Page 1

Installation and Operation Instructions Document 1330E

Installation and Operation

Instructions for

®

with Touchscreen Display

Modulating Boilers and

Volume Water Heaters

Outdoor models

NTH & NTV

Sizes 150 – 850 MBTU/h

Indoor models

NTH Sizes 285 – 850 MBTU/h

NTV Sizes 150 – 850 MBTU/h

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualied in hot water boiler and heater installation and maintenance. Improper installation and/or operation

could create carbon monoxide gas in ue gases which could cause serious injury, property damage, or

death. Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not

followed exactly, a re or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

ammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the re department.

Installation and service must be performed

by a qualied installer, service agency, or gas

supplier.

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion

ou pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inammables dans

le voisinage de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous

servir des téléphones dansle bâtiment où vous

vous trouvez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualié ou

par le fournisseur de gaz.

AVERTISSEMENT

H2374100E

Page 2

Table of Contents

LAARS Heating Systems

SECTION 1

General Information

1.A Introduction .......................................................1

1.B Warranty ...........................................................1

1.C ModelIdentication ...........................................1

1.D Safety ...............................................................2

1.E Appliance Overview .......................................4-9

1.F Dimensions, Indoor Models ............................10

1.G Dimensions, Outdoor Models .........................12

1.H The Installation Kit ..........................................14

SECTION 2

Locating the Appliance

2.A General Information ........................................ 16

2.B Locating Appliance for Correct Vent Distance

from Outside Wall or Roof Termination ...........16

SECTION 3

Venting and Combustion Air

3.A General Venting ..............................................17

3.B Combustion Air ...............................................17

3.C Venting ............................................................19

3.D Locating Vent & Combustion Air Terminals .....21

3.E Common V ent Test .........................................25

SECTION 4

Gas Supply and Piping

......................................26

SECTION 5

Pump Requirements

5.A Boiler Flow and

Head Requirements ........................................27

5.B Water Heater

Flow and Head Requirements ........................27

SECTION 6A

Water Connections - Boiler

6A.1 Boiler System Piping: Hot Supply

6A.2

6A.3

6A.4

6A.5

6A.6 Recognized Chemicals ...................................29

Connections

Boiler Cold W

Condensate Drain ...........................................29

Freeze Protection ...........................................29

Boiler Suggested Piping Schematics .........29-35

....................................................28

ater Make-Up ............................28

SECTION 6B

Water Connections - Water Heater

6B.1 Heater Water Quality ......................................36

6B.2

6B.3

6B.4

6B.5

6B.6

6B.7

Piping Requirements ......................................36

Cold W

Condensate Drain ...........................................37

Freeze Protection ...........................................37

Heater Suggested Piping Schematics ............37

Heater Suggested Pumps ..............................37

ater Make-Up ......................................36

SECTION 7

Electrical and Wiring Diagrams

7.A Installation Warnings .......................................39

7B Main Power Connections ................................39

7.B,1 Pump Connections and Operation .................. 39

7.B.2 Optional VARI-PRIMETM .................................39

7.C Hydronic Heating Using External Mod ............41

7.D Optional Field Connections .............................41

7.E Lead Lag Connections ....................................42

7.F Building Automation Systems Connections ....43

7.G System Wiring Diagram ..................................44

7.H Ladder Diagram .............................................. 45

i

Page 3

NEOT

HERM

Commercial Boilers and Water Heaters, 150 to 850 MBTU/h

SECTION 8

Using the Touch Screen

8.A The Touch Screen ........................................47

8.B Using the Touch Screen ................................47

8.C Login (required for some parameters) ...........48

8.D VericationProcessforSafety-Related

Parameters ....................................................49

8.E Checking Individual Parameters ....................50

8.F Setting the Date and Time..............................51

8.G The Conguration Menu

8.G.1 SystemIdentication&Access ...................53

8.G.2ACH-CentralHeatConguration...............53

2B Setting Up 4-20 mA Set Point ..................53

8.G.3 OutdoorResetConguration ......................54

8.G.4 DHW-DomesticHotWaterConguration .54

8.G.5 WarmWeatherShutdownConguration ....54

8.G.6 DemandPriorityConguration ...................55

8.G.7 ModulationConguration ............................55

8.G.8 Pump Connections .....................................55

8.G.9 StatisticsConguration ...............................56

8.G.10 High Limits ................................................56

8.G.11 Stack Limits ................................................56

8.G.12 Anti-CondensationConguration ..............56

8.G.13 FrostProtectionConguration ..................56

8.G.14 SystemConguration ...............................56

8.G.15 FanConguration .....................................57

8.G.16 SensorConguration ................................57

About Lead Lag

8.G.17LeadLagFollowerConguration ..............60

8.G.18LeadLagLeaderConguration ................62

8.H Congurefora

Building Automation System ..........................65

TheCongurationSub-Menus(ALL18) .......53

.............................. ................58

8.I Combustion Setup

8.J Adjusting CO2 ...............................................68

............................52

...................................66

SECTION 9

First Start Up and Adjustment

9.A Filling the Boiler System .................................71

9.B First Operation ................................................71

9.C Shutting Down the NeoTherm Unit .................72

9.D Restarting the NeoTherm Unit ........................72

SECTION 10

Maintenance

10.A System Maintenance ......................................73

10.B Appliance Maintenance and Component

Description ......................................................73

10.C Battery Back Up for Date and Time ................76

10.D Gas Conversion ..............................................76

SECTION 11

Troubleshooting

11.A About Lockouts, Holds, and Alerts ...................78

11.A.1 Responding to a Lockout, Hold, or Alert ......78

11.A.2 Viewing the Lockout and Alert Histories .......78

1 1.B T roubleshooting Table .................................80-87

11.C Diagnostic Tests and Input/Output Indicators ..88

11.D Lead Lag Follower Diagnostics ........................89

11.E Statistics ...........................................................89

11.F Analysis ............................................................89

11.G Control Snapshot .............................................89

11.H Operating Sequence ........................................ 90

SECTION 12

Replacement Parts

12.A General Information .......................................91

12.B Parts List ...................................................91-93

12.C Parts Illustrations ....................................93-100

ii

Page 4

LAARS Heating Systems

Page 5

NEOT

HERM

Commercial Boilers and Water Heaters, 150 to 850 MBTU/h

SECTION 1

GENERAL INFORMATION

1.A Introduction

This manual provides information necessary for the

installation, operation, and maintenance of LAARS

Heating Systems NeoTherm boilers and water heaters.

Read it carefully before starting the installation.

All application and installation procedures should

be reviewed completely before proceeding with the

installation. Consult the LAARS Heating Systems

factory, or local factory representative, with any

problems or questions regarding this equipment.

Experience has shown that most operating problems

are caused by improper installation.

NeoTherm is protected against over pressurization. A

pressure relief valve is included with each NeoTherm.

Some NeoTherms may require that the PRV be

installed prior to lling the system. Refer to Figures 2-9

for PRV locations.

1.B Warranty

LAARS Heating Systems NeoTherms are covered by a

limited warranty . The owner should complete the warranty

registration at www.Laars.com.

All warranty claims must be made to an authorized

LAARS Heating Systems representative. Claims must

include the serial number and model (this information

can be found on the rating plate), installation date, and

name of the installer. Shipping costs are not included in

the warranty coverage.

NOTE: Throughout the content of this manual,

the NeoTherm will be referred to as a ‘unit’.

NeoTherm = unit

Page 1

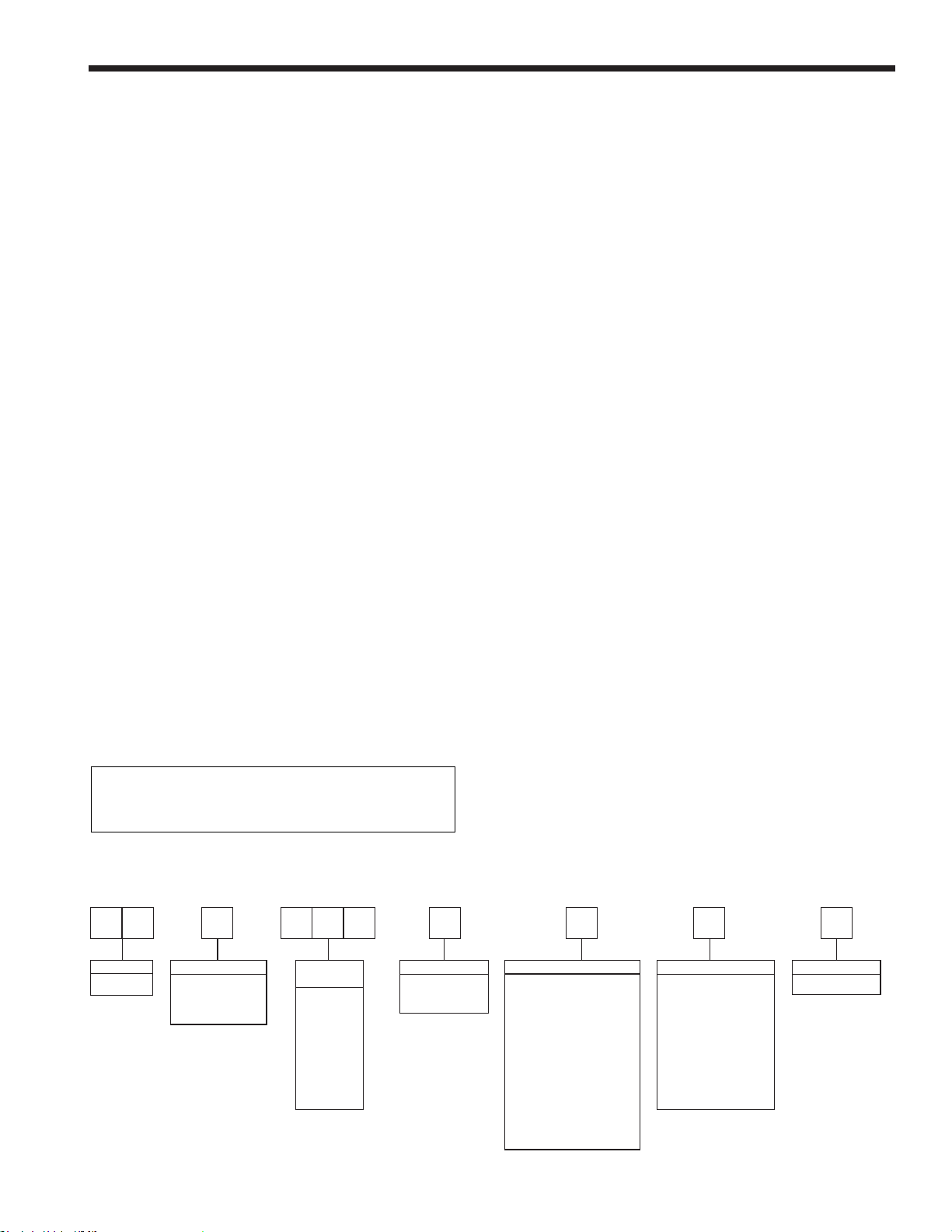

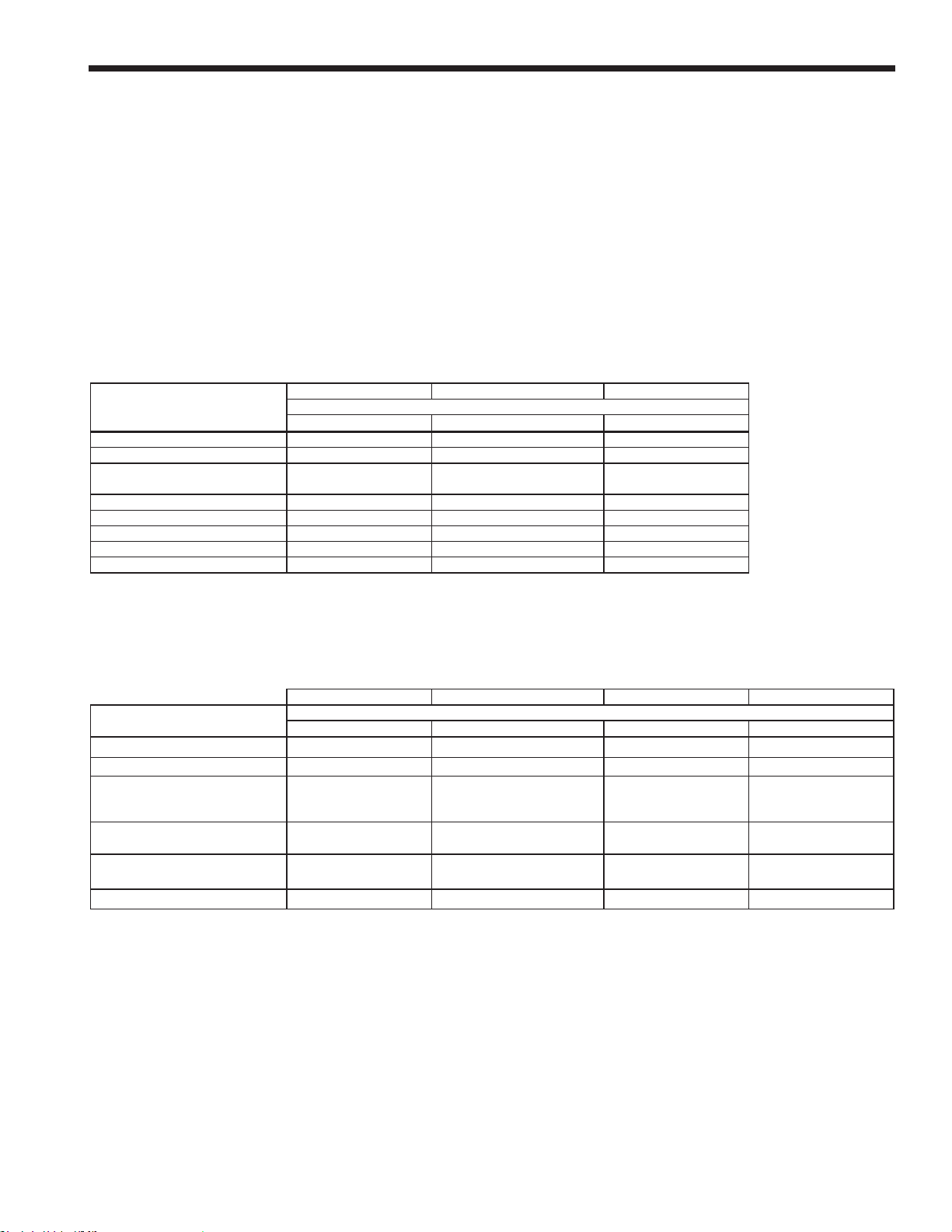

1.C Model Identication

Consult the Rating Plate on the side of the unit. The

following information describes the model nomenclature

(number structure).

(1-2) Model Series Designation

N T = NeoTherm

(3) Usage

H = Hydronic

V = Volume Water

(4-6) Size

1 5 0 = 150,000 BTU/hr input

1 9 9 = 199,000 BTU/hr input, Heater only

2 1 0 = 210,000 BTU/hr input, Boiler only

2 8 5 = 285,000 BTU/hr input

3 9 9 = 399,000 BTU/hr input

5 0 0 = 500,000 BTU/hr input

6 0 0 = 600,000 BTU/hr input

7 5 0 = 750,000 BTU/hr input

8 5 0 = 850,000 BTU/hr input

(7) Fuel

N = Natural Gas

P = LP Gas

(8) Options Code

X = Standard Unit

J = CSD-1, FM, GAP, IL Code (size 500-850 only)

C - STANDARD (Canada)

D - CSD-1 (Canada)

E - OUTDOOR

F - OUTDOOR (Canada)

G - CSD-1, OUTDOOR

H - CSD-1, OUTDOOR (Canada)

(9) Pump Options

N = Pump included (150-500 only)

X = No pump (conguration available for all sizes)

W = HLW w/ Pump (option for Heater only)

L = HLW w/out Pump (option for Heater only)

(10) Revision

3 = Third version

Model Nomenclature

1 2 3 4 5 6 7 8 9 10 11

SERIES

N T

USAGE

H -

HYDRONIC

V - VOLUME

WATER

SIZE

MBTU/h

1 5 0

1 9 9

2 1 0

2 8 5

3 9 9

5 0 0

6 0 0

7 5 0

8 5 0

FUEL

N - NATURAL

P - PROPANE

OPTIONS CODE

X -

STANDARD

J - CSD-1, FM, GAP ,

IL (500-850 only)

C - ST ANDARD (Canada)

D - CSD-1 (Canada)

E - OUTDOOR

F - OUTDOOR (Canada)

G - CSD-1, OUTDOOR

H - CSD-1, OUTDOOR

(Canada)

PUMP OPTIONS

N -

PUMP INCL.

