LAARS Mighty Therm PH Installation Manual

Installation and Operation Instructions Document 1049E

Installation and Operation

Instructions for

Mighty Therm

Hydronic Boilers

Models HH and PH

Sizes 500-1825

These instructions are to be stored in the pocket provided on the boiler

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water boiler installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency, or gas

supplier.

H0117400E

Page 2

LAARS Heating Systems

TABLE OF CONTENTS

SECTION 1.

General Information

1A. Introduction...................................................3

1B. Boiler Identification .......................................3

1C. Flow Requirements.......................................3

1D. Variable Water Flow Systems.......................4

1E. Warning Regarding Chilled

Water Systems ............................................. 5

1F. Freeze Protection ......................................... 5

SECTION 2.

Installation

2A. Boiler Placement ..........................................6

2B. Installation of Indoor Boilers..........................6

2B-1. Combustion Air Supply ................................. 6

2B-2. Venting .........................................................8

2C. Installation of Outdoor Boilers....................... 9

2D. Gas Supply and Piping ................................. 9

2E. Electrical Wiring .......................................... 10

2F. Water Piping of System .............................. 11

2G. Filling Fully-Connected System................... 11

SECTION 3.

Operation

3A. Controls - General ...................................... 12

3B. Initial Start-Up ............................................. 13

3C. To Start Up System .................................... 13

3D. To Turn Off Boiler ....................................... 14

3E. To Shut Down System ................................ 14

SECTION 4.

Maintenance

................................................................... 14

SECTION 5.

Troubleshooting and Analysis of

Service Problems

................................................................... 16

SECTION 6.

Parts Descriptions and

Order Numbers

................................................................... 18

SECTION 7.

Outdoor Parts Descriptions and

Order Numbers

................................................................... 26

SECTION 8.

Optional Parts Descriptions and

Order Numbers

................................................................... 28

Mighty Therm Hydronic Boiler

Page 3

SECTION 1.

General Information

1A. Introduction

This manual provides information for the

installation and operation of Laars hydronic boilers. It

is strongly recommended that all application and

installation procedures be reviewed completely before

proceeding with the installation. Consult the Laars

factory, or local factory representative with any

problems or questions regarding this equipment.

Experience has shown that most problems are caused

by improper installation not system design.

Some accessory items are shipped in separate

packages. Verify receipt of all items listed on the

package slip. Inspect everything for possible damage

upon delivery, and inform the carrier of any shortages

or impairments. Any such claims should be filed with

the carrier. The carrier, not the shipper, is responsible

for shortages and damage to the shipment whether

visible or concealed.

IMPORTANT WARNING:

The model HH and PH hydronic boilers must be

installed in accordance with the procedures outlined

in this manual. The warranty does not apply to boilers

not installed or operated in accordance with these

procedures. Consult local building and safety codes

before proceeding with work. The installation must

conform to the requirements of the authority having

jurisdiction or, in the absence of such requirements, to

the latest edition of the National Fuel Gas Code;

ANSI Z223.1, National Electrical Code ANSI/NFPA

70 and/ or in Canada CAN 1 -13149 requirement.

When required by the authority having

jurisdiction, the installation must conform to

American Society of Mechanical Engineers safety

codes for controls and safety devices for automatically

fired boilers No. CSD-1, and in Canada CGA 3.3. Any

modification to the boiler, its gas controls, gas

orifices, wiring or draft diverter may void the Laars

warranty. If field conditions require such

modifications, consult factory.

1B. Boiler Identification

Consult rating plate on the boiler. The following

example simplifies the boiler identification.

1 2 3456

PH 1670 I N 09 L

(1) Basic boiler model (see descriptions below).

(2) Input rate X 1000 BTU/hr.

(3) Indoor (1) or Outdoor (E) installation.

(4) Gas type: Natural (N) or Propane (P).

(5) Ignition system: I.I.D. (09) or continuous pilot

(16). Special option: I.I.D. (04) 115 volts.

(6) Firing modes:

On/Off (C)

2-stage (K)

4-stage (L)

Mechanical Modulation (H)

Motorized Modulation (F)

Motorized On/Off (R)

Motorized 2-stage (T).

Figure 1. Boiler Configuration.

Model HH hydronic heating boilers. There must

be a field installed pump to circulate water.

Model PH hydronic heating boilers are basically

the same as the HH models except that the PH boilers

come with integrally mount pumps. Pumps are sized

for pressure drop through the heat exchanger and short

runs of pipe for primary-secondary systems.

Laars hydronic boilers are available in two

configurations: an indoor version and an outdoor

version. Both are available from the factory (see

Figure 1).

