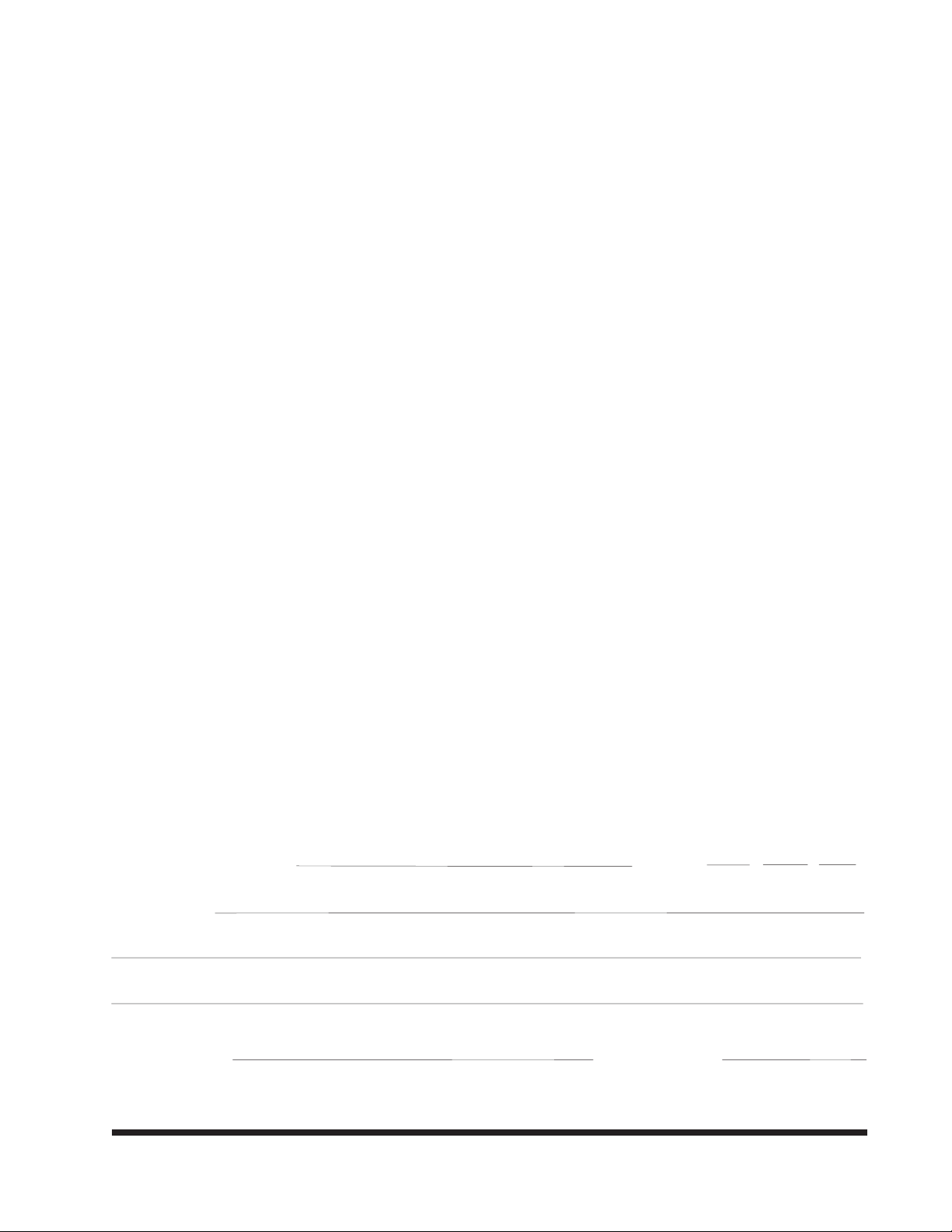

Landoll 3130 User Manual

MODEL 3130 SERIES

WING PACKER

OPERATOR’S MANUAL

1900 NORTH STREET

MARYSVILLE, KANSAS 66508

(785) 562-5381

F-334-1106 11/06

MODEL 3130 SERIES

WING PACKER

OPERATOR’S MANUAL

PURCHASED FROM: DATE / /

ADDRESS:

PHONE NO.: SERIAL NO.:

i

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE NO.

