Page 1

Workshop Manual

System Description & Operation

Page 2

FREELANDER 2001 TO 2004 MY

ONWARDS

WORKSHOP MANUAL - SYSTEM

DESCRIPTION AND OPERATION

Publication Part No. LRL0351 NAS - 5th Edition

Published by Land Rover

©2003 Land Rover

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form,

electronic, mechanical, recording or other means without prior written permission from Land Rover.

Page 3

Page 4

CONTENTS

ENGINE - K SERIES KV6......................................................................... 12-3-1

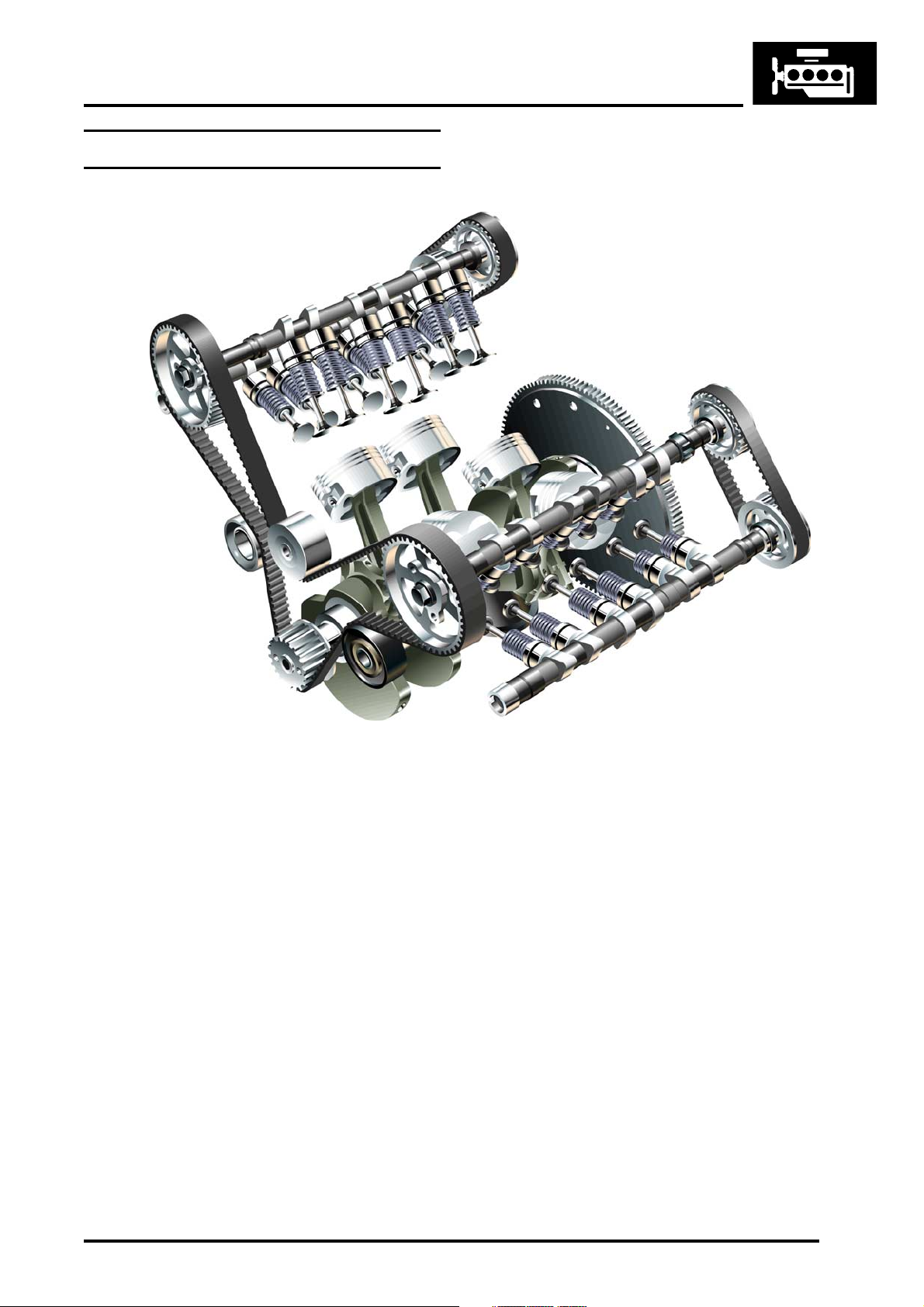

KV6 Engine – General View ........................................................................................................... 12-3-2

KV6 Engine – Internal View ............................................................................................................ 12-3-3

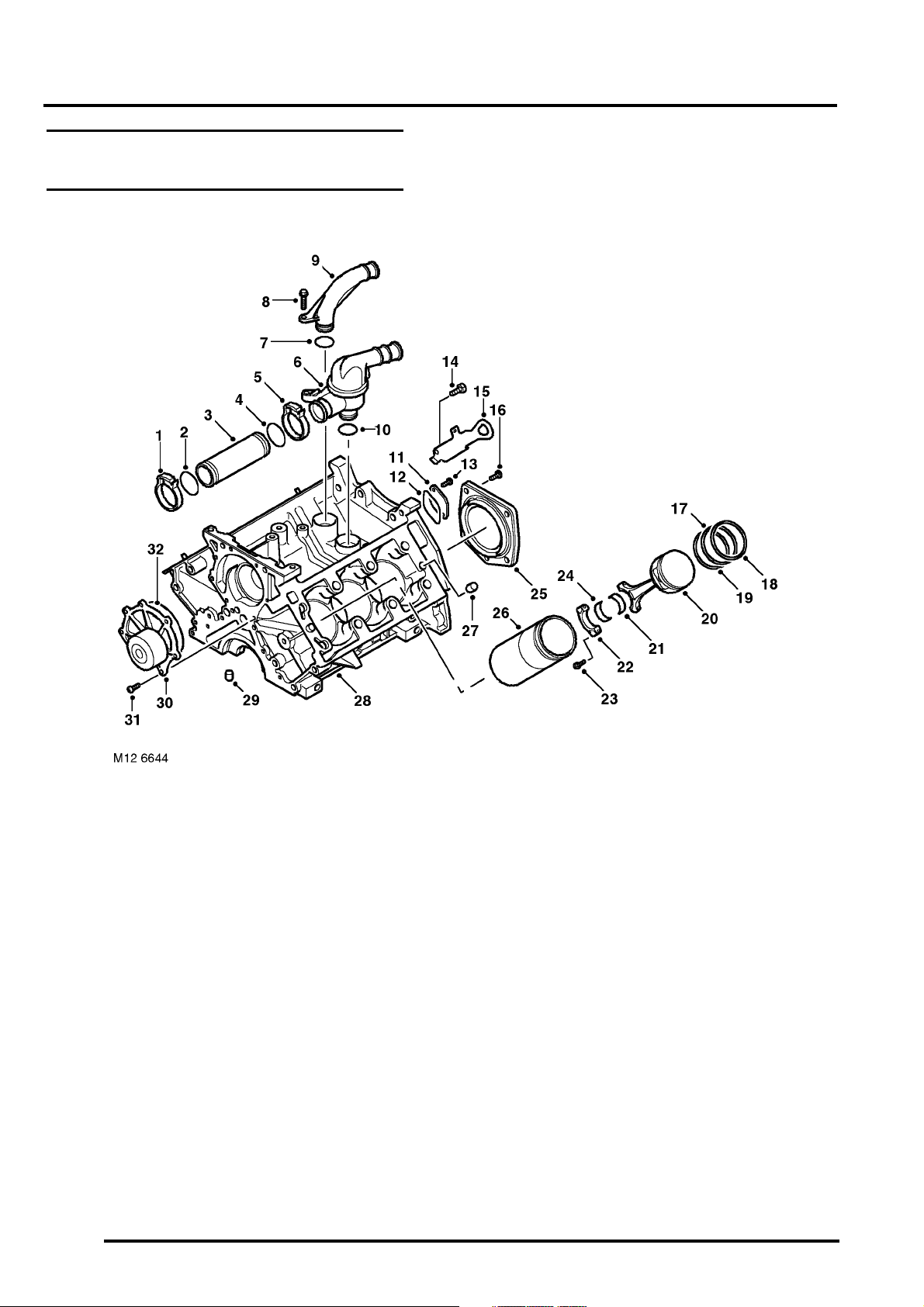

KV6 Engine – Cylinder Block Components..................................................................................... 12-3-4

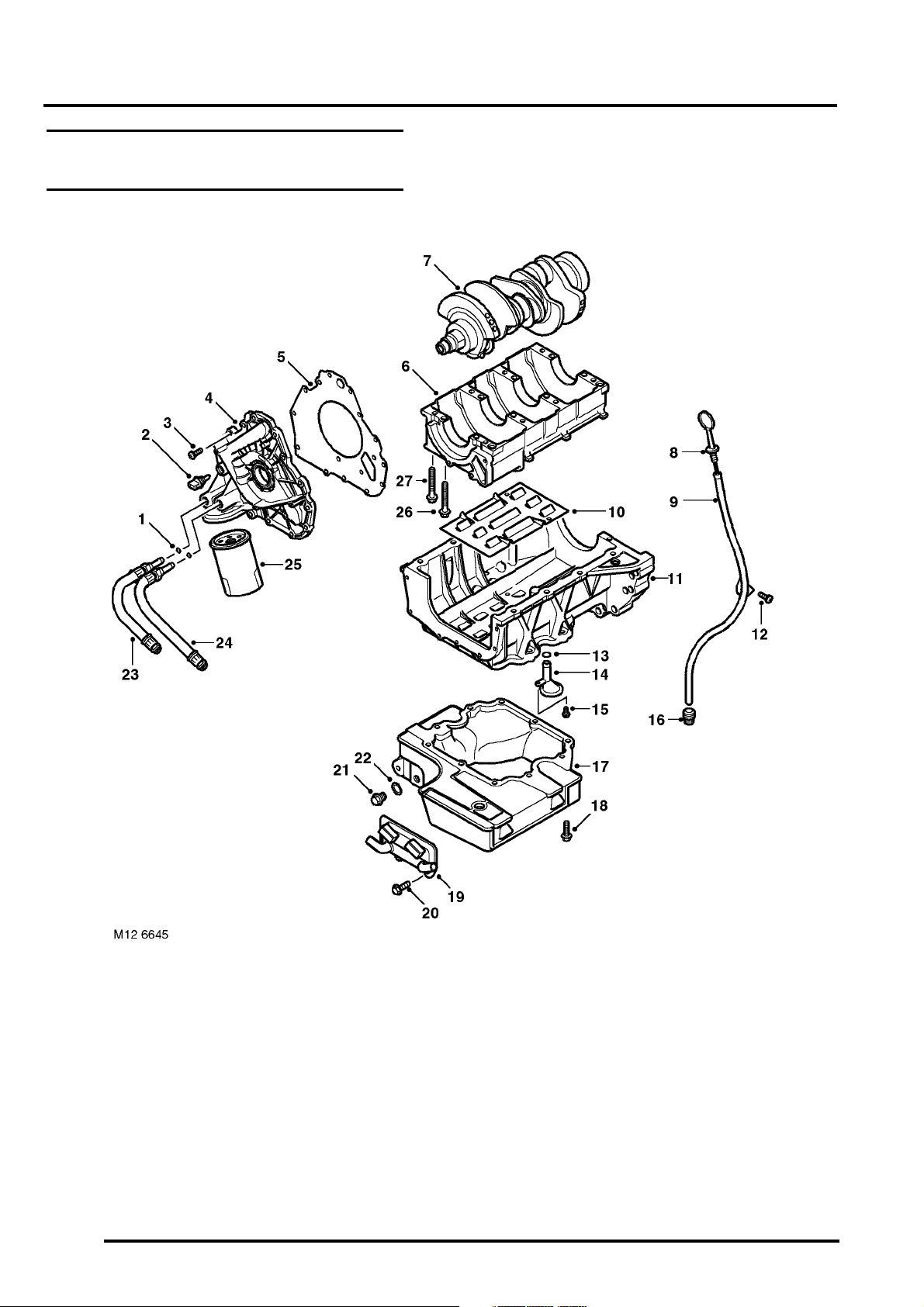

KV6 Engine – Crankshaft, Sump and Oil Pump Assembly............................................................. 12-3-6

