Page 1

Models

24A715,

Installation Manual

24A715M

Master Time/Program Clock

Document No. 427-12-00014 (02)

Page 2

Page 3

NOTICE

To ensure the performance of our products and systems, we may occasionally make tech

nological changes and updates. Therefore, the model number suffixes (A, B, C, etc.)

listed in the manual or in the drawings may not always match the model you are using.

Unless specifically noted, this will not affect the product or its installation, operation, or

service.

FCC COMPLIANCE STATEMENT

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

WARNING: Changes or modifications to this product not expressly approved by

the party responsible for compliance could void the user’s authority to operate this

equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or tele

vision reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

-

-

•

Reorient or relocate the receiving antenna.

•

Increase the separation between the equipment and receiver.

•

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

•

Consult the dealer or an experienced radio TV technician for help.

This Class B digital apparatus complies with Canadian ICES-003.

Page 4

FOR UNITS EQUIPPED WITH AN INTERNAL MODEM (24A715M)

NOTICE: This equipment complies with Part 68 of the FCC Rules. On the mounting

panel of this equipment is a label that contains, among other information, the FCC Regis

tration Number and Ringer Equivalence Number (REN) for this equipment. If requested,

provide this information to your Telephone Company.

The registration jack USOC for this equipment is (RJ-11). An FCC-compliant telephone

cord and modular plug is provided with this equipment. This equipment is designed to

connect to the telephone network or premises wiring using a compatible modular jack,

which is Part 68 compliant. See installation instructions for details.

-

The REN is useful to determine the quantity of devices that may be connected to the tele

phone line. Excessive RENs on the telephone line may result in the devices not ringing in

response to an incoming call. In most, but not all areas, the sum of REN of all devices

should not exceed five (5). To be certain of the number of devices that may be connected

to a line, as determined by the total REN, contact the local Telephone Company.

If your telephone equipment (Modem) causes harm to the telephone network, the Telephone Company will notify you in advance that temporary discontinuance of service may

be required, but if advance notice isn’t practical, you will be notified as soon as possible.

You will be advised of your right to file a complaint with the FCC if you believe it is

necessary.

Your Telephone Company may make changes in its facilities, equipment, operations,

or procedures that could affect the operation of your equipment. If they do, you will be

given advance notice so as to give you an opportunity to maintain uninterrupted service.

This equipment may not be used on public coin service provided by the Telephone

Company. Connection to party lines is subject to state tariffs. (Contact your state public

utility commission or corporation commission for information.)

-

Page 5

SUPPLIER’S DECLARATION OF CONFORMITY

Place of Issue: St. Charles, IL

Date of Issue: August 17, 2001

Dukane Corporation, located at 2900 Dukane Drive, St. Charles, IL 60174 in the United

States of America, hereby certifies that Master Clock model 24A715M bearing labeling

identification number US:A95DT06B24A715M complies with the Federal Communica

tions Commission’s (“FCC”) Rules and Regulations 47 CFR Part 68, and the

Administrative Council on Terminal Attachments (“ACTA”)—adopted technical criteria:

TIA/EIA/IS-968, Telecommunications—Telephone Terminal Equipment—Technical Re

quirements for Connection of Terminal Equipment to the Telephone Network, July 2001.

Rolf Goehler

Rolf Goehler

General Manager, Communications Systems Division

NOTICE: The Industry Canada label identifies certified equipment. This certification

means that the equipment meets certain telecommunications network protective, operational and safety requirements. The Industry Canada does not guarantee the equipment

will operate to the user’s satisfaction.

-

-

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of the local Telecommunications Company. This equipment must

also be installed using an acceptable method of connection. In some cases, the company’s

inside wiring associated with a single line individual service may be extended by means

of a certified connector assembly (telephone extension cord). The customer should be

aware that compliance with the above conditions may not prevent degradation of service

in some situations.

Any equipment repairs made by the user, or equipment malfunctions, may give the Tele

communications Company cause to request the user to disconnect the equipment.

Users should ensure, for their own protection, that the electrical ground connections of

the power utility, telephone lines, and internal metallic water pipe system, if present, are

connected together. This precaution may be particularly important in rural areas.

CAUTION: Users should not attempt to make such connections themselves, but should

contact the appropriate electric inspection authority or electrician, as appropriate.

NOTE: The Ringer Equivalence Number (REN) assigned to each terminal device pro

vides an indication of the maximum number of terminals allowed to be connected to a

telephone interface. The termination of an interface may consist of any combination of

devices subject only to the requirement that the sum of the Ringer Equivalence Numbers

of all the devices does not exceed five (5).

-

-

Page 6

A NOTE ABOUT THE LITHIUM BATTERY

The Lithium Battery (coin cell) contained in this product is NOT user-replaceable. When

replaced by an authorized Service Center, used batteries should be disposed of according

to the manufacturer’s instructions.

Page 7

Page 8

Page 9

Table

Contents

SECTION 1—INSTALLATION

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Mounting the Master Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Surface Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Semi-Flush Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Using the Installer’s Hooks to Hang the Display Below the Backbox . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Wiring the Master Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Wiring Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

of

Synchronizing Non-Compatible Clocks by External Pulse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

SECTION 2—CONFIGURATION

Setting Up the Master Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Programming Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Programming Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Entering the Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Setting the Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Enabling the Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Choosing the Clock Types to Synchronize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Manually Activating Bell Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Testing the Bells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Setting Daylight Saving Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Setting Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Securing the Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

24A715/24A715M Master Clock Installation Manual

i

Page 10

Table

of

Contents

SECTION 3—FUNCTION LIST

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Quick Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[*] READ STATUS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[1] VIEW EDIT KEYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

[3] 12/24 HOUR TOGGLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Programming Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

[0]=PASSWORD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

[1]=SET DATE / TIME. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

[2]=SELECT CLOCK CTL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

[3]=MANUAL BELL CTRL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

[4]=PROGRAM SCHEDULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

[5]=SCHEDULE CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

[6]=ENABLE CIRCUITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

[7]=DAYLIGHT SAVINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

[8]=CHANGE SCHEDULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

[9]=SYNCH. CLOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

[A]=PROGRAM HOLIDAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

[B]=COMMUNICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

[C]=CHANGE PASSWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

AUTO BELL TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

APPENDIX A—DAYLIGHT SAVING COUNTRY CODES

Daylight Saving Country Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Daylight Saving Time Codes and Duration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

ii

24A715/24A715M Master Clock Installation Manual

Page 11

Table

Contents

APPENDIX B—SECONDARY CLOCK TYPES

Secondary Clock Type Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Wiring Secondary Clocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Type 01—Synchronous Wired . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Type 02—Three-Wire Minute Impulse (59th Minute) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Type 02—Two-Wire Reverse Polarity Minute Impulse (59th Minute) . . . . . . . . . . . . . . . . . . . . . . . B-5

Type 03—Standard Electric Synchronous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Type 04—Standard Electric Time AR-2A Two-Wire, Dual Voltage . . . . . . . . . . . . . . . . . . . . . . . . B-7

Type 05—Three-Wire Minute Impulse (58th Minute) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Type 06—Synchronous Wired . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

of

Type 07—Dukane Digital Clocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

Type 08—Rauland 2410 Digital Clocks (24Vac and 120Vac). . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Type 09—Simplex 59th Minute, Dual Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

Type 10—Simplex 45th Minute, Dual Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

Type 11—Edwards Dual Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-15

Type 12—Cincinnati D6 Clocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-16

Type 13—Two-Wire Pulse Alternating (24Vdc) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-17

Type 14—Electronic Coded Clocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-18

Type 15—Straight Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-20

Type 16—Three-Wire Minute Impulse (59th Minute) with 12-Hour Correction . . . . . . . . . . . . . . B-21

Type 16—Two-Wire Reverse Polarity Minute Impulse (59th Minute) with 12-Hour Correction. . B-22

Type 17—Standard Electric Time AR-3 Three-Wire Impulse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-23

Type 18—National Synchronous Wired. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-24

Type 19—Stromberg Synchronous Wired (56th Minute) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-25

Type 20—Three-Wire Minute Impulse (44th Minute) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-26

Type 21—Cincinnati D1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-27

Type 22—Dukane Synchronous Wired (24A Series, Obsolete). . . . . . . . . . . . . . . . . . . . . . . . . . . . B-28

Type 23—Condor Digital Clocks (Model 2412) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-29

Type 24—Edwards Synchronous Wired Clocks, Type E1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-30

Type 27—Simplex 2310 Dual Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-31