1 INTRODUCTION 1-1

2 STANDARD SPECIFICATIONS 2-1

3 ASSEMBLY INSTRUCTIONS 3-1

3-1 ASSEMBLY - SAFETY ................................3-1

3-2 AFTER ASSEMBLY - SAFETY...........................3-3

3-3 ASSEMBLY INSTRUCTIONS ............................3-3

3-4 MAIN FRAME, ROLLER GANG, AND TONGUE ASSEMBLY -

19’, 20’, 22’, and 24’ MODELS...........................3-4

3-5 MAIN FRAME, ROLLER GANG, AND TONGUE ASSEMBLY -

27’, 31’, and 36’ MODELS ..............................3-5

3-6 WING FRAME ASSEMBLY .............................3-6

3-7 WING GANGS TO WING FRAMES .......................3-7

3-8 TRANSPORT AXLE TO MAIN FRAME .....................3-8

3-9 TRANSPORT CHAIN ..................................3-8

3-10 ELECTRICAL INSTALLATION ...........................3-9

3-11 HYDRAULIC ASSEMBLY..............................3-10

3-12 PULL TONGUE ADJUSTMENTS (SMALL MODELS ONLY) ....3-11

3-13 PULL TONGUE ADJUSTMENTS (LARGE MODELS ONLY) ....3-12

3-14 SCRAPER ASSEMBLY ...............................3-26

4 OPERATION AND MAINTENANCE 4-1

4-1 DECALS ...........................................4-5

4-2 TRACTOR PREPARATION .............................4-6

4-3 WING PACKER PREPARATION .........................4-6

4-4 ATTACHING TO TRACTOR .............................4-7

4-5 UNHITCHING FROM TRACTOR..........................4-7

4-6 FIELD OPERATION ...................................4-7

4-7 ROLLERS ..........................................4-8

4-8 ELECTRICAL SYSTEM AND REFLECTORS ................4-8

4-9 TRANSPORTING THE WING PACKER ....................4-9

4-10 GENERAL MAINTENANCE ............................4-10

4-11 LUBRICATION .....................................4-10

5 TROUBLESHOOTING GUIDE 5-1

ii

SAFETY PRECAUTIONS

THIS IS THE SAFETY ALERT SYMBOL. IT IS USED TO ALERT YOU

TO POTENTIAL INJURY HAZARDS. OBEY ALL SAFETY MESSAGES

THAT FOLLOW THIS SYMBOL TO AVOID POSSIBLE INJURY OR

DEATH.

DANGER

WARNING

CAUTION

CAUTION

DANGER INDICATES AN IMMINENTLY HAZARDOUS SITUA

TION WHICH, IF NOT AVOIDED, WILL RESULT IN DEATH OR

SERIOUS INJURY.

WARNING INDICATES A POTENTIALLY HAZARDOUS SITUA

TION WHICH, IF NOT AVOIDED, COULD RESULT IN DEATH OR

SERIOUS INJURY.

CAUTION INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, MAY RESULT IN MINOR OR

MODERATE INJURY.

CAUTION USED WITHOUT THE SAFETY ALERT SYMBOL INDI

CATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF

NOT AVOIDED, MAY RESULT IN PROPERTY DAMAGE.

-

-

-

iii

1INTRODUCTION

The Landoll 3130 Series Wing Packer is a quality product designed to give years of trouble free per

formance. By following each section of this manual, your system will perform as designed for you and your

operation.

SECTION 1 gives basic instructions on the use of this manual.

SECTION 2 gives product specifications. These specifications supply lengths and measures for your

equipment. A Standard Bolt Torque Table is provided to give guidelines for bolt torques

to be used when servicing this product.

SECTION 3 contains assembly instructions for your 3130 Series Wing Packer. When these proce

dures are correctly followed, your equipment should provide you years of trouble-free

operation and service.

-

SECTION 4 instructs how to operate your equipment before using it, and describes adjustments

needed. It also gives practical advice for the care and maintenance of your Landoll

equipment. Drawings in this section locate adjustment points on the equipment.

NOTE: IF THE EQUIPMENT IS IMPROPERLY ASSEMBLED OR MAINTAINED, THE

WARRANTY IS VOID. IF YOU HAVE ANY QUESTIONS CONTACT:

LANDOLL CORPORATION

1900 NORTH STREET

MARYSVILLE, KANSAS 66508

or phone:

(785) 562-5381 or

(800) 428-5655

or FAX:

(785) 562-4893

-

SECTION 5 is a troubleshooting guide to aid in diagnosing and solving problems with the equip

ment.

-

PARTS LIST is a separate manual showing the various assemblies, subassemblies, and systems.

Refer to that manual when ordering Landoll replacement parts. Order parts from your

Landoll dealer.

WARRANTY The Warranty Registration form is included with the product documents. Fill it out and

mail it within 15 days of purchase. The Warranty is printed inside the front cover.

NOTE: IMPROPER ASSEMBLY, MODIFICATION, OR MAINTENANCE OF YOUR

LANDOLL EQUIPMENT CAN VOID YOUR WARRANTY.

COMMENTS Address comments or questions regarding this publication to:

