Page 1

A-PDF Merger DEMO : Purchase from www.A-PDF.com to remove the watermark

PO;;;

TORQUE VALUES

Lubricants/sealants have been specified in certain applications for assembly purposes.

l

It is essential that all bolts are securely tightened and it is imperative that the correct torques values are

adhered to.

1987-91

*

These bolts must have threads coated with Loctite 572 prior to assembly. For this purpose it is

TORQUE VALUES

necessary to use an approved dispenser to apply the sealant/lubricant to the first three threads of the

bolts.

**

These bolts must have threads coated in lubricant

*

l These bolts must have threads coated in sealant Loctite 270 prior to assembly.

EXP16A (Marston

Lubricants) prior to assembly.

COOLING SYSTEM Nm

Oil cooler pipes.

Radiator filler plug (plastic)

EMISSION CONTROL

Lamda

sensor

............................................................................................

..........................................................................

................................................................................................. 20

26-34

5-6

ft lb

19-25

15

in lb

45-54

/.

ENGINE

Adaptor plate to crankshaft

Alternator mounting

Alternator to mounting bracket

Alternator to adjusting link..

Chainwheel to camshaft

Connecting rod bolt

Cylinder head:

/

:

..

.*.-.

.

Outer row

Centre row

Inner row

Damper to crankshaft

Distributor

Drive plate to converter

Engine mountings to engine and chassis

Engine mounting rubbers to brackets

Exhaust manifold to cylinder heads.

Fan to viscous unit

Flexible drive plate to crankshaft adaptor plate

Intake manifold to cylinder heads

Lifting eye to cylinder heads

Main bearing

Main bearing cap rear bolts

Manifold gasket clamp bolt

Oil pump cover to timing cover

Oil plug

Oil relief valve plug

Oil sump drain plug

Oil sump to cylinder block

Oil sump rear to cylinder block

Plenum chamber to ram housing

Ram housing to intake manifold

Rocker cover to cylinder

Rocker shaft bracket to cylinder head

Spark plug..

Starter motor attachment

Thermostat

Timing

cover

Viscous unit to water pump hub

Water

pump

Water pump timing cover to cylinder block

Water jacket to plenum chamber

.............................................................................................

...........................................................................................

..............................................................................................

clamp nut

cap

bolts

...........................................................................................................

.....................................................................................................

housing to intake manifold

to cylinder block

pulley to

..........................................................................

bracket

to cylinder

...................................................................

.........................................................................

...............................................................................

......................................................................................

...................................................................................

....................................................................................

................................................................................

head ...........................................

...................................................

...........................................................

........................................................................................

...............................................................

........................................................................

.................................................................................

........................................

.........................................................................

.........................................................................

..................................................................

.......................................................................................

......................................................................................

..........................................................................

...................................................................

................................................................

.................................................................

.....................................................................

head

.............................................................................

pump hub

water

........................................................

.....................................................

....................................................................

.................................................................

.....................................................

..............................................

................................................................

77 - 90 57 - 66

3s - 43 26 - 32

22 - 28 16 - 21

22 - 28 16 - 21

54 - 61 40 - 45

47 - 54 35 - 40

54 - 61 40 - 45

88 - 9s 65 - 70 l

88 - 95

257 - 285 190 - 210

19 - 22

35 - 42

52 38

17

-22 13 16

19 - 22 14 - 16

26 - 32

35 - 46

34 - 41 25 - 30

35 - 43 26 - 32

68 - 75 SO-55

88 - 95 65-70

14 - 20 10 - 15

11 - 14 8 - 10

24 - 30

40 - 47 30 - 35

40 - 47 30 - 35

7 - 11 5-8

17 - 20

22 - 28

20 - 27 15 - 20

7 - IO

34 - 40 25 - 30

19 . 22

41 - 47 30 - 35

24 - 30

24 .

30

40 - 50 30 - 37

8 - 12 6-9 l

24 .

3u

11 - 14

65 - 70

14 - 16

25-30 l *’

19 - 24

26-34 l **

18-

22

13 - 15

16 - 21

74

5-

14 - 16

18 - 22

18.

22

18 -

22

8-10

*

*

**

**

’

*

1989 Model Year

Oil cooler adaptor to oil

pump cover . . . . . . . . . . . . . . . .._.......................................

