Page 1

TECHNICAL INSTRUCTIONS

DAYTONA

1-POWER

ENGLISH

383033GB Pag. 1 November 2003

Page 2

TABLE OF CONTENTS

INTRODUCTION…………………………….………………………………………………………………. Pag. 6

- INTRODUCTION AND GENERAL INSTRUCTIOS

- INSTRUCTIONS FOR INSTALLATION

- SPECIAL INSTRUCTIONS FOR USE AND MAINTENANCE

GENERAL CHARACTERISTICS………………………………….……………………………………….Pag. 7

DAYONA 1-POWER MACHINE KEYPAD……………………………………………………………..…. Pag. 7

MACHINE FUNCTION MESSAGES………………………………………………………….…………... Pag. 8

MESSAGE OF MACHINE DOOR POSITIONING

1) MESSAGE OF GROUNDS BIN OUT OF POSITION

2) MESSAGE OF FULL GROUNDS BIN

3) MESSAGE OF COFFEE BOILER HEATING TEMPERATURE NOT REACHED

4) MESSAGE OF STEAM BOILER HEATING TEMPERATURE NOT REACHED

5) MESSAGE OF MANUAL GROUP CLEANING

6) MESSAGE OF MILKER CLEANING

STARTING UP PROCEDURE ………………………………………………………………………….… Pag. 9

MILK BOX HOLDER ASSEMBLY…………………………………………………………………………. Pag. 11

MACHINE DISPENSING…………………………………………………………………………………. Pag. 12

1) STANDARD MACHINE

2) MACHINE WITH WAITERS’ CARD

3) SELF MACHINE

4) SELF MACHINE WITH CREDIT CARD

5) SELF MACHINE WITH COIN MECHANISM

6) SELF MACHINE WITH CREDIT CARD + COIN MECHANISM

DISPENSING BY MEANS OF DECAFFEINATED COFFEE DOOR………………………………….. Pag. 16

CONTINUOUS DISPENSING………..……………………………………………………………………. Pag. 16

STEAM DISPENSING…………………………………………………………………………………… Pag. 16

HOT WATER DISPENSING…..…………………………………………………………………………… Pag. 17

SMART CARD FUNCTIONS………………………………………………………………………….. Pag. 17

1) WAITERS’ SMART CARD

2) OWNER’S SMART CARD

3) TECHNICIAN’S SMART CARD

4) SMART CREDIT CARD

5) READING-WRITING SMART CARD

AUTOMATIC WASHING CYCLE PROCEDURE……………………………………………………… Pag. 19

1) COFFEE GROUP AUTOMATIC TIMED WASHING

2) GROUP-MILKER AUTOMATIC WASHING WITH DETERGENT

2.1) GROUP WASHING

2.2) MILKER WASHING

DOSE PROGRAMMING PROCEDURE……………………………………………………………… Pag. 23

1) BEVERAGE NAME PROGRAMMING

1.1) DECAFFEINATED DOOR FUNCTION

1.2) MOTOR PUMP FUNCTION DURING FILTER COFFEE CYCLE OR LATTE MACCHIATO

1.3) GRIND TIME PROGRAMMING

1.4) PRE-INFUSION TIME PROGRAMMING

1.5) PRE-INFUSION TIME PROGRAMMING FOR FILTER COFFEE CYCLE

1.6) PAUSE PROGRAMMING DURING FILTER COFFEE CYCLE

1.7) COFFEE WATER DOSE PROGRAMMING

1.8) WATER DOSE PROGRAMMING FOR EXTRA WATER VOLUME

1.9) PROGRAMMING OF STEAMED MILK DISPENSING TIME BEFORE COFFEE

1.10 PROGRAMMING THE PAUSE TIME BETWEEN THE PRE STEAMED MILK AND PRE FOAMED MILK

DELIVERY.

1.11) PROGRAMMING OF FOAMED MILK DISPENSING TIME BEFORE COFFEE

1.12) PROGRAMMING OF PAUSE TIME BETWEEN MILK AND COFFEE DISPENSING

1.13) PROGRAMMING OF STEAMED MILK DISPENSING TIME AFTER COFFEE

1.14) PROGRAMMING THE PAUSE TIME BETWEEN THE POST STEAMED MILK AND POST FOAMED MILK

DELIVERY.

1.15) PROGRAMMING OF FOAMED MILK DISPENSING TIME AFTER COFFEE

1.16) PRICE PROGRAMMING OF A SET UP DOSE

1.17) CONTROL OF DELIVERIES OF PROGRAMMED DOSES

1.18) PROGRAMMING MENU FUNCTION FOR TWO CUPS

2) PROGRAMMING OF HOT WATER DOSE FOR TEA

2.1) PROGRAMMING HOT WATER DOSE FOR TEA

383033GB Pag. 2 November 2003

Page 3

2.2) PRICE PROGRAMMING OF A SET UP DOSE

3) STEAM DISPENSING PROGRAMMING

3.1) STEAM DISPENSING TIME PROGRAMMING

3.2) PRICE PROGRAMMING OF A SET UP DOSE

SYSTEM TEMPERATURE INFORMATION PROCEDURE.…………………………………………...Pag. 28

INFORMATION PROCEDURE AND DISPENSING RESET…………………………………………... Pag. 28

1) READ DOSE COUNTER

2) WAITER DOSE RESET

SMART CARD CREDIT CHARGE PROCEDURE ………..…………………………………………… Pag. 30

SYSTEM PROGRAMMING…………………………………………………………………………………Pag. 33

1) MACHINE PARAMETERS

1.1) LANGUAGE SELECTION PROGRAMMING

1.2) MACHINE TYPE CONFIGURATION PROGRAMMING

1.3) SERIAL DOOR FUNCTION

1.4) COFFEE GROUNDS NUMBER PROGRAMMING

1.5) AUTOMATIC CLEANING FUNCTION

1.5.a) WATER DOSE PROGRAMMING FOR AUTOMATIC CLEANING

1.5.b) START TIME PROGRAMMING OF AUTOMATIC CLEANING AFTER THE LAST COFFEE

1.5.c) TIME PROGRAMMING BETWEEN ONE CLEANING CYCLE AND THE NEXT

1.6) PROGRAMMING RINSE AFTER MILK DOSE.

1.6a) PROGRAMMING RINSE AFTER MILK DOSE.

1.7) AUTOMATIC RINSE MILKER MACHINE IN STAND-BY.

1.7a) START TIME PROGRAMMING OF AUTOMATIC MILKER RINSE AFTER THE LAST DOSE MILK BASED.

1.7b) TIME PROGRAMMING BETWEEN ONE MILKER RINSE CYCLE AND THE NEXT.

1.8) M1 TOOLS WORKING TIME PROGRAMMING FOR MAINTENANCE

1.9) WATER FILTER LITRE PROGRAMMING

1.10) GROUP CYCLE NUMBER PROGRAMMING FOR MAINTENANCE

1.11) GROUP CYCLE NUMBER PROGRAMMING FOR MANUAL GROUP CLEANING MESSAGE

1.12) PROGRAMMING BLOCKED DELIVERIES MESSAGE OF GROUP CLEANING

1.13) DOSE NUMBER PROGRAMMING FOR MILKER CLEANING MESSAGE

1.14) PROGRAMMING OF TIME OUT MESSAGE OF MILKER CLEANING

1.15) PROGRAMMING BLOCKED DELIVERIES MESSAGE OF MILKER CLEANING

1.16) COFFEE TEMPERATURE UNIT PROGRAMMING

1.17) CURRENCY DECIMAL NUMBER PROGRAMMING

1.18) MINIMUM CURRENCY UNIT PROGRAMMING

1.19) MAXIMUM CREDIT PROGRAMMING OF THE CREDIT CARD

1.20) COFFEE BOILER TEMPERATURE PROGRAMMING

1.21) STEAM BOILER TEMPERATURE PROGRAMMING

1.22) PROGRAMMING OF STEAM BOILER HEATING TIME AT EACH WATER FILLING UP

1.23) PROGRAMMING THE TIME-OUT BETWEEN ONE MILK-BASED DELIVERY AND THE NEXT.

1.24) PROGRAMMING TIME ADDITIONAL DOSE

1.25) PROGRAMMING OF TEMPERATURE DRAIN STOP OF STEAM BOILER

1.26) SEQUENTIAL HEATING FUNCTION OF COFFEE AND STEAM BOILERS

1.27) PROGRAMMING BUTTON N°16 FUNCTION

1.28) PROGRAMMING TEMPERATURE PROBE TYPE

1.29) PROGRAMMING MAXIMUM HIGER MOTOR IMPULSES

1.30) PROGRAMMING HIGER MOTOR STAND-BY POSITION IMPULSES

1.31) PROGRAMMING HIGER MOTOR DELIVERY POSITION IMPULSES

1.32) PROGRAMMING MAXIMUM LOWER IMPULSES

1.33) PROGRAMMING LOWER MOTOR STAND-BY POSITION IMPULSES

1.34) PROGRAMMING LOWER MOTOR EXPELLING POSITION IMPULSES

2) GROUP CLEANING PROGRAMMING

2.1) WATER DOSE PROGRAMMING FOR AUTOMATIC CLEANING WITH DETERGENT

2.2) PAUSE TIME PROGRAMMING DURING AUTOMATIC CLEANING WITH DETERGENT

2.3) PROGRAMMING OF CYCLE NUMBER

3) MILKER CLEANING PROGRAMMING

3.1) MILKER CLEANING TIME PROGRAMMING

4) SET-UP ENCODER

5) GROUP MANUAL MOVEMENTS

6) TEST ACTUATORS

7) SYSTEM DATA RESET INFO

7.1) RESET OF TOTAL DISPENSING NUMBER CARRIED OUT BY SELECTION BUTTONS

7.2) READING RESET OF AUTOMATIC GROUP CLEANING NUMBER WITH DETERGENT

7.3) READING RESET OF MILKER CLEANING NUMBER

7.4) READING RESET OF CYCLE NUMBER CARRIED OUT BY THE COFFEE GROUP

7.5) READING RESET OF M1 TOOLS WORKING TIME

7.6) READING RESET OF WATER LITRE NUMBER REGENERATED BY THE WATER FILTER

383033GB Pag. 3 November 2003

Page 4

7.7) READING RESET OF TOTAL CYCLE NUMBER CARRIED OUT BY THE COFFEE GROUP

8) ALARM DATA MEMORY

9) SMART CARD PROGRAMMING

9.1) DEVICE CODE DISPLAY AND MODIFICATION

9.2) WAITER’S CARD CREATION

9.2) WAITER’S CARD NUMBER ENABLE / DISABLE

9.3) OWNER’S CARD CREATION

9.4) CREDIT CARD CREATION

9.5) CREDIT CHARGE

9.6) TECHNICIAN’S CARD CREATION

10) PARAMETERS PRESET

11) FILES MANAGER

12) UPDATE SOFTWARE

13) HISTORY HIGER MOTOR

14) HISTORY LOWER MOTOR

ALARM MESSAGES – MACHINE SHUTDOWN…………………………………………………………...Pag. 64

1) GROUP MOVEMENT BOARD ALARM

2) TIME OUT IMPULSES, UPPER PISTON MOTOR

3) TIME OUT IMPULSES, LOWER PISTON MOTOR

4) TOO MUCH COFFEE ALARM

5) UPPER MOTOR ERROR ALARM

6) LOWER MOTOR ERROR ALARM

7) STEAM BOILER FILLING ALARM

8) STEAM BOILER MINIMUM LEVEL ALARM

9) VOLUME METER ALARM

10) WATER SOFTENER ALARM

11) TOOLS MAINTENANCE ALARM

12) COFFEE BOILER TEMPERATURE ALARM (TOO HIGH)

