Page 1

Installation and Operation Instructions Document 1254B

Installation and

Operation Instructions for

MINI-THERM

Residential

Gas-Fired

Hydronic Boilers

Models JVH, JVS

Sizes 50-225

JVS

U.S. Patent No. 1,609,692

Canada Patent No. 383,318

JVH

These instructions are to be stored next to the boiler for reference purposes.

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualied in hot water boiler installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in ue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not followed

exactly, a re or explosion may result causing

property damage, personal injury or loss of life.

Do not store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the

re department.

Installation and service must be performed by

a qualied installer, service agency, or gas

supplier.

Vent damper is optional in some provinces of Canada..

AVERTISSEMENT

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion

ou pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inammables dans

le voisinage de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas

vous servir des téléphones dansle bâtiment

où vous êtes.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur

de gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés

par un installateur ou un service d’entretien

qualié ou par le fournisseur de gaz.

H2355800B

Page 2

Page 2

LAARS Heating Systems

TABLE OF CONTENTS

SECTION 1.

General Information

1A. Introduction ....................................................3

1B. Warranty ........................................................ 3

1C. Heater Identication .......................................4

SECTION 2.

Boiler Assembly & Placement

2A. Field Assembly ..............................................4

2B. Boiler Placement ...........................................5

2C. Flooring ..........................................................5

2D. Dimensional Information ................................ 6

2E. Clearance / Closet Installations ..................... 8

SECTION 3.

Air and Venting

3A. Combustion Air Supply .................................. 9

3B. Venting .........................................................10

3C. Vertical Venting - Category I ........................ 11

3D-1 Horizontal Venting - Category III ..................12

3D-2 Venting Connections ....................................12

3D-3 Vent Terminations ........................................ 13

3E. Common Venting System ............................13

SECTION 6.

6A. Electrical Wiring ...........................................20

6B. Outdoor Reset .............................................20

SECTION 7.

7A. Filling the System ........................................25

SECTION 8.

Operating Procedures

8A. System Start-up ...........................................26

8B. Sequence of Operation ................................ 26

8C. Operating Instructions, JVH .........................27

8D. Operating Instructions, JVS ......................... 28

8E. Operating Temperature Control ...................29

SECTION 9.

9A. Maintenance ................................................ 31

9B. Electrical Troubleshooting ...........................32

SECTION 10. Replacement Parts

10A. Glossary of Terms ........................................35

10B. Parts List JVH ..............................................36

10C. Parts List JVS ..............................................38

SECTION 4.

Gas Connections

4A. Gas Supply and Piping ................................ 13

4B. Special Precautions for LP .........................15

SECTION 5.

Water Connections

5A. Water Piping ................................................ 15

5B. By-pass Piping ............................................. 17

5C. Adjusting the bypass ...................................17

5D. Alternate Auto-Bypass Operation ................17

5E. Flow Requirements ...................................... 18

5F. Chilled Water Systems ................................18

5G. Oxygen Permeable Systems ....................... 18

5H. Anti-Freeze ..................................................18

Page 3

Mini-Therm JV

SECTION 1.

General Information

1A. Introduction

This manual provides information necessary for the

installation, operation, and maintenance of the Laars

Model JV low pressure, copper tube hydronic boilers.

These boilers are available in two congurations; the

JVH has a hot surface pilot ignition system and the

JVS has an electronic intermittent ignition device

(I.I.D.). Look for the model designation on the rating

plate, which can be found on top of the boiler.

All application and installation procedures should

be reviewed completely before proceeding with

the installation. Consult the Laars factory, or local

factory representative, with any problems or questions

regarding this equipment. Experience has shown that

most operating problems are caused by improper

installation.

WARNING

This hydronic boiler must be installed in

accordance with the procedures detailed in this

manual, or the Laars warranty will be voided. The

installation must conform to the requirements of

the local jurisdiction having authority, and, in the

United States, to the latest edition of the National

Fuel Gas Code, ANSI Z223.1. In Canada, the

installation must conform with the latest edition of

CAN/CGA B149.1 OR .2 installation codes for gas

burning appliances, and/or local codes.

Any modications to the boiler, its gas controls,

gas orices, wiring or draft inducer assembly

may void the warranty. If eld conditions require

modications, consult the factory representative

before initiating such modications.

Page 3

1B. Warranty

The Laars Model JV boilers are covered by a limited

warranty. The owner should ll out the warranty

registration card and return it to Laars.

All warranty claims must be made to an authorized

Laars representative or directly to the factory. Claims

must include the boiler serial number and model (this

information can be found on the

rating plate), installation date, and name of the

installer. Shipping costs are not included in the

warranty coverage.

Some accessory items are shipped in separate

packages. Verify receipt of all packages listed on

the packing slip. Inspect everything for damage

immediately upon delivery, and advise the carrier of

any shortages or damage. Any such claims should be

led with the carrier. The carrier, not the shipper, is

responsible for shortages and damage to the shipment

whether visible or concealed.

The warranty does not cover damage caused by

improper assembly installation, operation or eld

modication.

ATTENTION

L' eau chaude chaudière doit être installé en

conformité avec les procédures détaillées dans

ce manuel, ou le Laars garantie sera annulée.

L'installation doit être conforme aux exigences

de la juridiction locale ayant l'autorité, et, aux

ÉTATS-UNIS , à la dernière édition du National

gaz carburant Code, ANSI Z223.1. Au Canada,

l'installation doit être conforme à la plus récente

édition de la norme CAN/CGA B149.1 ou .2 codes

d'installation gaz pour appareils de combustion et/

ou codes locaux.

Page 4

Page 4

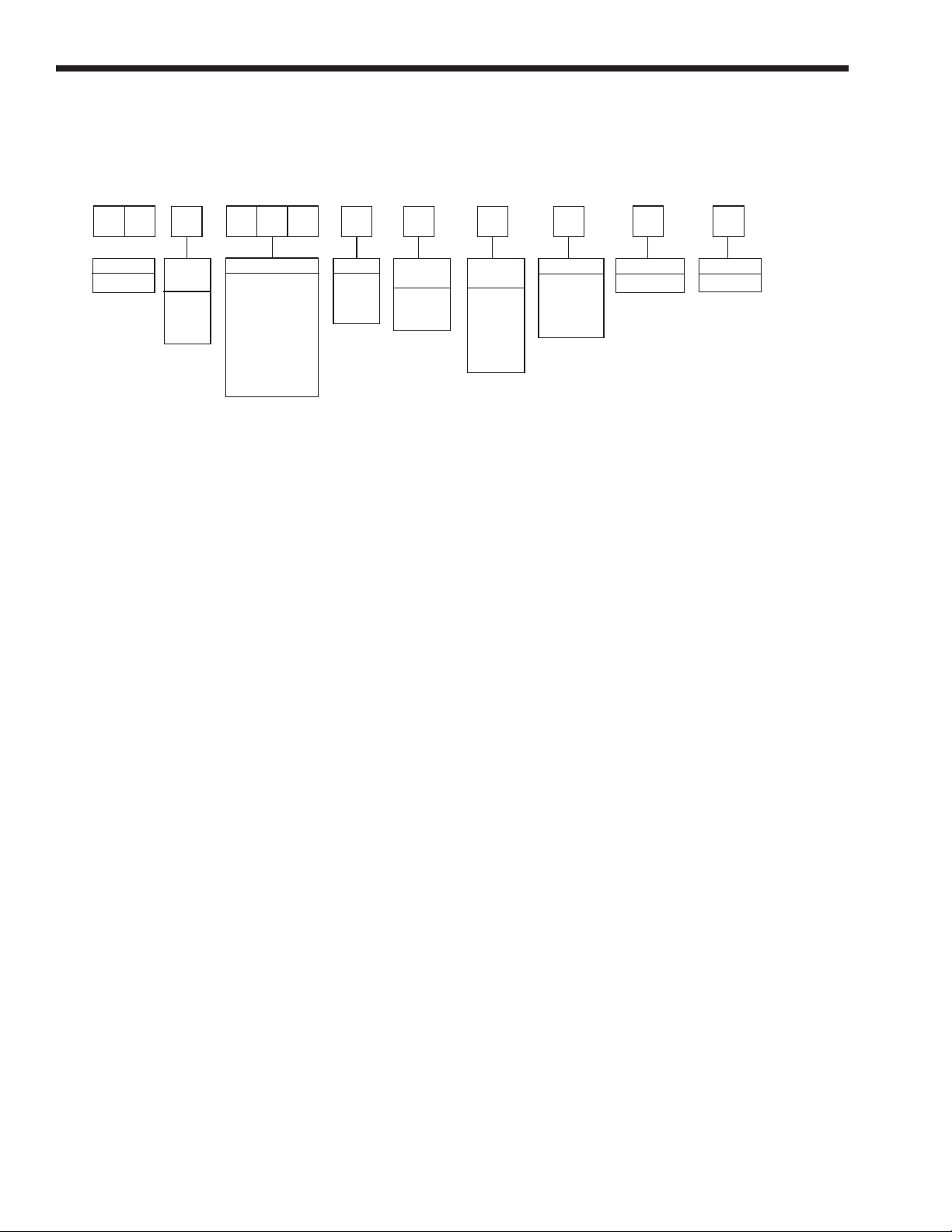

1C. Heater Identication

Consult the rating plate on the boiler. The following

example simplies the heater identication:

1 2 3 4 5 6 7 8 9 10 11 12

VJ U 2

LAARS Heating Systems

MODEL

J V

IGNIT

SYST

S

H

Table 1. Boiler Model Identication.

SIZE

0 5 0

0 7 5

1 0 0

1 2 5

1 6 0

2 2 5

FUEL

N

P

FIRING

SYST

JVH

1st and 2nd CharaCters (series name)

JV = mini-therm

3rd CharaCter (ignition system)

h = hot surfaCe pilot

4th thru 6th CharaCters (size)

input mBtu / h

7th CharaCter (fuel)

n = natural gas

p = propane gas

8th CharaCter (firing system)

C = on / off

9th CharaCter (ConstruCtion option)

s = standard

10th CharaCter (altitude in feet)

s = (0 - 2,000) natural or (0 - 5,000) propane

i = (5,001 - 8,000) natural and propane

J = (8,001 - 10,000 natural and propane

11th CharaCter (Country)

u = usa & Canada

12th CharaCter (reVision)

2 = seCond reVision

CONST

OPTION

C

D

S

P

I

J

ALTITUDE

S

I

J

COUNTRY

U

REVISION

2

JVS

1st and 2nd CharaCters (series name)

JV = mini-therm

3rd CharaCter (ignition system)

s = spark ignition

4th thru 6th CharaCters (size)

input mBtu / h

7th CharaCter (fuel)

n = natural gas

p = propane gas

8th CharaCter (firing system)

D = on / off

9th CharaCter (ConstruCtion option)

i = (standard)

J = pump (050-125 only)

10th CharaCter (altitude in feet)

s = (0 - 2,000) natural or (0 - 5,000) propane

i = (5,001 - 8,000) natural and propane

J = (8,001 - 10,000 natural and propane

11th CharaCter (Country)

u = usa & Canada

12th CharaCter (reVision)

2 = seCond reVision

SECTION 2.

Boiler Assembly and Placement

2A. Field Assembly

These boilers are available in two congurations; the

JVH has a hot surface ignition pilot and integral draft

fan, and the JVS has an electronic intermittent ignition

device (I.I.D.). Look for the model designation on the

rating plate, which can be found on top of the boiler in

the right rear corner.

The Laars automatic vent dampers are standard on

all JVS models. The Laars side wall power venters

can be used on JVS models. Special instructions for

their installation are included in the vent damper and

power venter package. Read them carefully before

installation.

Page 5

Mini-Therm JV

Vent Damper (JVS only):

1. Mini-Therm JVS boilers have built-in draft

diverter for natural draft operation.

2. Find the vent damper box which is located in the

boiler package.