LANDOLL CORPORATION

1900 NORTH STREET

MARYSVILLE, KANSAS 66508

ATTENTION: PUBLICATIONS -DEPT. 55

1-1

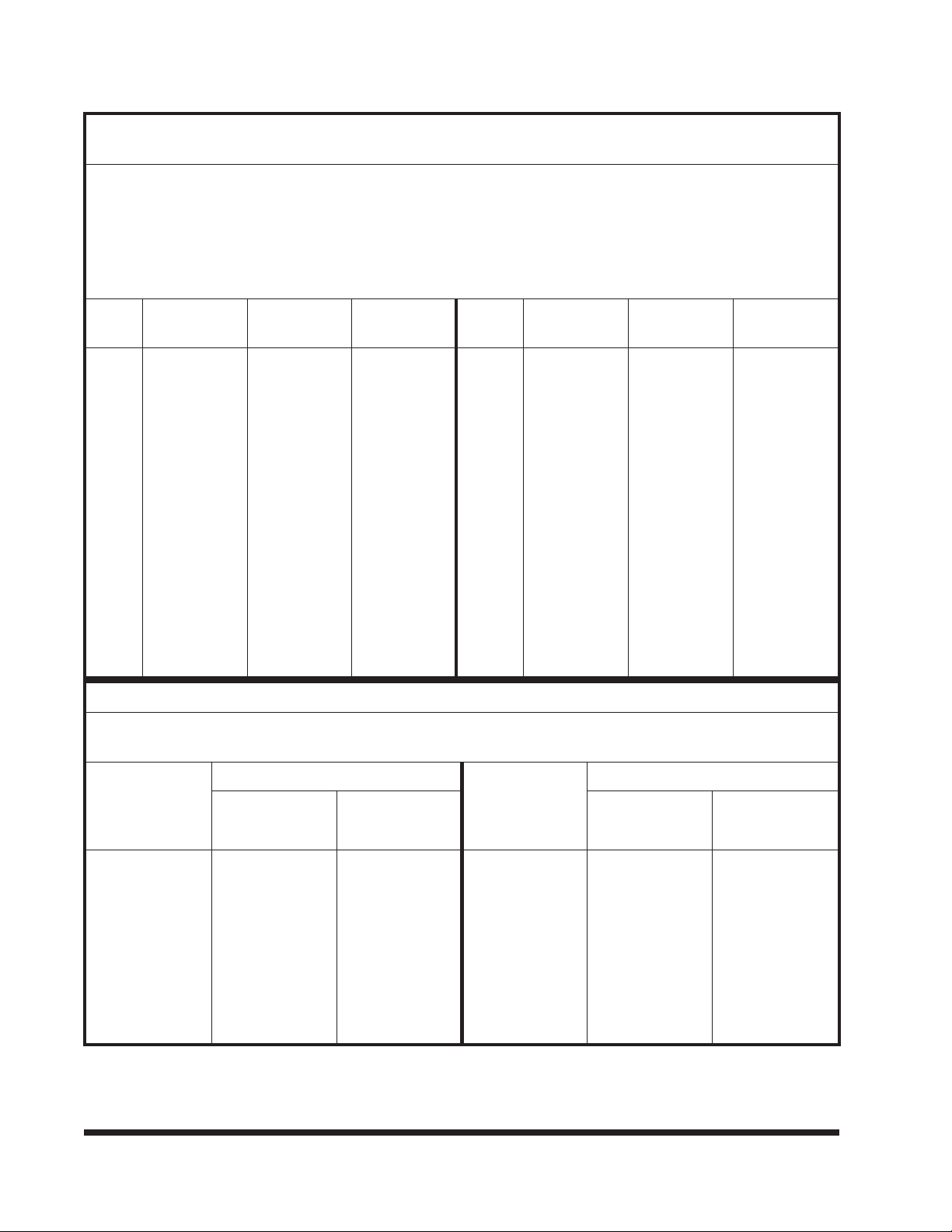

PACKER W/ SMOOTH ROLLERS

MODEL FRAME

WIDTH

3130-19 19’-1” 13’-6” 55 55 3232 3727

3130-20 20’-7” 13’-6” 61 59 3791 4322

3130-22 22’-8” 13’-6” 67 65 4012 4597

3130-24 24’-9” 13’-6” 73 71 4238 4877

3130-27 27’-7” 13’-6” 83 77 5710 6411

3130-31 31’-9” 13’-6” 94 89 6202 7011

3130-36 36’-0” 13’-6” 106 101 6704 7621

TRANSPORT

WIDTH

MIN.

TRACTOR

HP

ROLLER

QTY. PER

MACHINE

APPROXIMATE

WEIGHT (Lbs.)

17” SMOOTH

APPROXIMATE

WEIGHT (Lbs.)

19” SMOOTH

PACKER W/ CROWFOOT ROLLERS

MODEL FRAME

WIDTH

3130-19 19’-1” 13’-6” 55 37 2687 3242

3130-20 20’-7” 13’-6” 61 41 3243 3858

3130-22 22’-8” 13’-6” 67 45 3403 4078

3130-24 24’-9” 13’-6” 73 47 3519 4224

3130-27 27’-7” 13’-6” 83 52 4886 5666

3130-31 31’-9” 13’-6” 94 60 5266 6166

3130-36 36’-0” 13’-6” 106 68 5660 6680

TRANSPORT

WIDTH

MIN.

TRACTOR

HP

ROLLER

QTY. PER

MACHINE

APPROXIMATE

WEIGHT (Lbs.)

17” CROWFOOT

APPROXIMATE

WEIGHT (Lbs.)

20” CROWFOOT

2STANDARD SPECIFICATIONS

Options - Reversible Point Scrapers (all models); Dual Tires (3130-19 - 3130-24 models only)

Tractor Requirements:

Minimum tractor hydraulic pressure - 1500 psi.

NOTE: 19’ - 24’ MODELS ARE REFERRED TO AS SMALL MODELS THROUGHOUT MANUAL; 27’ -

36’ MODELS ARE REFERRED TO AS LARGE MODELS THROUGHOUT MANUAL.