(150-500 only)

X -

NO PUMP

W - HLW w/PUMP

(opt for Heater only)

L - HLW w/out

PUMP

(opt for Heater only)

3 N T

REVISION

3 - THIRD

Page 6

Page 2

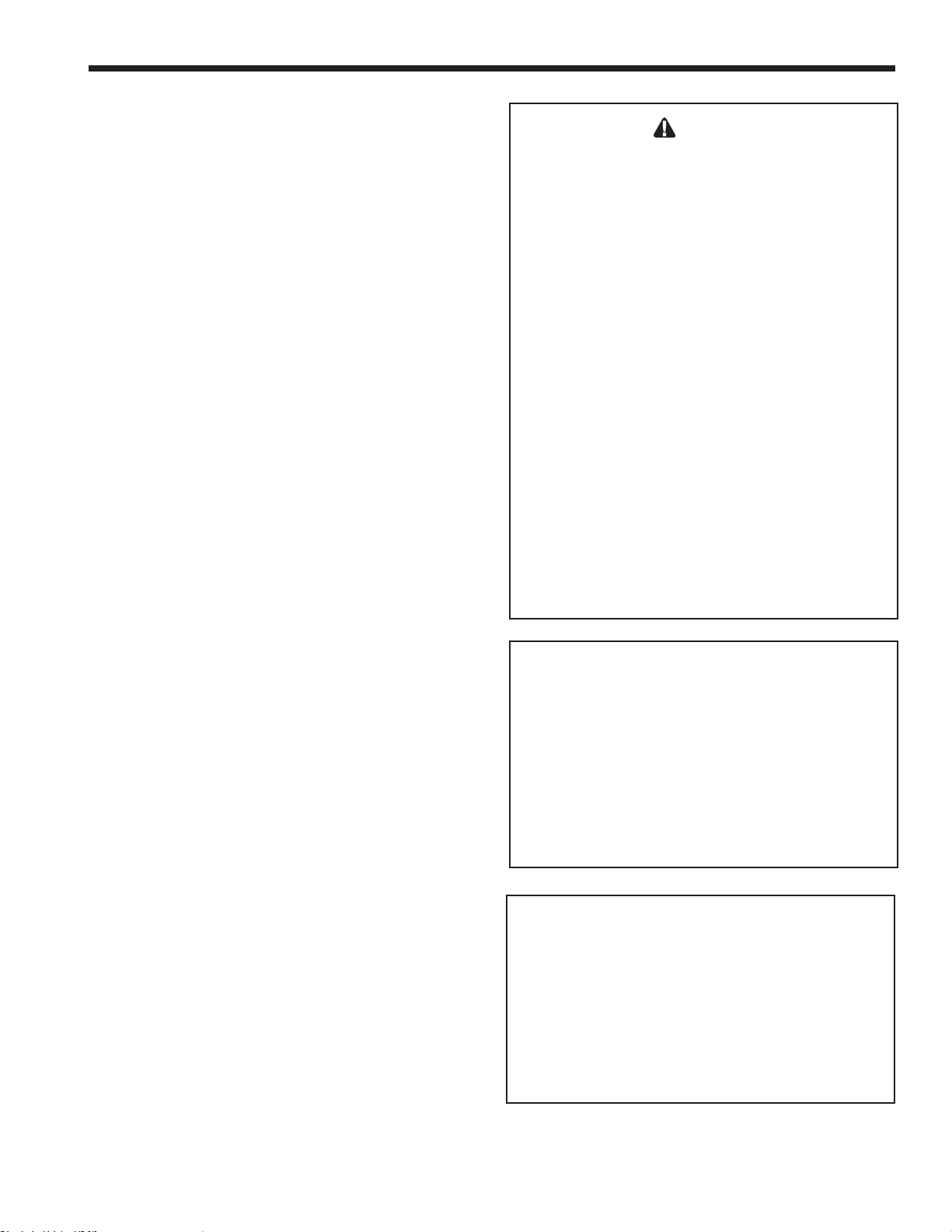

1.D Safety Notes

LAARS Heating Systems

WARNING

These units must be installed in accordance with

the procedures detailed in this manual, or the

Manufacturer’s warranty will be voided. The installation

must conform to the requirements of the local jurisdiction

having authority , and, in the United States, to the latest

edition of the National Fuel Gas Code, ANSI Z223.1/

NFPA54. In Canada, the installation must conform

to the latest edition of CSA B149.1 Natural Gas and

Propane Gas Installation Code, and/or local codes.

Where required by the authority having jurisdiction, the

installation of these units must conform to the Standard

for Controls and Safety Devices for Automatically Fired

Boilers, ANSI/ASME CSD-1. Any modications to the

boiler, its gas controls, or wiring may void the warranty. If

eld conditions require modications, consult the factory

representative before initiating such modications.

NOTE: All installations must be made in accordance with

1) American National Standard Z223.1/NFPA54-Latest

Edition “National Fuel Gas Code” or

2) CSA B149.1 “Natural Gas and Propane Installation

Code” or in Canada reference the B149.1 latest

edition and with the requirement of the local utility or

other authorities having jurisdiction. Such applicable

requirements take precedence over the general

instructions contained herein. All electrical wiring is to

be done in accordance with the local codes, or in the

absence of local codes, with: 1) The National Electrical

Code ANSI/NFPA No. 70-latest Edition, or

2) CSA STD. C22.1 “Canadian Electrical Code - Part

1”. This appliance must be electrically grounded in

accordance with these codes.

DANGER

• Water temperature over 125°F (52°C) can cause

severe burns instantly or death from scalds.

• Children, disabled and

elderly are at highest

risk of being scalded.

• See instruction manual

before setting temperature

at heating appliance.

• Feel water before bathing

or showering.

• If this appliance is used

to produce water that could scald if too hot, such

as domestic hot water use, adjust the outlet control

(limit) or use temperature limiting valves to obtain a

maximum water temperature of 125°F (52°C).

WARNING

Fire or Explosion Hazard

Improper conguration can cause fuel buildup and

explosion. Improper user operation may result in

property loss, severe physical injury, or death.

Any changes to safety-related conguration

parameters must only be done by experienced and/or

licensed burner/boiler operators and mechanics.

If any odor of gas is detected, or if the gas burner does

not appear to be functioning in a normal manner, close

the main gas shuto valve. Do not shut o the power

switch. Contact your heating contractor, gas company,

or factory representative.

DANGER

The inlet gas pressure to the appliance must not

exceed 13” W.C. (3.2kPa).

WARNING

:

Cancer and Reproductive Harm

www.P65Warnings.ca.gov

As required by the State of California Proposition 65.

Note: The unit is protected against over-pressurization.

A pressure relief valve is included with each unit.

WARNING

Carbon Monoxide Hazard

Improper adjustment of the burners may lead to poor

combustion quality , increasing the amount of carbon

monoxide produced. Excessive carbon monoxide levels

may lead to personal injury or death.

Page 7

NEOT

Electrical Shock Hazard

Edition, or 2) CSA STD. C22.1 “Canadian Electrical Code

HERM

Electrical shock can cause severe injury, death or

property damage. Disconnect the power supply before

beginning installation or changing the wiring to prevent

electrical shock or damage to the equipment. It may

be necessary to turn o more than one power supply

All electrical wiring is to be done in accordance with

local codes, or in the absence of local codes, with: 1)

The National Electrical Code ANSI/NFPA No. 70 - latest

- Part 1.” This appliance must be electrically grounded in

Commercial Boilers and Water Heaters, 150 to 850 MBTU/h

WARNING

disconnect.

accordance with these codes.

Page 3

Page 8

Page 4

1.E Model Overview

LAARS Heating Systems

These units are oered in both Indoor and Outdoor

models for all sizes. The physical appearance of the

indoor and outdoor units is drastically dierent because

the outdoor model oers a fully weathertight enclosure

that hides the touchscreen. Whereas the indoor model

is not fully weathertight and the touchscreen can be

accessed without having to open the unit. See Figure 1

through Figure 9.

Both the indoor and the outdoor models have the

On/O switch on the outside of the unit.

ON / OFF

SWITCH

Both also have the Rating Plate on the outside panel

to the right. See Figure 8 on page 8

The only component (interior) dierence between the

indoor and outdoor models is that all of the piping for the

outdoor model, with the exception of the exhaust vent, is

at the BACK of the unit. Figure 9 on page 9

The gas connection, the air inlet, and the water inlet and

outlet are all at the back of the unit. This is consistent for

all sizes.

THE TOUCH SCREEN ON

OUTDOOR UNIT IS LOCATED

BEHIND FRONT PANEL

2 SCREWS

FASTEN FRONT

PANEL INTO

PLACE

INDOOR OUTDOOR

Figure 1. All models open from the front

DOOR LATCHES

(RELEASE BOTH

LA TCHES T O

OPEN)

DOOR

HANDLE

(PULL TO OPEN)

