Page 1

Installation and Operation Instructions Document 2101B

Installation

and Operation

Instructions for

Mini-Combo id

Model MCH

Induced Draft

Residential Gas-Fired

Space/Water Heater

Note: This document is to be used in conjunction with Document 1080, Installation and Operating

Instructions for Mini-Therm JVi boilers.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause injury or property

damage. Refer to this manual. For assistance or additional information consult a qualified installer,

service agency, gas supplier, or call the factory.

H2100200B

Page 2

Page 2

LAARS Heating Systems

TABLE OF CONTENTS

SECTION 1.

General Information

1A. Hazards and Your Safety —

Hot Water Can Scald!...................................3

SECTION 2.

Installation .................................................

2A. Location........................................................ 5

2B. Heater Placement.........................................5

2C. Piping ........................................................... 5

2D. Wiring ...........................................................6

3

Page 3

Mini-Combo id

Page 3

SECTION 1.

General Information

WARNING

This manual supplies information on the application,

installation and operation of the indirect water

heater unit.

operation of the hydronic boiler (Document 1080) is

supplied along with this manual. Both manuals

should be reviewed completely before proceeding

with the installation.

• Failure to follow the instructions provided may

result in personal injury, death or substantial

property damage.

• Any modifications to the boiler, water tank, gas

and water connections, or wiring may void

warranty.

• Consult the factory or local factory

representative with any questions or problems

regarding this equipment.

Hazards and Your Safety — Hot Water

Can Scald!

Consumer Product Safety Commission and some

states/provinces recommend a temperature setting of

130°F (54°C) or less. The water heater thermostat is

factory set to approximately 120°F (49°C). If

thermostat will be set above factory setting, install an

anti-scald valve at either the water heater or at each

hot water faucet.

A complete instruction manual of the

• Studies have indicated that dangerous bacteria

can form in potable water distribution system if

certain minimum water temperatures are not

maintained. Contact local health department for

more information.

SECTION 2.

Installation

This installation must conform with the

instructions in this manual and, where applicable:

• Local, state, provincial, and national codes, laws,

regulations and ordinances.

• In Canada — CAN/CGA B149.1 or B149.2

installation Code.

Where the recommendations made in this manual

differ from local or national codes, the local or

national codes take precedence.

2A. Location

This water heater/boiler unit is not intended for

outdoor installation. Select a convenient location

where water leakage from the tank or connections will

not result in damage to areas adjacent to the appliance

or to lower floors of the structure. When a safe

location cannot be found, install a suitable drain pan

under the appliance, and pipe it to an adequate drain.

• Tempering valves are not anti-scald valves since

they do not have a positive shutoff in case cold

water supply fails. They are not recommended

for shower/tub service. If needed, install an antiscald valve at each shower/tub.

• Water heated to a temperature suitable for

clothes washing, dish washing and other

sanitizing needs can scald and cause permanent

injury.

• Children and elderly, infirm, or physically

handicapped persons are more likely to be

injured by hot water. Never leave them

unattended in a bathtub or shower. Never allow

small children to use a hot water tap or draw

their own bath. If anyone using hot water in the

building fits this description, or if state/province

laws or local codes require certain water

temperature at hot water taps, take special

precautions:

Install an anti-scald valve at water heater or at

each hot water faucet, bath, and shower outlet.

Use lowest practical temperature setting.

2

(51)

63.5

(1613)