KV6 Engine – Cylinder Head Components ..................................................................................... 12-3-8

KV6 Engine – Manifolds and Engine Cover Components .............................................................. 12-3-10

KV6 Engine – Camshaft Drive Belt Components............................................................................ 12-3-12

Description ...................................................................................................................................... 12-3-13

Operation ........................................................................................................................................ 12-3-17

EMISSION CONTROL - K SERIES KV6 .................................................. 17-3-1

Emission Control Component Layout – Crankcase and Exhaust ................................................... 17-3-1

Emission Control Component Layout – EVAP ................................................................................ 17-3-2

Description ...................................................................................................................................... 17-3-4

ENGINE MANAGEMENT SYSTEM - SIEMENS ...................................... 18-4-1

Engine Management System Component Location........................................................................ 18-4-2

Engine Management System Control Diagram – Sheet 1 of 2 ....................................................... 18-4-4

Engine Management System Control Diagram – Sheet 2 of 2 ....................................................... 18-4-6

Description ...................................................................................................................................... 18-4-8

Operation ........................................................................................................................................ 18-4-41

Cruise Control Component Location............................................................................................... 18-4-43

Cruise Control System Control Diagram......................................................................................... 18-4-44

Cruise Control Description .............................................................................................................. 18-4-46

Cruise Control Operation ................................................................................................................ 18-4-49

FUEL DELIVERY SYSTEM - K SERIES KV6 .......................................... 19-3-1

Fuel Delivery System Component Layout ...................................................................................... 19-3-1

Fuel Delivery System Schematic .................................................................................................... 19-3-2

Description ...................................................................................................................................... 19-3-3

Operation ........................................................................................................................................ 19-3-7

COOLING SYSTEM - K SERIES KV6...................................................... 26-3-1

Cooling System Component Layout - Sheet 1 of 2......................................................................... 26-3-2

Cooling System Component Layout - Sheet 2 of 2......................................................................... 26-3-4

Cooling System Coolant Flow ......................................................................................................... 26-3-5

Description ...................................................................................................................................... 26-3-6

Operation ........................................................................................................................................ 26-3-8

CONTENTS 1

Page 5

CONTENTS

MANIFOLD AND EXHAUST SYSTEM - K SERIES KV6 ......................... 30-3-1

Inlet Manifold Component Layout ................................................................................................... 30-3-1

Inlet Manifold Chamber Component Layout ................................................................................... 30-3-2

Exhaust System Component Layout – Sheet 1 of 2 ....................................................................... 30-3-3

Exhaust System Component Layout – Sheet 2 of 2 ....................................................................... 30-3-4

Description...................................................................................................................................... 30-3-5

Operation........................................................................................................................................ 30-3-7

INTERMEDIATE REDUCTION DRIVE ..................................................... 41-1

Intermediate Reduction Drive ......................................................................................................... 41-1

Description...................................................................................................................................... 41-2

Operation........................................................................................................................................ 41-3

AUTOMATIC GEARBOX - JATCO........................................................... 44-1

JATCO Automatic Gearbox Component Location .......................................................................... 44-1

JATCO Automatic Gearbox ............................................................................................................ 44-2

JATCO Automatic Gearbox - Exploded View ................................................................................. 44-3

JATCO Automatic Gearbox - Valve Block and Solenoid Valves .................................................... 44-4

JATCO Automatic Gearbox Control Diagram ................................................................................. 44-6

Description...................................................................................................................................... 44-8

Operation........................................................................................................................................ 44-43

DRIVESHAFTS ......................................................................................... 47-1

Drive Shaft and Propeller Shaft Component Layout....................................................................... 47-1

Front Drive Shaft Components ....................................................................................................... 47-2

Rear Drive Shaft Components........................................................................................................ 47-3

Propeller Shaft and VCU Components ........................................................................................... 47-4

Description...................................................................................................................................... 47-5

REAR AXLE AND FINAL DRIVE.............................................................. 51-1

Rear Differential.............................................................................................................................. 51-2

Description...................................................................................................................................... 51-4

STEERING ................................................................................................ 57-1

Steering Components - KV6........................................................................................................... 57-1

Description...................................................................................................................................... 57-2

Operation........................................................................................................................................ 57-10

FRONT SUSPENSION.............................................................................. 60-1

Front Suspension Component Location ......................................................................................... 60-1

Front Suspension Component Detail.............................................................................................. 60-2

Description...................................................................................................................................... 60-4

2CONTENTS

Page 6

CONTENTS

REAR SUSPENSION................................................................................ 64-1

Rear Suspension Component Location .......................................................................................... 64-1

Rear Suspension Component Detail............................................................................................... 64-2

Description ...................................................................................................................................... 64-4

BRAKES ................................................................................................... 70-1

Brake System Layout (KV6)............................................................................................................ 70-1

Description ...................................................................................................................................... 70-2

Operation ........................................................................................................................................ 70-14

Handbrake Component Layout ....................................................................................................... 70-21

Description ...................................................................................................................................... 70-22

RESTRAINT SYSTEMS............................................................................ 75-1

SRS Component Layout ................................................................................................................. 75-1

SRS Control Diagram ..................................................................................................................... 75-2

Description ...................................................................................................................................... 75-4

Operation ........................................................................................................................................ 75-11

Front Seat Belt Components........................................................................................................... 75-13

Rear Seat Belt Components - Three Door Models ......................................................................... 75-14

Rear Seat Belt Components - Five Door Models ............................................................................ 75-15

Description ...................................................................................................................................... 75-16

HEATING AND VENTILATION................................................................. 80-1

Heating and Ventilation System Component Layout ...................................................................... 80-1

Heater Assembly Components ....................................................................................................... 80-2

Description ...................................................................................................................................... 80-3

Operation ........................................................................................................................................ 80-11

AIR CONDITIONING................................................................................. 82-1

A/C Refrigerant System Component Layout – KV6 Series Engines............................................... 82-1

A/C System Schematic Layout ....................................................................................................... 82-2

A/C Control Component Layout ...................................................................................................... 82-3

A/C System Control Schematic....................................................................................................... 82-4

Description ...................................................................................................................................... 82-6

Operation ........................................................................................................................................ 82-20

WIPERS AND WASHERS ........................................................................ 84-1

Windscreen Wiper Components ..................................................................................................... 84-1

Rear Screen Wiper Components .................................................................................................... 84-2

Washer Components ...................................................................................................................... 84-3

Description ...................................................................................................................................... 84-4

Operation ........................................................................................................................................ 84-7

CONTENTS 3

Page 7

CONTENTS

CONTROL UNITS ..................................................................................... 86-3-1

Control Unit Locations .................................................................................................................... 86-3-1

Description...................................................................................................................................... 86-3-2

COMMUNICATION DATA BUSES ........................................................... 86-4-1

CAN Bus Control Diagram.............................................................................................................. 86-4-1

Diagnostic Buses (Up To 2002 Model Year) .................................................................................. 86-4-2

Diagnostic Buses (From 2002 Model Year).................................................................................... 86-4-4

Description...................................................................................................................................... 86-4-6

SECURITY................................................................................................. 86-5-1

Locking and Alarm System Component Layout.............................................................................. 86-5-1

Locking and Alarm System Control Diagram.................................................................................. 86-5-2

Description...................................................................................................................................... 86-5-4

Immobilisation System Component Layout .................................................................................... 86-5-11

Immobilisation System Control Diagram......................................................................................... 86-5-12

Description...................................................................................................................................... 86-5-13

Operation........................................................................................................................................ 86-5-16

WINDOWS................................................................................................. 86-6-1

Window Component Layout............................................................................................................ 86-6-1

Side Door Window Control Diagram............................................................................................... 86-6-3

Tail Door Window Control Diagram ................................................................................................ 86-6-5

Description...................................................................................................................................... 86-6-6

Operation........................................................................................................................................ 86-6-9

DRIVING AIDS .......................................................................................... 86-10-1

Park Distance Control..................................................................................................................... 86-10-1

Park Distance Control Control Diagram.......................................................................................... 86-10-2

Description...................................................................................................................................... 86-10-3

PDC System Operation .................................................................................................................. 86-10-7

NAVIGATION SYSTEM ............................................................................ 87-1

Navigation System Component Location........................................................................................ 87-1

Description...................................................................................................................................... 87-2

INSTRUMENTS......................................................................................... 88-1

Instrument Pack Component Location - Front View ....................................................................... 88-1

Instrument Pack Component Location - Front View (2004MY Only) .............................................. 88-2

Instrument Pack Component Layout - Rear View........................................................................... 88-3

Instrument Pack Components - Exploded View ............................................................................. 88-4

Description...................................................................................................................................... 88-5

