Laars newport NP 75, newport NP 85, newport NP 110, newport NP 135, newport NP 125 Installation, Operation And Maintenance Instructions

...

Installation, Operation and Maintenance Instructions Document 1100B

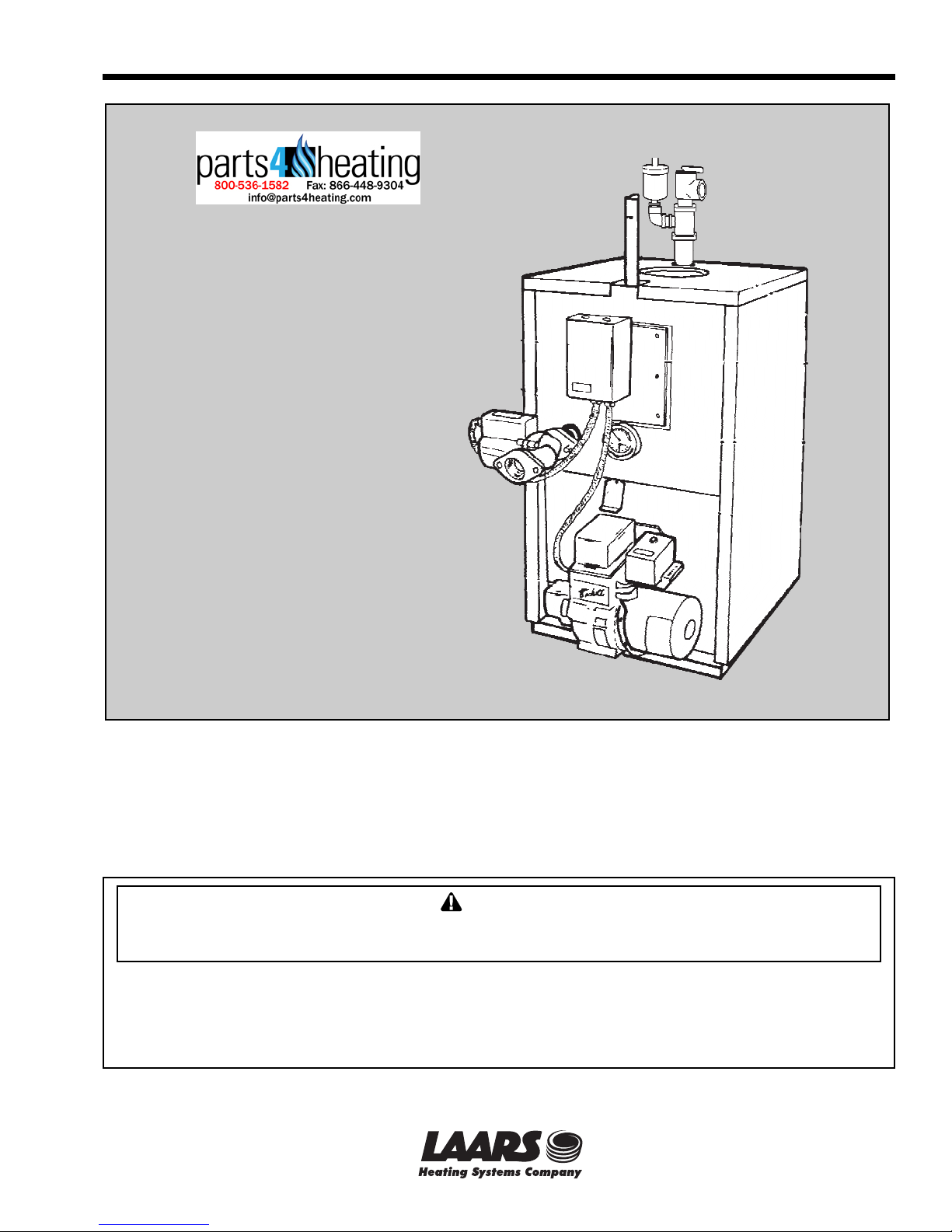

Installation,

Operation and

Maintenance

Instructions for

Newport

Oil Fired Boiler

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in boiler installation and maintenance. Improper installation and/or operation could create

carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

Installation and service must be performed by a qualified installer, service agency, or fuel oil

supplier.

