LAARS U.H.E. User Manual

Service Manual Document 11019A

Service Manual for

U.H.E.

Ultra High Efciency

Water Heaters

UHE60T125E*(NA,XA)(2)

UHE60T150E*(NA,XA)(2)

UHE60T199E*(NA,XA)(2)

UHE100T150E*(NA,XA)(2)

UHE100T199E*(NA,XA)(2)

UHE100T250E*(NA,XA)(2)

UHE100T300E*(NA,XA)(2)

UHE100T399E*(NA,XA)(2)

(*) Denotes Warranty Years

Troubleshooting Guide and Instructions for Service

These instructions are to be stored next to the boiler for reference purposes.

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualied in hot water boiler installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in ue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not followed

exactly, a re or explosion may result causing

property damage, personal injury or loss of life.

Do not store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the

re department.

Installation and service must be performed by

a qualied installer, service agency, or gas

supplier.

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion

ou pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inammables dans

le voisinage de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas

vous servir des téléphones dansle bâtiment

où vous êtes.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur

de gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés

par un installateur ou un service d’entretien

qualié ou par le fournisseur de gaz.

AVERTISSEMENT

Page 2

LAARS Heating Systems

U.H.E. Series Commercial Gas

Ultra High Efciency Water Heaters

Table of Contents

Page U.H.E.

Service Procedure

Introduction 3 - - -

How to use this manual 4 - - -

Tool required for service 4 - - -

Specifications 5 - - -

Sequence of Operation 8 - - -

Troubleshooting 10 - - -

Thermostat Circuit, Testing & Replacement 12 I

Combustion System Testing and Replacement 18 II

Burner Tube Inspection & Replacement 22 III

Gas Valve Replacement 24 IV

Blower Testing and Replacement 25 V

Exhaust Pressure Switch Testing and Replacement 27 VI

Hot Surface Igniter Testing and Replacement 30 VII

Flame Sensor Testing and Replacement 32 VIII

TM

Ignition Module/Control Board Replacement 34 IX

Transformer Replacement 35 X

Vent Safety Switch Testing and Replacement 36 XI

Anode & Flue Baffle Inspection and Replacement 38 XII

Installation Check List 43 - - -

Heater Service Report 44 - - -

Parts List 45 - - -

Glossary of Terms 48 - - -

2

U.H.E Service Manual

U.H.E. Series Commercial Gas

Ultra High Efciency Water Heaters

Introduction

The LAARS heating system Ultra High Efficiency Water Heater is designed to

deliver a remarkable thermal efficiency rating in a quiet running unit with venting

options that allow for installation flexibility. Several technologically advanced

design features are incorporated in the design that will require additional

knowledge on the part of the qualified service provider. The information in this

manual will instruct service and maintenance professionals on the function, proper

diagnosis and repair of LAARS Heating System Ultra High Efficiency Water

Heater.

Page 3

The LAARS heating system Ultra High Efficiency Water Heater uses a low Nox

premix power burner located at the top of the water heater to direct a turbulent

flame down into a submerged combustion chamber. This turbulence causes a

thorough mixing of gas and air for optimum combustion. The combustion gases

then travel through a three pass flue system keeping the gases moving at a high

velocity. The combination of high turbulence and velocity results in an optimum

transfer of heat from the flue gases into the water.

Burner operation is controlled using an electronic ignition module. The module

monitors the status of the electronic thermostat, vent temperature limit switch, vent

system pressure switches and a flame sensor to control output voltage to blower

motor, hot surface igniter and gas valve. The module contains programming which

determines the sequence of operation and timings for purge periods, trial for

ignition, flame sensing and lockout. The module will also provide diagnostic

information to help in determining the cause of system lockouts.

The contents in this manual are detailed informational tools to assist in the proper

diagnosis of the Ultra High Efficiency Water Heater operational faults. Please read

this service manual completely and provide as much information regarding the

Ultra High Efficiency Water Heater operation and installation specific concerns.

Page 4

It is intended for this manual to be used by qualified service personal for the primary purpose

of troubleshooting analysis and repair of the LAARS heating system Ultra High Efficiency

Water Heater. Understanding the sequence of operation section of this manual will contribute

greatly to troubleshooting this product.

An “Installation Check List” is shown on page 43. Compare the installation against the

installation check list to confirm all requirements are met.

An “UHE Service Report” is shown on page 44. Completing this form will assist in the

troubleshooting efforts. Should you need to call for technical support, Please provide the

information shown on this form to the support technician to insure accurate troubleshooting.

Troubleshooting begins with “System Observation” to determine failure mode as indicated by

the LED status of the ignition module. Troubleshooting continues with “Failure Modes and

Probable cause” listed on page 10 directing the service provider to a series of test

procedures to determine root cause of failure. Component replacement procedures directly

follow the test procedures for a given component.

LAARS Heating Systems

In some difficult to diagnose conditions, it may be necessary to isolate the heater from the

vent system to determine root cause.

Contact Technical support immediately if diagnosis is not determined using the methods

described in this service manual.

Tools Required for Service

Manometer: Two types available, a liquid “U” tube type or a digital (magna-helic)

type. This device is used to measure gas and/or air pressures and

vacuum.

Multi-Meter: A digital type is strongly recommended. This device is used to measure

electrical values. The meter you select must have the capability to

measure volts AC, volts DC, Amps, micro-amps and ohms.

Thermometer: Used to measure water temperature. An accurate thermometer is

recommended.

Water Pressure Gage: Used to measure water supply pressure. Also used to determine tank

pressure by adapting to the drain valve of the heater.

Jumper Leads: A length of wire (12" min.) with alligator clip at both ends.

Various Hand Tools: Pipe wrench, channel locks, open end wrench set, 12" crescent wrench,

Allen wrench set, torx bit set, screw drivers (common & phillips), long

reach (12") magnetic tip phillips head screw driver #2 tip, ¼" nut driver,

pliers (common & needle nose), socket set including a 1-1/16 deep well

socket, wire cutters, wire strippers, wire crimpers, torpedo level, small

shop vac, step ladder, and flashlight.

