Landoll HSB 71-1 User Manual

®

SOIL BUILDER

Coulter Chisel - Extended Frame

Models: SB, HSB 71-1 through 131-1

s

Operator’s Manual

LANDOLL CORPORATION

1900 North Street

Marysville, Kansas 66508

(785) 562-5381

800-428-5655 ~ WWW.LANDOLL.COM

791rev0514 1K705

Contents

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Location Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Parts Ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Suggestions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Sign Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Field Operatiion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Coulter Depth & Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10, 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11, 1 2

Shipping Bundles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Single Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16

Tandem Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-19

Transport Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Coulters & Coulter Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Drawbar Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Shanks & Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Wheel & Shank Layout Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-31

Cylinders & Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Warning Light Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

SMV Sign Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Machine Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

791rev1-10-08

1K705Page 1

Introduction

Introduction

Your Brillion Soil Builder is built with the best

materials and workmanship available. It has

been designed to give you years of trouble-free

operation.

SAFETY

This safety alert symbol is used to

call your attention to instructions

concerning personal safety. It means

“ATTENTION! BE ALERT!

YOUR SAFETY IS INVOLVED!”

Location Reference

Right hand, left hand and forward designations

are those related to the operator when sitting in

the operating position.

Study this manual carefully before attempting

to assemble or operate this machine. A special

section of this manual is devoted to assembly

of the Coulter-Chisel. Refer to the “Setting Up

Instructions” portion of this manual.

ALERT

The symbol is found throughout this manual

and on safety signs found on your machine.

It points out important safety precautions.

Read its message and be alert to the possibility of personal injury or death.

Parts Ordering

When ordering parts for this machine, include the

complete model number and serial number. Refer

to the name plate located on the outside of the

front left-side frame member. Please record these

numbers upon taking delivery of the unit.

Warranty Registration

ACKNOWLEDGMENT REQUIRED

Brillion shall have no obligation

Farm Equipment

under this warranty

Card included with your Operator’s Manual is

signed by Owner and Dealer and is delivered to

Brillion Farm Equipment within sixty (60) days from

the date of sale.

unless the Owner Registration

791rev5-30-05

1K705Page 3

S

afety Suggestions

S

afety Suggestions

Investigation has found that many farm accidents are caused by careless use of farm machinery. To

minimize as much as possible the chance of personal injury or even death, insist that all people working

with you or for you follow these instructions. Be sure to explain to the operator, in detail, the operation,

maintenance, adjustments, and safe operation instructions contained in this manual.

CAUTION: Relieve pressure in hydraulic lines before you attempt to work

with, connect or disconnect hydraulic hoses under pressure.

CAUTION: Whenever transporting a farm implement on public roads it is the

reponsibility of the operator to abide by state and local laws concern ing wide loads, speed, safety emblems, and safety lighting equipment.

CAUTION: Before initially applying hydraulic pressure to the system, be sure

all connections are tight and that lines and hoses are not damaged.

CAUTION: Do not stand between tractor and implement when attaching or

detaching implement unless both tractor and implement are not moving.

CAUTION: Do not make adjustments or lubricate machine while it is in

motion.

CAUTION: Do not allow anyone to ride on the tractor or machine when operating or

transporting.

CAUTION: Reduce speed when transporting over uneven or rough terrain.

Shift the tractor into a lower gear when transporting down hills or steep slopes.