52-206B

A subsidiary of BRADFORD WHITE Corporation

Page 2

LAARS HEATING SYSTEMS

TABLE OF CONTENTS

SECTION 1.

General Information

1A. Boiler Installation .......................................... 3

1B. Freight Claims .............................................. 3

1C. Boiler Location .............................................. 3

1D. Boiler Clearances (to combustibles) ............. 3

1E. Floor ............................................................. 3

1F. Combustion and Ventilation Air ..................... 3

1G. Chimney and Draft Requirements ................. 3

1H. Jacket (normally fitted) .................................. 3

1I. Oil Burner (normally fitted) ............................ 3

1J. Boiler Controls (normally fitted) ..................... 3

1K. Oil ................................................................. 3

1L. Oil Storage and Pipe Layout ......................... 3

1M. Electrical Wiring............................................ 4

1N. Operation

(Honeywell L.8124A aquastat relay) ............. 4

1O. Domestic Water Piping ................................. 4

1P. Cleaning the Boiler ....................................... 4

1Q. Cleaning the Chimney................................... 4

1R. Servicing the Burner ..................................... 5

1S. Maintenance of the Tankless Coil ................. 5

SECTION 2.

Part Numbers

................................................................... 11

Trianco Newport

Page 3

SECTION 1.

General Information

These boilers have been designed and

constructed according to ASME codes using heavy

gauge steel tubes and boiler plate.

The reliable heat exchanger incorporates special

flue baffles to assure quiet and efficient operation and

a purpose designed ceraform combustion chamber

minimizes base loss and also provides a tight

enclosure with the heat exchanger.

The domestic hot water coil is located at the top

of the boiler in the hottest zone for an ample supply of

hot water and a unique feature of its attachment is the

raised coil flange which allows the use of clamping

bolts rather than studs, thereby eliminating water leaks

caused by broken studs.

The complete unit comes pre-assembled for easy

installation and is encased by a fully insulated baked

enamel jacket.

1A. Boiler Installation

For recommended installation practice reference

should be made to the National Fire Protection

Standard for Oil Burning Equipment (NFPA 31 Latest Edition).

1B. Freight Claims

Inspection should be made of boiler and its

components for damage upon arrival. Any claims for

damage should immediately be filed against the

carrier by the consignee.

1C. Boiler Location

The boiler should be positioned as near to the

chimney as possible and have a minimum smoke pipe

connector length of 18"(457mm).

Caution

Newport boilers must not be directly connected to a

heating system using oxygen permeable tubing (see

warranty). Use a water to water heat exchanger

between boiler and system to prevent corrosion.

1F. Combustion and Ventilation Air

To insure an adequate supply of fresh air for

combustion and ventilation an inlet and outlet opening

should be provided at floor and ceiling level. Each

opening must have a minimum of one square inch

(16.5 sq. cm) of free area for every 1,000 BTU/h

(293kW) of input or 140 square inches (903 sq. cm)

per one gallon (3.785L) of oil burned per hour. The

openings must not be in a position liable to blockage.

1G. Chimney and Draft Requirements

To assure the safe and proper operation of the oil

burner the boiler must be connected to a chimney

having sufficient draft at all times to evacuate the flue

gases to atmosphere. A draft regulator must be

installed in the smoke-pipe as near to the flue as

possible and adjusted to achieve an overfire draft of

0.01 ins. W.C.

1H. Jacket (normally fitted)

If not fitted, assemble panels in accordance with

instructions in Figure 4.

1I. Oil Burner (normally fitted)

If not fitted, insert burner tube into boiler so that

it is approximately ¼" (6mm) from inside wall of

ceraform chamber, then clamp mounting flange and

bolt up to front-plate (see Figure 3).

The burner should be wired and connected to the

oil line in accordance with the manufacturer’s

instructions.

1J. Boiler Controls (normally fitted)

If controls are supplied separately, fit them to the

boiler in the positions shown in Figure 3, with jacket

in place.

Circulator - 1¼" return tapping at front of boiler.

Tridicator - temp/press. gauge.

Relief Valve - Provide ¾" tee and auto vent as

shown on front page for air elimination.

