Land Rover Freelander 2001, Freelander 2003, Freelander 2004 User Manual

Workshop Manual

System Description & Operation

FREELANDER 2001 TO 2004 MY

ONWARDS

WORKSHOP MANUAL - SYSTEM

DESCRIPTION AND OPERATION

Publication Part No. LRL0351 NAS - 5th Edition

Published by Land Rover

©2003 Land Rover

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form,

electronic, mechanical, recording or other means without prior written permission from Land Rover.

CONTENTS

ENGINE - K SERIES KV6......................................................................... 12-3-1

KV6 Engine – General View ........................................................................................................... 12-3-2

KV6 Engine – Internal View ............................................................................................................ 12-3-3

KV6 Engine – Cylinder Block Components..................................................................................... 12-3-4

KV6 Engine – Crankshaft, Sump and Oil Pump Assembly............................................................. 12-3-6

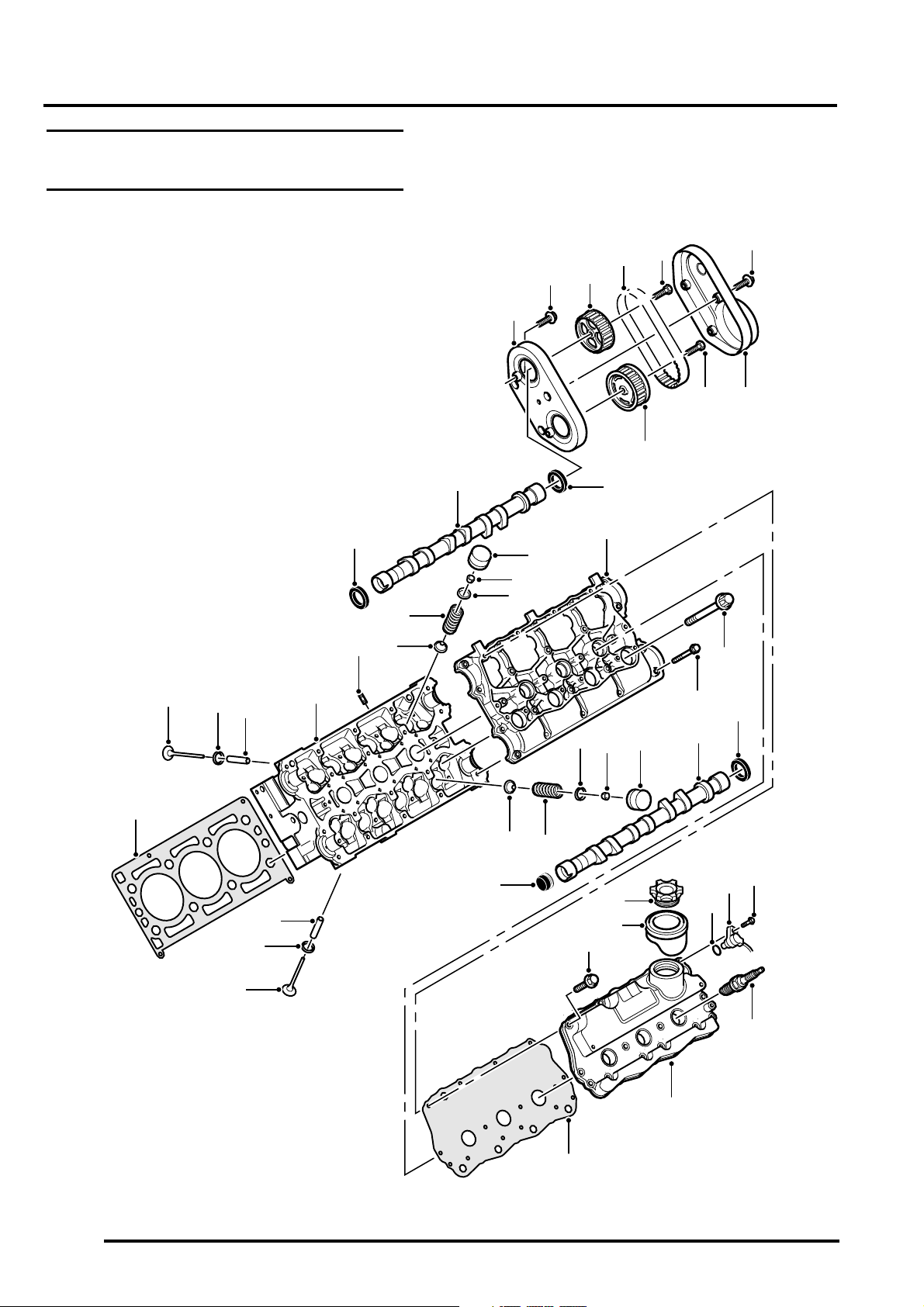

KV6 Engine – Cylinder Head Components ..................................................................................... 12-3-8

KV6 Engine – Manifolds and Engine Cover Components .............................................................. 12-3-10

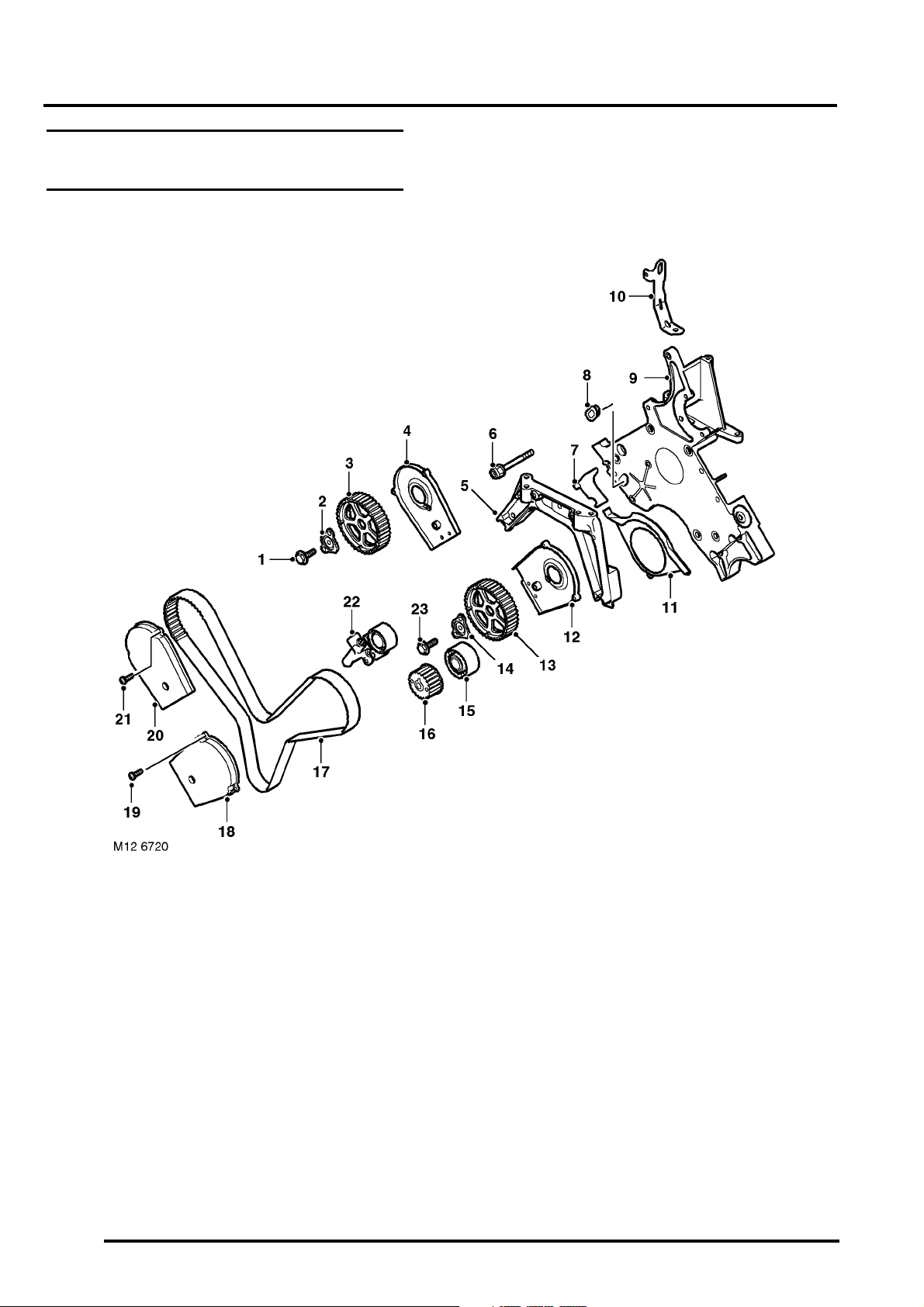

KV6 Engine – Camshaft Drive Belt Components............................................................................ 12-3-12