791rev5-30-05

1K705Page 4

Safety Signs

Safety Signs

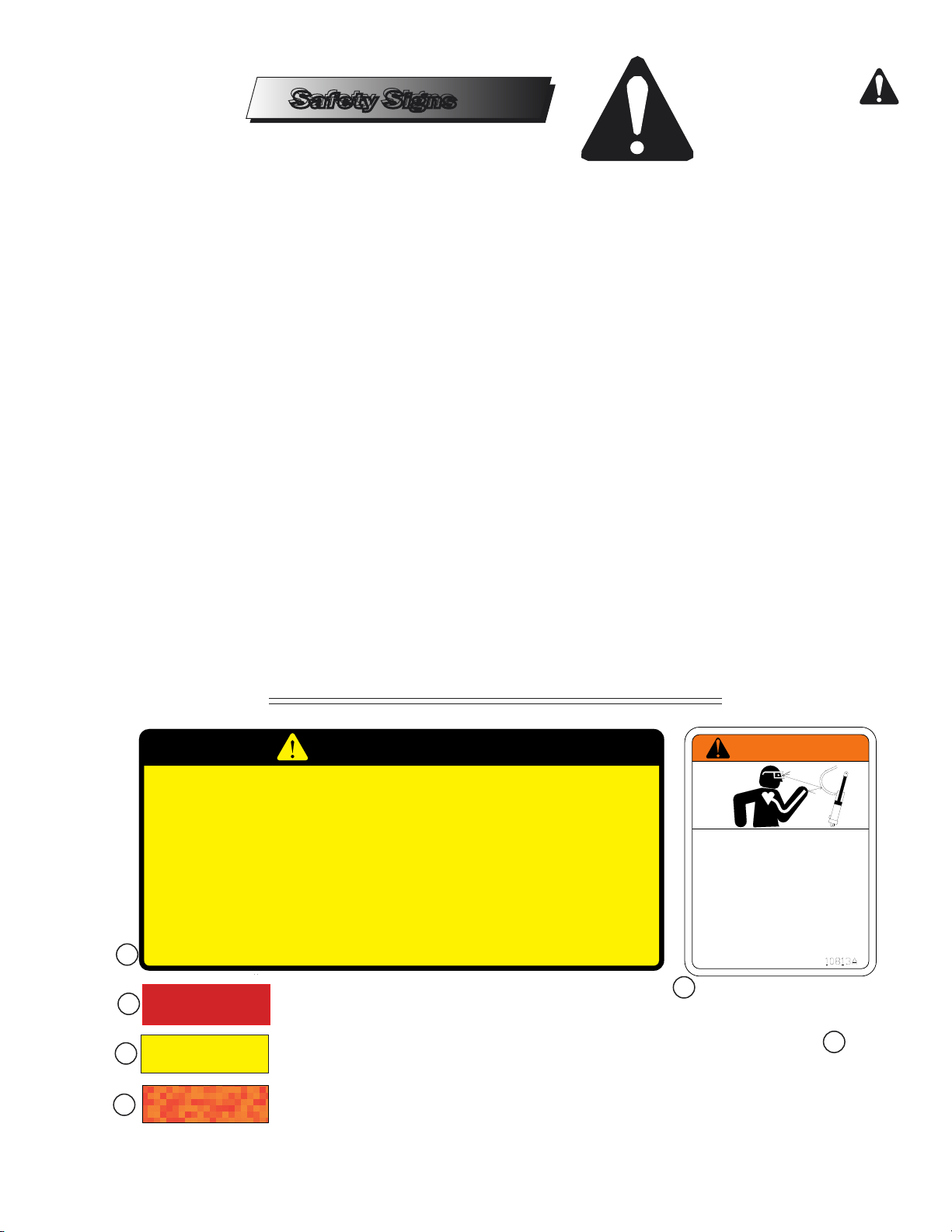

There are three levels of hazard intensity that appear with the safety alert symbol on safety decals:

DANGER, WARNING, and CAUTION. The level

of hazard intensity is determined by the following

defnitions:

DANGER - Immediate hazards which

WILL result in death or serious

personal injury.

WARNING - Hazards or unsafe practices

which COULD result in death or

serious personal injury.

CAUTION - Indicates potentially hazardous

situations, or directs attention to

unsafe practices which could

result in minor or moderate injury.

• Examine safety decals and be sure you

have the correct safety decals for the

machine.

• Order replacement decals through your

BRILLION dealer.