4CONTENTS

Page 8

ENGINE - K SERIES KV6DESCRIPTION AND OPERATION

ENGINE - K SERIES KV6

This page is intentionally left blank

Deze pagina werd opzettelijk niet gebruikt

Cette page est intentionnellement vierge

Diese Seite ist leer

Questa pagina è stata lasciata in bianco di proposito

Esta página foi deixada intencionalmente em branco

Esta página fue dejada en blanco intencionalmente

DESCRIPTION AND OPERATION 12-3-1

Page 9

ENGINE - K SERIES KV6

KV6 Engine – General View

M12 7452

12-3-2 DESCRIPTION AND OPERATION

Page 10

KV6 Engine – Internal View

ENGINE - K SERIES KV6

M12 6813

DESCRIPTION AND OPERATION 12-3-3

Page 11

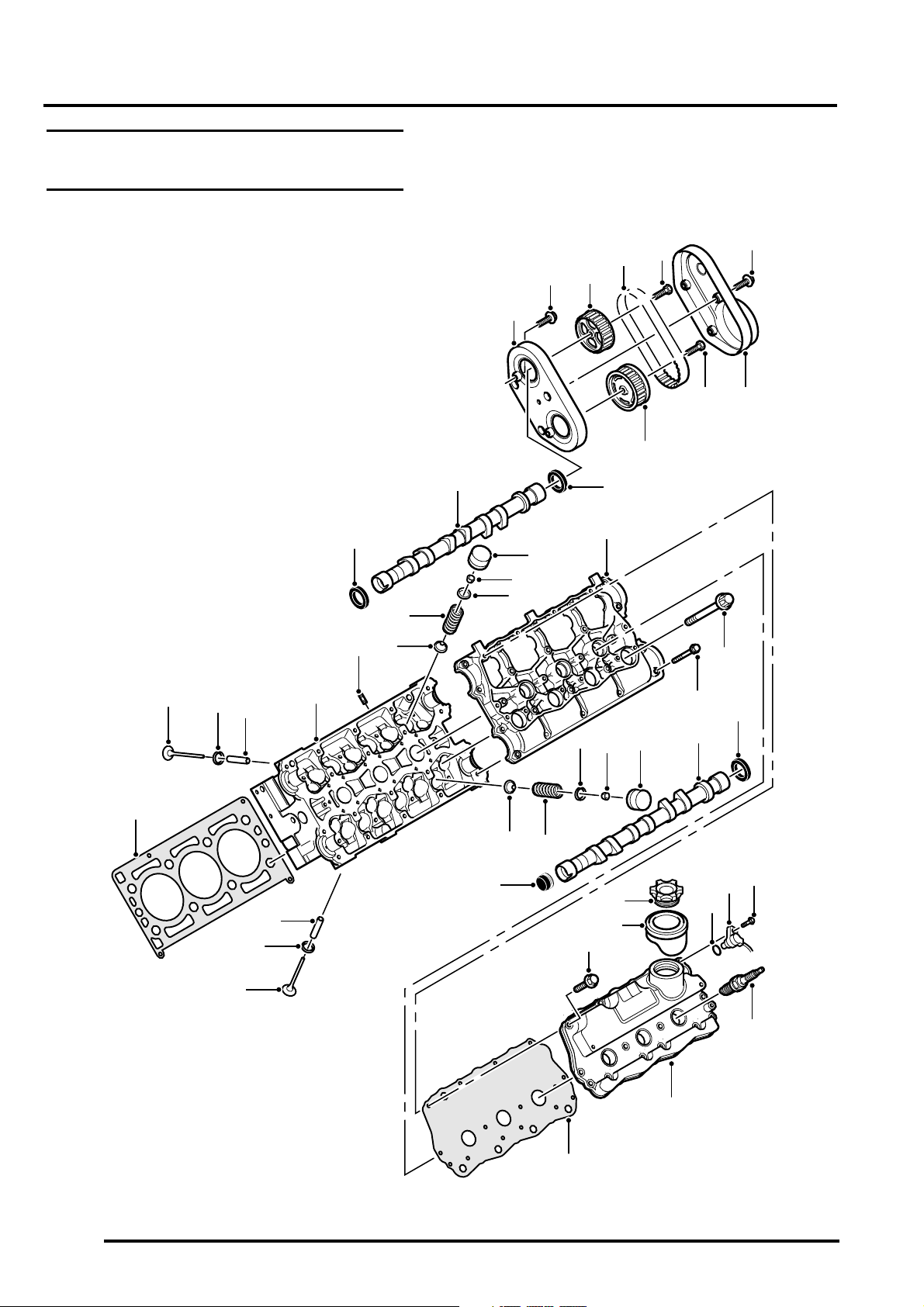

ENGINE - K SERIES KV6

KV6 Engine – Cylinder Block Components

12-3-4 DESCRIPTION AND OPERATION

Page 12

1 Clip – coolant pump to thermostat pipe

2 'O' ring – coolant pump to thermostat pipe

3 Pipe – coolant pump to thermostat

4 'O' ring – coolant pump to thermostat pipe

5 Clip – coolant pump to thermostat pipe

6 Thermostat housing

7 'O' ring – coolant outlet elbow to cylinder block

8 Bolt – coolant outlet elbow to cylinder block

9 Coolant outlet elbow

10 'O' ring – thermostat housing to cylinder block

11 Blanking plate – coolant outlet

12 Seal – blanking plate

13 Screw – blanking plate (2 off)

14 Bolt – engine lifting bracket, rear (2 off)

15 Engine lifting bracket – rear

16 Screw – crankshaft rear oil seal (5 off)

17 2nd compression ring

18 Top compression ring

19 Oil control ring

20 Piston

21 Big-end upper bearing shell

22 Big-end bearing cap

23 Bolt – big-end bearing cap to connecting rod

(2 off per piston)

24 Big-end lower bearing shell

25 Crankshaft rear oil seal

26 Cylinder liner (6 off)

27 Dowel – cylinder block to cylinder head (4 off)

28 Cylinder block

29 Dowel – cylinder block to lower crankcase

(4 off)

30 Engine coolant pump

31 Screw – coolant pump to cylinder block (7 off)

32 Seal – coolant pump to cylinder block

ENGINE - K SERIES KV6

DESCRIPTION AND OPERATION 12-3-5

Page 13

ENGINE - K SERIES KV6

KV6 Engine – Crankshaft, Sump and Oil Pump Assembly

12-3-6 DESCRIPTION AND OPERATION

Page 14

1 'O' rings – oil filter housing to oil cooler pipes

2 Oil pressure switch

3 Screw – oil pump to cylinder block (16 off)

4 Oil pump and oil filter housing assembly

5 Gasket – oil pump housing

6 Bearing ladder

7 Crankshaft

8 Dipstick

9 Dipstick tube

10 Baffle plate – lower crankcase extension

11 Lower crankcase extension

12 Screw – dipstick tube to cylinder block

13 'O' ring – oil pick-up pipe

14 Oil pick-up pipe with integral strainer

15 Screw – oil pick-up pipe to lower crankcase

16 Connector (quick fit) – dipstick tube to sump

17 Sump

18 Bolt – sump to lower crankcase

(10 off; 5 x short, 5 x long)

19 Oil cooler

20 Bolt – oil cooler to sump (3 off)

21 Oil drain plug

22 Seal – oil drain plug

23 Pipe – oil cooler to oil filter housing

24 Pipe – oil filter housing to oil cooler

25 Oil filter cartridge

26 Bolt (long) – bearing ladder to cylinder block

(8 off)

27 Bolt (short) – bearing ladder to cylinder block

(8 off)

ENGINE - K SERIES KV6

DESCRIPTION AND OPERATION 12-3-7

Page 15

ENGINE - K SERIES KV6

KV6 Engine – Cylinder Head Components

12

13

14

15

11

1

16

17

18

5

4

3

2

8

9

10

19

6

7

20

42

43

44

39

45

40

41

46

29

27

28

26

30

25

32

31

24

37

21

23

33

34

22

35

36

M12 6646

LH cylinder bank shown, RH cylinder bank similar

12-3-8 DESCRIPTION AND OPERATION

38

Page 16

1 Rear drive belt inner cover

2 Bolt – camshaft rear drive belt inner cover

(4 off)

3 Camshaft gear – rear inlet

4 Drive belt – rear camshaft

5 Bolt – inlet camshaft gear

6 Bolt – camshaft rear drive belt outer cover

(3 off)

7 Rear drive belt outer cover

8 Bolt – exhaust camshaft gear

9 Camshaft gear – rear exhaust

10 Seal – inlet camshaft, rear oil

11 Inlet camshaft

12 Seal – inlet camshaft, front oil

13 Stud – cylinder head to intake manifold (2 off)

14 Valve stem oil seal – inlet (6 off)

15 Valve spring – inlet (6 off)

16 Valve spring cap – inlet (6 off)

17 Collet – inlet valve (12 off)

18 Tappet – inlet valve (6 off)

19 Camshaft carrier

20 Bolt – cylinder head (8 off)

21 Bolt – camshaft carrier to cylinder head (22 off)

22 Seal – exhaust camshaft, rear oil

23 Exhaust camshaft

24 Tappet – exhaust valve (6 off)

25 Collet – exhaust valve (12 off)

26 Valve spring cap – exhaust (6 off)

27 Valve stem oil seal – exhaust (6 off)

28 Valve spring – exhaust (6 off)

29 Seal – exhaust camshaft, front oil

30 Bolt – camshaft cover (14 off)

31 Seal – oil filler cap

32 Oil filler cap

33 'O' ring – CMP sensor

34 CMP sensor

35 Bolt – CMP sensor

36 Spark plug (3 off)

37 Camshaft cover

38 Gasket – camshaft cover

39 Inlet valve (6 off)

40 Valve seat insert – inlet (6 off)

41 Valve guide – inlet (6 off)

42 Gasket – cylinder head

43 Exhaust valves (6 off)

44 Valve seat insert – exhaust (6 off)

45 Valve guides – exhaust (6 off)

46 Cylinder head

ENGINE - K SERIES KV6

DESCRIPTION AND OPERATION 12-3-9

Page 17

ENGINE - K SERIES KV6

KV6 Engine – Manifolds and Engine Cover Components

12-3-10 DESCRIPTION AND OPERATION

Page 18

1 Strap – engine acoustic cover

2 Bolt – engine acoustic cover strap to manifold

chamber

3 Engine acoustic cover

4 Bolt – manifold chamber to RH inlet manifold

(4 off)

5 Manifold chamber

6 Bolt – throttle body assembly to manifold

chamber (4 off)

7 Throttle body assembly

8 Inlet manifold, RH

9 Seal - manifold chamber to LH inlet manifold

(3 off)

10 Guide block – HT lead

11 Stud – HT lead guide block/acoustic cover

fixing

12 Inlet manifold, LH

13 Bolt – inlet manifold to cylinder head LH (7 off)

14 Gasket - inlet manifold to cylinder head (LH)

15 Fuel rail

16 Bolt – inlet manifold to cylinder head

17 Gasket – inlet manifold to cylinder head, RH

18 'O' ring - inlet manifold to top cover RH (3 off)

ENGINE - K SERIES KV6

DESCRIPTION AND OPERATION 12-3-11

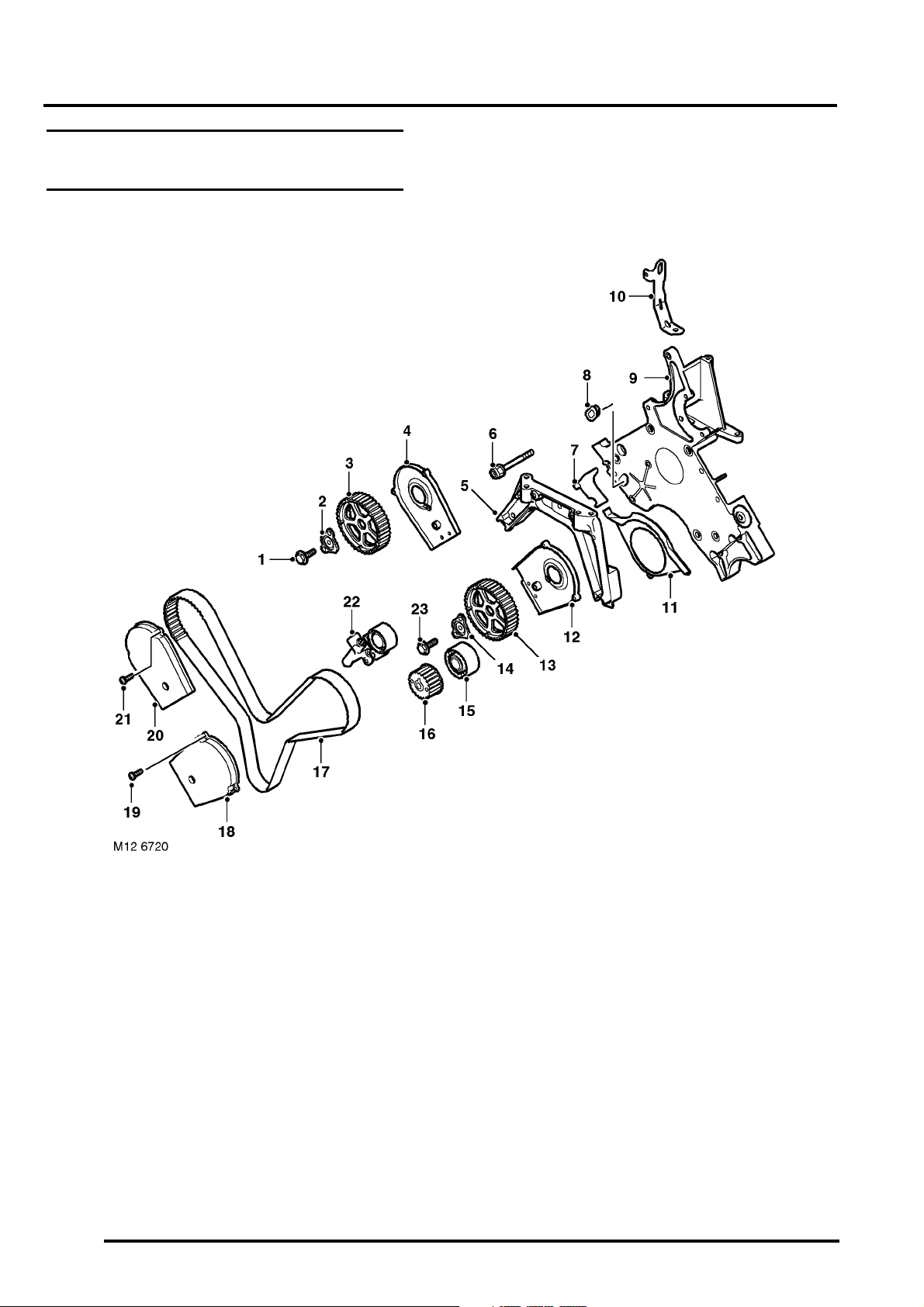

Page 19

ENGINE - K SERIES KV6

KV6 Engine – Camshaft Drive Belt Components

1 Bolt – timing gear to inlet camshaft (RH)

2 Hub – camshaft front timing gear (RH)

3 Camshaft front timing gear (RH)

4 Drive belt (front) backplate cover – RH

5 Engine mounting bracket

6 Bolt – engine mounting bracket to front plate

(4 off)