Page 9

NEOT

HERM

Commercial Boilers and Water Heaters, 150 to 850 MBTU/h

Page 5

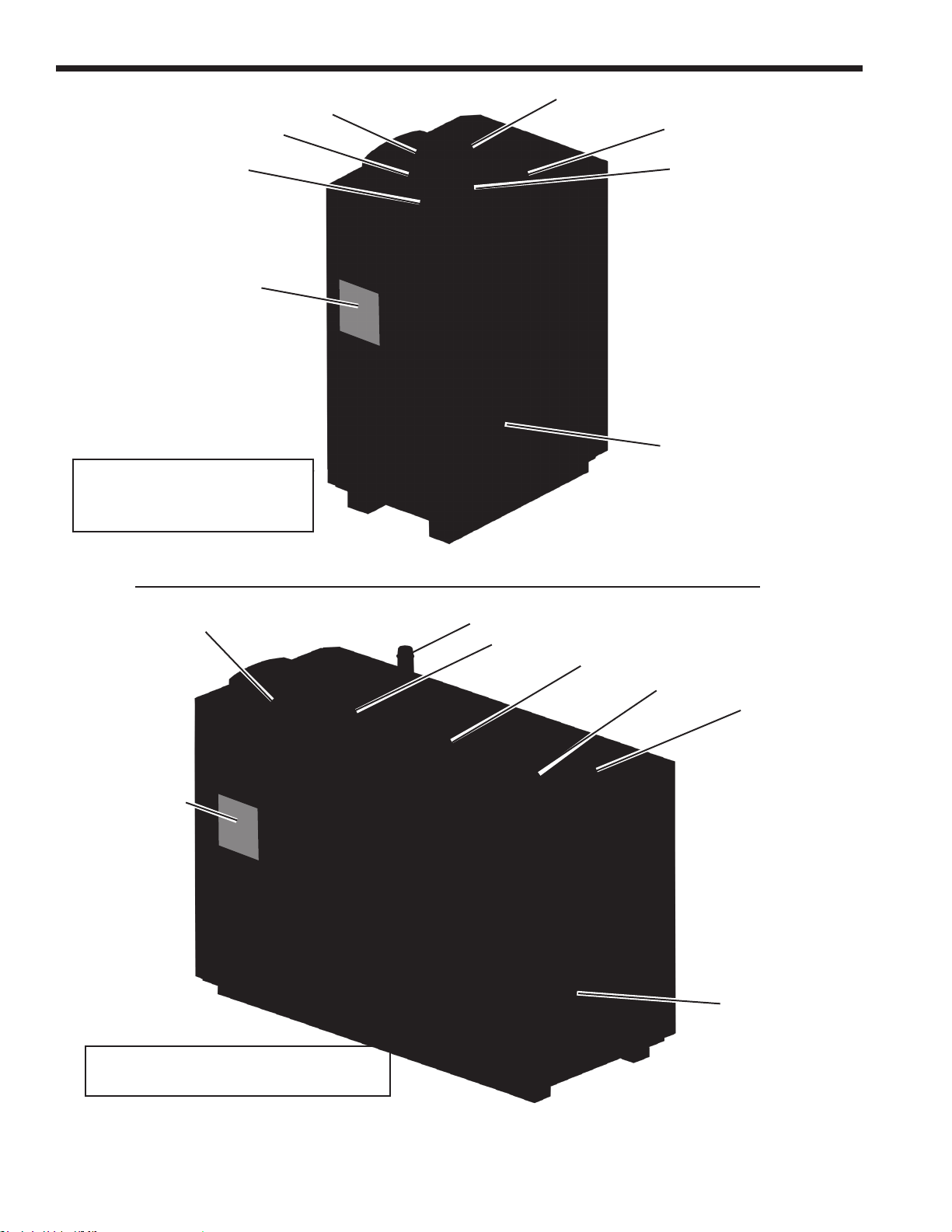

EXHAUST VENT CONNECTION

GAS CONNECTION

TOUCHSCREEN

HEAT EXCHANGER

AIR/ GAS

BLOWER

VENTURI

PRESSURE RELIEF VALVE

WATER INLET

WATER OUTLET

AIR INLET CONNECTION

AIR PRESSURE SWITCH

ON / OFF SWITCH

DRAIN VALVE

GAS VALVE

AIR TRANSITION

CONDENSATE TRAP

Figure 2. Location of Components, Sizes 150-210

EXHAUST VENT CONNECTION

AIR INLET CONNECTION

GAS CONNECTION

TOUCHSCREEN

HEAT EXCHANGER

GAS VALVE

AIR/ GAS

BLOWER

WATER INLET

WATER OUTLET

PRESSURE RELIEF VALVE

AIR PRESSURE SWITCH

ON / OFF SWITCH

DRAIN VALVE

CONDENSATE TRAP

VENTURI

AIR TRANSITION

Figure 3. Location of Components, Size 285

Page 10

Page 6

LAARS Heating Systems

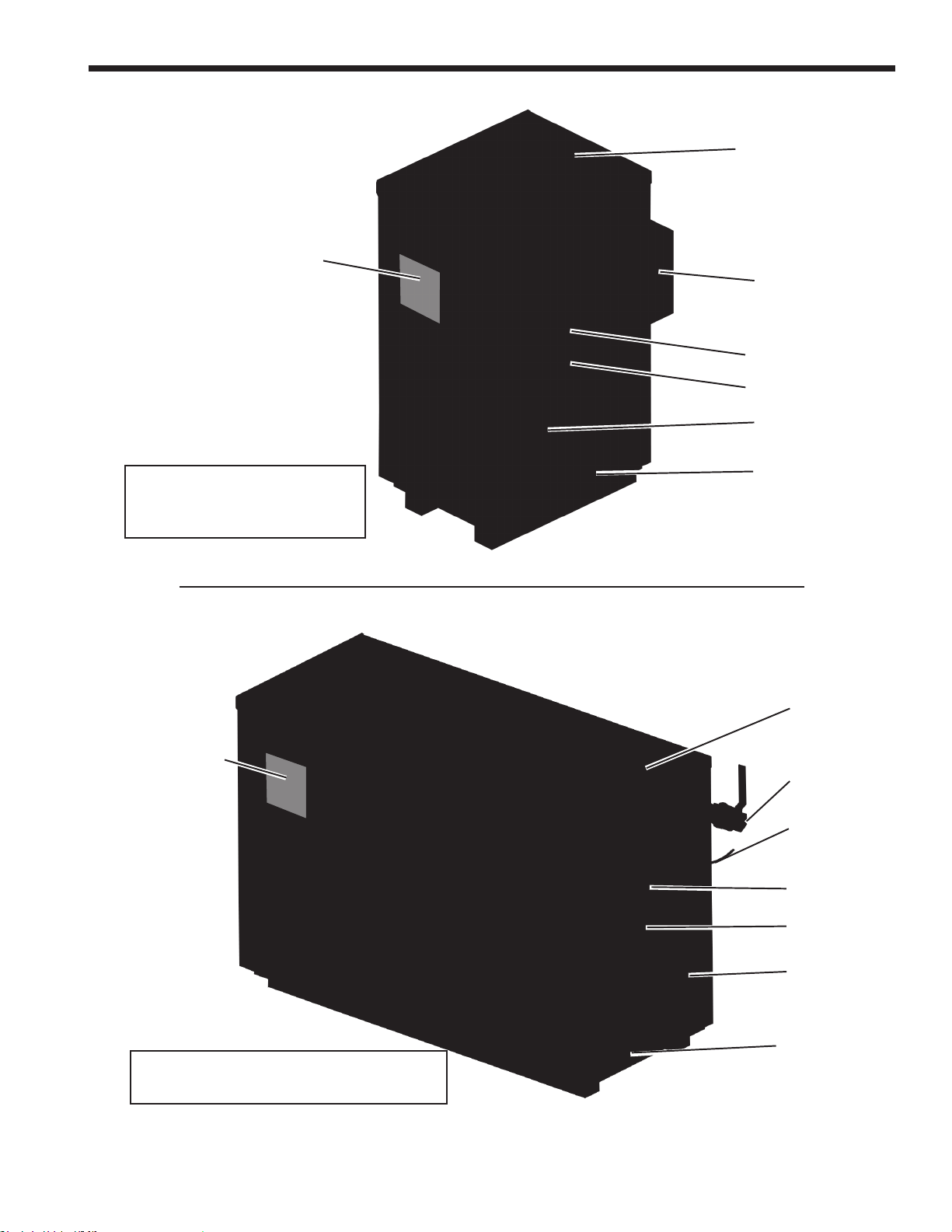

EXHAUST VENT CONNECTION

PRESSURE RELIEF VALVE

GAS CONNECTION

TOUCHSCREEN

HEAT EXCHANGER

MANUAL SHUTOFF

GAS VALVE

AIR/ GAS

BLOWER

VENTURI

WATER INLET

WATER OUTLET

AIR INLET CONNECTION

ON / OFF SWITCH

DRAIN VALVE

CONDENSATE TRAP

GAS VALVE

Figure 4. Location of Components, Indoor Size 399

EXHAUST VENT CONNECTION

PRESSURE RELIEF VALVE

GAS CONNECTION

TOUCHSCREEN

HEAT EXCHANGER

MANUAL SHUTOFF

GAS VALVE

VENTURI

GAS VALVE

GAS PRESSURE

SWITCH

WATER INLET

WATER OUTLET

AIR INLET CONNECTION

AIR PRESSURE SWITCH

ON / OFF SWITCH

DRAIN VALVE

CONDENSATE TRAP

AIR/ GAS BLOWER

Figure 5. Location of Components, Indoor Size 500

Page 11

NEOT

HERM

EXHAUST VENT CONNECTION

Commercial Boilers and Water Heaters, 150 to 850 MBTU/h

Page 7

GAS CONNECTION

PRESSURE RELIEF VALVE

TOUCHSCREEN

MANUAL SHUTOFF

GAS VALVE

HEAT EXCHANGER

GAS VALVE

MANUAL SHUTOFF

GAS VALVE

Figure 6. Location of Components, Size 600

WATER INLET

WATER OUTLET

AIR INLET CONNECTION

AIR PRESSURE SWITCH

ON / OFF SWITCH

DRAIN VALVE

CONDENSATE TRAP

AIR/ GAS BLOWER

VENTURI

GAS CONNECTION

PRESSURE RELIEF

VALVE

AIR INLET

TOUCHSCREEN

GAS VALVE

VENTURI

AIR/ GAS BLOWER

HEAT EXCHANGER

WATER INLET

EXHAUST VENT

CONNECTION

WATER OUTLET

ON / OFF SWITCH

DRAIN VALVE

MANUAL SHUTOFF

GAS VALVE

CONDENSATE TRAP

Figure 7. Location of Components, Sizes 750 and 850

Page 12

Page 8

LAARS Heating Systems

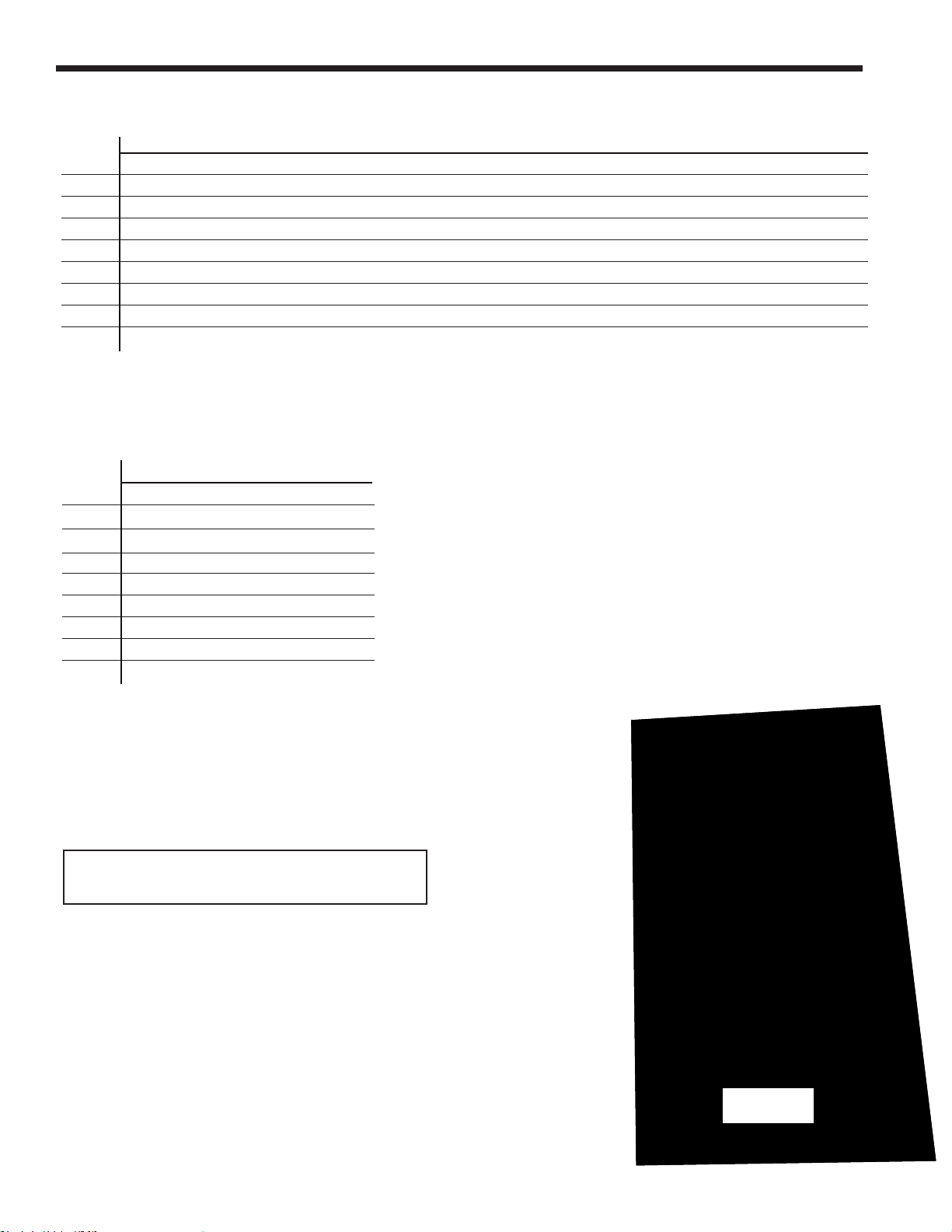

CONNECTION

WATER OUTLET

AIR INLET

RATING PLATE

Indoor 150 MBH

For piping dimensions/

locations for all Indoor units,

See Table 1 on page 10

GAS

PRV

EXHAUST

VENT

W

ATER INLET

CONDENSATE

TRAP OUTLET

(Trap is built-in)

AIR INLET

RATING PLATE

Indoor 850 MBH

For piping dimensiona/locations for all

Indoor units, See Table 1 on page 10

GAS CONNECTION

PRV

WATER OUTLET

W

ATER INLET

EXHAUST

VENT

CONDENSATE

TRAP OUTLET

(Trap is built-in)

GAS

CONNECTION

Figure 8. Connection piping is on the BACK for ALL Outdoor Sizes

Page 13

NEOT

HERM

Commercial Boilers and Water Heaters, 150 to 850 MBTU/h

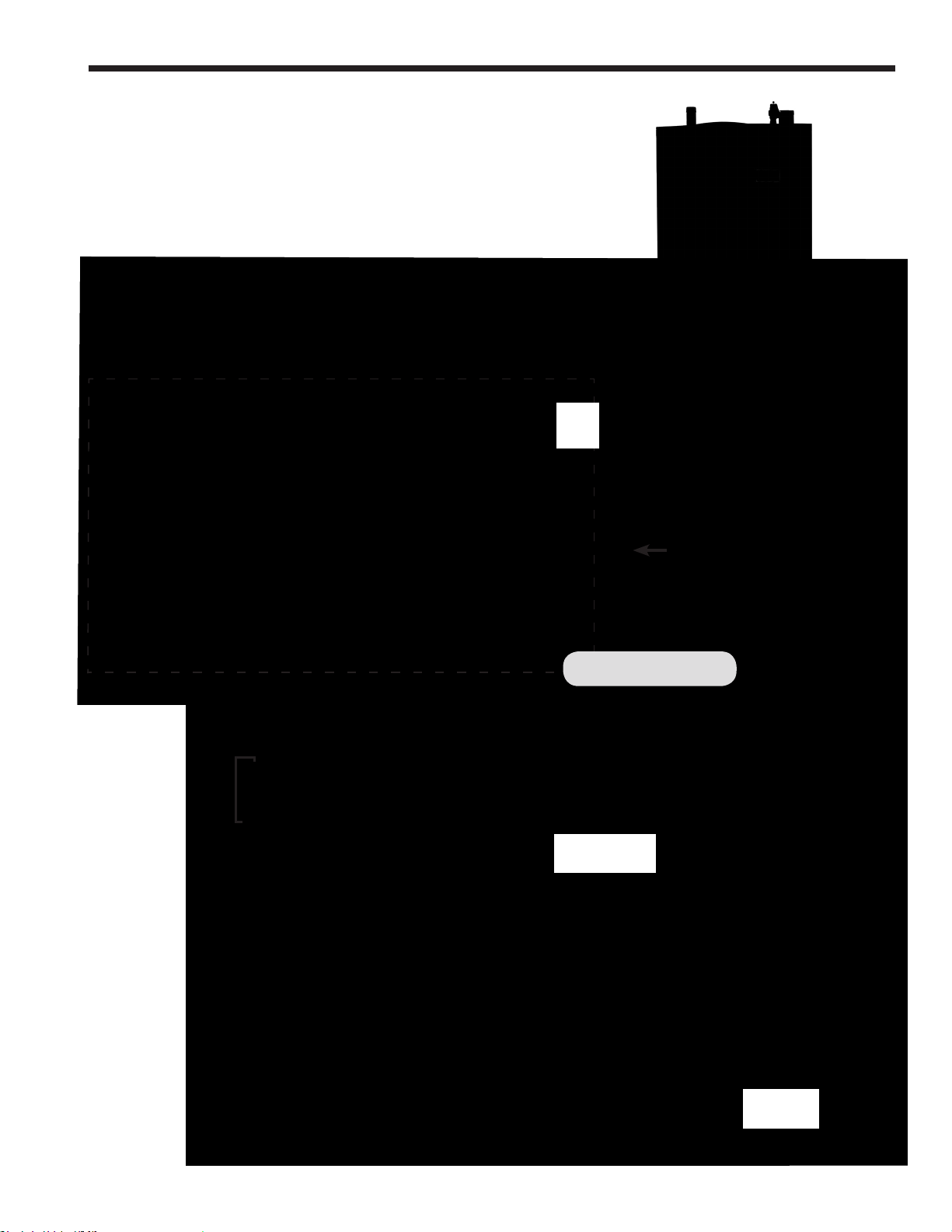

EXHAUST

VENT

RATING PLATE

AIR INLET

FILTER BOX

Page 9

Outdoor 150 MBH

For piping dimensions/

locations for all outdoor units,

See Table 2 on page 12

RATING PLATE

WATER OUTLET

WATER INLET

CONDENSA

TRAP OUTLET

(Trap is built-in)

CONNECTION

PRV must be added to this pipe

*

during installation.

TE

GAS

EXHAUST

VENT

GAS

CONNECTION

*

Outdoor 850 MBH

For piping dimensions/locations for all

Outdoor units, See Table 2 on page 12

Figure 9. Connection piping is on the BACK for ALL Outdoor Sizes

POWER SUPPLY

FOR PUMP

(if ordered with

WATER OUTLET

W

ATER INLET

AIR INLET

FILTER BOX

CONDENSATE

TRAP OUTLET

(Trap is built-in)

PRV must be added to this pipe

*

during installation.

a pump)

*

Page 14

Page 10

L

SUGGESTED SERVICE CLEARANCE

38

1

/

2

(98)

8

3

/

4

(22)

7

1

/

2

(19)

25 (64)

