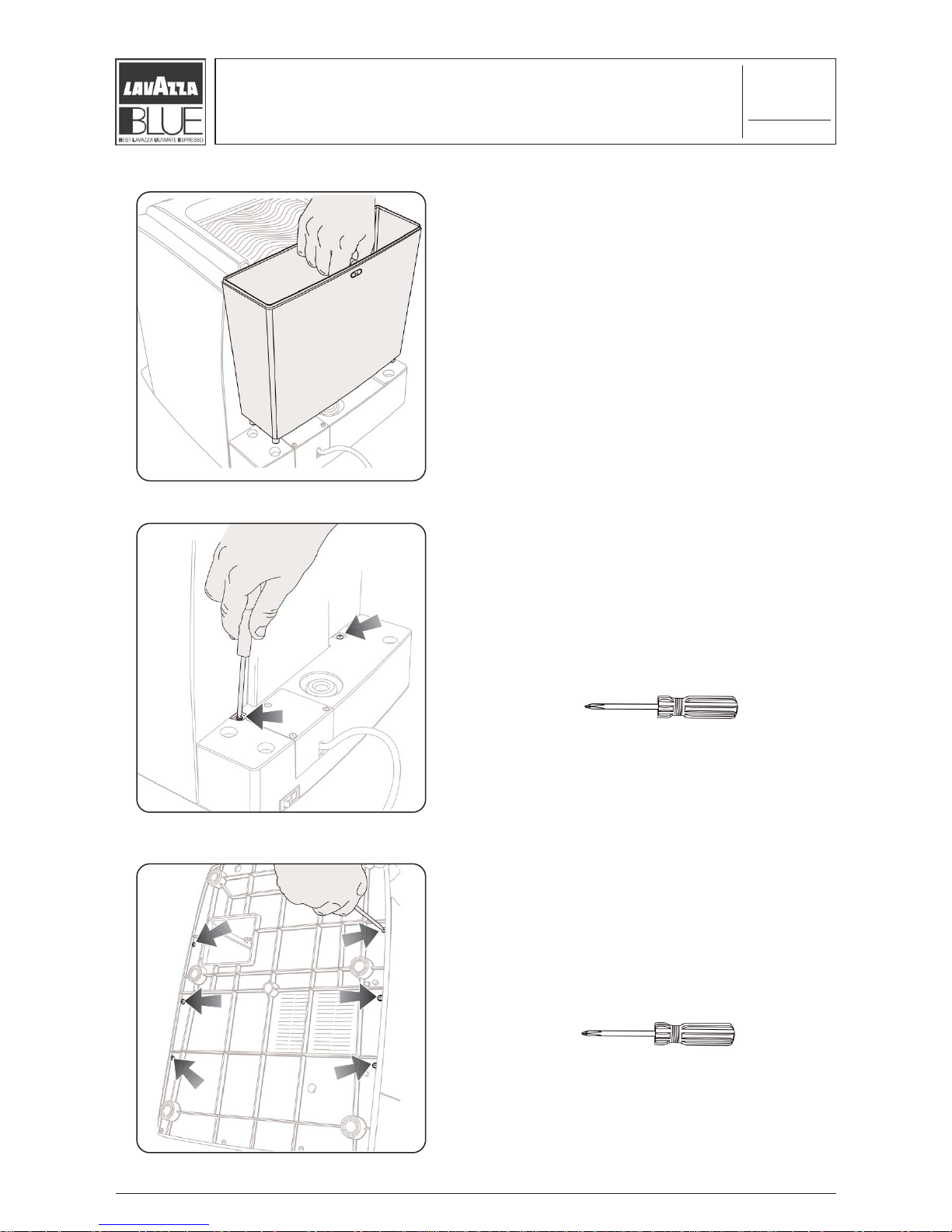

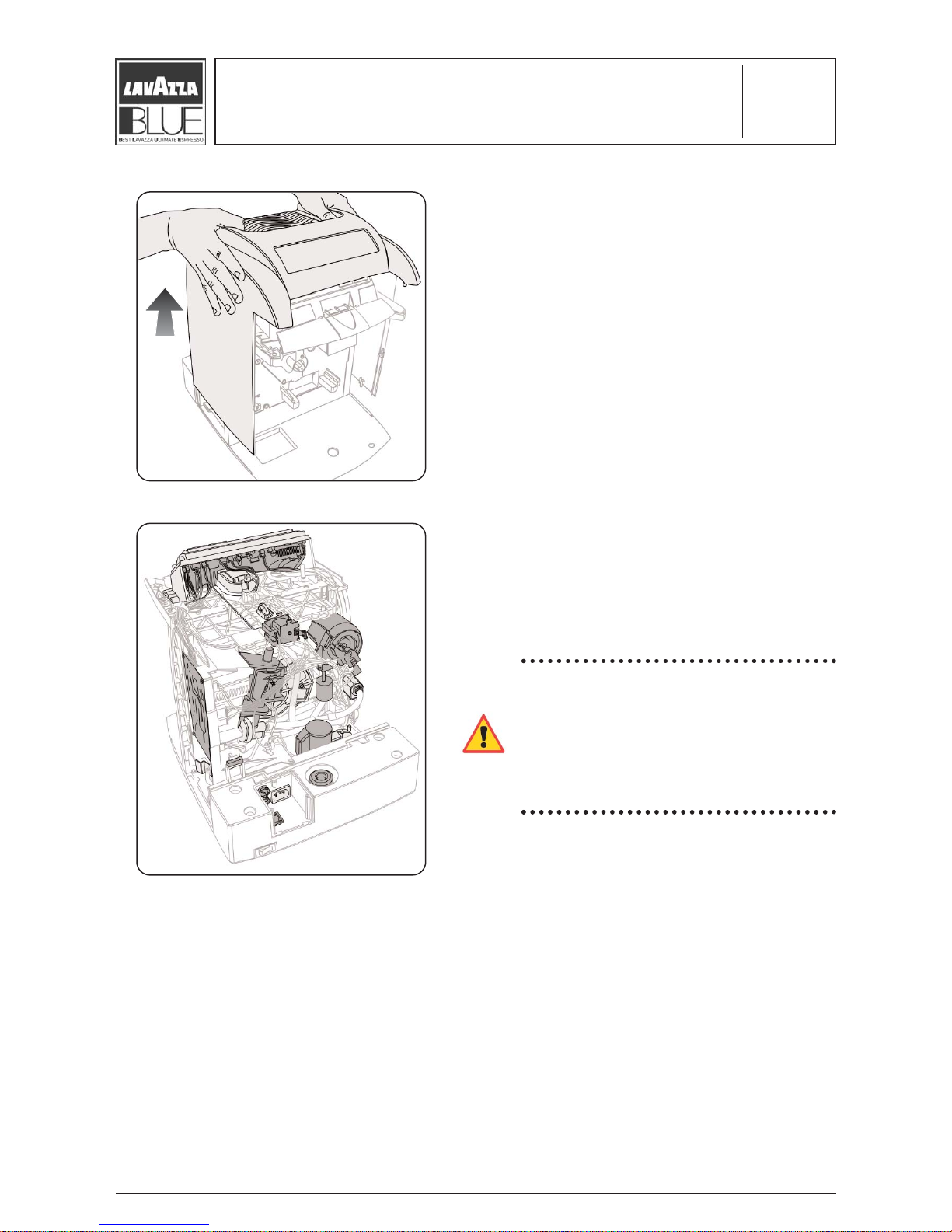

Remove the water tank by lifting it by its

handles.

Undo the rear screws which hold the cover.

Undo the 6 screws that secure the cover to

the base of the machine.

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

“LB 2000 OFFICE COFFEE SERVICE”

6

4/28

Machine disassembly

Rest the machine on its base.

Gently pull the cover with a little tug as

shown in the figure.

Now the operation of the internal

components of the machine can be checked.

Attention!

The machine now has no shielding , in

the machine there are electrical components

and components which generate heat.

Beware when operating under these

conditions.