7 Cover plate – drive belt

8 Blanking plug

9 Engine front plate

10 Engine lifting bracket – front

11 Cover – lower drive belt

12 Drive belt (front) backplate cover – LH

13 Camshaft front timing gear (LH)

12-3-12 DESCRIPTION AND OPERATION

14 Hub – camshaft front timing gear (LH)

15 Idler pulley – drive belt

16 Crankshaft timing gear

17 Drive belt – front

18 Front drive belt outer cover (LH)

19 Screw – front drive belt outer cover to inner

cover, LH (3 off)

20 Front drive belt outer cover (RH)

21 Screw – front drive belt outer cover to inner

cover, RH (3 off)

22 Tensioner assembly – front drive belt

23 Bolt – timing gear to inlet camshaft (LH)

Page 20

ENGINE - K SERIES KV6

Description

General

The KV6 is of all aluminium construction, with a 90° V configuration. The KV6 uses long cylinder head bolts engaging

in threads 70 mm below the mating face of the cylinder block to attach the cylinder head to the cylinder block. This

ensures sufficient structural stiffness to take advantage of the compressive strength of aluminium alloy and minimise

tensile loadings. There are 8 cylinder head bolts for each cylinder head, located below the camshafts.

The engine features 24 valves, sequential fuel injection, liquid cooling and is transverse mounted. It is controlled by

a Siemens engine management system utilising a range of sensors to constantly monitor and optimise engine

performance.

+ ENGINE MANAGEMENT SYSTEM - SIEMENS, DESCRIPTION AND OPERATION, Description.

Cylinder Block Components

The cylinder block components are described below:

Cylinder Block and Main Bearing Ladder

The cylinder block is constructed of an aluminium alloy and is cast in three sections:

l Cylinder block.

l Main bearing ladder.

l Lower crankcase extension.

For strength and rigidity, the main bearing ladder is manufactured from special alloy A357TF as used in manufacturing

components in the aerospace industry. The main bearing ladder is secured to the cylinder block with 16 bolts, thus

creating a very rigid crankcase 'box'. A separate outer crankcase extension adds further strength to the lower end of

the cylinder block. The lower crankcase extension is sealed to the underside of the cylinder block, using jointing

compound, and secured with 10 bolts. Fitted to the lower crankcase is an aluminium alloy sump.

Pistons and Cylinder Liners

The aluminium alloy, thermal expansion, lightweight pistons, with semi-floating gudgeon pins, are offset to the thrust

side and are carried on forged steel connecting rods. Pistons and cylinder liners are supplied in two grades, 'A' and

'B' and are also colour coded to assist identification. The pistons are marked to ensure they are correctly oriented in

the cylinder liner; the 'FRONT' mark should be toward the front of the engine.

The cylinder block is fitted with 'damp' cylinder liners, the bottom stepped half of the cylinder liner being a sliding fit

into the lower part of the cylinder block. The liners are sealed in the block with a bead of sealant applied around the

stepped portion of the cylinder liner. The top of the cylinder liner is sealed by a multi-layer steel cylinder head gasket

when the cylinder head is fitted.

The cylinder liner diameters are smaller than the big-end forging of the connecting rods and need to be removed

complete with pistons and connecting rods from the cylinder block.

Connecting Rods

The KV6 engine utilises forged steel H-sectioned connecting rods, with the gudgeon pin being an interference fit in

the small end of the connecting rod. The big-ends are horizontally split.

Big-end bearing diametric clearance is controlled by selective bearing shells with three grades of thickness. The bigend upper and lower bearing shells are plain with locating tags.

DESCRIPTION AND OPERATION 12-3-13

Page 21

ENGINE - K SERIES KV6

Piston Rings

Each piston is fitted with two compression rings and an oil control ring. The top compression rings are chrome-plated

steel. The 2nd compression rings are chrome-plated cast iron. The oil control rings have stainless steel top and

bottom rails and integral expander rings.

Crankshaft, Sump and Oil Pump Components

The crankshaft and sump components are described below:

Crankshaft

The short, stiff crankshaft is supported on four main bearings, with each pair of crankpins mutually offset by 30° to

give equal firing intervals. Cast in Spheroidal Graphite (SG) iron, the crankshaft has cold rolled fillets on all journals,

except the outer mains, for toughness and failure resistance. End-float is controlled by thrust washer halves at the top

and bottom of the rear main bearing.

Main Bearings

Oil grooves are provided in the upper halves of all the main bearing shells to supply oil, via drillings in the crankshaft,

to the connecting rod big-end bearings. The lower halves of the bearing shells in the bearing ladder are plain.

Sump

The cast aluminium sump is a wet-type, sealed to the lower crankcase extension using sealant applied to the sump

flange. The sump is fixed to the lower crankcase extension using 10 bolts. A baffle plate is fitted in the lower crankcase

extension to minimise the effects of oil slosh.

An oil pick-up with integral strainer is located in the centre of the sump oil well, as a source for the supply of engine

lubrication oil to the oil pump. Oil is sucked up though the end of the pick–up and strained to prevent solid matter from

entering the oil pump.

Oil Pump

The oil pump is directly driven from the crankshaft. The oil pump housing includes the oil pressure relief valve, oil filter,

oil pressure switch and return/supply outlets for the engine oil cooler.

Oil Filter

A full-flow, disposable canister-type oil filter is attached to the oil pump housing at the front of the engine.

Oil Cooler

A liquid cooled oil cooler keeps the engine lubrication oil cool, under heavy loads and high ambient temperatures.

The oil cooler is cooled by the engine cooling system and attached to a bracket secured to the front of the sump by

three bolts. Oil is delivered to and from the oil cooler through hoses connected to the oil pump housing. Hoses from

the engine cooling system are connected to two pipes on the oil cooler for the supply and return of coolant.

Oil Pressure Switch

The oil pressure switch is located in a port at the outlet side of the oil filter. It detects when a safe operating pressure

has been reached during engine starting and initiates the illumination of a warning light in the instrument pack if the

oil pressure drops below a given value.

12-3-14 DESCRIPTION AND OPERATION

Page 22

ENGINE - K SERIES KV6

Cylinder Head Components

The cylinder head components are described below:

Cylinder Head

The cross-flow cylinder heads are based on a four valve, central spark plug combustion chamber, with the inlet ports

designed to induce swirl and control the speed of the induction charge. This serves to improve combustion and hence

fuel economy, performance and exhaust emissions.

LH and RH cylinder heads are identical castings.

Camshafts

Twin camshafts on each cylinder bank are retained by a camshaft carrier, line bored with the cylinder head. The

camshafts are located by a flange which also controls end-float. A crossover drive for the exhaust camshaft, from the

rear of the inlet camshaft is by a short toothed belt, which allows for a much shorter and simpler run for the main

camshaft drive belt at the front of the engine.

The exhaust camshaft drive gears have dampers integral with the gear to minimise torsional vibration. The inlet

camshaft for the LH cylinder head incorporates a reluctor which is used in conjunction with the Camshaft Position

(CMP) sensor to measure engine position. The CMP sensor is bolted to the LH camshaft cover.

+ ENGINE MANAGEMENT SYSTEM - SIEMENS, DESCRIPTION AND OPERATION, Description.

Cylinder Head Gasket

The KV6 utilises a multi-layer stainless steel cylinder head gasket. The gasket comprises four stainless steel

functional layers, and a stainless steel distance layer to maintain fitted thickness. A full embossment profile is

employed to seal the combustion gases and half embossments are used to provide a durable fluid seal. Sealing

characteristics are further enhanced by the application of a fluro-elastomer surface coating to all layers of the gasket.

Hydraulic Tappets

Self-adjusting, lightweight, hydraulic tappets are fitted on top of each valve and are operated directly by the camshaft.

The valve stem oil seals are moulded onto a metal base which also acts as the valve spring seat on the cylinder head.

Valves

The exhaust valves are of the carbon break type. A machined profile on the valve stem removes any build up of carbon

in the combustion chamber end of the valve guide. All valve seats are machined in three planes, improving valve to

seat sealing.

Camshaft Cover and Engine Cover Components

The camshaft cover and engine cover components are described below:

Acoustic Cover

A moulded plastic acoustic cover is fitted over the engine to absorb engine generated noise. Foam is bonded on the

inside surface of the acoustic cover and a rubber seal is fitted around the oil filler cap.

The acoustic cover is located on the engine by two rubber studs on the underside of the acoustic cover. A rubber

strap, at the rear of the engine, and two quick release fasteners, at the front of the acoustic cover, secure the acoustic

cover in position.

Resonators and part of the engine intake duct are integrated into the acoustic cover, and the engine air filter is

installed in a compartment below a lid secured with two Torx bolts.

A metal foil heatshield is installed on the underside of the acoustic cover.

A rubber duct connects the engine intake duct in the acoustic cover to the RH inner wing. A further duct is installed

between the inner and outer wings to draw engine air from the base of the A post.

DESCRIPTION AND OPERATION 12-3-15

Page 23

ENGINE - K SERIES KV6

Throttle Body Assembly

The throttle body is an electrically actuated unit controlled by the Engine Control Module (ECM). The position of the

throttle plate is controlled by a DC motor and a return spring integrated into the throttle body. Two feedback

potentiometers supply throttle plate position signals to the ECM for closed loop control.

Four Torx bolts secure the throttle body to the inlet manifold chamber. A rubber seal, keyed into a groove in the inlet

manifold chamber, ensures the joint is air tight.

Inlet Manifold Chamber

The inlet manifold chamber is a sealed plastic assembly. The inlet manifold chamber combines plenum resonance for

good low speed torque, with variable length primary tracts for optimum mid and high speed torque.

The throttle body assembly feeds into a 'Y' piece which separates into two secondary inlet pipes. The secondary pipes

feed into two main plenums, one for each bank of three cylinders. At the closed end of the plenums is a balance valve,

controlled by an electric actuator, that connects the two plenums together.

The variable intake system uses valves and actuators to vary the overall tract length of the inlet manifold chamber.

The aluminium alloy inlet manifolds are sealed to each cylinder head with gaskets and to the inlet manifold chamber

with 'O' rings and seals.