2-1

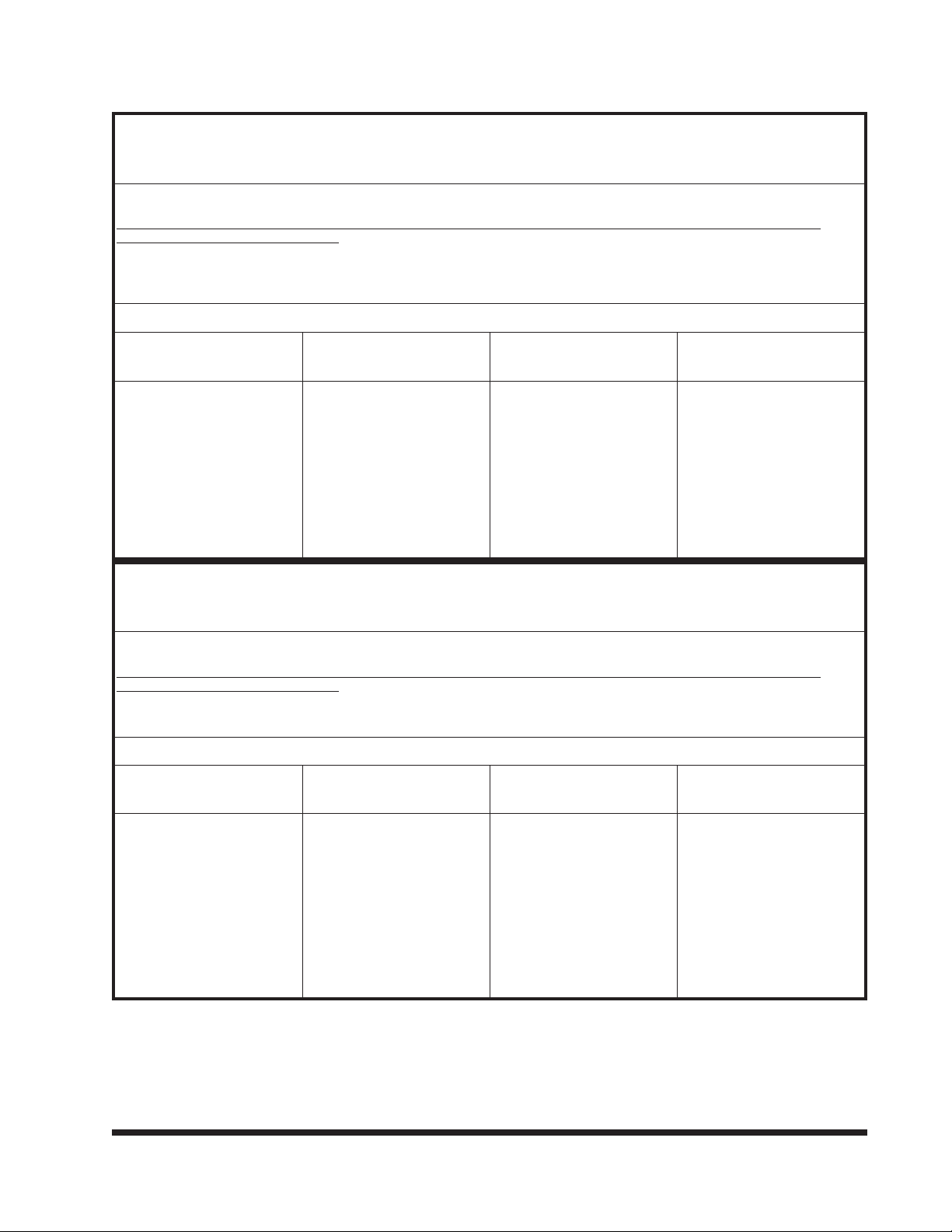

LANDOLL CORPORATION

GENERAL TORQUE SPECIFICATIONS (REV. 4/97)

THIS CHART PROVIDES TIGHTENING TORQUES FOR GENERAL PURPOSE APPLICATIONS WHEN SPECIAL TORQUES ARE NOT SPECIFIED

ON PROCESS OR DRAWING.

ASSEMBLY TORQUES APPLY TO PLATED NUTS AND CAPSCREWS ASSEMBLED WITHOUT SUPPLEMENTAL LUBRICATION (AS RECEIVED

CONDITION). THEY DO NOT APPLY IF SPECIAL GRAPHITE MOLY-DISULFIDE OR OTHER EXTREME PRESSURE LUBRICANTS ARE USED.

WHEN FASTENERS ARE DRY (SOLVENT CLEANED), ADD 33% TO AS RECEIVED CONDITION TORQUE.

BOLT HEAD IDENTIFICATION MARKS INDICATE GRADE AND MAY VARY FROM MANUFACTURER TO MANUFACTURER.

THICK NUTS MUST BE USED ON GRADE 8 CAPSCREWS.

USE VALUE IN [ ] IF USING PREVAILING TORQUE NUTS.

TORQUE IS SPECIFIED IN FOOT POUNDS

UNC

Size

1/4-20 4 [5] 6 [7] 9 [11] 1/4-28 5 [6] 7 [9] 10 [12]

5/16-18 8 [10] 13 [16] 18 [22] 5/16-24 9 [11] 14 [17] 20 [25]

3/8-16 15 [19] 23 [29] 35 [43] 3/8-24 17 [21] 25 [31] 35 [44]

7/16-14 24 [30] 35 [43] 55 [62] 7/16-20 27 [34] 40 [50] 60 [75]

1/2-13 35 [43] 55 [62] 80 [100] 1/2-20 40 [50] 65 [81] 90 [112]

9/16-12 55 [62] 80 [100] 110 [137] 9/16-18 60 [75] 90 [112] 130 [162]

5/8-11 75 [94] 110 [137] 170 [212] 5/8-18 85 [106] 130 [162] 180 [225]

3/4-10 130 [162] 200 [250] 280 [350] 3/4-16 150 [188] 220 [275] 320 [400]

7/8-9 125 [156] 320 [400] 460 [575] 7/8-14 140 [175] 360 [450] 500 [625]

1-8 190 [237] 408 [506] 680 [850] 1-14 210 [263] 540 [675] 760 [950]

1-1/8-7 270 [337] 600 [750] 960 [1200] 1-1/8-12 300 [375] 660 [825] 1080 [1350]

1-1/4-7 380 [475] 840 [1050] 1426 [1782] 1-1/4-12 420 [525] 920 [1150] 1500 [1875]

1-3/8-6 490 [612] 110 [1375] 1780 [2225] 1-3/8-12 560 [700] 1260 [1575] 2010 [2512]

1/1-2-6 650 [812] 1460 [1825] 2360 [2950] 1/1-2-12 730 [912] 1640 [2050] 2660 [3325]

SAE Grade2SAE Grade5SAE Grade8UNF

Size

SAE Grade2SAE Grade5SAE Grade

8

METRIC

COARSE THREAD METRIC CLASS 10.9 FASTENERS AND CLASS 10.0 NUTS AND THROUGH HARDENED FLAT WASHERS, PHOSPHATE

COATED, ROCKWELL “C” 38-45.

USE VALUE IN [ ] IF USING PREVAILING TORQUE NUTS.