REVISED: SEPT. 90

40-50

30-37

1

:. :.

Page 2

FUEL SYSTEM

Air-Bypass

All flexible house securing clamps

Fuel

1991

Fuel

valve

(stepper motor)

-

feed

Model Year

filter

hosetofuel rail

pipe

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1987-91

Nm

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17 - 22 13 - 16

I,1 -I,3

22 16

27-34

ft

lb in

20-25

;;"o"v';r;

lb

10 - 12

fi

_.

\\

EVAPORATIVE LOSS CONTROL SYSTEM

All flexible hose

Charts

belciw

SIZE

MS

Mb

Ma

Ml0

Ml2

Ml4

Ml6

securing clamps

give torque values for all screws and bolts used except for those that are specified otherwise.

METRIC 1 SIZE

Nm

5-7 3.7-5.2

7-10 5.2-7.4

22-28 16.2-20.7

40-50 29.5-36.9

80-100

90-120

160-200

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ft

lb

59.0-73.8

66.4-88.5

118.0-147.5

l/4

5116

318

7116

l/2

518

Nm

6.8-9.5

20.3-27.1

35.3-43.4

67.8-88.1

81.3-101.7

122.0-149.1

UNC

t

L

1,7

ft

lb

5-7

15-20

26-32

SO-65

60-75

90-110

l-

20.3-27.1

35.3-43.4

67.8-88.1

81.3-101.7

122.0-149.1

f

Nm

8.1-12.2

UNF

!

15

I

.

J

. . .

/.

:

1

.?.

2

REVISED: SEPT. 90

Page 3

;^o”v’;l;

1987

TORQUE VALUES

.

..F.

.’