3. Install the vent damper directly to the top of the

draft diverter outlet with the damper operator

facing to the front of the boiler, and with the ow

direction arrow pointing upward. Use the vent

damper wire harness provided with the boiler

to connect the vent damper to the boiler. The

bracket end of the harness should be connected to

the vent damper actuator.

4. For Model JVS only: Install the metal plug

provided with the vent damper onto the damper

plate hole.

5. Do not modify the automatic vent damper device.

It is very important that no other vents are closed.

Provide at least six inches clearance between

the automatic vent damper and combustible

construction, and be sure to allow access for

servicing the damper.

Temperature/Pressure Gauge: Install the temp/

pressure gauge provided in the parts box.

Page 5

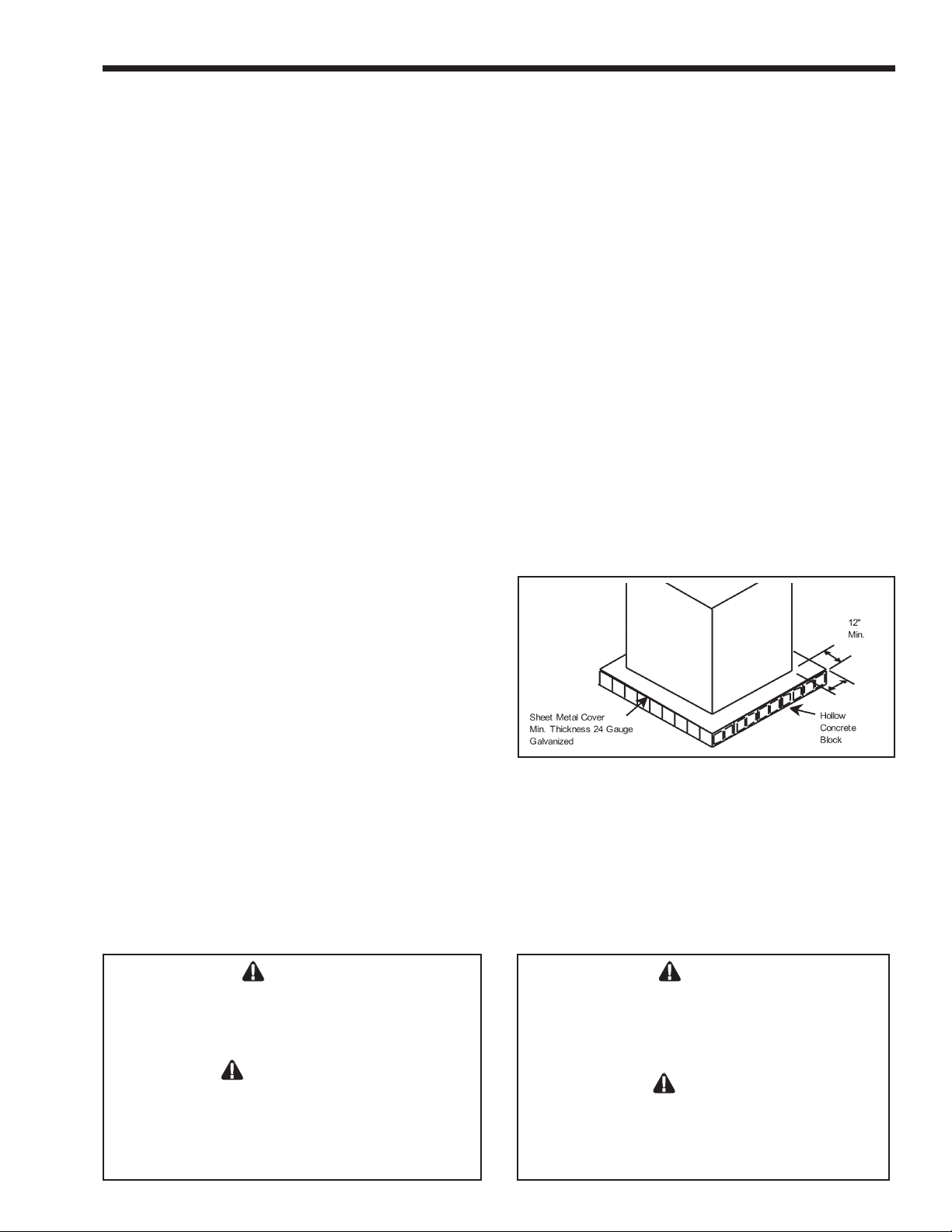

2C. Flooring

JVS model boilers can only be installed on

noncombustible ooring.

JVH model boilers are designed and certied for

installation on a combustible oor.

All boilers must be installed on a level oor and

must NEVER be installed on carpeting.

NEVER store objects on or around the boiler.

Noncombustible ooring is dened as ooring

material and surface nish not capable of being

ignited and burning and with no combustible materials

against the underside. Acceptable materials are those

consisting entirely of a combination of steel, iron,

brick, tile, concrete, slate, glass or plaster.

The JVS model boilers can be installed on a

combustible oor if a noncombustible base

assembly, available from Laars, is used. See the JVS

Parts List at the back of this manual for the appropriate

Noncombustible Base Kit part number.

2B. Boiler Placement

1. The boiler must be placed to provide clearances

on all sides for maintenance and inspection. There

must also be minimum distances maintained from

combustible surfaces. Avoid locations which can

be damaged by water or moisture.

2. A minimum of 15" (381mm) access must be

available in front of the boiler for burner tray

removal. Consult local codes for clearances to hot

water pipes and accessories.

3. If the boiler is to be installed in a garage, all

burners and burner ignition devices must have

a minimum 18" (457mm) clearance

above the oor.

4. Boilers can be installed in a closet as long as

the minimum clearances shown in Table 2 are

observed. Special attention should be paid to

clearances between the front of the boiler and the

closet door when it is closed (see Figure 2).

WARNING

This boiler is intended for indoor installation only.

Do not install this boiler in a location subject to

negative pressure, or improper operation will occur.

Avertissement

Cette chaudière est destiné pour une installation

intérieure uniquement. Ne pas installer cette

chaudière dans un endroit soumis à pression

négative, ou fonctionnement incorrect se produira

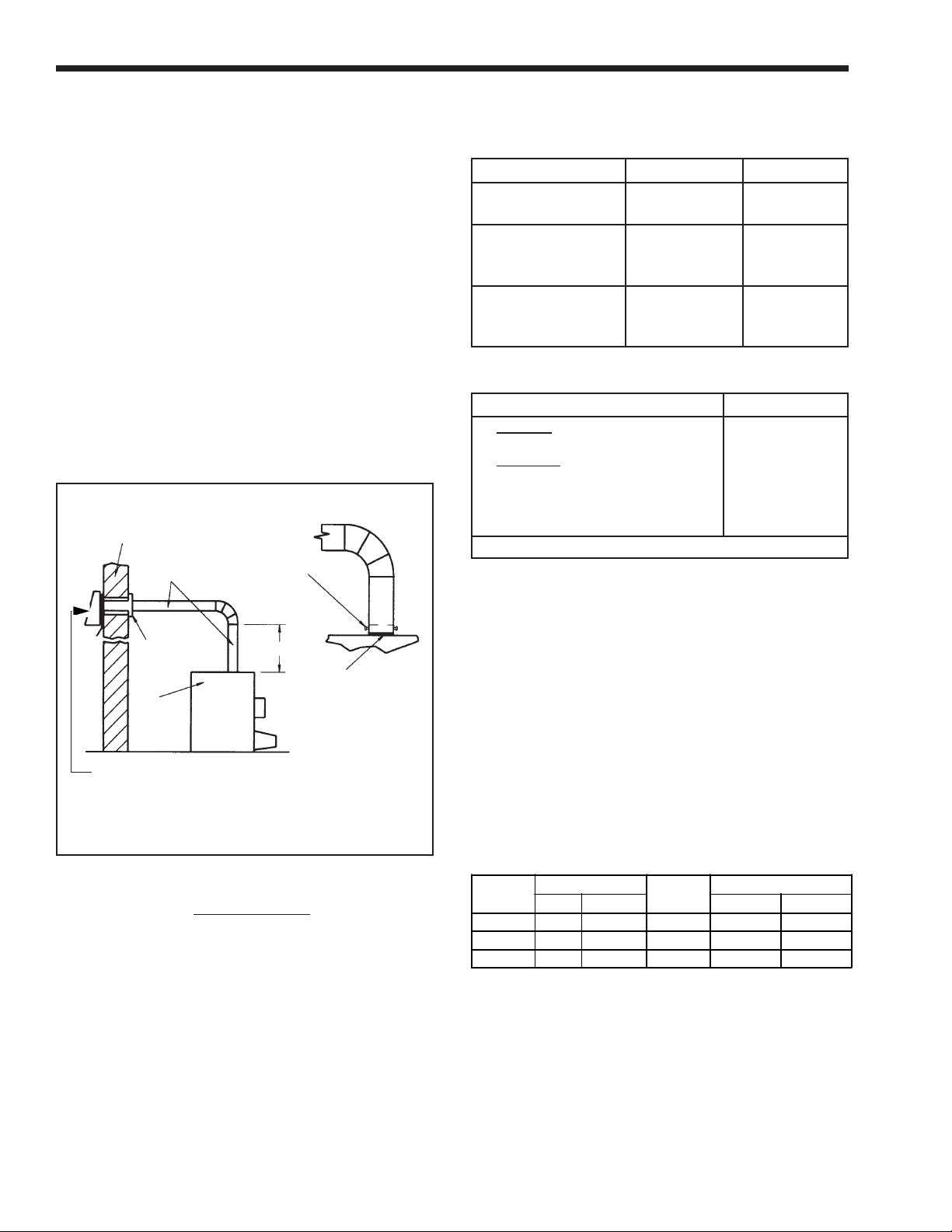

Figure 1. Typical Combustible Floor Installation.

As an alternative to the Laars Noncombustible Base

Kit, in the United States the National Fuel Gas

Code allows a heater to be placed on a combustible

surface when there is a platform under the heater

made of hollow masonry no less than 4 inches (102

millimeters [mm]) thick, covered with sheet metal at

least 24 gauge thick and extending beyond the full

Caution

Do not force motor operation when operator is

fastened to the damper by moving the damper

blade, turning the shaft or by turning the position

indicator.

Attention

Ne pas tourner le registre manuellement avec

ou sans courant électrique ou le moteur sera

endommagé.