LAARS Heating Systems

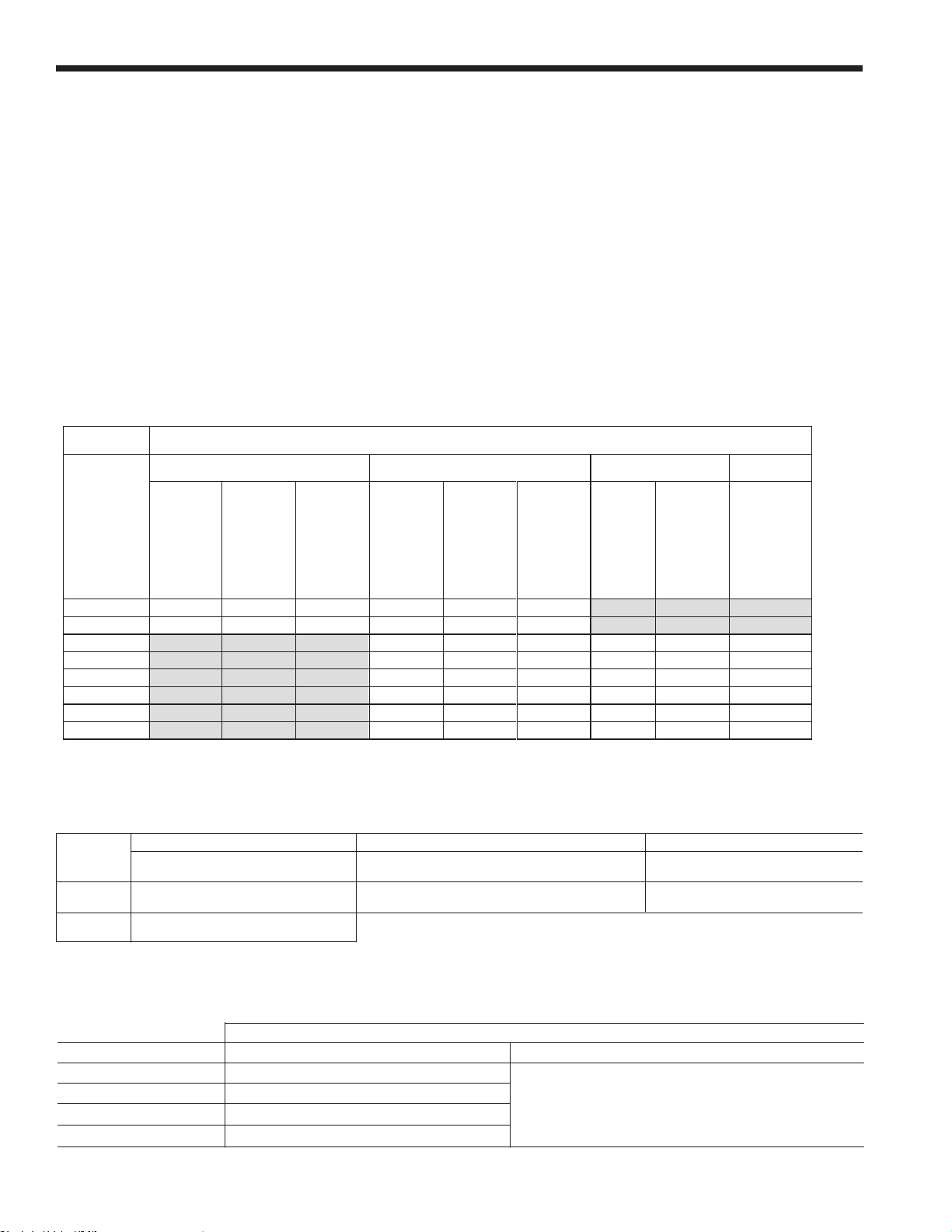

1.F Dimensions, Indoor Models

A B C D E F G J K M N

Size in cm in cm in cm in cm in cm in cm in cm in cm in cm in cm in cm

150 13¼ 34 5¼ 14 18¼ 46 3¼ 8 10¾ 28 7½ 19 14¼ 36 19½ 49 7½ 19 15¼ 39 13 33

199/210 20½ 52 5¼ 14 18¼ 46 3¼ 8 17¾ 45 7½ 19 14¼ 36 19½ 49 11¾ 30 15¼ 39 13 33

285 20¼ 52 7¼ 19 19½ 50 6¼ 16 11¼ 29 13½ 34 14 36 15 38 17 43 18¾ 48 13 33

399 25 64 5¼ 13 19½ 50 4¼ 11 14¾ 37 18½ 47 19¼ 49 16½ 42 21¾ 55 18¾ 48 13 33

500 30¼ 77 5¼ 13 19½ 50 4¼ 11 15¼ 38 20 51 20½ 52 19 48 26 66 18¾ 48 13 33

600 29¾ 76 5 13 19½ 50 4¼ 11 15 38 20 51 3 8 19 48 26 66 18¾ 48 8¼ 21

750 35½ 90 6 15 19½ 50 5¼ 13 19 48 40½ 103 3¼ 8 19 48 30¾ 78 18¾ 48 8¼ 21

850 39¾ 101 6 15 19½ 50 5¼ 13 19 48 44¾ 114 3½ 9 19 48 35 89 18¾ 48 8¼ 21

Table 1. Dimension Drawing, Indoor Sizes 150-850

SIZE in cm in cm in cm

L

AIR INLET VENT

(length)

150 19½ 49 3 7.6 3 7.6

199/210

285 26¾ 68 4 11 4 11

399 31½ 80 4 11 4 11

500 37¾ 96 4 11 4 11

600 37¾ 96 4 11 4 11

750 51 130 4 11 6 17

850 55¼ 140 4 11 6 17

26¾ 68 3 7.6

3 7.6

Table 1. (dimensions continued)

Dimensions are nominal and are shown

in inches, cm.

*Unit is shipped with adapters for the air

and vent that accept standard pipe of

the proper size and type.

For Water Connection Pipe Sizes, See “Table 14.

Water Connection Pipe Sizes” on page 28

Page 15

NEOT

L

SUGGESTED SERVICE CLEARANCE

38

1

/

2

(98)

8

3

/

4

(22)

7

1

/

2

(19)

HERM

Commercial Boilers and Water Heaters, 150 to 850 MBTU/h

All Indoor Units have a very

similiar component design with

piping dimensions/locations

that increase as the unit size

increases.

Water and gas piping is

always on the left side of the

unit. Table 1 gives the exact

dimensions for all of the

dierent model sizes.

Page 11

See “Table 3. Suggested

Service Clearances” on

page 16

ALL Models

Page 16

Page 12

SIZE

in cm in cm in cm in cm in cm in cm in cm in cm in cm in cm in cm in cm

150

6-1/4" 16 11" 28 13" 33 17-1/4" 43.8 23-1/2" 60 18" 45.7 27" 69 23-1/2" 60 5-1/4" 13 20" 60 25-1/2" 65 3 7.6

199 / 210

6-1/4" 16 11" 28 13" 33 17-1/4" 43.8 23-1/2" 60 18" 45.7 27" 69 24-1/2" 60 5-1/4" 13 27" 68.6 32-1/2" 82.5 3 7.6

285

6" 15.5 11" 28 5" 13 17-1/4" 43.8 24" 61 19" 48 28-1/4" 72 12" 30.5 7-1/4" 18.4 27" 68.6 32-1/2" 82.5 4 11

399

8" 15.5 19-1/2" 50 7-3/4" 20 17-1/4" 43.8 24" 61 19" 48 28-1/4" 72 12" 30.5 6" 15.2 31-1/4"" 80.5 37-3/4" 96 4 11

500

5" 13 17-3/4" 45 5" 13 8-1/4" 21

24" 61 19" 48 29-1/4" 74 12" 30.5 5.5" 14 38" 96.5 43-1/2" 110.5 4 11

600

33-1/2" 85 3.0" 8 5" 13 8-1/4" 21 24" 61 19" 48 29-1/4" 74 12" 30.5 5-3/4" 14.6 38" 96.5 43-1/2" 110.5 4 11

750

32-3/4" 83.2 3.0" 8 5-1/4" 13.4 17-1/4" 43.8 24" 61 19" 48 29-1/4" 74 12" 30.5 5-3/4" 14.6 51-1/4" 130 57-3/4" 146.7 6 17

850

32-3/4"

83.2

3.0"

8

5-1/4"

13.4

17-1/4"

43.8

24"

61

19"

48

29-1/4"

74

12"

30.5

5-3/4"

14.6

55-3/4" 141.5 61-1/4" 155.5 6 17

E

F

VENT

ABCDGJK

L (Length)

T (Total Length)

1.G Dimensions, Outdoor Models

Table 2. Dimension Drawing, OUTDOOR Sizes 150-850

LAARS Heating Systems

For Water Connection Pipe Sizes, See “Table 14.

Water Connection Pipe Sizes” on page 28

12 (31)

VENT

K

TOP VIEW

12 (31)

SUGGESTED SERVICE CLEARANCE

See “Table 3. Suggested Service Clearances” on page 16

8 (21)

(33)

13

12

(31)

1

38

/

(98)

2

Dimensions are nominal and are shown

in inches, cm.

*Unit is shipped with adapters for the air

and vent that accept standard pipe of

the proper size and type.

26 (66)

25 (64)

ALL Model Sizes

285 - 500 MBH

WATER

OUTLET

WATER

INLET

G

AIR FILTER

BOX

9 (23)

E

J

GAS INLET

A

L

Total length

T

1

/

5

(9)

2

F

RIGHT SIDE VIEW

CONDENSATE

TRAP OUTLET

D

B

BACK VIEW

C

Page 17

NEOT

F

8

21

13

33

8

21

13

33

SIZE

in cm in cm in cm in cm in cm in cm in cm in cm in cm in cm in cm in cm

150

6-1/4" 16 11" 28 13" 33 17-1/4" 43.8 23-1/2" 60 18" 45.7 27" 69 23-1/2" 60 5-1/4" 13 20" 60 25-1/2" 65 3 7.6

199 / 210

6-1/4" 16 11" 28 13" 33 17-1/4" 43.8 23-1/2" 60 18" 45.7 27" 69 24-1/2" 60 5-1/4" 13 27" 68.6 32-1/2" 82.5 3 7.6

285

6" 15.5 11" 28 5" 13 17-1/4" 43.8 24" 61 19" 48 28-1/4" 72 12" 30.5 7-1/4" 18.4 27" 68.6 32-1/2" 82.5 4 11

399

8" 15.5 19-1/2" 50 7-3/4" 20 17-1/4" 43.8 24" 61 19" 48 28-1/4" 72 12" 30.5 6" 15.2 31-1/4"" 80.5 37-3/4" 96 4 11

500

5" 13 17-3/4" 45 5" 13 8-1/4" 21

24" 61 19" 48 29-1/4" 74 12" 30.5 5.5" 14 38" 96.5 43-1/2" 110.5 4 11

600

33-1/2" 85 3.0" 8 5" 13 8-1/4" 21 24" 61 19" 48 29-1/4" 74 12" 30.5 5-3/4" 14.6 38" 96.5 43-1/2" 110.5 4 11

750

32-3/4" 83.2 3.0" 8 5-1/4" 13.4 17-1/4" 43.8 24" 61 19" 48 29-1/4" 74 12" 30.5 5-3/4" 14.6 51-1/4" 130 57-3/4" 146.7 6 17

850

32-3/4"

83.2

3.0"

8

5-1/4"

13.4

17-1/4"

43.8

24"

61

19"

48

29-1/4"

74

12"

30.5

5-3/4"

14.6

55-3/4" 141.5 61-1/4" 155.5 6 17

E

F

VENT

A

BCDGJ

K

L (Length)

T (Total Length)

5-3/4"

14.6

55-3/4" 141.5 61-1/4" 155.5 6 17

VENT

K

L (Length)

T (Total Length)

HERM

Commercial Boilers and Water Heaters, 150 to 850 MBTU/h

Table 2. (dimensions ontinued)

Page 13

Ø

WATER

OUTLET

AIR FILTER

BOX

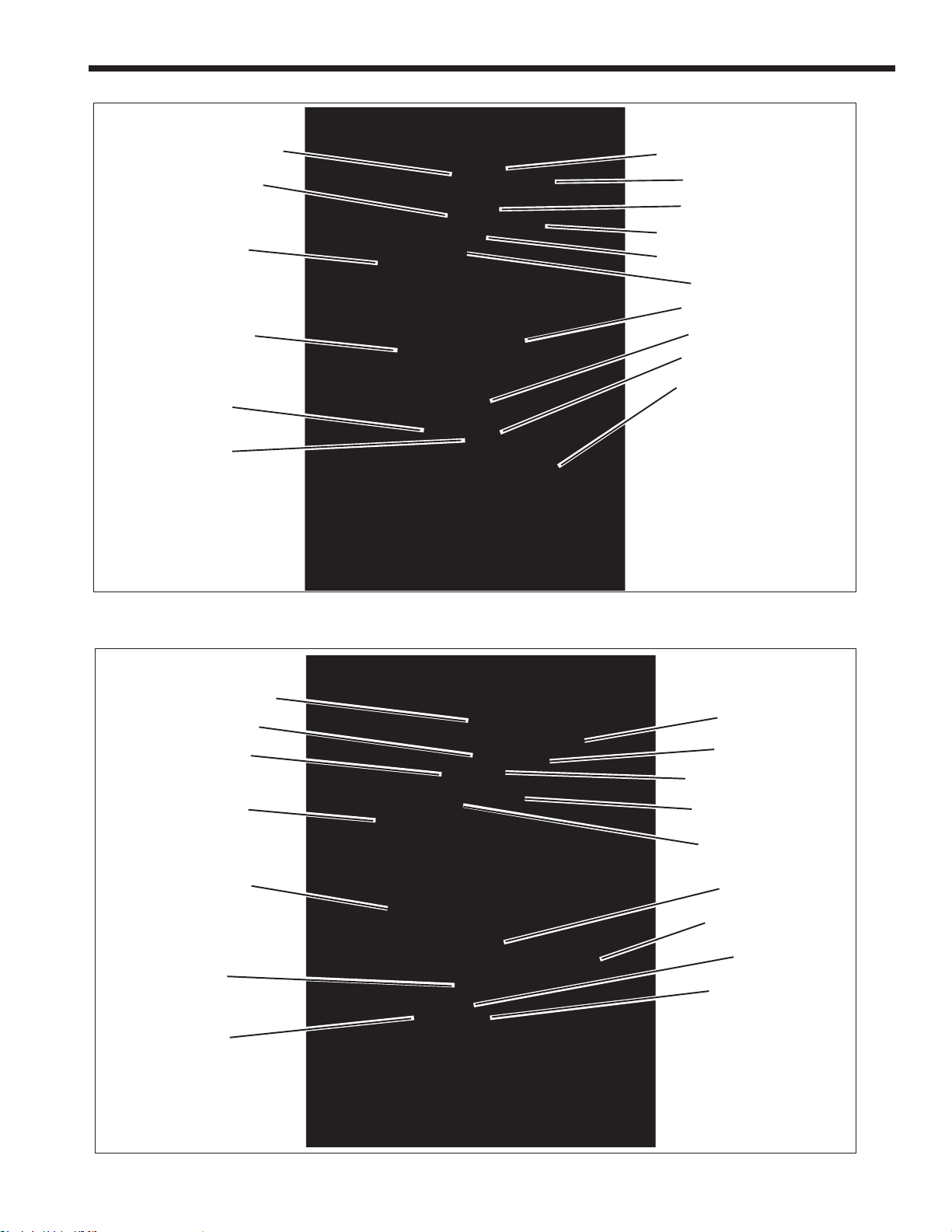

BACK VIEWS of the Outdoor Models

The Outdoor versions have a greater component location

variance than the Indoor models. 4 Back Views are given to

show the piping dimensions/locations for all of the dierent

piping layouts. Table 2 gives the exact dimensions for all of the

dierent model sizes.

600 MBH

WATER

OUTLET

WATER

INLET

B

GAS INLET

A

G

E

A

150 - 210 MBH

750 - 850 MBH

KNOCK-OUTS FOR

POWER TO

ALL OPTIONAL

EQUIPMENT

WATER

INLET

CONDENSATE

TRAP OUTLET

GAS INLET

D

B

GAS INLET

WATER

OUTLET

WATER

INLET

J

C

B

A

G

AIR FILTER

BOX

CONDENSATE

TRAP OUTLET

F

D

C

E

J

G

E

J

AIR FILTER

BOX

CONDENSATE

TRAP OUTLET

C

D

F

Page 18

Page 14

1.H The Installation Kit (installation parts box).

The Indoor models are shipped in a single crate with the

Installation Kit (cardboard box). Check the contents of the

Installation Kit with the items listed in Figure 10 and Figure 11.

Additional parts may be packed inside the unit.

Doc ument Bag

(all documents in one bag)

Term inal Block Jumper

(the Terminal Block Jumper is in the document bag)

Sen sor Kits (Tank, Outdoor and System Sensors, all in the

same bag (2 boxes, a sensor, and a wire).

Volume Water Heaters will not have an Outdoor Sensor

Air I ntake Terminal Assembly

(elbow and a screen)

Vent Pipe

Exh aust Terminal Assembly

(end pipe and a screen),

Tem p/Pressure Gauge Kit

(a bushing, an NPT Tee, and the gauge in a small box)

Figure 10. Standard Installation Components

LAARS Heating Systems

Some accessory

items may be shipped

in separate packages.

Verify receipt of all

packages listed on

the packing slip.

Inspect everything for

damage immediately

upon delivery, and

advise the carrier

of any shortages or

damage. Any such

claims should be led

with the carrier.

The carrier, not the

shipper, is responsible

for shortages and

damage to the

shipment whether

visible or concealed.