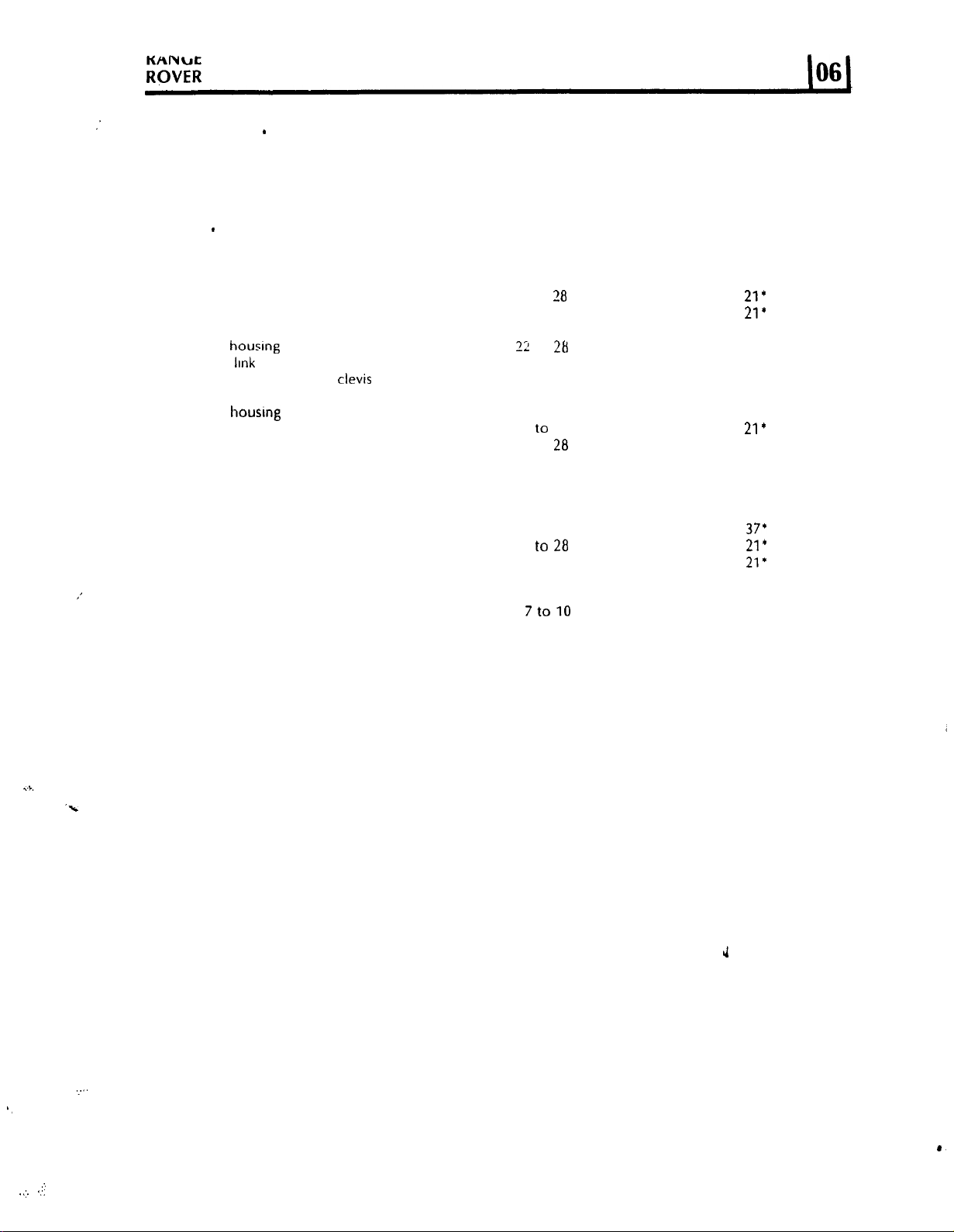

TORQUE VALUES - TRANSFER GEARBOX LT230

WARNING: Components in bold type must not be reused.

COMPONENT Nm ft lb

.........

...

Pinch bolt - operating arm to crank arm .........................

End cover gear change housing ......................................

Speedometer cable retainer

Rear

output/speedometer housing ..................................

Bottom cover to transler case

............................................

.........................................

Front output housing to transfer case .............................

Cross shaft housing to front output housing

Gear change

Pivot shaft to

Connecting rodtoadjustable

Anti-rotation

Front output

Pivot bracket to

housrng

IInk

plate

housrng

......................................................

arm .....................................................

clevis

................................

intermediate shaft ..............................

cover ............................................

extension housing .................................

..................

Finger housingtofront output housing ..........................

Bearing housing to transfer case .....................................

Brake drumtocoupling

flange ........................................

Bearing housing cover to transfer gearbox .....................

7 to 10

7

to 10

7

to 10

22 to 28

22 to 28

22 to 28

22 to 28

22 to 28

22 to 28

22 to

28

22 to 28

22t028

22 to 20

22 to 28

22 to 28

40

to 50

See note

5 to 7

5 to 7

5 to 7

16 to

21*

16 to

21’

16 to 21

16 to 21

16 to 21

16 to 21

16 to 21’

16 to 21’

16 to

21’

16 to 21’

16 to 21

16 to 21

29 to 37’

Rear output speedometer housing to

transfer gearbox

Selector finger to cross shaft high/low ............................

Selector

fork, high/lowtoshaft .......................................

Transmission

,’

Intermediate shaft stake nut .........................................

Gate plate

Plunger switch setting .....................................................

Gearbox

to

Gearbox to

Oil drain plug ..................................................................

Differential case (front to rear) ........................................

Output flanges ................................................................

Differential case rear stake nut ....................................

Oil filler/level plug ...........................................................

Transfer breather

..

.-%

Transfer box front drive flange to drive shaft ..................

Transfer box rear drive flange to drive shaft ....................

Transfer gearbox mounting brackets to chassis ...............

Mounting brackets to transfer gearbox ...........................

Mounting rubbers to

..............................................................

to speedometer housing

brake

to

grommet

plate

...........................................

..................

transfer case .................................................

transfer

case

.................................................

.............................................................

mounting brackets ........................

40

to 50

22t028

22 to 28

65 to

80

7to10

6.75 max

40 to 50

25 to 35

55 to

64

146to179

66 to

80

25 to 35

14 to

16

41 to

52

41 to

52

33 to 27

52

20 to 22

See text

See note

29 to

37’

16 to

21’

16 to

21*

48 to 59

5 to 7

4.82 max

29 to 37

19 to 26

40 to 47

108 to 132

50 to 59

19 to 26

10 to 12

30 to 38

30 to 38

24 to 20

38

13 to 16

NOTE: Studs to be assembled into casings with sufficient torque to wind them fully home, but this

torque must not exceed the maximum figure quoted for the associated nut on final assembly.