Page 6

Page 6

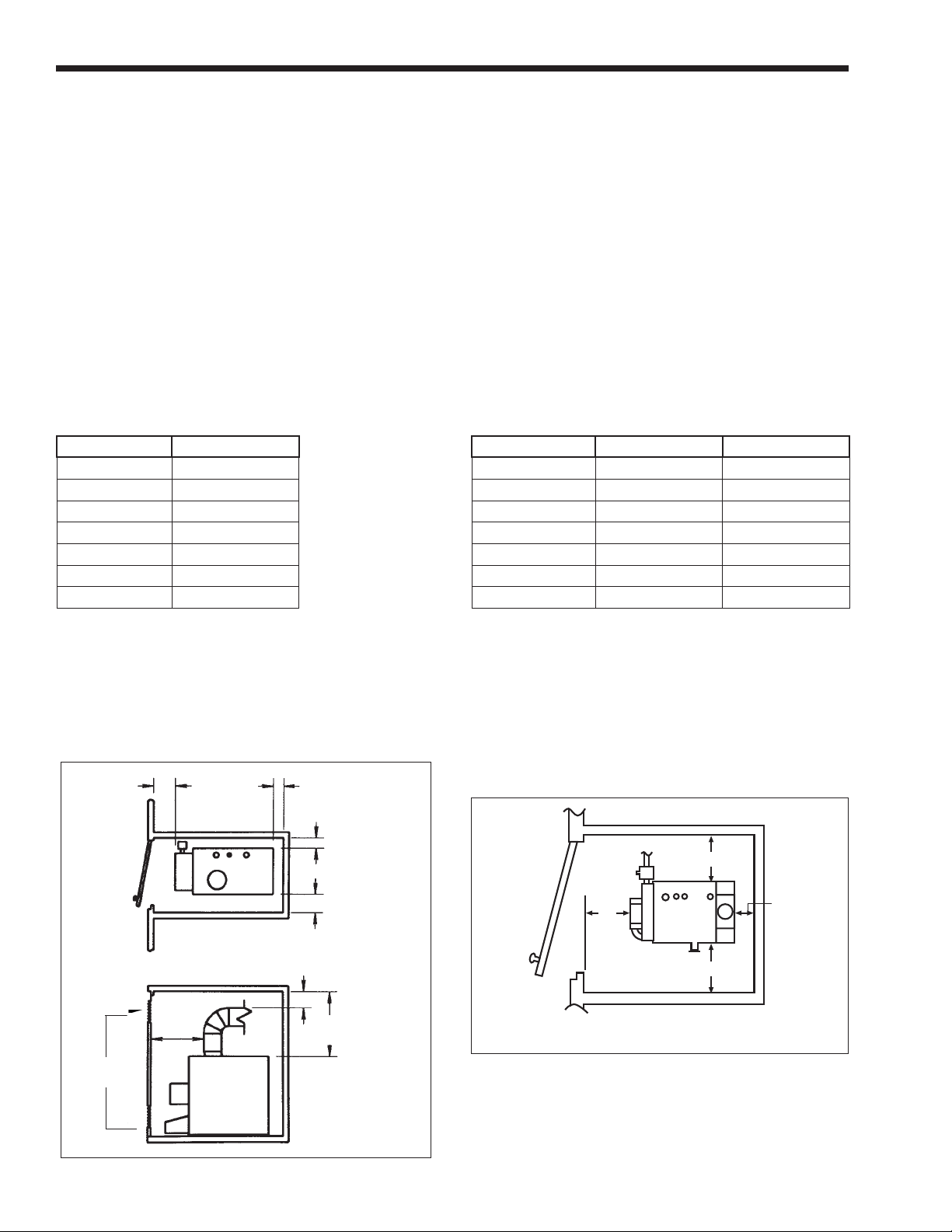

Size A B C

Wate r

Connection

Gas

Connection

in.

mm

in.

mm

in.

mm

50

75

100

125

160

225

13-3/8

13-3/8

16-7/8

16-7/8

20-3/8

25-5/8

340

340

429

429

518

651

3-1/8

2-1/4

5-3/4

5-1/2

7-1/4

10

79

57

146

140

184

254

2-7/8

2

2-7/8

2

2

2

73

51

73

51

51

51

1-1/4

1-1/4

1-1/4

1-1/4

1-1/4

1-1/4

1/2

1/2

1/2

1/2

1/2

3/4

JVH

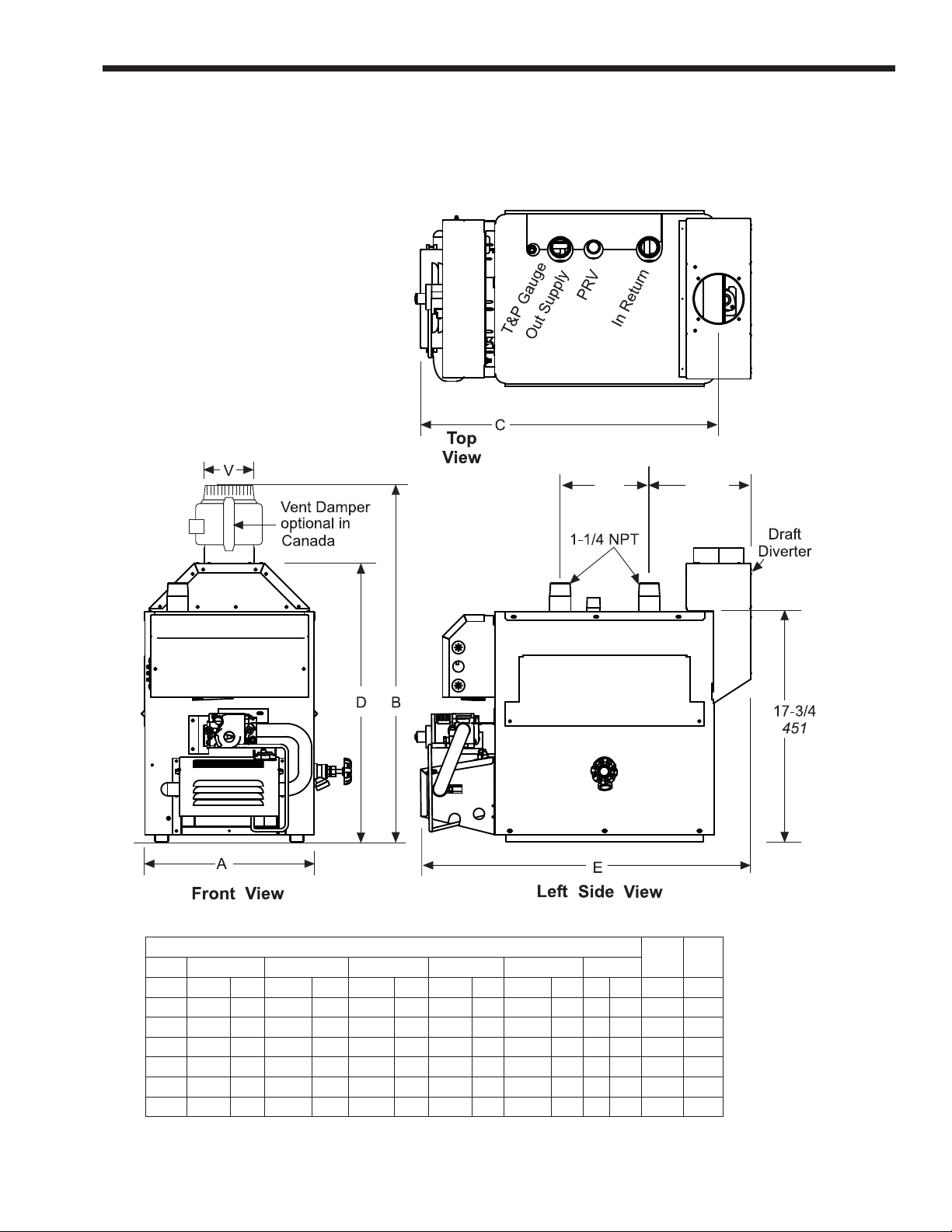

2D. JVH Dimensional Information

LAARS Heating Systems

Dimensions in

inches

mm

C B

7

180

6

152

2.4

61

25

635

JVH Dimensions

24

610

Page 7

6

152

7

180

C B

25

635

2.4

61

24

610

Mini-Therm JV

JVS

Page 7

2D. JVS Dimensional Information

Dimensions in

inches

mm

7

180

9 -1/4

240

Water

Size A B C D E V

in. mm in. mm in. mm in. mm in. mm in. mm 1-1/4 1/2

50 13-3/8 340 27-3/4 710 23-5/8 600 21-3/4 550 26-1/2 670 4 10 1-1/4 1/2

75 13-3/8 340 27-3/4 710 24-1/8 610 21-3/4 550 27-1/2 700 5 13 1-1/4 1/2

100 16-7/8 430 28-3/4 730 24-1/8 610 22-3/4 580 27-1/2 700 5 13 1-1/4 1/2

125 16-7/8 430 28-3/4 730 23-5/8 600 22-3/4 580 27-1/2 700 6 15 1-1/4 1/2

160 20-3/8 518 28-3/4 730 23-5/8 600 22-3/4 580 27-1/2 700 6 15 1-1/4 1/2

225 25-5/8 651 31-1/2 800 23-1/4 590 23-3/4 630 27-1/2 700 7 18 1-1/4 3/4

Conn

JVS Dimensions

Gas

Conn

Page 8

Page 8

width and depth of the heater by at least 12 inches

(305mm) in all directions. The masonry must be laid

with ends unsealed, and joints matched to provide

free circulation of air from side to side through the

masonry (see Figure 1). If the boiler is installed in a

carpeted alcove, the entire oor of the alcove must be

covered by a noncombustible platform.

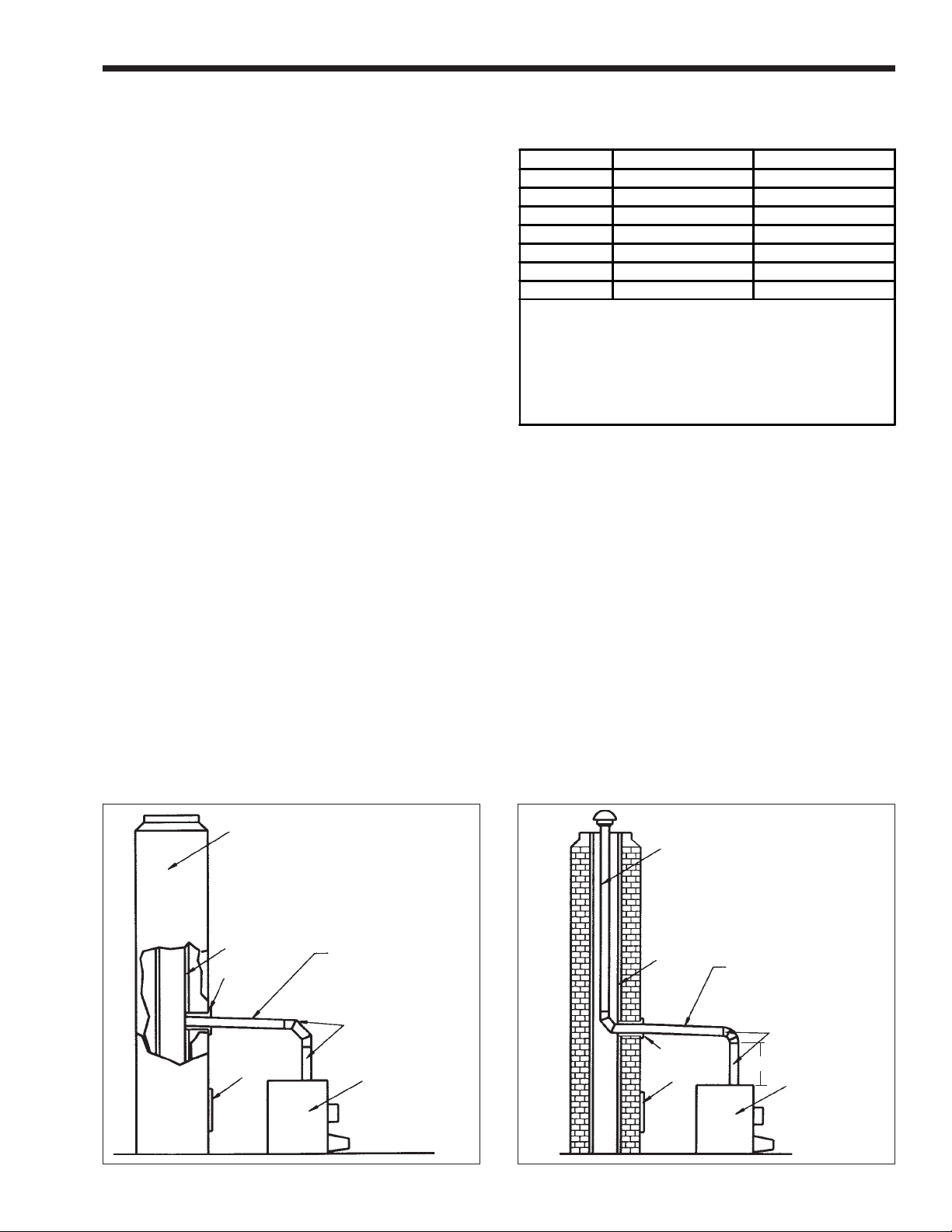

2E. Clearance / Closet Installations

All Mini-Therm JV's can be installed in a closet as

long as the minimum clearances are observed.

See Table 2JVH and Figure 2JVH for

clearances required for the Mini-Therm JVH.

See Table 2JVS and Figure 2JVS for

clearances required for the Mini-Therm JVS

LAARS Heating Systems

Special attention should be paid to clearances

between the front of the boiler and the closet door

when it is closed.