13) COFFEE BOILER TEMPERATURE ALARM (TOO LOW)

14) STEAM BOILER TEMPERATURE ALARM (TOO HIGH)

15) STEAM BOILER TEMPERATURE ALARM (TOO LOW)

16) FAULTY DATA ALARM

17) GROUP MAINTENANCE ALARM

18) MACHINE SHUTDOWN ALARM

19) INTERVENTION OF STEAM BOILER SAFETY THERMOSTAT

20) INTERVENTION OF STEAM BOILER SAFETY PROBE

21) MANUAL GROUP CLEANING MESSAGE

22) MILKER CLEANING MESSAGE

23) MILKER CLEANING MESSAGE WITH BLOCKED DELIVERIES

24) GROUP CLEANING MESSAGE WITH BLOCKED DELIVERIES

MACHINE COMPONENTS CALIBRATING……………………………………………………………… Pag. 71

1) CALIBRATING OF COFFEE BOILER EXPANSION VALVE

2) COFFEE DISPENSING PRESSURE CALIBRATING (PUMP PRESSURE)

3) COFFEE GRINDING DEGREE CALIBRATING

4) CALIBRATING OF COFFEE OUTLET FLOW ADJUSTMENT

5) DECANTER FUCNTION TO STOP THE RETURN OF THE MILK FLOW

6) COLD – HOT WATER MIX FLOW ADJUSTMENT FOR TEA.

BODY DISASSEMBLY PROCEDURE……………………………………………….…………………… Pag. 73

BOILER DRAINING PROCEDURE……………………………………………………………………….. Pag. 74

SPECIAL MAINTENANCE…………..…………………………………………………………………….. Pag. 74

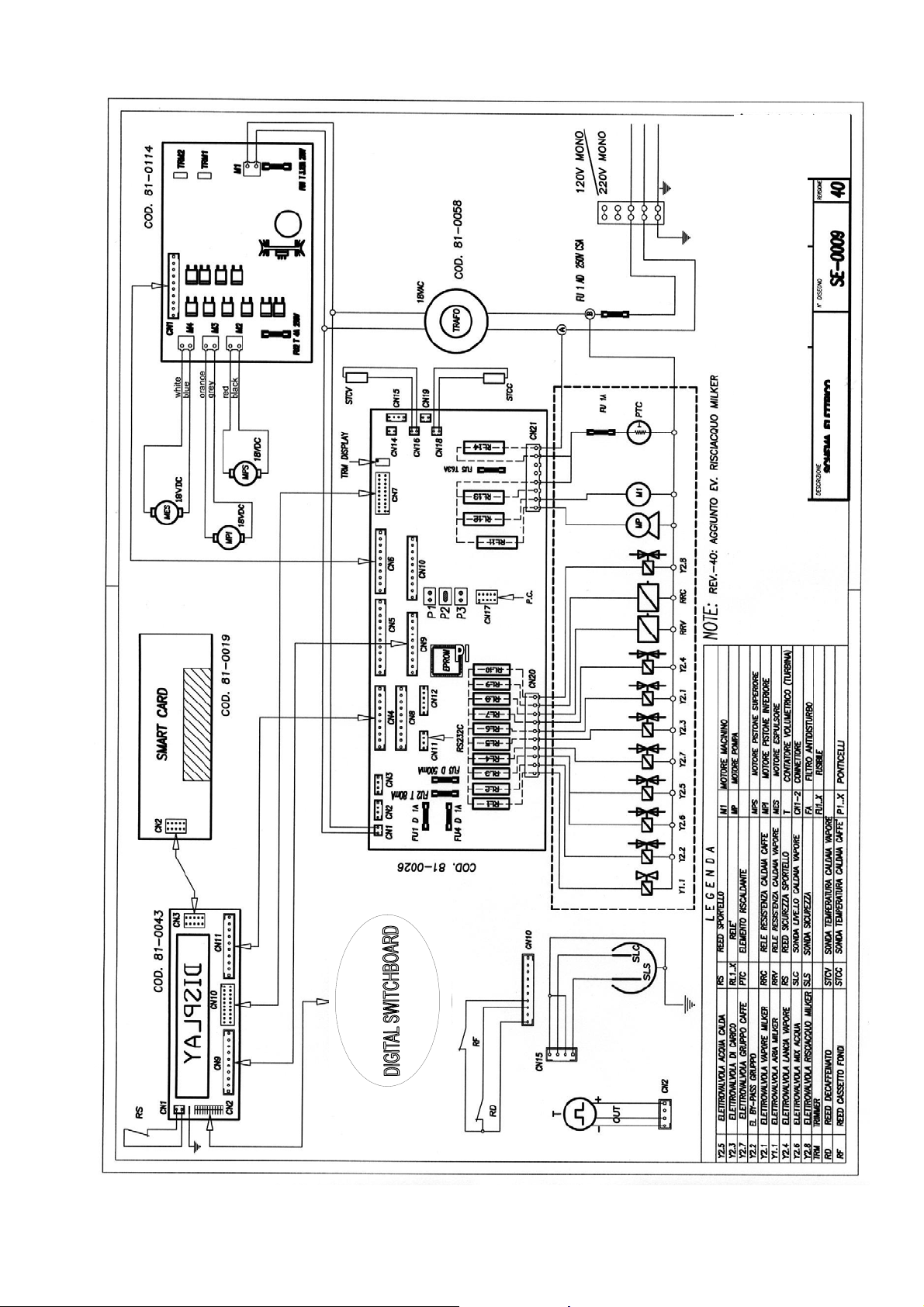

CONTROL UNIT LEGEND….……………………………………………………………………………...Pag. 75

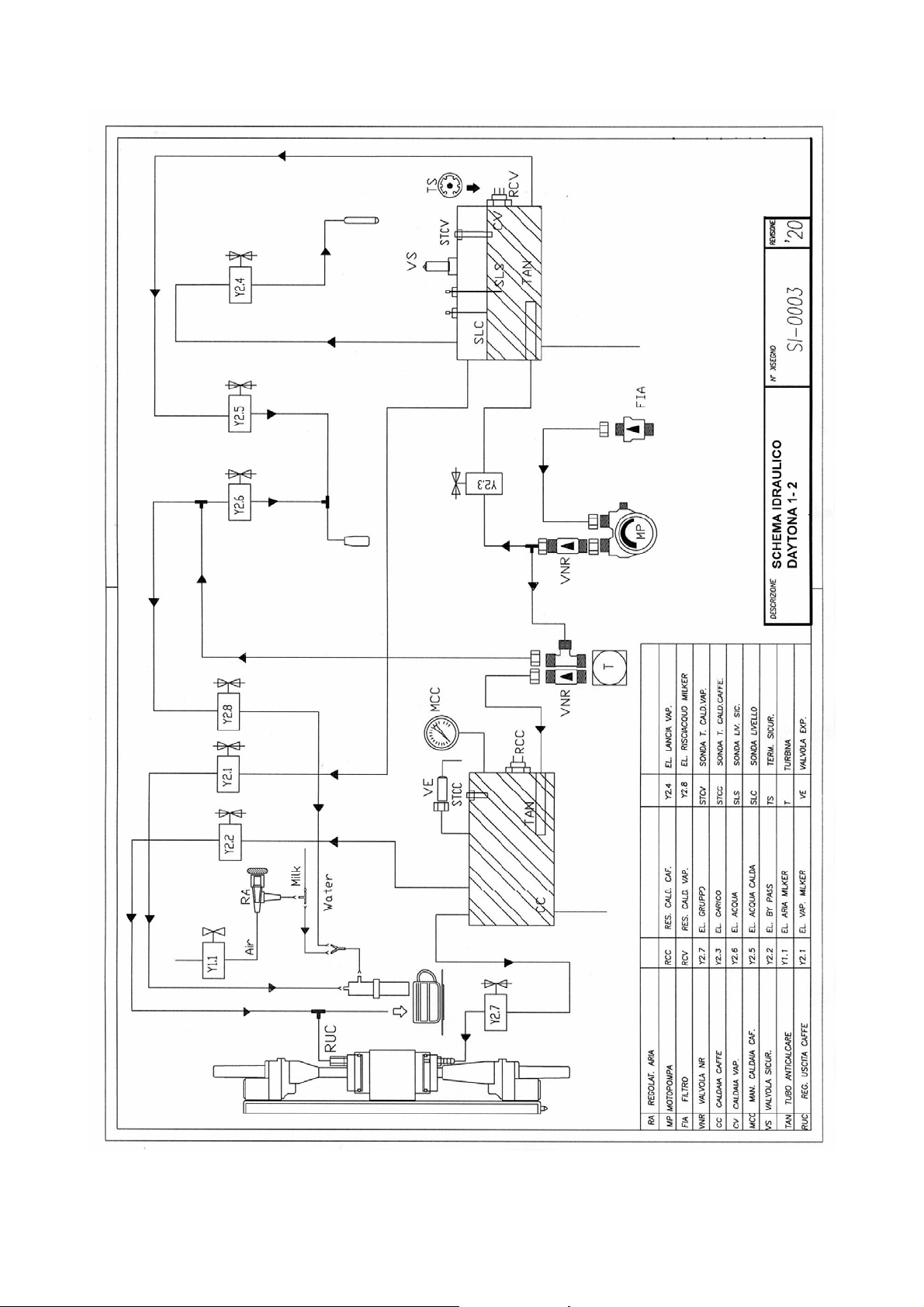

TABLE LEGEND …………………………………………………………………………………………….Pag. 76

383033GB Pag. 4 November 2003

Page 5

EU / UE

DICHIARAZIONE DI CONFORMITA’ – KONFORMITÄTSERKLÄRUNG

DECLARATION OF CONFORMITY – DECLARATION DE CONFORMITE

Noi, Wir, We, Nous

La Pavoni S.p.A.- Via Privata Gorizia, 7

20098 San Giuliano Milanese (MI)

dichiariamo sotto nostra responsabilità, che il prodotto

erklären in alleiniger Verantwortung, daß das Produckt

declare under our sole responsibility that the product

déclarons sous notre seule responsabilité que le produit

(Nome, tipo o modello, Nr. lotto, del campione o della serie, eventuali fonti e numero pezzi)