NOTE: ‘These bolts must have threads coated with Loctite 290 prior to assembly.

J

‘.“.

‘,

1

..I. ‘..

.>

REVISED: MARCH 90

Page 4

ZF4HP22

Coupling shaft to mainshaft ............................................

Filler tube to sump ..........................................................

Gear change lever to gearbox .......................................

Cooler pipe adaptor to gearbox ....................................

Securing screws - clutch

Securing screw - parking pawl .........................................

Securing screws -pump ..................................................

Intermediate plate plugs

Intermediate plate plugs

Bell housing mounting bolts

Governor mounting screws .............................................

Extension housing bolts

Control unit mounting bolts ...........................................

Sump plug .......................................................................

Mounting screws for sump ..............................................

Drive plate to converter ..................................................

Gearbox to engine ..........................................................

Strut (threaded end) ........................................................

Bottom cover to converter housing ................................

Cover - converter housing ..............................................

Drive

Adaptor to crankshaft

NOTE: *These bolts must have threads coated with Loctite 270 prior to assembly.

AUTOMATIC GEARBOX Nm

F

...............................................

(M20)

.......................................

(M14)

....................................... 40

........................................... 46

..................................................

plates to

crankshaft

adaptor

...................................................... 77 to 90

...................................

36

to 48

60 to 75

22 to 28

36 to 48

10

10

10

50

10

23

8

10

8

35 to 42

36 to 48

36 to 48

7 to 10

7 to

35

to 46

IO

ft lb

26 to 34’

45to 55

16 to 21

26 to 34

7

7

7

37

29

34

7

17

6

7

6

25to 30’

26 to 34

26 to 34

5 to

7

5 to 7

25 to

33’

55 to 65

FRONT AXLE Nm

Hub driving shaft to hub ................................................. 41 to 52

Brake disctohub ............................................................

Stub axle to swivel pin

Brake

caliper to swivel

Upper swivel pin to swivel pin housing ..........................

Lower swivel pin to swivel pin housing

Oil seal retainer to swivel pin housing ............................

Swivel bearing

Pinion housing

Crown wheel to differential

Differential bearing cap to pinion housing ......................

Differential drive flange to drive shaft .............................

Mudshield to bracket lower swivel pin ............................

Bevel

pinion nut ..............................................................

Draglink

Panhard

Radius arm to axle ........................................................... 190

Radius arm to chassis

Hub driving member to hub ........................................... 60 to 70

Stub

Oil seal retainer to swivel pin housing

rod to axle bracket

FRONT AXLE ABS VEHICLES

Brake disc to hub ............................................................

axle to

Brake caliper to swivel pin housing ................................. 75 lo 88

Upper swivel pin to swivel pin housing .......................... 60 to 70

Lower swivel pin to swivel pin housing..;;:

Swivel pin bearing housing to axle case .......................... 65 to 80

Disc shield .to bracket lower ............................................

housing

to axle case

to hub arm

swivel pin housing .......................................

housing

pin housing

to axle case

........................................................ 40

side member.. ............................... 190

.......................................

.................................

........................... 68 to 88

................................

.............................................

housing

............................................ 88

...............................

.:.

.................... 22 to 28

............................ 9 to

65 to 80

60 to 70

75 to 88

68 to 88

9 to 12

65 to 80

36 to

46

55 to 61

80 to 100

41

to 52

9 to 12

95 to 163

65 to 80

60 to 70

7 to 10

ft lb

30 to 38

48 to 59

44 to

52+

. . .

I

55 to 65

50 to

65’

50 to

65’

7 to 9

48 to 59’

26 to 34

40to45

59to 74

30 to 38

7 to 9

70to

120

30

65

140

140

44 to

52*

48 to 59’

44to 52.

55 to 65

’

44to 52

16 to

21’

I2

7 to 9

48 to 59’

5 to 7

NOTE: *These bolts to be coated with Loctite 270 prior to assembly.

2 REVISED: MARCH 90

Page 5

KMNU,f

ROVER

ls8’

TORQUE VALUES

REAR AXLE Nm

Axle shaft to hub .........................................................

Brake disc

Stub

Brake

Pinion housing to axle case ........................................

Crown

Differential bearing cap to pinion housing

Differential

Mudshield

Bevel pinion nut

Lower link to axle ........................................................