Description ...................................................................................................................................... 12-3-13

Operation ........................................................................................................................................ 12-3-17

EMISSION CONTROL - K SERIES KV6 .................................................. 17-3-1

Emission Control Component Layout – Crankcase and Exhaust ................................................... 17-3-1

Emission Control Component Layout – EVAP ................................................................................ 17-3-2

Description ...................................................................................................................................... 17-3-4

ENGINE MANAGEMENT SYSTEM - SIEMENS ...................................... 18-4-1

Engine Management System Component Location........................................................................ 18-4-2

Engine Management System Control Diagram – Sheet 1 of 2 ....................................................... 18-4-4

Engine Management System Control Diagram – Sheet 2 of 2 ....................................................... 18-4-6

Description ...................................................................................................................................... 18-4-8

Operation ........................................................................................................................................ 18-4-41

Cruise Control Component Location............................................................................................... 18-4-43

Cruise Control System Control Diagram......................................................................................... 18-4-44

Cruise Control Description .............................................................................................................. 18-4-46

Cruise Control Operation ................................................................................................................ 18-4-49

FUEL DELIVERY SYSTEM - K SERIES KV6 .......................................... 19-3-1

Fuel Delivery System Component Layout ...................................................................................... 19-3-1

Fuel Delivery System Schematic .................................................................................................... 19-3-2

Description ...................................................................................................................................... 19-3-3

Operation ........................................................................................................................................ 19-3-7

COOLING SYSTEM - K SERIES KV6...................................................... 26-3-1

Cooling System Component Layout - Sheet 1 of 2......................................................................... 26-3-2

Cooling System Component Layout - Sheet 2 of 2......................................................................... 26-3-4

Cooling System Coolant Flow ......................................................................................................... 26-3-5

Description ...................................................................................................................................... 26-3-6

Operation ........................................................................................................................................ 26-3-8

CONTENTS 1

CONTENTS

MANIFOLD AND EXHAUST SYSTEM - K SERIES KV6 ......................... 30-3-1

Inlet Manifold Component Layout ................................................................................................... 30-3-1

Inlet Manifold Chamber Component Layout ................................................................................... 30-3-2

Exhaust System Component Layout – Sheet 1 of 2 ....................................................................... 30-3-3

Exhaust System Component Layout – Sheet 2 of 2 ....................................................................... 30-3-4

Description...................................................................................................................................... 30-3-5

Operation........................................................................................................................................ 30-3-7

INTERMEDIATE REDUCTION DRIVE ..................................................... 41-1

Intermediate Reduction Drive ......................................................................................................... 41-1

Description...................................................................................................................................... 41-2

Operation........................................................................................................................................ 41-3

AUTOMATIC GEARBOX - JATCO........................................................... 44-1

JATCO Automatic Gearbox Component Location .......................................................................... 44-1

JATCO Automatic Gearbox ............................................................................................................ 44-2

JATCO Automatic Gearbox - Exploded View ................................................................................. 44-3

JATCO Automatic Gearbox - Valve Block and Solenoid Valves .................................................... 44-4

JATCO Automatic Gearbox Control Diagram ................................................................................. 44-6

Description...................................................................................................................................... 44-8

Operation........................................................................................................................................ 44-43

DRIVESHAFTS ......................................................................................... 47-1

Drive Shaft and Propeller Shaft Component Layout....................................................................... 47-1

Front Drive Shaft Components ....................................................................................................... 47-2

Rear Drive Shaft Components........................................................................................................ 47-3

Propeller Shaft and VCU Components ........................................................................................... 47-4

Description...................................................................................................................................... 47-5

REAR AXLE AND FINAL DRIVE.............................................................. 51-1

Rear Differential.............................................................................................................................. 51-2

Description...................................................................................................................................... 51-4

STEERING ................................................................................................ 57-1

Steering Components - KV6........................................................................................................... 57-1

Description...................................................................................................................................... 57-2

Operation........................................................................................................................................ 57-10

FRONT SUSPENSION.............................................................................. 60-1

Front Suspension Component Location ......................................................................................... 60-1

Front Suspension Component Detail.............................................................................................. 60-2

Description...................................................................................................................................... 60-4

2CONTENTS

CONTENTS

REAR SUSPENSION................................................................................ 64-1

Rear Suspension Component Location .......................................................................................... 64-1

Rear Suspension Component Detail............................................................................................... 64-2

Description ...................................................................................................................................... 64-4

BRAKES ................................................................................................... 70-1

Brake System Layout (KV6)............................................................................................................ 70-1

Description ...................................................................................................................................... 70-2

Operation ........................................................................................................................................ 70-14

Handbrake Component Layout ....................................................................................................... 70-21

Description ...................................................................................................................................... 70-22

RESTRAINT SYSTEMS............................................................................ 75-1

SRS Component Layout ................................................................................................................. 75-1

SRS Control Diagram ..................................................................................................................... 75-2

Description ...................................................................................................................................... 75-4

Operation ........................................................................................................................................ 75-11

Front Seat Belt Components........................................................................................................... 75-13

Rear Seat Belt Components - Three Door Models ......................................................................... 75-14

Rear Seat Belt Components - Five Door Models ............................................................................ 75-15

Description ...................................................................................................................................... 75-16

HEATING AND VENTILATION................................................................. 80-1

Heating and Ventilation System Component Layout ...................................................................... 80-1

Heater Assembly Components ....................................................................................................... 80-2

Description ...................................................................................................................................... 80-3

Operation ........................................................................................................................................ 80-11

AIR CONDITIONING................................................................................. 82-1

A/C Refrigerant System Component Layout – KV6 Series Engines............................................... 82-1

A/C System Schematic Layout ....................................................................................................... 82-2

A/C Control Component Layout ...................................................................................................... 82-3

A/C System Control Schematic....................................................................................................... 82-4

Description ...................................................................................................................................... 82-6

Operation ........................................................................................................................................ 82-20

WIPERS AND WASHERS ........................................................................ 84-1

Windscreen Wiper Components ..................................................................................................... 84-1

Rear Screen Wiper Components .................................................................................................... 84-2

Washer Components ...................................................................................................................... 84-3

Description ...................................................................................................................................... 84-4

Operation ........................................................................................................................................ 84-7

CONTENTS 3

CONTENTS

CONTROL UNITS ..................................................................................... 86-3-1

Control Unit Locations .................................................................................................................... 86-3-1

Description...................................................................................................................................... 86-3-2

COMMUNICATION DATA BUSES ........................................................... 86-4-1

CAN Bus Control Diagram.............................................................................................................. 86-4-1

Diagnostic Buses (Up To 2002 Model Year) .................................................................................. 86-4-2

Diagnostic Buses (From 2002 Model Year).................................................................................... 86-4-4

Description...................................................................................................................................... 86-4-6