4

U.H.E Service Manual

Page 5

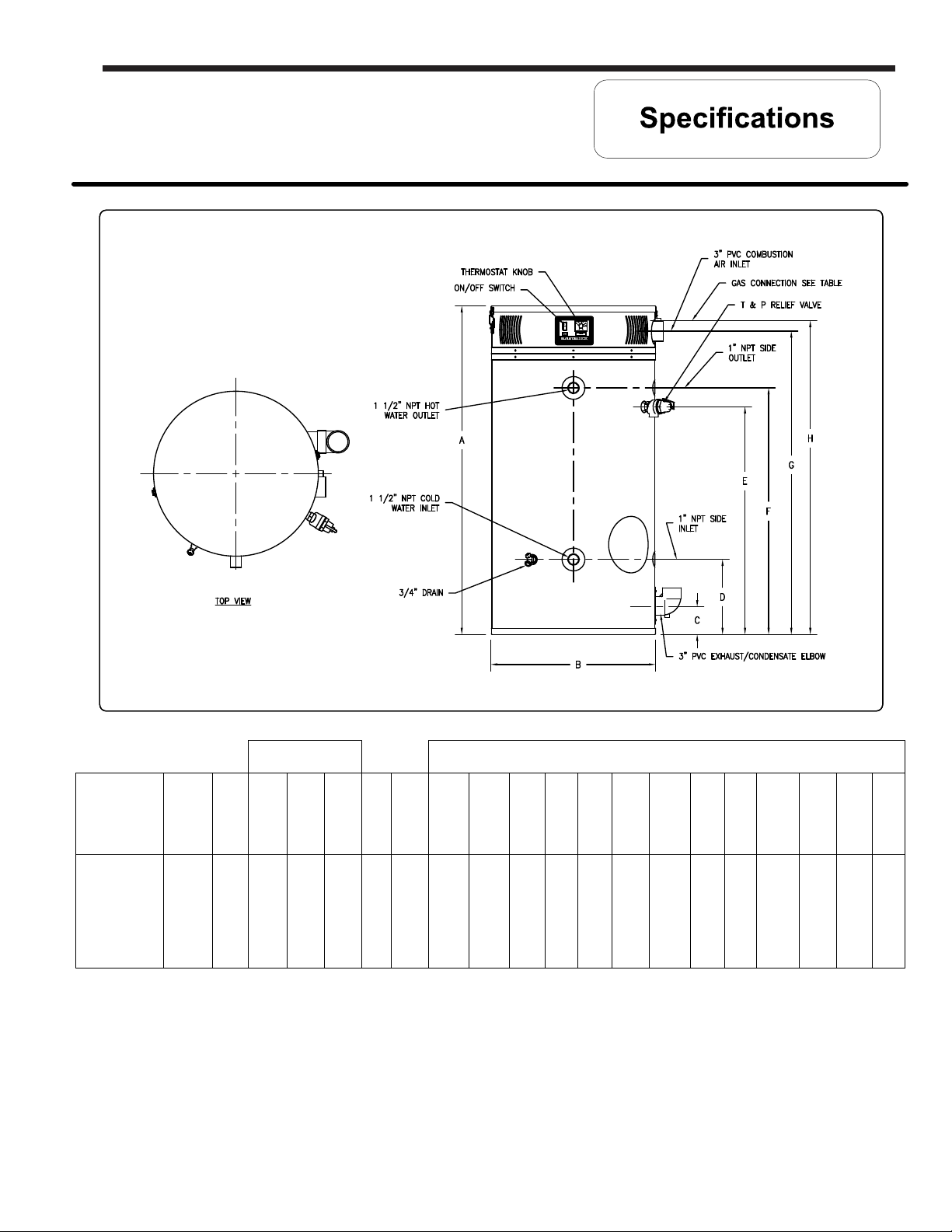

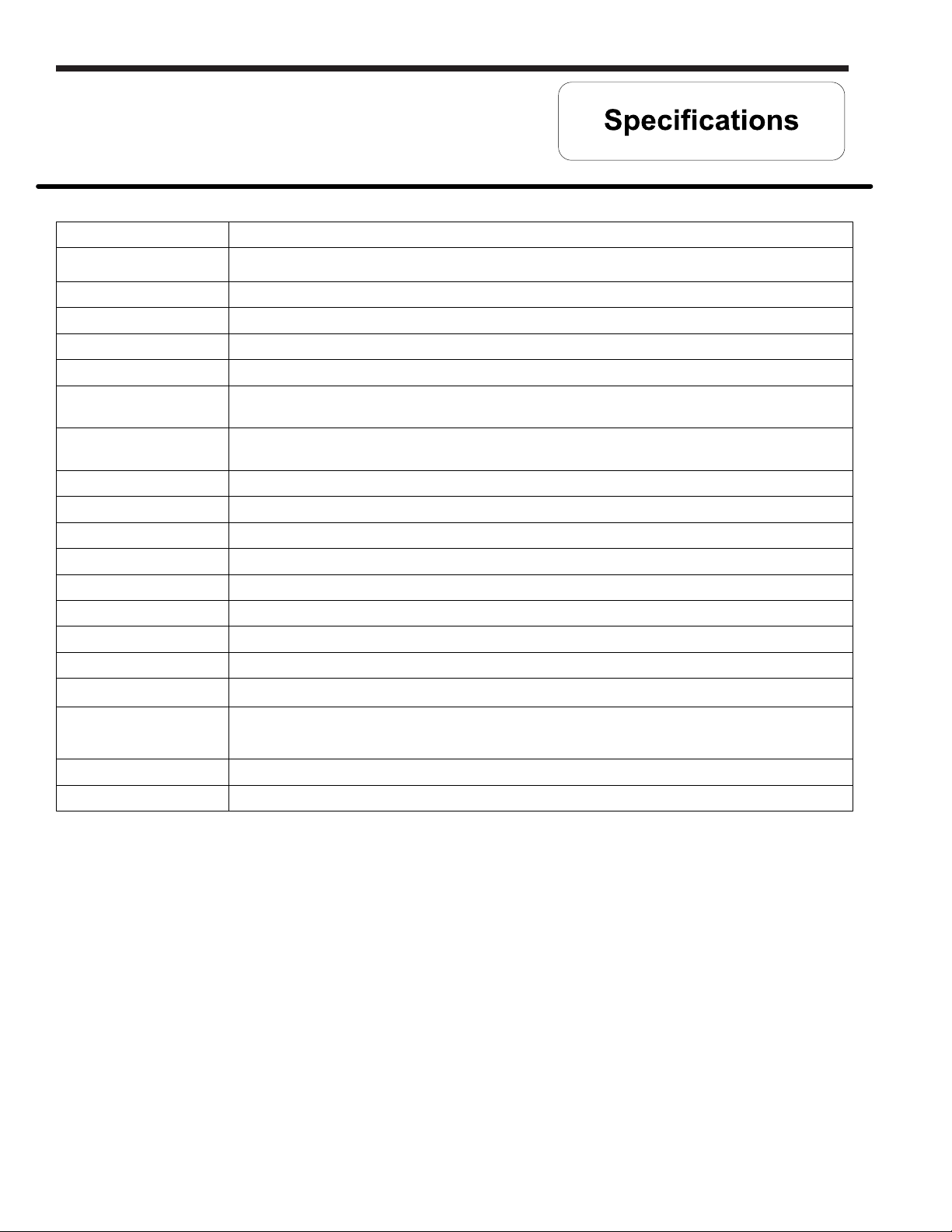

Model No

UHE60T125

UHE60T150

UHE60T199

UHE100T150

UHE100T199

UHE100T250

UHE100T300

UHE100T399

Input

Rate

BTU/h

125,000

150,000

199,999

150,000

199,999

250,000

300,000

399,999

1stHr

Del

Gal

@

100°F

Rise

187

211

265

250

309

364

405

521

363.6

422.7

557.6

450.5

597

734.8

836.4

1,127

Recovery GPH

at Degree Rise

145.5

169.1

223

180.2

238.8

293.9

334.5

451

140°F100°F40°F

103.9

120.8

158

129

171

210

239

322

Stg

Cap

U.S.

Gal

60

60

60

100

100

100

100

100

Therm

Eff

%

96.0

93.0

92.0

99.1

98.5

97.0

92.0

93.0

A

Ht

57

57

57

77 5/8

77 5/8

77 5/8

77 5/8

77 5/8

B

Dia

28 ¼

28 ¼

28 ¼

28 ¼

28 ¼

28 ¼

28 ¼

28 ¼

C

Flr

to

Vent

Outlet

5

5

5

5

5

5

5

5

D

Flr to

Inlet

Wtr

Conn

13

13

13

13

13

13

13

13

DIMENSIONS (INCHES)

F

E

Flr To

Flr to

Outlet

T&P

Wtr

Valve

Conn

Conn

40

42 ¼

40

42 ¼

40

42 ¼

60

62 ¼

60

62 ¼

60

62 ¼

60

62 ¼

¼

60

62

G

Flr. To

Air

Intake

52 ½

52 ½

52 ½

73 1/8

73 1/8

73 1/8

73 1/8

73 1/8

H

Flr to

Gas

Conn

53 ½

53 ½

53 ½

74 ¾

74 ¾

74 ¾

74 ¾

73 ¼

Front

Wtr

Conn

Dia

1 ½

1 ½

1 ½

1 ½

1 ½

1 ½

1 ½

1 ½

Space

Heating

Conn

Dia

1

1

1

1

1

1

1

1

Gas

Conn

Dia

(NPT)