Nominal

Thread

Diameter

2-2

Standard Torque Nominal

Newton-

mm

6 10 [14] 7 [10] 20 385 [450] 290 [335]

7 16 [22] 12 [16] 24 670 [775] 500 [625]

8 23 [32] 17 [24] 27 980 [1105] 730 [825]

10 46 [60] 34 [47] 30 1330 [1470] 990 [1090]

12 80 [101] 60 [75] 33 1790 [1950] 1340 [1450]

14 125 [155] 90 [115] 36 2325 [2515] 1730 [1870]

16 200 [240] 150 [180] 39 3010 [3210] 2240 [2380]

18 275 [330] 205 [245]

Meters

Foot-

Pounds

Thread

Diameter

mm

Standard Torque

Newton-

Meters

Foot-

Pounds

Table 2-1 General Torque Specifications

LANDOLL CORPORATION

HYDRAULIC FITTING TORQUE SPECIFICATIONS

THIS CHART PROVIDES TIGHTENING TORQUES FOR HYDRAULIC FITTING APPLICATIONS WHEN SPECIAL TORQUES ARE NOT SPECIFIED

ON PROCESS OR DRAWING.

ASSEMBLY TORQUES APPLY TO PLATED CARBON STEEL AND STAINLESS STEEL FITTINGS ASSEMBLED WITHOUT SUPPLEMENTAL

LUBRICATION (AS RECEIVED CONDITION). THEY DO NOT APPLY IF SPECIAL GRAPHITE MOLY-DISULFIDE OR OTHER EXTREME PRESSURE

LUBRICANTS ARE USED.

BRASS FITTINGS AND ADAPTERS - 65% OF THE TORQUE VALUE FOR STEEL. STAINLESS STEEL, ALUMINUM AND MONEL - THREADS ARE

TO BE LUBRICATED

TORQUE IS SPECIFIED IN FOOT POUNDS

.

o

37

JIC, ORS, & ORB (REV. 10/97)

PARKER BRAND FITTINGS

Dash

Size

-4 11-13 15-17 13-15

-5 14-16 — 21-23

-6 20-22 34-36 25-29

-8 43-47 58-62 40-44

-10 55-65 100-110 57.5-62.5

-12 80-90 134-146 75-85

-16 115-125 202-218 109-121

-20 160-180 248-272 213-237

-24 185-215 303-327 238-262

-32 250-290 — 310-340

37 Degree

JIC

O-Ring

(ORS)

O-Ring Boss

(ORB)

LANDOLL CORPORATION

HYDRAULIC FITTING TORQUE SPECIFICATIONS

THIS CHART PROVIDES TIGHTENING TORQUES FOR HYDRAULIC FITTING APPLICATIONS WHEN SPECIAL TORQUES ARE NOT SPECIFIED

ON PROCESS OR DRAWING.

ASSEMBLY TORQUES APPLY TO PLATED CARBON STEEL AND STAINLESS STEEL FITTINGS ASSEMBLED WITHOUT SUPPLEMENTAL

LUBRICATION (AS RECEIVED CONDITION). THEY DO NOT APPLY IF SPECIAL GRAPHITE MOLY-DISULFIDE OR OTHER EXTREME PRESSURE

LUBRICANTS ARE USED.

BRASS FITTINGS AND ADAPTERS - 65% OF THE TORQUE VALUE FOR STEEL.

TORQUE IS SPECIFIED IN FOOT POUNDS.

o

37

JIC, ORS & ORB (REV. 10/97)

AEROQUIP BRAND FITTINGS

Dash

Size

-4 11-12 10-12 14-16

-5 15-16 — 18-20

-6 18-20 18-20 24-26

-8 38-42 32-35 50-60

-10 57-62 46-50 72-80

-12 79-87 65-70 125-135

-14 — — 160-180

-16 108-113 92-100 200-220

-20 127-133 125-140 210-280

-24 158-167 150-165 270-360

-32 245-258 — —

37 Degree

JIC

O-Ring

(ORS)

O-Ring Boss

(ORB)

Table 2-2 Hydraulic Fitting Torque Specifications

2-3

NOTES:

2-4

3-1 ASSEMBLY - SAFETY

It is very important that your new 3130 Series

Wing Packer be properly assembled, adjusted and

lubricated before use. Illustrations in this section

show proper assembly procedures. Remove paint

from grease fittings. Replace any grease fittings

that are damaged or missing. Be sure to return

screws, clips, etc., to their original locations.

To insure alignment of assemblies, leave the

nuts loose until completion of final assembly.

Use lock washers or flat washers as specified.

Spread all cotter pins.

After completion of final assembly, tighten all

nuts evenly to prevent misalignment, distortion or

binding. Tighten all screws and nuts to the recom

mended torques shown in Tables 2-1 and 2-2.

3ASSEMBLY INSTRUCTIONS

CAUTION

1. THE PERSON OR PERSONS WHO

ASSEMBLE THIS MACHINE MUST

HAVE THE ABILITY TO READ, UNDER

STAND AND FOLLOW THE STEP BY

STEP ASSEMBLY PROCEDURES AND

SAFETY INSTRUCTION OUTLINED

HEREIN.

-

2. ASSEMBLY AREA SHOULD BE

LEVEL, CLEAN AND FREE OF DEBRIS

TO PREVENT ASSEMBLY PERSON

NEL FROM TRIPPING OR FALLING.

3. INSPECT ALL PARTS FOR SHARP

EDGES, GREASE, OIL OR DIRT WHICH

MIGHT CAUSE INJURY DURING ASSEMBLY.

-

-

3-1

WARNING

WARNING

1. USE LIFT CRANE, JACK, TACKLE

OR FORK LIFT TRUCK TO LIFT HEAVY

PARTS AND ASSEMBLIES.

2. KEEP CLEAR OF PARTS WHICH

MAY MOVE OR DROP WHEN REMOV

ING SHIPPING STRAPS OR BRACK

ETS.

3. IF MACHINE REQUIRES BLOCKING

UP, USE BLOCKING MATERIAL OF

ADEQUATE STRENGTH AND IN GOOD

CONDITION. BLOCKS MUST BE ON A

SMOOTH DRY SURFACE.