Pivot bracket

REAR AXLE ABS VEHICLES

Hub driving member to hub .......................................

Brake

Stub

Brake caliper io axle case ............................................

Disc shield

Sensor

NOTE: l These bolts to be coated with loctite 270 prior in assembly.

BORG WARNER TRANSFER GEARBOX

to

hub ........................................................

axle rear to axle case

caliper

to axle case

wheel to

disctohub ........................................................

axle rear to axle case

ring

differential

drive

flange to

to axle case

..........................................................

ball

joint

to axle case

to brake

..........................................

............................................

case

................................

..................

drive shaft .........................

...............................................

to axle

disc ............................................

....................................

..........................................

...............................................

41to 52

65 to 80

60 to 70

75to 88

36 to 46

55

to 61

80 to 100

41to 52

9 to 12

95

to 163

176

176 130

60 to 70

65 to 80

60 to 70

75

to

88

vto12

7 to 10

ft lb. in lb

30

to 38

48

to

59

44

to

52

55

to 65

26

to 34

40to 45

59to 74

30

to 38

7

to 9

70to 120

130

44

to

52’

48to59'

44

to 52

55

to 65

7

to 91

5

to 7

1)

,.

,’

. . .

Brake drum back plate to rear output

housing .......................................................................

Brake

drumtodrive

Centre differential (front

Centre differentialtosprocket ....................................

Drive flangestotransfer gearbox ................................

Drive

shaftstodrive flanges ........................................

Front cover to

Front

output housing

Gearbox

Mounting bracket

Neutral warning switch ................................................

Oil drain

Oil filler/level

Oil pump fixings.. ........................................................

Rear output housing

Selector lever shaft-Torx screw ...................................

Selector fork operating arm-Torx screw

CHARTS BELOW GIVE TORQUE

THAT ARE SPECIFIED OTHERWISE.

1

SIZE METRIC

mounting bracketstochassis .......................

plug ..............................................................

22-28

40-50

80-100

go-120

160-200

flange

..........................................

to rear)

rear cover-main

to main case

to gearbox

plug .......................................................

to main case

-i-

Nm

5-7

7-In

t

118.0-147.5

I

................................

case

...........................

.............................

.....................................

..............................

......................

SEl-FINGS

/SIZE

T

ft

lb

3.7-5.2

5.2-7.4

16.2-20.7

29.5-36.9

59.0-73.8

66.4-88.5

t

l/4

5116

318

7116

112

518

I

FOR ALL SCREWS AND BOLTS USED EXCEPT FOR THOSE

65-80

22-28

36-41

41-61

203-244

41-52

30-49

24-31

52

52

14-19

IV-30

IV-30

4-8.5

30-49

7-9

7-9

UNC

Nm

6.8-9.5

20.3-27.1

35.3-43.4/26-32 35.3-43.4

67.8-88.1

81.3-101.7

122.0-149.1

,!.-ft.lh

.

1

1

I

48-59

16-21

27-30

30-45

150-180

30-38

;;-;p

29-37

68-83

10-14

14-22

14-22

22-36

5-7

5-7

j

5-7

15-20 20.3-27.1 IS-20

50-65

60-75

9o-11o

- .**

35-75

60-84

60-84

II

Nm

8.1-12.2

6i.a-88.1

,

81.3-101.7

122.0-149.1 90-110

-

-.

UNF

fi

lb

6-9

26-32

50-65

60-75

/

REVISED: MARCH 90

3

Page 6

‘,

_.: ‘1:

,

:

.A’

.

. :

Page 7

PO;;;

1987

TORQUE VALUES

POWER STEERING BOX

Clamp bolt nuts ....................................................................

Ball joint nuts .......................................................................

Universal joint pinch bolt

Drop arm nut

Steering wheel

Sector shaft cover to steering box

Tie bar to steering box

Steering box to chassis ........................................................

Power steering pump mounting ...........................................

Pulley bolts, power steering pump

Union nut, inlet adaptor, power steering pump ...................

Steering column bracket nuts

FRONT SUSPENSION

Anti-roil bar front

-

Strap nyloc nuts .................................................................

-

Ball link self lock nut ..........................................................

-

Castellated nut

Drag link to axle ...................................................................