¾

¾

¾

¾

¾

¾

¾

1

T&P

Valve

Open

(NPT)

5

Shpg

Wt

(lbs)

¾

570

¾

570

¾

570

¾

900

¾

900

¾

900

¾

900

1

950

Page 6

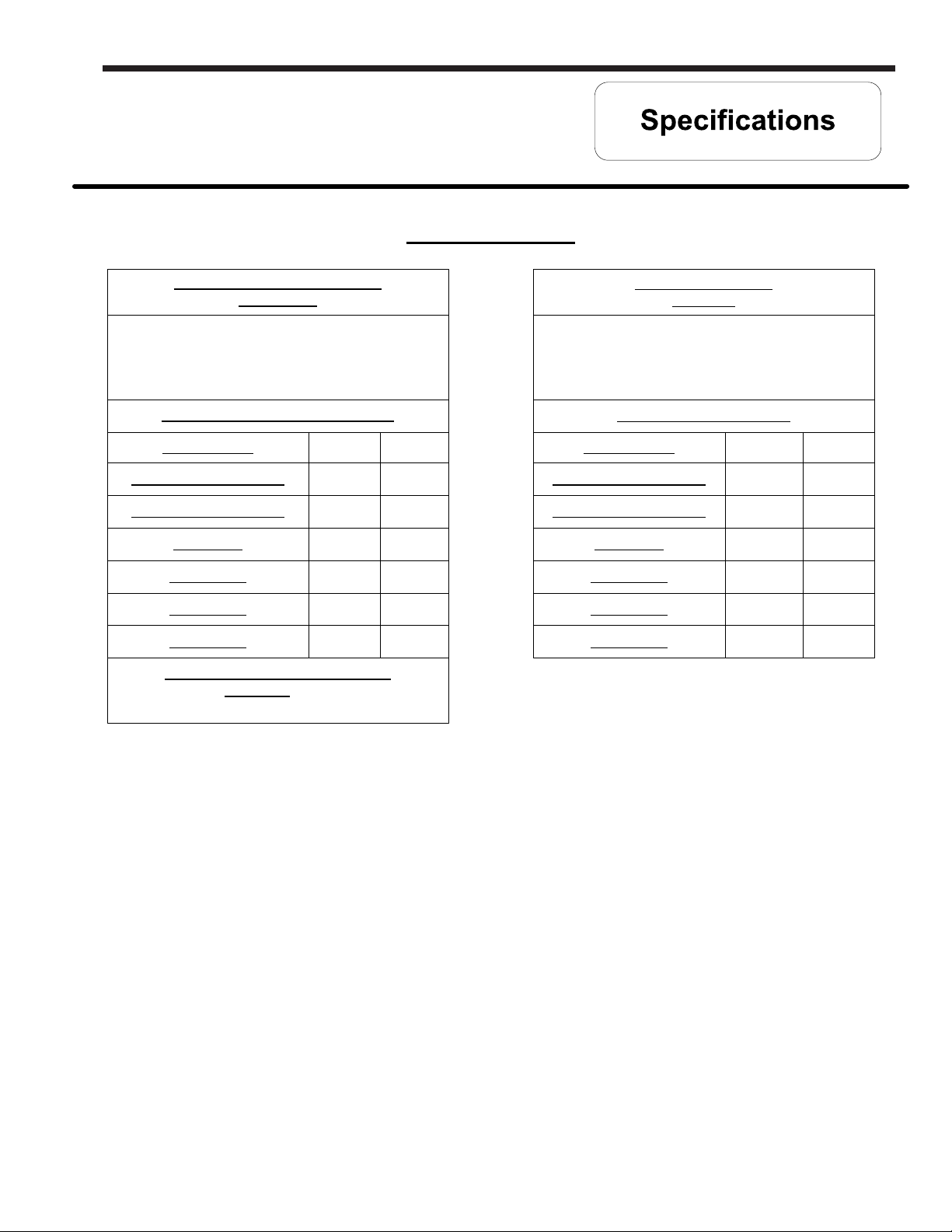

Power supply Dedicated 120 VAC, 60 Hz, 15A, GFI

Gas Supply

Approved Gas Type Natural or Propane. Unit must match gas type supplied.

Gas Pressure (Nat & L.P.) 14.0" W.C. maximum static, 4.5" W.C. minimum running (recommend 7.0" W.C. min running)

Venting System Power vent, balanced direct vent or unbalanced direct vent. See vent tables on page 7

Approved Vent Materials PVC, CPVC or ABS

Minimum Clearance

for Servicing

Maximum Water Supply

Pressure

Thermostat Sensor 11,900 Ohms @ 70°F, ECO opens @ 201°F Max., ECO close @ 100°F Min.

Temperature Dial Min. set point 5400-6600 ohms, Max set point 0-50 ohms.

Thermostat Board Max temp 180°F, Min temp 91°F, 24VAC, 60Hz max.

Ignition Module See page 9

Transformer 120VAC primary, 24VAC secondary, 40VA.

Hot Surface Igniter 120VAC, 30-120 ohms @ room temperature.

Flame Sensor Output Minimum 1 micro amp, Typical range 4 to 7 micro amps.

Gas Valve Negative regulation, 24 VAC, ½" PSI max., 4.5" W.C. Minimum running inlet.

Minimum 1" NPT for UHE100T399, all others ¾" NPT

(schedule 40 black iron pipe recommended)

18" from top, 24" from front, 4" sides and rear.

150 PSI

LAARS Heating Systems

Vent Safety Switch Normally closed, opens @ 350°F, manual reset.

Blocked Vent Pressure

Switch

Blower 120VAC, 60Hz, .6-1 amps, 6400 RPM.

Combustion Levels CO2: 10-11%, CO: less then 0.04 percent (400 PPM) air free

24VAC, normally closed, opens when pressure increases to +2.70 W.C.

6

U.H.E Service Manual

Page 7

Vent Tables

Balanced Direct Vent Systems

PVC, CPVC

Total length of intake piping and exhaust piping

added together must not exceed “Maximum

Combined Length”

Shown below

Maximum Combined Length (feet)

Model Number 3"

UHE60T125, UHE100T150 120'

UHE60T150, UHE100T199

UHE60T199 80' 130'

UHE100T250

UHE100T300

UHE100T399 50' 100'

Unbalanced Direct Vent Systems

Air intake CAN NOT exceed exhaust

by more than 30 feet

100'

80'

60'

4"

170'

150'

130'

110'

Power Vented Systems

PVC, CPVC

Total length of exhaust piping must not exceed

“Maximum Vent Length”

Shown below

Maximum Vent Length (feet)

Model Number 3"

UHE60T125, UHE100T150 120'

UHE60T150, UHE100T199

UHE60T199

UHE100T250 80' 130'

UHE100T300

UHE100T399 50' 100'

100'

80'

60'

4"

170'

150'

130'

110'

Notes:

1) Multiply the total number of 90° elbows (intake and exhaust) by 5 feet. Do not include the

termination fittings or 3" condensate elbow.

2) Multiply the total number of 45° elbows (intake and exhaust) by 2 ½ feet.

3) Add this to the total length of straight pipe - intake and exhaust.

4) The sum total of all elbows and straight pipe - intake and exhaust must not exceed maximum

lengths from tables above.

Example: UHE100T199

A 3" Balanced Direct vent system has 30 feet of straight exhaust pipe and 30 feet of straight intake pipe.

