Page 1

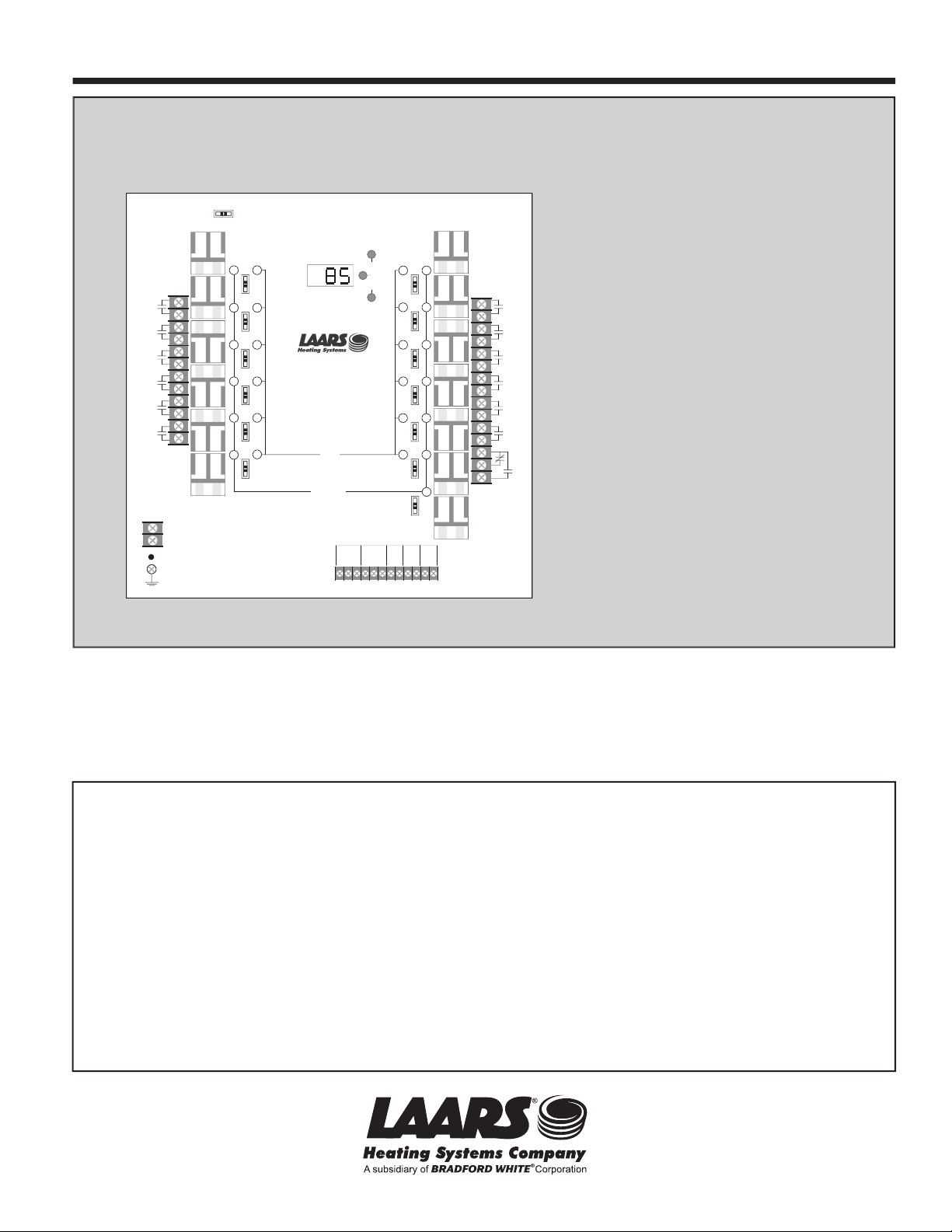

LINE

NEUT

OUTPUT 8

OUTPUT 9

OUTPUT 7

OUTPUT 10

OUTPUT 11

OUTPUT 12

INCREMENT

AUTO

OFF

LEAD STAGE

ROTATION

SELECT

SETTING

UP

DOWN

INPUTS

1 2 345 6 789

10

SAFETY

GROUND

MUST BE

CONNECTED

11

12

Sensor ComShield + SensorCom

DryContact

Only

DryContact

Only

TEMP

SHUTDOWN

/SETBACK

PROVE

/DHW

SYSTEM

Output 7

OFF

AUTO

ON

Output 8

OFF

AUTO

ON

Output 9

OFF

AUTO

ON

Output 10

OFF

AUTO

ON

Output 11

OFF

AUTO

ON

Output 12

OFF

AUTO

ON

OFF

AUTO

ON

OUTPUT 1

OUTPUT 2

OUTPUT 3

OUTPUT 4

OUTPUT 5

OUTPUT 6

Output 1

OFF

AUTO

ON

Output 2

OFF

AUTO

ON

Output 3

OFF

AUTO

ON

Output 4

OFF

AUTO

ON

Output 5

OFF

AUTO

ON

Output 6

OFF

AUTO

ON

System

LEAD

OUTPUT ON

4-20ma

OUTDOOR

SC

Page 2

SC FUNCTION CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

DIP SWITCH CHART

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION .

M

OUNTING THE SC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

S

ET THE DIP SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

W

IRING THE POWER INPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

WIRING THE INPUT TERMINALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

W

IRING THE STAGE OUTPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

WIRING THE SYSTEM OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

BEFORE POWER UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

P

OWER UP SEQUENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

ADJUSTING THE CONTROL SETTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SET POINT CONTROL WITH NORMAL SEQUENCING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DIP SWITCH 8 - OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SET POINT CONTROL WITH OSS SEQUENCING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

O

UTDOOR RESET WITH NORMAL SEQUENCING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

OUTDOOR RESET WITH OSS SEQUENCING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SC-6 AND SC-12 OUTPUT WIRING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

WIRING THE STAGE OUTPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SC-6P OUTPUT WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

WIRING THE STAGE OUTPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SAMPLE WIRING AND PLUMBING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

OUTPUT RELAY CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17

OPERATION . . 18

SET POINT CONTROL SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

OUTDOOR RESET SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

NORMAL SEQUENCING SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

O

VERSIZE SYSTEM SEQUENCING SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SYSTEM OUTPUT SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