Types 28, 29, and 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-31

24A715/24A715M Master Clock Installation Manual

iii

Page 12

Table

of

Contents

APPENDIX C—WIRING DIAGRAMS

Wiring Diagrams List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Wiring the Master Clock for 120Vac or 220/240Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Wiring Signal Devices to the Master Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Wiring the Communications Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Wiring the Host Communications Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Wiring the DDC4R Communications Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Wiring RS-485 Time Synchronization Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Using the Master Clock as a Slave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Wiring the 12 Volt AC Out Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Strain Relief for the Communications Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Connecting a Computer to the Front Access Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

APPENDIX D — POWER SUPPLY SCHEMATIC

Power Supply Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

iv

24A715/24A715M Master Clock Installation Manual

Page 13

Table

Contents

FIGURES

1-1 Master Clock Wall-Mount Assembly Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Hook Mounting the Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-3 L Brackets for Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-4 Plugging Quick Connects into the Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-5 Master Clock Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3-1 Status Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 Edit Keys Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

of

B-1 Three-Wire Synchronous (59th Minute, Dukane 24SS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B-2 Three-Wire Minute Impulse (59th Minute) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

B-3 Two-Wire Reverse Polarity Minute Impulse (59th Minute) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

B-4 Standard Electric Synchronous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

B-5 Standard Electric Time AR-2A Two-Wired, Dual Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

B-6 Three-Wire Minute Impulse (58th Minute) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

B-7 Synchronous Wired . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

B-8 Wiring Dukane 24F200, 24F750, and 24F750A Digital Clocks for 15Vdc . . . . . . . . . . . . . . . . . B-11

B-9 Wiring Dukane 24D20 and 24D40 Digital Clocks for 24Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

B-10 Wiring Rauland 2410 Digital Clocks for 120Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-13

B-11 Wiring Rauland 2410 Digital Clocks for 24Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-13

B-12 Simplex 59th and 45th, Dual Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

B-13 Edwards Dual Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-15

B-14 Cincinnati D6 Clocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-16

B-15 Two-Wire Pulse Alternating (24Vdc) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-17

B-16 Electronic Coded Clocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-19

B-17 Straight Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-20

B-18 Three-Wire Minute Impulse (59th Minute) with 12-Hour Correction. . . . . . . . . . . . . . . . . . . . . . B-21

B-19 Two-Wire Minute Impulse (59th Minute) with 12-Hour Correction. . . . . . . . . . . . . . . . . . . . . . . B-22

B-20 Standard Electric Time AR-3 Three-Wire Impulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-23

B-21 National Synchronous Wired . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-24

B-22 Stromberg Synchronous Wired (56th Minute). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-25

24A715/24A715M Master Clock Installation Manual

v

Page 14

Table

of

Contents

B-23 Three-Wire Minute Impulse (44th Minute) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-26

B-24 Cincinnati D1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-27

B-25 Dukane Synchronous Wired (24A Series, Obsolete). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-28

B-26 Condor Digital Clocks (Model 2412) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-29

B-27 Edwards Synchronous Wired Clocks, Type E1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-30

B-28 Simplex 2310 Dual Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-31

C-1 Wiring the 24A715/M for 120Vac Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

C-2 Wiring the 24A715/M for 220/240Vac Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

C-3 Typical Signal Device Wiring—Terminal Block P1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

C-4 Typical Signal Device Wiring—Terminal Block P2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

C-5 Typical Signal Device Wiring—Terminal Block P3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

C-6 The Communications Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

C-7 RS-232 Cable for Permanent Connection to the Communications Terminal Block . . . . . . . . . . . . C-5

C-8 Synchronizing RS-485 Time Synchronization Devices Without a Buffer . . . . . . . . . . . . . . . . . . . C-6

C-9 Using the Master Clock as a Slave to Allow 30 Extra RS-485 Time Synchronizing Devices . . . . C-6

C-10 Example of Cable Strain Relief . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

C-11 Computer Cable for Front Access Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

D-1 Power Supply Schematic for the 24A715/M Master Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

TABLES

2-1 Relay Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3-1 READ STATUS Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 List of Edit Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Windows is a registered trademark of Microsoft Corporation.

MasterLink is a trademark of Lathem Time Corporation.

vi

24A715/24A715M Master Clock Installation Manual

Page 15

Section

General Information

This installation manual covers the Model 24A715 and 24A715M Master Clocks. Both

clocks are installed and programmed in similar fashions. The main difference between

the clocks is the 24A715M is equipped with a built-in modem capable of communicating

with a PC, or for synchronizing with the NIST Atomic Clock. Both clocks have eight cir

cuits that can be programmed to ring bells or activate circuits for up to 99 seconds, and/or

synchronize the time on three types of clock systems (any two manufacturing brands of

clocks listed in Appendix B, plus compatible RS-485 time synchronization devices). You

can program up to 512 events to activate single or multiple circuits on a given day and

time. The 24A715M can also connect to a PC running Microsoft Windows

tional MasterLink™ software available from Lathem.

Unless otherwise specified, “master clock” refers to both units in this document.

The master clock can be programmed with these functions:

• User password

•

Date and time

•

Clock types to synchronize

•

Manual bell control (example: sounding a fire alarm)

•

Bell schedules (with events lasting up to 99 seconds)

Note: If a contact closurer in excess of 99 seconds is required, an external

latching relay will be required. This relay is not supplied by Dukane.

•

Dates when automatic schedule changes go into effect

•

Manual circuit disabling (example: for safety during maintenance)

•

Daylight saving time features

•

Instant bell schedule changes

•

Instant clock synchronization

•

Holiday schedules

•

Communications when using the master clock with an RS-485 network, modem

access, or the optional MasterLink programming software (available from Lathem)

Installation

®

using op

1

-

-

Parts List

Verify that the master clock came with these parts:

•

Master clock (ready to surface mount)

•

User guide (document number 427-07-00047)

•

Installation hardware kit with mounting screws and two extra cover screws

•

Two L-brackets used for rack mounting

•

Power supply box cover used for rack mounting

24A715/24A715M Master Clock Installation Manual

continued

1-1

Page 16

Optional equipment (ordered separately from Lathem):

Connection cable if the power supply relay PCB is up to 8 feet (2.4 m) from the

•

display unit

Lathem MasterLink programming software to control the master clock from a PC

•

Standalone modem

•

Remote schedule selector switch

•

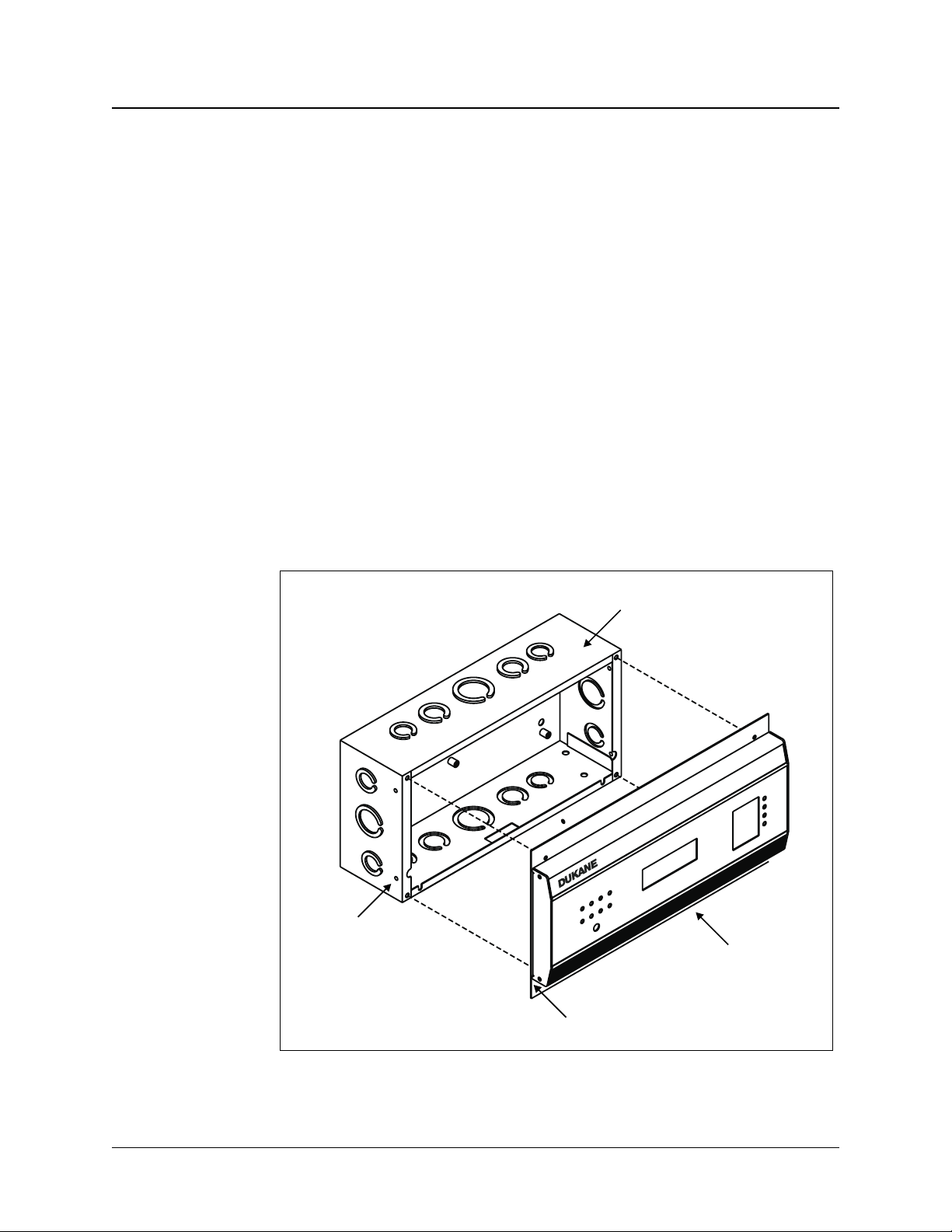

Mounting the Master Clock

The master clock is shipped ready to surface mount on a wall. It can also be semi-flush