• Keep these signs clean so they can be

observed readily. It is important to keep

these decals cleaned more frequently

than the machine. Wash with soap and

water or cleaning solution as required.

• Replace decals that become damaged or

lost. Also be sure that any new machine

components installed during repair

include decals which are assigned to

them by the manufacturer.

• When applying decals to the machine,

be sure to clean the surface to remove

any dirt or residue. Where possible, sign

placement should protect the sign from

abrasion, damage, or obstruction from

mud, dirty oil, etc.

• Decals for the Extended Frame Soil Builder

are pictured below. Their locations on the

machine are shown on the next page.

CAUTION

1. DO NOT LUBRICATE, ADJUST OR REPAIR WHEN MACHINE IS IN MOTION.

2. DO NOT TOW OR TRANSPORT FASTER THAN 15 MILES PER HOUR.

3. DO NOT RIDE OR ALLOW OTHERS TO RIDE ON THE MACHINE.

4. BLOCK UP ALL HYDRAULICALLY OR MECHANICALLY RAISED COMPONENTS TO PREVENT

UNINTENDED LOWERING OR LOWER THE MACHINE TO THE GROUND TO MAKE ADJUSTMENT

OR REPAIRS OR WHEN NOT IN USE.

5. KEEP ALL PERSONS AWAY FROM MACHINE DURING HITCHING AND OPERATING.

6. SLOW DOWN BEFORE MAKING SHARP TURNS OR USING THE BRAKE.

DRIVE SLOWLY OVER ROUGH GROUND, SIDE HILLS, AND AROUND CURVES TO AVOID TIPPING.

7. COMPLY WITH ALL LAWS WHEN TRANSPORTING THE MACHINE ON PUBLIC ROADWAYS.

8. INSTRUCT ALL OPERATORS IN THE SAFE OPERATION OF THE MACHINE.

REVIEW THE OPERATOR’S MANUAL FOR CORRECT PROCEDURES.

9. BLOCK IMPLEMENT TO PREVENT MOVEMENT WHEN UNHITCHED FROM TRACTOR.

10. KEEP ALL GUARDS AND SHIELDS IN PLACE WHILE MACHINE OR PARTS ARE IN MOTION.

1

3

1. 8J310 .... Decal, Caution List

4

5

791rev5-30-05

2. 3J706 .... Decal, Warning-Hydraulic Leaks

3. 528933 .... Decal,Reflective Red

4. 528934 .... Decal, Reflective Amber

5. 528938 ... Decal, Reflective Red-Orange

6. 2P151.......SMV Sign

8J310

WARNING

WARNING

DO NOT GO NEAR LEAKS

High pressure oil easily punctures

skin causing serious injury,

gangrene or death.

If injured, seek emergency medical

help. Immediate surgery is

required to remove oil.

Do not use fingers or skin to

check for leaks.

Lower load or relieve hydraulic

pressure before loosening fittings.