Consult the American National Standard Z21.13 for

more information concerning closet installations. In

Canada, refer to the latest edition of CSA-B149.1.

Boiler Sizes 50 - 225

Clearances in cm

Left side 2 5

Right side 5 15

Rear 2 5

Front 4 10

Flue (using B-vent) 6 15

Top 23 58

Boiler Sizes 50 - 125 160 - 225

Clearances in cm in cm

Left side 6 15 6 15

Right side 6 15 6 15

Rear 6 15 6 15

Front 4 10 4 10

Flue 6 15 6 15

Top 23 58 36 91

Table 2JVS Minimum Boiler ClearancesTable 2JVH Minimum Boiler Clearances

Note: Clearances listed are manufacturer’s tested values. These are given as minimum values. Where local and national

codes apply, and values are different than those listed use the greater value to ensure safe operation.

Minimum Boiler Clearances from Combustible Surfaces.

Dégagements Minimaux à Assurer Entre Ics Parois de L’appareil et leo Constructions Combustibles

A

2

(51)

2

(51)

TOP

VIEW

4*

10

5

(127)

6

(152)

6 15

6 15

6 15

6

(152)

MIN

Air

Openings

Figure 2JVH. Closet Installation.

B

SIDE

VIEW

Dimensions in

inches (mm).

Dimensions in inches cm.

*6" for models JV160 to JV225.

Figure 2JVS. Closet Installation

Page 9

Mini-Therm JV

Boiler Size Outside Air Area Inside Air Area

sq. in

sq. cm

sq. in.

sq. cm

50

15

97

100

645

75

20

129

100

645

100

25

161

100

645

125

32

206

125

807

160

40

258

160

1032

225

60

387

225

1452

*Area indicated is for one of two openings: one at floor level

and one at the ceiling, so the total net free area would be

double the figures shown. For special conditions, refer to

NFPA54 ANSI Z223.1. In Canada, refer to the National

Standard CAN1-B149.1 or .2, which differs from this table.

NOTE: Check with louver manufacturers for Net Free Area of

Louvers. Correct for screen resistance to the Net Free Area if a

screen is used.

SECTION 3.

Air and Venting

3A. Combustion Air Supply

The boiler location must provide sufcient air

supply for proper combustion, and ventilation of

the surrounding area as outlined in the latest edition

of U.S. ANSI standard Z223.1 or in Canada, CAN/

CGA-B149.1 or .2, and any local codes that may be

applicable.

In general, these requirements specify that the

boiler rooms which represent conned spaces should

be provided with two permanent air supply openings;

one within 12 inches (305mm) of the ceiling, the other

within 12 inches (305mm) of the oor.

Page 9

NOTE: In Canada, follow Canadian Standard,

CAN/CGA-B149 or local codes.

Outside Air Supply: When combustion air is

supplied directly through an outside wall, each

opening should have a minimum free area of one

square inch per 4,000 BTU/h (6 sq. cm per 1.2 kW)

input of the total input rating of all appliances in the

enclosed area.

Inside Air Supply: When combustion is supplied

from inside the building, each opening should have

a minimum free area of one square inch per 1,000

BTU/h (6 sq. cm per 0.3 kW) input of the total input

rating of all appliances in the enclosed area. These

openings should never be less than 100 square inches

(645 sq. cm).

CHIMNEY

Table 3. Minimum Recommended

Air Supply to Boiler Room

Exhaust Fans or Vents: Any equipment which

exhausts air from the boiler room can deplete the

combustion air supply or reverse the natural draft

action of venting system. This could cause ue

products to accumulate in the boiler room. Additional

air must be supplied to compensate for such exhaust.

The information in Table 3 is not applicable in

installations where exhaust fans or blowers of any

type are used. Such installations must be designed by

qualied engineers.

If a blower or fan is used to supply air to the boiler

room, the installer should make sure it does not create

drafts which could cause nuisance shutdowns. If a

blower is necessary to provide adequate combustion

air to the boiler, a suitable switch or equivalent must

CHIMNEY

LINER

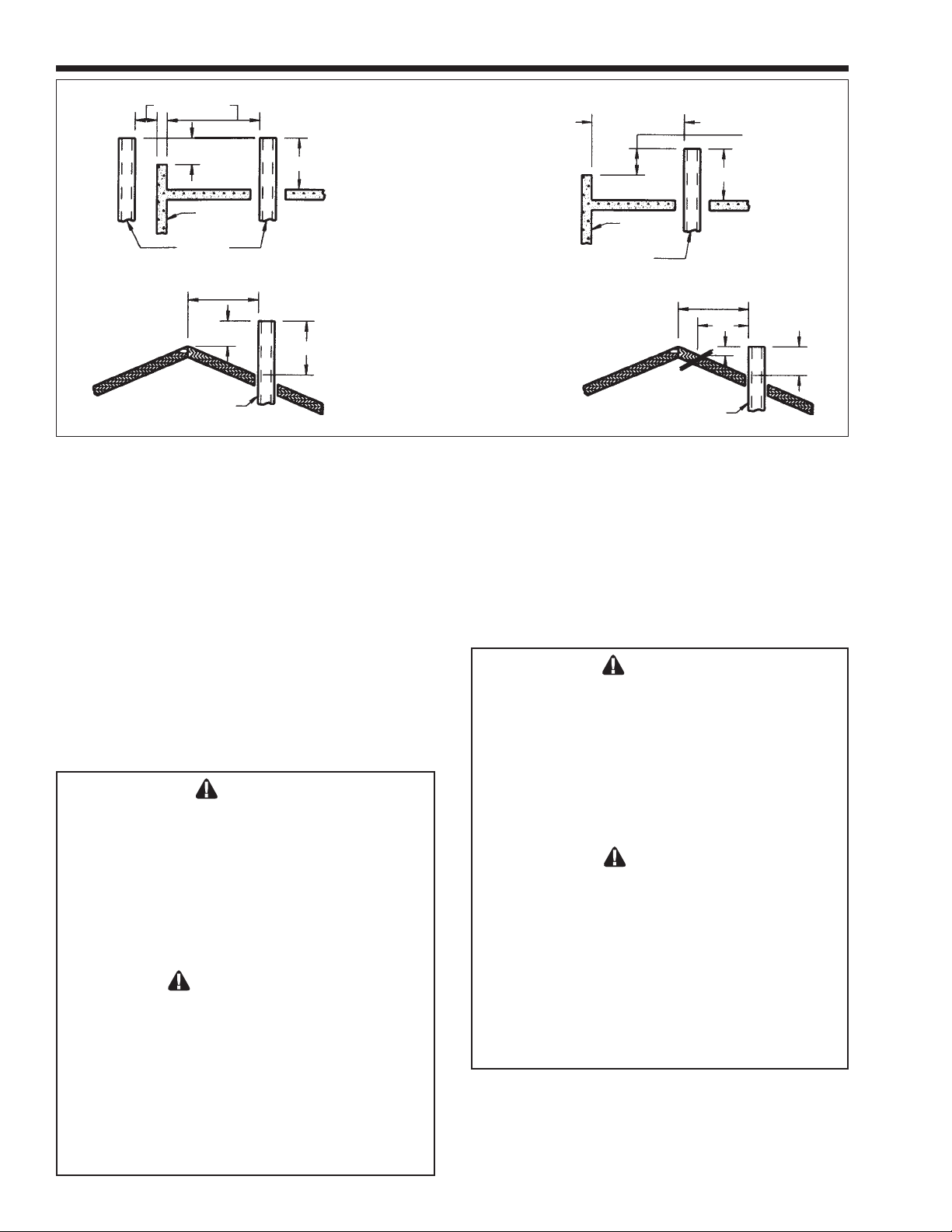

Figure 3. Chimney Venting. Figure 4. Vertical Venting.

THIMBLE

CLEANOUT

PER FT.

(20mm PER M)

SLOPE

SYSTEM

1/4"

VENT

BOILER

LINER

THIMBLE

CLEANOUT

1/4"

PER FT.

(20mm PER M)

SLOPE

VENT

SYSTEM

12" (305mm)

BOILER

Page 10

Page 10

10 (3.0) OR

LESS

LAARS Heating Systems

MORE THAN 10

(3.0)

2 (0.6) MIN.

WALL OR

PARAPET

CHIMNEY

10 (3.0)

OR LESS

2 (0.6)

RIDGE

Figure 5. Vertical Vent Termination.

MIN.

CHIMNEY

3 (0.9)

MIN.

TERMINATION

10 FT. (3.0m)

OR LESS FROM RIDGE,

WALL OR PARAPET

3 (0.9)

MIN.

Dimensions in feet (m).

be wired into the boiler control circuit to prevent the

boiler from ring unless the blower is operating.

The boiler must be completely isolated and

protected from any source of corrosive chemical

fumes such as those emitted by trichloroethylene,

perchloroethylene, chlorine, etc.

3B. Venting

3 (0.9)

MIN.

WALL OR

PARAPET

NOTE: NO HEIGHT

ABOVE PARAPET

REQUIRED WHEN

FROM WALLS OR

PARAPET IS MORE

THAN 10 FT. (3.0m)

CHIMNEY

RIDGE

MORE THAN 10

(3.0)

2 (0.6)

MIN.

CHIMNEY

10 (3.0)

3 (0.9)

MIN.

The boiler vent collar must be fastened directly to

an unobstructed vent pipe with rustproof sheet metal

screws no longer than 1/2” (13mm) and located to

prevent interference with the inducer damper.

Do not weld the vent pipe to the boiler collar. The

weight of the stack must not rest on the boiler. The

boiler top must be easily removable for normal boiler

service and inspection.

Vent Categories: Mini-Therm JVS is a natural draft

appliance for Category I venting only. JVH is a

fan-assisted product that can be vented vertically in a

properly-designed Category I system, or can be vented

horizontally as a Category III appliance, per this

installation manual.

WARNING

This boiler must be vented in accordance with

Part 7, Venting of Equipment, of the latest edition

of the National Fuel Gas code, ANSI Z223.1 and

all applicable local building codes. In Canada,

follow CAN/CGA B149 Installation codes.

Improper venting of this appliance can result in

excessive levels of carbon monoxide which can

result in severe personal injury or death!

AVERTISSEMENT

Cette chaudière doit être ventilé, conformément

aux dispositions de la partie 7, de la ventilation de

l'équipement, de la dernière édition du National

gaz carburant code, ANSI Z223.1 et tous les

codes du bâtiment locaux. Au Canada, CAN/

CGA B149 codes d'installation. Une mauvaise

ventilation de cet appareil peut entraîner des

niveaux excessifs de monoxyde de carbone qui

peut entraîner de graves blessures ou la mort!

IMPORTANT

Only JVH (induced draft) models may be side-wall

vented per Section 3D without the addition of a

properly sized and installed power venter.

JVS must be connected only using Category Type

I methods and materials per Section 3C. JVH may

be connected per Category I or III (See Section 3D)

methods and materials. See fuel gas code for more

information regarding your venting application.

IMPORTANT

Seulement JVH (induits projet) modèles peut être

paroi ventilé par chapitre 3D sans l'addition de la

bonne taille et de puissance installée venter. JVS

doivent être connectés uniquement en utilisant

Type de catégorie I méthodes et matériaux par

Section 3C. JVH peut être connecté par catégorie

I ou III (voir section 3D) Les méthodes et les

matériaux. Voir gaz combustible code pour plus

d'informations concernant votre application

d'aération.

Avoid terminating boiler vents near air conditioning

or air supply fans. The fans can pick up exhaust

ue products from the boiler and return them to the

building, creating a possible health hazard.

Avoid oversized vent pipe or extremely long runs

Page 11

Mini-Therm JV

Page 11

of the pipe, which may cause excessive cooling and

condensation.

3C. Vertical Venting - Category I

(JVS and JVH)

All venting must comply with fuel gas code and

be installed by a licensed professional.

The Mini-Therm JVS or JVH series boiler can

be vented into a masonry chimney, (see Figure 2)

provided several conditions are met:

1. The chimney must have an appropriate tile lining

that is clean, properly constructed and properly

sized.