SECURITY................................................................................................. 86-5-1

Locking and Alarm System Component Layout.............................................................................. 86-5-1

Locking and Alarm System Control Diagram.................................................................................. 86-5-2

Description...................................................................................................................................... 86-5-4

Immobilisation System Component Layout .................................................................................... 86-5-11

Immobilisation System Control Diagram......................................................................................... 86-5-12

Description...................................................................................................................................... 86-5-13

Operation........................................................................................................................................ 86-5-16

WINDOWS................................................................................................. 86-6-1

Window Component Layout............................................................................................................ 86-6-1

Side Door Window Control Diagram............................................................................................... 86-6-3

Tail Door Window Control Diagram ................................................................................................ 86-6-5

Description...................................................................................................................................... 86-6-6

Operation........................................................................................................................................ 86-6-9

DRIVING AIDS .......................................................................................... 86-10-1

Park Distance Control..................................................................................................................... 86-10-1

Park Distance Control Control Diagram.......................................................................................... 86-10-2

Description...................................................................................................................................... 86-10-3

PDC System Operation .................................................................................................................. 86-10-7

NAVIGATION SYSTEM ............................................................................ 87-1

Navigation System Component Location........................................................................................ 87-1

Description...................................................................................................................................... 87-2

INSTRUMENTS......................................................................................... 88-1

Instrument Pack Component Location - Front View ....................................................................... 88-1

Instrument Pack Component Location - Front View (2004MY Only) .............................................. 88-2

Instrument Pack Component Layout - Rear View........................................................................... 88-3

Instrument Pack Components - Exploded View ............................................................................. 88-4

Description...................................................................................................................................... 88-5