LEAD STAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

OUTPUT CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

EXTERNAL SET POINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5

Page 3

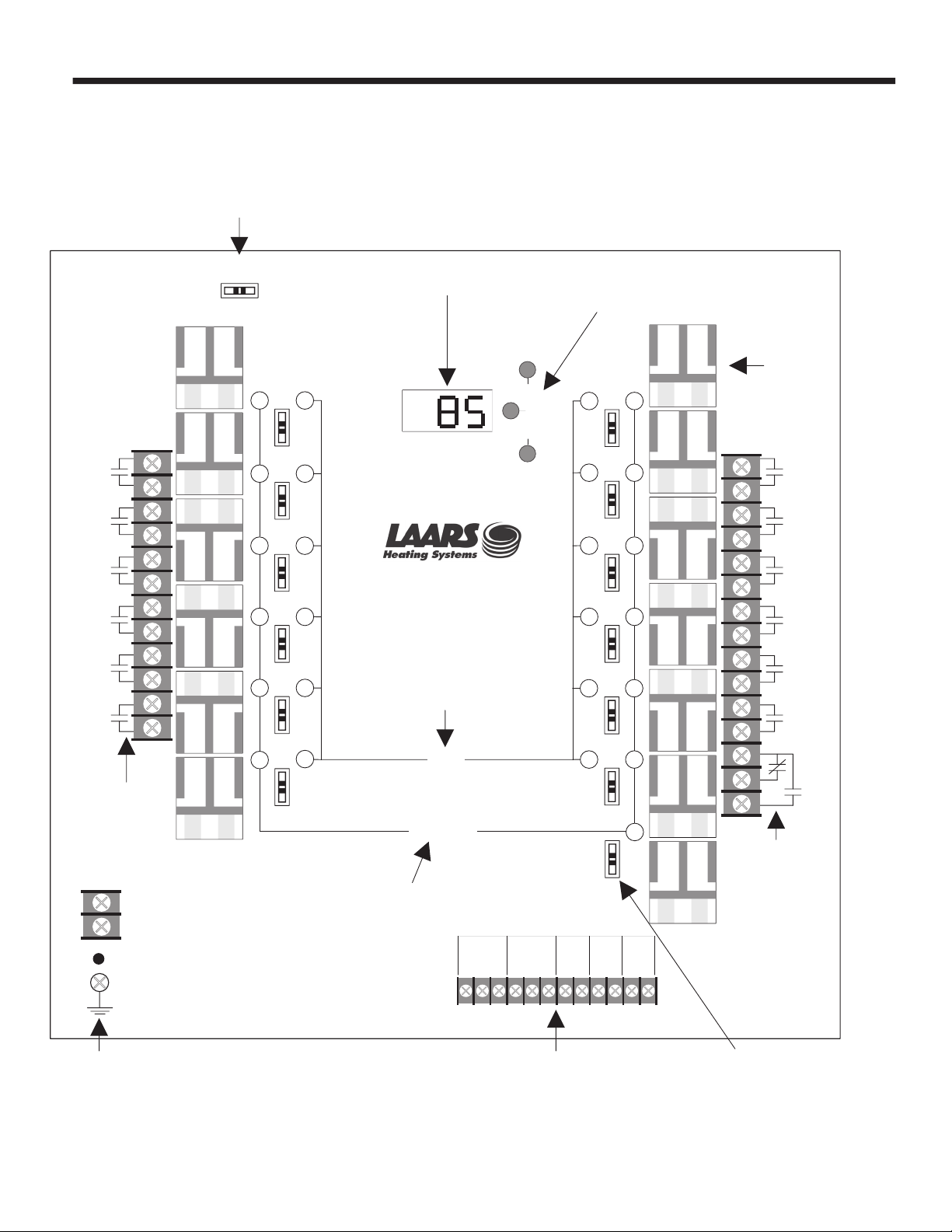

LINE

NEUT

OUTPUT 8

OUTPUT 9

OUTPUT 7

OUTPUT 10

OUTPUT 11

OUTPUT 12

INCREMENT

AUTO

OFF

LEAD STAGE

ROTATION

SELECT

SETTING

UP

DOWN

INPUTS

1 2 345 6 789

10

SAFETY

GROUND

MUST BE

CONNECTED

11

12

Sensor Com Shield + Sensor Com

DryContact

Only

DryContact

Only

TEMP

SHUTDOWN

/SETBACK

PROVE

/DHW

SYSTEM

Output 7

OFF

AUTO

ON

Output 8

OFF

AUTO

ON

Output 9

OFF

AUTO

ON

Output 10

OFF

AUTO

ON

Output 11

OFF

AUTO

ON

Output 12

OFF

AUTO

ON

OFF

AUTO

ON

OUTPUT 1

OUTPUT 2

OUTPUT 3

OUTPUT 4

OUTPUT 5

OUTPUT 6

Output 1

OFF

AUTO

ON

Output 2

OFF

AUTO

ON

Output 3

OFF

AUTO

ON

Output 4

OFF

AUTO

ON

Output 5

OFF

AUTO

ON

Output 6

OFF

AUTO

ON

System

LEAD

OUTPUT ON

4-20 ma

OUTDOOR

SC

Digital display reads

sensor value constantly

Install a relay for

each output stage

which will be active

Use these three buttons

to adjust the settings

In AUTO, the lead stage will automatically

rotate among the active outputs. Press to

INCREMENT for manual rotation.

Each Stage

Output has

one set of

N.O. contacts

The green LEAD stage

light indicates which

stage will be activated

first on a system call

The red OUTPUT lights

indicate when the relays

are energized and the

N.O. contacts are

continuous.

The System

Output is

SPDT

Each output can be switched

ON, AUTO, or OFF. In AUTO,

the output will be controlled

based on system requirements.