2. The chimney passage way shall be examined to

ascertain that it is clear and free of obstructions.

WARNING

Do not store any chemical, cleaners, or other

corrosive material near combustion air openings

or in the room. Avoid locating dryer vents in the

vicinity of combustion air openings. Failure to

prevent corrosive materials from mixing with

combustion air can result in reduced boiler life

and unsafe boiler operation.

AVERTISSEMENT

N’entrepposer aucun produit chimique, produit

nettoyant ou produit corrosif à proximité des

bouches d’air de combustion ou dans la pièce.

Éviter de placer des tuyaux de ventilation pour

sécheuse à proximité des bouches d’air de

combustion. Le fait de laisser des maitières

corrosives se mélanger à l’air de combustion

risque de réduire le cycle de vie de l’appareil

de chauffage et de compromettre son

fonctionnement.

3. If a chimney rebuild is required, it shall conform

to nationally recognized standards (see National

Building Code or ANSI/NFPA 211).

4. The boiler must not be connected to a replace,

wood stove or other solid fuel burning

equipment.

5. When the boiler and a hot water heater are to be

connected to the same chimney, they must have

their own vent connector and enter the chimney

at least 6” (152mm) apart.

IMPORTANT NOTE: Always provide a minimum

clearance of 6” (152mm) between Type C (single wall)

vent pipe and any combustible materials.

WARNING

Single wall vent pipe must NEVER pass through

interior walls or through oors or ceilings! Failure

to comply with this warning could result in a re

causing property damage, personal injury, or death!

AVERTISSEMENT

Paroi simple tuyau d'évent doit jamais passer par

l'intérieur les murs ou par planchers ou plafonds

! Le non-respect de cet avertissement peut

provoquer un incendie causant des dommages

matériels ou corporels, ou de mort!

When installing the vent system, all applicable

national and local codes must be followed! The use

of thimbles, restops and other protective devices,

when penetrating combustible or noncombustible

construction, must be in accordance with all applicable

national and local codes.

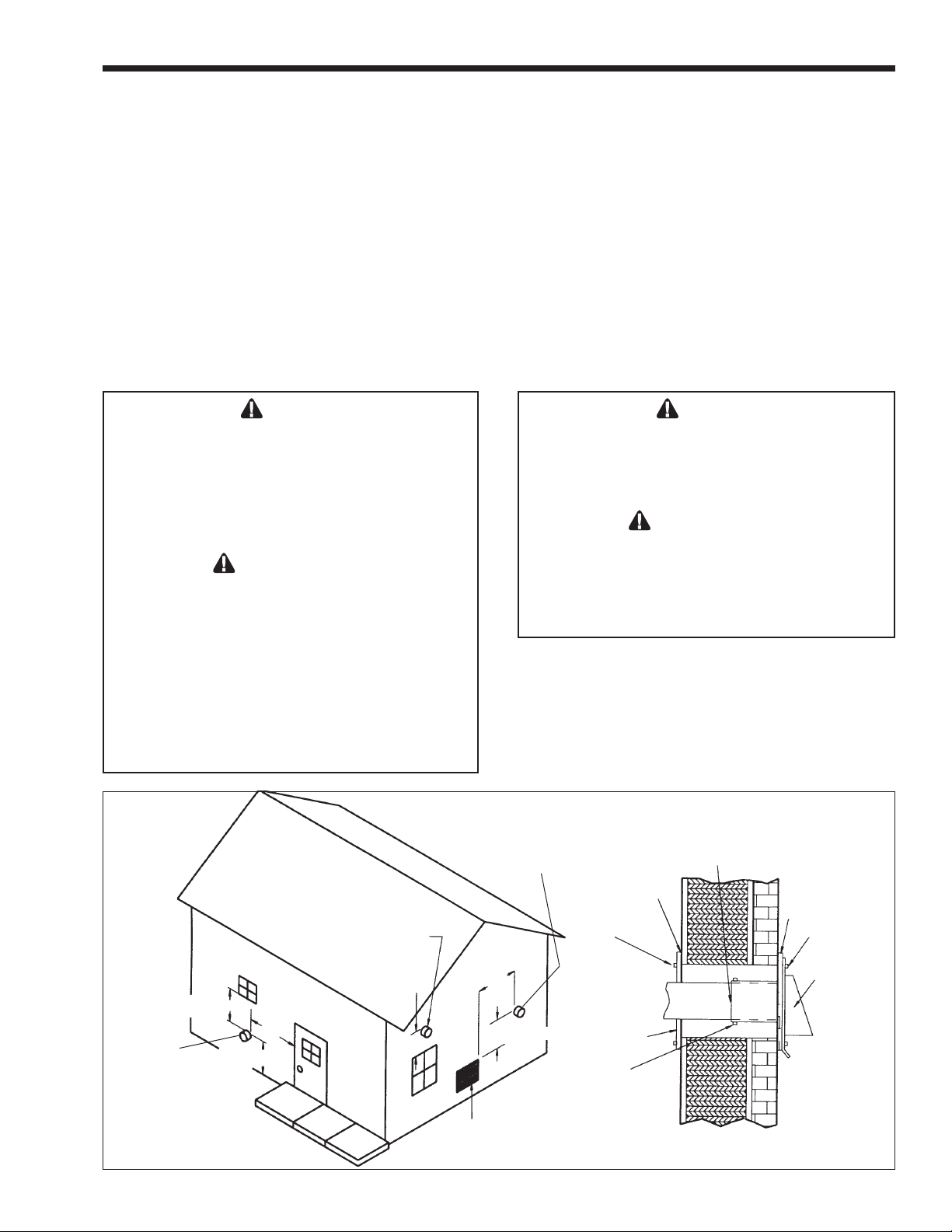

VENT TERMINAL

4 (1.2)

MIN.

VENT

TERMINAL

Dimensions in

feet (m).

Figure 6. Horizontal Vent Termination.

4 (1.2)

MIN.

12 (3.7)

MIN.

3 (0.9)

MIN.

VENT TERMINAL

LESS THAN

(3.0)

FORCED

AIR INLET

10

6 (1.8) MIN.

GRADE

CAULK JOINTS

ANCHORED

FASTENER

THIMBLE

SHEET METAL

SCREWS

SEAL ENTIRE

CIRCUMFERENCE

OF JOINT

CAULK JOINTS

ANCHORED

FASTENER

EXHAUST

HOOD

VENT TERMINAL DETAIL

Page 12

Page 12

Si ze

Diameter

No. of

Elbows

Horizontal Run Length

in.

mm

ft.

m

50 - 160

4

102

4

35

10.7

225

4

102

2

10

3.0

225

6

152

4

35

10.7

LAARS Heating Systems

Vertical vents of the induced draft JVH boilers must

be installed in accordance with the code requirement

for Category 1, Fan Assisted Appliances. Follow the

requirements as indicated in the latest edition of ANSI

Z223.1/NFPA 54, sizing of Category I Venting System

and Appendix G, or in Canada, follow the instruction

of CAN/CGA-B149 installation code.

An unused lined chimney can be used as a raceway

for single wall vent pipe, (see Figure 3). Never run

vent pipe through a ue that has another appliance

attached to it.

3D-1. Horizontal Venting - Category III

(JVH only)

When venting is horizontal, or cannot meet the

requirements of Category I, it can develop positive

pressure and must be installed in accordance with

this section and the specic vent manufacturer’s

instructions. Common venting is not allowed in

Category III systems.

BOILER VENTING

DETAIL

OUTSIDE WALL

VENT

SYSTEM

THIMBLE

BOILER

VENT TERMINAL

HOOD

Figure 7. Horizontal Venting.

SHEET METAL

SCREWS

12" (305mm)

*

MIN.

CAULK ENTIRE

JOINT, INCLUDING

THE SCREWS

*WHEN HORIZONTAL RUN

EXCEEDS 5 FT. (1.5m)

For best results, horizontal vent systems should

be as short and straight as possible. Material of vent

connectors shall be as follows:

Description Manufacturer Product

High Temperature

RTV

2" (51mm) wide

Aluminum foil tape

- adhesively backed

Dow Corning Trade Mate

Venture

Product

#3243

2" (51mm) wide

Aluminum foil tape

3M Product #433

- adhesively backed

Vent Sealing Materials.

Materials Vent Length

In U.S.A.: UL type 304, 316 or 294-C

stainless steel or equal 26 gauge minimum.

In Canada: Use "BH-Type" vent

material certied to ULD-S636 Class I

(more than 135°C, but not more than 245°C

ue gas temperature), made of AL29-4C

stainless steel or equal.

Do not use plastic venting of any kind.

Up to a maximum

of 55' (17m) of

equivalent pipe run

(including required

elbows).

The boiler vent collar must be fastened to the vent

pipe with rustproof metal screws no longer than 1/2”

(13mm) and sealed with high temperature (500ºF /

260ºC) silicone sealant. For larger diameter vent pipes,

use a sealed reducer fastened directly to the boiler

collar and seal all joints as indicated in Figure 7.

Allow the sealant to cure for 24 hours before operating

the boiler.

The entire vent system must not exceed the size

specied in Table 4.

The following criteria must be observed:

1. Attach a vertical pipe at least 12” (305mm) high

to the boiler outlet before the horizontal run if

run exceeds 5 feet (see Figure 5).

2. Support the vent run at 3’ (.9m) intervals with

overhead hangers.

3D-2. Vent Connections (JVH only)

The vent system must be gas tight. All seams and

joints must be sealed with silicone sealant or adhesive

tape having a minimum temperature rating of 400°F

(204ºC). Use at least three corrosion resistant screws at

each slip joint, when required.

For each elbow eliminated, add 5’ (1.5m) of allowable vent.

Table 4. Horizontal Venting Conguration.

3. Pitch down the vent run, toward the vent terminal

(hood), 1/4” per foot (20mm per meter).

4. Do not locate any joint screws at the bottom of

the vent run.

3D-3. Vent Termination (JVH only)

The side wall vent terminal (hood), Laars Part

Page 13

Mini-Therm JV

Page 13

Number D2004300 (4”) or D2000401 (6”), must be

used when the boiler is vented through a side wall.

It provides a means of installing vent pipe through

the building wall, and must be located in accordance

with ANSI Z223.1/NFPA 54, or in Canada CAN/

CGA-B149 and local applicable codes,

(see Figure 6 ).

Locate the vent terminal so that it cannot be

blocked by snow. Most codes requires termination of

at least 12” (305mm) above grade, but the installer

must follow local codes.

3E. Common Venting System

WARNING

Operation of appliances with a blocked common

vent may lead to serious injury or death. Safety

devices must be implemented to prevent blocked

common vent operation. If safe operation of all

appliances connected to a common vent cannot

be assured, including prevention of spillage of ue

gasses into living spaces, common venting should

not be applied, and appliances should each be

vented separately.

AVERTISSEMENT

Le fonctionnement des appareils avec un

système d’évacuation bloqué peut provoquer des

blessures graves, voire la mort. Des dispositifs

de sécurité doivent être installés pour éviter

le blocage des systèmes d’évacuation. Si le

fonctionnement de tous les appareils connectés

à un système d’évacuation commun ne peut

pas être assuré, y compris la prévention de la

dispersion des gaz toxiques dans les espaces

habités, on ne devrait pas installer un système

d’évacuation commun et chaque appareil devrait

être ventilé séparément.

3. Insofar as it is practical, close all building doors

and windows and all doors between the space in

which the appliances remaining connected to the

common venting system are located and other

spaces of the building. Turn on clothes dryers

and any gas burning appliance not connected

to the common venting system. Turn bathroom

exhausts, so they will operate at maximum speed.

Do not operate a summer exhaust fan. Close

replace dampers.

4. Place in operation the appliance being

inspected. Follow the lighting instructions.

Adjust thermostat so appliance will operate

continuously.

5. Test for spillage at the burner opening after ve

minutes of main burner operation.