It has 3- 90° elbows in the exhaust and 3- 90° elbows in the intake. It has 1- 45° elbow in the exhaust and

1- 45° elbow in the intake.

Therefore:

6- 90° elbows x 5 feet = 30 feet.

2- 45° elbows x 2½ feet = 5 feet.

60 feet of straight pipe + 30 feet + 5 feet = 95 feet.

System is within “Maximum Combined Length” from table above.

7

Page 8

1

Thermostat calls for heat.

LAARS Heating Systems

Prior to energizing blower, ignition module checks to make sure the vent temperature switch is in the normally closed

position. If the vent temperature switch is open, the control waits indefinitely for the temperature switch to close.

2

Blower energizes, pressure switch contacts are normally closed. If the pressure switch contacts are open, blower operates for up to

5 minutes waiting for contacts to close, then blower stops and flashes red PURGE LED indicating lock-out condition.

3

Blower pre-purge period (5 seconds) indicated by PURGE LED on the module

4

Igniter warm up (18 seconds), indicated by the IGNITER LED on the module. Note: The blocked vent pressure switch

must be in the normally closed position for the ignition cycle to start.

5

Trial for Ignition (4 seconds, 3 trials).

a) Flame establishing period (2.5 seconds), gas valve and igniter on, indicated by the IGNITER and VALVE LED on the

module.

b) Burner on, flame proving period (1.5 seconds, looking for minimum of 1 micro amps), indicated by the FLAME &

VALVE LED on the module.

Steady state operation.

6

Ignition module monitors:

- Thermostat circuit.

- When thermostat opens, gas valve is shut down and post purge begins.

- Safety circuit.

- If vent temperature switch opens, gas valve is shut down, system will post purge and wait for switch to close

before attempting re-ignition.

- If the blocked vent pressure switch opens, indicating a blocked exhaust vent condition, the gas valve is shut

down, blower shuts down for 30 seconds and is re-energized and system attempts re-ignition if the pressure

switch is closed. Blower operates for 5 minutes to wait for pressure switch to close, then shuts off with purge

light flashing (lock-out). Will restart in 1 hour to attempt to close the switch and restart ignition sequence.

- Flame sensor circuit.

- If flame is lost, gas valve is shut down, system will post purge and system attempts re-ignition.

7

Thermostat satisfied.

8

Burner off.

9

Blower post purge (15 seconds).

8

U.H.E Service Manual

Lockout Conditions

Lockout conditions:

The system will go into lock out mode for the following reasons:

Blocked vent pressure switch contacts open:

Check for obstruction in exhaust pipe and vent terminal.

Check for blocked condensate trap or drain line. In cold climates, make sure drain is not frozen.

No ignition after 3 attempts:

a) Check inlet and outlet gas pressures (pressure taps located on top of gas valve).

b) Igniter resistance too high (lower resistance preferred < 150 ohms).

c) Misadjusted veturi screw (should be 6.5 turns out from bottom).

d) Flame sense microamp not present (1.0 microamps minimum, should be 5 microamps or more). If burner lit,

check flame rod for deposits.

e) Check burner tube condition. Refer to section UHE-III for Burner Tube Inspection and Replacement.

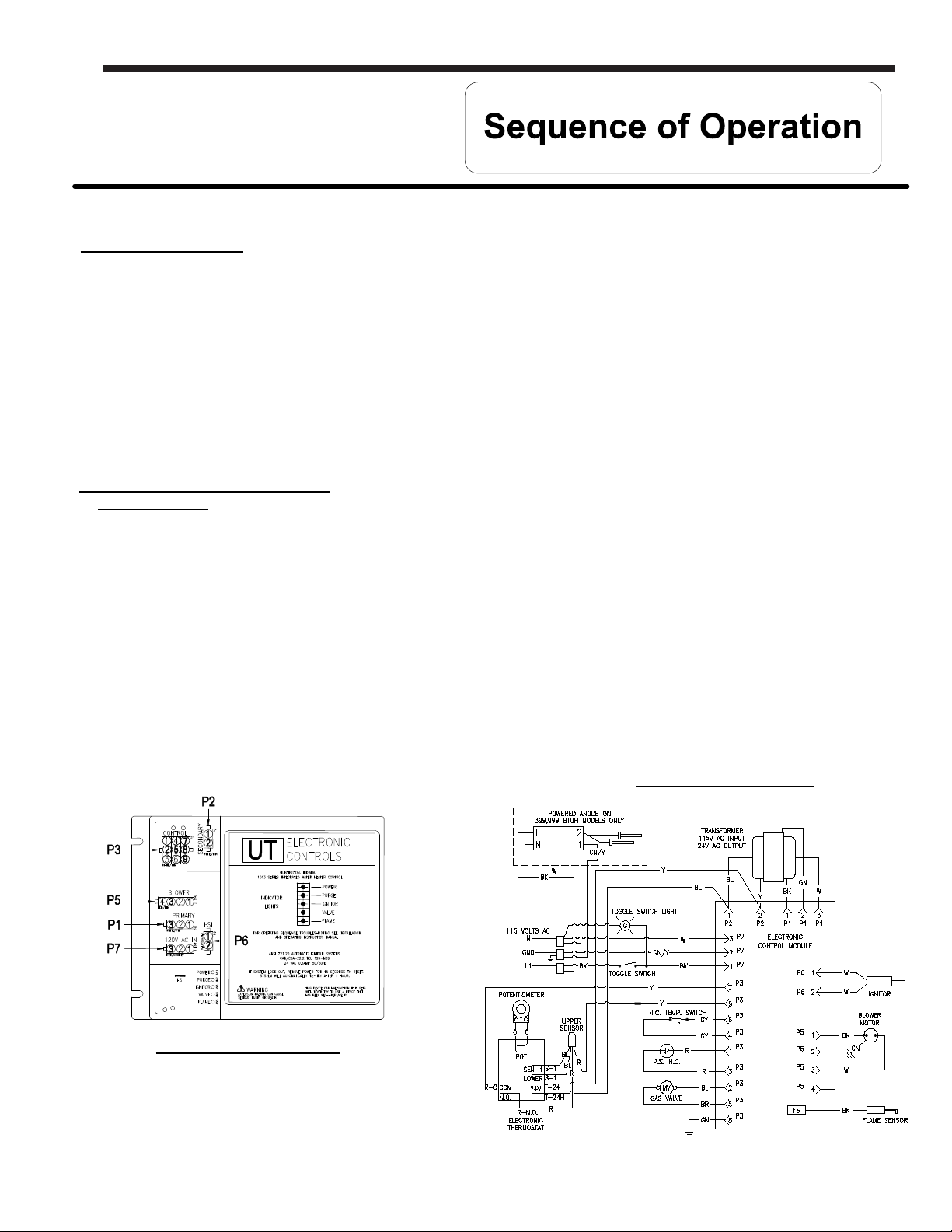

Ignition Module Specifications

Control Functions:

- Ignition & heating functions in response to thermostat.

- Hot surface ignition using a microprocessor to control timing, flame sensing using flame rectification & ignition

retries.

- Monitoring of system pressure switches and limit switches.

- Control of gas valve, inducer motor, and hot surface igniter element based on thermostat demand and status of

safety inputs.

- Diagnostic indicators to provide information on power to control and control status.

- Non-interchangeable polarized plug-in connectors for all interconnections.

Page 9

Control Inputs:

- Thermostat call for heat.

- Blocked vent pressure switch

(normally closed)

- Flame sensing.

- Low voltage supply.

- Line voltage supply.