“LB 2000 OFFICE COFFEE SERVICE”

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

6

5/28

Machine disassembly

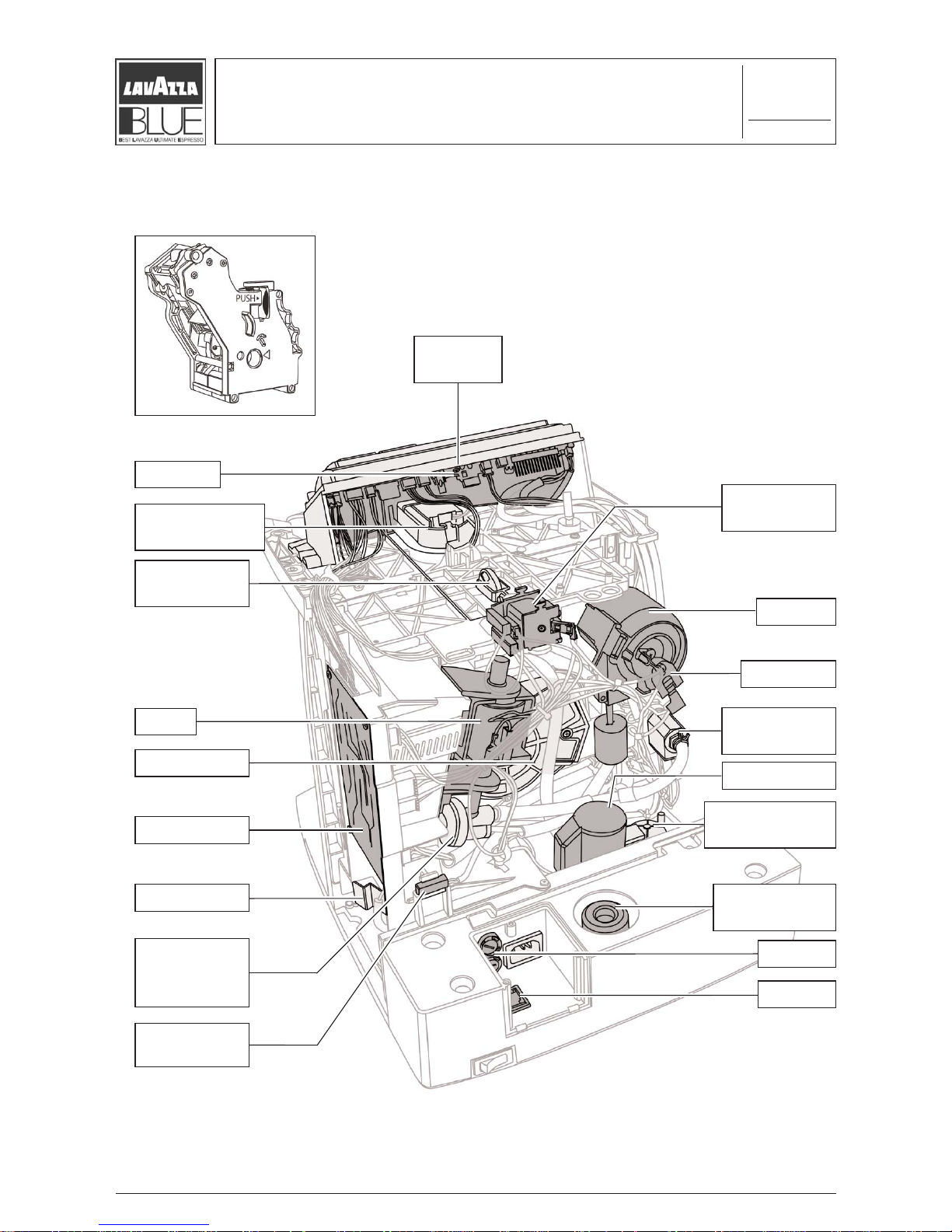

List of the machine components

POWER CARD

TRANSFORMER

COMPENSATION

AND SAFETY

VALVE

REED LEVEL

WATER

CAPSULE

RELEASE CAM

PUMP

GEAR MOTOR

CPU CARD

SUPPORT

CPU CARD

CAPSULE-LOADING

AREA

CAPSULE

RELEASE COIL

BOILER

THERMOSTAT

WATER

SOLENOID VALVE

LINE FILTER

VOLUME METERING

DEVICE

WATER TANK

COUPLING

FUSES

PLUG RJ11

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

“LB 2000 OFFICE COFFEE SERVICE”