2

6

1K705Page 5

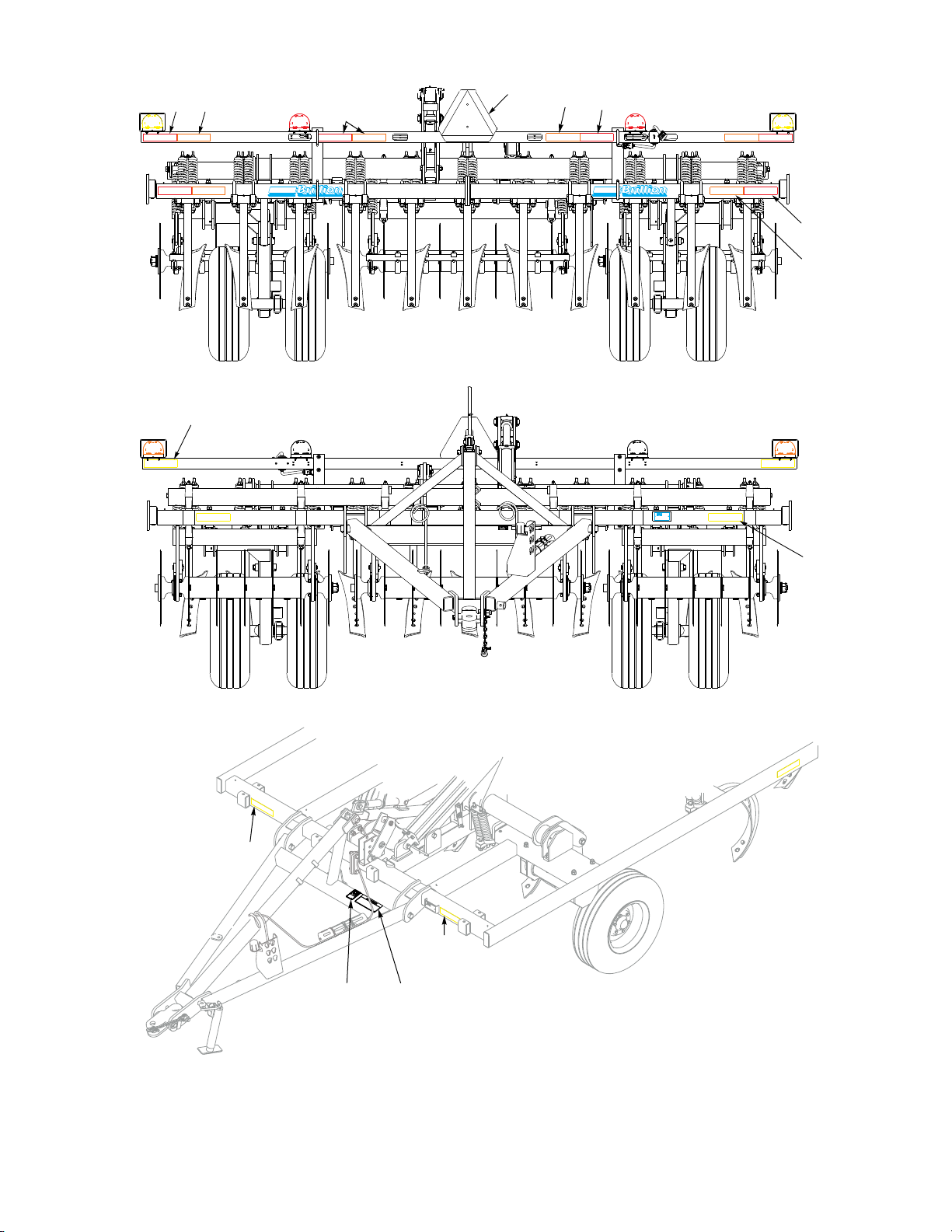

Safety Sign Locations

Center Decals

4

3

on 11 & 13 Shank

Only

6

3

4

4

3

REAR VIEW

11 & 13 SHANK

5

5

FRONT VIEW

4

4

2

1

1. 8J310 - Caution Decal

DRAWBAR and SIDE VIEW

2. 3J706 - Warning Hydraulic Leaks

3. 528938 - Orange Stripe

4. 528933 - Reflector, Red

5. 528934 - Reflector, Yellow

6. 2P151 - SMV Sign

Page 6 1K705

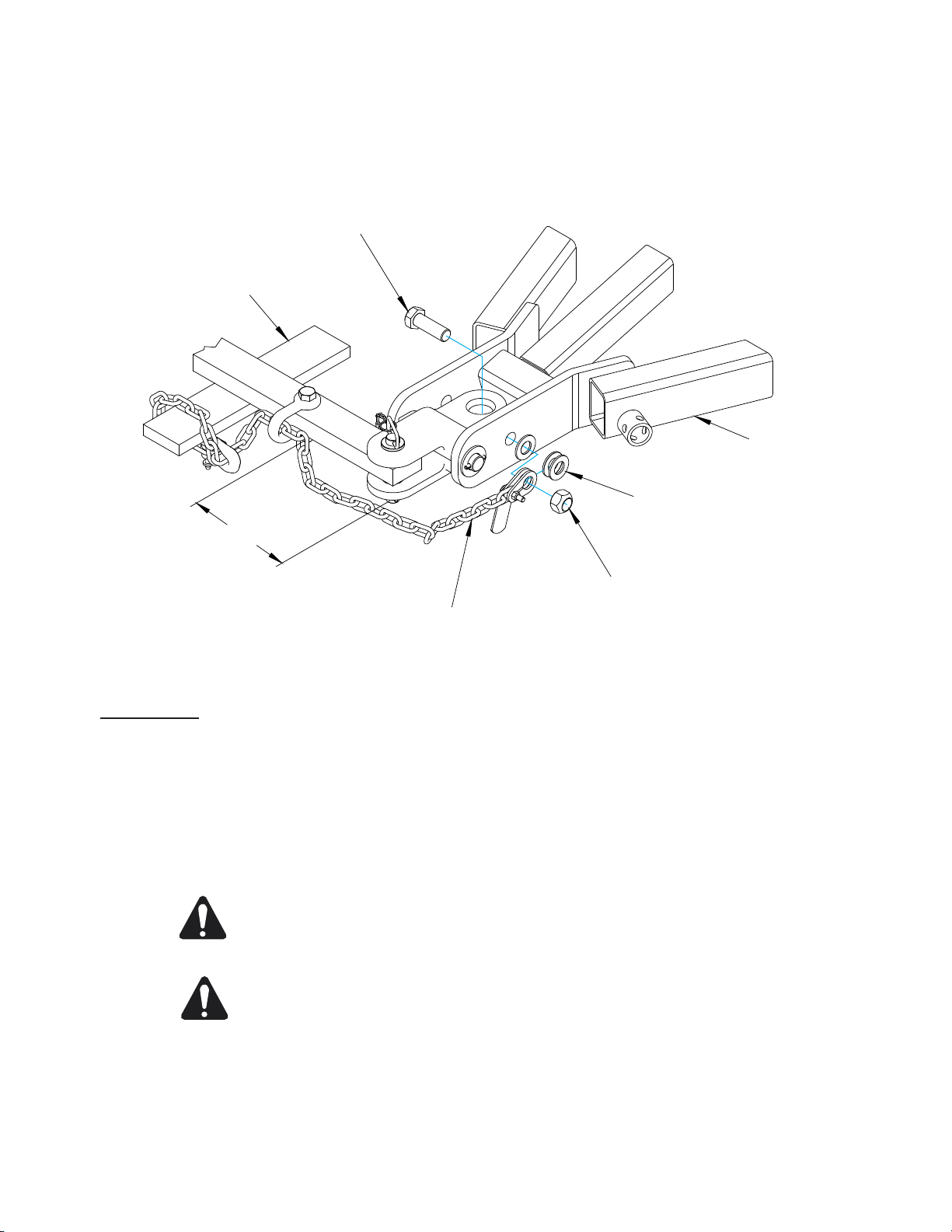

TRACTOR

DRAWBAR

Safety Chain

Figure 3

HHCS,1-8 x 3

DRAWBAR

FLAT WASHER,1" SAE

9" MAX

NUT,LOCK 1-8

SAFETY CHAIN

Safety Chain

WFPSafetyChain

Use of a 10,100# safety chain is recommended if the machine is towed on a public road or highway.

Total weight of towed machine must not exceed chain capacity as shown on the chain’s identification

tag.

Slack in the chain should be only enough to permit turning. Distance from hitch pin to attachment

point or intermediate support should not exceed 9”.

CAUTION If two or more machines are pulled in tandem, a larger chain may be

required. Chain capacity must be greater than the total weight of towed

implements. A second chain should be used between each implement.