(Bezeichnung Typ oder Modell, Los-, Chargen- oder Seriennummer, möglichst Herkunft und Stückzahl)

(Name, type or model, lot, batch or serial number, possible sources and number of items)

(Nom, type ou modèle, no de lot, d’échantillons ou de série, éventuellement sources et nombre

d’éxemplaires)

DAYTONA 1 – 2 POWER

al quale si riferisce questa dichiarazione, è conforme alla(e) norma(e) o ad altro(i) documento(i) della

normativa

auf das sich diese Erklärung bezieht, mit der/den folgenden Norm(en) oder normativen Dokument(en)

übereinstimmt

to which this declaration relates is in conformity with the following standard(s) or other normative

document(s)

auquel se référre cette déclaration est conforme à la (aux) norme(s) ou autre(s) document(s) normatif(s)

73/23 CE 97/23/CE 89/336 CE

(Intestazione e/o numero e data della pubblicazione della(e) Norma(e) o altro(i) documento(i) della

Normativa)

(Titel und/oder Nummer sowie Ausgabedatum der Norm(en) oder der anderen normativen Dokument(en))

(Title and/or number and date of issue of the standard(s) or other normative document(s))

(Titre et/ou no et date de publications de la (des) norme(s) ou autre(s) document(s) normatif(s))

Conformemente alle disposizioni della(e) Direttiva(e): Gemäss den Bestimmungen der Richtlinie(n):

following the regulations of the Directive(s): conformément aux dispositions de(s) Directive(s):

(se applicabile) (falls zutreffend) (if applicable) (le cas échéant)

89/392 CE

San Giuliano Milanese La Pavoni S.p.A.

15/06/2003 Il Procuratore

Dr. Eugenio Pennè

383033GB Pag. 5 November 2003

Page 6

INTRODUCTION AND GENERAL INSTRUCTIONS

Thoroughly read the instructions contained in this booklet because it gives important information regarding safety for installation, use and maintenance.

Keep this booklet in a safe and accessible place for further consultation.

This machine must be used only for the purpose it was designed:

dispensing coffee, cappuccino and pouring hot water

Any other use is to be considered inappropriate and therefore dangerous.

The manufacturer declines all responsibility for damage caused by any improper, incorrect and unreasonable use of the machine.

The use of any electric appliance implies the observance of some fundamental rules.

More specifically:

- do not touch the appliance with your hands or feet wet or damp

- do not use the appliance with bare feet

- do not pull the power cord to disconnect the plug from the power socket

- do not leave the appliance exposed to the weather (rain, sun, frost)

- do not let children or untrained persons use the appliance.

Before carrying out any cleaning and maintenance, disconnect the appliance from the power supply, pulling the plug from the power socket and turning off

the main switch.

In case of failure or malfunction turn the machine off and do not attempt to carry out any repairs or direct operations on the machine.

All repairs must be carried out in a LA PAVONI Authorised Service Centre, using original spare parts only.

Failure to comply with the above recommendations will compromise the safety of the machine and the warranty conditions.

If this machine is no longer used, we recommend that it is made inoperative by disconnecting the power cord and water tube from the power supply, and all

potentially dangerous parts are made harmless, especially to protect children who might use the machine for their games.

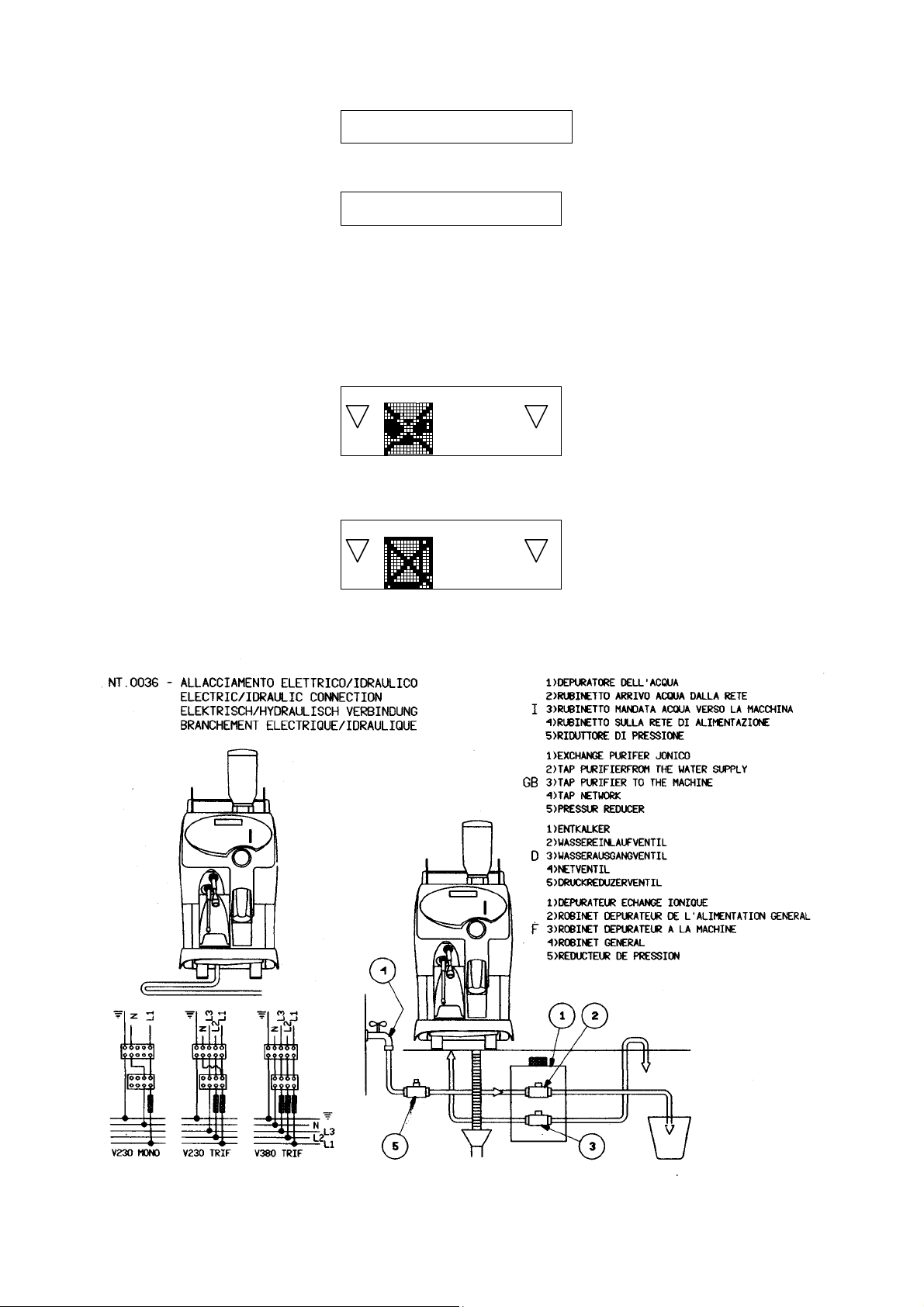

INSTRUCTIONS FOR INSTALLATION

Installation must be carried out according to the manufacturer’s instructions.

An incorrect installation can cause damage to persons, animals or things; the manufacturer declines all responsibility for such situation.

After unpacking check that the machine is not damaged.

If in doubt, do not use the machine and contact a LA PAVONI Authorised Service Centre.

All packing materials (plastic wrapping, polystyrene, nails, etc.) are potentially dangerous and must be kept out of children’s reach and disposed of in a safe

manner for the environment.

Before connecting the machine to the power supply make sure that the rating information of the machine correspond to that of the power supply: if the

power socket is not compatible with the plug of the machine (if supplied), replace the socket with a proper one, ensuring that the size of the cable is suitable

for the absorbed power of the machine. If you replace the power cord, use an H07RN-F cord again.

Make sure that the voltage rating of the machine corresponds to that of the power supply, and that the power supply is adequate to additional power

absorption of the machine.

After installing the main switch and fuses (see annex), connect the power cord of the machine to the main switch according to the attached electrical

diagram.

The use of adapters, multiple power boards and extension cords is not recommended.

If it is absolutely necessary, then use only single or multiple adapters and extension cords which comply with current safety regulations, ensuring also that

the electricity load capacity of the single adapters and extension cords and the maximum power rating of the multiple adapters is suitable.

The electrical safety of this machine can be guaranteed only if correctly connected to an efficient earth circuit as indicated by current electrical safety

regulations.

It is necessary to check this fundamental safety prerequisite, and in case of doubt, ask a professionally qualified technician to check the circuit.

The manufacturer declines all responsibility for any damage caused by failure to earth the machine.

In order to avoid any dangerous overheating, we recommend that the power cord be fully unwound.

The power cord of this machine must not be replaced by customers.

In case of damage to the cord, contact exclusively a LA PAVONI Authorised Service Centre.

Do not leave the machine connected unnecessarily.

Turn off the main switch of the machine when not in use.

Do not cover the ventilation openings of the machine.

Place the machine at an adequate distance from walls, objects, etc.

The machine must be connected to a system with a water pressure, which is not greater than 5 bar. (Kg/cm

If the pressure is greater, a pressure reducer must be installed.

Install a water softener above the machine.

2

).

SPECIAL INSTRUCTIONS FOR USE AND MAINTENANCE

For a correct functioning of the machine it is fundamental to comply with the manufacturer’s instructions, having qualified personnel to carry out ordinary

maintenance and to check all safety devices.

Avoid exposing hands or other parts of the body to the coffee dispensing spouts or to the hot water nozzle. The water from the nozzle is very hot and can

cause severe burns.

The water nozzle is very hot and therefore must be handled with care, holding it in the appropriate point.

Do not use the machine without water.

Do not leave the machine in rooms where the temperature is below zero °C or 32 °F without having first drained the boiler and the hydraulic circuit.

A softener needs to be used where the water is very hard and where the calcareous scaling is particularly extensive.