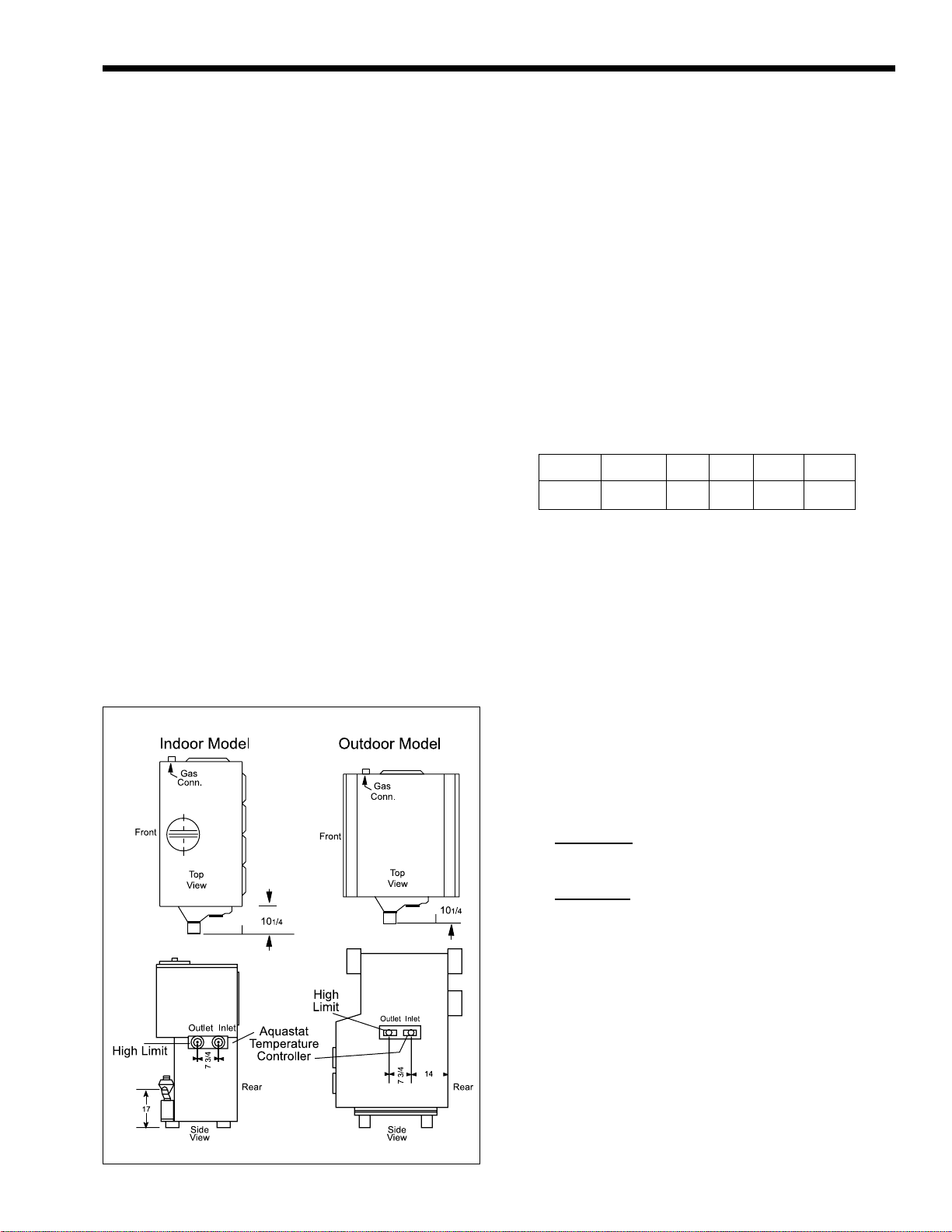

1C. Flow Requirements

All low volume hydronic boilers must have

continuous flow through the heat exchanger for proper

operation. The system pump must be capable of

developing sufficient pressure to overcome the

Page 4

Design T emperature Rise Across The Boiler

20°F 11°C 25°F 14°C 30°F 17°C 35°F 19°C

Indoor Outdoor Flow H/L Flow H/L Flow H/L Flow H/L

Sizes Sizes GPM l/s Ft. m GPM l/s Ft. m GPM l/s Ft. m GPM l/s Ft. m

500 — 38 2.4 1.4 0.4 31 2.0 1.1 0.3 26 1.6 0.9 0.3 22 1.4 0.6 0.2

— 500 41 2.6 1.7 0.5 33 2.1 1.1 0.3 27 1.7 0.9 0.3 23 1.5 0.7 0.2

600 — 49 3.1 2.3 0.7 39 2.5 1.6 0.5 32 2.0 1.1 0.3 28 1.8 0.9 0.3

— 600 49 3.1 2.3 0.7 39 2.5 1.6 0.5 32 2.0 1.1 0.3 28 1.8 0.9 0.3

715 — 56 3.5 2.5 0.8 45 2.8 1.9 0.6 37 2.3 1.5 0.5 32 2.0 1.0 0.3

— 715 58 3.7 3.2 1.0 47 3.0 2.2 0.7 39 2.5 1.6 0.5 33 2.1 1.1 0.3

850 — 66 4.2 3.4 1.0 53 3.3 2.5 0.8 44 2.8 2.0 0.6 38 2.4 1.4 0.4

— 850 69 4.4 3.6 1.1 55 3.5 3.1 0.9 46 2.9 2.2 0.7 39 2.5 1.6 0.5

1010 — 79 5.0 4.7 1.4 63 4.0 3.4 1.0 53 3.3 2.7 0.8 45 2.8 1.9 0.6

— 1010 82 5.2 5.0 1.5 66 4.2 3.6 1.1 55 3.5 3.1 0.9 47 3.0 2.2 0.7

1200 — 94 5.9 6.5 2.0 75 4.7 4.8 1.5 62 3.9 3.7 1.1 53 3.3 2.6 0.8

— 1200 98 6.2 6.9 2.1 78 4.9 4.9 1.5 65 4.1 3.6 1.1 56 3.5 3.1 0.9

1430 — 112 7.1 8.9 2.7 89 5.6 6.5 2.0 74 4.7 5.0 1.5 64 4.0 3.5 1.1

— 1430 117 7.4 9.5 2.9 93 5.9 6.7 2.0 78 4.9 5.0 1.5 67 4.2 3.7 1.1

1670 — * * * * 102 6.4 8.8 2.7 85 5.4 6.7 2.0 73 4.6 4.7 1.4

— 1670 * * * * 109 6.9 9.1 2.8 91 5.7 6.8 2.1 78 4.9 5.0 1.5

1825 — * * * * 114 7.2 10 3.0 95 6.0 8.0 2.4 81 5.1 5.5 1.7

— 1825 * * * * 119 7.5 10.4 3.2 99 6.2 8.3 2.5 85 5.4 5.7 1.7

LAARS Heating Systems

*Consult factory for recommendations

Table 1. Flow Requirements.