120 VAC Power Input

GND must be connected

Sensor, Shutdown/Setback,

Prove/DHW, and Outdoor

input terminals

Page 4

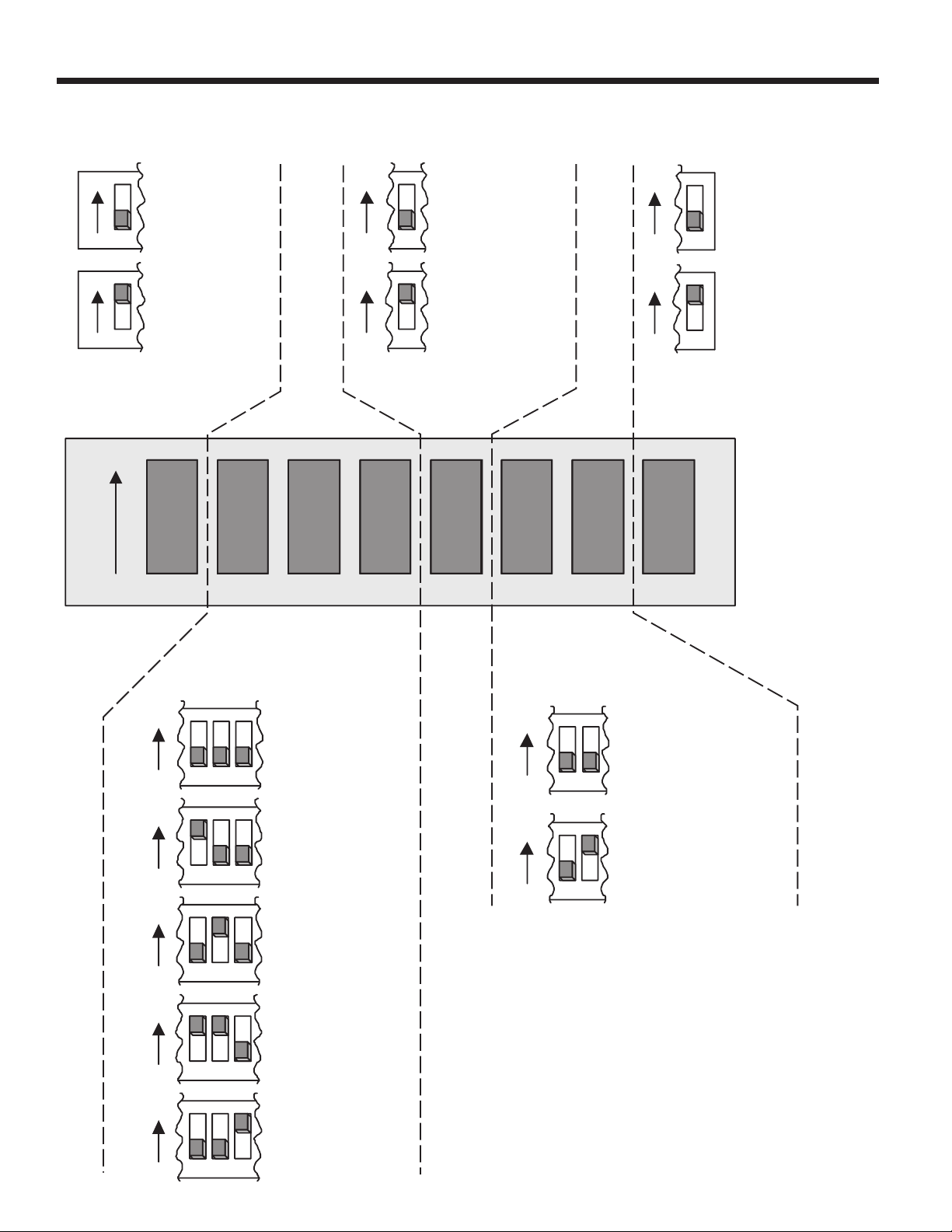

1 2 3 4 5 6 7 8

ON

Switch 1

System Output

Switch 5

Rotation

Switches 6 and 7

Input Type

5

First On/Last Off

Lead stage rotates

every 24 hours

5

First On/First Off

First stage on is

the first stage

turned off

Temperature

6 7

External Set Point

Available for temperature

systems only, 4-20mA

signal changes Set Point

6 7

ON

ON

ON

ON

Switch 8

Set Point or Reset

8

Set Point

Set Point control

for temperature

8

Outdoor Reset

Hydronic heating

control with

outdoor reset

ON

ON

1

System Pump

SYSTEM relay is on

based on outside

temp, Shutdown,

and DHW priority

1

Combustion Air

Damper/Prove

SYSTEM relay is

on when any

OUTPUT is on

ON

ON

Switches 2, 3, and 4

Stage Type

2Stage Lo/Lo/Hi/Hi

On load increase

sequence on Lo

stages first, then Hi

stages

2

On/Off Stages

Each stage is

either on or off

2 Stage Lo/Hi

On load increase

sequence Lo to Hi

then next Lo to Hi

3 4

2 3 4

2

3 Stages

On load increase

sequence Lo, Mid,

Hi

3 4

2 3 4

4 Stages

On load increase

sequence Lo,

LoMid, HiMid, Hi

2 3 4

ON

ON

ON

ON

ON

ON

Page 5

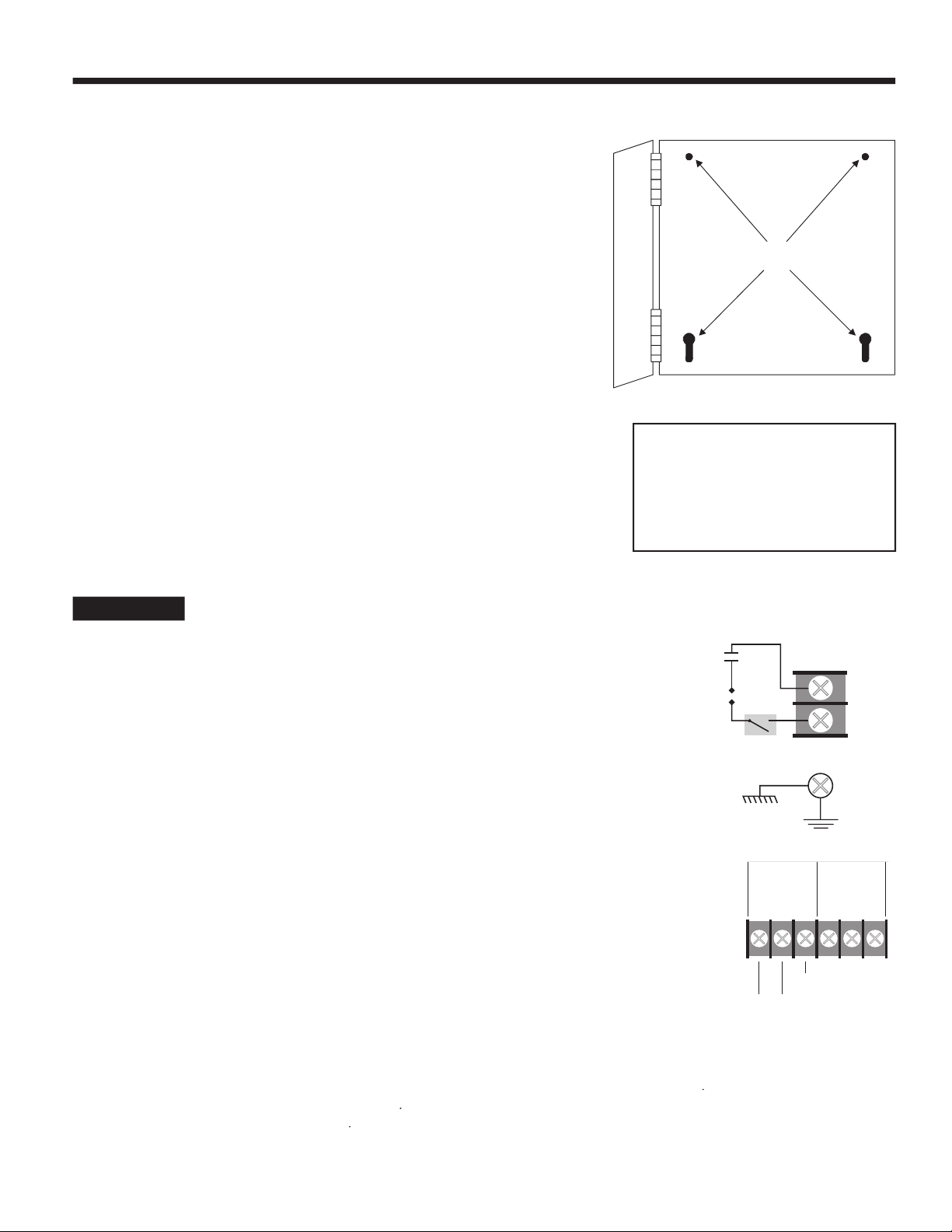

temperature is from 20 to 120°F.

the enclosure.

the metal front panel).

- System relay output type - Combustion Air Damper, or System Pump operation

- Stage type - On/Off, Lo/Hi, 3 Stage or 4 Stage

- Rotation Sequence - First On/Last Off or First On/First Off

- Input type - Temperature or External Set Point

- Operation - Set Point or Outdoor Reset

IMPORTANT

The dip switches must be set correctly. Carefully, check the details of the installation and

WIRING THE POWER INPUTS

voltage wiring.

LINE.

NEUT.

WIRING THE INPUT TERMINALS

and

NOT

be installed in between boiler connections to header. If the sensor does not

register the output of all the stages, it will not be able to Sequence properly.

2 COM

Mounting Holes

LINE

NEUT

Surge

Suppressor

Power Switch

Ground

Line

Neut

INPUTS

1 2 3

4

5 6

Sensor Com Shield + Sensor Com

TEMP PRES 4-20 ma

Shield

To Temperature Sensor

in Common Header

Page 6

6

and dip switch 7 must be

monitor the 4-20mA input to change the set point. (See wiring sensor on pg. 3) Also, see pg. 23 for

EMS programming parameters.

and

SETBACK

setting to 0 the

SHUTDOWN

feature is enabled by

were on will remain on until the System Delay is over, then they will also turn off.

SHUTDOWN

feature can be used whenever it is desirable to turn off the SC from a remote

SETBACK

is enabled by adjusting control

SETBACK

setting to a value higher

than 0 and closing a dry contact wired to terminals 7 and 8, the SC will immediately reduce the

temperature of the circulating hot water by the

SETBACK

setting amount (see pg. 20 to

SETBACK)

SHUTDOWN/SETBACK

signal must be a dry contact only to terminals 7 and 8. No voltage can be

placed across the

SHUTDOWN/SETBACK

terminals.

and

) and Domestic Hot Water (

).

PROVE

feature is used to check system components’ operation before activating any stages. See

pg. 24 for typical applications.

PROVE

input terminals are open, the SC will enable only the System Output relay. All Stage

PROVE

input is open.

DHW

) input is enabled by closing a dry contact, the Calculated water

temperature or the Set Point will change to 200°F and the decimal point on the left-most digit on the

DHW

input will take priority over the outdoor reset function or the Outdoor Cutoff temperature.

Regardless of outdoor temperature, when the

DHW

input is closed, the SC will Sequence stages to

hold 200°F.

NO

external conditions must be met before Stage Output is activated and terminals

and

are not used for Domestic Hot

Water (see pg. 25),

DO NOT

remove the factory installed jumper across the

PROVE/DHW

terminals.

PROVE/DHW

signal must be a dry contact only to terminals 9 and 10. No voltage can be placed across the

PROVE/DHW

terminals.

IMPORTANT

input terminals must be

and

).

). If it is installed, it will act as an Outdoor

windows, exhaust fans, vents, or other possible heat sources.

and 12.

Note that both sensor shields will be connected

to terminal 3.