80/105

Flow Switch Kit

150

199/210

285 399 500 600 7

(ow switch, 2 wires, and an NPT tee)

1 1 1 1

Exhaust Adapter Assembly

Grid Screen, Venting

2 2 2

Vent Adapter, 6” PVC to 6” Stainless Steel

NPT Pipe (for ow switch)

1 1 1 1

Grommets for ow switch wires

2 2 2 2

Figure 11. Additional Components, depending on model size.

50/850

1 1

1

Optional Indoor Pump Kit

Page 19

NEOT

EXPLODED VIEW

4

3

2

HARNESS

D

C

2

DWG NO.

50D4140

SH

1

REV

A

CJ 5/17/16

REVISIONS

REV.

CHANGE:

APPR

ENGR APPR

ECN

DRAFT

CHECK

REMOVED ITEM 2 A2116100 FROM 50D4140.

A

15-127N-05

XR 5/17/16

AIR FILTER

OUTLET

WATER

WATER

INLET

BOX

GAS INLET

CONDENSATE

TRAP OUTLET

J

A

C

G

E

VENT

K

8

(21)

13

(33)

9 (23)

38

1

/

2

(98)

TOP VIEW

SUGGESTED SERVICE CLEARANCE

12 (31)

12

(31)

12

(31)

HERM

Commercial Boilers and Water Heaters, 150 to 850 MBTU/h

The OUTDOOR Model Installation Kits, in

addition to what is shown in Figure 10 and

Figure 11, will include:

Some Class IV venting

components are not included with

units shipped to Canada.

Outdoor Pump Kit

Page 15

Vent Pipe Extender,

Pipe Adapter,

Bird Screen,

PRV,

NPT Pipe Tee

Figure 12. Additional components for

outdoor models.

EXPLODED VIEW

HARNESS

FLOW

SIDE PANEL

11

1/

4

6

1/

”

2

ASSEMBLED

VIEW

TOP PANEL

FLOW

SIDE PANEL

WATER INLET

”

11

1/

”

4

Figure 13. Outdoor Pump Kit

NOTE: The pump and outdoor housing will

typically be shipped inside the unit. Pump will

need to be piped and wired on site. A 62” long

wire harness is provided but a conduit will need

to be provided by the electrician at time of boiler

installation.

Page 20

Page 16

LAARS Heating Systems

SECTION 2

LOCATING THE UNIT

2.A General Information

The ‘Indoor’ unit is designed and CSA-certied

for indoor installations only.

The ‘Outdoor’ unit is designed and CSA-certied for

outdoor installations only.

If installing in a location that may experience freezing

temperatures, precautions must be taken to prevent water

in the heat exchanger and condensate inside and outside

of the boiler from freezing. Damage due to freezing water

or condensate is not covered by the warranty.

The appliance should be located to provide clearances on

all sides for maintenance and inspection. It should not be

located in an area where leakage of any connections will

result in damage to the area adjacent to the appliance or

to lower oors of the structure. When such a location is

not available, it is recommended that a suitable drain pan,

adequately drained, be installed under the appliance.

Always install the unit on a rm, level surface.

The unit is design certied by CSA-International for

installation on combustible ooring; in basements; in

closets, utility rooms or alcoves. These units must never be

installed on carpeting. The location for the unit should be

chosen with regard to the vent pipe lengths and external

plumbing and on a level surface.

The Indoor units shall be installed such that the gas ignition

system components are protected from water (dripping,

spraying, rain, etc.) during operation and service (circulator

replacement, control replacement, etc.). When vented

vertically, the unit must be located as close as practical to

the vertical section of the vent. If the vent terminal and/or

combustion air terminal terminate through a wall, and there

is potential for snow accumulation in the local area, both

terminals should be installed at an appropriate level above

grade or the maximum expected snow line.

The Outdoor units must be installed at least 10 ft (the vent

pipe) from any door or window. The exhaust vent shall

not be under any overhang or roof. Use only the vent

components included with the boiler.

The dimensions and requirements that are shown in Table

3 should be met when choosing the locations for the

appliance.

2.B Locating Appliance for Correct Vent

Distance from Outside Wall or

Roof Termination

The forced draft combustion air blower in the appliance

has sucient power to vent properly when the

guidelines in Table 4 are followed.

For concentric vent terminal kit (optional), follow

installation instructions included with the kit.

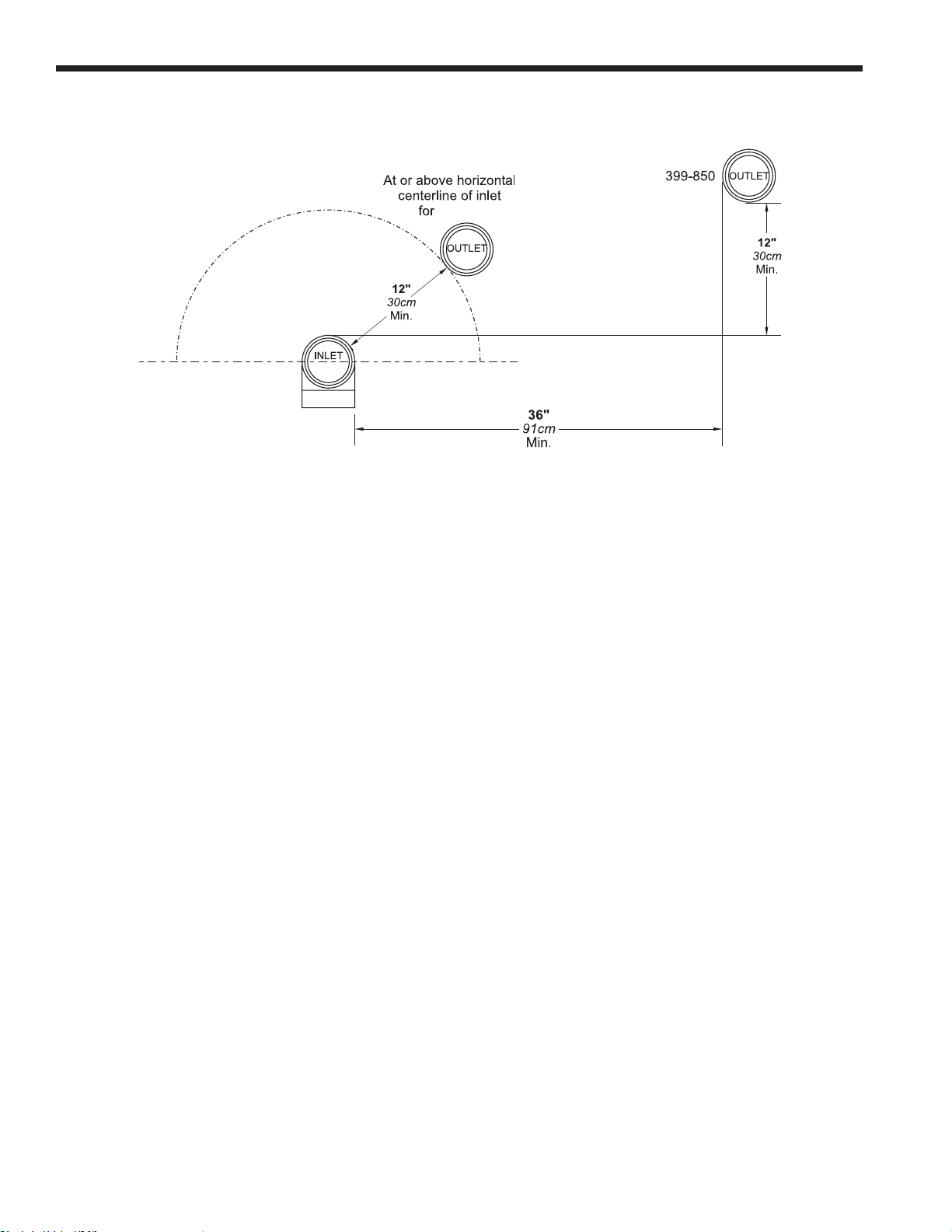

NOTE: When located on the same wall, the

combustion air intake terminal must be installed a

minimum of 12” below the exhaust terminal.

Models 399-850 also require a minimum horizontal

distance from intake to exhaust terminal of 36”.

INDOOR OUTDOOR

UNIT SURFACE INCHES CM INCHES CM

Left Side 1 2.5 12 31

Right Side 12 31 12 31

Top (for ue) 24 61 48 122

Back 6 15 12* 31

Closet, Front 1 2.5 1 2.5

Front 24 61 24 61

Vent Per Vent Manufacturer

Certied by CSA for zero clearance to combustible materials on all sides.

from lter box face. See “Table 2. Dimension Drawing, OUTDOOR

*

Sizes 150-850” on page 12

*

Table 3. Suggested Service Clearances

INTAKE / EXHAUST

STANDARD MAX EQUIV. OPTIONAL MAX EQUIV.

SIZE VENT FT. M VENT FT. M

150 3” 100 30 n/a — —

199/210 3” 100 30 n/a — —

285 4” 100 30 n/a — —

399 4” 100 30 n/a — —

500 4” 100 30 n/a — —

600

750 4” 40 6.1 6” 100 30

850 4” 40 6.1 6” 100 30

Combustion Intake and Vent must be the same size.

Installations in the U.S. require exhaust vent pipe that is a combination

of PVC & CPVC complying with ANSI/ASTM D1785 F441 or stainless

steel complying with the stainless steel vent suppliers listed in Section 3.

Installations in Canada require exhaust vent pipe that is certied to

ULC S636.

Intake (air) pipe must be PVC or CPVC that complies with ANSI/ASTM D1785

F441, ABS that complies with ANSI/ASTM D1527 or galvanized material.

The installer must comply fully with the manufacturer’s installation

instructions, including use of minimum exhaust length CPVC, to main-

tain ANSI Z21.13 safety certication.

Closet and alcove installations do not allow the use of PVC under any

circumstances

To calculate max equivalent length, measure the linear feet of the pipe,

and add 5 feet (1.5m) for each 90° elbow used. Add 2 1/2 feet (.76

meters) for each 45 elbow used.

*

feet, any even or uneven combination of length is allowed. For overall

lengths greater than 40 equivalent feet, the exhaust may be up to 20

feet greater than the intake length.

4” 40 6.1 6” 100 30

*

For any combination of vent and intake lengths up to 40 equivalent

Table 4. Vent / Air Pipe Sizes and Length

Page 21

NEOT

ALLOWABLE SINGLE WALL STAINLESS STEEL VENT SUPPLIERS AND PART NUMBERS

Safe-T Vent EZ Seal FasNSeal Z Flex

2SVSAxx (OD)

2SVSTTAxx (ID)

Horizontal Termination (bir d screen

Horizontal Termination

(bird screen)

IASPPxx (2" - 4")

IASSSxx (5" - 12")

IASSSxx (5" - 12")

xPPS-VTML (5"-8")

Trade Name / Model

Trade Name / Model

HERM

Commercial Boilers and Water Heaters, 150 to 850 MBTU/h

SECTION 3

VENTING AND COMBUSTION AIR

3.A General Venting

This product requires a special venting system. Refer to

venting supplier’s instructions for complete parts list and

method of installation. The manufacturers and product

lines listed on the following tables have been tested and

authorized to safely operate with this unit. Suppliers

of stainless steel and polypropylene venting that are

not listed on these tables are not permitted for use with

these category III/ IV products.

MFR MODEL NUMBER (ABBREVIATED)

Selkirk

Example Components

90° Elbow 9x14 FSELB90xx 2SVEExx90

Pipe 9x07 FSVLxxxx 2SVEPxxxx

Boiler Adapter 5x01BOI FSAAUx

9x92 FSBSx 2SVSTPXxx

Vertical Termination (rain cap) 5X00CI FSRCx 2SVSRCxx

Inlet Air Termination 9xTERM FSAIHXX* 2SVSTEXxx90

Adapter, SS to CPVC FSA-xxFNSM-xPVCF

Adapter SS to PP FSAAUx-xPP 2ZDCPVCx**

Table 5. Allowable Single Wall Stainless Steel Vent Suppliers and Part Numbers

Do not mix venting suppliers and models in venting

systems. Failure to comply could result in personal

injury, property damage, or death.

Installations must comply with applicable national, state

and local codes.

DuraVent

*4", 6" & 7" only **up to 6"

NovaFlex

Page 17

ALLOWABLE POLYPROPYLENE VENT MANUFACTURERS / TRADE NAMES

MFR MODEL NUMBER (ABBREVIATED)

CentroTherm DuraVent

Example Components

Single Wall Pipe ISVLxxxx xPPS-x 83x002 ZDPx

Elbow ISELxxxx xPPS-E90L 83x08 2ZDEx87

PVC Adapter ISAGLxxxx

Vertical Termination

Air Inlet 2ZDESx

InnoFlue PolyPro

xPPS-ADL (to 4")

xPPS-xxPVCM-xPPF (>4")

xPPS-BG (2" - 6")

IASPPxx (2" - 4")

xPPS-VKL (<5")

Table 6. Allowable Polypropylene Vent Manufacturers / Trade Names

NOTES:

1. “x”, “xx”, and “xxxx” refer to variations in nominal size. See manufacturer’s catalog for a particular application.

3.B Combustion Air

These boilers and water heaters must have provisions

for combustion and ventilation air in accordance with the

applicable requirements for Combustion Air Supply and

Ventilation in the National Fuel Gas Code, ANSI Z223 1;

or in Canada, the Natural Gas and Propane Installation

Code, CSA B149.1. All applicable provisions of local

building codes must also be adhered to.

These units can take combustion air from the space

in which it is installed, or the combustion air can be

ducted directly to the unit. Ventilation air must be

provided in either case.

Combustion Air From Room In the United States,

the most common requirements specify that the space

shall communicate with the outdoors in accordance

Selkirk

PolyFlue

83x040 2ZDCPVCx

83x050 2ZDESx

83x050 2ZDESx

NovaFlex

Z-Dens

Page 22

Page 18

HORIZONTAL INTAKE AND EXHAUST PVC VENT TERMINAL KITS

Size

2” PVC

3” PVC

4” PVC

6” PVC

Standard

Concentric

CA006000

Flush Mount

CA010100

Standard

CA005900

Concentric

239-44069-01

Flush Mount

CA010101

Standard

Flush Mount

CA010102

Standard

80

incl.

opt.

opt.

opt.

opt.

opt.

105

incl.

opt.

opt.

opt.

opt.

opt.

150

incl.

opt.

opt.

199/210

incl.

opt.

opt.

285

opt.

opt.

opt.

incl.

opt.

n/a

399

n/a

n/a

n/a

incl.

opt.

n/a

500

n/a

n/a

n/a

incl.

opt.

n/a

600

n/a

n/a

n/a

incl.

opt.

opt.

750

n/a

n/a

n/a

incl.

n/a

opt.

850

n/a

n/a

n/a

incl.

n/a

opt.

incl.

opt.

opt.

LAARS Heating Systems

with method 1 or 2, which follow. Where ducts are used,

they shall be of the same cross-sectional area as the

free area of the openings to which they connect.

Method 1: Two permanent openings, one commencing

within 12” (300mm) of the top and one commencing

within 12” (300mm) of the bottom, of the enclosure

shall be provided. The openings shall communicate

directly, or by ducts, with the outdoors or spaces

that freely communicate with the outdoors. When

directly communicating with the outdoors, or when

communicating to the outdoors through vertical ducts,

each opening shall have a minimum free area of 1

square inch per 4000 Btu/hr (550 square mm/kW) of

total input rating of all equipment in the enclosure. When

communicating to the outdoors through horizontal ducts,

HORIZONTAL INTAKE AND EXHAUST PVC VENT TERMINAL KITS

2” PVC 3” PVC 4” PVC 6” PVC

each opening shall have a minimum free area of not

less than 1 square inch per 2000 Btu/hr (1100 square

mm/kW) of total input rating of all equipment in the

enclosure.