4. NEVER PLACE ANY PART OF YOUR

BODY UNDER BLOCKED-UP ASSEMBLIES.

5. IF WELDING OR FLAME-CUTTING IS

REQUIRED, BE SURE NO FLAMMABLE

MATERIALS ARE IN THE AREA. ALSO,

CLEAR BYSTANDERS FROM AREA.

1. WEAR PERSONAL PROTECTIVE

EQUIPMENT (PPE) SUCH AS, BUT NOT

LIMITED TO, PROTECTION FOR EYES,

LUNGS, EARS, HEAD, HANDS AND

FEET WHEN OPERATING, SERVICING

-

-

OR REPAIRING EQUIPMENT.

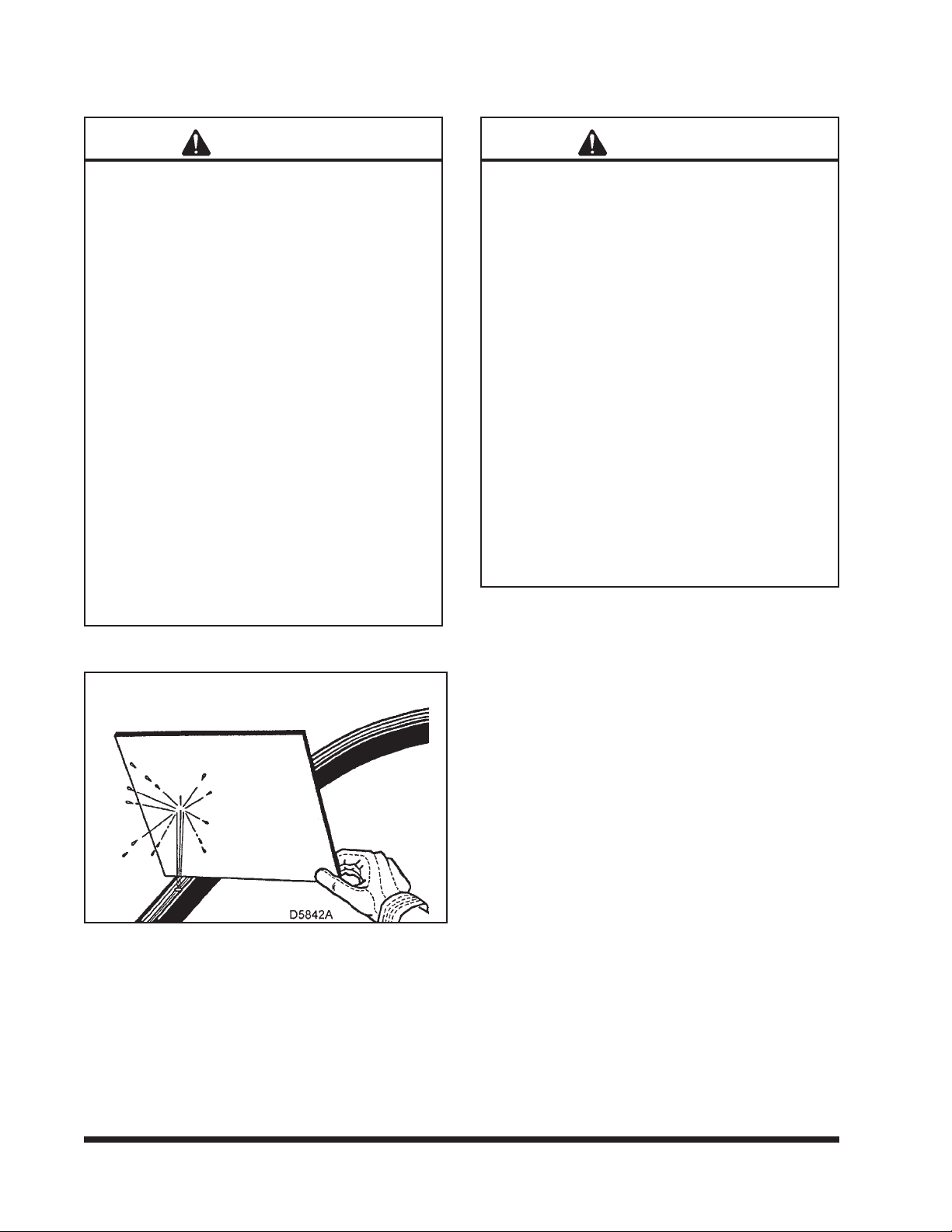

2. NEVER USE YOUR HANDS TO LO

CATE A HYDRAULIC LEAK. USE A

PIECE OF WOOD OR CARDBOARD.

HYDRAULIC FLUID ESCAPING UNDER

PRESSURE CAN PENETRATE THE

SKIN CAUSING SERIOUS INJURY.

3. OPENINGS IN THE SKIN AND MINOR

CUTS ARE SUSCEPTIBLE TO INFEC

TION FROM HYDRAULIC FLUID. IF INJURED BY ESCAPING FLUID, SEE A

DOCTOR AT ONCE. WITHOUT IMMEDIATE MEDICAL TREATMENT, SERIOUS

INFECTION CAN OCCUR.

-

-

3-2

Figure 3-1 Hydraulic Leak Detection

3-2 AFTER ASSEMBLY - SAFETY

WARNING

1. BE SURE ALL NUTS, BOLTS,

OTHER FASTENERS AND HYDRAULIC

FITTINGS ARE PROPERLY TIGHT

ENED. REFER TO THE BOLT TORQUE

CHART.

2. BE SURE ALL SAFETY GUARDS

AND SAFETY LOCKING DEVICES ARE

IN PLACE AND FUNCTION PROPERLY.

3-3

ASSEMBLY INSTRUCTIONS

3-3.1 The terms “right” and “left”, “front” and

“rear”, refer to the machine as viewed by facing in the direction of forward travel.