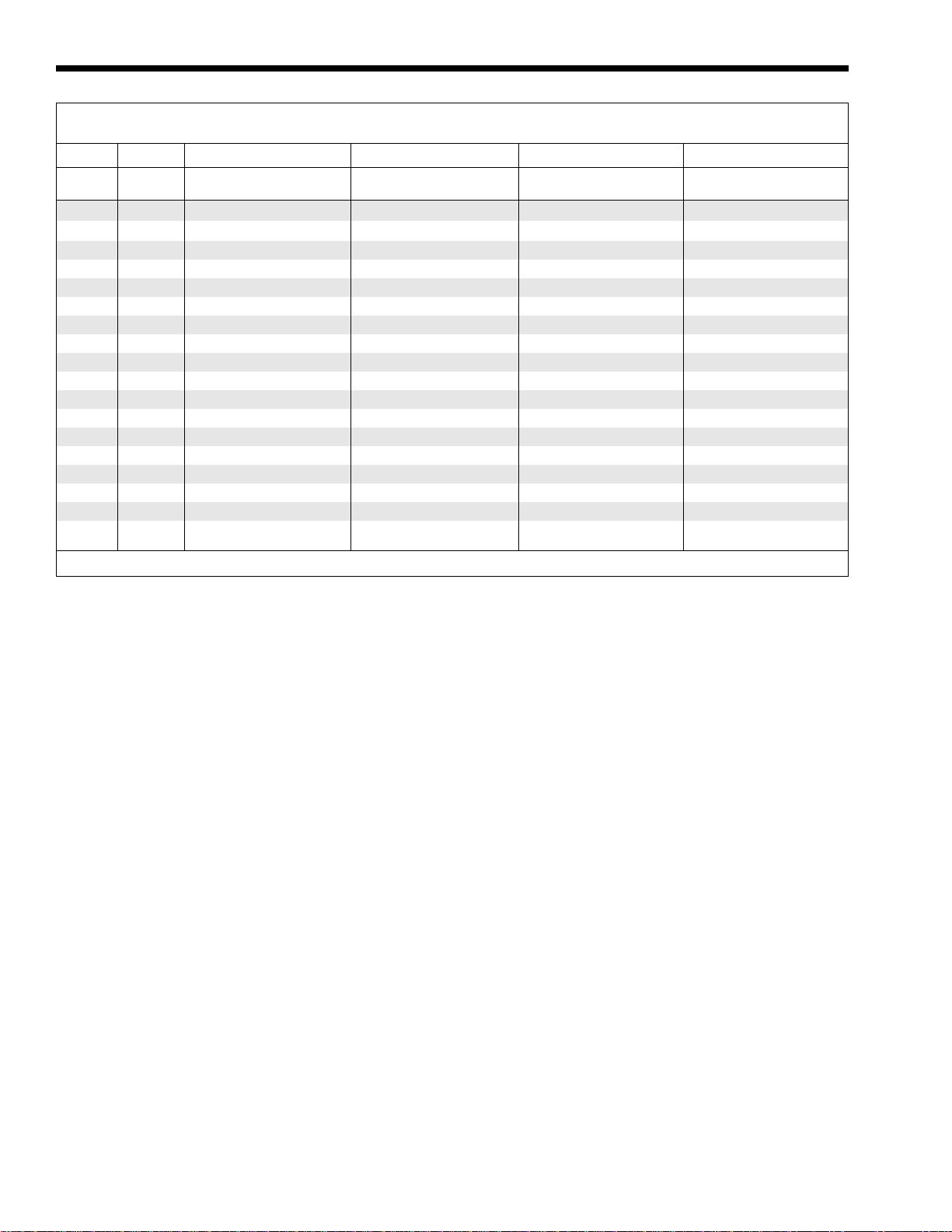

resistance of the boiler plus the entire circulating

system at the designated GPM (see Table 1). The

temperature rise across the boiler should never exceed

40°F (22°C). Primary-secondary pumping is the most

effective way to assure proper flow through the boiler

resulting in longer boiler life and greater system

efficiency (see Figure 2).

1D. Variable Water Flow Systems

Heating systems using zone valves, zone pumps

or 3-way valves can experience reduced water flow

through the boiler. This can result in an excessive

water temperature rise and unstable boiler operation.

If the system water flow is variable, it must not be

allowed to fall below 30% of full flow. The boiler

must be equipped with staged or modulated fire with

the temperature sensor installed in the outlet water.

State variable flow when ordering. Laars recommends

primary-secondary pumping for all variable flow

systems. Primary-secondary pumping is mandatory

for variable flow systems where minimum flows are

less than 30% of full flow conditions. The boiler

pump in a primary-secondary system maintains

constant flow through the boiler even though the

system flow is variable. In a primary-secondary

system the pressure drop of the boiler is not added to

the system (see Figure 2).

A Special Note About 3-Way Water Valves

3-way water valves (2 position or proportional)

are sometimes used to divert water around a boiler

and control the temperature of water being supplied to

the system. Valves installed in this manner must be

supplied with an end switch or some other suitable

control to shut off the boiler when the flow is reduced

to 30%. The boiler must be supplied with staged or

modulated fire as indicated in Section 1D, Variable

Water Flow Systems.

It is often possible to accomplish excellent water

temperature control without 3-way valves through

proper application of staged or modulated firing

systems. Consult the factory or local Laars

representative for assistance with such systems.

System Pressure Requirements

The model HH and PH boilers are designed to

operate on closed, pressurized systems. A minimum of

12 psi should be maintained on the system where

boiler supply water temperatures are 200°F (93°C) or

less. If higher temperatures are required, the minimum

system pressure should be at least 15 psi above the

water vapor pressure corresponding to the elevated

water temperature.

The hydronic boilers are not suitable for open

systems unless the supply water temperatures are kept

below 180°F (82°C), and minimum of 5 psi static

head is maintained within the boiler.

Mighty Therm Hydronic Boiler

Page 5

Figure 2. Typical Schematic for a Primary-Secondary System.