In any case, regularly check the boiler even where the water is not very hard, and if necessary, have the resistors and tubing descaled by specialised

technicians.

Failure to clean La Pavoni S.p.A. machines daily, especially for brewing unit and milk frother, using approved cleaning products and following

specified cleaning procedure will result in void warranty and service contract.

383033GB Pag. 6 November 2003

Page 7

GENERAL CHARACTERISTICS

Number of coffee dispensing groups 1

Number of grinders 1

Decaffeinated door 1

Automatic cappuccino nozzle 1

Hot water dispenser 1

Maximum quantity of coffee dispensed per hour 180

Width (mm) 360

Machine height (mm) 710

Machine height with hopper (mm) 840

Depth (mm) 580

Net weight (Kg) 30

Coffee boiler capacity (lt) 2

Steam boiler capacity (lt) 2

Boiler resistor (W) Coffee

Steam

Voltage (V)

Brewer group resistor PTC (W) 70

Materials used:

- Copper for boiler

- Copper for hydraulic tubes

- Nickel-plated brass for connections.

- Reinforced silicone for the flexible feed tube.

- Aluminium with stainless steel lining for the brewing group.

- Aluminium for the grinder.

- Other accessories in food plastic which are in contact with the ground coffee or drink.

- Aluminium bodywork

- ABS plastic for controls area.

- Stainless steel and ABS plastic for working area and cups tray.

230V-1+N – 50/60Hz

230V-3 – 50/60Hz

200V-1+N – 50/60Hz

200V-3 – 50/60Hz

400V-3+N – 50/60Hz

DAYTONA 1-POWER MACHINE KEYPAD

2000

2000

383033GB Pag. 7 November 2003

Page 8

MACHINE FUNCTION MESSAGES

1) Message of machine door positioning

This message is displayed with the following symbol

Cause

: open door. The reed does not touch the magnet on the door.

: shutdown of the machine functioning.

Result

Solution

2) Message of grounds bin out of position

This message is displayed with the following symbol

Cause

Result

Solution

3) Message of full grounds bin

This message is displayed with the following symbol

Cause

Result

Solution

: close the machine door.

: grounds bin out of position. The reed does not touch the magnet on the bin.

: shutdown of coffee-based dispensing keys.

: put the grounds bin into its housing.

: full grounds bin. The number of coffee grounds in the bin has reached the value set in the programming stage.

: shutdown of coffee-based dispensing keys.

: remove the grounds bin and empty it; put the bin back in when the display shows the following symbol

4) Message of coffee boiler heating temperature not reached

This message is displayed with the following symbol

Cause: the coffee boiler has not reached the set up heating temperature

Result: shut down of coffee based dispensing.

Solution: wait until the boiler has reached the set up heating temperature.

5) Message of steam boiler heating temperature not reached

This message is displayed with the following symbol

Cause: the steam boiler has not reached the set up heating temperature

Result: shut down of milk based dispensing and hot water and steam dispensing

Solution: wait until the boiler has reached the set up heating temperature.

6) Message of manual group cleaning

This message is displayed with the following symbol

: the number of set group cycles has been reached

Cause

Result

: according to the type of machine set up, the results are:

a) coffee-based deliveries are disabled after 10 deliveries from display of the message

b) the relevant icon is displayed without blocking machine functioning

Solution

7) Message of milker cleaning

This message is displayed with the following symbol

Cause

Result

a) milk-based doses are disabled after 10 deliveries from display of the message

b) milk-based deliveries are disabled when the timeout set after the last milker delivery has elapsed

c) the relevant icon is displayed without blocking machine functioning

: carry out manual group cleaning.

: the number of set milker dispensing has been reached, or the set time after the last miler dispensing is over

: according to the type of machine set up, the results are:

383033GB Pag. 8 November 2003

Page 9

STARTING UP PROCEDURE

After having connected the machine to the water and electric networks, turn the switch on (see diagram). The display

shows:

LA PAVONI

REV. X.XXX

Where REV. X.XXX indicates the version of the inserted version.

After a few seconds the display shows:

SELECT LANGUAGE

ENGLISH

Press the key N°13 (1x) or N°14 (2x) to display the available languages

Press the key N°16 (3.4.5…X) to confirm the chosen language, the display shows:

OFF

Press the key N°11( ON/OFF ), the display shows:

WARNING:

If the language choice procedure is not displayed, keep the machine in OFF mode; it is absolutely

necessary to carry out PARAMETERS PRESET procedure. See system-programming chapter.

STEAM BOILER FILLING UP

During this stage the steam boiler is being filled up.

WARNING:

The solenoid valve of the steam nozzle automatically opens to release the air inside the boiler.

When the steam boiler has been filled up, the display shows:

STEAM BOILER FILLING UP

PRESS KEY N°1

AT DISPENSING

During this stage the coffee boiler is being filled up

WARNING:

The upper piston of the coffee group positions itself inside the brewing chamber, and the coffee boiler starts filling up.

When the coffee spout starts dispensing water, press the key dose N° 1 to confirm that the filling up has been carried

out. When the coffee boiler has been filled up, the display shows:

COFFEE STEAM

BOILER BOILER

XXX°C

Where:

- XXX °C indicates the temperature of the coffee boiler

- YYY ° C indicates the temperature of the steam boiler

WARNING:

YYY°C

During this stage the solenoid valve of the steam nozzle will stay open until the temperature of 95°C is

reached. This will release the air from the boiler and generate steam.

When the set up temperature of both boilers has been reached, all beverage buttons will be operative and the display

shows:

SELECT DRINK

For machine configurations: Standard or Self

383033GB Pag. 9 November 2003

Page 10

INSERT CARD

For machine configurations: waiters’ card or Self with credit card

INSERT COINS

0000

For machine configuration: Self with coin mechanism

WARNING:

a) For Self-configuration the key N° 11 (ON/OFF) is only enabled for ON function.

To turn the machine in OFF mode, insert the smart card and either press the key N°11 (ON/OFF), or open the

machine door, or use the main switch (see diagram).

b) In case of temporary voltage drop, the machine will be automatically turned back to the stage previous to the voltage

drop.

c) The display shows:

SELECT DRINK

Where the displayed icon indicates that the set up heating temperature in the coffee boiler has not been reached yet, and

therefore coffee based dispensing is not enabled; or:

SELECT DRINK

Where the displayed icon indicates that the set up heating temperature in the steam boiler has not been reached yet, and

therefore milk based dispensing and hot water and steam dispensing are not enabled.

Wait until the boiler has reached the set up heating temperature.

383033GB Pag. 10 November 2003

Page 11

MILK BOX HOLDER ASSEMBLY

The machine is supplied complete with milk box holder assembly to be fixed to the machine left side, in case the

refrigerating unit is not being used.

See drawings to fix the milk box holder

383033GB Pag. 11 November 2003

Page 12

MACHINE DISPENSING

1) STANDARD MACHINE

The display shows:

SELECT DRINK

The arrows turned downwards indicate the enabled buttons

Press the desired selection button, the display shows:

XXXXXXXX

Where XXXXXXXXX is the name of the selected drink, while the arrows indicate the key N°13 (1x) and the key N°14

(2x). Press the key “1x” to confirm single cup dispensing, press the key “2x” to confirm double cup dispensing.

Extra foamed milk function.

Extra milk function enables to dispense extra foamed milk in the following way:

- Press any milk-based key and keep it pressed, after 2 seconds foamed milk will start being dispensed.

- Releasing the pressed key, dispensing will stop.

WARNING:

a) If you want to change the type of displayed selection, press the desired selection button again, before confirming the

dispensing by means of the key buttons “1x” o “2x”.

b) If dispensing is not confirmed after 30’’ time-out, the display will cancel the chosen selection.

c) If the selection button you have pressed immediately enables the dispensing cycle, it means that the chosen

selection is activated only for a single cup.

d) Pressing any key during dispensing can stop the selected dose.

In case of a milk-based dose, press twice to stop dispensing; press once to stop milk dispensing, and once to stop

coffee dispensing; the sequence depends on the type of dispensing.

2) MACHINE WITH WAITERS’ CARD

The display shows:

INSERT CARD

Insert the smart card into the proper slit, the display shows in order:

SELECT DRINK

CARD N° XX

WAITER XX

Where N°XX indicates the number of the inserted waiters’ card, while the arrows turned downwards indicate the enabled

buttons.

Press the desired selection button, the display shows:

XXXXXXXX

Where XXXXXXXXX is the name of the selected drink, while the arrows indicate the key N°13 (1x) and the key N°14

(2x). Press the key “1x” to confirm single cup dispensing, press the key “2x” to confirm double cup dispensing.

At this point you can take the smart card out

Extra foamed milk function.

Extra milk function enables to dispense extra foamed milk in the following way:

- Press any milk-based key and keep it pressed, after 2 seconds foamed milk will start being dispensed.

- Releasing the pressed key, dispensing will stop.

383033GB Pag. 12 November 2003

Page 13

WARNING:

a) Dispensing is enabled only when the smart card is inserted.

b) The number of carried out dispensing is saved in the counter relevant to the inserted card.

c) If you want to change the type of displayed selection, press the desired selection button again, before confirming

dispensing by means of the key buttons “1x” o “2x”.

d) If dispensing is not confirmed after 30’’ time-out, the display will cancel the chosen selection.

e) If the selection button you have pressed immediately enables the dispensing cycle, it means that the chosen

selection is activated only for a single cup.

f) Pressing any key during dispensing can stop the selected dose.

In case of a milk-based dose, press twice to stop dispensing; press once to stop milk dispensing, and once to stop

coffee dispensing; the sequence depends on the type of dispensing.

3) SELF MACHINE

The display shows:

SELECT DRINK

The arrows turned downwards indicate the enabled buttons.

Press the desired selection button, the display shows:

XXXXXXXX

Where XXXXXXXXX is the name of the selected drink.

WARNING:

a) On-Off button is enabled only when the smart card is inserted

b) Extra milk function is not enabled

c) Steam function is not foreseen and not enabled

d) Decaffeinated function is not foreseen and not enabled

e) Continuous dispensing is not enabled

f) Pressing any key during dispensing can stop the selected dose.

In case of a milk-based dose, press twice to stop dispensing; press once to stop milk dispensing, and once to stop

coffee dispensing; the sequence depends on the type of dispensing.

4) SELF MACHINE WITH CREDIT CARD

The display shows:

INSERT CARD

Insert the smart card into the proper slit, the display shows the message:

SELECT DRINK

alternated with the message

CREDIT XXXXX

Where XXXXX indicates the residual credit of the inserted card.

The arrows turned downwards indicate the enabled buttons.

Place a cup under the delivery spout.