CAUTION Replace chain if one or more links are broken, stretched, or otherwise

damaged or deformed.

SoilBuilder SafetyChain

Keep attaching hardware fastened securely.

If bolts are replaced, be sure to use grade 5 or higher unless otherwise specif

If you have any questions regarding the safety chain call your Brillion dealer.

791rev0514

Page 7

ed.

1K705

Operation

Operation

The Brillion Soil Builder should be inspected prior

to operation to see that all nuts and bolts are

tight and to be sure that it is in good operating

condition. (After the first few hours of initial

operation, check bolts once again to be sure they

haven’t loosened.)

Hitch the coulter-chisel to the tractor drawbar. It

may be necessary to adjust the adjustable brace

rod assembly of the coulter-chisel so that the

clevis is at the proper height for tractor drawbar.

A 3½ x 16 cylinder is used to raise and lower

the machine. With the cylinder installed, attach

hydraulic hoses to the tractor hydraulic system so

the machine will be lowered when moving control

lever forward.

Make sure the ratchet

is stored away from the

machine raising cylinder.

IMPORTANT! Remove the handle from the

ratchet jack before raising or lowering the machine

to prevent bending the handle. Store the handle

on the drawbar.

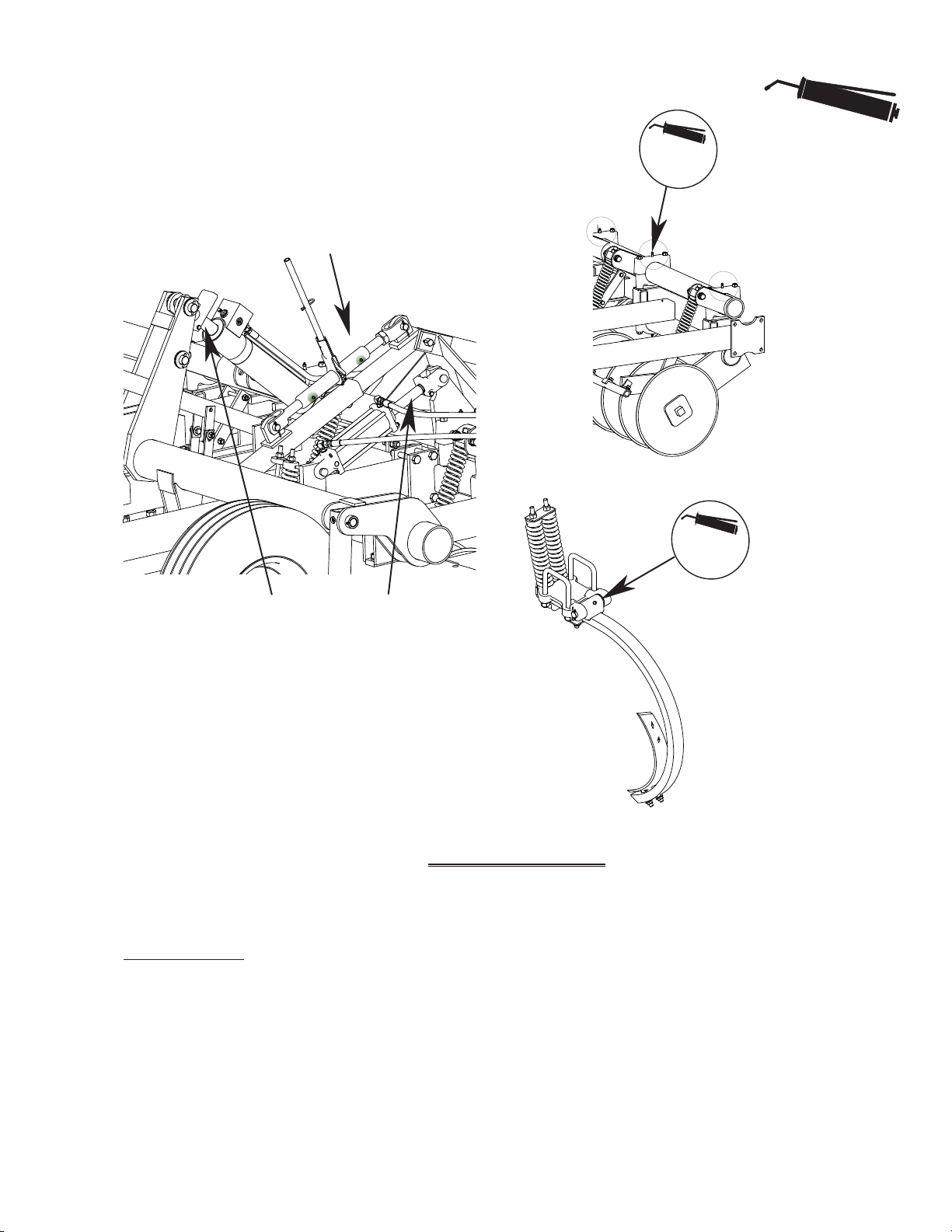

1

2

Handle

TRANSPORTING THE

COULTER-CHISEL

3

To transport the unit, extend the

transport cylinder completely

and raise the transport lock into

position by pulling the handle to

the front and latching the handle

in place. Then retract the

cylinder until the weight is taken

up by the lock. The machine is

now ready for transport.