6. After it has been determined that each appliance

remaining connected to the common venting

system properly vents when tested as outlined

above, return doors, windows, exhaust fans,

replace dampers and any other gas burning

appliance to their previous conditions of use.

7. Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code,

ANSI Z223.1. When re-sizing any portion

of the common venting system, the common

venting system should be re-sized to approach

the minimum size as determined using the

appropriate tables in Appendix G in the National

Fuel Gas Code, ANSI Z223.1.

SECTION 4.

Gas Connections

4A Gas Supply and Piping

When an existing boiler is removed from a common

venting system, the common venting system is likely

to be too large for proper venting of the appliances

remaining connected to it.

At the time of removal of an existing boiler, the

following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances

remaining connected to the common venting system

are not in operation.

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper

size and horizontal pitch and determine there is

no blockage or restriction, leakage, corrosion or

other deciencies which could cause an unsafe

condition.

WARNING

The Mini-Therm JVS and JVH boilers are

designed for use with either natural gas or LP

gas. Check the rating plate to be sure that the

boiler is designed to use the type of gas being

supplied. DO NOT ATTEMPT TO CONVERT

THIS HEATER FOR USE WITH ANY OTHER

TYPE OF FUEL.

AVERTISSEMENT

Les appareils de chauffage à faibles sont conçus

pour être utillsés avec du gaz naturel ou du gaz

de pétrole liquéé (GPL). Vériez l’information

inscrite sur la plaque signalétique du pour vous

assurer que l’appareil est conçu pour le type de

gaz fourni. NE PAS ESSAYER DE CONVERTIR

CET APPAREIL À UN AUTRE TYPE DE GAZ.\

Page 14

Page 14

LAARS Heating Systems

1. Gas piping installation must be in accordance

with the latest edition of ANSI Z223.1 and all

local codes. In Canada, the installation must be in

accordance with CSA-B149.1 and all local codes

that apply.

2. Check the gas supply to be sure that it is the

same as the gas indicated on the boiler’s plate.

Mini-Therm JVS and JVH boilers, as shipped

from the factory, are certied to operate within

the altitude range indicated on the rating plate.

If a eld conversion to a different altitude range

or different gas should be necessary, conversion

parts are available. Contact a Laars representative

or the factory for the correct part numbers to

order for conversions

Caution

Permanent damage to the gas valve will occur

if the following procedures are not followed.

Attention

Vous endommagerez la soupape de gaz

si vous ne respectez pas les procédures

suivantes.

3. Use the gures in Table 6 to size the gas inlet

piping from the gas meter to the heater. Check all

local codes for compliance before installing the

heater.

Supply Pressure Minimum Maximum

Natural Gas 5.5 Inches WC 10.5 Inches WC

(1.3 kPa) (2.5 kPa)

LP Gas 10.0 Inches WC 13.0 Inches WC

(2.4 kPa) (3.1 kPa)

Table 5. Gas Supply Pressure Requirements.

50-100'

15-30m

100-200'

30-60m

*Note: These gures are for Natural Gas (.65 Sp. Gr.), and

are based on 1/2" water column pressure drop. Check supply

pressure with a manometer, and local code requirements for

variations. For LPG, reduce pipe diameter one size, but maintain a 1/2" minimum diameter. A 'normal' number of Tees and

elbows have been taken into allowance.

Table 6. Natural Gas Pipe Size Requirements*

Gas Supply

Inlet

Tee

Fitting

3/4 3/4 3/4 1 1 1-1/4

3/4 1 1 1 1-1/4 1-1/4

To Equipment

Inlet

Boiler Size

Distance

From Gas

50 75 100 125 160 225

Meter

Pipe Size

0-50

0-15m

3" (76mm)

Figure 8. Gas Supply Piping.

1/2 3/4 3/4 3/4 1 1

DROP

HORIZONTAL

MIN.

TO BOILER

SEDIMENT TRAP

OR DRIP LEG

3 in.

(76mm) Min.

Nipple

Cap

Figure 9. Typical design for a sediment trap/drip leg.

TO BOILER

RISER

3" (76mm)

MIN.

SEDIMENT TRAP

OR DRIP LEG

Page 15

Mini-Therm JV

4. A sediment trap (drip leg) must be installed

ahead of the gas controls (see Figure 8). Fit the

trap with a threaded cap which can be removed

for cleaning.

5. Install a manual gas shutoff valve for service and

safety. Do not use a restrictive gas cock. Flexible

gas connectors, if used, must be CSA rated for

the total input rating of the boiler.

6. Disconnect the boiler and its individual shutoff

valve from the gas supply system during pressure

testing of the system at pressures higher than 1/2

pounds per square inch (psi) (3.45 kilopascals

[kPa]). If the test pressure is equal to or less than

1/2 psi (3.45 kPa), close the manual shutoff valve

on the heater during the piping pressure test.

7. If the gas supply pressure is less than required,

check for undersized pipe between the meter and

the boiler, a restrictive tting, or an undersized

gas meter. Gas supply pressures to the heater are

listed in Table 5.

NOTE: The maximum inlet gas pressure must not

exceed the specied value. The minimum value listed is

for the purpose of input adjustment. Refer to Table 5.

NOTE: The boiler and all other gas appliances

sharing the boiler gas supply line must be ring

at maximum capacity to properly measure the

inlet supply pressure. Low gas pressure could be

an indication of an undersize gas meter and/or

obstructed gas supply line.

8. The correct high re burner manifold gas

pressure is stamped on the rating plate. The

regulator is pre-set at the factory, and normally

requires no further adjustment. For two-stage

units (JVS 100-225) be sure unit is able to re at

both high and low re.

9. Before operating the boiler, the complete gas

supply system and all connections must be tested

for leaks using a leak detector solution. Do not

use an open ame.

Caution

Some leak test solutions (including soap and

water) may cause corrosion or stress cracking.

Rinse the piping with water after testing.

Attention

Certaines solultions d’essai d’étanchéité (y

compris l’eau et le savon) peuvent causer de

la corrosion ou de la ssuration. Rincez les

tuyaux à l’eau apprès l’essai d’étanchéité.

Page 15

4B Special Precautions for LP Gas

LP Gas is heavier than air and can therefore more

readily collect or “pool” in enclosed areas if provision

for proper ventilation is not made. Be sure to pay

special attention to proper ventilation for LP gas.

Locate boilers a safe distance from LP gas cylinders

and lling equipment. In the United States, consult

the “National Fuel Gas Code” (NFPA 54 / ANSI

Z223.1, latest edition) or in Canada, the Propane

Installation Code (CSA-B149.1), any local codes and

re protection authorities about specic installation

restrictions in your area.

SECTION 5.

Water Connections

5A. Water Piping

Figure 10. shows ‘typical’ plumbing installations. Be

sure to provide unions and isolation valves at the

boiler inlet and outlet so it can be isolated for service.

Check local codes for specic plumbing requirements

before beginning the installation.

An ASME pressure relief valve is supplied on

all JV boilers, and is pre-set at 30 PSI. The valve

outlet piping must discharge to a drain. Under no

circumstances should the relief valve piping be a

closed circuit.

A pressure reducing valve (automatic feed) must be

used to maintain the system at constant proper pressure

(see Figure 10). Supply properly installed purge

valves to eliminate air from each circuit.

A drain valve is supplied with the boiler, and can be

found in the plastic bag shipped with each boiler. This

valve is to be installed on the lower right side of the

boiler and is used for draining the unit. To drain the

boiler completely, open the drain valve and remove

the two drain plugs located on the lower left side of

the boiler.

Be sure to include air vent devices located at the

highest point in the system to eliminate trapped air,

and an air elimination device near the outlet side of the

JV boiler. Manual vent valves are recommended.

Hot water piping should be supported by suitable

hangers or oor stands, NOT by the boiler. Due

to expansion and contraction of copper pipe,

consideration should be given to the type of hangers

used. Rigid hangers could transmit noise through the

system caused by the piping sliding in the hangers.

It is recommended that padding be used when rigid

hangers are installed.

Gas piping should also be supported by suitable

hangers or oor stands, not the boiler.

A properly sized expansion tank must be included in

the system.

Page 16

Page 16

LAARS Heating Systems

Multi-Zone

Pump

System

JV

JV

Single Circuit System

Multi-Zone

Valve System

Primary

Secondary

Multi-Zone

Pump System

JV

JV

JV

Primary/Secondary Multi-Zone Valve System

Low Temperature Installation

KEY: PUMP CHECK VALVE VALVE ZONE VALVE UNION AUTO AIR BLEEDER

Figure 10. Typical Plumbing Installations.

Primary/Secondary Multi-Zone Valve System

JV

Page 17

Mini-Therm JV

15°F 8°C 20°F 11°C 25°F 14°C

Size Flow Rate Headloss Flow Rate Headloss Flow Rate Headloss

gpm l/s ft m gpm l/s ft m gpm l/s ft m

50 5.3 0.3 0.3 0.1 4 0.3 0.2 0.1 3.2 0.2 0.1 0

75 8 0.5 0.6 0.2 6 0.4 0.3 0.1 4.8 0.3 0.2 0.1

100 10.7 0.7 1.3 0.4 8 0.5 0.7 0.2 6.4 0.4 0.5 0.2

125 13.3 0.8 2.2 0.7 10 0.6 1.3 0.4 8 0.5 0.8 0.2

160 17 1.1 2.5 0.8 12.8 0.8 1.8 0.5 10.2 0.6 1.2 0.4

225 24 1.5 5 1.5 18 1.1 3.1 0.9 14.4 0.9 1.9 0.6

gpm = Water Flow in gallons per minute. l/s = Water ow in liters per second.

ft = Pressure drop (headloss) through the boiler in feet of water. m = Pressure drop (headloss) through the boiler in meters of water.

Notes: 1. Shaded area is the recommended ow and temperature rise.

2. Temperature rise and associated ow rates are based on high re operation at the Normal Input Rate from the rating plate.

Table 7. Temperature Rise °F °C.

Page 17

5B By-pass Piping

The following information and suggestions are made

on by-pass piping as it affects the temperature rise

at the boiler. A boiler temperature rise must be taken

on all JV boiler installations. If the temperature rise

exceeds 30°F (17°C) at full rate, it is an indication that

the boiler is not receiving adequate water ow. Check

the pump for any obstruction, replace the pump with a

larger size where necessary, or install a system by-pass

as indicated in Figures 10 and 11.

A full sized, 1¼" bypass with balancing valves is

strongly recommended for all systems, and required

when: 1) the boiler is installed without primarysecondary piping in a multiple zone system; 2) when

the return water temperature can be expected to be

lower than 120°F (44°C); or 3) whenever the system

piping on the outlet side of the boiler may allow

reduced ow through the heat exchanger, causing

excessive temperature rise (see Section 5.2).

Note: Laars strongly recommends a primary/

secondary piping system for all installations, especially

sizes 125, 160 and 225. In this system, a circulator is

dedicated to pumping the boiler only. This circulator

should be sized for the boiler head loss and ow rate.

5C Adjusting the bypass:

Refer to Figure 11. Provide a means of measuring

temperature on the inlet pipe to the boiler such as

using a strap on or infrared thermometer. Starting

with both balancing valves fully open, start the boiler.

Adjust the balancing valve on the return to the system

slowly to provide 120°F (44°C) water at the inlet to

the boiler, leaving the bypass balancing valve fully

open. As the system warms up, this valve may need

to be adjusted open. In rare cases, this valve will have

to be kept fully open, and the bypass balancing valve

adjusted toward closed to prevent heated bypass water

from satisfying the call for heat when the system is up

to temperature.

5D Alternate Auto-Bypass Operation

Use of the Laars thermostatic union, p/n 2400-030,

can provide automatic bypass operation in primary

- secondary piped systems (but cannot be used

when primary - secondary piping is not used). The

thermostatic union is installed on the outlet piping,

after the bypass assembly. It can be used in place of a

balancing valve. It opens fully at 140°F

(see Figure 11). Contact the factory for more

information.