Press the desired selection button, the display shows:

XXXXXXXX

383033GB Pag. 13 November 2003

Page 14

Where XXXXXXXX is the name of the selected drink.

ATTENZIONE:

a) On-Off button is enabled only when the smart card is inserted

b) If you press a selection button before inserting the smart card, the display shows the cost of the selected drink.

c) Extra milk function is not enabled

d) Steam function is not foreseen and not enabled

e) Decaffeinated function is not foreseen and not enabled

f) Continuous dispensing is not enabled

g) The selected dose cannot be stopped.

WARNING:

To disable the functioning of the machine with credit card, proceed as follows:

Turn the machine ON.

Insert the owner or technician’s smart card into the proper slit.

Press the key N°9, the display shows:

FREE DRINKS

XXXXXXXX

Where XXXXXXX indicates:

ENABLED (Self-configuration: the machine dispenses free drinks)

DISABILITATO (Coin mechanism: the machine dispenses drinks against payment)

Press the key N°13 (1x) or N°14 (2x) to modify the level mode.

Press the key N° 12 (gost1) to return to the previous environment and/or exit.

Press the key N°16 (3.4.5…X) to confirm, the display shows:

SELECT DRINK

WARNING:

The following configurations are available: self with credit card + self with coin mechanism. In this case the

display shows: “INSERT COINS” alternated with “INSERT CARD”.

5) SELF MACHINE WITH COIN MECHANISM

The display shows:

INSERT COINS

0000

Alternated with the message:

SELECT DRINK

Where “00000” indicates the money amount inserted in the machine.

The arrows turned downwards indicate the enabled buttons.

Place a cup under the coffee spout, insert coins, press the desired button, the display shows:

XXXXXXXX

Where XXXXXX is the name of the selected dose.

WARNING:

a) On-Off button is enabled only when the smart card is inserted

b) When pressing the selection button before inserting coins, the display shows the cost of the selected drink.

c) The credit will not be returned and will be available for the next selection.

d) To get the coins back before having selected the dose, press the relevant button of the coin mechanism.

e) Extra milk function is not enabled.

f) Steam function is not foreseen and not enabled.

g) Decaffeinated function is not foreseen and not enabled.

h) Continuous dispensing is not enabled.

i) The selected dose cannot be stopped.

WARNING:

To disable the coin mechanism, proceed as follows:

Turn the machine ON

Insert the owner or technician’s smart card into the proper slit.

383033GB Pag. 14 November 2003

Page 15

Press the key N°9, the display shows:

FREE DRINKS

XXXXXXXX

Where XXXXXXX indicates:

ENABLED (Self-configuration: the machine dispenses free drinks)

DISABLED (Coin mechanism: the machine dispenses drinks against payment)

Press the key N°13 (1x) or N°14 (2x) to modify the level mode.

Press the key N° 12 (gost1) to return to the previous environment and/or exit.

Press the key N°16 (3.4.5…X) to confirm, the display shows:

SELECT DRINK

6) SELF MACHINE WITH CREDIT CARD + COIN MECHANISM

The following configurations are available: self with credit card + self with coin mechanism.

In this case the display shows:

INSERT COINS

0000

alternated with:

INSERT CARD

For further information, see the following paragraphs.

383033GB Pag. 15 November 2003

Page 16

DISPENSING BY MEANS OF DECAFFEINATED COFFEE DOOR

The display shows:

SELECT DRINK

Open the decaffeinated door, pour in the powdered coffee, close the door.

The display shows:

SELECT DRINK

Where indicates that the selected dose will be dispensed without the activation of the grinders.

WARNING:

a) If the decaffeinated door is not closed, or if the dose button is not selected, the machine will automatically cancel this

function after 20’’. The coffee group will carry out a cleaning cycle of the chamber, the display shows:

b) This function is not enabled for self machine, for self machine with credit card, for self machine with coin

mechanism, and for self with credit card + coin mechanism.

CONTINUOUS DISPENSING

The display shows:

SELECT DRINK

Press the continuous key N°16 (3.4.5…X) as many times as the number of doses you want to dispense by means of the

continuous dispensing function, maximum value is 5; the display shows:

SELECT DRINK

X

Where X

WARNING:

a) If you want to stop the automatic continuous cycle just press the continuous button N°16 (3.4.5….X).

b) This function is not enabled for the decaffeinated cycle.

c) This function is not enabled for self machine, for self machine with credit card, for self machine with coin

mechanism, and for self with credit card + coin mechanism.

Put the steam nozzle into the drink you want to heat up. Press the key N°9 to start and stop dispensing.

The display shows:

WARNING:

a) Handle the steam nozzle with caution because it could cause burns, due to high temperature.

b) The steam message will not be displayed in case another dispensing is being carried out.

c) Steam cannot be dispensed simultaneously with hot water.

d) This function is not enabled for self machine, for self machine with credit card, for self machine with coin

mechanism, and for self with credit card + coin mechanism.

indicates the number of cycles the machine will automatically carry out for the dose you will select.

STEAM DISPENSING

STEAM

383033GB Pag. 16 November 2003

Page 17

HOT WATER DISPENSING

Place the decanter under the hot water spout. Press the key N°10 to start the hot water dose. Dispensing will be

automatically stopped once the programmed dose is reached.

The display shows:

HOT WATER

WARNING:

a) Handle the hot water spout with caution because it could cause burns, due to high temperature.

b) The hot water message will not be displayed in case another dispensing is being carried out.

c) Hot water cannot be dispensed simultaneously with steam.

d) Pressing the key N°10 can stop the dose, which is being dispensed.

SMART CARD FUNCTIONS

The machine is enabled to work in the various use procedures with or without the smart card according to the desired

operation, and to the type of machine configuration.

The available smart cards are:

1) Waiters’ Smart card Card number 1-25

2) Owner’s Smart card Card number P

3) Technician’s Smart card Card number T

4) Smart credit card Card number C

5) Reading-writing Smart card Card number LS

WARNING:

a) Waiter, owner, technician and credit cards can be created on the machine control panel (see chapter system

programming, smart card programming)

b) Owner, waiter and credit cards can be converted into smart cards with other functions

c) Technician’s cards cannot be converted into any other smart card

Smart card functions:

1) Waiters’ smart card

It is possible to set maximum 25 waiters’ cards for each single machine. This card is enabled to the following functions:

1.1) In case of machine configuration: Standard, Self, Self with credit card and Self with coin mechanism:

a) Automatic washing cycles

b) Total info

1.2) In case of machine configuration with waiters’ card:

a) Dispensing

b) Automatic washing cycles

c) Reading of dispensed drinks carried out by the same card

2) Owner’s smart card

It is possible to set an infinite number of owner’s cards. This card enables the following functions:

a) Dispensing

b) Disable the functioning with coin mechanism and credit card

c) Automatic washing cycles

d) Reading of dispensed drinks carried out by waiters’ cards

e) Reading of total dispensed drinks

f) Reading of alarm data memory

g) Reset of dispensing carried out by waiters’ cards

h) Reset of total dispensing

i) Reset of water softener alarm

j) Dose programming

k) Setting of waiters’ card, owner’s card, and credit card

WARNING:

d) Dispensing carried out with this card is not counted

e) Linked remote control systems (Interface I/O, coin mechanism) are disabled.

383033GB Pag. 17 November 2003

Page 18

3) Technician’s smart card

It is possible to set an infinite number of technician’s cards. This card enables all the machine functions:

WARNING:

a) Dispensing carried out with this card is not counted

b) Linked remote control systems (Interface I/O, coin mechanism) are disabled

c) Grounds bin reed and machine door are disabled.

4) Smart credit card

It is possible to set an infinite number of cards with credit. This card enables dispensing in case the machine has been

set as “self with credit card”.

5) Reading-writing Smart card

This card enables to read all machine data, and transfer them to another machine or read them by means of a P.C.

WARNING:

a) Wait at least 2” before removing the card from its proper slit; during this time the display shows a card icon. If the

card is removed during this stage, the card might suffer irreparable damages.

b) If you use a card having a card code different from the machine code, the card can no longer been used after two

failures.

383033GB Pag. 18 November 2003

Page 19

AUTOMATIC WASHING CYCLE PROCEDURE

1) COFFEE GROUP AUTOMATIC TIMED WASHING

A timed washing cycle of the brewing chamber is automatically carried out 15’ after the last dispensed drink and every

180’ when the machine is in stand-by mode.

The display shows:

AUTOMATIC CLEANING

WARNING:

a) The timed washing cycle is not enabled for self machine, for self machine with credit card, for self machine with coin

mechanism, and for self machine with credit card + coin mechanism.

b) The parameters of water quantity and activation time of automatic washing are modifiable (see chapter: machine

data configuration).

2) AUTOMATIC TIMED RINSE OF THE CAPPUCCINO MAKER.

This is a brewing chamber washing cycle, which is carried out by the machine automatically 10 minutes after the last

dose based milk and every 3 hours.

WARNING:

You can change the interval time before the automatic wash switches on (see machine parameter management chapter).

3) GROUP-MILKER AUTOMATIC WASHING WITH DETERGENT

To enter the automatic washing mode with detergent, proceed as follows:

Turn the machine ON.

Insert the Smart Card into the proper slit.

Press the key N° 12 (gost1), the display shows:

SELECT CLEANING

T1 GROUP CLEANING

T2 MILKER CLEANING

The arrows turned downwards indicate the keys enabled to choose the type of washing:

Press the key N°1 to start group washing

Press the key N°2 to start milker washing

WARNING:

a) Before starting milker washing, remove the milk infeed pipe from the milk carton and carefully read the washing

procedure.

b) The access to this function is enabled by means of the smart card only for Self-service configurations

3.1. GROUP WASHING

It is advisable to carry out this type of washing at the end of each working day.

The display shows:

GROUP CLEANING

PLEASE WAIT

The group moves to the tablet ejecting position and the display shows:

GROUP CLEANING

Open the door and clean

Open the machine door

NT.0017

383033GB Pag. 19 November 2003

Page 20

and by using the special brush supplied, clean the group pistons and the brewing chamber.

WARNING: if you move the ejector in order to optimise manual cleaning, remember to put it back to its ejection position.