4CONTENTS

ENGINE - K SERIES KV6DESCRIPTION AND OPERATION

ENGINE - K SERIES KV6

This page is intentionally left blank

Deze pagina werd opzettelijk niet gebruikt

Cette page est intentionnellement vierge

Diese Seite ist leer

Questa pagina è stata lasciata in bianco di proposito

Esta página foi deixada intencionalmente em branco

Esta página fue dejada en blanco intencionalmente

DESCRIPTION AND OPERATION 12-3-1

ENGINE - K SERIES KV6

KV6 Engine – General View

M12 7452

12-3-2 DESCRIPTION AND OPERATION

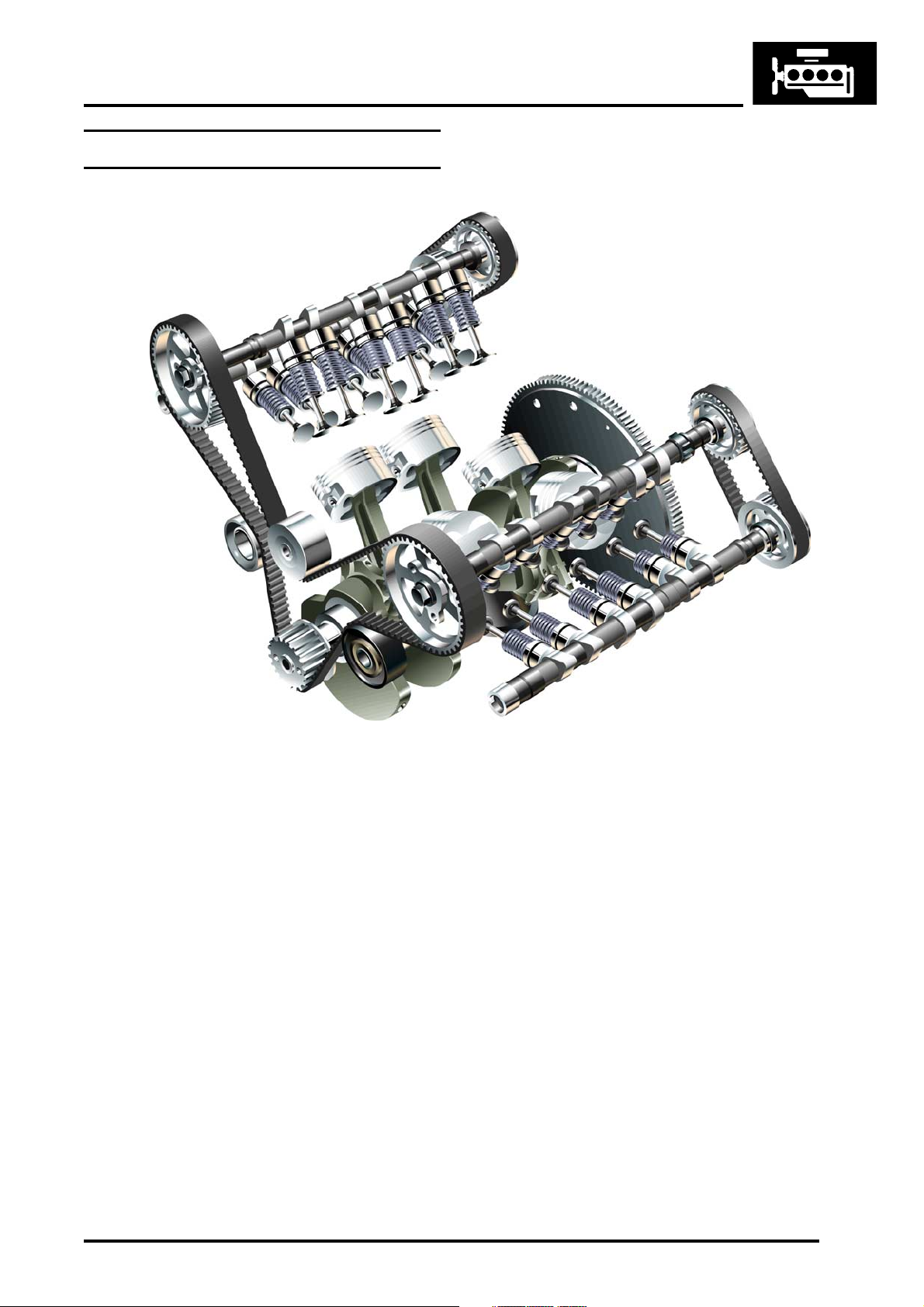

KV6 Engine – Internal View

ENGINE - K SERIES KV6

M12 6813

DESCRIPTION AND OPERATION 12-3-3

ENGINE - K SERIES KV6

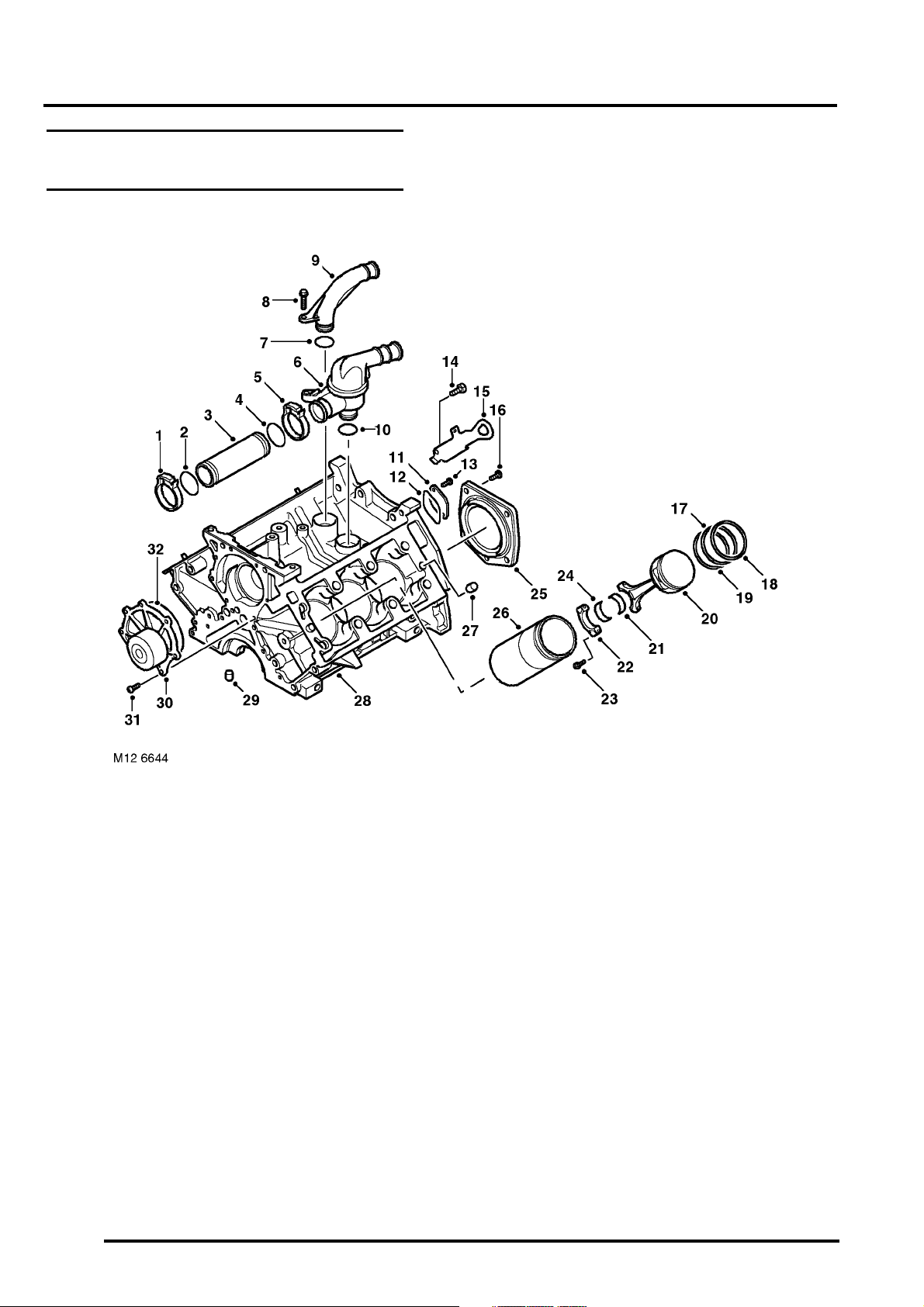

KV6 Engine – Cylinder Block Components

12-3-4 DESCRIPTION AND OPERATION

1 Clip – coolant pump to thermostat pipe

2 'O' ring – coolant pump to thermostat pipe

3 Pipe – coolant pump to thermostat

4 'O' ring – coolant pump to thermostat pipe

5 Clip – coolant pump to thermostat pipe

6 Thermostat housing

7 'O' ring – coolant outlet elbow to cylinder block

8 Bolt – coolant outlet elbow to cylinder block

9 Coolant outlet elbow

10 'O' ring – thermostat housing to cylinder block

11 Blanking plate – coolant outlet

12 Seal – blanking plate

13 Screw – blanking plate (2 off)

14 Bolt – engine lifting bracket, rear (2 off)

15 Engine lifting bracket – rear

16 Screw – crankshaft rear oil seal (5 off)

17 2nd compression ring

18 Top compression ring

19 Oil control ring

20 Piston

21 Big-end upper bearing shell

22 Big-end bearing cap

23 Bolt – big-end bearing cap to connecting rod

(2 off per piston)

24 Big-end lower bearing shell

25 Crankshaft rear oil seal

26 Cylinder liner (6 off)

27 Dowel – cylinder block to cylinder head (4 off)

28 Cylinder block

29 Dowel – cylinder block to lower crankcase

(4 off)

30 Engine coolant pump

31 Screw – coolant pump to cylinder block (7 off)

32 Seal – coolant pump to cylinder block

ENGINE - K SERIES KV6

DESCRIPTION AND OPERATION 12-3-5

ENGINE - K SERIES KV6

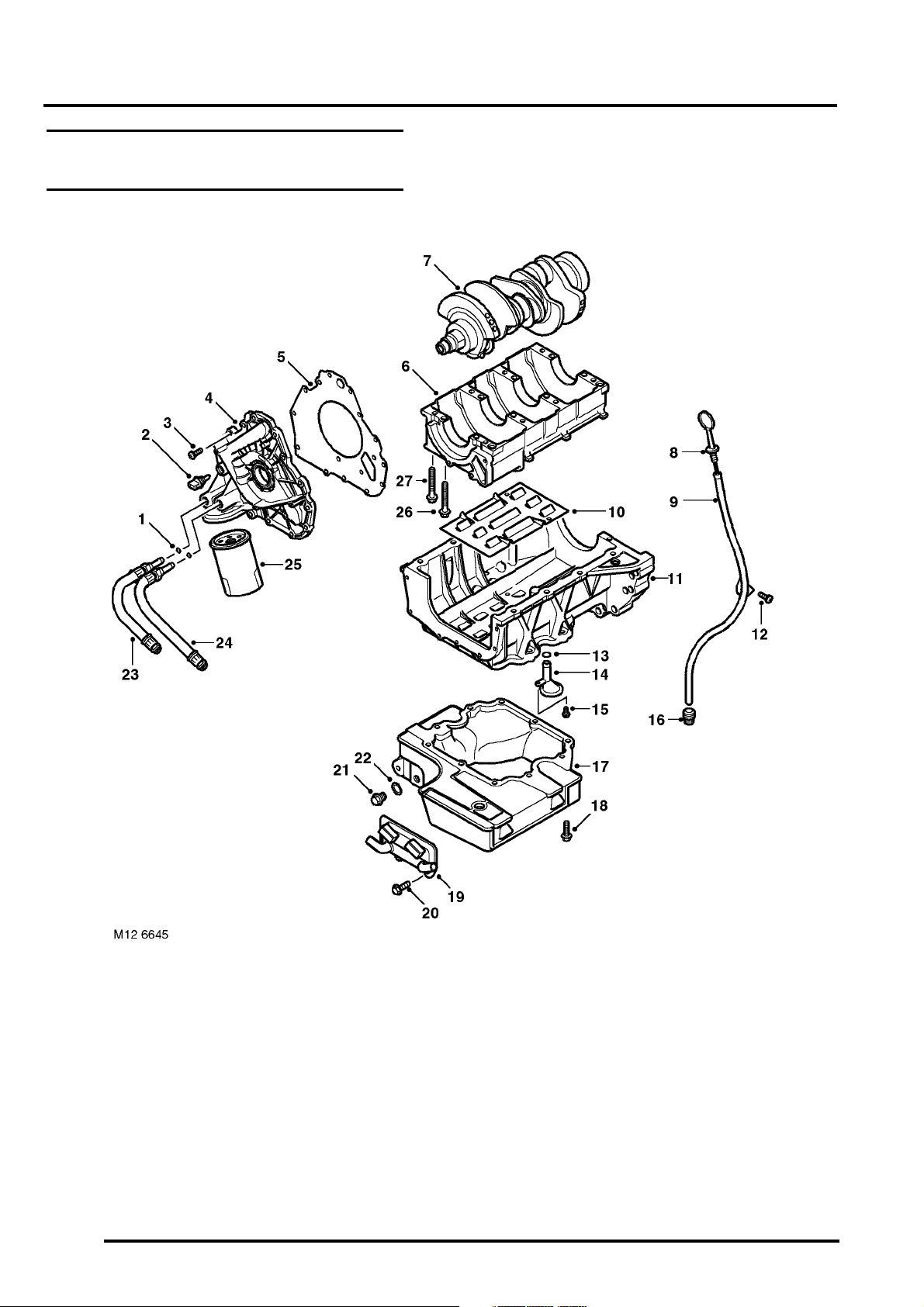

KV6 Engine – Crankshaft, Sump and Oil Pump Assembly

12-3-6 DESCRIPTION AND OPERATION

1 'O' rings – oil filter housing to oil cooler pipes

2 Oil pressure switch

3 Screw – oil pump to cylinder block (16 off)

4 Oil pump and oil filter housing assembly

5 Gasket – oil pump housing

6 Bearing ladder

7 Crankshaft

8 Dipstick

9 Dipstick tube

10 Baffle plate – lower crankcase extension

11 Lower crankcase extension

12 Screw – dipstick tube to cylinder block

13 'O' ring – oil pick-up pipe

14 Oil pick-up pipe with integral strainer

15 Screw – oil pick-up pipe to lower crankcase

16 Connector (quick fit) – dipstick tube to sump

17 Sump

18 Bolt – sump to lower crankcase

(10 off; 5 x short, 5 x long)