3-3.2 Open all bundles. Do not mix parts of one

bundle with those of another. Place all bundles where they will be easy to access.

3-3.3 Neatly arrange parts and tools within easy

reach of work area.

-

CAUTION

BEFORE OPERATING THE MACHINE,

BE SURE TO READ THE SAFETY AND

OPERATION SECTIONS OF THE OP

-

ERATOR’S MANUAL.

CAUTION

BEFORE DELIVERING THE MACHINE,

REVIEW MACHINE MAINTENANCE,

OPERATION AND SAFETY WITH THE

CUSTOMER.

3-3.4 Use the correct grade of bolt in the proper

locations as indicated. Refer to the bolt

torque chart for descriptive markings on bolt

heads.

3-3.5 Check axle for end burrs or nicks which

may have occurred during shipping. Using a

flat file, smooth any rough areas to assure

ease of assembly.

3-3.6 After completing each assembly step, re-

view next step in procedure before proceeding with that step.

3-3

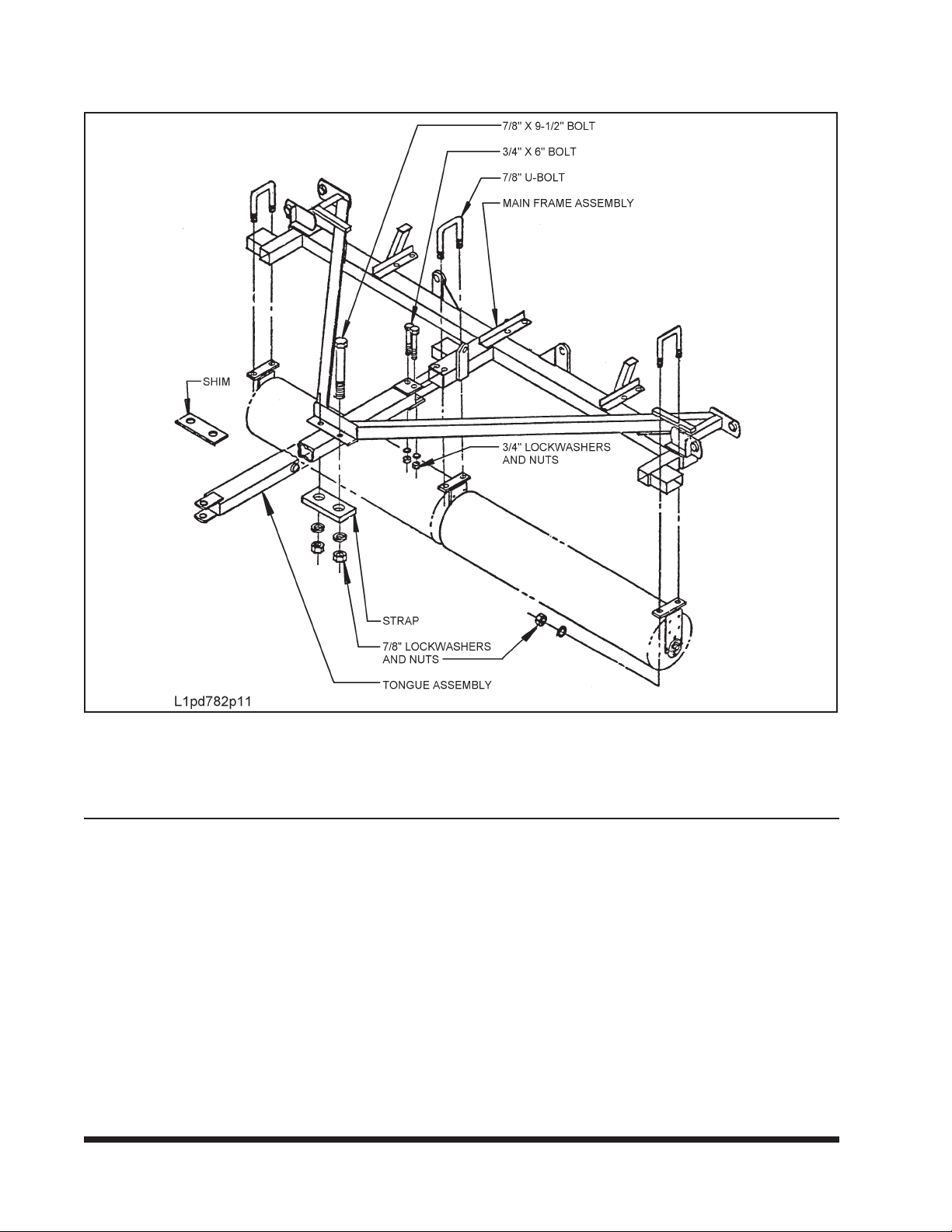

Figure 3-2 Main Frame Gang Assembly - 19’, 20’, 22’, and 24’ Models

3-4 MAIN FRAME, ROLLER GANG, AND TONGUE ASSEMBLY -

19’, 20’, 22’, and 24’ MODELS

3-4.1 Gang Assembly

a. Slide rollers, spacers and bearing hangers

onto the axle. See Figures 3-11 through

3-17 for the type of roller and the size of

your machine. Notice that the diagrams on

these pages are viewing the packer from the

rear. It is important to install the bearing hang

ers as shown. Be sure the grease fittings are

pointing to the rear. Be sure the rollers are

touching each other. Tighten lock collars.

3-4.2 Roller Gang To Main Frame

a. Raise the main frame off the floor.

b. Roll the main frame gang into position. Fas

ten gang to the main frame with three 7/8" ubolts, lockwashers and nuts (See Figure 3-2).

3-4

c. Check to make sure that the bearing hang

ers are perpendicular to the 4" x 6" tube.