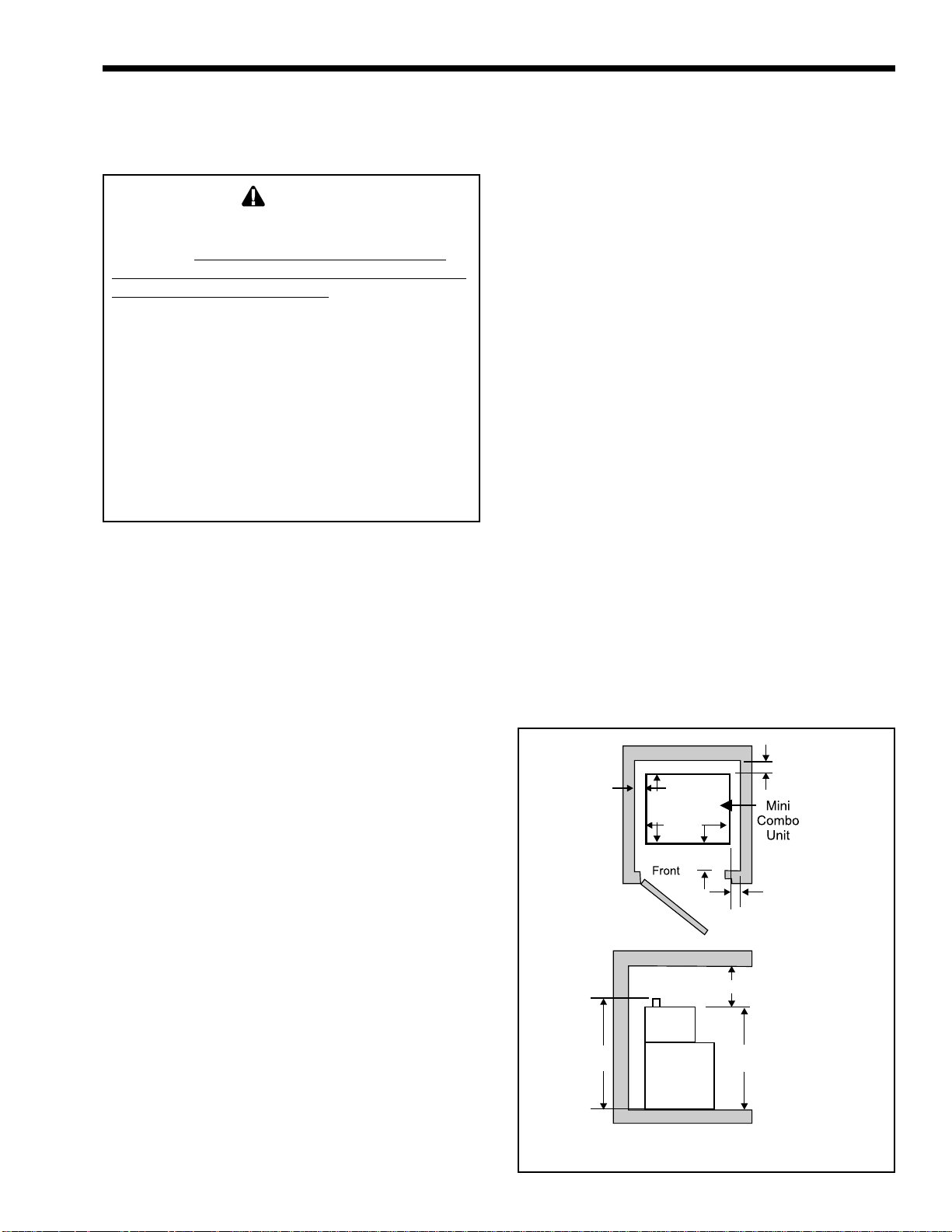

Figure 1. Closet Installation.

25.25

(641)

29

(737)

4 (102)

Top Clearance

23 (584)

57.75

(1467)

2 (51)

2

(51)

Dimensions

shown in inches

(mm).