+ MANIFOLD AND EXHAUST SYSTEM - K SERIES KV6, DESCRIPTION AND OPERATION, Description.

12-3-16 DESCRIPTION AND OPERATION

Page 24

ENGINE - K SERIES KV6

Operation

Lubrication Circuit

The lubrication system is of the full-flow filtration, force fed type.

Oil is drawn, via a strainer and pick-up pipe in the sump, through the bearing ladder and into a crankshaft driven oil

pump which has an integral pressure relief valve. The strainer in the pick-up pipe prevents any ingress of foreign

particles from passing through to the inlet side of the oil pump and damaging the oil pump and restricting oil drillings.

The oil pressure relief valve in the oil pump opens if the oil pressure becomes excessive and diverts oil back around

the pump.

Pressurised oil is pumped through a full-flow cartridge type oil filter, mounted on the oil pump housing. The lubrication

system is designed so that a higher proportion of oil flow is directed to the cylinder block main oil gallery while a lower

proportion of oil flow, (controlled by a restrictor in the oil filter housing), is directed to the engine oil cooler. The

remainder of the oil flow from the outlet side of the oil filter is combined with the return flow from the oil cooler before

being passed into the cylinder block main oil gallery.

The main oil gallery has drillings that direct the oil to the main bearings. Cross drillings in the crankshaft main bearings

carry the oil to the connecting rod big-end bearings.

The oil pressure switch is located at the outlet side of the oil filter housing to sense the oil pressure level before the

oil flow enters the main gallery in the engine block. A warning lamp in the instrument pack is illuminated if low oil

pressure is detected.

Oil at reduced pressure is directed to each cylinder bank via two restrictors in the cylinder block/cylinder head locating

dowels, one at the front on the LH bank and the other at the rear on the RH bank. Oil then passes through a drilling

in the cylinder head to the camshaft carrier, where it is directed via separate galleries to the camshaft bearings and

hydraulic tappet housings. Return oil from the cylinder head drains into the sump via the cylinder head bolt passages.

Crankcase Ventilation

A positive crankcase ventilation system is used to vent blow-by gas from the crankcase to the air intake system. The

blow-by gas passes through a gauze oil separator in the camshaft cover, and then through hoses into the throttle

housing and inlet manifold.

+ EMISSION CONTROL - K SERIES KV6, DESCRIPTION AND OPERATION, Description.