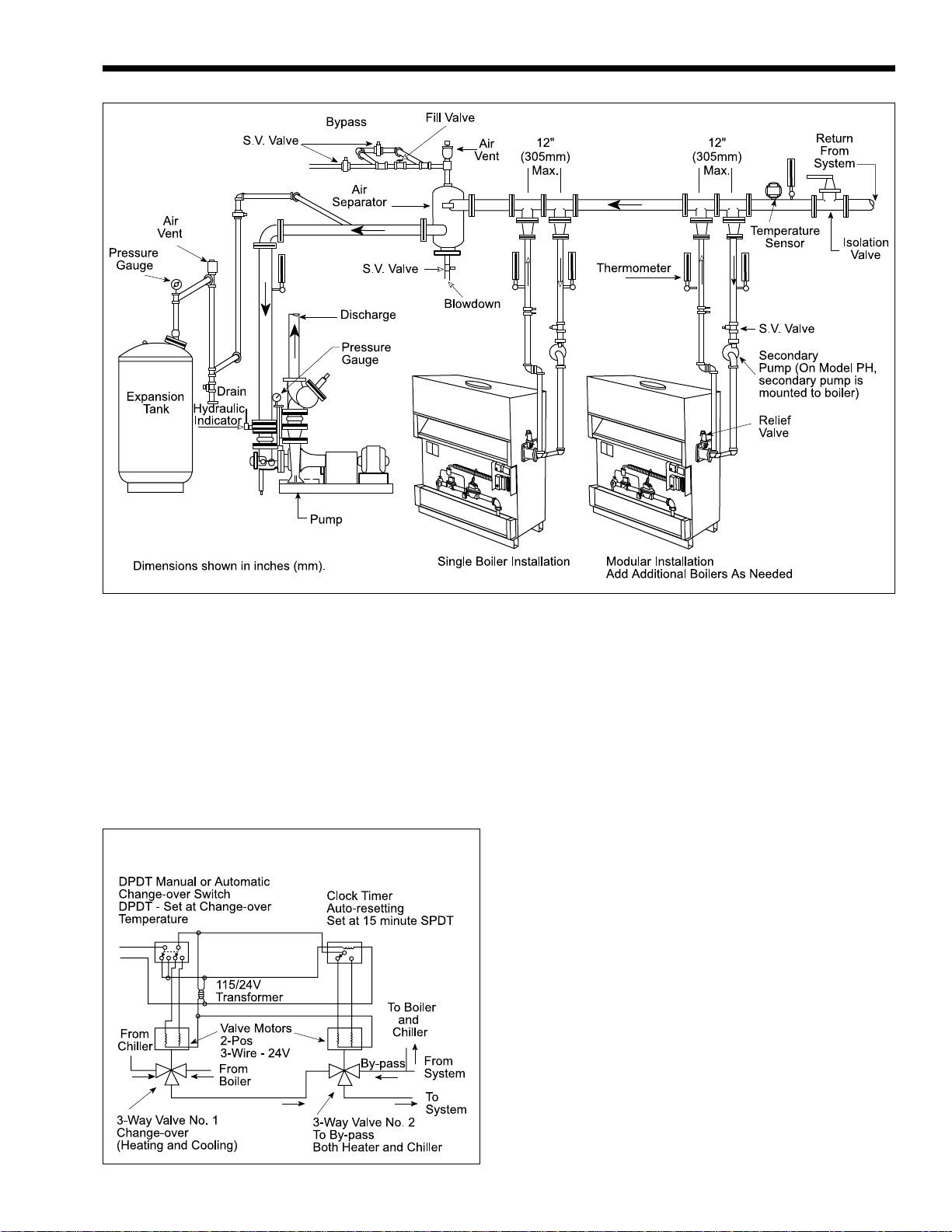

1E. Warning Regarding Chilled

Water Systems

When a boiler is connected to an air

conditioning system where the same water is used for

heating and cooling, chilled water must be prevented

from entering the boiler. When changing such a

system from cooling to heating, the chilled water

should be allowed to circulate through the building

(after the chiller has been turned off) for a period long

Suggested Wiring Diagram For Tempering System Water

at Change-over From Heating to Cooling.

Figure 3. Boiler-Chiller Installation.

enough for the water to warm up to at least 70°F

(21°C) before the water is allowed to flow into the

boiler. It is equally important to prevent hot water

from entering the chiller. The system shown in Figure

3 is suggested to make sure that the system water is

neither too hot nor too cold when a changeover from

heating to cooling, or vice versa, takes place. When a

boiler is connected to heating coils located in air

handling units (where they may be exposed to

refrigerated air circulation), the boiler piping system

shall be equipped with a flow control valve or other

automatic means to prevent gravity circulation of

chilled water through the boiler. Chilled water in the

boiler will create condensation on the boiler tubes

which will drip on the burners and may extinguish the

pilot.

Boilers installed in violation of either of the

above requirements may void the warranty.

1F. Freeze Protection

Boiler installations are not recommended in

areas where the danger of freezing exists unless

proper precautions are taken for freeze protection. The

preferred method of freeze protection is by

maintaining a mixture of no more than 50% properly

inhibited HVAC glycol. This mixture will protect the

boiler to temperatures of about -35°F (-37°C). To get

the desired temperature rise across the boiler when

this mixture is used, increase the water flow by 15%

above the original recommendation. Increase the head

loss requirement by 20%.

Page 6

LAARS Heating Systems

SECTION 2.

Installation

2A. Boiler Placement

The boiler must be placed to provide specific

clearances on all sides for maintenance and

inspection. There must also be minimum distances

maintained from combustible surfaces. These

clearances also apply to non-combustible materials,

because the boiler requires air circulation for proper

operation.

Boiler should be mounted on a level surface. An

integral combustible flooring base is provided as

standard equipment on all outdoor models.

models can be installed on a combustible floor with a

special base assembly which is available from the

factory, or with a base that complies with local code

requirements. See rating plate for part number of the

base assembly.

Do not install boiler on carpeting.