IGNITION MODULE

Control Outputs:

- Inducer motor

- Hot surface igniter

- Gas valve

- Status indicator LEDs

Power - Green

Purge - Red

Igniter - Red

Valve - Red

Flame - Red

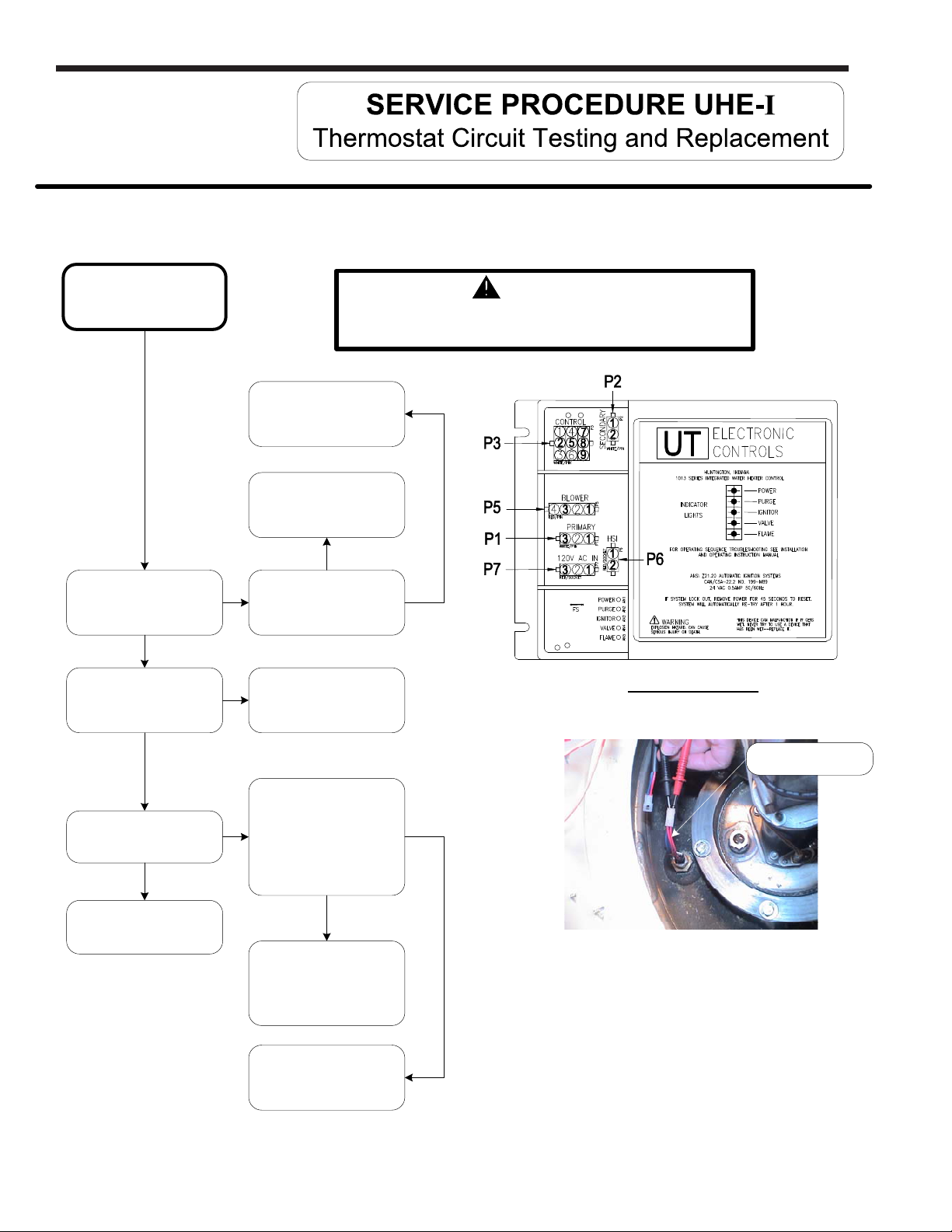

WIRING DIAGRAM

9

Page 10

LAARS Heating Systems

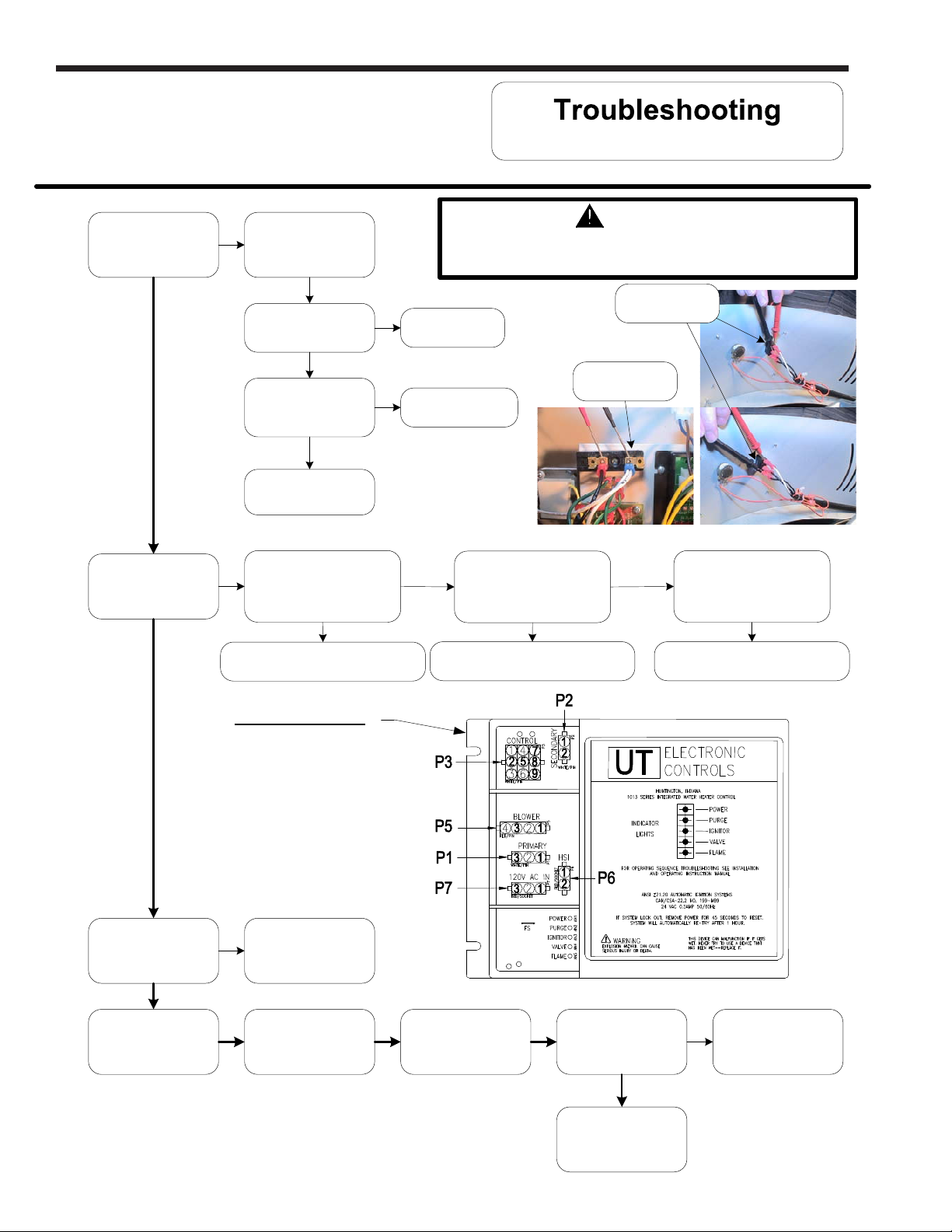

System Observation

Is front panel power

switch light on,

indicating power?

Y

Is ignition module

power light on?