mounted with the power supply recessed into the wall, or installed in a standard 19-inch

(48.3 cm) rack. See Figure 1-1 for wall mount assembly parts. The display unit can also

be hung on the wall with the power supply hidden in the floor or ceiling; contact Lathem

for details.

A qualified technician should install the master clock. The installation does not require

any special tools, but may require extra hardware, wire, or other materials as required by

local electrical codes.

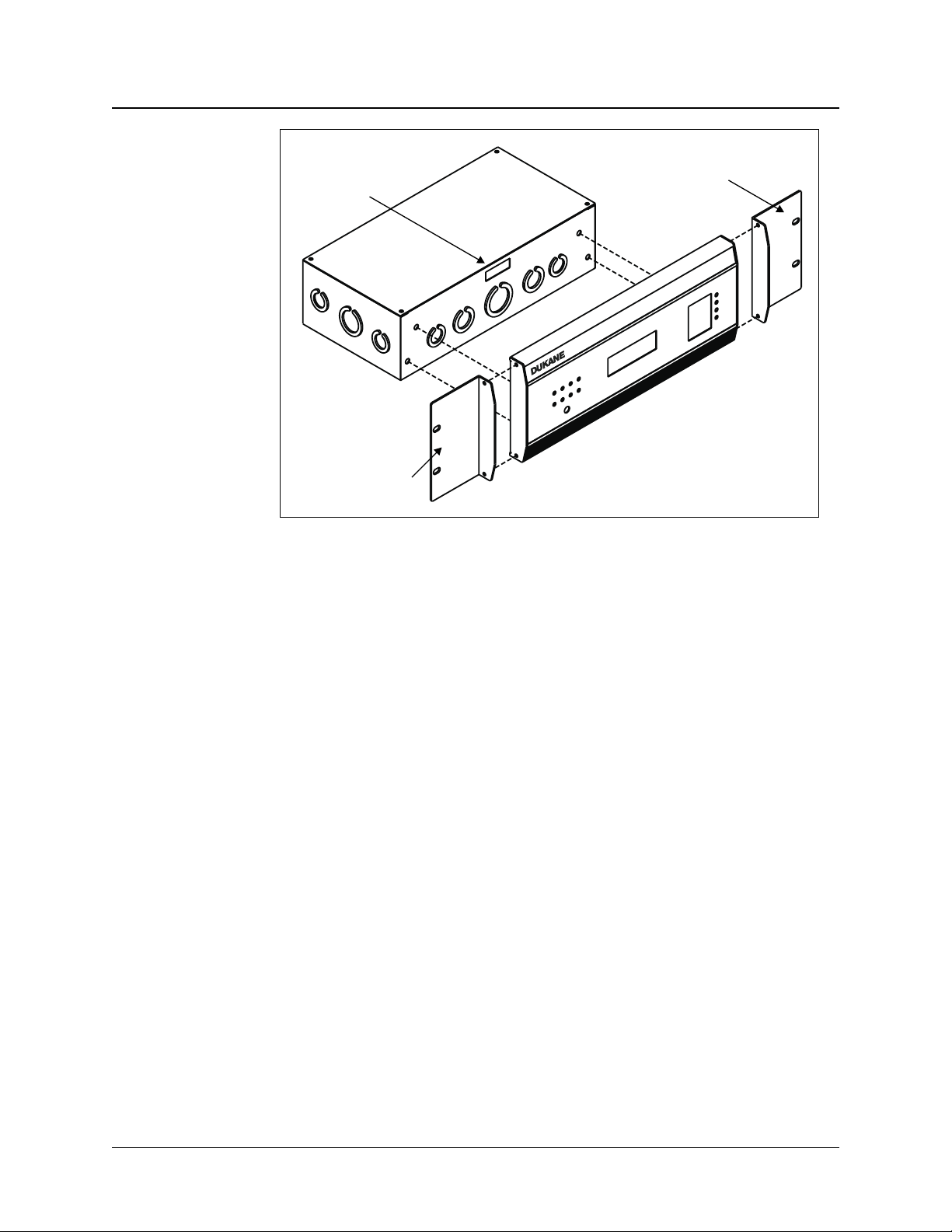

Side Screw Hole

Power Supply Backbox

Display Unit

Wall Mount Plate

1-2

Figure 1-1

Master Clock Wall-Mount Assembly Parts

24A715/24A715M Master Clock Installation Manual

Page 17

Surface Mounting

To surface mount the master clock:

1. Place the master clock on its back with the display unit facing up and the key pad to

the right.

2. Remove the two screws at the top of the display unit mounting plate.

3. Lift the display unit up and away from the backbox. Two rivets at the bottom of the

cover will prevent you from lifting it straight up.

4. Unplug the ribbon cable from the back of the display unit to disconnect it from the

power supply.

6. Making sure they are level, place two anchors 10 inches (25.4 cm) apart on the wall

where the clock is to be mounted. Use the appropriate anchors for the wall.

7. Screw two #8 screws into the wall anchors.

8. If needed, place two wall anchors 5 inches (12.7 cm) below the first two screws, to

accommodate the other two mounting screws.

9. Hang the power supply onto the top two screws using the keyholes on the back.

10. Screw two more #8 screws through the two holes at the bottom of the power supply

into the wall anchors.

11. Wire the clock. (See Wiring the Master Clock on page 1-8.)

12. Reconnect the ribbon cable.

13. Replace the display unit using the two screws removed in step 2.

24A715/24A715M Master Clock Installation Manual

1-3

Page 18

Semi-Flush Mounting

The power supply portion of the master clock can be recessed into the wall, so that

the display unit is semi-flush with the wall. This should only be done by a qualified

technician.

To mount the master clock semi-flush:

1. Place the master clock on its back with the display unit facing up and the key pad to

the right.

2. Remove the two screws at the top of the display unit mounting plate.

3. Lift the display unit up and away from the backbox. Two rivets at the bottom of the

cover will prevent you from lifting it straight up.

4. Unplug the ribbon cable from the back of the display unit to disconnect the power

supply.

5. Set the display unit aside.

6. Prepare the clock’s position in the wall:

The power supply backbox measures 12 inches (30.5 cm) wide by 6 inches (15.2 cm)

high by 3-3/8 inches (8.6 cm) deep.

The wall mount cover measures 13 inches (33 cm) wide by 7 inches (17.8 cm) high

by 1-1/4 inch (3.2 cm) deep, and extends ½ inch (1.8 cm) around the backbox.

Cut a 12-1/4 inch (31.1 cm) by 6-1/4 inch (15.9 cm) hole in the wall between two

studs where you want to hang the master clock.

7. Cut two blocks of wood for filler and attach them to the studs.

8. Screw the power supply box to the blocks using the two holes on each side of the box.

9. Wire the clock. (See Wiring the Master Clock on page 1-8.)

10. Reconnect the ribbon cable.

11. Replace the display unit using the two screws removed in step 2.

1-4

24A715/24A715M Master Clock Installation Manual

Page 19

Using the Installer’s Hooks to Hang the Display Below the Backbox

When mounting the clock in either semi-flush or surface installations, the hooks on the

back of the display unit mounting plate can be used to hang the display unit below the

backbox to allow access for circuit testing and programming. See Figure 1-2.

To use the hooks:

1. Remove the two screws securing the display unit to the backbox.

2. Lift the unit up and away from the backbox, leaving the ribbon cable attached. Two

rivets at the bottom of the cover will prevent you from lifting it straight up.