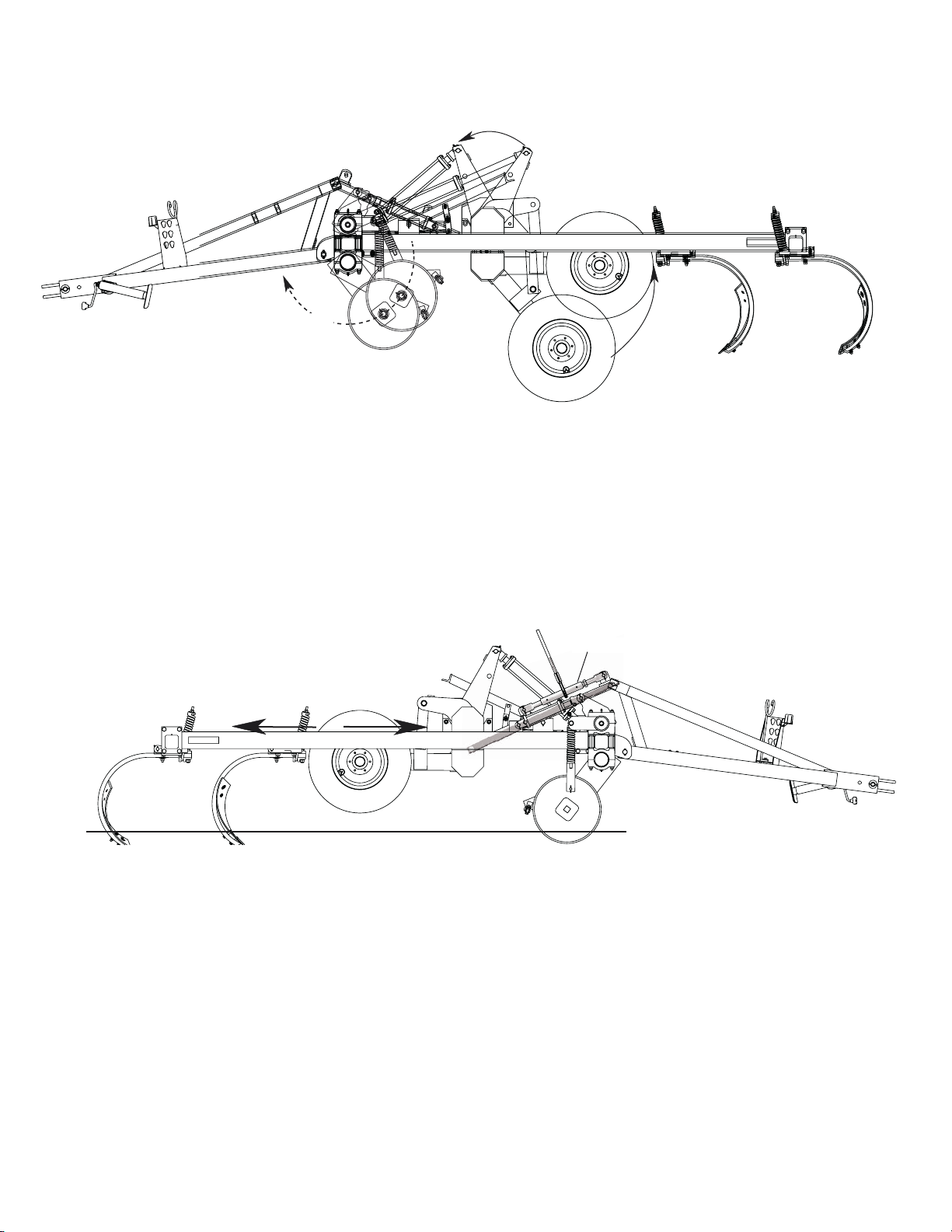

FIELD OPERATION

To release the transport lock,

extend the transport cylinder

full length and push the lock

handle to the rear to lower

the lock. Lower the machine

to the desired working depth.

If your cylinder is eqipped

with a depth stop, you may

set the depth by adjusting the

moveable hydraulic stop on the

cylinder rod.

791rev1-10-08

1K705Page 8

3” x 8” Cyllinder

Operates Coulters

3-1/2” x 16” Cyllinder

Operates Wheel Raising

Set the coulters to the desired depth by operating

the hydraulic cylinder on the coulter depth control

(or by moving the pins to the proper holes if your

machine is equipped with manually adjustable

coulters.)

For Field Operation, the spring bolts should

be tightened so that one inch of thread is exposed.

For chisel plowing tougher ground you may want to

clamp the spring tighter, but when this is done, the

shank and tooth will not pass over as great an obstruction.

Do not set the coulters deeper than necessary

to cut the surface residue. Setting the coulters

too deep in firm soil may prevent the shanks from

properly penetrating the soil.

Ratchet Jack

Now check to make sure the machine is level in

working position. The machine is leveled from

front to back by adjusting the ratchet jack on the

drawbar brace.

791rev1-10-08

For best results, operate tractor at 4 to 6 miles

per hour. Reduce speed when approaching the