Y

Position front panel

N

N

power switch to

“ON” position.

Is there 120VAC

across switch?

(see photo at right)

N

Is there 120VAC

across terminal block?

(see photo at right)

N

Determine power source

problem and correct.

Refer to ignition module

illustration, is there 120VAC

going to module at locations

P7(1) and P7(3)?

Replace ignition module.

(see page 24)

WARNING

120 volt potential exposure. Use caution

making voltage checks to avoid personal injury.

Power Switch

Light burned out,

Y

replace switch.

Terminal Block

Repair/replace wire

Y

harness to switch.

Y

N

Refer to ignition module

illustration, is there 120VAC

between P1(1) and P1(3)?

N

Replace ignition module.

(see page 24)

Y

Refer to ignition module

illustration, is there 24VAC

going to module at locations

P2(1) and P2(2)?

N

Replace transformer.

(see page 35)

Is ignition module

power and flame light

flashing?

N

Reset heater by

interrupting power.

IGNITION MODULE

Supply voltage polarity is

Y

incorrect.

Reestablish power and

Adjust thermostat to

call for heat,

tank must be cold.

Allow heater to run

through heating cycle.

Did heater complete

heating cycle and did

blower post purge?

Y

System is OK.

N

See next page

10

U.H.E Service Manual

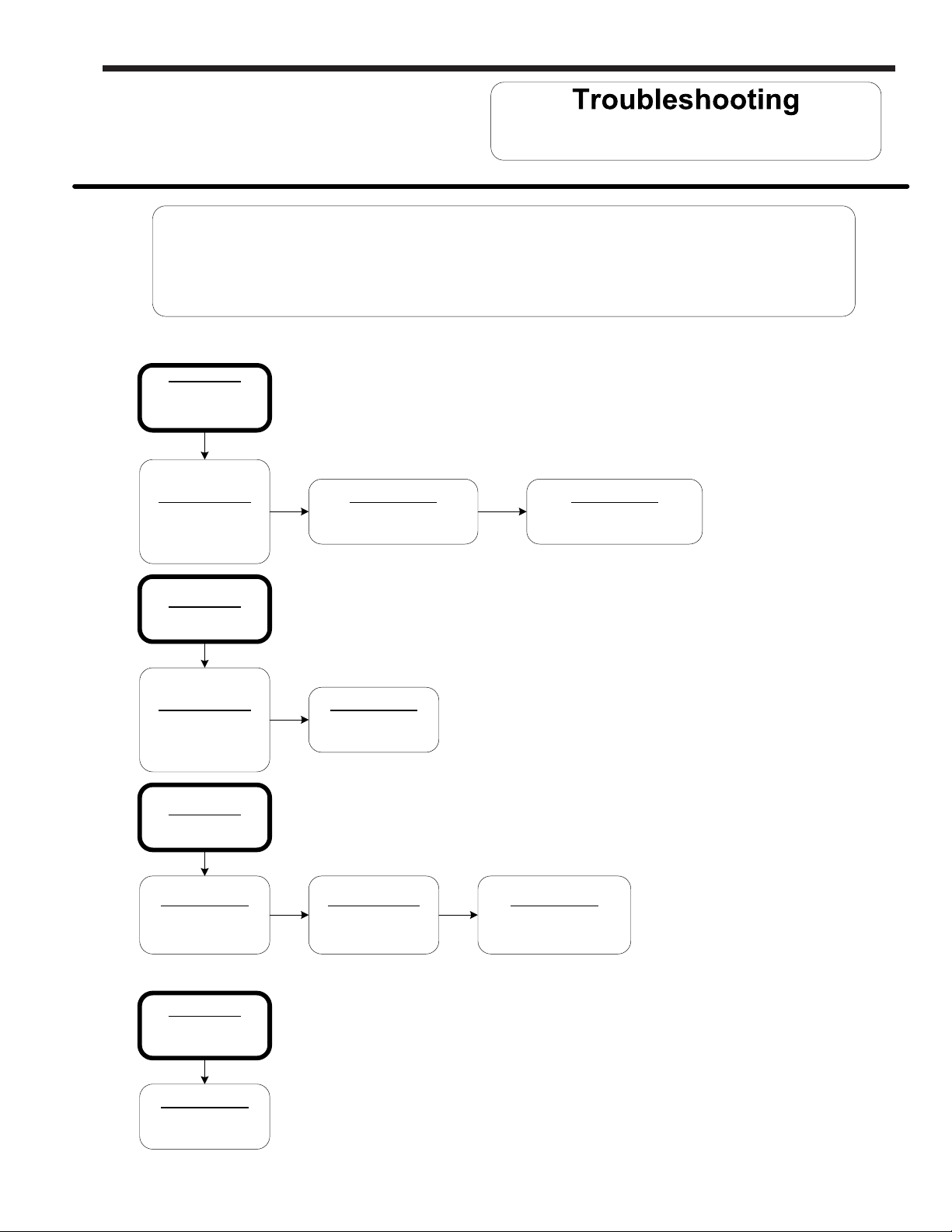

Determine failure mode by observing flashing LED status on ignition module.

* Denotes conditions that may require the water heater to be isolated from the vent

LED STATUS

Only power light

is on and water heater

will not function.

Page 11

LED status & probable cause

For models with Hot Surface Ignition

LED status and probable cause shown below.

system to determine root cause.

Probable Cause*

Exhaust pressure

switch. (see page 27)

LED STATUS

Purge light flashing.

Probable Cause*

Exhaust pressure

switch. (see page 27)

LED STATUS

Valve light flashing.

Probable Cause

Hot surface igniter.

(see page 30)

Probable Cause

Thermostat circuit.

(see page 12)

Probable Cause

Blower.

(see page 25)

Probable Cause*

Combustion system.

(see page 18)

Probable Cause

Vent safety switch.

(see page 36)

Probable Cause

Flame sensor.

(see page 32)

LED STATUS

Power & flame

light flashing.

Probable Cause

Supply voltage

polarity.