Aquastat Relay - L8124A - ¾" tapping in coil

plate.

Fit a drain valve (not supplied) in a tee at

hydronic return connection and check all connections

are made water tight.

1D. Boiler Clearances (to combustibles)

Top - 6" (152mm) Front - 24" (610mm)

Rear - 6" (152mm) Sides - 6" (152mm)

1E. Floor

The boiler must be mounted on a

noncombustible masonry or cement floor with no

combustibles underneath.

1K. Oil

USE ONLY No. 2 HEATING OIL. Do not use

gasoline, crankcase draining or any oil containing

gasoline.

1L. Oil Storage and Pipe Layout

Storage Tank: Consult local fire and building

codes for acceptable fuel storage methods in your area.

Fuel Line: A single pipe system of not less than

3/8" OD copper tubing is recommended when fuel

Page 4

LAARS HEATING SYSTEMS

storage level is not below the fuel unit. A two pipe

system of not less than 3/8" OD copper tubing is

recommended when lowest fuel level is below but not

more than 8 feet below fuel unit.

Important: Refer to burner (pump) instructions

for detailed fuel line and pump usage information. All

installations must conform to local and national codes.

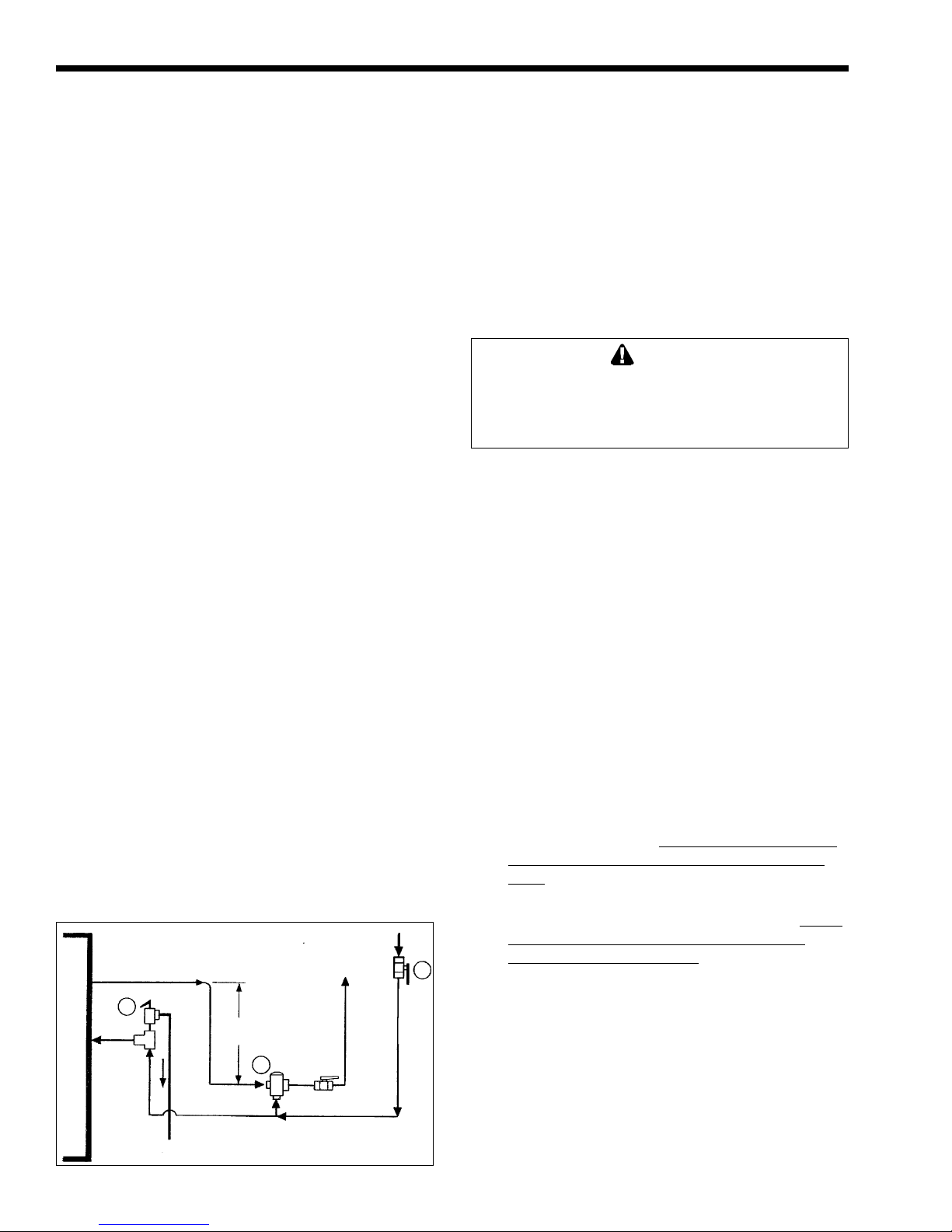

See Figures 5A and 5B.

Figure 5A One-pipe system - pipe and tank layout.

Figure 5B Two-pipe system - pipe and tank layout.

1M. Electrical Wiring

All wiring must comply with the National

Electrical Code, NFPA 70, local codes and ordinances

regarding wire size, type of insulation and enclosures

etc. (see Figure 6).

1N. Operation

(Honeywell L8124A aquastat relay)

A call for heat from the room thermostat causes

the relay to “make “ the burner circuit and also feed

the circulator provided the boiler water temperature is

above the low limit setting (usually 190°F [88°C] to

210°F [99°C]). The burner and circulator then

continue to run until the room thermostat is satisfied.

A high limit switch shuts off burner in the event

of water temperature exceeding the high limit setting,

usually 20°F (-7°C) to 30°F (-1°C) above the low limit

setting.

The low limit switch and circulator maintain

boiler water temperature for domestic hot water

services and prevents circulation of heating system

water if domestic water is not hot enough.

1O. Domestic Water Piping

1. Connect anti scald tempering valve (12) “HOT”

port to hot water outlet from unit. This valve