DESCRIPTION AND OPERATION 12-3-17

Page 25

ENGINE - K SERIES KV6

Crankshaft Oil Supply

1 Cylinder block main oil gallery

2 Cross drillings to crankshaft main bearings

3 Oil pick-up pipe with integral strainer

4 Oil cooler

5 Oil cooler supply pipe

12-3-18 DESCRIPTION AND OPERATION

6 Oil filter cartridge

7 Oil cooler return pipe

8 Oil pressure switch

9 Oil pump with integral oil pressure relief valve

Page 26

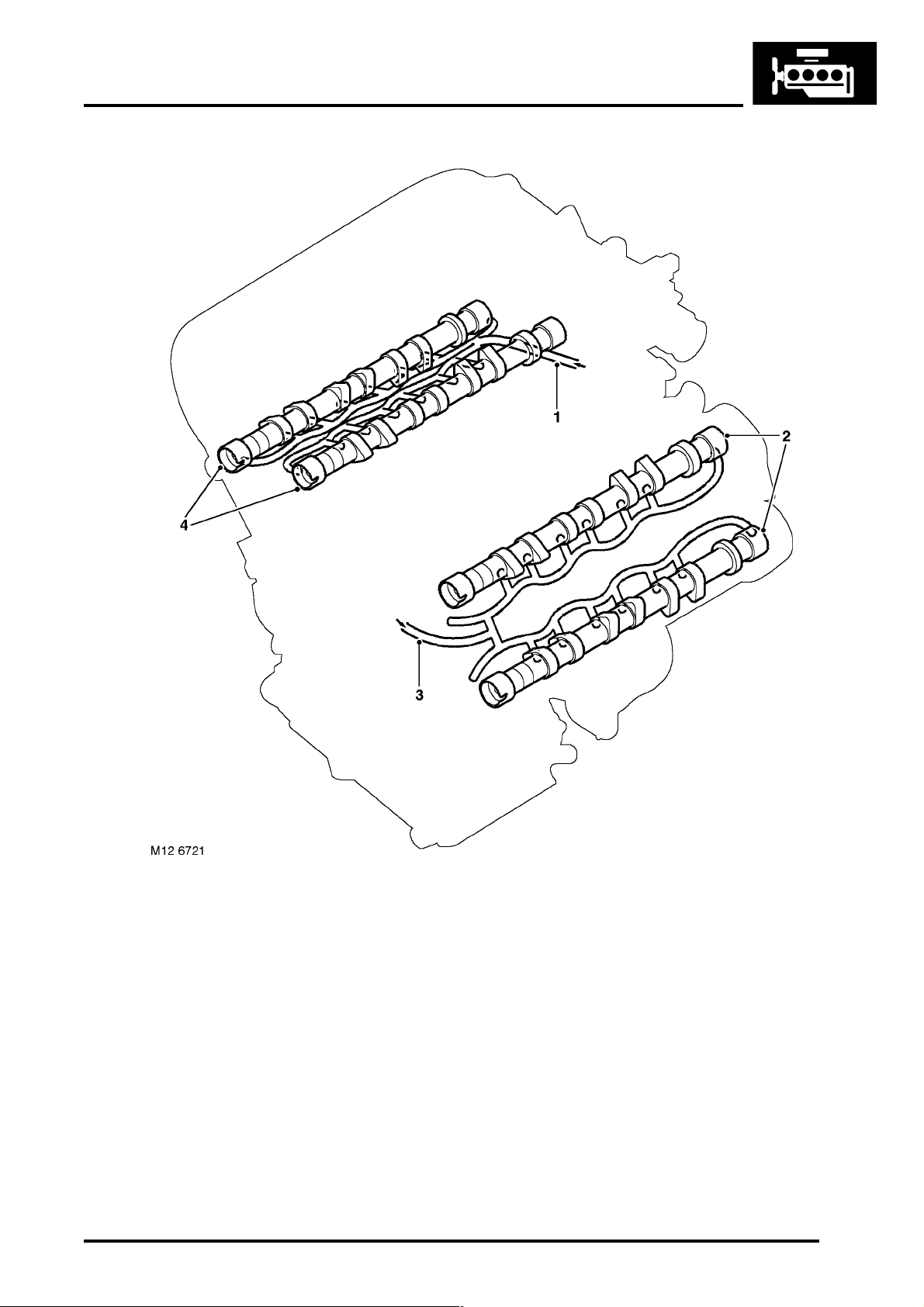

ENGINE - K SERIES KV6

Cylinder Head Component Oil Supply

1 From RH cylinder block main gallery

2 LH cylinder head camshafts

3 From LH cylinder block main gallery

4 RH cylinder head camshafts

DESCRIPTION AND OPERATION 12-3-19

Page 27

ENGINE - K SERIES KV6

12-3-20 DESCRIPTION AND OPERATION

Page 28

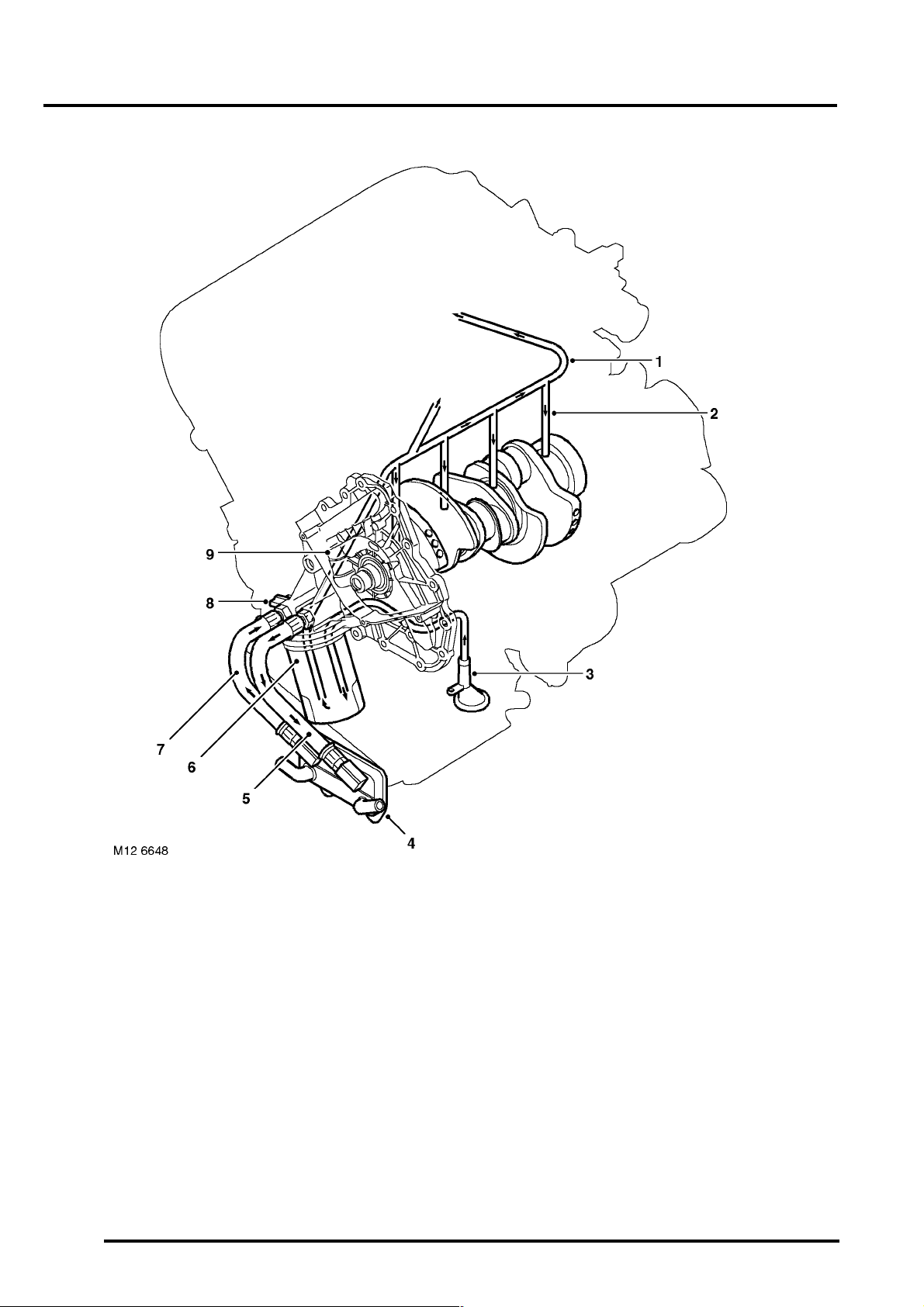

EMISSION CONTROL - K SERIES KV6

EMISSION CONTROL - K SERIES KV6DESCRIPTION AND OPERATION

Emission Control Component Layout – Crankcase and Exhaust

1 Crankcase breather hose to intake duct

2 Crankcase breather hose to inlet manifold

3 Catalytic converters

DESCRIPTION AND OPERATION 17-3-1

Page 29

EMISSION CONTROL - K SERIES KV6

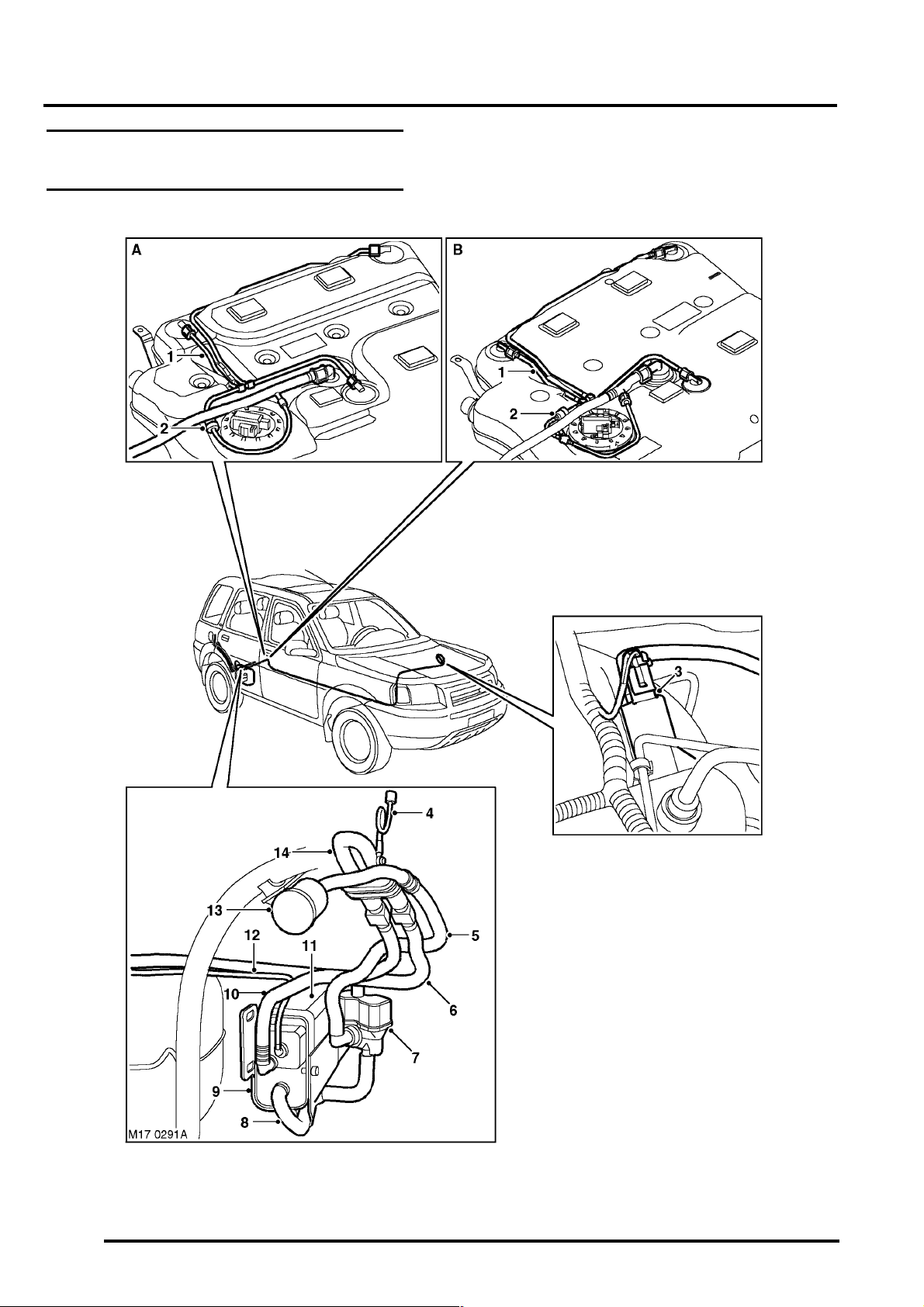

Emission Control Component Layout – EVAP

A = Vehicles up to 2002.5 Model Year

B = Vehicles from 2002.5 Model Year

17-3-2 DESCRIPTION AND OPERATION

Page 30

EMISSION CONTROL - K SERIES KV6

1 Fuel tank vent pipes

2 Two-way valve

3 Purge valve

4 Recirculation pipe

5 DMTL to air filter vent pipe

6 Fuel tank to vapour separator vent pipe

7 DMTL

8 Canister to DMTL vent pipe

9 Canister support bracket

10 Vapour separator to canister vent pipe

11 EVAP canister

12 Canister to purge valve vent pipe

13 Air filter

14 Vapour separator

DESCRIPTION AND OPERATION 17-3-3

Page 31

EMISSION CONTROL - K SERIES KV6

Description

General

The vehicle is fitted with the following control systems to reduce emissions released into the atmosphere:

l Crankcase emission control.

l Exhaust emission control.

l Evaporative emissions (EVAP) control.

CAUTION: In many countries it is against the law for a vehicle owner or an unauthorised dealer to modify or

tamper with emission control equipment. In some cases, the vehicle owner and/or the dealer may even be

liable for prosecution.

The emission control systems fitted to the vehicle are designed to keep the emissions within the legal limits, at the

time of manufacture, provided that the engine and the fuel system components are correctly maintained and in good

mechanical condition.

Crankcase Emission Control System

The crankcase is vented via the oil drain passages in the cylinder blocks and cylinder heads and two ports in each

camshaft cover. Plastic pipes connect the larger ports in the camshaft covers to the intake duct, on the upstream side

of the throttle disc. The smaller ports in the camshaft covers are connected to the inlet manifold, downstream of the

throttle body, also by plastic pipes. Each of the smaller ports incorporate a restrictor and a gauze oil separator to

prevent oil being drawn out of the camshaft covers with the blow-by gases. Quick release locking collars and 'O' rings

are used for all of the pipe connections with the camshaft covers, throttle body and air intake duct.

When the engine is running with the throttle disc closed, the depression downstream of the throttle disc draws

crankcase gases into the inlet manifold through the smaller ports in the camshaft covers. Clean air, from the upstream

side of the throttle disc, is drawn into the crankcase through the larger ports in the camshaft covers to limit the

depression produced in the crankcase.

When the engine is running with the throttle disc wide open, the upstream and downstream sides of the throttle disc,

and thus the two ports in each camshaft cover, are subjected to similar, relatively weak, depression levels. Crankcase

gases are then drawn out of both ports in each camshaft cover, with the majority being drawn out of the unrestricted

larger ports and into the throttle body.

At interim throttle disc positions the flow of the crankcase gases varies, between those produced at the closed and

wide open throttle disc positions, depending on the depression levels produced upstream and downstream of the

throttle disc.

Exhaust Emission Control

The engine management systems provide accurately metered quantities of fuel to the combustion chambers to

ensure the most efficient use of fuel and to minimise the exhaust emissions. In some markets, to reduce the carbon

monoxide and hydrocarbons content of the exhaust gases, catalytic converters are installed in the exhaust system.

A catalytic converter is integrated into each downpipe close to the exhaust manifolds.

17-3-4 DESCRIPTION AND OPERATION

Page 32

EMISSION CONTROL - K SERIES KV6

In the catalytic converters the exhaust gases are passed through honeycombed ceramic elements coated with a

special surface treatment called 'washcoat'. The washcoat increases the surface area of the ceramic elements by a

factor of approximately 7000. On top of the washcoat is a coating containing the elements which are the active

constituents for converting harmful emissions into inert by-products. The active constituents consist of platinum and

rhodium. Platinum adds oxygen to the carbon monoxide and the hydrocarbons in the exhaust gases, to convert them

into carbon dioxide and water respectively. The rhodium removes oxygen from the Nitrous Oxides (NOx) to convert

them into nitrogen.

The correct operation of the catalytic converters is dependent upon close control of the oxygen content of the exhaust

gas. The quantity of oxygen in the exhaust gas is monitored by the Engine Control Module (ECM) using an input from

the Heated Oxygen Sensor (HO2S) upstream of the catalytic converters. The ECM also monitors the condition of the

catalytic converters using an input from the HO2S downstream of the catalytic converters.

EVAP Control

The EVAP control system reduces the level of hydrocarbons released into the atmosphere by fuel vapour venting from

the fuel tank. A positive pressure leak detection function is incorporated to monitor the integrity of the system. The

EVAP control system comprises:

l A two way valve.

l A vapour separator.

l An EVAP canister.

l A purge valve.

l A Diagnostic Module for Tank Leakage (DMTL).

l An air filter.

l Interconnecting vent pipes.

The EVAP control system is connected to the Onboard Refuelling Vapour Recovery (ORVR) valve and/or the roll over

valves in the fuel tank. The ORVR valve and the roll over valves are float valves that allow inward and outward venting

of the fuel tank, but prevent the escape of fuel into the vent pipes due to fuel slosh or if the vehicle overturns. The

ORVR valve is normally closed when the fuel tank is full and normally open at all other fuel levels. The roll over valves

are normally open at all fuel levels.

When the fuel tank is less than full, venting is unrestricted through the ORVR valve. Only when the fuel tank is full

does venting occur, with changes of tank pressure, through the roll over valves and the two-way valve.

Vapour vented from the fuel tank passes through the EVAP control system to atmosphere. The EVAP canister

absorbs fuel from the vapour and relatively fuel free air vents to atmosphere. Since there is a limit to the storage

capacity of the EVAP canister, when the engine is running fuel is purged from the EVAP canister and burned in the

engine.

To reduce the load on the EVAP canister during refuelling, a proportion of the air expelled from the tank is recirculated

through a pipe connected between the top of the vapour separator and the filler tube. The recirculation flow is induced

by fuel in the filler tube flowing past a restrictor installed in the recirculation pipe connection on the filler tube. With the

recirculation flow present, less fresh air enters the tank, which reduces the volume of vapour generated and fuel

deposited in the EVAP canister.

The DMTL periodically checks the EVAP control system and fuel tank for leaks when the ignition is switched off.

On vehicles from 2002.5 model year – Modifications are introduced to increase the capacity of the fuel tank. The

modification comprises a change to the vent line from the forward Roll Over Valve (ROV). The vent from the ROV now

connects to the vent line between the two-way valve and the vapour separator. Venting from the forward ROV is no

longer restricted by the two-way valve. The ROV now controls the refuelling nozzle shut-off. When the ROV closes,

pressure in the tank increases, shutting off the refuelling nozzle. This modification allows up to 5 litres additional fuel

to be added to the fuel tank.

The fuel tank on vehicles from 2002.5 model year also incorporates a new fabric sleeve over the filler pipe inlet in the

fuel tank. The sleeve reduces the amount of vapour produced during refuelling and the subsequent load on the EVAP

canister.

DESCRIPTION AND OPERATION 17-3-5

Page 33

EMISSION CONTROL - K SERIES KV6

EVAP System Schematic – Vehicles up to 2002.5 Model Year

3

M17 0292

14

15

1

1

17

16

18

131313

12

11

2

10

9

4

6

5

M

8

7

1 Vapour separator

2 EVAP canister

3 DMTL

4 Change-over valve

5 0.5 mm (0.020 in) reference orifice

6 Air pump and motor

7 Air filter

8 ECM

9 Throttle body

10 Purge valve

11 Flap valve

12 Fuel tank

13 Roll over valve

14 ORVR valve

15 Two-way valve

16 Restrictor

17 Fuel filler cap

18 Filler tube

17-3-6 DESCRIPTION AND OPERATION

Page 34

EMISSION CONTROL - K SERIES KV6

EVAP System Schematic – Vehicles from 2002.5 Model Year

3

M17 0362

14

15

1

1

19

2

4

7

6

5

M

17

16

18

10

131313

12

11

9

8

1 Vapour separator

2 EVAP canister

3 DMTL

4 Change-over valve

5 0.5 mm (0.020 in) reference orifice

6 Air pump and motor

7 Air filter

8 ECM

9 Throttle body

11 Flap valve

12 Fuel tank

13 Roll over valve

14 ORVR valve

15 Two-way valve

16 Restrictor

17 Fuel filler cap

18 Filler tube

19 Fabric sleeve

10 Purge valve

Two-way Valve

The two-way valve limits the pressure and depression in the fuel tank and, during refuelling, induces automatic cutoff in the refuelling nozzle when the fuel in the tank reaches the full level. The two-way valve is installed in the vent

pipe from the tank, next to the fuel pump assembly.