11

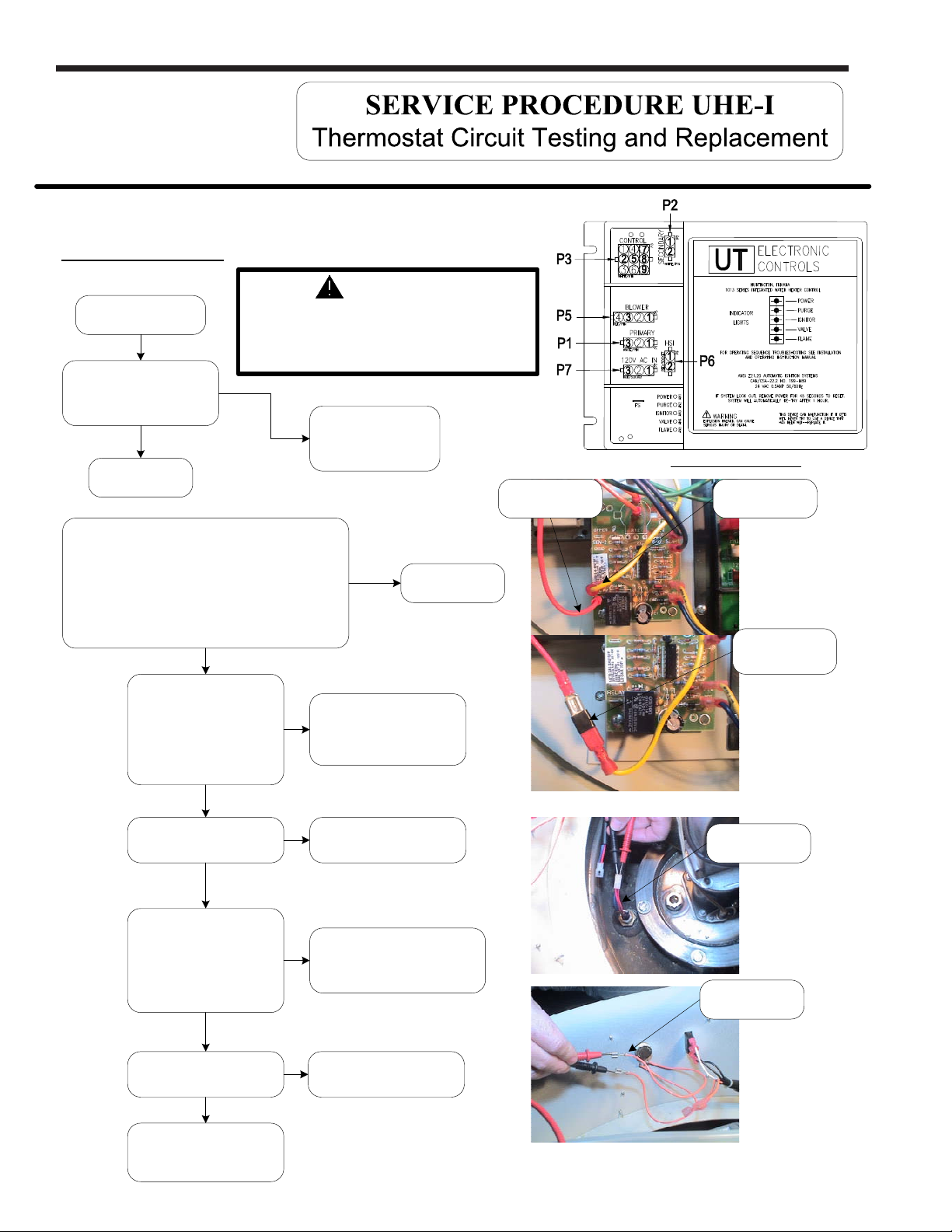

Page 12

LAARS Heating Systems

IMPORTANT NOTE: This procedure assumes a cool tank

WARNING

Rotate temperature

dial to highest setting.

120 volt potential exposure. Use

caution making voltage checks

to avoid personal injury.

Refer to ignition module

illustration, Is there 24VAC

between P3(7) and P3(8)?

N

Thermostat

not calling

Y

OK, thermostat is

calling for heat.

Red Wire

(N.O.)

IGNITION MODULE

Yellow Wire

(COM)

Disconnect YELLOW and RED wires from the

thermostat board at location N.O. and COM shown in

photo at right. Use a jumper to connect these two

Turn off power to heater.

wires together as shown in photo at right.

Restore power to heater.

Did heater cycle on?

Y

Check thermostat sensor

for proper resistance

(OHMS) across blue wires.

(See page 13)

Are readings correct?

(see photo at right)

Y

Check sensor harness

continuity.

Is there continuity?

Y

Check temperature dial for

proper resistance (OHMS)

(See Appendix B,

temperature dial resistance)

Are readings correct?

(see photo at right)

Y

N

N

N

N

Replace

thermostat sensor.

(see page 12)

Replace harness.

Replace temperature dial

(potentiometer).

(see page 16)

See page 14

Yellow & Red

wires shown

jumpered

Thermostat

Sensor

Temperature Dial

Check temperature dial

harness continuity.

Is there continuity?

Y

Replace thermostat

circuit board.

(see page 15)

N

Replace harness.

12

U.H.E Service Manual

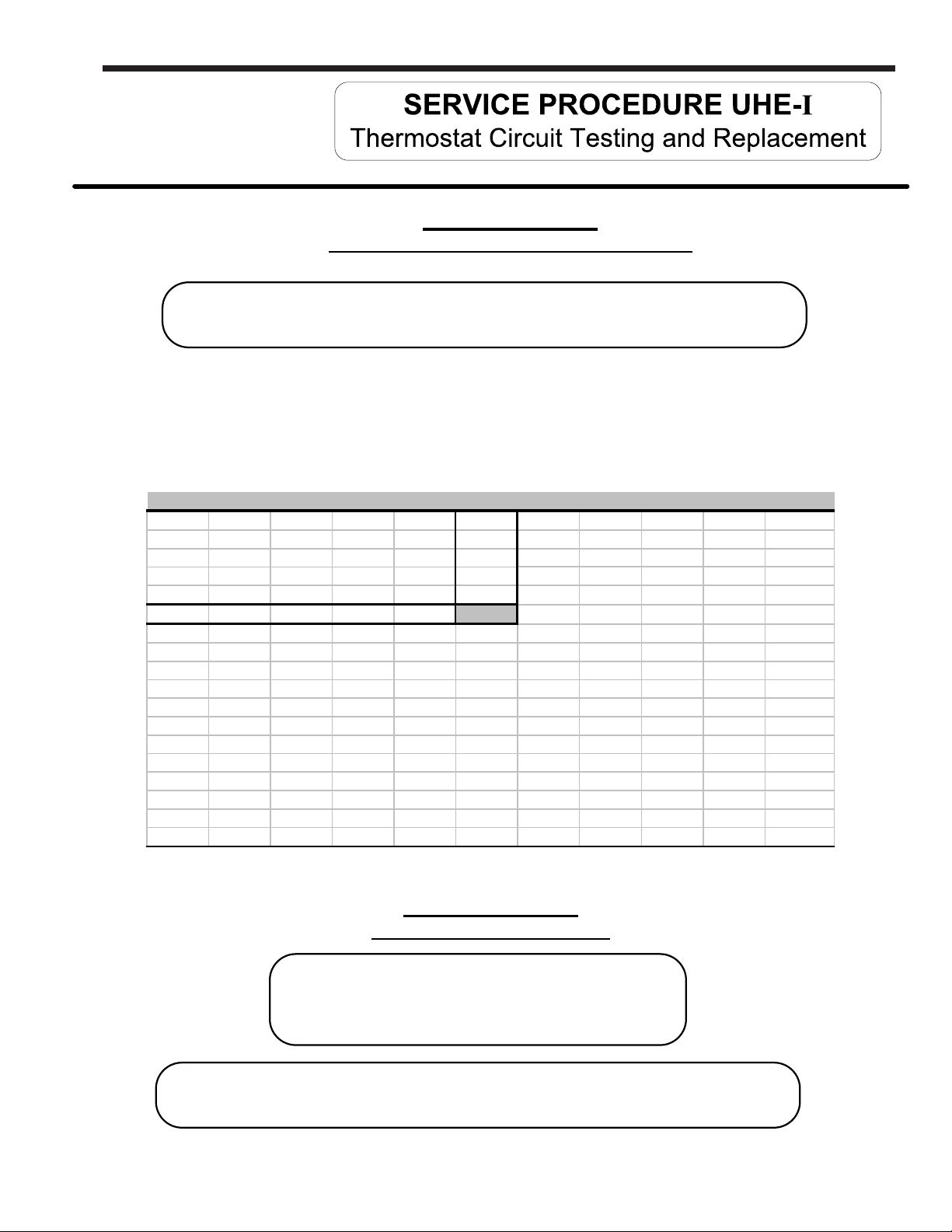

°F012345678 9

Example: If temperature of sensor is 84°F, then the resistance through the sensor would be 8449 (see shaded area).

Page 13

APPENDIX - A

Sensor Resistance at Various Temperatures

Be Careful When Making Voltage Measurements or Jumping Terminals

Not to Damage or Deform Connectors or Connector Pins.

Draw Water From The T&P Valve. Compare Temperature With

Temperature Ohms Chart Below.

NOTE: Sensor resistance increases as the temperature falls.