Dry Contact

Prove or Domestic

Hot Water Signal

INPUTS

5 6 7

8910

11

Sensor Com

DryContact

Only

DryContact

Only

SHUTDOWN

/SETBACK

PROVE

/DHW

OUTD

4-20 ma

INPUTS

5 6 7

89101112

Sensor Com

DryContact

Only

DryContact

Only

SHUTDOWN

/SETBACK

PROVE

/DHW

4-20 ma

OUTDOOR

To Outdoor Sensor

In Shade

Shield

2 3

4

Com Shield +

TEMP

4

5 6

+ Sensor Com

4-20 ma

SC Source Current

24VDC Excitation Voltage

(-) Input

(+) Signal

INPUTS

5 6 7

8

9

Sensor Com

DryContact

Only

DryContact

SHUTDOWN

/SETBACK

PROVE

4

+

4-20 ma

Dry Contact

Shutdown and

Setback Signal

4

5 6

+ Sensor Com

4-20 ma

EMS Sourcing Current

(-) Input

(+) Signal

Page 7

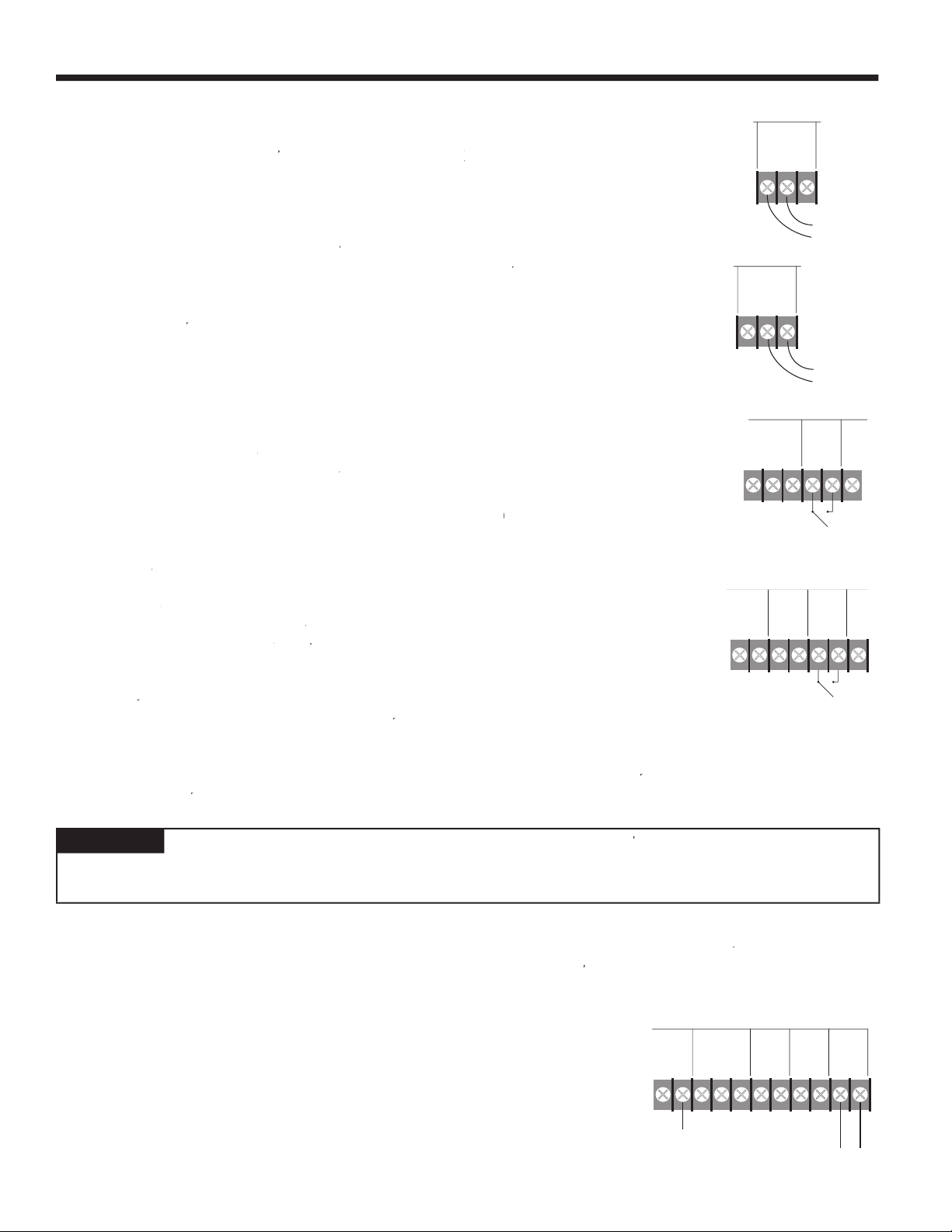

WIRING THE STAGE OUTPUTS

WIRING THE SYSTEM OUTPUT

- If there is no call for stage output, the System relay is off

- On a call for stage output, the System relay is energized

- When the

PROVE

input is made, the lead stage is energized

- The System relay remains energized as long as any stage is active

- When the last stage turns off, the System relay remains energized for the period of

time set by the System Delay (see pg. 22)

- Then the System relay is turned off.

PROVE

inputs. The

PROVE

input can be used in a

and the Shutdown is not

- The System relay will be energized when any stage is active

- After the last stage is turned off, the System relay will remain energized for the period of time set by the System Delay (see pg.

22) and then turn off.

- When the outdoor temperature below the Outdoor Cutoff + 2°F (

+ 2°F), the

- Otherwise, the System relay will be off above

+ 2°F (after the System Delay

has expired).• When the control is set

- The System relay will be off for an adjustable period of time set by the DHW Priority Time

- After the Priority Time has elapsed, when the outdoor temperature is below the Outdoor Cutoff + 2°F (

+ 2°F) setting, the

- When the outdoor temperature is 2°F above the Outdoor Cutoff (

+

2°F), the System relay will be off at all times.

switch in the

AUTO

position.

switch in the

position.

LEAD STAGE

switch in the

AUTO

position for automatic rotation.

SYSTEM

C.

N.C.

N.O.

Combustion

Air Damper

Line

Neut

SYSTEM

C.

N.C.

N.O.

System Pump

Line

Neut

WARNING

Page 8

the parameters are correct, there is no need to make any adjustments.

reapply power.

the SC will operate in Fahrenheit. If the display shows

then the SC will operate in Celsius.

button to increase the value,

DOWN

button to decrease the value.

and

(see pg. 25).

the Input terminals

and

will function in the Prove mode. If the display shows

then the same

terminals will function in the DHW mode.

button to increase the value, or

the

DOWN

button to decrease the value.

will fl ash.

Normal

or PID type Sequencing mode provides the most stable operation. Stages are turned on or off

based on the rate of change of the system temperature and the impact a stage has on that rate.

) Sequencing

mode that brings on stages proportionally, based on how high above or far below the Set Point the current system temperature is.

For more details, see pg. 21.

(Normal) then the SC will Sequence in the PID type mode. If the display shows

then SC will

around the Set Point

button to increase the value, or the

DOWN

button to decrease the value.

will fl ash. This completes the startup Sequence and the SC will display the sensor temperature.

the SC will operate in Fahrenheit. If the display shows

then the SC will operate in Celsius.

button to increase the value,

DOWN

button to decrease the value.

Minimum Water Temperature

INCREMENT

AUTO

OFF

LEAD STAGE

ROTATION

For Automatic Lead

Stage Rotation

Output

OFF

AUTO

ON

For Non-Active

Stages

For Stages Which are

to be Part of the

Automatic Sequence

Page 9

button to increase the

value, or the

DOWN

button to decrease the value.

will fl ash.

and

(see pg. 25).

the Input terminals

and

will function in the Prove mode. If the display shows

then the same

terminals will function in the DHW mode.

button to increase the value, or

the

DOWN

button to decrease the value.

will fl ash.

based on the rate of change of the system temperature and the impact a stage has on that rate.

Sequencing mode

that brings on stages proportionally, based on how high above or far below the Set Point the current system temperature is. For

more details, (see pg. 21).

then the SC will Sequence in the PID type mode. If the display shows

then SC will

button to increase the value, or the

DOWN

button to decrease the value.

will fl ash. This completes the startup Sequence and the SC will display the sensor temperature.

Page 10

ADJUSTING THE CONTROL SETTING

SELECT SETTING

button.

Set Point Control with Normal Sequencing Temperature or External Set Point pg. 10

Set Point Control with Oversize System Sequencing Temperature or External Set Point pg. 11

Outdoor Reset Control with Normal Sequencing pg. 12

Outdoor Reset Control with Oversize System Sequencing pg. 13

Press SELECT

SELECT

SETTING

UP

DOWN

Press and

Hold to

Adjust

Press to Scroll

Through Control

Settings

Control Settings

Display

Button

Once

Twice

♦

♦♦

3 Times

3 or 4 Times

4 or 5 Times

5 or 6 Times

6 or 7 Times

7 or 8 Times

7 or more Times

8 or more Times

8 or more Times

♦♦

♦♦

♦♦

SET POINT CONTROL WITH NORMAL SEQUENCING

Dip Switch 8 - OFF

DISPLAY Press and hold either the UP or DOWN button to adjust

The Set Point is the temperature which the SC will sequence stages to hold. Note that if you are

using the External Set Point, you will not be able to change the Set Point unless you adjust the 4-

Set Point

Outdoor Temp

Outdoor Cutoff

Reaction Time

System Delay

Purge Time

Boiler runtime

Program Offset

Last Stage Hold

Setback

DHW Priority Time

20mA input. The Set Point is adjustable between -30

This is the outdoor sensor temperature value.

Available only when the outdoor sensor is installed. When the outdoor temperature falls below the

Outdoor Cutoff value, the SC will activate stages for heat. The Outdoor Cutoff can be set ON or OFF

and from 40 to 100°F. Default is 60°F.