3. If you have a semi-flush installation, remove the green communications connector

plug from the back of the display unit. This allows the unit to sit flat against the wall.

4. Swing up the two hooks on the back of the unit and hook them over the bottom edge

of the backbox. You now have access to the key pad for making program changes or

manually activating the circuits, and access to the relay and connector blocks inside

the backbox.

Hook Mounting the Display Unit

24A715/24A715M Master Clock Installation Manual

Figure 1-2

1-5

Page 20

Rack Mounting

The two L-shaped brackets and the box cover supplied with the master clock can be used

to install it in a standard 19-inch (48.3 cm) rack. See Figure 1-3 on page 1-7.

To rack mount the clock:

1. Place the master clock on its back with the display unit facing up and the key pad to

the right.

2. Remove the two screws securing the display unit to the backbox.

3. Lift the display unit up and away from the backbox. Two rivets at the bottom of the

cover will prevent you from lifting it straight up.

4. Unplug the ribbon cable from the back of the display unit to disconnect the power

supply.

5. Detach the display unit from the wall mount plate by removing the four screws on the

back of the display unit. (IMPORTANT: Do not lose these screws. They are a specific

length so they do not interfere with the circuit board inside the display unit. Using any

other screws to attach the display unit to the case will void any warranty.)

6. Remove the rectangular knock out near the top of the power supply. See Figure 1-3

on page 1-7.

7. Using the four screws removed in step 5, attach the display unit to the bottom of the

power supply. To assist you, there are holes opposite the four screw holes where you

can fit a #1 Philips screwdriver with an 8-inch (20.3 cm) blade.

8. Reconnect the ribbon cable from the power supply to the display unit.

9. Remove the two screws from one side of the display unit, then use them to attach an

L bracket to the side of the unit. See Figure 1-3 on page 1-7. Repeat to attach the

other bracket to the other side.

10. Mount the unit in the rack.

11. Wire the clock before attaching the box cover. See Wiring the Master Clock on

page 1-8.

12. Attach the cover to the power supply using four 6-32 screws. Two of these screws

were removed from the display unit in step 2. The other two were supplied with the

clock.

1-6

24A715/24A715M Master Clock Installation Manual

Page 21

Rectangular

Knock Out

L Bracket

L Bracket

Figure 1-3

L Brackets for Rack Mounting

24A715/24A715M Master Clock Installation Manual

1-7

Page 22

Wiring the Master Clock

This section provides instructions on wiring the power source, secondary clocks, and sig

naling devices to the master clock. It does not cover the connection of the optional

modem, a computer, any RS-485 devices, and a power source for the optional remove

schedule selector. Instructions for those devices are provided in Appendix C.

Stranded wire is recommended for use inside the power

supply box, as it allows a firm connection to the quick

connect terminals. There is also less chance of stranded

wires interfering with the components on the relay board.

If solid wire must be used, join the stranded wire to the

solid wire in another box.

The master clock is supplied with quick connects. These

should be attached to the wires as necessary so that the

wiring can be connected to the terminal blocks as shown

in Figure 1-4.

Figure 1-4

Plugging Quick Connects

into the Terminal Block

—WARNING—

Failure to properly connect the ground wire

can increase interference and cause

unsafe operating conditions.

-

1-8

Wiring Procedure

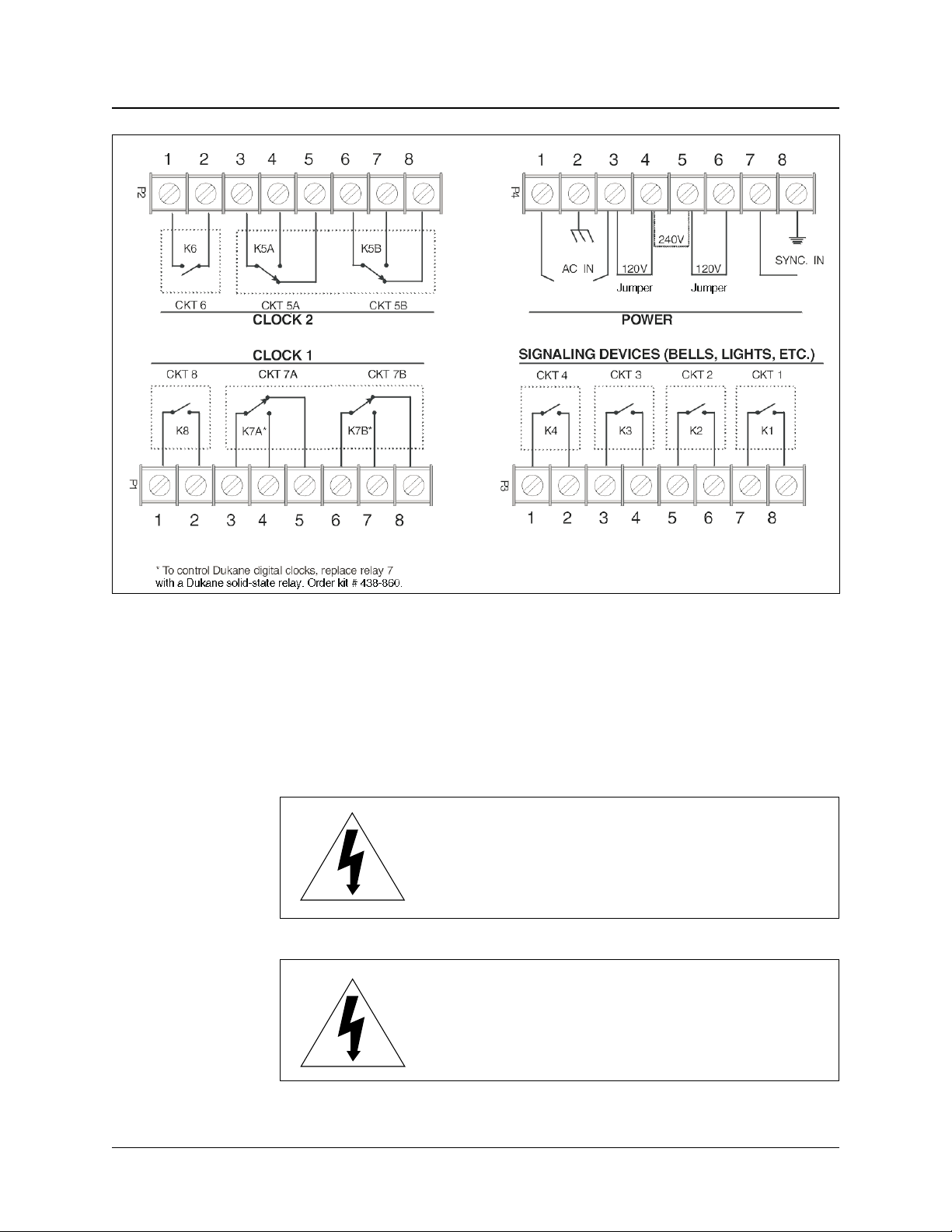

Figure 1-5 on page 1-9 shows terminal blocks P1 through P4, located on the PCB in the

power supply backbox. Follow the steps below the figure to wire the clocks, power

source, and signaling devices to the master clock.

Notes:

•

Circuits CKT1 through CKT4 designate bell controls. Circuit pairs CKT5/CKT6

and CKT7/CKT8 can function as clock synchronization circuits or as bell controls.

•

MOVs (Metal-Oxide Varistors) protect all relay contacts.

•

Voltage-select jumpers connect to terminal block P4 for 120Vac operation. For

clocks that must run at 220/240Vac, remove the 120V jumpers and install one

jumper wire for the 240V selection. The system will automatically adjust for oper

ation at 50Hz or 60Hz at either voltage. Also see Terminal Block P4 on page C-2.

•

Some clock setups may require external diodes or MOVs. See the wiring diagram

for your type clock (see Appendix B).

-

24A715/24A715M Master Clock Installation Manual

Page 23

Figure 1-5

Master Clock Terminal Blocks

1. Wire the power source to P4 as shown in either Figure C-1 or C-2 on page C-2.

Note:

The master clock is shipped set up for 120Vac operation. To wire it for 220/240Vac,

change the jumper settings as shown in Figure C-2.

—WARNING—

DO NOT turn on AC power, and keep the

power/relay unit’s toggle switch OFF until you

complete the rest of the wiring in this section.

—WARNING—

Applying 220/240Vac power to a system not

set up for that voltage level can severely

damage the electronic parts.

24A715/24A715M Master Clock Installation Manual

1-9

Page 24

2. Wire the secondary clocks to P1 and/or to P2. See Wiring Secondary Clocks on

page B-2 for complete instructions.