19 Oil cooler

20 Bolt – oil cooler to sump (3 off)

21 Oil drain plug

22 Seal – oil drain plug

23 Pipe – oil cooler to oil filter housing

24 Pipe – oil filter housing to oil cooler

25 Oil filter cartridge

26 Bolt (long) – bearing ladder to cylinder block

(8 off)

27 Bolt (short) – bearing ladder to cylinder block

(8 off)

ENGINE - K SERIES KV6

DESCRIPTION AND OPERATION 12-3-7

ENGINE - K SERIES KV6

KV6 Engine – Cylinder Head Components

12

13

14

15

11

1

16

17

18

5

4

3

2

8

9

10

19

6

7

20

42

43

44

39

45

40

41

46

29

27

28

26

30

25

32

31

24

37

21

23

33

34

22

35

36

M12 6646

LH cylinder bank shown, RH cylinder bank similar

12-3-8 DESCRIPTION AND OPERATION

38

1 Rear drive belt inner cover

2 Bolt – camshaft rear drive belt inner cover

(4 off)

3 Camshaft gear – rear inlet

4 Drive belt – rear camshaft

5 Bolt – inlet camshaft gear

6 Bolt – camshaft rear drive belt outer cover

(3 off)

7 Rear drive belt outer cover

8 Bolt – exhaust camshaft gear

9 Camshaft gear – rear exhaust

10 Seal – inlet camshaft, rear oil

11 Inlet camshaft

12 Seal – inlet camshaft, front oil

13 Stud – cylinder head to intake manifold (2 off)

14 Valve stem oil seal – inlet (6 off)

15 Valve spring – inlet (6 off)

16 Valve spring cap – inlet (6 off)

17 Collet – inlet valve (12 off)

18 Tappet – inlet valve (6 off)

19 Camshaft carrier

20 Bolt – cylinder head (8 off)

21 Bolt – camshaft carrier to cylinder head (22 off)

22 Seal – exhaust camshaft, rear oil

23 Exhaust camshaft

24 Tappet – exhaust valve (6 off)

25 Collet – exhaust valve (12 off)

26 Valve spring cap – exhaust (6 off)

27 Valve stem oil seal – exhaust (6 off)

28 Valve spring – exhaust (6 off)

29 Seal – exhaust camshaft, front oil

30 Bolt – camshaft cover (14 off)

31 Seal – oil filler cap

32 Oil filler cap

33 'O' ring – CMP sensor

34 CMP sensor

35 Bolt – CMP sensor

36 Spark plug (3 off)

37 Camshaft cover

38 Gasket – camshaft cover

39 Inlet valve (6 off)

40 Valve seat insert – inlet (6 off)

41 Valve guide – inlet (6 off)

42 Gasket – cylinder head

43 Exhaust valves (6 off)

44 Valve seat insert – exhaust (6 off)

45 Valve guides – exhaust (6 off)

46 Cylinder head

ENGINE - K SERIES KV6

DESCRIPTION AND OPERATION 12-3-9

ENGINE - K SERIES KV6

KV6 Engine – Manifolds and Engine Cover Components

12-3-10 DESCRIPTION AND OPERATION

1 Strap – engine acoustic cover

2 Bolt – engine acoustic cover strap to manifold

chamber

3 Engine acoustic cover

4 Bolt – manifold chamber to RH inlet manifold

(4 off)

5 Manifold chamber

6 Bolt – throttle body assembly to manifold

chamber (4 off)

7 Throttle body assembly

8 Inlet manifold, RH

9 Seal - manifold chamber to LH inlet manifold

(3 off)

10 Guide block – HT lead

11 Stud – HT lead guide block/acoustic cover

fixing

12 Inlet manifold, LH

13 Bolt – inlet manifold to cylinder head LH (7 off)

14 Gasket - inlet manifold to cylinder head (LH)

15 Fuel rail

16 Bolt – inlet manifold to cylinder head

17 Gasket – inlet manifold to cylinder head, RH

18 'O' ring - inlet manifold to top cover RH (3 off)

ENGINE - K SERIES KV6

DESCRIPTION AND OPERATION 12-3-11

ENGINE - K SERIES KV6

KV6 Engine – Camshaft Drive Belt Components

1 Bolt – timing gear to inlet camshaft (RH)

2 Hub – camshaft front timing gear (RH)

3 Camshaft front timing gear (RH)

4 Drive belt (front) backplate cover – RH

5 Engine mounting bracket

6 Bolt – engine mounting bracket to front plate

(4 off)

7 Cover plate – drive belt

8 Blanking plug

9 Engine front plate

10 Engine lifting bracket – front

11 Cover – lower drive belt

12 Drive belt (front) backplate cover – LH

13 Camshaft front timing gear (LH)

12-3-12 DESCRIPTION AND OPERATION

14 Hub – camshaft front timing gear (LH)

15 Idler pulley – drive belt

16 Crankshaft timing gear

17 Drive belt – front

18 Front drive belt outer cover (LH)

19 Screw – front drive belt outer cover to inner

cover, LH (3 off)

20 Front drive belt outer cover (RH)

21 Screw – front drive belt outer cover to inner

cover, RH (3 off)

22 Tensioner assembly – front drive belt

23 Bolt – timing gear to inlet camshaft (LH)

ENGINE - K SERIES KV6

Description

General

The KV6 is of all aluminium construction, with a 90° V configuration. The KV6 uses long cylinder head bolts engaging

in threads 70 mm below the mating face of the cylinder block to attach the cylinder head to the cylinder block. This

ensures sufficient structural stiffness to take advantage of the compressive strength of aluminium alloy and minimise

tensile loadings. There are 8 cylinder head bolts for each cylinder head, located below the camshafts.

The engine features 24 valves, sequential fuel injection, liquid cooling and is transverse mounted. It is controlled by

a Siemens engine management system utilising a range of sensors to constantly monitor and optimise engine

performance.

+ ENGINE MANAGEMENT SYSTEM - SIEMENS, DESCRIPTION AND OPERATION, Description.

Cylinder Block Components

The cylinder block components are described below:

Cylinder Block and Main Bearing Ladder

The cylinder block is constructed of an aluminium alloy and is cast in three sections:

l Cylinder block.

l Main bearing ladder.

l Lower crankcase extension.

For strength and rigidity, the main bearing ladder is manufactured from special alloy A357TF as used in manufacturing

components in the aerospace industry. The main bearing ladder is secured to the cylinder block with 16 bolts, thus

creating a very rigid crankcase 'box'. A separate outer crankcase extension adds further strength to the lower end of

the cylinder block. The lower crankcase extension is sealed to the underside of the cylinder block, using jointing

compound, and secured with 10 bolts. Fitted to the lower crankcase is an aluminium alloy sump.

Pistons and Cylinder Liners

The aluminium alloy, thermal expansion, lightweight pistons, with semi-floating gudgeon pins, are offset to the thrust

side and are carried on forged steel connecting rods. Pistons and cylinder liners are supplied in two grades, 'A' and

'B' and are also colour coded to assist identification. The pistons are marked to ensure they are correctly oriented in

the cylinder liner; the 'FRONT' mark should be toward the front of the engine.