The two-way valve is a normally closed valve that opens, to release pressure from the fuel tank, at 18 to 50 mbar (0.26

and 0.73 lbf/in

2

). Air is allowed to flow back into the fuel tank, as the pressure in the tank decreases, through a non

return valve within the body of the two-way valve. The nominal opening pressure of the non return valve is 1 mbar

(0.015 lbf/in

2

).

During refuelling, if the fuel in the tank reaches the full level outward venting becomes restricted, which creates a back

pressure in the filler tube and automatically closes the refuelling nozzle. The restriction is caused by the fuel closing

the ORVR valve.

DESCRIPTION AND OPERATION 17-3-7

Page 35

EMISSION CONTROL - K SERIES KV6

Vapour Separator

The vapour separator is installed at the front of the RH rear wheel arch, behind the wheel arch liner. The vapour

separator prevents the charcoal in the EVAP canister being saturated with fuel, by separating any liquid from the

vapour vented from the fuel tank. Separated fuel from the vapour separator drains back to the fuel tank through the

vent pipe.

EVAP Canister

The EVAP canister is installed at the front of the RH rear wheel arch, behind the wheel arch liner. Charcoal in the

EVAP canister absorbs and stores fuel from the vapour vented from the fuel tank. When the engine is running, fuel is

purged from the EVAP canister when the purge valve opens and clean air is drawn through the charcoal.

EVAP Canister

1 Canister housing

2 Purge valve connection

Purge Valve

The purge valve is installed on the inlet manifold chamber, next to the throttle body, and connected to the EVAP

canister by a vent pipe installed on the underside of the vehicle, next to the fuel delivery pipe.

The purge valve is controlled by the Engine Control Module (ECM) and remains closed below a preset coolant

temperature and engine speed, to protect engine tune and catalytic converter performance. When engine operating

conditions are suitable, the ECM opens the purge valve and the depression in the inlet manifold draws fuel vapour

from the EVAP canister.

DMTL

The DMTL is connected to the atmospheric vent of the charcoal canister and incorporates an electric air pump, a

normally open change-over valve and a 0.5 mm (0.020 in) reference orifice. The DMTL operates only after the ignition

is switched off and is controlled by the ECM, which also monitors the air pump and the change-over valve for faults.

Air Filter

The air filter prevents dust being drawn into the EVAP system. A breather tube connects the DMTL to the air filter,

which is located above the RH rear wheelarch liner, immediately below the fuel filler cap.

3 Vapour separator connection

4 DMTL connection

17-3-8 DESCRIPTION AND OPERATION

Page 36

EMISSION CONTROL - K SERIES KV6

Leak Diagnostic Operation

To check the fuel tank and EVAP system for leaks, the ECM operates the air pump in the DMTL and monitors the

current draw. Initially, the ECM establishes a reference current by pumping air through the reference orifice and back

to atmosphere. Having established a reference current, the ECM then closes the change-over valve, which seals the

EVAP system (the purge valve already being closed), and diverts the output from the air pump around the reference

orifice and into the EVAP system.

When the change-over valve is first closed, the load on the pump drops to zero, then, provided there are no leaks, the

pump begins to pressurise the EVAP system and the load and current draw of the pump begin to increase. By

monitoring the rate and level of current increase, the ECM can determine if there is a leak in the system.

During the leak check, the ECM energises a heating element in the air pump to prevent condensation forming and

producing an incorrect current reading.

Leaks are classified as minor (equivalent to hole diameter of 0.5 to 1.0 mm (0.02 to 0.04 in) or major (equivalent to

hole diameter of 1.0 mm (0.04 in) or greater).

The ECM conducts a check for major leaks each time the ignition is switched off, provided the following baseline

conditions are met:

l The ECM is in power down mode more than 3 seconds after the ignition is switched off.

l The vehicle speed is zero.

l The engine speed is zero.

l The pressure altitude (derived from engine load calculations) is below 1830 m (6000 ft).

l The engine coolant temperature is more than 2.25 °C (36 °F).

l The ambient temperature is between 0 and 40 °C (32 and 104 °F).

l The EVAP canister load factor is 3 or less (the load factor is a measure, between –1 and +30, of the amount of

fuel vapour stored in the EVAP canister, where –1 is 0% fuel vapour, 0 is stoichiometric fuel vapour level and

+30 is 100% saturated with fuel vapour).

l The fuel tank level is valid and between 15 and 85 % of the nominal capacity.

l The engine running time during the previous ignition on cycle was more than 20 minutes.

l Battery voltage is between 10.94 and 14.52 volts.

l The last engine off time was more than 150 minutes.

l No errors with the following functions or components:

l Road speed.

l EVAP system load monitoring.

l Engine coolant temperature.

l Ambient air temperature.

l Fuel level.

l Purge valve.

l DMTL.

DESCRIPTION AND OPERATION 17-3-9

Page 37

EMISSION CONTROL - K SERIES KV6

A check for minor leaks is only conducted after every 14th major leak check or after refuelling is detected.

At the end of the leak check the ECM stops the air pump and opens the change-over valve.

If the fuel filler cap is opened or refuelling is detected during the leak check, by a sudden drop in the current draw or

rise in fuel level, the leak check is aborted.

If a leak is detected during the check, the ECM stores an appropriate fault code in memory. If a leak is detected on

two consecutive checks, the ECM illuminates the MIL on the next drive cycle.

The duration of the leak check is between 40 and 270 seconds, depending on results and the level of fuel in the tank.

A leak test can be invoked using TestBook/T4, which overrides the baseline conditions requirement.

Leak Check Sequence

A = Pump motor current; B = Time

X = Current draw for tight system; Y = Current draw for minor leak; Z = Current draw for major leak

1 Pump motor energised: Air directed through reference orifice to atmosphere, to establish reference current.

2 Reference current.

3 Change-over valve energised: Air directed through EVAP canister into fuel tank.

4 Major leak check completed: If current is above stored value, no major leak present; if current is below stored

value, major leak present.

5 Minor leak check completed, with no minor leak detected, when current exceeds reference value.

6 Minor leak check completed, with minor leak detected, when current stabilises at or below reference current.

17-3-10 DESCRIPTION AND OPERATION

Page 38

ENGINE MANAGEMENT SYSTEM - SIEMENSDESCRIPTION AND OPERATION

ENGINE MANAGEMENT SYSTEM - SIEMENS

This page is intentionally left blank

Deze pagina werd opzettelijk niet gebruikt

Cette page est intentionnellement vierge

Diese Seite ist leer

Questa pagina è stata lasciata in bianco di proposito

Esta página foi deixada intencionalmente em branco

Esta página fue dejada en blanco intencionalmente

DESCRIPTION AND OPERATION 18-4-1

Page 39

ENGINE MANAGEMENT SYSTEM - SIEMENS

Engine Management System Component Location

18-4-2 DESCRIPTION AND OPERATION

Page 40

ENGINE MANAGEMENT SYSTEM - SIEMENS

1 APP sensor (Up to 2003 model year shown)

2 A/C compressor clutch relay

3 Main relay

4 ECM relay

5 Fuel pump relay

6 ECM

7 Electric throttle

8 IAT sensor

9 MAF sensor

10 CMP sensor

11 Thermostat monitoring sensor

12 CKP sensor

13 ECT sensor

14 LH bank ignition coil (x 3) (Up to 2003 model

year shown)

15 Fuel injector (x 6)

16 Knock sensors

17 RH bank ignition coil (x 3) (Up to 2003 model

year shown)

18 MIL

19 Engine malfunction lamp

20 Front HO2S (x 2)

21 Rear HO2S (x 2)

DESCRIPTION AND OPERATION 18-4-3

Page 41

ENGINE MANAGEMENT SYSTEM - SIEMENS

Engine Management System Control Diagram – Sheet 1 of 2

18-4-4 DESCRIPTION AND OPERATION

A = Hardwired connection

Page 42

ENGINE MANAGEMENT SYSTEM - SIEMENS

1 Ignition switch

2 Fuse 35, passenger compartment fusebox

3 ECM relay

4 Fuel injector (x 6)

5 Main relay

6 Fuse 4, engine compartment fusebox

7 A/C compressor relay

8 Cooling fan ECU

9 ECT sensor

10 Cruise control interface ECU

11 Fuse 3, engine compartment fusebox

12 LH front HO2S

13 RH front HO2S

14 LH rear HO2S

15 RH rear HO2S

16 CMP sensor

17 MAF sensor

18 Electric throttle

19 Knock sensors

20 APP sensor (Up to 2003 model year shown)

21 IAT sensor

22 Fuse 5, engine compartment fusebox

23 Thermostat monitoring sensor

24 Brake pedal sensor

25 Fuse 6, passenger compartment fusebox

26 Alternator

27 ECM

DESCRIPTION AND OPERATION 18-4-5

Page 43

ENGINE MANAGEMENT SYSTEM - SIEMENS

Engine Management System Control Diagram – Sheet 2 of 2

16

X

3

1

2

4

Y

18

4

3

2

x1000 RPM km/h

1

0

TC

5

6

7

8

120

100

140

80

160

60

180

40

200

2020

220

0

5

17

19

7

6

15

14

13

A

M19 3378

A = Hardwired connection; D = CAN bus; J = Diagnostic ISO 9141 K line

18-4-6 DESCRIPTION AND OPERATION

12

8

11

D

10

J

9

Page 44

ENGINE MANAGEMENT SYSTEM - SIEMENS

1 Fuse 10, engine compartment fusebox

2 Inertia fuel cut-off switch

3 Fuel pump relay

4 Fuel tank unit

5 Fuse 2, engine compartment fusebox

6 Ignition coil (x 6) (Up to 2003 model year

shown)

7 Fuse 1, engine compartment fusebox

8 DMTL

9 VIS balance valve motor

10 VIS power valves motor

11 EVAP canister purge valve

12 CKP sensor

13 Vacuum enhancer solenoid valve – Up to 2003

model year

14 Diagnostic socket

15 EAT ECU

16 ABS modulator

17 Immobilisation ECU

18 Instrument pack

19 ECM

DESCRIPTION AND OPERATION 18-4-7

Page 45

ENGINE MANAGEMENT SYSTEM - SIEMENS

Description

General

The KV6 engine is fitted with a Siemens MS43 Engine Management System (EMS), which is an adaptive system that

maintains engine performance at the optimum level throughout the life of the engine.

The EMS consists of an Engine Control Module (ECM) that uses inputs from engine sensors and from other vehicle

systems to continuously monitor driver demand and the current status of the engine. From the inputs the ECM

calculates the Air Fuel Ratio (AFR) and ignition timing required to match engine operation with driver demand, then

outputs the necessary control signals to the electric throttle, fuel injectors and ignition coils. The ECM also outputs

control signals to operate the:

l Air Conditioning (A/C) compressor.

+ AIR CONDITIONING, DESCRIPTION AND OPERATION, Description.

l Engine cooling fans.

+ COOLING SYSTEM - K SERIES KV6, DESCRIPTION AND OPERATION, Description.

l Evaporative emissions (EVAP) purge valve and Diagnostic Module for Tank Leakage (DMTL).

+ EMISSION CONTROL - K SERIES KV6, DESCRIPTION AND OPERATION, Description.

l Fuel pump.