The Reaction Time controls the minimum run time for a stage (1/2 the Reaction Time). Also, it controls how long should a stage run before it activates/subtracts another stage. It is adjustable from half

a minute (0.5) to 8.0 minutes. Default is 2 minutes.

The System Delay controls how long the System relay will remain energized after the last Output has

been turned off or the outdoor temperature rises above the Starter. The System Delay is adjustable

from 0 to 30 minutes. Default is 0.

The Purge Time should be set to the length of the unit’s purge cycle. The Purge Time will apply

when any ON/OFF unit is activated. On multiple stage units, the Purge Time will only apply to the Lo

stages. The Purge Time is adjustable from 0.0 to 10.0 minutes.

This is the minimum amount of time any boiler will run after the Purge cycle has been completed. This

timer does not apply when only one stage is running, the Last Stage Hold LSH applies in that case.

The Boiler Runtime is adjustable between 0 to 60 minutes. Default is 0.

The Programmed Offset fi ne tunes the External Set Point. With a known 4mA input, the offset can be

set to make the External Set Point 110°F. The Program Offset is adjustable between -10

Default is 0°F.

To prevent short cycling of the last stage in low load conditions, the system temperature can exceed

the Set Point by the amount selected by the Last Stage Hold before the last stage is turned off. The

Last Stage Hold is adjustable between 0°F to 20°F. Default is 10°F.

The Setback adjusts the number of degrees the Set Point water temperature will be reduced when

Input terminals 7 and 8 are closed. If the Setback is set to 0, then the system will Shutdown on a

closure. The Setback is adjustable from 0°F to 40°F. Default is 0°F.

Only available when the System Output is set to System Pump (dip switch 1 is ON and dip switch 6 is

OFF ) This setting adjusts the amount of time the System relay output will remain off during a DHW

call. If the DHW call is not satisfi ed before the DHW priority time has elapsed, the System relay will

energize to provide heat. The DHW Priority is adjustable from 0 to 4 hours in half hour increments.

Default is 0.

°F to 250°F. Default is 70°F.

Default is 0.

°F to +10°F.

8 or more Times

♦ Actual temperature values are not adjustable

♦♦ May not be available, depending on status of the outdoor sensor and dip switches.

♦

Default

The SC returns to the default display of system water temperature.

Page 11

Press SELECT

Button

Once

SET POINT CONTROL WITH OSS SEQUENCING

Dip Switch 8 - OFF

DISPLAY Press and hold either the UP or DOWN button to adjust

The Set Point is the temperature which the SC will sequence stages to hold. Note that if you are

Set Point

using the External Set Point, you will not be able to change the Set Point unless you adjust the 420mA input. The Set Point is adjustable between -30

°F to 250°F. Default is 70°F.

♦

Twice

3 Times

♦♦

3 or 4 Time

4 or 5 Times

4 or more Times

5 or more Times

5 or more Times

5 or more Times

Outdoor Temp

Outdoor Cutoff

System Delay

♦♦

Program Offset

Throttling Range

♦♦

Setback

♦♦

DHW Priority Time

♦

Default

This is the outdoor sensor temperature value.

Available only when the outdoor sensor is installed. When the outdoor temperature falls below the

Outdoor Cutoff value, the SC will activate stages for heat. The Outdoor Cutoff can be set ON or OFF

and from 40 to 100°F.

The System Delay controls how long the System relay will remain energized after the last Output has

been turned off or the outdoor temperature rises above the Starter. The System Delay is adjustable

from 0 to 30 minutes. Default is 0.

The Programmed Offset fi ne tunes the Pressure input or the External Set Point. With a known 4mA

input, the offset can be set to make the External Set Point 110°F. The Program Offset is adjustable

between -10°F to +10°F. Default is 0°F.

The throttling range sets the number of degrees or psi above and below the Set Point where stages

will be turned on or off. The Throttle Range is adjustable from 1

24 for details.

The Setback adjusts the number of degrees the Set Point water temperature will be reduced when

Input terminals 7 and 8 are closed. If the Setback is set to 0, then the system will Shutdown on a

closure. The Setback is adjustable from 0°F to 40°F. Default is 0°F.

Only available when the System Output is set to System Pump (dip switch 1 is ON and dip switch 6 is

OFF ) This setting adjusts the amount of time the System relay output will remain off during a DHW

call. If the DHW call is not satisfi ed before the DHW priority time has elapsed, the System relay will

energize to provide heat. The DHW Priority is adjustable from 0 to 4 hours in half hour increments.

Default is 0.

The SC returns to the default display of system water temperature.

Default is 60°F.

♦ Actual temperature values are not adjustable

♦♦ May not be available, depending on status of the outdoor sensor and dip switches.

°F to 20°F. Default is 5°F. See page

Page 12

Press SELECT

Button

Once♦

OUTDOOR RESET WITH NORMAL SEQUENCING

Dip Switch 6 and 7 - OFF and 8 - ON

DISPLAY Press and hold either the UP or DOWN button to adjust

This is the water temperature the SC will stage outputs to hold. It is based on outdoor temperature,

Calculated

Reset Ratio, and the Offset value. If OFF is shown, there is no call for heat. If PrF is shown, the SC

is waiting for a Prove signal before activating stages.

Twice

3 Times

4 Times

5 Times

6 Times

7 Times

8 Times

9 Times

10 Times

11 Times

12 Times

♦

Outdoor Temp

Outdoor Cutoff

Reset Ratio

Offset

Reaction Time

System Delay

Purge Time

Boiler runtime

Last Stage Hold

Setback

♦♦

DHW Priority Time

This is the outdoor sensor temperature value.

When the outdoor temperature falls below the Outdoor Cutoff value, the SC will give heat. When the

outdoor temperature is above the Outdoor Cutoff, the Calculated value will be OFF and no stages will

be activated except on a DHW call. The Outdoor Cutoff can be set ON or OFF and from 40 to 100°F.

Default is 60°F.

The Reset Ratio controls the amount of heat which enters the heating system based on the outdoor

temperature. A higher numbered Reset Ratio will result in a higher Calculated water temperature.

See the chart on pg. 19 for the reset curves. The Reset Ratio is adjustable from 1 to 12. Default is 7.

The Offset moves the reset curves vertically up or down. For example, changing the offset from 0 to

-10 will decrease the water temperature 10°F regardless of outdoor temperature or the reset curve

selected. The Offset is adjustable from -40

The Reaction Time controls the minimum run time for a stage (1/2 the Reaction Time). Also, it controls how long should a stage run before it activates/subtracts another stage. It is adjustable from half

a minute (0.5) to 8.0 minutes. Default is 2 minutes.

The System Delay controls how long the System relay will remain energized after the last Output has

been turned off or the outdoor temperature rises above the Starter. The System Delay is adjustable

from 0 to 30 minutes.

The Purge Time should be set to the length of the unit’s purge cycle. The Purge Time will apply

when any ON/OFF unit is activated. On multiple stage units, the Purge Time will only apply to the Lo

stages. The Purge Time is adjustable from 0.0 to 10.0 minutes.

This is the minimum amount of time any boiler will run after the Purge cycle has been completed. This

timer does not apply when only one stage is running, the Last Stage Hold LSH applies in that case.

The Boiler Runtime is adjustable between 0 to 60 minutes. Default is 0.

To prevent short cycling of the last stage in low load conditions, the system temperature can exceed

the Calculated water Temperature by the amount selected by the Last Stage Hold before the last

stage is turned off. The Last Stage Hold is adjustable between 0

The Setback adjusts the number of degrees the Set Point water temperature will be reduced when

Input terminals 7 and 8 are closed. If the Setback is set to 0, then the system will Shutdown on a

closure. The Setback is adjustable from 0°F to 40°F. Default is 0°F.

Only available when the System Output is set to System Pump (dip switch 1 is ON and dip switch 6 is

OFF ) This setting adjusts the amount of time the System relay output will remain off during a DHW

call. If the DHW call is not satisfi ed before the DHW priority time has elapsed, the System relay will

energize to provide heat. The DHW Priority is adjustable from 0 to 4 hours in half hour increments.

Default is 0.

°F to 40°F. Default is 0°F.

Default is 0.

°F to 20°F. Default is 10°F.

12 to 13 Times

♦

Default

The SC returns to the default display of system water temperature.

♦ Actual temperature values are not adjustable

♦♦ May not be available, depending on status of the outdoor sensor and dip switches.

