Landoll PFT User Manual

ASSEMBLY INSTRUCTIONS

BRILLION FARM EQUIPMENT

OPERATORS MANUAL

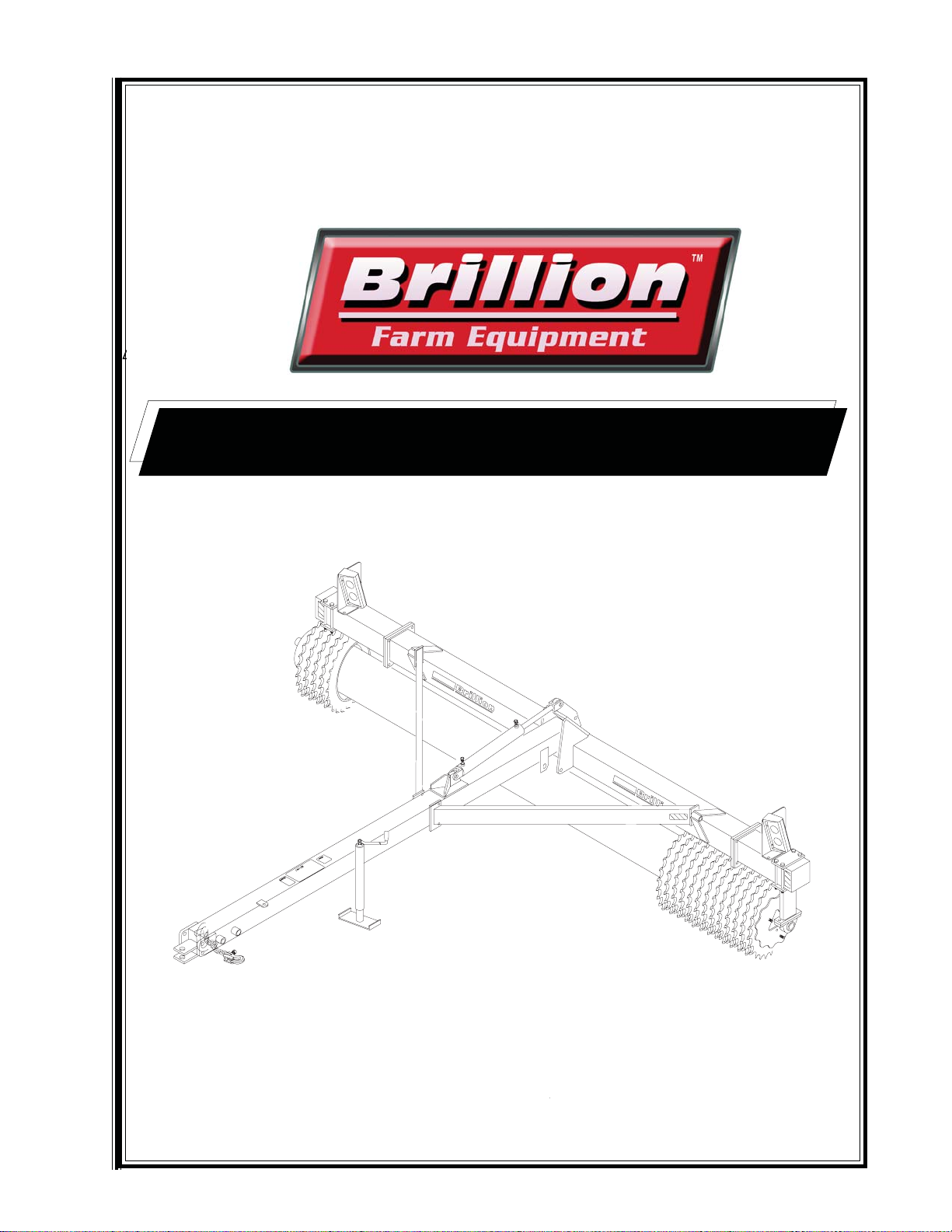

Floating Ring Pulverizer

MODELS: PF & PFT

298/rev401 BRILLION, WISCONSIN 54110 5K089

298rev401 5K089

BRILLION IRON WORKS, INC.

www.brillionfarmeq.com

298rev401 5K089

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

FLOATING RING PULVERIZER

CONTENTS

Introduction ............................................................................................................................................... 3