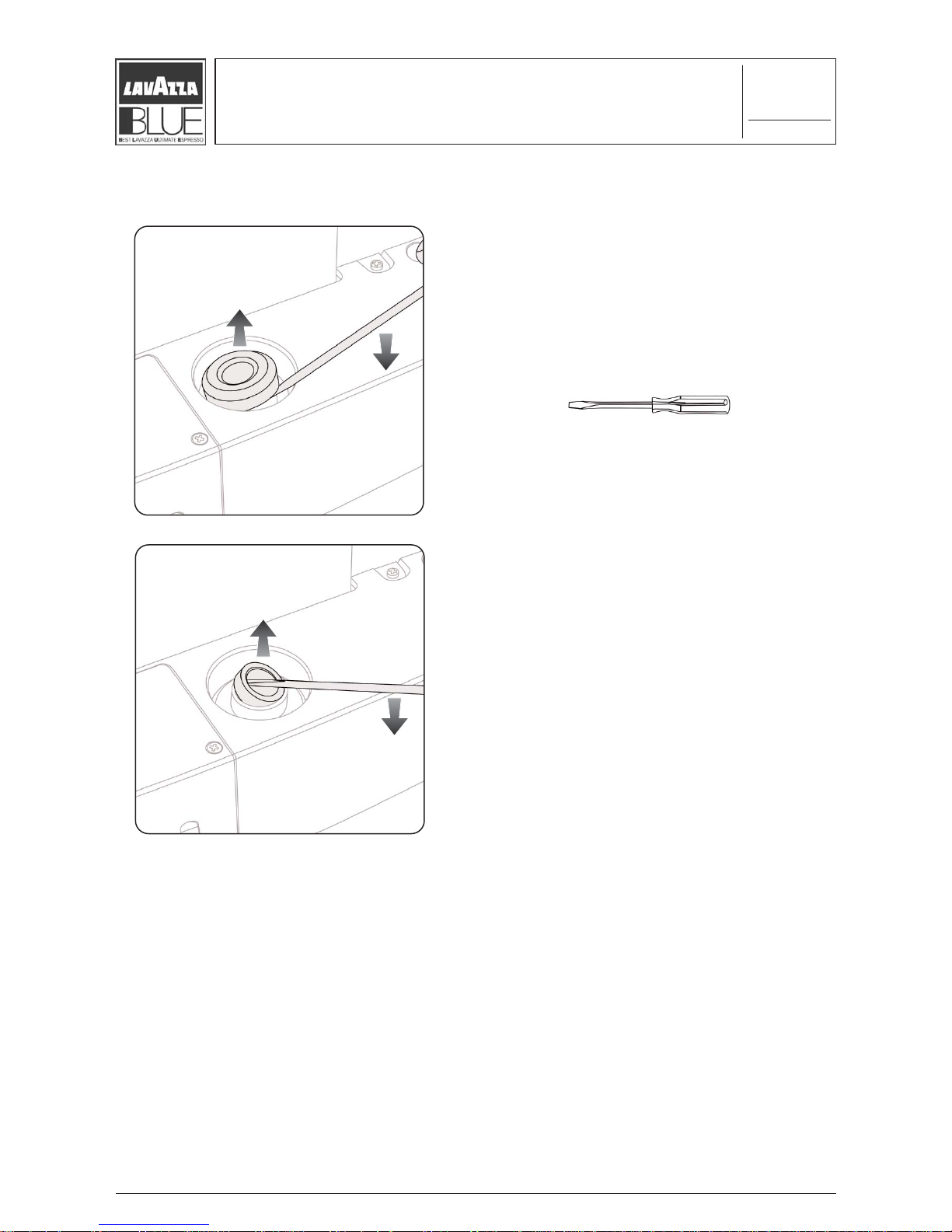

6.2 Disassembly of the GACO rubber

gasket

Preparation: follow the procedure

described in paragraph 6.1.

Using a screwdriver, remove the

cover of the rubber gasket.

Remove the rubber gasket with a screwdriver.

After having inserted a new rubber gasket ,

reposition the cover manually and press

firmly.