+ FUEL DELIVERY SYSTEM - K SERIES KV6, DESCRIPTION AND OPERATION, Description.

l Variable Intake System (VIS).

+ MANIFOLD AND EXHAUST SYSTEM - K SERIES KV6, DESCRIPTION AND OPERATION,

Description.

The ECM also interfaces with the:

l Immobilisation ECU, for re-mobilisation of the engine fuel supply.

+ SECURITY, DESCRIPTION AND OPERATION, Description.

l Cruise control interface ECU, to operate cruise control.

+ ENGINE MANAGEMENT SYSTEM - SIEMENS, DESCRIPTION AND OPERATION, Cruise Control

Description.

l Electronic Automatic Transmission (EAT) ECU, to assist with control of the gearbox.

+ AUTOMATIC GEARBOX - JATCO, DESCRIPTION AND OPERATION, Description.

Sensor inputs and engine performance are monitored by the ECM, which illuminates the SERVICE ENGINE SOON

(MIL) and/or the SERVICE ENGINE warning lamps in the instrument pack if a fault is detected.

As part of the security system's immobilisation function, a vehicle specific security code is programmed into the ECM

and the immobilisation ECU during production. The ECM cannot function unless it is connected to an immobilisation

ECU with the same code. In service, replacement ECM's are supplied uncoded and must be configured, using

TestBook/T4, to learn the vehicle security code from the immobilisation ECU.

A 'flash' Electronic Erasable Programmable Read Only Memory (EEPROM) allows the ECM to be externally

configured, using TestBook/T4, with market specific or new tune information up to 14 times. The current engine tune

data can be accessed and read using TestBook/T4.

The ECM memorises the position of the crankshaft and the camshaft when the engine stops. During cranking on the

subsequent start the ECM confirms their positions from sensor inputs before initiating fuel injection and ignition.

To achieve optimum performance the ECM is able to 'learn' the individual characteristics of an engine and adjust the

fuelling calculations to suit. This capability is known as adaptive fuelling. Adaptive fuelling also allows the ECM to

compensate for wear in engine components and to compensate for the tolerance variations of the engine sensors.

If the ECM suffers an internal failure, such as a breakdown of the processor or driver circuits, there is no back up

system or limp home capability. If a sensor circuit fails to supply an input, where possible the ECM adopts a substitute

or default value, which enables the engine to function, although with reduced performance in some cases.

18-4-8 DESCRIPTION AND OPERATION

Page 46

ECM

ENGINE MANAGEMENT SYSTEM - SIEMENS

The ECM is located in the engine compartment, in the E-box. Five connectors provide the interface between the ECM

and the vehicle wiring.

The E-box is a lidded container that provides a protected environment for the ECM and the EAT ECU. An open hub,

centrifugal fan powered by an electric motor ventilates the E-box with air from the passenger compartment. Exhaust

air from the E-box is directed back into the passenger compartment. The ventilating and exhaust air is routed between

the passenger compartment and the E-box through plastic ducting and corrugated rubber hoses. Operation of the

cooling fan is controlled by a thermostatic switch in the E-box. The thermostatic switch receives a power feed while

the ignition switch is in position II. If the temperature in the E-box reaches 35 °C (95 °F) the thermostatic switch closes

and connects the power feed to the fan, which runs to cool the E-box with air from the passenger compartment. When

the temperature in the E-box decreases to 27 °C (81 °F), the thermostatic switch opens and stops the fan. To prevent

the fan seizing up in colder climates, where it may not operate for long periods of time, the fan also receives a power

feed direct from the starter circuit so that it runs each time the engine is cranked.

ECM Harness Connectors

DESCRIPTION AND OPERATION 18-4-9

Page 47

ENGINE MANAGEMENT SYSTEM - SIEMENS

Connector C0331 Pin Details

Pin No. Description Input/Output

1 to 3 Not used –

4 Engine cooling fan control Output

5 and 6 Not used –

7 APP sensor earth 2 –

8 APP sensor signal 2 Input

9 APP sensor supply 2 Output

10 Fuel pump relay coil Output

11 Not used –

12 APP sensor earth 1 –

13 APP sensor signal 1 Input

14 APP sensor supply 1 Output

15 to 19 Not used –

20 DMTL pump motor Output

21 Alternator load sensing Input

22 Vehicle speed Input

23 VIS balance valve position feedback Input

24 Brake pedal sensor, Brake Lamp Switch (BLS) signal Input

25 Not used –

26 Ignition sense Input

27 Cruise control MFL signal Input

28 Brake pedal sensor, Brake Test Switch (BTS) signal Input

29 A/C compressor clutch relay coil Output

30 DMTL change-over valve Output

31 Not used –

32 Diagnostic ISO 9141 K line Input/Output

33 Immobilisation ECU Input

34 VIS power (butterfly) valves position feedback Input

35 Not used –

36 CAN bus high Input/Output

37 CAN bus low Input/Output

38 Thermostat monitoring sensor earth –

39 Thermostat monitoring sensor signal Input

40 Not used –

Connector C0332 Pin Details

Pin No. Description Input/Output

1 Ignition coil 5 Output

2 Ignition coil 3 Output

3 Ignition coil 1 Output

4 Not used –

5 Ignition earth –

6 Not used –

7 Ignition coil 4 Output

8 Ignition coil 6 Output

9 Ignition coil 2 Output

18-4-10 DESCRIPTION AND OPERATION

Page 48

ENGINE MANAGEMENT SYSTEM - SIEMENS

Connector C0603 Pin Details

Pin No. Description Input/Output

1 Ignition sense Input

2 and 3 Not used –

4 Electronic earth –

5 Fuel injector earth –

6 Power stage earth –

7 Battery power supply Input

8 Ignition power supply Input

9 Ignition power supply Input

Connector C0604 Pin Details

Pin No. Description Input/Output

1 LH bank front HO2S heater drive Output

2 to 6 Not used –

7 LH bank rear HO2S heater drive Output

8 to 12 Not used –

13 RH bank front HO2S heater drive Output

14 LH bank front HO2S signal Input

15 RH bank front HO2S signal Input

16 LH bank rear HO2S signal Input

17 Not used –

18 RH bank rear HO2S signal Input

19 RH bank rear HO2S heater drive Output

20 LH bank front HO2S earth –

21 RH bank front HO2S earth –

22 LH bank rear HO2S earth –

23 Main relay coil Output

24 RH bank rear HO2S earth –

Connector C0606 Pin Details

Pin No. Description Input/Output

1 MAF sensor signal Input

2 Not used –

3 Vacuum enhancer solenoid valve – Up to 2003 model year Output

4 Not used –

5 CMP sensor signal Input

6 Not used –

7 Throttle feedback potentiometer supply Output

8 CKP sensor signal Input

9 Not used –

10 Throttle feedback potentiometer 2 signal Input

11 VIS balance valve motor drive Output

12 to 16 Not used –

17 MAF sensor earth –

18 CMP sensor earth –

19 Throttle feedback potentiometer 1 signal Input

20 Throttle feedback potentiometer earth –

21 CKP sensor earth –

DESCRIPTION AND OPERATION 18-4-11

Page 49

ENGINE MANAGEMENT SYSTEM - SIEMENS

Pin No. Description Input/Output

22 IAT sensor signal Input

23 IAT sensor earth –

24 ECT sensor signal Input

25 ECT sensor earth –

26 and 28 Not used –

29 LH bank knock sensor Input

30 LH bank knock sensor Input

31 RH bank knock sensor Input

32 RH bank knock sensor Input

33 Fuel injector 1 Output

34 Fuel injector 3 Output

35 Fuel injector 5 Output

36 Fuel injector 2 Output

37 Fuel injector 6 Output

38 Fuel injector 4 Output

39 to 41 Not used –

42 EVAP purge valve drive Output

43 Throttle motor open drive Output

44 Throttle motor close drive Output

45 to 47 Not used –

48 Knock sensors screen Input

49 VIS power (butterfly) valves motor drive Output

50 Not used –

51 DMTL heater drive Output

52 Not used –

Controller Area Network (CAN) Bus

The ECM is connected to the Anti-lock Braking System (ABS) modulator, EAT ECU and the instrument pack by the

CAN bus.

18-4-12 DESCRIPTION AND OPERATION

Page 50

ENGINE MANAGEMENT SYSTEM - SIEMENS

Electric Throttle

The electric throttle controls the air flow into the engine. In addition to the normal engine power control function, the

electric throttle allows the cruise control, idle speed control and engine speed limiting functions to be performed

without the need for additional hardware.

The electric throttle consists of a throttle body which incorporates a throttle plate driven by a DC motor via reduction

gears. A return spring biases the throttle plate in the closed direction.

Operation of the DC motor is controlled by the ECM, which outputs two Pulse Width Modulated (PWM) signals to an

H bridge drive circuit in the motor. The ECM varies the speed and direction of the motor by varying the duty cycle of

the PWM signals.

To enable closed loop control, the position of the throttle plate is supplied to the ECM by two feedback potentiometers

in the throttle body. The feedback potentiometers have a common 5 volt supply and a common ground connection

from the ECM, and produce separate linear signal voltages to the ECM proportional to the position of the throttle plate.

The ECM uses the signal from feedback potentiometer 1 as the primary signal of throttle plate position, and the signal

from feedback potentiometer 2 for plausibility checks.

l The signal from feedback potentiometer 1 varies between 0.5 volt (0% throttle open) and 4.5 volts (100% throttle

open)

l The signal from feedback potentiometer 2 varies between 4.5 volts (0% throttle open) and 0.5 volt (100% throttle

open)

1 DC motor

2 Electrical connector

While the ignition is on, the ECM continuously monitors the two feedback potentiometers for short and open circuits

and checks the feedback potentiometer signals, against each other and the inputs from the Accelerator Pedal Position

(APP) sensor, for plausibility. If a fault is detected in the feedback potentiometer signals or the DC motor, the ECM:

l Stores a related fault code in memory.

l Illuminates the SERVICE ENGINE warning lamp in the instrument pack.

l Adopts a throttle limp home mode or disables throttle control, depending on the nature of the fault.

The throttle limp home mode adopted depends on the nature of the fault:

l If there is a fault with one feedback potentiometer, or the throttle position controller in the ECM, the ECM limits

vehicle acceleration by limiting throttle plate opening.

l If there is a fault with both feedback potentiometers, the ECM uses fuel injection cut-off to limit engine speed to

1300 rev/min maximum.

3 Reduction gear/ feedback potentiometer

4 Throttle plate

DESCRIPTION AND OPERATION 18-4-13

Page 51

ENGINE MANAGEMENT SYSTEM - SIEMENS

EMS Sensors

The EMS incorporates the following sensors:

l An APP sensor.

l A Crankshaft Position (CKP) sensor.

l A Camshaft Position (CMP) sensor.

l A Mass Air Flow (MAF) sensor.

l An Intake Air Temperature (IAT) sensor.

l An Engine Coolant Temperature (ECT) sensor.

l A thermostat monitoring sensor.

l Four Heated Oxygen Sensors (HO2S).

l Two knock sensors.

APP Sensor – Up to 2003 Model Year

The APP sensor enables the ECM to determine the throttle position requested by the driver on the accelerator pedal.

The APP sensor is installed on the pedal box and consists of a twin track potentiometer with wipers driven by a linkage

connected to the accelerator pedal. Each potentiometer track has a 5 volt supply and ground connection from the

ECM, and produces a linear signal voltage to the ECM proportional to the position of the accelerator pedal. The signal

voltage from track 1 of the potentiometer is approximately double that of the signal voltage from track 2.

From the sensor signals, the ECM determines driver demand as a percentage of pedal travel, where 0% is with the