All precautions must be taken by the installer to insure

that a maximum temperature rise through the boiler

does not exceed 30°F (17°C). The temperature rise

on boilers installed in multi-zone systems using zone

valves must be taken when the zone of the longest

length and/or the zone of the highest head loss is open.

A full size, 1¼" diameter by-pass with

balancing valve must be installed if a return water

temperature below 120°F (44°C) is expected under

operating conditions regardless of boiler size. This

may be expected in many systems, including inoor radiant and snow melt systems.

Page 18

Page 18

LAARS Heating Systems

To

System

From

System

A full size by-pass must be installed.

Figure 11. By-pass Piping.

Balancing

Valve

In

(Return)

Left Side View

Balancing Valve

or optional thermostat-

ic union, Laars P/N

2400-030. (Primary/

Secondary only)

Out

(Supply)

Drip

Leg

5E Flow Requirements

All high recovery, low volume water boilers must have

adequate ow for efcient operation. Pump selection

is critical to this goal, and pumps should be selected

to provide for system design water temperature rise.

Table 7 details temperature rise and water ow (GPM)

for the Mini-Therm boilers.

Damage from improper ow is not warranteed.

Failure to insure proper water ow through the heat

exchanger of the boiler will void the Laars warranty.

Flow can be veried by measuring the difference

in water temperatures between the boiler inlet and

outlet. For example: For a JV-100 installation, the

inlet water temperature is 160°F (71°C), and the outlet

temperature is 180°F (82°C) at Normal Input Rate

from the rating plate. That means there is a 20° (11°C)

temperature rise through the boiler. According to

Table 7, that would indicate a ow rate of 8 GPM

(0.5L/S). Temperature rise must be measured with the

longest (highest head) zone calling for heat alone.

Other factors to be considered before selecting a

pump are pipe size, the number of ttings throughout

the system, smoothness of the interior surface of the

pipe, the quantity of water owing through the pipe,

whether a glycol solution is being used, and the total

length of piping in the system. Table 8 provides

example pump selection criteria using Type L copper

piping, one zone valve and up to eight elbows for

single zone systems. Consult the factory or a qualied

system designer if you have more ttings or different

size or type of pipe.

1/2" Pipe 3/4" Pipe 1" Pipe 1-1/4" Pipe

Size Pump Pump Pump Pump

H.P. H.P. H.P. H.P.

1/25 1/12 1/25 1/12 1/6 1/25 1/12 1/6 1/25 1/12 1/6

50 50 99 390 680

75

* 35 160 300 460 640 * * * * *

100 * * 77 150 260 330 620 * * * *

125 * * 27 80 140 170 360 600 * * *

160 * * * 25 72 57 160 330 190 480 *

* * * * * * * 110 * 69 330

225

*A circulator and/or primary/secondary piping are required. Consult

factory.

1. Chart is based on 30°F (17°C) maximum temperature rise.

2. Calculations are based on Type L copper tubing with one zone

valve and eight elbows.

3. Typical circulating pumps:

SLC-25, Grundfos UP15-42F, or equivalent.

12, Grundfos UP26-42F, or equivalent.

Grundfos UP43-75, or equivalent.

Table 8. Maximum Suggested Circuit Length in Feet.

* * * * * * *

1

/25 HP=Taco 007, B&G LR-20 or

1

/

HP=B&G LR-

12

1

/

HP=B&G series HV,

6

5F Chilled Water Systems

If the boiler is installed in conjunction with

refrigeration systems, it shall be installed so that the

chilled medium is piped in parallel with the heating

boiler with appropriate valves to prevent the chilled

medium from entering the heating boiler.

When boiler piping is connected to heating

coils, which are in close proximity to refrigerated air

circulation, there must be ow control valves or other

automatic methods to prevent gravity circulation of the

boiler water during the cooling cycle.

5G Oxygen Permeable Systems

The JV boiler must not be direct connected to a

heating system utilizing oxygen permeable tubing.

Provide a water-to-water heat exchanger between

systems to prevent corrosion of ferrous metals such

as the boiler’s piping wet walls, etc. Air elimination

devices are not sufcient protection, and corrosion

damage is not covered under the limited warranty.

5H Anti-Freeze

Non-toxic HVAC anti-freeze may be added to the

hydronic system provided the concentration does

not exceed 50%, and the anti-freeze contains an anti

foamant and rust inhibitor. Follow the anti-freeze

manufacturer’s recommendations for yearly or

biannual replacement of system anti-freeze. Never use

automotive anti-freeze in a boiler system.

Page 19

Mini-Therm JV

Page 19

The preferred piping configuration for JV boilers is always using primary/secondary piping.

There are some applications that are acceptable without primary/secondary piping, see below.

LOW TEMP SYSTEMS

Pump

To

System

From

System

System Loop with Tempering Valve and Pump with Boiler Loop

To

System

From

System

To

System

with Tempering Valve and Pump

Pump

Balancing

Valve

Primary/Secondary Piping with Field Balancing

(for Fixed Low Return Temperatures)

Pump

Tempering

Valve

Tempering

Valve

Primary/Secondary

Balancing

Valve

Variable Speed

Control

Isolation Valve

Pump

Isolation Valve

Pump

Isolation

Isolation Valve

JV

Isolation

Valve

JV

Valve

Isolation

To

System

From

System

Primary/Secondary Piping with Automatic By-Pass

System

System

System

To

From

To

Pump

Auto

By-Pass

Valve

Balancing

Valve

Pump

Balancing

Pump

Primary/Secondary Piping with By-Pass

(for Fixed Low Return Temperatures)

Laars

Thermostatic

Union

PN 2400-030

Pump

Valve

Pump Isolation

Valve

Isolation

Valve

Valve

Isolation

Valve

Isolation

Valve

JV

JV

JV

120°+

From

System

Primary/Secondary Piping with Variable Speed Injection

Pump

Isolation

Valve

From

System

Primary/Secondary Piping with Laars

Thermostatic Union as an Automatic Bypass

Balancing

Valve

Isolation

Pump

Valve

NON-LOW TEMPERATURE SYSTEMS

(120°F+ Return Temps)

Pump

Isolation

Valve

Isolation

Valve

To

System

From

System

Tempering

Valve

Pump

Tempering Valve with System Loop

and Boiler Loop Pump

Isolation Valve

Pump

Isolation

Valve

JV

To

System

From

System

Simple Primary/Secondary Piping-Hydronic-Not Low Temp

Pump

Figure 12. Typical Plumbing Diagrams.

NOTE: All closed loop systems should include air elimination, expansion tank and feed water inlet. Place at point of lowest

pressure (typically at the inlet of pump).

NOTE: Ball valves should not be used as balancing valves. Only use for shutoff apps.

JV

JV

Page 20

Page 20

LAARS Heating Systems

SECTION 6.

6A. Electrical Wiring

Follow these instructions to make the necessary

initial electrical connections.

1. Remove the two screws attaching the front cover

of the control box.

2. There are wires coiled in the area on the right

side of the control box, supplied with wire nuts:

black wires and white wires.

3. Follow the schematic in Figures 14A. and 14B.

Remove the wire nut from the two sets of wires,

and connect the hot lead from the 115V power

supply, and the neutral lead to the white wires.

4. Attach the leads from the wall thermostat to

the terminal strip, located on the left side of the

control box.

5. Check the boiler wiring and pump for correct

voltage, frequency and phase. If the pump circuit

is other than 115V, be sure there is an appropriate

transformer or relay installed. The pump relay is

suitable for pumps of 1/3 HP or less (max 5A).

6. For systems with multiple zone pumps or valves

(see Figure 17).

WARNING

The boiler must be electrically grounded in

accordance with the requirements of the authority

having jurisdiction or, in the absence of such

requirements, with the latest edition of the national

Electrical Code, ANSI/NFPA 70, in the U.S. and with

the latest edition of CSA C22.1 Canadian Electrical

Code, Part 1, in Canada. Do not rely on the gas or

water piping to ground the metal parts of the boiler.

Plastic pipe or dielectric unions may isolate the boiler

electrically. Service and maintenance personnel who

work on or around the boiler may be standing on wet

oors and could be electrocuted by an ungrounded

boiler.

AVERTISSEMENT

La chaudière doit être mis à la terre conformément

aux prescriptions de l'autorité ayant juridiction ou,

en l'absence de telles exigences, avec la dernière

édition du national Electrical Code, ANSI/NFPA

70, aux ÉTATS-UNIS et à la dernière édition de la

norme CSA C22.1 Code électrique canadien, partie

1, au Canada. Ne pas compter sur le gaz ou l'eau

tuyauterie à la masse des pièces métalliques de la

chaudière. Tuyau en plastique ou diélectrique les

syndicats peuvent isoler la chaudière électrique.

A means of disconnecting the electrical supply must

be provided within sight of the boiler. The pump and

boiler must be wired as shown to insure that the pump

is running whenever the boiler is ring.

Flow Switch: If the system includes a ow switch,

it should be wired in series with the high-limit switch.

The boiler will not re unless the pump is running and

the ow switch is closed.

Field installed safety devices and operating

controllers, such as valve end switches, relays, timers,

can be connected to the boiler through the wall

thermostat circuit. Do not exceed a draw of 40VA on

the transformer secondary. A 2-Amp fuse is here to

protect the transformer.

Terminals

Figure 13A

Figure 13B

6B. Outdoor Reset.

To comply with Federal Law, the Mini-Therm JV

automatically sets water temperature based on outdoor

temperature. A sensor (E2347400) supplied must

be located outdoors yet out of direct sunlight. If not

connected, the boiler may not be fully functional.

Connect the sensor to the terminals labeled "COM"

and "OUTDOOR" located on the left side of the

control box, using outdoor rated min 24 gauge wire.

(See Figures 13A and 13B)

Page 21

Mini-Therm JV

(220V OPT)

TRANSFORMER

24V 115V

R

CURVE

WWSD

DHW CALL

HEAT CALL

POWER

12

34

BOILER

SENSOR

120 VAC L

SWITCHED 120 VAC TO PUMP

0.4

2.0

3.6

OFF ON

FIELD

WIRING

INDUCER FAN

BK

BL

BOX

R

R

PILOT

HSI

BOILER

SENSOR

HI

LIMIT

FAN

PROVING

FLAME

ROLL

OUT

DIVIDER

W

BK

(Fourni Lors De

Boiler

Pump 5A Max

(Field Supplied)

Pompe À Chaleur

L'Installation)

R

W

FUSE

O BK

24

3 1

BR

BL

INDUCED DRAFT

MODEL JVH

Y

GAS VALVE/

CONTROLLER

SV9501, SV9601

FAN

Y

R

HOT CHAUD

115/60HZ (220V50Hz OPTIONAL)

POWER SUPPLY

NEUTRAL

NEUTRE

GROUNDING

CONDUCTOR

CABLE DE MISE

A LA TERRE

W

Y

P

G-VERT

G-GREEN

P-MAUVE

P-PURPLE

BK-BLACK

BK-NOIR

W-WHITE

W-BLANC

R-RED

R-ROUGE

Y-YELLOW

Y-JAUNE

BL-BLUE

BL-BLEU

BR-BROWN

BR-BRUN

O-ORANGE

O-ORANGE

THE BOILER WILL NOT OPERATE

WITHOUT THE AUTOMATIC VENT

DAMPER. THE VENT DAMPER WIRE

HARNESS MUST BE INSERTED INTO

THE VENT DAMPER RECEPTACLE.

IN CANADA:

SOME UNITS ARE

SUPPLIED WITH VENT DAMPER

JUMPER PLUG. DO NOT REMOVE

JUMPER UNLESS VENT DAMPER

IS TO BE INSTALLED.

LA CHAUDIÈRE NE FONCTIONNERA

PAS SANS LE VOLET MOTORISÉ

AUTOMATIQUE. LE F AISCEAU DE

CÂBLES DU VOLET MOTORISÉ DOIT

ÊTRE INSÉRÉ DANS LA PRISE DU

VOLET MOTORISÉ

AU CANADA: CERTAINS APPAREILS

SONT MUNIS D’UN CAVAL IER DE

VOLET MOTORISÉ. NE PAS RETIR ER

LE CAVALLIER À MOINS Q UE LE

VOLET MOTORISÉ NE SOIT INST ALLÉ

NOTE:

1. 4-PIN MOLEX AS VIEWED FROM REAR OF BOARD.