When properly installed, there should be no

end thrust or side load on the bearings.

d. Tighten the 7/8" nuts to at least 200 ft.-lbs.

of torque.

3-4.3 Tongue To Main Frame

a. Assemble the tongue to the main frame us

ing 7/8” x 9-1/2” and 3/4” x 6” bolts, lockwash

ers, and nuts as shown.

b. By adding shims above or below the tube,

the tongue can be raised or lowered as de

-

sired. This adjustment is described in Section

3-12, but must be done after the machine is

completely assembled.

-

-

-

-

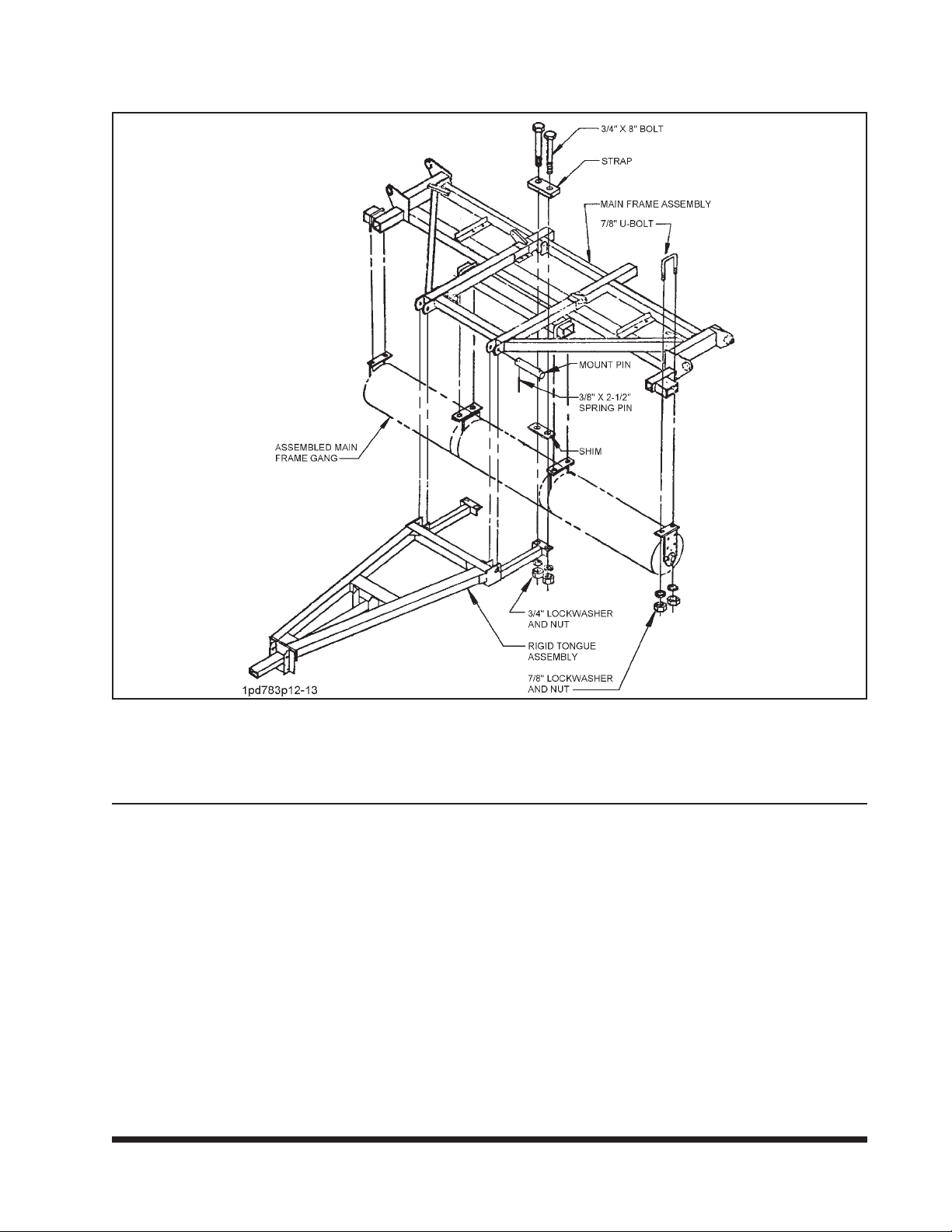

Figure 3-3 Main Frame Gang Assembly - 27’, 31’, and 36’ Models

3-5 MAIN FRAME, ROLLER GANG, AND TONGUE ASSEMBLY -

27’, 31’, and 36’ MODELS

3-5.1 Gang Assembly

a. Slide rollers, spacers and bearing hangers

onto the axle. See Figures 3-18 through

3-23 for the type of roller and the size of

your machine. Notice that the diagrams on

these pages are viewing the packer from the

rear. It is important to install the bearing hang

ers as shown. Be sure the grease fittings are

pointing to the rear. Be sure the rollers are

touching each other. Tighten lock collars.

3-5.2 Roller Gang To Main Frame

a. Raise the main frame off the floor.

b. Roll the main frame gang into position. Fas

ten gang to the main frame with three 7/8" ubolts, lockwashers and nuts (See Figure 3-2).

c. Check to make sure that the bearing hang

ers are perpendicular to the 4" x 6" tube.

When properly installed, there should be no

end thrust or side load on the bearings.

d. Tighten the 7/8" nuts to at least 200 ft.-lbs.

of torque.

3-5.3 Tongue To Main Frame

a. Assemble the tongue assembly to the main

frame using mount pins, 3/8” x 2-1/2” spring

pins, 3/4” x 8” bolts, straps, lockwashers, and

nuts.

b. By adding shims above or below the tube,

-

the tongue can be raised or lowered as de

sired. This adjustment is described in Section

3-13, but must be done after the machine is

completely assembled.

-

-

3-5

Loading...

Loading...