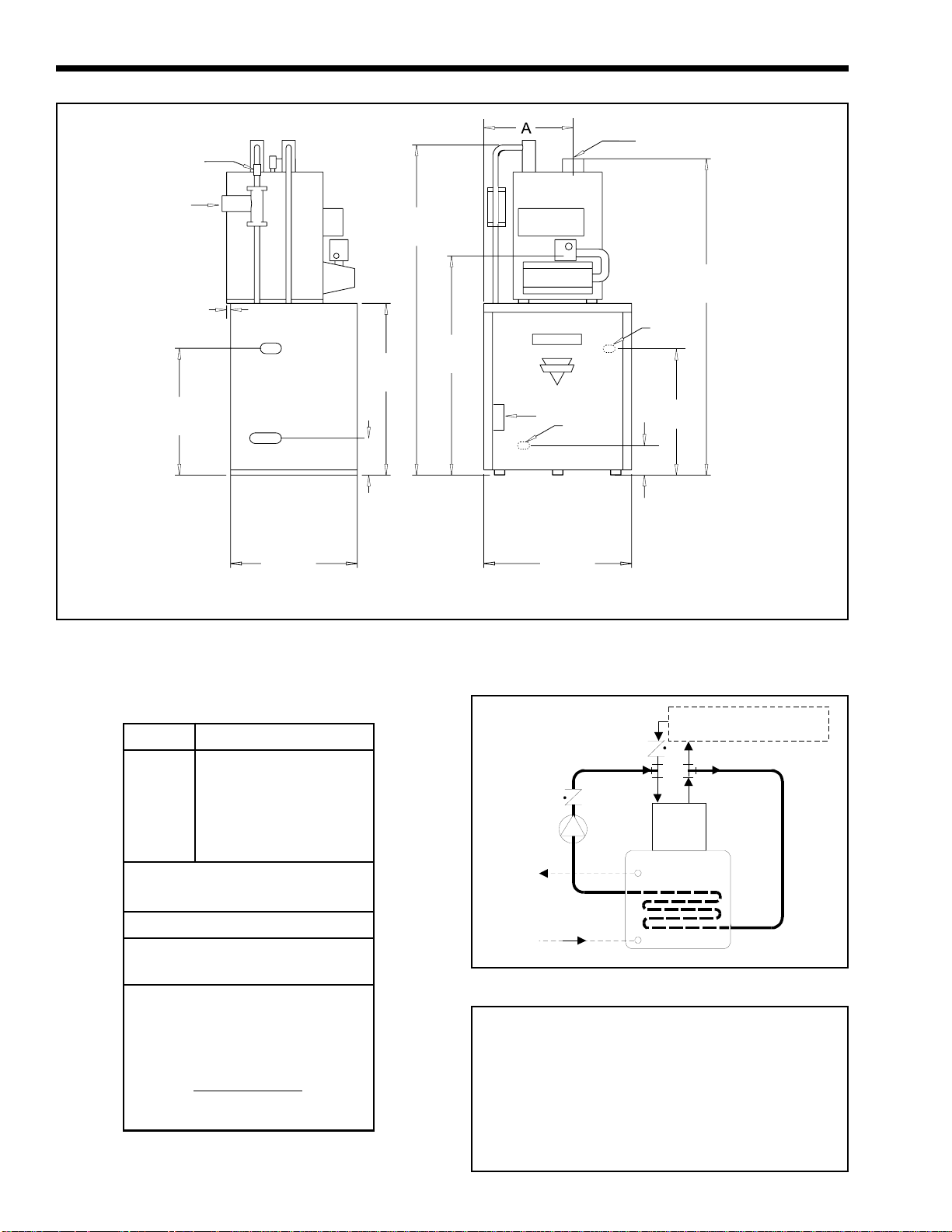

Page 4

Page 4

Check Valve

Tank

Pump

.75

(19)

24

(610)

Domestic

Hot Water

Outlet

Cold Water

Inlet

32.5

(826)

62.5

(1588)

41.5

(1054)

Tank

Aquastat

Drain

Valve

LAARS Heating Systems

Boiler Flue Collar 4 (102)

60

(1521)

Tank

Relief

Valve

24

(610)

7

(178)

(610)

Figure 2. Dimensional Information.

Dimensions inches mm

Size A

50 14 356

75 15 381

100 16 406

125 17 432

Boiler In/Out NPT

(all sizes) 1¼

Gas NPT (all sizes) ½*

Domestic Hot Water (all sizes)

Inlet/Outlet NPT ¾

Minimum clearances from

combustible surfaces:

Left Side: 2" 51mm

Right Side: 2" 51mm

Rear: 2" 51mm

Front: 4" 102mm Top: 23" 584mm

Service clearances:

Allow 4" 102mm on each side

for piping access.

7

(178)

24

Side View Front View

Hot

Water

Supply

Cold

Water

Supply

28

(711)

Figure 3. Piping Schematic.

Dimensions shown

in inches (mm).

Space Heating -

Refer to Doc u me n t 1 080

Boiler

Tank

*¾" for model 125 Natural.

Figure 4. Typical Expansion Tank Installation.