end of the field. When turning or backing up raise

the coulter-chisel clear of the ground to prevent

damage to the shanks and disc gang assemblies.

1K705Page 9

LUBRICATION

On your Brillion Soll Builder the

following grease fittings should

be greased after each 8 hours

of operation.

The four cast bearings on the

coulter gangs, the six steel

bearings on the wheel arms

and rockshaft and the center

bearing on the rockshaft.

8

HRS.

791rev5-30-05

8

HRS.

Also the four pins on the

links from rockshaft to the

wheel arms.

Each season repack the wheel

bearings and the walking beam

pivot bearings on machines

equipped with walking beam axles.

Page 10

1K705

Grease the ratchet jack as

needed to prevent rusting, .

Coat the cylinder rods with grease to prevent the

rods from rusting if the machine will be stored

outside or for a prolonged period of time.

Daily

8

HRS.

If your machine

is equipped with

spring cushion

shanks, grease the

shank pivot after

each 8 hours of

operation.

On machines

equipped with

hydraulic coulter

adjustment,

grease the cast

bearings daily.

MAINTENANCE

Clean dirt, weeds, and any other foreign material

from the coulter-chisel before storing at the end of

the season. Repaint areas where paint has worn

791rev5-30-05

Page 11

off. Repair or replace any broken or damaged

parts. Store in a dry, protected place.

1K705

Loading...

Loading...