Page 13

Press SELECT

Button

Once♦

OUTDOOR RESET WITH OSS SEQUENCING

Dip Switch 6 and 7 - OFF and 8 - ON

DISPLAY Press and hold either the UP or DOWN button to adjust

This is the water temperature the SC will stage outputs to hold. It is based on outdoor temperature,

Calculated

Reset Ratio, and the Offset value. If OFF is shown, there is no call for heat. If PrF is shown, the SC

is waiting for a Prove signal before activating stages.

Twice

3 Times

4 Times

5 Times

6 Times

7 Times

8 Times

9 Times

♦

Outdoor Temp

Outdoor Cutoff

Reset Ratio

Offset

System Delay

Throttling Range

Setback

♦♦

DHW Priority Time

This is the outdoor sensor temperature value.

When the outdoor temperature falls below the Outdoor Cutoff value, the SC will give heat. When the

outdoor temperature is above the Outdoor Cutoff, the Calculated value will be OFF and no stages will

be activated except on a DHW call. The Outdoor Cutoff can be set ON or OFF and from 40 to 100°F.

Default is 60°F.

The Reset Ratio controls the amount of heat which enters the heating system based on the outdoor

temperature. A higher numbered Reset Ratio will result in a higher Calculated water temperature.

See the chart on pg. 19 for the reset curves. The Reset Ratio is adjustable from 1 to 12.

The Offset moves the reset curves vertically up or down. For example, changing the offset from 0 to

-10 will decrease the water temperature 10°F regardless of outdoor temperature or the reset curve

selected. The Offset is adjustable from -40

The System Delay controls how long the System relay will remain energized after the last Output has

been turned off or the outdoor temperature rises above the Starter. The System Delay is adjustable

from 0 to 30 minutes.

The throttling range sets the number of degrees or psi above and below the Set Point where stages

will be turned on or off. The Throttle Range is adjustable from 1°F to 20°F. Default is 5°F. See page 21

for details.

The Setback adjusts the number of degrees the Set Point water temperature will be reduced when

Input terminals 7 and 8 are closed. If the Setback is set to 0, then the system will Shutdown on a

closure. The Setback is adjustable from 0°F to 40°F. Default is 0°F.

Only available when the System Output is set to System Pump (dip switch 1 is ON and dip switch 6 is

OFF ) This setting adjusts the amount of time the System relay output will remain off during a DHW

call. If the DHW call is not satisfi ed before the DHW priority time has elapsed, the System relay will

energize to provide heat. The DHW Priority is adjustable from 0 to 4 hours in half hour increments.

Default is 0.

°F to 40°F. Default is 0°F.

Default is 7.

9 to 10 Times♦

Default

The SC returns to the default display of system water temperature.

♦ Actual temperature values are not adjustable

♦♦ May not be available, depending on status of the outdoor sensor and dip switches.

Page 14

Additional output relays can be

WARNING

This Laars Heating Systems control is strictly an operating control; it should

SC

Outputs

Output

NO

C

Limit

Circuit

ON/OFF Units

Lo

Output

2 Stage Units

Hi

Output

NO

C

Hi

Circuit

Lo

Output

3 Stage Units

NO

C

Mid

Output

Hi

Output

Lo

Output

4 Stage Units

LoMid

Output

HiMid

Output

Hi

Output

NO

C

Limit

Circuit

NO

C

Limit

Circuit

NO

C

Mid

Circuit

NO

C

Hi

Circuit

NO

C

Limit

Circuit

NO

C

LoMid

Circuit

NO

C

HiMid

Circuit

NO

C

Hi

Circuit

through

) which is to be used must have

position (see pg. 23).

WIRING THE STAGE OUTPUTS

SYSTEM,

must not exceed 15A.

contacts associated with it.

2 Stage (Lo/Hi) Units

relays associated with it.

relays associated with it.

4 Stage (Lo/LoMid/HiMid/Hi) Units

relays associated with it.

Page 15

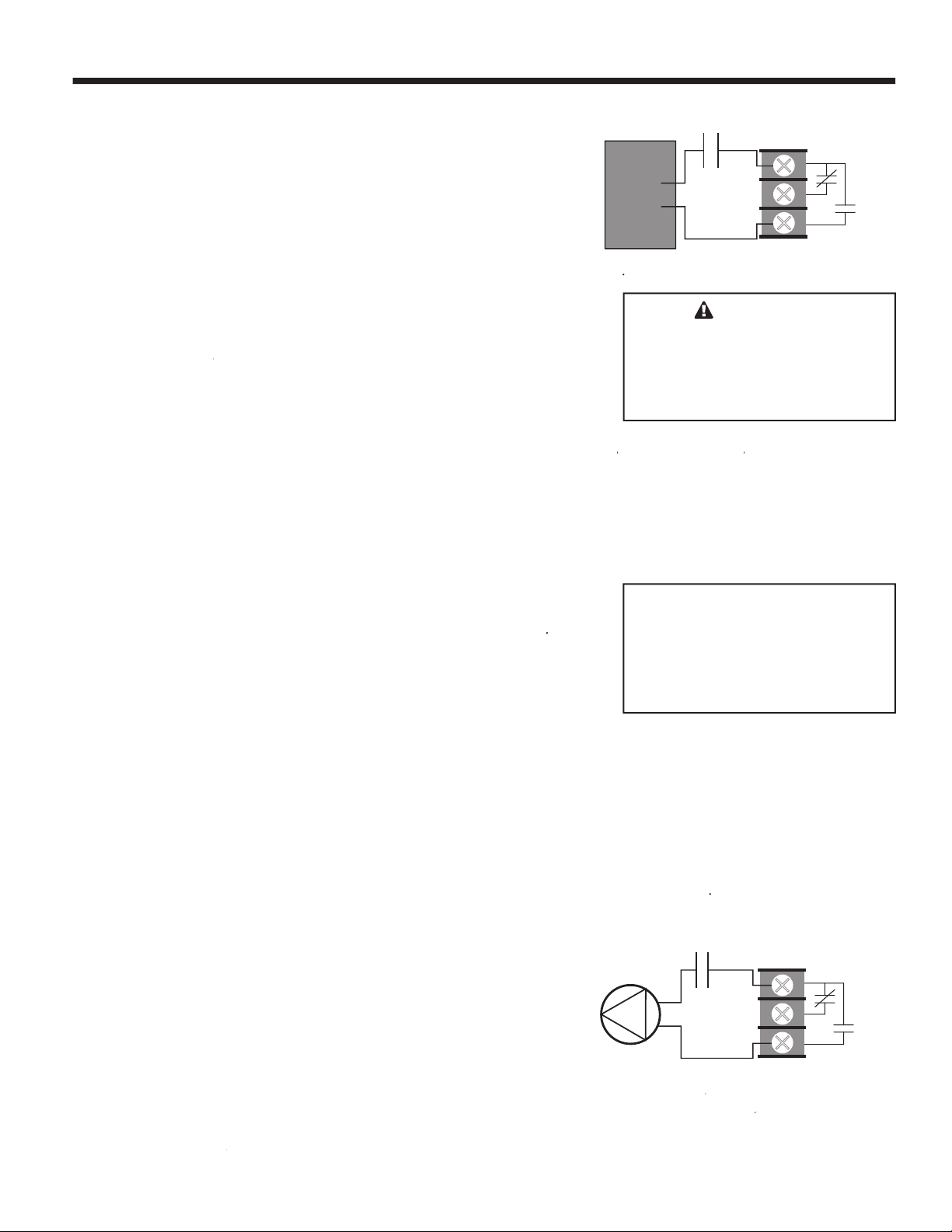

which is to be used must have a relay installed in the socket.

SYSTEM

relay which can be used for main or system pumps, or

particular type of installation.

which does not have a relay must have its stage switch to the OFF

position (see pg. 23).

WIRING THE STAGE OUTPUTS

SYSTEM

must not exceed 15A.

2 Stage (Lo/Hi) Units

positions.

positions.

4 Stage (Lo/Mid/Hi) Units

positions.

SC

Outputs

ON/OFF Units

2 Stage Units

3 Stage Units

4 Stage Units

NO

C

To Pump

Starter

NO

C

Limit

Circuit

Boiler Pump

Output

Boiler

Output

NO

C

To Pump

Starter

Boiler Pump

Output

NO

C

Limit

Circuit

Lo

Output

NO

C

Hi

Circuit

Hi

Output

NO

C

To Pump

Starter

Boiler Pump

Output

NO

C

Limit

Circuit

Lo

Output

NO

C

Mid

Circuit

Mid

Output

NO

C

Hi

Circuit

Hi

Output

NO

C

To Pump

Starter

Boiler Pump

Output

NO

C

Limit

Circuit

Lo

Output

NO

C

LoMid

Circuit

LoMid

Output

NO

C

HiMid

Circuit

HiMid

Output

NO

C

Hi

Circuit

Hi

Output

WARNING

This Laars Heating Systems control is strictly an operating control; it should

verify proper operation and correct any safety problems prior to the installation of

this Laars Heating Systems control.