Method 2: One permanent opening, commencing

within 12” (300mm) of the top of the enclosure, shall

be permitted. The opening shall directly communicate

with the outdoors or shall communicate through a

vertical or horizontal duct to the outdoors or spaces that

directly communicate with the outdoors and shall have a

minimum free area of 1 square inch per 3000 Btu/hr (734

square mm/kW) of the total input rating of all equipment

located in the enclosure. This opening must not be less

than the sum of the areas of all vent connectors in the

conned space.

Size

Concentric vent terminal = 10 ft. pipe length

incl.

Standard

opt.

Concentric

CA006000

opt.

Flush Mount

CA010100

Standard

CA005900

Concentric

239-44069-01

Flush Mount

CA010101

Standard

Flush Mount

CA010102

Standard

Table 7. PVC Vent Terminal Kits

PRO TECH (FasNSeal) HEAT FAB (Saf-T-Vent) Z FLEX (Z-Vent)

SIZE Boiler Flue Intake Air Boiler Intermediate Flue Intake Air Boiler Flue Intake Air

Adapter Termination Termination Adapter Adapter Termination Termination Adapter Termination Termination

399-600 F303759 FSBS4 FSAIH04 KB285600 9454BUREZ-1* 9492 9414TERM 2SVSLA04 2SVSTP04

FSRC4(R.C) 303888 5400CI 2SVSRCX04

750-850 F303759 FSBS6 FSAIH04

303888

Figure 14. Approved Stainless Terminations and Adapters

INSTALLATION STANDARDS

MATERIAL UNITED STATES CANADA

ABS ANSI/ASTM D1527

PVC, sch 40 ANSI/ASTM D1785 or D2665 Air pipe material must be chosen

CPVC, sch 40 ANSI/ASTM F441

Single wall galv. steel 26 gauge

based upon the intended application of the boiler.

2SVSTEX0490

Figure 15. Required Combustion Air Pipe Material

Page 23

NEOT

Other methods of introducing combustion and ventilation

air are acceptable, providing they conform to the

requirements in the applicable codes listed above.

In Canada, consult local building and safety codes or, in

absence of such requirements, follow CAN/CSA B149.

Ducted Combustion Air

The combustion air can be taken through the wall, or

through the roof. When taken from the wall, it must be

taken from out-of-doors by means of a horizontal wall

terminal, kit, See Table 7.

See Table 4 to select the appropriate diameter air

pipe. When taken from the roof, a eld-supplied rain cap

or an elbow arrangement must be used to prevent entry

of rain water. (See Figure 17)

Use ABS, PVC, CPVC or galvanized pipe for the

combustion air intake. (See Table 4.) The pipe should

be sized per Table 2. Route the intake to the boiler as

directly as possible. Seal all joints. Provide adequate

hangers. The unit must not support the weight of the

combustion air intake pipe. Maximum linear pipe length

allowed is shown in Table 4. Subtract 5 allowable linear

ft. (1.5m) for every elbow used.

The connection for the intake air pipe is at the top of the

unit.

In addition to air needed for combustion, air shall also be

supplied for ventilation, including air required for comfort

and proper working conditions for personnel. Refer to

the applicable codes.

HERM

Commercial Boilers and Water Heaters, 150 to 850 MBTU/h

3.C Venting

This unit is a Category IV appliance and may be

installed with PVC and CPVC that complies with ANSI/

ASTM D1785 F441, polypropylene that complies with

ULC-S636 Class IIb, or a stainless steel venting system

that complies with UL 1738 Standard. (See Table 6)

The unit’s vent can terminate through the roof, or

through an outside wall.

When using PVC/CPVC for vent material, venting

must be connected to the CPVC section included with

sizes 80-850. The CPVC vent section included with

the unit may be broken by CPVC ttings if necessary,

but never reduced in total length. See Table 4 to

select the appropriate vent pipe diameter. When using

polypropylene, all vent material must be produced by

the same manufacturer, and have a ULC-S636 rating.

All installations should be done following the vent

supplier’s recommended installation techniques.

If manufacturer’s instructions are not available

for the material used, follow the manufacturers

recommendations.

Route vent pipe to the heater as directly as possible.

Please see Table 4 on page 16 for proper diameter vs.

length allowed.

Page 19

WARNING

Failure to use polypropylene CPVC or stainless steel

venting for the rst 20” (285-600) / 30” (199 / 210)

of vent material or for any part of the venting that is

installed inside a closet may lead to property damage,

personal injury or death. The proper length of this

material is supplied with boiler. Boilers in the U.S. may

use pipe included with the boiler.

Failure to use the appropriate vent material,

installation techniques, glues/sealants could lead to

vent failure causing property damage, personal injury

or death.

Use of cellular core PVC (ASTM F891), cellular core

CPVC, or Radel® (polyphenolsulfone) in non-metallic

venting systems is prohibited and that covering nonmetallic vent pipe and ttings with thermal insulation is

prohibited.

All venting must be installed according to this manual

and any other applicable local codes, including but

not limited to, ANSI Z223.1/NFPA 54, CSA B149.1,

CSAB149.2 and ULC-S636. Failure to follow this

manual and applicable codes may lead to property

damage, severe injury, or death.

NOTE: The ue temperature of the unit changes

dramatically with changes in operating water

temperature. Therefore, it is necessary to assess

the application of the boiler to determine the

required certied vent class. If the unit is installed

in an application where the ambient temperature

is elevated, and/or installed in a closet/alcove,

polypropylene, CPVC or stainless steel material is

required. If the system temperatures are unknown

at the time of installation, Class IIB or higher

venting material is recommended.

NOTE: The vent pipe must pitch upward, toward

the vent terminal, not less than 1/4” per foot, so

that condensate will run back to the unit and drain

out thru the condensate trap. Horizontal portions of

the venting system must be supported to prevent

sagging and may not have any low sections that

could trap condensate. Seal all joints and provide

adequate hangers as required in the venting system

manufacturer’s Installation Instructions. The unit must

not support the weight of the vent pipe.

Page 24

Page 20

INSTALLATION STANDARDS

MATERIAL UNITED STATES CANADA

Stainless Steel UL 1738 Venting must be ULC-S636 certied for use as

PVC, sch 40 ANSI/ASTM D1785 venting material. The venting material class must be

CPVC, sch 40 ANSI/ASTM F441 chosen based upon the maximum ue gas temperature

Polypropylene

ULC-S636 and the intended application of the boiler.

LAARS Heating Systems

Figure 16. Required Exhaust Vent Material

Venting Requirements Unique to Canada

These boilers and water heaters are Vent Category IV

appliances. Per the requirements of CAN/CSA-B149.1,

*

*

only BH vent systems can be connected to these units

and such vent systems, either ULC S636 certied

stainless steel or other ULC S636 certied BH vent (eg.

*

*

plastics) must be installed per the vent manufacturer’s

*

certied installation instructions.

As a result, two items listed in the Installation Kit (Figure

10 and Figure 11) are not included with these units for

Canada (underlined):

In Canada, refer to CAN/CSA B199.1

*

*

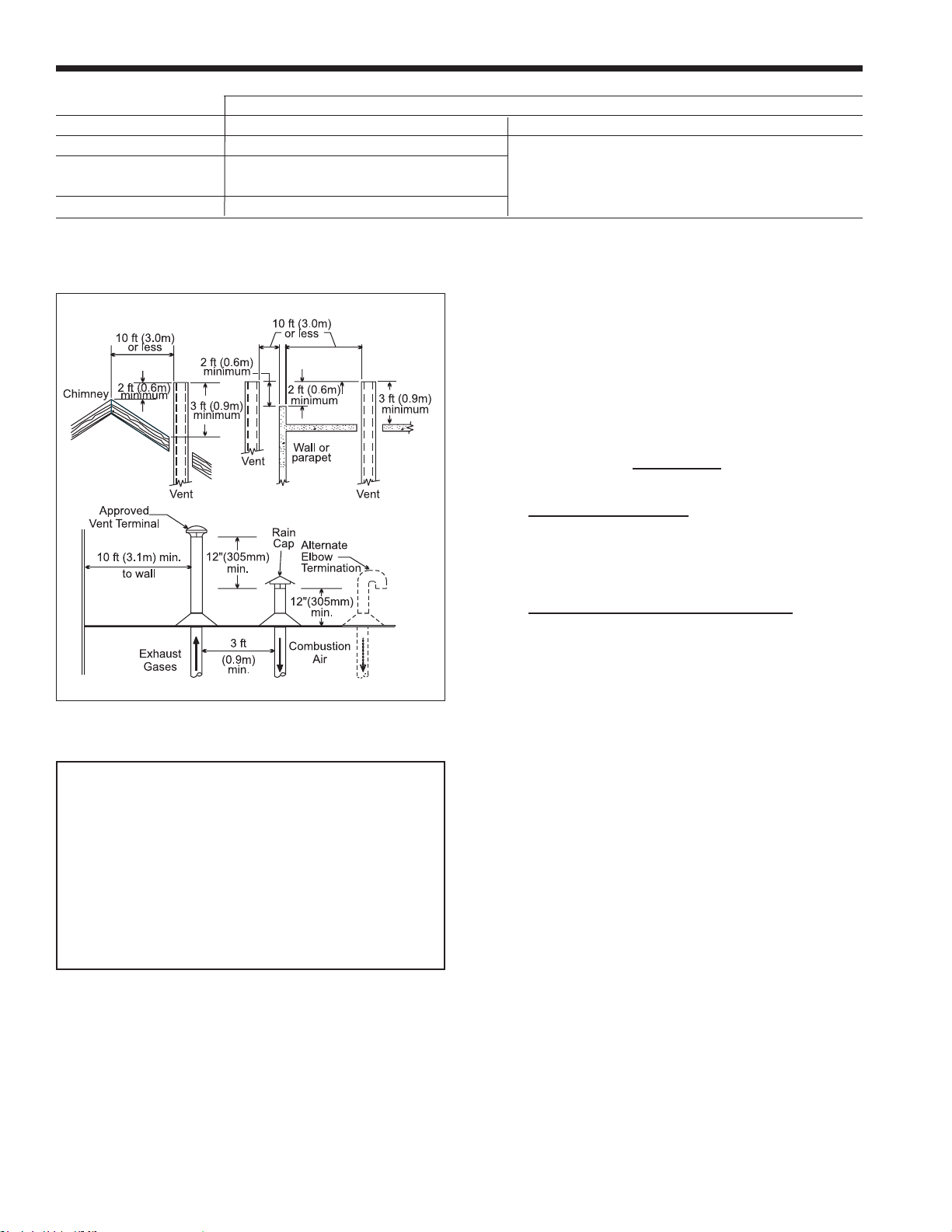

Figure 17. Combustion Air and Vent Through Roof

REMARQUE : Acheminer le tube d’évent à l’appareil de

chauage le plus directement possible. Veuillez voir le

tableau 4 à la page 13 pour le bon diamètre vs. longueur

autorisée. Le tuyau d’évacuation doit pitch vers le haut,

vers la borne d’évent, pas moins de 1/4 “ par pied,

de sorte que les condensats courir vers l’ et appareil

écouler thru le réservoir des condensats. Portions

horizontales du système d’aération doit être soutenu

pour empêcher l’aaissement et peut ne pas avoir de

faibles sections qui pourraient piéger des condensats

IMPORTANT NOTE ABOUT COMMON VENTING: A

single vent that is shared by multiple units MUST be

engineered by a competent venting specialist, and

involves the selection of draft inducing equipment,

hardware and controls to properly balance ue gas

pressures. Do not common vent units unless the

vent system meets this requirement. These units

are never permitted to share a vent with Category I

appliances.

A exhaust vent terminal (not included)

B. air intake terminal

C. temperature/pressure gauge kit

D. circulator pump/wire harness (units with pump)

E. CPVC exhaust pipe section (80-500) (not incl.)

F. outdoor/system sensor kit

G. ow switch kit (399-850)

H. alternate size vent/terminal screens

J. exhaust vent adapter CPVC/ST ST (750-850)

It is the responsibility of the appropriately licensed

technician installing this unit to use ULC S636 certied

vent material consistent with the requirements as

described in the Venting and Combustion Air section.

Class I venting systems are suitable for gas-red

appliances producing ue gas temperature of more than

135°C, but not more than 245°C.

Class II venting systems are suitable for gas-red

appliances producing ue gas temperatures of 135°C or

less.

Class II venting systems are further classied into four

temperature ratings as follows:

A Up to and including 65°C

B Up to and including 90°C

C Up to and including 110°C, and

D Up to and including 135°C

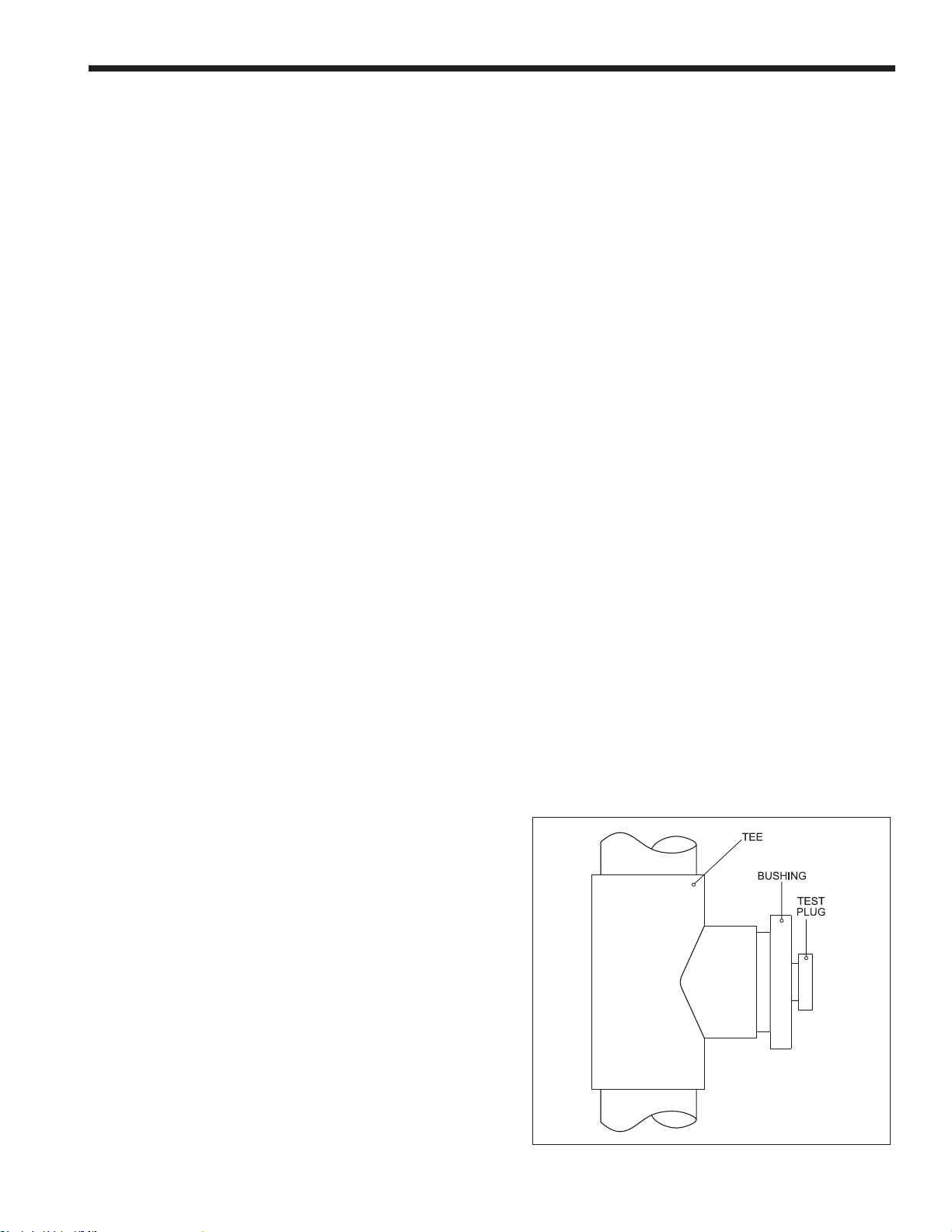

IMPORTANT! It is also the responsibility of the installer

to ensure that a ue gas sampling port is installed in

the vent system. This ue gas sampling port must be

installed near the ue connection of the unit: within

Page 25

NEOT

HERM

Commercial Boilers and Water Heaters, 150 to 850 MBTU/h

Page 21

2 feet of the ue connection. There is no ue gas

sampling port internal to the unit, so one must be

installed in the vent system external to the unit. A ue

gas sampling port available as a component of the

ULC S636 certied vent system is preferred. However,

if one is not available with the certied vent system,

the manufacturer suggests using a tee with the

branch connection sized to allow for insertion of a ue

gas analyzer probe. The branch connection must be

resealable with a cap or other by other means to ensure

the vent system remains sealed. (See Figure 18)

Consideration must be given to the placement and

orientation of the ue gas sampling port to ensure that

condensate is free to ow back into the unit and not

collect anywhere in the vent system - including in the

ue gas sampling port.