should be mounted 3" (76mm) to 6" (152mm)

below the outlet and set for 120° F mixed

delivery temperature or as local codes dictate

(see Figure 1).

13

B

O

I

L

E

11

3 - 6"

(76mm - 152mm)

12

R

Figure 1. Domestic water piping.

2. Connect gate or shutoff valve (13) to anti scald

tempering valve (12) “MIX” port, and another to

the cold water inlet.

3. Connect pressure relief valve (11) (if required

by codes), maximum 150 PSI as close to the unit

as possible. No other valves or restrictions may

be installed between the DHW coil and the

relief valve.

(DO NOT USE A TEMPERATURE/

PRESSURE RELIEF VALVE AS THIS IS NOT A

STORAGE HOT WATER HEATER).

WARNING

Flue gases are dangerous - do not operate boiler if

there is an escape of flue gas. Call a qualified

serviceman and have the entire flue and venting

system inspected.

1P. Cleaning the Boiler

To maintain the high thermal efficiency and a

long life from your boiler, it should be cleaned at least

once a year, preferably at the end of the heating

season. This is particularly important as rusting can

occur when the boiler is idle.

It is recommended that a service contract be

arranged with a properly equipped serviceman who

will be able to do the job efficiently and without mess.

1. Switch off electrical supply to the boiler.

2. Remove smoke-pipe from boiler.

3. Remove top jacket panel.

4. Unscrew the securing nuts and remove flue

collector.

5. Remove baffles from flue tubes.

6. Remove burner by unscrewing the flange

mounting nuts.

7. Remove soot and scale deposits from tubes with

a flexible wire brush,

taking care not to damage

“ceraform” combustion chamber, below outer

tubes.

8. Vacuum out accumulated deposits from

combustion chamber through burner port,

taking

care not to damage “ceraform” combustion

chamber, below outer tubes.

9. Replace all parts, ensuring flue-baffles are

correctly located. Ensure flue collector and

smoke-pipe are tightly sealed.

1Q. Cleaning the Chimney

Sweep all soot deposits from chimney and

smoke-pipe once a year, preferably at the end of the

heating season. It is also advisable to inspect the

chimney and smoke-pipe at the beginning of heating

season as birds may have built their nest inside or

other material may be causing a blockage.

Loading...

Loading...