Close the door, the display shows:

GROUP CLEANING

PLEASE WAIT

The group is brought to its rest position, the display shows:

GROUP CLEANING

Insert detergent

Open the decaffeinated door nor the machine (for Self-service configurations), insert the detergent tablet and close the

decaffeinated door, the display shows:

GROUP CLEANING

Washing will automatically start; when the washing cycle is over, the display shows:

SELECT DRINK

WARNING:

a) The washing cycle is disabled after 30’’ time-out in any stage before inserting the detergent, except when the

machine door is open

b) The washing cannot be interrupted after the detergent has been inserted.

c) If the washing cycle is interrupted by any type of operation unrelated to the washing cycle, when the machine

functioning is set back again, the washing cycle will be automatically activated.

d) The hot water parameters and activation times of the washing cycle are modifiable (see chapter: group-washing

procedure).

e) The cleaning cycle can also be activated by keeping a dose key (T1-T8) pressed for about 3 seconds, if previously

configurated as “GROUP CLEANING” (see chapter beverage name programming).

The display shows:

GROUP CLEANING

Open the front door and clean

Repeat the same procedures to carry out the washing cycle.

2.2) MILKER WASHING

It is advisable to carry out this type of washing at the end of each working day

WARNING:

Before starting automatic milker washing, proceed as follows:

a) remove the milk infeed pipe from the milk carton.

b) Put the milk infeed pipe into a glass of cold water. If you use a detergent it must be liquid, no-foaming and food-type.

The display shows:

MILKER CLEANING

When the washing cycle is over, the display shows:

SELECT DRINK

383033GB Pag. 20 November 2003

Page 21

WARNING:

a) The washing cycle cannot be interrupted.

b) If the washing cycle is interrupted with any type of operation unrelated to the washing cycle, when the machine

functioning is set back again, the washing cycle will automatically be activated.

c) At the end of each working day the milker should be dismantled and cleaned by hand. To dismantle the milker,

remove the cover of the coffee-milker spout (see diagram).

d) The plunged tube needs to be periodically cleaned, therefore we suggest dismantling the two parts of the

tube(1-2) and carefully clean them, as well as the bulkhead (3) fixed on the side of the machine, by means

of the supplied brush.

WARNING:

When the washing is over, check that the milker infeed pipes are correctly connected; see below diagram:

NT.0030

383033GB Pag. 21 November 2003

Page 22

e) The cleaning cycle can also be activated by keeping a dose key (T1-T8) pressed for about 3 seconds, if previously

configurated as “MILKER CLEANING” (see chapter beverage name programming).

The display shows:

MILKER CLEANING

When the cleaning cycle is over, the display shows:

SELECT DRINK

383033GB Pag. 22 November 2003

Page 23

DOSE PROGRAMMING PROCEDURE

To enter programming mode, proceed as follows.

Insert the owner or technician’s smart card into the proper slit ,with machine ON or OFF.

Press the key N°16 (3.4.5…X) for 5 seconds, the display shows:

DOSE PROGRAMMING

SELECT BUTTON

WARNING:

a) During selection key programming, it is possible to choose another selection key, remaining in the same

programming level, if the selection key is enabled to this function

b) When the technician’s smart card is inserted the machine can be programmed even in OFF mode.

c) After 30’’ time-out, any type of mode and/or programming environment will be abandoned.

1) BEVERAGE NAME PROGRAMMING

Press a selection button, the display shows:

DOSE PROGRAMMING

SELECT NAME

TY XXXXX

Where:

T Y indicates the number of the selected button.

XXXXX indicates the name of the selected button.

Press the key N°13 (1x) or N°14 (2x) to modify the level mode.

Press the key N°16 (3.4.5…X) to confirm the modification carried out and shift to the next level

Press the key N°15 (gost2) to shift to the next level without saving the modifications carried out.

Press the key N° 12 (gost1) to return to the previous environment and/or exit.

The available choices are the following:

COFFEE-BASED DRINKS MILK-BASED DRINKS FILTER DRINKS

Kaffee creme Schnaps Cappuccino Caffè latte Pot Decanter

Espresso Kaennchen Macchiato Renversè Jug Becher

Coffee Lutz Latte macchiato Cafè au lait Filter Kaffee

Kaffee Fertig Milchkaffee Cafè chauffeur

Black coffee Grosser brauner Café 2 Espressi

Ristretto Kleiner brauner 2 Ristretti 2 Cafés

Schale Verlaengerter

Entkoffeiniert Melange ONLY-MILK DRINKS NO DRINK

Koffeinfrei Schuemli Lait chaud Latte Disabled

Fruehestueck Cafè petit dèjeuner Milk Milch

SERVICES

Sans cafèine

espresso

WARNING:

a) Depending on the type of chosen drink, the necessary programming levels will be activated to set the drink.

b) If the chosen drink refers to “FILTER DRINKS”, the coffee group cycle will be automatically modified so that ground

coffee is not pressed. Besides, additional programming levels are activated, enabling to optimise the infusion of the

selected drink.

c) If the selected name is not enabled, the button will not be enabled to dispensing.

d) If the selected name refers to “SERVICES”, the button is enabled to group or milker cleaning function (see par.

automatic cleaning cycle procedure).

Sans cafèine

caffè

Group cleaning Milker cleaning

383033GB Pag. 23 November 2003

Page 24

Descriptions of the levels of programming doses

1.1) Decaffeinated door function

This level will not be displayed for only milk drinks

DOSE PROGRAMMING

DECAFFEINATED

XXXXXXXX

Where XXXXXXX indicates:

ENABLED (the selected dose button is enabled to the use of the door to insert decaffeinated coffee)

DISABLED (the selected dose button is not enabled to the use of the door to insert decaffeinated coffee)

WARNING:

This programming level is not enabled for self machine, self with credit card and self with coin mechanism

1.2) Motor pump function during filter coffee cycle or latte macchiato

This level will be displayed only for filter drinks or for milk-based drinks

DOSE PROGRAMMING

MOTOR PUMP

XXXXXXXX

Where XXXXXXX indicates:

ENABLED (the selected dose will be dispensed by means of the motor pump)

DISABLED (the selected dose will be dispensed without the activation of the motor pump, only by using

the pressure of the hydraulic network)

WARNING:

This function is enabled in order to allow dispensing of filter drinks without using the motor pump and obtain an infusion

similar to that of percolators, that is without pressure.

1.3) Grind time programming

This level will not be displayed for only-milk drinks.

DOSE PROGRAMMING

GRIND TIME M1 XX s

GRIND TIME M2 XX s

Where XX s indicates the time in seconds during which the grinder will be activated.

WARNING:

To check the set up grind time and therefore the corresponding coffee quantity, proceed as follows:

a) Open the machine door.

b) Remove the coffee chute, disassembling the components according to the procedure shown in the picture

383033GB Pag. 24 November 2003

Page 25

c) Place a paper cup at the exit of the grinder chute to collect the coffee that will be ground.

d) Press the dose button you are programming.

e) Weigh the ground coffee obtained.

To ease the procedure, we suggest removing the upper piston, or taking out the coffee chute and directly taking the

ground coffee from the coffee outlets of the grinders.

1.4) Pre-infusion time programming

This level will not be displayed for filter and only-milk drinks.

DOSE PROGRAMMING

PRE – INFUSION X.X s

Where X.X s indicates the time in seconds necessary to wet coffee in the brewing chamber before dispensing.

1.5) Pre-infusion time programming for filter coffee cycle

This level will be displayed for filter drinks only.

DOSE PROGRAMMING

PRE – INFUSION X.X CC

Where X.X CC indicates the water quantity in cm3 necessary to wet coffee in the brewing chamber before dispensing.

1.6) Pause programming during filter coffee cycle

This level will be displayed only for filter drinks

DOSE PROGRAMMING

PAUSE XX s

Where XX s indicates the pause time in seconds carried out by the coffee group cycle after pre-infusion cycle.

WARNING: This function has been enabled to optimise the infusion of filter drinks.

1.7) Coffee water dose programming

This level will not be displayed for only milk drinks

DOSE PROGRAMMING

INFUSION XX CC

Where XX CC indicates the water quantity in cm3 of the selected dose.

1.8) Water dose programming for extra water volume

This level will be displayed only for coffee-based and filter-based drinks.

DOSE PROGRAMMING

EXTRA WATER VOLUME XX CC

Where XX CC indicates the water quantity in cm3 dispensed by means of the by-pass solenoid valve

WARNING:

The extra water dose (by-pass) is equivalent to the amount of water dispensed by the by-pass solenoid valve

simultaneously with the coffee group solenoid valve during the final dispensing stage. The amount of water set up in the

previous programming level remains the same.

1.9) Programming of steamed milk-dispensing time before coffee

This level will not be displayed for filter-based and coffee-based drinks

STEAMED MILK PRE XX s

Where XX s indicates the time in seconds during which steamed milk will be dispensed before the coffee dose.

383033GB Pag. 25 November 2003

Page 26

1.10) Programming the pause time between the PRE steamed milk and PRE foamed milk delivery.

This level will not be displayed for coffee and filter based drinks.

DOSE PROGRAMMING

PAUSE MILK PRE XX

Where XX s indicates the time in seconds of the pause between the PRE steamed milk and PRE foamed milk delivery.

PLEASE NOTE:

This function has been enabled to allow the hot milk and the frothy milk to stratify before the coffee is dispensed.

1.11) Programming of foamed milk-dispensing time before coffee

This level will not be displayed for filter-based and coffee-based drinks

DOSE PROGRAMMING

FOAMED MILK PRE XX s

Where XX s indicates the time in seconds during which foamed milk will be dispensed before the coffee dose.

1.12) Programming of pause time between milk and coffee dispensing

This level will not displayed for filter-based and coffee-based drinks.

DOSE PROGRAMMING

MILK-COFFEE PAUSE XXs

Where XX s indicates the pause time in seconds passing between milk and coffee dispensing.

WARNING:

This function has been implemented to allow steamed and foamed milk to stratify before coffee dispensing.

1.13) Programming of steamed milk-dispensing time after coffee

This level will not be displayed for filter-based and coffee-based drinks

DOSE PROGRAMMING

STEAMED MILK POST XX s

Where XX s indicates the time in seconds during which steamed milk will be dispensed after coffee doses.

1.14) Programming the pause time between the POST steamed milk and POST foamed milk delivery.

This level will not be displayed for coffee and filter based drinks.

DOSE PROGRAMMING

PAUSE MILK POST XX s

Where XX s indicates the time in seconds of the pause between the POST steamed milk and POST foamed milk

delivery.

PLEASE NOTE:

This function has been enabled to allow the hot milk and the frothy milk to stratify before the coffee is dispensed.

1.15) Programming of foamed milk-dispensing time after coffee

This level will not be displayed for filter-based and coffee-based drinks

DOSE ROGRAMMING

FOAMED MILK POST XX s

Where XX s indicates the time in seconds during which foamed milk will be dispensed after the coffee dose.

1.16) Price programming of a set up dose

DOSE PROGRAMMING

DOSE PRICE XXXXX

Where XXXXXXX indicates the dose price given to the selection button that is being programmed.