INTENDED SIZE:

C

B

1

2

3

4

SOFTWARE

DWG. NO:

B

SHEET 1 OF 1

REV.

AE23446

HOT SURFACE IGN. NAT/LP

WIRE DIAGRAM JVH

1/8"

TITLE:

FRACTIONS

1

.010 DECIMALS .XXX

.03DECIMALS .XX

.1

S

PM 9-20-11

N/A

N/A

FINISH

MATERIAL:

TOLERANCES ARE:

DECIMALS .X

DIMENSIONS ARE IN INCHES.

UNLESS OTHERWISE SPECIFIED:

APPR

ENGR

DRAFT

APPROVALS

ANGLES

DO NOT SCALE DRAWING.

THIRD ANGLE PROJECTION.

SCALE: NONE

SYS

COM

OUT

HEAT CALL

COM CALL

DHW CALL

Page 21

Figure 14A. Wiring Diagram, JVH

Page 22

Page 22

LAARS Heating Systems

IR ER

SOME UNITS ARE

ÊTRE INSÉRÉ DANS LA PRISE DU

VOLET MOTORISÉ

AU CANADA: CERTAINS APPAREILS

SONT MUNIS D’UN CAVAL IER DE

CÂBLES DU VOLET MOTORISÉ DOIT

LA CHAUDIÈRE NE FONCTIONNERA

AUTOMATIQUE. LE F AISCEAU DE

IS TO BE INSTALLED.

THE VENT DAMPER RECEPTACLE.

IN CANADA:

SUPPLIED WITH VENT DAMPER

JUMPER PLUG. DO NOT REMOVE

WITHOUT THE AUTOMATIC VENT

DAMPER. THE VENT DAMPER WIRE

HOT CHAUD

POWER SUPPLY

NEUTRAL

NEUTRE

GROUNDING

CONDUCTOR

CABLE DE MISE

115/60Hz (220V/50Hz OPTIONAL)

A LA TERRE

HARNESS MUST BE INSERTED INTO

THE BOILER WILL NOT OPERATE

PAS SANS LE VOLET MOTORISÉ

JUMPER UNLESS VENT DAMPER

VOLET MOTORISÉ. NE PAS RET

LE CAVALLIER À MOINS Q UE LE

VOLET MOTORISÉ NE SOIT INST ALLÉ

Pompe À Chaleur

Boiler Pump 5A Max

(Field Supplied)

(Fourni Lors De L'Installation)

JVS H2355500D

W

BK-NOIR

R-ROUGE

W-BLANC

BL-BLEU

BR-BRUN

P-MAUVE

Y-JAUNE

W

BK

BK-BLACK

W-WHITE

R-RED

Y-YELLOW

BOX

DIVIDER

24V 115V

TRANSFORMER

(220V OPT)

1. 4-PIN MOLEX AS VIEWED RNOTE:

FROM REAR OF BOARD.

Y

R

Y

Y

Y

BK

FUSE

3.6

2.0

CURVE

0.4

FIELD

WIRING

12

3

BOILER

4

SENSOR

COM CALL

DHW CALL

1 2 3 4

OFF ON

WWSD

POWER

DHW CALL

HEAT CALL

120 VAC L

SWITCHED 120 VAC TO PUMP

SYS

OUT

COM

HEAT CALL

INDUCER FAN

Pilot Burner

with Spark

Electrode Sensor

R

BL

BK

SPARK

G-VERT

O-ORANGE

BL-BLUE

BR-BROWN

O-ORANGE

P-PURPLE

G-GREEN

Veilleuse À

Capteur

D'Électrode À Étincelles

Figure 14B. Wiring Diagram, JVS

R

SENSOR

TEMPERATURE

BL

(2-STAGE ONLY)

Y

Limite

High Limit

Supérieure

6

O

54

321

Power Venter Receptacle

P

R

Roll-Out

See Doc. 1077

Prise De Ventilation

À Air Pulsé (Voir Manuel)

BKBK

Switch

Limiteur

De Retour

De Falmme

BK

t

Safety

Switch

Blocked

Ven

43

Vent Damper Receptacle

Prise Du Faisceau De

Câbles De Volet Motorisé

R

R

JUMPER

1 2

CAVALIER

IGNITION

CONTROL

8 MV

7 TH-W

6 24V

4 GND

3 PV

Y

C

MV

BR

Disconnect

for 2 stage

operation

5 24 V (GR)

O

9 SPARK

BK (2-STAGE ONLY)

Gas Valve

HW VR8304

PV

H

HW VR8304

Soupape De Gaz

2 MV/PV

1 MV

BR

Y

REMOTE FLAME SENSOR

Page 23

Mini-Therm JV

Y

O

BR

IGNITION CONTROL

2nd STAGE ONLY

GAS VALVE

MV

MV/PV

PV

H

BK

TEMP CONTROL

3

5

PV

C

6

MV

BLOCKED

VENT

ROLLOUT

SW

BKBKBK

POWER VENTER

HI LIMIT

BL

1

DAMPER

R

24

GND

R

R

BK

N

JVS

BK

TEMP CONTROL

PUMP

5A MAX

TRANSFORMER

110 VAC

FUSE

2A

P

TEMP

CONTROL

TEMP

CONTROL

FAN

PROVING

ROLLOUT

SW

GAS VALVE

R

24

GND

R

BL

R

N

JVH

BK

TEMP CONTROL

BOILER

PUMP

TRANSFORMER

110V

110 VAC

FUSE

1

BR

INDUCER

FAN

TEMP CONTROL

CONTROL

RLY

CONTROL

RLY

24V

31

TEMP

CONTROL

HI LIMIT

GAS

VALVE

4

Page 23

JVH PILOT

1.25

(32)

Figure 15A. JVH Ladder Diagram

0.16

(4)

MAIN BURNER

FLAME PATTERN

Figure 15B. JVS Ladder Diagram

1.25

(32)

JVS PILOT

0.10 TO 0.35

(3 to 9)

MINIMUM FLAME

LENGTH

0.50

(13)

Figure 16. Main Burner/Pilot Flame Pattern.

Dimensions in

inches (mm).

MINIMUM FLAME

LENGTH

0.50

(13)

Page 24

Page 24

COM

HEAT

LAARS Heating Systems

Wiring

with Taco

Zone Valves

COM

HEAT

COM

HEAT

Wiring with

Honeywell

Zone Valves

Wiring

with Multiple

Zone Pumps

Figure 17. Multiple Zone Wiring.

Page 25

Mini-Therm JV

SECTION 7.

7A Filling the System

Page 25

It is crucial to the efcient operation of the system

that all air be removed from the circuit. For this

reason, an air scoop and vent should be located close

to the boiler outlet, and there should be a minimum

distance between cold water feed and system purge

valve.

1. When the system has been completely installed,

close all air vents and open the makeup water

valve. Allow the circuit to ll slowly.

2. If a make-up water pump is employed, adjust the

pressure to provide a minimum of 12 psi (83kPa)

at the highest point in the circuit. If a pressure

regulator is also installed in the line, adjust it to

the same pressure.

3. Close all valves. Purge one circuit at a time as

follows:

a. Open one circuit drain valve and let water

drain out for at least 5 minutes. Be certain

there are no air bubbles visible in the water

stream before closing the drain valve.

b. Repeat this procedure for each circuit.

4. Open all valves after all circuits have been

purged.

5. Run the system circulating pump for a minimum

of 30 minutes with the boiler shut off.

6. Open all strainers in the system, and check for

debris.

7. Recheck all air vents as described in Step 3.

8. Inspect the liquid level in the expansion tank,

with the system full of water, and under normal

operating pressure, to ensure proper water level

in the expansion tank.

9. Start up boiler according to the procedures

described in Section 2 and operate the system,

including the pump, boiler, and radiation units,

for one hour.

10. Recheck the water level in the expansion tank. If

it exceeds 1/2 of the volume of the tank, open the

tank drain and reduce the water level.

11. Shut down the entire system, and vent all

radiation units and high points in the system.

12. Close the water makeup valve and check the

strainer in the pressure reducing valve for

sediment or debris. Reopen the water makeup

valve.

13. Verify system pressure with the boiler pressure

gauge before beginning regular operation.

14. Within 3 days of start-up, recheck and bleed

all air vents and the expansion tank using these

instructions.

Page 26

Page 26

SECTION 8.

Operating Procedures

Before placing the boiler in operation, check and

reset the safety shutoff devices. Once the boiler is

connected to the gas and water piping and after all the

requirements in previous pages have been met, follow

these procedures:

LAARS Heating Systems

8A. System Start-up

1. Verify that the pump system is operating

properly:

a. Shut off the manual gas valve located

outside the boiler.

b. Raise the wall thermostat high enough to

call for heat.

c. The pump should come on immediately. If

it does not, test the electrical circuits.

2. Pilot and Main Burner Lighting:

a. The JV boiler does not require manual

lighting. The pilot is controlled by the

automatic ignition system.

b. Different models of the JV boiler utilize

various gas valves. Although the gas valves

may have different control knobs, they are

all similar in operation.

c. Understand and follow the operating

instructions that are applicable to the type

of ignition system installed on the boiler.

3. The pilot and main burners will automatically

ignite when there is a call for heat.

8B. Sequence of Operation

1. Wall thermostat will call for heat.

2. Pump relay will turn on the circulating pump.

3. If water temperature is below the limit setting,

the inducer motor relay will turn on the draft

inducer (JVH).

4. Pressure switch will sense the fan (JVH only)

operation and send 24 volts to the ame rollout

switch.

5. In normal conditions, the ame rollout switch

will be in a closed position. 24 volts will be sent

to the gas valve/controller, the igniter will

glow/spark and the pilot valve will open, lighting

the pilot.

6. After pilot is proven to be lit, the main gas valve

will open, the main burners will ignite and

continue until either the primary control, hi-limit

or wall thermostat opens.

7. When the wall thermostat is satised, the burners

will shut off. The relays will turn off the draft

inducer (JVH only) and the circulating pump.

When the room temperature falls below the wall

thermostat setting, the cycle will repeat.

Page 27

Mini-Therm JV

Page 27

8C. Operating Instructions

Mini-Therm JVH

Page 28

Page 28

LAARS Heating Systems

8D. Operating Instructions

Mini-Therm JVS

Page 29

Page 29

1.

Control Access

2.

Panel

Figure 18A.

8.E Operating Temperature Controls

Note: The Temperature Controllers, the Dip switch

panel, and the LED panel can be found under the

Control Access Panel after removing the bolts.

Two temperature controls are now standard on all

JVS and JVH boilers.

1. The primary temperature controller maintains

all normal heating operations.

2. A secondary, mechanical high-limit aquastat

provides safe shutdown, should the primary

controller fail.

Important: If the secondary controller (See Figure

18A and Figure 18B) dial is set below 220F, it may

inhibit proper operation of the primary controller.

Prior to calling for technical support, please ensure

high limit control is set for at least 220F.

Figure 18B. Secondary, mechanical high-limit

aquastat

Pump Operation. When a call for HEAT and/

or DHW is present the boiler pump will turn on. Post

purge can be selected via dip switch #5, Pump Post

Purge Inactive (Off) /Active 3 min. (On). In the On

position the pump will continue to run for 3 min after

the last call has been satised. When the dip switch is

Off there is no post purge of the pump, the pump turns

off immediately after the last call is removed. Laars

strongly recommends using a pump post purge. During

WWSD and a call for HEAT is present the pump will

remain off.

Pump Exercising The control exercises the

boiler pump every 3 days of inactivity. While the

control is exercising the pump all LEDs will turn off

and the power LED will ash for 10 seconds.

Staging (where applicable – factory setting):

Dip #1 is used to select the number of stages: 2-Stage

(Off) / Single Stage (On).

Note: Use of 2-Stage operation may reduce

efciency.