Page 5

Mini-Combo id

Page 5

2B. Heater Placement

The heater must be placed to provide clearances

on all sides for maintenance and inspection. Allow 4

inches on each side for piping access. There must also

be minimum distances maintained from combustible

surfaces. Figure 1 shows minimum clearance from

combustible surfaces. The Mini-Combo unit can be

installed in a closet, as long as the minimum

clearances are maintained. Special attention should be

paid to the air supply opening to the closet. Refer to

Table 1.

Net Free Area — square inches sq. cm

Model Inside Air Outside Air

MC50 100 645 15 97

MC75 100 645 20 129

MC100 100 645 25 161

MC125 125 806 32 206

Area indicated is for one of two openings: One at floor level and

one at the ceiling, so the total free area would be double the

figures indicated. Refer to Document 1080 for more information.

Table 1. Minimum Recommended Air Supply.

persons. Attach run-off tube to T&P valve and

run tube within 6" (152mm) from floor. No

reducing couplings, valves, or any other type of

restriction is to be installed in this line. This runoff tube must be installed to allow free and

complete drainage of both valve and run-off tube.

• Filling Storage Water Tank

1. Open hot water faucet in house to allow air

in the tank and in piping to escape.

2. Open shut-off valve(s) in cold water supply

line.

3. Open shut-off valve(s) in hot water supply

line.

2C. Piping

• To prevent damage to the unit, all soldering is to

be done prior to assembling the cold and hot

water, and any other connections to the tank.

• Use suitable pipe dope or tape.

• Before piping the boiler to the heating system,

be sure to install the system check valve

(provided with the unit) onto the inlet (return)

tee of the boiler with arrow pointed downward

(see Figure 3).

• If anti-freeze is used in boiler system, local codes

may require a backflow preventer on cold supply

line. Use anti-freeze specifically intended for

hydronic heating system. Inhibited propylene

glycol is recommended.

WARNING

Do not use automotive or ethylene glycol antifreeze, or any undiluted anti-freeze. This can

cause severe personal injury, death or substantial

property damage.

If a backflow preventer, pressure reducing valve

or check valve is in cold water supply, install an

expansion tank on cold water supply line (see

Figure 4) to prevent normal thermal expansion from

repeatedly forcing open the T&P relief valve.

• T&P relief valve's discharge piping must be

directed so that hot water flows away from all

Figure 5. MCH Schematic.

Page 6

Page 6

LAARS Heating Systems

WALL

THERMOSTAT

(FIELD

SUPPLIED)

R

W

A

TERMINAL

STRIP

BL

SENSOR

R

AQUASTAT

(OPTIONAL)

BK - BLACK

W-WHITE

R-RED

Y-YELLOW

BL - BLUE

BR - BROWN

O-ORANGE

P-PURPLE

G-GREEN

BL/Y - BLUE/YELLOW STRIPE

BR/Y - BROWN/YELLOW STRIPE

IF ANY OF THE ORIGINAL WIRE (AS

SUPPLIED WITH THE APPLIANCE) MUST

BE REPLACED, IT MUST BE REPLACED

WITH APPLIANCE WIRING MATERIAL

SUITABLE FOR 105 DEGREES C OR ITS

EQUIVALENT

115V-FACTORY WIRED

115V-FIELD WIRED

24V-FACTORY WIRED

24V-FIELD WIRED

Figure 6. Wiring Diagram.

BR

P

R

PRESSURE

SWITCH

ROLL-OUT

SAFETY

SWITCH

AQUASTAT

R

HIGH

LIMIT

TANK

24V

COM

SEN

NC

P

GAS VAL VE

MOLEX

COM

BL

TRANSFORMER

R

NO

P

O

BL

Y

R

O

Y

Y

P

24V 115V

G

Y

R

R

Y

R

R

BL

Y

R

R

R

4

265

4

265

4

265

ZONE

PUMP

RELAY

1

3

1

3

TANK

PUMP

RELAY

1

INDUCER

MOTOR

RELAY

3

BK

W

BK

BK

BR

BK

BR

PUMP

(FIELD

SUPPLIED)

BR

INDUCER

W

W

Y

W

HOT

115/60HZ

POWER SUPPLY

NEUTRAL

GROUNDING

CONDUCTOR

TANK

PUMP

MODEL MCH

H2021000A

4. When water discharges from the faucet,

close it. Check for system leaks and repair

if necessary.

• Filling and connecting boiler pipes:

Consult the JV boiler manual, Document 1080.