Under the National Fuel Gas Code, ANSI

Z223.1, it is permissible to place the boiler on floors

other than non-combustible when the installation

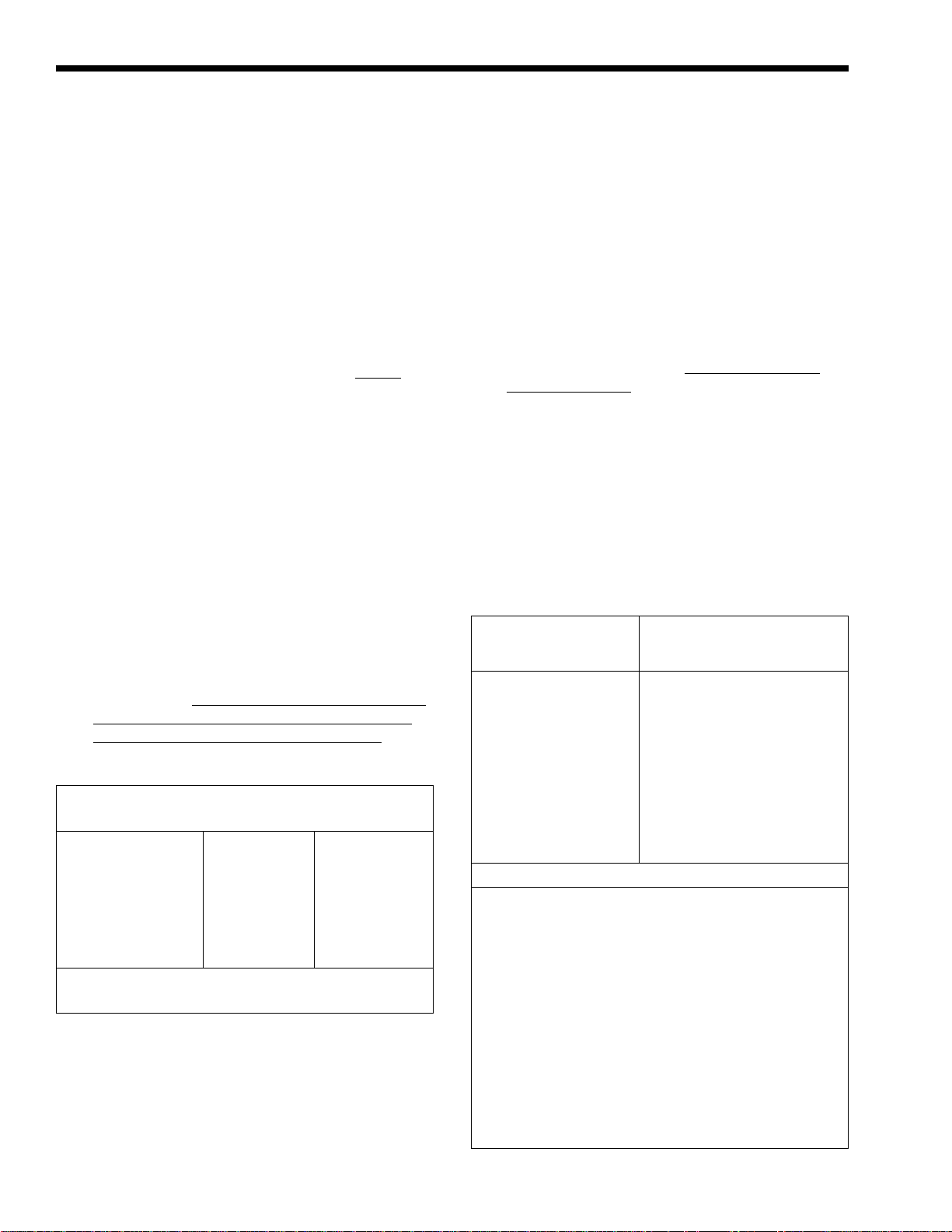

complies with the American Insurance Code. Figures

5, 6, 7, and 8 show common installation on

combustible flooring.

Indoor

2B-1. Combustion Air Supply

1. The boiler location must provide sufficient air

supply for proper combustion and ventilation of

the surrounding area as outlined in the latest

edition of ANSI standard Z223.1 and/or in

Canada CAN 1 - B1 49 requirements, and any

local codes that may be applicable. Inadequate

combustion air supply may result in incomplete

combustion, sooting of the heat exchanger, and

unsafe operation of the boiler.

2. (a.) In the United States, the general

requirements specify that boiler rooms should be

provided with two permanent air supply

openings communicating

directly through the

wall to outside air; one within 12 inches

(305mm) of the ceiling, and the other within 12

inches (305mm) of the floor. Each opening

should have a minimum free area of one square

inch per 4,000 BTUH input of the total input

rating of all appliances in the enclosed area. See

Table 3 for recommended air supply for each

model. An improperly ventilated equipment

room can get excessively hot and cause

accelerated deterioration of controls and

electrical components.