Location Reference ......................................................................................................................3

Parts Ordering .............................................................................................................................. 3

Safety Suggestions ...................................................................................................................................4

Safety Information ........................................................................................................................ 5

Safety Chain (Optional) ................................................................................................................5

Safety Sign Description and Illustration ....................................................................................... 6

Decal Location .............................................................................................................................6

Pre-operating Checks ............................................................................................................................... 7

Maintenance .............................................................................................................................................7

Lubrication ................................................................................................................................... 7

Operating Instructions ...............................................................................................................................8

Transport Speed ........................................................................................................................... 8

Turning ......................................................................................................................................... 8

Use with Other Implements ..........................................................................................................8

Transport Lock ............................................................................................................................. 9

Field Operation & Dual Mounted Wheels .................................................................................. 10

Replacing or Adding Rollers ....................................................................................................... 11

Assembly Instructions ............................................................................................................................ 12

Frame & Drawbar ....................................................................................................................... 12

Wheel Arms ............................................................................................................................... 13

Hydraulic Cylinder ..................................................................................................................... 14

Hydraulics .................................................................................................................................. 14

Transport Pin ............................................................................................................................. 14

Warning Lights ........................................................................................................................... 15

Machine Specifications ........................................................................................................................... 16

298rev401 5K089Page I

298rev401 5K089

INTRODUCTION

To obtain maximum benefits from the FLOATING RING PULVERIZER, please study this manual carefully

before starting assembly or operation. A special section, Assembly Instructions, is included. If items in this

manual are not understood, contact your local BRILLION dealer or call BRILLION IRON WORKS, INC., at

(920) 756-3720.

The symbol shown here appears in this book and on your

machine where special attention is needed to safeguard

yourself against harm. It warns, ATTENTION! BE ALERT!

YOUR SAFETY IS INVOLVED! The message following

the symbol points out important safety precautions. Read it

and be alert to the possibility of personal injury or death.

BE ALERT!

YOUR SAFETY IS INVOLVED

Location Reference

Right Hand, Left Hand, and Forward designations are made from the viewpoint of standing behind the machine

and facing the direction it will travel during field operation.