Securing ring for mounting turret

Radius arm to chassis

Panhard

Panhard

Panhard

Tie bar to

Radius arm to axle (front only)

.......................................................................

nut

...................................................................

rod mounting arm to chassis ..................................

rod to axle

rod to mounting bracket

Panhard

rod .........................................................

.....................................................

...............................................................

.......................................

.........................................................

....................................... 8-12

...............................................

.........................................

...........................................................

..............................................................

........................................ 88

............................................. 197

Nm

14 10

40

35

176 130

38 28

22 - 27

81

81

35

38 - 41 28 - 30

27 20

30

68 50

40

40

14 10

176 130

88

88

88

ft lb

30

26

16-20

60

60

26

6-9

22

30

30

65

65

65

65

145

in lb

REAR SUSPENSION

Anti-roll bar rear

-

Strap nyloc nuts

-

Ball link self lock nut

-

Castellated nut

Ball joint - levelling unit to rear axle

Top link to levelling unit .......................................................

Top link to mounting bracket

Upper joint to levelling unit

Lower joint to levelling unit .................................................

Bottom link to axle

Bottom link to chassis ..........................................................

Top link bracket to rear cross member ................................

Levelling unit to cross

Shock absorber to axle

BRAKES

Brake pipe connections to:

-

Brake calipers

- Jump

hoses to brackets .....................................................

- Jump

hose to three - way connection ...............................

-

Front caliper jump hoses

-

Rear caliper jump hoses

-

Jump hoses to calipers (all)

PDWA switch (AP type master cylinder)

Master cylinder to servo

(AP

type master cylinder

Brake caliper to swivel pin housing

Parking

Brake disc to hubs ................................................................

Bleed screws

brake

.................................................................

..........................................................

...................................................................

.....................................

...............................................

.................................................

...

............................................................

member ............................................

.........................................................

.....................................................................

....................................................

.....................................................

................................................

...............................

and

linkage to transfer box

.......................................................................

.....................................

servo)

......................................

...................................

30

68

40

176

115

176

34

34

176

176 130

47

47

37

12

11 - 13.5

12

11 - 13.5

11 - 13.5

12

1.4 - 1.7

13.6 - 17

75 - 88

26 - 32

65 -'80

9-

11

22

50

30

130

85

130

25

25

130

35

35

28

9

8 -10

9

8-10

8 -10

9

1 - 1.3

10 -

12.5

55 - 65

19-

24

48-

59

.;

80 -100

Continued

REVISED: SEPT. 90

Page 8

..

.:

.; :

Support plate and tube to valve body

Separator shell to valve body

Clamp ring to servo

Lucas

Cirling

Servo assembly

Brake pipes to master cylinder .............................................

Master cylinder to servo .......................................................

Bleed screws ........................................................................

Support plate and tube to valve body (servo)

Clamp ring to servo

Wabco

ABS system

Brake pipe connections to:

-

Hydraulic booster-Ml0

....................................................................................

- MI2

-

Calipers

- Fourway

- lump

-

lump

-

Hydraulic pump and accumulator

-

PCRV-Ml0

- PCRV -

-

Hydraulic booster to pedal box .........................................

-

Securing bolt, reservoir bracket

ROAD WHEELS

Wheel nuts

-

Alloy wheels . . . . . . . . . . . . . . . . . . . . . . . . . .

..............................................................................

connector rear axle

hose to brackets .......................................................

hose

Ml2

(AP

servo and master cylinder

to pedal

to valve

..............................................................

female

connectors ...........................................

.......................................................................

.......................................................................

(AP

type servo)

box

...............................................

................................................

L _

(AP

type

servo)

type servo) ......................

....................................

......................

...................................Separator shell body (servo)

..............................................

......................................

.........................................

.._..........................................

........

Nm

2-3

13.5 - 17

1 - 1.6

22 -

25

9-11

21 - 29

9-11

2-3

13.5 -

17

1 - 1.6

12 - 16

15 - 20

9-11

9-

11

11 - 13,s

11 - 13.5

12 - 16

11 -

13,5

12 - 14

22.5 - 27,5

9 - 11

122

-

129

ft

lb

16 - 19

7-8

15 - 22

9-12

11 - 15

7-8

7-8

8 -10

8 -10

9-12

8-10

9-10

17-20

7-8

90 - 95

in lb

16

-

20

120

-

150

10-15

80 - 100

16-20

120-150

IO-15

BODY

Front and rear seat belt fixings (ALL)

Front door hinges to door and body ...................................