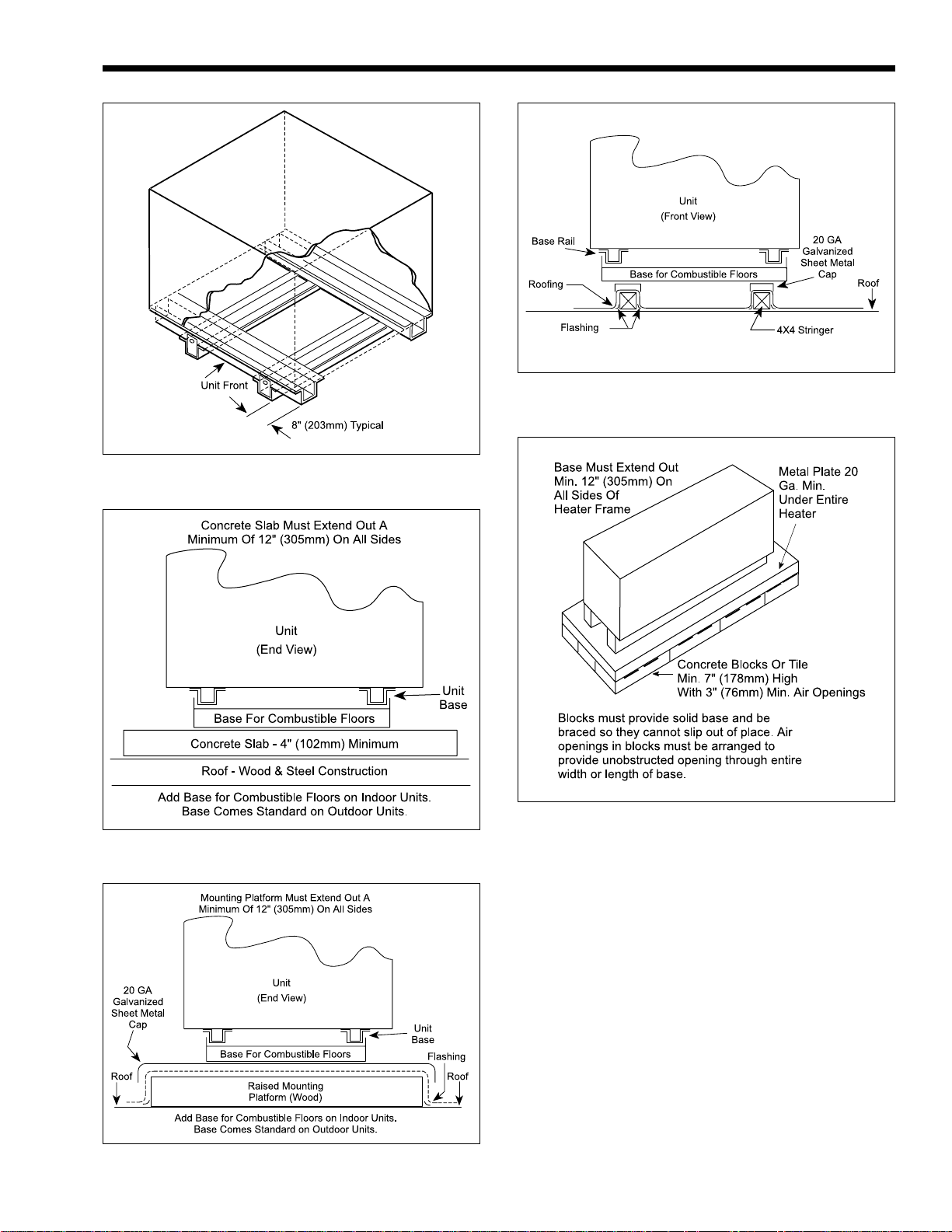

2B. Installation of Indoor Boilers

1. Locate the boiler to provide adequate

clearance for inspection and service on all sides

(see Table 2).

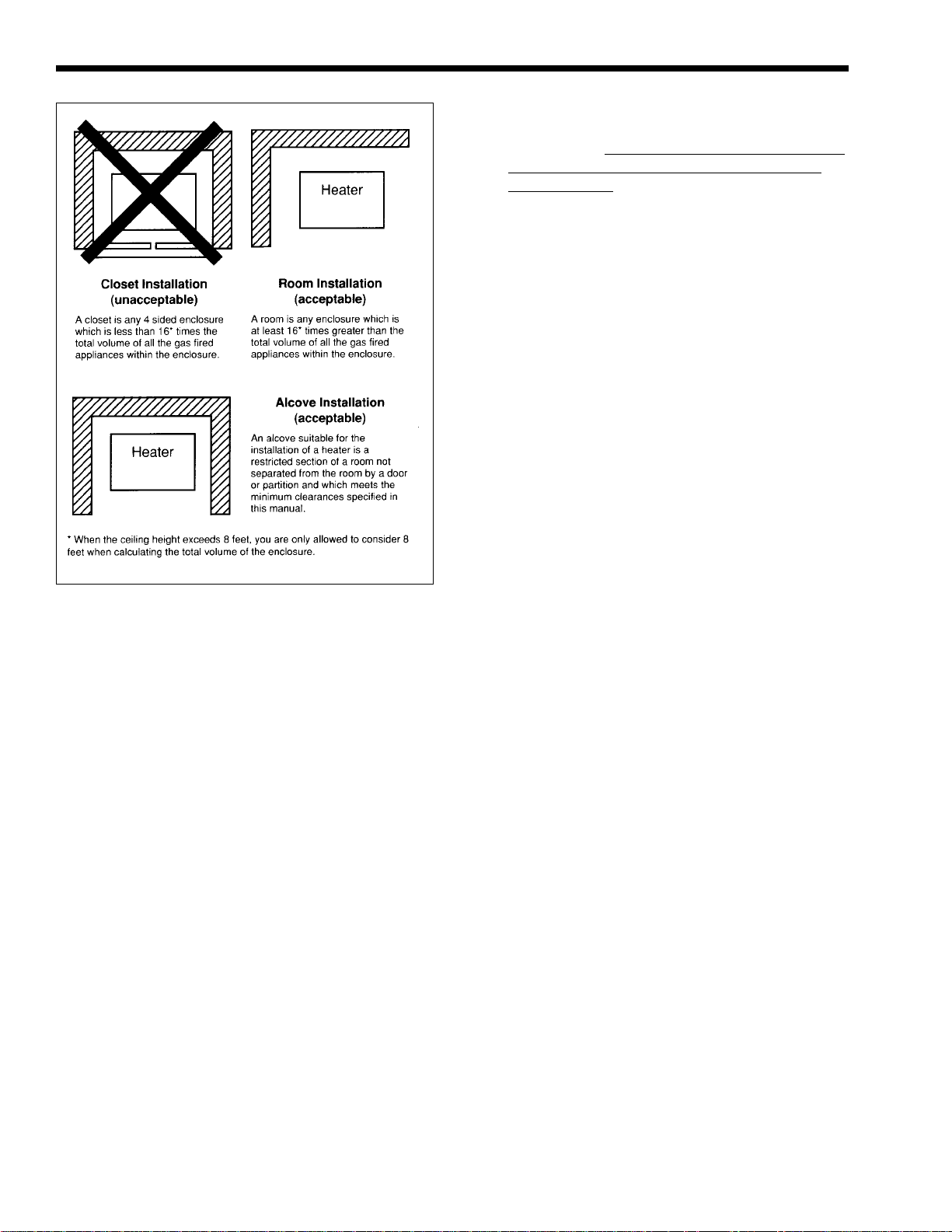

from front (for proper access to and service of

controls) and 18" at water connection end. For

alcove installation, see Figure 9.

Clearance Indoor Outdoor

From inches mm inches mm

Top 30 762 unobstruct

Water Conn. Side 12 305 24 610

Opposite Side 6 152 24 610

Front Alcove Unobstruct

Rear 8 203 24 610

Vent Pipe* 6 152 —

Hot Water Pipes Per Code Per Code

*1" when using type B Vent (refer to Manufacturer's

Instructions

Table 2. Minimum Boiler Clearances

2. Install the boiler on a waterproof floor with an

adequate floor drain and a 6" (152mm)

minimum curb on all four sides to protect the

building if boiler repairs are required. The

manufacturer will not be held liable for any

water damage in connection with this boiler.