Note:

You may need to add external metal-oxide varistors (MOVs) or diodes to synchronize

a specific clock type. See the clock wiring diagrams in Appendix B.

3. Wire the signaling devices to P3. See Typical Signal Device Wiring on page C-3.

Note:

If the master clock is not connected to any secondary clocks, signaling devices can be

wired to P1 and P2.

4. Although the master clock is fused internally to protect its electronics, the incoming

AC line must also be fused as required by your local electrical code. Dukane recom

mends connecting the unit to a dedicated 10-amp circuit.

5. Turn the toggle switch in the power supply to the ON position.

6. Complete any mounting steps in the previous section, Mounting the Master Clock

on page 1-2.

-

Synchronizing Non-Compatible Clocks by External Pulse

The master clock can synchronize to other systems if necessary. For example, you have a

non-compatible time clock that cannot be synchronized by the master clock, but it has a

built-in bell ringer. By shorting terminals 7 and 8 on terminal block P4, or terminals 6

and 7 of the communications terminal on the back of the display unit, the master clock

will immediately reset to 00:00 (midnight). If you can program the other device to close

its circuit at 00:00 (midnight) then the two systems will remain reasonably in sync.

—WARNING—

DO NOT apply power to the external

pulse-sync terminals. Simply close

the circuit for 1–5 seconds.

1-10

24A715/24A715M Master Clock Installation Manual

Page 25

Section

Setting Up the Master Clock

Once the master clock is installed, it is ready for programming. This chapter covers the

programming instructions needed to set the master clock for operations.

Note:

To completely clear the clock of all settings and reset the master clock to its factoryshipped configuration, press the following number sequence on the master clock key

pad: 355379768274. This clears all programmed schedules and reinitializes the

master clock.

Programming Relays

If the master clock will control one type of secondary clock, relays #7 and #8 on terminal

block P1 are used for this purpose. If the master clock will control a second clock type,

relays #5 and #6 on terminal block P2 are used for those clocks. See Table 2-1.

Configuration

2

Bell

Zone #1

Relay#1Relay2#Relay#3Relay#4Relay#5Relay#6Relay#7Relay

Here are some possible ways to program the master clock relays:

•

Eight bell zones that can last from 1 to 99 seconds. Use this setup if the master clock

will not be used to synchronize secondary clocks. (Note: The maximum closure time

provided by this master clock is 99 seconds. Closures longer than 99 seconds will re

quire an external latching relay. This is not provided by Dukane.)

•

Six bell zones and one wall clock synchronization control. Use this setup if the master

clock will only synchronize one type of clock in one string.

•

Four bell zones and two wall clock synchronization controls. Use this setup if the mas

ter clock will synchronize two clock types, or if there are two strings of clocks

(typically 20 to 35 clocks to a string).

Bell

Zone #2

Bell

Zone #3

Bell

Zone #4

Table 2-1

Relay Usage

Bell

Zone #5

Clock Sync #2 Clock Sync #1

Bell

Zone #6

Bell

Zone #7

Bell

Zone #8

#8

-

-

24A715/24A715M Master Clock Installation Manual

2-1

Page 26

Programming Functions

This section explains how to put the master clock in program mode and configure the

necessary functions to get the master clock running. For definitions of all functions, key

pad commands, and the bell test, see Section 3—Function List.

The master clock is normally in clock mode, displaying the date and time. To access pro

gram mode, press [#] on the key pad. Pressing [*] stops programming so you can re-enter

a setting or quit.

Entering the Password

The administrative password provides access to both advanced functions and user functions.

The user password only provides access to user functions.

The factory-programmed user password is 000000, and can be changed (see page 3-6).

User passwords are explained further in the Master Clock User Guide, document

427-07-00047.

The factory-programmed administrative password is 332537, or DEALER (as spelled out

on a telephone key pad). It cannot be changed.

Note:

To keep the administrative functions secure, only give this guide to authorized personnel.

The following shows the key sequence to enter the password, and the resulting clock

display:

-

Administrative Password: User Password:

Press Display Press Display

[#] SELECT FUNCTION CODE [#] SELECT FUNCTION CODE

[0] [0] = ENTER PASSWORD [0] [0] = ENTER PASSWORD

[#] PASSWORD: 000000 [#] PASSWORD: 000000

[3][3][2][5][3][7] PASSWORD: 332537 [user password] PASSWORD: NNNNNN

[#] ADMINISTRATOR [#] PASSWORD ACCEPTED

PASSWORD ACCEPTED

The display returns to clock mode (the time and date) after a few seconds.

Notes:

A password expires after approximately five minutes. If the master clock starts block

ing access to programming functions, re-enter the password.

To manually expire a password, see Securing the Setup on page 2-9.

2-2

24A715/24A715M Master Clock Installation Manual

-

Page 27

Setting the Date and Time

Use the [1]=SET DATE / TIME function to set the date and time.

Enter the user password as shown on page 2-2, then follow the key sequences below:

Press Display

[#] SELECT FUNCTION CODE

[1] [1]=SET DATE / TIME

[#] ENT. DATE: MM-DD-YYYY

[0]...[8] Enter the numbers for the month, date, and year (four-digit year)

[#] ENTER DAY-OF-WEEK: D

1=SUNDAY...7=SATURDAY

[1]...[7] Enter a number [1]–[7] for the day of the week, Sunday through

Saturday

TODAY IS (selected day)

[#] ENTER TIME: HH:MM

[0]...[8] Enter the time of the next upcoming minute, using either 12-hour of

24-hour format. If using 24-hour format, enter midnight as 00:00.

[#] SELECT [0]PM / [1]AM

You will only see this if you enter a time less than 13:00 (1:00 PM).

[0] or [1] PRESS [#] IF CORRECT

[#] Clock returns to time display.

24A715/24A715M Master Clock Installation Manual

2-3

Page 28

Enabling the Relays

Use the [6]=ENABLE CIRCUITS function to enable or disable the master clock’s con

trol relays during circuit wiring or maintenance. This function can also hold back clocks

to manually adjust for daylight saving time in the fall if the daylight saving function is

not in use (see Setting Daylight Saving Time on page 2-7). The ENABLE CIRCUITS

function only enables the relays; it does not turn them on. See Manually Activating Bell

Controls on page 2-6 to turn on the relays.

Enter the administrative password as shown on page 2-2, then follow the key sequences

below:

Press Display

[#] SELECT FUNCTION CODE

[6] [6]=ENABLE CIRCUITS

[#] SELECT ACTIVE

BELL ZONES 12345678

CLOCK CKTS

PRESS [#] IF CORRECT

[1]...[8] Enter the circuit numbers that you want to enable or disable by

toggling the numbers; when you see all the circuits you want

enabled on the display, press [#].

[#] PRESS [#] TO CONFIRM

2-4

24A715/24A715M Master Clock Installation Manual

Page 29

Choosing the Clock Types to Synchronize

To select a clock type for the master clock to synchronize, use the [2]=SELECT CLOCK

CTL function. This allows you to match the master clock to the type of secondary clocks

installed. This function configures both clock #1 (relays 7 and 8) and clock #2 (relays 5

and 6), if present.

Notes:

To check the current master clock configuration, use the quick command [*] while the

clock is in clock mode. The CLK1 and CLK2 clock type code numbers appear in the

fourth line of the display. (See Appendix B for a list of the clock codes.)

If the master clock will synchronize Dukane digital clocks, verify that relay 7 has

been replaced with the solid-state relays available in the Dukane kit #438-860. Then

assign code 07 to CLK1.

Enter the administrative password as shown on page 2-2, then follow the key sequences

below:

Press Display

[#] SELECT FUNCTION CODE

[2] [2]=SELECT CLOCK CTL

[#] ENABLE CLOCK CIRCUIT

SELECT CLK1 CODE: NN

[#] FOR CODE LIST

Refer to Appendix B, or press [#] repeatedly to scroll the code list.

[0]...[9] Enter the two-digit code for CLK1, then press [#]. If you will not use

a CLK1, enter 00.

[#] CLK TYPE CODE: NN

If you chose a CLK1 type other than 00, you will see:

SELECT CLK2 CODE: NN

[0]...[9] Enter the code for CLK2, or 00 if you will not use a CLK2.

[#] PRESS [#] IF CORRECT

[#] Press [#] to accept, or [*] to cancel and try again.

24A715/24A715M Master Clock Installation Manual

2-5

Page 30

Manually Activating Bell Controls

Use the [3]=MANUAL BELL CTRL function to test the bell circuits.