The cylinder block is fitted with 'damp' cylinder liners, the bottom stepped half of the cylinder liner being a sliding fit

into the lower part of the cylinder block. The liners are sealed in the block with a bead of sealant applied around the

stepped portion of the cylinder liner. The top of the cylinder liner is sealed by a multi-layer steel cylinder head gasket

when the cylinder head is fitted.

The cylinder liner diameters are smaller than the big-end forging of the connecting rods and need to be removed

complete with pistons and connecting rods from the cylinder block.

Connecting Rods

The KV6 engine utilises forged steel H-sectioned connecting rods, with the gudgeon pin being an interference fit in

the small end of the connecting rod. The big-ends are horizontally split.

Big-end bearing diametric clearance is controlled by selective bearing shells with three grades of thickness. The bigend upper and lower bearing shells are plain with locating tags.

DESCRIPTION AND OPERATION 12-3-13

ENGINE - K SERIES KV6

Piston Rings

Each piston is fitted with two compression rings and an oil control ring. The top compression rings are chrome-plated

steel. The 2nd compression rings are chrome-plated cast iron. The oil control rings have stainless steel top and

bottom rails and integral expander rings.

Crankshaft, Sump and Oil Pump Components

The crankshaft and sump components are described below:

Crankshaft

The short, stiff crankshaft is supported on four main bearings, with each pair of crankpins mutually offset by 30° to

give equal firing intervals. Cast in Spheroidal Graphite (SG) iron, the crankshaft has cold rolled fillets on all journals,

except the outer mains, for toughness and failure resistance. End-float is controlled by thrust washer halves at the top

and bottom of the rear main bearing.

Main Bearings

Oil grooves are provided in the upper halves of all the main bearing shells to supply oil, via drillings in the crankshaft,

to the connecting rod big-end bearings. The lower halves of the bearing shells in the bearing ladder are plain.

Sump

The cast aluminium sump is a wet-type, sealed to the lower crankcase extension using sealant applied to the sump

flange. The sump is fixed to the lower crankcase extension using 10 bolts. A baffle plate is fitted in the lower crankcase

extension to minimise the effects of oil slosh.

An oil pick-up with integral strainer is located in the centre of the sump oil well, as a source for the supply of engine

lubrication oil to the oil pump. Oil is sucked up though the end of the pick–up and strained to prevent solid matter from

entering the oil pump.

Oil Pump

The oil pump is directly driven from the crankshaft. The oil pump housing includes the oil pressure relief valve, oil filter,

oil pressure switch and return/supply outlets for the engine oil cooler.

Oil Filter

A full-flow, disposable canister-type oil filter is attached to the oil pump housing at the front of the engine.

Oil Cooler

A liquid cooled oil cooler keeps the engine lubrication oil cool, under heavy loads and high ambient temperatures.

The oil cooler is cooled by the engine cooling system and attached to a bracket secured to the front of the sump by

three bolts. Oil is delivered to and from the oil cooler through hoses connected to the oil pump housing. Hoses from

the engine cooling system are connected to two pipes on the oil cooler for the supply and return of coolant.

Oil Pressure Switch

The oil pressure switch is located in a port at the outlet side of the oil filter. It detects when a safe operating pressure

has been reached during engine starting and initiates the illumination of a warning light in the instrument pack if the

oil pressure drops below a given value.

12-3-14 DESCRIPTION AND OPERATION

ENGINE - K SERIES KV6

Cylinder Head Components

The cylinder head components are described below:

Cylinder Head

The cross-flow cylinder heads are based on a four valve, central spark plug combustion chamber, with the inlet ports

designed to induce swirl and control the speed of the induction charge. This serves to improve combustion and hence

fuel economy, performance and exhaust emissions.

LH and RH cylinder heads are identical castings.

Camshafts

Twin camshafts on each cylinder bank are retained by a camshaft carrier, line bored with the cylinder head. The

camshafts are located by a flange which also controls end-float. A crossover drive for the exhaust camshaft, from the

rear of the inlet camshaft is by a short toothed belt, which allows for a much shorter and simpler run for the main

camshaft drive belt at the front of the engine.

The exhaust camshaft drive gears have dampers integral with the gear to minimise torsional vibration. The inlet

camshaft for the LH cylinder head incorporates a reluctor which is used in conjunction with the Camshaft Position

(CMP) sensor to measure engine position. The CMP sensor is bolted to the LH camshaft cover.

+ ENGINE MANAGEMENT SYSTEM - SIEMENS, DESCRIPTION AND OPERATION, Description.

Cylinder Head Gasket

The KV6 utilises a multi-layer stainless steel cylinder head gasket. The gasket comprises four stainless steel

functional layers, and a stainless steel distance layer to maintain fitted thickness. A full embossment profile is

employed to seal the combustion gases and half embossments are used to provide a durable fluid seal. Sealing

characteristics are further enhanced by the application of a fluro-elastomer surface coating to all layers of the gasket.

Hydraulic Tappets

Self-adjusting, lightweight, hydraulic tappets are fitted on top of each valve and are operated directly by the camshaft.

The valve stem oil seals are moulded onto a metal base which also acts as the valve spring seat on the cylinder head.

Valves

The exhaust valves are of the carbon break type. A machined profile on the valve stem removes any build up of carbon

in the combustion chamber end of the valve guide. All valve seats are machined in three planes, improving valve to

seat sealing.

Camshaft Cover and Engine Cover Components

The camshaft cover and engine cover components are described below:

Acoustic Cover

A moulded plastic acoustic cover is fitted over the engine to absorb engine generated noise. Foam is bonded on the

inside surface of the acoustic cover and a rubber seal is fitted around the oil filler cap.

The acoustic cover is located on the engine by two rubber studs on the underside of the acoustic cover. A rubber

strap, at the rear of the engine, and two quick release fasteners, at the front of the acoustic cover, secure the acoustic

cover in position.

Resonators and part of the engine intake duct are integrated into the acoustic cover, and the engine air filter is

installed in a compartment below a lid secured with two Torx bolts.

A metal foil heatshield is installed on the underside of the acoustic cover.

A rubber duct connects the engine intake duct in the acoustic cover to the RH inner wing. A further duct is installed

between the inner and outer wings to draw engine air from the base of the A post.

DESCRIPTION AND OPERATION 12-3-15

ENGINE - K SERIES KV6

Throttle Body Assembly

The throttle body is an electrically actuated unit controlled by the Engine Control Module (ECM). The position of the

throttle plate is controlled by a DC motor and a return spring integrated into the throttle body. Two feedback

potentiometers supply throttle plate position signals to the ECM for closed loop control.

Four Torx bolts secure the throttle body to the inlet manifold chamber. A rubber seal, keyed into a groove in the inlet

manifold chamber, ensures the joint is air tight.

Inlet Manifold Chamber

The inlet manifold chamber is a sealed plastic assembly. The inlet manifold chamber combines plenum resonance for

good low speed torque, with variable length primary tracts for optimum mid and high speed torque.

The throttle body assembly feeds into a 'Y' piece which separates into two secondary inlet pipes. The secondary pipes

feed into two main plenums, one for each bank of three cylinders. At the closed end of the plenums is a balance valve,

controlled by an electric actuator, that connects the two plenums together.

The variable intake system uses valves and actuators to vary the overall tract length of the inlet manifold chamber.

The aluminium alloy inlet manifolds are sealed to each cylinder head with gaskets and to the inlet manifold chamber

with 'O' rings and seals.

+ MANIFOLD AND EXHAUST SYSTEM - K SERIES KV6, DESCRIPTION AND OPERATION, Description.

12-3-16 DESCRIPTION AND OPERATION

ENGINE - K SERIES KV6

Operation

Lubrication Circuit

The lubrication system is of the full-flow filtration, force fed type.