‘.

Rear passenger door hinges to door and

Charts below give torque values for all screws and bolts used except for those that are specified

otherwise.

SIZE

MS

Mb

MB

Ml0

Ml2

Ml4

Ml6

METRIC

Nm

5-7 3.7-5.2 114

7-10 5.2-7.4 S/16 20.3-27.1

22-28 16.2-20.7

40-50 29.5-36.9

80-100

go-120

160-200

h

59.0-73.8 II2 81.3-101.7

66.4-88.5 518 122.0-149.1

118.0-147.5

....................................

lb

318 35.3-43.4 26-32

7116 67.8-88.1 50-65

body

SIZE

20.3

25

....................

Nm

6.8-9.5 5-7 8.1-12.2

25

UNC

ft lb

15-20 20.3-27.1

60-75 81.3-101.7

90-110

IS

19

19

Nm

35.3-43.4

67.8-88.1

122.0-149.1

UNF

ft lb

6-9

15-20

26-32

50-65

60-75

90-l IO

.:

REVISED: SEPT. SO

Page 9

PO;;;

1987

TORQUE VALUES

TORQUE VALUES 06

l-l

AIR CONDITIONING

Compressor hose .............................................................

Receiver drier hose ...........................................................

Receiver drier switch ........................................................

Compressor

oil filler

plug .................................................

Nm

34

to 40

14to21

21to25

8to12

ELECTRICAL

Alternator mounting bracket to cylinder head ..................

Alternator to mounting bracket ........................................

Alternator to adjusting link ...............................................

Alternator shaft nut .......................................................... 27.2 to 47.5

Alternator through bolts ................................................... 4.5 to 6.2

Alternator rectifier bolts ...................................................

Amplifier module screws ..................................................

Amplifier heat sink screws ................................................

Auxiliary driving

Distributor clampbolt

Drstributor prck-up bearing

Distributor pick-un barrel nuts .........................................

Drstrioutor

Spark

plug ........................................................................

Starter motor to engine bolts ........................................... 40.6 to 47.4

Starter motor through bolts ............................................. 6.2

Solenoid fixing screws ......................................................

Solenoid battery terminal nut ...........................................

Solenoid statter terminal nut ............................................ 3.2

Reverse light switch .......................................................... 20 to 27

Wiper motor yoke retaining bolts .................................... 1.35 to 1.8

lamp

vacuum

mounting bolts

.......................................................

plate support pillars .............. 1.0 to 1.2

unit

....................................................

.............................. 13.6 to 20.4

34

24

24

3.4

to 3.96

1.0 to

1.4

1 .O to 1.2

19to22

1 1toI.5

1.7to2.7

19

to 21.7

6.1

4

ft lb

24 to 29

10to15

15to19

6 to 9

25

17

17

20to 35

lot015

14 to 16

14 to 16

3oto 35

15to

20

in lb

4oto 55

30to

35

9to

12

9to11

9to11

10 to 12

15 to 24

55

55

35

28

12 to 16

Charts below give torque values for all screws and bolts used-except for those that are specified.

SIZE METRIC SIZE UNC UNF

Nm

MS

M6

M8 22-28

Ml0

Ml2

Ml4 go-120

Ml6 160-200

5-7 3.7-5.2 II4 6.8-9.5 5-7 8.1-12.2 6-9

7-10

40-50

80-100

ft lb

5.2-7.4 5116 20.3-27.1

16.2-20.7 318 35.3-43.4

29.5-36.9

59.0-73.8

66.4-88.5 518 122.0-149.1

118.0-147.5

7116 67.8-88.1

II2 81.3-101.7

Nm

ft lb

IS-20

26-32

SO-65

60-75

go-110

Nm

20.3-27.1

35.3-43.4

67.8-88.1

81.3-101.7

122.0-149.1

ft lb

15-20

26-32

SO-65

60-75

go-110

REVISED: DEC. 87

,,..

Page 10

74VIRE

I

BACK-UP

,A

CONNECTOR WIRING DIAGRAM

/

TO BATTERY

TO BRAKE

WACK)

(BLUE)

TO TRAILER

#6593B

PnntKl 1” u.5

A.

Loading...

Loading...