An exhaust vent terminal must be installed. If an

exhaust vent terminal is not available with the certied

vent system, the manufacturer suggests the use of a

coupler tting from the certied vent system into which

the vent terminal screen, included with the unit and

shown in the Unpacking section, be installed. Be sure to

install and terminate both vent and combustion air pipes

per the Venting and Combustion Air section of the unit’s

instructions.

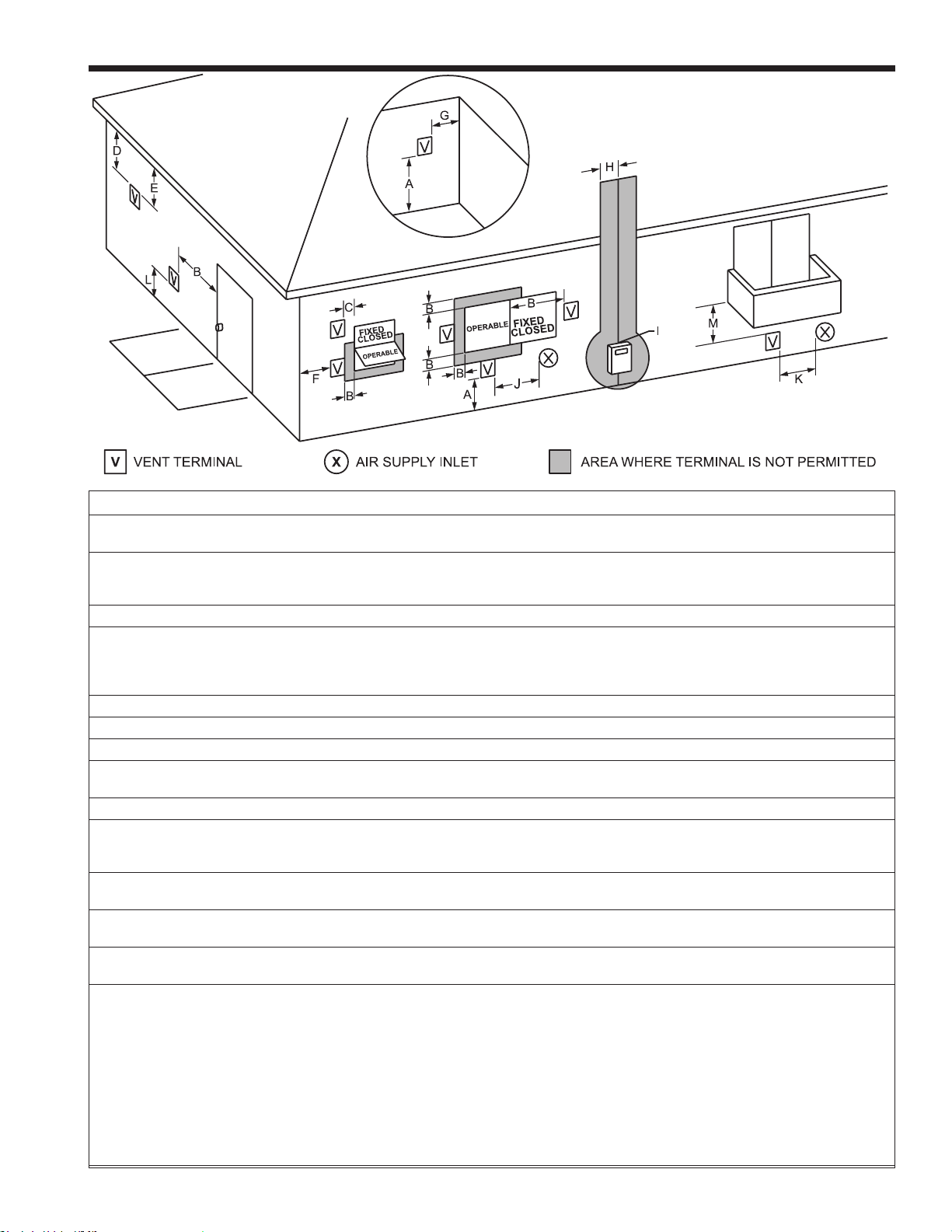

3.D Locating Vent and Combustion Air

Terminals

Side Wall Vent Terminal

The appropriate side wall vent terminal must be used.

The terminal must be located in accordance with

ANSI Z223.1/NFPA 54 and applicable local codes. In

Canada, the installation must be in accordance with

CSA B149.1 or .2 and local applicable codes. Consider

the points listed on the following page when installing

the terminal.

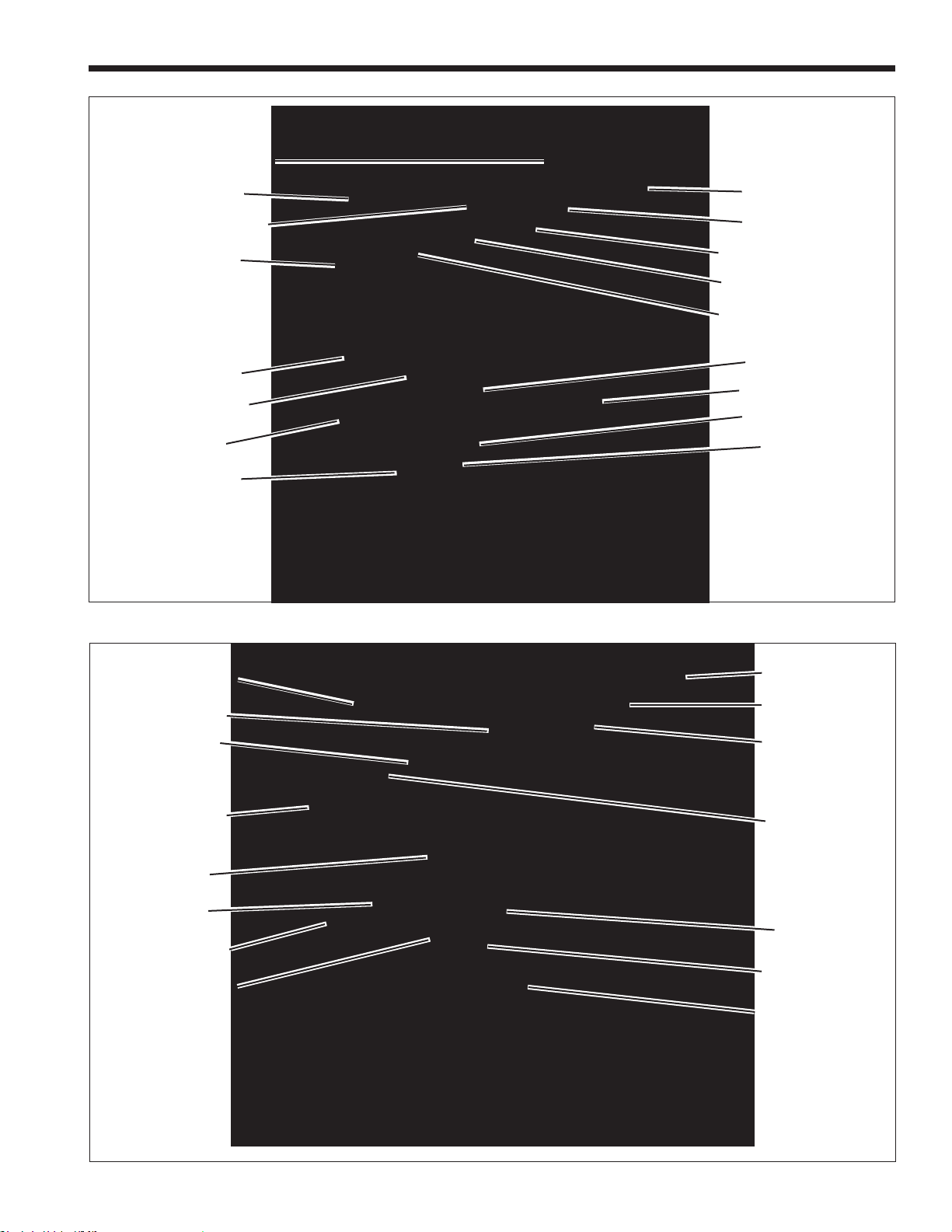

1. Figure 20 shows the requirements for mechanical

vent terminal clearances for the U.S. and Canada.

The outdoor models must be installed at least 10

ft (the vent pipe) from any door or window that

can be opened. The exhaust vent shall not be

under any overhang or roof. Use only the vent

components included with the boiler.

2. Vent terminals for condensing appliances or

appliances with condensing vents are not

permitted to terminate above a public walkway,

or over an area where condensate or vapor could

create a nuisance or hazard.

3. Locate the vent terminal so that vent gases cannot

be drawn into air conditioning system inlets.

4. Locate the vent terminal so that vent gases cannot

enter the building through doors, windows, gravity

inlets or other openings. Whenever possible, avoid

locations under windows or near doors.

5. Locate the vent terminal so that it cannot be

blocked by snow. The installer may determine

that a vent terminal must be higher than the

minimum shown in codes, depending upon

local conditions.

6. Locate the terminal so the vent exhaust does

not settle on building surfaces or other nearby

objects. Vent products may damage surfaces or

objects.

7. If the boiler or water heater uses ducted

combustion air from an intake terminal located on

the same wall.

If the vent termination is located in an area exposed to

high winds, an optional PVC tee (the same diameter as

the vent pipe) may be used. The tee’d vent termination

oers greater protection from wind related operating

issues.

Side Wall Combustion Air Terminal

The side wall combustion air terminal, or concentric

terminal must be used when the heater takes air from

a side wall. (See page 18 ) Contact manufacturer

for AL29-4C termination ttings. Consider the following

when installing the terminal. (See Figure 20 through

Figure 19.)

1. Do not locate the air inlet terminal near a source

of corrosive chemical fumes (e.g., cleaning uid,

chlorine compounds, etc.)

2. Locate the terminal so that it will not be subject to

damage by accident or vandalism. It must be at

least 7 feet (2.1m) above a public walkway.

3. Locate the combustion air terminal so that it

cannot be blocked by snow. The National Fuel

Gas Code requires that it be at least 12 inches

(30cm) above grade, but the installer may

Figure 18. Test Port - ULC-S636 system

Page 26

Page 22

determine it should be higher, depending upon

local conditions.

4. For concentric vent, follow instructions

included with vent kit.

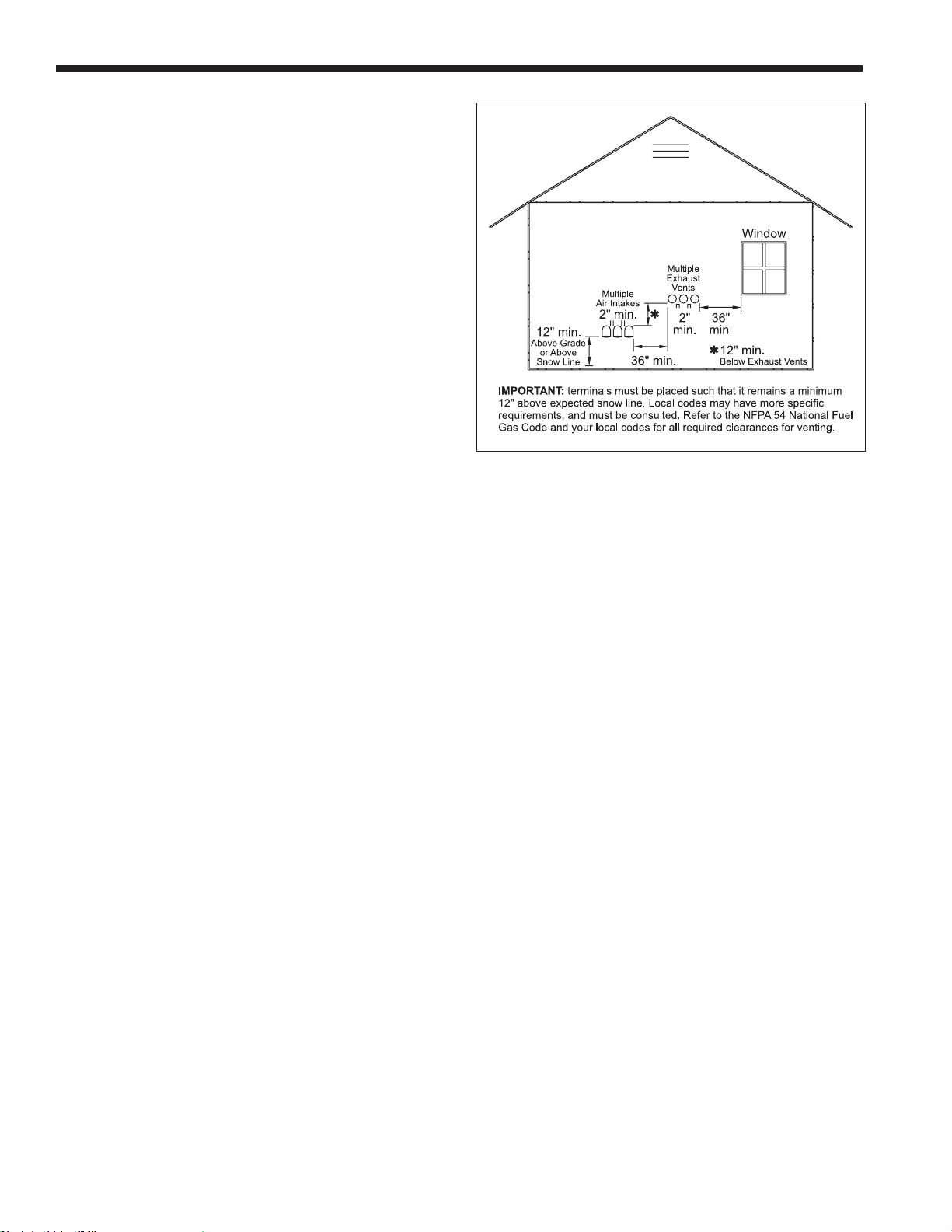

5. Multiple vent kits should be installed such that the

horizontal distance between the outlet group and

the inlet group is 36” (90cm). (Figure 21.)

6. The vent outlet for models 199-285 must be no

lower than the center of the air inlet, and must be

at least 12” (30cm) away from the air inlet. Vent

outlets for models 399-850 must be at least 12”

above the top of the air inlet, and must be at least

36” (90cm) horizontally from the air inlet. (page

24.)

Vertical Vent Terminal

When the unit is vented through the roof, the vent must

extend at least 3 feet (0.9m) above the point at which

it penetrates the roof. It must extend at least 2 feet

(0.6m) higher than any portion of a building within a

horizontal distance of 10 feet (3.0m), and high enough

above the roof line to prevent blockage from snow.

The vent terminal included with the unit can be used

in both vertical and horizontal applications. When the

combustion air is taken from the roof, the combustion

air must terminate at least 12” (30cm) below the vent

terminal. (See Figure 17.)