383033GB Pag. 26 November 2003

Page 27

1.17) Control of deliveries of programmed doses

DOSE PROGRAMMING

DOSE TEST

Press a dose key to carry out one delivery and check the previously set values

1.18) Programming menu function for two cups

This level will not be enabled for only milk-based drinks.

DOSE PROGRAMMING

X2 XXXXXXXXXX

Where XXXXXXX indicates:

ENABLED (the dose button is enabled to single and double dispensing (X1 e/o X2)).

DISABLED (the dose button is only enabled to single dispensing)

WARNING:

a) When the function 2X is enabled, the above menu is displayed again to set up the doses for two cups.

b) This programming level is not enabled for self machine, self with credit card, self with coin mechanism, self with

credit card + coin mechanism.

2) PROGRAMMING OF HOT WATER DOSE FOR TEA

Press hot water button, the display shows:

2.1) Programming hot water dose for tea

DOSE PROGRAMMING

HOT WATER

WATER XXX.X

where XXX.X indicates the time in seconds during which hot water will be dispensed; the value varies between 0-120s;

10s are the standard set up value.

Press the key N°13 (1x) or N°14 (2x) to modify the level mode.

Press the key N°16 (3.4.5…X) to confirm the modification carried out and shift to the next level

Press the key N°15 (gost2) to shift to the next level without saving the modifications carried out.

Press the key N° 12 (gost1) to return to the previous environment and /or exit.

2.2) Price programming of a set up dose

DOSE PROGRAMMING

DOSE PRICE XXXXX

where XXXXX indicates the dose price given to the selection button that is being programmed.

WARNING:

If the dose is programmed to zero, the button is disabled.

3) STEAM DISPENSING TIME PROGRAMMING

Press the hot water key, the display shows:

3.1) Steam dispensing time programming

DOSE PROGRAMMING

STEAM TIME

XXX

383033GB Pag. 27 November 2003

Page 28

where XXX indicates the time in seconds during which steam will be dispensed; the value varies between 0-255s; 255s

are the standard set up value.

Press the key N°13 (1x) or N°14 (2x) to modify the level mode.

Press the key N°16 (3.4.5…X) to confirm the modification carried out and shift to the next level

Press the key N°15 (gost2) to shift to the next level without saving the modifications carried out.

Press the key N° 12 (gost1) to return to the previous environment and /or exit.

3.2) Price programming of a set up dose

DOSE PROGRAMMING

DOSE PRICE XXXXX

where XXXXX indicates the dose price given to the selection button that is being programmed.

WARNING:

If the dose is programmed to zero, the button is disabled.

SYSTEM TEMPERATURE INFORMATION PROCEDURE

To enter the environment of info temperature system, proceed as follows:

Turn the machine ON or OFF.

Press the key N° 15 (gost2), the display shows:

INFO TEMPERATURE SYSTEM

COFFEE TEMPERA. XX°Z

STEAM TEMPERA.YY°Z

Where:

XX°C indicates the temperature of the coffee boiler, and Z indicates the unit expressed in ° Centigrade or ° Fahrenheit

YY°C indicates the temperature of the steam boiler, and Z indicates the unit expressed in ° Centigrade or ° Fahrenheit

WARNING:

a) The system temperatures will be displayed for 5”.

b) This function is enabled without the use of the smart card

INFORMATION PROCEDURE AND DISPENSING RESET

To enter the information environment and dispensing reset, proceed as follows:

Turn the machine ON

Insert the smart card into the proper slit

Press the key N°15 (gost2), the display shows:

DISPENSING INFO

DOSE READING

Press the key N°16 (3.4.5…X) to confirm entering the environment

Press the key N°13 (1x) or N°14 (2x) to display the available environments

Press the key N° 12 (gost1) to exit the environment

The display shows:

DISPENSING INFO

DOSE READING

DISPENSING INFO

WAITERS’ DOSE

RESET

383033GB Pag. 28 November 2003

Page 29

WARNING:

a) Dispensing info environment of the waiters’ card reset is only enabled by means of machine configuration “waiters”.

b) Dispensing info environment of the waiters’ card reset is only enabled by means of the owner or technician’s card.

Descriptions of information environments and dose reset:

1) READ DOSE COUNTER

1.1) In case of machine configuration: standard, self, self with credit card, self with coin mechanism, self with credit

card + coin mechanism, the display shows:

DISPENSING INFO

READ DOSE COUNTER

Press N°16 (3.4.5…X) to confirm entering the environment, the display shows:

DISPENSING INFO

TOTAL TAKINGS

XXXXXXXX

Where XXXXXXXX indicates the total takings of the machine

WARNING:

The total takings will be calculated if a selling price has been set for each dose

Press the key N° 16 (3.4.5…X) to confirm entering the next environment, the display shows:

DISPENSING INFO

READ DOSE COUNTER

SELECT BUTTON

Press the key dose whose number of drinks you want to display; the display shows:

DISPENSING INFO

READ DOSE COUNTER

XXXXX

1X YY 2X ZZ ♥ JJ

Where: “XXXX” indicates the name of the selected button

1X YY indicates the number of single cup dispensed drinks

2X ZZ indicates the number of double cup dispensed drinks

♥ JJ indicates the number of decaffeinated dispensed drinks

1.2) In case of machine configuration with waiters’ card, the display shows:

DISPENSING INFO

READ DOSE COUNTER

Press the key N°16 (3.4.5…X) to confirm entering the environment, the display shows:

DISPENSING INFO

READ DOSE COUNTER

WAITER 1

Where 1 indicates the number of the waiter’s card.

Press the key N°13 (1x) or N°14 (2x) to change the number of the waiter’s card or the machine total T

Press the key N° 12 (gost1) to exit the environment.

Press the key N°16 (3.4.5…X) to confirm, the display shows:

DISPENSING INFO READ

DOSE COUNTER WAITER Y

TOTAL TAKINGS

XXXXXXXX

383033GB Pag. 29 November 2003

Page 30

Where Y indicates:

from 1 to 25 the waiter’s number

T all the waiters.

Where XXXXXXXX indicates the total takings made by the relevant waiter 1-25 or by all the waiters T.

WARNING:

The total takings will be calculated if a selling price has been set for each dose

Press the key N° 16 (3.4.5…X) to confirm entering the next environment, the display shows:

DISPENSING INFO READ

DOSE COUNTER WAITER 1

Press the key dose whose number of drinks you want to display; the display shows:

DISPENSING INFO READ

DOSE COUNTER WAITER 1

XXXXX

1X YY 2X ZZ ♥ JJ

Where: “XXXX” indicates the name of the selected button

1X YY indicates the number of single cup dispensed drinks

2X ZZ indicates the number of double cup dispensed drinks

♥ JJ indicates the number of decaffeinated dispensed drinks

Press the key (gost1) to return to the level enabling to select the card number.

WARNING:

a) If the waiters’ card is inserted, it is not possible to display info about other cards.

b) If the owner or technician’s card is inserted, info about each waiter card or of all the waiters’ key can be displayed.

2) WAITER DOSE RESET

The display shows:

DISPENSING INFO

WAITER DOSE REST

Press the key N°16 (3.4.5…X) to display the next level, the display shows:

DISPENSING INFO

DOSE RESET

WAITER’S CARD N° XX

Where XX indicates the number of the waiter’s card you want to reset.

Press the key N°13 (1x) or N°14 (2x) to display the number of the desired waiter’s card.

Press the key N°16 (3.4.5…X) to confirm the number of the waiter’s card.

Press the key N° 12 (gost1) to exit the environment.

The display shows:

WAITER’S CARD RESET N°XX

After 3” the display shows:

DISPENSING INFO

DOSE RESET

WAITER’S CARD N° XX

Repeat the above procedures to reset the other waiters’ cards.

383033GB Pag. 30 November 2003

Page 31

SMART CARD CREDIT CHARGE PROCEDURE

This procedure is enabled only for the following machine configurations: self with credit card, self with credit card + coin

mechanism.

To enter the credit charge environment, proceed as follows:

Turn the machine in ON mode

Insert the owner or technician’s smart card into the proper slit.

Press the key N°16 (3.4.5…X), the display shows:

SYSTEM PROGRAMMING

CREDIT CHARGE

Press the key N°16 (3.4.5…X) to confirm entering the environment.

The display shows:

SYSTEM PROGRAMMING

CREDIT CHARGE

INSERT SMART CARD

Remove the technician or owner’s card, and insert the card where you want to programme the credit.

Once the card to be programmed has been inserted, the display will automatically show the machine device code:

SYSTEM PROGRAMMING

CARD CODE

XXXX

X

Insert the code relevant to the card to be programmed.

To insert the card code, proceed as follows:

The blinking X

Press the key N°13 (1x) or N°14 (2x) to modify the figure.

Press the key N°16 (3.4.5…X) to confirm the modification.

Press the key N°15 (gost2) to enter the next level without saving the modification carried out.

Press the key N° 12 (gost1) to return to the previous environment and/or exit.

After having modified the first figure and confirmed the operation, the display shows:

Where the blinking X

Repeat the above operations for all the other figures.

Once the card code has been entered, the display shows:

a)

Where:

XXXXXXX indicates the residual card credit

YYYYYYY indicates the value that can be added to the card

Press the key N°13 (1x) or N°14 (2x) to modify the value to be credited.

Press the key N°16 (3.4.5…X) to confirm the modification.

Press the key N°15 (gost2) to enter the next level without saving the modification carried out.

Press the key N° 12 (gost1) to return to the previous environment and/or exit.

The display shows:

number indicates the first figure of the code to be modified:

SYSTEM PROGRAMMING

CARD CODE

XX

XXX

number indicates the second figure to be modified, etc. etc.

SYSTEM PROGRAMMING

CREDIT CHARGE

CURRENT CREDIT XXXXXXX

ADD YYYYYYY

SYSTEM PROGRAMMING

CARD CODE

FUCNTION OVER

383033GB Pag. 31 November 2003

Page 32

Remove the created credit card, the display shows:

SYSTEM PROGRAMMING

INSERT CARD

XXXXXXXX

Where XXXXXXXX indicates:

TECHNICIAN if the card inserted to enable the programming of the waiter’s card was the technician’s

OWNER if the card inserted to enable the programming of the waiter’s card was the owner’s.

Insert the requested card, the display shows:

SYSTEM PROGRAMMING

CREDIT CHARGE

WARNING:

The value that can be inserted is determined by the difference between the maximum programming value of the card

(value that is fixed in the environment “system programming, machine parameters”) and the residual credit of the

inserted card.

b)

CREDIT CHARGE

CARD CODE

NOT VALID

This message is displayed if the inserted card code does not correspond to that of the inserted card.