Caution

Never use water heater/boiler unless it is

completely filled with water.

2D. Wiring

Priority System: Under this wiring the storage

tank will be supplied before space heating. This will

insure that it gets adequate hot water flow from the

boiler to maintain a fully rated delivery of domestic

hot water.

Caution

In this priority mode, any demand for space heating

is postponed until the storage water tank has

reached set temperature. This delay in supplying

the space heating zones is usually not noticed by

the inhabitants of the living spaces. However, in the

event of certain storage water tank malfunctions,

space heating could be delayed indefinitely. If

undetected and un-corrected, freezing damage to

piping could result.

WARNING

Electrical shock can cause severe personal injury or

death. Disconnect power supply to the boiler before

doing any electrical work.

Electrical Connection (see Figures 5 and 6).

1. Remove the two screws attaching the front cover

of the control box.

2. There are six wires coiled in the area on the right

side of the control box, supplied with wire nuts:

2 black wires twisted together, 3 white wires

twisted together, and a brown wire.

3. Follow the schematics in Figures 5 and 6.

Remove the wire nut from the two black wires,

and connect the hot lead from a 115 volt power

supply to both wires. Secure the three wires in

the wire nut.

4. The three white, neutral wires should be joined

to the other neutral lead coming from the 115

volt power supply, and the neutral lead coming

from the pump (space heating).

5. The brown wire attaches to the hot side of the

space heating pump.

Page 7

Mini-Combo id

Page 7

115 Volts Supply

Transformer

Sequence of Operation

Tank Stat

(common)

Domestic Demand

(N.C.)

Tank Pump

(energized)

Heating Demand

(N.O.)

Heating Pump

(energized)

High Limit

Switch

Inducer

Energized

Fan Proving

Switch

Flame Roll-Out

Safety Switch

Main Gas Valve

(energized)

Figure 7. Sequence of Operation.

Boiler On

Page 8

Page 8

LAARS Heating Systems

Figure 8. Parts Identification.

Page 9

Mini-Combo id

# Qty Part # Description

1 1 20085700 Weldment, Panel, Base

2 1 20085600 Weldment, Panel, Top

3 1 20086300 Weldment, Panel, Door

4 1 20086400 Panel, Side, Right

5 1 20127900 Weldment, Panel, Side, Left

6 1 20085900 Panel, Rear

7 1 20086500 Panel, Access

8 1 20084000 Bracket, Mounting, Left

9 4 20085400 Bracket, Support, Tank

10 2 P2019200 Cross, Black Iron, 1¼" NPT

11 4 P2014800 Fitting, Brass Compression,

7

/8" OD x ¾"

12 1 A2085600 Valve, Check, ¾" NPT

7

13 7.2ft P2015000 Tubing, Copper, Type “L”,

/8" OD

14 1 A2085700 Valve, Drain, Tank, ¾" NPT

15 1 E0205000 Temperature Control, Electronic

16 1 A2085400 Valve, Relief, Temp & Pressure

17 1 A2085301 30 Gal. Water Tank,

Double Wall HX

1 A2085300 30 Gal. Water Tank,

Single Wall HX

18 2 20087300 Door Latch Assembly

19 1 A0066500 Pump, Circulator

20 1 A2086600 Valve, Check, 1¼" NPT

21 1 A2087600 Handle, Door

22 2 A2086700 Flange, Pump, ¾" NPT

23 1 A2085900 Well, Immersion, ¾" NPT

24 1 A2000400 Gauge, Pressure/Temperature

25 1 A2000600 Gauge, Temperature

26 1 20084001 Bracket, Mounting, Right

27 1 E2103100 Sensor

Page 9

Page 10

Page 10

LAARS Heating Systems

Page 11

Mini-Combo id

Page 11

Page 12

Laars Heating Systems Company reserves the right to change specifications, components, features, or to discontinue products without notice.

800.900.9276 • Fax 800.559.1583 (Customer Service, Service Advisors)

20 Industrial Way, Rochester, NH 03867 • 603.335.6300 • Fax 603.335.3355

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 • 905.238.0100 • Fax 905.366.0130

www.Laars.com Litho in U.S.A. © Laars Heating Systems 0806 Document 2101B

H2100200B

Loading...

Loading...