Additional output relays can be

Page 16

Boiler 3 Boiler 2 Boiler 1

Output 1

Output 2

Output 3

Outdoor

Sensor

System

Temperature

Sensor

System

Pump

DHW

Dry Contact

(optional)

SC

Laars

Connecting the SC Control to

three Pump-Mounted Boilers (or Boilers with Built-in

Pump Time Delay) and Domestic Hot Water

using Outdoor reset Setting

System

Output

Power

Sensor Inputs

Boiler 3 Boiler 2 Boiler 1

Output 1

Output 2

Output 3

Connect to 120VAC

see page 5

Outdoor

Sensor

System

Temperature

Sensor

System

Pump

DHW

Dry Contact

(optional)

SC

Laars

Connecting the SC6P Control to

three Non-Pump-Mounted Boilers and Domestic

Hot Water using Outdoor reset Setting

System

Output

Power

Sensor Inputs

Pump 3

Pump 2

Pump 1

Pump 3 Pump 2 Pump 1

Connect to 120VAC

see page 5

Plumbing

Class 1 Wiring

Class 2 Sensor Wiring

The laars SC Sequencing control DOES NOT source power for boiler stages or pumps. It operates as dry contact switch.

A separate power source for the burners and pumps must be supplied.1.Laars is aware that each installation is unique. Thus, Laars is not responsibe for any installation related to any electrical

or plumbing diagram generated by Laars. The provided illustrations are to demonstrate Laars' control operating concept only.

2.

The drawings do not necessrily depict the locations of inlet and outlet water connections. Inlet and outlet connections vary

by product type.

3.

Pump 3* Pump 2* Pump 1*

External Pump is used when boiler does not have mounted pump.

Pump is interlocked with boiler's pump time delay.

*

Page 17

6 Stage Sequencer - SC 6

The

SYSTEM

relay will be energized when any Stage Output relay is energized.

2 3 4 5 6 1 2 3 1 2 1

On/Off On/Off On/Off On/Off On/Off

Output 1 Limit Limit Limit Limit Limit Limit Limit Limit Limit Limit Limit

Output 2 Limit Limit Limit Limit Limit HiFire HiFire HiFire MidFire MidFire LoMid

Output 3 Limit Limit Limit Limit Limit Limit HiFire HiFire HiMid

Output 4 Limit Limit Limit HiFire HiFire Limit HiFire

Output 5 Limit Limit Limit MidFire

Output 6 Limit HiFire HiFire

System

♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦

Lo/Hi Lo/Hi Lo/Hi 3 Stages 3 Stages 4 Stages

12 Stage Sequencer - SC 12

7 8 9 10 11 12 4 5 6 3 4 2 3

On/Off On/Off On/Off On/Off On/Off

Output 1 Limit Limit Limit Limit Limit Limit Limit Limit Limit Limit Limit Limit Limit

Output 2 Limit Limit Limit Limit Limit Limit HiFire HiFire HiFire MidFire MidFire LoMid LoMid

Output 3 Limit Limit Limit Limit Limit Limit Limit Limit Limit HiFire HiFire HiMid HiMid

Output 4 Limit Limit Limit Limit Limit Limit HiFire HiFire HiFire Limit Limit HiFire HiFire

Output 5 Limit Limit Limit Limit Limit Limit Limit Limit Limit MidFire MidFire Limit Limit

Output 6 Limit Limit Limit Limit Limit Limit HiFire HiFire HiFire HiFire HiFire LoMid LoMid

Output 7 Limit Limit Limit Limit Limit Limit Limit Limit Limit Limit Limit HiMid HiMid

Output 8 Limit Limit Limit Limit Limit HiFire HiFire HiFire MidFire MidFire HiFire HiFire

Output 9 Limit Limit Limit Limit Limit Limit HiFire HiFire Limit

Output 10 Limit Limit Limit HiFire HiFire Limit LoMid

Output 11

Output 12 Limit HiFire HiFire HiFire

System

♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦

Limit Limit Limit MidFire HiMid

Lo/Hi Lo/Hi Lo/Hi Lo/Hi 3 Stages 3 Stages 4 Stages 4 Stages

6 Stage Sequencer with Pumps - SC 6P

2 3 4 5 6 2 3 4 2 3 2

On/Off On/Off On/Off On/Off On/Off

Output 1 Pump Pump Pump Pump Pump Pump Limit Pump Pump Pump Pump

Output 2 Limit Limit Limit Limit Limit Limit Limit Limit Limit Limit Limit

Output 3 Pump Pump Pump Pump Pump HiFire HiFire HiFire MidFire MidFire LoMid

Output 4 Limit Limit Limit Limit Limit Pump Pump Pump HiFire HiFire HiMid

Output 5 Pump Pump Pump Pump Limit Limit Limit Pump Pump HiFire

Output 6 Limit Limit Limit Limit HiFire HiFire HiFire Limit Limit Pump

Output 7 Pump Pump Pump Pump Pump MidFire MidFire Limit

Output 8 Limit Limit Limit Limit Limit HiFire HiFire LoMid

Output 9 Pump Pump HiFire HiFire Pump HiMid

Output 10

Output 11

Output 12

System

♦

♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦

Limit Limit Pump Limit HiFire

Pump Limit MidFire

Limit HiFire HiFire

Lo/Hi Lo/Hi Lo/Hi 3 Stages 3 Stages 4 Stages

Page 18

temperature around the Set Point.

because of the Setback setting (see pg. 24) or the DHW mode (see pg. 25).

then the Outdoor Cutoff or the Shutdown is active (see below and pg. 24).

Pushing the

or

DOWN

buttons while the Set Point is being displayed will not change the value of the Set Point.

terminals are open. In this case, the SC

will control the system to maintain the Set Point temperature.

not register a fault from the Outdoor sensor (

Open or

short).

unless there is a DHW call.

and

can be programmed to provide either a lower Set Point temperature in

heating or Shutdown.

INPUT

terminals

7

and

to Shutdown, set the Setback/Shutdown value to 0. When the SC is Shutdown, the Set

Point display will show

Page 19

temperature display will show

to indicate this condition.

to indicate this condition.

below the Calculated temperature. The size of the fl uctuation depends on the number of stages, the size of each stage, the system

pressing the

or

DOWN

button while it is displayed.

for open or

for

not register a fault from the Outdoor sensor (

Open or

short).

unless there is a DHW call.

temperature.

temperature. The Reset Ratios are shown as Outdoor Temperature:Water

water temperature will raise 1 degree.

Note that this is not the point where the SC will begin giving heat. That point

Outdoor Temperature (in °F)

70 60

50

40 20

30 0 -10

10 -20

W ater Tempera ture (in °F)

100

120

110

130

140

150

160

180

170

190

200

210

220

12 11 10 9

8

7

6

4

3

2

5

1

1:4 1:3 1:2 1:1.5

1:1.25

1:1

1.25:1

1.5:1

2:1

3:1

4:1

8:1

temperature setting.

Page 20

value of the Calculated water temperature by the same amount.

the specifi c outdoor temperature and Reset Ratio, then increasing the

to 160°F.

temperatures are warm in the warm weather, decrease the Offset. If the

baseboard radiation is to change the Offset by

4° for every degree you wish to change the building temperatures. For

radiant heat applications, change the Offset by 1° or 2° for every degree

you wish to change the building temperature.

INPUT

terminals

and

can be programmed to provide either a lower

INPUT

terminals

7

and

to Shutdown, set the Setback/

by the Calculated water temperature display showing

be reduced by the amount of the Setback. This will be indicated by

the System Temperature display fl ashing and the Calculated water

temperature display fl ashing the new value.

Reaction Time has elapsed. The Purge Time

and Last Stage Hold

also change the

If the Reaction Time is shorter than this, the SC may activate additional Stage Outputs before it can see the impact of each Stage

time to settle out.

) to eight minutes (

).

Outdoor Temperature

Water Temperature

70 405060

130

120

110

100

1:3

4:1

1:1

Outdoor Temperature

Water Temp erature

70 405060

110

100

90

80

1:3

4:1

1:1

Outdoor Temperature

Water Temperature

70 405060

150

140

130

120

1:3

4:1

1:1

With a 0° Offset, the

ratio curves begin at

100° WaterTemperature.

With a -20° Offset, the

ratio curves begin at

80° WaterTemperature.

With a +20° Offset, the

ratio curves begin at

120° WaterTemperature.

Page 21

has elapsed, then the SC will begin counting down the Reaction Time. Therefore, if the Purge Time applies to a particular Stage

to 10 minutes (

).

turned off. In those cases, the Last Stage Hold

(see below) applies.

) to 6 minutes (

).

then turn off as soon as the Purge Time

water temperature plus the Last Stage Hold value.

will be turned on or off.

below the Set Point. A second stage will be activated when the temperature falls two full Throttling Ranges below the Set Point,

to prevent the last stage from short cycling when the load is low or when the stage is oversized.

Throttling Range Example

Heating Application Set Point = 180°F Throttling Range(

) = 5°F 4 Boiler Stages, A, B, C, and D

Falling Temperature Rising Temperature

Temperature Calculation Stage Turned On Stages On Stage Turned Off Stages On

185°F

180°F 180 - (0)THR None None None A

175°F 180 - (1)THR A A B A

171 to 174°F --- --- A --- A,B

170°F 180 - (2)THR B A,B C A,B

166 to 169°F --- --- A,B --- A,B,C

165°F 180 - (3)THR C A,B,C D A,B,C

161 to 165°F --- --- A,B,C None A,B,C,D

160°F 180 - (4)THR D A,B,C,D None A,B,C,D

180 + (1)THR

None None A None

Page 22

will remain energized for a period set by the System Delay.

by the System Delay.

for System Pump operation.

will allow the DHW call to be satisfi ed more quickly.

provide heat to the building.

indicate which Stage Output is currently the Lead Stage.

LEAD STAGE

switch controls the rotation of the Stage Outputs.

switches is not set to

AUTO

(see pg. 23). Any unit which has one or more of

is not considered as part of the rotation.

LEAD STAGE

switch is in the

position, whichever stage is presently the Lead Stage will always remain the Lead

LEAD STAGE

switch to the

INCREMENT

position and then release it. The green

LEAD STAGE

switch to the

AUTO

position (see rotation types below).

position.

Page 23

position.

switch.

AUTO

AUTO

used for testing individual outputs.

(see chart on pg.17). Also, if a Stage Output needs maintenance or is not working properly, it can be switched

to the

position.

indicate which outputs are energized.

the SC to provide an outdoor air reset function for hot water heat.

and dip switch 7 must be

Point.

knob.

NOTE: The Set Point will read

whenever the 4-20mA signal falls below 3.9mA or rises above 20.1mA.

4-20mA Input SC Set Point

4 60°F

6 80°F

8 100°F

10 120°F

12 140°F

14 160°F

16 180°F

18 200°F

20 220°F

Page 24

water temperature will be maintained at 200°F. When the call for DHW is removed, the SC will then resume Shutdown.

) control setting must be set to zero. Zero is the default value. Any

nonzero number will enable Setback

(see pg. 22).

times. When the time clock contacts open, then the SC will resume circulating the higher temperature water.

) control setting must be set to the desired number of Setback degrees. If the

and

are shorted.

During the DHW call, the water

temperature will be maintained at 200°F. When the call for DHW is removed, the SC will return to the Setback

Set Point

temperature.

PROVE

input terminals must be continuous for any Stage Output to be active. If the

PROVE

inputs are opened when Stage

the System Delay time).

and

provide a DHW input. To check or change the function of these terminals, see pgs. 6 and 8.

to indicate when stages are not being energized because the

Prove signal is not made.

PROVE

input does not affect the status of the System Output.

PROVE

input terminals.

wired to open a combustion air damper. An end switch on the damper can then be wired back to the

PROVE

input terminals. The

PROVE

input must be shorted for Stage Outputs to be activated. When not using the Prove function, the

PROVE

input must

be shorted. (The SC is shipped with a jumper to short out the

PROVE

terminals.)

PROVE

input, see pg. 6.

WARNING

The SC

input can not be used as a safety limit. All equipment must have its own certifi ed limit and safety

wired into the SC

Page 25

DHW

terminals are closed, the SC Set Point immediately changes to 200°F. This will happen regardless of outdoor

temperature, the status of the Setback/Shutdown inputs, or the External Set Point (if that function is being used).

DHW

input is wired to an aquastat which monitors the domestic hot water temperature. When the aquastat calls

DHW

input terminals.

- The System relay output will be open for the time set by the DHW Priority time

- After the DHW priority time has elapsed, the System relay output will revert to its normal mode of operation (that is either

on or off depending on outdoor temperature.)

Page 26

Check the 120VAC power input to the SC. Turn power to the SC off and back on.

First check the dip switch (see pg. 4 ) to be sure the SC is confi gured to read a temperature

Incorrect Temperature Display.

The SC sees a short across the input terminals. Remove the wires from the

&

)

Remove the wires from the

(

and

) inputs. The display should change to read

If it doesn’t, the SC may be damaged. Take an ohm reading across the detached sensor wires.

Check the wires from the outdoor sensor are continuous to the SC. Then follow the procedure

The SC sees a short across the input terminals. Remove the wires from the

and

) inputs. The display should change to read

Remove the wires from the

(

) inputs. The outdoor temperature display

right. If it doesn’t, the sensor may be damaged.

Check the dip switch (pg. 4).

Check that the wiring is appropriate for the application (see pg. 23). Then use an ampmeter to measure the 4-20mA input. If the

There is no green lead stage light on

Check the 120VAC power input to the SC. Turn power to the SC off and back on. If more than one lead stage LED lights, the

unit may be damaged.

TEMPERATURE

(in Degrees F)

0 42683

10 31215

20 23089

25 19939

30 17264

35 14985

40 13040

45 11374

50 9944

55 8714

60 7653

70 5941

80 4649

90 3667

100 2914

110

120 1879

130 1524

140 1243

150 1021

160 842

170 699

180 583

190 489

200 412

Value

(in Ohms)

2332

Page 27

There are more than one green lead stage lights on

Check the 120VAC power input to the SC. Turn power to the SC off and back on. If only one lead stage LED does not light, the

unit may be damaged.

Only units which have (all stages of) their

switches in the

AUTO

position and which are designated as Unit or

Lo stages (see chart on pg. 19) can be lead. If there is more than one stage which meets this criteria, the SC may be damaged.

Check the dip switch is set up for First On/Last Off rotation (see pg. 4). Check the lead stage can be rotated as described above.

Finally, check if the

INCREMENT/OFF/AUTO

switch is in the

AUTO

position. In the

AUTO

position, the lead stage should

rotate among the possible lead stages every 12 hours after the unit is fi rst powered up, and then every 24 hours thereafter. If the

panel loses power, the lead stage and the rotation counters will be reset.

Check the dip switch is set up for First On/First Off rotation (see pg. 4). Check the lead stage can be rotated as described above.

Finally check if the

INCREMENT/OFF/AUTO

switch is in the

AUTO

position.

When switched to

Remove any wires attached to the SC output. Check for continuity across the SC N.O. contacts. If there is continuity, the SC

The SC is calling for this unit to be on. Follow the procedure above.

which may be causing it to run.

Make sure that the red output lights on the SC correspond to the stage’s operation. If they don’t, follow the steps above.

temperature is correct and the display does not read

or

stage switches. Only

units which (have all stages) switched to

AUTO

will be part of the automatic Sequencing.

When switched to

component does not come on

Remove any wires attached to the SC

SYSTEM

terminals. Check for continuity across the N.O. contacts. Then check the

N.C. terminals are open. If both are true, the SC is working correctly. Check the wiring and the component being energized to

component is not on

The SC is calling for the unit. Follow the procedure above.

component is on

The SC is not calling for the unit to run. Remove any wires attached to the SC

SYSTEM

output terminals. Check the N.O.

terminals are open. Then check the N.C. terminals are closed. If both conditions are true, the SC output is working correctly.

Page 28

800.900.9276 • Fax 800.559.1583 (Customer Service, Service Advisors)

20 Industrial Way, Rochester, NH 03867 • 603.335.6300 • Fax 603.335.3355

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 • 905.238.0100 • Fax 905.366.0130

www.Laars.com Litho in U.S.A. © Laars Heating Systems 0806 Document 4200

Loading...

Loading...