We recommend minimums of 24"

From Combustible Surfaces.

Boiler Each Opening*

Model Sq. Inches Sq. cm

500 125 806.5

600 150 967.8

715 179 1154.9

850 213 1374.3

1010 253 1632.4

1200 300 1935.6

1430 358 2309.8

1670 418 2696.9

1825 457 2948.6

*Net Free Area in Square Inches

Area indicated is for one of two openings; one at

floor level and one at the ceiling, so the total net

free area could be double the figures indicated.

For special conditions refer to the latest edition of

ANSI Z223.1.

Consult factory if not communicating directly

through the walls with the outdoors.

Note: Check with louver manufacturers for net

free area of louvers. Correct for screen

resistance to the net free area if a screen is

installed. Check all local codes applicable to

combustion air.

Table 3. Minimum Recommended

Air Supply to Boiler.

Mighty Therm Hydronic Boiler

Figure 4. Base for Combustible Floors.

Page 7

Figure 7. Typical Boiler Installation on Roof Using a

4 x 4 Stringer.

Figure 5. Typical Boiler Installation on Concrete Slab.

Figure 6. Typical Boiler Installation on Raised Platform

(Wood).

Figure 8. Installation on Concrete Blocks or Tile.

(b.) In Canada, consult local building and safety

codes or, in the absence of such requirements,

follow CGA requirements and/or CAN 1 - B149

standard. (Table 3 does not apply).

3. Exhaust Fans or Vents: Any equipment which

exhausts air from the boiler room can deplete the

combustion air supply or reverse the natural

draft action of the venting system.

The boiler must be completely isolated and this

could cause flue products to accumulate in the

room. Additional air must be supplied to

compensate for such exhaust. The information in

Table 3 is not applicable in installations where

exhaust fans or blowers of any type are used.

Such installations must be designed by qualified

engineers.

Page 8

Figure 9. Alcove Installation.

4. If a blower or fan is used to supply air to the

heater room, the installer should make sure it

does not create drafts which could cause

nuisance shutdowns of the pilot. If a blower is

necessary to provide adequate combustion air to

the boiler, a suitable switch or equivalent must

be wired into the boiler control circuit to prevent

the boiler from firing unless the blower is

operating.

5. The boiler must be completely isolated and

protected from any source of corrosive chemical

fumes such as trichlorethylene, perchlorethylene,

chlorine, etc.

2B-2. Venting

1. Laars boilers have built-in draft diverters for

natural draft operation and must not be

connected to any portion of a mechanical draft

system under positive pressure. The flue outlet

must be connected to a clear, unobstructed vent

of adequate capacity ending above the highest

point of the building with an approved vent cap.

The venting system should be installed

according to the latest edition of ANSI Z223.1

and/or, in Canada, CAN1-13149 requirement

and any local codes having jurisdiction.

IMPORTANT NOTE: Do not use sheet metal

screws at the snap lock joints of Type B gas vents.

LAARS Heating Systems

2. Do not weld or fasten the vent pipe to the boiler

draft hood. The weight of the stack must not rest

on the boiler.

The draft hood and boiler top must

be easily removable for normal boiler service

and inspection.

3. Avoid using long horizontal runs of the vent

pipe, and too many 90° elbows, reductions or

restrictions. Horizontal runs should have at least

a 1/4" rise per foot in the direction of flow. A

vent connector should be supported for the

design and weight of the material used to

maintain clearances and prevent physical

damage and separation of joints.

4. Avoid ending heater vents near air conditioning

or air supply fans. The fans can pick up exhaust

flue products from the boiler and return them

inside the building, creating a possible health

hazard. A minimum of 4 feet (1.2m) horizontal

distance must be maintained from electrical

meters, gas meters, and relief equipment.

5. Always use double-wall or insulated vent pipe

(Type B or equivalent). In cold weather,

uninsulated outside vents can chill the rising flue

products, blocking the natural draft action of the

venting system. This can create a health hazard

by spilling flue products into the boiler room.

6. Avoid oversize vent piping or extremely long

runs of the pipe which may cause excessive

cooling and condensation. Rule of Thumb: The

total length of the vent, including the connector

and any offset, should not exceed 15 feet (4.6m)

for every inch of vent diameter. Longer total

lengths shown in venting tables are based on

maximum capacity, not condensation factors.

7. When the installation of a draft fan is necessary

in connecting a venting system to a Laars boiler,

the installation should be engineered by

competent personnel following good engineering

practices. The draft fan supplier should be

consulted for correct size. The installation

should be in accordance with the latest edition of

ANSI Z223.1 and/or, in Canada, CAN 1-B149

requirement and any local codes having

jurisdiction. When a draft fan is installed, a

suitable draft switch must be wired into the

boiler control circuit at terminal designated

“Field Interlock” to prevent firing of the boiler

unless a positive draft has been established.

8. When an existing boiler is removed from a

common venting system, the common venting

system is likely to be too large for proper venting

of the appliances remaining connected to it.

At the time of removal of an existing boiler, the

following steps shall be followed with each

appliance remaining connected to the common

venting system placed in operation, while the

Mighty Therm Hydronic Boiler

Page 9

other appliances remaining connected to the

common venting system are not in operation.

(a) Seal any unused openings in the common

venting system.

(b) Visually inspect the venting system for

proper size and horizontal pitch and

determine there is no blockage or

restriction, leakage, corrosion and other

deficiencies which could cause an unsafe

condition.

(c) Insofar as is practical, close all building

doors and windows and all doors between

the space in which the appliances

remaining connected to the common

venting system are located and other spaces

of the building. Turn on clothes dryers and

any appliance not connected to the common

venting system. Turn on any exhaust fans,

such as range hoods and bathroom

exhausts, so they will operate at maximum

speed. Do not operate a summer exhaust

fan. Close fireplace dampers.