Remove the card to be reprogrammed, the display shoes:

CREDIT CHARGE

INSERT CARD

XXXXXXXX

Where XXXXXXXX indicates

TECHNICIAN if the card inserted to enable the programming of the waiter’s card was the technician’s

OWNER if the card inserted to enable the programming of the waiter’s card was the owner’s.

Insert the requested card, the display shows:

SYSTEM PROGRAMMING

CREDIT CHARGE

Repeat the procedure.

WARNING:

After 4 (four) failed attempts the card can no longer be used

c)

SYSTEM PROGRAMMING

BROKEN CARD

This message is displayed if one has repeatedly tried to programme the card and a wrong card code has been entered.

The card can no longer be used.

Press the key N°16 (3.4.5…X), the display shows:

SYSTEM PROGRAMMING

SMART CARD PROGRAMMING

383033GB Pag. 32 November 2003

Page 33

SYSTEM PROGRAMMING

To enter the system-programming environment, proceed as follows:

Turn the machine OFF.

Insert the owner or technician’s smart card into the proper slit.

Press the key N°16 (3.4.5.), the display shows:

SYSTEM PROGRAMMING

MACHINE PARAMETERS

Press the key N°13 (1x) or N°14 (2x) to display the available environments.

Press the key N°16 (3.4.5…X) to confirm entering the desired environment.

Press the key N° 12 (gost1) to return to the previous environment and/or exit.

SYSTEM PROGRAMMING

PROGRAMMING

GROUP CLEANING

SYSTEM PROGRAMMING

PROGRAMMING

MILKER CLEANING

SYSTEM PROGRAMMING

SET-UP ENCODER

SYSTEM PROGRAMMING

GROUP MANUAL MOVEMENTS

SYSTEM PROGRAMMING

TEST ACTUATORS

SYSTEM INFORMATION

RESET DOSES COUNTER

SYSTEM DATA

SYSTEM PROGRAMMING

ALARM DATA MEMORY

SYSTEM PROGRAMMING

SMART CARD PROGRAMMING

SYSTEM PROGRAMMING

PRESET CONFIGURATION DATA

SYSTEM PROGRAMMING

FILE MANAGER

SYSTEM PROGRAMMING

UPDATE SOFTWARE

SYSTEM PROGRAMMING

HISTORY HIGER MOTOR

SYSTEM PROGRAMMING

HISTORY LOWER MOTOR

Descriptions of the machine programming environments:

1) MACHINE PARAMETERS

Only the technician’s card is enabled to enter this environment.

The display shows:

383033GB Pag. 33 November 2003

Page 34

SYSTEM PROGRAMMING

MACHINE PARAMETERS

Press the key N°16 (3.4.5…X) to display the available levels.

Press the key N°13 (1x) or N°14 (2x) to modify the level mode.

Press the key N°16 (3.4.5…X) to confirm the modification and shift to the next level

Press the key N°15 (gost2) to shift to the next level without saving carried out the modifications.

Press the key N° 12 (gost1) to return to the previous environment and/or exit.

1.1) Language selection programming

MACHINE PARAMETERS

LANGUAGE

XXXXXXX

Where XXXXXX indicates the type of set up language: Italian, English, German, and French.

1.2) Machine type configuration programming

MACHINE PARAMETERS

MACHINA CONFIGURATION

XXXXXXX

Where XXXXXX indicates:

STANDARD (the machine works without the use of waiters’ smart card)

WAITERS’ CARD (the machine works with the use of waiters’ smart card only)

SELF (the machine works as Self Service version)

SELF with Credit card (the machine works with the use of the smart credit card)

SELF Credit card +COIN MECHANISM

(the machine works with the use both of the smart credit card and coin mechanism)

1.3) Serial door function

MACHINE PARAMETERS

SERIAL

XXXXXXXX

Where XXXXXX indicates:

Disabled (the machine works without connected peripheral)

I/O HARTWALL (the machine works with connected interface I/O)

RM5Coin Box (the machine works with connected standard coin mechanism)

Change Giver Executive (the machine works with Executive protocol to run external devices, not sold by la Pavoni

for instance change giver coin mechanism)

1.4) Coffee grounds number programming

MACHINE PARAMETERS

GROUNDS NUMBER XX

Where XX indicates the set up grounds number, variable value between 0-100, 60 set up standard value.

WARNING:

XX (The machine works with the use of coffee grounds bin; when the set up grounds number is

reached, the relevant message “grounds bin full” will be displayed)

00 (The machine works without the use of coffee grounds bin; direct grounds discharge installed)

1.5) Automatic cleaning function

MACHINE PARAMETERS

AUTO CLEANING

XXXXXXXX

Where XXXXXXX indicates:

ENABLED (the machine automatically carries out coffee group cleaning)

DISABLED (the machine does not carry out coffee group cleaning automatically)

If automatic cleaning is activated, the following programming levels are displayed:

383033GB Pag. 34 November 2003

Page 35

1.5.a) Water dose programming for automatic cleaning

MACHINE PARAMETERS

AUTO CLEANING

WATER XX CC

Where XX CC indicates set up water quantity, which will be dispensed; variable value between 0-300CC; 70cc set up

standard value.

1.5.b) Start time programming of automatic cleaning after the last coffee

MACHINE PARAMETERS

AUTOMATIC CLEANING

T.O. AFTER COFFEE XX min

Where XX min indicates set up time in minutes passed between the last drink dispensed and the first automatic cleaning

cycle; variable value between 0-255’; 15’ set up standard value.

1.5.c) Time programming between one cleaning cycle and the next

MACHINE PARAMETERS

AUTO CLEANING

T.O. REPETITION XX min

Where XX min indicates the set up time in minutes passed between the first automatic washing and the next one;

variable value between 0-255’; 180’ set up standard value.

1.6) Programming rinse after milk dose.

RINSE AFTER MILK DOSE

XXXXXXXX

Where XXXXXXX indicates:

ENABLED (the machine automatically carries out a rinse after milk dose)

DISABLED (the machine does not carry out a rinse after milk automatically)

- If this parameter is enabled, a rinse at end of every dose milk based starts automatically.

- The start of the cleaning may be changed by programming a time pause , the following programmation livel will be displayed :

1.6a) Programming pause rinse after milk dose.

RINSE AFTER MILK DOSE

PAUSE AFTER MILK SEC.

XXX

Where Sec. XXX indicates the time in seconds of the pause between the end of milk dose and the start of rinse.

variable value between 3” - 10” ; 3” set up standard value.

1.7) Automatic rinse milker machine in stand-by .

RINSE AFTER MILK STAND-BY

XXXXXXXX

Where XXXXXXX indicates:

ENABLED (the machine automatically carries out coffee milker rinsing)

DISABLED (the machine does not carry out milker rinsing automatically)

If automatic cleaning is activated, the following programming levels are displayed:

383033GB Pag. 35 November 2003

Page 36

1.7.a) Start time programming of automatic milker rinse after the last dose milk based.

RINSE AFTER MILK STAND-BY

PAUSE XX MIN

Where XX min indicates set up time in minutes passed between the last drink milk based dispensed and the first

automatic rinsing cycle; variable value between 1'-10’; 10' set up standard value.

1.7.b) Time programming between one milker rinse cycle and the next.

RINSE AFTER MILK STAND-BY

REPETITION XX MIN

Where XX min indicates the set up time in minutes passed between the first automatic milker rinsing and the next one;

variable value between 1'-180' ; 180’ set up standard value.

1.8) M1 tools working time programming for maintenance

MACHINE PARAMETERS

TOOLS WORKING TIME 1

XXX

Where M1 XXX h indicates the time in hours of set up functioning for the grinder tools M1 ; variable value between 0-

999; 300 set up standard value.

1.9) Water filter litre programming

MACHINE PARAMETERS

WATER FILTER LITRES

XXXX

Where XXXX indicates the set up number of water filter litres; variable value between 0-15000; 5000 set up standard

value.

WARNING:

XXXX (The machine works with the water filter; when the set up number of litres has been reached,

the relevant message to renew the water filter is displayed)

00 (The machine works without counting water filter litres)

1.10) Group cycle number programming for maintenance

MACHINE PARAMETERS

GROUP CYCLES

XXXX

Where XXXX indicates the set up number of group cycles; variable value between 0-65000

WARNING:

10000 (The number of group cycles is enabled; when the set up number of cycles has been reached,

the relevant message to verify the group is displayed).

00 (The machine works without counting the number of group cycles).

If you set up a value higher than zero, the display shows:

MACHINE PARAMETERS

MACHINE SHUTDOWN

XXXX

Where XXXX indicates:

YES (the machine shuts down when the set up number of cycles has been reached).

NO (the machine does not shut down when the set up number of cycles has been reached).

383033GB Pag. 36 November 2003

Page 37

1.11) Group cycle number programming for manual group cleaning message

MACHINE PARAMETERS

GROUP CLEANING ALARM

XXXX

Where XXXX indicates the programmed group cycle number; variable value between 0-10000; 0 set up standard value.

WARNING:

XXXX (The machine will display the message manual group cleaning when the set up cycle number has been

reached)

0 (The machine works without counting the group cycle number)

1.12) Programming blocked deliveries message of group cleaning

This programming level is displayed, if a value higher than zero is inserted in the programming of the dispensing number

message of group cleaning, the display shows:

MACHINE PARAMETERS

GROUP CLEANING ALARM

STOP DRINK

XXXX

Where XXXX indicates:

ENABLED a) coffee-based deliveries are disabled after 10 deliveries from display of the message

DISABLED b) the message is displayed without disabling deliveries

1.13) Dispensing number programming for milker cleaning message

MACHINE PARAMETERS

MILKER CLEANING ALARM

CYCLES XXXX

Where XXXX indicates the programmed number of milk-based dispensing; variable value between 0-10000; 0 set up

standard value.

WARNING:

XXXX (The machine will display the message manual milker cleaning when the programmed dispensing

number has been reached)

0 (The machine works without counting the milker dispensing number)

1.14) Programming of time out message of milker cleaning

MACHINE PARAMETERS

MILKER CLEANING ALARM

TIME X min.

Where X min. indicates the programmed time in min.; variable value between 0-60; 0 set up standard value.

WARNING:

XXXX (The machine will display the message manual milker cleaning when the time set after the last milker

dispensing is running out)

0 (The machine works without counting the time out)

1.15) Programming blocked deliveries message of milker cleaning

This programming level is displayed, if a value higher than zero is inserted in the programming of the dispensing number

message of milker cleaning, the display shows: