Page 1

Installation and Operation Instructions Document 1204D

Heating Systems Company

A subsidiary of CorporationBRADFORD WHITE

®

®

Installation and Operation

Instructions for

Low Temperature

™

PENNANT

Hydronic Boiler

Model PNCH

Water Heater

Model PNCV

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water boiler installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or

death. Improper installation and/or operation will void the warranty. For indoor installations, as an

additional measure of safety, Laars strongly recommends installation of suitable Carbon Monoxide

detectors in the vicinity of this appliance and in any adjacent occupied spaces.

WARNING

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from

a nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the fire department.

Installation and service must be performed

by a qualified installer, service agency, or gas

supplier.

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion ou

pour éviter tout dommage matériel, toute blessure

ou la mort.

Ne pas entreposer ni utiliser d’essence ni d’autres

vapeurs ou liquides inflammables dans le voisinage

de cet appareil ou de tout autre appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous

servir des téléphones dansle bâtiment où vous

trouvez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualifié ou

par le fournisseur de gaz.

AVERTISSEMENT

H2319100D

Page 2

Page 2

LAARS Heating Systems

TABLE OF CONTENTS

SECTION 1. General Information

1.1 Introduction ...................................................... 3

1.2 Model Identication .......................................... 4

1.3 Warranty .......................................................... 4

1.4 Dimensions ...................................................... 4

1.5 Locating the Appliance..................................... 4

1.6 Locating Pump-Mounted Water Heater

with Respect to Storage Tank(s) ...................... 6

1.7 Locating Pump-Mounted Boiler with

Respect to Return/Supply Header ................... 6

1.8 Locating Appliance for Correct

Horizontal Vent/Ducted Air Distance

From Outside Wall ........................................... 6

SECTION 2. Venting and Combustion Air

2.1 Combustion Air ................................................ 7

2.1.1 Combustion Air From Room ............................ 7

2.1.2 Intake Combustion Air...................................... 7

2.2 Venting ............................................................. 8

2.2.1 Vent Categories ............................................... 8

2.2.2 Category I Vent ................................................ 8

2.2.3 Common Venting Systems .............................. 8

2.2.4 Category III Vent .............................................. 9

2.3 Locating Vent & Combustion Air Terminals ...... 9

2.3.1 Side Wall Vent Terminal ................................... 9

2.3.2 Side Wall Combustion Air Terminal ................ 12

2.3.3 Vertical Vent Terminal .................................... 12

2.3.4 Vertical Combustion Air Terminal ................... 12

2.4 Common Vent Test – Boilers ......................... 12

2.5 Vent Terminals for Outdoor Units ................... 13

SECTION 3. Gas Supply and Piping

3.1 Gas Supply and Piping .................................. 14

SECTION 4A.

Water Connections – Pennant Boiler

4A.1 Heating System Piping:

Hot Supply Connections – Boiler ................... 16

4A.2 Cold Water Make-Up – Boiler ........................ 16

4A.3 Water Flow Requirements – Boiler ................ 16

4A.4 Freeze Protection – Boiler ............................. 16

SECTION 4B. Water Connections –

Pennant Water Heater

4B.1 Water System Piping – Water Heater ............ 17

4B.2 Hot Water Supply Piping – Water Heater ...... 17

4B.3 Water Flow Requirements – Water Heater .... 17

4B.4 Combined Water (potable)

Heating and Space Heating ........................... 17

4B.5 Freeze Protection – Water Heater ................. 17

SECTION 5. Electrical Connections

5.1 Main Power .................................................... 20

5.1.1 Sizes 500-1500 .............................................. 21

5.1.2 Sizes 1750-2000 ............................................ 21

5.1.3 Separate Pump Circuit................................... 21

5.1.4 All Sizes ......................................................... 21

5.2 Field Wiring ................................................... 21

SECTION 6. Operating Instructions

6.1 Filling the Boiler System ................................ 28

6.2 Sequence of Operation .................................. 28

6.3 Temperature (Operating) Control ................... 29

6.3.1 Temperature Control Overview ...................... 29

6.3.2 Programming Parameters-Boilers ................. 29

6.3.3 Programming Parameters-Water Heaters ..... 30

6.4 Limit Controls ................................................. 30

6.5 Operating the Burner and Set Up .................. 30

6.5.1 Set Up for 0 to 2500 Feet Altitude.................. 30

6.5.2 High Altitude Adjustment and Set Up ............. 31

6.6 Shutting Down the Pennant ........................... 31

6.7 To Restart the Pennant .................................. 31

SECTION 7. Maintenance

7.1 System Maintenance ..................................... 32

7.2 Appliance Maintenance and

Component Description ................................. 32

7.2.1 Burners .......................................................... 32

7.2.2 Filter ............................................................... 33

7.2.3 Gas Valves ..................................................... 33

7.2.4 Manual Reset High Limit Control ................... 33

7.2.5 Automatic Reset High Limit Control ............... 33

7.2.6 Temperature Control ...................................... 33

7.2.7 Ignition Control............................................... 33

7.2.8 Ignitor ............................................................. 34

7.2.9 Transformer ................................................... 34

7.2.10 Blowers .......................................................... 34

7.2.11 Flow Switch ....................................................34

7.2.12 Heat Exchanger Coil ...................................... 34

SECTION 8. Trouble Shooting

8.1 Resolving Lockouts........................................ 35

8.2 Delayed Ignition – Possible Causes .............. 35

8.3 Short Cycling – Boiler .................................... 35

8.4 Short Cycling – Water Heater ........................ 36

8.5 High Gas Consumption.................................. 36

8.6 Troubleshooting Pennant Controls ................ 36

SECTION 9. Replacement Parts

9.1 General Information ....................................... 36

9.2 Parts List ........................................................ 36

Page 3

Low Temperature Pennant

SECTION 1.

General Information

USING THIS MANUAL – Because the

Pennant Boilers and Pennant Water Heaters are

identical appliances, with the exception of materials

of manufacture, labels and ultimate use application,

this manual provides information for the proper

installation, operation and maintenance of both

products. Where differences exist between the

application of the appliances and their operation,

the sections pertinent to only one appliance or the

other will be so identied.

In the Commonwealth of Massachusetts, this

appliance must be installed by a licensed plumber or

gas tter.

WARNING

To minimize the risk of electric shock, fire or other

hazards which could result in property damage,

injury, or death. The Pennant hydronic, boiler or

water heater must be installed in accordance with

the procedures detailed in this manual, or the Laars

Heating Systems warranty may be voided. The

installation must conform to the requirements of

the local jurisdiction having authority, and, in the

United States, to the latest edition of the National

Fuel Gas Code, ANSI Z223.1/NFPA54. In Canada,

the installation must conform to the latest edition

of the Natural Gas and Propane Installation Code,

CSA B149.1 and/or applicable local codes. Where

Afin de réduire au minimum les risques de

commotion électrique, de feu ou d’autre nature,

qui pourraient causer des dommages matériels,

des blessures ou des accidents mortels, les

chaudières à eau chaude ou les chauffe-eau

Pennant doivent être installés conformément aux

directives détaillées contenues dans ce manuel, à

défaut de quoi la garantie fournie par Laars Heating

Systems serait annulée. L’installation doit être

conforme aux exigences de la réglementation locale

en vigueur et, aux États-Unis, à l’édition la plus

récente du Natural Fuel Gas Code (Code pour le

gaz combustible naturel) ANSI Z223.1/NFPA54. Au

Canada, l’installation doit respecter les exigences

de la plus récente édition du Code d’installation du

gaz naturel et du propane CSA B149.1, et/ou des

codes locaux de construction en vigueur. Lorsque

la réglementation locale l’exige, l’installation des

appareils électroménagers Pennant doit respecter

les exigences du Standard for Controls and Safety

Devices for Automatically Fired Boilers (Code pour

les équipements de commande et de sécurité des

chaudières à combustion automatique), ANSI/

ASME CSD-1. Toute modification apportée à la

chaudière, aux régulateurs de gaz ou au câblage,

peut compromettre la garantie. Si certaines

conditions particulières rendent des adaptations

nécessaires, consulter un représentant du fabricant

avant d’entreprendre ces modifications.

required by the authority having jurisdiction, the

installation of Pennant appliances must conform

to the Standard for Controls and Safety Devices

for Automatically Fired Boilers, ANSI/ASME

CSD-1. Any modifications to the boiler, its gas

controls, or wiring may void the warranty. If field

conditions require modifications, consult the factory

representative before initiating such modifications.

All application and installation procedures

should be reviewed completely before proceeding with

the installation. Consult the Laars Heating Systems

factory, or local factory representative, with any issues

or questions regarding this equipment. Experience

has shown that most operating issues are caused by

improper installation.

The Pennant appliance is protected against over

1.1 Introduction

This manual provides information necessary for

the installation, operation, and maintenance of Laars

Heating Systems’ Low temperature Pennant copper

tube appliances, sizes 500-2000 (standard appliances

pressurization. A pressure relief valve is tted to all

appliances. It is installed on the outlet header, at the

water outlet of the appliance.

IMPORTANT: The inlet gas pressure to the appliance

must not exceed 13 in. w.c. (3.2 kPa).

are covered in a separate manual). Read it carefully

before installation.

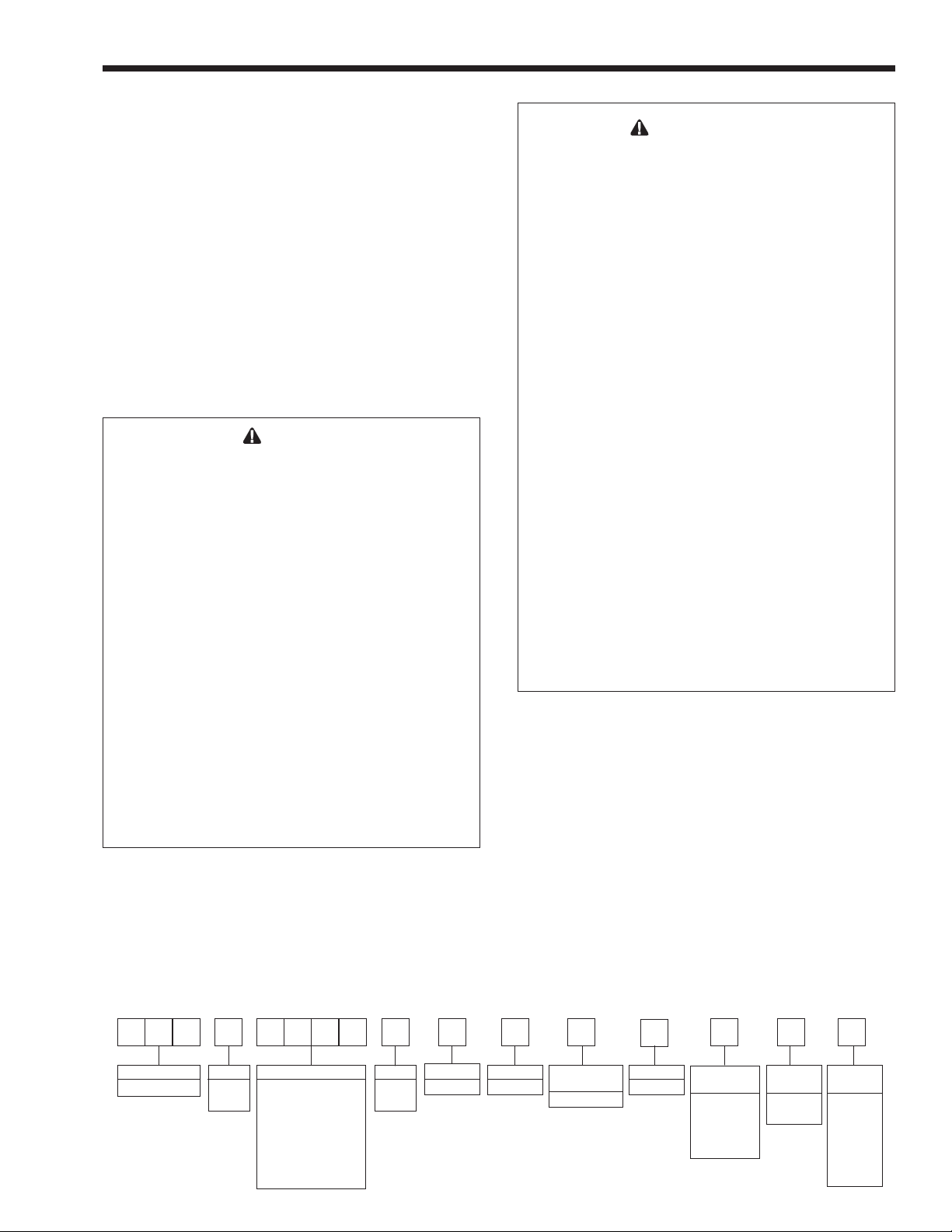

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

P N C A C C 2

AVERTISSEMENT

Page 3

SERIES

P N C

USAGE

H

V

SIZE

0 5 0 0

0 7 5 0

1 0 0 0

1 2 5 0

1 5 0 0

1 7 5 0

2 0 0 0

FUEL

N

P

ALTITUDE

A

LOCATION

C

FIRING

MODE

C ON-OFF

REVISION

2

HEAT

EXCHANGER

B

C

N

P

OPTIONS

CODE

X

J

PUMP

OPTIONS

H

N

S

C

B

D

Page 4

Page 4

LAARS Heating Systems

All installations must be made in accordance

with:

1) In the U.S., the " National Fuel Gas Code "ANSI

Z223.1/NFPA54, Latest Edition and all applicable

local codes as required by the Authorities Having

Jurisdiction (AHJ), or

2) In Canada, the "Natural Gas and Propane

Installation Code", CSA B149.1, latest edition and all

applicable local codes as required by the AHJ.

All electrical wiring is to be done in accordance with:

1). In the U.S., the "National Electrical Code" (NEC),

ANSI/NFPA 70, latest Edition and all applicable local

codes as required by the AHJ, or

2). In Canada, the “Canadian Electrical Code - Part

1”, CSA STD. C22.1 and all applicable local codes as

required by the AHJ.

This appliance must be electrically grounded in

accordance with the applicable codes and standards

referenced above.

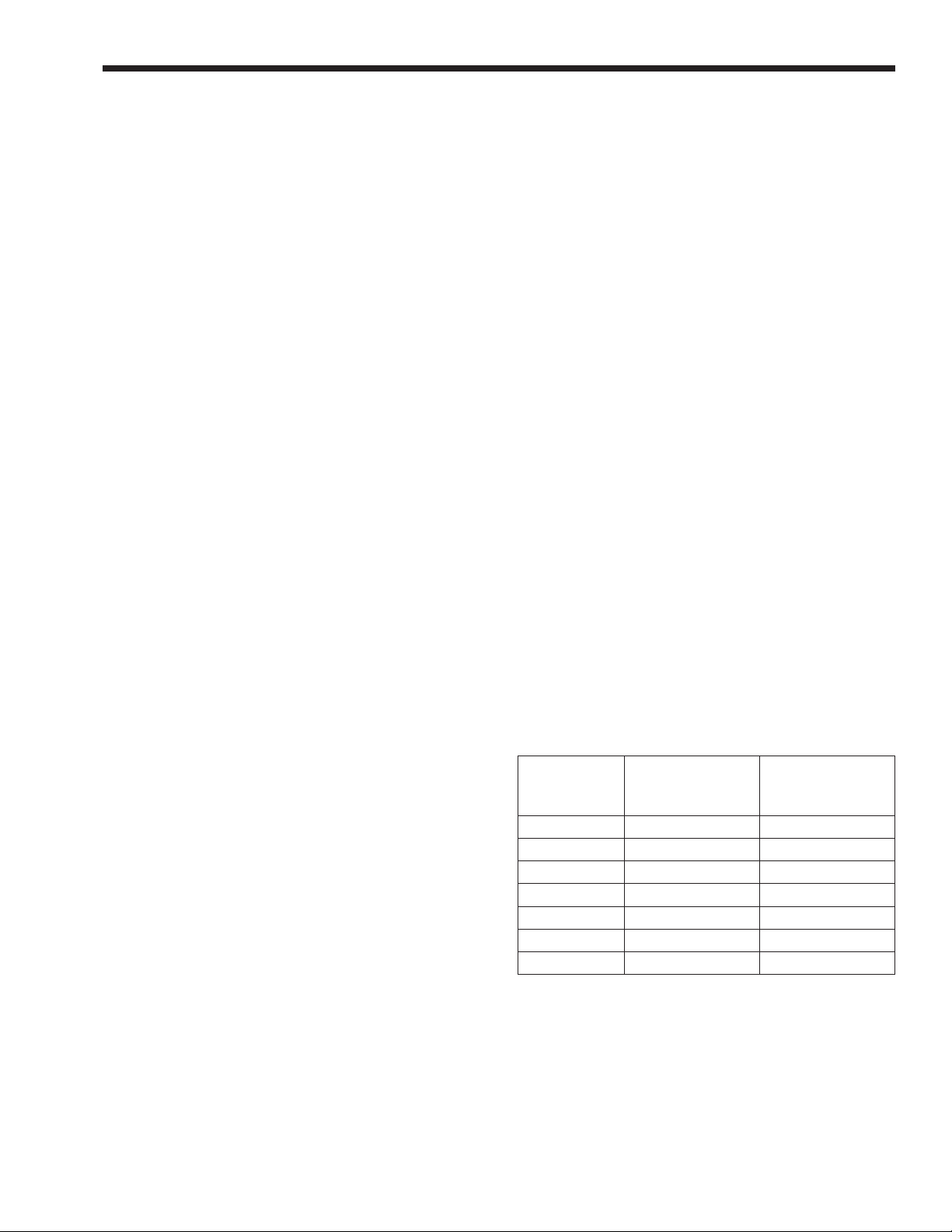

1.2 ModelIdentication

Consult the rating plate on the unit. The

following information describes the model number

structure.

Model Character Designation

1-3 Model Series Designation

P N C = Pennant

4 Usage

H = Hydronic

V = Volume Water

5-8 Size

0 5 0 0 = 500,000 BTU/h input

0 7 5 0 = 750,000 BTU/h input

1 0 0 0 = 999,000 BTU/h input

1 2 5 0 = 1,250,000 BTU/h input

1 5 0 0 = 1,500,000 BTU/h input

1 7 5 0 = 1,750,000 BTU/h input

2 0 0 0 = 1,999,000 BTU/h input

9 Fuel

N = Natural Gas

P = Propane

10 Altitude

A = 0-10,000 feet

11 Location

C = Indoor and Outdoor

12 Firing Mode

C = On-Off

13 Revision

2 = Revision Level 2

14 Heat Exchanger

B = Glass-lined CI / copper / brz trim (std. PNCV)

C = Glass-lined cast iron / copper (std. PNCH)

N = Glass-lined cast iron / cu-nickel

P = Glass-lined cast iron / cu-nickel / brz trim

15 Option Code

X = Standard Low Temp Control

J = CSD-1, FM, IRI, IL

16 Pump Options

H = TACO, Hard water pump (PNCV only)

N = TACO, Normal water pump

S = TACO, Soft water pump (PNCV only)

C = B&G, Hard water pump (PNCV only)

B = B&G, Normal water pump

D = B&G, Soft water pump (PNCV only)

1.3 Warranty

Laars Heating Systems’ appliances are covered

by a limited warranty. Owners should submit online

warranty registration at www.Laars.com.

All warranty claims must be made to an authorized

Laars Heating Systems representative, directly to

Customer Service, or online at www.Laars.com.

Claims must include the serial number and model

(this information can be found on the rating plate),

installation date, and name of the installer. Shipping

costs are not included in the warranty coverage.

Some accessory items are shipped in separate

packages. Verify receipt of all packages listed on

the packing slip. Inspect everything for damage

immediately upon delivery, and advise the carrier of

any shortages or damage. Any such claims should be

led with the carrier. The carrier, not the shipper, is

responsible for shortages and damage to the shipment

whether visible or concealed.

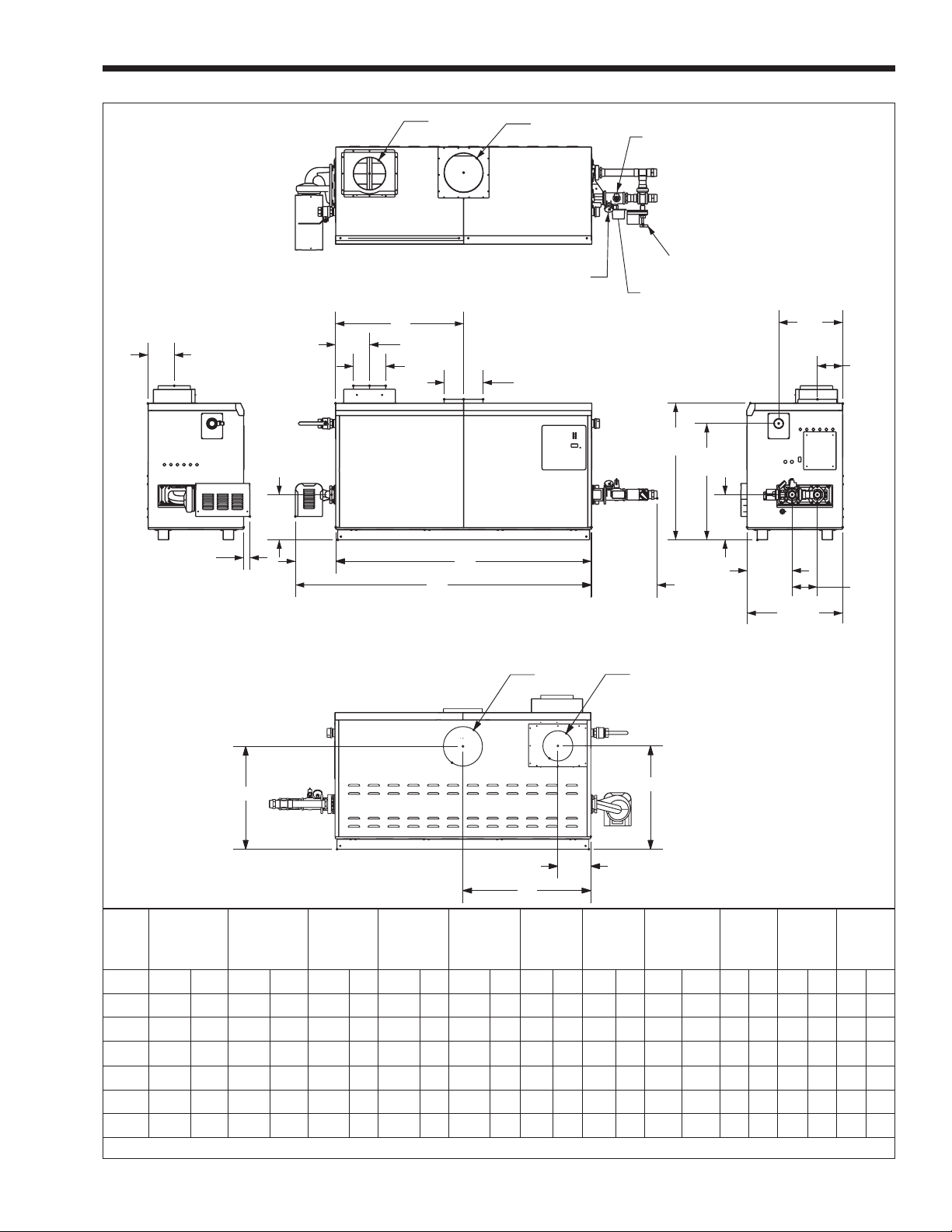

1.4 Dimensions

See Figure 1.

1.5 Locating the Appliance

The appliance should be located to provide

clearances on all sides for maintenance and inspection.

It should not be located in an area where leakage of

any connections will result in damage to the area

adjacent to the appliance or to lower oors of the

structure.

When such a location is not available, it is

recommended that a suitable drain pan, adequately

drained, be installed under the appliance.

The appliance is design certied by CSAInternational for installation on combustible ooring;

in basements; in closets, utility rooms or alcoves.

Pennant Boilers or Water Heaters must never be

installed on carpeting. The location for the appliance

should be chosen with regard to the vent pipe lengths

and external plumbing. The unit shall be installed such

that the gas ignition system components are protected

from water (dripping, spraying, rain, etc.) during

operation and service (circulator replacement, control

replacement, etc.). When vented vertically, the Pennant

must be located as close as practical to a chimney or

outside wall. If the vent terminal and/or combustion

air terminal terminate through a wall, and there is

potential for snow accumulation in the local area, both

terminals should be installed at an appropriate level

Page 5

Low Temperature Pennant

13.7

35

B

C

W*

V*

A

12.4

31

H

20.24

514

FRONT VIEW

REAR VIEW

W*

V*

TOP VIEW

FLOW SWITCH

INLET

OUTLET

3WAY ACTUATOR

TEMPERATURE

SWITCH

PRV

F

(W)

2

5

LEFT SIDE VIEW

PUMP

PUMP

G

(V)

19.7

50

41.5

105

35.3

89

29.3

74

7.75

20

13.8

35

13.7

35

RIGHT SIDE VIEW

D

C

W*

B

V*

E

Dimensions shown in

inches cm

Page 5

Size A B C D E F G H

500 33½ 85 15¾ 40 5¾ 15 29¾ 76 32¾ 83 7¾ 20 8¾ 22 46 117 6 15 8 20 6 15

750 45½ 11 6 21¾ 55 5¾ 15 29¾ 76 32¾ 83 7¾ 20 8¾ 22 58 147 6 15 10 25 8 20

Air

Conn.

W*

Vent

Conn.

V*

Horiz.

Vent

Pipe

1000 57½ 146 28¾ 73 5¾ 15 29¾ 76 32¾ 83 7¾ 20 7 18 70 178 8 20 10 25 8 20

1250 68 172 34 86 101∕826 30¾ 78 29½ 75 8¾ 22 8¾ 22 80 203 8 20 12 30 8 20

1500 78½ 199 39¾ 101 101∕826 30¾ 78 29½ 75 8¾ 22 8¾ 22 91 231 8 20 12 30 8 20

1750 89 226 44½ 113 101∕826 30¾ 78 29½ 75 8¾ 22 8¾ 22 101 256 8 20 14 36 8 20

2000 99½ 253 49¾ 126 101∕826 30¾ 78 29½ 75 8¾ 22 8¾ 22 112 284 12 30 14 36 12 30

*Air and vent connections may be on top or back of the Pennant, and are eld convertible. Dimensions in inches cm

Figure 1. Dimensional Data.

Page 6

Page 6

LAARS Heating Systems

above grade such that blockage of the terminal from

accumulated debris or precipitation is prevented.

The dimensions and requirements that are shown

in Table 1 should be met when choosing the locations

for the appliance.

1.6 Locating Pump-Mounted Water Heater

with Respect to Storage Tank(s)

For best results, the Pennant water heater should

be located within 15 feet (4.6m) of the storage tank(s).

The pump is sized for 30 feet (9.1m) of piping.

If the appliance must be installed with longer

piping runs, then larger diameter pipe or tubing may be

acceptable. Consult the factory for assistance.

Appliance

Surface

Left Side 1 2.5 24 61

Right Side 1 2.5 24 61

Top 1 2.5 12 30

Back 1 2.5 12** 30**

Front 1 2.5 36 91

Vertical

(Category 1)

Vent

Horizontal

(Category 3)

Vent

*1" (2.5 cm) when b-vent is used.

**When vent and/or combustion air connects to the back,

recommended clearance is 36" (91cm).

Required

Clearance From

Combustible Material

inches cm inches cm

6* 15.2*

per UL 1738 venting

system supplier's

instructions

Table 1. Clearances.

Recommended

Service Access

Clearance

1.7 Locating Pump-Mounted Boiler with

Respect to Return/Supply Header

For the best results, Pennant should be located

within 15 feet (4.6m) of the supply and return headers.

The pump is sized for 30 feet (9.1m) of piping.

If the appliance must be installed with longer

piping runs, then larger diameter tubing may be

acceptable. Consult the factory for assistance.

1.8 Locating Appliance for Correct

Horizontal Vent/Ducted Air Distance

From Outside Wall

The forced draft combustion air blower(s) in the

appliance has/have sufcient power to pull air and vent

properly when the guidelines for horizontal air and

vent are followed (see Table 2).

NOTE: On some models, the vent collar size is

larger than the size of the vent pipe that can be

used. Vent collar size and horizontal pipe diameters

can be found in Table 1. The larger vent collar

size is to accommodate Category I (vertical) vent

systems.

NOTE: When located on the same wall, the

Pennant combustion air intake terminal must

be installed a minimum of 12" (30cm) below the

exhaust vent terminal and separated by a minimum

of 36 inches (91cm) horizontally.

The air intake terminal must be installed high

enough to avoid blockage from snow, leaves and other

debris.

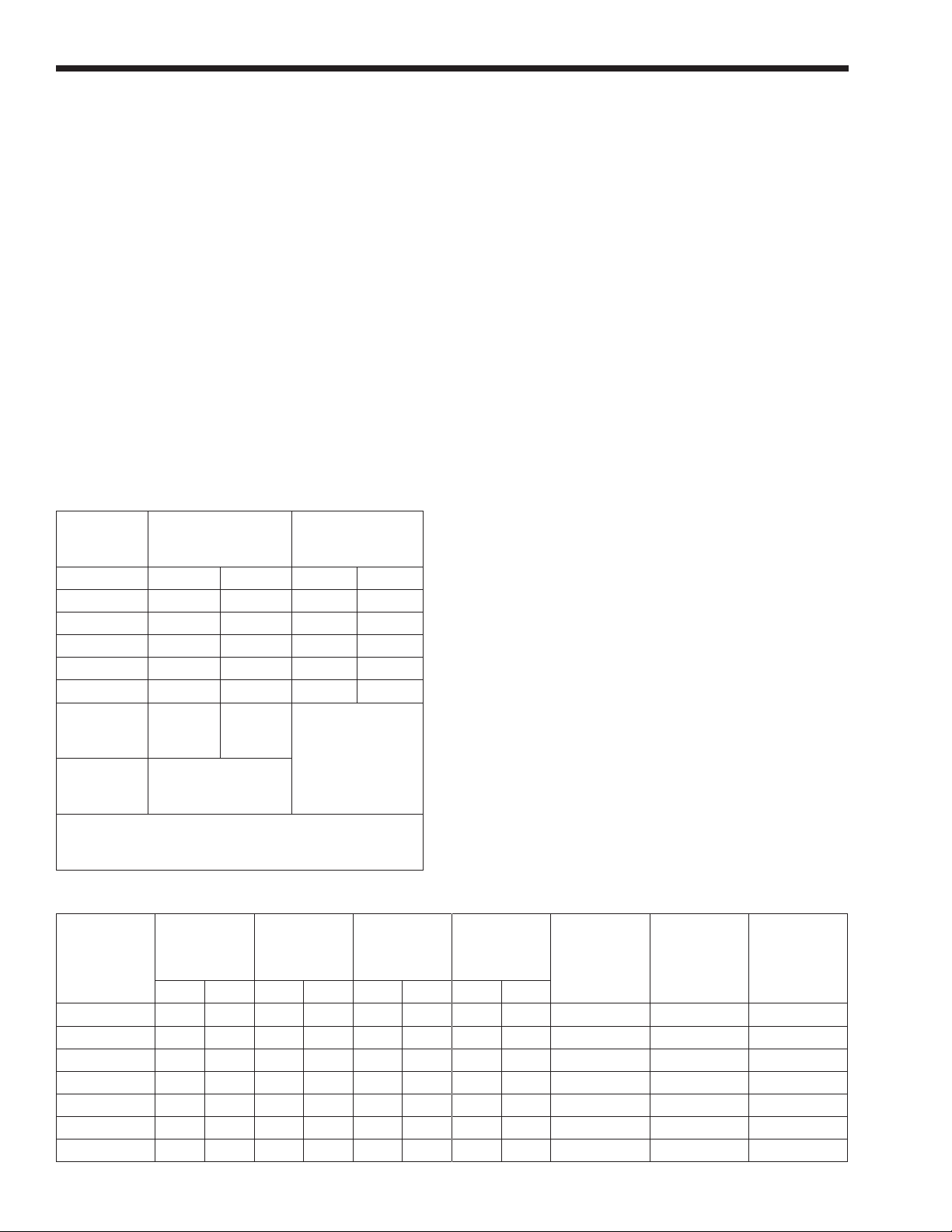

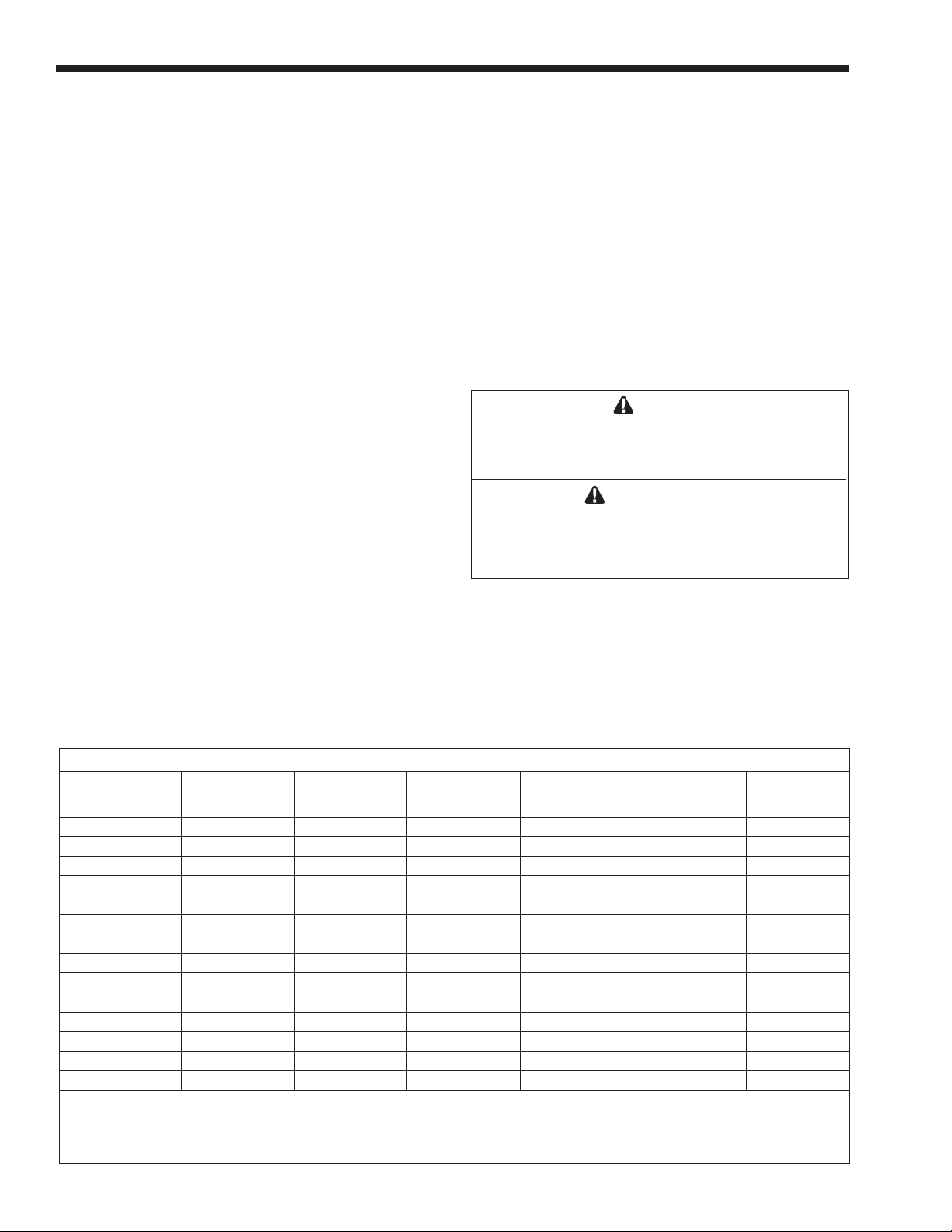

Size

500 8 20 6 15 6 15 50 15 3 CA001401 20260701

750 10 25 8 20 6 15 50 15 3 CA001401 20260701

1000 10 25 8 20 8 20 50 15 3 CA001402 20260703

1250 12 30 8 20 8 20 50 15 3 CA001403 20260703

1500 12 30 8 20 8 20 50 15 3 CA001403 20260703

1750 14 36 8 20 8 20 50 15 3 CA001403 20260703

2000 14 36 12 30 12 30 50 15 3 CA001404 20260706

Vent Collar

Size

in cm in cm in cm ft m

Horizontal

Vent Pipe

Diameter

Table 2. Horizontal Vent / Combustion Air Parameters.

Intake

Air Collar

& Pipe

Diameter

Max. Pipe

Length

Max. No.

of Elbows

Side Vent

Terminal

Part Number

Side Wall

Combustion

Air Terminal

Part Number

Page 7

Low Temperature Pennant

Page 7

SECTION 2.

Venting and Combustion Air

WARNING

For indoor installations, as an additional measure

of safety, Laars strongly recommends installation of

suitable Carbon Monoxide detectors in the vicinity of

this appliance and in any adjacent occupied spaces.

AVERTISSEMENT

Pour des installations intérieures, Laars

recommande fortement, comme mesure de sécurité

supplémentaire, l’installation de détecteurs de

monoxyde de carbone adaptés dans le voisinage

de l’appareil et dans chacune des pièces habitées

adjacentes.

2.1 Combustion Air

Pennant boilers and water heaters must have

provisions for combustion and ventilation air in

accordance with the applicable sections addressing

requirements for air for combustion and ventilation of

the National Fuel Gas Code, ANSI Z223.1. In Canada,

the applicable sections of the Natural Gas and Propane

Installation Code (CSA B149.1) must be followed. In

all cases any and all applicable local installation codes

must also be followed.

A Pennant appliance may receive combustion

air from the space in which it is installed, or it can be

ducted directly to the unit from the outside. Proper

ventilation air must be provided in either case.

2.1.1 Combustion Air From Room

In the United States, the most common

requirements specify that the space shall communicate

with the outdoors in accordance with method 1 or 2,

which follow. Where ducts are used, they shall be of

the same cross-sectional area as the free area of the

openings to which they connect.

Method 1: Two permanent openings, one

commencing within 12 inches (30 cm) of the top

and one commencing within 12 inches (30 cm) of

the bottom, of the enclosure shall be provided. The

openings shall communicate directly, or by ducts,

with the outdoors or spaces that freely communicate

with the outdoors. When directly communicating

with the outdoors, or when communicating to the

outdoors through vertical ducts, each opening shall

have a minimum free area of 1 square inch per 4000

Btu/hr (5.5 square cm/kW) of total input rating of all

equipment in the enclosure. When communicating to

the outdoors through horizontal ducts, each opening

shall have a minimum free area of not less than

1 square inch per 2000 Btu/hr (11 square cm/kW) of

total input rating of all equipment in the enclosure.

Table 3 shows data for this sizing method, for each

Pennant model.

Method 2: One permanent opening, commencing

within 12 inches (30 cm) of the top of the enclosure,

shall be permitted. The opening shall directly

communicate with the outdoors or shall communicate

through a vertical or horizontal duct to the outdoors

or spaces that directly communicate with the outdoors

and shall have a minimum free area of 1 square inch

per 3000 Btu/hr (7 square cm/kW) of the total input

rating of all equipment located in the enclosure. This

opening must not be less than the sum of the areas of

all vent connectors in the conned space.

Other methods of introducing combustion and

ventilation air are acceptable, providing they conform

to the requirements in the applicable codes listed

above.

In Canada, consult local building and safety

codes or, in absence of such requirements, follow

CSA B149.1, the Natural Gas and Propane Installation

Code.

2.1.2 Intake Combustion Air

The combustion air can be taken through the

wall, or through the roof. When taken from the wall, it

must be taken from out-of-doors by means of the Laars

horizontal wall terminal (see Table 2). When taken

from the roof, a eld-supplied rain cap or an elbow

arrangement must be used to prevent entry of rain

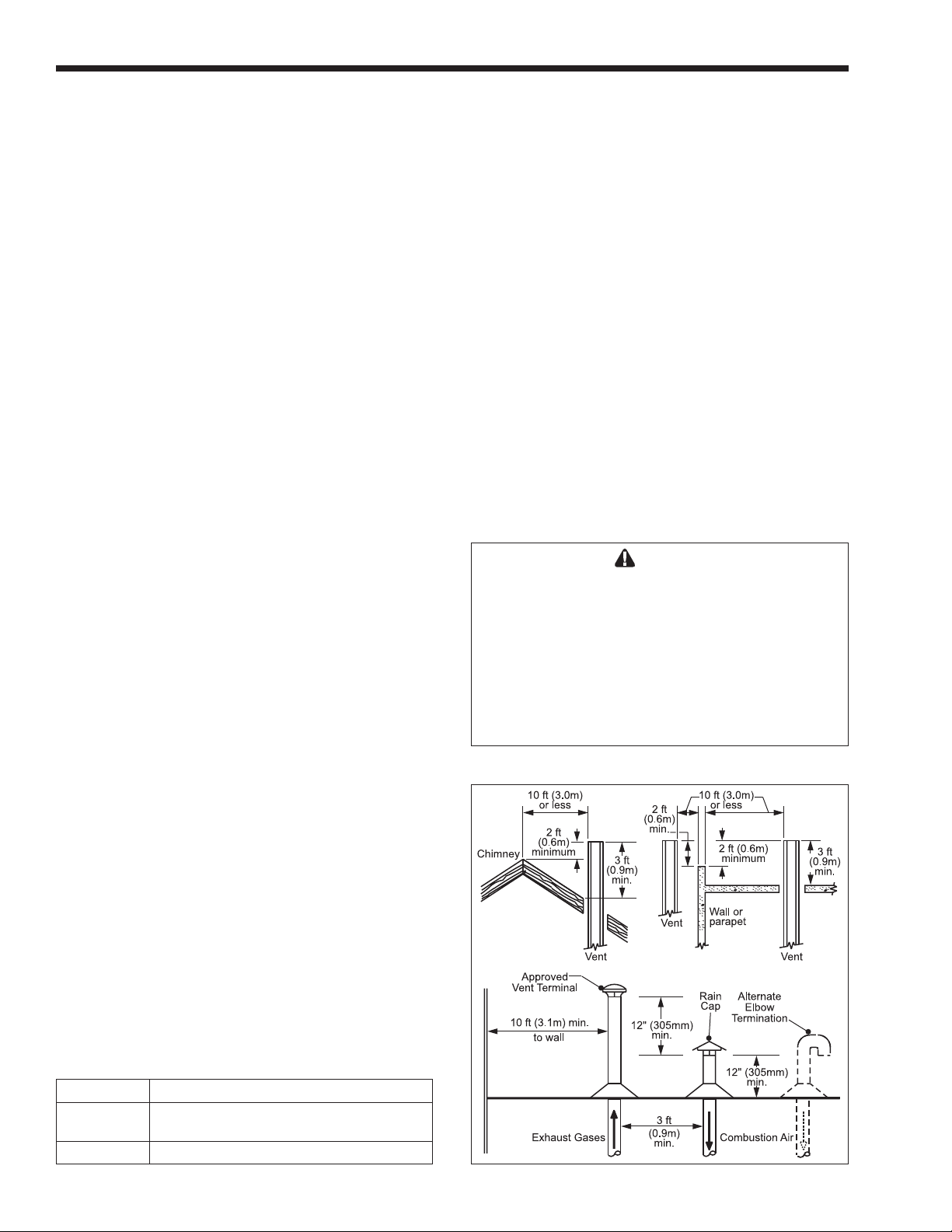

water (see Figure 2).

Use single-wall galvanized pipe, per Table

4, for the combustion air intake (see Table 2 for

appropriate size). Route the intake to the heater as

directly as possible. Seal all joints with tape. Provide

adequate hangers. The unit must not support the

weight of the combustion air intake pipe. Maximum

linear pipe length allowed is 50 feet (15.2m). Three

elbows have been calculated into the 50-foot (15.2m)

Size

500 125 807

750 188 1213

1000 250 1613

1250 313 2020

1500 375 2420

1750 438 2826

2000 500 3226

*Net Free Area in Square Inches / Square cm

Area indicated is for one of two openings; one at oor level

and one at the ceiling, so the total net free area could be

double the gures indicated.

This chart is for use when communicating directly with the

outdoors. For special conditions and alternate methods, refer

to the latest edition of ANSI Z223.1.

Note: Check with louver manufacturers for net free area of

louvers. Correct for screen resistance to the net free area

if a screen is installed. Check all local codes applicable to

combustion air.

Table 3. Combustion Air Openings.

Square inches Square cm

Each Opening*

Page 8

Page 8

LAARS Heating Systems

linear run. Subtract 10 allowable linear feet (3.0m) for

every additional elbow used (see Table 2). When fewer

than 3 elbows are used, the maximum linear pipe

length allowed is still 50 feet (15.2m).

The connection for the intake air pipe is on the

lter box. Pennant appliances may have venting and

combustion air ducting attached to the top or the back.

They are shipped with the connections at the top. For

attaching either or both pipes to the back, the mounting

anges are reversible by removing the mounting

screws and orienting the anges in the desired

position. Replace the screws after positioning anges.

Run a bead of silicone around the collar and slide the

pipe over the collar. Secure with sheet metal screws.

In addition to air needed for combustion, air

shall also be supplied for ventilation, including all air

required for comfort and proper working conditions

for personnel. The Pennant loses less than 1 percent of

its input rating to the room, but other heat sources may

be present.

2.2 Venting

2.2.1 Vent Categories

Depending upon desired Pennant venting, it may

be considered a Category I or a Category III appliance.

In general, a vertical vent system will be a Category

I system. However, in rare instances, a Pennant’s

vertical vent system may be considered Category

III. In the U.S., the National Fuel Gas Code (ANSI

Z223.1), or in Canada the Natural Gas and Propane

Installation Code (CSA B149.1), denes a Category I

vent system, and includes rules and tables to size these

vent systems. If the Pennant’s vertical vent system

does not satisfy the criteria for Category I venting, it

must be vented as a Category III system.

All Pennant vent systems which discharge

horizontally (without the use of a power venter) are

considered Category III vent systems.

(negative) 0.1 in. w.c.

If using a power venter for any type of Category

I venting, the draft should be set between (negative)

0.01 and 0.05 in. w.c.

2.2.3 Common Venting Systems

Pennant units are Category I fan-assisted when

vented vertically and adhering to all applicable codes.

Pennant units are not allowed to be vented into a

common horizontal vent system, unless a properly

sized vent fan is used, and the common vent system

is properly designed by the vent fan manufacturer or

a qualied engineer. When common venting Pennant

fan-assisted unit with other appliances through

one shared vertical duct called a “common vent”,

special care must be taken by the installer to ensure

safe operation. In the event that the common vent

is blocked, it is possible, especially for fan-assisted

devices, to vent backwards through non-operating

appliances sharing the vent, allowing combustion

products to inltrate occupied spaces. If the

appliances are allowed to operate in this condition,

serious injury or death may occur.

WARNING

Operation of appliances with a blocked common

vent may lead to serious injury or death. Safety

devices must be implemented to prevent blocked

common vent operation. If safe operation of all

appliances connected to a common vent cannot

be assured, including prevention of spillage of flue

gasses into living spaces, common venting should

not be applied, and appliances should each be

vented separately.

2.2.2 Category I Vent

When vented as a Category I appliance, the

vent system must conform to the National Fuel Gas

Code (ANSI Z223.1-Latest Edition) in the U.S., or in

Canada, to the Natural Gas and Propane Installation

Code (CSA B149.1 latest edition). The vent system

must be sized and installed for a Category I FanAssisted Appliance.

If chimney height is greater than 25 feet, or

if multiple units are vented into the same vertical

vent, a barometric damper must be installed on each

appliance, such that the ue draft does not exceed

Term Description

Pipe Single-wall galvanized steel pipe, 24 gauge

minimum (either insulated or non-insulated)

Joint Sealing Permanent duct tape or aluminum tape

Table 4. Required Combustion Air Piping Material.

Figure 2. Combustion Air and Vent Through Roof.

Page 9

Low Temperature Pennant

Page 9

AVERTISSEMENT

Le fonctionnement d’appareils connectés à un

évent commun bouché peut provoquer de sérieuses

blessures corporelles ou la mort. Des dispositifs de

sécurité doivent être mis en place pour empêcher

que les appareils soient utilisés avec un évent

commun bouché. Si un fonctionnement sécuritaire

de tous les appareils reliés à un évent commun et si

la prévention des dégagements accidentels de gaz

de combustion dans des zones habitées ne peuvent

pas être assurés, un évent commun ne doit pas

être mis en place et les appareils doivent être munis

d’évents individuels séparés.

It is for this reason that, in addition to

following proper vent sizing, construction and safety

requirements from the National Fuel Gas Code,

ANSI Z223.1 or in Canada, from the Natural Gas and

Propane Installation Code (CSA B149.1) as well as

all applicable local codes, it is required that installers

provide some means to prevent operation with a

blocked common vent. It is suggested that a blocked

vent safety system be employed such that if the switch

from one appliance trips due to excessive stack spill

or back pressure indicating a blocked vent condition,

that all appliances attached to the vent be locked out

and prevented from operating. Note that the Pennant

is equipped with a blocked vent safety (pressure)

switch, as shipped. However, this safety switch has

only been designed and tested to be effective in

installations where the Pennant is vented separately

and NOT common vented with other appliances. As an

additional precaution, it is recommended that a Carbon

Monoxide (CO) alarm be installed in all enclosed

spaces containing combustion appliances. If assistance

is required in determining how a blocked vent safety

system should be connected to a LAARS product,

please call Applications Engineering at the Rochester

phone number on the back cover of this manual.

Refer to the installation and operating

instructions on all appliances to be common vented

for instructions, warnings, restrictions and safety

requirements. If safe operation of all appliances

connected to a common vent cannot be assured,

including prevention of spillage of ue gases into

living spaces, common venting should not be applied,

and appliances should each be vented separately.

2.2.4 Category III Vent

When the Pennant is vented with horizontal

discharge, it must be installed per this installation

manual and the venting system manufacturer’s

installation instructions. The vent system must be

sealed stainless steel, per Table 5.

Route the vent pipe to the heater as directly as

possible. Seal all joints and provide adequate hangers

as required in the venting system manufacturer’s

installation instructions. Horizontal portions of the

venting system must be supported to prevent sagging

and may not have any low sections that could trap

condensate.

The unit must not support the weight of the vent

pipe. Horizontal runs must slope downwards not less

than ¼ inch per foot (2 cm/m) from the unit to the vent

terminal.

L’appareil ne doit pas supporter le poids de la

gaine d’évent. Les parties horizontales doivent être

installées avec une pente de 2 cm/m (1/4 inch par pied)

descendant de l’appareil vers la sortie de l’évent.

Reference Table 2 for the size of the Category

III vent system. Up to three elbows can be used with

50 linear feet (15.2m) of pipe. Subtract 10 allowable

linear feet (3.0m) for every additional elbow used.

2.3 Locating Vent & Combustion Air

Terminals

2.3.1 Side Wall Vent Terminal

The appropriate Laars side wall vent terminal

must be used, and is listed in the installation and

operation manual. The terminal provides a means of

installing the vent piping through the building wall,

and must be located in accordance with ANSI Z223.1/

NFPA 54 and applicable local codes. In Canada, the

installation must be in accordance with CSA B149.1

and local applicable codes. Consider the following

when installing the terminal:

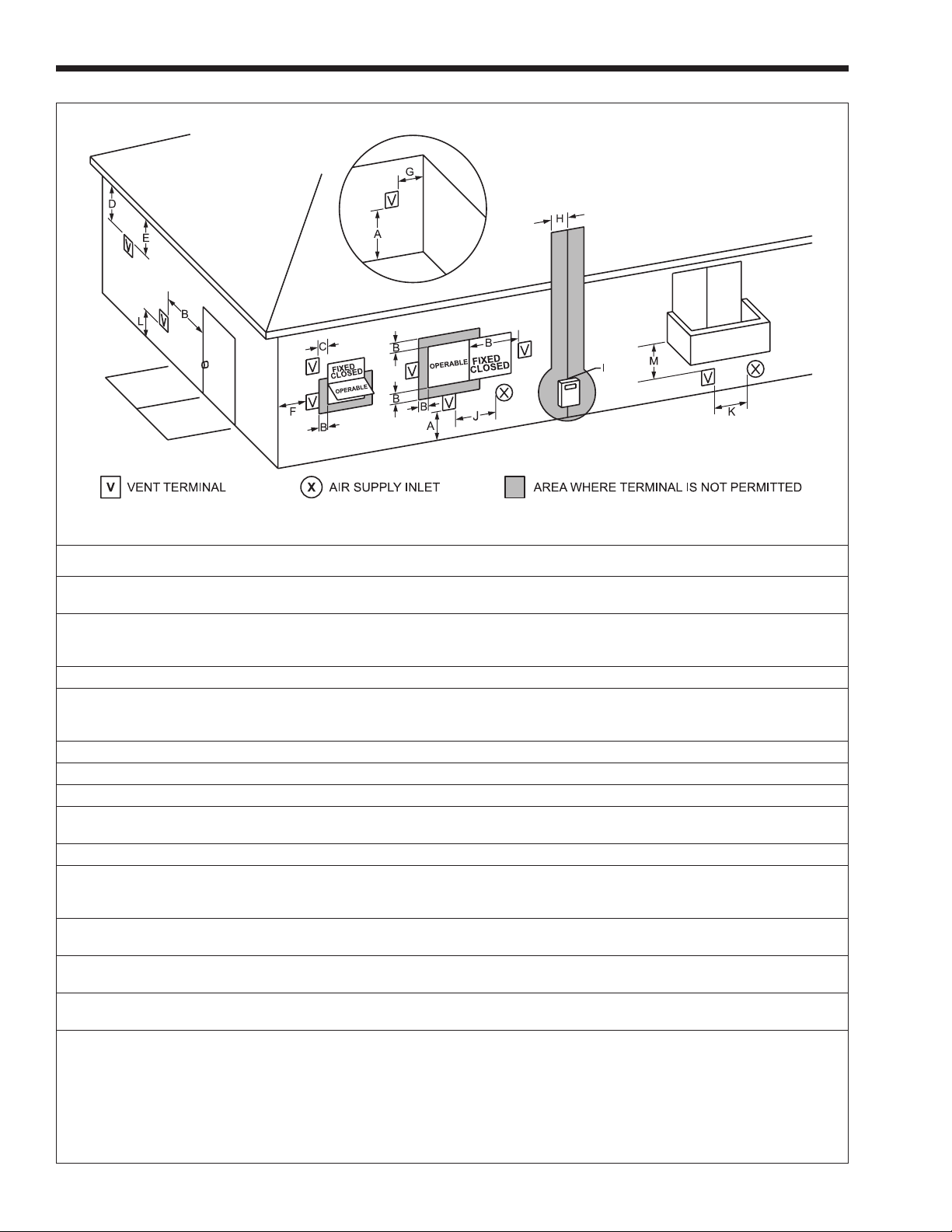

1. Figure 3 shows the requirements for mechanical

vent terminal clearances for the U.S. and Canada.

2. Locate the vent terminal so that vent gases cannot

be drawn into air conditioning system inlets.

3. Locate the vent terminal so that vent gases cannot

enter the building through doors, windows,

gravity inlets or other openings. Whenever

possible, locations under windows or near doors

should be avoided.

4. Locate the vent terminal so that it cannot be

blocked by snow. The installer may determine

that a vent terminal must be higher than the

minimum shown in codes, depending upon local

conditions.

5. Locate the terminal so the vent exhaust does

not settle on building surfaces or other nearby

objects. Vent products may damage such surfaces

or objects.

6. If the boiler or water heater uses ducted

combustion air from an intake terminal located

on the same wall, locate the vent terminal at least

Term Description

Pipe Must comply with UL Standard 1738 such

as Type AL29-4C Stainless Steel

(either insulated or non-insulated).

Joint

Sealing

Table 5. Required Horizontal Venting Material.

Follow vent manufacturer's instructions.

Page 10

Page 10

LAARS Heating Systems

U.S. Installations (see note 1) Canadian Installations (see note 2)

A= Clearance above grade, veranda, porch, 12 inches (30 cm) 12 inches (30 cm)

deck, or balcony

B= Clearance to window or door that may Direct Vent Only: 12 inches (30 cm)

be opened Other Than Direct Vent: 4 feet (1.2 m) below or 36 inches (91 cm)

to side of opening; 1 foot (30 cm) above opening

C= Clearance to permanently closed window See note 4 See note 5

D= Vertical clearance to ventilated soffit located

above the terminal within a horizontal See note 4 See note 5

distance of 2 feet (61cm) from the center line of the terminal

E= Clearance to unventilated soffit See note 4 See note 5

F= Clearance to outside corner See note 4 See note 5

G= Clearance to inside corner See note 4 See note 5

H= Clearance to each side of center line See note 4 3 feet (91 cm) within a height 15 feet

extended above meter/regulator assembly above the meter/regulator assembly

I= Clearance to service regulator vent outlet See note 4 3 feet (91 cm)

J= Clearance to non mechanical air supply Direct Vent Only: 12 inches (30 cm)

inlet to building or the combustion air inlet Other Than Direct Vent: 4 feet (1.2 m) below or 36 inches (91 cm)

to any other appliance to side of opening; 1 foot (30 cm) above opening

K= Clearance to a mechanical air supply inlet 3 feet (91 cm) above if within 10 feet (3 m) 6 feet (1.83 m)

horizontally

L= Clearance above paved sidewalk or paved Vent termination not allowed in this location Vent termination not allowed in this

driveway located on public property location

M= Clearance under veranda, porch, deck, See note 4 12 inches (30 cm) (see note 3)

or balcony

Notes:

1. In accordance with the current ANSI Z223.1 / NFPA 54 National Fuel Gas Code.

2. In accordance with the current CSA B149.1, Natural Gas and Propane Installation Code.

3. Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the floor.

4. For clearances not specified in ANSI Z223.1 / NFPA 54, clearance is in accordance with local installation codes and the requirements of

the gas supplier.

5. For clearances not specified in CSA B149.1, clearance is in accordance with local installation codes and the requirements of the gas

supplier.

Figure 3. Vent Terminal Clearances.

Page 11

Low Temperature Pennant

Page 11

3 feet (0.9m) horizontally from the combustion

air terminal, and locate the vent terminal at least

1 foot (0.3m) above the combustion air terminal.

WARNING

The outdoor vent terminal gets hot. Unit must be

installed in such a way as to reduce the risk of

burns from contact with the vent terminal.

AVERTISSEMENT

La sortie d’évent à l’extérieur devient très chaude.

Elle doit être installée de façon à réduire le risque

de brûlures au contact de l’extrémité de l’évent.

Important Note: Massachusetts Code Requirement.

From Massachusetts Rules and Regulations 248

CMR 5.08:

(a) For all side wall horizontally vented gas

fueled equipment installed in every dwelling,

building or structure used in whole or in

part for residential purposes, including those

owned or operated by the Commonwealth and

where the side wall exhaust vent termination

is less than seven (7) feet above nished grade

in the area of the venting, including but not

limited to decks and porches, the following

requirements shall be satised:

1. INSTALLATION OF CARBON MONOXIDE

DETECTORS.

At the time of installation of the side wall

horizontal vented gas fueled equipment, the

installing plumber or gastter shall observe that

a hard-wired carbon monoxide detector with

an alarm and battery back-up is installed on

the oor level where the gas equipment is to be

installed. In addition, the installing plumber or

gastter shall observe that a battery operated or

hard-wired carbon monoxide detector with an

alarm is installed on each additional level of the

dwelling, building or structure served by the side

wall horizontal vented gas fueled equipment.

It shall be the responsibility of the property

owner to secure the services of qualied licensed

professionals for the installation of hard-wired

carbon monoxide detectors.

a. In the event that the side wall

horizontally vented gas fueled equipment

is installed in a crawl space or an attic, the

hard-wired carbon monoxide detector with

alarm and battery back-up may be installed

on the next adjacent oor level.

b. In the event that the requirements of

this subdivision cannot be met at the time of

completion of installation, the owner shall

have a period of thirty (30) days to comply

with the above requirements; provided,

however, that during said thirty (30) day

period, a battery operated carbon monoxide

detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE

DETECTORS.

Each carbon monoxide detector as required

in accordance with the above provisions shall

comply with NFPA 720 and be ANSI/UL 2034

listed and IAS certied.

3. SIGNAGE.

A metal or plastic identication plate shall be

permanently mounted to the exterior of the

building at a minimum height of eight (8) feet

above grade directly in line with the exhaust vent

terminal for the horizontally vented gas fueled

heating appliance or equipment. The sign shall

read, in print size no less than one-half (½) inch

in size, “GAS VENT DIRECTLY BELOW.

KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION.

The state or local gas inspector of the side

wall horizontally vented gas fueled equipment

shall not approve the installation unless, upon

inspection, the inspector observes carbon

monoxide detectors and signage installed in

accordance with the provisions of 248 CMR

5.08(2)(a) 1 through 4.

(b) EXEMPTIONS: The following equipment is

exempt from 248 CMR 5.08(2)(a) 1 through 4:

1. The equipment listed in Chapter 10 entitled

“Equipment Not Required To Be Vented” in the

most current edition of NFPA 54 as adopted by

the Board; and

2. Product Approved side wall horizontal vented gas

fueled equipment installed in a room or structure

separate from the dwelling, building or structure

used in whole or in part for residential purposes.

(c) MANUFACTURER REQUIREMENTS –

GAS EQUIPMENT VENTING SYSTEM

PROVIDED. When the manufacturer of

Product Approved side wall horizontally

vented gas equipment provides a venting

system design or venting system components

with the equipment, the instructions provided

by the manufacturer for installation of the

equipment and the venting system shall

include:

1. Detailed instructions for the installation of the

venting system design or the venting system

components; and

2. A complete parts list for the venting system

Page 12

Page 12

LAARS Heating Systems

design or venting system.

(d) MANUFACTURER REQUIREMENTS –

GAS EQUIPMENT VENTING SYSTEM

NOT PROVIDED. When the manufacturer

of a Product Approved side wall horizontally

vented gas fueled equipment does not

provide the parts for venting the fuel gases,

but identies “special venting systems”, the

following requirements shall be satised by

the manufacturer:

1. The referenced “special venting system”

instructions shall be included with the appliance

or equipment installation instructions; and

2. The “special venting systems” shall be Product

Approved by the Board, and the instructions for

that system shall include a parts list and detailed

installation instructions.

(e) A copy of all installation instructions for all

Product Approved side wall horizontally

vented gas fueled equipment, all venting

instructions, all parts lists for venting

instructions, and/or all venting design

instructions shall remain with the appliance

or equipment at the completion of the

installation.

2.3.2 Side Wall Combustion Air Terminal

The Laars side wall combustion air terminal

(listed in Table 2) must be used when the unit takes

its combustion air through a duct from a side wall.

Consider the following when installing the terminal:

1. Do not locate the air inlet terminal near a source

of corrosive chemical fumes (e.g., cleaning uid,

chlorinated compounds, etc.)

2. Locate the terminal so that it will not be subject

to damage by accident or vandalism.

3. Locate the combustion air terminal so that it

cannot be blocked by snow. The National Fuel

Gas Code requires that it be at least 12 inches (30

cm) above grade, but the installer may determine

it should be higher, depending upon local

conditions.

4. If the Pennant is side-wall vented to the same

wall, locate the vent terminal at least 3 feet

(0.9m) horizontally from the combustion air

terminal, and locate the vent terminal at least 1

foot (0.3m) above the combustion air terminal

(see Figure 3).

2.3.3 Vertical Vent Terminal

When the unit is vented through the roof, the

vent must extend at least 3 feet (0.9m) above the point

at which it penetrates the roof. It must extend at least

2 feet (0.6m) higher than any portion of a building

within a horizontal distance of 10 feet (3.0m), and high

enough above the roof line to prevent blockage from

snow. When the combustion air is taken from the roof,

the combustion air must terminate at least 12" (30cm)

below the vent terminal (see Figure 2).

2.3.4 Vertical Combustion Air Terminal

When combustion air is taken from the roof, a

eld-supplied rain cap or an elbow arrangement must

be used to prevent entry of rain water (see Figure 2).

The opening on the end of the terminal must be at least

12" (30cm) above the point at which it penetrates the

roof, and high enough above the roof line to prevent

blockage from snow. When the vent terminates on the

roof, the combustion air must terminate at least 12"

(30cm) below the vent terminal.

2.4 Common Vent Test — Boilers

When an existing boiler is removed from a

common venting system, the common venting system

is likely to be too large for proper venting of the

appliances remaining connected to it.

At the time of removal of an existing boiler, the

following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances

remaining connected to the common venting system

are not in operation.

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper

size and horizontal pitch and determine there is

non blockage or restriction, leakage, corrosion

and other deciencies which could cause an

unsafe condition.

3. Insofar as it is practical, close all building doors

and windows and all doors between the space in

which the appliances remaining connected to the

common venting system are located and other

spaces of the building. Turn on clothes dryers

and any appliance not connected to the common

venting system. Turn on any exhaust fans, such

as range hoods and bathroom exhausts, so they

will operate at maximum speed. Do not operate a

summer exhaust fan. Close replace dampers.

4. Place in operation the appliance being

inspected. Follow the lighting instructions.

Adjust thermostat so appliance will operate

continuously.

5. Test for spillage at the draft hood relief opening

after 5 minutes of main burner operation. Use

the ame of a match or candle, or smoke from a

cigarette, cigar or pipe.

6. After it has been determined that each appliance

remaining connected to the common venting

system properly vents when tested as outlined

above, return doors, windows, exhaust fans,

replace dampers and any other gas burning

appliance to their previous conditions of use.

7. Any improper operation of the common venting

system should be corrected so that the installation

Page 13

Low Temperature Pennant

Page 13

conforms with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 and/or CSA B149.1,

Natural Gas and Propane Installation Codes.

When resizing any portion of the common

venting system, the common venting system

should be resized to approach the minimum size

as determined using the appropriate tables in

Appendix F in the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and/or CSA B149.1, Natural

Gas and Propane Installation Codes.

2.4 Véricationdeséventscommuns—

Chaudières

Lorsqu’une chaudière existante est déconnectée

du réseau d’évents commun, ce réseau d’évents

commun devient probablement trop grand pour

les appareils qui lui restent connectés. Lorsqu’une

chaudière existante est retirée, les étapes suivantes

doivent être accomplies pour chaque appareil qui

reste connecté au réseau d’évents commun utilisé,

alors que les autres appareils qui sont encore

connectés au réseau commun d’évents ne sont pas en

fonctionnement.:

1. Sceller toutes les ouvertures non utilisées du

système d'évacuation.

2. Inspecter de façon visuelle le système

d'évacuation pour déterminer la grosseur et

l'inclinaison horizontale qui conviennent et

s'assurer que le système est exempt d'obstruction,

d'étranglement, de fuite, de corrosion et autres

défaillances qui pourraient présenter des risques.

3. Dans la mesure du possible, fermer toutes les

portes et les fenêtres du bâtiment et toutes les

portes entre l'espace où les appareils toujours

raccordés au système d'évacuation sont installés

et les autres espaces du bâtiment. Mettre en

marche les sécheuses, tous les appareils non

raccordés au système d'évacuation common

et tous les ventilateurs d'extraction comme

les hottes de cuisinière et les ventilateurs des

salles de bain. S'assurer que ces ventilateurs

fonctionnent à la vitesse maximale. Ne pas faire

fonctionner les ventilateurs d'été. Fermer les

registres des cheminées.

4. Mettre l'appareil inspecté en marche. Suivre les

instructions d'allumage. Réegler le thermostat de

façon continue.

5. Faire fonctionner le brûleur principal pendant

5 min ensuite, déterminer si le coupe-tirage

déborde à l'ouverture de décharge. Utiliser la

amme d'une allumette ou d'une chandelle ou la

fumée d'une cigarette, d'un cigare ou d'une pipe.

6. Une fois qu'il a été déterminé, selon la méthode

indiquée ci-dessus, que chaque appareil

raccordé au système d'évacuation est mis à l'air

libre de façon adéquate. Remettre les portes

et les fenêtres, les ventilateurs, les registres de

cheminées et les appareils au gaz à leur position

originale.

7. Tout mauvais fonctionnement du système

d'évacuation commun devrait être corrigé

de façon que l'installation soit conforme au

National Fuel Gas Code, ANSI Z223.1/NFPA

54 et (ou) aux codes d'installation CSA-B149.1.

Si la grosseur d'une section du système devrait

être modié, le système devrait être modié pour

respecter les valeurs minimales des tableaux

pertinents de l'appendice F du National Fuel Gas

Code, ANSI Z223.1/NFPA 54 et (ou) les codes

d'installation CSA-B149.1

2.5 Vent Terminals for Outdoor Units

For outdoor applications, the vent and

combustion air openings must be covered with proper

terminals to prevent rain, snow and other objects from

falling into the Pennant.

If local codes allow, outdoor installations may

use 1' (one foot) of appropriately sized galvanized

single wall or type "B" vent and a rain cap for exhaust

vent termination in the default conguration (venting

out of the top). An appropriately sized 90° elbow,

positioned with the opening facing down, may be used

on the combustion air inlet in the default conguration

on the back of the unit. Note that some local codes

may require a higher vertical vent height, extending

above any perimeter fencing, etc. In installations

where the appearance of the vent is objectionable, the

low prole vent terminals listed in Table 6 may be

used.

Part numbers for the low prole terminals to

cover the vent and combustions air openings are

shown in Table 6.

Size Outdoor

Vent

Terminal

500 20254703 D2007900

750 20254705 D2007900

1000 20254705 D2008000

1250 D2007700 D2008000

1500 D2007700 D2008000

1750 D2007800 D2008000

2000 D2007800 D2008200

Table 6. Vent Terminals for Outdoor Units.

Outdoor

Combustion

Air Terminal

Page 14

Page 14

LAARS Heating Systems

SECTION 3.

Gas Supply and Piping

3.1 Gas Supply and Piping

Gas piping should be supported by suitable

hangers or oor stands, not by the appliance.

The Pennant’s gas train allows the user to pipe

the gas from either the right side or the left side of

the unit. As shipped, the right side of the gas train is

capped off, and there is a manual valve on the left side.

If desired, the manual valve on the left side of the gas

train may be moved to the right side, and the cap on

the right side may be moved to the left.

Review the following instructions before

proceeding with the installation.

1. Verify that the appliance is tted for the proper

type of gas by checking the rating plate. Pennant

appliances are equipped to operate at elevations

up to 10,000 feet (3050m). Pennant appliances

may be adjusted to operate properly at altitudes

above 2500 feet (see Section 6.5.2) and the input

will be reduced if the heating value of the gas

supply is below sea level values.

2. The maximum inlet gas pressure must not

exceed 13" w.c. (3.2kPa). The minimum inlet gas

pressure is 5 in. w.c. (1.2 kPa).

3. Refer to Table 7, size supply.

4. Run gas supply line in accordance with all

applicable codes.

5. Locate and install manual shutoff valves in

accordance with state and local requirements.

6. A sediment trap must be provided upstream of

the gas controls.

7. All threaded joints should be coated with

piping compound resistant to action of liqueed

petroleum gas.

8. The appliance and its individual shutoff valve

must be disconnected from the gas supply piping

during any pressure testing of that system at test

pressures in excess of 0.5 psig (3.45 kpa).

9. The unit must be isolated from the gas supply

system by closing its individual manual shutoff

valve during any pressure testing of the gas

supply piping system at test pressures equal to or

less than 0.5 psig (3.45 kpa).

10. The appliance and its gas connection must be

leak tested before placing it in operation.

11. Purge all air from gas lines.

WARNING

Do not use open flame to check for leaks. An open

flame could lead to explosion, which could result in

property damage, serious injury or death.

AVERTISSEMENT

Ne recherchez pas les fuites avec une flamme nue.

Une flamme nue peut provoquer une explosion qui

peut causer des dommages matériels, de sérieuses

blessures corporelles ou la mort.

NOTE: The Pennant appliance and all other gas

appliances sharing the gas supply line must be firing

at maximum capacity to properly measure the inlet

supply pressure. The pressure can be measured at

the supply pressure port on the gas valve. Low gas

pressure could be an indication of an undersized

gas meter, undersized gas supply lines and/or an

obstructed gas supply line.

Distance from Gas Meter or Last Stage Regulator

Size and

Gas Type 0-100'

500 natural 1½" 3.8 cm 2" 5.1 cm 2" 5.1 cm

500 propane 1" 2.5 cm 1½" 3.8 cm 1½" 3.8 cm

750 natural 2" 5.1 cm 2" 5.1 cm 2½" 6.4 cm

750 propane 1½" 3.8 cm 1½" 3.8 cm 2" 5.1 cm

1000 natural 2" 5.1 cm 2½" 6.4 cm 3" 7.6 cm

1000 propane 1½" 3.8 cm 2" 5.1 cm 2½" 6.4 cm

1250 natural 2½" 6.4 cm 2½" 6.4 cm 3" 7.6 cm

1250 propane 2" 5.1 cm 2" 5.1 cm 2½" 6.4 cm

1500 natural 2½" 6.4 cm 3" 7.6 cm 3" 7.6 cm

1500 propane 2" 5.1 cm 2½" 6.4 cm 2½" 6.4 cm

1750 natural 2½" 6.4 cm 3" 7.6 cm 3" 7.6 cm

1750 propane 2" 5.1 cm 2½" 6.4 cm 2½" 6.4 cm

2000 natural 3" 7.6 cm 3" 7.6 cm 3½" 8.9 cm

2000 propane 2½" 6.4 cm 2½" 6.4 cm 3" 7.6 cm

Notes:

1. These gures are based on 1/2" (0.12 kPa) water column pressure drop.

2. Check supply pressure and local code requirements before proceeding with work.

3. Pipe ttings must be considered when determining gas pipe sizing.

0-31 m 100-200' 31-61m 200-300' 61-91m

Table 7. Gas Piping Size.

Page 15

Low Temperature Pennant

SENSOR

VALV E

THERMOMETER

SENSOR

TEMPERATURE

GLOBE VALV E

CHECK VALV E

W/ FAST FILL BYPASS

PRESSURE REDUCING VALV E

WITH AIR SCOOP AND

AUTO AIR VENT

EXPANSION TANK

3-WAY VALVE

VALV E

VALV E

PURGE

PUMP

ADDITIONAL REQUIREMENTS.

WITH LOCAL CODES AND ORDINANCES FOR

PIPING CONFIGURATION AND VA LVING, CHECK

WARNING: THIS DRAWING SHOWS SUGGESTED

INSTALLAIR VENTS AT HIGH POINTS IN SYSTEM.

PIPING&SIZING OF EXPANSION TANK

PER TANK MANUFACTURER'S INSTRUCTIONS.

PRIMARY/SECONDARY MANDATORY FOR ALL

VARIABLE FLOW SYSTEMS.

BOILER WATER CONNECTIONS (INLET/OUTLET)

MAYVARY. VERIFY CONNECTION ORIENTATION.

BOILER CIRCUIT PIPING MUST BE EQUAL

BOILER WATER CONNECTION SIZE.

DIMENSION "C" TO BE4PIPE DIAMETERS.

DOTTED DEVICES INDICATE ALTERNATE

LOCATIONS.

TEMPERATURE SENSORS REQUIRE FIELD

INTERLOCK TO BOILER CONTROLS.

COMBINED FLOW OF ALL BOILERS.

COMMON PIPING MUST BE SIZED FOR

BOILER CIRC. PUMP SIZED FOR FLOW THROUGH

BOILER AND 30 FEET OF FULL-SIZED PIPING.

MINIMUM INLET WATER TEMP = 70°F

LEGEND

Cold Water

Make-Up

Pump

System

Supply

System

System

Return

C

3-Way Valve

Mounted on Pennant

Pump Mounted

on Pennant

System

Return

PRIMARY/SECONDARY MANDATORY FOR ALL

VARIABLE FLOW SYSTEMS.

INSTALLAIR VENTS AT HIGH POINTS IN SYSTEM.

PIPING&SIZING OF EXPANSION TANK

PER TANK MANUFACTURER'S INSTRUCTIONS.

COMMON PIPING MUST BE SIZED FOR

COMBINED FLOW OF ALL BOILERS.

BOILER WATER CONNECTIONS (INLET/OUTLET)

MAYVARY. VERIFY CONNECTION ORIENTATION.

BOILER CIRCUIT PIPING MUST BE EQUAL

BOILER WATER CONNECTION SIZE.

BOILER CIRC. PUMP SIZED FOR FLOW

THROUGH BOILER

FULL-SIZED PIPING.

DIMENSION "C" TO BE4PIPE DIAMETERS.

MINIMUM INLET WATER TEMP = 70°F

DOTTED DEVICES INDICATE ALTERNATE

LOCATIONS.

TEMPERATURE SENSORS REQUIRE FIELD

INTERLOCK TO BOILER CONTROLS.

AND 30 FEET OF

WARNING: THIS DRAWING SHOWS SUGGESTED

PIPING CONFIGURATION AND VALVING, CHECK

WITH LOCAL CODES AND ORDINANCES FOR

ADDITIONAL REQUIREMENTS.

C

C

System

Pump

Cold Water

Make-Up

3-Way Valve

Mounted on Pennant

System

Supply

Page 15

THERMOMETER

TEMPERATURE

Figure 4. Suggested Piping - Hydronic Boiler.

GLOBE VA LV E

CHECK VA LV E

LEGEND

PRESSURE REDUCING VA LVE

W/ FAST FILL BYPASS

PURGE

Pump Mounted

3-WAY VALV E

VALV E

on Pennant

EXPANSION TANK

WITH AIR SCOOP AND

AUTO AIR VENT

PUMP

Figure 5. Hydronic Piping — One Boiler, Multi-Temperature System.

Page 16

Page 16

LAARS Heating Systems

SECTION 4A.

Water Connections —

Pennant Boiler

4A.1 Heating System Piping:

Hot Supply Connections — Boiler

NOTE: This appliance must be installed in a closed

pressure system with a minimum of 12 psig (82.7

kPa) static pressure at the boiler.

Hot water piping should be supported by suitable

hangers or oor stands. Do not support piping with

this appliance. Due to expansion and contraction of

copper pipe, consideration should be given to the type

of hangers used. Rigid hangers may transmit noise

through the system resulting from the piping sliding in

the hangers. It is recommended that padding be used

when rigid hangers are installed. Maintain 1" clearance

to combustibles for hot water pipes.

Pipe the discharge of the relief valve (full size)

to a drain or in a manner to prevent injury in the event

of pressure relief. Install an air purger, an air vent,

a diaphragm-type expansion tank, and a hydronic

ow check in the system supply loop. Minimum ll

pressure must be 12 psig (82.7 kPa). Install shutoff

valves where required by code.

See suggested piping diagrams (Figures 4-5).

These diagrams are meant only as a guide. Com ponents required by local codes must be properly installed.

Note the recommended location of the

temperature sensor on the diagrams; you must provide

a location for the additional sensor shipped with the

Pennant. This sensor may be strapped onto pipe from

1" to 4" diameter, or inserted into an immersion well.

4A.2 Cold Water Make-Up — Boiler

1. Connect the cold water supply to the inlet

connection of an automatic ll valve.

2. Install a suitable back ow preventer between the

automatic ll valve and the cold water supply.

3. Install shut off valves where required.

NOTE: The boiler, when used in connection with a

refrigeration system, must be installed so the chilled

medium is piped in parallel with the boiler with

appropriate valves to prevent the chilled medium from

entering the boiler.

The boiler piping system of a hot water heating

boiler connected to heating coils located in air

handling appliances where they may be exposed to

refrigerated air circulation must be equipped with ow

control valves or other automatic means to prevent

gravity circulation of the boiler water during the

cooling cycle.

A boiler installed above radiation level, or as

required by the authority having jurisdiction, must be

provided with a low water cutoff device either as a part

of the boiler or at the time of boiler installation.

4A.3 Water Flow Requirements — Boiler

Low Temperature Pennant Boilers are equipped

with a mounted pump. The pumps are sized for the

boiler’s head loss and 30 feet of full-size piping (same

size as boiler outlet), with a normal number of ttings.

The boilers must be piped in a primary-secondary sys-

tem, such that the boiler’s pump only serves the boiler.

Figures 4 and 5 show examples of this type of piping.

The minimum inlet water temperature to the

Pennant is 70°F (20°C). The mixing system on the

Pennant will ensure that the heat exchanger in the

Pennant does not see water that is less than 120°F

(49°C), so that excessive condensation does not form

on the heat exchanger.

Table 8 shows a relationship between water ow

through the boiler and the temperature difference (rise)

between the inlet and outlet of the boiler. This table

will enable the user to test the boiler for proper water

ow. Since the boiler has a mixing system that sends

a portion of the hot water from the boiler outlet to the

boiler inlet, the water ow coming out of the mixing

system will vary, depending on the return water

temperature.

4A.4 Freeze Protection — Boiler

Boiler installations are not recommended in

areas where the danger of freezing exists unless proper

precautions are made for freeze protection. A non

toxic, heating system, anti-freeze may be added to the

hydronic system provided that the concentration does

not exceed 50% and the anti freeze contains an anti

foamant. Power outage, interruption of gas supply,

failure of system components, activation of safety

devices, etc., may prevent a boiler from ring. Any

time a boiler is subjected to freezing conditions,

and the boiler is not able to re, and/or the water

is not able to circulate, there is a risk of freezing in

the boiler or in the pipes in the system. When water

freezes, it expands. This can result in bursting of pipes

in the system, or damage to the boiler, which could

result in leaking or ooding conditions.

IMPORTANT NOTES: Different glycol products may

provide varying degrees of protection. Glycol products

must be maintained properly in a heating system, or

they may become ineffective. Consult the glycol specifications, or the glycol manufacturer, for information

about specific products, maintenance of solutions, and

set up according to your particular conditions. Never

use ethylene glycol (automotive antifreeze).

Size 20°F (11°C) 25°F (14°C) 30°F (17°C) 35°F (19°C)

gpm lpm gpm lpm gpm lpm gpm lpm

500 43 161 34 129 26 107 24 92

750 64 241 51 193 43 161 36 138

1000 85 321 68 257 57 214 49 184

1250 106 401 85 322 71 269 61 231

1500 128 483 102 386 85 322 73 276

1750 N/R N/R 11 9 451 99 375 85 322

2000 N/R N/R 103 515 113 429 97 368

Notes: gpm = gallons per minute, lpm = liters per minute,

Maximum temperature rise is 35°F (19°C), as shown.

N/R = not recommended.

Table 8. Temperature Rise - Boiler.

Page 17

Low Temperature Pennant

Page 17

SECTION 4B.

Water Connections —

Pennant Water Heater

4B.1 Water System Piping —

Water Heater

Hot water piping should be supported by suitable

hangers or oor stands. Do not support piping with

this appliance. Due to expansion and contraction of

copper pipe, consideration should be given to the type

of hangers used. Rigid hangers may transmit noise

through the system resulting from the piping sliding in

the hangers. It is recommended that padding be used

when rigid hangers are installed.

The Pennant can be used with several different

types of readily available storage tanks. Pennant units

have a circulating pump built into the water heater.

The pumps used are sized for the head loss through the

heater, plus 30 feet (9.1 m) of full-sized piping (same

size as boiler outlet) and a normal number of ttings.

Pumps used are sized for soft, normal or hard water,

so make sure the unit matches the water quality of the

installation.

Pipe the outlet from the heater’s relief valve

such that any discharge from the relief valve will be

conducted to a suitable place for disposal when relief

occurs. Do not reduce line size or install any valves in

this line. The line must be installed to allow complete

drainage of both the valve and the line.

Suggested piping diagrams are shown in Figures

6,7,8 and 9. These diagrams are meant only as a guide.

Components required by local codes must be properly

installed.

Note the recommended location of the

temperature sensor on the diagrams. The Pennant is

shipped with an additional sensor that can be used in

the storage tank, in lieu of a separate tank thermostat.

The minimum inlet water temperature for the

Low-Temp Pennant is 70°F (20°C). The mixing

system on the Pennant will ensure that the heat

exchanger in the Pennant does not see water that is

less than 120°F (49°C), so that excessive condensation

does not form on the heat exchanger.

4B.2 Hot Water Supply Piping —

Water Heater

Follow the tank manufacturer’s guidelines for

completion of the hot water system connections.

NOTE: A listed temperature and pressure relief

valve listed as complying with the Standard for

Relief Valves and Automatic Gas Shutoff Devices

for Hot Water Supply Systems (ANSI Z21.22/

CSA 4.4), of suitable discharge capacity must be

installed in the separate storage tank system.

If the Pennant water heater is installed in a closed

water supply system, such as one having a backow

preventer in the cold water supply line, the relief valve

may discharge periodically, due to thermal expansion.

Means (such as a properly-sized expansion tank) shall

be provided to control thermal expansion. Contact the

water supplier or local plumbing inspector on how to

control this situation.

4B.3 Water Flow Requirements —

Water Heater

In a water heating application (an open system),

new water is constantly being introduced. With the

new water comes a fresh supply of minerals that can

be deposited on the unit’s heat exchanger. This is

commonly known as scaling. The amount of minerals

will depend upon the hardness of the water. Water can

also be aggressive, and can erode metals, including

copper, if the water is moved too quickly. The water

ow requirements for the Pennant water heater are

based upon the hardness of the water. The water ow

is kept high enough to prevent scaling, but low enough

to prevent tube erosion. For extremely soft or hard

water, cupro-nickel tubes are available. Contact a

Laars representative if you have questions or concerns

about water quality.

Pennant water heaters are built with a mounted

pump that is sized for soft, normal or hard water. The

pumps used are sized for the head loss through the

heater, plus 30 feet (9.1m) of full-sized piping (same

size as heater outlet) and a normal number of ttings.

Table 9 species water ow rates for water

heaters, which will enable the user to ensure that the

Pennant is getting the correct water ow when it is in

operation.

4B.4 Combined Water Heating (potable)

and Space Heating — Water Heater

NOTE: Combined systems must be allowed by and

installed per local codes.

Piping and components connected to this water

heater for the space heating application shall be

suitable for use with potable water.

Toxic chemicals, such as used for boiler

treatment, shall not be introduced into the potable

water used for space heating.

This water heater when used to supply potable

water shall not be connected to any heating system

or component(s) previously used with a non-potable

water heating appliance.

When the system requires water for heating at

temperatures higher than required for other uses,

an anti-scald mixing or tempering valve shall be

installed to temper the water for those uses in order

to reduce scald hazard potential.

4B.5 Freeze Protection — Water Heater

Although Pennant water heaters are design-

Page 18

Page 18

LAARS Heating Systems

certied for outdoor installations, such installations

are not recommended in areas subject to freezing

temperatures, unless proper precautions are taken.

Power outage, interruption of gas supply, failure

of system components, activation of safety devices,

etc., may prevent a heater from ring. Any time a

heater is subjected to freezing conditions, and the

heater is not able to re, and/or the water is not

able to circulate, there is a risk of freezing in the

heater or in the pipes in the system. When water

freezes, it expands. This can result in bursting of pipes

in the system, or damage to the heater, which could

result in leaking or ooding conditions.

Contact the local factory representative or Laars

for additional information.

Size

500 45 68 90 19 13 9 170 257 341 10 7 5

750 45 68 90 28 19 14 170 257 341 16 10 8

1000 45 68 90 38 25 19 170 257 341 21 14 10

1250 68 68 90 31 31 24 257 257 341 17 17 13

1500 68 68 90 38 38 28 257 257 341 21 21 16

1750 68 68 90 44 44 33 257 257 341 24 24 18

2000 112 112 112 30 30 30 424 424 424 17 17 17

Notes:

Soft Water = 1 to 7.5 grains hardness

Normal Water = 7.6 to 17 grains hardness

GPM Water Flow Temperature Rise °F LPM Water Flow Temperature Rise °C

Soft Normal Hard Soft Normal Hard Soft Normal Hard Soft Normal Hard

Hard Water = more than 17 grains hardness

GPM = gallons per minute

LPM = liters per minute

Table 9. Temperature Rise — Water Heater.

Figure 6. Suggested Piping — One Water Heater, One Tank.

Page 19

Low Temperature Pennant

Page 19

Figure 7. Suggested Piping — Multiple Water Heaters, One Tank.

Figure 8. Suggested Piping — One Water Heater, Multiple Tanks.

Page 20

Page 20

LAARS Heating Systems

Figure 9. Suggested Piping — Multiple Water Heaters, Multiple Tanks.

SECTION 5.

Electrical Connections

WARNING

The appliance must be electrically grounded in

accordance with the requirements of the authority

having jurisdiction or, in the absence of such

requirements, with the latest edition of the National

Electrical Code, ANSI/NFPA 70, in the U.S. and

with latest edition of CSA C22.1 Canadian Electrical

Code, Part 1, in Canada. Do not rely on the gas

or water piping to ground the metal parts of the

boiler. Plastic pipe or dielectric unions may isolate

the boiler electrically. Service and maintenance

personnel, who work on or around the boiler, may be

standing on wet floors and could be electrocuted by

an ungrounded boiler.

L’appareil doit être relié à la terre conformément

aux exigences de la réglementation locale ou,

en l’absence d’une telle réglementation, à la plus