Oil is drawn, via a strainer and pick-up pipe in the sump, through the bearing ladder and into a crankshaft driven oil

pump which has an integral pressure relief valve. The strainer in the pick-up pipe prevents any ingress of foreign

particles from passing through to the inlet side of the oil pump and damaging the oil pump and restricting oil drillings.

The oil pressure relief valve in the oil pump opens if the oil pressure becomes excessive and diverts oil back around

the pump.

Pressurised oil is pumped through a full-flow cartridge type oil filter, mounted on the oil pump housing. The lubrication

system is designed so that a higher proportion of oil flow is directed to the cylinder block main oil gallery while a lower

proportion of oil flow, (controlled by a restrictor in the oil filter housing), is directed to the engine oil cooler. The

remainder of the oil flow from the outlet side of the oil filter is combined with the return flow from the oil cooler before

being passed into the cylinder block main oil gallery.

The main oil gallery has drillings that direct the oil to the main bearings. Cross drillings in the crankshaft main bearings

carry the oil to the connecting rod big-end bearings.

The oil pressure switch is located at the outlet side of the oil filter housing to sense the oil pressure level before the

oil flow enters the main gallery in the engine block. A warning lamp in the instrument pack is illuminated if low oil

pressure is detected.

Oil at reduced pressure is directed to each cylinder bank via two restrictors in the cylinder block/cylinder head locating

dowels, one at the front on the LH bank and the other at the rear on the RH bank. Oil then passes through a drilling

in the cylinder head to the camshaft carrier, where it is directed via separate galleries to the camshaft bearings and

hydraulic tappet housings. Return oil from the cylinder head drains into the sump via the cylinder head bolt passages.

Crankcase Ventilation

A positive crankcase ventilation system is used to vent blow-by gas from the crankcase to the air intake system. The

blow-by gas passes through a gauze oil separator in the camshaft cover, and then through hoses into the throttle

housing and inlet manifold.

+ EMISSION CONTROL - K SERIES KV6, DESCRIPTION AND OPERATION, Description.