This function does not require a password. Follow the key sequences below:

Press Display

[#] SELECT FUNCTION CODE

[3] [3]=MANUAL BELL CTRL

[#] MANUAL BELL CONTROLS

1-2-3-4-5-6-7-8

PRESS AND HOLD [#]

TO EXECUTE. [*] TO END

[1]...[8] Enter the circuit numbers to be tested, then press and hold [#]. Those

circuits will turn on their relays, as shown by the green panel lights,

and the bells connected to the activated circuits will sound. When you

release the [#], the circuits will turn off their relays. Either choose and

test other circuits, or press [*] to quit.

Note:

Only circuits configured as bell zones will appear. Circuits 5–8 will

not appear if the master clock has been programmed to use these

relays for control of secondary clocks.

[*] Return to time and date display (clock mode).

2-6

24A715/24A715M Master Clock Installation Manual

Page 31

Testing the Bells

Use the AUTO BELL TEST function to turn on all bell relays once per minute at the start

of each minute. This tests the continuity of the bell wiring circuits. This function does not

require a password.

1. If you have entered a password within the last several minutes, deactivate it by fol

lowing the instructions under Securing the Setup on page 2-9. If you do not, you will

toggle the clock between 12- and 24-hour format during this procedure.

2. Use the [6]=ENABLE CIRCUITS function to disable any relays that you do not want

to include in the test (see Enabling the Relays on page 2-4).

3. While the clock is displaying the time, press [2][3][5][5][8][7][8] to start the bell test.

While entering this code, ignore anything that displays on the screen.

Note:

After you enter the test command, there may be a delay before the bells sound.

4. When done, re-enter [2][3][5][5][8][7][8] to stop the test.

5. Use the [6]=ENABLE CIRCUITS function to re-enable any relays disabled in step 2.

Setting Daylight Saving Time

If your region observes daylight saving time, use the [7]=DAYLIGHT SAVINGS function to enter the country code so the master clock will automatically adjust for daylight

saving time. The factory-programmed country code is 08 (United States). See Appendix

A for a list of country codes.

Notes:

If your nation does not appear in the country code list, or if the dates for daylight sav

ing in your country have changed, choose code 00 and use the optional Lathem

MasterLink software to program clock adjustments. If your region does not observe

daylight saving time, choose code 00.

-

-

Enter the administrative password as shown on page 2-2, then follow these key sequences:

Press Display

[#] SELECT FUNCTION CODE

[7] [7]=DAYLIGHT SAVINGS

[#] ENTER COUNTRY CODE

FOR DAYLIGHT SAVINGS

TIME ADJUSTMENT:

[0]...[9] Enter the country code (see Appendix A).

[#] Press [#] to accept or [*] to cancel.

24A715/24A715M Master Clock Installation Manual

08 (default)

2-7

Page 32

Setting Communications

The [B]=COMMUNICATIONS function is used to enter data transmission speed and a

terminal ID number. Use this function if the clock will be programmed to call the NIST atomic

clock, or if you are using the optional Lathem MasterLink software to program the master clock.

The clock can be set up using RS-232 (serial), RS-485 (networked), or modem (remote) com

munications. You must enter the same settings for the Model 24A715M in the programming

software.

You can view the current terminal ID# and baud rate by using the quick command [*]

when the master clock is in clock mode.

Enter the administrative password as shown on page 2-2, then follow the key sequences

below:

Press Display

[#] SELECT FUNCTION CODE

[9] [9]=SYNCH. CLOCKS

[0][0] [B]=COMMUNICATIONS

[#] COMMUNICATIONS SETUP

[2] or [9] Press [2] for 2,400 baud or [9] for 9,600 baud (9,600 is the default)

-

SELECT BAUD RATE:

[2]400 -OR- [9]600

Note: If the clock will be programmed to call the NIST atomic clock,

you must select 9,600 baud.

9600 (or 2400) BAUD SELECTED

ENTER TERM ID# NNN

[0]...[9] Enter a unique terminal ID# from 00–127 (065 is the default)

[#] PRESS [#] TO CONFIRM

[#] Press [#] to accept or [*] to cancel and try again.

2-8

24A715/24A715M Master Clock Installation Manual

Page 33

Securing the Setup

At this point you have finished the basic setup of the master clock and it should be up and

running. The clock can now be programmed with user-specific settings such as bell

schedules and holidays. For detailed information, see the Master Clock User Guide, doc

ument 427-07-00047.

The master clock automatically exits from program mode if you stop using the key pad

for five minutes. To exit programming mode immediately and prevent others from ac

cessing the master clock, simply enter an invalid password. For example:

Press Display

[#] SELECT FUNCTION CODE

[0] [0]=ENTER PASSWORD

[#]

[9][9][#]

[*] Returns clock to time display.

-

-

PASSWORD: 000000

INVALID PASSWORD

24A715/24A715M Master Clock Installation Manual

2-9

Page 34

Notes

2-10

24A715/24A715M Master Clock Installation Manual

Page 35

Section

Introduction

This chapter list all functions accessible through the master clock key pad. For detailed

instructions on these functions, see Section 2—Configuration and the Master Clock

User Guide, document 427-07-00047.

Quick Commands

Quick commands are used to display system information for about two seconds. You can

press the quick keys, [*], [1], or [3], when the master is displaying the time and date.

Function List

3

[*] READ STATUS

Any time the master clock is in clock mode (displaying time and date), press [*] to see

the master clock status. See Figure 3-1 and Table 3-1.

Display Description

Date Displays current programmed date

ID# xxx Terminal ID#

TIME Shows if display is in 12- or 24-hour format

CLK1 | CLK2 Clock types this master clock will synchronize

VER. x.xx Firmware version

BAUD Baud rate for network communications

DST Daylight saving time country code

02-13-01 VER.1.06

ID# 065 |BAUD9600

TIME12HR| D ST 08

CLK1 01|CLK2 00

Figure 3-1

Status Display

24A715/24A715M Master Clock Installation Manual

Table 3-1

READ STATUS Definitions

3-1

Page 36

[1] VIEW EDIT KEYS

Any time the master clock is in clock mode (displaying time and date), press [1] to see

the edit key designations. See Figure 3-2 and Table 3-2. The edit keys are used when

programming bell schedules, automatic schedule change dates, and holiday dates. Quick

command [1] only displays a listing of the edit keys for reference; you cannot make a se

lection from this display.

EDITINGCOMMANDS

[1]EDIT[*]ABORT/EXIT

[3]PRV [#]NXT/ENTER

[6]ADD [4]DEL[9]1ST

Figure 3-2

Edit Keys Display

Display Description

[1] EDIT Edit the displayed record

[3] PRV Show the previous record

[6] ADD Add a new record

[*] ABORT/EXIT End and exit

[#] NXT/ENTER Show the next record

[4] DEL Delete the displayed record

[9] 1ST Show the first record (in ascending order)

-

3-2

[3] 12/24 HOUR TOGGLE

Any time the master clock is in clock mode (displaying time and date), enter the user

password, then press [3] to toggle the time between 12-hour and 24-hour format. The up

per right corner displays AM or PM for 12-hour format, or the day of the week for

24-hour format (for example, WE for Wednesday or HO for Holiday).

Table 3-2

List of Edit Keys

-

24A715/24A715M Master Clock Installation Manual

Page 37

Programming Commands

To access the master clock’s programming functions, press [#] to enter program mode.

When SELECT FUNCTION CODE appears on the display, the clock is ready for

programming. The master clock will automatically exit out of program mode if you have

not made a key pad entry for five minutes.

[0]=PASSWORD

A password is required for most programming functions. To enter either the administra

tive or user password, press [#][0][#], followed by the six-digit password, then press [#].

You can now program the master clock until the password expires. A password expires

after approximately five minutes. If the master clock starts blocking access to program

ming functions, re-enter the password.

The administrative password 332537 [DEALER] enables you to access both user and advanced functions.

The default user password 000000 is used to access user functions. Use the

[C]=CHANGE PASSWORD function to change your user password (see page 3-6). You

cannot change the administrative password.

[1]=SET DATE / TIME

To set the date and time, see Setting the Date and Time on page 2-3.

-

-

[2]=SELECT CLOCK CTL

This function requires the administrative password. Use this function to choose the clock

types that the master clock will synchronize.

See Choosing the Clock Types to Synchronize on page 2-5.

24A715/24A715M Master Clock Installation Manual

3-3

Page 38

[3]=MANUAL BELL CTRL

This function does not require a password. Use this function to test bell circuits or to

manually ring a bell at an unscheduled time.

See Manually Activating Bell Controls on page 2-6.

[4]=PROGRAM SCHEDULE

Use this function to set bell schedules. Bell schedules are defined as the days and times

when the bell circuits will turn on.

Enter the password, then press [#][4][#]. See the Master Clock User Guide, document

427-07-00047, for complete instructions.