In Degrees F

40 26109 25400 24712 24045 23399 22771 22163 21573 21000 20445

50 19906 19383 18876 18383 17905 17440 16990 16553 16128 15715

60 15314 14925 14548 14180 13823 13477 13140 12812 12494 12185

70 11884 11592 11308 11032 10763 10502 10248 10000 9760 9526

80 9299 9078 8862 8653 8449 8250 8057 7869 7685 7507

90 7333 7165 7000 6839 6683 6531 6383 6238 6098 5961

100 5827 5697 5570 5446 5326 5208 5094 4982 4873 4767

110 4663 4562 4464 4368 4274 4183 4094 4006 3922 3839

120 3758 3679 3602 3527 3453 3382 3312 3244 3177 3112

130 3048 2986 2925 2866 2808 2752 2697 2643 2590 2538

140 2488 2439 2391 2344 2298 2253 2209 2166 2124 2083

150 2043 2004 1966 1928 1891 1856 1820 1786 1753 1720

160 1688 1656 1625 1595 1566 1537 1509 1481 1454 1427

170 1402 1376 1351 1327 1303 1280 1257 1235 1213 1191

180 1170 1150 1129 1110 1090 1071 1053 1035 1017 999

190 982 965 949 933 917 901 886 871 857 842

200 828 814 801 788 775 762 749 737 725 713

APPENDIX - B

Temperature Dial Resistance

Proper Readings Should Be 5400-6600 Ohms at Minimum Setting

And 0-50 Ohms at Maximum.

Be Careful When Making Voltage Measurements or Jumping Terminals

Not to Damage or Deform Connectors or Connector Pins.

13

Page 14

LAARS Heating Systems

Thermostat circuit.

(continued from page 12)

Refer to ignition module

illustration, Is there 120VAC

between P1(1) and P1(3)?

Y

Refer to ignition module

illustration, Is there

22 - 27VAC between

P2(1) and P2(2)?

Y

Check AC source to

determine why there is no

N

illustration, Is there 120VAC

between P7(3) and P7(1)?

N

power.

Replace

ignition module.

(see page 34)

Y

Refer to ignition module

Replace transformer.

(see page 35)

WARNING

120 volt potential exposure. Use caution

making voltage checks to avoid personal injury.

N

IGNITION MODULE

Red Wires

(Temperature Sensor)

Refer to ignition module

illustration, Is there 24VAC

between P3(9) and P2(1).

N

Replace ignition module.

(see page 34)

Check continuity through

ECO, red wires of

Y

thermostat sensor.

Check at temperature

less than 160°F

Is there continuity?

(see photo at right)

Check wire harness

continuity. Replace

thermostat sensor or wire

harness as necessary.

(see page 17)

Replace thermostat

circuit board.

(see page 15)

Y

N

14

U.H.E Service Manual

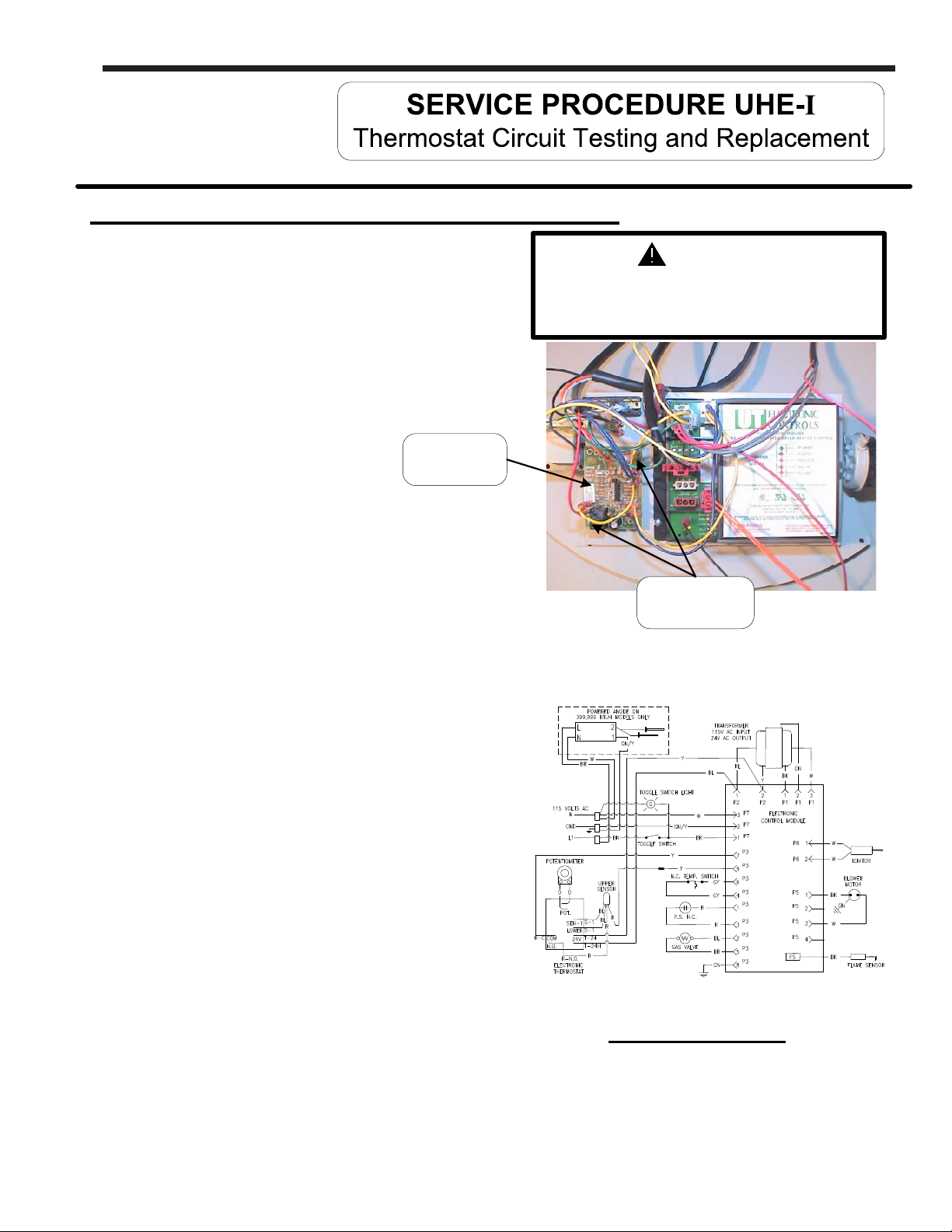

Thermostat Board Replacement Procedure

Page 15

Step 1. Position main power switch to “OFF”

Step 2. Disconnect (unplug) water heater from 120

volt power source.

Step 3. Un-latch and remove top surround cover

from top of heater.

Step 4. Locate thermostat board on control panel.

(see photo at right)

Thermostat

Board

Step 5. Carefully disconnect all wires from thermostat

board.

Note: it may be necessary to identify wires

for proper re-connection.

Step 6. Remove the two screws (Phillips head screw

driver) that secure thermostat board to

control panel.

Step 7. Install new thermostat board to control panel using

screws from step 6.

WARNING

120 volt potential exposure. Isolate the

appliance and reconfirm power is

disconnected using a multi-meter.

Mounting

screw locations

Step 8. Carefully reconnect wiring per the wire

diagram below. Reconfirm wire

connections are correct prior to putting

heater back in service

Step 9. Restore 120 volt power supply to water

heater and confirm proper operation following

the lighting instructions on the lighting

instruction label or the lighting instruction

located in the installation and operating

instruction manual.

Step 10. Replace surround cover on top of heater.

WIRING DIAGRAM

Loading...

Loading...