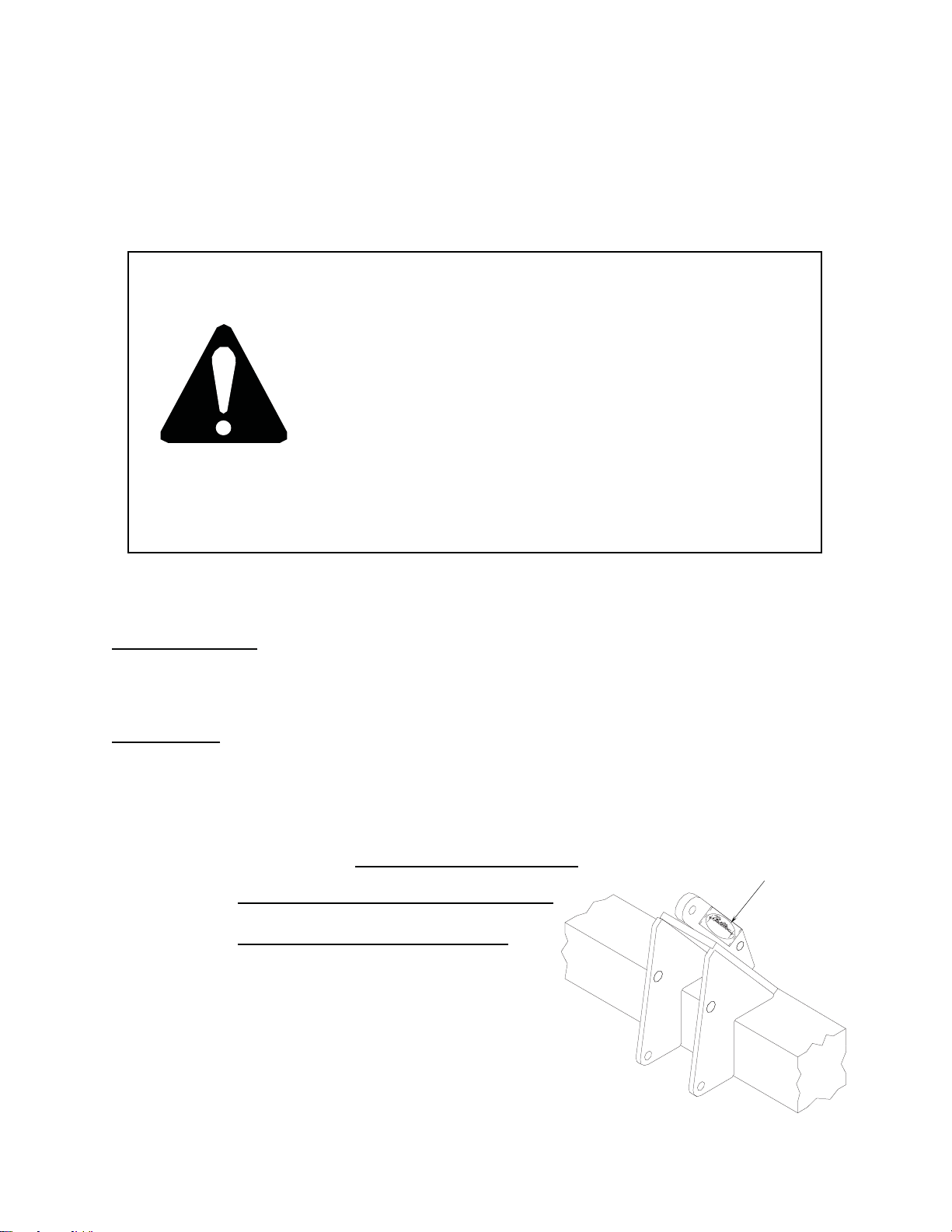

Parts Ordering

When ordering parts for this machine, include the complete model number and serial number. Refer to the

name plate on the right front corner of the main frame as shown in Figure 1. Please read and record this

number upon taking delivery of this machine.

FLOATING PULVERIZER Model

Serial Number

Date Purchased

Be sure to read the warranty card which is shipped

with the machine. Return the proper portion of the

card for recording at the factory.

Name Plate

FIGURE 1

298rev401 5K089

Page 3

SAFETY SUGGESTIONS

Federal law requires that you explain the safety and operating instructions furnished with this

machine to all employees before they are allowed to operate the machine. These must be

repeated to the employees at the beginning of each season. Be sure to observe and follow the

instructions for the safety of anyone who is operating or near the machine.

Investigation has shown that nearly 1/3 of all farm accidents are caused by careless use of

machinery.

You can do your part in improving safety by observing the following suggestions. Insist that all

people working with you or for you abide by them.

1. Do not stand between the tractor and implement when attaching or detaching implement

unless both are not moving.

2. Before applying hydraulic pressure to the system, be sure all connections are tight and

that hydraulic lines and hoses are not damaged.

3. Escaping fluid under pressure can be nearly invisible and have enough force to penetrate

the skin causing serious injury. Use a piece of cardboard, rather than hands, to search

for suspected leaks. If injured by fluid, see a doctor at once.

4. Do not make adjustments or lubricate machine while it is in motion.

5. Do not allow anyone to ride on tractor or machine.

6. Always use transport locks while transporting the machine.

7. Do not transport at speeds over 20 mph. Avoid sudden stops or turns when transporting

because the weight of the machine may cause the operator to lose control of the tractor.

Use a tractor heavier than the machine. Do not allow tractor drawbar to swing when in

transport.

8. Hitch pins and other hitching devices should be provided with a retainer to prevent

accidental unhitching.

9. Use caution when towing behind articulated steering tractors; fast or sharp turns may

cause the machine to shift sideways.

10. When transporting the machine on a road or highway, use adequate warning symbols,

reflectors, lights, and slow moving vehicle signs as required. Use a safety chain.

11. Block machine so it will not roll when unhitched from tractor.

12. Relieve pressure in hydraulic lines before uncoupling hydraulic hoses from tractor. On

most tractors this can be done by operating valves after engine is stopped.

13. Securely block machine when working on or under it to prevent injury in case of hydraulic

failure or inadvertent lowering by another person.

14. Lower machine to ground when not in use.

298rev401 5K089

Page 4