[5]=SCHEDULE CHANGES

Use this function to activate schedules on a specific start date and time. Use this function

if you wish to activate schedules at future dates. You can program up to 16 changes at a

time.

Enter the password, then press [#][5][#]. See the Master Clock User Guide, document

427-07-00047, for complete instructions.

[6]=ENABLE CIRCUITS

This function requires the administrative password. Use this function to enable and dis

able bell relays during circuit wiring or maintenance. This function can also hold back

clocks to manually adjust for daylight saving time in the fall if you do not use the

[7]=DAYLIGHT SAVINGS function.

Note:

Disabled relays will ignore any schedules, and you cannot manually turn them on.

See Enabling the Relays on page 2-4.

-

3-4

24A715/24A715M Master Clock Installation Manual

Page 39

[7]=DAYLIGHT SAVINGS

This function requires the administrative password. Programming the master clock with

the appropriate two-digit country code enables it to automatically adjust for daylight sav

ing time.

See Appendix A for the country code list, and see Setting Daylight Saving Time on

page 2-7.

[8]=CHANGE SCHEDULES

Use this function to override any active bell schedules that were set up using the

[5]=SCHEDULE CHANGES function, or to immediately run a schedule set up using the

[4]=PROGRAM SCHEDULE function.

Enter the password, then press [#][8][#]. See the Master Clock User Guide, document

427-07-00047, for complete instructions.

-

[9]=SYNCH. CLOCKS

Use this function to immediately synchronize any secondary clocks. This function is primarily used during initial installation, or if power to the secondary clocks is interrupted.

Enter the password, then press [#][9][#]. See the Master Clock User Guide, document

427-07-00047, for complete instructions.

[A]=PROGRAM HOLIDAYS

The master clock can be programmed with up to 16 holidays. During holidays, only the

events that are set to occur on holidays will turn on when they reach the scheduled time.

Enter the password, then press [#][9][0][#]. See the Master Clock User Guide, document

427-07-00047, for complete instructions.

24A715/24A715M Master Clock Installation Manual

3-5

Page 40

[B]=COMMUNICATIONS

This function requires the administrative password. Use this function to set the master

clock’s terminal ID# and baud rate.

See Setting Communications on page 2-8.

[C]=CHANGE PASSWORD

Use this function to change the default user password (000000) to another six-digit num

ber to prevent unauthorized access to the master clock’s programming functions. Keep a

copy of this password in a safe place.

Enter the current user password, then press [#][9][0][0][0][#]. See the Master Clock User

Guide, document 427-07-00047, for complete instructions.

AUTO BELL TEST

No password is required for this function. Use the AUTO BELL TEST function to turn

on all bell relays once per minute at the start of each minute when you need to test the

continuity of the bell wiring circuits.

See Testing the Bells on page 2-7.

-

3-6

24A715/24A715M Master Clock Installation Manual

Page 41

Appendix

Daylight Saving Country Codes

DAYLIGHT SAVING COUNTRY CODES

ALBANIA 02 ENGLAND 01 MALTA 02

ANDORRA 02 ESTONIA 02 MONACO 02

ARMENIA 02 FALKLAND ISLANDS 10 NETHERLANDS 02

AUSTRIA 02 FINLAND 02 NEW ZEALAND 11

AZERBJAN 02 FRANCE 02 NORWAY 02

AZORES 02 GERMANY 02 POLAND 02

BAHAMAS 08 GIBRALTER 02 PORTUGAL 02

BALEARIC ISLANDS 02 GREECE 02 ROMANIA 02

BELARUS 02 GREENLAND 07 RUSSIA 02

BELGIUM 02 HAITI 07 SAN MARINO 02

BERMUDA 08 HUNGARY 02 SCOTLAND 02

BOSNIA/HERZEGOVINA 02 IRAN 02 SLOVAKIA 02

BRAZIL 13 IRAQ 03 SLOVENIA 02

BULGARIA 02 IRELAND 02 SPAIN 02

CANADA 08 ISRAEL 04 SWEDEN 02

CHANNEL ISLANDS 01 ITALY 02 SWITZERLAND 02

CHILE 12 JAMAICA 08 SYRIA 03

CROATIA 02 JORDAN 05 TURKEY 02

CUBA 06 KAZAKHSTAN 02 UKRAINE 02

CYPRUS 02 KYRGYZSTAN 02 UNITED KINGDOM 02

CZECH REP 02 LATVIA 02 UNITED STATES 08

DENMARK 02 LEBANON 02 VATICAN CITY 02

EASTER ISLAND 02 LIECHTENSTEIN 02 YUGOSLAVIA FED. 02

EGYPT 09 LUXEMBURG 02 USER-SPEC. DATES 00

A

24A715/24A715M Master Clock Installation Manual

continued

A-1

Page 42

DAYLIGHT SAVING TIME CODES AND DURATION

Code Start and end date Code Start and end date

01 Last Sunday in March, 3rd Sunday in October 08 First Sunday in April, last Sunday in October

02 Last Sunday in March, last Sunday in

09 First day of May, last day of September

September

03 First day of April, last day of September 10 Second Sunday in September, 2rd Sunday in

March

04 First Friday in April, 1st Sunday in September 11 First Sunday in October, 3rd Sunday in March

05 First Friday in April, 3rd Friday in September 12 Second Sunday in October, 2nd Saturday in

February

06 First Sunday in April, 1st Saturday in October 13 Third Sunday in October, 2nd Sunday in

07 First Sunday in April, last Sunday in October

February

A-2

24A715/24A715M Master Clock Installation Manual

Page 43

Appendix

Secondary Clock Types

SECONDARY CLOCK TYPE CODES

Type Description Type Description

01 Synchronous Wired 06 Faraday

01 Lathem Type SS 06 Honeywell ST402A

01 Cincinnati D10 07 Dukane 24F200 Digital (Obsolete)

01 Dukane 24SS Series 07 Dukane 24F750, 24F750A (Obsolete)

01 IBM 77 Series 07 Dukane 24D20, 24D20A, 24D40

01 Simplex 77 Series 08 Rauland 2410 Digital

01 Simplex 93-9 09 Simplex Dual Motor/59

01 Simplex 91-9 10 Simplex Dual Motor/45

01 Simplex 941-9 11 Edwards Dual Motor

01 Simplex 943-9 12 Cincinnati D6

01 Standard Electric D10, D12 13 Two-Wire Pulse Alternating

01 Stromberg 3000 14 Electronic Coded

02 Three-Wire Minute Impulse/59 15 Straight Frequency

02 Lathem ISC Two- and Three-Wire 16 Impulse with 12-Hour Correction/59

02 Cincinnati D2-D4 17 Standard Electric Time AR2/3

02 Dukane 24ISC Series 18 National Synchronous Wired

02 Edwards Impulse 18 Dukane 240 Series (Obsolete)

02 Faraday Impulse 18 Rauland 2463 Series (Analog)

02 IBM 75 Series 19 Stromberg Synchronous Wired/56

02 Simplex 75 Series 19 Lathem SS Modified

02 Simplex 91-4 20 Three-Wire Minute Impulse/44

02 Simplex 93-4 21 Cincinnati D1

02 Simplex 941-4 22 Dukane Synchronous Wired

02 Simplex 943-4 23 Condor 2412 Digital

02 Standard Impulse 23 Rauland 2422 Digital

02 Stromberg Impulse 24 Edwards Synchronous Wired Clocks, Type E1

03 Standard Electric Synchronous 27 Simplex 2310 Dual Motor

04 Standard Electric Time AR-2A 28 Stromberg 12-Hour

05 Three-Wire Minute Impulse/58 29 Type 01 Special

06 Synchronous Wired 30 Type 14 Special

06 Cincinnati D8

B

Note:

Types 25 and 26 are used by manufacturer for internal testing only.

24A715/24A715M Master Clock Installation Manual

B-1

Page 44

Wiring Secondary Clocks

The next several pages contain wiring diagrams and theory of operation for the secondary

clocks. These are listed in numerical order according to type code number.

Note:

All circuits should be fused or protected by a circuit breaker (10A maximum).

The 24A715 and 24A715M master clocks are factory-equipped to operate analog clocks

on the CLK1 output (relays 7 and 8), and CLK2 output (relays 5 and 6).

—IMPORTANT—

If the master clock will operate Dukane digital clocks, the digital clocks MUST

be operated from the CLK1 output (relays 7 and 8), and relay 7 MUST be

replaced with a solid-state relay to support the digital clocks. To obtain the

required solid-state relay, order Model 438-860 from Dukane.

TYPE 01—Synchronous Wired

For a list of Type 01 clocks, see the chart on the first page of this appendix.