Vertical Combustion Air Terminal

When combustion air is taken from the roof, a eld-

supplied rain cap or an elbow arrangement must be

used to prevent entry of rain water. (Figure 17.) The

opening on the end of the terminal must be at least 12”

(30cm) above the point at which it penetrates the roof,

and high enough above the roof line to prevent blockage

from snow. When the vent terminates on the roof, the

combustion air must terminate at least 12” (30cm) below

the vent terminal.

Installations in the Commonwealth of

Massachusetts

In Massachusetts the following items are required if the

side-wall exhaust vent termination is less than seven

(7) feet above nished grade in the area of the venting,

including but not limited to decks and porches. From

Massachusetts Rules and regulations 248 CMR 5.08

(begininning on 2nd page following):

1. Installation of Carbon Monoxide Detectors

At the time of installation of the side wall vented gas

fueled appliance, the installing plumber or gas-tter

shall observe that a hard-wired carbon monoxide

detector with an alarm battery back-up is installed

on the oor level where the gas appliance is to

be installed. In addition, the installing plumber or

gastter shall observe that a battery operated or

LAARS Heating Systems

Figure 19. Multiple Side-Wall Terminals,

hard-wired carbon monoxide detector with an alarm

is installed on each additional level of the dwelling,

building or structure served by the side-wall

horizontally vented gas fueled equipment. It shall

be the responsibility of the property owner to secure

the services of qualied licensed professionals

for installation of hard-wired carbon monoxide

detectors.

a. In the event that the side-wall horizontally vented

gas fueled equipment is installed in a crawl space or

an attic, the hard-wired carbon monoxide with alarm

and battery back-up may be installed on the next

adjacent oor level.

b. In the event that the requirements of the

subdivision cannot be met at the time of completion

of installation, the owner shall have a period of thirty

(30) days to comply with the above requirements,

provided, however, that during said thirty (30)

day period, a battery operated carbon monoxide

detector with an alarm be installed.

2. Approved Carbon Monoxide Detectors

Each carbon monoxide detector shall comply with

NFPA 720 and be ANSI/UL 2034 listed and IAS

certied.

3. Signage

A metal or plastic identication plate shall be

permanently mounted to the exterior of the building

at a minimum height of eight (8) feet above grade

directly in line with the exhaust vent terminal for

horizontally vented gas fueled heating appliance or

equipment. The sign shall read, in print no less than

one-half (1/2) inch in size: “GAS VENT DIRECTLY

BELOW, KEEP CLEAR OF ALL OBSTRUCTIONS.”

Page 27

NEOT

HERM

Commercial Boilers and Water Heaters, 150 to 850 MBTU/h

*When vent terminal is less than 10 feet (3m) horizontally

from a forced air inlet, the terminal must be at least 3 feet

(0.9m) above the air inlet. (US only)

Page 23

U.S. Installations (see note 1) Canadian Installations (see note 2)

A= Clearance above grade, veranda, porch, 12 inches (30 cm) 12 inches (30 cm)

deck, or balcony See note 6 See note 6

B= Clearance to window or door that may be Direct vent only: 12 inches (30cm); 36 inches (91 cm)

opened Other than Direct vent: 4 ft (1.2m) below or to NT 80 only - 12 inches (30 cm)

side of opening; 1 ft (30cm) above opening

C= Clearance to permanently closed window See note 4 See note 5

D= Vertical clearance to ventilated sot located

above the terminal within a horizontal See note 4 See note 5

distance of 2 feet (61cm) from the center

line of the terminal

E= Clearance to unventilated sot See note 4 See note 5

F= Clearance to outside corner See note 4 See note 5

G= Clearance to inside corner See note 4 See note 5

H= Clearance to each side of center line 3 feet (91 cm) within a height 15 feet

extended above meter/regulator assembly See note 4 above the meter/regulator assembly

I= Clearance to service regulator vent outlet See note 4 3 feet (91 cm)

J= Clearance to nonmechanical air supply Direct vent only: 12” (30cm) 80-285; 36” (91cm)

inlet to building or the combustion air inlet 399-850. Other than Direct vent: 4 ft (1.2m) below 36 inches (91 cm)

to any other appliance or to side of opening; 1 ft (30cm) above opening NT 80 only - 12 inches (30 cm)

K= Clearance to a mechanical air supply inlet 3 feet (91 cm) above if within 10 feet (3 m) 6 feet (1.83 m)

horizontally

L= Clearance above paved sidewalk or paved Vent termination not allowed in this location 7 ft (2.1 m)

driveway located on public property for category IV appliances. See note 5

M= Clearance under veranda, porch, deck, See note 4 12 inches (30 cm) (see note 3)

or balcony

Notes:

1. In accordance with the current ANSI Z223.1 / NFPA 54 National Fuel Gas Code.

2. In accordance with the current CAN/CSA-B149.1 Installation Codes.

3. Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the oor.

4. For clearances not specied in ANSI Z223.1 / NFPA 54, clearance is in accordance with local installation codes and the requirements of the

gas supplier.

5. For clearances not specied in CAN/CSA-B149, clearance is in accordance with local installation codes and the requirements of the gas

supplier.

6. IMPORTANT: Terminal must be placed such that it remains a minimum 12” above expected snow line. Local codes may have more

specic requirements, and must be consulted.

Figure 20. Combustion Air and Vent Through Side Wall

Page 28

Page 24

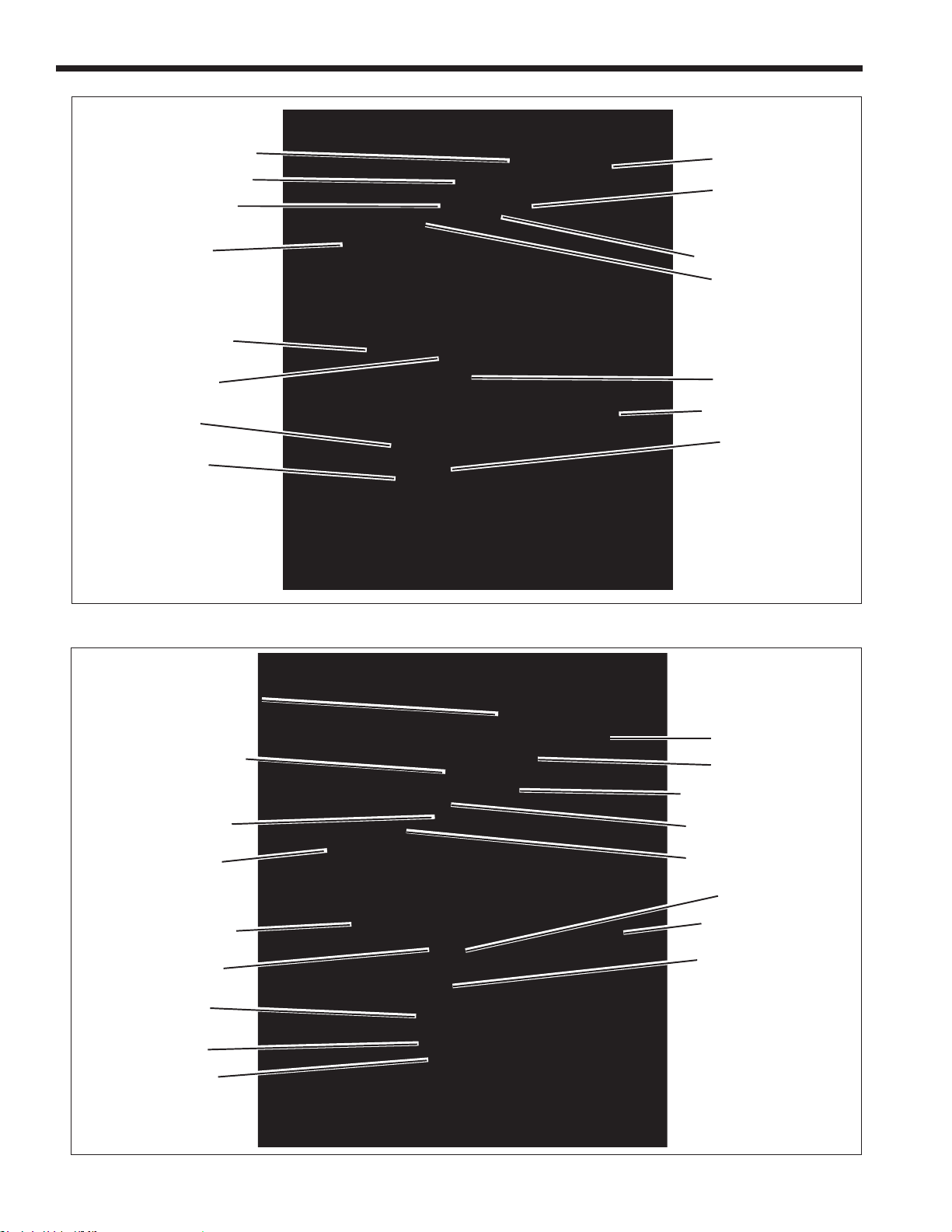

150-285

Figure 21. Minimum Venting Distance

LAARS Heating Systems

4. Inspection

The state or local gas inspector of the side-wall

horizontally vented gas fueled appliance shall not

approve the installation unless, upon inspection, the

inspector observes carbon monoxide detectors and

signage installed in accordance with the provisions of

248 CMR 5.08(2)(a) 1-4.

Page 29

NEOT

HERM

Commercial Boilers and Water Heaters, 150 to 850 MBTU/h

Page 25

3.E Common Vent Test

NOTE: This section does not describe a method for

common venting these high eciency condensing units. It

describes what must be done when a unit is removed from

a common vent system. These units require special vent

systems and fans for common vent. Contact the factory if

you have questions about common venting these units.

NOTE: When an existing boiler is removed from a

common venting system, the common venting system is

likely to be too large for proper venting of the appliances

remaining connected to it.

At the time of removal of an existing boiler, the following

steps shall be followed with each appliance remaining

connected to the common venting system placed in

operation, while the other appliances remaining connected

to the common venting system are not in operation.

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper size

and horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deciencies which

could cause an unsafe condition.

3. Insofar as it is practical, close all building doors and

windows and all doors between the space in which the

appliances remaining connected to the common venting

system are located and other spaces of the building. Turn

on clothes dryers and any appliance not connected to

the common venting system. Turn on any exhaust fans,

such as range hoods and bathroom exhausts, so they will

operate at maximum speed. Do not operate a summer

exhaust fan. Close replace dampers.

4. Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust the thermostat so

the appliance will operate continuously .

5. Test for spillage at the draft hood relief opening after

5 minutes of main burner operation. Use the ame of a

match or candle, or smoke from a cigarette, cigar or pipe.

6. After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, replace dampers and any

other gas burning appliance to their previous conditions of

use.

7. Any improper operation of the common venting

system should be corrected so that the installation

conforms to the National Fuel Gas Code, ANSI Z223.1/

NFPA 54 and/or CSA B149.1, Installation Codes. When

resizing any portion of the common venting system, the

common venting system should be resized to approach

the minimum size as determined using the appropriate

tables and guidelines in the National Fuel Gas Code, ANSI

Z223.1 NFPA 54 and/or CSA B149.1, Installation Codes.

REMARQUE : Lorsqu’une chaudière existante est

supprimée d’un système de ventilation commun, le

système de ventilation commun est susceptible d’être

trop grande pour garantir une aération correcte des

appareils restant connecté à elle. Lors de la dépose

d’une chaudière existante, les étapes suivantes

doivent être suivies avec chaque appareil reste

connecté à la système de ventilation commun mis en

opération, alors que les autres appareils connectés

restants à la politique commune de système d’aération

ne sont pas en opération.

1.

Joint les ouvertures inutilisées dans le système de

ventilation commun.

Inspecter visuellement le système de ventilation

2.

à la taille correcte et espacement horizontal et

déterminer il n’y a pas de blocage ou de restriction,

de

fuite, de corrosion et d’autres lacunes que pourrait

causer une condition dangereuse

3.

Dans la mesure où cela est pratique, fermer

tous les bâtiments de portes et fenêtres et toutes

les portes entre l’espace dans lequel les appareils

connectés restants à la système de ventilation

commun

Allumer les sécheuses et tout appareil non connecté

au système de ventilation commun. Mettez sous

tension tous les ventilateurs d’échappement d’air, tels

que les hottes de cuisine et salle de bains exhausts,

an qu’ils fonctionnent à la vitesse maximum. Ne pas

faire fonctionner un ventilateur d’échappement d’été.

Fermer cheminée amortisseurs.

4.

inspecté. Suivez les instructions d’éclairage. Réglez

le thermostat de sorte que l’appareil fonctionnera en

continu.

5.

Test pour les pertes sur les projets d’ouverture de

secours de capot après 5 minutes de fonctionnement

du brûleur principal. Utilisez la amme d’une

allumette ou une bougie allumée, ou de la fumée

d’une cigarette, un cigare ou une pipe.

6.

reste connecté au système de ventilation commun

correctement évents lorsque testé comme décrit

ci-dessus, le retour des portes, des fenêtres,

ventilateurs d’échappement, amortisseurs de

cheminée et tout autre appareil de combustion du

gaz à leurs conditions d’utilisation précédente.

Tout fonctionnement incorrect du système de

7.

ventilation commun devrait être corrigée de sorte

que l’installation est conforme aux code de gaz

combustible National, ANSI Z223.1/NFPA 54 et/

ou CSA B149.1, Codes d’installation. Lors du

redimensionnement de toute portion de la système

de ventilation commun, le système de ventilation

commun doit être redimensionné à l’approche de la

taille minimale, déterminée en utilisant les tableaux

appropriés et des lignes directrices dans le National

sont situés et d’autres espaces du bâtiment.

Place dans le fonctionnement de l’appareil

Après qu’il a été déterminé que chaque appareil

Code de gaz combustible, ANSI Z223.1 NFPA 54 et/

ou CSA B149.1, Codes d’installation.

Page 30

Page 26

LAARS Heating Systems

SECTION 4

GAS SUPPLY AND PIPING

All Installations must conform to the National Fuel

Gas Code ANSI Z223.1/NFPA54, and/or local codes.

In Canada, the installation must conform to the latest

edition of CSA B149.1 Natural Gas and Propane Gas

Installation Code, and/or local codes. Gas piping should

be supported by suitable hangers or oor stands, not

the appliance.

Review the following instructions before proceeding

with the installation.

1. Verify that the appliance is tted for the proper type of

gas by checking the rating plate. The unit will function

properly without the use of high altitude modication

at elevations up to 10,000 feet (3050 m).

2. The maximum inlet gas pressure must not

exceed 13” W.C. (3.2kPa). The minimum inlet gas

pressure is 4” W.C. (1.0kPa).

3. Refer to Table 8 to size the piping.

4. Run gas supply line in accordance with all

applicable codes.

5. Locate and install manual shuto valves in

accordance with state and local requirements.

6. A sediment trap must be provided upstream of the

gas controls.

7. All threaded joints should be coated with

piping compound resistant to action of liqueed

petroleum gas.

8. The appliance and its individual shuto valve

must be disconnected from the gas supply piping

during any pressure testing of that system at test

pressures in excess of 1/2 PSIG (3.45kPa).

9. The unit must be isolated from the gas supply

system by closing its individual manual shuto

valve during any pressure testing of the gas

supply piping system at test pressures equal to or

less than 1/2 PSIG (3.45kPa).

10. The appliance and its gas connection must be

leak tested before placing it in operation.

11. Purge all air from gas lines.

WARNING:

Open ame can cause gas to ignite and result in

property damage, severe injury, or loss of life.

NOTE: This appliance and all other gas appliances sharing

the gas supply line must be ring at maximum capacity to

properly measure the inlet supply pressure. The pressure can

be measured at the supply pressure port on the gas valve.

Low gas pressure could be an indication of an undersized gas

meter, undersized gas supply lines and/or an obstructed gas

supply line. Some units are equipped with low and high gas