(d) Place in operation the appliance being

inspected. Follow the lighting instructions.

Adjust thermostat so appliance will operate

continuously.

(e) Test for spillage at the draft hood relief open-

ing after 5 minutes of main burner operation.

Use the flame of a match or candle, or smoke

from a cigarette, cigar or pipe.

(f) After it has been determined that each

appliance remaining connected to the

common venting system properly vents

when tested as outlined above, return

doors, windows, exhaust fans, fireplace

dampers and any other gasburning

appliance to their previous conditions of

use.

(g) Any improper operation of the common

venting system should be corrected so the

installation conforms with the latest edition

of the National Fuel Gas Code, ANSI

Z223.1. When resizing any portion of the

common venting system, the common

venting system should be resized to

approach the minimum size as determined

using the appropriate tables in Appendix G

in the National Fuel Gas Code,

ANSI Z223. 1.

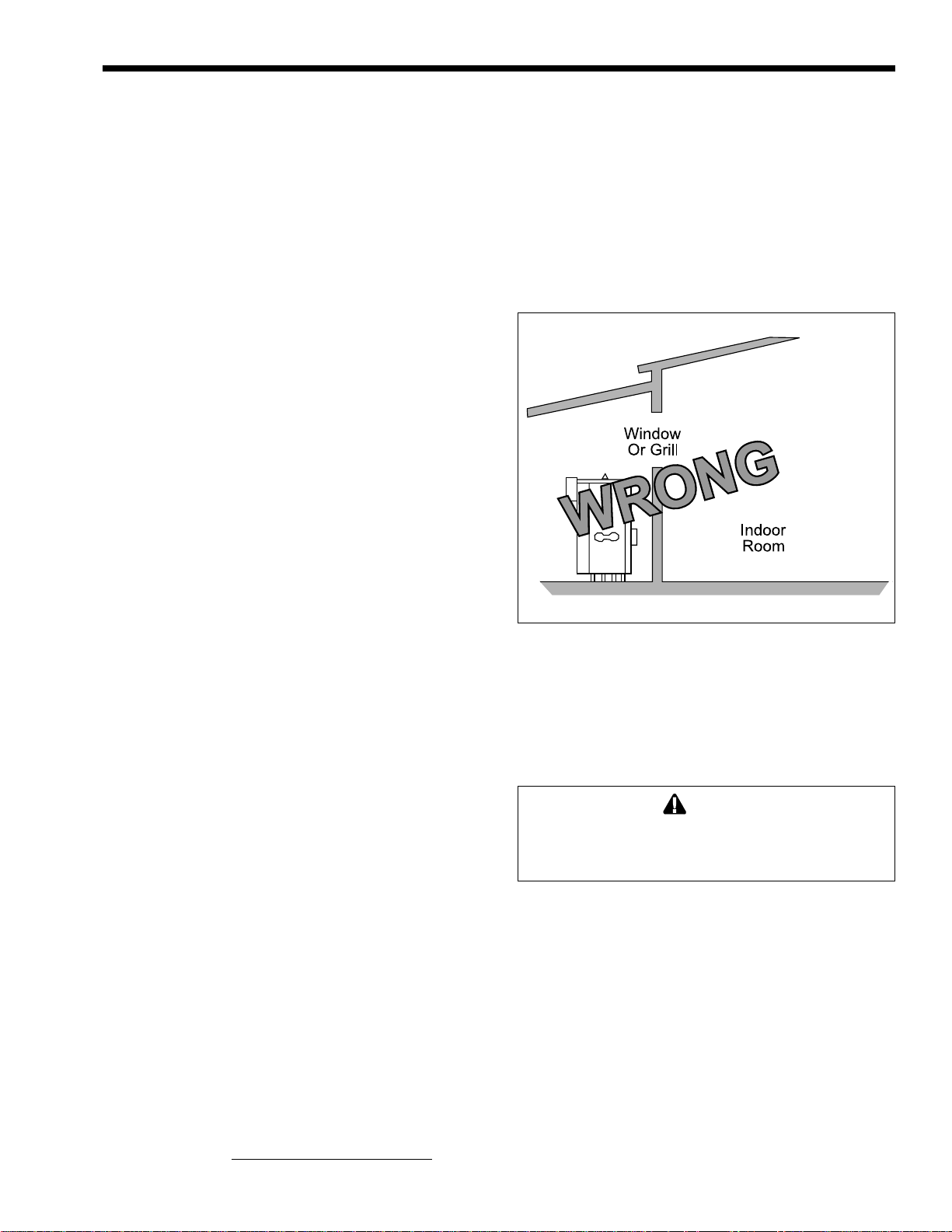

2C. Installation of Outdoor Boilers

1. Locate the boiler to provide the minimum

clearances as listed in Table 2, “Boiler

Clearances.”

2. Do not place the boiler in an enclosure or wall

recess. Avoid locations where wind deflection

See Service Clearance, 2 B.1.

off structures might cause a down draft. When

such wind conditions are possible, place the

boiler at least three (3) feet (0.9m) from the

structures.

3. Never install the boiler under any kind of roof

overhang. Do not place the boiler below or

adjacent to any doors, windows, louvers, grills,

etc. which connect in any way with an inhabited

area of a building. This includes other structures

such as garages or utility rooms (see Figure 10).

Figure 10. Incorrect Outdoor Installation.

4. Although these models are AGA designed

certified for outdoor installations, such

installations are not recommended in areas

where the danger of freezing exists unless proper

precautions are taken for freeze protection.

Caution

Outdoor installations are not recommended

in areas where the danger of

snow blockage exists.

2D. Gas Supply and Piping

Review the following instructions before

proceeding with the installation.

1. Verify that the boiler is fitted for the proper type

of gas by checking the rating plate. Laars boilers

are normally equipped to operate below a 2000

foot (610m) altitude. Boilers equipped to operate

at higher altitudes have appropriate stickers or

tags attached.

2. Use the figures in Table 4 to provide adequate

gas piping from the gas meter to the boiler.

3. A trap (drip leg) must be provided ahead of the

gas controls (see Figure 11). A manual gas

Loading...

Loading...