In normal operation, the synchronous secondary clocks are operated from 24Vac or

120Vac, using the 60Hz power source to maintain clock accuracy. An error in the time

displayed by the secondary clock can be introduced by a power failure. The master clock

will correct the time displayed on the secondary clock using two synchronization methods: minute hand correction and absolute correction.

Minute hand correction takes place once every hour, even if there is no error in the dis

played time. The master clock sends an eight-second pulse to the secondary clock’s

correction circuit, starting at the 57th minute and 54th second, and lasting until the 58th

minute and 2nd second of every hour. This causes the secondary clock to advance its

hands until the minute hand is correct. The hour hand will still be in error at the end of

this cycle if the error at the beginning of the cycle was in excess of one hour.

If the secondary clocks are more than one hour off, the master clock initiates an absolute

correction by sending a six-second pulse, beginning at 5:58:02 (both AM and PM) and

ending at 5:58:08. This correction cycle takes a long time to completely update the sec

ondary clocks. Depending on how far off the secondary clocks are, the correction cycle

can take many hours to complete. The correction cycle does not run continuously, so it

may be difficult to establish whether or not the secondary clocks have completed their

correction activities.

-

-

B-2

24A715/24A715M Master Clock Installation Manual

Page 45

Please note that the relay contacts used in the CLK2 circuit are rated at 10 amps. The

combined load of the correction circuit and the run circuit should not exceed 8 amps. In

general, 20–35 analog clocks can be operated on a single string. This number depends on

the clock style and the distances involved. To estimate clock loads for Dukane 24SS se

ries clocks, see the Dukane Analog Clock Installation Guide (document number

402-455).

X = Normally open contact

I = Normally closed contact

= V250LA4 MOV or equal

1

RELAY

K6 (K8)

x

x

RELAY

K5 (K7)

II

x

-

x

CLK1 OR CLK2

24 OR 120 VAC

NEUTRAL

MASTER CLOCK

12345678

10 ASB MAX.

1

FIELD CONNECTIONS

1

Figure B-1

Three-Wire Synchronous (59th Minute, Dukane 24SS)

CORRECTION CIRCUIT

TO CORRECTION COIL

RUN CIRCUIT TO

ANALOG CLOCK MOTOR

NEUTRAL

24A715/24A715M Master Clock Installation Manual

B-3

Page 46

TYPE 02—Three-Wire Minute Impulse (59th Minute)

There are two types of Type 02 secondary clocks: the three-wire minute impulse covered on

this page, and the two-wire reverse polarity minute impulse on the following page.

Note:

For a list of Type 02 clocks, see the chart on the first page of this appendix.

From the 58th second to 00 seconds each minute, a 24Vdc pulse is transmitted to the sec

ondary clocks. From the 59th minute through the 49th minute, the pulse is transmitted on

both the A and B lines. From the 50th minute to the 59th minute, the pulse is transmitted

on the A line only.

Clocks that reach the 59th minute ahead of the master clock stop, since at this time they

respond only to the pulses transmitted on the B line. During the 59th minute, from 10 sec

onds through the 50th second, 20 rapid pulses are transmitted at 0.5Hz on the A line to

advance all slow clocks.

An accumulator, designed in the software, counts the number of minutes lost due to

power failure. Upon resumption of power, the master clock transmits pulses on lines A

and B to immediately advance the slow clocks to the proper time. Resetting the time after

a power failure terminates these correction signals.

Manual clock advances and daylight saving advances cause the master clock to transmit

62 pulses (1 second ON and 1 second OFF at 0.5Hz). The first five pulses are transmitted

on lines A and B. The remainder of the pulses are transmitted on line A only. Normal

minute pulses are inhibited during these pulses.

X = Normally open contact

I = Normally closed contact

= 1N4004 diode or equal

2

RELAY

K6 (K8)

x

x

RELAY

K5 (K7)

II

x

-

-

x

B-4

CLK1 OR CLK2

10 ASB MAX.

+

24Vdc

–

12345678

2

Figure B-2

Three-Wire Minute Impulse (59th Minute)

24A715/24A715M Master Clock Installation Manual

MASTER CLOCK

FIELD CONNECTIONS

B

2

A

C

Page 47

TYPE 02—Two-Wire Reverse Polarity Minute Impulse (59th Minute)

There are two kinds of Type 02 secondary clocks: the two-wire reverse polarity minute im

pulse covered on this page, and the three-wire minute impulse on the previous page.

Note:

For a list of Type 02 clocks, see the chart on the first page of this appendix.

Every minute, from the 58th second to 00 seconds, a 24Vdc pulse is transmitted to the

secondary clocks. From the 59th minute through the 49th minute, the pulse is transmitted

with line AB positive with respect to PC. From the 50th minute to the 59th minute, the pulse

is transmitted with line AB negative with respect to PC. Clocks that reach the 59th min

ute ahead of the master clock stop, since at this time they respond only to pulses

transmitted with line AB positive with respect to PC.

During the 59th minute, from 10 seconds through the 50th second, 20 rapid pulses are

transmitted at 0.5Hz to advance all slow clocks. During the rapid pulsing, line AB is neg

ative with respect to PC. Connect a diode as shown in Figure B-3 for arc suppression of

the relay contacts.

An accumulator, designed in the software, counts the number of minutes lost due to

power failure. When power is restored, the master clock transmits pulses with line AB

positive with respect to PC to immediately advance the slow clocks to the proper time.

Resetting the time after a power failure terminates these correction signals.

Manual clock advances and daylight saving advances cause the master clock to transmit

62 pulses (1 second ON and 1 second OFF at 0.5Hz). The first five pulses are transmitted

with line AB positive with respect to line PC. The remainder of the pulses are transmitted

with line AB negative with respect to line PC. Normal minute pulses are inhibited during

these pulses.

-

-

X = Normally open contact

I = Normally closed contact

= V250LA4 MOV or equal

1

= 1N4004 diode or equal

2

CLK1 OR CLK2

10 ASB MAX.

–

24–36 Vdc

+

Two-Wire Reverse Polarity Minute Impulse (59th Minute)

24A715/24A715M Master Clock Installation Manual

RELAY

K6 (K8)

x

x

12345678

2

RELAY

K5 (K7)

II

x

1

x

Figure B-3

MASTER CLOCK

FIELD CONNECTIONS

AB

PC

B-5

Page 48

TYPE 03—Standard Electric Synchronous

During normal operation, 120Vac is applied to the run motor. A 15-minute correction

signal on the correction motor line causes a 12-hour correction from 5:12:00 to 5:28:00.

This occurs twice daily (AM and PM). Run motor power is connected during the 12-hour

correction. A 29-second signal is applied to the correction motor line from HH:59:30 to

HH:59:59 to cause hourly corrections. During hourly corrections, power is disconnected

from the run motor line.

X = Normally open contact

I = Normally closed contact

= V250LA4 MOV or equal

1

RELAY

K6 (K8)

x

x

II

x

RELAY

K5 (K7)

x

CLK1 OR CLK2

120Vac

AC RTN

10 ASB MAX.

12345678

1

Figure B-4

Standard Electric Synchronous

MASTER CLOCK

FIELD CONNECTIONS

CORRECTION MOTOR

1

RUN MOTOR

RETURN

B-6

24A715/24A715M Master Clock Installation Manual

Page 49

TYPE 04—Standard Electric Time AR-2A Two-Wire, Dual Voltage

Each minute, from 58 seconds to 00 seconds, a low-voltage pulse (24Vdc) is transmitted.

The secondary clocks receive the pulses until the 59th minute. At this time, from 50 sec

onds to 00 seconds, a higher voltage pulse (48Vdc) is required to advance to the hour.

Manual clock advances and daylight saving advances cause the master clock to transmit

62 pulses (one second ON and one second OFF at 0.5Hz), all at 24Vdc. Normal minute

pulses are inhibited during these pulses.

X = Normally open contact

I = Normally closed contact

= 1N4004 diode or equal

2

RELAY

K6 (K8)

x

x

RELAY

K5 (K7)

II

x

x

-

CLK1 OR CLK2

12345678

24Vdc

48Vdc

RTN

Figure B-5

Standard Electric Time AR-2A Two-Wired, Dual Voltage

MASTER CLOCK

FIELD CONNECTIONS

10 ASB MAX.

AB

2

PC

24A715/24A715M Master Clock Installation Manual

B-7

Page 50

TYPE 05—Three-Wire Minute Impulse (58th Minute)

Each minute, from the 58th second to 00 seconds, a 24Vdc pulse is transmitted to the sec

ondary clocks. From the 58th minute through the 48th minute, the pulse is transmitted on