6

6/28

Machine disassembly

“LB 2000 OFFICE COFFEE SERVICE”

MANUAL CODE 83356 / REL. 0.00 / MARCH 2005

6

7/28

Machine disassembly

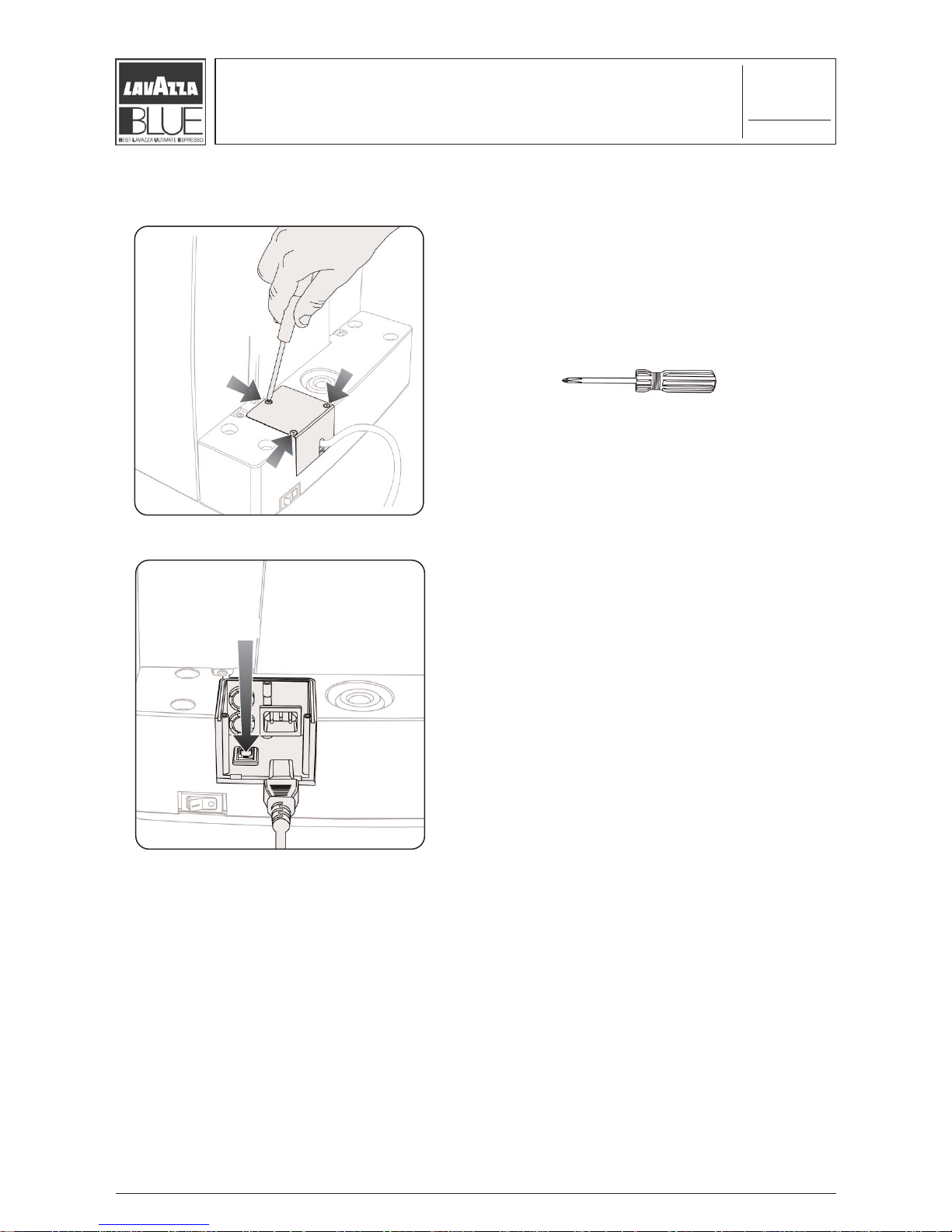

6.3 Replacement of electrical cord

Preparation: follow the procedure

described in paragraph 6.1.

Undo the screws that secure the shield of the

electrical cord space.

After the cover has been removed, the

electrical cord can be removed and the fuses

can be accessed.

In this area is the RJ11 plug to connect the

machine to a data collection system (see

ch.15).

RJ11

Loading...

Loading...