DESCRIPTION AND OPERATION 12-3-17

ENGINE - K SERIES KV6

Crankshaft Oil Supply

1 Cylinder block main oil gallery

2 Cross drillings to crankshaft main bearings

3 Oil pick-up pipe with integral strainer

4 Oil cooler

5 Oil cooler supply pipe

12-3-18 DESCRIPTION AND OPERATION

6 Oil filter cartridge

7 Oil cooler return pipe

8 Oil pressure switch

9 Oil pump with integral oil pressure relief valve

ENGINE - K SERIES KV6

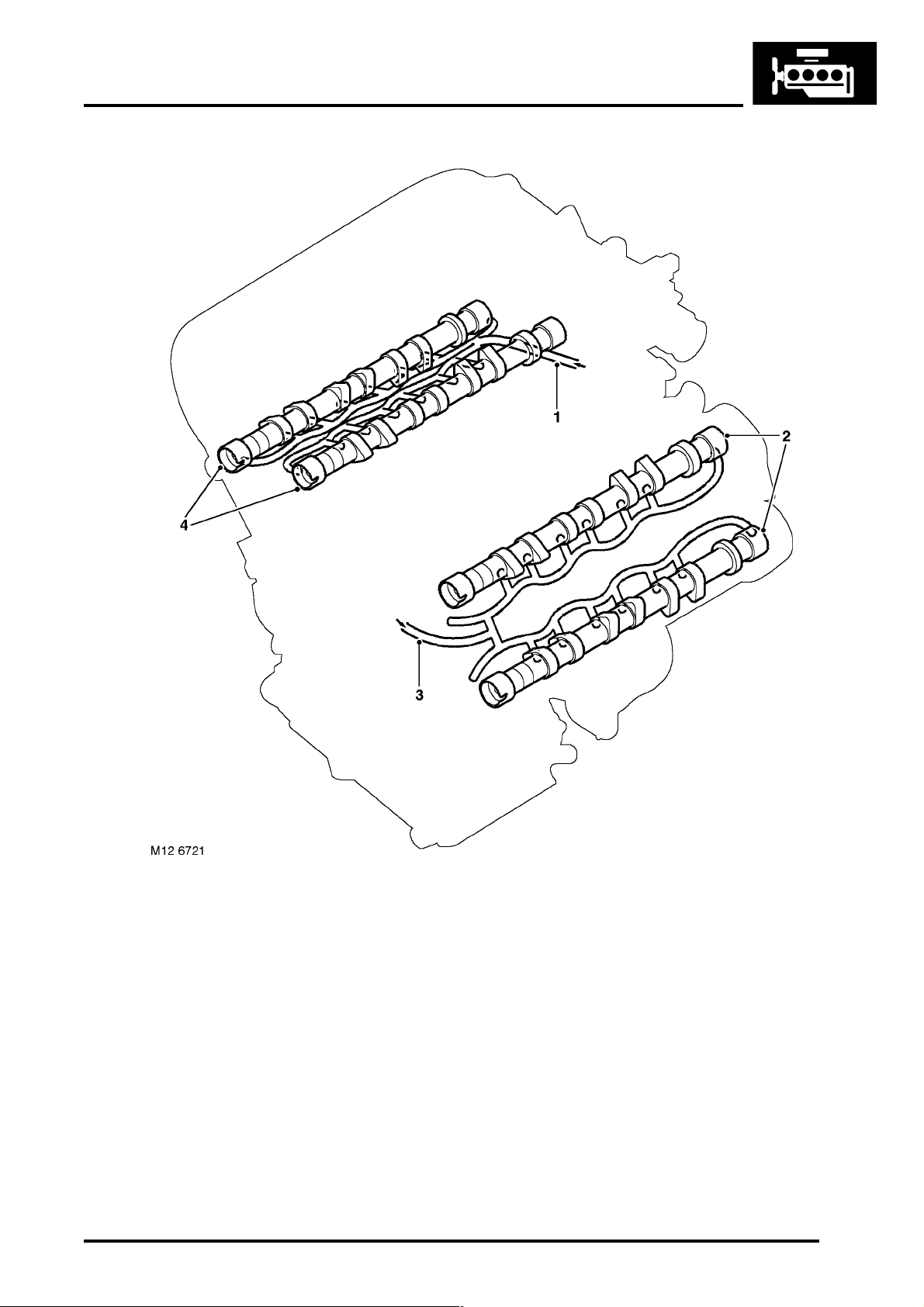

Cylinder Head Component Oil Supply

1 From RH cylinder block main gallery

2 LH cylinder head camshafts

3 From LH cylinder block main gallery

4 RH cylinder head camshafts

DESCRIPTION AND OPERATION 12-3-19

ENGINE - K SERIES KV6

12-3-20 DESCRIPTION AND OPERATION

EMISSION CONTROL - K SERIES KV6

EMISSION CONTROL - K SERIES KV6DESCRIPTION AND OPERATION

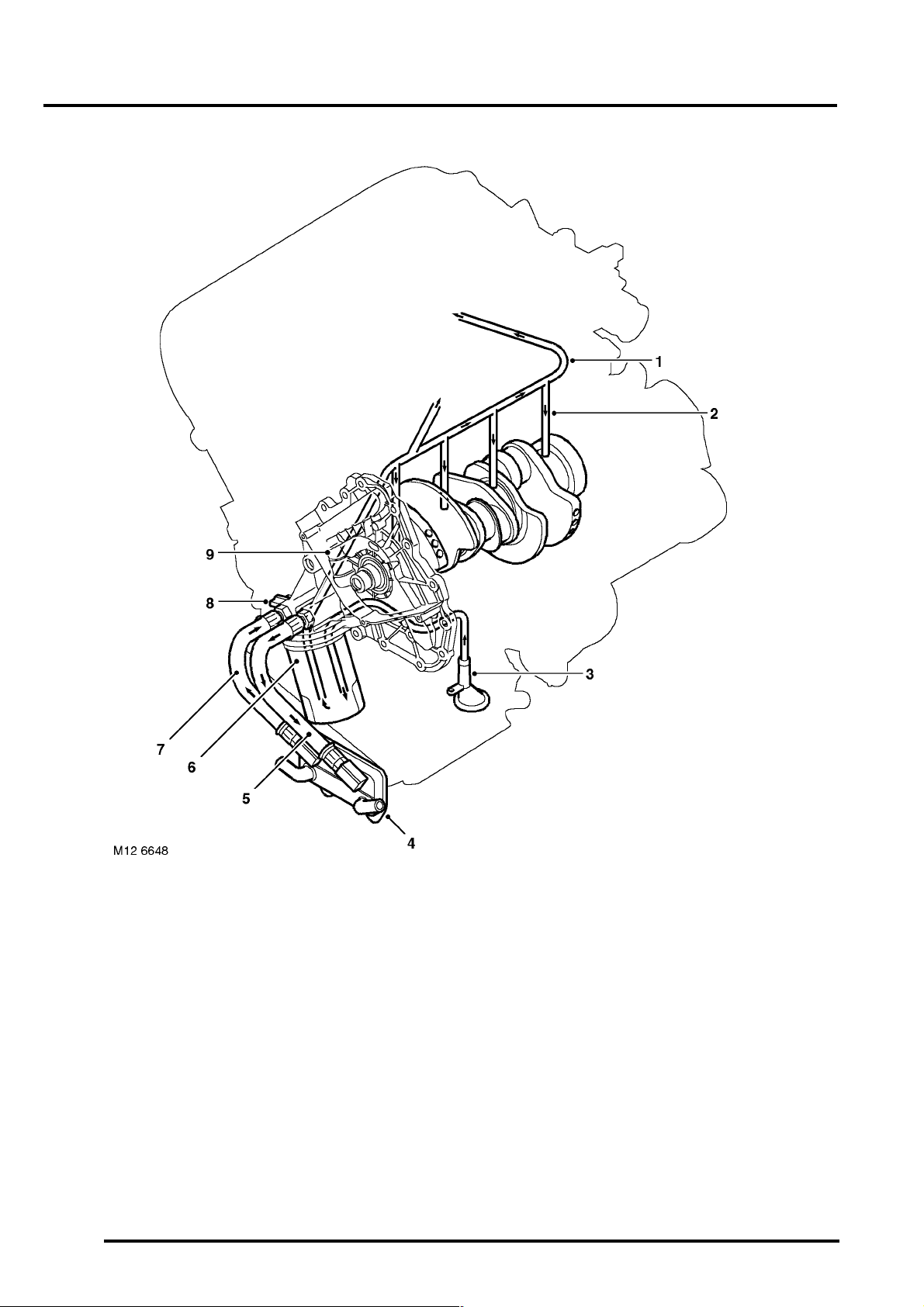

Emission Control Component Layout – Crankcase and Exhaust

1 Crankcase breather hose to intake duct

2 Crankcase breather hose to inlet manifold

3 Catalytic converters

DESCRIPTION AND OPERATION 17-3-1

EMISSION CONTROL - K SERIES KV6

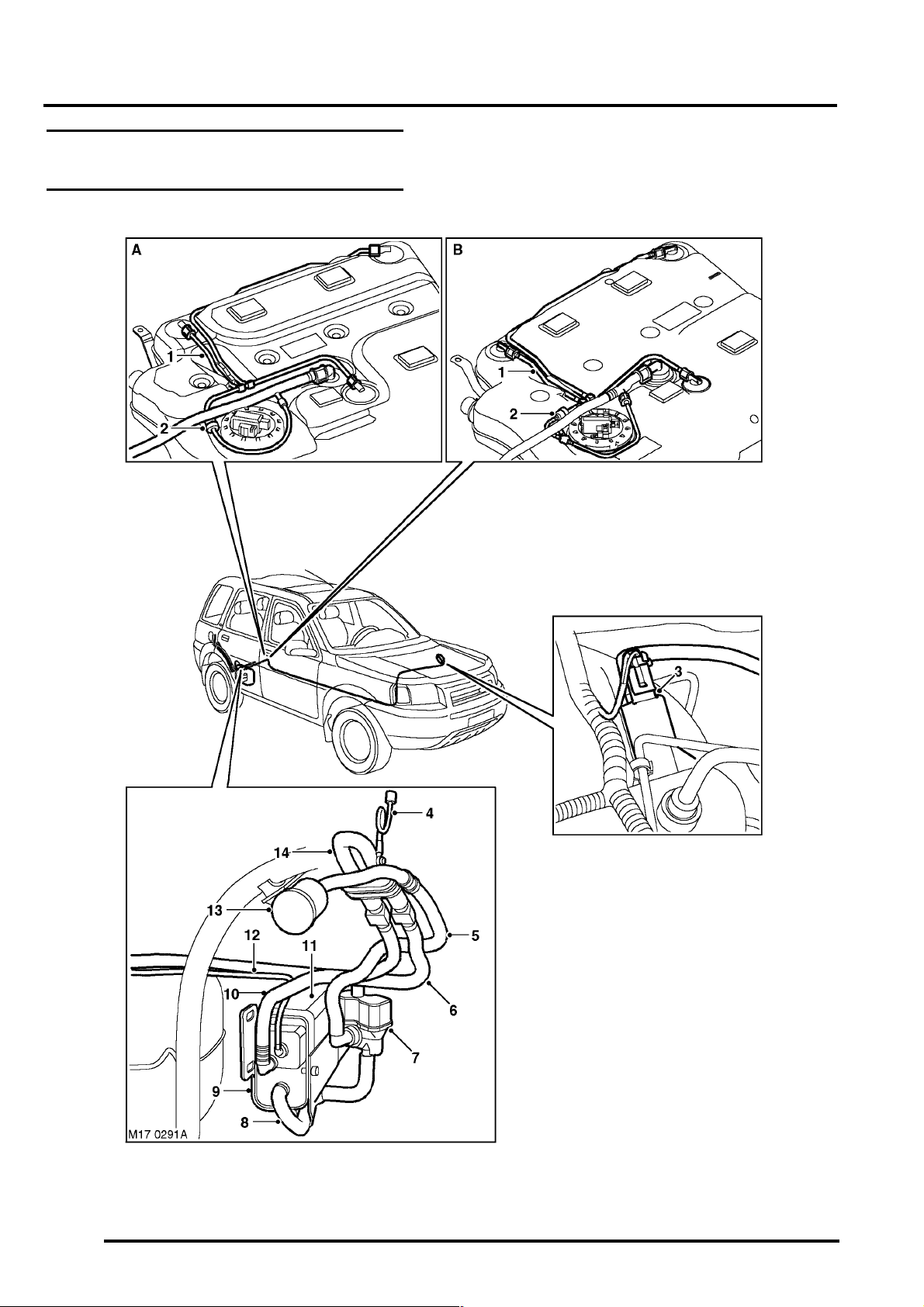

Emission Control Component Layout – EVAP

A = Vehicles up to 2002.5 Model Year

B = Vehicles from 2002.5 Model Year

17-3-2 DESCRIPTION AND OPERATION

EMISSION CONTROL - K SERIES KV6

1 Fuel tank vent pipes

2 Two-way valve

3 Purge valve

4 Recirculation pipe

5 DMTL to air filter vent pipe

6 Fuel tank to vapour separator vent pipe

7 DMTL

8 Canister to DMTL vent pipe

9 Canister support bracket

10 Vapour separator to canister vent pipe

11 EVAP canister

12 Canister to purge valve vent pipe

13 Air filter

14 Vapour separator

DESCRIPTION AND OPERATION 17-3-3

Loading...

Loading...